Page 1

Installation

Operation

Maintenance

RTAD-SVX01E-E4

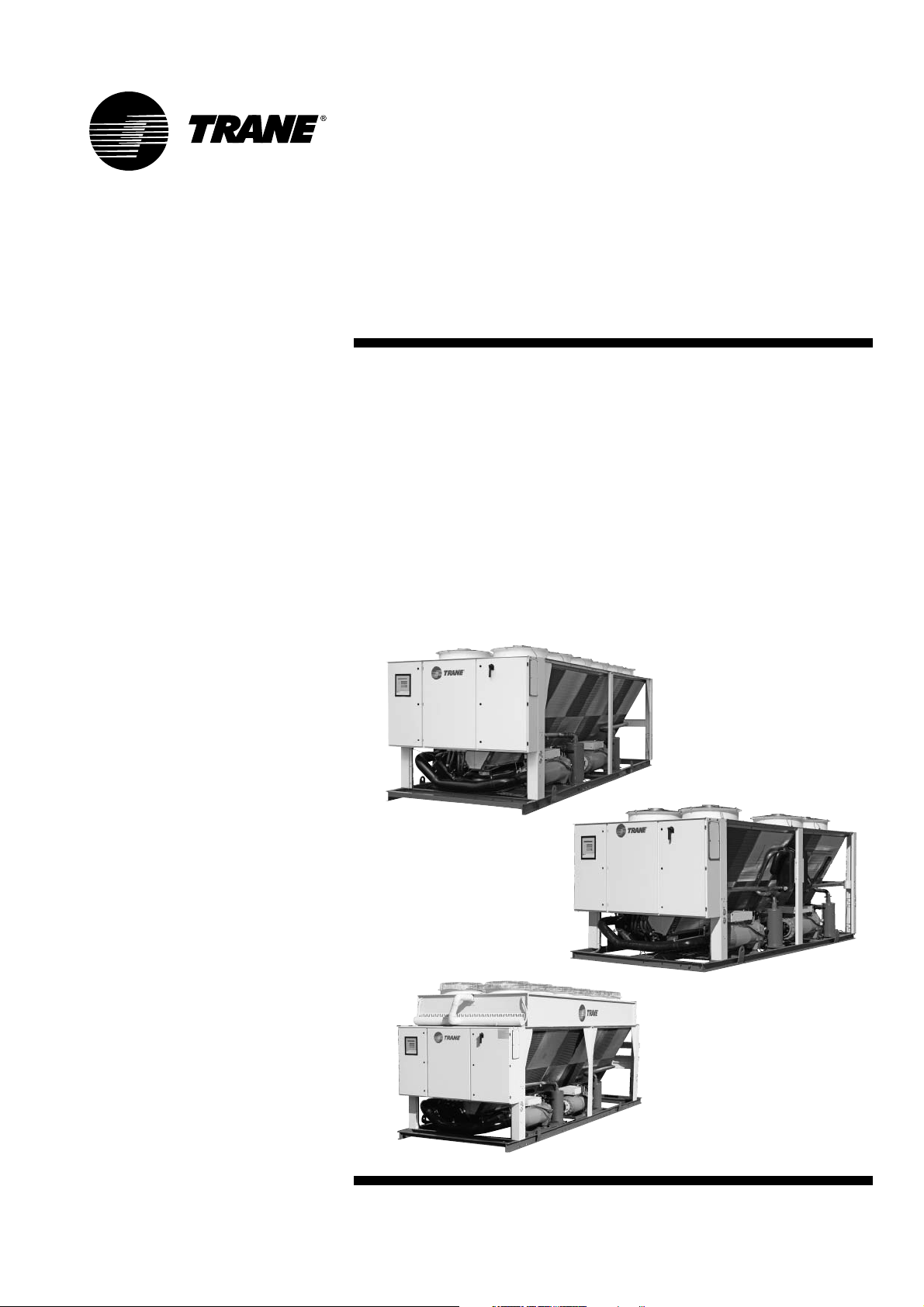

Series R™ Air-Cooled Helical Rotary

Liquid Chiller

RTAD 085 - 180 (50Hz)

Standard, Free Cooling and Heat

Recovery models

Page 2

RTAD-SVX01E-E4

©American Standard Inc. 2006

Foreword

These instructions are given as a

guide to good practice in the

installation, start-up, operation, and

maintenance by the user, of Trane

RTAD chillers. They do not contain

full service procedures necessary for

the continued successful operation of

this equipment. The services of a

qualified technician should be

employed through the medium of a

maintenance contract with a

reputable service company. Read

this manual thoroughly before unit

start-up.

Units are assembled, pressure

tested, dehydrated, charged and run

tested before shipment.

Warnings and cautions

Warnings and Cautions appear at

appropriate sections throughout this

manual. Your personal safety and the

proper operation of this machine

require that you follow them

carefully. The constructor assumes

no liability for installations or

servicing performed by unqualified

personnel.

WARNING! Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION! Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury. It may also be used

to alert against unsafe practices or

for equipment or property-damageonly accidents.

Safety recommendations

To avoid death, injury, equipment or

property damage, the following

recommendations should be

observed during maintenance and

service visits:

1. The maximum allowable pressures

for system leak testing on low and

high pressure side are given in the

chapter "Installation". Always

provide a pressure regulator.

2. Disconnect the main power supply

before any servicing on the unit.

3. Service work on the refrigeration

system and the electrical system

should be carried out only by

qualified and experienced

personnel.

Reception

On arrival, inspect the unit before

signing the delivery note.

Reception in France only:

In case of visible damage: The

consignee (or the site representative)

must specify any damage on the

delivery note, legibly sign and date

the delivery note, and the truck

driver must countersign it. The

consignee (or the site representative)

must notify Trane Epinal Operations Claims team and send a copy of the

delivery note. The customer (or the

site representative) should send a

registered letter to the last carrier

within 3 days of delivery.

Note: for deliveries in France, even

concealed damage must be looked

for at deli

very and immediately

treated as visible damage.

General information

Page 3

RTAD-SVX01E-E4 3

General information

Reception in all countries except

France:

In case of concealed damage: The

consignee (or the site representative)

must send a registered letter to the

last carrier within 7 days of delivery,

claiming for the described damage. A

copy of this letter must be sent to

Trane Epinal Operations - Claims

team.

Warranty

Warranty is based on the general

terms and conditions of the

manufacturer. The warranty is void if

the equipment is repaired or

modified without the written

approval of the manufacturer, if the

operating limits are exceeded or if

the control system or the electrical

wiring is modified. Damage due to

misuse, lack of maintenance or

failure to comply with the

manufacturer's instructions or

recommendations is not covered by

the warranty obligation. If the user

does not conform to the rules of this

manual, it may entail cancellation of

warranty and liabilities by the

manufacturer.

Refrigerant

The refrigerant provided by the

manufacturer meets all the

requirements of our units. When

using recycled or reprocessed

refrigerant, it is advisable to ensure

its quality is equivalent to that of a

new refrigerant. For this, it is

necessary to have a precise analysis

made by a specialized laboratory. If

this condition is not respected, the

manufacturer warranty could be

cancelled.

Maintenance contract

It is strongly recommended that you

sign a maintenance contract with

your local Service Agency. This

contract provides regular

maintenance of your installation by

a specialist in our equipment.

Regular maintenance ensures that

any malfunction is detected and

corrected in good time and

minimizes the possibility that

serious damage will occur. Finally,

regular maintenance ensures the

maximum operating life of your

equipment. We would remind you

that failure to respect these

installation and maintenance

instructions may result in immediate

cancellation of the warranty.

Training

To assist you in obtaining the best

use of it and maintaining it in perfect

operating condition over a long

period of time, the manufacturer has

at your disposal a refrigeration and

air conditioning service school. The

principal aim of this is to give

operators and technicians a better

knowledge of the equipment they

are using, or that is under their

charge. Emphasis is particularly

given to the importance of periodic

checks on the unit operating

parameters as well as on preventive

maintenance, which reduces the cost

of owning the unit by avoiding

serious and costly breakdown.

Page 4

Contents

4 RTAD-SVX01E-E4

General Information 2

Unit Inspection 7

Loose Parts Inventory 7

General Data - Standard cooling unit 8

General Data - Free-cooling unit 16

General Data - Heat Recovery unit 18

Unit Dimensions 23

Installation - Mechanical 24

Installation Responsibilities 24

Nameplates 24

Storage 26

Location Requirements 26

Isolation and Sound Emission 26

Neoprene Isolator Installation 26

Noise Considerations 26

Foundation 27

Clearances 27

Drainage 28

Unit Water Piping 28

Unit Piping 28

Entering Chilled Water Piping 29

Leaving Chilled Water Piping 29

Heat Recovery Water Piping 29

Evaporator Drain 29

Evaporator Flow Switch 29

Water Treatment 30

Water Pressure Gauges 41

Water Pressure Relief Valves 41

Freeze Protection 41

Page 5

Installation - Electrical 42

General Recommendations 43

Installer-Supplied Components 48

Power Supply Wiring 48

Control Power Supply 48

Heater Power Supply 48

Water Pump Power Supply 48

Interconnecting Wiring 49

Chilled Water Flow (Pump) Interlock 49

Chilled Water Pump Control 49

Alarm and Status Relay Outputs

(Programmable Relays) 52

Low Voltage Wiring 54

External Emergency Stop 54

External Auto/Stop 54

External Circuit Lockout - Circuit 1 and Circuit 2 54

Ice Making Option 55

External Chilled Water Setpoint (CWS) 55

External Current Limit Setpoint (CLS) 56

Outdoor Air Temperature Sensor 56

Communication Card CSR 57

Communication link connection procedure 57

LonTalk communication interface 58

Operating Principles 64

System schematics 64

Pre-Start Checkout 67

Installation Checklist 67

Receiving 67

Unit Location and Mounting 67

Unit Piping 67

Electrical Wiring 67

General 68

Unit Voltage Power Supply 69

Unit Voltage Imbalance 69

Unit Voltage Phasing 69

Water System Flow Rates 70

Water System Pressure Drop 70

Contents

RTAD-SVX01E-E4 5

Page 6

6 RTAD-SVX01E-E4

Contents

Unit Start-up Procedures 71

Daily Unit Start-Up 71

General 72

Seasonal Unit Start-Up Procedure 73

System Restart After Extended Shutdown 73

Unit Shutdown Procedures 74

Temporary Shutdown And Restart 74

Extended Shutdown Procedure 74

Maintenance 75

General 75

Weekly Maintenance 75

Monthly Maintenance 75

Annual Maintenance 75

Maintenance Procedures 76

Refrigerant Emission Control 76

Refrigerant and Oil Charge Management 77

R134a Field Charging Procedure 77

Refrigerant Charging 77

Isolating the Refrigerant in the High Pressure Side 78

Isolating the Refrigerant in the Low Pressure Side 78

Adding Refrigerant 79

Refrigerant Filter Changing Procedure 79

Lubrication System 80

Oil Charging Procedure 80

Factory (initial) Oil Charging Procedure 81

Field Oil Charging Procedure 82

Evaporator Heat Tape Checkout Procedure 83

Safety recommendations 83

Page 7

RTAD-SVX01E-E4 7

General Information

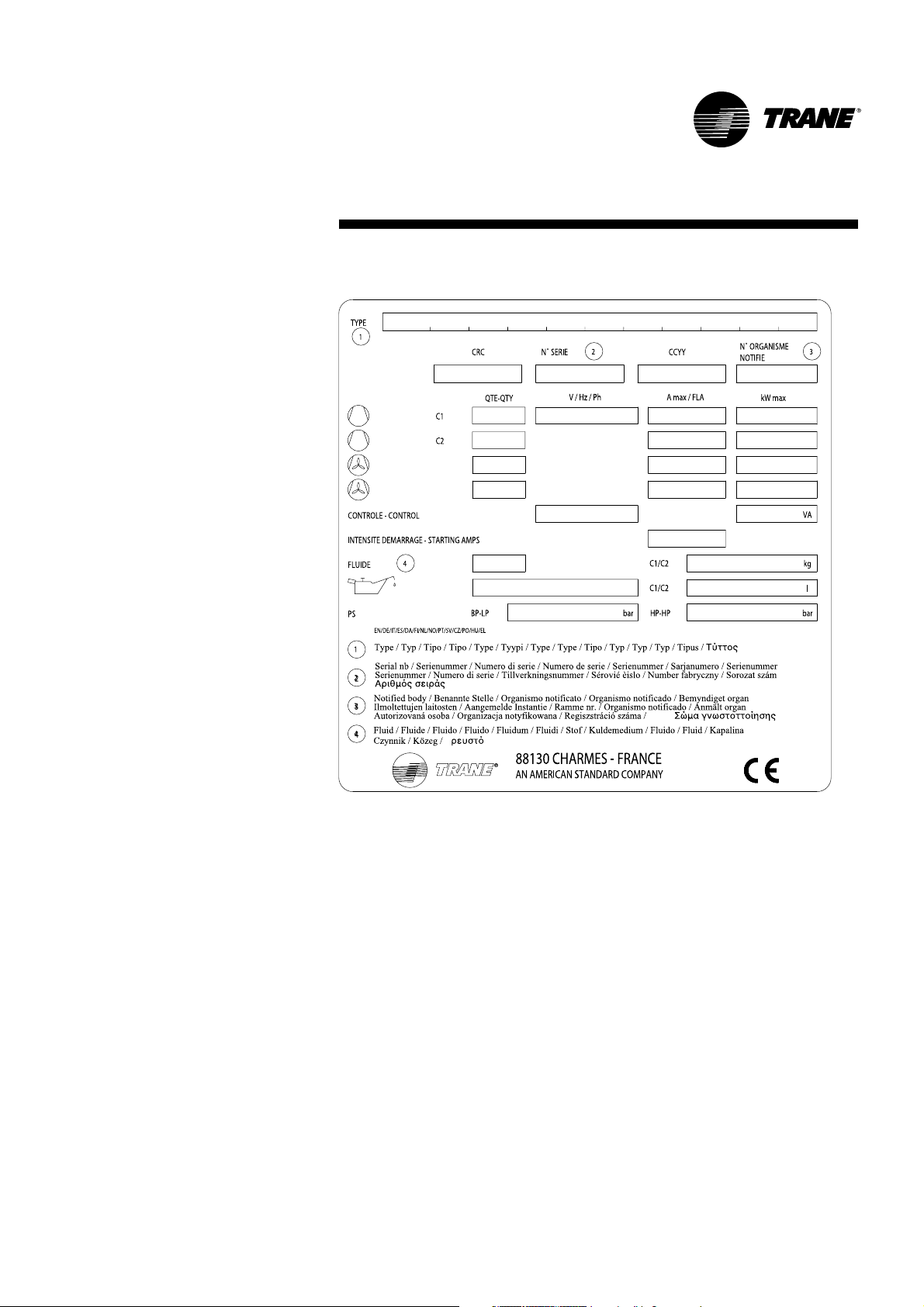

Unit Inspection

When the unit is delivered, verify

that it is the correct unit and that it is

properly equipped. Compare the

information which appears on the

unit nameplate with the ordering

and submittal information. A typical

unit nameplate is shown in Figure 1.

Loose Parts Inventory

Check all the accessories and loose

parts which are shipped with the

unit against the shipping list.

Included in these items will be water

vessel drain plugs, rigging and

electrical diagrams, and service

literature, which are placed inside

the control panel and/or starter

panel for shipment.

Figure 1 - Typical Unit Nameplate

Page 8

8 RTAD-SVX01E-E4

General Information

General Data - SI Units

Table 1 - General Data RTAD Standard

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 270 222 204 204 204 415 415

Minimum Flow (l/s) 4.1 6.0 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 22222222

Coil Length (mm) 2743 3658 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 23.4 28.5 27.0 27.0 37.0 39.0 44.9 46.8

Nominal RPM 915 915 915 915 915 915 915 915

Tip Speed (m/s) 36.5 36.5 36.5 36.5 36.5 36.5 36.5 36.5

Motor kW (kW) 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05

Min Starting/Oper Ambient (2)

Standard Unit (°C) 00000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 24/24 30/32 35/36 36/37 44/48 44/48 61/59 61/61

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 2660 3105 3555 3570 4260 4520 5440 5525

Shipping Weight (4) (kg) 2554 2838 3333 3368 4057 4317 5023 5108

Table 2 - General Data RTAD High Efficiency

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (l) 270 222 204 204 415 415

Minimum Flow (l/s) 6.0 7.3 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 20.8 24.8 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 222222

Coil Length (mm) 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 27.0 31.2 35.0 39.0 44.8 46.8

Nominal RPM 915 915 915 915 915 915

Tip Speed (m/s) 36.5 36.5 36.5 36.5 36.5 36.5

Motor kW (kW) 2.05 2.05 2.05 2.05 2.05 2.05

Min Starting/Oper Ambient (2)

Standard Unit (°C) 000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 32/34 35/36 42/45 42/45 59/61 59/61

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 3240 3370 3905 4000 5390 5445

Shipping Weight (4) (kg) 2973 3148 3702 3797 4973 5028

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 9

RTAD-SVX01E-E4 9

General Information

Table 3 - General Data RTAD Standard Low Noise

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 270 222 204 204 204 415 415

Minimum Flow (l/s) 4.1 6.0 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 22222222

Coil Length (mm) 2743 3658 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 18.1 22.4 21.0 21.0 28.7 30.1 34.7 36.2

Nominal RPM 730 730 730 730 730 730 730 730

Tip Speed (m/s) 29.1 29.1 29.1 29.1 29.1 29.1 29.1 29.1

Motor kW (kW) 1.30 1.30 1.30 1.30 1.30 1.30 1.30 1.30

Min Starting/Oper Ambient (2)

Standard Unit (°C) 00000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 24/24 30/32 35/36 36/37 44/48 44/48 61/59 61/61

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 2760 3205 3655 3670 4360 4620 5540 5625

Shipping Weight (4) (kg) 2654 2938 3433 3468 4157 4417 5123 5208

Table 4 - General Data RTAD High Efficiency Low Noise

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (l) 270 222 204 204 415 415

Minimum Flow (l/s) 6.0 7.3 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 20.8 24.8 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 222222

Coil Length (mm) 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 21.0 24.1 27.2 30.1 34.7 36.1

Nominal RPM 690 690 690 690 690 690

Tip Speed (m/s) 27.5 27.5 27.5 27.5 27.5 27.5

Motor kW (kW) 1.30 1.30 1.30 1.30 1.30 1.30

Min Starting/Oper Ambient (2)

Standard Unit (°C) 000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 32/34 35/36 42/45 42/45 59/61 59/61

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 3340 3470 40 05 4100 5490 5545

Shipping Weight (4) (kg) 3073 3248 3802 3897 5073 5128

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 10

10 RTAD-SVX01E-E4

General Information

Table 5 - General Data RTAD Standard Low Noise with Night Noise Set Back option

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 270 222 204 204 204 415 415

Minimum Flow (l/s) 4.1 6.0 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 22222222

Coil Length (mm) 2743 3658 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 2/2 3/3 3/3 3/3 4/4 4/4 5/5 5/5

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 13.4 20.5 19.3 19.3 25.0 25.0 30.7 30.7

Nominal RPM 550 550 550 550 550 550 550 550

Tip Speed (m/s) 21.9 21.9 21.9 21.9 21.9 21.9 21.9 21.9

Motor kW (kW) 1.05 1.05 1.05 1.05 1.05 1.05 1.05 1.05

Min Starting/Oper Ambient (2)

Standard Unit (°C) 00000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 24/24 30/32 35/36 36/37 44/48 44/48 61/59 61/61

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 2660 3205 3655 3670 4310 4520 5490 5525

Shipping Weight (4) (kg) 2554 2938 3433 3468 4107 4317 5073 5108

Table 6 - General Data RTAD High Efficiency Low Noise with Night Noise Set Back option

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (l) 270 222 204 204 415 415

Minimum Flow (l/s) 6.0 7.3 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 20.8 24.8 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 222222

Coil Length (mm) 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 4/4 4/4 5/5 5/5

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 19.2 19.2 24.9 25.0 30.6 30.6

Nominal RPM 550 550 550 550 550 550

Tip Speed (m/s) 21.9 21.9 21.9 21.9 21.9 21.9

Motor kW (kW) 1.05 1.05 1.05 1.05 1.05 1.05

Min Starting/Oper Ambient (2)

Standard Unit (°C) 000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 32/34 35/36 42/45 42/45 59/61 59/61

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 3340 3370 40 05 4000 5440 5445

Shipping Weight (4) (kg) 3073 3148 3802 3797 5023 5028

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 11

RTAD-SVX01E-E4 11

General Information

Table 7 - General Data RTAD Standard High External Static Pressure

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 270 222 204 204 204 415 415

Minimum Flow (l/s) 4.1 6.0 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 22222222

Coil Length (mm) 2743 3658 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 23.7 29.5 27.6 27.6 37.6 39.5 45.5 47.4

Nominal RPM 935 935 935 935 935 935 935 935

Tip Speed (m/s) 37.3 37.3 37.3 37.3 37.3 37.3 37.3 37.3

Motor kW (kW) 2.21 2.21 2.21 2.21 2.21 2.21 2.21 2.21

Min Starting/Oper Ambient (2)

Standard Unit (°C) 00000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18 -18 -18

General Unit

Refrigerant R134a R134a R134a R134a R134a R134a R134a R134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 24/24 30/32 35/36 36/37 44/48 44/48 61/59 61/61

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 2660 3105 3555 3570 4260 4520 5440 5525

Shipping Weight (4) (kg) 2554 2838 3333 3368 4057 4317 5023 5108

Table 8 - General Data RTAD High Efficiency High External Static Pressure

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (l) 270 222 204 204 415 415

Minimum Flow (l/s) 6.0 7.3 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 20.8 24.8 30.7 30.7 38.0 38.0

Condenser

Qty of Coils 222222

Coil Length (mm) 3658 3658 4572 4572 5486 5486

Coil Height (mm) 1626 1626 1626 1626 1626 1626

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 27.6 31.5 35.6 39.4 45.4 47.3

Nominal RPM 935 935 935 935 935 935

Tip Speed (m/s) 37.3 37.3 37.3 37.3 37.3 37.3

Motor kW (kW) 2.21 2.21 2.21 2.21 2.21 2.21

Min Starting/Oper Ambient (2)

Standard Unit (°C) 000000

Low Ambient Unit (°C) -18 -18 -18 -18 -18 -18

General Unit

Refrigerant R134a R134a R134a R134a R134a R134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (kg) 32/34 35/36 42/45 42/45 59/61 59/61

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 3240 3370 3905 4000 5390 5445

Shipping Weight (4) (kg) 2973 3148 3702 3797 4973 5028

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 12

12 RTAD-SVX01E-E4

General Information

English Units

Table 9 - General Data RTAD Standard

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (Gallon) 28.0 71.3 58.7 53.9 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 65.2 95.1 115.0 139.2 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 274.6 329.9 393.1 486.4 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 22222222

Coil Length (inch) 108 144 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (inch) 30 30 30 30 30 30 30 30

Total Air Flow (CFM) 49556 60460 57194 57248 78439 82716 95103 99250

Nominal RPM 915 915 915 915 915 915 915 915

Tip Speed (Ft/s) 119.8 119.8 119.8 119.8 119.8 119.8 119.8 119.8

Motor kW (kW) 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32 32 32

Low Ambient Unit (°F) 00000000

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (lbs.) 52.9/52.9 66.1/70.5 77.2/79.4 79.4/81.6 97/105.8 97/105.8 134.5/130.1 134.5/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.38/2.38 2.64/2.64 2.64/2.64 2.64/2.64 3.96/2.91 3.96/3.96

Operating Weight (4) (lbs.) 5864 6845 7837 7871 9392 9965 11993 12181

Shipping Weight (4) (lbs.) 5631 6257 7348 7425 8944 9517 11074 11261

Table 10 - General Data RTAD High Efficiency

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (Gallon) 71.3 58.7 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 95.1 115.0 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 329.9 393.1 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 222222

Coil Length (inch) 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (inch) 30 30 30 30 30 30

Total Air Flow (CFM) 57108 66046 74100 82628 95008 99132

Nominal RPM 915 915 915 915 915 915

Tip Speed (Ft/s) 119.8 119.8 119.8 119.8 119.8 119.8

Motor kW (kW) 2.05 2.05 2.05 2.05 2.05 2.05

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32

Low Ambient Unit (°F) 000000

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (lbs.) 70.5/75.0 77.2/79.4 92.6/99.2 92.6/99.2 130.1/134.5 130.1/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.64/2.64 2.64/2.64 2.91/2.91 2.91/2.91

Operating Weight (4) (lbs.) 7143 7430 8609 8818 11883 120 04

Shipping Weight (4) (lbs.) 6554 6940 8162 8371 10964 11085

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 13

RTAD-SVX01E-E4 13

General Information

Table 11 - General Data RTAD Standard Low Noise

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (Gallon) 28.0 71.3 58.7 53.9 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 65.2 95.1 115.0 139.2 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 274.6 329.9 393.1 486.4 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 22222222

Coil Length (inch) 108 144 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (inch) 30 30 30 30 30 30 30 30

Total Air Flow (CFM) 38246 47434 44514 44568 60751 63878 73628 76644

Nominal RPM 730 730 730 730 730 730 730 730

Tip Speed (Ft/s) 95.6 95.6 95.6 95.6 95.6 95.6 95.6 95.6

Motor kW (kW) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32 32 32

Low Ambient Unit (°F) 00000000

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (Lbs.) 52.9/52.9 66.1/70.5 77.2/79.4 79.4/81.6 97/105.8 97/105.8 134.5/130.1 134.5/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.38/2.38 2.64/2.64 2.64/2.64 2.64/2.64 3.96/2.91 3.96/3.96

Operating Weight (4) (Lbs.) 6085 7066 8058 8091 9612 10185 12214 12401

Shipping Weight (4) (Lbs.) 5851 6477 7568 7646 9165 9738 11294 11482

Table 12 - General Data RTAD High Efficiency Low Noise

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (Gallon) 71.3 58.7 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 95.1 115.0 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 329.9 393.1 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 222222

Coil Length (inch) 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (inch) 30 30 30 30 30 30

Total Air Flow (CFM) 44426 50964 57562 63784 73521 76510

Nominal RPM 690 690 690 690 690 690

Tip Speed (Ft/s) 90.3 90.3 90.3 90.3 90.3 90.3

Motor kW (kW) 1.3 1.3 1.3 1.3 1.3 1.3

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32

Low Ambient Unit (°F) 000000

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (Lbs.) 70.5/75.0 77.2/79.4 92.6/99.2 92.6/99.2 130.1/134.5 130.1/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.64/2.64 2.64/2.64 2.91/2.91 2.91/2.91

Operating Weight (4) (Lbs.) 7363 7650 8830 9039 12103 12225

Shipping Weight (4) (Lbs.) 6775 7161 8382 8591 11184 11305

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 14

14 RTAD-SVX01E-E4

General Information

Table 13 - General Data RTAD Standard Low Noise with Night Noise Set Back option

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (Gallon) 28.0 71.3 58.7 53.9 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 65.2 95.1 115.0 139.2 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 274.6 329.9 393.1 486.4 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 22222222

Coil Length (inch) 108 144 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 37318 37289 37318 37318 37318 37318 37318 37318

Condenser Fans

Quantity (1) 2/2 3/3 3/3 3/3 4/4 4/4 5/5 5/5

Diameter (inch) 30 30 30 30 30 30 30 30

Total Air Flow (CFM) 28479 43376 40791 40842 52929 52962 64956 65000

Nominal RPM 550 550 550 550 550 550 550 550

Tip Speed (Ft/s) 72.0 72.0 72.0 72.0 72.0 72.0 72.0 72.0

Motor kW (kW) 1.05 1.05 1.05 1.05 1.05 1.05 1.05 1.05

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32 32 32

Low Ambient Unit (°F) 00000000

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (lbs.) 52.9/52.9 66.1/70.5 77.2/79.4 79.4/81.6 97/105.8 97/105.8 134.5/130.1 134.5/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.38/2.38 2.64/2.64 2.64/2.64 2.64/2.64 3.96/2.91 3.96/3.96

Operating Weight (4) (lbs.) 5864 7066 8058 8091 9502 9965 12103 12181

Shipping Weight (4) (lbs.) 5631 6477 7568 7646 9054 9517 11184 11261

Table 14 - General Data RTAD High Efficiency Low Noise with with Night Noise Set Back option

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (Gallon) 71.3 58.7 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 95.1 115.0 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 329.9 393.1 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 222222

Coil Length (inch) 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 37318 37318 37318 37318 37318 37318

Condenser Fans

Quantity (1) 3/3 3/3 4/4 4/4 5/5 5/5

Diameter (inch) 30 30 30 30 30 30

Total Air Flow (CFM) 40710 40746 52846 52904 64872 64906

Nominal RPM 550 550 550 550 550 550

Tip Speed (Ft/s) 72.0 72.0 72.0 72.0 72.0 72.0

Motor kW (kW) 1.05 1.05 1.05 1.05 1.05 1.05

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32

Low Ambient Unit (°F) 000000

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (lbs.) 70.5/75.0 77.2/79.4 92.6/99.2 92.6/99.2 130.1/134.5 130.1/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.64/2.64 2.64/2.64 2.91/2.91 2.91/2.91

Operating Weight (4) (lbs.) 7363 7430 8830 8818 11993 12004

Shipping Weight (4) (lbs.) 6775 6940 8382 8371 11074 11085

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 15

Table 15 - General Data RTAD Standard High External Static Pressure

Size 085 100 115 125 145 150 165 180

Compressor Quantity 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (Gallon) 28.0 71.3 58.7 53.9 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 65.2 95.1 115.0 139.2 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 274.6 329.9 393.1 486.4 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 22222222

Coil Length (inch) 108 144 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 37683 37654 37683 37683 37683 37683 37683 37683

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (inch) 30 30 30 30 30 30 30 30

Total Air Flow (CFM) 50118 62540 58514 58578 79569 83640 96363 100368

Nominal RPM 935 935 935 935 935 935 935 935

Tip Speed (Ft/s) 122.4 122.4 122.4 122.4 122.4 122.4 122.4 122.4

Motor kW (kW) 2.21 2.21 2.21 2.21 2.21 2.21 2.21 2.21

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32 32 32

Low Ambient Unit (°F) 00000000

General Unit

Refrigerant R134a R134a R134a R134a R134a R134a R134a R134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Refrigerant Charge (1) (lbs.) 52.9/52.9 66.1/70.5 77.2/79.4 79.4/81.6 97/105.8 97/105.8 134.5/130.1 134.5/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.38/2.38 2.64/2.64 2.64/2.64 2.64/2.64 3.96/2.91 3.96/3.96

Operating Weight (4) (lbs.) 5864 6845 7837 7871 9392 9965 11993 12181

Shipping Weight (4) (lbs.) 5631 6257 7348 7425 8944 9517 11074 11261

Table 16 - General Data RTAD High Efficiency High External Static Pressure

Size 085 100 115 125 145 150

Compressor Quantity 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (Gallon) 71.3 58.7 53.9 53.9 109.6 109.6

Minimum Flow (GPM) 95.1 115.0 139.2 139.2 184.0 184.0

Maximum Flow (GPM) 329.9 393.1 486.4 486.4 603.0 603.0

Condenser

Qty of Coils 222222

Coil Length (inch) 144 144 180 180 216 216

Coil Height (inch) 64 64 64 64 64 64

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 37683 37683 37683 37683 37683 37683

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (inch) 30 30 30 30 30 30

Total Air Flow (CFM) 58412 66796 75432 83562 96257 100248

Nominal RPM 935 935 935 935 935 935

Tip Speed (Ft/s) 122.4 122.4 122.4 122.4 122.4 122.4

Motor kW (kW) 2.21 2.21 2.21 2.21 2.21 2.21

Min Starting/Oper Ambient (2)

Standard Unit (°F) 32 32 32 32 32 32

Low Ambient Unit (°F) 000000

General Unit

Refrigerant R134a R134a R134a R134a R134a R134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Refrigerant Charge (1) (Lbs.) 70.5/75.0 77.2/79.4 92.6/99.2 92.6/99.2 130.1/134.5 130.1/134.5

Oil Charge (1) (Gallon) 1.59/1.59 1.85/1.85 2.64/2.64 2.64/2.64 2.91/2.91 2.91/2.91

Operating Weight (4) (Lbs.) 7143 7430 8609 8818 11883 120 04

Shipping Weight (4) (Lbs.) 6554 6940 8162 8371 10964 11085

Notes:

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(3) Percent minimum load is for total machine at 10°C (50F) ambient and 7°C (44F) leaving chilled water temp. Not each individual circuit.

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

RTAD-SVX01E-E4 15

General Information

Page 16

16 RTAD-SVX01E-E4

General Information

Table 17 - General Data RTAD FC Standard

Unit Size 085 100 115 125 145 150 165 180

Number of Compressors 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 270 222 204 204 204 415 415

Minimum Flow (l/s) 4.1 6 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38 38

Free-Cooler

Number of Coils 11111111

Fin series (Fins/ft) 152 152 122 122 152 152 152 152

Number of Rows 44665555

Water Storage (l) 265 481 538 520 531 531 806 806

(Evap+Free-Cooler)

Condenser

Number of Coils 22222222

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 4/4 5/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 17.9/13.0 21.6/15.7 20.4/14.7 23.5/17.2 28.4/20.6 29/21.2 34.2/24.8 34.7/25.4

Nominal Speed (rpm) 935/740 935/740 935/740 935/740 935/740 935/740 935/740 935/740

Motor kW (kW) 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85

Min Starting/ (°C) -18 -18 -18 -18 -18 -18 -18 -18

Oper Ambient(2)

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Weight. Capacities & Dimensions

Refrigerant Charge (1) (kg) 24/24 30/32 35/36 36/37 44/48 44/48 61/59 61/61

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 3685 4492 5291 5446 6296 6241 7884 7969

Shipping Weight (4) (kg) 3300 3740 4530 4720 5560 5505 6665 6750

Length (mm) 3900 4850 4850 4850 5770 5770 6810 6810

Width (mm) 2420 2420 2420 2420 2420 2420 2460 2460

Height (mm) 2605 2605 2605 2605 2645 2645 2745 2745

Water Connection (mm) 139.7 139.7 139.7 139.7 139.7 139.7 168.3 168.3

Diameter

Water Connection Type Victaulic Victaulic Victaulic Victaulic Victaulic Victaulic Victaulic Victaulic

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s wind across the condenser

(3) Percent minimum load is for total machine at 10°C ambient and 7°C leaving chilled water temp. Not each individual circuit.

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Note:

All Free Cooling units must be freeze protected with 30% Ethylene Glycol in the cooling loop circuit which is the most convenient percentage in order

to protect the unit against freezing.

Protection coverage with 30% Ethylene Glycol:

- freezing point without burst effect = -13°C;

- freezing point with burst effect = -50°C.

Page 17

RTAD-SVX01E-E4 17

General Information

Table 18 - General Data RTAD FC High Efficiency

Unit Size 085 100 115 125 145 150

Number of Compressors 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG 140 EG 170 EG 200 EG 200 EG 250 EG 250

Water Storage (l) 270 222 204 204 415 415

Minimum Flow (l/s) 6 7.3 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 20.8 24.8 30.7 30.7 38 38

Free-Cooler

Number of Coils 111111

Fin series (Fins/ft) 152 122 152 152 152 152

Number of Rows 465555

Water Storage (l) 481 538 531 531 806 806

(Evap+Free-Cooler)

Condenser

Number of Coils 222222

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 20.8/15.1 23.5/17.2 26/18.9 28.9/21.2 34.1/24.8 34.7/25.4

Nominal Speed (rpm) 935/740 935/740 935/740 935/740 935/740 935/740

Motor kW (kW) 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85 1.7/0.85

Min Starting/ (°C) -18 -18 -18 -18 -18 -18

Oper Ambient (2)

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Weight. Capacities & Dimensions

Refrigerant Charge (1) (kg) 32/34 35/36 42/45 42/45 59/61 59/61

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 4627 5106 5905 6000 7834 7889

Shipping Weight (4) (kg) 3875 4345 5170 5265 6615 6670

Length (mm) 4850 4850 5770 5770 6810 6810

Width (mm) 2420 2420 2420 2420 2460 2460

Height (mm) 2605 2605 2645 2645 2745 2745

Water Connection (mm) 139.7 139.7 139.7 139.7 168.3 168.3

Diameter

Water Connection Type Victaulic Victaulic Victaulic Victaulic Victaulic Victaulic

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s wind across the condenser

(3) Percent minimum load is for total machine at 10°C ambient and 7°C leaving chilled water temp. Not each individual circuit.

(4) Weights with aluminium fins, power disconnect switch, isolators and pressure gauges

Page 18

18 RTAD-SVX01E-E4

General Information

Table 19 - General Data RTAD Heat Recovery Standard

Unit Size 085 100 115 125 145 150 165 180

Number of Compressors 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 269 223 204 204 204 415 415

Minimum Flow (l/s) 4.1 6 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38.0 38.0

Water Connection Type Victaulic

Water Connection (inch-mm) 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3

Diameter

Heat Recovery Heat-Exchanger

Type Brazed Plates

Water connection type Victaulic

PHR

Connection diameter (inch-mm) 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3

Water Storage capacity (l) 8 8 9 9 11 11 12 12

THR

Connection diameter (inch-mm) -

2" - 60.3 2" - 60.3 2" - 60.3 3" O.D. - 3" O.D. - 3" O.D. - 3" O.D. -

76.1 76.1 76.1 76.1

Water Storage capacity (l) - 10 14 14 16 16 19 19

Condenser

Number of Coils 22222222

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 23.4 28.5 27.0 27.0 37.0 39.0 44.9 46.8

Nominal Speed (rpm) 930 930 930 930 930 930 930 930

Motor kW (kW) 1.72 1.72 1.72 1.72 1.72 1.72 1.72 1.72

Min Starting/Oper Ambient (2)

PHR (°C)00000000

THR (°C) -18 -18 -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Weight. Capacities & Dimensions

PHR

Refrigerant Charge (1) (kg) 26/26 33/35 38/39 39/40 47/51 47/51 65/63 65/65

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 2736 3176 3635 3650 4345 4605 5535 5622

Shipping Weight (4) (kg) 2622 2899 3403 3437 4130 4390 5108 5195

THR

Refrigerant Charge (1) (kg) - 55 / 52 67 / 64 68 / 64 86 / 84 86 / 84 100 / 95 100 / 98

Oil Charge (1) (l) - 5 / 4 8 / 7 8 / 7 8 / 7 8 / 7 13 / 7 13 / 12

Operating Weight (4) (kg) - 3347 3833 3848 4615 4875 5806 5891

Shipping Weight (4) (kg) - 3061 3589 3623 4382 4642 5359 5444

Dimensions

Length (mm) 3507 4426 4426 4426 5351 5351 6370 6370

Width (mm) 2260 2260 2260 2260 2260 2260 2260 2260

Height (mm) 2095 2095 2095 2095 2115 2115 2215 2215

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s wind across the condenser.

(3) Percent minimum load is for total machine at 10°C ambient and 7°C leaving chilled water temp. Not each individual circuit.

(4) With aluminum fins

5"1/2 O.D.-

139.7

Page 19

RTAD-SVX01E-E4 19

General Information

Table 20 - General Data RTAD Heat Recovery High Efficiency

Unit Size 085 100 115 125 145 150

Number of Compressors 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (l) 269 223 204 204 415 415

Minimum Flow (l/s) 6 7.3 8.8 8.8 11.6 11.6

Maximum Flow l/s) 20.8 24.8 30.7 30.7 38.0 38.0

Water Connection Type Victaulic

Water Connection (inch-mm) 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3

Diameter

Heat Recovery Heat-Exchanger

Type Brazed Plates

Water connection type Victaulic

PHR

Connection diameter (inch-mm) 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3

Water Storage capacity (l) 88991111

THR

Connection diameter (inch-mm) 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 3" O.D. - 76.1 3" O.D. - 76.1

Water Storage capacity (l) 10 10 14 14 16 16

Condenser

Number of Coils 222222

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 27.0 31.2 35.0 39.0 44.9 46.8

Nominal Speed (rpm) 930 930 930 930 930 930

Motor kW (kW) 1.72 1.72 1.72 1.72 1.72 1.72

Min Starting/Oper Ambient (2)

PHR (°C) 000000

THR (°C) -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Weight. Capacities & Dimensions

PHR

Refrigerant Charge (1) (kg) 35/37 38/39 45/48 45/48 63/65 63/65

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 3311 3441 3984 4079 5474 5529

Shipping Weight (4) (kg) 2375 2504 3045 3140 4532 4587

THR

Refrigerant Charge (1) (kg) 63 / 60 65 / 62 86 / 84 86 / 84 97 / 95 97 / 95

Oil Charge (1) (l) 5 / 4 5 / 4 8 / 7 8 / 7 8 / 7 8 / 7

Operating Weight (4) (kg) 3494 3624 4238 4333 5731 5786

Shipping Weight (4) (kg) 3208 3384 4013 4108 5287 5342

Dimensions

Length (mm) 4426 4426 5351 5351 6370 6370

Width (mm) 2260 2260 2260 2260 2260 2260

Height (mm) 2095 2095 2115 2115 2215 2215

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s wind across the condenser.

(3) Percent minimum load is for total machine at 10°C ambient and 7°C leaving chilled water temp. Not each individual circuit.

(4) With aluminum fins

Page 20

20 RTAD-SVX01E-E4

General Information

Table 21 - General Data RTAD Heat Recovery Standard Low Noise

Unit Size 085 100 115 125 145 150 165 180

Number of Compressors 22222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85 100/85 100/100

Evaporator

Evaporator Model EG120 EG140 EG170 EG200 EG200 EG200 EG250 EG250

Water Storage (l) 106 269 223 204 204 204 415 415

Minimum Flow (l/s) 4.1 6 7.3 8.8 8.8 8.8 11.6 11.6

Maximum Flow (l/s) 17.3 20.8 24.8 30.7 30.7 30.7 38.0 38.0

Water Connection Type Victaulic

Water Connection (inch-mm) 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3

Diameter

Heat Recovery Heat-Exchanger

Type Brazed Plates

Water connection type Victaulic

PHR

Connection diameter (inch-mm) 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3

Water Storage capacity (l) 889911111212

THR

Connection diameter (inch-mm) -

2" - 60.3 2" - 60.3 2" - 60.3 3" O.D. - 3" O.D. - 3" O.D. - 3" O.D. -

76.1 76.1 76.1 76.1

Water Storage capacity (l) - 10 14 14 16 16 19 19

Condenser

Number of Coils 22222222

Fin series (Fins/ft) 192 192 192 192 192 192 192 192

Number of Rows 3/3 2/2 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 3/3 3/3 3/3 5/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762 762 762

Total Air Flow (m3/s) 18.1 22.4 21.0 21.0 28.7 30.1 34.7 36.2

Nominal Speed (rpm) 750 750 750 750 750 750 750 750

Motor kW (kW) 1.23 1.23 1.23 1.23 1.23 1.23 1.23 1.23

Min Starting/Oper Ambient (2)

PHR (°C)00000000

THR (°C) -18 -18 -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 22222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17 17 17

Weight. Capacities & Dimensions

PHR

Refrigerant Charge (1) (kg) 26/26 33/35 38/39 39/40 47/51 47/51 65/63 65/65

Oil Charge (1) (l) 6/6 7/7 9/9 10/10 10/10 10/10 15/11 15/15

Operating Weight (4) (kg) 2836 3276 3735 3750 4445 4705 5635 5722

Shipping Weight (4) (kg) 2082 2520 2978 2991 3686 3946 4873 4960

THR

Refrigerant Charge (1) (kg) - 55 / 52 67 / 64 68 / 64 86 / 84 86 / 84 100 / 95 100 / 98

Oil Charge (1) (l) - 5 / 4 8 / 7 8 / 7 8 / 7 8 / 7 13 / 7 13 / 12

Operating Weight (4) (kg) - 3447 3933 3948 4715 4975 5906 5991

Shipping Weight (4) (kg) - 3161 3689 3723 4482 4742 5459 5544

Dimensions

Length (mm) 3507 4426 4426 4426 5351 5351 6370 6370

Width (mm) 2260 2260 2260 2260 2260 2260 2260 2260

Height (mm) 2095 2095 2095 2095 2115 2115 2215 2215

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s wind across the condenser.

(3) Percent minimum load is for total machine at 10°C ambient and 7°C leaving chilled water temp. Not each individual circuit.

(4) With aluminum fins

5"1/2 O.D.-

139.7

Page 21

Table 22 - General Data RTAD Heat Recovery High Efficiency Low Noise

Unit Size 085 100 115 125 145 150

Number of Compressors 222222

Nominal Size (1) (Tons) 40/40 50/50 60/60 70/70 85/70 85/85

Evaporator

Evaporator Model EG140 EG170 EG200 EG200 EG250 EG250

Water Storage (l) 269 223 204 204 415 415

Minimum Flow (l/s) 6 7.3 8.8 8.8 11.6 11.6

Maximum Flow l/s) 20.8 24.8 30.7 30.7 38 38

Water Connection Type Victaulic

Water Connection (inch-mm) 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3 6" - 168.3

Diameter

Heat Recovery Heat-Exchanger

Type Brazed Plates

Water connection type Victaulic

PHR

Connection diameter 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3

Water Storage capacity (l) 88991111

THR

Connection diameter (inch-mm) 2" - 60.3 2" - 60.3 2" - 60.3 2" - 60.3 3" O.D. - 76.1 3" O.D. - 76.1

Water Storage capacity (l) 10 10 14 14 16 16

Condenser

Number of Coils 222222

Fin series (Fins/ft) 192 192 192 192 192 192

Number of Rows 3/3 3/3 3/3 3/3 3/3 3/3

Condenser Fans

Quantity (1) 3/3 4/4 4/4 5/5 6/5 6/6

Diameter (mm) 762 762 762 762 762 762

Total Air Flow (m3/s) 21.0 24.1 27.2 30.1 34.7 36.2

Nominal Speed (rpm) 750 750 750 750 750 750

Motor kW (kW) 1.23 1.23 1.23 1.23 1.23 1.23

Min Starting/Oper Ambient (2)

PHR (°C) 000000

THR (°C) -18 -18 -18 -18 -18 -18

General Unit

Refrigerant HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a HFC 134a

No. Of independent 222222

Refrigerant Circuits

% Min. Load (3) 17 17 17 17 17 17

Weight. Capacities & Dimensions

PHR

Refrigerant Charge (1) (kg) 35/37 38/39 45/48 45/48 63/65 63/65

Oil Charge (1) (l) 6/6 7/7 10/10 10/10 11/11 11/11

Operating Weight (4) (kg) 3411 3541 4084 4179 5574 5629

Shipping Weight (4) (kg) 2655 2784 3325 3420 4812 4867

THR

Refrigerant Charge (1) (kg) 63 / 60 65 / 62 86 / 84 86 / 84 97 / 95 97 / 95

Oil Charge (1) (l) 5 / 4 5 / 4 8 / 7 8 / 7 8 / 7 8 / 7

Operating Weight (4) (kg) 3594 3724 4338 4433 5831 5886

Shipping Weight (4) (kg) 3308 3484 4113 4208 5387 5442

Dimensions

Length (mm) 4426 4426 5351 5351 6370 6370

Width (mm) 2260 2260 2260 2260 2260 2260

Height (mm) 2095 2095 2115 2115 2215 2215

(1) Data containing information on two circuits shown as follows: ckt1/ckt2

(2) Minimum start-up/operation ambient based on a 2.22 m/s wind across the condenser.

(3) Percent minimum load is for total machine at 10°C ambient and 7°C leaving chilled water temp. Not each individual circuit.

(4) With aluminum fins

RTAD-SVX01E-E4 21RTAD-SVX01E-E4 21

General Information

Page 22

22 RTAD-SVX01E-E4

General Information

The below hydraulic module operating weight must be added to the RTAD operating

weight.

Table 23 - Hydraulic module additional operating weight - SI units (kg)

RTAD 115 HE - RTAD 125 HE RTAD 145 SE - RTAD 150 SE Expansion vessel

Pump type Pump model Without 50 litres 80 litres

LRN 208-13/5.5 - LRN 208-14/7.5 400 460 500

SIL 208-16/11 - SIL 208-17/15 455 515 555

JRN 208-13/5.5 - JRN 208-14/7.5 490 550 590

SIL 208-16/11 - SIL 208-17/15 600 660 700

RTAD 145 HE - RTAD 150 HE RTAD 165 SE - RTAD 180 HE Expansion vessel

LRN 208-13/5.5 - LRN 208-14/7.5 510 570 610

SIL 208-16/11 - SIL 208-17/15 565 625 665

JRN 208-13/5.5 - JRN 208-14/7.5 600 660 700

SIL 208-16/11 - SIL 208-17/15 710 770 810

Hydraulic module addtional operating weight - English units (lbs)

RTAD 115 HE - RTAD 125 HE RTAD 145 SE - RTAD 150 SE Expansion vessel

Pump type Pump model Without 50 litres 80 litres

LRN 208-13/5.5 - LRN 208-14/7.5 882 1014 1102

SIL 208-16/11 - SIL 208-17/15 1003 1135 1224

JRN 208-13/5.5 - JRN 208-14/7.5 1080 1213 1301

SIL 208-16/11 - SIL 208-17/15 1323 1455 1543

RTAD 145 HE - RTAD 150 HE RTAD 165 SE - RTAD 180 HE Expansion vessel

LRN 208-13/5.5 - LRN 208-14/7.5 1124 1257 1345

SIL 208-16/11 - SIL 208-17/15 1246 1378 1466

JRN 208-13/5.5 - JRN 208-14/7.5 1323 1455 1543

SIL 208-16/11 - SIL 208-17/15 1565 1698 1786

Single

Single

Dual

Dual

Single

Single

Dual

Dual

Page 23

RTAD-SVX01E-E4 23

General Information

Unit Dimensions

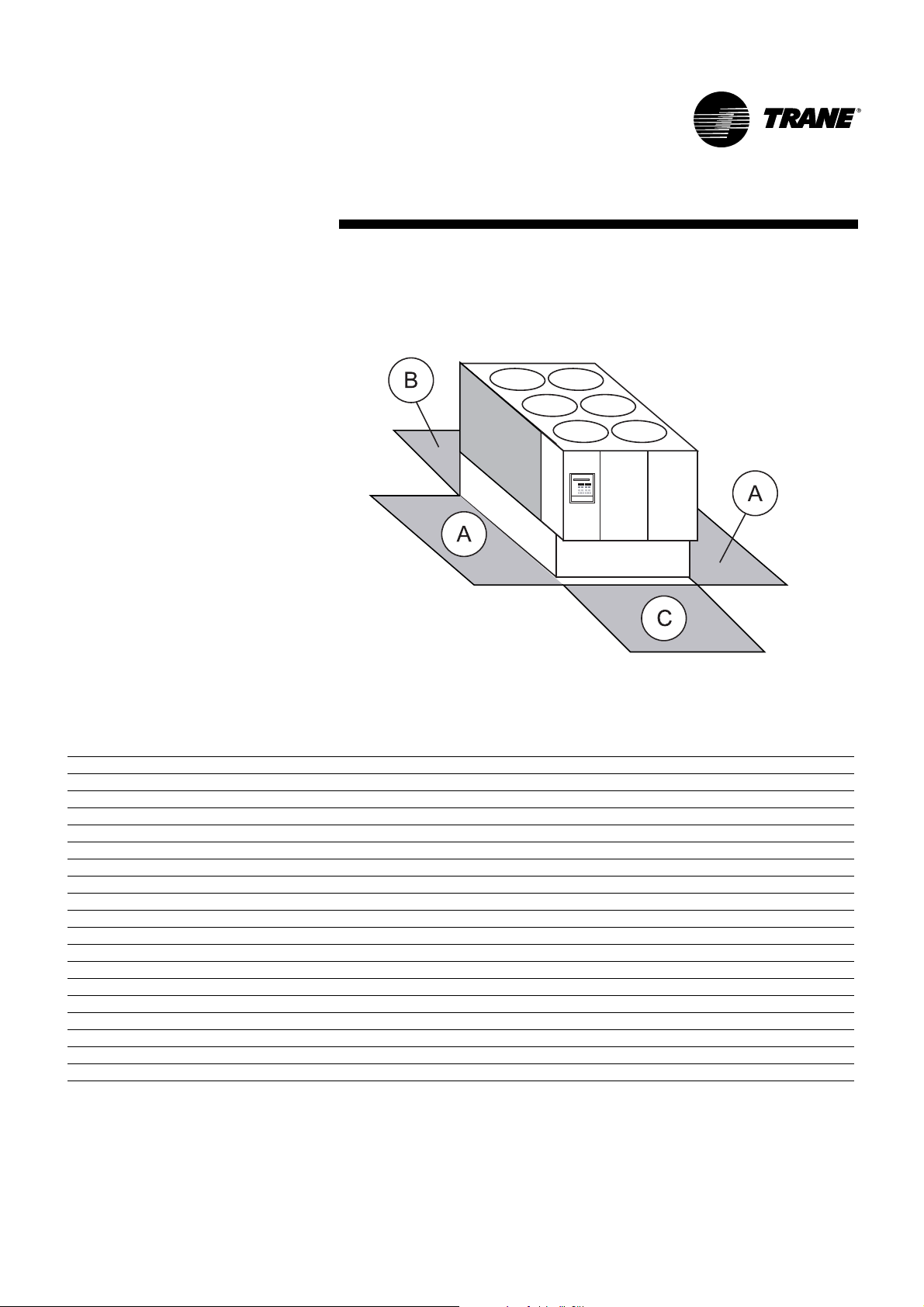

Figure 2 - Unit Dimensions and Minimum Recommended Clearances

Table 24

Note: Size 085 does not exist for Total Heat Recovery option but HE version is available

Unit Dimensions (mm) Minimum clearances (mm)

Length Width Height A B C

Unit Size

Standard, Partial Heat Recovery, and Total Heat Recovery

RTAD 085 3507 2260 2095 1200 1000 1000

RTAD 100-115-125 4426 2260 2095 1200 1000 1000

RTAD 145-150 5351 2260 2115 1200 1000 1000

RTAD 165-180 6370 2260 2215 1200 1000 1000

RTAD 085-100 HE 4426 2260 2095 1200 1000 1000

RTAD 115-125 HE 5351 2260 2115 1200 1000 1000

RTAD 145-150 HE 6370 2260 2215 1200 1000 1000

Free Cooling

RTAD 085 3900 2420 2605 1200 1000 1000

RTAD 100-115-125 4850 2420 2605 1200 1000 1000

RTAD 145-150 5770 2420 2645 1200 1000 1000

RTAD 165-180 6810 2460 2745 1200 1000 1000

RTAD 085-100 HE 4850 2420 2605 1200 1000 1000

RTAD 115-125 HE 5770 2420 2645 1200 1000 1000

RTAD 145-150 HE 6810 2460 2745 1200 1000 1000

Page 24

24 RTAD-SVX01E-E4

Installation - Mechanical

Installation Responsibilities

Generally, the contractor must do

the following when installing an

RTAD unit:

❏ Install unit on a flat foundation,

level (within 1/4" [6 mm] across

the length of the unit), and strong

enough to support unit loading.

❏ Install unit per the instructions

contained in this manual.

❏ Install any optional sensors and

make electrical connections at the

UCM-CLD.

❏Where specified, provide and

install valves in water piping

upstream and downstream of

evaporator water connections to

isolate the evaporator for

maintenance, and to balance/trim

system.

❏ Furnish and install flow switch

and/or auxiliary contacts to prove

chilled water flow.

❏ Furnish and install pressure

gauges in inlet and outlet piping

of the evaporator.

❏ Furnish and install a drain valve to

the bottom of the evaporator shell.

❏ Supply and install a vent cock to

the top of the evaporator shell.

❏ Furnish and install strainers ahead

of all pumps and automatic

modulating valves.

❏ Provide and install field wiring.

❏ Install heat tape and insulate the

chilled water lines and any other

portions of the system, as

required, to prevent sweating

under normal operating conditions

or freezing during low ambient

temperature conditions.

❏ Start unit under supervision of a

qualified service technician.

Nameplates

The RTAD outdoor unit nameplates

(Figure 1) are applied to the exterior

of the control panel. A compressor

nameplate is located on each

compressor.

Outdoor Unit Nameplate

The outdoor unit nameplate

provides the following information:

• Unit model and size description

• Unit serial number

• Identifies unit electrical

requirements

• Lists correct operating charges of

R-134a and refrigerant oil (Trane

OIL00048)

• Lists unit test pressures

Compressor Nameplate

The compressor nameplate provides

following information:

• Compressor model number.

• Compressor serial number.

• Compressor electrical

characteristics.

• Utilization range

• Recommended refrigerant

Page 25

RTAD-SVX01E-E4 25

Installation - Mechanical

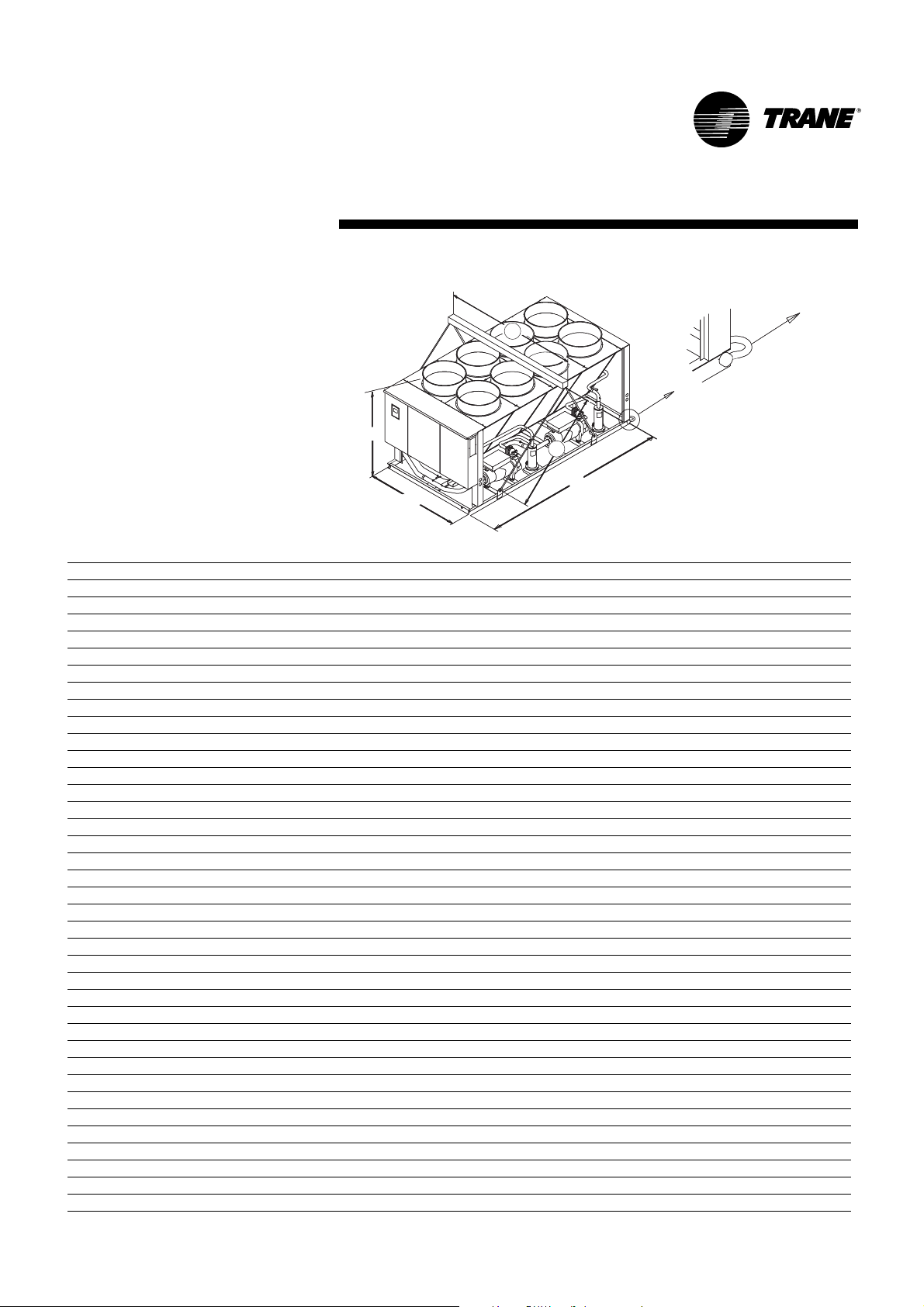

Figure 3 - Rigging the Unit

Table 25

Note: Size 085 does not exist for Total Heat Recovery option but HE version is available

(1) Maximum weight with all options

Unit Size Lengths (mm) Maximum weight (kg)(1)

A B L H max W Aluminium Copper

Standard

RTAD 085 4000 2400 3507 2215 2260 2740 3070

RTAD 100-115-125 4000 2400 4426 2215 2260 3565 4005

RTAD 145-150 4000 2400 5351 2215 2260 4530 4940

RTAD 165-180 4000 2400 6370 2215 2260 5345 5855

RTAD 085-100 HE 4000 2400 4426 2215 2260 3345 3785

RTAD 115-125 HE 4000 2400 5351 2215 2260 4010 4560

RTAD 145-150 HE 4000 2400 6370 2215 2260 5265 5775

Partial Heat Recovery

RTAD 085 4000 2400 3507 2215 2260 2810 3140

RTAD 100-115-125 4000 2400 4426 2215 2260 3635 4075

RTAD 145-150 4000 2400 5351 2215 2260 4605 5015

RTAD 165-180 4000 2400 6370 2215 2260 5430 5940

RTAD 085-100 HE 4000 2400 4426 2215 2260 3405 3845

RTAD 115-125 HE 4000 2400 5351 2215 2260 4080 4630

RTAD 145-150 HE 4000 2400 6370 2215 2260 5340 5850

Total Heat Recovery

RTAD 100 4000 2400 4426 2215 2260 3260 3540

RTAD 115-125 4000 2400 4426 2215 2260 3820 4260

RTAD 145-150 4000 2400 5351 2215 2260 4855 5265

RTAD 165-180 4000 2400 6370 2215 2260 5680 6190

RTAD 085-100 HE 4000 2400 4426 2215 2260 3580 3845

RTAD 115-125 HE 4000 2400 5351 2215 2260 4320 4870

RTAD 145-150 HE 4000 2400 6370 2215 2260 5580 6090

Free Cooling

RTAD 085 4600 2600 3900 2605 2420 3485 RTAD 100-115-125 4600 2600 4850 2605 2420 4920 RTAD 145-150 4600 2600 5770 2645 2420 5720 RTAD 165-180 4600 2600 6810 2745 2460 6985 RTAD 085-100 HE 4600 2600 4850 2605 2420 4540 RTAD 115-125 HE 4600 2600 5770 2645 2420 5480 RTAD 145-150 HE 4600 2600 6810 2745 2460 6905 RTAD 145-150 SE 4000 2400 5351 2215 2260 5265 5675

RTAD 165-180 SE 4000 2400 6370 2215 2260 6145 6655

RTAD 115-125 HE 4000 2400 5351 2215 2260 4740 5150

RTAD 145-150 HE 4000 2400 6370 2215 2260 6145 6655

B

H

A

L

W

Page 26

26 RTAD-SVX01E-E4

Installation - Mechanical

Location Requirements

Isolation and Sound Emission

The most effective form of isolation

is to locate the unit away from any

sound sensitive area. Structurally

transmitted sound can be reduced

by elastomeric vibration eliminators.

Spring isolators are not

recommended. Consult an acoustical

engineer in critical sound

applications. For maximum isolation

effect, isolate water lines and

electrical conduit. Wall sleeves and

rubber isolated piping hangers can

be used to reduce the sound

transmitted through water piping. To

reduce the sound transmitted

through electrical conduit, use

flexible electrical conduit. State and

local codes on sound emissions

should always be considered. Since

the environment in which a sound

source is located affects sound

pressure, unit placement must be

carefully evaluated. Sound power

levels for Trane air-cooled RTAD

chillers are available on request.

For additional reduction of sound

and vibration, install the optional

neoprene isolators. Construct an

isolated concrete pad for the unit or

provide concrete footings at the unit

mounting points. Mount the unit

directly to the concrete pads or

footings. Level the unit using the

base rail as a reference. Use shims

as necessary to level the unit.

Neoprene Isolator (optional)

Installation

Refer to submittals for diagrams.

1 Secure the isolators to the

mounting surface using the

mounting slots in the isolator base

plate. DO NOT fully tighten the

isolator mounting bolts at this

time.

2 Align the mounting holes in the

base of the unit with the threaded

positioning pins on the top of the

isolators.

3 Lower the unit onto the isolators

and secure the isolator to the unit

with a nut. Maximum isolator

deflection should be 1/4 inch

(6 mm).

4 Level the unit carefully. Fully

tighten the isolator mounting

bolts.

Noise Considerations

Locate the outdoor unit away from

sound sensitive areas. If required,

install rubber vibration isolators in

all water piping and use flexible

electrical conduit. Consult an

acoustical engineer for critical

applications. Also refer to Trane

Engineering Bulletins for application

information on RTAD chillers.

Important note for Free-cooling

units:

To reduce sound levels, a sound

enclosure can be mounted around

the compressors. For further sound

level reduction, the fan speed

should be forced onto low speed

(e.g. 740 rpm). This can be done

using the control panel. Make sure

that option 20, shown on the wiring

diagram, is correctly wired.

Storage

Extended storage of the outdoor unit

prior to installation requires the

following precautionary measures:

• Store the outdoor unit in a secure

area.

• At least every three months

(quarterly), check the pressure in

the refrigerant circuits to verify that

the refrigerant charge is intact. If it

is not, contact a qualified service

organization and the appropriate

Trane sales office.

• Close the discharge and liquid line

isolation valves.

CAUTION! Refer to nameplate for

unit weight and additional

installation instructions contained

inside the control panel. Other lifting

arrangements may cause equipment

damage or serious personal injury.

Page 27

RTAD-SVX01E-E4 27

Installation - Mechanical

Foundation

Provide rigid, non-warping mounting

pads or a concrete foundation of

sufficient strength and mass to

support the outdoor unit operating

weight (i.e., including completed

piping, and full operating charges of

refrigerant, oil and water). Refer to

Tables 1-23 for unit operating

weights. Once in place, the outdoor

unit must be level within 1/4" (6 mm)

over its length and width. A base or

foundation is not required if the

selected unit location is level and

strong enough to support the unit's

operating weight. Trane is not

responsible for equipment problems

resulting from an improperly

designed or constructed foundation.

Note: To allow for cleaning under the

condensing coil, it is recommended

that an opening be left between the

unit base and the concrete pad.

Clearances

Refer to Figure 2 for minimum

clearances. Provide enough space

around the outdoor unit to allow the

installation and maintenance

personnel unrestricted access to all

service points. Refer to submittal

drawings for the unit dimensions. A

minimum of four feet is

recommended for compressor

service. Provide sufficient clearance

for the opening of control panel

doors. In all cases, local codes which

require additional clearances will

take precedence over these

recommendations.

Unobstructed flow of condenser air

is essential to maintain chiller

capacity and operating efficiency.

When determining unit placement,

give careful consideration to

assuring a sufficient flow of air

across the condenser heat transfer

surface. Two detrimental conditions

are possible and must be avoided if

optimum performance is to be

achieved: warm air recirculation and

coil starvation. Warm air

recirculation occurs when discharge

air from the condenser fans is

recycled back to the condenser coil

inlet. Coil starvation occurs when

free airflow to (or from) the

condenser is restricted. Both warm

air recirculation and coil starvation

cause reduction in unit efficiency

and capacity due to the increased

head pressures. Debris, trash,

supplies etc. should not be allowed

to accumulate in the vicinity of the

unit. Supply air movement may

draw debris into the condenser coil,

blocking spaces between coil fins

and causing coil starvation. Special

consideration should be given to

low ambient units. Condenser coils

and fan discharge must be kept free

of snow or other obstructions to

permit adequate airflow for

satisfactory unit operation.

Page 28

Unit Water Piping

Thoroughly flush all water piping to

the unit before making the final

piping connections to the unit.

CAUTION! If using an acidic

commercial flushing solution,

construct a temporary bypass

around the unit to prevent damage

to internal components of the

evaporator. To avoid possible

equipment damage, do not use

untreated or improperly treated

system water.

CAUTION! As the unit contains

pressure approved vessels and

sensitive electronic equipment, do

not use arc welding directly on the

unit or even close to the unit. Do

not weld near the Victaulic

connections.

Unit Piping

Components and layout will vary

slightly, depending on the location

of connections and the water source.

Note: The chilled water piping to the

evaporator is to be Victaulic type

connections. For Free Cooling units,

Free Cooling coil connections are

also to be Victaulic

TM

type

connections.

To prevent damage to chilled water

components, do not allow

evaporator pressure (maximum

working pressure) to exceed 16 bar.

Provide shutoff valves in lines to the

gauges to isolate them from the

system when they are not in use.

Use rubber vibration eliminators to

prevent vibration transmission

through the water lines. If desired,

install thermometers in the lines to

monitor entering and leaving water

temperatures. Install a balancing

valve in the leaving water line to

control water flow balance. Install

shutoff valves on both the entering

and leaving water lines so that the

evaporator can be isolated for

service.

CAUTION! A pipe strainer must be

installed in the entering water line.

Failure to do so can allow

waterborne debris to enter the

evaporator.

"Piping components" include all

devices and controls used to provide

proper water system operation and

unit operating safety. These

components and their general

locations are given below.

In situations where equipment must

be installed with less clearance than

recommended, such as frequently

occurs in retrofit and rooftop

applications, restricted airflow is

common. The Main Processor will

direct the unit to make as much

chilled water as possible given the

actual installed conditions. Consult

your Trane sales engineer for more

details.

Note: If the outdoor unit

configuration requires a variance to

the clearance dimensions, contact

your Trane Sales Office

Representative. Also refer to Trane

Engineering Bulletins for application

information on RTAD chillers.

Drainage

Provide a large capacity drain for

water vessel drain-down during

shutdown or repair. The evaporator

is provided with a drain connection.

All local and national codes apply.

The vent on the top of the

evaporator shell is provided to

prevent a vacuum by allowing air

into the evaporator for complete

drainage.

28 RTAD-SVX01E-E4

Installation - Mechanical

Page 29

RTAD-SVX01E-E4 29

Installation - Mechanical

Leaving Chilled Water

Piping

❏ Air vents (to bleed air from

system).

❏Water pressure gauges with

shutoff valves.

❏Vibration eliminators.

❏ Shutoff (isolation) valves.

❏Thermometers.

❏ Clean-out tees.

❏ Balancing valve.

❏ Flow Switch

CAUTION! To prevent evaporator

damage, do not exceed 16 bar

evaporator water pressure.

Heat Recovery Water Piping

Entering:

❏ Air vents

❏Water pressure gauges

❏Vibration eliminator / expansion

compensator

❏ Shutoff valve

❏Thermometers

❏ Pipe strainer

❏ Clean-out tees

Leaving:

❏ Air vents

❏Water pressure gauges

❏Vibration eliminator / expansion

compensator

❏ Shutoff valve

❏Thermometers

❏ Balancing valve

❏ Clean-out tees

Evaporator Drain

A 3/4" drain connection is located

under the evaporator shell. This may

be connected to a suitable drain to

permit evaporator drainage during

unit servicing. A shutoff valve must

be installed on the drain line.

Evaporator Flow Switch

Specific connection and schematic

wiring diagrams are shipped with

the unit. Some piping and control

schemes, particularly those using a

single water pump for both chilled

and hot water must be analyzed to

determine how and or if a flowsensing device will provide desired

operation.

Follow the manufacturer's

recommendations for selection and

installation procedures. General

guidelines for flow switch

installation are outlined below

1. Mount the switch upright, with a

minimum of 5 pipe diameters of

straight horizontal run on each

side. Do not install close to

elbows, orifices or valves.

Note: The arrow on the switch must

point in the direction of flow.

2. To prevent switch fluttering,

remove all air from the water

system.

Note: The UCM-CLD provides a

6-second time delay after a "loss-offlow" diagnostic before shutting the

unit down. Contact a qualified

service representative if nuisance

machine shutdowns persist.

3. Adjust the switch to open when

water flow falls below nominal.

Evaporator data is given in

Tables 1-22. Flow switch contacts are

closed on proof of water flow.

4. Install a pipe strainer in the

entering evaporator water line to

protect components from

waterborne debris.