Page 1

Engineering Bulletin

Starters, Drives, and Electrical Components

for CenTraVac™ Chillers

Models: CVHE, CVHF, CVHG, CDHF, CDHG

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury.When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

December 2011 CTV-PRB004-EN

SAFETY WARNING

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual.Warnings are provided to alert installing contractors

to potential hazards that could result in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

Read this manual thoroughly before operating or servicing this unit.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout this

literature. Read these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only

accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally

occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the

identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants-including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified.The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

© 2011Trane All rights reserved CTV-PRB004-EN

WARNING

Page 3

Warnings, Cautions and Notices

WARNING

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS

sheets and OSHA guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put on all Personal Protective Equipment

(PPE) in accordance with NFPA 70E or other country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

Trademarks

Adaptive Frequency, CenTraVac, Duplex,TOPSS,Tracer AdaptiView,Tracer Summit,Trane, and the

Trane logo are trademarks or registered trademarks ofTrane in the United States and other

countries.Trane is a business of Ingersoll Rand. All trademarks referenced in this document are the

trademarks of their respective owners.

Cutler-Hammer is a registered trademark of Eaton Corporation.

CTV-PRB004-EN 3

Page 4

Table of Contents

Introduction ............................................................ 6

About Starters .......................................................... 7

What a Starter Does ................................................ 7

Motor Types and Voltage Classes ........................................ 8

Voltage Classes .................................................... 8

Motors ........................................................... 8

Chiller Selection and Electrical Specification ............................. 10

Standard Components of Trane Starters ............................. 10

Chiller Selection Report ............................................ 10

Motor Protection ...................................................... 13

Low-Voltage Starter Types ............................................. 17

Low Voltage—Wye-Delta ........................................... 18

Low Voltage—Solid-State .......................................... 22

Low Voltage—Unit-Mounted Adaptive Frequency Drive ................ 25

Low Voltage—Remote-Mounted Adaptive Frequency Drive ............. 28

Wye-Delta Starters ........................................... 18

Solid-State Starters ........................................... 22

Medium-Voltage Starter Types (2,300–6,600 Volts) ....................... 31

Medium Voltage—Across-the-Line (2.3–6.6 kV) .......................32

Across-the-Line Starter (2,300–6,600 volts) ........................ 32

Medium Voltage—Primary Reactor (2.3–6.6 kV) ....................... 35

Primary Reactor Starter (2,300–6,600 volts) ....................... 35

Medium Voltage—Autotransformer (2.3–6.6 kV) ...................... 38

Autotransformer Starter (2,300–6,600 volts) .......................38

Unit-Mounted Starter Top Hat—NEC 2005 Code Requirement ........ 40

Medium Voltage—Remote-Mounted Adaptive Frequency Drive ......... 42

Chiller Unit Control Features for the AFD ......................... 43

Medium-Voltage Starter Types (10,000–13,800 Volts) .....................45

Medium Voltage—Across-the-Line (10–13.8 kV) ....................... 45

Across-the-Line Starter (10,000–13,800 volts) ...................... 45

Medium Voltage—Primary Reactor (10–13.8 kV) ...................... 47

Primary Reactor Starter (10,000–13,800 volts) ..................... 47

Medium Voltage—Autotransformer (10–13.8 kV) ...................... 48

Autotransformer Starter (10,000–13,800 volts) .....................48

Electrical System—Ratings ............................................. 49

Electrical System—Design Guidelines ................................... 52

4 CTV-PRB004-EN

Page 5

Disconnect Means ............................................ 52

Short-Circuit Interruption ...................................... 53

Power Circuit Requirements ....................................54

Electrical System–Power Wire Sizing .................................... 56

Starter Options ........................................................ 61

Multiple Starter Lineups (2,300–6,600 volts) ....................... 61

Industrial-Grade Starters ...................................... 63

Glossary .............................................................. 73

CTV-PRB004-EN 5

Page 6

Introduction

This document explains key electrical concepts and starter product information relating toTrane

water chillers.Topics include voltage classes, motors, motor protection, starter types, variablefrequency drives, wire sizing, power factor correction, and electrical term definitions.

Information in this document changes frequently.To make sure you are viewing the most recent

version, be sure to download the latest copy available on e-Library.

Dimensional data

Job specific submittals are always the best source of dimensional data. General starter dimensions

are shown with the descriptions of each starter type in this document.

Wiring information

The best source for additional information is the Installation, Operation, and Maintenance manual

shipped with the chiller. Field connection diagrams are also available on the website.

All unit-mounted starters are designed for top-entry line power only. Remote starters are typically

designed for top-entry line power and a bottom exit for load wires.The medium-voltage starter

submittals show conduit space for alternate wiring options. Additional wiring options may be

available.

For your convenience, power wire sizing charts for various voltages and conduit combinations are

provided.

Fuse and circuit breaker sizing

Proper sizing of fuses and circuit breakers upstream of the starter is the responsibility of the

customer or the electrical engineer. Disconnects and circuit breakers are options that can be

installed within theTrane

or local code requirements for installation of overcurrent devices.

Important: Trane, in presenting electrical information and system design and application

concepts, assumes no responsibility for the performance or desirability of any

resulting system design. Design of the HVAC and related electrical system is the

prerogative and responsibility of the engineering professional.Trane has a policy of

continuous product and product information improvement and reserves the right to

changedesign and specifications without notice. Consult the chiller submittal for the

most up-to-date information as applied to the specific chiller under consideration.

®

starters. WhatTrane would install may not necessarily satisfy UL, NEC,

®

6 CTV-PRB004-EN

Page 7

About Starters

What a Starter Does

Electric, centrifugal, water-cooled chillers use relatively large induction motors to drive the

compressors.These motors use a control device to connect to and disconnect from the electrical

power source.These control devices are referred to as combination controllers or, most commonly,

as motor starters. Variable-frequency drives or Adaptive Frequency™ Drives (AFDs) also serve as

motor starters, but their capabilities extend beyond starting and stopping the motor.

There are three main functions of the motor starter.The first function is to serve as the link between

the chiller’s motor and the electrical distribution system. It is used during the starting and stopping

sequence.

Starting an induction motor from standstill causes a large electrical current draw for a few seconds.

The extra current is used to develop the required torque to get the compressor motor running at

full speed.The initial rush of current decreases as the compressor motor ramps up to full speed,

and is commonly referred to as inrush current.

The second function of the starter is to keep the initial current inrush below a specified level.Third,

the starter communicates with the unit controller to coordinate motor protection.

Starters can be as simple or as complex as necessary to meet various engineering specifications

and/or customer needs. A variable-speed drive can provide starter functions, among other things

(see “Low Voltage—Unit-Mounted Adaptive Frequency Drive,” p. 25 and “Medium Voltage—

Remote-Mounted Adaptive Frequency Drive,” p. 42). It will be classified as a starter type for the

purposes of this document.

Several voltage classes and starter types are available as indicated on the chart below. Each one

is described in greater detail in this document.

Table 1. Trane CenTraVac chiller starter choices

Low Voltage (208–600 V) Medium Voltage (2,300–6,600 V)

Remote-Mounted Unit-Mounted Remote-Mounted Unit-Mounted Remote-Mounted

Wye-Delta

Up to 1,700 amps

Solid-State

(Up to 1,120 amps with

disconnect or circuit breaker

required)

Adaptive Frequency

Drive

460/480/575/600 V

Up to

1,360 amps (460/480 V)

1,120 amps (575/600 V)

Wye-Delta

Up to 1,316 amps

(Up to 1,120 amps with

disconnect/circuit breaker

option)

Solid-State

(Up to 1,120 amps with

disconnect or circuit breaker

required)

Adaptive Frequency

Drive

Up to 1,210 amps

Circuit breaker standard

460–480 V

Across-the-Line

Up to 360 amps

Isolation switch, power

fuses standard

Primary Reactor

Up to 360 amps

Isolation switch, power

fuses standard

Autotransformer

Up to 360 amps

Isolation switch, power

fuses standard

Adaptive Frequency

Drive

Up to 250 amps

Isolation switch, power

fuses standard

Across-the-Line

Up to 288 amps

Isolation switch, power

fuses standard

Primary Reactor

Up to 205 amps

Isolation switch, power

fuses standard

Autotransformer

Up to 205 amps

Isolation switch, power

fuses standard

Medium Voltage

(10–13.8 kV)

Across-the-Line

Up to 94 amps

Isolation switch, power

fuses standard

Primary Reactor

Up to 94 amps

Isolation switch, power

fuses standard

Autotransformer

Up to 94 amps

Isolation switch, power

fuses standard

CTV-PRB004-EN 7

Page 8

MotorTypes and Voltage Classes

Voltage Classes

There are two primary voltage classes typically used in the water-cooled chiller industry: low and

medium. For centrifugal chillers this is generally restricted to three-phase power only.

Low voltage ranges from 208 to 600 volts. Starters and frequency drives in this voltage range

include sizes up to 1,700 amps.

Medium voltage has two main voltage groups. One ranging from 2,300 to 6,600 volts and the other

ranging from 10,000 to 13,800 volts. Starters in this class have sizes up to 360 amps and 94 amps

respectively.

For a given power (kW), the higher the voltage the lower the amperage.The voltage is typically

established prior to creating the job plans and specifications.

Motors

A centrifugal motor is a relatively simple motor. Specifically, it is referred to as a three-phase,

squirrel-cage, 3,600-rpm, alternating-current induction motor with two-pole construction.

The squirrel-cage motor consists of a fixed frame, or stator, carrying the stator windings and a

rotating member called the rotor. Figure 1 shows a cutaway of a typical low-voltage motor.The

rotor is built by rigidly mounting steel laminations to the motor shaft.The motor winding consists

of aluminum bars that are die-cast into slots in the rotor.The aluminum bars are connected at each

end by a continuous ring.This skeleton of rotor bars with end rings looks like a squirrel cage and

gives the motor its name.

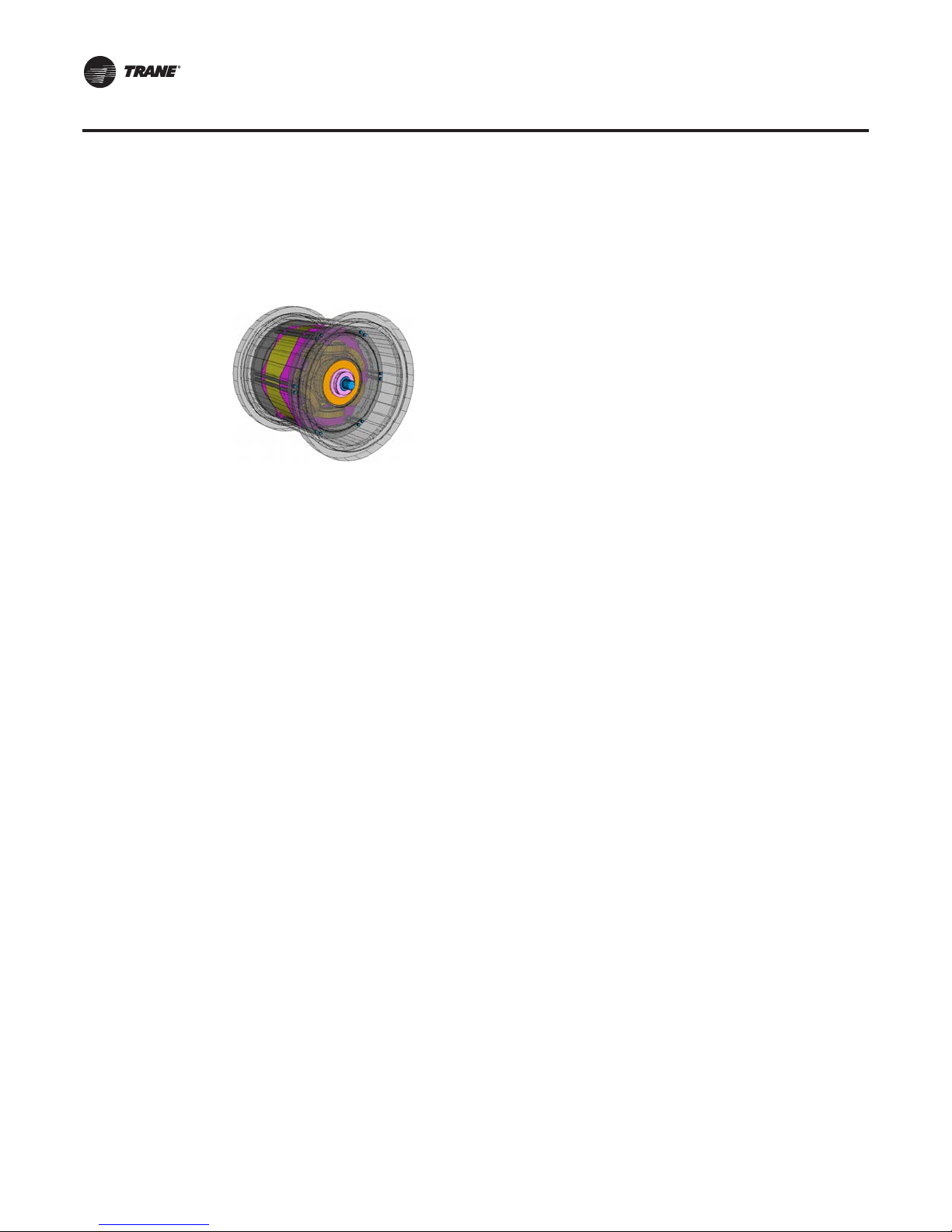

Figure 1. Low-voltage motor Figure 2. Medium-voltage motor

Stator

Stator

Squirrel-cage

Squirrel-cage

Rotor shaft

Rotor shaft

Stator

Stator

In a three-phase motor, three windings on the stator connect to a motor terminal board, and

ultimately to the power grid via the starter.When the polyphase alternating current flows through

the stator winding it produces a rotating magnetic field.The resulting magnetic forces exerted on

the rotor bars cause the rotor to spin in the direction of the stator field.The motor accelerates until

a speed is reached corresponding to the slip necessary to overcome windage and friction losses.

This speed is referred to as the no-load speed.

Low-voltage motors typically have six motor terminals to electrically connect the motor in a wye

(star) or delta configuration. Most low-voltage motors are random-wound motors, but larger

amperage higher horsepower motors are form wound for better heat dissipation. Connecting links

can be used to convert the six motor electrical connections to three connections.

Medium-voltage motors (2,300–6,600 V) have three motor terminals. Figure 2 shows a typical

medium-voltage motor minus the rotor shaft.You can visually compare most low- and medium-

8 CTV-PRB004-EN

Page 9

MotorTypes and Voltage Classes

voltage motors. Medium-voltage motors are always form wound and you can see that the

insulation is thicker and the windings are more evenly spaced.

Figure 3. Ceramic insulators on medium-voltage motor (10-13.8 kV)

Medium-voltage motors (10–13.8 kV) have the same design and construction attributes as other

medium-voltage motors with some externally visible differences. Ceramic insulators and larger

spacing of the motor terminals are commonly found on typical 10–13. kV medium-voltage motors.

Internally, these motors are form wound and structurally similar to other medium-voltage motors.

The ceramic insulators combined with the larger spacing between the motor terminals help

prevent electrical arcing.

Higher voltage motors and starters are being used in large chiller plants where incoming line power

makes 10–13.8 kV accessible. In some cases, higher voltage chillers allow for the elimination of

electrical components with their associated space requirements and energy losses. In particular,

chiller installations with on-site or dedicated power generation, such as district cooling, higher

education, hospitals, industrials, and airports have opportunities for electrical distribution system

simplification and energy savings.

Benefits of 10,000–13,800 volts include:

• No need for step-down transformer

• No transformer losses

• Higher uncorrected power factor

• Reduced electrical design and labor

• Reduced mechanical room space

Note: Motors and starters at 10,000–13,800 volts typically cost more, and the motor efficiency is

lower than 2,300–6,600-volt motors.

Motors are available in specific power sizes, which are rated in kilowatts or horsepower.The

TOPSS™ computer software selection program selects the proper motor to meet the specific

cooling duty of the application.

CTV-PRB004-EN 9

Page 10

Chiller Selection and Electrical Specification

Standard Components of Trane Starters

• A 4 kVA control-power transformer (CPT) supports all of the chiller auxiliary power needs—

3 kVA control-power transformer supplied with AFDs.

• Primary and secondary current transformers (CTs) support the overload and momentary power

loss protection functions of the unit controller.This allows amps per phase and percent amps

to be displayed at the unit controller.

• Potential transformers (PTs) support motor protection functions such as under/overvoltage

within the unit controller.This allows voltage per phase, kilowatts, and power factor to be

displayed at the unit controller.

• Grounding provisions are standard.

• A terminal block for line power connection is standard. Load-side lugs are standard for remote

starters.The lug sizes and configuration are shown on the submittal drawing.TheTrane

has a circuit breaker as standard. Medium-voltage starters have provisions for a bolted

connection.

Chiller Selection Report

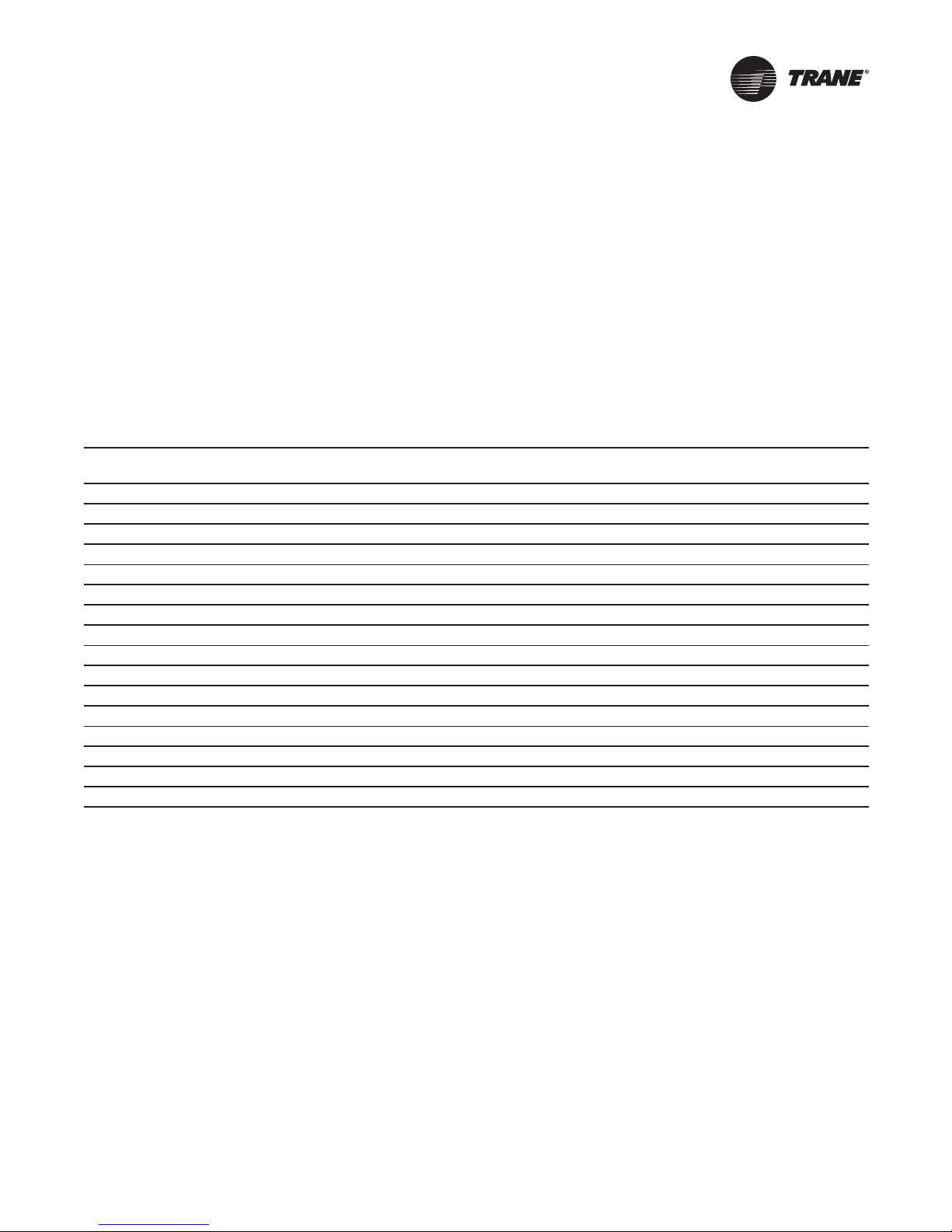

The following terms are found on a typicalTOPSS product report. Review the example selection

output report shown in Figure 4, p. 12.

Electrical information

Usually the primary RLA (incoming line), compressor motor RLA, and kW of the chiller are used as

nameplate values. In this section, we will review the typical electrical data presented on the

selection report.

®

AFD

A. Motor size (kW). The motor size is listed on the program report based on its output kW.The

output kW is the motor’s full, rated power capacity.There is an amperage draw associated with the

motor size called full-load amps (FLA). FLA is the amperage the motor would draw if it were loaded

to its full rated capacity, i.e. the motor size. The FLA is not available from the chiller selection

program, but it can be obtained from motor data sheets upon request.

B. Primary power (kW). The primary power is the power the chiller uses at its design cooling

capacity.The primary power will always be less than or equal to the motor size.

C. Motor locked-rotor amps (LRA). There is a specific locked-rotor amperage value associated

with each specific motor.This is the current draw that would occur if the rotor shaft were

instantaneously held stationary within a running motor. LRA is typically six to eight times the motor

full-load amps (FLA). LRA is also used commonly in discussing different starter types and the

inrush amperages associated with the motor start. For example, a wye-delta starter will typically

draw approximately 33 percent of the motor LRA to start. A solid-state starter will draw

approximately 45 percent of the motor LRA to start.

D. Primary rated-load amps (RLA [incoming line]). The RLA is also commonly referred to as

the selection RLA or unit RLA.This is the amperage that is drawn on the line side when the chiller

is at full cooling capacity. Nameplate RLA (usually the same as primary RLA [incoming line]) is the

key number used to size the starter, disconnects, and circuit breaker. Primary RLA (incoming line)

is also the value used to determine the minimum circuit ampacity (MCA) for sizing conductors.

Primary RLA (incoming line) is always less than or equal to the motor full-load amps (FLA).

E. Compressor motor RLA. This is the amperage between the motor and starter or AFD. If the

unit is a starter, the compressor motor RLA will be almost identical to the primary RLA (incoming

line). If the unit is an AFD, typically, the compressor motor RLA will be larger.This value is used

to size the AFD.The primary RLA (incoming line) is lower due to the improved power factor of the

AFD.

10 CTV-PRB004-EN

Page 11

Chiller Selection and Electrical Specification

F. Minimum circuit ampacity (MCA). This term appears on the chiller nameplate and is used

by the electrical engineer to determine the size and number of conductors needed to bring power

to the starter.

MCA = 1.25 x (Primary RLA [incoming line])+

… with this number rounded up to the next whole number. Said another way, the MCA is

125 percent of the motor design primary RLA (incoming line) plus 100 percent of the amperage of

other loads (sump heater, oil pump, purge, etc.).The MCA is listed on the chiller selection report.

Power cable sizes and conduits are discussed in “Electrical System–PowerWire Sizing,” p. 56. If the

AFD is a remote, free-standing AFD, the MCA will be based on the compressor motor RLA.

(

4000

volts

motor

)

G. Maximum overcurrent protection (MOP or MOCP). The MOP appears on the chiller

nameplate.The electrical engineer often wants to know the MOP when the chiller is selected for

sizing fuses and upstream circuit breakers. Understand that the MOP is a maximum, NOT a

recommended fuse size. Improperly sized circuit breakers or fuses can result in nuisance trips

during the starting of the chiller or insufficient electrical protection. MOP is also NOT used to size

incoming power wiring—the MCA is used for this purpose.

CTV-PRB004-EN 11

Page 12

Chiller Selection and Electrical Specification

8QLW,QIRUPDWLRQ

&9+(

+]

+]

\

6

6

7(&8

7(&8

7ZRSDVVHYDSZDWHUER[

7ZRSDVVFRQGZDWHUER[

'HVLJQ,QIRUPDWLRQ

WRQV

\

OE

N:

OE

N:WRQ

\

OE

N:WRQ

1R

1R

8QLWPRXQWHGORZYROWDJH$)'

$

6WDQGDUGFRROLQJ

0%K

0%K

$

(YDSRUDWRU,QIRUPDWLRQ

)

S

S

IW+2

JSP

ZDWHU

)

1$

JSPWRQ

\

QRQPDULQH

SVLJ

KUVTIWGHJ)%WX

&RQGHQVHU,QIRUPDWLRQ

)

IW+2

JSP

ZDWHU

)

S

1$

JSPWRQ

QRQPDULQH

KUVTIWGHJ)%WX

SVLJ

(OHFWULFDO,QIRUPDWLRQ

$

$

$

\

$

$

Figure 4. Excerpt from chiller selection report

0RGHO

,PSHOOHUVL]H

0RWRUVL]H

0RWRUIUHTXHQF\

,QFRPLQJOLQHIUHTXHQF

(YDSVKHOOVL]H

(YDSEXQGOHVL]H

(YDSWXEHW\SH

(YDSWXEHWKLFNQHVV

(YDSSDVVHV

A

&RROLQJFDSDFLW

3ULPDU\SRZHU

3ULPDU\HIILFLHQF

13/9

/RZYROWDJH$)'W\SH

B

&RPSUHVVRUVL]H

2ULILFHVL]H

0RWRUYROWDJH

,QFRPLQJOLQHYROWDJH

&RQGVKHOOVL]H

&RQGEXQGOHVL]H

&RQGWXEHW\SH

&RQGWXEHWKLFNQHVV

&RQGSDVVHV

+&)&UHIULJHUDQWFKDUJH

6KLSSLQJZHLJKW

2SHUDWLQJZHLJKW

)UHHFRROLQJRSWLRQ

*UHHQ6HDOFHUWLILFDWLRQ

8QLWKHDWUHMHFWHGWRDPELHQW

)'KHDWUHMHFWHGWRDPELHQW

(YDSOHDYLQJWHP

(YDSIORZUDWH

(YDSHQWHULQJWHPS

(YDSIORZFDSDFLW

(YDSIRXOLQJIDFWRU

&RQGHQWHULQJWHPS

&RQGIORZUDWH

&RQGOHDYLQJWHP

&RQGIORZFDSDFLW\

&RQGIRXOLQJIDFWRU

0RWRU/5$

3ULPDU\5/$,QFRPLQJOLQH

8QFRUUHFWHGSRZHUIDFWRU

SSOLFDWLRQW\SH

(YDSSUHVVXUHGUR

(YDSIOXLGW\SH

(YDSIOXLGFRQFHQWUDWLRQ

(YDSZDWHUER[W\SH

(YDSZDWHUER[SUHVVXUH

C

D

&RQGSUHVVXUHGURS

&RQGIOXLGW\SH

&RQGIOXLGFRQFHQWUDWLRQ

&RQGZDWHUER[W\SH

&RQGZDWHUER[SUHVVXUH

&RPSUHVVRUPRWRU5/$

0LQFLUFXLWDPSDFLW

0D[RYHUFXUUHQWSURWHFWLRQ

E

F

G

12 CTV-PRB004-EN

Page 13

Motor Protection

Historically, motor protection was provided in the starter by some type of monitoring system.

Starter manufacturers usually provide a full range of optional equipment mounted on the starter.

Eaton Cutler-Hammer

Today,Trane provides most of the key motor protection and metering functions (see Table 2, first

column) within the chiller microprocessor control panel as standard. Having the motor control and

chiller control in one panel provides better integration and optimization of the two control systems.

For example, the chiller controller can unload the chiller when approaching an overload “trip”

point, so that the chiller stays online.

Table 2 and Table 3, p. 14 can be used to compare the standard electrical features of the chiller

controller with those of other common Eaton Cutler-Hammer

Additional starter-mounted metering and motor protection may not be required and could be

considered redundant.These devices are not available for AFDs.

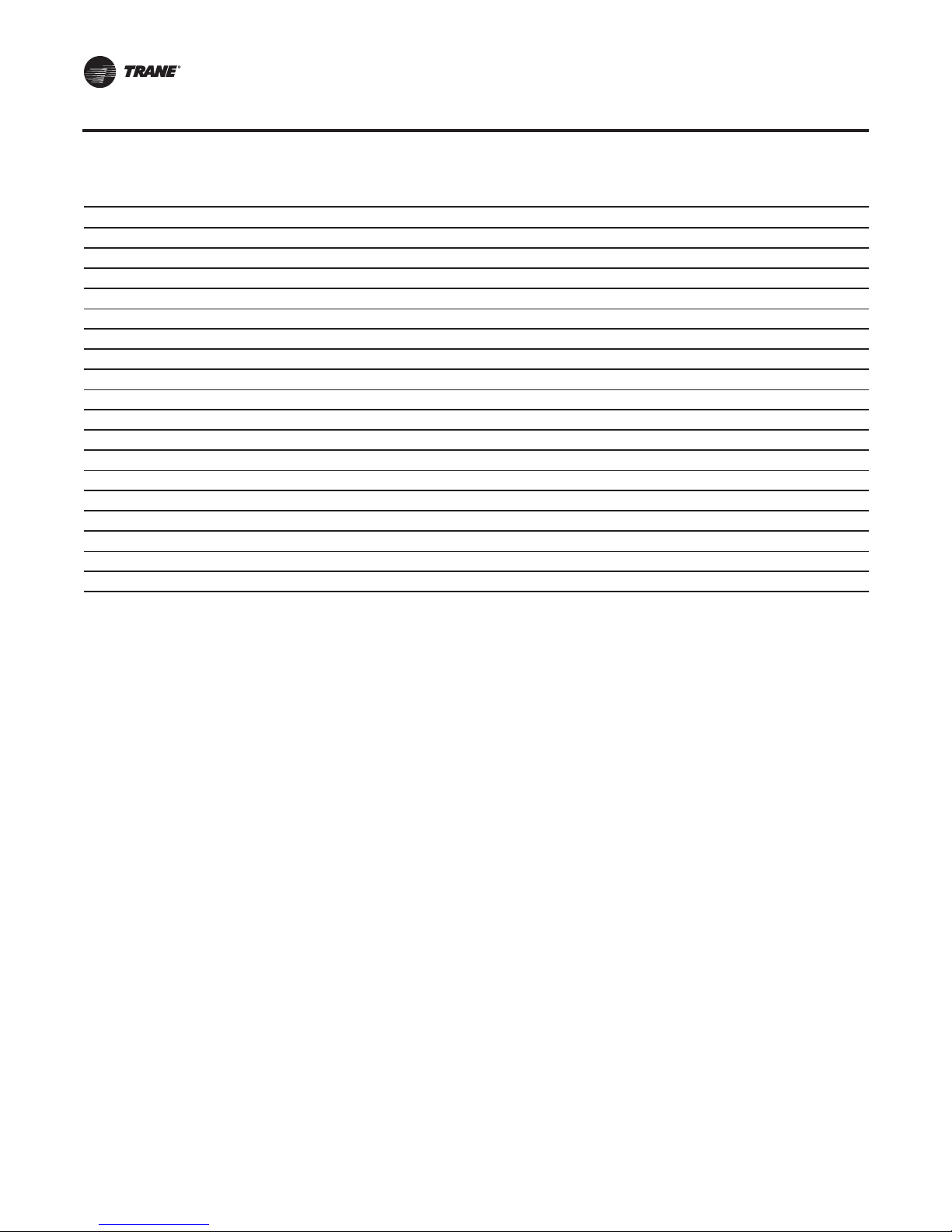

Table 2. Protection and functions by motor packages

®

offers IQ metering and motor protection products for their starters.

®

starter-only-mounted devices.

Protection Functions

Communications Optional Optional Optional Optional

Ground fault Optional

Long acceleration Standard Standard N/A N/A

Maximum number of starts Standard Standard N/A N/A

Momentary power loss (distribution fault) Standard N/A N/A N/A

Motor overload Standard Standard N/A N/A

Motor winding temperature Standard

Over temperature Standard N/A N/A N/A

Overvoltage Standard

Phase imbalance Standard Standard N/A Standard

Phase loss Standard Standard N/A Standard

Phase reversal Standard N/A N/A Standard

Run timer Standard Standard N/A N/A

Separate alarm levels

Surge capacitor/lightning arrestor Optional N/A N/A N/A

Undervoltage Standard

(a)The MP 3000 features Intel-I-Trip overload protection, enhanced custom trip curve development, UL 1053 ground fault, and advanced data logging and

diagnostics.

(b)For low voltage, a Trane-supplied circuit breaker or non-fused disconnect is also required when ground fault is specified.

(c) The chiller controller monitors the motor temperatures of all three phases with one resistance temperature detector (RTD) per phase

(d)For this option, add one or two sets (three RTDs per set) of 100-ohm platinum RTDs to the motor. Contact La Crosse Field Sales Support.

(e) Under/over phase-voltage sensors include volts per phase, kW, power factor, kWh, and under/overvoltage. A required pick on medium-voltage starters.

(f) Three alarm levels are used: warning only, nonlatching (auto-reset), and latching (manual reset required).

(f)

Tracer

AdaptiView MP 3000

(b)

(c)

(e)

Standard Standard N/A N/A

(e)

Standard N/A N/A

Optional

N/A N/A Standard

N/A N/A Standard

(d)

(a)

IQ 150 IQ DP 4130

N/A N/A

CTV-PRB004-EN 13

Page 14

Motor Protection

Table 3. Starter ONLY: metering functions and accuracies

Metering Functions Tracer AdaptiView MP 3000

Ampere demand N/A N/A Standard (±0.25%) Standard (±0.3%)

Current (%RLA) Standard (±3% to ±7%) Standard N/A N/A

Current (3-phase) Standard (±3%) Standard Standard (±0.25%) Standard (±0.3%)

Voltage (3-phase) Standard

Frequency N/A N/A Standard Standard

Harmonic distortion current N/A N/A N/A Standard (31

Harmonic distortion voltage N/A N/A N/A Standard (31

Kilowatt Standard

Power factor Standard

VA (volt-amperes) N/A N/A Standard (±0.5%) Standard (±0.6%)

VA demand N/A N/A Standard (±0.5%) Standard (±0.6%)

VA hours N/A N/A Standard (±0.5%) Standard

VARs (volt-amperes reactive) N/A N/A Standard (±0.5%) Standard (±0.6%)

VAR demand N/A N/A Standard (±0.5%) Standard (±0.6%)

VAR-hours N/A N/A Standard (±0.5%) Standard

Watt, see Kilowatt Standard

Watt demand Standard N/A Standard (±0.5%) Standard (±0.6%)

Watt-hours Standard N/A Standard (±0.5%) Standard

(a)The MP 3000 features Intel-I-Trip overload protection, enhanced custom trip curve development, UL 1053 ground fault, and advanced data logging and

diagnostics.

(b)Under/over phase-voltage sensors include volts per phase, kW, power factor, kWh, and under/overvoltage. A required pick on medium-voltage starters.

(b)

(±2%) N/A Standard (±0.25%) Standard (±0.3%)

(b)

(±5%) N/A N/A N/A

(b)

(±5%) N/A Standard Standard

(b)

N/A Standard (±0.5%) Standard (±0.6%)

(a)

IQ 150 IQ DP 4130

st

)

st

)

Overload protection

Overload or overcurrent protection shields the motor from small levels of overcurrent ranging from

107 to 140 percent of the primary RLA of the chiller. In contrast, fuses and circuit breakers are used

to protect against short-circuit currents which may range to well over 100,000 amps.

Inductive loads, such as a chiller motor, behave differently than resistive loads such as electric

heaters.Their current draw is greatest at startup and corresponds to the existing load when

running. In other words, a motor operating normally draws rated amps (RLA) at rated load, fewer

amps at less-than-rated load and more amps at greater-than-rated load. It is the latter condition that

requires overload protection.

Adding an overload protection device prevents the motor from drawing more than its rated

amperage for an extended period. Basic overload devices simply open the circuit when current

draw reaches the “trip” point. More sophisticated devices attempt to restore normal motor

operating conditions by reducing the load, but will disconnect the motor if overloading persists.

As with most overload devices, the chiller controller determines the “trip time” by measuring the

magnitude of the overload. It then compares the overload to the programmed RLA “time-to-trip”

curve. At startup, the standard overload protection is bypassed for the starter’s acceleration time,

or until the motor is up to speed. Refer to Figure 5, p. 15 for the chiller controller’s overload timeto-trip curve.

14 CTV-PRB004-EN

Page 15

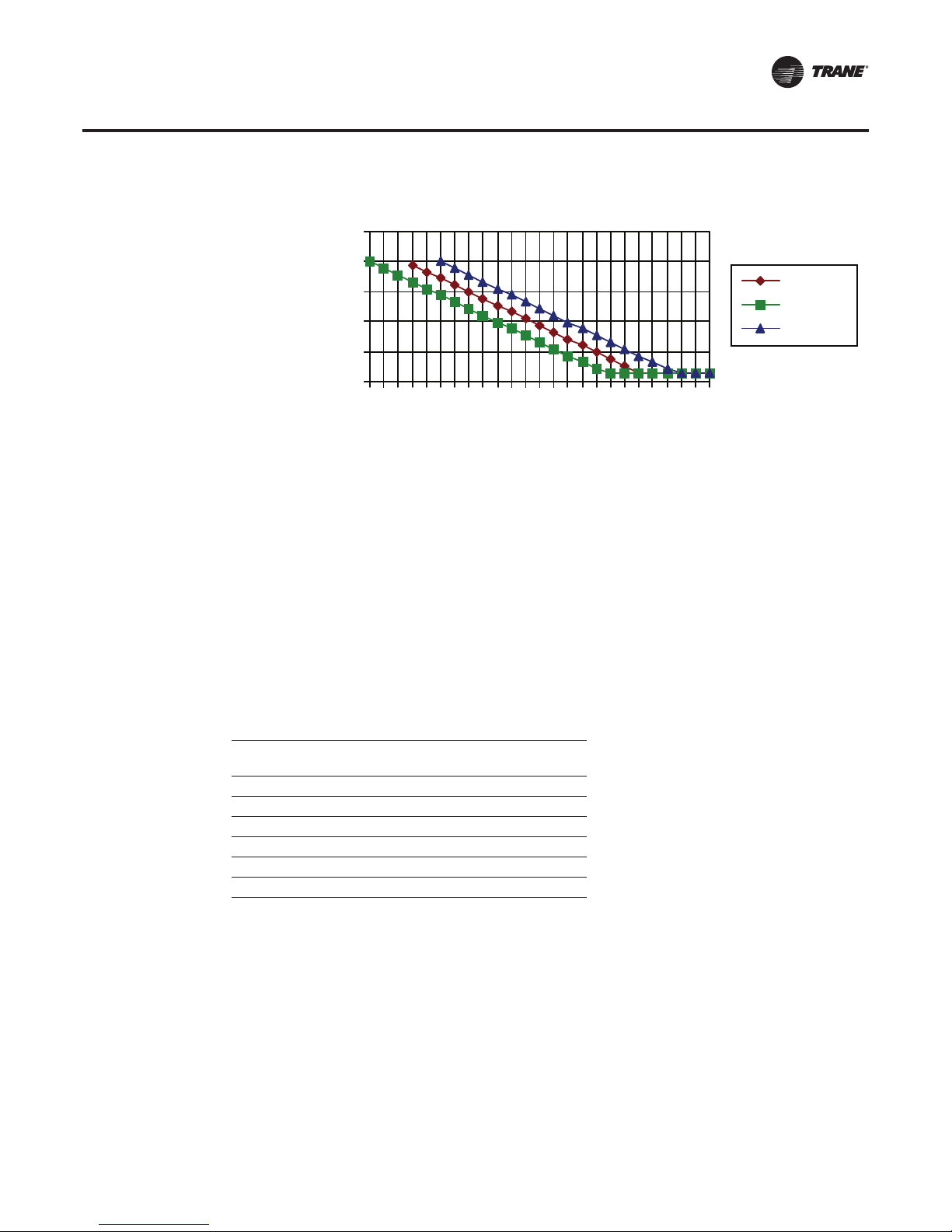

Figure 5. Tracer AdaptiView chiller controller overload time-to-trip curves

25

20

Overload Trip

Time (sec)

15

10

5

0

Motor Protection

Nominal

Minimum

Maximum

108

102

Overload situations, left unchecked by protection, can cause excessive motor heat, that can

permanently damage the windings and lead to motor failure.The time until motor damage

depends mainly on the magnitude of the overcurrent and has an inverse time versus current

relationship.The greater the overcurrent, the less time it takes to cause motor damage.

Overcurrent can be the result of motor overload, low line voltage, unbalanced line voltage, blocked

load (rotor cannot freely rotate), single phasing, bad connections, broken leads, or other causes.

It can occur in any one winding, a set of windings, or in all the motor windings.

The threshold of overcurrent is generally the primary RLA, which may be raised for service factor

or lowered due to any derating factor, such as ambient temperature or line-voltage imbalance.

Overload protection is bypassed during a start due to the high currents associated with locked rotor

and motor acceleration. Maximum allowed acceleration times per the AdaptiView unit controller

are listed in Table 4.

Table 4. Long acceleration protection

Starting Method

(starter type)

Wye-Delta 27

Solid-State 27

Variable-Frequency Drive 12

Across-the-Line 6

Primary Reactor 16

Autotransformer 16

Maximum Setting for the

Acceleration Timer (sec)

114

120

126

132

% Run-Load Amps

138

144

150

Motor overheat protection

The unit controller monitors the motor winding temperatures in each phase and terminates chiller

operation when the temperature is excessive.This feature also prevents the chiller from starting

if the motor temperature is too high.

Momentary power loss protection (distribution fault)

Momentary power losses longer than two or three line cycles will be detected and cause the chiller

to shut down, typically within six cycles. The chiller can also shut down due to excessive or rapid

voltage sags. Shutting down the chiller prevents power from being reapplied with different motor

phasing.

CTV-PRB004-EN 15

Page 16

Motor Protection

Phase failure/loss protection

The chiller will shut down if any of the three-phases of current feeding the motor drop below

10 percent RLA for 2.5 seconds.

Phase imbalance protection

Based on an average of the three phases of current, the ultimate phase-imbalance trip point is

30 percent.The RLA of the motor can be derated depending on the percent of this imbalance.The

phase-imbalance trip point varies based on the motor load.

Phase reversal protection

Detects reverse-phase rotation and shuts the chiller down (backwards rotation).

Under/overvoltage protection

The chiller is shut down with an automatic reset due to excessive line voltage ±10 percent of the

design voltage.

Short cycling protection

Prevents excessive wear on the motor and starter due to heating from successive starts.The unit

controller uses an algorithm based on a motor heating constant and a background timer

(measuring the running time since the last start).

Supplemental motor protection

This is a set of optional motor protection features, offered as a option in addition to the Enhanced

Electrical Protection Package (see “SMP, Supplemental Motor Protection—Medium voltage only

(Enhanced Electrical Protection Package option),” p. 66).

16 CTV-PRB004-EN

Page 17

Low-Voltage StarterTypes

Table 5 shows the most common low-voltage starter types available and lists their advantages and

disadvantages.Typical inrush acceleration profiles for these starters are shown in Figure 6, p. 18.

It is very uncommon to see a full-voltage starter in a low-voltage application due to the high inrush

current; however, it is represented on the chart to provide a frame of reference.

Which starter type is best?

The wye-delta starter has been around a long time and, except for an AFD, it draws the lowest

inrush current.Wye-delta starters are electromechanical and service technicians are typically more

comfortable with them.The solid-state starter is a relatively newer design compared to the wyedelta, and has a slightly higher inrush current in chiller applications.The solid-state starter inrush

can be set lower (the starter takes longer to get the motor up to speed), but it must be above the

minimum inrush required to develop the proper starting torque.The solid-state starter is

comparable in price to the wye-delta starter and has a smoother inrush curve without any current

spikes.The wye-delta’s transition spike is not long enough to set utility demand ratchets or reduce

the life of the motor.The starter type chosen ultimately depends on the application.

Table 5. Comparison of low-voltage starter types

Starter Type

(closed-transition

Wye-Delta

(Star-Delta)

Solid-State ~45 33 15%

Adaptive Frequency

Drive (AFD)

Inrush

Current

% LRA

33 33 60%

<13

(<RLA)

Percent

Rated

Torque

varies 25%

How

Often

Used Advantages Disadvantages

Trane Adaptive Frequency Drives provide motor control, but they are much more than just starters.

They also control the operating speed of the compressor-motor by regulating output voltage in

proportion to output frequency. Varying the speed of the compressor-motor can translate into

significant energy savings.

Applications that favor the use of an AFD exhibit increased operating hours at reduced condenser

water temperatures and high energy costs. However, it is important to recognize that all variablespeed drives, including theTraneAFD, require more energy near full-load design conditions, often

coinciding with the peak electrical demand of the building.This may result in higher demand

chargesand diminish the overall energy savings.An analysis of the full-year operation of the chiller

plant using an hour-by-hour simulation program that does not use blended kW and kWh energy

rates will help determine whether an AFD is appropriate for a specific application and location.

• Equal reduction of torque and

inrush current

• Low cost

• Can be unit mounted

• Gradual inrush/ramp up

• No “spike” at transition

• Price comparable to the wyedelta

• Lowest inrush current

• Better chiller efficiency at

reduced lift

• Only applicable up to

600 volts

• “Spike” at transition

• Higher level of service

expertise than wye-delta

• Higher inrush current than

wye-delta

• Starting harmonics may be an

issue

• Most expensive

• Efficiency loss at full load

• Harmonics may be an issue

Typical

Acceleration

Time

(seconds)

5–12

5–12

8–30

Unit or remote mounted?

Unit-mounted starters can save on installed cost and space, and they can be tested in the factory

and shipped on the chiller in a NEMA 1 enclosure. Remote-mounted starters provide more options

for multiple starter lineups, and may be chosen in order to implement some of the industrial starter

options such as high-fault and NEMA 12/3R.

CTV-PRB004-EN 17

Page 18

Low-Voltage StarterTypes

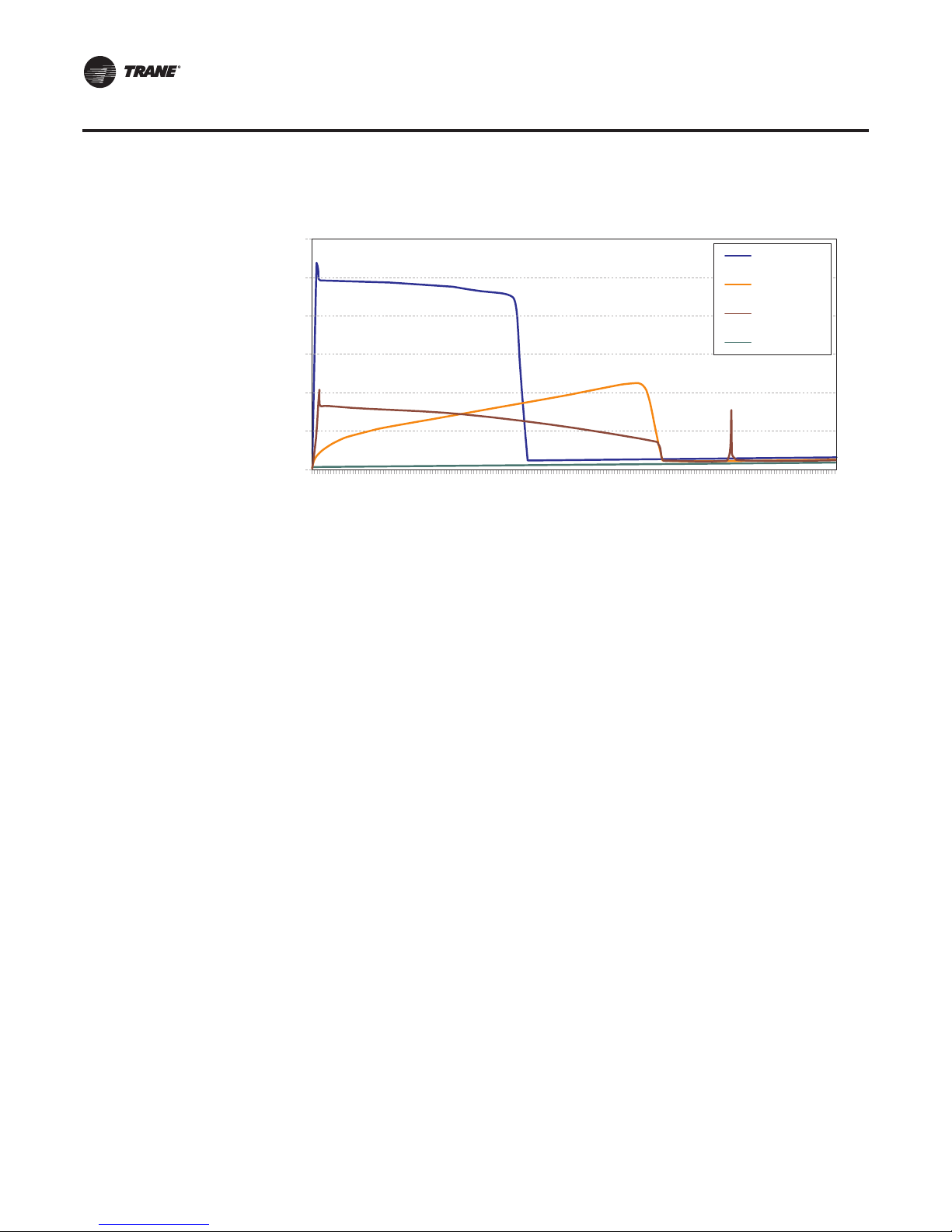

Figure 6. Comparison of low-voltage starting current

120

100

80

60

% LRA

40

20

0

0

Low Voltage—Wye-Delta

Wye-Delta Starters

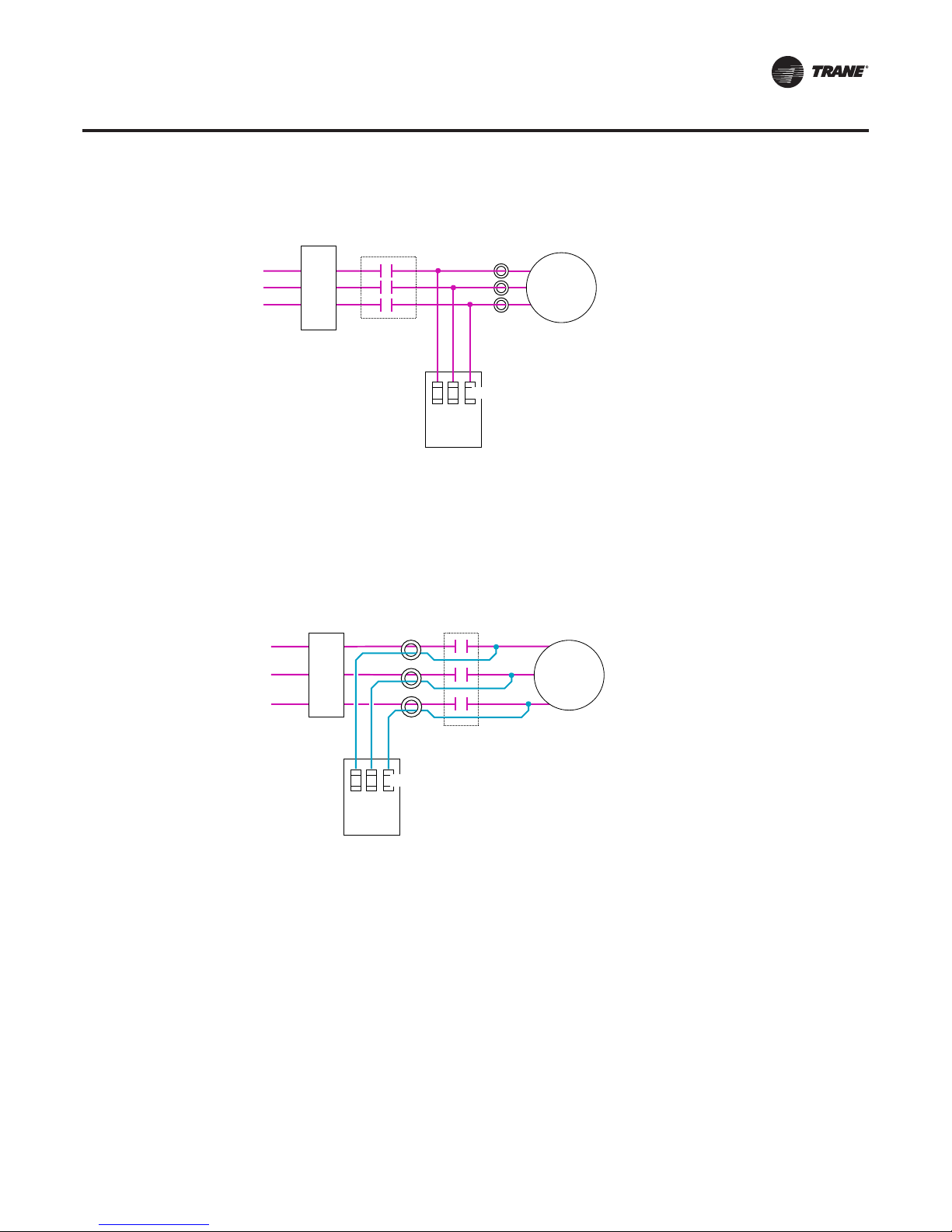

One of the most common starters in the industry is the wye/star-delta. It is an electromechanical

starter initially set up in a “wye” or “star” configuration, then it transitions to a “delta”

configuration during the starting sequence.To illustrate a typical starting sequence using a generic

(non-Trane) schematic, refer to Figure 7, p. 19 and its “Starting sequence,” p. 19.

X-Line

Solid-State

Wye-Delta

AFD

123456789

Time (seconds)

10

18 CTV-PRB004-EN

Page 19

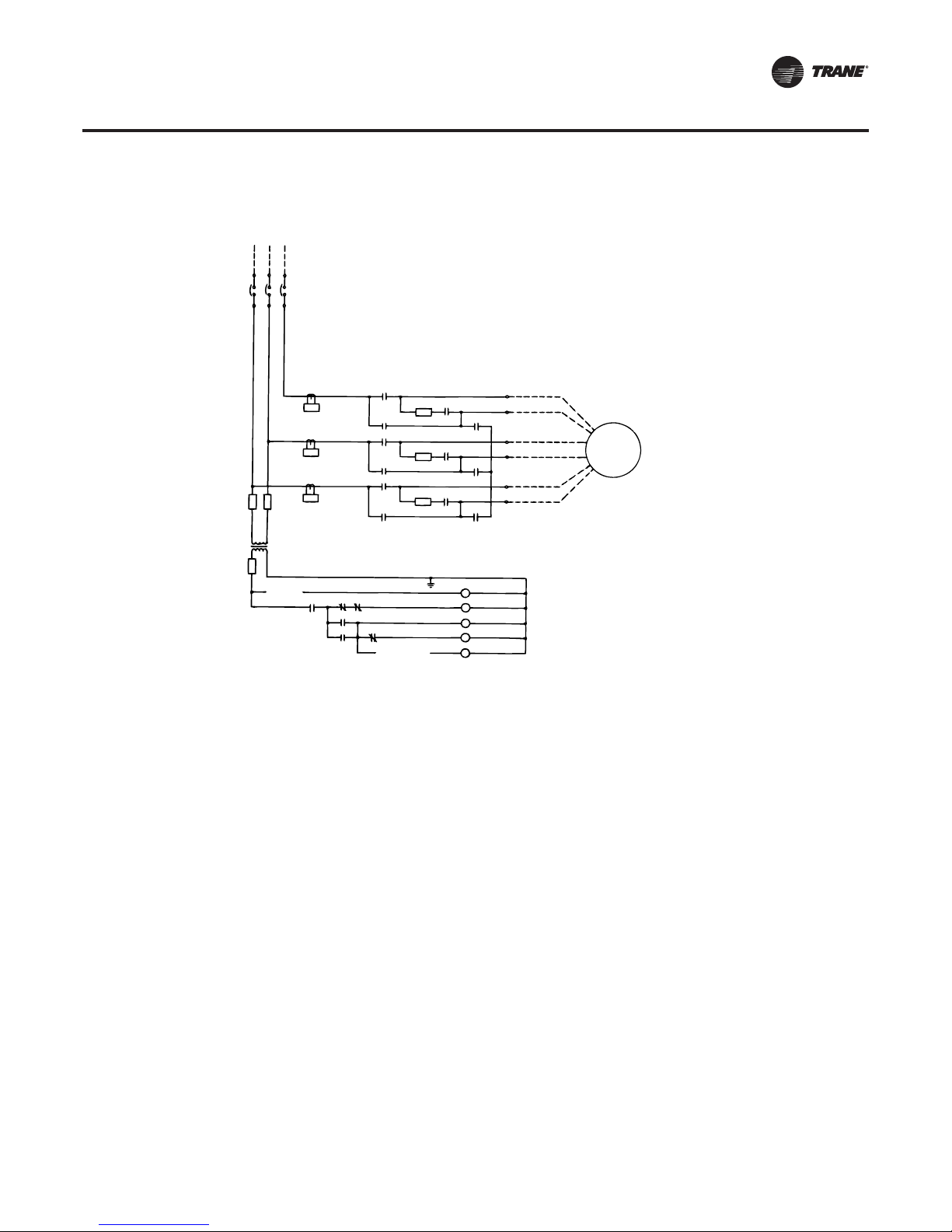

Figure 7. Simplified wye-delta wiring schematic

LINE

VOLTAGE

WYE-DELTA

STARTER WIRING

Low-Voltage StarterTypes

1A

1M

S

2M

S

1M

2M

1M

2M

1M

2M

TRANSITION

1A

R

R

R

S

1A

S

1A

S

PR

S

1M

2M

1A

MOTOR

OL

OL

OL

F

CPT

F

START-

STOP

PR

Starting sequence

1. The “start” signal from the CenTraVac controller energizes the pilot relay (PR).

2. The PR contacts close to energize the star contactor (S).

3. The S contacts close to connect the motor in the star configuration.

4. An S interlock closes to energize the start contactor (1M).

5. The 1M contacts close to connect the motor to the line.

6. A time delay relay or current monitoring device initiates transition by energizing the resistor

contactor

. 1A contacts close to connect the resistors to the line in the star configuration and in parallel with

7

the compressor

8. A 1A interlock now opens to de-energize the S contactor.

9. The S contacts open to connect the resistors and motor windings in series in the delta

configuration.

10. An S interlock closes to energize the run contactor (2M).

11. The 2M contacts close to bypass the resistors and connect the compressor motor directly to the

line

(1A).

motor.

in

the delta configuration.

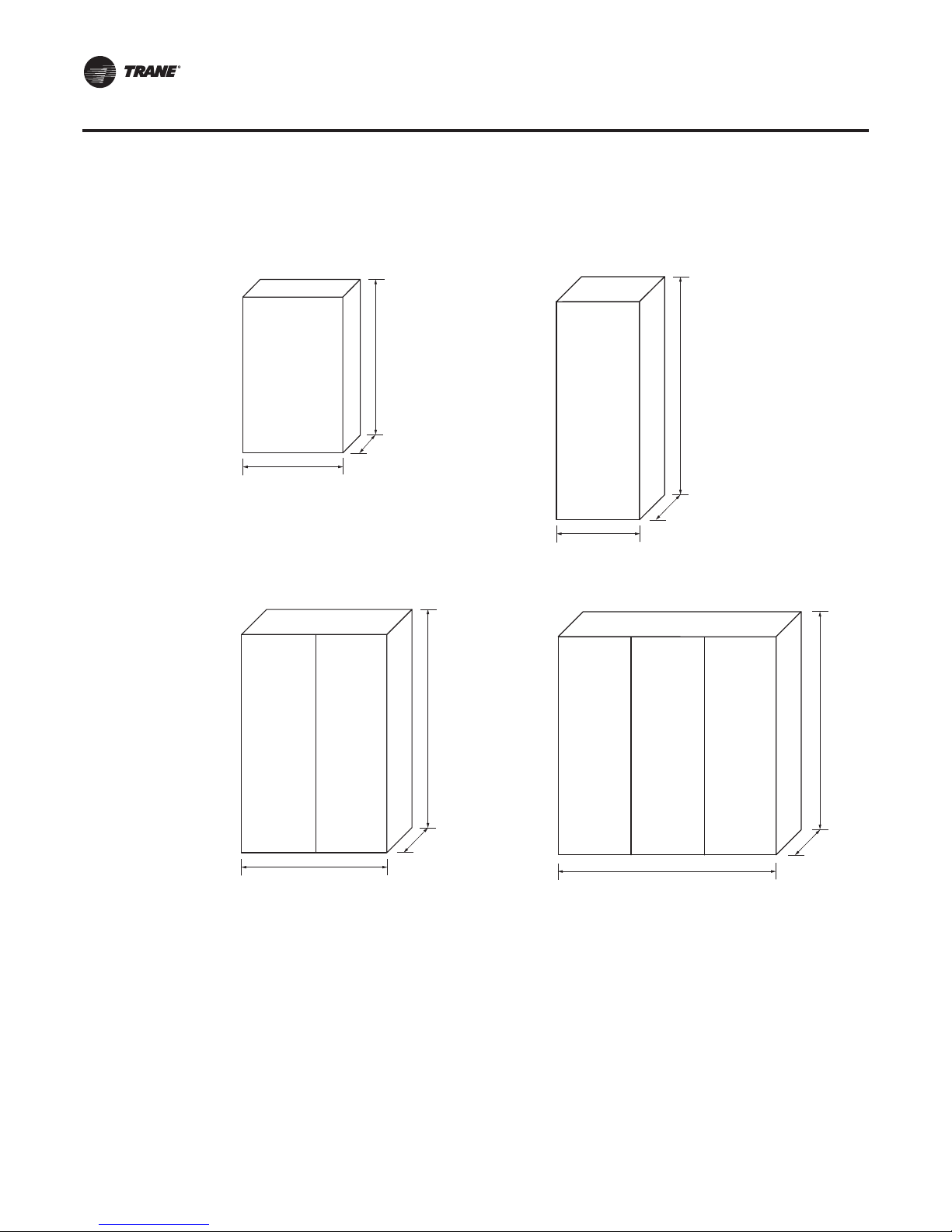

Dimensions

The typical unit-mounted wye-delta starter size is shown in Figure 9, p. 20. Typical remote-

mounted one-, two- and three-door starter sizes are shown in Figure 10, p. 20, Figure 11, p. 20, and

Figure 12, p. 21. Always consult the submittal drawings for as-built dimensions.

CTV-PRB004-EN 19

Page 20

Low-Voltage StarterTypes

The one-door remote-mounted starter size is generally used for 155- to 606-amp starters with no

disconnect.The two-door size is used for 640- to 1,700-amp starters with no disconnect.The threedoor size is used for 1,385- to 1,700-amps when disconnects are included.

Figure 8. Unit-mounted WD Figure 9. Remote 1-door WD

Stator

Squirrel-cage

60”

84”

Rotor shaft

13.5”

38.5”

32”

Figure 10. Remote 2-door WD Figure 11. Remote 3-door WD

Stator

19.3”

Stator

Squirrel-cage

84”

Rotor shaft

Stator

84”

56”

20 CTV-PRB004-EN

19.3”

19.3”

84”

Page 21

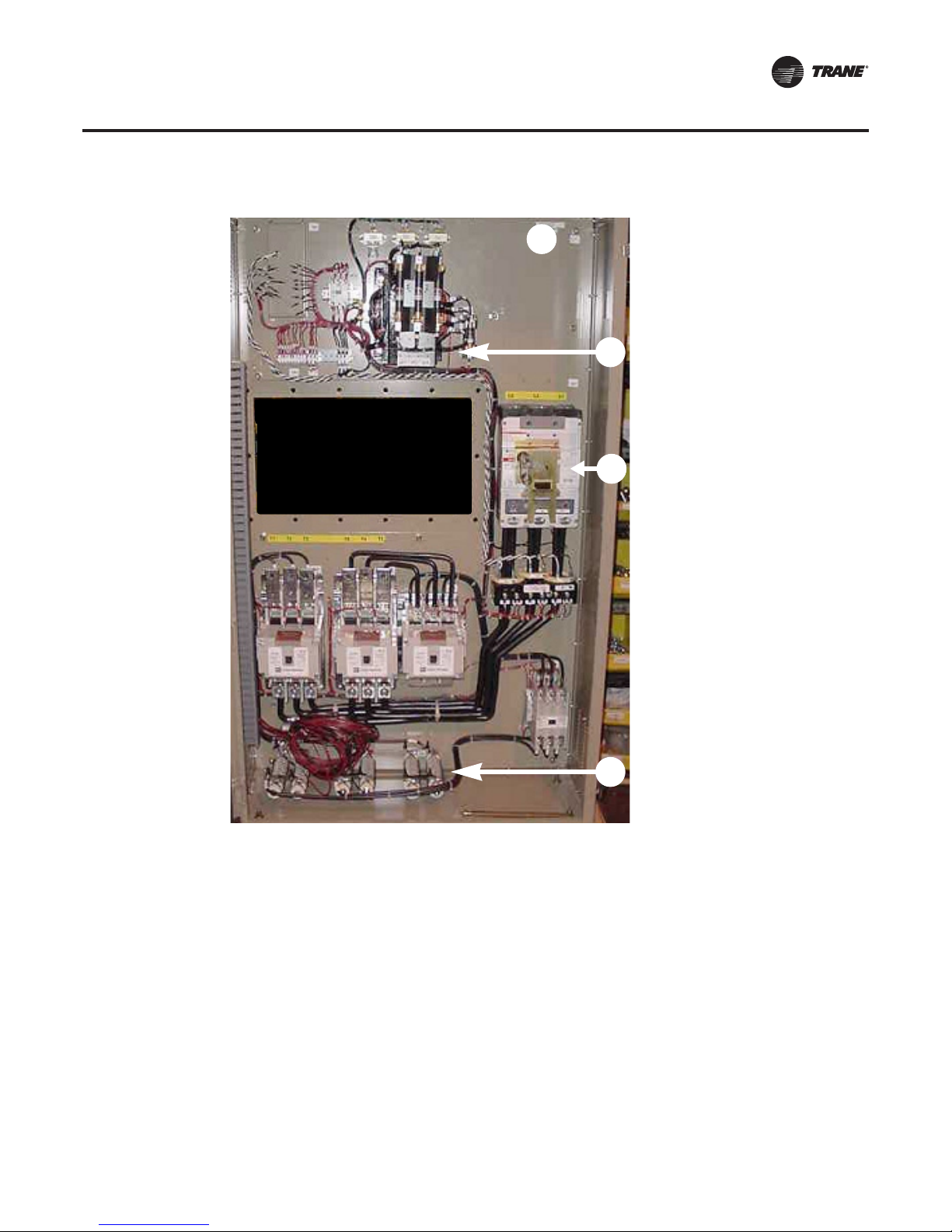

Figure 12. Unit-mounted, wye-delta starter

2

Low-Voltage StarterTypes

1. Top-entry power only

1

2

3

2. 4 kVA control-power

transformer

3. Circuit breaker (optional)

4. Transition resistors

4

Standard features

• Unit or floor mounted

• Control-power transformer

• Padlock tab for additional locking of the starter door

• Line-side connection terminal block/main lug only

• UL and CUL certified

• Environmental specification

• Designed, developed, and tested in accordance with UL 508

• NEMA 1 enclosure as standard

• Operation from sea level to 6,000 ft (1,829 m)

• Operating ambient temperature range 32°F to 104°F (0°C to 40°C)

• Relative humidity, non-condensing 5 percent to 95 percent

• Non-operating ambient temperature range -40°F to 158°F (-40°C to 70°C)

• Voltage utilization range ±10 percent

CTV-PRB004-EN 21

Page 22

Low-Voltage StarterTypes

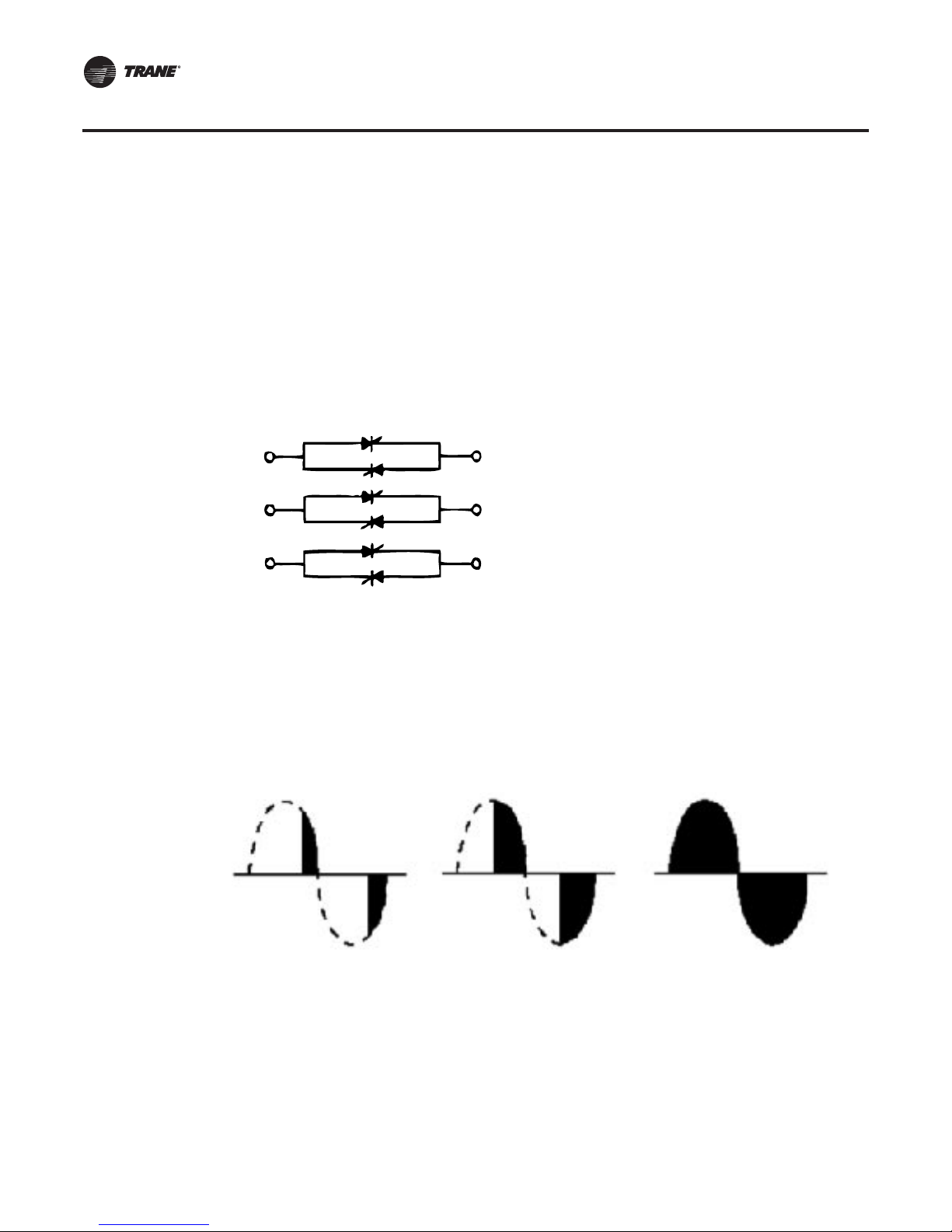

Low Voltage—Solid-State

Solid-State Starters

TheTrane®solid-state starter produces a soft start with a gradual inrush current and no transition

spikes. It controls the starting characteristics of a motor by controlling the voltage to the motor. It

does so through the use of silicon controlled rectifiers (SCRs), which are solid-state switching

devices, and an integral bypass contactor for power control. An SCR will conduct current in one

direction only when a control signal (gate signal) is applied. Because solid-state starters use

alternating current (AC), two SCRs per phase are connected in parallel, opposing each other so that

current may flow in both directions. For three-phase loads, a full six-SCR configuration is used, as

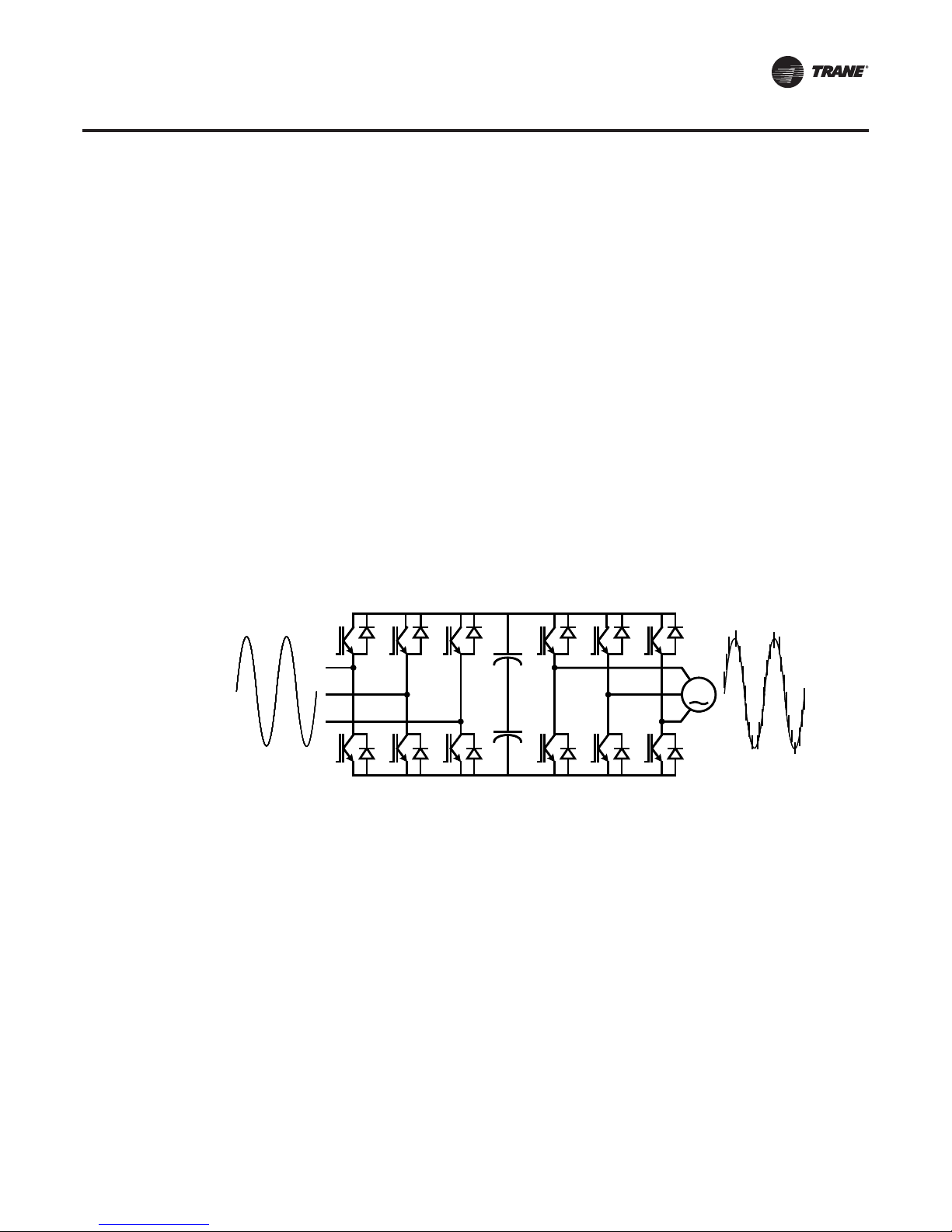

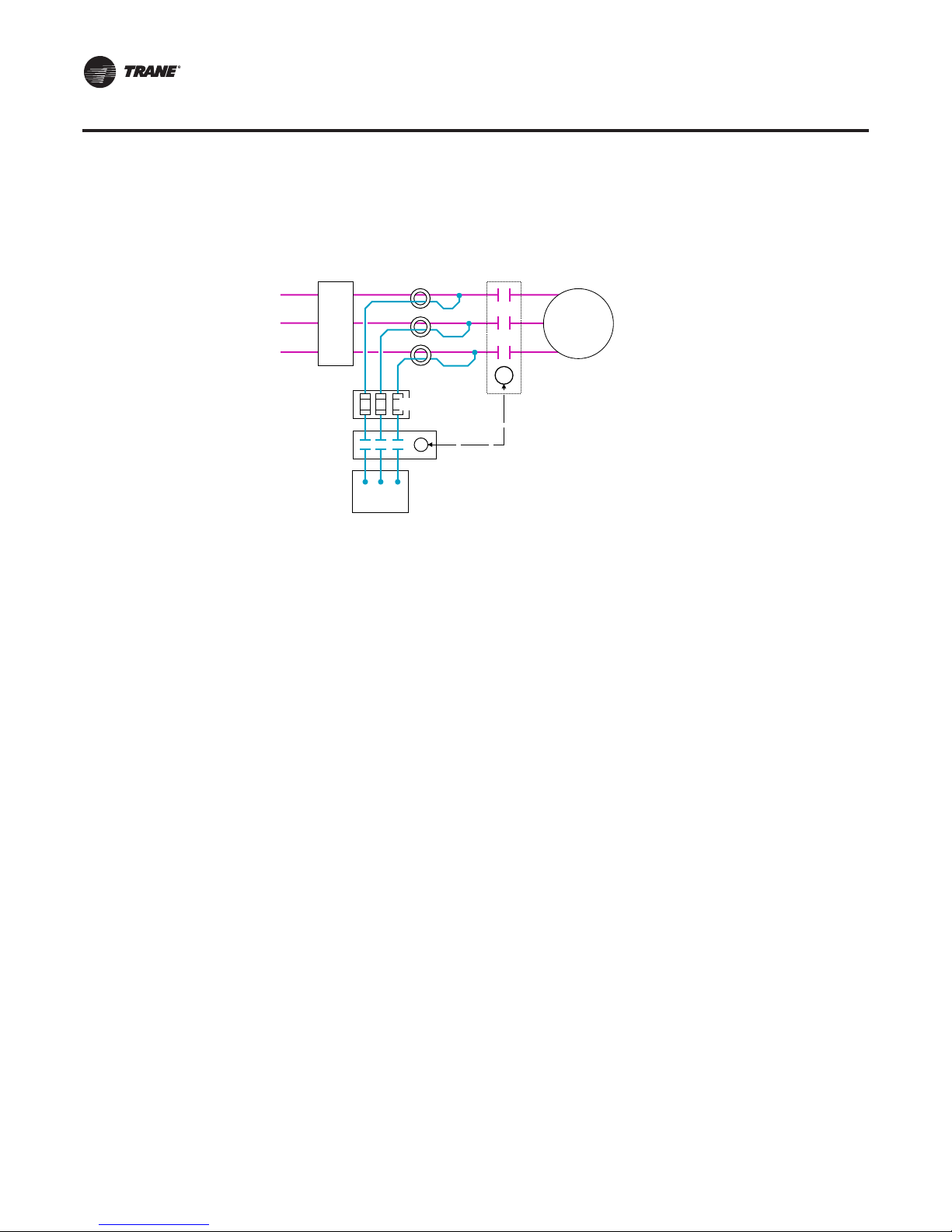

shown in Figure 13.

Figure 13. Six-SCR arrangement

L1

L2

L3

T1

T2

T3

Starting sequence

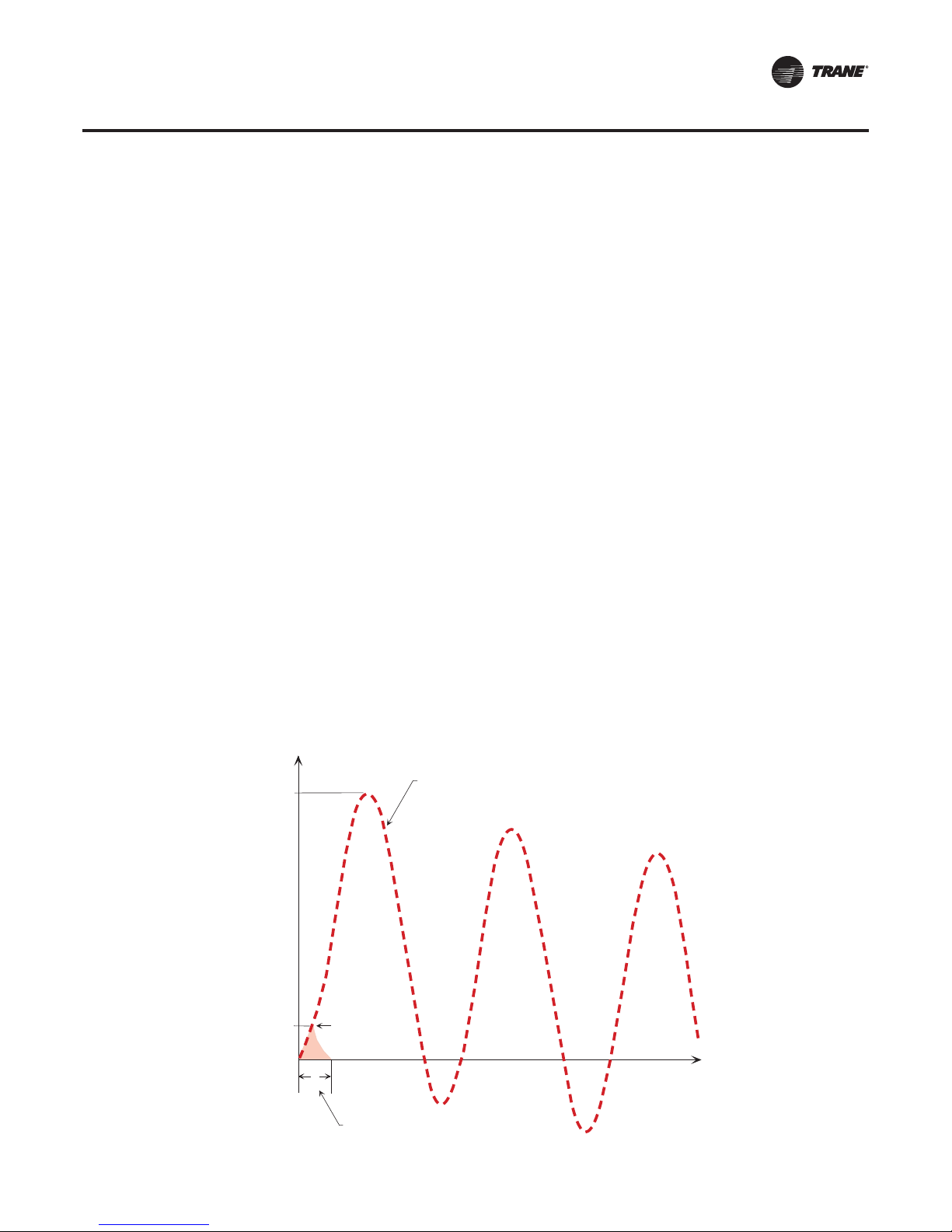

During starting, control of current or acceleration time is achieved by gating the SCRs “on” at

different times within the half-cycle.The gate pulses are originally applied late in the half-cycle and

then gradually applied sooner in the half-cycle. If the gate pulse is applied late in the cycle, only a

small increment of the wave form is passed through, and the output is low. If the gate pulse is

applied sooner in the cycle, a greater increment of the wave form is passed through, and the output

is increased. By controlling the SCRs ’ output voltage, the motor’s acceleration characteristic and

current inrush are controlled as illustrated in Figure 14.

Figure 14. Starting sequence wave forms

25% voltage 50% voltage full voltage

When the SCRs are fully “phased on,” the integral bypass contactors are energized.The current

flow is transferred from the power pole to the contactors.This reduces the energy loss associated

with the power pole, and extends contactor life.When the starter is given the stop command, the

SCRs are gated “full voltage” and the bypass contactor is de-energized.The current flow is

transferred from the contactors back to the power poles. Less than one second later, the SCRs are

turned off and the current flow stops.

22 CTV-PRB004-EN

Page 23

Low-Voltage StarterTypes

Features

• Unit- and floor-mounted models are available

• Control-power transformer

• Starting current is factory set and field adjustable

• Starting torque is factory set and adjustable via a voltage “notch” setting

• Six-SCR power section

• Air-cooled design with bypass contactor eliminates need for a water-cooling circuit, pump, and

heat exchanger

• Bypass contactor rated to carry 100 percent of the full-load motor phase current

• Protection from shorted SCRs and high starter heatsink temperature

• Protection from transient voltage through resistor-capacitor (RC) snubbers across SCRs and

metal oxide varistors (MOVs)

• Padlock tab for additional locking of starter door

• Line-side connection terminal block/main lug only

• UL and CUL certified

Dimensions

Typical dimensions for unit- or remote-mounted solid-state starters are shown in Figure 15. Always

consult the submittal drawings for as-built dimensions.

Figure 15. Solid-state dimensions

38.5"

60"

13.5"

CTV-PRB004-EN 23

Page 24

Low-Voltage StarterTypes

Figure 16. Unit-mounted, solid-state starter

1. Top-entry line power

1

2. Intelligent technology (IT)

controller

3. Starter control board

4. Potential transformers

5. 4 kVA control-power

transformer

2

3

4

5

Environmental specification

• Designed, developed, and tested in accordance with UL 508

• NEMA 1 enclosure as standard

• Operation from sea level to 6,000 ft (1,829 m)

• Operating ambient temperature range 32°F to 104°F (0°C to 40°C)

• Relative humidity, non-condensing 5% to 95%

• Non-operating ambient temperature range -40°F to 158°F (-40°C to 70°C)

• Voltage utilization range ±10%

24 CTV-PRB004-EN

Page 25

Low-Voltage StarterTypes

Low Voltage—Unit-Mounted Adaptive Frequency Drive

TheTrane Adaptive Frequency Drive is a refrigerant-cooled, microprocessor controlled design.The

AFD is used in lieu of a constant-speed starter and is currently available for use with 460 or 480 volts

only. Adaptive Frequency is a trademarked term for theTrane

proprietary control logic and made toTrane specifications.

About the Trane AFD

The AFD is unit-mounted and ships completely assembled, wired, and tested from the factory.The

AFD controller is designed to interface with the chiller controller. It adapts to the operating ranges

and specific characteristics of the chiller.The optimum chiller efficiency is created by coordinating

the compressor-motor speed with the compressor inlet guide vanes.The chiller controller and the

AFD controller work together to maintain the chilled-water setpoint and avoid surge. If surge is

detected, the chiller controller’s surge-avoidance logic in the chiller controller makes the proper

adjustments to move the operating point away from surge.

How it works

The frequency drive regulates output voltage in proportion to output frequency to maintain ideal

motor flux and constant torque-producing capability.Or put simply, a variable-speed drive controls

load-side frequency and voltage to adjust the compressor motor speed.The AFD is a voltagesource, pulse-width modulated (PWM) design. It consists of three primary power sections as

shown in Figure 17: the active rectifier, the DC bus, and the inverter.

®

variable-speed drive, using

Figure 17. AFD power sections

M

M

Rectifier DC Bus Inverter

Rectifier DC Bus Inverter

Determines line-side harmonics Determines load-side harmonics

Determines line-side harmonics Determines load-side harmonics

Rectifier (active). Takes incoming AC power, filters it with an LCL filter (not shown), and then

converts it to a fixed DC voltage. The insulated-gate bipolar transistor (IGBT) active rectifier

significantly reduces the amount of line-side harmonic levels and the amount of ripple on the DC

bus.The active rectifier also has some traditional post-generation filtering capabilities to further

smooth out remaining line-side harmonics.

DC bus. Capacitors store the DC power provided by the rectifier until it is needed by the inverter.

Inverter. Converts the DC voltage into a synthesized AC output voltage.This synthesized output

controls both the voltage and the frequency.The synthesized output waveform consists of a series

of pulses, hence the “pulse” in PWM.

Starting sequence

Trane AFDs are programmed to start the compressor motor using low frequency and low voltage,

thereby minimizing the inrush current.The motor is then brought up to speed by gradually

increasing both frequency and voltage at the same time.Thus, current and torque are much lower

during startup and motor acceleration than the high current, high torque associated with acrossthe-line or even reduced-voltage starters; refer to the inrush current vs. time graph (Figure 6, p. 18).

CTV-PRB004-EN 25

Page 26

Low-Voltage StarterTypes

Figure 18. Trane AFD

1

2

4

• The AFD is rated by output current and is limited to a maximum of 100-percent continuous RLA

(rated-load amps) by theTrane

results in 100-percent torque generated by the motor.

®

chiller unit controller. A 100-percent output current capability

1. Pre-charge contactor

2. Inductor (behind the panel)

3. Adjustable-speed drive

5

(inverter)

4. Circuit breaker (standard)

5. Active rectifier

6. 3 kVA control-power

transformer

3

6

Features

The standard design features for the AFD include:

• NEMA 1, ventilated enclosure with a hinged door, tested to a short-circuit current rating of

65,000 amps.

• Padlock-able, door-mounted circuit breaker/shunt trip with an AIC rating of 65,000 amps.

• SCCR/AIC rating of 100,000 amps available as a design special.

• UL/CUL listed as a package.

• Simple, modular construction.

• 480/60/3 input power ±10 percent, with drive overload capability of 100 percent continuous to

150 percent for five seconds.

Note: For voltages other than 460/480 V, a transformer is currently needed to produce

460/480 V.

• Motor thermal overload protection 102 percent continuous, 108 percent for 60 seconds,

140 percent for 1.5 seconds.

• Minimum efficiency of 97 percent at rated load and 60 hertz.

• Soft-start, controlled acceleration, coast-to-stop.

• Adjustable frequency from 38 to 60 hertz.

• Control circuit voltages physically and electrically isolated from power circuit voltage.

• 150 percent instantaneous torque available for improved surge control.

• Output line-to-line and line-to-ground short-circuit protection.

• Ground fault protection (UL listed).

26 CTV-PRB004-EN

Page 27

Low-Voltage StarterTypes

Environmental specification

• 32°F to 104°F (0°C to 40°C) operating ambient temperature.

• Altitude to 3,300 feet (1,000 m), amperage derate of 1 percent per every 300 feet above

3,300 feet.

• Humidity, 95 percent non-condensing.

Dimensions

Typical dimensions for the unit-mounted Adaptive Frequency Drive are shown in Figure 19 and

Figure 20. Always consult the submittal drawings for as-built dimensions.

Figure 19. AFD dimensions

(405- and 608-amp design)

Figure 20. AFD dimensions

(900- and 1,210-amp design)

Door

swing

62"

Each door

swing

75"

32.5" & 24.5"

from front

of AFD

18"

is 31

"

from front

of AFD

26"

60"

98"

Motor-AFD mutual protection

The chiller unit-controller capabilities allow the control/configuration interface to, and the retrieval/

display of AFD-related data. AFD standard design features controlled through theTracer

AdaptiView™ include:

• Current limited to 100 percent.

• Motor overload protection.

• Motor over-temperature protection.

• Phase loss, phase reversal, and phase imbalance protection.

• Undervoltage and overvoltage protection.

• Output speed reference via IPC3 communication bus from the chiller controller to the AFD.

Digital data display

The following points are digitally displayed at the chiller controller:

• Output speed in hertz

• Output speed in rpm

• Input frequency

• Input/output line voltage

• Input/output kW

• Input/output current

• Average output current in percent RLA

• Load-side power factor

• AFD transistor temperature

• Fault

CTV-PRB004-EN 27

Page 28

Low-Voltage StarterTypes

Harmonics

Harmonics has become a frequently used term in the power quality arena. Of all the power quality

issues encountered today, harmonics is the least understood and most feared; unfortunately, this

has resulted in overstating the impact of harmonics.

Harmonics is not a “thing” but a way to define current or voltage distortion on a power line.

Harmonics can be directly linked to nonlinear loading of a power system. Nonlinear loads are

created by devices connected to a given power system that draw current from the power source

with a waveform that is not a pure sine wave.

All nonlinear loads, including variable-frequency drives, will create current and voltage distortion.

Typically harmonics is not an insurmountable issue when applying an AFD on a centrifugal chiller.

Harmonic attenuation

Harmonic attenuation is standard on the unit-mounted refrigerant-cooled AFDs and includes:

• Integrated active rectification control of the building AC power assures low line-generated

harmonics back to the user’s power grid.This results in less than 5 percent current harmonic

distortion (TDD) as measured at the AFD.

• Active input rectifier will regulate to a displacement power factor of 0.98 or better at full load

and a value of 0.96 at part load.

• Full motor voltage is applied regardless of the input voltage.

Note: TDD is a direct affect of variable-frequency drives and is a larger and more critical value than

the amount of total harmonic distortion (THD). As measured at the AFD, the amount ofTHD

will be less than theTDD.

IEEE 519

It is important to recognize that IEEE 519 relates to the entire system, not specifically to any one load

or product. IEEE 519 establishes requirements at the point of common coupling (PCC) where the

building connects to the utility system.The standard contains no specific requirements for the

internal electrical loads.

Even thoughTrane AFD-equipped chillers will attenuate their own harmonics, other nonlinear

loads on the same system could still create harmonic problems. In buildings where harmonics

might be a concern,Trane recommends conducting a power-distribution system analysis to

determine if there is a need to further attenuate harmonics at the system level.

Low Voltage—Remote-Mounted Adaptive Frequency Drive

Depending on the application,Trane also offers a remote free standing Adaptive Frequency Drive

(AFD).The remote AFD comes as a complete, free-standing package that includes the necessary

controls, control power and programming needed for operation. EachTrane Adaptive Frequency

Drive arrives completely programmed with all chiller control communication logic installed. Input

voltage options include 460, 480, 575, and 600 volts. Most of the low-voltage AFDs in the industry

are designed to work at 460/480 volts only. In HVAC applications were the voltage is 575/600, a

transformer would be need to apply an AFD. With theTrane remote AFD, a transformer would not

be needed, thereby eliminating the associated extra design time, space requirements, installation

costs and energy losses.

The design

The remoteAFD design is a voltage-source, pulse-width modulated (PWM) type. It consists of three

primary power sections.

Rectifier. Constructed of silicon controlled rectifiers (SCR), which convert the incoming utility AC

sine wave into DC voltage that will be stored in the DC Bus section

DC Bus Section. A capacitor bank that is used to store energy for use within the inverter section

28 CTV-PRB004-EN

Page 29

Low-Voltage StarterTypes

Inverter IGBTs. Use the pulse width modulation (pwM) method to convert the DC voltage from

the capacitor bank into a synthesized output AC voltage that controls both the voltage and

frequency applied to the motor

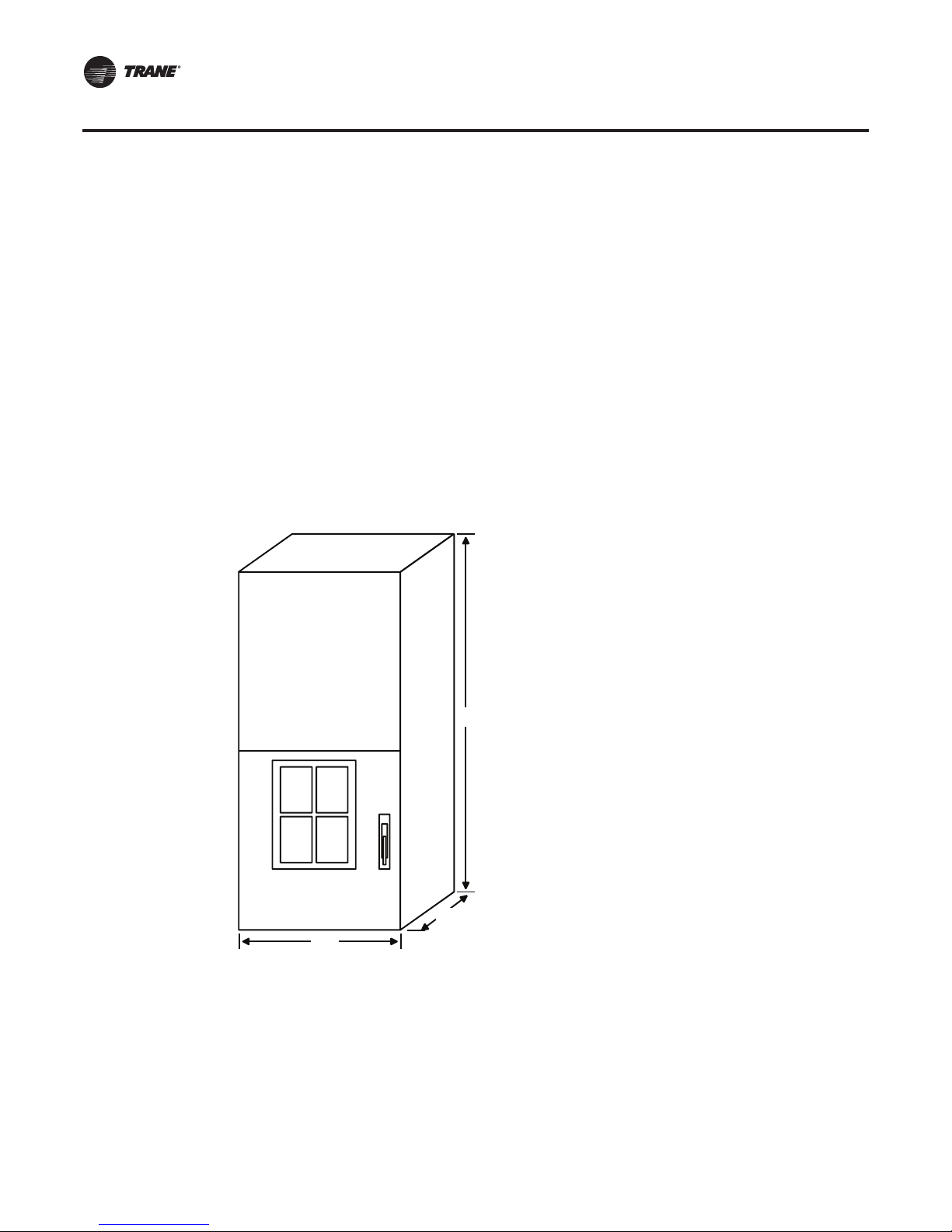

Figure 21. Front view, remote-mounted AFD

Features

The standard design features for the AFD include:

• Free standing NEMA 1, ventilated enclosure with a hinged door, tested to a short-circuit current

rating of 65,000 amps. Enclosure locking provisions are standard.

• Lockable, door-mounted circuit breaker/shunt trip with an AIC rating of 65,000.

• Amps, and enclosure short circuit rating of 65,000 amps standard.

• UL/CUL listed as a package.

• Simple, front access only design.

• 460/480/60/3 input power ±10 percent.

• 575/600/60/3 input power ±10 percent.

• Minimum efficiency of 97 percent at rated load and 60 hertz.

• Displacement power factor at 0.96 at all loads.

• Soft-start, linear acceleration, coast-to-stop.

• Adjustable frequency from 38 to 60 hertz.

• 150 percent instantaneous torque available for improved surge control.

• Output line-to-line and line-to-ground short-circuit protection.

• Ground fault protection (UL listed).

Optional Items

• NEMA 12 enclosure.

• 100,000 amp enclosure short-circuit current rating (SCCR) with 100,000-amp AIC circuit breaker

available as a design special.

CTV-PRB004-EN 29

Page 30

Low-Voltage StarterTypes

Environmental specification

• Operating temperature: 32°F to 104°F (0°C to 40°C).

• Storage temperature: -4°F to 149°F (-20°C to 65°C).

• Humidity: 95 percent non-condensing.

• Maximum elevation: 3280 ft (1000 m) rated output current.

• Derate 4 percent/3280 ft over rated altitudes up to 9840 ft (30 00 m).

Dimensions

Table 6 provides some basic reference dimensions and weights for the remote AFD. Always refer

and use theTrane submittals for actual dimensions.

Table 6. Remote AFD dimensions

460 Vac 575 Vac

Frame

D3/D4 150–350 394 150–400 356 48 24 86 1220

E2 450–600 649 450 400 56 24 90 1635

N/A N/A 500–650 560 64 24 90 1680

F3 650–750 791 750–1050 840 127 24 90 2885

950–1050 1031 N/A N/A 127 24 90 3185

F4 1150–1350 1360 1150–1550 1258 150 24 90 3720

Width (in.) Depth (in.) Height (in.) Weight (lb)Power (hp) Max. Amps Power (hp) Max. Amps

Digital data display

The following points are digitally displayed at the chiller controller:

• Frequency command

• Input line voltage

• Load-side amps

Harmonics

The remote AFD is a standard six pulse design. Therefore the harmonic level is ~35 percent total

demand distortionTDD as measured at the AFD input. If lower levels of attenuation are required,

upstream filtering would be required.

30 CTV-PRB004-EN

Page 31

Medium-Voltage Starter Types (2,300–6,600 Volts)

Table 7 shows the most common medium-voltage starter types available and compares inrush

current, torque, frequency of use, advantages and disadvantages, and typical acceleration time.

The inrush profiles are shown in Figure 22.

Which starter type is best?

One question often asked is: “Which is better, full voltage or reduced voltage?” Because mediumvoltage starters by nature use less current than low voltage, and therefore have significantly less

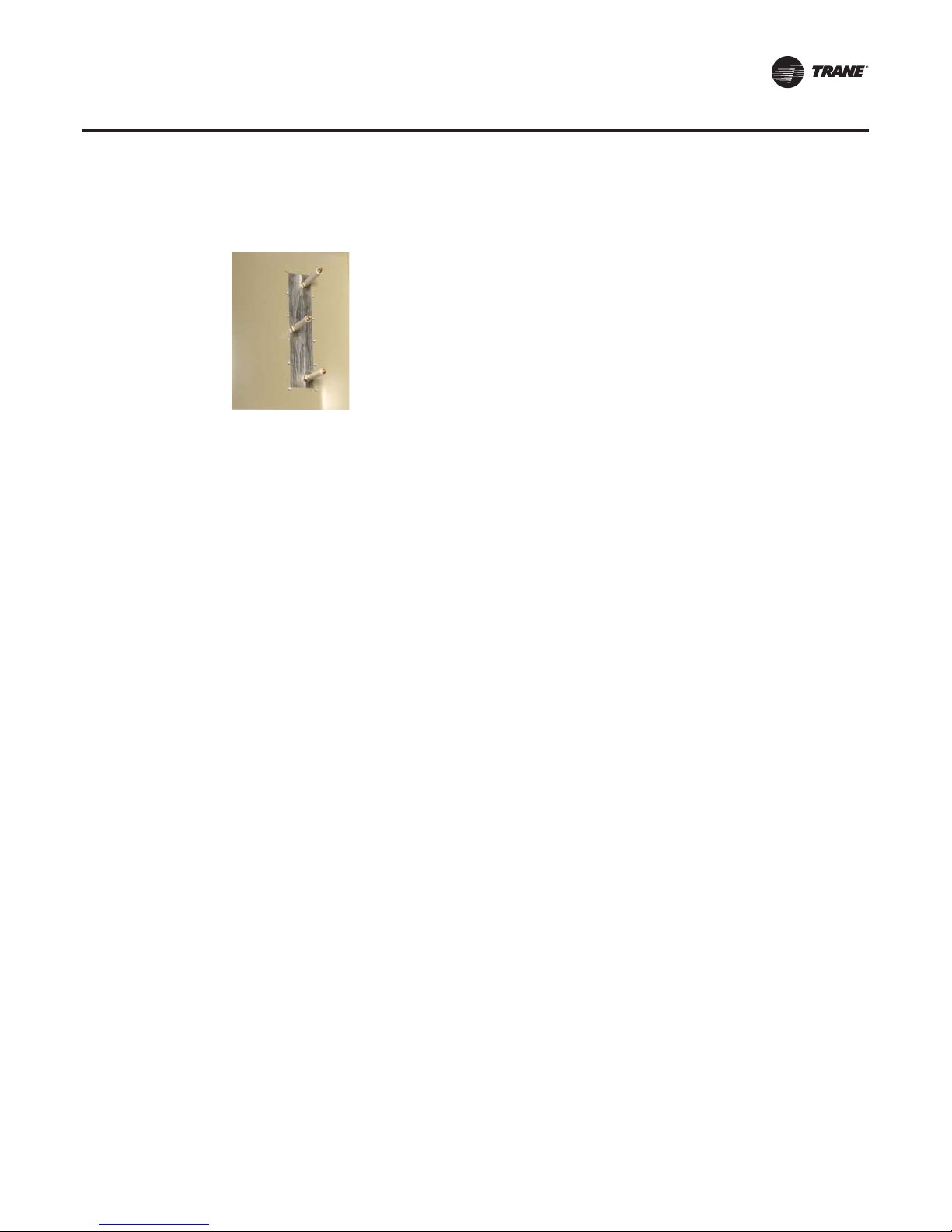

current inrush. Across-the-line medium-voltage starters are more commonly used; however, in

certain applications reduced voltage will be used to minimize starting strain on the electrical

system.

Table 7. Comparison of medium-voltage starters (2,300–6,600 volts)

Starter Type

(closed-transition)

Across-the-Line

(Full Voltage)

Primary Reactor

65% TAP

Autotransformer

65% TAP

AFD

Inrush

Current

% LRA

100 100 27%

65 42 49%

45 42 22%

<13

(<RLA)

Percent

Rated

Torque

Varies 2%

How

Often

Used Advantages Disadvantages

• Low cost

• Least complex

• Least maintenance

• Good compromise between

first cost and inrush current

reduction

• Almost equal reduction of

torque and inrush current

• Lowest inrush current

• Efficiency at part lift

• Power factor

Figure 22. Comparison of medium-voltage starting current

120

100

80

60

% LRA

40

• Draws highest inrush current

at startup

• More expensive than Acrossthe-Line

• Larger than Across-the-Line

• Most expensive

• Larger than Across-the-Line

• Very expensive

• Large and heavy

• Complex

Across-the-Line

Primary Reactor (65% tap)

Autotransformer (65% tap)

AFD

Typical

Acceleration

Time

(seconds)

3–5

5–12

5–12

5–12

20

0

01

Unit- or remote-mounted?

Unit-mounted medium-voltage starters can save on installed cost and space.They are tested in the

factory and are shipped on the chiller. Remote-mounted starters are sometimes bussed together

in various configurations as shown in “Multiple Starter Lineups (2,300–6,600 volts),” p. 61. Remote-

mounted starters fromTrane can have special NEMA options, whereas unit-mounted starters are

NEMA 1. All starters conform to ANSI/NEMA ICS-6 enclosure standards unless otherwise noted.

CTV-PRB004-EN 31

2345678910

Time (seconds)

Page 32

Medium-Voltage StarterTypes (2,300–6,600 Volts)

Other options for remote-mounted starters are available in the Enhanced Electrical Protection

Package (see “Industrial-Grade Starters,” p. 63.)

NEC 2005 changes for medium-voltage (2,300–6,600 volt) wire

NEC code for 2005 requires that medium-voltage cable is shielded. This affects the power wire

selection and connection provisions to the chiller, and between the chiller and starter when it is

remote mounted. When you use shielded cable, you must also use stress cones at the termination

points (motor terminal connection, remote starter, or unit-mounted starter connection). Stress

cones are composed of electrical shielding wrap and are typically 9–12 inches in length. Stress

cones are used to confine the dielectric field and reduce electrical stresses at the termination point.

®

Trane

that is shown in our as-built submittal drawings.The top hat is enclosed in the starter cabinet

during shipment and then reversed for field installation. Motor terminal boxes and remotemounted starters are designed to accommodate stress cones without an additional enclosure.

Refer to the appropriate submittals drawings to verify that the starter has sufficient connection

space for your requirements. For more information regarding the top hat, refer to “Unit-Mounted

StarterTop Hat—NEC 2005 Code Requirement,” p. 40.

unit-mounted medium-voltage starters now ship with a field-installed accessory “top hat”

Medium Voltage—Across-the-Line (2.3–6.6 kV)

Across-the-Line Starter (2,300–6,600 volts)

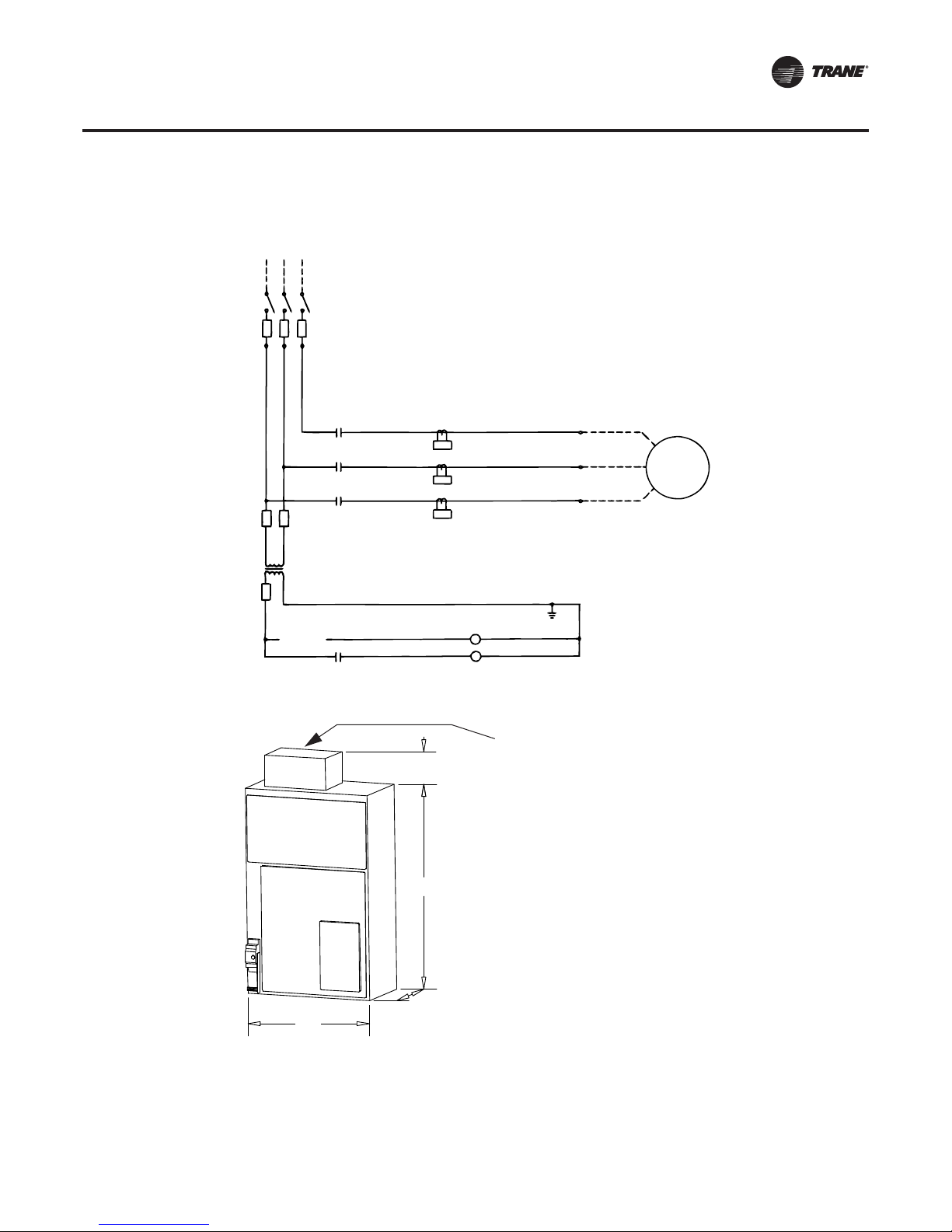

Figure 23, p. 33 shows a schematic for the most basic starter type; the across-the-line (X-Line)

starter, which is also known as a full-voltage starter.To illustrate a typical starting sequence using

a generic (non-Trane) schematic, refer to Figure 23, p. 33 and the starting sequence below.

Starting sequence

1. A “start” signal from the chiller controller energizes the pilot relay (PR).

2. The PR contacts close to energize the start/run contactor (1M).

3. The 1M contacts close to connect the compressor motor directly to the line.

32 CTV-PRB004-EN

Page 33

Medium-Voltage StarterTypes (2,300–6,600 Volts)

Figure 23. Simplified across-the-line wiring diagram

LINE

VOLTAGE

ACROSS-THE-LINE

STARTER WIRING

1M

1M

1M

F

CPT

F

START-

STOP

PR

OL

OL

OL

PR

1M

Figure 24. Unit-mounted, across-the-line starter dimensions

Top Hat

9.13"

MOTOR

27"

38"

Standard features

• Control-power transformer

• Primary and secondary current transformers (CTs)

• Potential transformers (PTs)

CTV-PRB004-EN 33

60"

26.2"

40"

20"

Page 34

Medium-Voltage StarterTypes (2,300–6,600 Volts)

• Grounding provisions

• Bolted line-power connections

• Bolted load-side connections for remote starters

• Standard motor protection

Environmental specification

• Designed, developed, and tested in accordance with UL 347

• NEMA 1 enclosure as standard

• Operation from sea level to 6,000 ft (1,829 m)

• Operating ambient temperature range 32°F to 104°F (0°C to 40°C)

• Relative humidity, non-condensing 5 percent to 95 percent

• Non-operating ambient temperature range -40°F to 158°F (-40°C to 70°C)

• Voltage utilization range ±10 percent

Dimensions

Typical dimensions for unit- and remote-mounted across-the-line starters are shown in Figure 24,

p. 33 and Figure 25, p. 34. Always consult the submittal drawings for as-built dimensions.

Figure 25. Remote-mounted XL

80"

30"

36"

34 CTV-PRB004-EN

Page 35

Medium-Voltage StarterTypes (2,300–6,600 Volts)

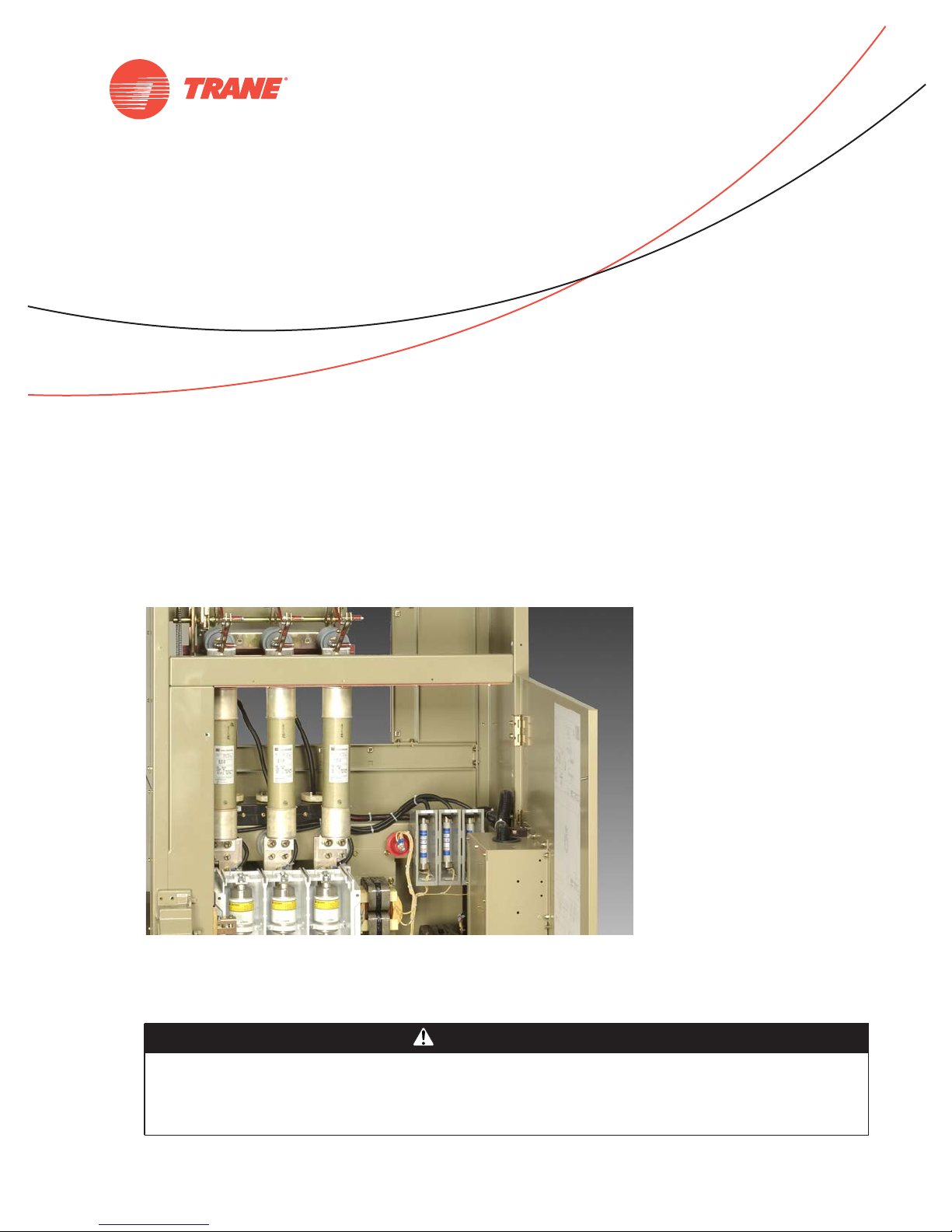

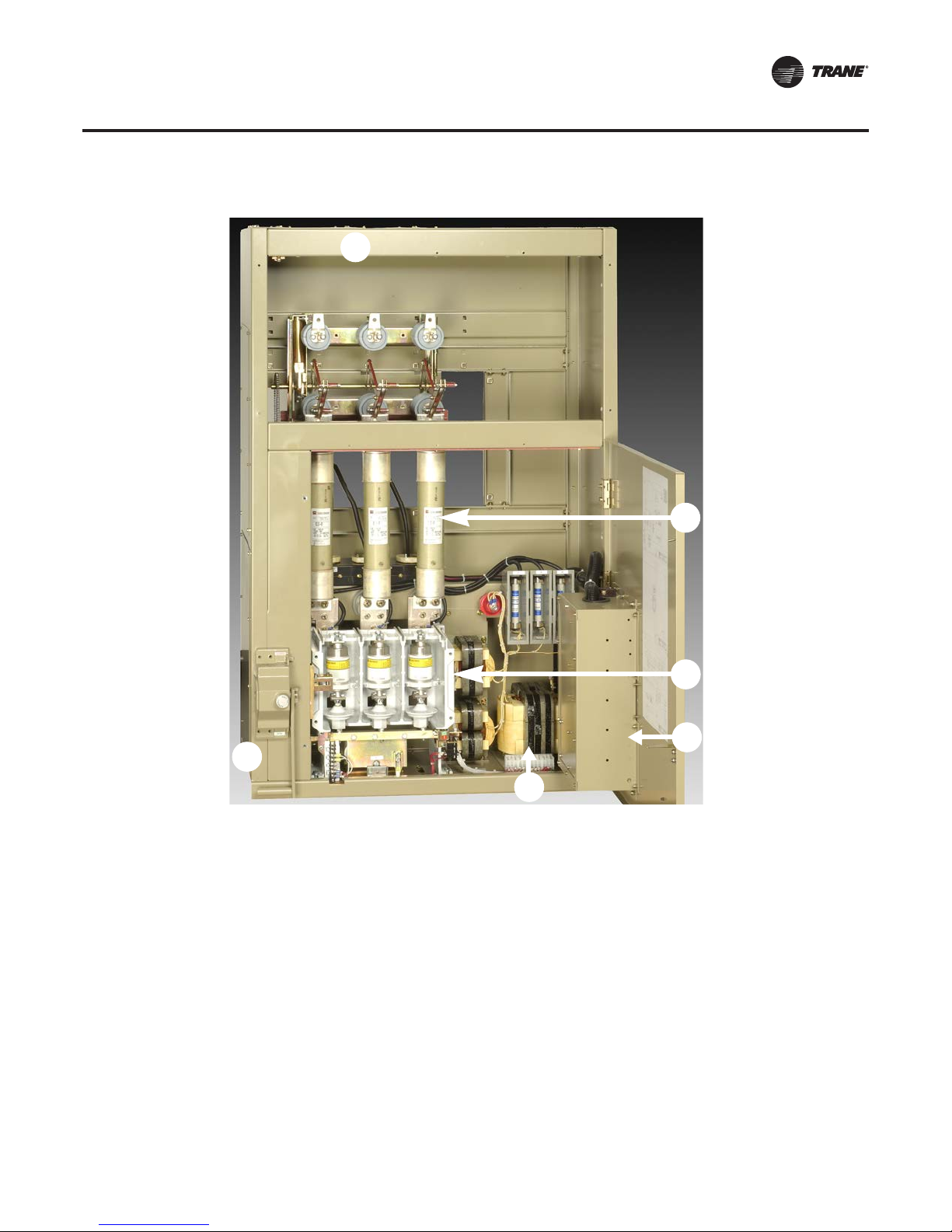

Figure 26. Unit-mounted, across-the-line, medium-voltage starter

1

1. Top-entry power

connection

2. Current-limited

power fuses

3. Vacuum

contactors

4. Low-voltage

section

5. Isolation switch

(provision for one

lock)

6. Control-power

transformer

2

5

6

Medium Voltage—Primary Reactor (2.3–6.6 kV)

Primary Reactor Starter (2,300–6,600 volts)

One of the most common starters in the industry is the primary reactor.To illustrate a typical

starting sequence using a generic (non-Trane) schematic, refer to Figure 27, p. 36 and the starting

sequence below.

Starting sequence

1. A “start” signal from the chiller controller energizes the pilot relay (PR).

2. The PR contacts close to energize the start contactor (1M).

3. The 1M contacts close to connect the compressor motor to the line with the motor in series with

the reactor

4. A time delay or current monitoring device initiates transition by energizing the run contactor

(2M).

.

3

4

CTV-PRB004-EN 35

Page 36

Medium-Voltage StarterTypes (2,300–6,600 Volts)

5. The 2M contacts close to bypass the reactor and connect the compressor motor directly to the

line.

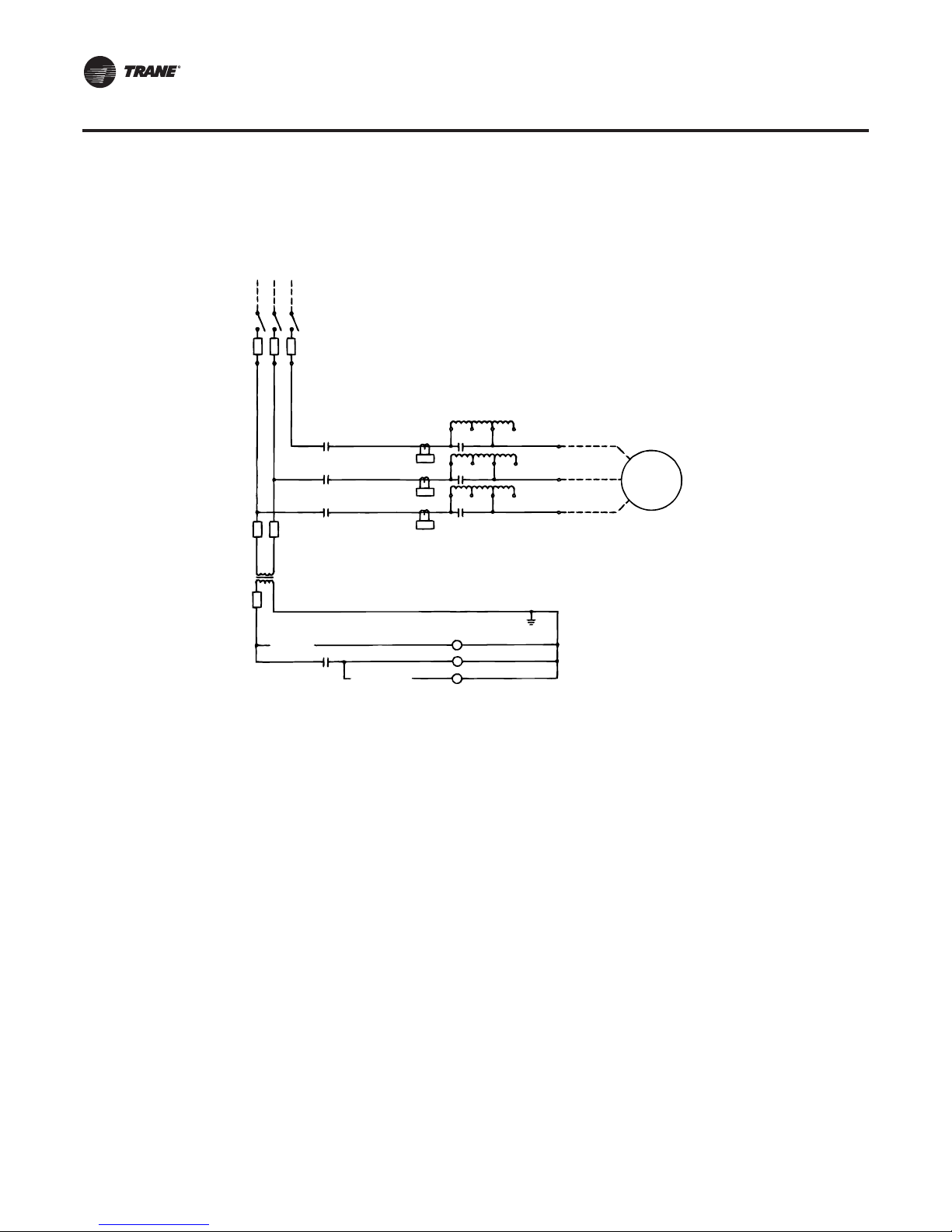

Figure 27. Simplified primary reactor wiring diagram

LINE

VOLTAGE

PRIMARY REACTOR

80%

1M

OL

2M

65%

50%

1M

1M

F

CPT

F

START-

STOP

PR

TRANSITION

OL

OL

2M

2M

MOTOR

PR

1M

2M

Standard features

• Control-power transformer

• Primary and secondary current transformers (CTs)

• Potential transformers (PTs)

• Grounding provisions

• Bolted line-power connections

• Bolted load-side connections for remote starters

• Standard motor protection

Environmental specification

• Designed, developed, and tested in accordance with UL 347

• NEMA 1 enclosure as standard

• Operation from sea level to 6,000 ft (1,829 m)

• Operating ambient temperature range 32°F to 104°F (0°C to 40°C)

• Relative humidity, non-condensing 5% to 95%

• Non-operating ambient temperature range -40°F to 158°F (-40°C to 70°C)

• Voltage utilization range ±10%

Dimensions

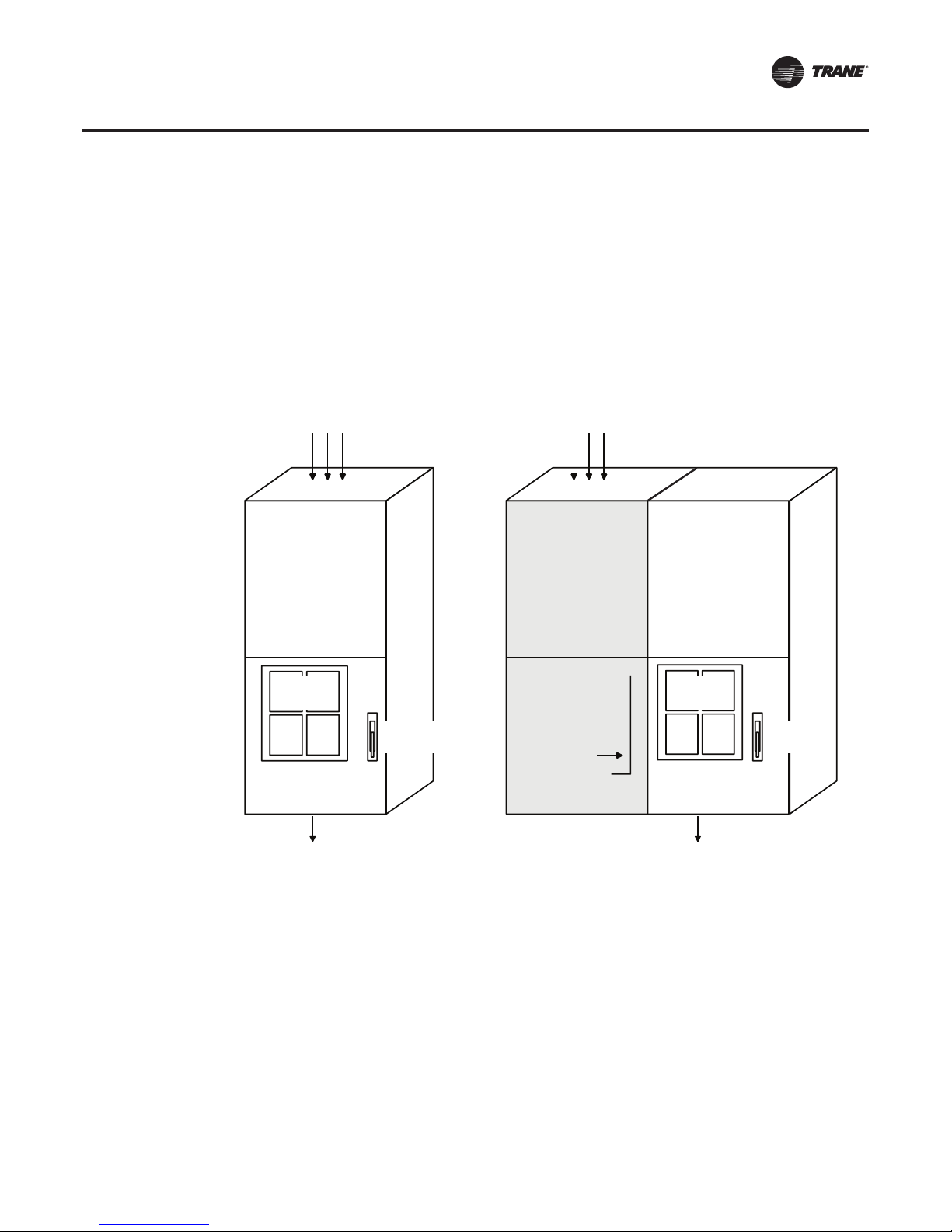

Typical dimensions for remote-mounted primary reactor starters are shown in Figure 28, p. 37.

Unit-mounted primary reactor starter dimensions are shown in Figure 29, p. 37. Always consult the

submittal drawings for as-built dimensions.

36 CTV-PRB004-EN

Page 37

Medium-Voltage StarterTypes (2,300–6,600 Volts)

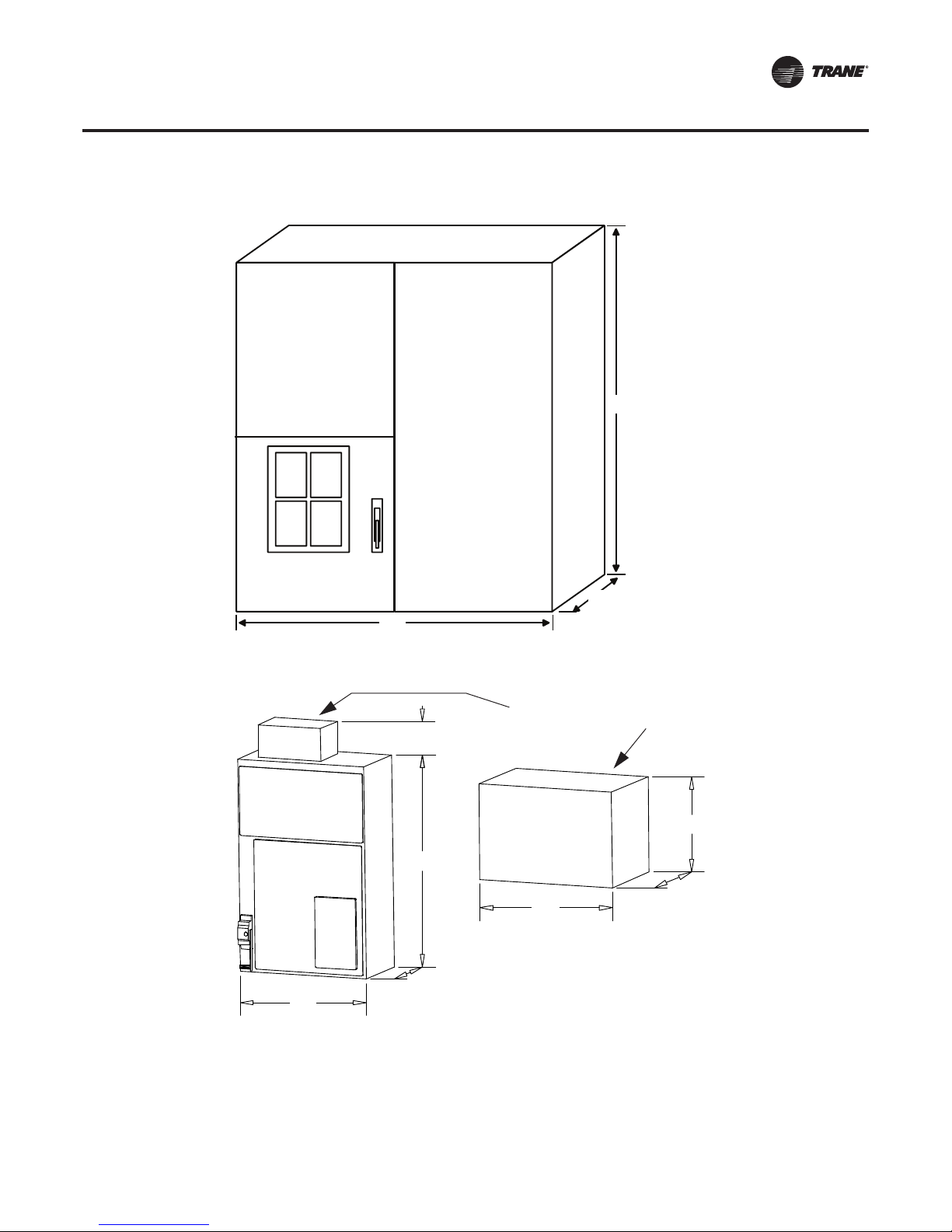

Figure 28. Remote-mounted, reduced-voltage starter dimensions

80"

30"

72"

Figure 29. Reduced-voltage, unit-mounted starter dimensions

Top Hat

9.13"

60"

40"

20"

38"

Reduced-Voltage

Section (mounted

on the condenser)

27"

26.2"

CTV-PRB004-EN 37

Page 38

Medium-Voltage StarterTypes (2,300–6,600 Volts)

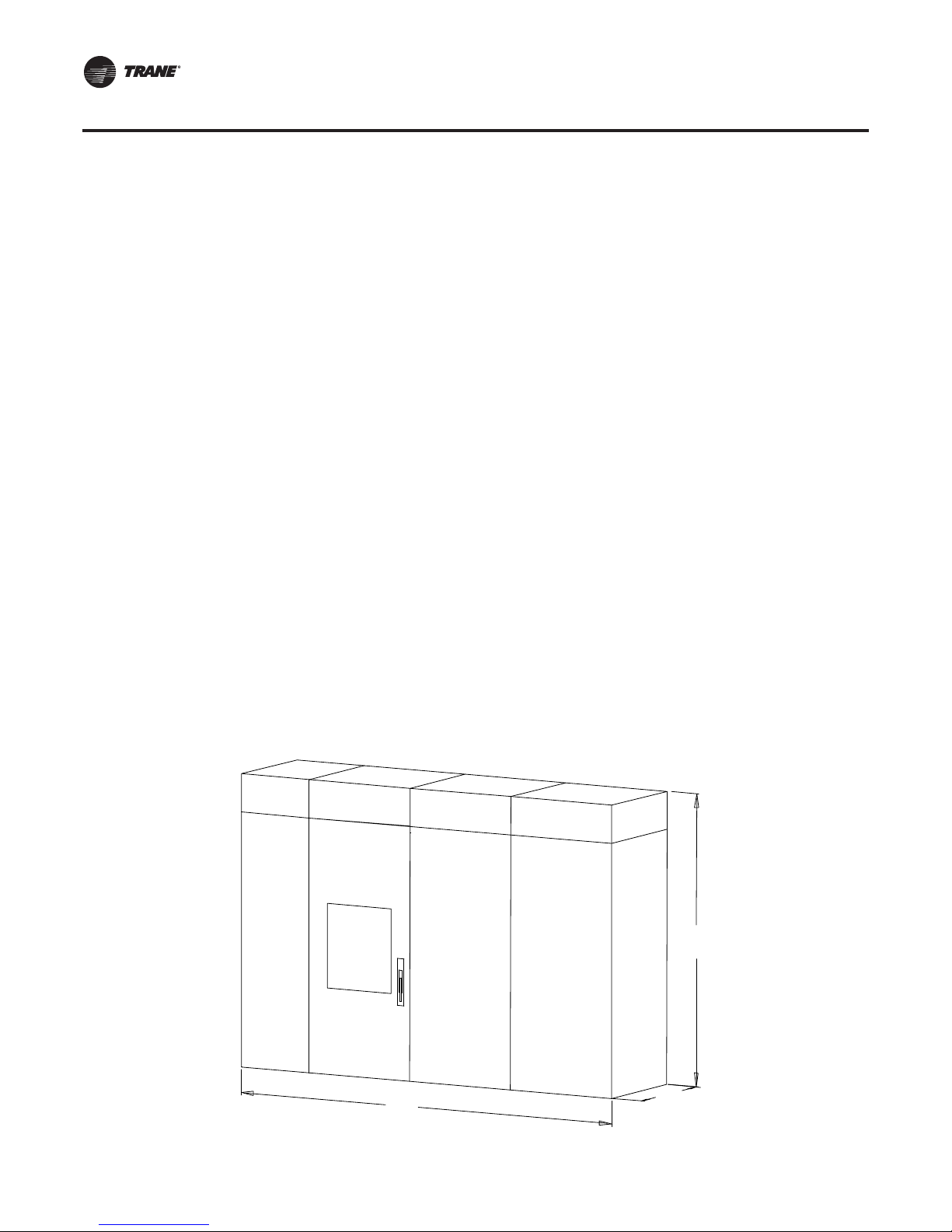

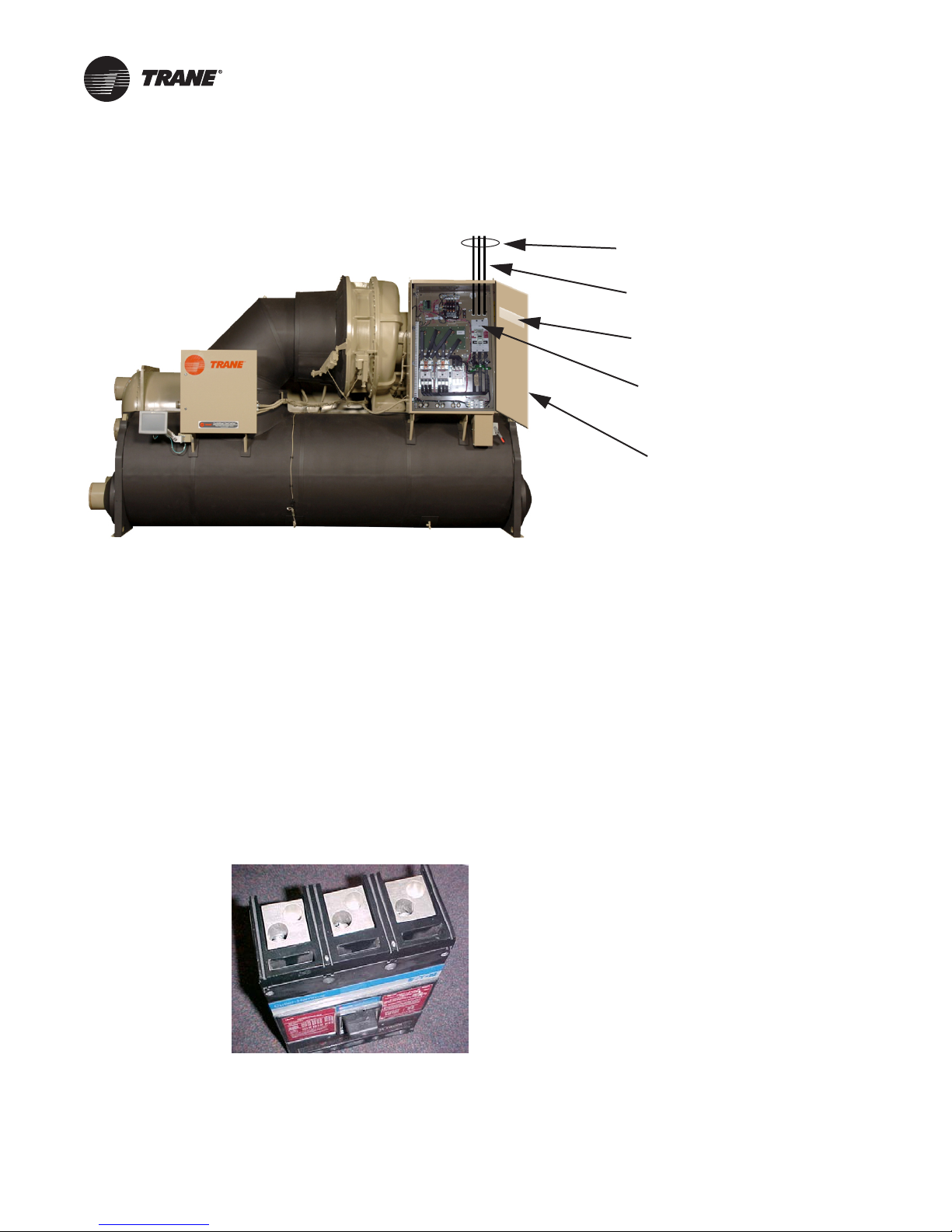

Figure 30. CenTraVac with a reduced-voltage autotransformer starter (CH530 unit controller)

Medium Voltage—Autotransformer (2.3–6.6 kV)

Autotransformer Starter (2,300–6,600 volts)

Another medium-voltage starter type is the autotransformer.To illustrate a typical starting

sequence using a generic (non-Trane) schematic, refer to Figure 31, p. 39 and the starting sequence

below.

Starting sequence

1. A “start” signal from the chiller controller energizes the pilot relay (PR).

2. The pilot relay contacts close to energize the shorting contactor (S).

3. The S contacts close to complete the autotransformer circuit.

4. An S interlock closes to energize the start contactor (1M).

5. The 1M contacts close to connect the compressor motor to the line with the motor in series with

autotransformer.

the

6. A time-delay relay or current-monitoring device initiates transition by energizing the transition

relay (T).

. TheT contacts open to de-energize the S contactor.

7

38 CTV-PRB004-EN

Page 39

Medium-Voltage StarterTypes (2,300–6,600 Volts)

8. The S contacts open to open the autotransformer circuit.

9. The autotransformer is now connected as a series reactor with the motor.

10. Now, a secondT interlock and a second S interlock both close to energize the run contactor (2M).

11. The 2M contacts close to bypass the transformer and connect the compressor motor directly

the line.

to

Figure 31. Simplified autotransformer wiring diagram

LINE

VOLTAGE

AUTO-TRANSFORMER

1M

1M

1M

F

CPT

F

START-

STOP

2M

T

PR

S

1M

TRANSITION

S

T

2M

OL

80%

S

S

100%

OL

2M

OL

50%

65%

PR

S

1M

T

2M

Standard features

• Control-power transformer

• Primary and secondary current transformers (CTs)

• Potential transformers (PTs)

• Grounding provisions

• Bolted line-power connections

• Bolted load-side connections for remote starters

• Standard motor protection

MOTOR

Environmental specification

• Designed, developed, and tested in accordance with UL 347

• NEMA 1 enclosure as standard

• Operation from sea level to 6,000 ft (1,829 m)

• Operating ambient temperature range 32°F to 104°F (0°C to 40°C)

• Relative humidity, non-condensing 5% to 95%

• Non-operating ambient temperature range -40°F to 158°F (-40°C to 70°C)

• Voltage utilization range ±10%

CTV-PRB004-EN 39

Page 40

Medium-Voltage StarterTypes (2,300–6,600 Volts)

Dimensions

Typical dimensions for both unit-mounted and remote-mounted autotransformer starters are the

same as the primary reactor starters shown in Figure 28, p. 37 and Figure 29, p. 37. A chiller with

a unit-mounted autotransformer starter is pictured in Figure 30, p. 38. Always consult the submittal

drawings for as-built dimensions.

Solid state medium-voltage starters

If you look at the medium-voltage chiller industry, there are three primary electro-mechanical

starter types commonly used: 1) Full Voltage (X-Line), 2) Primary Reactor, and 3) AutoTransformer.

Of these, X-Line and Primary Reactor make up a majority of the business.The balance is in

AutoTransformer and some solid state. Cost increases as you move from X-Line to

AutoTransformer, as does the relative complexity, and size.These starters are considered simple

to begin with in comparison to solid state starters; however, we always want to use the simplest

design if the performance (inrush level) meets the requirements of the application.This is why the

X-Line type is often used at this voltage, because the amps are generally low to begin with based

on the voltage class (i.e., 4,160 volts). Trane has shipped thousands of chillers and starters with

these electromechanical starter types. We know of no better way to offer the highest reliability,

lowest inrush, and still meet the 30-year life expectancy.

Over the years solid state starters have been available, however when the pros and cons are

evaluated, a traditional electro-mechanical is typically the best choice. Many claim that the solid

state is a “soft starter.” What does this really mean? For most, this means a ramped inrush profile

with no transients; however, because we are dealing with large induction motors, the ramp-up is