Page 1

CGA-SVX01A-EN

Installation

Operation

Maintenance

Air-Cooled Cold Generator

Air-Cooled Cold Generator

With Heat Pump Option

®

®

Page 2

© American Standard Inc. 2001 CGA-SVX01A-EN

2

MODEL NOMENCLATURE

INSTALLATION

RIGGING

MOUNTING

WATER PIPING

FIGURE 1: RECOMMENDED HOISTING ARRANGEMENT

FIGURE 2: DIMENSION FOR MOUNTING

FIGURE 3: SERVICE & MAINTENANCE CLEARANCE

ELECTRICAL WIRING

UNIT POWER SUPPLY

FIGURE 4: TYPICAL PIPING ARRANGEMENT

FIGURE 5: TYPICAL SYSTEM APPLICATION

ELECTRICAL DATA

FLOW SWITCH INTERLOCK

CIRCUIT DIAGRAM FOR CGAK 030 - 075

CIRCUIT DIAGRAM FOR CGAR 030 - 075

CIRCUIT DIAGRAM FOR CGAK 100 - 200

CIRCUIT DIAGRAM FOR CGAR 100 - 150

INSTALLATION CHECKLIST

PRE-START PROCEDURE

VOLTAGE UTILIZATION RANGE

VOLTAGE IMBALANCE

WATER FLOW RATE

UNIT WATER PRESSURE DROP

FIGURE 6: HYDRAULIC CHARACTERISTIC

PRE-START CHECKLIST

OPERATION

START-UP PROCEDURE

EXTENDED UNIT SHUT-DOWN/WINTERIZATION

STANDARD AMBIENT OPERATION

OPTIONAL LOW AMBIENT OPERATION (CGAK)

OPTIONAL HEAT PUMP OPERATION (CGAR)

ELECTRICAL CONTROL & PROTECTION SYSTEM

MAINTENANCE

TROUBLE ANALYSIS

TABLE OF CONTENTS

3

4

11

12

17

22

26

27

Page 3

3

CGA

1,2,3

K4050

5,6,7

58D9F10R11M12R13N14A

15

CGA-SVX01A-EN

MODEL NOMENCLATURE

DIGIT 1,2,3

CGA=Air-Cooled Cold Generator

®

DIGIT 4 - Model

K=Cooling Only (030~200)

R=Cooling With Heat Pump Option (030~150)

DIGIT 5,6,7 - Number

030

040

050

075

100

125

150

175

200

DIGIT 8 - Voltage

1=220V/60Hz/1Ph

(For model 030,040,050)

2=220V/60Hz/3Ph

(For model 050,075,100,125,150, 175, 200)

3=380V/60Hz/3Ph

(For model 050,075,100,125,150, 175, 200)

4=460V/60Hz/3Ph

(For model 050,075,100,125,150, 175, 200)

5=380V/50Hz/3Ph

(For model 050,075,100,125,150, 175, 200)

6=400V/50Hz/3Ph

(For model 050,075,100,125,150, 175, 200)

7=415V/50Hz/3Ph

(For model 050,075,100,125,150, 175, 200)

DIGIT 9 - Development Sequence

D=Fourth Design

DIGIT 10 - Controls

F=Fixed Entering Water Temperature Control

(Standard Option)

A=Adjustable Entering Water Temperature

Control

(Microprocessor Controller)

(For CGAK Models as Optional)

(For CGAR Models as Standard Option)

DIGIT 11- Water Pump

N = No Pump

R = Standard Pump

(Standard Option)

DIGIT 12 - Refrigerant Pressure Gauges

M = No

(Standard Option)

G = With High/Low Pressure Gauges

DIGIT 13 - Temperature Kit

R = Standard Ambient Temperature Kit

(Standard Option)

L = Low Ambient Temperature Kit

(For CGAK Models Only)

DIGIT 14 - Other Options

M = Standard Fin + Standard Grille Cover

N = Standard Fin + Luxury Grille Cover

C = Blue Fin + Standard Grille Cover

B = Blue Fin + Luxury Grille Cover

DIGIT 15 - Service Sequence

A = First

Page 4

© American Standard Inc. 2001

4

INSTALLATION

Table 1 - Unit Shipping Weights

Maximum Shipping Weight (Kg)

230

250

260

370

450

500

530

550

570

Model

030

040

050

075

100

125

150

175

200

CGA-SVX01A-EN

Complete the “Installation Checklist” during

installation to verify completion of all

recommended procedures before unit

start-up.

RIGGING

Each unit is bolted to a shipping skid for

shipment to the job site. Move the unit using

a forklift of suitable capacity. See Table 1 for

unit shipping weights.

Locate the unit near a large-capacity drain to

allow system drainage during unit shutdown

and repair. Rig the unit using canvas belt.

Fasten the belt to the unit over the unit’s

base as show in Figure 1.

MOUNTING

Mounting methods that will minimize sound

and vibration problems are:

1. Mount the unit directly on an isolated

concrete pad or on isolated concrete

footings at each unit mounting point.

2. Install the optional neoprene or spring

isolators at each mounting location.

Refer to Figure 2 for unit and base

dimensions and Figure 3 for recommended

service clearance.

WATER PIPING

Thoroughly flush all water system piping

before making the final piping connections to

the unit.

Page 5

5

Figure - 1:

Recommended Hoisting Arrangement

(CGAK-075 As Shown)

CGA-SVX01A-EN

Page 6

© American Standard Inc. 2001

6

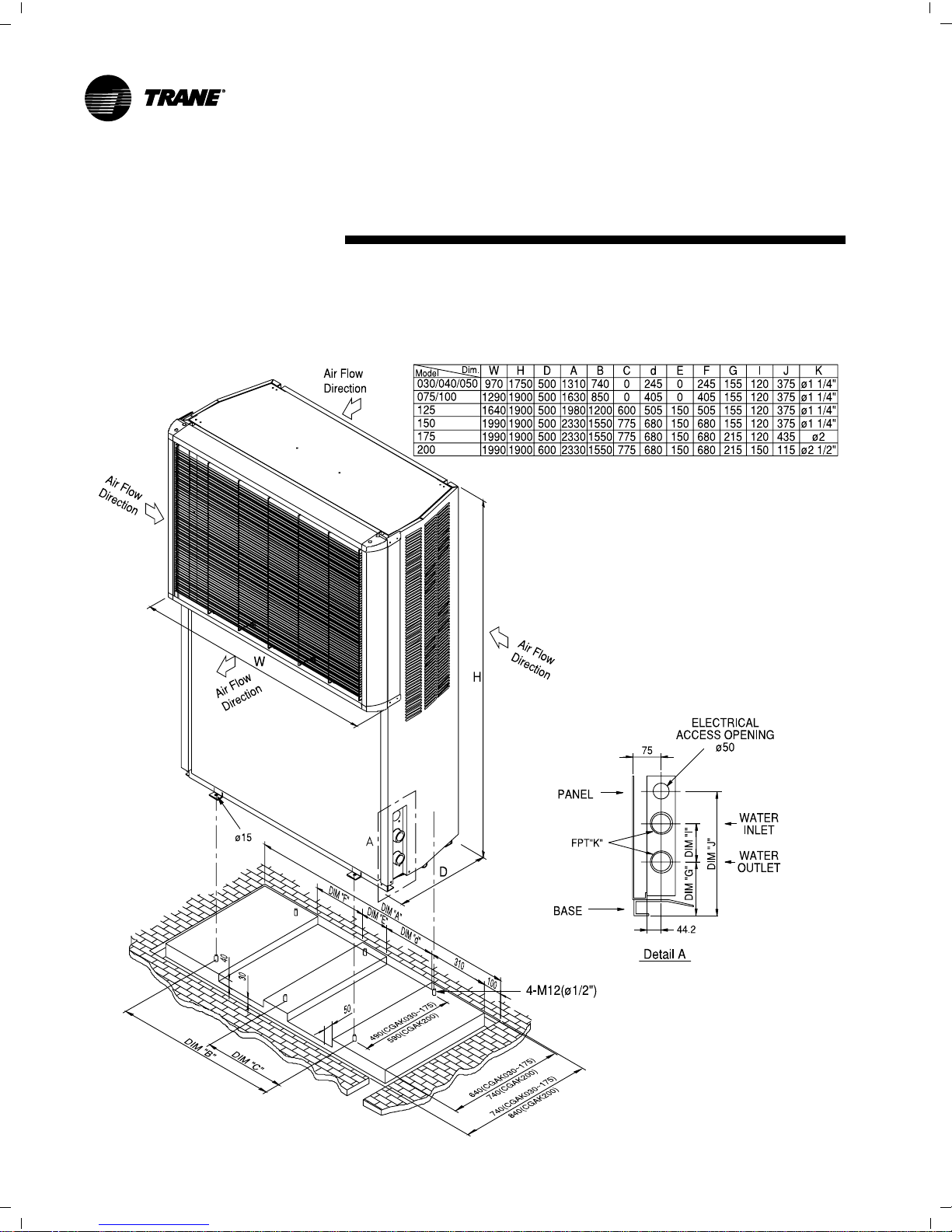

Figure - 2:

Dimension for Mounting

(CGAK-075 As Shown)

Note: All Dimensions in Millimeter

CGA-SVX01A-EN

Page 7

7

Figure - 3:

Service and Maintenance Clearance

(CGAK-075 As Shown)

CGA-SVX01A-EN

Page 8

© American Standard Inc. 2001

8

CGA-SVX01A-EN

CAUTION: If using an acidic commercial

flushing solution, construct a temporary

bypass around the unit to prevent

damage to the evaporator.

CAUTION: To avoid possible equipment

damage, do not use untreated or

improperly treated water.

For unit’s water connection sizes and

locations, please refer to Figure 2.

CAUTION: To prevent unit damage, do

not reverse system piping connections to

the unit; water entering the unit must

enter at the designated “Water In” and

leaving water must exit the unit through

the designated “Water Out” connection.

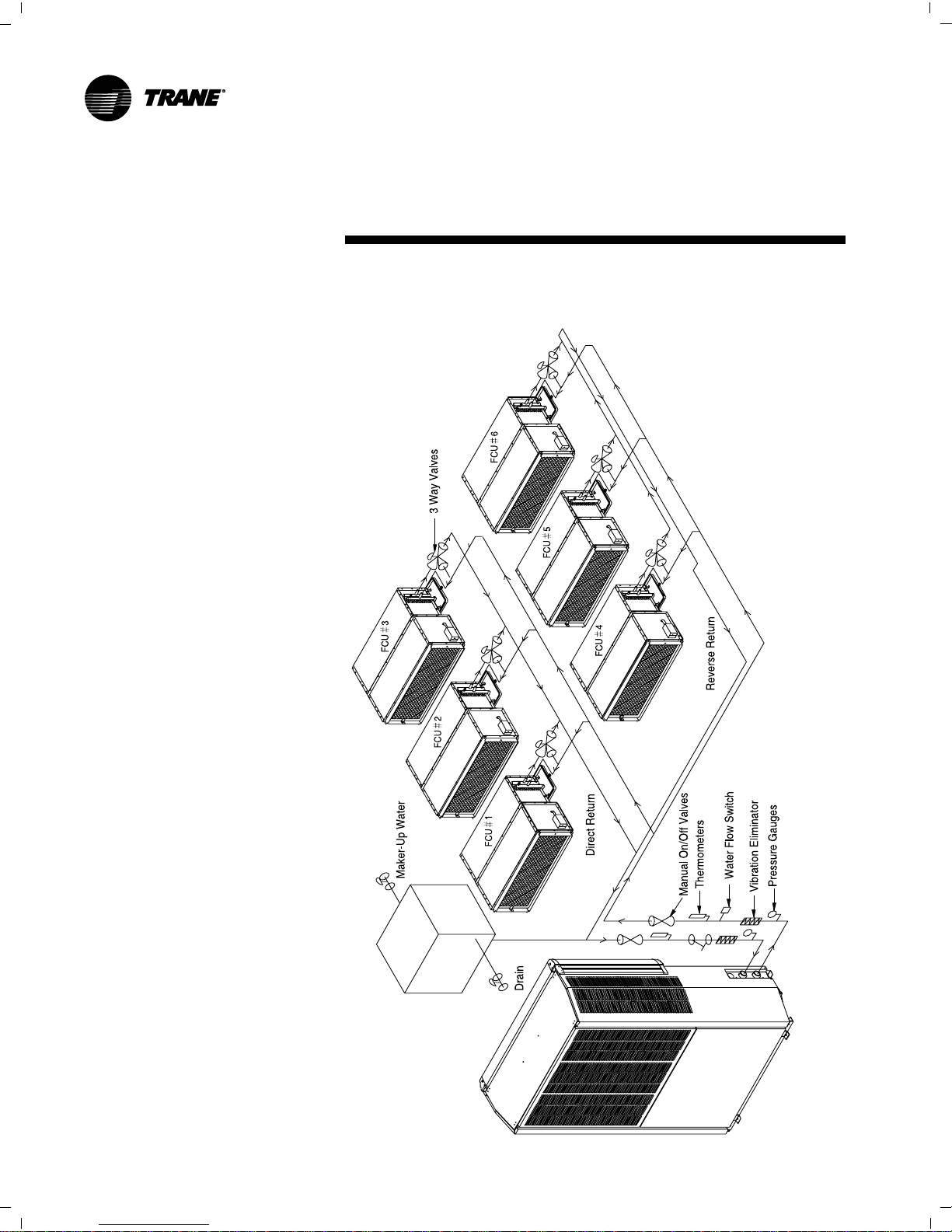

Figure 4 illustrates typical unit piping

components. Components and layout will

vary slightly depending upon the locations

of the connections and water source.

Figure 5 gives a schematic of a typical

system application for this unit.

Provide vents at high points in the piping to

bleed air from the chilled water system.

Install pressures gage(s) to monitor entering

and leaving chilled water pressure.

CAUTION: To prevent damage to the

waterside components of unit, do not

allow evaporator pressure to exceed 100

psig (i.e. maximum working pressure).

Use an expansion tank to isolate this

pressure if water pressure exceeds this

value.

ELECTRICAL WIRING

WARNING: To prevent injury or death,

disconnect electrical power source

before completing wiring connections to

the unit.

CAUTION: Use only copper conductors

for terminal connections to avoid

corrosion or over heating.

Figure 2 shows the location of the unit

electrical access openings. Table 2 provides

minimum circuit ampacities, recommended

fuse sizes, and motor electrical data.

UNIT POWER SUPPLY

Refer to the unit wiring schematic fixed to

the control panel cover. The installer must

provide a power supply of proper voltage

and a fused disconnect switch to the unit.

Run properly sized power wirings through the

electrical access opening on the side of the

unit, and connect it to the Voltage Terminal

Block (1TB1) in the unit control panel. Install

a fused disconnect switch as required by

local codes. Provide proper equipment

grounds for the ground connections in the

unit control panel and at the fused disconnect

switch.

Refer to wiring diagrams from Page 13 to

Page 16 for reference of a typical unit installation. For actual wiring diagram, refer to the

one fixed to the control panel cover.

FLOW SWITCH INTERLOCK

To avoid possible evaporator freeze-up

resulting from reduced water flow, install a

flow switch ( or other flow sensing device) in

the evaporator outlet water line. This sensing

device must be adjusted to stop compressor

operation if water flow to the evaporator

drops below 70% of the system design fullflow rate.

The installer must provide interconnecting

wiring between the unit control panel and the

water flow sensing switch in the evaporator

water line.

Page 9

9

Figure - 4:

Typical Piping Arrangement

(CGAK-075 As Shown)

CGA-SVX01A-EN

Page 10

© American Standard Inc. 2001

10

Figure - 5:

Typical System Application

(CGAK-075 And Fans As Shown)

CGA-SVX01A-EN

Page 11

11

CGA-SVX01A-EN

ELECTRICAL DATA

Table 2 - Electrical Data

60Hz

Electrical

Power

(V/Hz/Ph)

220/60/1

220/60/1

220/60/1

220/60/1

220/60/3

380/60/3

220/60/3

380/60/3

220/60/3

380/60/3

220/60/3

380/60/3

220/60/3

380/60/3

220/60/3

380/60/3

220/60/3

380/60/3

Model

Water

Pump

FLA

4.4

4.4

4.4

6.5

2.7

1.6

4.2

2.4

4.2

2.4

5.4

3.1

5.4

3.1

6.0

3.5

9.1

5.3

Comp

1

RLA

14.4

19.4

24.4

24.4

15.3

8.8

23.0

13.3

15.3

8.8

17.4

10.1

23.0

13.2

26.0

15.0

32.4

18.7

Comp

2

RLA

-

-

-

24.4

-

-

-

-

15.3

8.8

17.4

10.1

23.0

13.2

26.0

15.0

32.4

18.7

Fan

1

FLA

2.8

2.8

2.8

4.3

3.0

1.7

3.0

1.7

4.5

2.6

4.5

2.6

3.0

1.7

4.5

2.6

4.5

2.6

Fan

2

FLA

-

-

-

-

-

-

-

-

-

-

-

-

3.0

1.7

4.5

2.6

4.5

2.6

Unit

MCA

25.2

31.5

37.7

65.7

24.8

14.3

36.0

20.7

43.1

24.8

49.1

28.4

63.2

36.2

73.5

42.5

91.0

52.6

Rec.

Fuse

Size

28.8

36.3

43.8

71.8

28.7

16.5

41.7

24.1

47.0

27.0

53.4

31.0

68.9

39.5

80.0

46.2

99.1

57.3

Max

Fuse

Size

39.6

50.9

62.1

90.1

40.1

23.1

59.0

34.0

58.4

33.6

66.5

38.5

86.2

49.4

99.5

57.5

123.4

71.3

030

040

050

100

050

050

075

075

100

100

125

125

150

150

175

175

200

200

50Hz

Electrical

Power

(V/Hz/Ph)

380-415/50/3

380-415/50/3

380-415/50/3

380-415/50/3

380-415/50/3

380-415/50/3

380-415/50/3

Model

Water

Pump

FLA

1.1

1.4

1.4

1.7

1.7

2.0

2.8

Comp

1

RLA

7.4

11.6

7.4

8.7

11.6

13.0

15.1

Comp

2

RLA

-

-

7.4

8.7

11.6

13.0

15.1

Fan

1

FLA

1.5

1.5

2.2

2.2

1.5

2.2

2.2

Fan

2

FLA

-

-

-

-

1.5

2.2

2.2

Unit

MCA

11.9

17.4

20.3

23.5

30.8

36.5

41.2

Rec.

Fuse

Size

13.7

20.3

22.1

25.7

33.7

39.8

45.0

Max

Fuse

Size

19.3

29.0

27.7

32.2

42.4

49.5

56.3

050

075

100

125

150

175

200

Note:

• All voltages supply must fall within the utilization range of ±10 %

• Minimum Circuit Ampacity (MCA) = Largest Load x 1.25 + Sum of additional Loads. (Used for sizing wire)

• Recommended Fuse Size (REC) = Largest Load x 1.5 + Sum of additional Loads. (Select closest fuse size)

• Maximum Fuse Size (MFS) = Largest Load x 2.25 + Sum of additional Loads. (Select equal or next lower fuse size)

Page 12

© American Standard Inc. 2001

12

Circuit Diagram:

For CGAK 030 - 075

CGA-SVX01A-EN

FLOW SWITCH INTERLOCK

Page 13

13

Circuit Diagram:

For CGAR 030 - 075

CGA-SVX01A-EN

Page 14

© American Standard Inc. 2001

14

Circuit Diagram:

For CGAK 100 - 200

CGA-SVX01A-EN

Page 15

15

Circuit Diagram:

For CGAR 100 - 150

CGA-SVX01A-EN

Page 16

© American Standard Inc. 2001

16

CGA-SVX01A-EN

INSTALLATION CHECKLIST

RECEIVING

Verify that unit nameplate data

corresponds with sales order information.

Inspect unit for shipping damages and

material shortages; report any damages

or shortages found to the carrier.

UNIT LOCATION AND MOUNTING

Inspect unit installation location for

adequate ventilation.

Provide drainage facilities for water

accumulated from the base.

Remove and discard any shipping

materials (e.g. cartons, crates, etc.)

Inspect to determine that service access

clearances are adequate.

Install optional unit neoprene-in-shear or

spring isolators.

Secure unit to mounting surface.

Level the unit.

EVAPORATOR PIPING

Flush and clean all chilled water piping.

CAUTION: If using an acidic commercial

flushing solution, construct a temporary

bypass around the unit to prevent

damage to the evaporator.

CAUTION: To avoid possible equipment

damage, do not use untreated or

improperly treated water.

Make evaporator water connections.

Vent the air from chilled water system at

high points.

Install pressure gauges, thermometers

and shutoff valves on water inlet and

outlet piping.

Install water strainer in evaporator supply

line.

Install balancing valve and flow switch on

water outlet piping.

ELECTRICAL WIRING

CAUTION: Use only copper conductors

to prevent galvanic corrosion and

overheating at terminal connections.

Connect unit power supply wiring (with

fused disconnect) to appropriate

terminals on terminal block (TB) in power

section of unit control panel.

In order to turn on/off the chiller from

indoors, connect wiring across reserved

terminals 2 & 3 in the unit control panel

from an indoor REMOTE OFF/ON switch.

For heat pump options only, in addition to

an indoor REMOTE ON/OFF switch, an

indoor cooling mode and heating mode

switch should be connected. Please

connect another set of wiring to switch

between cooling mode and heating mode

indoors. For CGAR-030 to CGAR-075,

connect wiring across terminals 12 & 13

for cooling mode, terminals 12 & 17 for

heating mode. For CGAR-100, CGAR150, and CGAR-150, connect wiring

across terminals 17 & 18 for cooling

mode and terminals 17 & 27 for heating

mode.

Properly ground the unit, the chilled water

pump motor, all disconnects, and other

devices which require grounds.

Install wiring to connect flow switch to unit

control panel.

FOR NO-PUMP OPTION ONLY

Connect chilled water pump power supply

wiring (with fused disconnect) to the

proper terminals of the chilled water

pump.

Install wiring to connect chilled water

pump switch to chilled water pump

starter.

Connect auxiliary contacts of chilled

water pump starter to flow switch and unit

control panel.

Page 17

17

CGA-SVX01A-EN

PRE-START PROCEDURES

VOLTAGE UTILIZATION

RANGE

Electrical power to the unit must meet

stringent requirements for unit to operate

properly. Total voltage supply and voltage

imbalance between phases should be within

the following tolerances.

Measure each leg supply voltage at all line

voltage disconnect switches. Readings must

fall within the voltage utilization range shown

on the unit nameplate (±10%). If voltage on

any leg does not fall within the tolerance,

notify the power company to correct this

situation before operating the unit.

Inadequate voltage to the unit will cause

control components to malfunction and

shorten the life of electrical components and

compressor motors.

VOLTAGE IMBALANCE

Excessive voltage imbalance between

phases in all 3-phase system will cause

motors to overheat and eventually fail.

Maximum allowable imbalance is 2 %.

Voltage imbalance is defined as follows:

The 2.2% imbalance that exists in the

example above exceeds maximum

allowable imbalance by 0.2 %. This much

imbalance between phases can equal as

much as 20 % current imbalance with a

resulting increase in winding temperature

that will decrease compressor motor life.

WATER FLOW RATE

Establish a balanced water flow through the

unit. Flow rates should fall between the

minimum and maximum values indicated in

TABLE 3. Evaporator water flow rates below

the minimum acceptable values will result in

a stratified flow; this reduces heat transfer

and causes either loss of expansion valve

control or repeated nuisance low pressure

cutouts. Conversely, excessively high flow

rate may cause erosion in the water system.

% Voltage Imbalance =

Where

Va = (V1 + V2 +V3) / 3(Average Voltage)

V1, V2, V3 = Line Voltages

Vd = Maximum Line Voltage deviation from Va

Example:

If the three voltages measured at the line 221

Volts, 230 Volts, and 227 Volts, the average

(Va) would be:

Va = (221 + 230 + 227)/3 = 226 Volts

then Vd = 221 Volts

The percentage of imbalance is then:

100x Va-Vd

Va

100x 226-221

226

2.2%

Page 18

© American Standard Inc. 2001

18

TABLE 3 - Unit Water Flow Rate - 60HZ

60Hz

Model

030

040

050

075

100

125

150

175

200

Minimum Flow

18.5

22.9

30.2

44.9

59.1

74.7

89.5

102.6

120.0

Rated Flow

27.7

34.3

45.3

67.3

88.7

112.0

134.3

154.0

180.0

Maximum Flow

38.8

48.0

63.4

94.2

124.2

150.0

150.0

175.0

240.0

Model

050

075

100

125

150

175

200

Minimum Flow

25.1

37.3

49.1

62.1

74.4

85.5

98.3

Rated Flow

37.7

56.0

73.7

93.3

111.7

128.3

149.0

Maximum Flow

56.6

84.0

110.6

140.0

150.0

160.0

190.0

CGA-SVX01A-EN

Units: LPM

50Hz Units: LPM

UNIT WATER PRESSURE

DROP

Measure the water pressure rise across the

standard unit (with built-in pump). The

Externally Available Head (E.A.H) should

approximate those indicated by the E.A.H.

curves, with the corresponding flow rates.

For units (without built-in pump) with fieldinstalled pump outside the unit, water

pressure drop across the unit should

approximate those indicated by the Internal

Pressure Loss (I.P.L.) curves, with the

corresponding flow rates.

For standard unit with built-in pump, refer to

the E.A.H. curve for the system hydraulic

design. For optional unit without a built-in

pump, refer to the I.P.L. curves. (Refer to

Figure 6 for hydraulic characteristics of all

models.)

Page 19

19

CGA-SVX01A-EN

Figure - 6:

Hydraulic Characteristics - 60Hz

Page 20

© American Standard Inc. 2001

20

CGA-SVX01A-EN

Figure - 6:

Hydraulic Characteristics - 50Hz

Page 21

21

CGA-SVX01A-EN

PRE-START CHECKLIST

Inspect all wiring connections; electrical

connections should be clean and tight.

Check power supply voltage to the unit at

the main power fused disconnect switch.

Fill the chilled water circuit, leaving the

system air vents open. Close vents after

all air is out, and the system is completely

filled.

Remove jumper wire across terminals 1

and 5 (in the control panel) for water

system testing.

Close the fused disconnect switch and

start the unit by turning the REMOTE/

OFF/ON switch to ON position. Pump

should start and with water circulating

through the chilled water system, inspect

all piping connections for leaks and make

any necessary repairs.

Adjust the water flow rate through the

chilled water circuit, and check the

external available water pressure of the

unit (for standard unit) or the evaporator

water pressure drop for the no-pump

option unit.

NOTE: With the water pump operating,

throttle the water flow to approximately

50% of the full flow rate. Following the

manufacturer’s instructions, adjust the

flow switch contacts to open at this

point. Use an ohmmeter to verify opening

and closure of the flow switch contacts.

Stop the chilled water pump.

Open all fused disconnect switches.

Make electrical connection of flow switch

to terminals 1 & 5 in the control panel.

Page 22

© American Standard Inc. 2001

22

CGA-SVX01A-EN

OPERATION

START-UP PROCEDURE

Close the fused disconnect switch and

turn REMOTE/OFF/ON switch to ON.

Pump will start immediately. After 2

minutes, compressors1 will start. 1

minute later, compressor2 will start

(only in units with two refrigerant circuits).

For CGAR models, turn REMOTE/OFF/

ON switch to ON as described above,

turn the already installed indoors cooling

and heating mode switch to cooling

mode, then the operation of the chiller

would be similar to what is described

above (see section on electrical wiring of

the installation checklist). As for start-up

with heating mode, first turn REMOTE/

OFF/ON switch to OFF. Then, turn the

cooling and heating mode switch to

heating. Finally, turn the REMOTE/OFF/

ON switch to ON.

To start-up the CGAR at the chiller i.e.

outdoors, remove the wiring of indoors

cooling and heating mode switch. For

CGAR-030 to CGAR-075, connect wiring

across terminals 12 & 13 for cooling

mode, terminals 12 & 17 for heating

mode. For CGAR-100, CGAR-125, and

CGAR-150, connect wiring across

terminals 17 & 18 for cooling mode and

terminals 17 & 27 for heating mode. After

the completion of testing, reconnect the

wiring of indoors cooling and heating

mode switch back to the original

terminals.

Once the unit has operated for at least 30

minutes and the system has stabilized,

complete the following checklist to ensure

proper unit operation.

Re-check unit water flow and pressure

rise (for no built-in pump unit with field-

installed pump system). These readings

should be stable at proper levels.

Measure unit suction and discharge

pressures by installing pressure gauges

on the discharge and suction line access

ports. Normal operation should render

suction pressure in the range of 50-85

psig and discharge pressure 200-310

psig.

Check compressor amp draw.

Check electrical power supply.

Check the liquid line sight glasses.

NOTE: Bubbles in the liquid line may

indicate either a low refrigerant charge,

or excessive pressure drop in the liquid

line. Such a restriction can often be

identified by a noticeable difference in

line temperature on either side of the

restricted area. (Frost often forms on the

outside of the liquid line at the point of

restriction, as well). Bubbles are not

necessarily a symptom of improper

system operation.

CAUTION: A clear sight glass does not

necessarily mean that the system is

sufficiently charged; be sure to consider

system superheat, subcooling, and unit

operating pressures and ambient

temperatures.

Proper unit refrigerant charge-per circuit-is

indicated on the unit nameplate.

Measure system superheat.

Normal system superheat is 6.7°C to 8.3°C

for each circuit at ARI conditions (12.2°C

entering water, 6.7°C leaving water, and

35°C ambient temperature). If the superheat

measured for either circuit does not fall

within this range, alter the setting of the

superheat adjustment on the thermal

expansion valve to obtain the desired

reading. Allow 15 to 30 minutes between

adjustments for the expansion valve to

stabilize at each new setting.

Measure system subcooling.

Normal subcooling for each circuit is 6.7°C

to 12.2°C ARI conditions (12.2°C entering

water, 6.7°C leaving water, and 35°C

ambient temperature). If subcooling for

either circuit is normal but subcooling is not

in this range, check superheat for the circuit

and adjust, if required. If superheat is normal

but subcooling is not, contact a qualified

service technician.

If operating pressure, sight

glass,superheat and subcooling readings

indicate refrigerant shortage, find and

repair leaks and, gas-charge refrigerant

into each circuit. Refrigerant shortage is

indicated if operating pressures are low

and subcooling is also low.

CAUTION: If suction and discharge

pressures are low, but subcooling is

normal, no refrigerant shortage exists.

Adding refrigerant will result in

overcharging.

Add refrigerant vapor with the unit running

by charging through the access port on the

suction line until operating pressures are

normal.

If operating pressures indicate an

overcharge, slowly (to minimize oil loss)

recover refrigerant at the liquid line

service valve.

Be sure that all remote sensing bulbs are

properly installed in bulb wells with heat

transfer grease. Remote bulb capillary

tubes must be secured (i.e. protected

from vibration and abrasion) and

undamaged.

Inspect the unit. Remove any debris,

tools and hardware. Secure all exterior

panels, including the control and

compressor access panels. Replace and

tighten all retaining screws.

Page 23

23

CGA-SVX01A-EN

EXTENDED UNIT SHUT-DOWN/

WINTERIZATION

If the system is taken out of operation for

long periods of time for any reasons (e.g.,

seasonal shutdown), use this procedure to

prepare the system for shutdown.

1. Check the refrigerant piping for leaks,

fixing any that exist.

2. Service the chilled water pump and any

air handling equipment according to the

manufacturers recommendtions.

3. Open both electrical disconnect switches

for the unit and chilled water pump; lock

both disconnects in the open position.

WINTERIZATION: Close all evaporator

water supply valves and drain the

evaporator by removing the drain plug

and opening the vent on the entering

water line just outside the unit. Re-install

the drain plug. Since the evaporator does

not drain completely, add ethylene glycol

antifreeze to the remaining water through

the vent or evaporator drain hole, to keep

the water from freezing. Protect system

to 5.5°C below the expected ambient

temperature.

SYSTEM RESTART AFTER EXTENDED

SHUTDOWN

1. Remove winterization antifreeze as it can

reduce system capacity.

2. Fill the chilled water circuit by opening the

gate valves at the returning and supply

water piping. Be sure to vent the system

while filling it, and close the vents when

system is full.

3. Remove compressor delay on timer(s)

(TR1, TR2). Record down the original

socket for the respective timer so that the

correct timer(s) are replaced correctly

later.

4. Close the unit disconnect switch for power

supply.

5. Turn the REMOTE/OFF/ON switch to ON

position. With water circulating through

the chilled water system, inspect all

piping connections for leaks and make

any necessary repairs.

6. Adjust the water flow rate, using the

balancing valve, through the chilled water

circuit, and check the water pressure rise

(or drop) through the unit.

7. Adjust the flow switch (installed on the

unit outlet piping) to provide proper

operation.

NOTE: With the unit operating, throttle

the water flow to approximately 50% of

the full flow rate. Following the

manufacturer’s instructions, adjust the

flow switch contacts to open at this

point. Use an ohmmeter to check for

contact opening and closure.

8. Stop the unit by turning the REMOTE/

OFF/ON switch to OFF position.

9. Replace compressor delay on timer (TR1,

TR2) back to their original sockets.

This unit now is ready for normal operation.

STANDARD AMBIENT

OPERATION

Standard unit will operate in outdoor ambient

temperature down to 15°C.

OPTIONAL LOW AMBIENT

OPERATION (CGAK)

A factory installed Low Ambient Unit (LAU)

option will enable units to operate at outdoor

ambient temperature down to 4°C (except

Model 100).

When the unit is started at ambient

temperature below 15.6°C, the low ambient

mode is activated. Timer TR3 & TR4 will

activate the solenoid valve connected

across the thermostatic expansion valves for

a period of 1.5 minutes, bypassing

refrigerant, to prevent suction pressure

dipping too low. Also, a fan cycle switch

prevents the condenser fan from starting

until the condensing pressure reaches 350

psig. This switch switches off condensing

fan when condensing pressure drops to 115

psig.

OPTIONAL HEAT PUMP

OPERATION (CGAR)

A factory installed heat pump unit (CGAR)

option will enable units to get either cooling

and heating performance (not simultaneous).

When the unit is switched to heating mode,

the four-valve is activated. Evaporator

becomes the condenser while the condenser

becomes the evaporator. There are two

liquid lines in a CGAR unit. One is for cooling

mode while another is for heating mode.

To carefully measure the high pressure,

there are two access ports in these two

liquid lines. If you operate this unit in cooling

mode, connect high pressure gauge to the

access port of the cooling liquid line. While

operating this unit in heating mode, must

change the connection to the access port of

the heating liquid line.

A timer override low pressure switch delays

for 2 minutes to prevent nuisance trip-outs.

Page 24

© American Standard Inc. 2001

24

CGA-SVX01A-EN

ELECTRICAL CONTROL &

PROTECTION SYSTEM

Low Pressure Cutouts (LP1, LP2)

These units are protected by low pressure

cutouts that open and stop compressor

operation if the operating pressure drops

below 45 ± 4 psig . The cutout automatically

resets when the pressure reaches 60 ± 4

psig. The LP is a SPDT device and if it

opens at low ambient start-up, there will be

a 1.5 minute override to prevent nuisance

trip-outs ( for LAU only).

For CGAR unit, the low pressure cutout

setpoints 25 ± 4 psig.

High Pressure Cutouts (HP1, HP2)

These units have high pressure cutouts that

open and stop compressor operation if the

discharge pressure reaches 405 ± 7 psig.

The cutout automatically resets when

pressure drops to 300 ± 20 psig.

Reset Relays (CR1,CR2)

If the unit is shut down by safety devices

(LP, HP, FS, FU, KF etc.) the reset relay

locks out the compressor contactor (MC1,

MC2). This prevents the system from

recycling until the condition that caused the

safety devices to trip is determined and

corrected.

CAUTION: To prevent unit damage, do

not reset the control circuit until the

cause of the safety lockout is identified

and corrected.

To reset CR1 and CR2, open and reclose

the unit REMOTE/OFF/ON switch.

Anti-freeze Cutout (FS1, FS2, FU)

The FS and FU are designed to protect the

evaporator from freeze damage in the event

of a water temperature thermostat (WTT)

malfunction or restricted water flow. The

FU’s remote sensing bulb is mounted at the

outlet end of the evaporator, where it

monitors leaving water temperature. If

during normal unit operation, the leaving

chilled water temperature falls to the trip

point, the FU will open to interrupt compressor operation.

When leaving chilled water temperature falls

down, the suction temperature also falls

down. For further protection to avoid freeze

damage, another freezestat ( FS1 , FS2 ) in

contact with the suction line. If suction

temperature falls to the trip point , the FS1

(FS2) will open to interrupt compressor

operation.

Motor Overloads

These units have internal compressor and

condenser fan motor overloads to protect

the motors from overcurrent and overheating conditions and automatically reset as

soon as they cool sufficiently. Pump motor

has thermal overload installed at the load

contactor. Pump overload needs manual

reset.

Cooling Mode

Water Temperature Thermostat

Operation (TS1, TS2) for cooling mode

For Double Refrigeration Circuit Operation

At Start-up, the pump will come on immediately. Two minutes after the pump is on and

EWT(entering water temperature)is above

14.0 °C, compressor 1 will start. One

minute later, if the EWT is above 13.5°C,

compressor 2 will start.

When cooling demand is met and EWT

drops to 10.0 °C. Compressor 1 will stop,if

EWT continues to fall to 9.5 °C,compressor

2 will stop. Subsequently,when load

builds up and EWT rises to 13.5 °C compressor 2 comes on, and if EWT rises

further to 14.0°C, compressor 1 comes on.

Pump remains on unless the unit is turned

off.

For Single Refrigeration Circuit Operation

For units with only one refrigerant circuit, the

operation of water pump, fan and compressor is exactly the same. The only difference

is the unit will operate the single compressor

from any temperature over 14.0 °C and

10.0°C when the compressor will stop.

Heating Mode

Water Temperature Thermostat

Operation (TS3, TS4) for cooling mode

For Double Refrigeration Circuit Operation

At start-up, pump will come on immediately.

Two minutes after the pump is on and EWT

(entering water temperature)is below

38.0°C, compressor 1 will start. One

minute later, if EWT is below 39.0 °C,

compressor 2 will start.

When heating demand is met and EWT

rises to 42.0 °C, compressor 1 will stop, if

EWT continues to rise to 43.0

°C,compressor 2 will stop.

Subsequently,when load builds up and EWT

drops to 39.0 °C, compressor 2 comes on,

and if EWT drops further to 38.0 °C,

compressor 1 comes on. Pump remains

on unless the unit is turned off.

For Single Refrigeration Circuit Operation

For units with only one refrigerant circuit, the

operation of water pump, fan and compressor is exactly the same. The only difference

is the unit will operate the single compressor

from any temperature below 38.0 °C and

42.0 °C when the compressor will stop.

Page 25

25

Table 4 - Range of Operating Ambient

Model

All Models Cooling Mode

All Models Heating Mode

Standard Unit

15˚C-46˚C

Over 4˚C

Low Ambient Unit (If LAU option is added)

15°C-46°C

Over -4˚C

Table 5 - Control Settings and Time Delays

Control Description

High Pressure Cutoff

Low Pressure Cutoff (CGAK)

Low Pressure Cutoff (CGAR)

Antifreeze Cutout (Refrigerant Side)

Antifreeze Cutout (Water Side)

1st compressor On Delay

2nd compressor On Delay

Low Suction Pressure Override Delay

Low Suction Pressure Override Delay

(LAU Only)

Electrical Designation

HP1, HP2

LP1, LP2

LP1, LP2

FS1, FS2

FU

TR1

TR2

TR3, TR4

TR3, TR4

Contacts Open

4057 psig

454 psig

254 psig

-3˚C2.0˚C

1.8˚C1.5˚C

Normally Open, Time Closed

Normally Open, Time Closed

Normally Closed, Time Open

Normally Closed, Time Open

Contacts Close (Reset)

30020 psig

604 psig

504 psig

3˚C2.0˚C

7˚C1.5˚C

2 Minutes

3 Minutes

2 Minutes

1.5 Minutes

CGA-SVX01A-EN

Page 26

© American Standard Inc. 2001

26

Maintenance

CGA-SVX01A-EN

Once the unit has been operating for about

30 minutes and the system has stabilized,

check operating conditions and complete the

checkout procedure described below:

Monthly

Check suction and discharge pressures

for normal operating pressures.

Check the liquid line sight glass indicator

for normal operating conditions.

If operating pressures and sight glass

conditions indicate a refrigerant shortage,

measure system superheat and

subcooling.

If operating conditions indicate an

overcharge, slowly (to minimize oil loss)

recover refrigerant from the schraeder

valve.

Open the unit disconnect switch; then

manually rotate the condenser fan(s) to

ensure proper orifice clearance.

Inspect the fan mounting bolts for

tightness.

Check fan set screws for tightness.

Please clean up internal and pipe’s

strainer once the unit first starts running

and monthly after use.

Annually

Perform all monthly maintenance

procedure.

Have a qualified service technician check

the setting and function of each control

and inspect the condition of all contactors

and replace as necessary.

Drain water from unit. Inspect piping for

damage. Clean out the built-in water

strainer and any other in-line water

strainer.

Clean and repaint any corroded surfaces.

Clean condenser coil with soft brush and

water spray.

Inspect the expansion valve(s) sensing

bulbs for cleanliness; clean if required.

These bulbs must make good contact

with the suction lines and must be

properly insulated.

Clean condenser fan.

Page 27

27

TROUBLE ANALYSIS

CGA-SVX01A-EN

Probable Cause

(1) No power to unit

(2) No call for cooling

(3) Compressor start delay (TR1,TR2) timer has not timed out time out

(4) Unit locked out by reset relay (CR)

(5) Compressor contactor will not close

(6) Compressor winding stat open

Recommended Action

Check for followings:

a. Disconnect switch open

b. Fuse(s) blown

Check for followings:

a. Defective thermostat

b. Broken or improper control wiring

c. Blown control power fuse

Wait at least 2 minutes for the timer to time out

Check for the followings:

a. Excessive discharge pressure

b. Defective high pressure control

c. Low charge; Low pressure cut-out

d. Gate/water valve not open causing flow switch or anti-freeze

cutoff to trip

e. Fan motor internal temperature switch open

f . Defective reset relay contact

Check for the followings:

a. Defective compressor contactor

b. Improper wiring

c. Reset relay (CR) open

d. Low pressure cut-out open

Check compressor amp draw

A. Compressor Neither Starts Nor Hums

B. Compressor Hums, But Will Not Start

Probable Cause

(1) Low voltage at compressor

(2) Defective compressor

(3) Insufficient starting voltage (Single-Phase Units Only)

Recommended Action

Check for the followings:

a. Single blown fuse

b. Low line voltage

c. Defective compressor contactor

d. Loose wiring connections

Check for the followings:

a. Open motor winding

b. Excessive amp draw on all phases

Check for the followings:

a. Defective start capacitor

b. Defective start relay

Page 28

© American Standard Inc. 2001

28

CGA-SVX01A-EN

C. 2nd Stage Compressor Fails To Start

Probable Cause

(1) Time delay contacts fail to close

(2) No call for cooling

(3) Unit locked out by reset relay (CR)

(4) Compressor contactor will not close

Recommended Action

Replace time delay relay

Check for the followings:

a. Defective thermostat

b. Broken or improper control winding

See (A) item (4)

See (A) item (5)

D. Compressor Short Cycles

Probable Cause

(1) Intermittent contact in control circuit

Recommended Action

Check for the followings:

a. Defective relay contacts

b. Loose wiring connections

E. Compressor Runs Continuously

Probable Cause

(1) Unit undersized for load (cannot maintain water temperature)

(2) Thermostat setpoint too low

(3) Defective thermostat or control wiring

(4) Welded contacts on compressor contactor

(5) Leaky valves in compressor (indicated by abnormally low

discharge and high suction pressures)

(6) Shortage of refrigerant (indicated by reduced capacity, high

superheat, low subcooling, and low suction pressure)

Recommended Action

Check for cause of excessive load

Readjust thermostat

Replace thermostat

Replace or repair control wiring

Repair or replace contactor

Replace compressor

Find and repair refrigerant leak

Recharge system

F. Compressor Motor Winding Stat Open

Probable Cause

(1) Excessive load on evaporator (indicated by high supply water

temperature)

(2) Lack of motor cooling (indicated by excessive superheat)

(3) Improper voltage at compressor

(4) Internal parts of compressor damaged

Recommended Action

Check for the followings:

a. Excessive water flow

b. High return water temperature

Check for the followings:

a. Improper expansion valve setting

b. Faulty expansion valve

c. Restriction in liquid line

Check for the followings:

a. Low or imbalanced line voltage

b. Loose power wiring

c. Defective compressor contactor

Replace compressor

Page 29

29

CGA-SVX01A-EN

G. Compressor is Noisy

Probable Cause

(1) Internal parts of compressor damaged or broken (compressor

knocks)

(2) Liquid floodback (indicated by abnormally cold suction line and

low superheat)

(3) Liquid refrigerant in compressor at start-up (indicated by

abnormally cold compressor shell)

Recommended Action

Replace compressor

Check and adjust superheat

Check for refrigerant overcharge

H. System Short of Capacity

Probable Cause

(1) Low refrigerant charge (indicated by high superheat and low

subcooling)

(2) Clogged filter drier (indicated by temperature change in

refrigerant line through drier)

(3) Incorrect expansion valve setting

(4) Expansion valve stuck or obstructed(i.e., high superheat and

high water temperature)

(5) Low evaporator water flow

(6) Noncondensibles in system

(7) Leaky valves in compressor (i.e., operation at abnormally high

suction and low discharge pressures)

Recommended Action

Add refrigerant

Replace filter drier or filter drier core

Readjust expansion valve

Repair or replace expansion valve

Check strainers. Adjust water flow

Evacuate and recharge system

Replace compressor

I. Suction Pressure Too Low

Probable Cause

(1) Shortage of refrigerant (i.e., high superheat, low subcooling)

(2) Thermostat set too low (i.e., low discharge pressure, low leaving

water temperature)

(3) Low water flow

(4) Clogged filter drier

(5) Expansion valve power assembly has lost charge

(6) Obstructed expansion valve (i.e., high superheat)

Recommended Action

Find and repair leak; recharge system

Readjust thermostat

Check for clogged strainers and ncorrect balancing valve settings

Check for frost on filter drier. Replace if needed

Repair or replace expansion valve power head assembly

Clean or replace valve

J. Suction Pressure Too High

Probable Cause

(1) Excessive cooling load (i.e., high supply water temperatures)

(2) Expansion valve overfeeding (i.e.,superheat too low, liquid

flooding to compressor)

(3) Suction valves broken (i.e. noisy compressor)

Recommended Action

See (E) above

Adjust superheat setting; verify that remote bulb is properly attached

to suction line

Replace compressor

Page 30

© American Standard Inc. 2001

30

CGA-SVX01A-EN

K. Discharge Pressure Too Low

Probable Cause

(1) Shortage of refrigerant (i.e., low subcooling, high superheat,

bubbles in sight glass)

(2) Broken or leaky compressor discharge valves

(3) Defective low pressure switch

(4) Unit running below minimum operating ambient

Recommended Action

Find and repair leak; recharge system

Replace compressor

Replace defective control

Provide adequate head pressure controls, or an ambient lockout

switch

L. Discharge Pressure Too High

Probable Cause

(1) Too little or too warm condenser air; airflow restricted

(2) Air or non-condensable gas in system (i.e., exceptionally hot

condenser)

(3) Refrigerant overcharge (i.e., high subcooling, low superheat,

high suction pressure)

(4) Excessive system load

(5) Defective condenser fan or fan pressure control (i.e., 1 fan off,

high condenser pressure)

Recommended Action

Clean coil; Check fans and motors for proper function

Evacuate and recharge system

Recover excess refrigerant

Reduced load

Repair or replace switch

M. System Cannot Heating Mode (CGAR Model Only)

Probable Cause

(1) Broken or improper control wiring

(2) Defective four-way valve

Recommended Action

Check control wiring

Replace four-way valve

N. Suction Pressure Too Low - Heating Mode (CGAR Model Only)

Probable Cause

(1) Low refrigerant charge

(2) Too little or too cold evaporator air; airflow restricted

(3) Unit running below minimum operating ambient

(4) Expansion valve power assembly has lost charge

Recommended Action

Add refrigerant

Clean coil; Check fans and motors for proper function

Provide an ambient lockout switch

Repair or replace expansion valve power head assembly

O. Discharge Pressure Too High - Heating Mode (CGAR Model Only)

Probable Cause

(1) Low water flow

(2) Defective heating thermostat switch

Recommended Action

Check for clogged strainers and incorrect balancing valve settings

a. Verify that sense bulb is properly inserted bulbwell of

heat-exchanger

b. Replace heating thermostat switch

Page 31

31

CGA-SVX01A-EN

NOTE

Page 32

Literature Order Number

File Number

Supersedes

Stocking location

CGA-IOM-6

CGA-SVX01A-EN-0701

CGA-IOM-5

Taipei Taiwan

ISO 9002 Qualified factory - Trane Taiwan

FM38631

An American-Standard Company

Since The Trane Company has a policy of continuous product improvement, it reserves the right to change design and

specifications without notice.

North American Group

The Trane Company

3600 Pammel Creek Road

La Crosse, Wl 54601-7599

http : // www.trane.com

Loading...

Loading...