Page 1

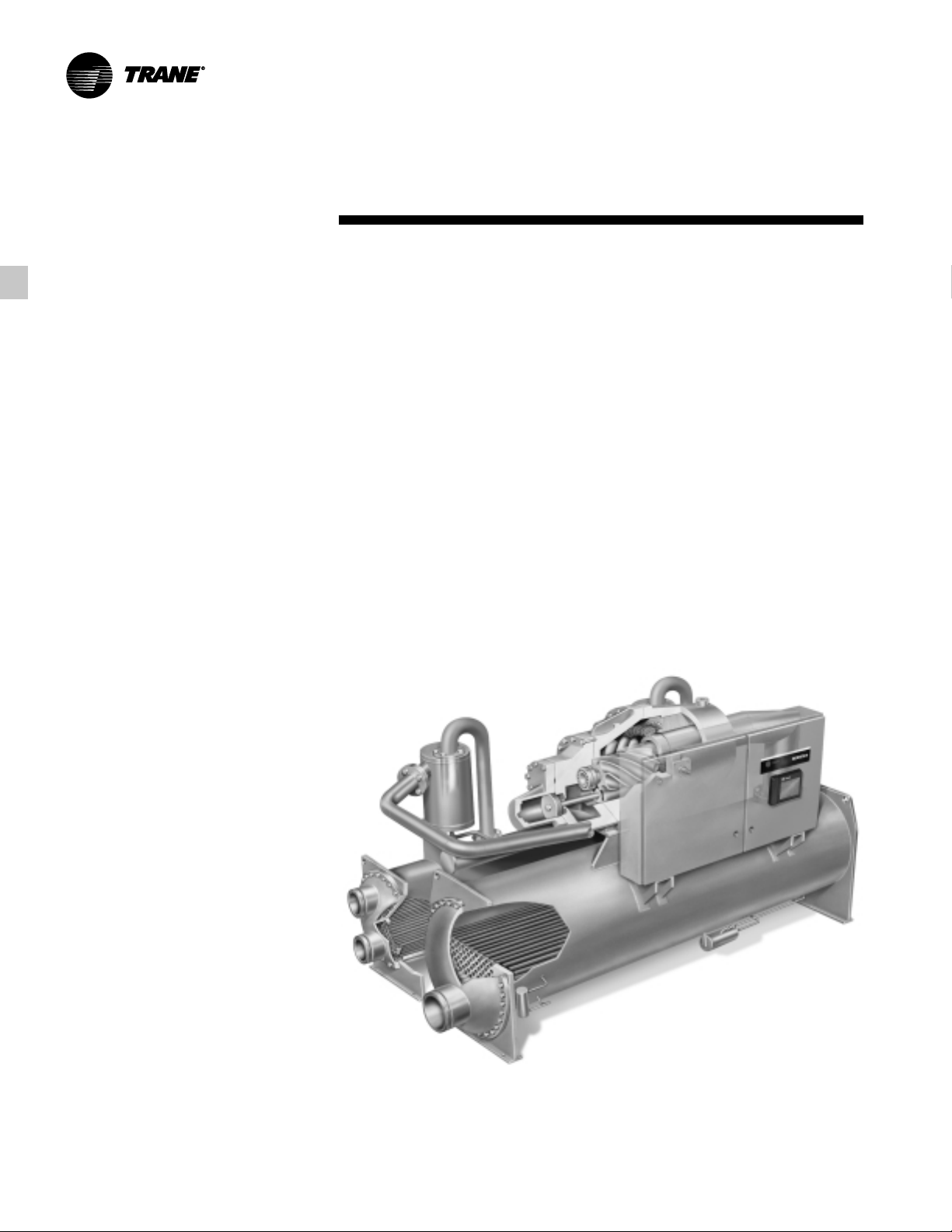

Series R™ Helical Rotary

Liquid Chillers

Model RTHD

175-450 Tons (60 Hz)

125-450 Tons (50 Hz)

Built for Industrial and Commercial Applications

RLC-PRC020-ENApril 2003

Page 2

Introduction

To meet a wide range of applications in

the medium-tonnage, water-cooled

market, Trane is proud to introduce the

model RTHD helical rotary liquid chiller.

The introduction of this next-generation

chiller an exciting step forward in

application versatility, ease of

installation, control precision, reliability,

energy-efficiency, and operational costeffectiveness. The new RTHD chiller is

designed to deliver proven Series R

performance, plus all the benefits of an

advanced heat transfer design and a

low-speed, direct-drive compressor.

Important Design Advances

and New Features

Major design advances include:

• Higher full-load energy efficiency

reduces both operating and life-cycle

costs.

• CH530 controls enable:

- scrolling access to inputs and

operating information via the LCD

touch-screen display;

- freedom from interoperability

concerns with LonMark

communications;

- job-specific communication options

that allow greater reporting flexibility.

• Improved startup temperature

capabilities and reduced sensitivity to

condenser water temperatures alleviate

the most common startup concerns.

• Removed Liquid Vapor Separator,

providing lighter unit weight and

simplified refrigerant piping, for less

expensive handling, separation, and

installation.

The industrial-grade design of the Series

R helical rotary chiller is ideal for both

industrial and commercial markets, in

applications such as office buildings,

hospitals, schools, retail buildings, and

industrial facilities. The linear unloading

compressor, wide operating temperature

range, advanced controls, electronic

expansion valve, short anti-recycle

timers, and industry-leading efficiencies

mean that this latest Trane Series R

chiller is the perfect choice for tight

temperature control in almost any

application temperatures, and under

widely varying loads.

RLC-PRC020-EN© 2003 American Standard Inc. All rights reserved.

Page 3

Contents

Introduction

Features and Benefits

Options

Display

Application Considerations

Selection Procedure

Model Nomenclature

General Data

Electrical Data and Connections

Dimensions and Weights

Mechanical Specifications

2

4

6

8

9

11

13

15

17

20

27

RLC-PRC020-EN

3

Page 4

Features and

Benefits

Application Versatility and High

Performance

• Screw compressor technology and the

electronic expansion valve provide

reliable performance in an expanded

range of operating temperatures.

• Tight water temperature control

extends to operation of multiple chillers

in parallel or series configurations,

offering further system design flexibility

for maximum efficiency.

• Advanced design enables chilled water

temperature control to +/- 0.5°F (.28°C)

for flow changes up to 10 percent per

minute, plus handling of flow changes

up to 30 percent per minute for comfort

cooling.

• Two-minute stop-to-start and fiveminute start-to-start anti-recycle timer

allows tight chilled water temperature

control in constant or transient lowload applications.

• LonMark communications capability

provides excellent, trouble-free

interoperability.

Applications in this catalog specifically

excluded from the ARI certification

program are:

• Low temperature applications,

including ice storage

• Glycol

• 50Hz units below 200 nominal tons

• Generic Building Automation System

points are available for easy access to

operational information.

• Extensive information on professional

design selection and layout is available

in a simple, highly readable electronic

format.

• Standard model RTHD configurations

are in stock and available for immediate

delivery, and Trane offers the fastest

ship cycles in the industry for built-toorder units.

• Industrial / Low Temperature Process

Cooling – Excellent operating

temperature range and precise control

capabilities enable tight control with

single chiller or series configuration.

• Ice/Thermal Storage – Specifiers and

operators benefit from dual setpoint

control and industry-leading

temperature, efficiency, and control

capabilities, plus outstanding support

through partnership with Calmac, a

strong Trane partner providing proven

installation examples, templates, and

references that minimize design time

and energy costs.

• Heat Recovery – Maximum condenser

temperature exceeds those of previous

technologies, providing hot water and

tight control that minimizes operating

costs for the chilled water plant and

boiler/hot water heater, and consistent

dehumidification.

Simple, Economical Installation

• Compact size makes the model RTHD

well suited for the retrofit and

replacement market.

• All units fit through standard doublewidth doors.

• Bolt-together construction makes for

fast, easy unit disassembly.

• Small RTHD footprint saves valuable

equipment room space and alleviates

access concerns for most retrofit jobs.

• Lightweight design simplifies rigging

requirements, further reducing

installation time requirements and

costs.

• Full factory refrigerant or nitrogen and

oil charges reduce required field labor,

materials, and installation cost.

• Only evaporator and condenser water

piping is required; no starter water

cooling (with its associated safety

concerns) or field piping is necessary.

• Oil cooler and purge system

connections have been eliminated.

• Simple power connection simplifies

overall installation.

• Standard unit-mounted starter for

Wye-Delta and Solid State eliminates

additional jobsite installation

considerations and labor requirements.

• Trane has conducted extensive factory

testing, and also offers options for inperson and/or documented system

performance verification.

• CH530 controls easily interface with

Tracer Summit™ building automation

systems through single twisted-pair

wire.

Pueblo

Business Unit

RLC-PRC020-EN4

Page 5

Features and

Benefits

State-of-the-Art, Precision Control

• Microprocessor-based CH530 controls

monitor and maintain optimal

operation of the chiller and its

associated sensors, actuators, relays,

and switches, all of which are factoryassembled and extensively tested.

• Easy interface with computers hosting

Tracer Summit

energy management systems allows

the operator to efficiently optimize

comfort system performance and

minimize operating costs.

• PID (proportional integral derivative)

control strategy ensures stable, efficient

chilled water temperature control,

maintaining +/- 1°F (0.56°C) control by

proactively reacting to instantaneous

load changes of up to 50 percent.

• Adaptive Control

chiller operation under adverse

conditions, when many other chillers

might simply shut down.

• Easy-to-use operator interface displays

all operating and safety messages, with

complete diagnostics information, on a

highly readable panel with a scrolling

touch-screen display.

• The RTHD features a complete range of

chiller safety controls.

• Over 120 diagnostic and operating

points are available, with standard

displays including chiller current draw,

condenser pressure, and evaporator

pressure.

Reliability and Ease of Maintenance

• Direct drive, low-speed compressor – a

simple design with only three moving

parts – provides maximum efficiency,

high reliability, and low maintenance

requirements.

• Electronic expansion valve, with fewer

moving parts than alternative valve

designs, offers highly reliable

operation.

• Suction gas-cooled motor stays

uniformly cool at lower temperatures

for longer motor life.

™

building automation/

™

attempts to maintain

• The Trane helical rotary compressor is

a proven design resulting from years of

research and thousands of test hours,

including extensive testing under

extraordinarily severe operating

conditions.

• Trane is the world’s largest

manufacturer of large helical rotary

compressors, with tens of thousands of

commercial and industrial installations

worldwide demonstrating a reliability

rate of greater than 99 percent in the

first year of operation.

Operating and Life Cycle

Cost-Effectiveness

• Electronic expansion valve enables

exceptionally tight temperature control

and extremely low superheat, resulting

in more efficient full-load and part-load

operation than previously available.

• Precise compressor rotor tip clearance

ensures optimal efficiency.

• Condenser and evaporator tubes use

the latest heat transfer technology for

increased efficiency.

• The RTHD includes standard electrical

demand limiting.

• Chilled water reset based on return

water temperature is standard.

• High compressor lift capabilities and

tight chilled water temperature control

allow highly efficient system design

with minimal operational concerns.

Design capabilities include:

• variable primary flow;

• series chiller arrangements for

evaporator and/or condenser;

• low evaporator and condenser flow.

RLC-PRC020-EN

5

Page 6

Options

Model RTHD Options

Insulation

All low-temperature surfaces are

covered with 3/4" (19.05 mm) Armaflex II

or equal (K = 0.28) insulation; this

includes the evaporator and water

boxes, suction line, motor housing, and

liquid/vapor separator.

Low-Temperature Evaporator

Addition of an oil cooler to the oil circuit

enables evaporator operation down to

minimum leaving water temperature of

10°F (-12.2°C).

High-Temperature Condenser

Addition of an oil cooler to the oil circuit

enables condenser operation up to

maximum leaving water temperature of

114°F (45.6°C).

Smooth-Bore Condenser Tubes

Smooth-bore copper or premium cupronickel condenser tubes, 3/4" (19.05 mm)

in diameter with .035" (0.889 mm) wall

thickness, are available for high fouling

water applications.

Refrigerant Isolation Valves

Factory-installed condenser inlet and

outlet refrigerant valves allow isolation

of the full refrigerant charge in the

condenser while servicing the chiller.

Marine Water Boxes

Addition of marine water boxes for the

condenser allows tube cleaning without

water pipe interference.

300 psig Evaporator and Condenser

Water Boxes

Water boxes are designed for 300 psig

maximum waterside working pressure,

and grooved pipe water connections are

provided for ease of installation.

Tracer Summit Communications

Link to factory-installed, tested

communication board, via single

twisted-pair wiring, adds Tracer Summit

communications to the system.

LonTalk LCI-C Interface

LonTalk (LCI-C) communications

capabilities are available, with

communication link via single twistedpair wiring to factory-installed, tested

communication board.

External Chilled Water Setpoint

External Chilled Water Setpoint is

communicated to a factory-installed,

tested communication board through a

2-10Vdc or 4-20mA signal.

External Current Limiting

External Current Limit Setpoint is

communicated to a factory-installed,

tested communication board through a

2-10Vdc or 4-20mA signal.

External Base Loading

External Base Loading is communicated

to a factory-installed and tested

communication board through a

2-10Vdc or 4-20mA signal.

Ice Making Control

Controls and safeties allow operation

with brine temperatures down to 20°F

(-6.7°C) , and dual setpoints enable both

ice making and daytime comfort cooling.

Programmable Relays

Default-set, factory-installed,

programmable relays allow the operator

to select four relay outputs from a list of

eight. Available relays are: AlarmLatching, Alarm-Auto Reset, General

Alarm, Warning, Chiller Limit Mode,

Compressor Running, Head Pressure

Relief Request, and Tracer Control.

Chilled Water Reset – Outdoor Air

Temperature

Controls, sensors, and safeties allow

reset of chilled water temperature, based

on temperature signal, during periods of

low outdoor air temperature. (Chilled

water reset based on return chilled water

temperature is standard.)

Condenser-Regulating Valve Control

Chiller applies a Proportional Integrative

Control (PID) algorithm to control water

regulating valve via 0-10Vdc signal.

Percent of Full Run Load Amps Output

Control system indicates the active

chiller percent of full run load amps,

based on a 0-10Vdc signal.

Condenser Pressure Output

Control system indicates chiller

differential pressure or condenser

pressure, based on a 0-10Vdc signal.

Refrigerant Monitor Input

Control system indicates refrigerant

monitor status of 0-100 or 0-1000 ppm

(user selectable), based on a 2-10Vdc /

4-20 mA signal.

Solid State Starter

Solid State Starter is unit-mounted with

a NEMA 1 gasketed enclosure. To extend

starter life, contactors bypass current

from the silicon control rectifiers (SCRs)

after startup.

Under/Over-Voltage Protection

Unit receives protection against

variations in voltage. (Current lag and

spike protection is standard.)

RLC-PRC020-EN6

Page 7

Options

Main Power Disconnect

Options:

Non-fused Disconnect

A UL-approved non-fused molded case

disconnect switch, factory pre-wired with

terminal block power connections and

equipped with a lockable external

operator handle, is available to

disconnect the chiller from main power.

Standard Interrupting Capacity Circuit

Breaker

A UL-approved standard interrupting

molded case capacity circuit breaker,

factory pre-wired with terminal block

power connections and equipped with a

lockable external operator handle, is

available to disconnect the chiller from

main power.

High Interrupting Capacity Circuit

Breaker

A UL-approved high interrupting

molded case capacity circuit breaker,

factory pre-wired with terminal block

power connections and equipped with a

lockable external operator handle, is

available to disconnect the chiller from

main power.

Ground Fault Circuit Breaker

A UL-approved standard interrupting

molded case capacity circuit breaker

with ground fault interrupting capability,

factory pre-wired with terminal block

connections and equipped with a

lockable external operator handle, is

available to disconnect the chiller from

main power.

More Options:

2-Way Condenser Water Regulating Valve

For water regulation, a field-installed,

2-way butterfly-type (lug-style) valve,

with integral electrical operator and

factory-mounted valve actuator, is

available. The single-phase, reversible

motor can be factory-wired for 115 VAC,

60 Hz or 220 VAC, 50 Hz; the 2-way valve

is field-wired and controlled by the

chiller regulating valve control output;

valves are available in 6" and 8" (152.4

and 203.2 mm) sizes.

Nitrogen Charge

Unit is shipped with a nitrogen holding

charge in lieu of refrigerant.

Seal Kit for Reassembly

Ideal for situations when the bolttogether construction of the RTHD will

be separated for installation, this seal kit

provides replacement gaskets and rings

for reassembly.

Performance and Witness Tests

ARI-certified RTHD Performance and

Witness Tests are available, based on

requested operating points, to certify

chiller performance before delivery.

RLC-PRC020-EN

7

Page 8

Display

LCD Touch-Screen Display

with Multi-Language Support

The standard DynaView display

provided with the CH530 control panel

features an LCD touch-screen, allowing

access to all operational inputs and

outputs. This display supports eight

languages: English, Spanish, Traditional

Chinese, Simplified Chinese, Japanese,

Portuguese (for Brazil), Korean, and Thai.

Additional Display Features Include:

• LCD touch-screen with LED

backlighting, for scrolling access to

input and output operating information

• Weather-proof enclosure for reliable

operation in non-standard indoor

environments

• Spin value buttons to allow

continuously variable setpoints when

applicable

• Radio and action buttons for easy, onetime actions and settings

• Single-screen, folder/tab-style display

of all available information on

individual components (evaporator,

condenser, compressor, etc.)

• Automatic and immediate stop

capabilities for standard or immediate

manual shutdown

• Manual override indication

• Password entry/lockout system to

enable or disable display

• Fast, easy access to available chiller

data in tabbed format, including:

— Modes of operation, including

normal cooling and icemaking

— Water temperatures and setpoints

— Loading and limiting status and

setpoints

— Average line current

— Outdoor air temperature

— Start/stop differential timers

— Auto/Manual mode for EXV, slide

valve, and head pressure control

— Pump status and override

— Chilled water reset, start point, ratio,

and outdoor start point

— External setpoints, including:

- chilled water

- current limit

- ice building

- base loading

— Display specifics, including:

- date

- format

- time

- display lockout

- display units

- language setting

- Reports, listed on a single tabbed

screen for easy access, including:

• ASHRAE, containing all guideline

3 report information

• Evaporator

• Condenser

• Compressor

— Evaporator, condenser, and

compressor reports containing all

operational information on

individual components, including:

- Water and air temperatures

- Refrigerant levels, temperatures,

and approach

- Oil pressure

- Flow switch status

- EXV position

- Head pressure control command

- Compressor starts and run-time

- Line phase percent RLA, amps, and

volts

— Alarm and diagnostic information,

including:

- Flashing alarms with touch-screen

button for immediate address of

alarm condition

- Scrollable list of last ten active

diagnostics

- Specific information on applicable

diagnostic from list of over onehundred

- Automatic or manual resetting

diagnostic types

RLC-PRC020-EN8

Page 9

Application

Considerations

Condenser Water Temperatures

Reduced sensitivity to condenser water

startup temperatures is one major

enhancement in the newest-generation

water-cooled Series R chiller. With the

model RTHD chiller, a condenser water

control method is necessary only if the

unit starts with entering water

temperatures below 55°F (12.8°C), or

between 45°F (7.2°C) and 55°F (12.8°C),

when a temperature increase of 1°F

(0.56°C) per minute to 55°F (12.8°) is not

possible.

When the application requires startup

temperatures below the prescribed

minimums, a variety of options are

available. To control a 2-way or 3-way

valve, Trane offers a Condenser

Regulating Valve Control option for the

CH530 controls. This option enables the

CH530 controls to send a signal for

opening and closing the valve as

necessary to maintain chiller differential

pressure. The 2-way valves are available

as a ship-with option. Tower bypass is

also a valid control method if the chiller

temperature requirements can be

maintained.

Trane Series R chillers start and operate

successfully and reliably over a range of

load conditions with controlled entering

condenser water temperature. Reducing

the condenser water temperature is an

effective method of lowering chiller

power input required, but the ideal

temperature for optimizing total system

power consumption will depend on the

overall system dynamics. From a system

perspective, some improvements in

chiller efficiency may be offset by the

increased tower fan and pumping costs

required to achieve the lower tower

temperatures.

Contact your local Trane

systems solution provider for more

information on optimizing system

performance.

The minimum acceptable refrigerant

pressure differential between condenser

and evaporator is 25 psid. The chiller

control system will attempt to obtain and

maintain this differential at startup, but

for continuous operation a design

should maintain a 25°F (13.9°C)

differential from evaporator leaving

water temperature to condenser leaving

water temperature.

Variable Evaporator Flow and Short

Evaporator Water Loops

Variable evaporator flow is an energysaving design strategy which has quickly

gained acceptance as advances in chiller

and controls technology have made it

possible. With its linear unloading

compressor design and advanced CH530

controls, the RTHD has excellent

capability to maintain leaving water

temperature control within +/-0.5°F

(0.28°C) , even for systems with variable

evaporator flow and small chilled water

volumes.

Some basic rules should be followed

whenever using these system design

and operational savings methods with

the RTHD. The proper location of the

chilled water temperature control sensor

is in the supply (outlet) water. This

location allows the building to act as a

buffer, and it assures a slowly changing

return water temperature. If there is

insufficient water volume in the system

to provide an adequate buffer,

temperature control can be lost,

resulting in erratic system operation and

excessive compressor cycling. To ensure

consistent operation and tight

temperature control, the chilled water

loop should be at least two minutes. If

this recommendation cannot be

followed, and tight leaving water

temperature control is necessary, a

storage tank or larger header pipe

should be installed to increase the

volume of water in the system.

For variable primary flow applications,

the rate of chilled water flow change

should not exceed 10 percent of design

per minute to maintain +/-0.5°F (0.28°C)

leaving evaporator temperature control.

For applications in which system energy

savings is most important and tight

temperature control is classified as

+/-2°F (1.1°C), up to 30 percent changes

in flow per minute are possible. Flow

rates should be maintained between the

minimum and maximum allowed for

any particular chiller configuration.

RLC-PRC020-EN

9

Page 10

Application

Considerations

Series Chiller Arrangements

Another energy-saving strategy is to

design the system around chillers

arranged in series, on the evaporator,

condenser, or both. The actual savings

possible with such strategies depends

on the application dynamics and should

be researched by consulting your Trane

Systems Solutions Representative and

applying the Trane System Analyzer

program. It is possible to operate a pair

of chillers more efficiently in a series

chiller arrangement than in a parallel

arrangement. It is also possible to

achieve higher entering-to-leaving chiller

differentials, which may, in turn, provide

the opportunity for lower chilled water

design temperature, lower design flow,

and resulting installation and operational

cost savings. The Trane screw

compressor also has excellent

capabilities for “lift,” which affords an

opportunity for savings on the

evaporator and condenser water loops.

Like series arrangements on the

evaporator, series arrangements on the

condenser may enable savings. This

approach may allow reductions in pump

and tower installation and operating

costs. Maximizing system efficiency

requires that the designer balance

performance considerations for all

system components; the best approach

may or may not involve multiple chillers,

or series arrangement of the evaporators

and/or condensers.

design integrity with installation and

operating cost considerations can also

be obtained by consulting a Trane

representative and applying the Trane

System Analyzer program.

Water Treatment

The use of untreated or improperly

treated water in chillers may result in

scaling, erosion, corrosion, and algae or

slime buildup. It is recommended that

the services of a qualified water

treatment specialist be engaged to

determine what treatment, if any, is

advisable. Trane assumes no

responsibility for the results of using

untreated or improperly treated water.

This ideal balance of

Water Pumps

Where noise limitation and vibration-free

operation are important, Trane strongly

encourages the use of 1750-rpm (60 Hz),

1450-rpm (50 Hz) pumps. Specifying or

using 3600-rpm (60 Hz), 3000-rpm (50 Hz)

condenser water and chilled water

pumps must be avoided, because such

pumps may operate with objectionable

levels of noise and vibration. In addition,

a low frequency beat may occur due to

the slight difference in operating rpm

between 3600-rpm (60 Hz), 3000-rpm

(50 Hz) water pumps and Series R chiller

motors.

water pump must not be used to stop

the chiller.

Acoustic Considerations

For chiller sound ratings, installation tips,

and considerations on chiller location,

pipe isolation, etc., refer to

Water-Cooled Series R Chillers Sound

Ratings and Installation Guide

information provided in this bulletin,

contact a certified sound consultant to

aid in proper mechanical room design

and treatment.

Important Note: The chilled

the Trane

. Using the

RLC-PRC020-EN10

Page 11

Selection

Procedure

Trane Series R chiller performance is

rated in accordance with the ARI

Standard 550/590-1998 Certification

Program. Chiller selection assistance and

performance information can be

obtained by using the Series R chiller

selection program, available through

local Trane sales offices.

Performance

The computerized Series R chiller

selection program provides performance

data for each possible chiller selection at

both full-load and part-load design

points, as required.

It should be noted that changing the

number of water passes or the water

flow rates will generally alter the

performance of a particular chiller. To

attain maximum benefit from the wide

range of chiller models and options

available, designers are encouraged to

first develop performance specifications

and then use the chiller selection

program to optimize all selections. This

will help ensure selection of the

compressor-evaporator-condenser

combination that most closely meets the

job requirements. To optimize system

performance, all selections should also

be balanced with other system

components.

Fouling Factors

ARI Standard 550 includes a definition of

clean tube fouling. The recommended

standard fouling adjustments are 0.0001

hr-sq ft-deg F/Btu (0.044 sq m-deg C/kW)

for the evaporator and 0.00025 hr-sq ft

deg F/Btu (0.0176 sq m-deg C/kW) for the

condenser, from an increment of 0.0000

“clean.” Chiller specifications should be

developed using the most current

standard fouling factors.

Unit Performance with Fluid Media

Other Than Water

Series R chillers can be provided with a

wide variety of fluid media other than

water, including ethylene glycol and

propylene glycol— in the evaporator,

condenser or both. Chillers using media

other than water are excluded from the

ARI 550/590-98 Certification Program,

but are rated in accordance with ARI

Standard 550/590-98. Trane factory

performance tests are only performed

with water as the cooling and heatrejection media. When considering

selection of media other than water,

contact the local Trane sales office for

chiller selections and factory

performance testing information.

Fluid media other than water lowers the

heat transfer coefficient, and therefore

reduces chiller performance. In general,

it is good practice to hold the percent

glycol added to within the minimum

allowed by the Trane selection program,

based on either (a) unit operating

temperatures, or (b) the operating

temperatures the evaporator or

condenser water will experience under

its full range of conditions. Adding more

glycol than required for the specific

application is equivalent to selecting a

less efficient chiller. Lower-viscosity

glycols such as ethylene will have less

adverse impact on chiller performance

than higher-viscosity glycols such as

propylene.

Dimensional Drawings

Dimensional drawings provided for

selection purposes illustrate overall

measurements of the unit. The

recommended service clearances are

those required to easily service the

Series R chiller.

All catalog dimensional drawings are

subject to change, and current submittal

drawings should be referenced for more

detailed dimensional information.

Dimensional drawings are also available

from the selection program. Contact the

local Trane sales office for submittal

information.

Electrical Data Tables

Compressor motor electrical data is

provided in the data section for each

compressor size. Rated load amperes

(RLA), locked rotor wye amperes (LRA)

and expected inrush for the Wye-delta

and Solid State Starter configurations

are shown.

Although the terms “LRA” and

“expected inrush” are often used

interchangeably, the distinction applied

here is that LRA is the rated inrush for

the motor, but expected inrush is that

allowed by the starter, based on the

specific configuration.

Selecting starters in the Wye-delta or

Solid State configuration lowers

expected inrush vs. the Delta (or “acrossthe-line”) configuration. A Solid State

Starter configuration lowers the

expected inrush by approximately 50

percent, while Wye-Delta lowers it by

approximately 66 percent.

RLC-PRC020-EN

11

Page 12

Selection

Procedure

The RLA is based on the motor’s

performance when reaching full rated

horsepower. The kW rating of the motor

will equal or exceed the kW requirement

indicated by the Series R computer

selection program at design conditions.

If motor kW draw at design conditions is

less than the kW rating of the motor, the

RLA at design conditions is determined

by multiplying the motor RLA (at the

desired voltage) by this ratio: design kW/

motor kW rating. This calculation is

performed within the Series R chiller

computer selection program, making

RLA available as part of the design

predictions. Predicted values include

power factor variation from point to

point.

A voltage utilization range is tabulated

for each voltage listed. Series R chillers

are designed to operate satisfactorily

over a utilization range of ±10 percent of

the standard design voltages: (a) 200 V,

230 V, 380 V, 460 V, and 575 V for 60

Hertz, 3-phase, and (b) 380 V, 400 V,

415 V for 50 Hertz, 3-phase.

Evaporator and Condenser Pressure

Drop

Pressure drop data is determined by the

Series R chiller computer selection

program available through local Trane

sales offices.

Part Load Performance

Actual air-conditioning system loads are

frequently less than full-load design

conditions. Depending on the number of

chillers on the job and the load profile,

chillers may operate at full load a small

percentage of the time. With their

excellent part-load performance

characteristics and highly energyefficient operation, Series R chillers can

provide significant operating savings at

these part-load conditions.

System Considerations

Part-load chiller operation is frequently

associated with reduced condenser

water temperatures. However, rather

than focusing only on the chiller, it is

important to balance these temperatures

to achieve the most efficient system

operation possible. At part-load

operation, the heat rejected to the

cooling tower is less than at full-load

operation.

Part-load chiller operation is also

typically associated with reduced outside

wet bulb temperatures, resulting in

improved cooling tower performance.

The net result of reduced heat rejection

and lower wet bulb temperatures can be

cooler condenser water entering the

chiller, ultimately improving unit

performance. However, this does not

improve pump or tower efficiency. To

achieve the most efficient system

operation possible, it is best to minimize

the total power draw of the chiller, tower,

and pumps, which may not mean

limiting the condenser water

temperature to what the tower can

provide. To determine specific unit and

system part-load performance for chiller

selection purposes, use the Series R

chiller computer selection program or

contact the local Trane sales office.

RLC-PRC020-EN12

Page 13

Model

Nomenclature

RTH D U D 2 F 0 A0 U A G 3 A 4 L A L G 3 F 2 L A L

1,2,3 4 5 6 7 8 9 10,11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

Digits 01, 02, 03 – Series R

RTH = Series R

Digit 04 – Dev Sequence

D = 4th Major Development

Digit 05 – Design Control

U = WCBU

Digit 06 – Compressor Frame

B = B Compressor

C = C Compressor

D = D Compressor

E = E Compressor

Digit 07 – Compressor Capacity

1 = Smaller Capacity for Frame

2 = Larger Capacity for Frame

3 = 50Hz Capacity

Digit 08 – Unit Power Supply

A = 200V/60Hz/3Ph power

C = 230V/60Hz/3Ph power

D = 380V/60Hz/3Ph power

R = 380V/50Hz/3Ph power

T = 400V/50Hz/3Ph power

U = 415V/50Hz/3Ph power

F = 460V/60Hz/3Ph power

H = 575V/60Hz/3Ph power

™

Digit 09 – Specials

X = No specials

C = All specials denoted by digits elsewhere

S = Uncategorized special not denoted by

other digits

Digits 10, 11 – Design Sequence

** = First Design, etc. increment when parts

are affected for service purposes

Digit 12 – Agency Listing

X = No agency listing

U = C/UL

Digit 13 – Pressure Vessel Code

A = ASME

L = Chinese Pressure Vessel Code

Digit 14 – Evaporator Frame

B = B Frame

C = C Frame

D = D Frame

E = E Frame

F = F Frame

G = G Frame

Digit 15 – Evaporator Capacity

1 = Tube count #1

2 = Tube count #2

3 = Tube count #3

4 = Tube count #4

5 = Tube count #5

6 = Tube count #6

Digit 16 – Evaporator Tube Type

A = Enhanced Fin Copper

Digit 18 – Evaporator Water Connection

L = Left Hand Evaporator Connection

R = Right Hand Evaporator Connection

Digit 19 – Evaporator Connection Type

A = Standard Grooved Pipe

Digit 20 – Evaporator Waterside Pressure

L = 150 psi

H = 300 psi

Digit 21 – Condenser

B = B Frame

D = D Frame

E = E Frame

F = F Frame

G = G Frame

Digit 22 – Condenser Capacity

1 = Tube count #1

2 = Tube count #2

3 = Tube count #3

4 = Tube count #4

5 = Tube count #5

Digit 23 – Condenser Tube Type

A = Enhanced Fin Copper

B = Smooth Bore Copper

C = Smooth Bore 90/10 CU/NI

Digit 24 – Condenser Passes

2 = 2 Pass

Digit 25 – Condenser Water Connection

L = Left Hand Connection

R = Right Hand Connection

RLC-PRC020-EN

Digit 17 – Evaporator Water Pass

Configuration

2 = 2 pass

3 = 3 pass

4 = 4 pass

Digit 26 – Condenser Connection Type

A = Standard Grooved Pipe

C = Marine

Digit 27 – Condenser Waterside Pressure

L = 150 psi

H = 300 psi

13

Page 14

Model

Nomenclature

A V X Q X E X A A B D Y 444 D A X A 4 X X X R X V X

28 29 30 31 32 33 34 35 36 37 38 39 40,41,42 43 44 45 46 47 48 49 50 51 52 53 54

Digit 28 – Condenser Leaving Water

Temperature

A = Standard

Digit 29 – Refrigerant Specialties

X = No Refrigerant Isolation Valves

V = With Refrigerant Isolation Valves

Digit 30 – Oil Cooler

X = Without Oil Cooler

C = With Oil Cooler

Digit 31 – Thermal Insulation

X = No Insulation

Q = Factory Installed Insulation

Digit 32 – Acoustic Insulation

X = No Insulation

A = Standard Insulation

Digit 33 – Control, Label, and Literature

Language

E = English

Digit 34 – Safety Devices

X = Standard

Digit 35 – Factory Charge

A = Factory Refrigerant Charge (134a)

B = Factory Nitrogen Charge

Digit 36 – Shipping Package

A = Standard

B = Standard + Shrink Wrap

C = Standard + Skid

D = Standard + Skid + Shrink Wrap

Digit 37 – Flow Switch

X = No Flow Switch

A = Evaporator (NEMA 1)

B = Evaporator and Condenser (NEMA 1)

C = Evaporator (Vapor Proof)

D = Evaporator and Condenser (Vapor Proof)

Digit 38 – Factory Test

X = Standard Test

C = Witness Test

D = Performance Test

Digit 39 – Starter Type

Y = Wye Delta Closed Transition Starter

A = Solid State Starter

Digits 40, 41, 42 – Design RLA (for starter)

*** = Selection Assigned

Digit 43 – Power Line Connection Type

A = Terminal Blocks

B = Mechanical Disconnect Switch

D = Circuit Breaker

F = High Interrupt Circuit Breaker

H = Ground Fault Circuit Breaker

J = Ground Fault High Interrupt Circuit

Breaker

Digit 44 – Enclosure Type

A = NEMA 1

Digit 45 – Under/Over Voltage Protection

X = None

U = With Under/Over Voltage Protection

Digit 46 – Operator Interface Language

A = Dyna-View/English

D = Dyna-View/French

G = Dyna-View/Traditional Chinese

H = Dyna-View/Simple Chinese

J = Dyna-View/Japanese

K = Dyna-View/Portuguese

L = Dyna-View/Korean

M = Dyna-View/Thai

Digit 47 – Digital Communication Interface

X = None

4 = Tracer Interface

5 = LCI-C (LonTalk)

Digit 48 – External Chilled Water and Current

Limit Setpoint

X = None

4 = 4-20mA input

2 = 2-10Vdc

Digit 49 – External Base Loading

X = None

4 = 4-20mA input

2 = 2-10Vdc input

Digit 50 – Icemaking

X = None

A = Icemaking with Relay

B = Icemaking without Relay

Digit 51 – Programmable Relays

X = None

R = With

Digit 52 – Chilled Water Reset

X = Chilled Water Reset – Return Water

T = Chilled Water Reset – Outdoor Air

Temperature

Digit 53 – Control Outputs

X = None

V = Condenser Regulating Valve Control &

Percent RLA

P = Condenser Pressure (% HPC) & Percent

RLA

D = Chiller Differential Pressure & Percent

RLA

Digit 54 – Refrigerant Monitor Input

X = None

A = 100 ppm / 4-20mA

B = 1000 ppm / 4-20mA

C = 100 ppm / 2-10Vdc

D = 1000 ppm / 2-10Vdc

RLC-PRC020-EN14

Page 15

General Data

Nominal Data

Nominal Compressor B1 B2 C1 C2 D1 D2 D3 E3

Tonnage (60 Hz) 175-200 200-225 225-275 275-325 325-400 375-450 N/A N/A

Tonnage (50 Hz) 125-150 150-175 175-225 225-275 275-325 300-350 325-375 375-450

Notes:

1. Chiller selections can be optimized through the use of the ARI-Certified Series R selection program and by contacting your

local Trane sales office.

General Data

Compressor Evaporator Condenser Water Storage Water Storage Refrigerant Charge

Code Code Code Gallons Liters Gallons Liters Type lb kg

B1 B1 B1 41 155 28 106 HFC-134a 410 186

B1 C1 D1 55 208 31 117 HFC-134a 490 222

B2 B2 B2 45 170 29 110 HFC-134a 410 186

B2 C2 D2 58 220 34 129 HFC-134a 490 222

C1 D6 E5 45 170 29 110 HFC-134a 420 191

C1 D5 E4 52 197 32 121 HFC-134a 490 222

C1 E1 F1 82 310 60 226 HFC-134a 525 238

C2 D4 E4 52 197 32 121 HFC-134a 490 222

C2 D3 E3 78 295 47 178 HFC-134a 490 222

C2 G1 G1 136 515 79 299 HFC-134a 700 318

D1 D1 E1 69 261 44 166 HFC-134a 475 216

D1 F1 F2 102 386 57 216 HFC-134a 625 284

D1 G2 G2 144 545 91 344 HFC-134a 700 318

D2/D3 D2 E2 74 280 47 178 HFC-134a 475 216

D2/D3 F2 F3 107 405 61 231 HFC-134a 625 284

D2/D3 G3 G3 159 602 97 367 HFC-134a 700 318

E3 D2 E2 74 280 47 178 HFC-134a 475 216

E3 F2 F3 107 405 61 231 HFC-134a 625 284

E3 G3 G3 159 602 97 367 HFC-134a 700 318

Evaporator Condenser Refrigerant

RLC-PRC020-EN

15

Page 16

General Data

Minimum/Maximum Evaporator Flow Rates (GPM)

Evaporator Nominal Nominal Nominal

Code Min Max Conn Size (In.) Min Max Conn Size (In.) Min Max Conn Size (In.)

B1 303 1104 8 200 736 6 —- —- —-

B2 346 1266 8 233 844 6 —- —- —-

C1 346 1412 8 254 941 6 —- —- —-

C2 375 1531 8 276 1022 6 —- —- —-

D1 498 1812 8 330 1206 8 —- —- —-

D2 541 1980 8 357 1320 8 —- —- —-

D3 584 2131 8 389 1417 8 —- —- —-

D4 422 1542 8 281 1028 8 —- —- —-

D5 422 1542 8 281 1028 8 —- —- —-

D6 352 1287 8 233 860 8 —- —- —-

E1 487 1980 8 357 1320 8 —- —- —-

F1 676 2478 10 454 1655 8 —- —- —-

F2 725 2667 10 487 1780 8 —- —- —-

G1 —- —- —- 606 2218 10 454 1666 8

G2 —- —- —- 660 2413 10 492 1807 8

G3 —- —- —- 747 2732 10 557 2050 8

Notes:

1. All water connections are grooved pipe.

Two Pass Three Pass Four Pass

Minimum/Maximum Evaporator Flow Rates (Liters/Second)

Evaporator Nominal Nominal Nominal

Code Min Max Conn Size (mm) Min Max Conn Size (mm) Min Max Conn Size (mm)

B1 19 70 200 13 46 150 —- —- —-

B2 22 80 200 15 53 150 —- —- —-

C1 22 89 200 16 59 150 —- —- —-

C2 23 97 200 17 65 150 —- —- —-

D1 31 114 200 21 76 200 —- —- —-

D2 34 125 200 23 83 200 —- —- —-

D3 37 134 200 25 89 200 —- —- —-

D4 27 97 200 18 65 200 —- —- —-

D5 27 97 200 18 65 200 —- —- —-

D6 22 81 200 15 54 200 —- —- —-

E1 28 125 200 23 83 200 —- —- —-

F1 43 156 250 29 104 200 —- —- —-

F2 46 168 250 31 112 200 —- —- —-

G1 —- —- —- 38 140 250 29 105 200

G2 —- —- —- 42 152 250 31 114 200

G3 —- —- —- 47 172 250 35 129 200

Notes:

1. All water connections are grooved pipe.

Two Pass Three Pass Four Pass

Minimum/Maximum Condenser Flow Rates

(GPM)

Condenser Nominal

Code Min Max Conn Size (In.)

B1 230 850 6

B2 255 935 6

D1 230 850 6

D2 255 935 6

E1 350 1280 8

E2 380 1390 8

E3 390 1420 8

E4 295 1080 8

E5 250 910 8

F1 450 1650 8

F2 430 1560 8

F3 460 1700 8

G1 530 1960 8

G2 650 2360 8

G3 710 2600 8

Notes:

1. All water connections are grooved pipe.

Two Pass

Minimum/Maximum Condenser Flow Rates

(Liters/Second)

Condenser Nominal

Code Min Max Conn Size (mm)

B1 15 54 150

B2 16 59 150

D1 15 54 150

D2 16 59 150

E1 22 81 200

E2 24 88 200

E3 25 90 200

E4 19 68 200

E5 16 57 200

F1 28 104 200

F2 27 98 200

F3 29 107 200

G1 33 124 200

G2 41 149 200

G3 45 164 200

Notes:

1. All water connections are grooved pipe.

Two Pass

RLC-PRC020-EN16

Page 17

Electrical Data

and Connections

Compressor Motor Electrical Data (60 Hertz)

Compressor Voltage 180/ 208/ 342/ 414/ 516/

Code Utilization Range 220 254 418 506 633

B1, B2 RLA @ Max kW 557 484 291 241 193

C1, C2 RLA @ Max kW 812 698 421 349 279

D1, D2 RLA @ Max kW 1047 918 549 455 367

Notes:

1. See Selection Procedure Section for details.

2. The RLA @ Max kW is based on the performance of the motor developing full rated horsepower.

3. Electrical component sizing should be based on actual jobsite operating conditions. This factor can be obtained through the

use of the Series R chiller selection program available through local Trane sales offices.

Nominal Voltage 200 230 380 460 575

Max kW 174 174 174 174 174

LRAY 970 818 488 400 329

LRAD 3103 2617 1561 1280 1053

Max kW 249 249 249 249 249

LRAY 1173 936 558 469 375

LRAD 3634 2901 1727 1453 1162

Max kW 329 329 329 329 329

LRAY 1690 1532 850 730 612

LRAD 5477 4966 2755 2366 1984

Compressor Motor Electrical Data (50 Hertz)

Compressor Voltage 342/ 360/ 374/

Code Utilization Range 418 440 457

B1, B2 RLA @ Max kW 233 233 233

C1, C2 RLA @ Max kW 349 349 349

D1, D2, D3 RLA @ Max kW 455 455 455

E3 RLA @ Max kW 488 488 488

Notes:

1. See Selection Procedure Section for details.

2. The RLA @ Max kW is based on the performance of the motor developing full rated horsepower.

3. Electrical component sizing should be based on actual jobsite operating conditions. This factor can be obtained through the

use of the Series R chiller selection program available through local Trane sales offices.

Nominal Voltage 380 400 415

Max kW 139 145 148

LRAY 391 412 428

LRAD 1229 1296 1348

Max kW 201 209 213

LRAY 456 480 498

LRAD 1414 1488 1544

Max kW 271 280 284

LRAY 711 748 776

LRAD 2303 2424 2515

Max kW 288 301 306

LRAY 711 748 776

LRAD 2303 2424 2515

RLC-PRC020-EN

Electrical Connections

Starter Panel Selection Lug Size

Connection RLA L1-L3 (Each Phase)

Terminals Only 000-760 (2) #4-500 MCM

Main Circuit 000-185 (1) #4-350 MCM

Breaker or 186-296 (2) 2/0-250 MCM

Non-Fused 297-444 (2) 3/0-350 MCM

Disconnect Switch 445-592 (2) #1-500 MCM

Note:

1. Lug sizes are independent of starter type.

761-935 (4) 4/0-500 MCM

593-888 (4) 4/0-500 MCM

17

Page 18

Electrical Data

and Connections

RLC-PRC020-EN18

Page 19

Electrical Data

and Connections

RLC-PRC020-EN

19

Page 20

Dimensions and

Weights

Shipping and Operating Weights

Compressor Evaporator Condenser Operating Weight Shipping Weight

Code Code Code (lbs) (kg) (lbs) (kg)

B1 B1 B1 9867 4,476 9292 4,215

B1 C1 D1 10554 4,787 9837 4,462

B2 B2 B2 10019 4,545 9402 4,265

B2 C2 D2 10653 4,832 9953 4,515

C1 D6 E5 13397 6,077 12780 5,797

C1 D5 E4 13673 6,202 12973 5,884

C1 E1 F1 15818 7,175 14718 6,676

C2 D4 E4 13672 6,201 12972 5,884

C2 D3 E3 15044 6,824 14002 6,351

C2 G1 G1 19715 8,943 17923 8,130

D1 D1 E1 15385 6,978 14443 6,551

D1 F1 F2 17537 7,955 16187 7,342

D1 G2 G2 21065 9,555 19107 8,667

D2, D3 D2 E2 15570 7,062 14562 6,605

D2, D3 F2 F3 18220 8,264 16820 7,629

D2, D3 G3 G3 21641 9,816 19508 8,849

E3 D2 E2 15728 7,134 14720 6,677

E3 F2 F3 18356 8,326 16956 7,691

E3 G3 G3 21786 9,882 19653 8,914

Notes:

1. All weights +- 3%.

2. Shipping weights include standard 150 psig water boxes, refrigerant charge, and oil charge.

3. Operating weights include refrigerant, oil, and water charges.

RLC-PRC020-EN20

Page 21

Dimensions and

Weights

BBB Configuration

Front 36" (914 mm)

Back 36" (914 mm)

Either End 36" (914 mm)

Other End* 108" (2743 mm)

Top 36" (914 mm)

* Clearance for tube removal

Note:

1. Dimensions are based on 3 Pass Evap / 2 Pass

Cond and LH/LH water connections. Refer to

submittals for exact configuration.

2. Refer to the Nominal Capacity Data table in the

General Data section for capacity ranges of each

compressor.

Recommended Clearances

RLC-PRC020-EN

21

Page 22

Dimensions and

Weights

BCD Configuration

Front 36" (914 mm)

Back 36" (914 mm)

Either End 36" (914 mm)

Other End* 126" (3200 mm)

Top 36" (914 mm)

* Clearance for tube removal

Note:

1. Dimensions are based on 3 Pass Evap / 2 Pass

Cond and LH/LH water connections. Refer to

submittals for exact configuration.

2. Refer to the Nominal Capacity Data table in the

General Data section for capacity ranges of each

compressor.

Recommended Clearances

RLC-PRC020-EN22

Page 23

Dimensions and

Weights

CDE, DDE, EDE Configuration

Front 36" (914 mm)

Back 36" (914 mm)

Either End 36" (914 mm)

Other End* 108" (2743 mm)

Top 36" (914 mm)

* Clearance for tube removal

Note:

1. Dimensions are based on 3 Pass Evap / 2 Pass

Cond and LH/LH water connections. Refer to

submittals for exact configuration.

2. Refer to the Nominal Capacity Data table in the

General Data section for capacity ranges of each

compressor.

Recommended Clearances

RLC-PRC020-EN

23

Page 24

Dimensions and

Weights

CEF Configuration

Front 36" (914 mm)

Back 36" (914 mm)

Either End 36" (914 mm)

Other End* 126" (3200 mm)

Top 36" (914 mm)

* Clearance for tube removal

Note:

1. Dimensions are based on 3 Pass Evap / 2 Pass

Cond and LH/LH water connections. Refer to

submittals for exact configuration.

2. Refer to the Nominal Capacity Data table in the

General Data section for capacity ranges of each

compressor.

Recommended Clearances

RLC-PRC020-EN24

Page 25

Dimensions and

Weights

DFF, EFF Configuration

Front 36" (914 mm)

Back 36" (914 mm)

Either End 36" (914 mm)

Other End* 126" (3200 mm)

Top 36" (914 mm)

* Clearance for tube removal

Note:

1. Dimensions are based on 3 Pass Evap / 2 Pass

Cond and LH/LH water connections. Refer to

submittals for exact configuration.

2. Refer to the Nominal Capacity Data table in the

General Data section for capacity ranges of each

compressor.

Recommended Clearances

RLC-PRC020-EN

25

Page 26

Dimensions and

Weights

CGG, DGG, EGG Configuration

Front 36" (914 mm)

Back 36" (914 mm)

Either End 36" (914 mm)

Other End* 126" (3302 mm)

Top 36" (914 mm)

* Clearance for tube removal

Note:

1. Dimensions are based on 3 Pass Evap / 2 Pass

Cond and LH/LH water connections. Refer to

submittals for exact configuration.

2. Refer to the Nominal Capacity Data table in the

General Data section for capacity ranges of each

compressor.

Recommended Clearances

RLC-PRC020-EN26

Page 27

Mechanical

Specifications

General

Exposed metal surfaces are painted with

air-dry beige, direct-to-metal, singlecomponent paint. Each unit ships with

full operating charges of refrigerant and

oil. Molded neoprene isolation pads are

supplied for placement under all support

points. Startup and operator instruction

by factory-trained service personnel are

included.

Compressor and Motor

The unit is equipped with a semihermetic, direct-drive, 3600-rpm (3000

rpm @ 50 Hz) rotary compressor that

includes a capacity control slide valve, oil

sump heater, and differential pressure

refrigerant oil flow system. Four

pressure-lubricated, rolling-element

bearing groups support the rotating

assembly.

The motor is a suction gas-cooled,

hermetically sealed, two-pole, squirrel

cage induction-type.

Evaporator and Condenser

Shells are carbon steel plate. The

evaporator and condenser are designed,

tested, and stamped in accordance with

ASME Code for refrigerant-side/

working-side pressure of 200 psig.

All tube sheets are made of carbon steel;

tubes are mechanically expanded into

tube sheets and mechanically fastened

to tube supports. Evaporator tubes are

1.0-inch (25.4 mm) diameter and

condenser tubes are 0.75-inch

(19.05 mm) diameter. Both types can be

individually replaced. Standard tubes are

externally finned, internally enhanced

seamless copper with lands at all tube

sheets.

All water pass arrangements are

available with grooved connections (150

or 300 psig waterside). All connections

may be either right- or left-handed.

Waterside shall be hydrostatically tested

at 1.5X design working pressure.

Refrigerant Circuit

An electronically controlled expansion

valve is provided to maintain proper

refrigerant flow.

Unit Controls (CH530)

The microprocessor-based control panel

is factory-installed and factory-tested.

The control system is powered by a

control power transformer, and will load

and unload the chiller through

adjustment of the compressor slide

valve. Microprocessor-based chilled

water reset based on return water is

standard.

The CH530 microprocessor

automatically acts to prevent unit

shutdown due to abnormal operating

conditions associated with low

evaporator refrigerant temperature, high

condensing temperature, and/or motor

current overload. If an abnormal

operating condition continues and the

protective limit is reached, the machine

should shut down.

The panel includes machine protection

shutdown requiring

following conditions:

• low evaporator refrigerant temperature

and pressure

• high condenser refrigerant pressure

• low oil flow

• critical sensor or detection circuit faults

• motor current overload

manual reset

for the

• high compressor discharge

temperature

• lost communication between modules

• electrical distribution faults: phase loss,

phase imbalance, or phase reversal

• external and local emergency stop

• starter transition failure

The panel also includes machine

protection shutdown with

reset

for the following correctable

conditions:

• momentary power loss

• under/over voltage

• loss of evaporator or condenser water

flow

When a fault is detected, the control

system conducts more than 100

diagnostic checks and displays results.

The display will identify the fault,

indicate date, time, and operating mode

at time of occurrence, and provide type

of reset required and a help message.

The diagnostic history will display the

last ten diagnostics with their times and

dates of occurrence.

Clear Language Display Panel

Factory-mounted to the control panel

door, the operator interface has an LCD

touch-screen display for operator input

and information output. This interface

provides access to the following

information: evaporator report,

condenser report, compressor report,

ASHRAE Guideline 3 report, operator

settings, service settings, service tests,

and diagnostics. All diagnostics and

messages are displayed in “clear

language.”

automatic

RLC-PRC020-EN

27

Page 28

Mechanical

Specifications

Data contained in available reports

includes:

• Water and air temperatures

• Refrigerant levels and temperatures

• Oil pressure

• Flow switch status

• EXV position

• Head pressure control command

• Compressor starts and run-time

• Line phase percent RLA, amps, and

volts

All necessary settings and setpoints are

programmed into the microprocessorbased controller via the operator

interface. The controller is capable of

receiving signals contemporaneously

from a variety of control sources, in any

combination, and priority order of

control sources can be programmed.

The control source with priority

determines active setpoints via the

signal it sends to the control panel.

Control sources may be:

• the local operator interface (standard)

• a 4-20 mA or 2-10 VDC signal from an

external source (interface optional;

control source not supplied)

• Trane Tracer Summit

™

system

(interface optional)

• Generic BAS (optional points; control

source not supplied)

• LonTalk LCI-C (interface optional;

control source not supplied)

Unit-Mounted Starter

The unit is supplied with a NEMA 1 type

enclosure with top power-wiring access

and three-phase, solid state overload

protection. The starter is available in a

Wye-Delta configuration, factorymounted and fully pre-wired to the

compressor motor and control panel. A

factory-installed, factory-wired 600VA

control power transformer provides all

unit control power (120 VAC secondary)

and CH530 module power (24 VAC

secondary). Optional starter features

include circuit breakers, ground fault

circuit breakers, and mechanical, nonfused disconnects.

Trane

A business of American Standard Companies

www.trane.com

For more information, contact

your local sales office or

e-mail us at comfort@trane.com.

Literature Order Number

File Number

Supersedes

Stocking Location

Trane has a policy of continuous product and product data improvement and reserves the right to change

design and specifications without notice.

RLC-PRC020-EN

PL-RF-RLC-000-PRC020-EN-0403

RLC-DS-6-0899

Electronic Only

Loading...

Loading...