Trane CLCH-SVX02C-EN, Energy Wheels Installation Operation & Maintenance

Installation

Operation

Maintenance

Energy Wheels

for M-Series Climate Changer™ Air

Handlers

February 2004 CLCH-SVX02C-EN

General

Information

Use this manual to install, startup, operate, and maintain the energy wheel

module for M-Series Climate Changer™ air handlers. Carefully review the

procedures discussed in this manual to minimize installation and startup

difficulties. The startup and adjustment procedures discussed in this manual

should be done by qualified, experienced HVAC technicians.

Your personal safety and the proper operation of this machine depend upon

the strict observance of these precautions.

Warnings and Cautions

NOTICE: Warnings and Cautions appear at appropriate sections

throughout this literature. Read these carefully.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

CAUTION: Indicates a situation that may result in equipment or property-damage only accidents.

© 2004 American Standard Inc. All rights reserved CLCH-SVX02C-EN

Contents

Introduction

General Information .......................................................2

Description

How the Modules Arrive at the Job Site....................... 4

Receiving Inspection.......................................................5

Storage ............................................................................ 5

Contractors’ Responsibilities ......................................... 5

Installation

Service Clearance ...........................................................6

Rigging/Lifting.................................................................6

Assembly.........................................................................7

Actuator Installation ....................................................... 7

Module-to-Module Assembly ........................................8

Wiring

Energy Wheel Motor....................................................... 9

Options ............................................................................ 9

Operation

Energy Wheel Startup .................................................. 10

Routine Maintenance

Cleaning the Energy Wheel.......................................... 11

Segment Removal/Replacement ................................. 11

Cleaning the Energy Wheel Motor .............................. 14

Cleaning the Module .................................................... 15

Bearing and Motor Lubrication.................................... 15

Energy Wheel Drive Belt Adjustment.......................... 15

Air Filters ....................................................................... 15

Service and Repair

Bearing/Drive Belt Replacement.................................. 16

Seal Adjustment............................................................17

Drive Motor and Pulley Replacement .........................18

Troubleshooting

Probable Causes/Actions..............................................19

CLCH-SVX02C-EN 3

Description

The M-Series Climate Changer™ air

handler energy wheel module is an

efficient, low-maintenance energy

recovery device. It is an integral part

of an entire air-handling system. The

module consists of the energy wheel

cassette assembly and access on

either side of the energy wheel.

All energy wheel modules feature

removable individual segments for

cleaning and replacement.

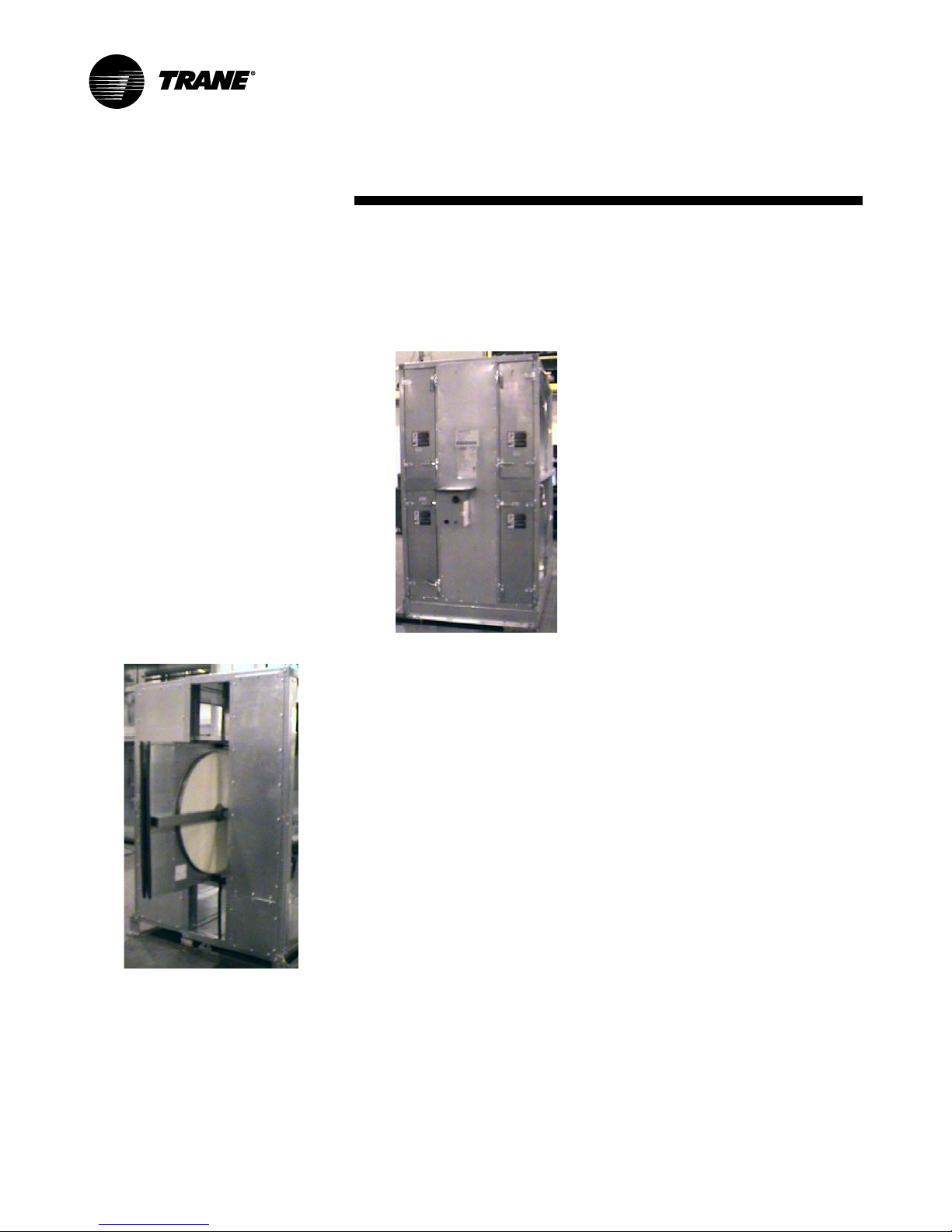

M-Series air handlers sizes 3 to 8 are

designed for the energy wheel

cassette to slide out of the module

for changing bearings, motors, and

belts. A removable panel is provided

on both sides for this purpose (see

Figure 1).

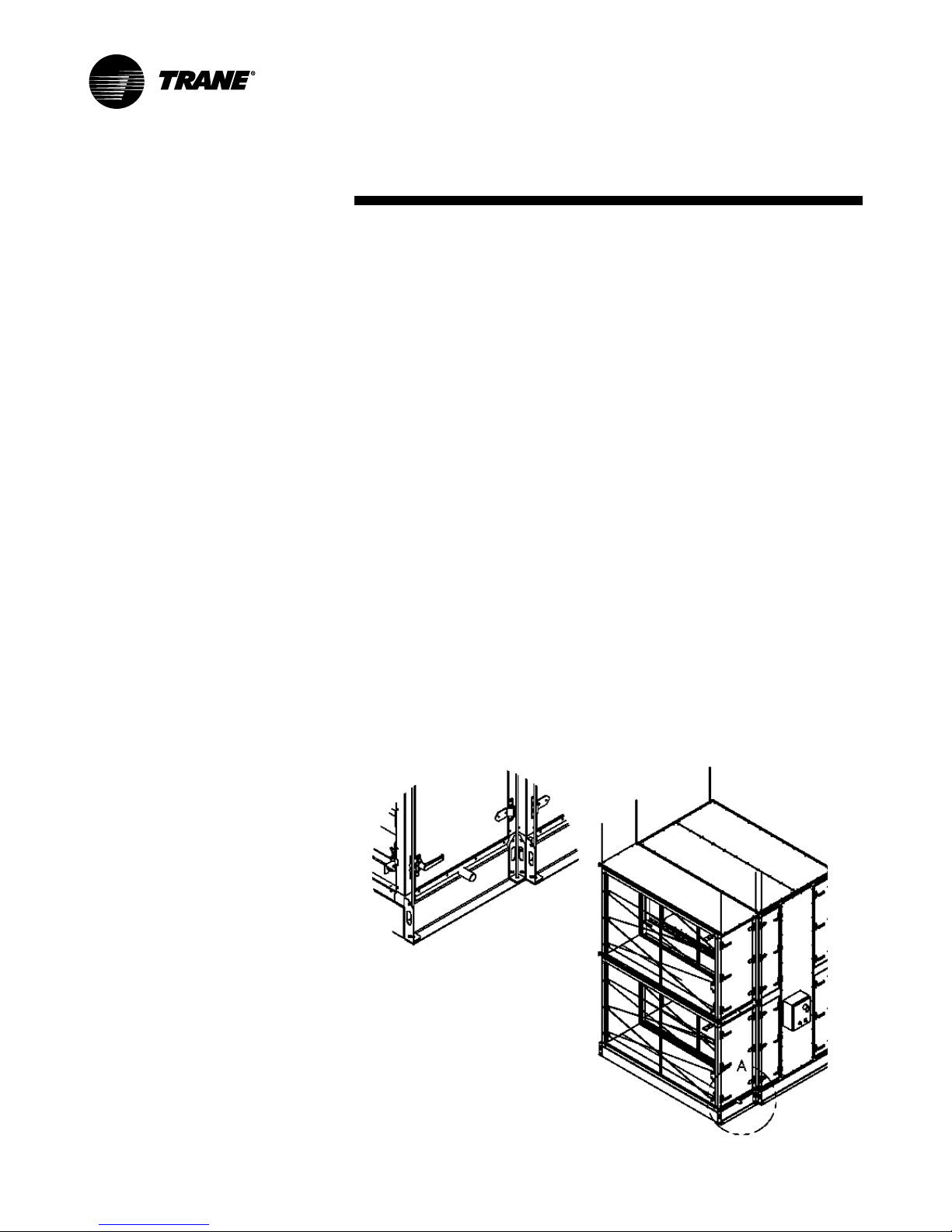

Figure 1. M-Series air handler

energy wheel module with

removable access panel, size 3 to 8

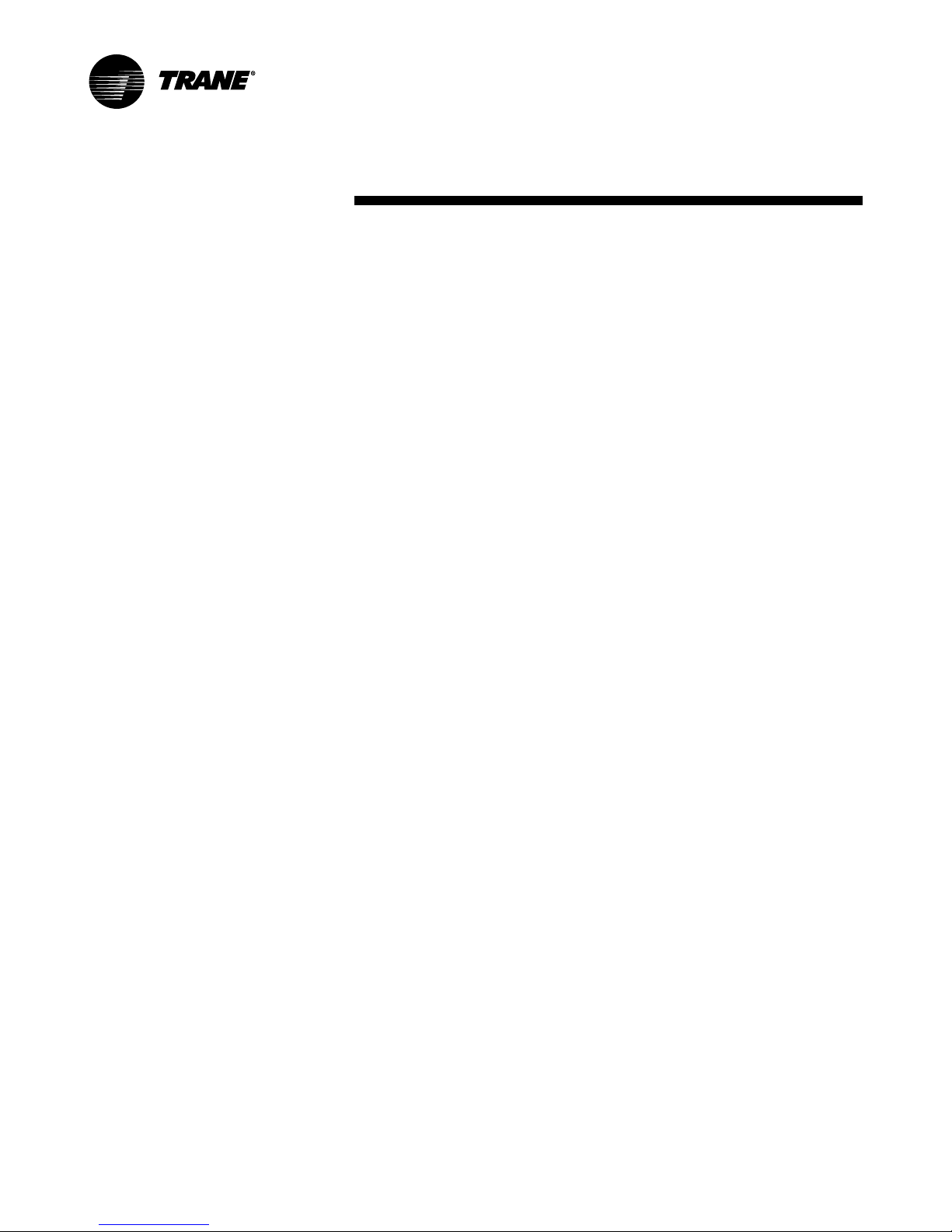

The energy wheel cassette in unit

sizes 10 to 50 is permanently

installed in the module. Four access

doors are provided for cleaning and

maintenance (see Figure 2).

.

Figure 2. M-Series air handler

energy wheel module with four

access doors, sizes 10 to 50

Optional air bypass dampers may

ship with the module. If ordered,

these dampers are factory-installed

in the same bulkhead wall as the

energy wheel cassette. Optional

actuators may be attached to the

dampers.

How the Module

Arrives at the Job

Site

No Base Rail Option If the optional

base rail was not ordered, the energy

wheel module will arrive mounted to

a wood skid. The module is held on

to the skid with steel bands and/or

screws. Leave the module mounted

to the wood skid until it is ready to

install in the equipment room to help

protect it from damage during

rigging and handling. Note: The

mounting legs will be pre-installed to

the module and attached to the skid.

Take care that the legs are not

discarded. Refer to the instruction

sheets in the ship-with kit.

Base Rail Option The base rail is an

optional steel channel frame that is

used to elevate the module off the

floor or to suspend it from the

ceiling. If ordered, the base rail is

attached for unit sizes 3 to 40. The

energy wheel module will arrive

mounted on the base rail. For unit

size 50, the base rail is shipped

banded to a separate skid for field

installation. If separate, wood skid

boards are attached to the bottom of

the base channels. Leave the wood

skid boards attached to the base rail

until it is ready to install in the

equipment room to protect it from

damage during rigging and

handling.

®

Amowrap

openings of the module are

protected by Amowrap reinforced

plastic covering. The Amowrap

covering is held on to the module

with a wood frame and sheet metal

screws. Leave the Amowrap

covering attached to the module until

it is ready to install in the equipment

room to prevent debris from entering

the module.

Hardware Kit Hardware kits ship

inside the module. The kits contain

gasketing, brackets, and screws,

which are used when fastening the

module to the air handler. Keep the

hardware kit with the energy wheel

module until it is ready to install in

the equipment room.

Access Doors

secured for shipment with a bracket.

Remove and discard bracket when

the module arrives.

Covering The large

Access doors are

4 CLCH-SVX02C-EN

Description

Receiving

Inspection

Upon receipt of the module, inspect

it for damage that may have occurred

during shipment. Report damage

immediately to the freight company

and make a note on the shipping tally

sheet.

• Remove the access door

shipping clamps (flat brackets)

and check for internal, hidden

damage. Concealed damage

must be reported within 15

days of receipt. Trane is not

responsible for shipping

damage.

• Locate the bags containing the

hardware kits.

• Examine the energy wheel

motor, drive, and energy

transfer segments for damage.

• Cut the banding loose from the

skid. Do not remove the module

from the skid at this time.

• Manually rotate the energy

wheel to ensure free movement

of the bearings and drive.

Storage

Trane recommends indoor storage of

the module. If outdoor storage is

necessary, select a solid, welldrained area. Concrete or black top

surfaces are recommended. If

concrete or black top is not available,

set the module on wood timbers to

prevent dirt, mud, snow, etc. from

getting into the module. Cover the

module with a canvas tarp. Covering

the module with clear or black plastic

sheeting is not recommended as this

material traps condensed moisture,

which can cause equipment damage

due to rust and corrosion. If

equipped with a factory-installed

starter, it will be covered with plastic

during shipping. The plastic covering

must be removed before outdoor

storage. Trane warranty does not

cover equipment damage due to

negligence during storage.

Contractors’

Responsibilities

Installing Contractor

• Unpack the module and remove

the skid or skid boards.

• Remove the Amowrap

protective covering.

Electrical and/or Controls

Contractor

• Provide high voltage power to

the energy wheel. For voltage

requirements, see Table 3 in

“Wiring” on page 9.

• Provide and install a starter or

starting contactor, disconnect,

fuses, etc. (as required by local

codes) for the energy wheel

motor if a factory-installed

starter is not provided.

• Provide, install, and connect

damper actuators if the module

is equipped with optional air

bypass dampers less the

actuators.

• Provide, install, and connect

temperature sensors for energy

wheel controls if the module is

not equipped with factoryinstalled sensors.

• Provide, install, and connect

required control devices for

energy wheel controls if the

module is not equipped with

factory-installed devices, or

connect to factory-installed

devices that were not ordered

factory-wired.

CLCH-SVX02C-EN 5

• Rig and/or move the module

into the equipment room. The

contractor must provide slings,

spreader bars, clevis hooks,

pins, etc., for rigging.

• Provide a reasonably level floor,

pad, or ceiling suspension

system for the air handler.

• Assemble the energy wheel

module to the air-handling

system.

Installation

WARNI NG

Improper Unit Lift!

Do not lift the unit from top! Lift from

lifting lugs only located at bottom of

unit. Test lift unit approximately 24

inches to verify proper center of

gravity lift point. To avoid dropping

of unit, reposition lifting point if unit

is not level. Failure to properly lift

unit could result in death or serious

injury or possible equipment or

property-only damage.

WARNI NG

Heavy Objects!

Follow good lifting practices before

lifting the unit, such as estimating

center of gravity and test lifting the

unit to check for balance and

stability.

or slings) used to lift the unit must be

capable of supporting the entire

weight of the unit. Lifting cables

(chains or slings) may not be of the

same length. Adjust as necessary for

even unit lift. Other lifting

arrangements could cause

equipment or property-only damage.

Failure to properly lift unit could

result in death or serious injury.

Each of the cables (chains

Service Clearance

Recommendations

For unit sizes 3 to 8, locate the

module to allow removal of the

energy wheel cassette through the

access panel. Typically, the minimum

clearance is equal to the module

width plus 12 inches.

Rigging/Lifting

Refer to the M-Series air handler

installation and maintenance

manual, CLCH-SVX03B-EN, for

instructions on equipment rigging

and lifting. This manual ships inside

the air handler fan module.

Module Weights and

For unit sizes 10 to 50, locate the

module to allow all access doors to

open fully. Make provisions for

temporary access on either side of

the module for complete removal of

the cassette/wheel frame. This would

be required if complete replacement

of the entire cassette/wheel

assembly were needed. The

minimum recommended clearance

for this is equal to the module width

plus 12 inches.

Local electrical code clearance

requirements must be considered

when a factory-installed starter is

provided.

.

Figure 3. Use all lifting lugs when suspending energy wheel modules

Dimensions

Refer to Trane catalog CLCH-PRC006EN or equipment submittals for

module weights and dimensions.

Suspending Modules with

Base Rails

When suspending an energy wheel

module, it is required to suspend it

from all lifting lungs on both the

energy wheel module and any

adjoining modules (see Figure 3).

6 CLCH-SVX02C-EN

Loading...

Loading...