Trane Duplex Water-Cooled Hermetic CenTraVac Installation Manual

Installation

Duplex Water-Cooled

™

Hermetic CenTraVac

CH530 Controller

With

Cooling Only

Direct Drive with CH530 Control Panel

X39640669020

CDHF-SVN01B-EN

Warnings and

Cautions

Warnings and Cautions

Notice that warnings and cautions

appear at appropriate intervals

throughout this manual. Warnings

are provided to alert installing

contractors to potential hazards that

could result in personal injury or

death, while cautions are designed

to alert personnel to conditions that

could result in equipment damage.

Your personal safety and the proper

operation of this machine depend

upon the strict observance of these

precautions.

NOTICE:

Warnings and Cautions appear at appropriate sections throughout this manual.

Read these carefully.

WARNING – Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION – Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

CAUTION – Indicates a situation that may result in equipment or property-damage-only accidents.

© 2005 American Standard Inc. All rights reserved. CDHF-SVN01B-EN

Contents

Warnings and Cautions

General Information

Water Piping

Vent Line Piping

Insulation

Electrical Information

Trane Supplied Starter

Customer Supplied Starter

Line Power Supply

PFCC

PFCC and Unit Mounted Starters

Remote Starter

2

4

25

35

41

43

44

45

47

48

50

51

CDHF-SVN01B-EN

Starter to UCP Control Wiring

Control Circuit Wiring

System Control Wiring

Wiring Diagrams

53

54

56

59

3

General Information

About this Manual

Original date of manual:

This manual contains information

regarding installation of Models

CDHF 60 Hz and CDHG 50 Hz chillers

equipped with Tracer CH530

controller. Reference is made to the

CDHF. All installation procedures

described for the CDHF apply also to

the CDHG. By carefully reviewing the

information in this manual and

following the instructions given

along with the submittal package

provided for the unit will assure that

the chiller is installed correctly.

Product Description Block

Trane 60 Hz. Model CDHF hermetic

CenTraVac

product definition and selection

system (PDS). Each unit is defined by

the product description block which

appears on the unit nameplate. An

explanation of the PDS product code

is provided in the unit operation and

maintenance literature.

™

units are defined by the

4

CDHF-SVN01B-EN

General Information

Commonly Used Acronyms

ASME = American Society of

Mechanical Engineers

ASHRAE = American Society of

Heating, Refrigerant and Air

Conditioning Engineers

BAS = Building Automation System

LBU = La Crosse Business Unit

CABS = Auxiliary Condenser TubeBundle Size

CDBS = Condenser Bundle Size

CDSZ = Condenser Shell Size

CWR = Chilled Water Reset

DTFL = Delta-T at Full Load (i.e., the

difference between entering and

leaving chilled water temperatures at

design load)

EVBS = Evaporator Bundle Size

EVSZ = Evaporator Shell Size

GPM = Gallons-per-Minute

HVAC = Heating, Ventilating, and Air

Conditioning

IE = Internally Enhanced Tubes

IPC = Interprocessor Communication

PFCC = Power Factor Correction

Capacitor

PSID = Pounds-per-Square-Inch

(differential pressure)

PSIG = Pounds-per-Square-Inch

(gauge pressure)

UCP = Chiller Control Panel

CH530 = Tracer CH530 Chiller

Controller

Warnings and Cautions

Notice that WARNINGS and

CAUTIONS appear at appropriate

intervals throughout this manual.

WARNINGS are provided to alert

installing contractors to potential

hazards that could result in personal

injury or death, while CAUTIONS are

designed to alert personnel to

conditions that could result in

equipment damage.

Your personal safety and the proper

installation of this machine depend

upon the strict observance of these

precautions.

Unit Nameplate

The CDHF unit nameplate is located

on the left side of the left hand unit

control panel (UCP). A typical unit

nameplate is illustrated in Figure 1.

The following information is

provided on the CDHF unit

nameplate.

- Unit model and size descriptor

- Unit serial number

- Unit electrical requirements

- Correct operating charge and type

of refrigerant.

- Unit test pressures and maximum

operating pressures

- Unit Installation and Operation and

Maintenance manuals

- Product description block (identifies

all unit components and unit

“design sequence” used to order

literature and make other inquiries

about the unit).

CDHF-SVN01B-EN

Metric Conversion

The following conversions apply for

tables and charts in this manual,

In. x 2.54 = cm

Ft. x 30.48 = cm.

Lb. x .453 = kg.

5

General Information

Figure 1 – Information from a Typical CDHF Unit Nameplate

MODEL: CDHF2000 DATE OF MFG (DD/MM/YY): @TODAY05

MODEL NO:

CDHF2000KR0TA2802745B0A106B0A1CFFRR10W4C0010330001S

SERIAL NO: S.O. NO: SAMPLE

RATED VOLTAGE: 4160 VOLTS 60 HZ 3 PH

VOLTAGE UTILIZATION RANGE: 3744-4576 VAC

LH CIRCUIT RH CIRCUIT

MINIMUM CIRCUIT AMPACITY: 96 AMPS 103 AMPS

MAXIMUM OVERCURRENT

PROTECTIVE DEVICE: 150 AMPS 175 AMPS

COMPRESSOR MOTOR MAX

VOLTS-AC HZ PH RLA KW LRAY

LH CIRCUIT 4160 60 3 75 480 400

RH CIRCUIT 4160 60 3 82 523 473

VOLT HZ PH

OIL TANK HEATER (LH&RH): 115 60 1 750 WATTS

CONTROL CIRCUIT (LH&RH): 115 60 1 4000 VA MAX

CARBON TANK HEATER (LH&RH):115 60 1 1.7 RLA

PUMPOUT COMPRESSOR(LH&RH): 115 60/50 1 1.55 RLA

PURGE COMP MTR(LH&RH): 115/110 60/50 1 8RLA 34.6LRA

WHEN MOTOR CONTROLLER PROVIDED BY OTHERS

TRANE ENGINEERING SPEC. S6516-0513 APPLIES

REFRIGERANT SYSTEM LH RH

FIELD CHARGED WITH: 1850 1850 LBS. OF R-123

ACTUALLY CHARGED WITH: LBS. OF R-123

MAXIMUM WORKING PRESSURE: 15 15 PSIG HIGH SIDE

MAXIMUM WORKING PRESSURE: 15 15 PSIG LOW SIDE

FACTORY TEST PRESSURE:

HIGH SIDE 45 PSIG LOW SIDE 45 PSIG

FIELD LEAK TEST PRESSURE 8 PSIG MAX.

TESTED AT PSIG

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING

U.S. PATENTS: 4232533 4686834 4689967 4715190

4751653 4800732 5031410 5056032 5058031 5355691

5434738 5537830 5553997 5563489 5600960 5675978

5836382 5848538 6065297 6098422 6250101

SERVICE LITERATURE

INSTALLATION MANUAL: CDHF-SVN01A-EN

OPERATION/MAINTENANCE MANUAL: CDHF-SVU01A-EN

PRODUCT DESCRIPTION:

TVSQ 1 PTON 1975 VTR1 165 VTR2 165

CTM1 75 CTM2 100 MAC1 6 MAC2 6

MODL CDHF DSEQ R0 NTON 2000 VOLT 4160

HRTZ 60 CPM1 512 CPD1 280 CPM2 588

CPD2 274 EVSZ 210D EVBS 1850 EVTM TECU

EVTH 35 EFLD WATE EVWT MAR EVWP 1

EVWC STD EVPR 150 EVCO VICT EVWA RRLR

CDSZ 210D CDBS 1900 CDTM TECU CDTH 35

CFLD WATE CDWT MAR CDWP 1 CDWC STD

CDPR 150 CDCO VICT CDWA LFRF ORC1 1265

ORC2 1265 AGLT UL TEST CWSP TTOL SPCL

WCNM BNMP CNIF CH53 OPST YES WPSR WFC

TRMM TRM4 EPRO YES CDRP YES SPKG DOM

ASCL OUTS APTY STD SRT1 CXL SRT2 CXL

SOPT 3RTD GENR NO

6

CDHF-SVN01B-EN

General Information

Responsibilities of Installing

Contractors

For your convenience, a summary of

the contractor responsibilities

typically associated with the chiller

installation process is provided

below. Table 1 further categorizes

these responsibilities by

differentiating between Tranesupplied and field-supplied and field

installed components.

Refer to the Installation section of

this manual for more detailed

instructions.

• Locate and maintain the loose

parts, i.e. isolators, bulb wells,

temperature sensors, flow sensors

or other factory-ordered field

installed options, for installation as

required. Loose parts are located in

the starter panel on units with

factory-installed unit-mounted

starters or in the motor terminal

box for units with remote-mounted

starters.

• Install unit on a foundation with flat

support surfaces level within 1/16”,

and of sufficient strength to

support concentrated loading.

Place manufacturer-supplied

isolation pad assemblies under

unit. (Use spring isolators for upper

floor installations).

• Install unit per applicable Trane

installation manual.

• Complete all water piping and

electrical connections.

Note: Field-piping must be arranged

and supported to avoid stress on the

equipment. It is strongly

recommended that the piping

contractor refrain from piping closer

than 3’-0” minimum to the

equipment. This will allow for proper

fit-up upon arrival of the unit at the

jobsite. Any adjustment that is

necessary can be made to the piping

at that time.

• Where specified, supply and install

valves in water piping upstream

and downstream of evaporator and

condenser water boxes to isolate

shells for maintenance, and to

balance/trim system.

• Supply and install flow switches (or

equivalent devices) in both chilled

water and condenser water piping.

Interlock each switch with proper

pump starter to ensure unit can

only operate when water flow is

established.

• Supply and install taps for

thermometers and pressure

gauges in water piping adjacent to

inlet and outlet connections of both

evaporator and condenser.

• Supply and install drain valves on

each water box.

• Supply and install vent cocks on

each water box.

• Where specified, supply and install

strainers ahead of all pumps and

automatic modulating valves.

• Supply and install pressure relief

piping from pressure-relief rupture

disc to atmosphere.

• If necessary, supply sufficient

Refrigerant-HCFC-22 (maximum of

1 lb. per machine) and dry nitrogen

(8 psig per machine) for pressure

testing under manufacturer’s

supervision.

• Start unit under supervision of a

qualified service technician.

• Where specified, supply and

insulate evaporator and any other

portions of machine as required to

prevent sweating under normal

operating conditions.

• Unit-Mounted Starters Only,

remove top of starter panel and cut

access area for line-side wiring;

front left quadrant of top provides

recommended access to starter

lugs.

• Supply and install wire terminal

lugs to starter.

• Unit-Mounted Starters Only,

Supply and install field wiring to

line-side lugs of starter.

• Supply and install a Refrigerant

Monitor per ASHRAE 15

specifications. Reference the

compliance to ASHRAE Standard

15 as shown on the “Model

CenTraVac

Request for Serviceman”.

To obtain a copy of “Model

CenTraVac

for Serviceman” (Form 1-27.08-6)

order from your local Trane office.

™

Checksheet and

™

Checksheet and Request

CDHF-SVN01B-EN

7

General Information

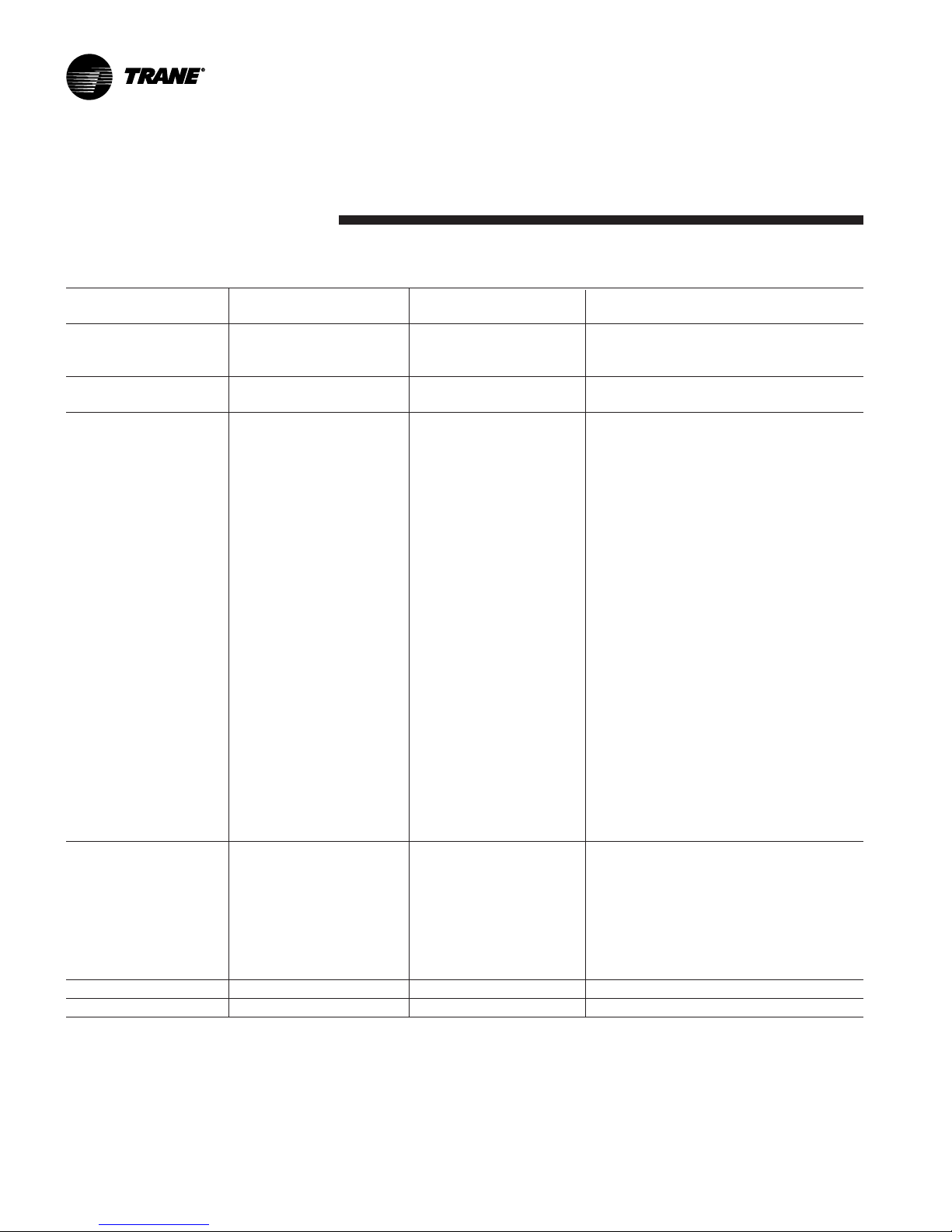

Table 1 – Installation Requirements

Type of Trane-Supplied Trane-Supplied Field-Supplied

Requirement Trane-Installed Field-Installed Field-Installed

Rigging A. Safety chains

B. Clevis connectors

C. Lifting beam

Isolation A. Isolation pads or A. Isolation pads or spring isolators

spring isolators

Electrical A. Circuit breakers or A. Jumper bars A. Circuit breakers or fusible

fusible disconnects B. Temperature sensor disconnects (optional)

(optional) (optional outdoor air) B. Remote-mounted starter

B. Unit-mounted C. Flow switches (may C. PFCCs (Remote-mounted

starter (optional) be field supplied) starter option only)

C. PFCCs (optional) D. Terminal lugs

E. Ground connection(s)

F. Jumper bars

G. BAS wiring (optional)

H. IPC wiring (remote-

mounted starters only

I. Control voltage wiring

(remote-mounted starters only)

J. Oil pump interlock wiring

(remote-mounted

starters only)

K. High condenser pressure

interlock wiring

(remote-mounted starters only).

L. Chilled water pump contactor

and wiring

M.Condenser water pump

contactor and wiring

N. Option relays and wiring

(See Table 14 & 16)

Water Piping A. Flow switches (May A. Thermometers

be field supplied) B. Water flow pressure gauges

C. Isolation and balancing valves

water piping

D. Vents and drain valves

(1 each per class)

E. Pressure-relief valves

(for water boxes as required)

Rupture Disc A. Rupture disc assy A. Vent line and flexible connector

Insulation A. Insulation (Optional) A. Insulation

8

CDHF-SVN01B-EN

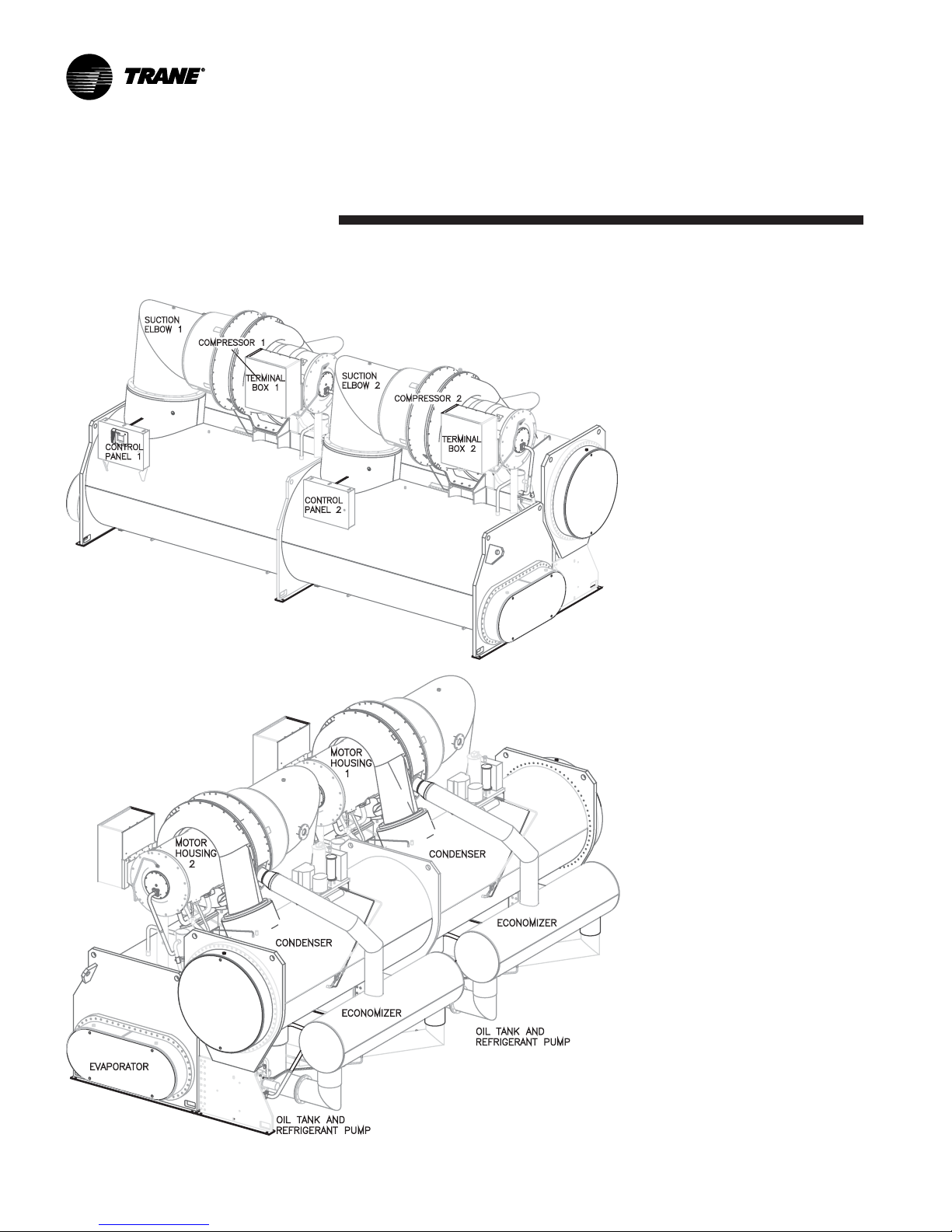

General Information

Unit Shipment

Each chiller ships from the factory as

a hermetically assembled package; it

is factory piped, wired and tested. All

openings are covered or plugged to

prevent contamination during

shipment and handling.

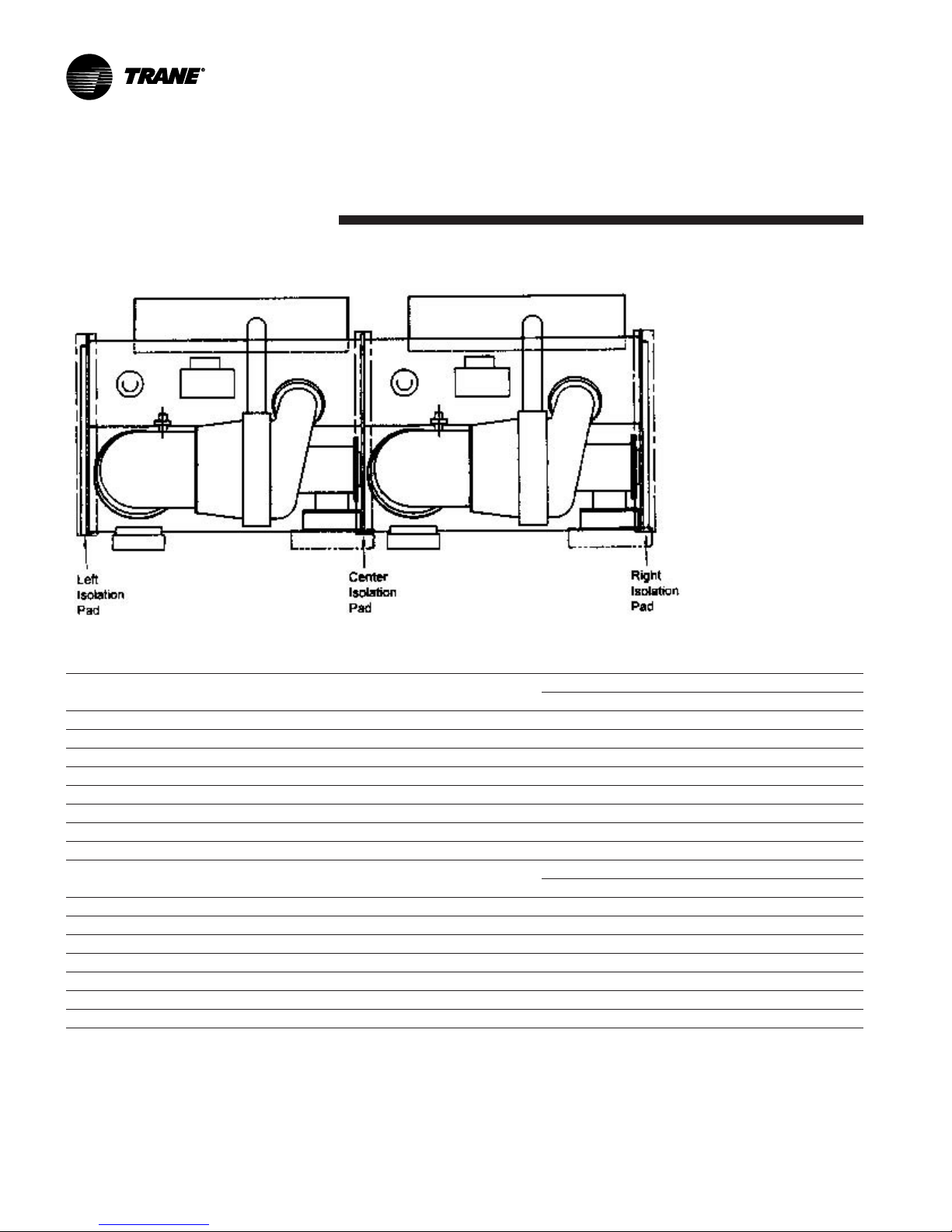

See Figure 2 for an illustration of a

typical unit and its components. As

soon as the unit arrives at the job

site, inspect it thoroughly for

damage and material shortages. In

addition:

1. Verify the chiller’s hermetic

integrity by checking the

evaporator pressure for an

indication of holding charge

pressure.

Note: Since there are two refrigerant

circuits both must be checked.

To prevent damaging moisture from

entering the unit and causing

corrosion, each chiller is pressurized

with dry nitrogen before shipment.

Note: The holding charge should

register approximately 5 psig (at sea

level) on the gauge. If the charge has

escaped, contact your local Trane

sales office for instructions.

2. Check the oil sump sight glasses

to verify that the sump was

factory-charged with 9 gallons of

oil. If no oil level is visible, contact

your local Trane sales office.

3. Compare the unit nameplate data

(including electrical characteristics)

with the corresponding ordering

and shipping information to verify

that the correct unit was shipped

to the job site.

If a thorough inspection of the

chiller reveals damage or material

shortages, be sure to file these

claims with the carrier

immediately. Specify the extent

and type of damage found, and

notify the appropriate Trane sales

representative. Do not install a

damaged unit without the sales

representative’s approval!

Storage

If the chiller will be stored at the job

site for an extended period of time

before it is installed, exercise these

precautionary measures to protect

the unit from damage:

1. Do not remove the protective

coverings factory-installed on the

control panel and compressor

inlet vane actuator for shipment.

2. Store the chiller in a dry vibration

free and secure area. If factory

insulated, protect chiller from

prolonged exposure to sunlight.

CAUTION

Insulation Damage!

To prevent damage to the factoryinstalled insulation, do not allow

excessive exposure to sunlight.

3. Periodically check the condenser

and evaporator pressure to verify

that the 5 psig dry nitrogen at 72°F

ambient holding charge is still in

the chiller. If this charge escapes,

contact a qualified service

organization and the Trane sales

engineer that handled the order.

Note: The storage range for the

microcomputer-based devices in the

unit control panel is -40°F to 158°F

(-40°C to 70°C).

CDHF-SVN01B-EN

9

Figure 2 – Typical CDHF Chiller

General Information

10

CDHF-SVN01B-EN

General Information

Recommended Unit

Clearances

Adequate clearance around and

above the chiller is required to allow

sufficient access for service and

maintenance operations.

Figure 3 illustrates the

recommended clearances for units

with and without options. Figure 4

shows tube bundle locations. Notice

that, in each instance, the minimum

vertical clearance above the chiller is

3-feet.

In addition, be sure to provide at

least 3-feet of working space in front

of the unit control panel to satisfy the

National Electrical Code, and/or local

codes.

Important! Do not install piping or

conduit above the compressor

motor assembly or behind the

suction elbow!

Note: Specific unit clearance

requirements are also indicated in

the submittal package provided for

your unit.

Operating Environment

Besides assuring that the site

selected for chiller installation

provides the necessary clearances,

consider the equipment’s operating

environment.

To assure that electrical components

operate properly, do not locate the

chiller in an area exposed to dust,

dirt, corrosive fumes, or excessive

heat and humidity. Note that the

maximum ambient temperature for

chiller operation is 95 to 100°F (35° 38° C).

CAUTION

Equipment Failure!

CDHF operation at ambient

temperatures exceeding 100°F

(38°C) can fatigue the unit’s rupture

disc, causing it to break at a reduced

refrigerant pressure (i.e., <15 psig).

Starter component damage can also

occur because of the panel’s inability

to dissipate heat adequately.

If any of these adverse operating

conditions are present, take

whatever action is necessary to

improve the equipment room

environment.

Foundation Requirements

Provide rigid, non-warping

mounting pads or a concrete

foundation as a mounting surface for

the chiller. Ensure that the base is of

sufficient strength and mass to

properly support the chiller at its full

operating weight (i.e., including

completed piping, and full operating

charges of refrigerant, oil and water).

For your convenience, a summary of

standard unit shipping and operating

weights is provided in Table 2.

Notice that the floor loading for all

sizes of chillers is 60 pounds per

square inch.

To assure proper unit operation, the

chiller must be level within 1/16”

over its length and width when set

into place on the mounting surface.

Trane will not assume responsibility

for equipment problems resulting

from an improperly designed or

constructed foundation.

CDHF-SVN01B-EN

11

General Information

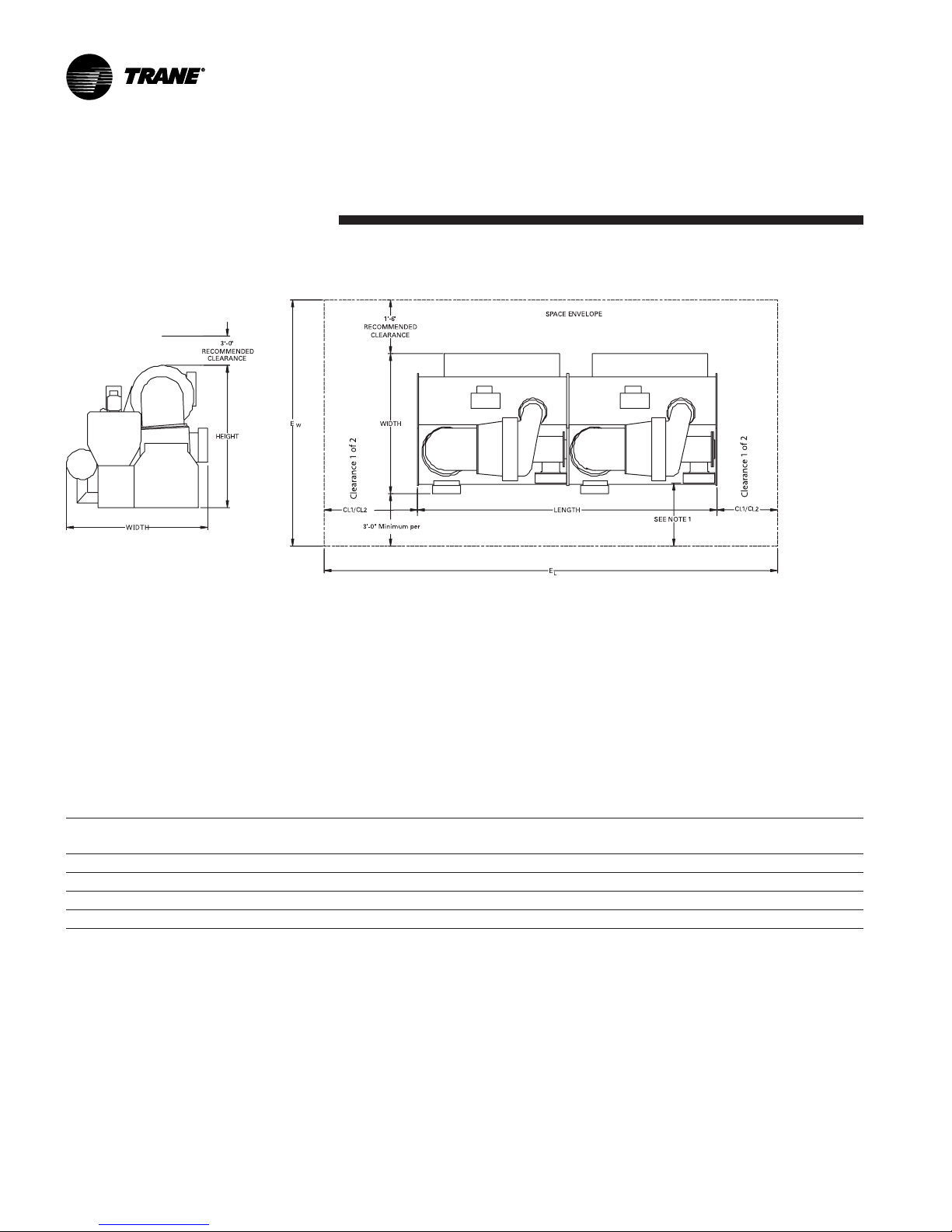

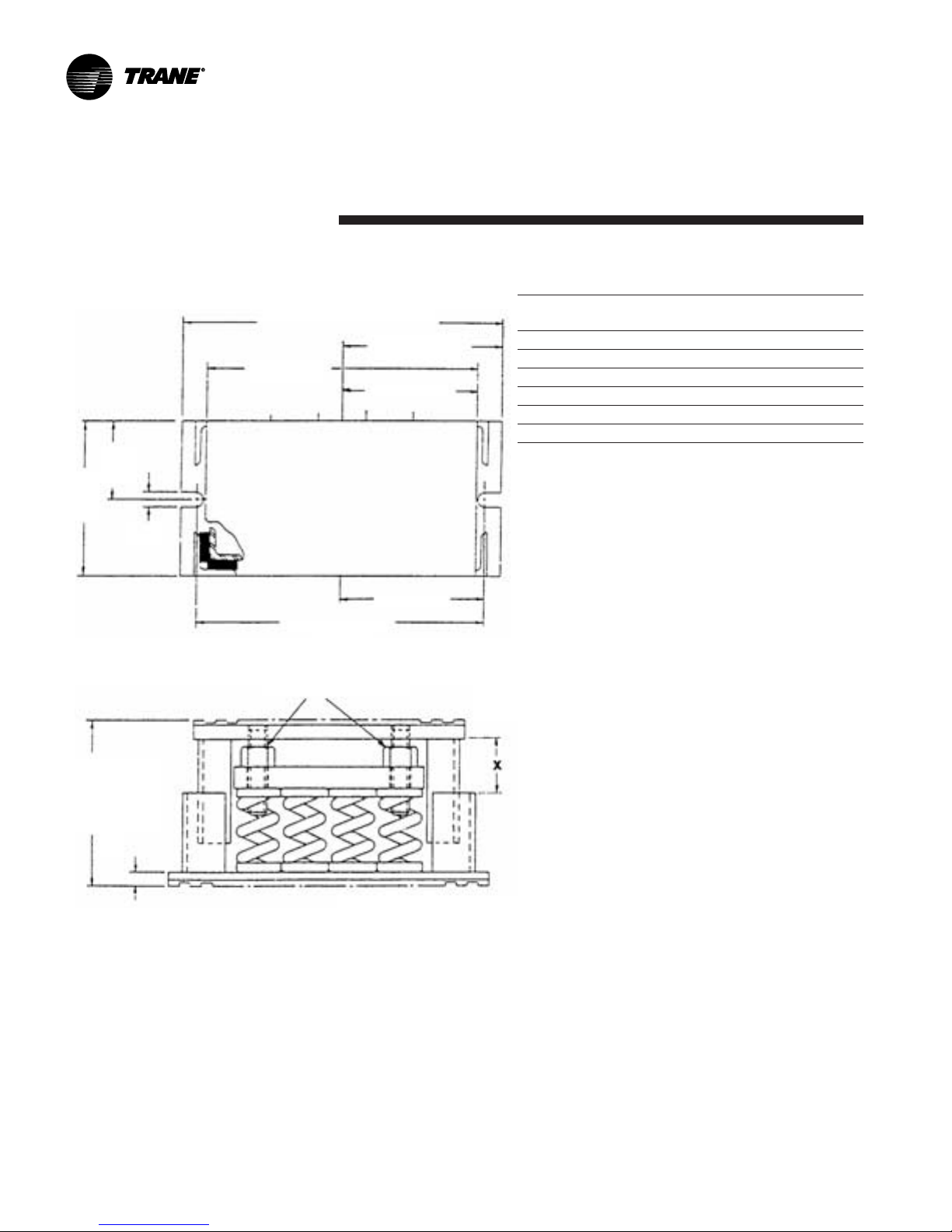

Figure 3 – Clearance Requirements for Standard CDHF

Notes:

1. Per NEC Article 110 - Unit mounted starters from 0-600V require 42" clearance; 601-2500V require 48" clearance;

2501-9000V require 60" clearance.

2. Clearance 1 can be at either end of machine and is required for tube pull clearance

Clearance 2 is always at the opposite end of machine from Clearance1 and is required for service clearance

3. Clearance requirement for evaporator tube removal does not include water box. Add water box dimension to this

figure.

UCP Clearance Requirements for Standard CDHF

CL1 CL2

Shell Width Entire Width Height Length Entire Length Clearance 1 Clearance 2

210 D 130.875 184.875 132.750 258.000 606.000 264.000 84.000

250 D 142.625 196.625 136.875 258.000 606.000 264.000 84.000

250 M 142.625 196.625 141.375 312.000 714.000 318.000 84.000

250 X 142.625 196.625 141.375 360.000 810.000 366.000 84.000

12

CDHF-SVN01B-EN

General Information

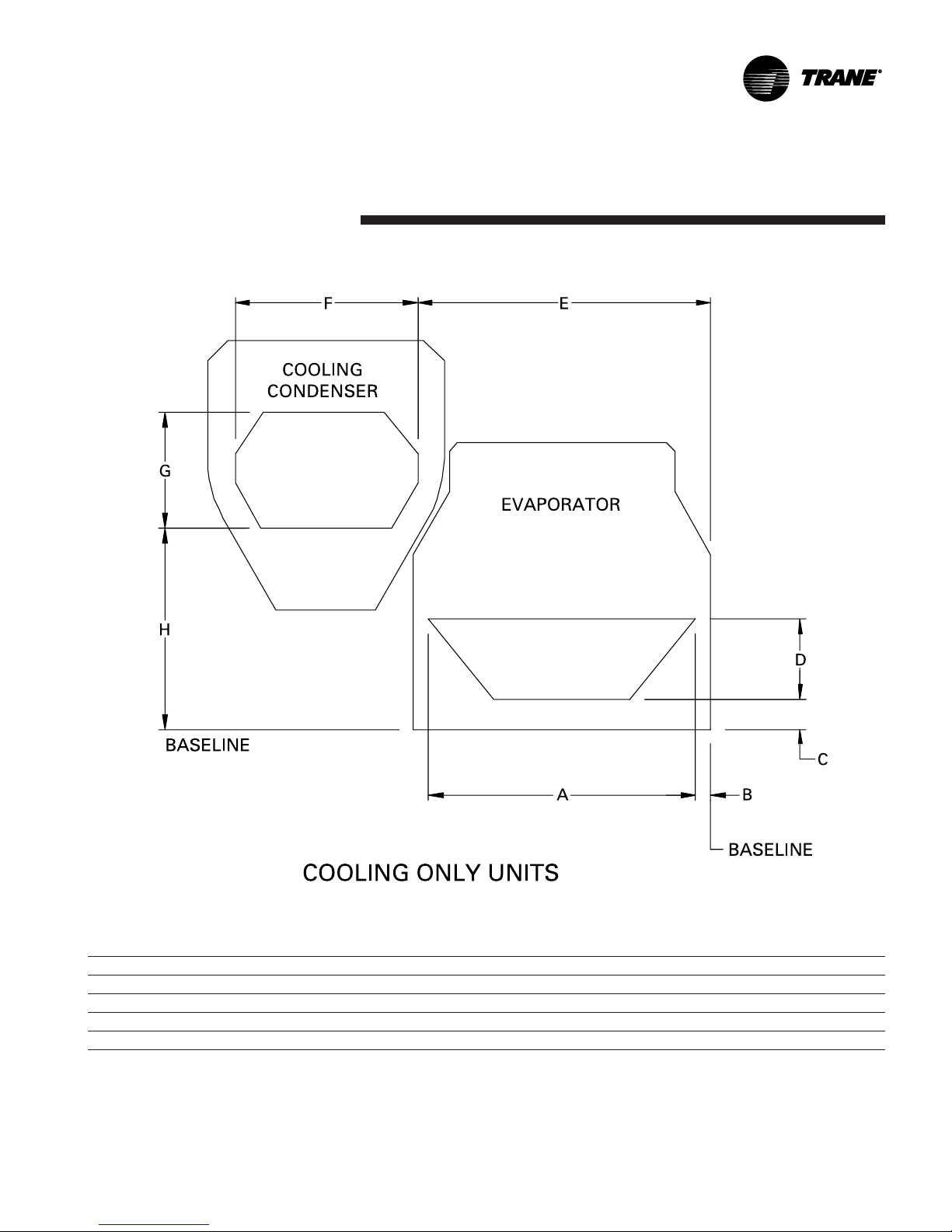

Figure 4 – Tube Bundle Locations for Model CDHF Units

Cooling Only and Free Cooling Units

EVSZ CDSZ A B C D E F G H

210 D 210 D 4’-5-7/16" 5"-3/8" 7’-9/16" 1’-4-1/4" 5’-0-1/8" 3’-5-1/4" 2’-5" 3’-10-3/16"

250 D 250 D 5’-0-3/4" 5"-1/4 6"-1/2 1’-7-1/4" 5’-8-3/4" 3’-10-5/8" 2’-4-1/8" 3’-11-5/8"

250 M 250 M 5’-0-3/4" 5"-1/4 6"-1/2 1’-7-1/4" 5’-8-3/4" 3’-10-5/8" 2’-4-1/8" 3’-11-5/8"

250 X 250 X 5’-0-3/4" 5"-1/4 6"-1/2 1’-7-1/4" 5’-8-3/4" 3’-10-5/8" 2’-4-1/8" 3’-11-5/8"

CDHF-SVN01B-EN

13

General Information

Table 2 – Typical Shipping and Operating Weights

Operating Weight Shipping Weight

TYPE NTON CPKW EVSZ CDSZ (lbs) (kg) (lbs) (kg)

CDHF 1500-2000 957 210D 210D 80171 36366 68629 31130

CDHF 2100-2500 1228 250D 250D 93186 42269 79213 35931

CDHG 1250-1750 716 210D 210D 82349 37354 70807 32118

CDHG 2150 892 210D 210D 89680 197710 78288 172595

CDHG 2150 892 250D 250D 96964 43983 82991 37645

CDHF 3000 1340 250M 250M 106659 48381 89425 40563

CDHF 3500 1340 250X 250X 114445 51912 95077 43127

Notes:

Weights shown above are accurate within +/- 3% and are based on the following

Operating weights include refrigerant, oil charge and water

Shells are with largest bundles and TECU .028 wall tubes

Compressor weight with medium voltage motor and above CPKW

Starter weights not included

Waterboxes are 1 pass, 150 psig Non-Marine

For other configurations refer to submittal package

14

CDHF-SVN01B-EN

General Information

Note: Immediately report any unit

damage incurred during handling or

installation at the job site to the

Trane sales office.

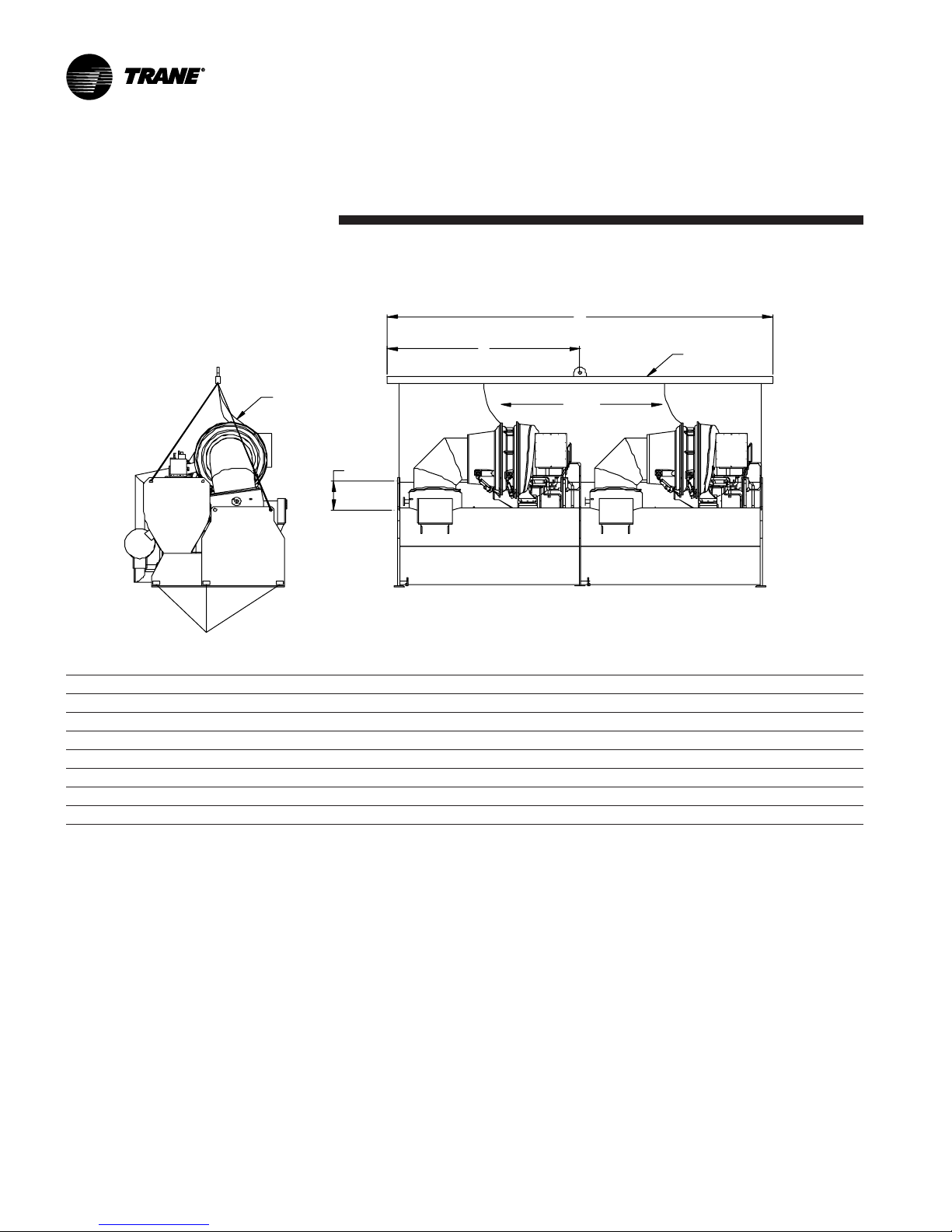

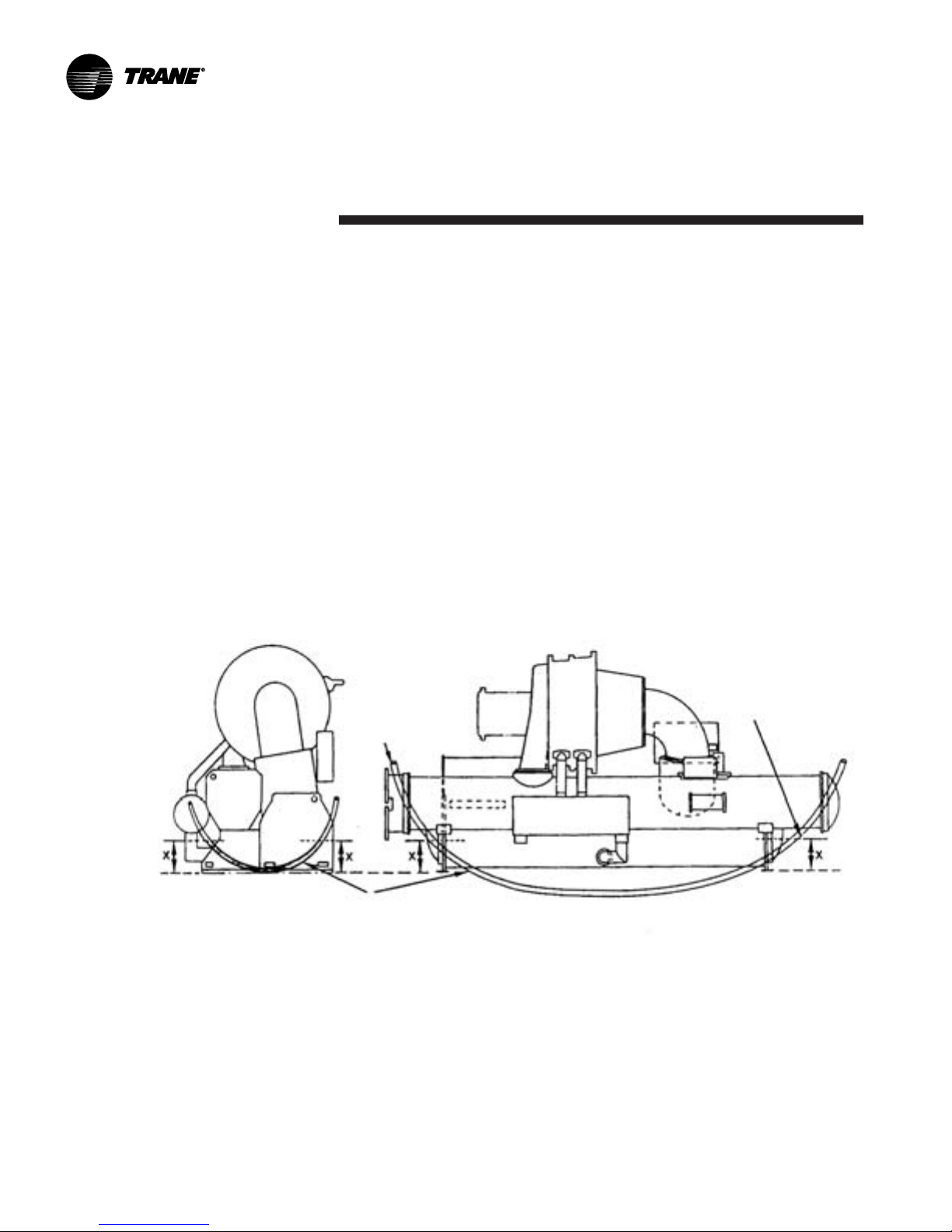

Rigging

Lifting is the recommended method

for moving chillers. Suggested lifting

arrangements for standard units are

illustrated in Figure 5.

Note that each of the cables used to

lift the unit must be capable of

supporting the entire weight of the

chiller. (See Table 2 for unit shipping

and operating weights.) Notice that

the lifting beam used to lift the unit

must be at least 23 feet long.

See Figure 5 and Table 2 for

guidance in selecting cable or sling

lengths.

WARNING

Test Lift!

Verify chiller remains horizontal.

To avoid serious injury and possible

equipment damage, lift the chiller

horizontally; use the lifting

arrangement and rigging shown in

Figure 5. Failure to lift unit as

recommended could result in death

or serious injury or lead to

equipment damage.

To lift the chiller properly, insert

clevis connections at the points

indicated in Figure 5; a 2-1/2”

diameter lifting hole is provided at

each of these points. Next, attach the

lifting cables or slings.

Once the lifting cables are in place,

attach a safety cable or sling

between the first-stage casting of the

compressor and the lifting beam. To

do this, remove a retaining bolt from

the compressor first-stage casting

and replace it with an eyebolt, or

swivel clevis.

Note: There should not be tension

on this safety cable; it is used only to

prevent the unit from rolling during

the lift.

When the lift is completed, detach

the clevis connections and safety

chain, then remove the eyebolt that

was used to secure the safety chain

to the compressor, and reinstall the

retaining bolt in its place. If the chiller

cannot be moved using the

conventional rigging method just

described, consider these points.

1. If job site conditions require

rigging of the chiller at an angle

greater than 45° from horizontal

(end-to-end), dowel-pin the compressor and remove it from the

unit. Be sure to contact a qualified

service organization for specific

rigging instructions.

2. When lifting the chiller is either

impractical or undesirable, attach

cables or chains to the jacking

slots shown in Figure 5; then push

or pull the unit across a smooth

surface. Should the chiller be on a

shipping skid, it is not necessary to

remove the shipping skid from the

chiller before moving it into place.

CAUTION

Equipment Damage!

To prevent possible equipment

damage, do not use a fork lift to

move the chiller!

CAUTION

Compressor Alignment!

Lifting the compressor/motor

assembly from the shells without

factory-installed doweling in the

compressor casting flanges may

result in misalignment of the

compressor castings.

3. Position isolator pads (or spring

isolators) beneath the chiller feet;

see “Unit Isolation” section for

instructions.

4. Once the isolators are in place,

lower the chiller; again, work from

end to end in small increments to

maintain stability.

CDHF-SVN01B-EN

CAUTION

Oil Loss!

To prevent oil migration out of the

oil tank during lifting procedures,

remove the oil from the oil tank if

the unit will be lifted at any angle

greater than 15° from horizontal

end-to-end. If oil is allowed to run

out of the oil tank into other areas of

the chiller, it will be extremely

difficult to return the oil to the oil

tank even during operation.

15

General Information

Figure 5 – Recommended Lifting Arrangements for CDHF

Y

B

Jacking

A

Points

Safety

C

Chain

X

Safety

Chain

H

LIFTING

BEAM

TYPE NTON EVSZ CDSZ X Y H

CDHF 1500-2000 210D 210D 143 in. 23 ft 24.75 in

CDHF 2100-2500 250D 250D 143 in. 23 ft 24.75 in

CDHG 1250-1750 210D 210D 143 in. 23 ft 24.75 in

CDHG 2150 210D 210D 143 in. 23 ft 24.75 in

CDHG 2150 250D 250D 143 in. 23 ft 24.75 in

CDHF 3000 250M 250M 172 in. 27.5 ft 24.75 in

CDHF 3500 250X 250X 199 in. 31.5 ft 24.75 in

Notes:

1. Lifting chains (or cables) are not the same length between point A and B, or between points A and C. Adjust as

necessary for an even lift.

2. Lifting holes provided on chillers to attach chains are 2 1/2 inch in diameter.

3. Attach safety chain (or cable) as shown, and without tension. The safety chain is not used for lifting, but is there to

prevent the unit from rolling.

4. Do not fork-lift the unit.

16

CDHF-SVN01B-EN

General Information

Unit Isolation

To minimize sound and vibration

transmission through the building

structure - and to assure proper

weight distribution over the

mounting surface, always install

isolation pads or spring isolators

under the chiller feet.

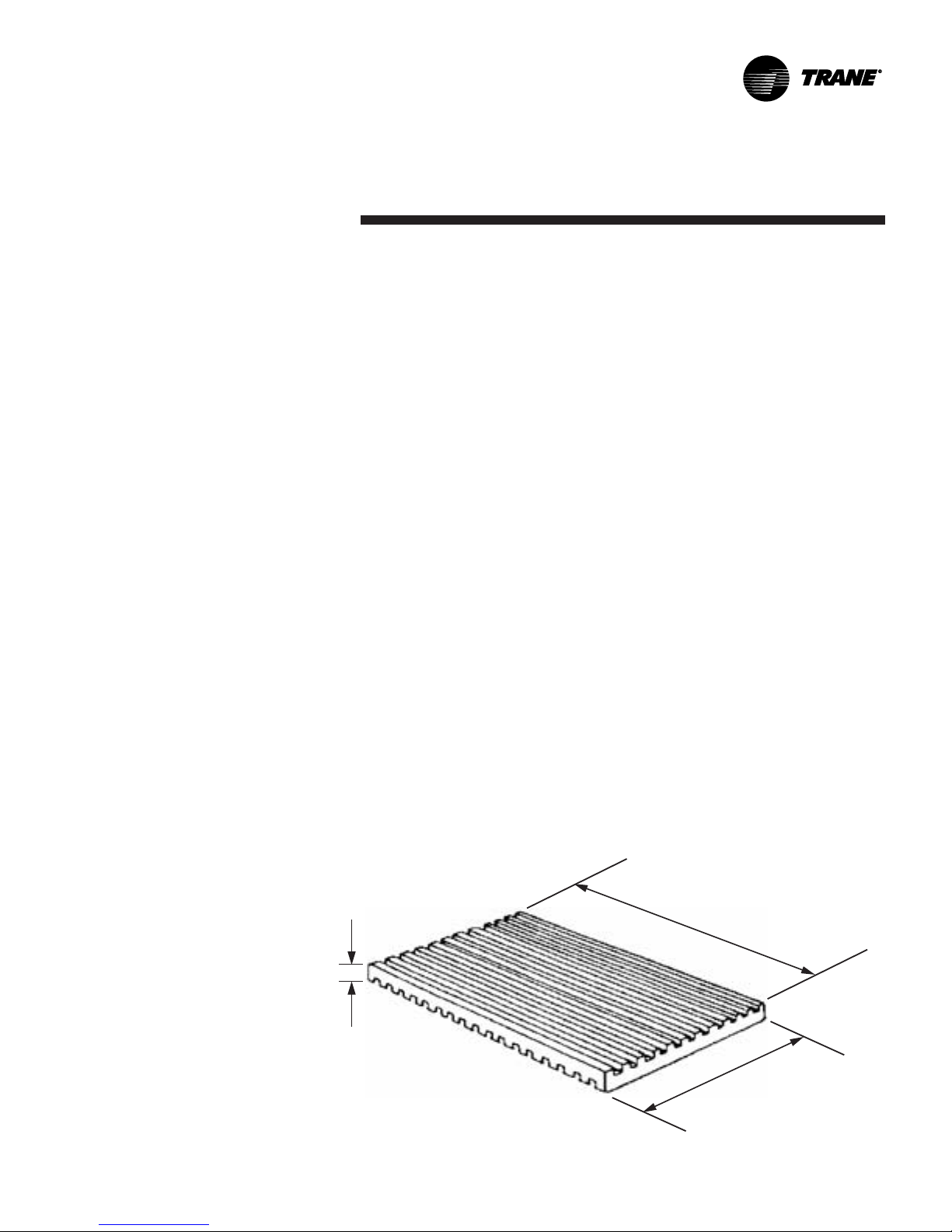

Note: Isolation pads (Figure 6) are

provided with each chiller unless

spring isolators are specified on the

sales order.

Note: The center support is

approximately 1/2" shorter (higher)

than the end supports. After unit

leveling, shim the center isolator

pads. If spring isolators are used,

shim the isolators for the center

support. See Figure 7.

Specific isolator loading data is

provided in the unit submittal

package. If necessary, contact your

local Trane sales office for further

information.

Important! When determining

placement of isolation pads or spring

isolators, remember that the control

panel side of the unit is always

designated as the unit front.

Isolation Pads

When the unit is ready for final

placement, position isolation pads

under the chiller feet as shown in

Figure 7.

Remember that the chiller must be

level within 1/16” over its length and

width after it is lowered onto the

isolation pads. In addition, all piping

connected to the chiller must be

properly isolated and supported so

that it does not place any stress on

the unit.

Spring Isolators

Spring isolators should be

considered whenever chiller

installation is planned for an upper

story location. Base isolator selection

and placement on the information

presented in Figures 8-10a. (Notice

that 3 types of spring isolators - each

with its own maximum loading

characteristics are used with CDHF

chillers).

Spring isolators typically ship

assembled and ready for installation.

To install and adjust the isolators

properly, follow the instructions

given.

Note: Do not adjust the isolators

until the chiller is piped and charged

with refrigerant and water.

1. Position the spring isolators under

the chiller as shown in Figures 8

and 9. Make sure that each isolator

is centered in relation to the tube

sheet.

Note: Spring isolators shipped with

the chiller are not identical! Be sure

to compare the data provided in the

unit submittal package and Figures 8

through 10a to determine proper

isolator placement.

2. Set the isolators on the sub-base;

shim as necessary to provide a

flat, level surface at the same

elevation for the end supports,

and approximately 1/2" higher for

the center support. Be sure to

support the full underside of the

isolator base plate; do not straddle

gaps or small shims.

[8-10 mm]

CDHF-SVN01B-EN

Figure 6 – Isolation Pad

18"

[457 mm]

5/16-3/8"

6"

[152.4 mm]

17

General Information

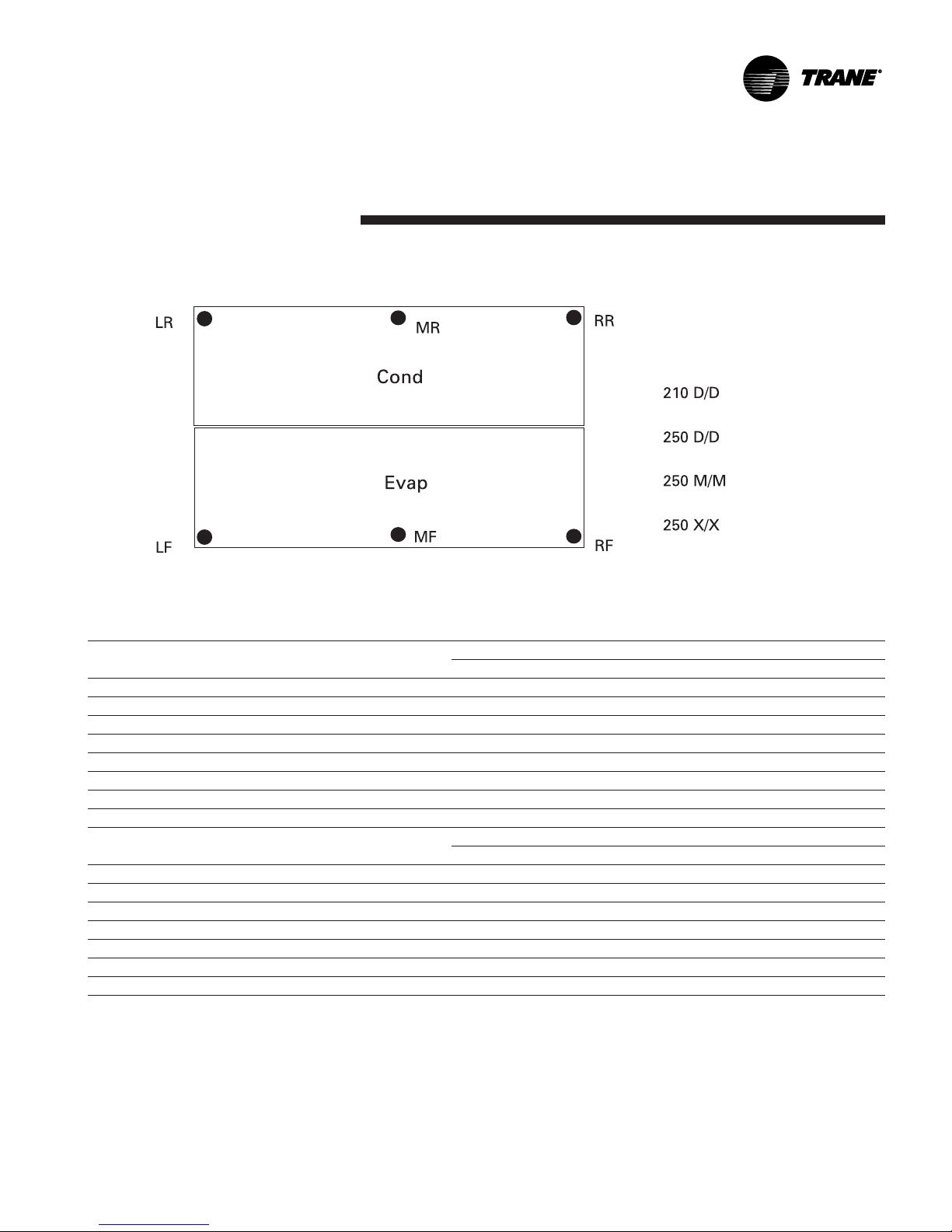

Figure 7 – Isolation Pad Placement - CDHF, CDHG

Important:

Center support is 1/2" (13mm) shorter than end supports. Requires 1/2" steel shim under pad for Center

Support at installation after leveling.

Isolation Pad Loading (lb)

TYPE NTON CPKW EVSZ CDSZ Left Pad Center Pad Right Pad

CDHF 1500-2000 957 210D 210D 25150 26718 28304

CDHF 2100-2500 1228 250D 250D 29292 31056 32838

CDHG 1250-1750 716 210D 210D 25997 27446 28907

CDHG 2150 892 210D 210D 26507 29850 33322

CDHG 2150 892 250D 250D 20680 32316 33967

CDHF 3000 1340 250M 250M 33527 35546 37586

CDHF 3500 1340 250X 250X 35975 38140 40330

TYPE NTON CPKW EVSZ CDSZ Left Pad Center Pad Right Pad

CDHF 1500-2000 957 210D 210D 11408 12119 12839

CDHF 2100-2500 1228 250D 250D 13287 14087 14895

CDHG 1250-1750 716 210D 210D 11792 12449 13112

CDHG 2150 892 210D 210D 58438 65808 73462

CDHG 2150 892 250D 250D 13916 14659 15407

CDHF 3000 1340 250M 250M 15208 16123 17049

CDHF 3500 1340 250X 250X 16318 17300 18294

Notes:

Isolator pad loading is based on the following

Operating weights include refrigerant, oil charge and water

Shells are with largest bundles and TECU .028 wall tubes

Compressor weight with medium voltage motor and above CPKW

Starter weights not included

Waterboxes are 1 pass, 150 psig Non-Marine

For other configurations refer to submittal package

18

Isolation Pad Loading (kg)

CDHF-SVN01B-EN

General Information

Figure 8 – Spring Isolator Placement - CDHF, CDHG

Estimated Spring Isolator Loading (lb)

TYPE NTON CPKW EVSZ CDSZ LF MF RF LR MR RR

CDHF 1500-2000 957 210D 210D 14120 14948 15785 11029 11770 12519

CDHF 2100-2500 1228 250D 250D 13861 14721 15591 15431 16334 17247

CDHG 1250-1750 716 210D 210D 14432 15193 15960 11564 12253 12947

CDHG 2150 892 210D 210D 15623 17428 19299 10884 12422 14023

CDHG 2150 892 250D 250D 14413 15209 16012 16267 17108 17955

CDHF 3000 1340 250M 250M 15865 16850 17845 17663 18696 19741

CDHF 3500 1340 250X 250X 17023 18080 19148 18952 20060 21182

Estimated Spring Isolator Loading (kg)

TYPE NTON CPKW EVSZ CDSZ LF MF RF LR MR RR

CDHF 1500-2000 957 210D 210D 6405 6780 7160 5003 5339 5679

CDHF 2100-2500 1228 250D 250D 6287 6678 7072 7000 7409 7823

CDHG 1250-1750 716 210D 210D 6546 6892 7239 5246 5558 5873

CDHG 2150 892 210D 210D 34443 38422 42547 23995 27386 30915

CDHG 2150 892 250D 250D 6538 6899 7263 7379 7760 8145

CDHF 3000 1340 250M 250M 7196 7643 8095 8012 8480 8954

CDHF 3500 1340 250X 250X 7722 8201 8686 8597 9099 9608

Notes:

Vibration isolator loading is based on the following

Operating weights include refrigerant, oil charge and water

Shells are with largest bundles and TECU .028 wall tubes

Compressor weight with medium voltage motor and above CPKW

Starter weights not included

Waterboxes are 1 pass, 150 psig Non-Marine

For other configurations refer to submittal package

CDHF-SVN01B-EN

19

General Information

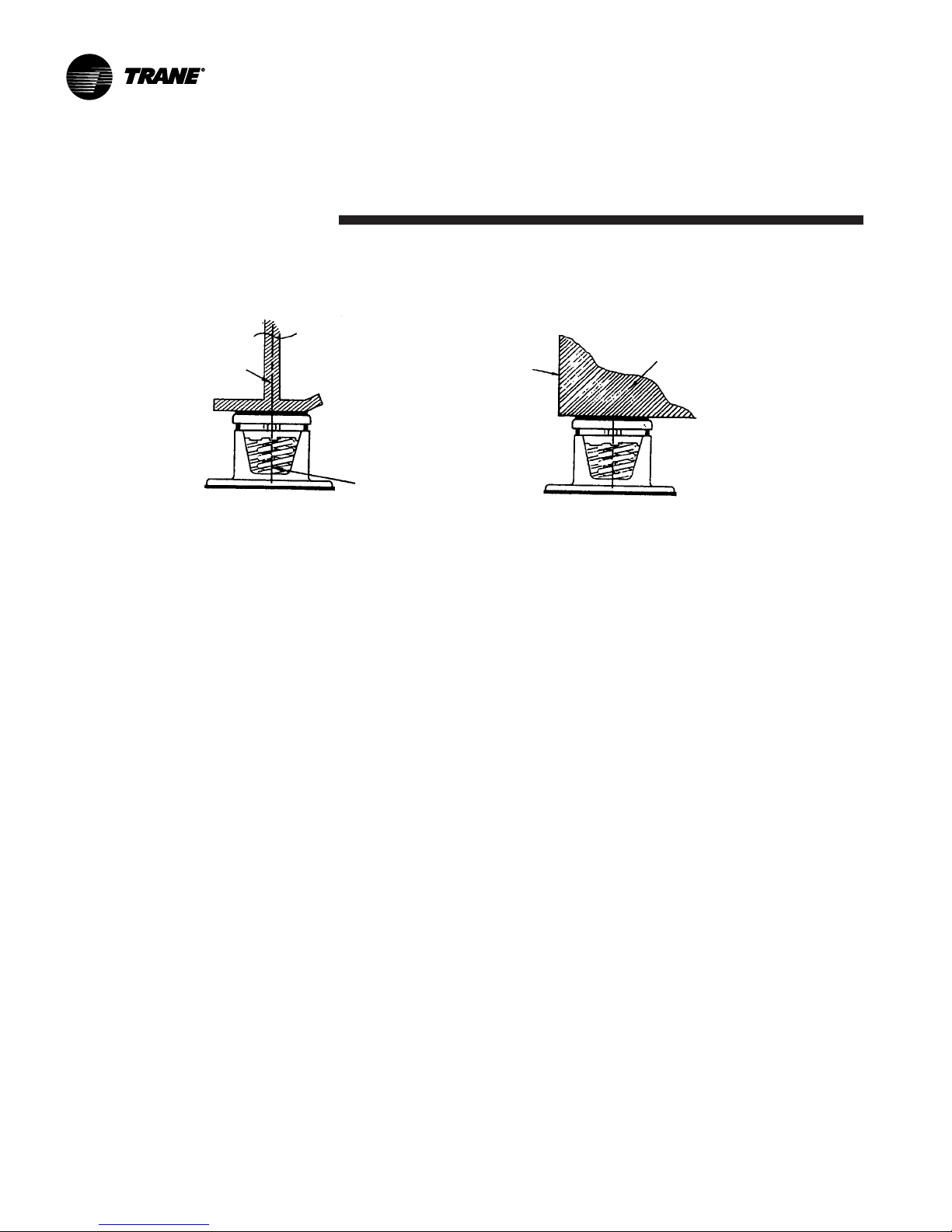

Figure 9 – Chiller Foot/Isolator Orientation

Side View of Unit

Center tube sheet

support leg

Center of

Isolator Spring

Note: The spring isolator must be centered in relation

to the tube sheet. Do not align the isolator with the

flat part of the chiller foot, because the tube sheet is

often off-center.

3. If required, bolt the isolators to the

floor through the slots provided,

or cement the pads.

Note: Fastening the isolators to the

floor is not necessary unless

specified.

4. If the chiller must be fastened to

the isolators, insert capscrews

through the chiller base and into

the holes tapped in the upper

housing of each isolator. However,

do not allow the screws to

protrude below the underside of

the isolator upper housing. An

alternative method of fastening

the chiller to the isolators is to

cement the neoprene pads.

5. Set the chiller on the isolators;

refer to “Rigging” for lifting

instructions.

The weight of the chiller will force

the upper housing of each isolator

down, perhaps causing it to rest

on the isolator’s lower housing.

(Figure 10, 10a illustrates spring

isolator construction.)

6. Check the clearance (labeled X in

Figure 10, 10a ) on each isolator. If

this dimension is less than 1/4” on

any isolator, use a wrench to turn

the adjusting bolt one complete

revolution upward.

Note: When the load is applied to

the isolators (Step 5), the top plate

of each isolator moves down to

compress the springs until either:

a. The springs support the load; or

b. The top plate rests on the

bottom housing of the isolator.

1. If the springs are supporting

End View of Unit

Outside edge of

tube sheet

Note: Place isolator near outside

edge of tube sheet as shown.

the load, screwing down on

the adjusting bolt (Step 7) will

immediately begin to raise

the chiller.

End of tube

sheet

7. Turn the adjusting bolt on each of

the remaining isolators to obtain

the required minimum clearance

at X (Figure 10, 10a ) of 1/4”.

8. Once the minimum required

clearance is obtained on each of

the isolators, level the chiller by

turning the adjusting bolt on each

of the isolators on the low side of

the unit. Be sure to work from one

isolator to the next. Remember

that the chiller must be level to

within 1/16”: over its length and

width, and that clearance X of

each isolator must be at least 1/4

inch.

20

CDHF-SVN01B-EN

General Information

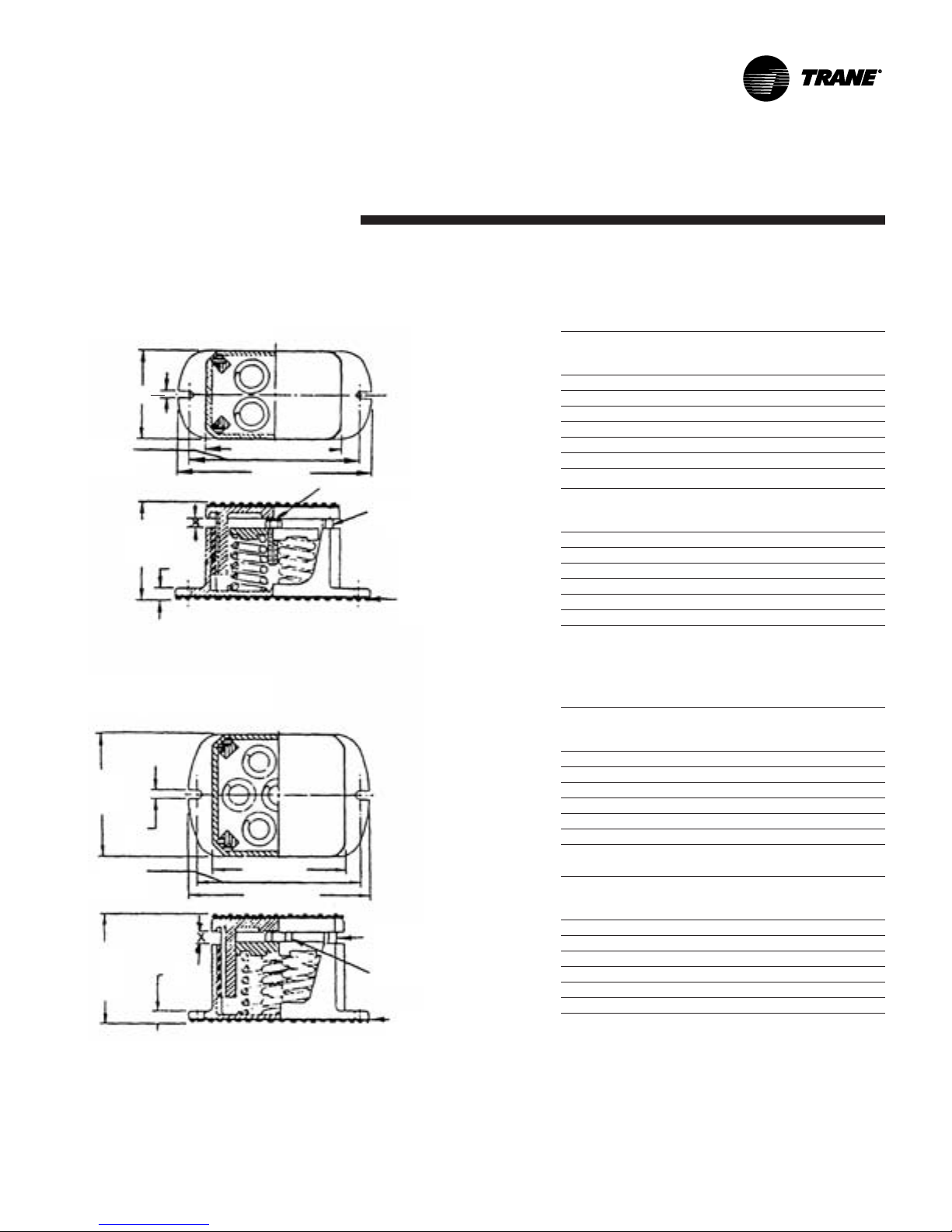

Figure 10 – Typical Spring Isolator Types and Construction

Type CT-4 Spring Isolators

5/8" [16 mm]

9-1/4"

[235 mm]

C-C

foundation

bolts

6-1/2" [165 mm]

Free Height

7-1/2" [191 mm]

10-1/4"

[260 mm]

Adjusting Bolt

Adjust the isolator so

that the upper

housing clears the

lower housing by at

least 1/4” [6 mm]

Acoustical nonskid

neoprene pad (top

and bottom)

Isolator Maximum Spring

Type Load Deflection Color

and Size (lbs.) (Inches) Coding

CT-4-25 1,800 1.22 Red

CT-4-26 2,400 1.17 Purple

CT-4-27 3,000 1.06 Orange

CT-4-28 3,600 1.02 Green

CT-4-31 4,400 0.83 Gray

CT-4-32 5,200 0.74 White

Isolator Maximum Spring

Type Load Deflection Color

and Size (Kg) (mm) Coding

CT-4-25 816 31 Red

CT-4-26 1,089 30 Purple

CT-4-27 1,361 27 Orange

CT-4-28 1,633 26 Green

CT-4-31 1,996 21 Gray

CT-4-32 2,359 19 White

Type CT-7 Spring Isolators

5/8"

[16 mm]

8-3/4" [222

mm] C-C

foundation

bolts

6-5/8" [168

mm] Free

Height

5/8"

[16 mm]

7-1/4"

[184 mm]

9-3/4"

[248 mm]

Adjust the isolator so that

the upper housing clears the

lower housing by at least

1/4” [6 mm]

Adjusting Bolt

Acoustical nonskid

neoprene pad (top

and bottom)

Isolator Maximum Spring

Type Load Deflection Color

and Size (lbs.) (Inches) Coding

CT-7-25 3,150 1.22 Red

CT-7-26 4,200 1.17 Purple

CT-7-27 5,250 1.06 Orange

CT-7-28 6,300 1.02 Green

CT-7-31 7,700 0.83 Gray

CT-7-32 9,100 0.74 White

Isolator Maximum Spring

Type Load Deflection Color

and Size (Kg) (mm) Coding

CT-7-25 1,429 31 Red

CT-7-26 1,905 30 Purple

CT7-27 2,381 27 Orange

CT-7-28 2,858 26 Green

CT-7-31 3,493 21 Gray

CT-7-32 4,128 19 White

CDHF-SVN01B-EN

21

General Information

Figure 10A – Typical Spring Isolator Types and Construction

CT-12 Spring Isolators

14-3/4" [375 mm]

7-3/8" [187 mm]

6-1/2"

[165 mm]

6-5/8"

[168 mm]

7"

[178

mm]

3-1/2"

[89 mm]

5/8"

[16 mm]

12-1/2"

[318 mm]

13-1/4" [337 mm]

Isolator Max Deflection Spring

Type/Size Load lb (kg) inches (mm) Color Code

CT-12-25 5,400 1.22 Red

CT-12-26 7,200 1.17 Purple

CT-12-27 9,000 1.06 Orange

CT-12-28 10,800 1.02 Green

CT-12-31 13,200 0.83 Gray

CT-12-32 15,600 0.74 White

8-1/8" [206

mm] Free

Height

5/8"

[16 mm]

(2) Adjusting Bolts

Adjust the isolator so that

the upper housing clears the

lower housing by at least

1/4” [6.4 mm]

Acoustical nonskid

neoprene pad (top

and bottom)

22

CDHF-SVN01B-EN

CT-16 and CT20

Spring Isolators

General Information

Isolator Max Deflection Spring

Type/Size Load lb (kg) inches (mm) Color Code

CT 16-26 9600 (4355) 1.17 (29.7) Purple

CT 16-27 12000 (5443) 1.06 (26.9) Orange

CT 16-28 14400 (6532) 1.02 (25.9) Green

CT 16-31 17600 (7983) 0.83 (21.1) Gray

CT 16-32 20800 (9435) 0.74 (18.8) White

Isolator Max Deflection Spring

Type/Size Load lb (kg) inches (mm) Color Code

CT 20-26 12000 (5443) 1.17 (29.7) Purple

CT 20-27 15000 (6804) 1.06 (26.9) Orange

CT 20-28 18000 (8165) 1.02 (25.9) Green

CT 20-31 22000 (9979) 0.83 (21.1) Gray

CT 20-32 26000 (11794) 0.74 (18.8) White

CDHF-SVN01B-EN

23

General Information

Unit Leveling

Follow the instructions outlined

below and illustrated in Figure 11 to

determined whether or not the

chiller is set level.

1. Measure an equal distance up

from each foot of the chiller

(identified as X in Figure 11) and

make a punch mark at each

measured distance.

2. Suspend a clear plastic tube along

the length of the chiller as shown

in Figure 11.

Figure 11 – Checking Unit Levelness

Raise chiller at one

end to align match

marks with water

level.

3. Fill the tube with water until the

level aligns with the punch mark at

one end of the chiller; then check

the water level at the opposite

mark.

If the water level does not align

with the punch mark, use fulllength shims to raise one end of

the chiller until the water level at

each end of the tube aligns with

the punch marks at both ends of

the chiller

4. Once the unit is level across its

length, repeat Steps 1 through 3 to

see if unit is level across the width.

5. If isolation pads have been used,

shim the center support.

Measure and mark

an equal distance

up from each

chiller foot.

Clear Plastic Tube

(Fill tube with water to punch mark.)

24

CDHF-SVN01B-EN

Loading...

Loading...