Trane City RTSF050, City RTSF060, City RTSF070, City RTSF090, City RTSF100 Installation Operation & Maintenance

...Page 1

Installation

Operation

Maintenance

Water-cooled Liquid Chillers

with Helical Rotary Compressors

RTSF: 180-385kW (R1234ze)

RLC-SVX023A

Page 2

Contents

Introduction .......................................................................................................3

Unit model number description ....................................................................... 5

General Data ......................................................................................................7

Unit Description ................................................................................................. 8

Installation - Mechanical ................................................................................. 10

Installation - Electrical ..................................................................................... 21

Operating Principles Mechanical ....................................................................27

Typical Operating map ....................................................................................33

Controls/Tracer TD7 Operator Interface ......................................................... 34

Pre-Start Checkout ..........................................................................................35

Unit Start-up .................................................................................................... 37

Periodic Maintenance ...................................................................................... 38

Maintenance Procedures ................................................................................41

Recommended service routine frequencies .................................................. 46

Additional services .......................................................................................... 47

2 © Trane 2019

RLC-SVX023A

Page 3

Introduction

Foreword

These instructions are given as a guide to good practice

in the installation, start-up, operation, and maintenance

by the user, of Trane City chiller RTSF, manufactured in

France. A separate manual is available for the use and

maintenance of the unit’s control, Tracer™ UC800. They

do not contain full service procedures necessary for the

continued successful operation of this equipment. The

services of a qualified technician should be employed

through the medium of a maintenance contract with a

reputable service company. Read this manual thoroughly

before unit start-up.

Units are assembled, pressure tested, dehydrated,

charged and tested in accordance with factory standard

before shipment.

Warnings and Cautions

Warnings and Cautions appear at appropriate sections

throughout this manual. Your personal safety and the

proper operation of this machine require that you follow

them carefully. The constructor assumes no liability

for installations or servicing performed by unqualified

personnel.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices or for equipment or property-damage-only

accidents.

Safety Recommendations

To avoid death, injury, equipment or property damage,

the following recommendations should be observed

during maintenance and service visits:

1. The maximum allowable pressures for system leak

testing on low and high pressure side are given in

the chapter “Installation”. Insure to do not exceed test

pressure by using appropriate device.

2. Disconnect all power supplies before any servicing on

the unit.

3. Service work on the refrigeration system and the

electrical system should be carried out only by qualified

and experienced personnel.

4. To avoid any risk, it is recommended to place the unit

on an area with restricted access.

Reception

On arrival, inspect the unit before signing the delivery

note. Specify any visible damage on the delivery note,

and send a registered letter of protest to the last carrier

of the goods within 7 days of delivery.

Notify the local TRANE sales office at the same

time. The delivery note must be clearly signed and

countersigned by the driver.

Any concealed damage shall be notified by a registered

letter of protest to the last carrier of the goods within

7 days of delivery. Notify the local TRANE sales office

at the same time.

Important notice: No shipping claims will be accepted

by TRANE if the above mentioned procedure is not

respected.

For more information, refer to the general sales

conditions of your local TRANE sales office.

Note: Unit inspection in France. Delay to send registered

letter in case of visible and concealed damage is only

72 hours.

Loose Parts Inventory

Check all the accessories and loose parts that are

shipped with the unit against the shipping list. Included

in these items will be the Water Flow Switch (optional),

rigging and electrical diagrams, service literature, which

are placed inside the control panel and/or starter panel

for shipment.

If optional elastomeric isolators are ordered with

the unit they are shipped mounted on the horizontal

support frame of the chiller. The isolators’ location and

distribution weight diagram is placed with the service

literature inside the starter/control panel.

Warranty

Warranty is based on the general terms and conditions

of the manufacturer. The warranty is void if the

equipment is repaired or modified without the written

approval of the manufacturer, if the operating limits are

exceeded or if the control system or the electrical wiring

is modified. Damage due to misuse, lack of maintenance

or failure to comply with the manufacturer’s instructions

or recommendations is not covered by the warranty

obligation. If the user does not conform to the rules of

this manual, it may entail cancellation of warranty and

liabilities by the manufacturer.

RLC-SVX023A

3

Page 4

Introduction

Unit Description

The RTSF units are helical-rotary type, water-cooled,

liquid chillers, designed for installation indoors.

The RTSF units are packaged with an evaporator

and condenser.

Note: Each RTSF unit is a completely assembled,

hermetic package that is factory-piped, wired, leak

tested, dehydrated, charged and tested for proper control

operations prior to shipment. The chilled water inlet and

outlet openings are covered for shipment.

The RTSF series features Trane’s exclusive Adaptive

Control logic with UC800 controls. It monitors the control

variables that govern the operation of the chiller unit.

Adaptive Control logic can correct these variables, when

necessary, to optimize operational efficiencies, avoid

chiller shutdown, and keep producing chilled water.

Compressor loading/unloading is provided by AFD

(Adaptive Frequency Drive) coordinated with slide

valve operation.

Each refrigerant circuit is provided with filter, sight glass,

electronic expansion valve, and charging valves on

the RTSF.

The evaporator and condenser are manufactured

in accordance with Pressure Equipment Directive

standards. The evaporator and the condenser are

insulated according the option ordered. Both evaporator

and condenser water pipes are equipped with water

drain and vent connections.

Maintenance contract

It is strongly recommended that you sign a maintenance

contract with your local Trane Service Agency. This

contract provides regular maintenance of your

installation by a specialist in our equipment. Regular

maintenance ensures that any malfunction is detected

and corrected in good time and minimizes the possibility

that serious damage will occur. Finally, regular

maintenance ensures the maximum operating life of

your equipment. We would remind you that failure to

respect these installation and maintenance instructions

may result in immediate cancellation of the warranty.

Training

To assist you in obtaining the best use of it and

maintaining it in perfect operating condition over a long

period of time, the manufacturer has at your disposal

a refrigeration and air conditioning service school. The

principal aim of this is to give operators and technicians

a better knowledge of the equipment they are using,

or that is under their charge. Emphasis is particularly

given to the importance of periodic checks on the

unit operating parameters as well as on preventive

maintenance, which reduces the cost of owning the unit

by avoiding serious and costly breakdown.

Refrigerant

Consult the addendum to Manuals for units with

refrigerant, for conformity to the Pressure Equipment

Directive (PED) 97/23/EC or 2014/68/EU and Machinery

Directive 2006/42/EC and for specific caution for R1234ze.

4

RLC-SVX023A

Page 5

Unit model number description

Digit 1, 2, 3, 4 – Unit Model

RTSF

Digit 5, 6, 7 – Unit size

50 = 50 Nominal tons

60 = 60 Nominal tons

70 = 70 Nominal tons

90 = 90 Nominal tons

100 = 100 Nominal tons

110 = 110 Nominal tons

Digit 8 – Unit Power supply

D = 400 V – 50 Hz – 3Ph

Digit 9 – Factory

E = Europe

F = ICS

Digit 10 & 11 – Design sequence

(Factory assigned)

Digit 12 & 13 – Not used

Digit 14 – Agency listing

C = CE marking

Digit 15 – Pressure Vessel Code

2 = PED (Pressure Equipment Directive)

Digit 16 – Unit Application

X = Cooling Mode - Below 50°C Leaving Condenser Temp

H = Cooling Mode - Above 50°C Leaving Condenser Temp

L = Heat pump - Below 50°C Leaving Condenser Temp

M = Heat pump - Above 50°C Leaving Condenser Temp

Digit 27 – Not Used

Digit 28 – Evaporator pump

X = Without

Digit 29 – Condenser Size

A = Condenser A

B = Condenser B

C = Condenser C

D = Condenser D

Digit 30 & 31 – Not Used

Digit 32 – Condenser Pump

X = Without

Digit 33 – Condenser Water side pressure

X = 10 Bar Condenser Water Pressure

Digit 34 – Condenser Thermal Insulation

X = Without

H = With Condenser Insulation

Digit 35 – Oil cooler

X = Without

C = With

Digit 36 – Evaporator Pump Smart Flow control

X = Without

E = VPF Constant Delta T Evaporator

Digit 37 – Power Protection

F = Disconnect switch with fuses

B = Disconnect switch with circuit breakers

Digit 17 – Refrigerant

Z = R1234ze unit with Factory charge (with oil)

Y = R1234ze with pre-charge (with oil)

L = R1234ze unit with Nitrogen (no oil)

Digit 18 – Sound Attenuation Package

X = Without

A = Aesthetic option

L = Sound attenuation package

Digit 19 – Relief Valve Option

L = Single Relief Valve Condenser

2 = Single Relief Valve Condenser & Evaporator

D = Dual relief valve with 3 way valve condenser

4 = Dual relief valve with 3 way valve condenser & Evaporator

Digit 20 – Compressor Type

L = CHHP Low VI

H = CHHP or CHHW High VI

Digit 21 – Evaporator Size

A = Evaporator A

B = Evaporator B

C = Evaporator C

D = Evaporator D

Digit 22 & 23 & 24 – Not Used

Digit 25 – Evaporator Water side Pressure

X = 10 Bar Evaporator Water Pressure

Digit 26 – Evaporator application

N = Comfort Cooling (above 5°C)

P = Process Cooling below 5°C

C = Ice Making (from -7°C to 20°C)

Digit 38 – Not Used

Digit 39 – Relay Card

1 = With additional relay card

Digit 40 – Smart com protocol

X = Without

B = BACnet MSTP interface

C = BACnet IP interface

M = Modbus RTU interface

L = LonTalk interface

Digit 41 – Communication customer input/output

X = Without

A = External Set points & Capacity outputs – Voltage Signal

B = External Set points & Capacity outputs – Current Signal

Digit 42 – Outdoor Air Temperature Sensor

X = Without

A = Outdoor Air Temperature Sensor – CWR/Low Ambient

Digit 43 – Not Used

Digit 44 – Master Slave Set

X = Without

M = With

RLC-SVX023A

5

Page 6

Unit model number description

Digit 45 – Energy meter

X = Without

M = With

Digit 46 – Condenser Pump Smart Flow Control/Other Condenser

Pressure Control Outputs

X = Without

1 = Condenser Pressure in % HPC

2 = Differential Pressure

3 = Condenser Head Pressure Flow Control

4 = VPF Constant Delta T Condenser Flow Control

Digit 47 – Power socket

X = Without

P = Included (230V-100W)

Digit 48 – Factory test

X = Without

B = Visual Inspection

E = Test E - 1 point with Report Non Witnessed

S = Special test

Digit 49 – Installation Accessory

X = Without

1 = Neoprene isolators

4 = Neoprene pads

Digit 50 – Connection Accessory

X = Grooved pipe connection

W = Grooved pipe with coupling and pipe stub

Digit 51 – Flow switch

X = Without

A = Evaporator or Condenser

B = Evaporator and Condenser

Digit 52 – Literature Language

C = Spanish

D = German

E = English

F = French

H = Dutch

I = Italian

M = Swedish

P = Polish

R = Russian

T = Czech

V = Portugese

6 = Hungarian

8 = Turkish

Digit 53 – Not Used

Digit 54 – EXV selection

X = Standard EXV

Digit 55 – AFD Selection

A = AFD A

B = AFD B

C = AFD C

D = AFD D

E = AFD E

F = AFD F

Digit 56 – Design special

X = Without

S = Special

6

RLC-SVX023A

Page 7

General Data

Table 1 – General Data RTSF Standard efficiency - R1234ze

Indicative performances (1)

Cooling Capacity (1) (kW) 183 220 264 314 363 388

Total Power input in cooling (1) (kW) 37 43 53 64 80 90

Unit Electrical data (2) (5)

Low VI compressor - digit 20 =L

Maximum Power Input (kW) 66 77 91 111 130 Unit rated amps (2) (A) 100 117 138 168 196 Unit start up amps (2) (A) 100 117 138 168 196 Displacement power factor 0.95 0.95 0.95 0.95 0.95 -

High VI compressor - Digit 20 = H

Maximum Power Input (kW) 87 103 125 150 178 178

Unit rated amps (2) (A) 131 155 190 227 270 270

Unit start up amps (2) (A) 131 155 190 227 270 270

Displacement power factor 0.95 0.95 0.95 0.95 0.95 0.95

Short Circuit Unit Capacity (kA) 35 35 35 35 35 35

Max Power cable (cross) mm² 1x 240 1x 240 1x 240 1x 240 1x 240 1x 240

Disconnect switch size (3) (A) 400 400 400 400 400 400

Compressor

Type Screw Screw Screw Screw Screw Screw

Model 60 70 85 100 120 140

Low VI compressor - digit 20 =L

Max compressors Power Input (kW) 65 76 91 110 129 Max Amps (3) (6) (A) 98 115 136 166 194 Start up Amps (A) 98 115 136 166 194 -

High VI compressor - Digit 20 = H

Max compressors Power Input (kW) 86 102 124 149 177 177

Max Amps (3) (6) (A) 129 153 188 225 268 268

Start up Amps (A) 129 153 188 225 268 268

Motor RPM (rpm)

Oil sump heater (kW) 0.275 0.275 0.275 0.275 0.275 0.275

Evaporator

Type BPHE BPHE BPHE BPHE BPHE BPHE

Evaporator model C B B A A A

Evaporator Water Content volume (l) 52 59 69 92 92 92

Evap. Water Flow rate - Minimum (4) (l/s) 3.6 4.8 4.8 6.4 6.4 6.4

Evap. Water Flow rate - Maximum (4) (l/s) 38.6 38.6 38.6 38.6 38.6 38.6

Nominal water connection size (Grooved coupling) (in) - (mm) 4" 4" 4" 4" 4" 4"

Condenser

Type BPHE BPHE BPHE BPHE BPHE BPHE

Condenser model B B A A A A

Condenser Water Content volume (l) 49 49 69 69 69 69

Cond. Water Flow rate - Minimum (4) 1.9 1.9 2.7 2.7 2.7 2.7

Cond. Water Flow rate - Maximum (4) 39 39 39 39 39 39

Nominal water connection size (Grooved coupling) (l) 4” 4” 4” 4” 4” 4”

Dimensions

Unit Length (mm) 2334 2334 2334 2334 2334 2334

Unit Width (mm) 922 922 922 922 922 922

Unit Height (mm) 1941 1941 1959 1959 1959 1959

Weights

Shipping Weight (5) (kg) 1611 1675 1900 1986 1986 1986

Operating Weight (5) (kg) 1690 1771 2018 2127 2127 2127

System data (6)

Nb of refrigerant circuits # 1 1 1 1 1 1

Minimum cooling load % % 25% 25% 25% 25% 25% 25%

Standard unit

R1234ze refrigerant charge (6) (kg) 31 34 42 47 47 47

Oil charge (6) (l) 5 5 7 7 7 7

POE Oil type OIL0066E/OIL0067E

RTSF050 RTSF060 RTSF070 RTSF090 RTSF100 RTSF110

(1) Indicative performance at Evaporator water temperature: 12°C / 7°C - Condenser water temperature 30 / 35°C - for detailed performances consult

order write up.

(2) Under 400V/3/50Hz.

(3) Option fuse + disconnect switch.

(4) Height reaches 2050 mm with the sound attenuation package option.

(5) Additional weight of + 158kg in case of a sound attenuation package option.

(6) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

RLC-SVX023A

7

Page 8

Unit Description

Component location for typical RTSF Unit

16

13

2

5

17

18

15

14

2 = Power cable gland plate

for customer wiring

4 = Suction line

5 = Oil separator

6 = Condenser water outlet

7 = Condenser water inlet

4

5

9

8 = Evaporator water outlet

9 = Evaporator water inlet

13 = External control wiring

cable gland plate for

customer wiring

14 = Compressor

15 = Discharge line

16 = Unit nameplate (on the

side of starter/control

panel)

17 = EXV

18 = Condenser

1 = Control panel

3 = Tracer TD7 interface

4 = Suction line

10 = Auxiliary Oil Cooler (Optional)

11 = Evaporator

12 = Adaptive Frequency Drive

8

6

4

10

11 12

7

3

1

8

RLC-SVX023A

Page 9

Unit Description

Installation overview and

requirements

Contractor responsibilities

A list of the contractor responsibilites typically associated

with the installation process is provided in Table 2.

• Locate and maintain the loose parts. Loose parts are

located in the control panel.

• Install the unit on a foundation with flat support surfaces,

level within 5 mm and of sufficient strength to support

concentrated loading. Place the manufacturer-supplied

isolation pad assemblies under the unit.

• Install the unit per the instructions outlined in the

“Mechanical Installation” section.

• Complete all water piping and electrical connections.

Note: Field piping must be arranged and supported to

avoid stress on the equipment. It is strongly recommended

that the piping contractor provide at least 1m of clearance

between the pre-installation piping and the planned location

of the unit. This will allow for proper fit-up upon arrival

of the unit at the installation site. All necessary piping

adjustments can be made at that time

• Where specified, supply and install valves in the water

piping upstream and downstream of the evaporator and

condenser, to isolate the heat exchangers for maintenance

and to balance/trim the system.

• Supply and install flow switches or equivalent devices

in both the chilled water and condenser water piping.

Interlock each switch with the proper pump starter and

Tracer UC800, to ensure that the unit can only operate

when water flow is established.

• Supply and install taps for thermometers and pressure

gauges in the water piping, adjacent to the inlet and outlet

connections of both the evaporator and the condenser.

• Where specified, supply and install strainers ahead of all

pumps and automatic modulating valves.

• Supply and install refrigerant pressure relief piping from

the pressure relief to the atmosphere.

• Start the unit under supervision of a qualified service

technician.

• Where specified, supply and insulate the evaporator

and any other portion of the unit, as required, to prevent

sweating under normal operating conditions.

• For unit-mounted starters, cutouts are provided at the top

of the panel for line-side wiring.

• Supply and install the wire terminal lugs to the starter.

• Supply and install field wiring to the line-side lugs of the

starter.

Table 2 – Installation Responsibility

Requirement

Foundation Meet foundation requirements

Rigging Safety chains

Isolation Isolation pads Other type of isolators

Electrical - Circuit breakers or fusible

Water piping Flow switches (may be eld

Insulation Insulation Insulation

Water piping connection

components

Caution on exposure to

refrigerant

Trane supplied

Trane installed

disconnects (Optional)

- Unit mounted starter

- Wye Delta starter or AFD

(Adaptive Frequency Drive)

- Grooved pipe

- Grooved pipe to agged

connection (optional)

Trane supplied

Field installed

- Flow switches (may be eld

supplied)

- Harmonic lters (on request

according to customer electrical

network and equipment)

supplied)

Customer supplied

Customer installed

Clevis connectors

Lifting beams

- Circuit breakers or fusible disconnect

- Electrical connections to unit mounted

starter (optional)

- Electrical connections to remote

mounted starter (optional)

- Wiring sizes per submittal and local

regulations

- Terminal lugs

- Ground connections

- BAS wiring (optional)

- Control voltage wiring

- Chilled water pump contactor and

wiring including interlock

- Option relays and wiring

- Taps for thermometers and gauges

- Thermometers

- Strainers (as required)

- Water ow pressure gauges

- Isolation and balancing valves in water

piping

- Vents and drain on waterbox valves

- Pressure relief valves for water side

Respect recommendation of IOM

addendum

RLC-SVX023A

9

Page 10

Installation - Mechanical

Storage

If the chiller is to be stored more than one month prior to

installation, observe the following precautions:

• Do not remove the protective coverings from the

electrical panel.

• Store the chiller in a dry, vibration-free, secure area.

• At least every three months, attach a gauge and

manually check the pressure in the refrigerant circuit.

If the refrigerant pressure is below 3.4 bar at 21°C (2 bar

at 10 °C), call a qualified service organization and the

appropriate Trane sales office.

NOTE: Pressure will be approximately 1.0 bar if shipped

with the optional nitrogen charge.

Noise Considerations

• Refer to Engineering Bulletin for sound consideration

applications.

• Locate the unit away from sound-sensitive areas.

• Install the isolation pads under the unit. Refer to “Unit

Isolation.”

• Install rubber vibration isolators in all water piping.

• Use flexible electrical conduit for final connection to the

Tracer UC800.

• Seal all wall penetrations.

NOTE: Consult an acoustical engineer for critical

applications.

Foundation

Provide rigid, non-warping mounting pads or a concrete

foundation of sufficient strength and mass to support the

chiller operating weight (including completed piping and

full operating charges of refrigerant, oil and water).

Refer to General information for unit operating weights.

Once in place, level the chiller within 5 mm over its

length and width.

The manufacturer is not responsible for equipment

problems resulting from an improperly designed or

constructed foundation.

Clearances

Provide enough space around the unit to allow the

installation and maintenance personnel unrestricted

access to all service points. A minimum of 1 m is

recommended for compressor service and to provide

sufficient clearance for the opening of control panel

doors. In all cases, local codes will take precedence

over these recommendations. If the room configuration

requires a variance to the clearance dimensions, contact

your sales representative.

NOTE: Required vertical clearance above the unit is at

least 1 m. There should be no piping or conduit located

over the compressor motor.

NOTE: Maximum clearances are given. Depending on

the unit configuration, some units may require less

clearance than others in the same category.

Ventilation

The unit produces heat even though the compressor is

cooled by the refrigerant. Make provisions to remove

heat generated by unit operation from the equipment

room. Ventilation must be adequate to maintain an

ambient temperature lower than 40°C. Vent the pressure

relief valves in accordance with all local and national

codes. Refer to “Pressure Relief Valves”. Make provisions

in the equipment room to keep the chiller from being

exposed to ambient temperatures below 10°C.

Water Drainage

Locate the unit near a large capacity drain for water

vessel drain-down during shutdown or repair. Condenser

and evaporator water pipes are provided with drain

connections. Refer to “Water Piping.” All local and

national codes apply.

Access Restrictions

Refer to the unit submittals for specific dimensional

information (documents supplied in document package

coming with unit).

Vibration Eliminators

• Provide rubber boot type isolators for all water piping

at the unit.

• Provide flexible conduit for electrical connections to the

unit.

• Isolate all pipe hangers and be sure they are not

supported by main structure beams that could

introduce vibration into occupied spaces.

• Make sure that the piping does not put additional stress

on the unit.

NOTE: Do not use metal braided type eliminators on the

water piping. Metal braided eliminators are not effective

at the frequencies at which the unit will operate.

10

RLC-SVX023A

Page 11

Handling Procedure

INSTRUCTIONS DE LEVAGE ET DE MANUTENTION

IL EST RECOMMANDE D'UTILISER LES ORGANES DE LEVAGE ET DE MANUTENTION

MONTRES PAR LE SCHEMA ET DE SUIVRE LES INSTRUCTIONS SUIVANTES :

1 -ATTENTION : CETTE UNITE DOIT ETRE LEVEE ET MANUTENTIONNEE AVEC

PRECAUTIONS. EVITER LES A-COUPS LORS DU LEVAGE ET DE LA MANUTENTION.

ANWEISUNGEN FUER DEN TRANSPORT MIT HEBEZEUG

ES WIRD EMPFOHLEN, DIE MASCHINE ENTSPRECHEND DER ZEICHNUNG MIT EINEM

KRAN ANZUHEBEN UND DIE FOLGENDEN ANWEISUNGEN ZU BEACHTEN :

1 -BEIM ANHEBEN VORSICHTIG VORGEHEN, STOESSE UND ERSCHUETTERUNGEN

UNBEDINGT VERMEIDEN.

SPECIAL LIFTING AND MOVING INSTRUCTIONS

IT IS RECOMMENDED TO USE THE SPECIAL BUILT-IN RIGGING POINTS SHOWN

IN THE DIAGRAM AND TO FOLLOW THE FOLLOWING INSTRUCTIONS :

1 -CAUTION : THIS UNIT MUST BE LIFTED AND HANDLED WITH CARE. AVOID SHOCKS

WHILE HANDLING.

ISTRUZIONI PER IL SOLLEVAMENTO E LA MOVIMENTAZIONE DELL'UNITA

SI RACCOMANDA DI SEGUIRE LE ISTRUZIONI QUI RIPORTATE PER IL SOLLEVAMENTO

E LA MOVIMENTAZIONE DELL'UNITA :

1 -ATTENZIONE : EFFETTUARE IL SOLLEVAMENTO DELL'UNITA CON LA MASSIMA CURA

EVITARE CARICHI ECCESSIVI, SOLLEVARE LENTAMENTE E UNIFORMEMENTE.

HIJS EN TRANSPORT INSTRUCTIES

DE TOE TE PASSEN HIJSMETHODE IS ALS VOLGT VOORGESCHREVEN :

1 -WAARSCHUWING : DEZE MACHINE VOORZICHTIG VERPLAATSEN. VOORKOM

SCHOKKEN EN STOTEN BIJ HET HIJSEN.

INSTRUCCIONES DE TRANSPORTE Y DESCARGA

SE RECOMIENDA SEGUIR LAS INSTRUCCIONES SIGUIENTES PARA LA CARGA Y

DESCARGA DE LA UNIDAD :

1 -ATENCION : ESTA UNIDAD DEBE SER DESCARGADA CON EL MAYOR CUIDADO

PARA EVITAR CHOQUES. DESCARGAR DESPACIO Y CUIDADOSAMENTE.

B

RTSF

050-060-070-090-100-110

57384397

Sheet 1 of 2

Date: Revision: B

19-DEC-2018

INSTRUCTIONS DE LEVAGE ET DE MANUTENTION

IL EST RECOMMANDE D'UTILISER LES ORGANES DE LEVAGE ET DE MANUTENTION

MONTRES PAR LE SCHEMA ET DE SUIVRE LES INSTRUCTIONS SUIVANTES :

1 -ATTENTION : CETTE UNITE DOIT ETRE LEVEE ET MANUTENTIONNEE AVEC

PRECAUTIONS. EVITER LES A-COUPS LORS DU LEVAGE ET DE LA MANUTENTION.

ANWEISUNGEN FUER DEN TRANSPORT MIT HEBEZEUG

ES WIRD EMPFOHLEN, DIE MASCHINE ENTSPRECHEND DER ZEICHNUNG MIT EINEM

KRAN ANZUHEBEN UND DIE FOLGENDEN ANWEISUNGEN ZU BEACHTEN :

1 -BEIM ANHEBEN VORSICHTIG VORGEHEN, STOESSE UND ERSCHUETTERUNGEN

UNBEDINGT VERMEIDEN.

SPECIAL LIFTING AND MOVING INSTRUCTIONS

IT IS RECOMMENDED TO USE THE SPECIAL BUILT-IN RIGGING POINTS SHOWN

IN THE DIAGRAM AND TO FOLLOW THE FOLLOWING INSTRUCTIONS :

1 -CAUTION : THIS UNIT MUST BE LIFTED AND HANDLED WITH CARE. AVOID SHOCKS

WHILE HANDLING.

ISTRUZIONI PER IL SOLLEVAMENTO E LA MOVIMENTAZIONE DELL'UNITA

SI RACCOMANDA DI SEGUIRE LE ISTRUZIONI QUI RIPORTATE PER IL SOLLEVAMENTO

E LA MOVIMENTAZIONE DELL'UNITA :

RELEASED 21/Dec/2018 09:34:29 GMT

Follow instructions given in the lifting and handling

document supplied with documentation package

shipped with the unit.

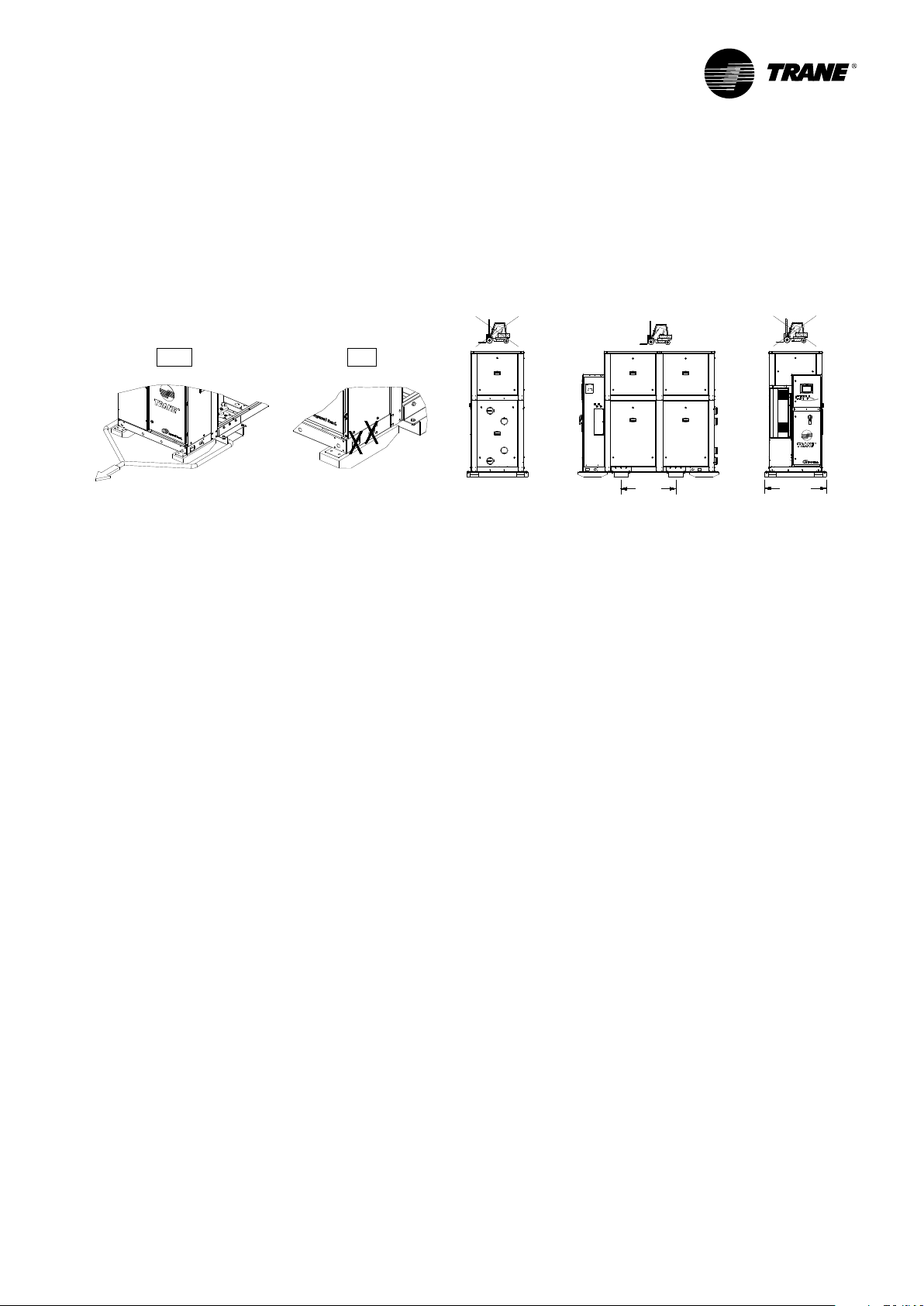

Figure 1 – Handling

YES NO

Installation - Mechanical

Isolation Pads

1. The elastomeric pads shipped (as standard) are

adequate for most installations. For additional details

on isolation practices, consult an acoustical engineer

for sensitive installations. It is possible that some

vibration frequencies can be transmitted into the

foundations. This depends on the building structure.

It is recommended for these situations to use neoprene

isolators instead of elastomeric pads.

Drawings to locate isolation pads are supplied with

unit document package.

2. During final positioning of the unit, place the isolation

pads as indicated in submittal drawings. Level

the unit.

Drawings to locate isolation pads are included with in

document package sent with the unit.

RLC-SVX023A

930

1042

11

Page 12

Installation - Mechanical

Unit Leveling

NOTE: The electrical panel side of the unit is designated

as the “front” of the unit.

1. Check unit level end-to-end by placing a level on the

chiller structure (compressor frame for example).

2. Adjust to within 5 mm of level front-to-back.

Water Piping

Piping Connections

To prevent equipment damage, bypass the unit if using

an acidic flushing agent.

Make water piping connections to the evaporator

and condenser. Isolate and support piping to prevent

stress on the unit. Construct piping according to local

and national codes. Insulate and flush piping before

connecting to unit.

The chilled water connections to the evaporator are to be

grooved-pipe type connections. Do not attempt to weld

these connections. Refer to submittal for dimension of

tube stub for grooved connection. Refer to submittal for

dimension of tube stub for grooved connection.

To prevent damage to chilled water components, do not

allow evaporator pressure (maximum working pressure)

to exceed 10 bar.

Reversing Water Connections is prohibited

It is critical to keep the factory layout for water

connections. Therefore reversing water connections may

lead to functional disorder.

NOTE: Dimensions of tube stub for grooved connection

are included in submittal drawings.

Vents and Drains

Install pipe plugs in evaporator and condenser water

connections drain and vent connections before filling

the water systems. To drain water, remove vent and drain

plugs, install a NPT connector in the drain connection

and connect a hose to it.

Water Treatment

WARNING: Do not use untreated or improperly treated

water. Use of untreated or improperly treated water may

result in equipment damage.

The following disclamatory label is provided on

each unit:

The use of improperly treated or untreated water in this

equipment may result in scaling, erosion, corrosion,

algae or slime. The services of a qualified water

treatment specialist should be engaged to determine

what treatment, if any, is advisable. The warranty

specifically excludes liability for corrosion, erosion

or deterioration of the manufacturer’s equipment.

The manufacturer assumes no responsibilities for the

results of the use of untreated or improperly treated

water, or saline or brackish water.

12

RLC-SVX023A

Page 13

Installation - Mechanical

Evaporator Piping Components

Note: Make sure all piping components are between the

shutoff valves, so that isolation can be accomplished

on both the condenser and the evaporator. “Piping

components” include all devices and controls used

to provide proper water system operation and unit

operating safety. These components and their general

locations are given below.

Entering Chilled Water Piping

• Air vents (to bleed air from system)

• Water pressure gauges with shutoff valves

• Pipe unions

• Vibration eliminators (rubber boots)

• Shutoff (isolation) valves

• Thermometers

• Clean out tees

• Pipe strainer

Leaving Chilled Water Piping

• Air vents (to bleed air from system)

• Water pressure gauges with shutoff valves

• Pipe unions

• Vibration eliminators (rubber boots)

• Shutoff (isolation) valves

• Thermometers

• Clean out tees

• Balancing valve

• Pressure relief valve

To prevent evaporator damage, do not exceed 10 bar

evaporator water pressure for standard units.

To prevent heat exchangers damage, install a strainer

in the evaporator water inlet piping.

Condenser Piping Components

“Piping components” include all devices and controls

used to provide proper water system operation and unit

operating safety. These components and their general

locations are given below.

Entering Condenser Water Piping

• Air vents (to bleed air from system)

• Water pressure gauges with shutoff valves

• Pipe unions

• Vibration eliminators (rubber boots)

• Shutoff (isolation) valves

• Thermometers

• Clean out tees

• Pipe strainer

• Flow switch

Leaving Condenser Water Piping

• Air vents (to bleed air from system)

• Water pressure gauges with shutoff valves

• Pipe unions

• Vibration eliminators (rubber boots)

• Shutoff (isolation) valve

• Thermometers

• Clean out tees

• Balancing valve

• Pressure relief valve

To prevent condenser damage, do not exceed 10 bar

water pressure for standard units.

To prevent heat exchangers damage, install a strainer in

condenser water inlet piping.

Water Pressure Gauges and

Thermometers

Install field-supplied thermometers and pressure gauges

(with manifolds, whenever practical). Locate pressure

gauges or taps in a straight run of pipe; avoid placement

near elbows, etc. Be sure to install the gauges at the

same elevation on each shell if the shells have oppositeend water connections.

RLC-SVX023A

13

Page 14

Installation - Mechanical

Water Pressure Relief Valves

Install a pressure relief valve in both evaporator and

condenser water systems. Failure to do so could result

in Heat Exchanger damage.

When shutoff valves are installed on the water circuits,

the water temperature can increase and create a high

pressure in the water systems. Refer to applicable

regulation for relief valve installation guidelines.

Flow Sensing Devices

Use field-provided flow switches or differential pressure

switches with pump interlocks to sense system water

flow.

To provide chiller protection, install and wire flow

switches in series with the water pump interlocks, for

both chilled water and condenser water circuits (refer to

the “Installation Electrical” section). Specific connections

and schematic wiring diagrams are shipped with the

unit.

Flow switches must stop or prevent compressor

operation if either system water flow drops off

drastically. Follow the manufacturer’s recommendations

for selection and installation procedures. General

guidelines for flow switch installation are outlined below.

• Mount the switch upright, with a minimum of 5 pipe

diameters of straight, horizontal run on each side.

• Do not install close to elbows, orifices or valves.

Note: The arrow on the switch must point in the direction

of the water flow. To prevent switch fluttering, remove all

air from the water system.

Note: The Tracer UC800 provides a 6-second time delay

on the flow switch input before shutting down the unit

on a loss-of-flow diagnostic. Contact a qualified service

organization if nuisance machine shutdowns persist.

Adjust the switch to open when water flow falls below

nominal. Refer to the General Data table for minimum

flow recommendations. Flow switch contacts are closed

on proof of water flow.

Refrigerant Pressure Relief Valve

Venting

To prevent injury due to inhalation of refrigerant gas, do

not discharge refrigerant anywhere. If multiple chillers

are installed, each unit must have separate venting for

its relief valves. Consult local regulations for any special

relief line requirements.

All relief valve venting is the responsibility of the

installing contractor. All RTSF units use condenser

pressure relief valves that must be collected. Relief valve

connection sizes and locations are shown in the unit

submittals. Refer to national regulations for relief valve

vent line sizing information.

Do not exceed vent piping code specifications. Failure

to heed specifications could result in capacity reduction,

unit damage and/or relief valve damage.

Note: Once opened, relief valves tend to leak.

14

RLC-SVX023A

Page 15

0.1

1

10

100

1000

1.0 10.0 100.0

Pressure Drop (kPa)

WaterFlow (L/s)

RTSF condensers Pressure drop on waterside

A

B

C

D

1

10

100

1000

1.0 10.0 100.0

Pressure Drop (kPa)

WaterFlow (L/s)

RTSF evaporators Pressure drop on waterside

A

B

C

D

Installation - Mechanical

RTSF condensers Pressure drop on waterside

RTSF evaporators Pressure drop on waterside

RLC-SVX023A

15

Page 16

Installation - Mechanical

Freeze protection

For all chillers it is extremely important to keep full water

flow in the evaporator and condenser for an extended

time after last compressor stops. This will protect

evaporator tube from freezing by refrigerant migration.

This is why both evaporator and condenser water

pump output relay must be used to control the chilled

water pump. It is mandatory even if glycol is used with

protection down to lowest ambient expected.

For unit operation in a low temperature environment,

adequate protection measures must be taken against

freezing. Freeze protection can be accomplished by

adding sufficient glycol to protect against freezing below

the lowest ambient expected.

Important: Be sure to apply appropriate LERTC (Low

Evaporator Refrigerant Temperature Cutout) and LWTC

(Low Water Temperature Cutout) control setpoints based

on the concentration of the freeze inhibitor or solution

freeze point temperature.

Avoid the use of very low or near minimum chilled fluid

flow rates through the chiller. Higher velocity chilled fluid

flow reduces freeze risk in all situations. Flow rates below

published limits have increased freeze potential and have

not been considered by freeze protection algorithms.

• Avoid applications and situations that result in a

requirement for rapid cycling or repeated starting and

stopping of the chiller. Keep in mind that chiller control

algorithms may prevent a rapid compressor restart

after shutting down when the evaporator has been

operating near or below the LERTC limit.

• Maintain refrigerant charge at appropriate levels. If

charge is in question, contact Trane service. A reduced

or low level of charge can increase the likelihood of

freezing conditions in the evaporator and/or LERTC

diagnostic shutdowns.

16

RLC-SVX023A

Page 17

Installation - Mechanical

RTSF Low Refrigerant temperature Ethylene Glycol and Propylene Glycol and Freeze protection settings.

Table 3 – Recommended low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout

(LWTC) for RTSF chillers

Ethylene Glycol Mono Propylene Glycol

Glycol

Percentage

(weight %)

0 0.0 0.0 2.8 0.0 0.0 2.8

2 -0.6 -1.4 2.2 -0.6 -1.4 2.2

4 -1.3 -2.1 1.5 -1.2 -2.0 1.6

5 -1.7 -2.5 1.1 -1.5 -2.3 1.3

6 -2.0 -2.9 0.7 -1.8 -2.6 1.0

8 -2.8 -3.6 0.0 -2.5 -3.3 0.3

10 -3.6 -4.5 -0.8 -3.1 -4.0 -0.4

12 -4.5 -5.3 -1.7 -3.8 -4.7 -1.1

14 -5.4 -6.2 -2.6 -4.6 -5.4 -1.8

15 -5.9 -6.7 -3.1 -5.0 -5.8 -2.2

16 -6.3 -7.2 -3.6 -5.4 -6.2 -2.6

18 -7.4 -8.2 -4.6 -6.2 -7.0 -3.4

20 -8.4 -9.3 -5.7 -7.1 -7.9 -4.3

22 -9.6 -10.4 -6.8 -8.0 -8.8 -5.2

24 -10.8 -11.6 -8.0 -9.0 -9.9 -6.3

25 -11.4 -12.3 -8.7 -9.6 -10.4 -6.8

26 -12.1 -12.9 -9.3 -10.1 -11.0 -7.4

28 -13.5 -14.3 -10.7 -11.3 -12.2 -8.5

30 -15.0 -15.8 -12.2 -12.6 -13.4 -9.8

32 -16.5 -17.3 -13.7 -14.0 -14.8 -11.2

34 -18.2 -19.0 -15.0 -15.5 -16.3 -12.7

35 -19.0 -19.9 -15.0 -16.3 -17.1 -13.5

36 -19.9 -20.6 -15.0 -17.1 -17.9 -14.3

38 -21.8 -20.6 -15.0 -18.8 -19.6 -15.0

40 -23.8 -20.6 -15.0 -20.7 -20.6 -15.0

42 -25.9 -20.6 -15.0 -22.6 -20.6 -15.0

44 -28.1 -20.6 -15.0 -24.8 -20.6 -15.0

45 -29.3 -20.6 -15.0 -25.9 -20.6 -15.0

46 -30.5 -20.6 -15.0 -27.1 -20.6 -15.0

48 -33.0 -20.6 -15.0 -29.5 -20.6 -15.0

50 -35.6 -20.6 -15.0 -32.1 -20.6 -15.0

Solution

Freeze

Point (°C)

Minimum

Recommended

LRTC

(°C)

Minimum

Recommended

LWTC

(°C)

Solution

Freeze

Point (°C)

Minimum

Recommended

LRTC

(°C)

Minimum

Recommended

LWTC

(°C)

CAUTION!

1. Additional glycol beyond the recommendations will adversely

affect unit performance. The unit efficiency will be reduced and the

saturated evaporator temperature will be reduced. For some operating

conditions this effect can be significant.

2. If additional glycol is used, then use the actual % glycol to establish the

low refrigerant cutout set point.

3. The minimum low refrigerant cutout set point allowed is - 20.6°C.

This minimum is established by the solubility limits of the oil in the

refrigerant.

RLC-SVX023A

4. With glycol application, ensure that there is no fluctuation of brine

flow versus Order Write Up value, as a reduction of flow will adversely

affect unit performance and behaviour.

5. Tables above should not be interpreted as suggesting operating ability

or performance characteristics at all tabulated glycol percentages.

Full unit simulation is required for proper prediction of unit

performance for specific operating conditions. For information on

specific conditions, contact Trane.

17

Page 18

3

Installation - Mechanical

Condenser Water Temperatures

With the model RTSF chiller, a condenser water control

method is necessary only if the unit starts with entering

water temperatures below 13°C, or between 7°C and

13°C, when a temperature increase of 0.6°C per minute

to 13°C is not possible.

When the application requires startup temperatures

below the prescribed minimums, a variety of options are

available. To control a 2-way or 3-way valve, Trane offers

a Condenser Regulating Valve Control option for the

Tracer UC800 controls.

Condenser leaving water temperature must be 9°C

higher that evaporator leaving water temperature within

2 minutes after start-up. A minimum of 14°C differential

must be maintained afterwards.

The minimum acceptable refrigerant pressure differential

between condenser and evaporator is 1.7 Bar. The chiller

control system will attempt to obtain and maintain this

differential at startup, but for continuous operation

a design should maintain a 14°C differential from

evaporator leaving water temperature to condenser

leaving water temperature.

CAUTION! In case of low evaporator leaving water

temperature applications, the non use of glycol on the

condenser side may result in condenser plate freeze-up.

Condenser Water Regulation

The Condenser Head Pressure Control Option provides

for a 0-10VDC (maximum range -a smaller range is

adjustable) output interface to the customer’s condenser

water flow device. This option enables the Tracer UC800

controls to send a signal for opening and closing a

2-way or 3-way valve as necessary to maintain chiller

differential pressure.

Methods other than those shown can be employed to

achieve the same results. Contact your local Trane office

for details.

Contact the manufacturer of the cooling device for

compatibilty with variable water flow.

Throttling valve (Figure 2)

This method maintains condensing pressure and

temperature by throttling water flow leaving the

condenser in response to condenser pressure or system

differential pressures.

Advantages:

• Good control with proper valve sizing at relatively low

cost.

• Pumping cost can be reduced.

Disadvantages:

• Increased rate of fouling due to lower condenser water

velocity.

• Requires pumps that can accommodate variable flow.

Figure 2

1

CO

4

2B

7

CI

5A

6

CDS

4

EO

EVP

EI

18

RLC-SVX023A

Page 19

Installation - Mechanical

3

Cooling device bypass – Figure 3

Cooling device bypass is also a valid control method if

the chiller temperature requirements can be maintained.

Advantage:

• Excellent control by maintaining constant water flow

through the condenser.

Disadvantage:

• Higher cost because of the dedicated pump required for

each chiller if condenser pressure is the control signal.

Figure 3

1

CO

4

2A

7

CI

5A

6

CDS

4

EO

EVP

Condenser water pump with variable frequency drive –

Figure 4

Advantages:

• Pumping cost can be reduced. Good cooling device

temperature control.

• Relatively low first cost.

Disadvantage:

• Increased rate of fouling due to lower water velocity in

the condenser.

Figure 4

7

CO

CDS

CI

5B

4

8

EO

EI

EVP

EI

1 = Electric valve actuator

2A = 3-way valve or 2 butterfly valves

2B = 2 butterfly valves

3 = RTSF controller

4 = Refrigerant pressure line

5A = Condenser water pump

5B = Condenser water pump with VFD

6 = To/from cooling load

7 = To/from cooling device

8 = Electric controller

EI = Evaporator Inlet

EO = Evaporator Outlet

CI = Condenser Inlet

CO = Condenser Outlet

RLC-SVX023A

19

Page 20

Installation - Mechanical

Condenser Water Regulating Valve

Adjustment

A separate Settings Menu tab entitled “Condenser

Head Pressure Control -Setup” that is only visible if

the configuration is selected, contain the following

settings and manual overrides for user adjustments and

commissioning all under one tab:

• “Off State” Output Command (0-10 Vdc, 0.1 volt

increments, Default 2.0 Vdc)

• Output Voltage @Desired Minimum Flow (Adj: 0 to 10.0

in 0.1 volt increments, Default 2.0 Vdc)

• Desired Minimum Flow (Adj:0-100% of full flow in

1%intervals, Default 20%)

• Output Voltage @Desired Maximum Flow (Adj: 0 to 10.0

in 0.1 volt increments (or finer),Default 10 Vdc)

• Actuator Stroke Time (Min to Max Range Time)(Adj: 1 to

1000 seconds, in 1 second increments, Default 30s)

• Damping Coefficient (adj: 0.1 to 1.8, in 0.1 increments,

Default .5)

• Head Pressure Control Override (enumeration of:

disabled (auto),”off” state, minimum, maximum

(100%),) default : disabled (auto). When this setting is in

“disabled (auto)”

• Condenser Water Pump Prerun Time

WARNING: In low temperature chilled water

applications, in the case of a power loss, there is a risk

of a condenser freeze-up. For low temperature chilled

water applications, it is recommended to take freeze

protection measures.

20

RLC-SVX023A

Page 21

Installation - Electrical

General Recommendations

For proper electrical component operation, do not locate

the unit in areas exposed to dust, dirt, corrosive fumes,

or excessive humidity. If any of these conditions exist,

corrective action must be taken.

When reviewing this manual keep in mind:

• All field-installed wiring must be in accordance with

local regulations, CE directives and guidelines. Be sure

to satisfy proper equipment grounding requirements

according to CE.

• The following standardized values - Maximum Amps -

Short Circuit Amps - Starting Amps are displayed on

unit nameplate.

• All field-installed wiring must be checked for proper

terminations, and for possible shorts or grounds.

Note: always refer to wiring diagrams shipped with

chiller or unit submittal for specific electrical schematic

and connection information.

Important: to prevent control malfunctions, do not run

low voltage wiring (<30V) in conduit with conductors

carrying more than 30 volts.

WARNING! Hazardous Voltage with Capacitor!

Disconnect all electric power, including remote

disconnects and discharge all motor start/run and

AFD (Adaptive Frequency™ Drive) capacitors before

servicing. Follow proper lockout/tagout procedures to

ensure the power cannot be inadvertently energized.

• For variable frequency drives or other energy storing

components provided by Trane or others, refer to the

appropriate manufacturer’s literature for allowable

waiting periods for discharges capacitors. Verify with

an appropriate voltmeter that all capacitors have

discharged.

• DC bus capacitors retain hazardous voltages after input

power has been disconnected. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized.

After disconnecting input power, wait twenty (20) minutes

for units which are equipped with variable frequency drive

(0V DC) before touching any internal components.

Failure to follow these instructions could result in death

or serious injury.

For additional information regarding the safe discharge

of capacitors, see “Adaptive Frequency™ Drive (AFD3)

Capacitor Discharge”.

• However, for any intervention in the AFD, the indicated

time on the label of the AFD must be respected.

Before installing the chiller with AFD, the user must

evaluate the potential electromagnetic problems in the

surrounding area. The following should be considered:

a) the presence above , below and adjacent to the unit of

for example: welding equipment or other power cables,

control cables or signaling and telephone cables;

b) receivers and transmitters, radio and television;

c) computer and other control equipment ;

d) the critical safety equipment, eg protection of

industrial equipment ;

e) the health of neighboring persons, for example, use of

pacemakers or appliances against deafness ;

f) the immunity of other equipment in the environment.

The user must ensure that the other materials used

in the environment are compatible. This may require

additional protection measures ;

If electromagnetic disturbances are detected, it shall be

the responsibility of the user to resolve the situation.

In any case, the electromagnetic interferences have to be

reduced until they are no longer troublesome.

All wiring must comply with national electric regulations.

Minimum circuit ampacities and other unit electrical

data is on the unit nameplate. See the unit order

specifications for actual electrical data. Specific electrical

schematics and connection diagrams are shipped with

the unit.

Do not allow conduit to interfere with other components,

structural members or equipment. Control voltage

(110V) wiring in conduit must be separate from conduit

carrying low voltage (<30V) wiring. To prevent control

malfunctions, do not run low voltage wiring (<30V) in

conduit with conductors carrying more than 30V.

RLC-SVX023A

21

Page 22

Installation - Electrical

Power Supply Wiring

Model RTSF chillers are designed according to European

standard EN 60204-1; therefore, all power supply wiring

must be sized and selected accordingly by the project

engineer.

Water Pump Power Supply

Provide power supply wiring with fused disconnect for

both the chilled water and condenser water pumps.

Electrical Panel Power Supply

Power supply wiring instructions for the starter/control

panel are:

Run the line voltage wiring in conduit to the access

opening(s) on the starter/control panel. See the product

catalog for wire sizing and selection information

and refer to general data that show typical electrical

connection sizes and locations. Always refer to submittal

information for your actual unit specifications.

Some connections required the user to provide an

external source of power. The 110V control power

transformer is not sized for additional load.

CAUTION

Unit with AFD version must not be linked to the neutral

wiring of the installation.

Units are compatible with the following neutral

operating conditions:

TNS IT TNC TT

Standard Special Special Special

- on request - on request - on request

Differential protection should be suited for industrial

machinery with current leak which can be higher than

500 mA (several motors and frequency drives).

CAUTION! To avoid corrosion, overheating or general

damage, at terminal connections, unit is designed for

copper Conductors only. In case of aluminum cable,

bi-material connecting devices are mandatory. Cable

routing inside control panel should be made case by

case by installer.

Compressor Motor Phase

Sequencing

Always verify that proper rotation of the chiller

compressor is established before the machine is started.

Proper motor rotation requires confirmation of the

electrical phase sequence of the power supply. The

motor is internally connected for clockwise rotation with

the incoming power supply phased A, B, C (L1, L2, L3).

To confirm the correct phase sequence (ABC), use a

phase meter.

Basically, voltages generated in each phase of a

polyphase alternator or circuit are called phase voltages.

In a 3-phase circuit, 3 sine wave voltages are generated,

differing in phase by 120 electrical degrees. The order

in which the 3 voltages of a 3-phase system succeed

one another is called phase sequence or phase rotation.

This is determined by the direction of rotation of the

alternator. When rotation is clockwise, phase sequence is

usually called “ABC.”

This direction may be reversed outside the alternator

by interchanging any two of the line wires. It is this

possible interchange of wiring that makes a phase

sequence indicator necessary if the operator is to quickly

determine the phase rotation of the motor.

Module and Control Panel

Connectors

All connectors can be unplugged or the wires can be

removed. If an entire plug is removed, make sure the

plug and the associated jack are marked for proper

location identification during reinstallation.

All electrical drawings, schematics and control panel

layout are included in the documentation package sent

with the chiller.

22

RLC-SVX023A

Page 23

Interconnecting Wiring (Field Wiring

Required)

Important: Do not turn chiller on or off using the chilled

water pump interlocks.

When making field connections, refer to the appropriate

field layout, wiring, schematics and controls diagrams

that ship with the unit. Whenever a contact closure

(binary output) is referenced, the electrical rating is:

At 120 VAC 7.2 amp resistive

2.88 amp pilot duty

250 W, 7.2 FLA,

43.2 LRA

At 240 VAC 5.0 amp resistive

2.0 amp pilot duty

250 W, 3.6 FLA,

21.3 LRA

Installation - Electrical

Whenever a dry contact input (binary input) is

referenced, the electrical rating is 24VDC, 12 mA.

Whenever a control voltage contact input (binary input)

is referenced, the electrical rating is 120 VAC, 5mA.

Some connections require the user to provide an

external source of power. The 110V control power

transformer is not sized for additional load.

Chilled Water Pump Control

Tracer UC800 has a evaporator water pump output

relay that closes when the chiller is given a signal to

go into the Auto mode of operation from any source.

The contact is opened to turn off the pump in the event

of most machine level diagnostics to prevent the build

up of pump heat. To protect against the build-up of

pump heat for those diagnostics that do not stop and/

or start the pump and to protect against the condition

of a bad flow switch, the pump shall always be stopped

when refrigerant pressure is seen to be close to heat

exchanger design pressure.

Chilled Water Flow Interlock

Tracer UC800 has an input that will accept a contact

closure from a proof-of-flow device such as a flow

switch. The flow switch is to be wired in series with the

chilled water pump starter’s auxiliary contacts. When

this input does not prove flow within 20 minutes relative

to transition from Stop to Auto modes of the chiller, or

if the flow is lost while the chiller is in the Auto mode

of operation, the chiller will be inhibited from running

by a non-latching diagnostic. The flow switch input

shall be filtered to allow for momentary openings and

closings of the switch due to turbulent water flow. This

is accomplished with a 6 seconds filtering time. The

sensing voltage for the condenser water flow switch is

115/240 VAC.

IMPORTANT! DO NOT cycle the chiller through starting

and stopping the chilled water pump. This could cause

the compressor to shut down fully loaded. Use the

external stop/start input to cycle the chiller.

RLC-SVX023A

23

Page 24

Installation - Electrical

Condenser Water Pump Control

Tracer UC800 provides a contact closure output to start

and stop the condenser water pump. It will allow to run

the condenser pump after compressor stop to avoid risk

of freezing due to refrigerant migration from evaporator.

Condenser Water Pump Prestart time has been added to

help with cold condenser water problems. In very cold

outdoor ambient, the cooling device’s sump would reach

the chiller some time after the low system differential

pressure protection had run through its ignore time,

and result in an immediate shutdown and latching

diagnostic. By simply starting the pump earlier, and

allowing mixing of the warmer indoor loop with the

cooling device’s sump, this problem can be avoided.

Condenser Water Flow Interlock

The Tracer UC800 shall accept an isolated contact closure

input from a customer installed proof-of-flow device

such as a flow switch and customer provided pump

starter auxiliary contact for interlocking with condenser

water flow.

The input shall be filtered to allow momentary openings

and closings of the switch due to turbulent water flow,

etc. This shall be accomplished with a 6 seconds filtering

time. The sensing voltage for the condenser water flow

switch is 115/240 VAC.

On a call for cooling after the restart inhibit timer has

timed out, the Tracer UC800 shall energize the condenser

water pump relay and then check the condenser water

flow switch and pump starter interlock input for flow

confirmation.

Startup of the compressor will not be allowed until flow

has proven. If flow is not initially established within

1200 seconds (20 minutes) of the condenser pump

relay energizing, an automatically resetting diagnostic

“Condenser Water Flow Overdue” shall be generated

which terminates the prestart mode and denergizes

the condenser water pump relay. This diagnostic is

automatically reset if flow is established at any later

time.

Note: This diagnostic would never automatically reset

if Tracer UC800 was in control of the condenser pump

through its condenser pump relay since it is commanded

off at the time of the diagnostic. It could however reset

and allow normal chiller operation if the pump was

controlled from some external source.

Programmable Relays (Alarm and Status)

Tracer UC800 provides a flexible alarm or chiller status

indication to a remote location through a hard wired

interface to a dry contact closure. 4 relays are available

for this function as a Quad Relay Output LLID and

a second quad relay board can be field mounted if

more than 4 different alarm/status are needed (refer to

your local Trane service). The events/states that can be

assigned to the programmable relays are listed in the

following table.

24

RLC-SVX023A

Page 25

The Tracer UC800 Service Tool (TU) is used to install and

assign any of the above listed events or status to each of

the 4 relays. The default assignments for the 4 available

relays are listed below.

Installation - Electrical

LLID Name

Operating Status

Programmable Relays

LLID Software

Relay Designation Output Name Default

Relay 0 Status Relay 1, J2-1,2,3 Evaporator Freeze Avoidance

Relay 1 Status Relay 2, J2-4,5,6 Condenser Freeze Avoidance

Relay 2 Status Relay 3, J2-7,8,9 Compressor Running

Relay 3 Status Relay 4, J2-10,11,12 Latching Alarm

If the evaporator/condenser pump request relays are

not used to manage the evaporator/condenser water

pumps then the evaporator/condenser freeze avoidance

request relays must be connected to the water pump

management system to switch the water pumps ON

when the Tracer UC800 identifies a risk of freeze up.

Latching input

The Tracer UC800 provides auxiliary control for a

customer specified/installed latching trip out. When

this customer-furnished remote contact is provided,

the chiller will run normally when the contact is closed.

When the contact opens, the unit will trip off on a

manually resettable diagnostic. This condition requires

manual reset at the chiller switch on the front of the

control panel.

External Auto/Stop

If the unit requires the external Auto/Stop function, the

installer must provide leads from the remote contacts to

the proper terminals of the LLID on the control panel. The

chiller will run normally when the contacts are closed.

When the contact opens, the compressor(s), if operating,

will go to the RUN : UNLOAD operating mode and cycle

off. Unit operation will be inhibited. Re-closure of the

contacts will permit the unit to automatically return to

normal operation.

NOTE: A “panic “ stop (similar to “emergency “ stop) can

be manually commanded by pressing the STOP button

twice in a row, the chiller will immediately shut down,

but without creating a latching diagnostic.

Request

Request

Soft Loading

Soft loading will prevent the chiller from going to full

capacity during the pull-down period. The Tracer UC800

control system has two soft loading algorithms running

all of the time. They are capacity control soft loading and

current limit soft loading. These algorithms introduce the

use of a Filtered Chilled Water Setpoint and a Filtered

Current Limit Setpoint. After the compressor has been

started, the starting point of the filtered chilled water

setpoint is initialized to the value of the Evap Leaving

Water Temperature. The filtered current limit setpoint

is initialized to the value of the Current Limit Softload

Starting Percent. These filtered setpoints allow for a

stable pull-down that is user adjustable in duration. They

also eliminate sudden transients due to setpoint changes

during normal chiller operation.

3 settings are used to describe the behavior of soft

loading. The setup for soft loading can be done using TU.

• Capacity Control Softload Time: This setting controls the

time constant of the Filtered Chilled Water Setpoint. It is

settable between 0 and 120 min.

• Current Limit Control Softload Time: This Setting

controls the time constant of the Filtered Current Limit

Setpoint. It is settable between 0 and 120 minutes.

• Current Limit Softload Starting %: This setting controls

the starting point of the Filtered Current Limit Setpoint.

It is adjustable from 20 to 100% RLA.

RLC-SVX023A

25

Page 26

Installation - Electrical

LonTalk Communication Interface - Optional

Tracer UC800 provides an optional LonTalk

Communication Interface (LCI-C) between the chiller and

a BAS. An LCI-C LLID shall be used to provide “gateway”

functionality between the LonTalk protocol and the

chiller.

Bacnet Communication Interface - Optional

Tracer UC800 provides an optional Bacnet

communication interface between the chiller and a BAS.

Bacnet communication capability is fully integrated on

UC800. For further information see Integration Guide.

Modbus Communication Interface - Optional

Tracer UC800 provides an optional Modbus

communication Interface between the chiller and a BAS.

Modbus communication capability is fully integrated on

UC800. For further information see the Integration guide.

Ice Making Contact - Optional

Tracer UC800 accepts a contact closure input to

initiate Ice Building. When in the ice building mode,

the compressor will be fully loaded (not given a low

setpoint) and will continue to operate until the ice

contacts open or the return water temperature reaches

the Ice Termination Setpoint. If terminated on return

setpoint, Tracer UC800 will not allow the chiller to restart

until the ice making contact is opened.

Ice Machine Control - Optional

Tracer UC800 provides an output contact closure that

can be used as a signal to the system that ice building

is in operation. This relay will be closed when ice

building is in progress and open when ice building has

been terminated by either Tracer UC800 or the remote

interlock. It is used to signal the system changes required

to convert to and from ice making.

External Chilled Water Setpoint - Optional

Tracer UC800 will accept either a 2-10 VDC or a 4-20 mA

input signal, to adjust the chilled water setpoint from a

remote location.

Auxiliary Chilled/Hot Setpoint Contact - Optional

Tracer UC800 accepts a contact closure input to switch

from BAS/External/Front Panel setpoint to a customer

defined auxiliary setpoint. By default, chilled water

auxiliary setpoint is set to 9°C and hot water auxiliary

setpoint is set to 33°C.

External Current Limit Setpoint - Optional

Tracer UC800 will accept either a 2-10VDC or a 4-20mA

input signal to adjust the current limit setpoint from a

remote location.

Percent Condenser Pressure Output - Optional

Tracer UC800 provides a 2-10 VDC analog output to

indicate condenser pressure in percent of software High

Pressure Cutout (soft HPC).

Percent HPC =(Lowest Condenser Pressure of all running

circuits (abs) / Soft HPC (abs))*100.

Refrigerant Differential Pressure Indication - Optional

Tracer UC800 provides a 2-10 VDC analog output

to indicate refrigerant differential pressure with the

endpoints customer defined.

Refrigerant Differential Pressure = Lowest of (condenser

refrigerant pressure cktx - evaporator refrigerant

pressure cktx).

Compressor Percent RLA Output - Optional

Tracer UC800 provides a 0-10 Vdc analog output to

indicate %RLA of compressor starter average phase

current. 2 to 10 Vdc corresponds to 0 to 120% RLA.

26

RLC-SVX023A

Page 27

Operating Principles Mechanical

This section contains an overview of the operation

and maintenance of RTSF chillers equipped with

microcomputer-based control systems. It describes the

overall operating principles of the design. Following

the section is information regarding specific operating

instructions, detailed descriptions of the unit controls

and options and maintenance procedures that must be

performed regularly to keep the unit in top condition.

Diagnostic information is provided to allow the operator

to identify system malfunctions.

Note: To ensure proper diagnosis and repair, contact a

qualified service organization if a problem should occur.

General

The unit is mono compressor, single circuit, watercooled liquid chillers. These units are equipped with unit

mounted starter/control panels. The basic components

of RTSF unit are:

• Unit-mounted panel containing starter and Tracer

UC800 controller and Input/output LLIDS

• Helical-rotary compressor

• Evaporator

• Electronic expansion valve

• Water-cooled condenser

• Oil supply system

• Oil cooler (application dependent)

• Related interconnecting piping

• AFD (Adaptive Frequency Drive)

Refrigeration (Cooling) Cycle

The refrigeration cycle of the chiller is conceptually

similar to that of other Trane chiller products. It makes

use of a BPHE evaporator.

The compressor is a twin-rotor helical-rotary type. It

uses a suction gas-cooled motor that operates at lower

motor temperatures under continuous full- and partload operating conditions. An oil management system

provides oil-free refrigerant to the BPHE to maximize

heat transfer performance, while providing lubrication

and rotor sealing to the compressor. The lubrication

system ensures long compressor life and contributes to

quiet operation.

Condensing is accomplished in BPHE.

Refrigerant is metered through the flow system using

an electronic expansion valve that maximizes chiller

efficiency at part load.

A unit-mounted starter AFD and control panel is

provided on every chiller. Microprocessor-based unit

control modules (Tracer UC800) provide for accurate

chilled BPHE water control as well as monitoring,

protection and adaptive limit functions. The “adaptive”

nature of the controls intelligently prevents the chiller

from operating outside of its limits, or compensates for

unusual operating conditions, while keeping the chiller

running rather than simply tripping due to a safety

concern. When problems do occur, diagnostic messages

assist the operator in troubleshooting.

RLC-SVX023A

27

Page 28

Operating Principles Mechanical

Cycle Description

The refrigeration cycle for the chiller can be described

using the pressure-enthalpy diagram shown in

Figure 5. Key State Points are indicated on the figure

and are referenced in the discussion following. Typical

schematics of the system showing the refrigerant flow

loop as well as the lubricant flow loop is shown in

Figure.

Evaporation of refrigerant occurs in the evaporator that

maximizes the heat transfer performance of the heat

exchanger while minimizing the amount of refrigerant

charge required. A metered amount of refrigerant liquid

enters a distribution system in the evaporator and is

then distributed to plates in the evaporator.

The refrigerant vaporizes as it cools the water flowing

through the evaporator plates. Refrigerant vapor leaves

the evaporator as superheated vapor (State Point 1).

The refrigerant vapor generated in the evaporator flows

to the suction end of the compressor where it enters

the motor compartment of the suction-gas-cooled

motor. The refrigerant flows across the motor, providing

the necessary cooling, then enters the compression

chamber. Refrigerant is compressed in the compressor to

discharge pressure conditions. Simultaneously, lubricant

is injected into the compressor for two purposes: (1) to

lubricate the rolling element bearings, and (2) to seal the

very small clearances between the compressor’s twin

rotors.

Immediately following the compression process the

lubricant and refrigerant are effectively divided using

an oil separator. The oil-free refrigerant vapor enters

the condenser at State Point 2. The lubrication and oil

management issues are discussed in more detail in the

compressor description and oil management sections

that follow.

Cooling device water, circulating through the condenser

plates, absorbs heat from this refrigerant and

condenses it.

Refrigerant leaves the condenser as subcooled liquid and

travels to the electronic expansion valve (State Point 4).

The pressure drop created by the expansion process

vaporizes a portion of the liquid refrigerant. The resulting

mixture of liquid and gaseous refrigerant then enters the

Evaporator Distribution system (State Point 5).

The chiller maximizes the evaporator heat transfer

performance while minimizing refrigerant charge

requirements. This is accomplished by metering the

liquid refrigerant flow to the evaporator’s distribution

system using the electronic expansion valve.

A compressor suction superheat measurement provides

feedback information to the Tracer UC800 unit controller,

which commands the electronic expansion valve to

reposition when necessary.

Figure 5 – Pressure /Enthalpy Curve

28

RLC-SVX023A

Page 29

Operating Principles Mechanical

Refrigerant flow diagram

Refrigerant flow diagram for unit is supplied with drawing package with unit order.

Figure 6 – Example of typical refrigerant flow diagram

1 = Screw compressor

2 = Brazed plate evaporator