Trane CGWR30, CGWR65, CCAR30, CCAR20, CGWR40 Installation, Operation And Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Cold Generator™ Scroll Liquid Chillers

Model CGWR and CCAR

20 to 65 Tons (60 Hz)

Water-Cooled and Compressor Chillers

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

September 2017

SAFETY WARNING

CG-SVX038A-EN

Page 2

Introduction

Read this manual thoroughly before operating or servici ng

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

CAUTIONs

NOTICE

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified according to local rules. For

the USA, the Federal Clean Air Act (Section 608) sets forth

the requirements for handling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that is

used in these service procedures. In addition, some states

or municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2017 Ingersoll Rand CG-SVX038A-EN

Page 3

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in

death or serious injury.

• All Ingersoll Rand personnel must follow Ingersoll

Rand Environmental, Health and Safety (EHS)

policies when performing work such as hot work,

electrical, fall protection, lockout/tagout, refrigerant

handling, etc. All policies can be found on the BOS

site. Where local regulations are more stringent than

these policies, those regulations supersede these

policies.

• Non-Ingersoll Rand personnel should always follow

local regulations.

WARNING

Refrigerant under High Pressure!

Failure to follow instructions below could result in an

explosion which could result in death or serious injury

or equipment damage. System contains oil and

refrigerant under high pressure. Recover refrigerant to

relieve pressure before opening the system. See unit

nameplate for refrigerant type. Do not use nonapproved refrigerants, refrigerant substitutes, or

refrigerant additives.

Introduction

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

CG-SVX038A-EN 3

Page 4

Table of Contents

Model Number Descriptions . . . . . . . . . . . . . . 5

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . 6

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inspection Check List and Unit Identification 9

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensions and Weights . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unit Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . 27

Unit Controller—Software Installation and

Setup

Unit Startup Procedures . . . . . . . . . . . . . . . . . 33

Unit Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . 35

Unit Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical Schematics . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4 CG-SVX038A-EN

Page 5

Model Number Descriptions

Digit 1, 2, 3, 4 — Unit Type

CGWR=Water-Cooled Chiller

CCAR= Compressor Chiller

Digit 5, 6, 7 — Unit Nominal

Tonnage

020 = 20 Nominal Tons

030 = 30 Nominal Tons

040 = 40 Nominal Tons

050 = 50 Nominal Tons

065 = 65 Nominal Tons

Digit 8 — Unit Voltage

A = 208V/60/3

B = 230V/60/3

F = 460V/60/3

G = 575V/60/3

Digit 9, 10 — Design Sequence

A0 = Factory Assigned

Digit 11 — Agency Listing

N= None

E = ETL/ETL-C Listed to meet U.S.

and Canadian Safety Standards

Digit 12 — Condenser Water

Regulating Valve

0=None

1=With

Digit 13 — Evaporator Wye

Strainer

0=None

1 = Nominal Flow Wye Strainer

2 = Nominal Flow Wye Strainer with

installation kit

1

Digit 14 — Evaporator Temp

Range

0 = Standard Cooling

42 to 60°F [4.4 to 5.5°C]

1 = Standard Cooling/Ice Making

20 to 60°F [-6.7 to 15.6°C]

Digit 15 — Power Connection

T = Terminal Block

D = Non-Fused Disconnect Switch

F = Fused Disconnect Switch

Digit 16 — Short Circuit Rating

(SCCR)

0 = Standard 5 kA Rating

1 = Optional 100 kA Rating

Digit 17 — Sound Attenuator

0 = No Sound Attenuation

3 = Compressor Sound Blanket(s)

9 = Factory Sound Enclosure

Cabinet(s)

Digit 18 — Local Unit Controller

Interface

0 = Keypad with Dot Pixel Display

1 = Color Touchscreen

Digit 19 — Remote BMS

Interface (Digital Comm)

0=None

2=LonTalk

4=BACnet® Ms/TP

5 = BACnet IP

6=MODBUS

8 = Johnson N2

®

®

Digit 20 — Power Monitor

0=None

1=With

Digit 21 — Neoprene Isolator

Pads

0=None

1=With

Digit 22 — Flow Switch

0=None

1=With

Digit 23 — Evaporator Fluid

Type

0=Water

2 = Ethylene Glycol

3 = Propylene Glycol

4=Methanol

Digit 24 — Condenser Fluid Type

0=Water

2 = Ethylene Glycol

3 = Propylene Glycol

4=Methanol

9 = Not Applicable —

Compressor-Chiller

Digit 25 — Special Options

0=None

1=With

1

Nominal flow wye strainer installation kit includes pipe adaptors, differential pressure ports and blowdown valve.

CG-SVX038A-EN 5

Page 6

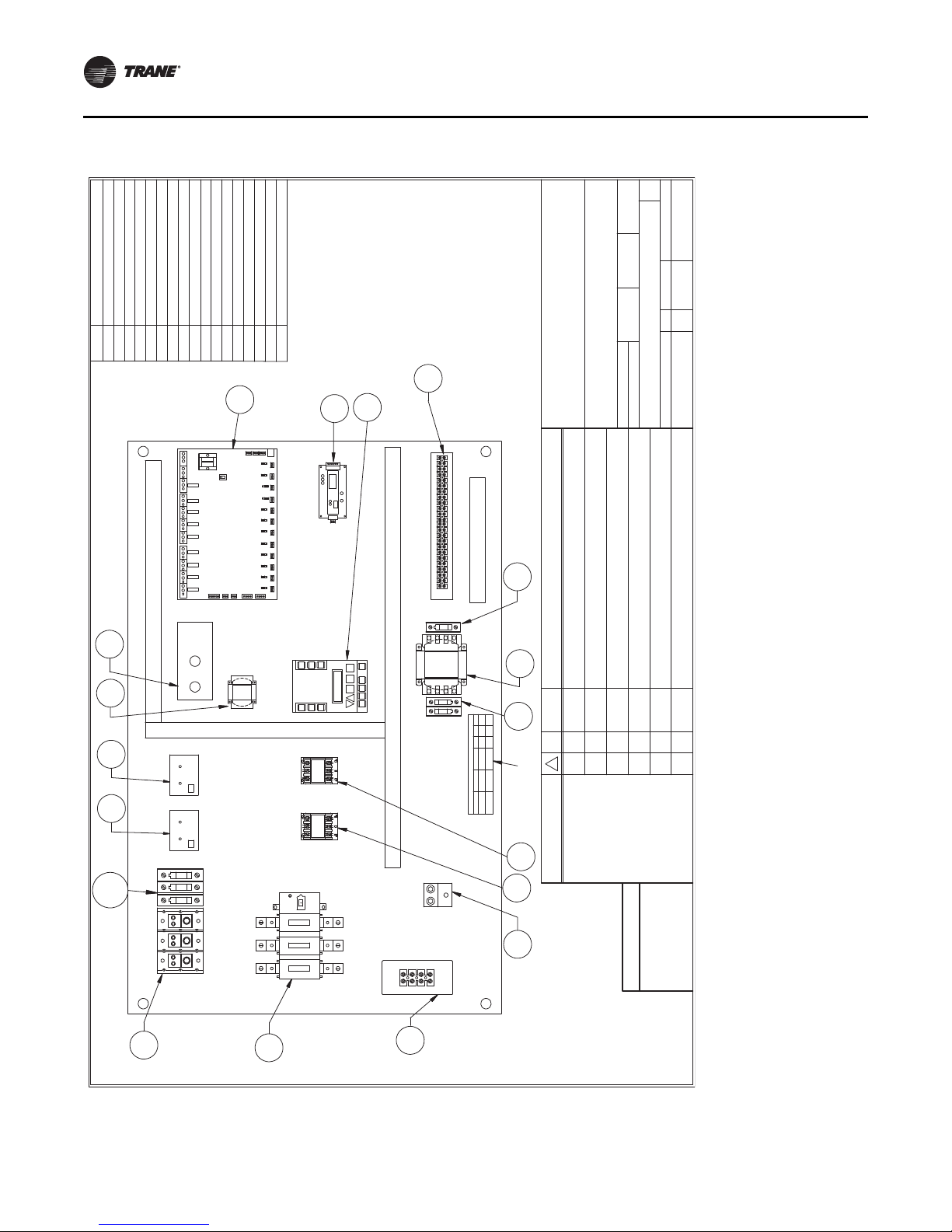

Unit Components

Forklift Pockets

Optional Disconnect

Switch Location

Evaporator Water

Inlet (Vic)

Evaporator Water

Outlet (Vic)

Condenser Water

Outlet (FPT)

Condenser Water

Inlet (FPT)

Power Wiring

Location

Unit Nameplate

(inside door)

Optional 15.4” Color Touchscreen

(Keypad w/ Display comes standard)

Rigging Bracket

Install Pockets

Removable Water

Plate on Shell-andTube Condenser

Suction Line

(1 per circuit)

TXV

(1 per circuit)

Charging Port

(1 per circuit)

Relief Valve

(1 per circuit)

Filter Drier

(1 per circuit)

Hot Gas Injection

Solenoid Valve

(1 per circuit)

Liquid Line

(1 per circuit)

Solenoid Valve

(1 per circuit)

Sight Glass

(1 per circuit)

Compressor

Nameplate

6 CG-SVX038A-EN

Page 7

General Data

Table 1. General data for CGWR water-cooled chillers

Unit Size 20 30 40 50 65

Compressor

Quantityeach22333

Nominal Tons tons 10/10 15/15 10/10, 20 12/12, 25 15/15, 30

Steps of Unloading % 100-50 100-50 100-75-50-25 100-75-50-25 100-75-50-25

Compressor Sound Data

Compressor Sound Data with Sound

Blankets Only(a)

Evaporator

Water Storage gal 2.1 3.0 3.1 3.7 4.6

Minimum Flowgpm30456682104

Maximum Flow gpm 104 151 207 237 295

Condenser (each)

Water Storage (each) gal 3.0 4.5 5.5 7.4 9.2

Minimum Flow (each)gpm2839496484

Maximum Flow (each) gpm 119 167 207 271 342

General Unit

Refrigerant R-410A R-410A R-410A R-410A R-410A

Number of Independent

Refrigerant Circuits

Refrigerant Charge per Circuit (approx.) lb 25 37 24, 24 26, 26 31, 31

Oil Charge (each compressor) oz 112/112 113/113 112/112, 227 112/112, 227 112/112, 227

Notes:

1. Data containing information on two circuits formatted as follows: Circuit 1, Circuit 2

2. Nominal compressor sizes based on 60 Hz.

(a)Compressor manufacturer sound power reported at rated compressor AHRI conditions measured in free space for individual compressors.

(a)

dBA 81.0 84.0 87.2 87.5 90.2

dBA 75.0 78.0 82.8 83.0 85.8

11222

Oil Type POE 160SZ POE 160SZ POE 160SZ POE 160SZ POE 160SZ

Table 2. General data for CCAR compressor chillers

Unit Size 20 30 40 50 65

Compressor

Quantityeach22333

Nominal Tons tons 10/10 15/15 10/10, 20 12/12, 25 15/15, 30

Steps of Unloading % 100-50 100-50 100-75-50-25 100-75-50-25 100-75-50-25

Compressor Sound Data

Compressor Sound Data with Sound

Blankets Only

Evaporator

Water Storage gal 2.1 3.0 3.1 3.7 4.6

Minimum Flowgpm30456682104

Maximum Flow gpm 104 151 207 237 295

General Unit

Refrigerant R-410A R-410A R-410A R-410A R-410A

Number of Independent

Refrigerant Circuits

Refrigerant Charge per Circuit (approx.) lb 16 19 12,12 13,13 16,16

Oil Charge (each compressor) oz 112/112 113/113 112/112, 227 112/112, 227 112/112, 227

Notes:

1. Data containing information on two circuits formatted as follows: Circuit 1, Circuit 2

2. Nominal compressor sizes based on 60 Hz.

(a)Compressor manufacturer sound power reported at rated compressor AHRI conditions measured in free space for individual compressors.

(a)

dBA 81.0 84.0 87.2 87.5 90.2

dBA 75.0 78.0 82.8 83.0 85.8

11222

Oil Type POE 160SZ POE 160SZ POE 160SZ POE 160SZ POE 160SZ

CG-SVX038A-EN 7

Page 8

General Data

Ambient Limits —

CCAR/CAUJ Combination

Minimum Ambient Temperature Limit

Refer to SS-APG014*-EN Application Guide – Pairing Trane

CCAR Compressor Chillers (20 to 65 tons) with Trane CAUJ

Air-Cooled Condensers (20 to 80 tons).

In general, the minimum outdoor ambient temperature for

operation of CCAR compressor chiller in combination with

a CAUJ air cooled condenser is 40°F. In some cases, with

factory application approval, the CCAR/CAUJ combination

can be operated down to the 20°F ambient.

This minimum is primarily driven by compressor chiller

starting considerations and not by effectiveness of

condenser ambient controls once the system is up and

running. Fan cycling and optimal low ambient dampers do

not mitigate the low ambient starting challenge. On a cold

day with outdoor ambient temperature below 40°F, the

liquid line pressure at the expansion valve inlet, in most

circumstances, is extremely low. On start, the suction

pressure tends to plunge into the freezing range

potentially causing a nuisance fault.

Contact the factory to request application approval for

applications where CCAR/CAUJ combination is intended

for operation with ambient temperature below 40°F.

Maximum Ambient Temperature Limit

The maximum ambient temperature limit for the CCAR/

CAUJ operation is 110°F.

8 CG-SVX038A-EN

Page 9

Inspection Check List and Unit Identification

To protect against loss due to damage incurred in transit,

complete the following checklist upon receipt of the unit.

• Inspect the individual pieces of the shipment before

accepting the unit. Check for obvious damage to the

unit or packing material.

• Inspect the unit for concealed damage as soon as

ssible after delivery and before it is stored.

po

Concealed damage must be reported within 15 days.

• If concealed damage is discovered, stop unpacking the

ipment. Do not remove damaged material from the

sh

receiving location. Take photos of the damage, if

possible. The owner must provide reasonable

evidence that the damage did not occur after delivery.

• Notify the carrier’s terminal of the damage

mediately, by phone and by mail. Request an

im

immediate, joint inspection of the damage with the

carrier and the consignee.

• Notify the Trane sales representati

repair. Do not repair the unit, however, until damage is

inspected by the carrier’s representative.

After completing the in

with the unit nameplate, packing list and ordering

information. The unit nameplate is mounted inside the

control box.

Refer to “Model Number Descriptions,” p. 5 for additional

data that can be found on the nameplate.

Check all items against the shipping list. Verify that it is the

correct unit and that it is properly equipped. If optional

neoprene or spring isolators (or other ship-loose items)

are ordered, they are secured in place on the shipping skid

or inside the unit control box.

The Installation, Operation, and Maintenance manual can

also be found in the unit control box. Be sure to read all of

this literature before installing and operating the unit.

spection checklist, identify the unit

ve and arrange for

Each unit is completely assembled with refrigerant piping,

power and control wiring, and top coated with two-part

epoxy. Refrigeration circuits are leak-tested and

dehydrated prior to introduction of refrigerant. CGWR and

CCAR units are then fully charged with compressor oil and

refrigerant, and run tested prior to shipment.

• CGWR units are shipped with full operating charge of

compressor oil

• CCAR units are shipped with a

compressor oil and a holding charge of dry nitrogen.

CCAR units are to be field piped to condenser,

dehydrated and charged with refrigerant by others.

Note that compressor oil charge may have to be

adjusted. See SS-APG014*-EN, Application Guide,

Pairing Trane CCAR Compressor Chillers with Trane

CAUJ Air-Cooled Condensers for application

guidelines.

and refrigerant.

nominal charge of

Unit Description

Trane CGWR water-cooled chillers and CCAR compressor

chillers (condenserless chillers) are designed for

installation on a prepared surface in a suitable,

weatherproof location above freezing (32°F).

• CGWR/CCAR 20 and 30 ton chiller units have one

refrigerant c

compressor set piped in parallel.

• CGWR/CCAR 40, 50 and 65 ton chiller units have two

refrigerant circuits. One refrigerant circuit is fit

a manifolded scroll compressor set piped in parallel,

and the other refrigerant circuit has a single scroll

compressor.

Units also have brazed plate e

condenser (CGWR only) and control box with integral

control panel, all mounted on a common frame.

CG-SVX038A-EN 9

ircuit fitted with a manifolded scroll

vaporator, shell-and-tube

ted with

Page 10

Electrical Data

Table 3. Electrical data — CGWR water cooled chillers & CCAR compressor chillers

Unit Wiring Data Compressors

Unit

Size

200-230/3/60 88 125 100

20

30

40

50

65

Notes:

1. Data containing information on two circuits formatted as follows: Circuit 1, Circuit 2

2. Add 31 VA to control power for optional water regulating valve (WRV)

3. Use copper conductors only.

4. Local codes may take precedence.

5. Voltage Utilization Range:

460/3/60 42 60 50 19/19 142/142 98

575/3/60 35 50 40 15/15 103/103 98

200-230/3/60 108 150 125

460/3/60 56 80 60 25/25 197/197 98

575/3/60 50 70 60 22/22 135/135 98

200-230/3/60 162 225 175

460/3/60 78 110 90 19/19, 33 142/142, 215 159

575/3/60 64 80 70 15/15, 26 103/103, 175 159

200-230/3/60 185 250 225

460/3/60 88 125 100 19/19, 40 147/147, 260 159

575/3/60 69 90 80 17/17, 29 122/122, 210 159

200-230/3/60 232 300 250

460/3/60 113 150 125 25/25, 51 197/197, 320 159

575/3/60 93 125 110 22/22, 38 135/135, 235 159

Rated Voltage

208-230/3/60

460/3/60

380/3/60

575/3/60

Circuit

Ampacity

Utilization Range

187-253

414-506

342-418

518-632

Maximum

Fuse Size

Minimum

Recommended

Dual Element

Fuse Size Qty

Refrig.

Circuits

2 1 10/10

2 1 15/15

3 2 10/10, 20

3 2 12/12, 25

3 2 15/15, 30

Nom.

Tons

RLA

(ea)

39/39 267/267 98

48/48 351/351 98

39/39, 67 267/267, 485 159

41/41, 82 304/304, 560 159

48/48, 109 351/351, 717 159

LRA

(ea)

Control

KWRated Voltage

10 CG-SVX038A-EN

Page 11

Dimensions and Weights

B

C

A

B*

1

2

5

8

11

12

6

7

R

N

V

W

S

U

R*

N*

3

4

D

E

F

G

T (4 PLACES)

M

H

I

J

K

L

9

10

15

13 14

16

Dimensions

The Trane application manual and/or project submittals

contain dimensional data, application data, and electrical

data as required.

Figure 1. CGWR/CCAR 20 to 30 ton mechanical drawing

Refer to name plate on control box door (inside) for

specific unit electrical data.

These documents can be forwarded for specific jobs as

part of a job submittal package upon request.

CG-SVX038A-EN 11

Page 12

Dimensions and Weights

Table 4. CGWR/CCAR 20 to 30 ton — in (mm)

Dimension CGWR 20 CGWR30 CCAR 20 CCAR30

(a)

A

B 59.8 (1519) 59.8 (1519) 45.8 (1163)* 45.8 (1163)*

C 19.3 (490) 20.1 (511) N/A N/A

D 26.7 (678) 26.7 (678) 26.7 (678) 26.7 (678)

E 28.9 (734) 28.9 (734) 28.9 (734) 28.9 (734)

F 37.0 (940) 37.0 (940) 37.0 (940) 37.0 (940)

G 17.0 (432) 17.0 (432) 17.0 (432) 17.0 (432)

H 20 (508) 20 (508) N/A N/A

I 36 (914) 36 (914) 36 (914) 36 (914)

(b)

J

K(b) 36 (914) 36 (914) 36 (914) 36 (914)

L 24 (610) 24 (610) 24 (610) 24 (610)

M 36 (914) 36 (914) 36 (914) 36 (914)

N 53.5 (1359) 53.5 (1359) 39.5 (1003)* 39.5 (1003)*

R 33.1 (841) 33.1 (841) 19.1 (485)* 19.1 (485)*

S 13.4 (240) 13.4 (240) N/A N/A

T 0.6 (15) 0.6 (15) 0.6 (15) 0.6 (15)

U 10.2 (259) 10.2 (259) 10.2 (259) 10.2 (259)

V 10.3 (262) 10.4 (264) N/A N/A

W 13.9 (353) 15.3 (389) N/A N/A

1 2 (51) VIC 2.5 (64) VIC 2 (51) VIC 2.5 (64) VIC

2 2 (51) VIC 2.5 (64) VIC 2 (51) VIC 2.5 (64) VIC

3 2 (51) FPT 2.5 (64) FPT N/A N/A

4 2 (51) FPT 2.5 (64) FPT N/A N/A

76.6 (1946) 77.5 (1969) 70.4 (1788) 70.4 (1788)

36 (914) 36 (914) 36 (914) 36 (914)

Reference

1 Evaporator Water Inlet 9

2 Evaporator Water Outlet 10

3 Condenser Water Inlet (CGWR only) 11 Condenser (CGWR only)

4 Condenser Water Outlet (CGWR only) 12 Evaporator

5 Power Disconnect (Optional) 13 Panel Power Section — door swing 24 in (610 mm)

6 Power Wire Entry 14 Panel Control Section — door swing 24 in (610 mm)

7 Control Wire Entry 15

8 Control Panel 16

(a)For CGWR020 and 030: If water regulating valve option is ordered, the overall length is 90.9 in and 93.1 in, respectively.

(b)Exceptions:

1. A minimum clearance of 42 in (1067mm) is required to other electrically grounded parts.

2. A minimum clearance of 48 in (1220mm) is required betw een two u nits opp osit e eac h oth er (front-t o-front o r back-to - back) o r to other electrically

live parts. See Section 110.26 of National Electrical code (NEC).

Condenser Return Waterbox End (CGWR only)-

minimum clearance (for maintenance)

Condenser Inlet/Outlet End (CGWR only) minimum clearance (for maintenance)

Additional minimum clearance needed for units with w ater

regulating valve option

Location of CCAR refrigerant line connections, 7/8 in liquid

line and 1-3/8 in discharge lines

12 CG-SVX038A-EN

Page 13

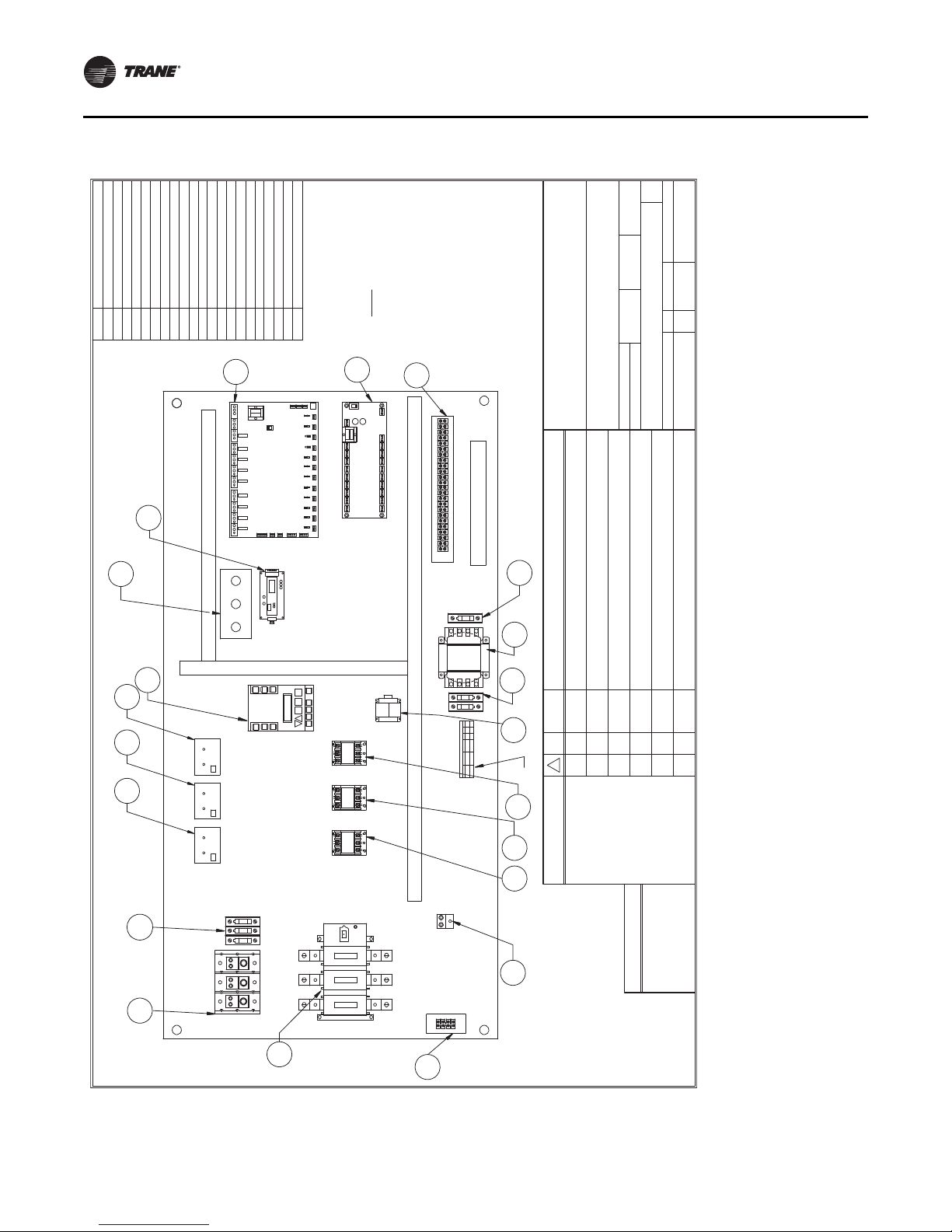

Figure 2. CGWR/CCAR 40 to 65 ton mechanical drawing

C

B*

B

A

5

8

11

12

7

16

2

1

6

R*

N*

V

W

R

N

U

S

3

4

G

F

D

E

T

(4 PLACES)

M

H

I

J

K

L

15

10

13 14

9

Dimensions and Weights

CG-SVX038A-EN 13

Page 14

Dimensions and Weights

Table 5. CGWR/CCAR 40 to 65 ton — in (mm)

Dimension CGWR40 CGWR50 CGWR65 CCAR40 CCAR50 CCAR65

(a)

A

B 59.8 (1519) 59.8 (1519) 59.8 (1519) 45.8 (1163)* 45.8 (1163)* 45.8 (1163)*

C 13.1 (333) 13.6 (345) 13.6 (345) N/A N/A N/A

D 26.7 (678) 26.7 (678) 26.7 (67 8) 26.7 (678) 26.7 (678) 26.7 (678)

E 29.6 (752) 29.9 (759) 29.9 (759) 29.0 (737) 29.0 (737) 29.0 (737)

F 51.0 (1295) 51.0 (1295) 51.0 (1295) 51.0 (1295) 51.0 (1295) 51.0 (1295)

G 19.2 (488) 19.2 (488) 19.2 (488) 19.2 (488) 19.2 (488) 19.2 (488)

H 20 (508) 20 (508) 20 (508) N/A N/A N/A

I 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

(b)

J

K(b) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

L 24 (610) 24 (610) 24 (610) 24 (610) 24 (610) 24 (610)

M 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

N 49.6 (1260) 49.6 (1260) 49.6 (1260) 35.6 (904)* 35.6 (904)* 35.6 (904)*

R 34.0 (864) 34.0 (864) 34.0 (864) 20.0 (508)* 20.0 (508)* 20.0 (508)*

S 13.4 (340) 13.4 (340) 13.4 (340) N/A N/A N/A

T 0.6 (15) 0.6 (15) 0.6 (15) 0.6 (15) 0.6 (15) 0.6 (15)

U 12.2 (310) 12.2 (310) 12.2 (310) 12.2 (310) 12.2 (310) 12.2 (310)

V 10.6 (269) 11.0 (279) 11.0 (279) N/A N/A N/A

W 15.5 (394) 16.8 (427) 16.8 (427) N/A N/A N/A

1 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC

2 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC 3.0 (76) VIC

3 2.5 (64) FPT 3.0 (76) FPT 4.0 (102) FPT N/A N/A N/A

4 2.5 (64) FPT 3.0 (76) FPT 4.0 (102) FPT N/A N/A N/A

83.8 (2128) 83.8 (2128) 83.8 (2128) 87.6 (2225) 87.6 (2225) 87.6 (2225)

36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

Reference

1 Evaporator Water Inlet 9

2 Evaporator Water Outlet 10

3 Condenser Water Inlet (CGWR only) 11 Condenser (CGWR only)

4 Condenser Water Outlet (CGWR only) 12 Evaporator

5 Power Disconnect (Optional) 13 Panel Power Section — door swing 31.3 in (795 mm)

6 Power Wire Entry 14 Panel Control Section — door swing 31.3 in (795 mm)

7 Control Wire Entry 15

8 Control Panel 16

(a)For CGWR040, 050 and 065: If water regulating valve option is ordered, the overall length is 93.8 in, 95.0 in, and 96.2 in respectively.

(b)Exceptions:

1. A minimum clearance of 42 in (1067mm) is required to other electrically grounded parts.

2. A minimum clearance of 48 in (1220mm) is required between two units opposite each other (front-to-front or back-to-back), or to other electrically

live parts. See Section 110.26 of National Electrical code (NEC).

Condenser Opposite Inlet/Outlet End (CGWR only) —

minimum clearance (for maintenance)

Condenser Inlet/Outlet End (CGWR only) —

minimum clearance (for maintenance)

Additional minimum clearance needed for units with w ater

regulating valve option

Location of CCAR refrigerant line connections, (2) 1-1/8 in

liquid line and (2) 1-3/8 in discharge lines

14 CG-SVX038A-EN

Page 15

Weights

Table 6. Weights

Shipping Operating

Unit Size lbs kg lbs kg

20 1116 506 1042 473

30 1252 568 1242 563

CGWR

CCAR

40 1659 753 1577 715

50 1847 838 1833 831

65 2039 925 2005 909

20 846 384 732 332

30 909 412 809 367

40 1265 574 1110 503

50 1304 591 1152 523

65 1484 673 1336 606

Dimensions and Weights

CG-SVX038A-EN 15

Page 16

Installation

General Installation Information

• Where specified, supply and install valves in the water

piping upstream and downstream of the evaporator

and condenser, to isolate the heat exchangers for

maintenance and to balance/trim the system.

• Supply and install condense

Refer also to Trane publication RLC-PRB021-EN

available from Trane Sales Offices for additional

technical assistance. Provisions must be made for the

control of condenser water that results in stable

Saturated Discharge Pressure between 80°F and 128°F

through all steady state, part load and transient

operating conditions. Trane recommends optional

factory installed integral Water Regulating Valve

operated by onboard controller.

• Optional Water Regulating Valv

installed and integrated water regulating valve

designed to stabilize discharge pressure at all full and

part load conditions. Factory installed water regulating

valve is controlled by the chiller’s unit controller and is

available on all models.

• Supply and install an approved f

flow proving device, in the chilled water line as shown

in Figure 3, p. 21. Flow switch must be interlocked with

chiller’s unit controller to ensure the unit cannot

perate when chilled water flow through the unit is

o

below the minimum chilled water flow limit. See fieldwiring diagram for flow proving device connection

points. A factory approved flow switch may be ordered

with the unit as a shipped-loose option, for field

installation by others.

• Supply and install drain vent points

both chilled and condenser water line to vent air and

drain lines and equipment for service.

• Install a wye strainer ahead of all system pumps and

control valve

Note: A w

installed in the chilled water pipe immediately

adjacent to the evaporator inlet. See Figure 3, p. 21.

A factory approved wye strainer may be ordered

with the unit as a shipped-loose option, for field

installation by others.

• Supply and install su

piping from the pressure relief to the atmosphere if

required. Follow ANSI/ASHRAE 15-2007 guidelines,

relief manu

standards when working with relief piping.

• If necessary, supply enough refrigerant and dry

nitrogen (1

• Start the unit under supervision of a qualified service

hnician.

tec

• Where specified, supply and insulate the chilled water

ping as required, to prevent sweating under normal

pi

s.

ye strainer with twenty mesh screen must be

itable refrigerant pressure relief

facturer’s guidelines, and industry

50 psig) for pressure testing (CCAR).

r water control valve.

e — Trane offers a fully

low switch, or suitable

with valves on

operating conditions. Trane provides factory

insulation on evaporator and related components.

Storage

NOTICE:

Store Units Above Freezing!

Store these units in a protected area above freezing

(32°F) only. Do not store outdoors with a protective

covering such as a plastic shroud. This can result in

excessive water condensation that could damage

controls and other components.

These units are designed for indoor installation above

freezing (32°F) only. Store the unit in a suitable

weatherproof location above 32°F, vibration free, and

secure area. Periodically check the pressure in each

refrigerant circuit to verify that the refrigerant charge is

intact. If it is not, contact a qualified service organization

and the appropriate sales office. If the unit is still under

factory warranty, you must follow warranty procedure

prior to calling for service.

Noise Considerations

Locate the unit away from sound-sensitive areas. If

necessary, install the optional isolators under the unit and/

or the optional factory sound attenuation compressor

blankets or attenuation cabinet. Install vibration isolators

in all piping and use flexible electrical conduit. Consult an

acoustical engineer for critical applications.

Foundation

A base or foundation is recommended for most

installations. Provide a level surface strong enough to

support the unit. Refer to “Dimensions and Weights,” p. 11

for dimensions and weights. A flexible (isolated) concrete

foundation or footings at each loading point will reduce

transmission of vibration. Install anchor bolts in the

concrete to secure the unit. If the floor is warped, uneven

or in poor condition, make necessary repairs before

positioning the unit. Once the unit is in place, it should be

level, within 1/4 inch over its entire length and width.

Clearances

Provide enough space around the unit to allow the

installation and maintenance personnel unrestricted

access to all service points. Unit dimensions are given in

“Dimensions and Weights,” p. 11. There should be

adequate clearance for condenser and compressor

servicing. A minimum of three feet is recommended for

effective compressor service. A minimum clearance of

3 ft.-6 inches is required to open the control panel doors.

16 CG-SVX038A-EN

Page 17

Installation

40"

BACK VIEW

LEFT END VIEW

A minimum clearance of 42 in (2067 mm) is required to

other electrically grounded parts. A minimum clearance of

48 in (1220 mm) is required between two units opposite

each other (front-to-front or back-to-back) or to other

electrically live parts. See Section 110.26 of National

Electrical Code (NEC).

Important: In all cases, local codes will take precedence

over these recommendations.

Ventilation

Provisions must be made to remove heat generated by

unit operation from the equipment room. Ventilation must

be adequate to maintain an ambient temperature lower

than 125°F.

The condenser relief valve on these units must be vented

in accordance with all local and national codes.

Drainage

Locate the unit near a large capacity drain for condenser

drain-down during shutdown or repair.

Handling

Rigging/Lifting Procedure

If the CGWR/CCAR is not moved using a forklift and the

forklift pockets provided as part of the chiller's frame, then

the chiller should be lifted and moved by using the lifting

rails as outlined in Step 1 through Step 8.

A set of lifting rails is shipped loose and attached to the unit

skid. Install the lifting rails and lift as shown below:

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

CCAR and CGWR units are shipped stretch-wrapped and

bolted to a shipping skid (unless other than standard

shipping is selected).

The skidded unit can be moved by using a fork truck of

suitable capacity. Refer to “Dimensions and Weights,”

p. 11 for unit weights.

When moving the unit, the lifting forks must be positioned

under the shipping skid as wide as possible where labeled.

Lift the unit and move it to the desired location.

Once the unit is at the installation location, remove the

stretch wrap. Inspect the unit for damage and report if

damage is found.

The optional unit isolators (if ordered) are secured to the

shipping skid or in the unit control panel. Other optional

“ship loose” items may be attached to the skid or shipped

separately depending on options selected.

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

CG-SVX038A-EN 17

Page 18

Installation

1. Remove the stretch wrap from the unit as described In

the Handling section, leaving the unit mounted to the

skid. The lifting rails should be mounted to the skid.

Remove the rails from the skid.

2. The hardware used to secure the lifting rails to the unit

frame can be found in a box in the unit control panel.

Insert the lifting rails as shown in the above figure.

Using the mounting hardware, secure the lifting rails to

the unit frame by torquing the 1/2” bolts to 70 ft-lbs.

3. Install clevis connectors or equivalent in the 1-1/4 inch

ifting holes provided at each end of the lifting rails.

l

4. Attach certified lifting chains (cables) to these points.

ach chain (cable) alone must be strong enough to lift

E

the unit.

5. Attach chains (or cables) to a li

chains (cables) so that they do not contact the unit

piping or the unit control panel. Use a suitable

spreader bar to insure proper weight distribution.

fting beam. Position the

NOTICE:

Equipment Damage!

To prevent damage to the unit, position the lifting beam

and chains (cables) so that they do not contact the unit

piping or the unit control panel.

6. Remove the bolts that secure the unit to the shipping

skid.

7. Raise the unit just off the skid

is level when lifted. Adjust chain (cable) lengths as

required for level lifting.

8. Lift the unit off of the skid a

location.

to make sure that the unit

nd place in the installation

Access Restrictions

All CCAR/CGWR units are designed to pass through a

standard 36-inch doorway. Refer to outline drawings for

other important dimensions.

Trane does not recommend disassembling a CGWR/CCAR

to gain access through challenging rigging paths and

installation locations. If disassembly/reassembly of a

chiller does take place, please note the following:

1. A qualified Trane technician must perform the task

2. Use technical support for any questions that m

during the task

3. Be aware that disassembly/reassembly could possibly

fect warranty status of the chiller, especially if failure/

af

issues occur that point toward improper reassembly &

installation

4. All required installation and star

required to be completed and promptly returned for

review, including the required running data log as

instructed in the startup checklist

tup checklists are still

ay arise

Direct Mounting

The unit can be installed directly on an isolated, rigid

mounting surface as long as the surface is level and will

support the weight of the unit. A mounting hole is

provided at each of the unit mounting locations. Provide a

means of securely anchoring the unit to the mounting

surface. Level the unit carefully.

Neoprene Isolator Pad Mounting

(Optional)

The optional neoprene isolator pads are to be placed

between the direct mounting surface and each of the

chiller's mounting locations. To help distribute the chiller's

load to the neoprene pads, place the 6" x 6" mounting

plates between each pad and the chiller. Provide a means

of securely anchoring the chiller to the mounting surface.

Level the unit carefully as instructed in “Unit Leveling,”

p. 18.

Compressor Mounting

All compressors are rigidly bolted with compressor

isolation mounts to compressor mounting rails (tandem

compressor sets) or directly to the unit base. No additional

isolation or leveling is required. Inspect prior to start up to

insure bolts are present and tight, and that no shipping

damage has occurred.

Unit Leveling

Before tightening the mounting bolts, level the unit frontto-back and end-to-end. Unit must be level within 1/4”

from front-to-back and within 1/4” over the length of the

unit. The unit’s base deck can be used for leveling. Use

shims as required to properly level unit base.

Compressor Nameplate

The nameplate for the hermetic scroll compressor is

mounted on the compressor housing, near the motor

terminal junction box.

Evaporator Nameplate

The evaporator nameplate is mounted on evaporator

under the insulation. To view the evaporator nameplate,

remove the insulation over the area if covered and spread

the insulation. The serial number information is also on

record at the factory.

Condenser Nameplate

The condenser ASME nameplate is mounted on the side of

the condenser.

18 CG-SVX038A-EN

Page 19

Unit Piping

Water Piping — General

Make water piping connections to the evaporator and

condenser (CGWR only). Isolate and support piping to

prevent stress on the unit. Use unions, flanges or grooved

lock type fittings to simplify disassembly and facilitate

service procedures. Use vibration eliminators to prevent

transmitting vibrations to the water lines. Install

thermometers in the lines to monitor evaporator and

condenser water temperatures. Install balancing cocks in

both the leaving chilled water and condenser water lines.

These valves can be used to establish a balanced water

flow. Entering and leaving chilled and condenser water

lines should have shutoff valves installed to isolate the

heat exchanger for service. See Figure 3, p. 21 for chilled

water piping schematic and Figure 4, p. 22 for condenser

water piping schematic.

Do not overtighten connections. Use a pipe sealant such as

®

Te fl o n

piping before attaching to the unit. Unit MUST be

bypassed if using a flushing agent.

tape on all threaded water connections. Flush all

NOTICE:

Equipment Damage!

To prevent equipment damage, you MUST follow

instructions below:

• Bypass unit if using a flushing agent.

• Chilled water piping must rise above the chiller to

insure the evaporator is full of water and void of air at

all times.

• Do not overtighten connections.

waterside system design. If an accurate

measurement of flow rate is required, an accurate

flow measurement device must be installed in the

water line.

Water Treatment

NOTICE:

Proper Water Treatment Required

The use of untreated or improperly treated water in this

unit could result in scaling, erosion, corrosion, algae or

slime. It is recommended that the services of a qualified

water treatment specialist be engaged to determine

what water treatment, if any, is required. Trane

assumes no responsibility for equipment failures which

result from untreated or improperly treated water, or

saline or brackish water.

Using untreated or improperly treated water in these units

may result in inefficient operation and possible tube and/

or brazed plate damage. Consult a qualified water

treatment specialist to determine if treatment is needed.

NOTICE:

Waterborne Debris!

To prevent evaporator or condenser damage,

evaporator and condenser strainers must be installed in

the water supplies to protect components from water

born debris. Removal of wye strainer or screen will void

the warranty on the brazed plate evaporator.

Chilled Water Piping

Piping and specialties must be installed in accordance

with national and local codes.

Water Flow Rates

Establish balanced water flow through both the

evaporator and condenser. Flow rates should fall between

the minimum and maximum values given in General Data

Tab l e 1 and Table 2, p. 7. Flow rates above or below these

values can cause equipment damage or improper unit

operation. Measure the evaporator and condenser water

pressure drop at the gauge ports located adjacent to the

heat exchanger, before any piping specialty components,

such as wye strainer. Evaporator water pressure drop

curves are shown in Table 5, p. 23. Condenser pressure

drop curves are shown in Table 6, p. 23.

Optional inlet wye strainer has an outlet port that can be

used for measuring inlet evaporator water pressure, if it is

installed immediately adjacent to the evaporator inlet.

Note: Evaporator and condenser pressure drop

measurement is for an approximation and is to be

used as a tool to estimate flow rate and as an aid in

CG-SVX038A-EN 19

Chilled water piping and associated components shall be

installed in accordance with Figure 3, p. 21. Chilled water

inlet and outlet types, sizes and locations are provided in

Table 4, p. 12 and Table 5, p. 14. Chilled water piping must

rise above the chiller to ensure the evaporator is full of

water and void of air at all times. All chilled water lines

must be insulated to minimize heat gain and prevent

condensation.

Brazed Plate Evaporator

Trane CGWR/CCAR chillers are equipped with brazed plate

evaporators made of stamped stainless steel plates,

furnace brazed together with copper to form a durable

high efficiency heat exchanger. Because of the small

complex geometry of the flow passages, it is imperative

customers take all precautions to ensure these

evaporators are not fouled by large particles or internal

mineral deposits. For this reason, a 20 mesh wye strainer

is required in the inlet chilled water line. Operation of the

chiller without this wye strainer or the wye strainer 20

mesh screen will void the chiller warranty. Chemical

Page 20

Unit Piping

treatment of the chilled water loop is required and must be

performed by a qualified water specialist.

NOTICE:

Proper Water Treatment!

The use of untreated or improperly treated water could

result in scaling, erosion, corrosion, algae or slime. It is

recommended that the services of a qualified water

treatment specialist be engaged to determine what

water treatment, if any, is required. Trane assumes no

responsibility for equipment failures which result from

untreated or improperly treated water, or saline or

brackish water.

Wye Strainer — Required

A wye strainer with 20 mesh screen must be installed

immediately adjacent to the inlet water connection to the

evaporator.

Important: Operation of the chiller without this wye

strainer AND 20 mesh screen in place will

void the unit warranty.

Flow Proving Device — Required

unacceptable system control problems and the potential

for evaporator failure.

Table 7. Minimum system volumes

CGWR/CCAR Unit Size

(tons)

20 157

30 226

40 311

50 355

65 442

Minimum System Volume

(gal)

Condenser Water Piping

Condenser water piping and associated components shall

be installed in accordance with condenser water piping

schematic Figure 4, p. 22. Condenser water inlet and outlet

types, sizes and locations are provided in Table 4, p. 12 and

Table 5, p. 14.

NOTICE:

Excessive Water Pressure!

To prevent condenser or regulating valve damage, do

not exceed nameplate condenser water pressure.

NOTICE:

Unexpected Chiller Start!

Failure to follow instructions could cause the chiller to

start unexpectedly which could result in equipment or

property damage. An external source (EMS, time clock

or any other means) should not be allowed to bring on

a pump that would trigger the flow switch to start the

chiller. The flow switch is meant to act as a safety

switch and not a start/stop mechanism.

Optional chilled water flow switch or other factory

approved flow proving device is mandatory. It is fieldinstalled by others. Flow switch is to be installed and

maintained in accordance with manufacturer’s

recommendations and interconnected to the unit control

panel as described in the field-wiring diagram. To provide

additional chiller protection, wire the flow proving device

control circuit in series with a chilled water pump starter

normally open auxiliary contact to create a chilled water

pump interlock. See “Chilled Water Flow Switch,” p. 28.

Chilled Water System Volume

Trane requires minimum system volumes as indicated in

Tab l e 7 . Special applications may allow deviation from

these volumes, but only with approval of Trane

engineering. Operation below these volumes will cause

Discharge Pressure Control/

Optional Factory-Installed Water

Regulating Valve

A means of maintaining stable discharge pressure during

full-load, part-load and transient conditions is required.

Saturated discharge temperature must be maintained

between 80°F and 128°F. Trane offers an optional factory

installed water regulating valve that is controlled by the

unit controller. The optional water regulating valve

maintains condensing pressure and temperature by

throttling water flow leaving the condenser in response to

compressor discharge pressure. Field-supplied water

regulating valves must be adjusted for proper operation

during full-load, part-load and transient conditions. Fieldsupplied water regulating valves must also b e a d ju s te d fo r

proper positioning when unit is off.

Alternative field-supplied methods for condensing

pressure/temperature control include the use of cooling

tower control strategies. Cooling tower systems may

include a manual or automatic bypass valve that can alter

water flow rate and basin temperature to maintain stable

condensing temperature at the chiller.

Well or city water condensing systems should include a

water regulating valve and potentially a pressure reducing

valve. A pressure reducing valve should be installed to

reduce water pressure entering the condenser if water

pressure can exceed tube-side maximum allowable

working pressure as indicated on the condenser

nameplate. This is also necessary to prevent damage to

20 CG-SVX038A-EN

Page 21

disc and seat type water regulating valves caused by

excessive pressure drops through the valve.

Under full load AHRI standard conditions, and with

approximately 3 gpm/ton cooling water flow through the

condenser, the temperature rise across the condenser will

be approximately 10°F. In all cases, the minimum inlet

condenser water temperature is 65°F.

Figure 3. Chilled water piping schematic

Unit Piping

8

4

T3

T2

T1

UNIT

7

5

5

FT

3

Table 8. Reference numbers

Item Description

1Bypass Valve

2 Isolation Valves

3 Vibration Eliminators

4 Evaporator Heat Exchangers

5 Inlet and Outlet Chilled Water Lines

6 Valves for Pressure Measurement

(a)

Strainer with 20 mesh screen

7

8 Evaporator Manual Air Vent Valve w/Plug

A Isolator Unit for initial water loop cleaning

(b)

Arrangement for Measuring Differential Pressure

B

(c)

Water Flow S witch

FT

Pi Pressure Gauge

T1 Evaporator outlet temperature sensor

T2 Evaporator inlet temperature sensor

T3 Evaporator core temperature sensor

T4 Chiller inlet temperature gauge

T5 Chiller outlet temperature gauge

(a) Strainer with 20 mesh screen is required.

(b)Must account for water head differenc e when calculating tot al unit pres-

sure differential.

6

3

T4

Pi

2

B

6

2

T5

CUSTOMER PIPING

(c) Chilled water flow-proving device is required.

1

A

CG-SVX038A-EN 21

Page 22

Unit Piping

Vibration Eliminator

Vibration Eliminator

Optional

Water

Regulating

Valve

UNIT

FACTORY

INSTALLED

OPTIONS

(IF ORDERED)

T

T

P

Condenser Out

Condenser In

Bypass Valve

Isolation Valve

Isolation Valve

Pressure Gauge

Temperature Gauge

Temperature Gauge

Valve for Pressure Measurement

Valve for Pressure Measurement

CUSTOMER PIPING

Figure 4. Condenser piping schematic

22 CG-SVX038A-EN

Page 23

Water Pressure Drop Curves

Pressure Drop, ft of H2O

0

5

10

15

20

25

30

35

0.00

2.00

4.00

6.00

8.00

10.00

12.00

14.00

16.00

18.00

20.00

052002051001050

Pressure Drop, psi

Flow, GPM

pp

20 TON

30 TON

40 TON

50 TON

65 TON

Pressure Drop, ft of H2O

0.00

5.00

10.00

15.00

20.00

25.00

0.00

2.00

4.00

6.00

8.00

10.00

12.00

14.00

16.00

18.00

0.0 50.0 100.0 150.0 200.0 250.0

Pressure Drop, psi

Flow, GPM

30 TON

50 TON

40 TON

65 TON

20 TON

Figure 5. Evaporator water pressure drop

Unit Piping

Figure 6. Condenser water pressure drop

CG-SVX038A-EN 23

Page 24

Unit Piping

Low Suction Temperature and Pressure Cutouts/

Percent Glycol Recommendations

Tab l e 9 shows the low suction temperature and pressure

cutouts for different glycol levels.

Additional glycol beyond the recommendations will

adversely affect unit performance. The unit efficiency will

be reduced and the saturated evaporator temperature will

For some operating conditions this effect can be

significant.

If additional glycol is used, then use the actual percent

glycol to establish the Low and Unsafe refrigerant suction

pressure cutout set points.

be reduced.

Table 9. Minimum recommended setpoints

Ethylene Glycol/Water Propylene Glycol/Water

(°F)

(°F)

38.0

36.9

35.9

35.4

34.8

33.5

32.2

30.6

29.0

28.2

27.3

25.6

23.9

21.9

19.7

18.7

17.4

15.2

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

(c)(d)

(e)

Glycol

Mass)

%

(By

0

2

4

5

6

8

10

12

14

15

16

18

20

22

24

25

26

28

30

32

34

35

36

38

40

42

44

45

46

48

Solution

Freeze

Point

(°F)

32.0

30.9

29.7

29.1

28.5

27.3

26.1

24.8

23.6

22.9

22.1

20.7

19.2

17.5

15.6

14.6

13.7

11.5

9.2

6.6

3.9

2.5

0.8

-2.5

-6.0

-9.8

-14.0

-16.1

-18.3

-23.1

LOW

SUCTION

(psig)

101.12

98.87

96.46

95.26

94.08

91.75

89.45

87.00

84.78

83.51

82.0

6

79.57

76.96

74.07

70.92

69.30

67.86

64.42

60.95

60.65

60.65

60.6

5

60.65

60.65

60.65

60.65

60.65

60.65

60.65

60.65

(a)

UNSAFE

(b)

SUCT

(psig)

71.58

69.79

67.86

66.91

65.97

64.12

62.29

60.35

58.60

57.59

56.45

54.49

52.43

50.16

47.69

46.42

45.30

42.62

39.91

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

FREEZE

CORE FREEZE

Glycol

Mass)

(a) “LOW SUCTION” refers to the low suction pressure cutout.

(b)“UNSAFE SUCT” refers to the unsafe suction pressure cutout.

(c) “FREEZE” refers to the low leaving fluid temperature cutout.

(d)The minimum leaving fluid temperature set point, “CW OUT TRGT,” should not be less than 5°F above the low fluid temperature cutout, “FREEZE,” and

(e) “CORE FREEZE” refers to the evaporator core fluid temperature cutout.

Solution

%

(By

Point

(°F)

Freeze

0

2

4

5

6

8

10

12

14

15

16

18

20

22

24

25

26

28

30

32

34

35

36

38

40

42

44

45

46

48

50 -28.9 60.65 39.68 15.0 50 -28.3 60.65 39.68 15.0

the core fluid temperature cutout, “CORE FREEZE.”

32.0

30.9

29.9

29.4

28.8

27.5

26.2

24.6

23.0

22.2

21.3

19.6

17.9

15.9

13.7

12.7

11.4

9.2

6.7

4.2

1.4

-0.2

-1.5

-4.6

-8.1

-11.7

-15.5

-17.6

-19.7

-24.0

LOW

SUCTION

(psig)

101.12

98.87

96.86

95.86

94.67

92.13

89.64

86.63

83.69

82.24

80.63

77.65

74.75

71.42

67.86

66.28

64.27

60.95

60.65

60.65

60.65

60.65

60.65

60.65

60.65

60.65

60.65

60.65

60.65

60.65

(a)

UNSAFE

(b)

SUCT

(psig)

71.58

69.79

68.18

67.39

66.44

64.42

62.44

60.06

57.73

56.59

55.32

52.98

50.69

48.08

45.30

44.07

42.50

39.91

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

39.68

FREEZE

CORE FREEZE

(°F)

(°F)

38.0

36.9

35.7

35.1

34.5

33.3

32.1

30.8

29.6

28.9

28.1

26.7

25.2

23.5

21.6

20.6

19.7

17.5

15.2

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

15.0

(c)(d)

(e)

24 CG-SVX038A-EN

Page 25

Unit Piping

Refrigerant Piping (CCAR only)

Note: If using a Trane CAUJ air-cooled condenser with a

Trane CCAR compressor chiller, please refer to the

Application Guide - Pairing Trane CCAR

Compressor Chillers with Trane CAUJ Air-Cooled

Condensers SS-APG014*-EN. This guide provides

line sizing, field-component selection, application

considerations and more. If not using a Trane CAUJ

air-cooled condenser, please consider the

following general guidelines and

recommendations when designing your split

system.

Refer to the industry standards for refrigerant piping

selection information; contact the factory if you do not

have access to this data. Refrigerant pipe size selected

must be within the velocity and pressure drop limitations

required for proper system operation. It is essential that

refrigerant piping be properly sized and applied since

these factors have a significant effect on performance.

Note: Use Type K refrigerant-grade copper tubing only.

The use of a lower grade tubing can cause

operating problems.

General Guidelines

Keep these general guidelines in mind as you review the

recommendations specific to field piping refrigerant lines:

• Limit overall line length. Enough sub-cooling may be

lost as refrigerant travels up the liquid riser to cause

flashing. Review any questionable applications with

the factory.

• Pipe sizing software suc

Toolbox can help to quickly determine proper sizes for

refrigerant lines based on current engineering data.

Liquid Line

Sufficient sub-cooling must be maintained at the

expansion valve. To provide proper operation throughout

the range of operating conditions, the liquid-line pressure

drop should not exceed the unit’s minimum sub-cooling

value less 5°F. To achieve this objective, keep these liquidline considerations in mind:

1. Select the smallest, practical line size for the

application. Limiting the refrigerant charge improves

compressor reliability.

2. When designing the liquid l

conditioning application (i.e., one with an operating

range of 40°F to 110°F), remember that every 10 feet of

tical rise will reduce sub-cooling by 2.8°F, while

ver

every 10 feet of vertical drop will add 1.1°F of subcooling.

3. Provide a 1-inch pitch toward the e

10 feet of run.

h as Trane Engineering

ine for a typical air-

vaporator for every

4. If the liquid line must be routed through an area

armer than outdoor air temperature, insulate the line

w

to prevent the refrigerant from flashing.

5. A replaceable core liquid line filter drier must be

stalled as close as possible to the compressor chiller.

in

The core should be changed whenever the system is

opened for service. Trane compressor chillers do not

include a filter-drier as standard, but one may be

ordered if the installing contractor desires a factory

type.

6. A moisture-indicating sight glass permits

check of the liquid column for bubbles. Sight glasses

are included on the Trane compressor-chiller. However,

never use the sight glass to determine whether the

system is properly charged! Instead, either charge the

system based on the required sub-cooling or calculate

the amount of refrigerant needed and add it based on

weight.

a visual

Discharge (Hot Gas) Line

Limit the pressure drop in the discharge line to 6 psid

whenever possible to minimize the adverse effect on unit

capacity and efficiency. While a pressure drop of as much

as 10 psid is usually permissible, note that a 6-psid

pressure drop reduces unit capacity by 0.9 percent and

efficiency by 3 percent.

Pitch discharge lines in the direction of hot gas flow at the

rate of 1/2-inch per each 10 feet of horizontal run.

Discharge line sizing is based on required velocity to

provide good oil movement. Basic discharge line

parameters are:

Max allowable pressure drop 6 psig (1F)

Maximum Velocity 3500 fpm

Minimum Velocity (at minimum load)

Horizontal lines 500 fpm

Vertical lines (up flow) 1000 fpm

To design the discharge line properly, follow the

recommended guidelines:

• Choose the shortest route from the compre

condenser.

• Use different pipe sizes for horizontal and vertical lines

make it easier to match line pressure drop and

to

refrigerant velocity to discharge-line requirements.

• To assure proper oil entrainm

sound levels, size the discharge line so refrigerant

velocity equals or exceeds the minimum velocity in

Ta bl e 10 and remains below 3,500 fpm.

• Prevent oil and condensed refrigerant from flowing

k into the compressor during “off” cycles by:

bac

a. pitching the discharge line tow

and

b. routing the discharge line so that it rises to the top

of the condenser, then drops to the level of the

condenser inlet, creating an inverted trap.

ent and avoid annoying

ard the condenser,

ssor to the

CG-SVX038A-EN 25

Page 26

Unit Piping

• Double risers are generally unnecessary. The scroll

compressors in Trane units unload to the extent that a

single, properly sized riser can transport oil at any load

condition.

Table 10. Minimum discharge-line velocities for oil

entrainment

Refrigerant Velocity, fpm

Nom. Pipe Size, in. Riser

7/8 375 285

1-1/8 430 325

1-3/8 480 360

1-5/8 520 390

2-1/8 600 450

• Riser traps are also unnecessary. Avoid using riser

traps. If the discharge riser is sized to maintain the

proper refrigerant velocity, adding a trap will only

increase the pressure drop.

Reliability determines the success of a split airconditioning system. Intercon

play an instrumental role in that success. It’s up to us to

ensure that our system design practices evolve with

equipment technologies.

This can be summarized as five fundamental “rules”:

1. Choose the right system (i.e., don’t specify splitsystem equipment when a packaged chiller is best

suited for the job).

2. Size the interconnecting lines to av

and double risers.

3. Slope the liquid lines tow

4. Minimize the length of the interconnecting tubing.

5. Keep the system clean.

necting refrigerant lines

ard the evaporator.

Horizontal

oid the use of traps

Final Leak Test

WARNING

Hazard of Explosion!

Failure to follow instructions below could result in

death or serious injury or equipment or property-only

damage. Use only dry nitrogen with a pressure

regulator for pressurizing unit. Do not use acetylene,

oxygen or compressed air or mixtures containing them

for pressure testing. Do not use mixtures of a hydrogen

containing refrigerant and air above atmospheric

pressure for pressure testing as they may become

flammable and could result in an explosion.

Refrigerant, when used as a trace gas should only be

mixed with dry nitrogen for pressurizing units.

Once refrigerant piping is completed, thoroughly test the

system for leaks.

System Evacuation

WARNING

Risk of Internal Arc Flash!

Failure to follow instructions could result in death,

serious injury and compressor damage. Do not use a

megohmmeter or apply power to compressor windings

under vacuum as it could result in an arc flash inside

the compressor.

For field evacuation after leak checking, use a vacuum

pump capable of pulling a vacuum of 100 microns or less.

Follow the pump manufacturer’s instructions for proper

use of the pump. Insure that all sections of the system are

properly evacuated before proceeding.

Refrigerant Charging

Initial Leak Test

As shipped, Trane compressor-chillers contain a holding

charge of nitrogen only. Before connecting refrigerant

piping, momentarily crack open a Schraeder valve on the

liquid line to insure that the unit is still pressurized. If no

gas escapes thru the valve, leak test the unit to determine

the source of the refrigerant leak prior to installation and

repair any leaks located.

Refrigerant Piping Sizes

Refer to the Trane guide TRG-TRC006-EN and/or ASHRAE

publications to determine piping selection information.

Refrigerant pipe sizes selected must be within the velocity

and pressure drop limitations required for proper system

operations. It is essential that refrigerant piping be

properly sized and applied since these factors have a

significant effect on system performance and reliability.

26 CG-SVX038A-EN

NOTICE:

Equipment Damage!

To prevent damage to the evaporator and condenser,

never charge liquid refrigerant into either of these

vessels without adequate flow to prevent the

temperature/pressure relationship to fall below 35°F.

Once the system is properly installed, leak tested and

evacuated, refrigerant charging can begin. Liquid

refrigerant must be charged into each circuit through the

liquid line access with the compressor(s) off.

Charge refrigerant into the system by weight. Use an

accurate scale or charging cylinder to determine the exact

charge entering the system. Failure to charge the system

accurately can lead to under or over-charging and result in

unreliable operation.

If system pressure equalize before the full charge enters

the system, close the charging port and proceed to start-up

procedure.

Page 27

Electrical Wiring

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

General Recommendations

WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical hazards,

MUST follow precautions in this manual and on the

tags, stickers, and labels, as well as the following

instructions: Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks.

Power and Control Wiring

Unit Power Wiring

The installing contractor must connect appropriate power

wiring (with fused disconnects) to the terminal block or

non-fused, unit-mounted disconnect in the power section

of the unit control panel. Electrical schematics and

component location drawings are also mounted on the

inside of the control panel door.

The unit power fused disconnect switch should be located

in the general area of the unit, to comply with NEC or local

codes. Some codes require line-of-sight disconnect

locations. The optional unit unfused disconnect can be

used as an emergency shutdown device.

Scroll Compressor Electrical Phasing

General

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury. Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/tagout procedures to ensure the

power can not be inadvertently energized.

NOTICE:

Compressor Damage!

Operating compressors in reverse rotation will cause

damage or failure of the compressor.

NOTICE:

Use Copper Conductors Only!

Failure to use copper conductors could result in

equipment damage as the equipment was not designed

or qualified to accept other types of conductors.

The wiring procedures, as described in this portion of the

manual, must be accomplished to obtain proper operation

of the unit.

All wiring must comply with National Electrical Code

(NEC) and state and local requirements. Outside the

United States, the national and/or local electrical

requirements of other countries shall apply. The installer

must provide properly sized system interconnecting and

power supply wiring with appropriate fused disconnect

switches. Type and locations of disconnects must comply

with all applicable codes.

Minimum circuit ampacities, recommended fuse sizes and

other unit electrical data are provided on the unit

nameplate.

CG-SVX038A-EN 27

It is critical that proper rotation of the scroll compressors

be established before the machine is started. Proper motor

rotation requires confirmation of the electrical phase

sequence of the power supply. The motor is internally

connected for clockwise rotation with the inlet power

supply phased “ABC” or “L1, L2, L3”.

The order in which the three voltages of a three-phase

system succeed one another is called phase sequence or

phase rotation. When rotation is clockwise, phase

sequence is usually called “ABC” and when

counterclockwise, “CBA”.

This direction may be reversed by interchanging any two

of the line wires. It is this possible interchange of wiring

that makes a phase sequence indicator necessary, if the

operator is to quickly determine the phase rotation of the

motor.

Setting Proper Electrical Phase Sequence

Proper compressor motor electrical phasing can be quickly

determined and, if necessary, corrected before starting the

unit. Use a quality instrument, such as an Associated

Page 28

Electrical Wiring

Research Model 45 Phase Sequence indicator or

equivalent and follow this procedure.

1. Verify that all operating controls for the unit are in the

“Off” position.

2. Disconnect power to the power distribution block in

the unit control panel

3. Connect the phase sequence indicator

power distribution block as follows:

Phase Seq. Lead Terminal ID

Black (Phase A) L1

Red (Phase B) L2

Yellow (Phase C) L3

4. Turn power on by closing the unit supply power fused

disconnect switch.

5. Read the phase sequence disp

The “ABC” LED on the face of the phase indicator will

glow if phase sequence is ABC.

6. If the “CBA” indicator glows instead, open the unit

ain power disconnect and switch two line leads on

m

the power distribution block in the unit control panel.

Close the main power disconnect and recheck phasing.

7. Open the unit disconnect and re

indicator.

layed on the indicator.

leads to the

move the phase

Voltage Imbalance

Excessive voltage imbalance between phases in a threephase system will cause motors to overheat and

eventually fail. Maximum allowable imbalance is

2 percent. Voltage imbalance is defined as 100 times the

maximum deviation of the three voltages (three phases)

subtracted from the average (without regard to sign),

divided by the average voltage.

Example:

If the three voltages measured at the line voltage fused

disconnect are 221 volts, 230 volts and 227 volts, the

average would be:

221 + 230 + 227

3

The percentage of imbalance is then:

100 (226-221)

In the preceding example, 221 is used because it is the

farthest from the average. The 2.2 percent imbalance that

exists exceeds maximum allowable imbalance by

0.2 percent. This much imbalance between phases can

equal as much as 20 percent current imbalance with a

resulting increase in winding temperature that will

decrease compressor motor life.

= 226 volts

= 2.2%

226

Unit Voltage

Electrical power to the unit must meet stringent

requirements for the unit to operate properly. Total voltage

supply and voltage imbalance between phases should be

within the tolerances discussed below.

Voltage Supply

WARNING

Live Electrical Components!