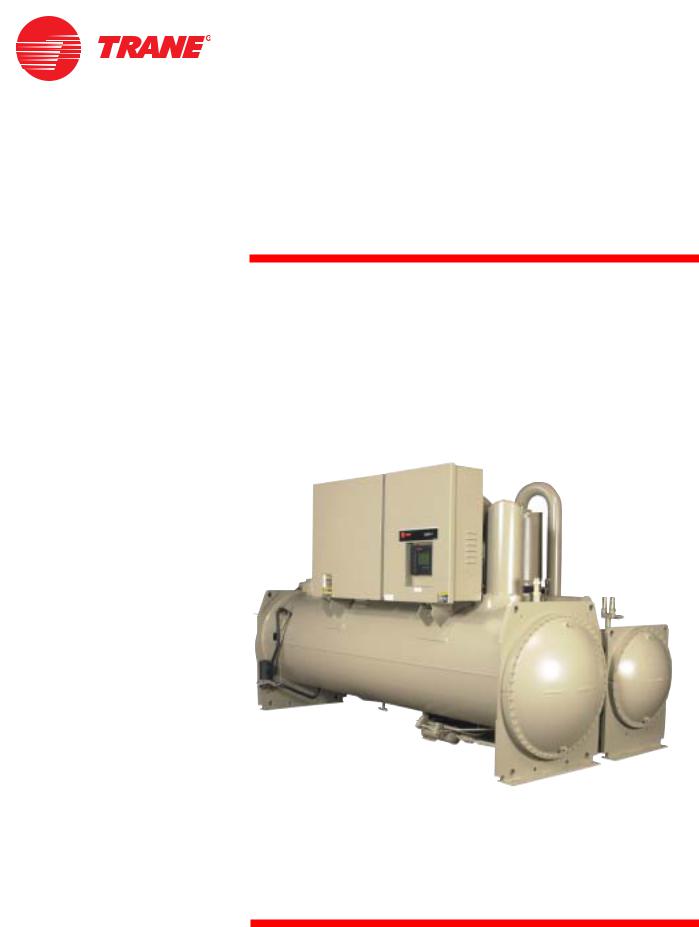

Trane RTHD User Manual

Series R™ Helical Rotary

Liquid Chillers

Model RTHD

175-450Tons (60 Hz)

125-450Tons (50 Hz)

Built for Industrial and Commercial Applications

June 2006 |

RLC-PRC020-EN |

Introduction

To meet a wide range of applications in the medium-tonnage, water-cooled market,Trane is proud to introduce the model RTHD helical rotary liquid chiller. The introduction of this next-generation chiller an exciting step forward in application versatility, ease of installation, control precision, reliability, energyefficiency, and operational cost-effectiveness.The new RTHD chiller is designed to deliver proven Series R performance, plus all the benefits of an advanced heat transfer design and a lowspeed, direct-drive compressor.

Important Design Advances

and New Features

Major design advances include:

•Higher full-load energy efficiency reduces both operating and life-cycle costs.

•CH530 controls enable:

-scrolling access to inputs and operating information via the LCD touch-screen display;

-freedom from interoperability concerns with LonMark communications;

-job-specific communication options that allow greater reporting flexibility.

•Improved startup temperature capabilities and reduced sensitivity to condenser water temperatures alleviate the most common startup concerns.

•Removed LiquidVapor Separator, providing lighter unit weight and simplified refrigerant piping, for less expensive handling, separation, and installation.

The industrial-grade design of the Series R helical rotary chiller is ideal for both industrial and commercial markets, in applications such as office buildings, hospitals, schools, retail buildings, and industrial facilities.The linear unloading compressor, wide operating temperature range, advanced controls, electronic expansion valve, short anti-recycle timers, and industry-leading efficiencies mean that this latestTrane Series R chiller is the perfect choice for tight temperature control in almost any application temperatures, and under widely varying loads.

© 2004 American Standard Inc. All rights reserved. |

RLC-PRC020-EN |

Contents

Introduction |

2 |

Features and Benefits |

|

4 |

|

Options |

|

6 |

|

Controls |

|

8 |

|

Application Considerations |

|

10 |

|

Selection Procedure |

|

12 |

|

Model Nomenclature |

|

14 |

|

General Data |

|

16 |

|

Electrical Data and Connections |

|

19 |

|

Dimensions andWeights |

|

22 |

|

Mechanical Specifications |

|

29 |

|

Conversion Table |

|

30 |

|

|

|

RLC-PRC020-EN |

3 |

Features and

Benefits

ApplicationVersatility and High

Performance

•Screw compressor technology and the electronic expansion valve provide reliable performance in an expanded

range of operating temperatures.

•Tight water temperature control extends to operation of multiple chillers in parallel or series configurations, offering further system design flexibility for maximum efficiency.

•Advanced design enables chilled water temperature control to +/- 0.5°F (.28°C) for flow changes up to 10 percent per

minute, plus handling of flow changes up to 30 percent per minute for comfort cooling.

•Two-minute stop-to-start and five-minute start-to-start anti-recycle timer allows tight chilled water temperature control in constant or transient low-load applications.

•LonMark communications capability provides excellent, trouble-free interoperability.

Applications in this catalog specifically excluded from the ARI certification program are:

•Low temperature applications, including ice storage

•Glycol

•50Hz units below 200 nominal tons

•Generic Building Automation System points are available for easy access to operational information.

•Extensive information on professional design selection and layout is available in a simple, highly readable electronic format.

•Standard model RTHD configurations are in stock and available for immediate delivery, andTrane offers the fastest ship cycles in the industry for built-to- order units.

•Industrial / LowTemperature Process Cooling – Excellent operating temperature range and precise control capabilities enable tight control with single chiller or series configuration.

•Ice/Thermal Storage – Specifiers and operators benefit from dual setpoint control and industry-leading temperature, efficiency, and control capabilities, plus outstanding support through partnership with Calmac, a strongTrane partner providing proven installation examples, templates, and references that minimize design time and energy costs.

•Heat Recovery – Maximum condenser temperature exceeds those of previous technologies, providing hot water and tight control that minimizes operating costs for the chilled water plant and boiler/hot water heater, and consistent dehumidification.

Simple, Economical Installation

•Compact size makes the model RTHD well suited for the retrofit and replacement market.

•All units fit through standard doublewidth doors.

•Bolt-together construction makes for fast, easy unit disassembly.

•Small RTHD footprint saves valuable equipment room space and alleviates access concerns for most retrofit jobs.

•Lightweight design simplifies rigging requirements, further reducing installation time requirements and costs.

•Full factory refrigerant or nitrogen and oil charges reduce required field labor, materials, and installation cost.

•Only evaporator and condenser water piping is required; no starter water cooling (with its associated safety concerns) or field piping is necessary.

•Oil cooler and purge system connections have been eliminated.

•Simple power connection simplifies overall installation.

•Standard unit-mounted starter for Wye-Delta and Solid State eliminates additional jobsite installation

considerations and labor requirements.

•Trane has conducted extensive factory testing, and also offers options for inperson and/or documented system performance verification.

•CH530 controls easily interface with Tracer Summit™ building automation systems through single twisted-pair wire.

Pueblo

Business Unit

4 |

RLC-PRC020-EN |

Features and

Benefits

State-of-the-Art, Precision Control

•Microprocessor-based CH530 controls monitor and maintain optimal operation of the chiller and its associated sensors, actuators, relays, and switches, all of which are factory-assembled and extensively tested.

•Easy interface with computers hosting Tracer Summit™ building automation/ energy management systems allows the operator to efficiently optimize comfort system performance and minimize operating costs.

•PID (proportional integral derivative) control strategy ensures stable, efficient chilled water temperature control, maintaining +/- 1°F (0.56°C) control by proactively reacting to instantaneous load changes of up to 50 percent.

•Adaptive Control™ attempts to maintain chiller operation under adverse conditions, when many other chillers might simply shut down.

•Easy-to-use operator interface displays all operating and safety messages, with complete diagnostics information, on a

highly readable panel with a scrolling touch-screen display.

•The RTHD features a complete range of chiller safety controls.

•Over 120 diagnostic and operating points are available, with standard displays including chiller current draw, condenser pressure, and evaporator pressure.

Reliability and Ease of Maintenance

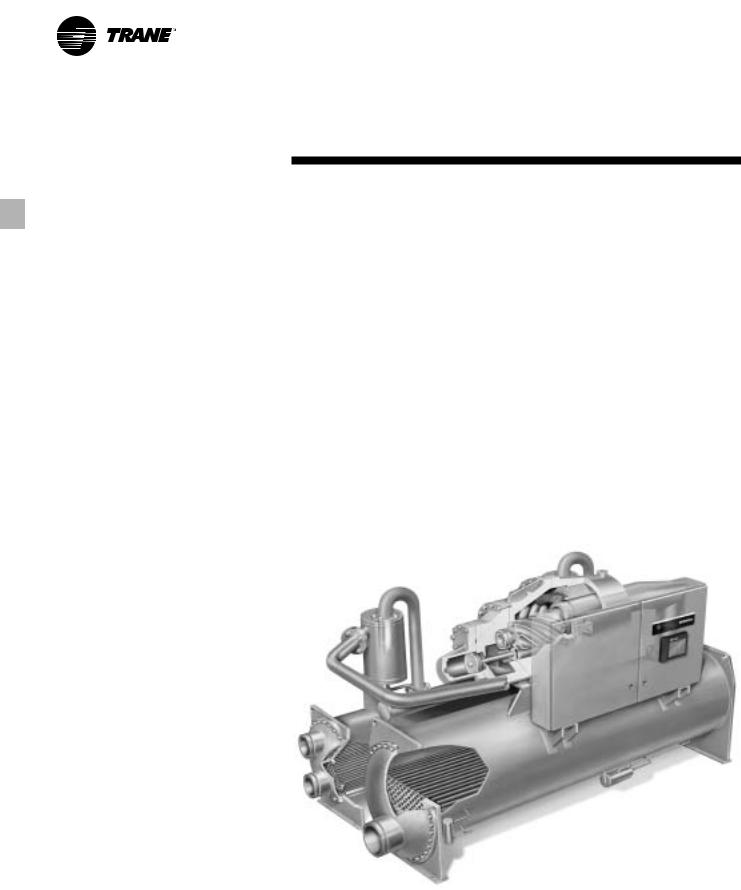

•Direct drive, low-speed compressor – a simple design with only three moving parts – provides maximum efficiency, high reliability, and low maintenance requirements.

•Electronic expansion valve, with fewer moving parts than alternative valve designs, offers highly reliable operation.

•Suction gas-cooled motor stays uniformly cool at lower temperatures for longer motor life.

•TheTrane helical rotary compressor is a proven design resulting from years of research and thousands of test hours, including extensive testing under extraordinarily severe operating conditions.

•Trane is the world’s largest manufacturer of large helical rotary compressors, with tens of thousands of commercial and industrial installations worldwide demonstrating a reliability rate of greater than 99 percent in the first year of operation.

Operating and Life Cycle

Cost-Effectiveness

•Electronic expansion valve enables exceptionally tight temperature control and extremely low superheat, resulting in more efficient full-load and part-load operation than previously available.

•Precise compressor rotor tip clearance ensures optimal efficiency.

•Condenser and evaporator tubes use the latest heat transfer technology for increased efficiency.

•The RTHD includes standard electrical demand limiting.

•Chilled water reset based on return water temperature is standard.

•High compressor lift capabilities and tight chilled water temperature control allow highly efficient system design with minimal operational concerns.

Design capabilities include:

•variable primary flow;

•series chiller arrangements for evaporator and/or condenser;

•low evaporator and condenser flow.

RLC-PRC020-EN |

5 |

Options

Insulation

All low temperature surfaces are covered with factory installed 3/4 inch (19.05 mm) Armaflex II or equal (k=0.28) insulation, including the evaporator and water boxes, suction line, and motor housing. 3/8" foam insulation is used on the liquid level sensor and gas pump assembly, including piping.

Low-Temperature Evaporator

Addition of an oil cooler to the oil circuit enables evaporator operation down to minimum leaving water temperature of 10°F (-12.2°C).

High-Temperature Condenser

Addition of an oil cooler to the oil circuit enables condenser operation up to maximum leaving water temperature of 114°F (45.6°C).

Smooth-Bore CondenserTubes

Smooth-bore copper or premium cupronickel condenser tubes, 3/4" (19.05 mm) in diameter with .035" (0.889 mm) wall thickness, are available for high fouling water applications.

Refrigerant Isolation Valves

Factory-installed condenser inlet and outlet refrigerant valves allow isolation of the full refrigerant charge in the condenser while servicing the chiller.

MarineWater Boxes

Addition of marine water boxes for the condenser allows tube cleaning without water pipe interference.

300 psig Evaporator and Condenser Water Boxes

Water boxes are designed for 300 psig maximum waterside working pressure, and grooved pipe water connections are provided for ease of installation.

2-Way CondenserWater RegulatingValve

For water regulation, a field-installed, 2-way butterfly-type (lug-style) valve, with integral electrical operator and factory-mounted valve actuator, is available.The single-phase, reversible motor can be factory-wired for 115VAC, 60 Hz or 220VAC, 50 Hz; the 2-way valve is field-wired and controlled by the chiller regulating valve control output; valves are available in 6" and 8" (152.4 and 203.2 mm) sizes.

Nitrogen Charge

Unit is shipped with a nitrogen holding charge in lieu of refrigerant.

Seal Kit for Reassembly

Ideal for situations when the bolt-together construction of the RTHD will be separated for installation, this seal kit provides replacement gaskets and rings for reassembly.

Solid State Starter

Solid State Starter is unit-mounted with a NEMA 1 gasketed enclosure.To extend starter life, contactors bypass current from the silicon control rectifiers (SCRs) after startup.

Under/Over-Voltage Protection

Unit receives protection against variations in voltage (current lag and spike protection is standard).

Performance andWitnessTests

ARI-certified RTHD Performance and WitnessTests are available, based on requested operating points, to certify chiller performance before delivery.

Main Power Disconnect

Options:

Non-fused Disconnect

A UL-approved non-fused molded case disconnect switch, factory pre-wired with terminal block power connections and equipped with a lockable external operator handle, is available to disconnect the chiller from main power.

Standard Interrupting Capacity Circuit Breaker

A UL-approved standard interrupting molded case capacity circuit breaker, factory pre-wired with terminal block power connections and equipped with a lockable external operator handle, is available to disconnect the chiller from main power.

High Interrupting Capacity Circuit Breaker

A UL-approved high interrupting molded case capacity circuit breaker, factory prewired with terminal block power connections and equipped with a lockable external operator handle, is available to disconnect the chiller from main power.

Ground Fault Circuit Breaker

A UL-approved standard interrupting molded case capacity circuit breaker with ground fault interrupting capability, factory pre-wired with terminal block connections and equipped with a lockable external operator handle, is available to disconnect the chiller from main power.

6 |

RLC-PRC020-EN |

Options

ControlOptions:

Tracer Summit Communications

Link to factory-installed, tested communication board, via single twistedpair wiring, addsTracer Summit communications to the system.

LonTalk LCI-C Interface

LonTalk (LCI-C) communications capabilities are available, with communication link via single twisted-pair wiring to factory-installed, tested communication board.

External ChilledWater Setpoint

External ChilledWater Setpoint is communicated to a factory-installed, tested communication board through a 2- 10Vdc or 4-20mA signal.

External Current Limiting

External Current Limit Setpoint is communicated to a factory-installed, tested communication board through a 2- 10Vdc or 4-20mA signal.

External Base Loading

External Base Loading is communicated to a factory-installed and tested communication board through a 2-10Vdc or 4-20mA signal.

Ice Making Control

Controls and safeties allow operation with brine temperatures down to 20°F (-6.7°C) , and dual setpoints enable both ice making and daytime comfort cooling.

Programmable Relays

Default-set, factory-installed, programmable relays allow the operator to select four relay outputs from a list of eight. Available relays are: AlarmLatching, Alarm-Auto Reset, General Alarm,Warning, Chiller Limit Mode, Compressor Running, Head Pressure Relief Request, andTracer Control.

ChilledWater Reset – OutdoorAir Temperature

Controls, sensors, and safeties allow reset of chilled water temperature, based on temperature signal, during periods of low outdoor air temperature (chilled water reset based on return chilled water temperature is standard).

Condenser-RegulatingValve Control

Chiller applies a Proportional Integrative Control (PID) algorithm to control water regulating valve via 0-10Vdc signal.

Percent of Full Run LoadAmps Output

Control system indicates the active chiller percent of full run load amps, based on a 0-10Vdc signal.

Condenser Pressure Output

Control system indicates chiller differential pressure or condenser pressure, based on a 0-10Vdc signal.

Refrigerant Monitor Input

Control system indicates refrigerant monitor status of 0-100 or 0-1000 ppm (user selectable), based on a 2-10Vdc / 4-20 mA signal.

RLC-PRC020-EN |

7 |

Controls

LCDTouch-Screen Display with Multi-Language Support

The standard DynaView display provided with the CH530 control panel features an LCD touch-screen, allowing access to all operational inputs and outputs.This display supports eleven languages: English, Chinese, Dutch, French, German, Italian, Japanese, Korean, Portugese, Spanish andThai.

Additional Display Features Include:

•LCD touch-screen with LED backlighting, for scrolling access to input and output operating information

•Weather-proof enclosure for reliable operation in non-standard indoor environments

•Spin value buttons to allow continuously variable setpoints when applicable

•Radio and action buttons for easy, onetime actions and settings

•Single-screen, folder/tab-style display of all available information on individual components (evaporator, condenser, compressor, etc.)

•Automatic and immediate stop capabilities for standard or immediate manual shutdown

•Manual override indication

•Password entry/lockout system to enable or disable display

•Fast, easy access to available chiller data in tabbed format, including:

—Modes of operation, including normal cooling and icemaking

—Water temperatures and setpoints

—Loading and limiting status and setpoints

—Average line current

—Outdoor air temperature

—Start/stop differential timers

—Auto/Manual mode for EXV, slide valve, and head pressure control

—Pump status and override

—Chilled water reset, start point, ratio, and outdoor start point

—External setpoints, including:

-chilled water

-current limit

-ice building

-base loading

—Display specifics, including:

-date

-format

-time

-display lockout

-display units

-language setting

-Reports, listed on a single tabbed screen for easy access, including:

•ASHRAE, containing all guideline 3 report information

•Evaporator

•Condenser

•Compressor

—Evaporator, condenser, and compressor reports containing all operational information on individual components, including:

-Water and air temperatures

-Refrigerant levels, temperatures, and approach

-Oil pressure

-Flow switch status

-EXV position

-Head pressure control command

-Compressor starts and run-time

-Line phase percent RLA, amps, and volts

—Alarm and diagnostic information, including:

-Flashing alarms with touch-screen button for immediate address of alarm condition

-Scrollable list of last ten active diagnostics

-Specific information on applicable diagnostic from list of over onehundred

-Automatic or manual resetting diagnostic types

8 |

RLC-PRC020-EN |

Controls

Trane Chiller PlantAutomation

Trane’s depth of experience in chillers and controls makes us a well-qualified choice for automation of chiller plants using aircooled Series R® chillers®.The chiller plant control capabilities of theTraneTracer Summit® building automation system are unequaled in the industry. Our chiller plant automation software is fully preengineered and tested. It is a standard software application, not custom programming which can prove to be difficult to support, maintain, and modify.

Energy Efficiency

Trane chiller plant automation intelligently sequences starting of chillers to optimize the overall chiller plant energy efficiency. Individual chillers are designated to operate as base, peak, or swing based on capacity and efficiency. Sophisticated software automatically determines which chiller to run in response to current conditions.The software also automatically rotates individual chiller operation to equalize runtime and wear between chillers.

Trane chiller plant automation enables unique energy-saving strategies. An example is controlling pumps, and chillers from the perspective of overall system energy consumption.The software intelligently evaluates and selects the lowest energy consumption alternative.

Regulatory Compliance Documentation

Comprehensive documentation of refrigerant management practices is now a fact of life.Trane chiller plant automation generates the reports mandated in ASHRAE Guideline 3.

Keeping Operators Informed

A crucial part of efficiently running a chiller plant is assuring that the operations staff is instantly aware of what is happening in the plant. Graphics showing schematics of chillers, piping, pumps, and towers clearly depict the chiller plant system, enabling building operators to easily monitor overall conditions. Status screens display both current conditions and upcoming automated control actions to add or subtract chiller capacity. Series R™ and other chillers can be monitored and controlled from a remote location.

Tracer Summit features standard report templates listing key operating data for troubleshooting and verifying performance. Reports for each type of Trane chiller and three and six-chiller systems are also standard. Detailed reports showing chiller runtimes aid in planning for preventative maintenance.

Swift Emergency Response

We understand the importance of maintaining chilled water production while protecting your chillers from costly damage. If no water flow is detected to a chiller’s piping, the start sequence is aborted to protect the chiller.The next chiller in the sequence is immediately started to maintain cooling.

In the event of a problem, the operator receives an alarm notification and diagnostic message to aid in quick and accurate troubleshooting. A snapshot report showing system status just prior to an emergency shutdown helps operators determine the cause. If emergency conditions justify an immediate manual shutdown, the operator can override the automatic control.

Integrated Comfort™ Capabilities

When integrated with aTracer Summit building management system performing building control,Trane chiller plant automation coordinates withTracer Summit applications to optimize the total building operation.With this system option, the full breadth ofTrane’s HVAC and controls experience are applied to offer solutions to many facility issues. If your project calls for an interface to other systems,Tracer Summit can share data via BACnet™, the ASHRAE open systems protocol.

LonTalk Chiller Controls

LonTalk is a communications protocol developed by the Echelon Corporation. The LonMark association develops control profiles using the LonTalk communication protocol. LonTalk is a unit level communications protocol, unlike BACNet used at the system level.

LonTalk Communications Interface for Chillers (LCI-C) provides a generic automation system with the LonMark chiller profile inputs/outputs. In addition to the standard points,Trane provides other commonly used network output variables for greater interoperability with any automation system. The complete reference list ofTrane LonTalk points is available on the LonMark website. Trane controls or another vendor’s system can use the predefined list of points with ease to give the operator a complete picture of how the system is running.

Hardwire Points

Remote devices wired from the control panel are another reliable method of providing auxiliary control to a building automation system. Inputs and outputs can be communicated via a typical 4-20 mA electrical signal (or an equivalentVdc signal of 0-10 or 2-10) or by utilizing contact closures.

•External ChilledWater Setpoint

•External Current Limit Setpoint

•Condenser-RegulatingValve Control

•Percent of Full Run Load Amps Output

•Condenser Pressure Output

•Refrigerant Monitor Input

•Programmable Relays

Allows the selection of 4 relay outputs from a list of eight different default settings: Alarm-Latching, Alarm-Auto Reset, General Alarm,Warning, Chiller Limit Mode, Compressor Running, Head Pressure Relief Request, andTracer Control. These contact closures may be used to trigger jobsite supplied audible or visual alarms

• Ice Making Control

Provides an interface with ice making control system and safeties, enabling both ice making and daytime comfort cooling

• ChilledWaterTemperature Reset Supplies controls, sensors and safeties to reset the chilled water temperature setpoint based upon return water temperature (standard) or outdoor air temperature (optional)

RLC-PRC020-EN |

9 |

Application

Considerations

Condenser WaterTemperatures

Reduced sensitivity to condenser water startup temperatures is one major enhancement in the newest-generation water-cooled Series R chiller.With the model RTHD chiller, a condenser water control method is necessary only if the unit starts with entering water temperatures below 55°F (12.8°C), or between 45°F (7.2°C) and 55°F (12.8°C), when a temperature increase of 1°F (0.56°C) per minute to 55°F (12.8°) is not possible.

When the application requires startup temperatures below the prescribed minimums, a variety of options are available.To control a 2-way or 3-way valve,Trane offers a Condenser RegulatingValve Control option for the CH530 controls.This option enables the CH530 controls to send a signal for opening and closing the valve as necessary to maintain chiller differential pressure.The 2-way valves are available as a ship-with option.Tower bypass is also a valid control method if the chiller temperature requirements can be maintained.

Trane Series R chillers start and operate successfully and reliably over a range of load conditions with controlled entering condenser water temperature. Reducing the condenser water temperature is an effective method of lowering chiller

power input required, but the ideal temperature for optimizing total system power consumption will depend on the overall system dynamics. From a system perspective, some improvements in chiller efficiency may be offset by the increased tower fan and pumping costs required to achieve the lower tower temperatures. Contact your localTrane systems solution provider for more information on optimizing system performance.

The minimum acceptable refrigerant pressure differential between condenser and evaporator is 23 psid.The chiller control system will attempt to obtain and maintain this differential at startup, but for continuous operation a design should maintain a 25°F (13.9°C) differential from evaporator leaving water temperature to condenser leaving water temperature.

Variable Evaporator Flow and Short EvaporatorWater Loops

Variable evaporator flow is an energysaving design strategy which has quickly gained acceptance as advances in chiller and controls technology have made it possible.With its linear unloading compressor design and advanced CH530 controls, the RTHD has excellent capability to maintain leaving water temperature control within +/-0.5°F (0.28°C) , even for systems with variable evaporator flow and small chilled water volumes.

Some basic rules should be followed whenever using these system design and operational savings methods with the RTHD.The proper location of the chilled water temperature control sensor is in the supply (outlet) water.This location allows the building to act as a buffer, and it assures a slowly changing return water temperature. If there is insufficient water volume in the system to provide an adequate buffer, temperature control can be lost, resulting in erratic system operation and excessive compressor cycling.To ensure consistent operation and tight temperature control, the chilled water loop should be at least two minutes. If this recommendation cannot be followed, and tight leaving water temperature control is necessary, a storage tank or larger header pipe should be installed to increase the volume of water in the system.

For variable primary flow applications, the rate of chilled water flow change should not exceed 10 percent of design per minute to maintain +/-0.5°F (0.28°C) leaving evaporator temperature control. For applications in which system energy savings is most important and tight temperature control is classified as +/-2°F (1.1°C), up to 30 percent changes in flow per minute are possible. Flow rates should be maintained between the minimum and maximum allowed for any particular chiller configuration.

10 |

RLC-PRC020-EN |

Loading...

Loading...