Page 1

Installation

Operation

Maintenance

RTUB 207-224 - Liquid chillers with

helical rotary compressors

RTCA 108-216 - Remote air-cooled

condenser

RLC-SVX03A-E4

Page 2

RLC-SVX03A-E4

Foreword

These installation, operation and

maintenance instructions are given

as a guide to good practice in the

installation, putting into service,

operation, and maintenance by the

user of Trane RTUB and RTCA units.

They do not contain full service

procedures necessary for the

continued successful operation of

this equipment; The services of a

qualified technician should be

employed through the medium of a

maintenance contract with a

reputable service company.

Warranty

Warranty is based on the general

terms and conditions of Société

Trane or Trane UK Ltd. The warranty

is void if the equipment is repaired

or modified without the written

approval of Trane, if the operating

limits are exceeded or if the control

system or the electrical wiring is

modified.

Damage due to misuse, lack of

maintenance or failure to comply

with the manufacturer's instructions

or recommendations is not covered

by the warranty obligation.

If the user does not conform to the

rules of chapter "Maintenance", it

may entail cancellation of warranty

and liabilities by Trane.

Reception of the

unit

On arrival, inspect the unit before

signing the delivery note. Specify

any damage on the delivery note,

and send a registered letter of

protest to the last carrier of the

goods within 72 hours of delivery.

Notify the local Trane Sales Office at

the same time. The unit should be

totally inspected within 7 days of

delivery. If any concealed damage is

discover, send a registered letter of

protest to the carrier within 7 days of

delivery and notify the local Trane

Office.

Units are shipped with the

refrigerant operating or holding

charge and should be examined with

an electronic leak detector to

determine the hermetic integrity of

the unit. The refrigerant charge is not

included in the standard Trane

Warranty Cover.

Cautions and

warnings

Cautions and warnings appear at

appropriate places in this instruction

manual. Your personal safety and the

proper operation of this machine

require that you follow them

carefully. The constructor assumes

no liability for installations or

servicing performed by unqualified

personnel.

Refrigerant

The refrigerant provided by Société

Trane or Trane UK Ltd meets all the

requirements of our units. When

using recycled or reprocessed

refrigerant, it is advisable to ensure

its quality is equivalent to that of a

new refrigerant. For this, it is

necessary to have a precise analysis

made by a specialized laboratory. If

this condition is not respected, the

Société Trane UK Ltd warranty could

be cancelled.

©American Standard Inc. 2002

Page 3

RLC-SVX03A-E4 3

Contents

Foreword 2

Warranty 2

Reception of unit 2

Cautions and warnings 2

Refrigerant 2

General information

Unit Inspection 5

Inspection Checklist 5

Loose Parts Inventory 6

Description of the Unit 6

General Data RTUB 7

General Data RTCA 8

Installation

Installation Responsibilities 9

Storage 9

Special Lifting and Moving Instructions 10

Isolation 10

Foundation 10

Clearances 11

Drainage 12

Releasing the Nitrogen Holding Charge 12

Water Connections (RTUB) 12

Flow Switch Installation 13

Water Pressure Gauges 13

Refrigeration Safety Valves 14

Water Pressure Relief Valves 14

Installing and Connecting Temperature Sensors 14

Connecting RTUB with the Remote Air-cooled Condenser 15

Page 4

4

Operation

Pre-start Checkout 21

Unit Voltage Power Supply 21

Unit Voltage Imbalance 21

Unit Voltage Phasing 21

Water System Flow Rates 22

Water System Pressure Drop 22

Daily Unit Start-up Procedure 22

Seasonal Unit Start-up Procedure 23

Temporary Shutdown and Restart 23

Extended Shutdown Procedure 23

System Restart after Extended Shutdown 23

Maintenance

Periodic Maintenance 25

Refrigerant and Oil Charge Management 27

R134a Field-charging Procedure 28

Charge Isolation on the High or Low Side of the System 28

Filter Replacement Procedure 29

Lubrication System 29

Oil Charging Procedure 29

Safety Recommendations 32

Maintenance Contract 32

Training 32

CG-PRC010-E4

Contents

Page 5

RLC-SVX03A-E4

5

General information

This manual describes installation,

operation, and maintenance of RTUB

and RTCA units.

A separate manual is available for

the use and maintenance of the

RTUB controls (UCM-CLD).

Unit Inspection

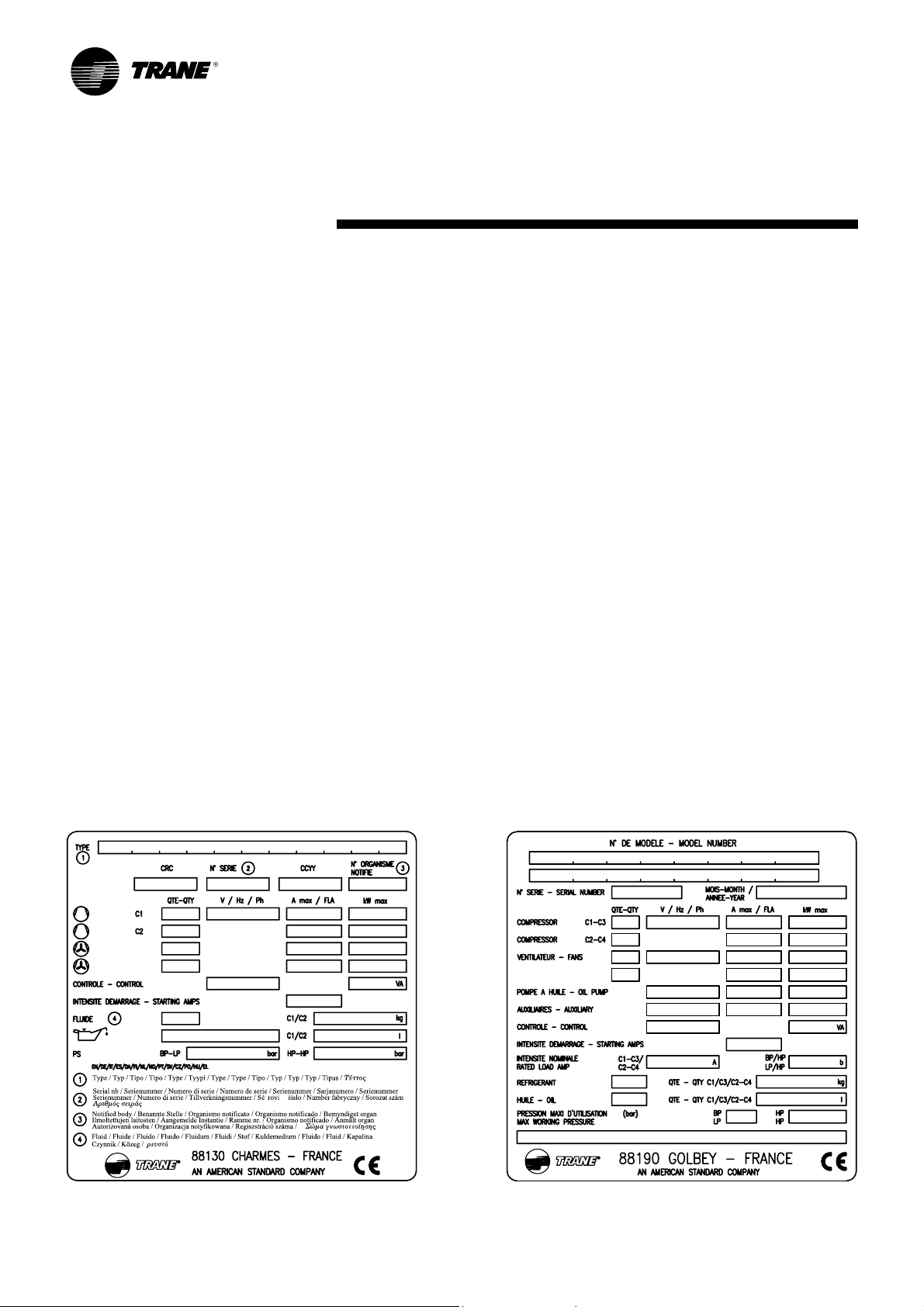

When the unit is delivered, verify

that it is the correct unit and that it is

property equipped. Compare the

information that appears on the unit

nameplate with the ordering and

submittal information. A typical unit

nameplate is shown in Figure 1.

Inspect all exterior components for

visible damage. Report any apparent

damage or material shortage to the

carrier and make a "unit damage"

notation on the carrier's delivery

receipt. Specify the extent and type

of damage found and notify the

appropriate Trane Sales Office. Do

not proceed with installation of a

damaged unit without sales office

approval.

Inspection Checklist

To protect against loss due to

damage incurred in transit, complete

the following checklist upon receipt

of the unit.

• Inspect the individual pieces of the

shipment before accepting the unit.

Check for obvious damage to the

unit or packing material.

• Inspect the unit for concealed

damage as soon as possible after

delivery and before it is stored.

Concealed damage must be

reported within 15 days.

If concealed damage is discovered,

stop unpacking the shipment. Do not

remove damaged material from the

receiving location. Take photos of the

damage, if possible. The owner must

provide reasonable evidence that the

damage did not occur after delivery.

• Notify the carrier's terminal of the

damage immediately, by phone and

by mail. Request an immediate,

joint inspection of the damage with

the carrier and the consignee.

Page 6

6

• Notify the Trane sales

representative and arrange for

repair. Do not repair the unit,

however, until damage is inspected

by the carrier's representative.

Loose Parts Inventory

Check all the accessories and loose

parts that are shipped with the unit

against the shipping list. Included in

these items will be water vessel

drain plugs, rigging and electrical

diagrams, and service literature,

which are placed inside the control

panel and/or starter panel for

shipment.

Description of the Unit

The RTUB units are liquid chillers

equipped with two helical rotary

compressors and an evaporator

designed to operate with remote

RTCA air-cooled condensers or other

manufacturers' remote condensers.

The RTUB is shipped once it has

been assembled and wired in the

factory. The discharge piping is

blocked at the oil separator outlet.

Water connections - chilled water

inlet and outlet - are blocked for

transportation. Both RTUB and RTCA

units are dried and vacuum-pumped

in the factory, and contain a nitrogen

holding charge when shipped.

General information

RLC-SVX03A-E4

RTCA

RTUB

Figure 1 - Typical Unit Nameplates

é

Page 7

7

Table 1 - General data - RTUB

Unit size 207 208 210 211 212 214

Compressor

Type/quantity Helical rotary/2

Nominal size (tons) 35/35 40/40 50/50 60/50 60/60 70/70

Evaporator

Evaporator Model EG 120 EG 120 EG 140 EG 170 EG 170 EG 200

Water Storage (l) 105 105 365 220 220 200

Minimum Flow (l/s) 4.5 4.5 6.0 7.0 7.0 9.0

Maximum Flow (l/s) 13.4 13.4 18.0 21.0 21.0 25.0

Evaporator inlet diameter (inches) 556666

Evaporator outlet diameter (inches) 556666

Minimum Starting/

Operating Ambient (°C) 5

Refrigerant R134a

Number of Independent

Refrigerant Circuits 2

Percent Minimum Load (%) 17

Refrigerant Charge (kg) 26 26 40 40 40 40

Oil Charge (l) 12 12 14 14 14 16

Operating Weight (kg) 2130 2130 2845 2845 2845 3250

Shipping Weight (kg) 1860 1860 2570 2570 2570 2975

Unit size 216 217 218 220 222 224

Compressor

Type/Quantity Helical rotary/2

Nominal size (tons) 70/85 85/85 100/85 100/100 120/100 120/120

Evaporator

Evaporator Model EG 200 EG 200 EG 250 EG 250 EG 340 EG 340

Water Storage (l) 200 200 415 415 560 560

Minimum Flow (l/s) 9.0 9.0 11.0 11.0 14.0 14.0

Maximum Flow (l/s) 25.0 25.0 33.0 33.0 43.0 43.0

Evaporator inlet diameter (inches) 666666

Evaporator outlet diameter (inches) 666666

Minimum Starting/

Operating Ambient (°C) 5

Refrigerant R134a

Number of Independent

Refrigerant Circuits 2

Percent Minimum Load (%) 17

Refrigerant Charge (kg) 40 40 46 46 50 50

Oil Charge (l) 16 16 16 16 19 22

Operating Weight (kg) 3250 3250 3880 4050 4480 4550

Shipping Weight (kg) 2975 2975 3405 3575 3855 3925

General information

RLC-SVX03A-E4

Page 8

RLC-SVX03A-E4

8

General information

Table 2 - General data - RTCA

Unit size 108 109 111 113 115 116

Condenser

Condenser type Aluminium fins/copper tubes

Fin spacing (fins/ft) 168 168 144 168 168 144

Frontal surface area (m²) 5.7 6.9 6.9 11.3 11.7 13.7

Airflow

Standard unit (m3/h) 42500 50400 69300 77200 84700 98500

Low noise unit (m3/h) 34500 40900 56300 62700 68800 80000

Condenser fans

Number of fans 4468812

Fan speed

Standard unit (rpm) 690

Low noise unit (rpm) 560

Nominal fan power

Standard unit (kW) 0.85

Low noise unit (kW) 0.54

Current fan amps

Standard unit (A) 2.4

Low noise unit (A) 1.2

Minimum Starting/

Operating Ambient (1) (°C) 7 Standard units/-18 Low ambient units

Refrigerant R134a

Number of Independent

Refrigerant Circuits 111111

Refrigerant Charge (kg) 22 26 36 44 52 72

Operating Weight (2) (kg) 810 890 1090 1535 1770 2050

Shipping Weight (2) (kg) 1020 110 0 1300 1870 2170 2450

Hot gas connection (inches) 1 5/8 1 5/8 1 5/8 1 5/8 1 5/8 1 5/8

Liquid connection (inches) 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

Unit size 208 209 211 213 215 216

Condenser

Condenser type Aluminium fins/copper tubes

Fin spacing (fins/ft) 168 168 144 168 168 144

Frontal surface area (m²) 5.7 6.9 6.9 11.3 11.7 13.7

Airflow

Standard unit (m3/h) 42500 50400 69300 77200 84700 98500

Low noise unit (m3/h) 34500 40900 56300 62700 68800 80000

Condenser fans

Number of fans 2 x 2 2 x 2 2 x 3 2 x 4 2 x 4 2 x 6

Fan speed

Standard unit (rpm) 690

Low noise unit (rpm) 560

Nominal fan power

Standard unit (kW) 0.85

Low noise unit (kW) 0.54

Current fan amps

Standard unit 2.4

Low noise unit 1. 2

Minimum Starting/

Operating Ambient (1) (°C) 7 Standard units/-18 Low ambient units

Refrigerant R134a

Number of Independent

Refrigerant Circuits 222222

Refrigerant Charge (kg) 2 x 11 2 x 13 2 x 18 2 x 22 2 x 26 2 x 36

Operating Weight (2) (kg) 810 890 1090 1535 1770 2050

Shipping Weight (2) (kg) 1020 110 0 1300 1870 2170 2450

Hot gas connection (inches) 1 5/8 1 5/8 1 5/8 1 5/8 1 5/8 1 5/8

Liquid connection (inches) 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

(1) Based on a 2.2 m/s wind across the condenser

(2) With aluminium fins

Page 9

RLC-SVX03A-E4

9

Installation responsibilities

Generally, the contractor must do the

following when installing an

RTUB/RTCA unit.

• Install the units on a flat

foundation, level (within 1/4"

[6 mm] across the length of the

unit), and strong enough to support

unit loading.

• Install the units per the instructions

contained in the Installation section

of this manual.

• Install any optional sensors and

make electrical connections at the

UCM-CLD.

• Where specified for the RTUB,

provide and install valves in the

water piping upstream and

downstream of the evaporator

water connections, to isolate the

evaporator for maintenance and to

balance and trim the system.

• Furnish and install a flow switch

and/or auxiliary contacts to prove

chilled-water flow.

• Furnish and install pressure gauges

in the inlet and outlet piping of the

evaporator (for RTUB).

• Furnish and install a drain valve to

the bottom of the evaporator water

box (for RTUB).

• Supply and install a vent cock to the

top of the evaporator water box (for

RTUB).

• Furnish and install strainers ahead

of all pumps and automatic

modulating valves.

• Furnish and install check valves on

the discharge lines (between oil

separators and condenser) in order

to avoid any refrigerant migration

leading to catastrophic damages to

evaporator and/or compressor (due

to freeze-up or liquid slugging).

• Interconnect the RTUB and the

remote condenser.

• Provide and install field wiring.

• Install heat tape and insulate the

chilled-water lines and any other

portions of the system, as required,

to prevent sweating under normal

operating conditions or freezing

during low-ambient temperature

conditions.

• Start the unit under the supervision

of a qualified service technician.

Storage

If the chiller is stored for a long period

of time prior to installation, the

following precautionary measures must

be taken:

• Store the unit in a safe place

sheltered from bad weather

• At least every three months

(quarterly), check the pressure in

the refrigerant circuits to verify that

the nitrogen holding charge is

intact. If it is not, contact a qualified

service organization and the

appropriate Trane sales office.

• Close the discharge and liquid-line

isolation valves.

Installation

Page 10

10

Special Lifting and Moving

Instructions

A specific lifting method is

recommended as follows:

1. Four lifting points are built into the

unit.

2. Slings and spreader bar to be

provided by rigger and attached to

the four lifting points.

3. Minimum rated lifting capacity

(vertical) of each sling and

spreader bar shall be no less than

the tabulated unit shipping weight.

CCAAUUTTIIOONN

This unit must be lifted with the

utmost care. Avoid shock load by

lifting slowly and evenly.

WWAARRNNIINNGG

To prevent any damage, position the

lifting bar so that the slings do not

touch the unit.

Isolation

The most effective form of isolation

is to locate the unit away from any

sound-sensitive area. Structurally

transmitted sound can be reduced by

elastomeric vibration eliminators.

Spring isolators are not

recommended for units equipped

with helical rotary compressors.

Consult an acoustical engineer in

critical sound applications. For

maximum isolation effect, isolate

water lines and electrical conduit.

Wall sleeves and rubber- isolated

piping hangers can be used to

reduce the sound transmitted

through water piping. To reduce the

sound transmitted through electrical

conduit, use flexible electrical

conduit. State and local codes on

sound emissions should always be

considered.

Foundation

Provide rigid, non-warping mounting

pads or a concrete foundation of

sufficient strength and mass to

support the unit's operating weight

(that is, including completed piping,

and full operating charges of

refrigerant, oil, and water). After it is

in place, the unit must be level

within 1/4" [6 mm] over its length

and width. Use shims if necessary.

The manufacturer is not responsible

for equipment problems resulting

from an improperly designed or

constructed foundation.

Note for RTCA: The unit must be

positioned so that the airflow

through the condensation coils is not

hindered by any obstacle. The

Installation

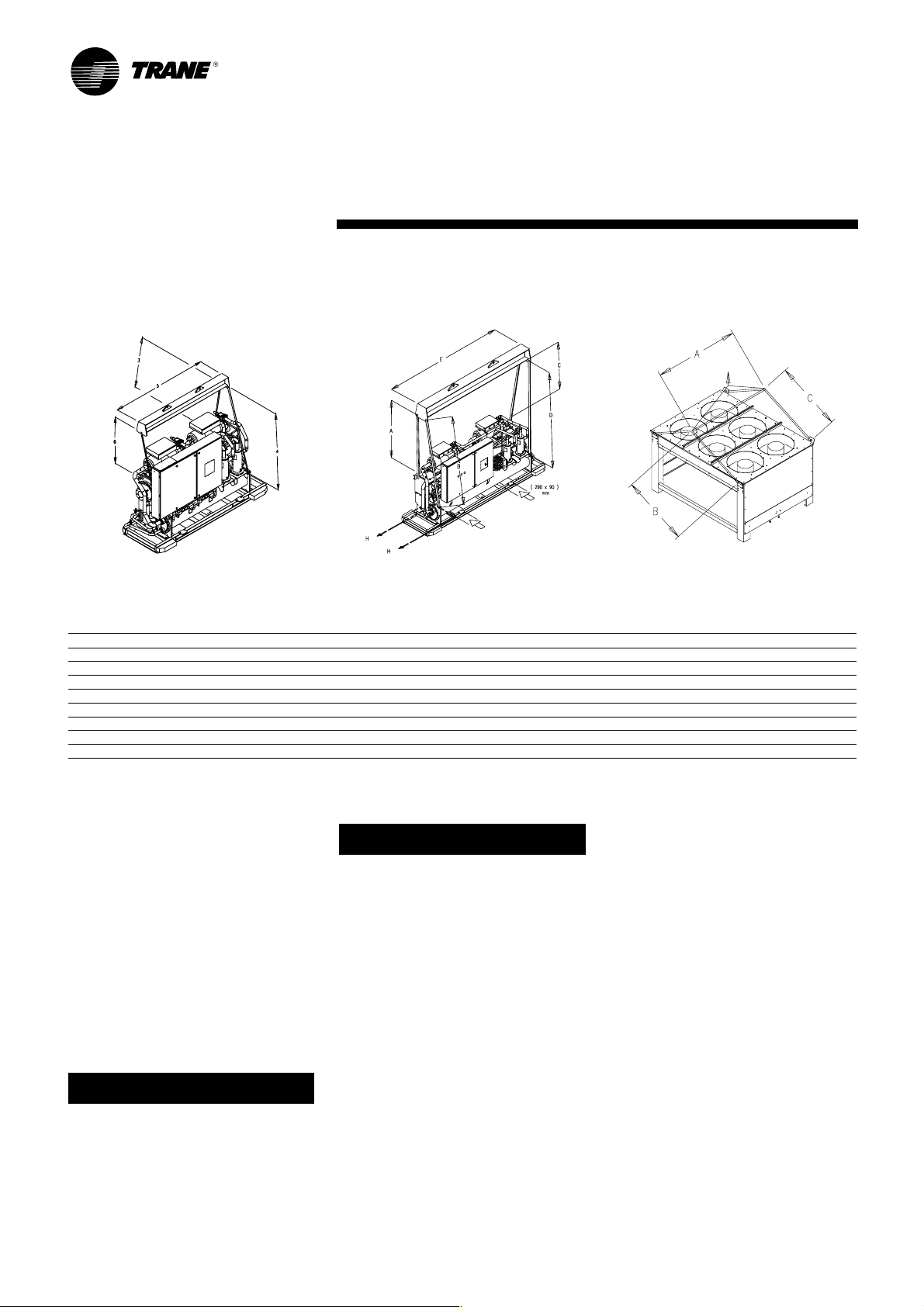

Figure 2- Rigging the unit - RTUB 207-208 Figure 3- Rigging the unit - RTUB 210-224 Figure 4- Rigging the unit - RTCA 108-216

Table 3 - Sling Lengths (mm) for lifting

ABCDE

RTUB unit size

207-208 2200 3000 2600 2100 210-211-212 2400 3000 2550 3150 3650

214-216-217 2500 3000 2550 3150 3650

218-220 2450 3050 2600 3150 3650

222-224 2450 3100 2650 3150 3650

RTCA unit size

108/109/111/208/209/211 2240 1700 1700 - 113/115/115/213/215/216 2240 2800 2800 - -

RLC-SVX03A-E4

Page 11

11

Installation

condensation coils must be

protected from side winds when

their speed exceeds 16 km/h.

Position the unit above the average

height of snow observed in the

region where it is installed. Never

install temporary or permanent

objects (tarp or roof) over the unit,

because recycling of hot air would

reduce the capacity of the

condensation coils. Discharged air

from the fans must not be

obstructed. It is prohibited to install

ducts for the fan discharge air (even

short ones). This is because the fans

supplied on standard units do not

generate any additional static

pressure.

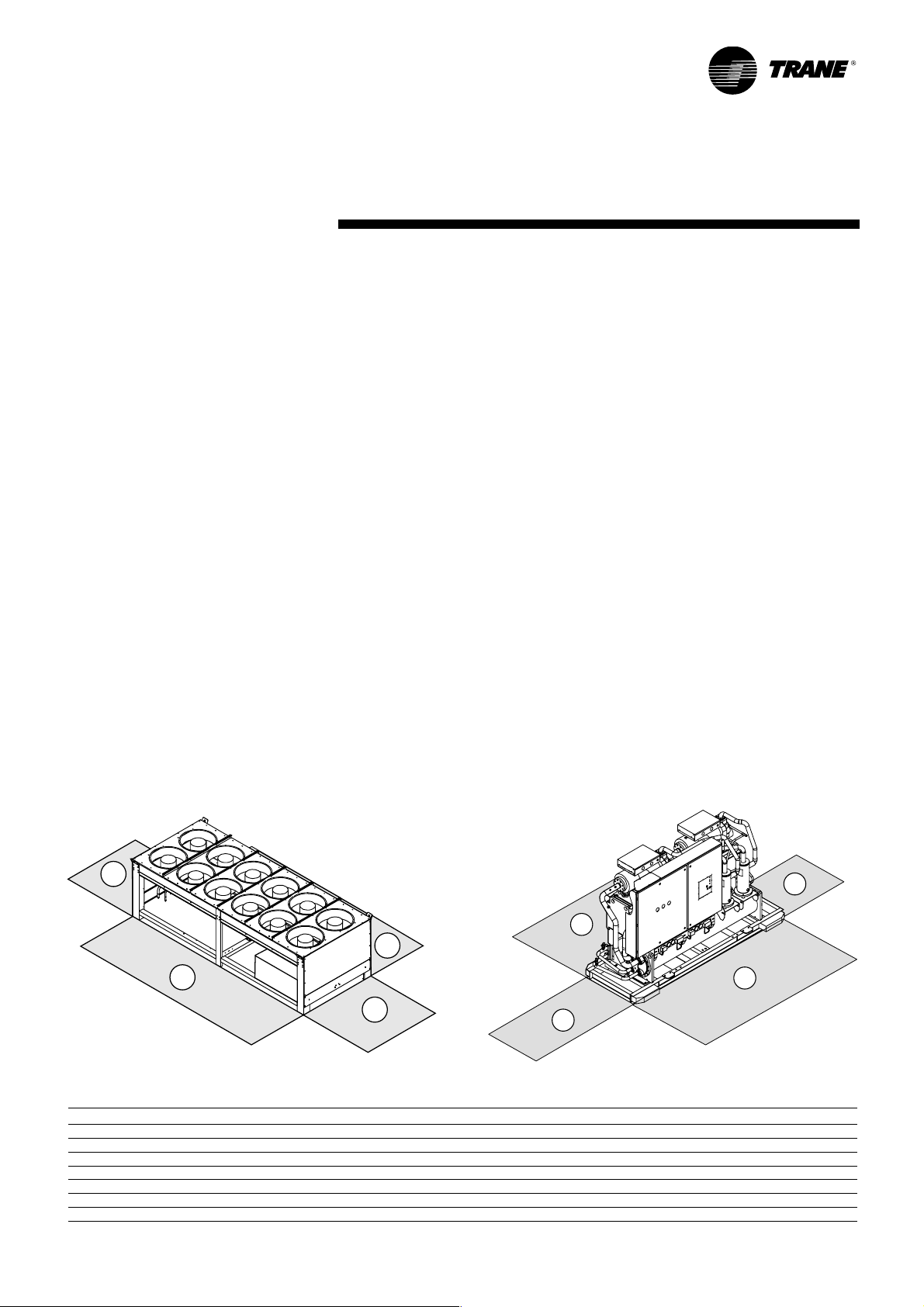

Clearances

Provide enough space around the

unit to allow the installation and

maintenance personnel unrestricted

access to all service points. Refer to

Figure 5 and Table 4 for unit

Figure 5: Unit Dimensions and

Recommended Minimum

Clearances - RTCA

Figure 6: Unit Dimensions and

Recommended Minimum

Clearances - RTUB

Table 4 - Unit Dimensions and Recommended Minimum Clearances (mm)

Length Width Height A B C D

RTCA 108/109/111/208/209/211 2870 2285 1630 1000 1000 1000 1000

RTCA 113/213 4610 2285 1630 1000 1000 1000 1000

RTCA 115/116/215/216 5450 2285 1630 1000 1000 1000 1000

RTUB 207/208 2880 890 1789 950 800 1800 500

RTUB 210/211/212/214/216/217 4150 890 1832 950 800 2750 500

RTUB 218/220 4150 890 1932 950 800 2750 500

RTUB 222/224 4150 890 2041 950 800 2750 500

dimensions and recommended

clearances. Unobstructed flow of

condenser air is essential to maintain

chiller capacity and operating

efficiency.

Note for RTCA: When determining

unit placement, give careful

consideration to ensuring a sufficient

flow of air across the condenser

heat-transfer surface.

RLC-SVX03A-E4

C

B

A

D

D

B

A

C

Page 12

12

Drainage

Provide a large-capacity drain for

water vessel drain-down during

shutdown or repair. The evaporator

is provided with a drain connection.

All local and national codes apply.

The vent on the top of the

evaporator water box is provided to

prevent a vacuum, by allowing air

into the evaporator for complete

drainage.

Releasing the Nitrogen

Holding Charge

The nitrogen holding charge can be

released into the atmosphere.

CCAAUUTTIIOONN

When releasing nitrogen holding

charge, ventilate the room. Avoid

breathing in the nitrogen.

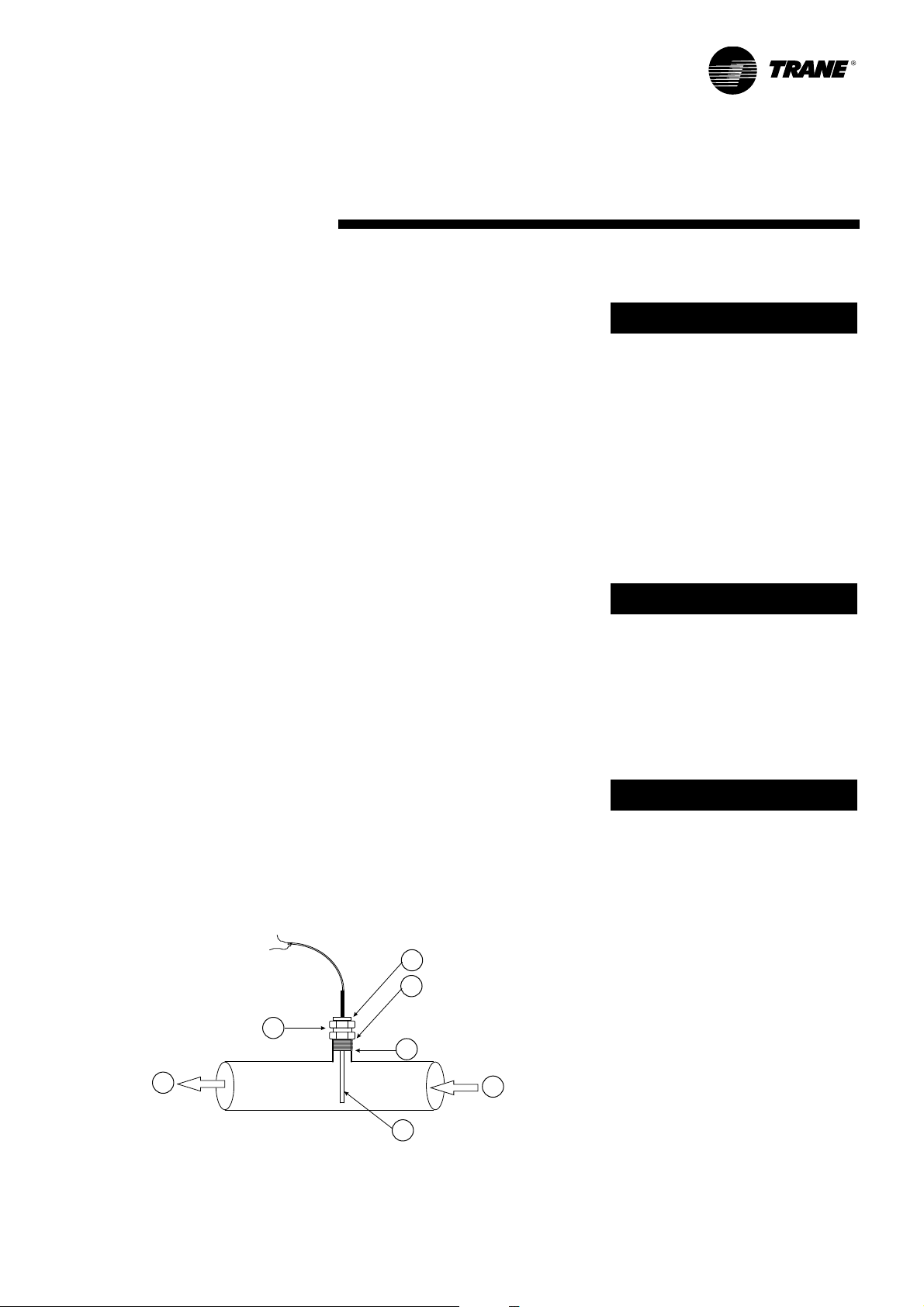

Water Connections (RTUB)

Thoroughly flush all water piping to

the unit before making the final

piping connections to the unit.

CCAAUUTTIIOONN

If using an acidic commercial

flushing solution, construct a

temporary bypass around the unit to

prevent damage to internal

components of the evaporator. To

avoid possible equipment damage,

do not use untreated or improperly

treated system water.

When making the water connections,

use flange connectors. Insulate all

piping to reduce temperature

increases and to prevent

condensation. Figure 7 shows all the

piping systems for the evaporator

and its components. The

arrangement of the pipes and the

other components varies slightly

according to the positioning of the

connections and the water source.

CCAAUUTTIIOONN

The chilled water connections to the

evaporator are Victaulic connections.

Do not attempt to weld these

connections, because the heat

generated from welding can cause

microscopic and macroscopic

fractures on the cast- iron water

boxes that can lead to premature

failure of the water box.

A vent line is located on the top part

of the evaporator at the water return

piping end. Install additional vent

lines at the highest points in the

piping to vent the air present in the

chilled water circuit. Install

manometers to monitor the pressure

of chilled water entering and leaving

the evaporator.

CCAAUUTTIIOONN

To prevent damage to chilled-water

components, do not allow

evaporator pressure (maximum

working pressure) to exceed 10.5

bars.

Provide shutoff valves in lines to the

gauges, in order to isolate them from

the system when they are not in use.

Use rubber vibration eliminators to

prevent vibration transmission

through the water lines. If desired,

install thermometers in the lines to

monitor entering- and leaving-water

temperatures. Install a balancing

valve in the leaving-water line to

control water flow balance. Install

shutoff valves on both the enteringand leaving-water lines so that the

evaporator can be isolated for

service. A pipe strainer must be

installed in the entering water line.

Failure to do so can allow

waterborne debris to enter the

evaporator.

"Piping components" include all

devices and controls used to provide

proper water system operation and

unit operating safety. These

components and their general

locations are given in Figure 7.

Entering Chilled-Water Piping

• Air vents (to bleed air from system).

• Water pressure gauges with shutoff

valves.

• Vibration eliminators.

• Shutoff (isolation) valves.

• Thermometers (if desired).

• Clean out tees.

• Pipe strainer.

CCAAUUTTIIOONN

Install a strainer in the evaporatorwater inlet piping. Failure to do so

can result in evaporator tube

damage.

Leaving Chilled-Water Piping

• Air vents (to bleed air from system).

• Water pressure gauges with shutoff

valves.

• Vibration eliminators.

• Shutoff (isolation) valves.

• Thermometers (if desired).

• Clean out tees.

• Balancing valve.

• Flow Switch

Evaporator Drain

A 3/4" drain connection is located

under the outlet end of the

evaporator water box. This may be

connected to a suitable drain to

permit evaporator drainage during

unit servicing. A shutoff valve must

be installed on the drain line.

Evaporator Flow Switch (accessory)

The chilled water flow is protected

by the UCM-CLD without the

assistance of a chilled water flow

switch. The flow switch is optional,

but if it is not installed, a signal must

be sent to the chiller to indicate the

water flow is established, for

example the auxiliary contacts of the

chilled water pump starter.

If additional protection of the chilled

water flow proves necessary,

connect a flow switch installed on

site, or a differential pressure switch

to control the system's water flow.

Connect the flow switch in series

with the auxiliary contacts of the

chilled water pump motor starter. A

special connector is supplied with

the unit, with the wiring diagrams.

Some piping and control schemes,

particularly those using a single

water pump for both chilled- water

and hot water, must be analyzed to

determine how and/or if a flowsensing device will provide the

desired operation.

Installation

RLC-SVX03A-E4

Page 13

13

Follow the manufacturer's

instructions for the installation

procedures.

Flow Switch Installation

1. Mount the switch upright, with a

minimum of 5 pipe diameters of

straight horizontal run on each

side. Do not install close to

elbows, orifices, or valves. Note:

The arrow on the switch must

point in the direction of flow.

2. To prevent switch fluttering,

remove all air from the water

system. Note: The UCM-CLD waits

for six seconds after a “flow loss”

diagnosis before stopping the unit.

Contact a qualified service

representative if nuisance machine

shutdowns persist.

3. Adjust the switch to open when

water flow falls below nominal.

Evaporator data is given in Table 1.

Flow-switch contacts are closed on

proof of water flow.

4. Install a pipe strainer in the

entering evaporator-water line to

protect components from

waterborne debris.

Water Treatment

CCAAUUTTIIOONN

If calcium chloride is used for waste

treatment, an applicable corrosion

inhibitor must also be used. Failure

to do so may result in damage to

system components. Dirt, scale,

products of corrosion, and other

foreign material will adversely affect

heat transfer between the water and

system components. Foreign matter

in the chilled-water system can also

increase pressure drop and,

consequently, reduce water flow.

Proper water treatment must be

determined locally, depending on the

type of system and local water

characteristics. Neither salt nor

brackish water is recommended for

use in Trane units. Use of either will

lead to a shortened life to an

indeterminable degree. The Trane

Company encourages the

employment of a reputable water

treatment specialist, familiar with

local water conditions, to assist in

this determination and in the

establishment of a proper watertreatment program.

Water Pressure Gauges

Install field-supplied pressure

components as shown in Figure 7.

Locate pressure gauges or taps in a

straight run of pipe; avoid placement

near elbows, and so forth. Be sure to

install the gauges at the same

elevation on each shell if the shells

have opposite-end water

connections. Note: After the unit is

installed at a site, one vertical (or one

diagonal) unit support can be

permanently removed if it creates an

obstruction for water piping. To read

Installation

Figure 7 - Typical piping of the evaporator (RTUB)

1 Air vent

2 Balance valve

3 Flow switch

4 Thermometers

5 Expansion joints

6 Stop valves

7 Manometer

8 Evaporator

9 Filter

10 Drainage

RLC-SVX03A-E4

2

1

7

3

8

6

5

4

6

9

10

Page 14

14

Installation

the values given by the pressure

gauges, open one valve and close

the other.

Refrigerant Safety Valves

Discharge valves are an option for

the RTUB. If installation requires this

valve to be mounted, it is mandatory

to install two safety valves: one

between the compressor and the

service valve and the other after the

service valve to protect the

condenser.

CCAAUUTTIIOONN

The safety valve calibration must not

exceed 25 bars. The liquid line must

be connected at the inlet to the drier

filter which is supplied with a bend

blocked by a brazed plug. The

connection piping must be correctly

dimensioned and installed, because

these factors have a substantial

impact on the system's performance

and reliability.

Water Pressure-Relief

Valves

CCAAUUTTIIOONN

To prevent shell damage, install

pressure-relief valves in the

evaporator water system. Install a

water pressure-relief valve in the

evaporator inlet piping, between the

evaporator and the inlet shutoff

valve. Water vessels with closecoupled shutoff valves have a high

potential for hydrostatic pressure

buildup on a water temperature

increase. Refer to applicable codes

for relief-valve installation

guidelines.

Installing and connecting

temperature sensors

General Recommendations

Regardless of the type of monitoring

sensor required by a particular

application, the sensor must always

be positioned far enough from the

evaporator or condenser to enable

the sensor to read a correct

temperature for the mixed water.

Install the sensor at 4 o'clock on the

water piping to prevent any

condensation. When installing

standard or optional temperature

sensors described in the following

paragraphs, comply with the

instructions:

Put thermocontact paste in each

sensor bulbwell before inserting the

sensor. All the temperature sensors

installed on site have an

identification number and a serial

number marked on the part body.

Also note that both sensors in each

pair have the same serial number.

WWAARRNNIINNGG

To prevent degraded operation due

to electrical interference, run the

sensor cables in a duct. However, do

not lay sensor cables with other

cables whose voltage is greater than

30 VAC.

Extension of sensor power cable

A temperature sensor's power cable

may not be long enough to reach the

UCM. If this is the case for your

installation, connect the cable to a

junction box installed in a more

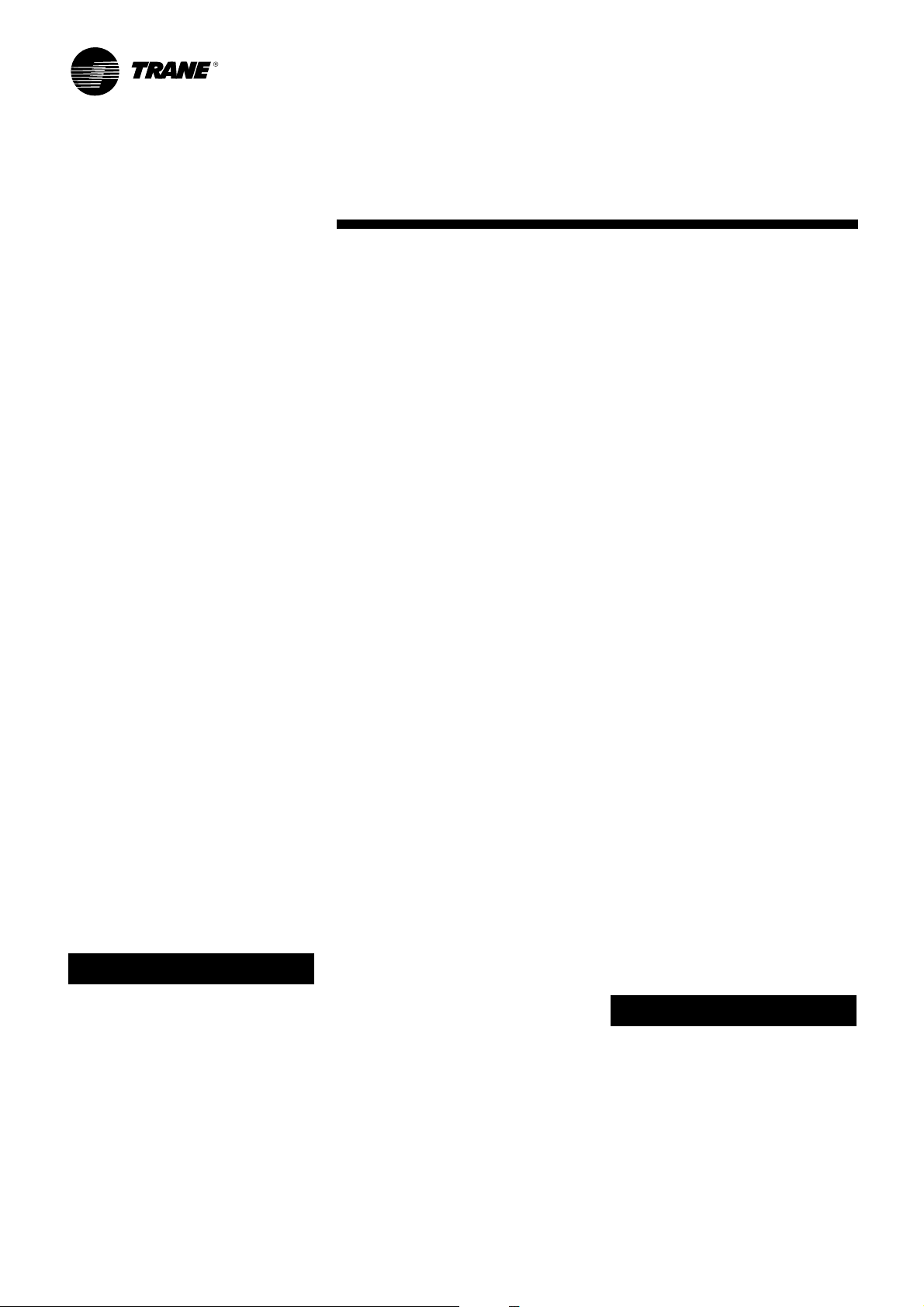

Figure 8- RTUB Evaporator water pressure drops

Evaporator Water Pressure Drop

Water Flow Rate l/s

kPa

RLC-SVX03A-E4

Page 15

15

Installation

withstanding high temperatures

without degradation.

CCAAUUTTIIOONN

A defect in fixing or insulating the

condensation sensors may cause

incorrect adjustment and/or damage

to the compressor.

If the sensor cannot be mounted in

the place where the saturated gas

enters the sub-cooler, it must be

positioned on the sub-cooler side

and not on the condenser side. If the

condenser temperature cannot be

measured, it is preferable to

measure the liquid temperature

instead of the discharge

temperature.

CCAAUUTTIIOONN

To prevent interference, separate the

sensor cables from the power cables.

Electrical connections

performed by the installer

All wiring must comply with local

codes. Specific electrical schematics

and connection diagrams are

shipped with the unit.

CCAAUUTTIIOONN

To avoid corrosion and overheating

at terminal connections, use copper

conductors only. Failure to do so

may result in damage to the

equipment. Do not allow conduit to

interfere with other components,

structural members or equipment.

Control voltage (110 V) wiring in

conduit must be separate from

conduit carrying low voltage (<30 V)

wiring. To prevent control

malfunctions, do not run low voltage

wiring (<30 V) in conduit with

conductors carrying more than 30 V.

Connecting the RTUB with a remote

air-cooled condenser

The RTUB unit is shipped with a

holding nitrogen charge and a

separate oil charge. The RTCA

condenser is designed to operate

with the RTUB unit. To ensure

optimum operation and

performance, the RTUB must be

installed with the RTCA condenser. If

correctly, refer to the general

recommendations. Connect the

outside air sensor 5R3 to terminals 1

and 2 on terminal board 1. Connect

the condenser sensor 5R56-1 to

terminals 4 and 5 on terminal board

J4 on module A20-1. Connect the

condenser sensor 5R56-2 to

terminals 4 and 5 on terminal J4 on

module A20-2.

If the condenser is not an RTCA,

ambient temperature and condenser

temperature sensors must be

connected to the RTUB to monitor it.

The ambient temperature sensor

must be installed in a position which

represents most accurately the

condenser's surrounding

environment. It must not be exposed

to sunlight or precipitation. Ensure

that the sensor is not located in the

flow of recycled air from the

condenser discharge. The

condensation temperature sensors

must be installed on the refrigerant

piping at the place where it leaves

the condenser to enter the subcooler. It is necessary to install a

condenser temperature sensor on

each refrigerant circuit. This sensor

must be fixed in compliance with the

method used to attach the bulb for a

thermostat expansion valve. This

sensor can be fixed outside the

piping if it is sufficiently insulated

with insulation capable of

convenient position. Plug the sensor

cable and the cable connected to the

control panel into the junction box.

The shielded cable can be cut to the

required length.

Note: To lengthen the sensor's power

cable, use 0.75 to 1.25 mm²

conductors, 600V. The cable used

between the junction box and the

control panel must either be shielded

or in a duct. If a shielded cable is

used, make sure it is not used with

other cables carrying 30 V or more.

Evaporator leaving water

temperature sensor 5R51 (standard)

Install this temperature sensor in the

evaporator's leaving water piping

system. To install it correctly, refer to

the general recommendations.

Connect this sensor to terminals

X7-1 and X7-2.

Evaporator entering water

temperature sensor 5R52 (standard)

Install this sensor in the evaporator

water piping. To install it correctly,

refer to the general

recommendations. Connect this

sensor across terminals X6-1 and

X6-2.

Condenser sensors 5R56-1, 5R56-2,

5R3 (option)

If an RTCA condenser is used with an

RTUB, the sensors required are

installed on the RTCA. To install them

Figure 9: UCM water temperature sensor installation

1 In

2 Out

3 UCM sensor

4 ¼" NPT coupling (customer-supplied)

5 Compression fitting (Trane-supplied)

6 Fitting body

7 Clamping nut

RLC-SVX03A-E4

5

2

7

6

4

1

3

Page 16

16

another manufacturer's condenser in

used, operation and performance

may be degraded. Depending on the

fan settings, malfunctioning may

damage the RTUB due to instability

of the high pressure.

Sound and vibration attenuating

device installation on the discharge

lines is strongly recommended in

order to avoid any acoustical

annoyance and distubing vibrations

leading to discharge line failures.

WWAARRNNIINNGG

If the condenser connected to a dualcircuit RTUB is not an RTCA, it must

comprise two refrigerant circuits,

each with its own ventilation. The

ventilation cannot be common to the

two circuits.

For this type of installation, (nonRTCA condenser), an On/Off signal is

available on the unit control module

(UCM) of the RTUB for each

refrigerant circuit, indicating whether

the fans on each condenser circuit

are on or off. The now autonomous

control of the fan on each condenser

circuit must comprise the following

staging:

For an ambient temperature between

0 and 40°C, there must be four

airflow control stages for each circuit

(i.e. 25% of the nominal airflow in

each stage).

Installation

13 2

57

1 Sensor

2 Connector

3 Brazed connector on the condenser

Figure 10 - Detail of positions of refrigerant sensors 5R56-1 and 5R6-2

RLC-SVX03A-E4

Page 17

17

Installation

Figure 11: Units on the same level

Limitations:The distance between the two units must not exceed 60 m in reality or the equivalent of 90 m taking into

account pressure drops. The height of the liquid line in relation to the unit base must be less than 5 m. It is

recommended to place a trap on the discharge line at the oil separator outlet, if this discharge line is horizontal for a

distance greater than 5 m, at a height greater than the connection to the oil separators.

Figure 12: RTCA (or other manufacturer's condenser) above the RTUB

Limitations:The distance between the two units must not exceed 60 m in reality or the equivalent of 90 m taking into

account pressure drops. Each 30 m level difference causes a 2% efficiency loss.

RLC-SVX03A-E4

1

2

4

3

Page 18

18

Installation

Figure 13: RTCA (or other manufacturer's condenser) below the RTUB

Limitations:The distance between the two units must not exceed 60 m in reality or the equivalent of 90 m taking into

account pressure drops. The height of the liquid line in relation to the condenser base must be less than 5 m.

Legend for Figures 11-12-13:

1 Discharge line connections

2 Liquid line connections

3 Trap

4 Counter-trap

RLC-SVX03A-E4

3

Page 19

19

Equivalent pressure drops

To correctly determine the size of the

liquid and discharge lines for

connection on site, it is first

necessary to establish the equivalent

pressure drops for each line,

comprising the additional flow

resistances, from bends, valves, etc.

As a first approximation, we can

estimate the equivalent pressure

drops at 1.5 times the piping length.

Size of the liquid line

The standpipe must not be more

than 5 m above the air-cooled

condenser base. It is not necessary

to slope the liquid line. It is

recommended to have a line

diameter as small as possible, while

maintaining an acceptable pressure

drop so as to minimize the

refrigerant charge (length and

maximum pressure drops defined

above).

Determine the size using the

following criteria:

1. Operating conditions with full load

2. Maximum pressure drops of

100-kPa

3. Liquid speed not exceeding 3 m/s

(to prevent liquid shocks)

In normal operating conditions

(suction temperature 4.5°C,

condenser air inlet temperature 35°C

or condensation temperature of

52°C), the liquid leaving the

condenser is sub-cooled by

approximately 10°C. Take this value

as a basis to determine the

maximum permitted pressure drops,

and use it to calculate the liquid line

pressure drops.

Discharge line

Install them so as to obtain a gas

speed in the horizontal and vertical

lines making it possible to carry

along the compressor oil. Determine

the dimensions of the suction line

using the following criteria:

1. 2.5 m/s (minimum) in the

horizontal parts

2. 5.0 m/s (minimum) in the vertical

parts

3. Maximum speed 20 m/s

The minimum slope of the suction

line to the condenser must be 5%.

Isolate refrigerant fluid lines from the

building to prevent the vibrations

normally generated by the ducts

from being transmitted to the

building's structure. Also avoid

bypassing the unit's isolation system

by fixing the refrigerant fluid lines or

the electrical ducts very rigidly. Any

vibrations may be propagated into

the building via rigid piping or lines.

Pressure tests and leak

detection

WWAARRNNIINNGG

During these operations, take the

following precautions:

1. Do not use oxygen or acetylene

instead of the refrigerant fluid and

nitrogen to detect leaks. This may

cause a violent explosion.

2. Always use the expansion valve,

safety valves and manometers to

control the test pressure in the

system. Excessive pressure may

cause piping to rupture, damage

the unit or cause explosion

resulting in personal injury.

Carry out the liquid line and hot gas

line pressure tests using the

standards in force. The test pressure

applied to the liquid line and the

discharge line must comply with

local regulations. Insert enough

refrigerant fluid into the circuit to

obtain a pressure of 1 bar.

By injecting dry nitrogen using a

pump, increase this pressure to

7 bars. Look for leaks in the entire

system using a detector.

If leaks are detected, evacuate the

fluid from the system and repair the

defective component. Repeat the test

process to check the repair is

watertight.

Installation

RLC-SVX03A-E4

Page 20

20

Vacuum pumping

For this operation, use a vane pump

making it possible to obtain a partial

vacuum or 100 microns or less.

When pumping out to create a

vacuum, it is important to connect

the pump to the high and low

pressure sides of the system. Follow

the pump manufacturer's

recommendations. The pipes used to

connect the pump to the system

must be made of copper, with the

largest diameter possible. A large

pipe diameter reduces flow

resistance and shortens the duration

of the vacuum pumping.

Do not use rubber or synthetic pipes

which retain humidity, increase the

duration of the vacuum pumping

and cause pressure rises during the

vacuum tests. An electronic vacuum

measurement manometer must be

installed upstream of the vacuum

pump stop valve.

1. Close valve B and open valve A.

After a few minutes, the

manometer reading indicated the

lowest vacuum level that can be

obtained by the pump.

2. Open valve B and operate the

vacuum pump until 1500 Hg

microns (0.67 mbar) or less is

obtained. Close valve A when you

read the manometer.

3. Once the value of 500 microns or

less has been reached and valve A

has been closed, the pressure will

rise.

The maximum permissible increase

is 200 microns after 15 minutes. If

this limit is exceeded and the value

remains constant, there is too much

humidity in the system. A continuous

increase in pressure indicates there

is a leak in the system.

Installation

Figure 14 - Vacuum pump connection

1 Header

2 Valve B

3 Vacuum pump

4 Vacuum manometer

5 Valve A

6 Low pressure side

7 High pressure side

RLC-SVX03A-E4

2

1

4

6

5

3

7

Page 21

21

Pre-start checkout

Installation Checklist

When installation is complete, but

prior to putting the unit into service,

the following pre-start procedures

must be reviewed and verified:

• Inspect all wiring connections to be

sure they are clean and tight.

WWAARRNNIINNGG

Disconnect all electric power,

including remote disconnects, before

servicing. Failure to disconnect

power before servicing can cause

severe personal injury or death.

CCAAUUTTIIOONN

• Check the tightness of all

connections in the compressor

power circuit (disconnects, terminal

block, contactors, compressor

junction box terminals,…). Loose

connections can cause overheating

at the connections and

undervoltage conditions at the

compressor motor.

• Open all refrigerant valves in the

discharge, liquid, oil, and oil return

lines.

CCAAUUTTIIOONN

Do not operate the unit with the

compressor, oil discharge, liquid-line

service valves, or the manual shutoff

on the refrigerant supply to the

auxiliary coolers "CLOSED." Failure

to have these "OPEN" may cause

serious compressor damage.

• Check the power-supply voltage to

the unit at the main-power fuseddisconnect switch. Voltage must be

within the voltage utilization range

and also stamped on the unit

nameplate. Voltage imbalance must

not exceed 2%.

• Check the unit power phasing L1L2-L3 in the starter to ensure that it

has been installed in an "A B-C"

phase sequence.

CCAAUUTTIIOONN

Improper power phasing can result

in equipment damage due to reverse

rotation.

Do not use untreated or improperlytreated water. Equipment damage

may occur.

• Fill the evaporator chilled-water

circuit. Vent the system while it is

being filled. Open the vents on the

top of the evaporator water box

while filling and close when filling

is completed.

The use of improperly-treated or

untreated water in this equipment

may result in scaling, erosion,

corrosion, algae, or slime. The

services of a qualified watertreatment specialist should be

engaged to determine what

treatment, if any, is advisable. Trane's

warranty specifically excludes

liability of corrosion, erosion, or

deterioration of Trane equipment.

Trane assumes no responsibilities for

the results of the use of untreated or

improperly-treated water, or saline or

brackish water.

• Close the fused-disconnect

switch(es) that supplies power to

the chilled-water pump starter.

• Start the chilled-water pump to

begin circulation of the water.

Inspect all piping for leakage and

make any necessary repairs.

• With water circulating through the

system, adjust the water flow and

check the water pressure drop

through the evaporator.

• Adjust the chilled-water flow switch

for proper operation.

WWAARRNNIINNGG

Use extreme caution when

performing the following procedure

with power applied. Failure to do so

can result in personal injury or

death.

• Reapply power to complete the

procedures.

• Prove all Interlock and

Interconnecting Wiring Interlock

and External as described in the

Installation section.

• Check and set, as required, all

UCM-CLD menu items.

• Stop the chilled-water pump.

• Energize the compressor and oil

separators 24 hours prior to unit

startup.

Unit Voltage Power Supply

Voltage to the unit must meet the

criteria given in the Installation

section. Measure each leg of the

supply voltage at the main power

fused-disconnect switch for the unit.

If the measured voltage on any leg is

not within the specified range, notify

the supplier of the power and correct

the situation before operating the

unit.

CCAAUUTTIIOONN

Provide adequate voltage to the unit.

Failure to do so can cause control

components to malfunction and

shorten the life of relay contact,

compressor motors and contactors.

Unit Voltage Imbalance

Excessive voltage imbalance

between the phases of a three-phase

system can cause motors to

overheat and eventually fail. The

maximum allowable imbalance is

2%. Voltage imbalance is determined

using the following calculations:

% Imbalance = [(Vx - V ave) x 100]/V

ave

V ave = (V1 + V2 + V3)/3

Vx = phase with the greatest

difference from V ave (without

regard to the sign)

For example, if the three measured

voltages are 391, 407, and 402 volts,

the average would be:

(391+407+402)/3 = 400

The percentage of the imbalance is

then:

[100(400-391)]/400 = 2.25%

This exceeds the maximum

allowable (2%) by 0.25%

Unit Voltage Phasing

It is imperative that L1, L2, and L3 in

the starter be connected in the A-B-C

phase sequence to prevent

equipment damage due to reverse

rotation.

It is important that proper rotation of

the compressors be established

before the unit is started. Proper

Operation

RLC-SVX03A-E4

Page 22

22

Operation

motor rotation requires confirmation

of the electrical phase sequence of

the power supply. The motor is

internally connected for clockwise

rotation with the incoming power

supply phased A-B-C.

When rotation is clockwise, the

phase sequence is usually called

"ABC;" when counterclockwise,

"CBA." This direction may be

reversed outside the alternator by

interchanging any two of the line

wires. It is this possible interchange

of wiring that makes a phase

sequence indicator necessary if the

operator is to quickly determine the

phase rotation of the motor.

1. Press the Stop key on the UCMCLD.

2. Open the electrical disconnect or

circuit protection switch that

provides line power to the linepower terminal block(s) in the

starter panel (or to the unitmounted disconnect).

3. Connect the phase-sequence

indicator leads to the line power

terminal block as follows:

Phase Sequence Lead Terminal

Black (Phase A) L1

Red (Phase B) L2

Yellow (Phase C) L3

4. Turn power on by closing the unit

supply-power fused-disconnect

switch.

5. Read the phase sequence on the

indicator. The "ABC" LED on the

face of the phase indicator will

glow if the phase is "ABC."

WWAARRNNIINNGG

To prevent injury or death due to

electrocution, take extreme care

when performing service procedures

with electrical power energized.

6. If the "CBA" indicator glows

instead, open the unit main-power

disconnect and interchange two

line leads on the line-power

terminal block(s) (or the unitmounted disconnect). Close the

main-power disconnect and

recheck the phasing.

Do not interchange any load leads

that are from the unit contactors or

the motor terminals. Doing so may

damage the equipment.

7. Reopen the unit disconnect and

disconnect the phase-sequence

indicator.

Water-System Flow Rates

Establish a balanced chilled-water

flow through the evaporator. The flow

rates should be between the

minimum and maximum values

given on the pressure-drop curves.

Water-System Pressure Drop

Measure the water-pressure drop

through the evaporator at the fieldinstalled pressure taps on the system

water piping. Use the same gauge for

each measurement. Do not include

valves, strainers, or fittings in the

pressure-drop readings.

Start-up Procedures

Daily Unit Start-up Procedure

When the verification operations

prior to start-up have been performed

(see previous sections), the unit is

ready to start.

• Press the Stop key on the UCM-CLD.

• If necessary, adjust the setpoint

values in the UCM-CLD reports

(refer to the UCM-CLD user guide).

• Close the fused disconnect switch

for the chilled water pumps and the

cooling water pumps.

• Energize the pumps to start the

water circulation.

• Check the service valves on the

discharge line, suction line, oil line

and liquid line for each circuit.

These valves must be open before

starting the compressors.

WWAARRNNIINNGG

To prevent compressor damage, do

not operate the unit until all

refrigerant and oil-line valves are

opened.

• Verify that the chilled water pump

runs for one minute after the chiller

is commanded to stop for normal

chilled water systems).

• Press the Auto key. If the chiller

control calls for cooling and all the

safety interlocks are closed, the unit

will start. The compressor(s) will

load and unload in response to the

temperature of the leaving chilledwater temperature.

After the system has been operating

for approximately 30 minutes and

has become stabilized, complete the

start-up procedure as follows:

• Check the evaporator refrigerant

pressure and the condenser

refrigerant pressure in the

Refrigerant report of the UCM-CLD.

• Measure the system overheat.

• Measure the system subcooling.

A shortage of refrigerant is indicated

if the operating pressures and the

subcooling are low. If the operating

pressures, superheat, and

subcooling readings indicate a

refrigerant shortage, gas-charge

refrigerant into each circuit as

required. With the unit running, add

refrigerant vapor by connecting the

charging line to the suction service

valve and charging through the

backseat port until operating

conditions become normal.

WWAARRNNIINNGG

If both suction and discharge

pressures are low and subcooling is

normal, a problem other than

refrigerant shortage exists. Do not

add refrigerant, as this may result in

overcharging the circuit.

Only use the refrigerant specified on

the unit nameplate.

• If operating conditions indicate a

refrigerant overcharge, remove

refrigerant at the liquid line service

valve. Allow refrigerant to escape

slowly to minimize oil loss. Do not

discharge refrigerant into the

atmosphere.

WWAARRNNIINNGG

Do not allow refrigerant to directly

contact skin, or injury from frostbite

may result.

Overheating

Normal overheating for each circuit

is approximately 3-4°C at full

RLC-SVX03A-E4

Page 23

23

operating load. Overheating may

vary slightly on the circuit if the

system load is lower, when the slide

valve is moving.

Overheating must stabilize at

approximately 4°C when the above

components have stabilized.

Subcooling

Normal subcooling for each circuit

ranges from 8-10°C, depending on

the units. If subcooling for either

circuit does not fall within these

values, check the overheating for the

circuit and adjust if necessary. If

overheating is normal but

subcooling is not, contact a qualified

service technician.

Seasonal Unit Start-up

1. Close all valves and reinstall the

drain plugs in the evaporator.

2. Service the auxiliary equipment

according to the startup and

maintenance instructions provided

by the respective equipment

manufacturers.

3. Close the vents in the evaporator

chilled-water circuits.

4. Open all the valves in the

evaporator chilled-water circuits.

5. Open all refrigerant valves to

verify they are in the open

condition.

6. If the evaporator was previously

drained, vent and fill the

evaporator and chilled-water

circuit. When all air is removed

from the system (including each

pass), install the vent plugs in the

evaporator water boxes.

CCAAUUTTIIOONN

Ensure that the compressor and oilseparator heaters have been

operating for a minimum of 24 hours

before starting. Failure to do so may

result in equipment damage.

7. Check the adjustment and

operation of each safety and

operating control.

8. Close all disconnect switches.

9. Refer to the sequence for daily

unit startup for the remainder of

the seasonal startup.

Shutdown procedures

Temporary Shutdown and Restart

To shut the unit down for a short

time, use the following procedure:

1. Press the Stop key on the UCMCLD. The compressors will

continue to operate and, after

unloading for 20 seconds, will stop

when the compressor contactor

de-energizes.

2) Stop the water circulation by

disconnecting the power supply to

the chilled water and cooling

water pumps.

CCAAUUTTIIOONN

Under freezing conditions, the chilled

water pump must remain in

operation during the full shutdown

period of the chiller if the chilled

water loop does not contain glycol,

to prevent any risk of evaporator

freeze-up.

Extended period shutdown

The procedure below must be

performed if the system has to be

stopped for a prolonged period, for

example seasonal shutdown.

1. Test the unit for refrigerant leakage

and repair as necessary.

2. Open the electrical disconnect

switches for the chilled-water

pump. Lock the switches in the

"Open" position.

CCAAUUTTIIOONN

Lock the chilled-water pump

disconnects open to prevent pump

damage.

3. Close all chilled-water supply

valves. Drain the water from the

evaporator.

4. Open the unit main electrical

disconnect and unit-mounted

disconnect (if installed) and lock in

the "Open" position. If the optional

control-power transformer is not

installed, open and lock the 115 V

disconnect.

CCAAUUTTIIOONN

Lock the disconnects in the "Open"

position to prevent accidental startup

Operation

and damage to the system when it

has been set up for extended

shutdown.

5. At least every three months

(quarterly), check the refrigerant

pressure in the unit to verify that

the refrigerant charge is intact.

CCAAUUTTIIOONN

During an extended shutdown

period, especially over the winter

season, the evaporator must be

drained of water, if the chilled water

loop does not contain glycol, to

prevent any risk of evaporator freezeup.

System Restart After Extended

Shutdown

1. Verify that the liquid-line service

valves, oil line, compressor

discharge service valves, and

suction service valves are open

(backseated).

CCAAUUTTIIOONN

To prevent damage to the

compressor, ensure that all

refrigerant valves are open before

starting the unit.

2. Check the oil separator oil level

(see Maintenance section).

3. Fill the evaporator water circuit.

Vent the system while it is being

filled. Open the vent on the top of

the evaporator and condenser

while filling, and close it when

filling is completed.

CCAAUUTTIIOONN

Do not use untreated or improperly

treated water. Equipment damage

may occur.

4. Close the fused-disconnect

switches that provide power to the

chilled-water pump.

5. Start the evaporator water pump

and, while water is circulating,

inspect all piping for leakage.

Make any necessary repairs before

starting the unit.

6. While the water is circulating,

adjust the water flows and check

the water pressure drops through

the evaporator. Refer to "Water-

RLC-SVX03A-E4

Page 24

24

Operation

System Flow Rates" and "WaterSystem Pressure Drop."

7. Adjust the flow switch on the

evaporator piping for proper

operation.

8. Stop the water pump. The unit is

now ready for startup as described

in "Startup Procedures."

RLC-SVX03A-E4

Page 25

25

Perform all maintenance procedures

and inspections at the recommended

intervals. This will prolong the life of

the chiller and minimize the

possibility of costly failures. After the

unit has been operating for

approximately 30 minutes and the

system has stabilized, check the

operating conditions and complete

the following procedures:

Weekly Maintenance

While the unit is running in stable

conditions:

1. Check the UCM pressure for

Evaporator, Condenser, and

Intermediate Oil.

2.Measure the subcooling entering

the EXV. The subcooling should

never be less than 2.2°C under any

circumstances.

CCAAUUTTIIOONN

Also check the rest of the system

operating conditions.

3. Inspect the entire system for

unusual conditions and inspect the

condenser coils for dirt and debris.

If the coils are dirty, refer to coil

cleaning.

Monthly Maintenance

1. Perform all weekly maintenance

procedures.

2. Record the system subcooling.

3. Record the system superheat.

4. Make any repairs necessary.

Annual Maintenance

1. Perform all weekly and monthly

procedures.

2. Check the oil sump oil level while

the unit is off.

Note: Routine changing of the oil is

not required. Use an oil analysis to

determine the condition of the oil.

3. Have a qualified laboratory

perform a compressor oil analysis

to determine system moisture

content and acid level. This

analysis is a valuable diagnostic

tool.

4. Contact a qualified service

organization to leak-test the chiller,

to check operating and safety

controls, and to inspect electrical

components for deficiencies.

5. Inspect all piping components for

leakage and damage. Clean out

any inline strainers.

6. Clean and repaint any areas that

show signs of corrosion.

7. Clean the condenser coils.

WWAARRNNIINNGG

Position all electrical disconnects in

the "Open" position and lock them

to prevent injury or death due to

electrical shock.

8. Check and tighten all electrical

connections as necessary.

Coil Maintenance

Because seacoast applications are

considered to be a "dirty"

environment for condenser coils, it is

logical that the coils will need to be

cleaned more often than a coil

located inland. Cleaning four times a

year may be required or even more if

conditions are very poor or if

corrosion damage begins to occur.

To clean the coils, use a soft brush

and a sprayer (garden pump-up

type). A high-quality detergent, such

as "Trane Coil Cleaner, CHM0021" is

recommended for both standard and

coils with aluminium coating.

Follow the directions included with

the detergent. The most effective

method of coil cleaning is to remove

the condenser end panels and clean

the coils from the inside out using

the sprayer.

CCAAUUTTIIOONN

If the detergent used is strongly

alkaline (pH greater than 8.5), an

inhibitor must be added.

Rinse the coil thoroughly after

cleaning. Failure to completely flush

the detergent from the coil can result

in accelerated coil corrosion. Blow

excess water from the coil using lowpressure air. The water used to clean

the coils should always be clean,

fresh water (it should not be

brackish, or contain excessive

dissolved minerals, chlorine, or

water softener salts.)

Chemical Cleaning of the Evaporator

(RTUB)

The chilled water circuit is a closed

circuit, and therefore should not

accumulate scale or sludge. If the

chiller becomes obstructed, you can

attempt to unblock it by reversing

the water flow direction. If

unsuccessful after several attempts,

clean the evaporator chemically.

WWAARRNNIINNGG

Do not use an acid cleaning product

which might damage steel,

galvanized steel, polypropylene and

copper parts.

Contact a local water treatment

company advice on a suitable

chemical product for this unit. The

supplier of the cleaning product

must supply or approve:

• All devices used in the circuit

• The quantity of chemical product to

use

• The duration for which the chemical

product must circulate in the

evaporator

• Safety precautions and

recommendations for using and

handling the chemical product

Replacing the Oil Filter

Note: Routine changing of the oil or

oil filter is not recommended. The oil

filter is oversized for this application

and should not require replacement.

The oil and filter should be replaced

only if analysis reveals that the oil is

contaminated. Oil type and system

capacities are shown in Table 1.

Pressure drop across the oil filter is

shown in Figure 15. Oil filter

pressure drop is the difference

between the two pressure-control

ports.

To change the oil filter in the unit,

refer to Figure 15 and follow the

steps listed.

Maintenance

RLC-SVX03A-E4

Page 26

26

For units without discharge valve

option

1. Shut off the compressor and

disconnect all electrical service to

the compressor.

2. Vacuum the refrigerant out of the

circuit.

3. Remove the seven bolts on the oil

filter cover. A pan may be

necessary to catch any oil that is

released after the cover is

loosened.

4. Remove the cover and the oil filter

element.

5. Install the new filter element.

6. Coat the new cover gasket with

refrigerant oil.

7. Install the cover plate and cover

plate gasket.

8. Install a new copper gasket under

the bolt head that had one at time

of removal. Replace all other bolts

and tighten to 89.5 Nm.

9. Vacuum the refrigerant circuit at

500 micron and isolate the

vacuum pump.

10. Confirm that no moisture or leaks

are present by letting the vacuum

stand for 2 hours. The pressure

should not raise more than

250 microns.

11. Charge the unit with oil, in a

quantity equal to what has been

removed, by using the charging

valve placed on the oil filter.

Note: the oil is very sensitive to

moisture. Use the oil immediately

after the oil can has been opened.

12. Charge the unit with refrigerant

R134a refer to charging

procedure).

For units with the discharge valve

option:

1. Close the angle valve placed on

the refrigerant liquid line to store

the refrigerant in the condenser.

2. After the compressor stops, close

the compressor discharge valve

and disconnect the unit.

Note: Do not make successive

vacuums by using the compressor.

Irreversible compressor damage

could occur.

3. Vacuum the remaining refrigerant

in the evaporator.

4. Remove the seven bolts on the oil

filter cover. A pan may be

necessary to catch any oil that is

released after the cover is

loosened.

5. Remove the cover and the oil filter

element.

6. Install the new filter element.

7. Coat the new cover gasket with

refrigerant oil.

8. Install the cover plate and cover

plate gasket.

9. Install a new copper gasket under

the bolt head that had one at time

of removal. Replace all other bolts

and tighten to 89.5 Nm.

10. Vacuum the refrigerant circuit at

500 micron and isolate the

vacuum pump.

11. Confirm that no moisture or leaks

are present by letting the vacuum

stand for 2 hours. The pressure

should not raise more than

250 microns.

12. Charge the unit with oil, in a

quantity equal to what has been

removed, by using the charging

valve placed on the oil filter.

Note: the oil is very sensitive to

moisture. Use the oil immediately

after the oil can has been opened.

13. Open all the valves before

restarting the chiller.

Maintenance

Figure 15 - Oil filter change

1. Oil charging valve

2. Oil pressure control port

3. Oil pressure control port

Figure 16 - Oil filter pressure drop

Condensing Pressure - Suction Pressure (bar)

Oil filter pressure drop (bar)

Normal pressure drop

Maximum pressure drop

RLC-SVX03A-E4

Page 27

27

Follow the steps listed below and

refer to the notes listed in Figure 17.

1. Turn off the unit.

2. Attach the hoses and sight glass to

the oil-separator Schrader valves,

as shown in Figure 17. Remove

non-condensables.

3. After the unit has been off for

10 minutes, move the sight glass

up and down until the level can be

seen.

4. After the level has been

determined, remove the sight

glass and hoses.

Refrigerant and Oil-Charge

Management

Proper oil and refrigerant charge is

essential for proper unit operation,

unit performance, and

environmental protection. Only

trained and licensed service personal

should service the unit.

Some symptoms of a refrigerant

under-charged unit:

• Low subcooling

• Larger-than-normal evaporator

approach temperatures (LeavingWater Temperature - Saturated

Evaporator Temperature)

• Low Evaporator-Refrigerant

Temperature Limit

• Low Refrigerant-Temperature

Cutout diagnostic

• Fully-open expansion valve

• Possible whistling sound coming

from liquid line (due to high vapor

velocity)

• High Condenser + Subcooler

Pressure drop

Some symptoms of a refrigerant

over-charged unit:

• High subcooling

• Larger-than-normal condenser

approach temperatures (EnteringCondenser Saturated Temperature Entering-Air Temperature)

• Condenser Pressure Limit

• High-Pressure Cutout diagnostic

• More-than-normal number of fans

running

• Erratic fan control

• Higher-than-normal compressor

power

• Very low discharge superheat at

startup

• Compressor rattle or grinding

sound at startup

Some symptoms of an oil overcharged unit:

• Larger-than-normal evaporator

approach temperatures (LeavingWater Temperature - Saturated

Evaporator Temperature)

• Low Evaporator-Refrigerant

Temperature Limit

• Low Refrigerant-Temperature

Cutout diagnostic

• Low unit capacity

• Compressor rattle or grinding

sound

• High oil-sump level after normal

shutdown

Checking the separator oil

level

Figure 17 - System Oil Specifications

1 Oil separator

2 Valve

3 ¼" refrigeration hose

4 Sight glass

5 Minimum oil level

6 Maximum oil level

Table 5 - Oil level limit

Oil separator diameter (mm)

152 203 254

Minimum oil level (mm) 90 120 145

Maximum oil level (mm) 155 205 235

Maintenance

RLC-SVX03A-E4

Page 28

28

Some symptoms of an oil undercharged unit:

• Compressor rattle or grinding

sound

• Lower-than-normal pressure drop

through oil system

• Seized or Welded Compressors

• Low oil-sump level after normal

shutdown

• Lower-than-normal oil

concentrations in the evaporator

R134a Field-Charging

Procedure

Be certain that the electrical power to

the unit is disconnected before

performing this procedure.

WWAARRNNIINNGG

Position all electrical disconnects in

the "Open" position and lock them to

prevent injury or death due to

electrocution. Follow this procedure

when the unit is empty of all

refrigerant and under a vacuum.

CCAAUUTTIIOONN

Water must be flowing through the

evaporator during the entire

charging process to avoid freezing

and rupturing of the evaporator

tubes.

1. Find the weight of the amount of

charge given in Table 1.

2. Attach the charging hose to the

evaporator service valve (3/8"

[9 mm] flare). Open the service

valve.

3. Add charge to the evaporator to

bring the total circuit charge up to

the level given in Table 1.

4. Close the service valve and

disconnect the charging hose.

Adding charge

This procedure should be followed

when adding charge to an

undercharged unit. When low charge

is indicated by low subcooling in the

liquid line, charge should be added

until sufficient subcooling is

achieved.

1. Attach the charging hose to the

evaporator service valve (3/8"

[9 mm] flare). Open the service

valve.

2. Add 4.5 kg of refrigerant (R134a)

charge.

3. Close the valve, remove the

charging hose and start the unit.

Monitor subcooling.

4. If subcooling is still insufficient,

return to step number 2.

Note: Proper subcooling can be

determined from run-log history,

service experience, or by contacting

Trane technical service. The service

tool may include a calculation

module that determines the proper

subcooling for any operating

condition (Trane Service only).

Charge Isolation in the high

or low side of the system

All the refrigerant may be trapped

into the high side (condenser) of the

unit for maintenance on the

compressor (or low side). With the

suction-line service valve option,

charge may also be isolated in the

evaporator for maintenance on the

compressor (or high side). It is much

more preferable to isolate the charge

in the evaporator, if this option is

available.

High side charge isolation procedure:

1. Make sure the circuit is off.

2. Shut the liquid-line service valve.

3. Shut the oil return-line service

valve.

4. Start the circuit with the service

tool in charge-isolation mode:

• All fans will turn on

• EXV will open 100%

• The oil return-line solenoid will

open

• The unit will start at minimum load

• The unit will run until it cuts out on

low pressure (~6 psia) [0.41 bar].

5. When the unit trips, the discharge

check valve and the oil-line shutoff

valve close.

6. Close the discharge isolation

valve.

7. Close the oil-line shutoff valve.

8. Remove the remainder of the

charge with the vacuum pump.

Recommendation: Do not pump

the remaining charge into the high

side. This may introduce noncondensable gasses and other

contaminants into the unit.

9. The low side and the compressor

may be serviced at this time.

Returning the unit to running

condition:

1. Open all the valves.

2. Manually open EXV for 15 minutes

to allow the refrigerant to drain to

the evaporator by gravity.

3. Let the unit sit with heaters on to

drive refrigerant out of the oil and

warm up the compressor

bearings. Depending upon

ambient conditions, this may take

up to 24 hours.

4. After the oil level has returned to

normal, the unit can be put back

into operation.

Low-side charge-isolation procedure:

After normal shutdown, most of the

charge resides in the evaporator.

Running cold water through the

evaporator may also drive much of

the refrigerant to the evaporator.

1. Make sure the circuit is off.

2. Close the suction-line isolation

valve.

3. Close the oil return-line service

valve.

4. Close the liquid line service valve.

5. Manually open the EXV.

6. Use a liquid pump or vacuum

pump to move refrigerant from