Page 1

CGAM air-cooled

scroll chiller

Highly efficient, yet extremely quiet

Page 2

Balancing energy effi ciency

and quiet operation

Energy effi ciency, sound, reliability, controls and

service are all vitally important to the effective

operation of a building. Trane engineers know

how important all these factors are to you—so

we designed them all into our new 20-130 ton

model CGAM chiller. Using the best elements of

each design we created an extremely quiet and

highly effi cient chiller.

High effi ciency and quiet operation

Most air-cooled chillers require you to choose

between a highly-effi cient unit or a low-noise

unit. A quieter fan often produces less air fl ow,

reducing effi ciency. With the Trane CGAM chiller,

we have designed these two very important

benefi ts into one chiller.

Our design team compiled the best approaches

from around the globe to optimize the CGAM

chiller so that it meets global green initiatives

and ASHRAE energy effi ciency standards.

The Trane CGAM chiller is one of the most

effi cient air-cooled chillers, even among screw

compressor equipment. Low sound levels are

standard, with a 5–8db reduction compared to

previous Trane air-cooled chiller models. And,

with factory-installed attenuation, Trane further

reduces sound levels—up to an additional 3db.

Reliability you can count on

Energy effi ciency and quiet operation are

increasingly critical. As a result, we perform

extensive testing on the compressors and units,

confi rming their robust design and durability

while ensuring our high standards for reliability.

Our testing includes:

• Extreme testing includes cold ambient starts,

hot water starts and high ambient operation

• Compressor accelerated life cycle testing,

including high pressure ratio, high load test,

fl ooded starts/stops, start/stop testing

and phase reversal

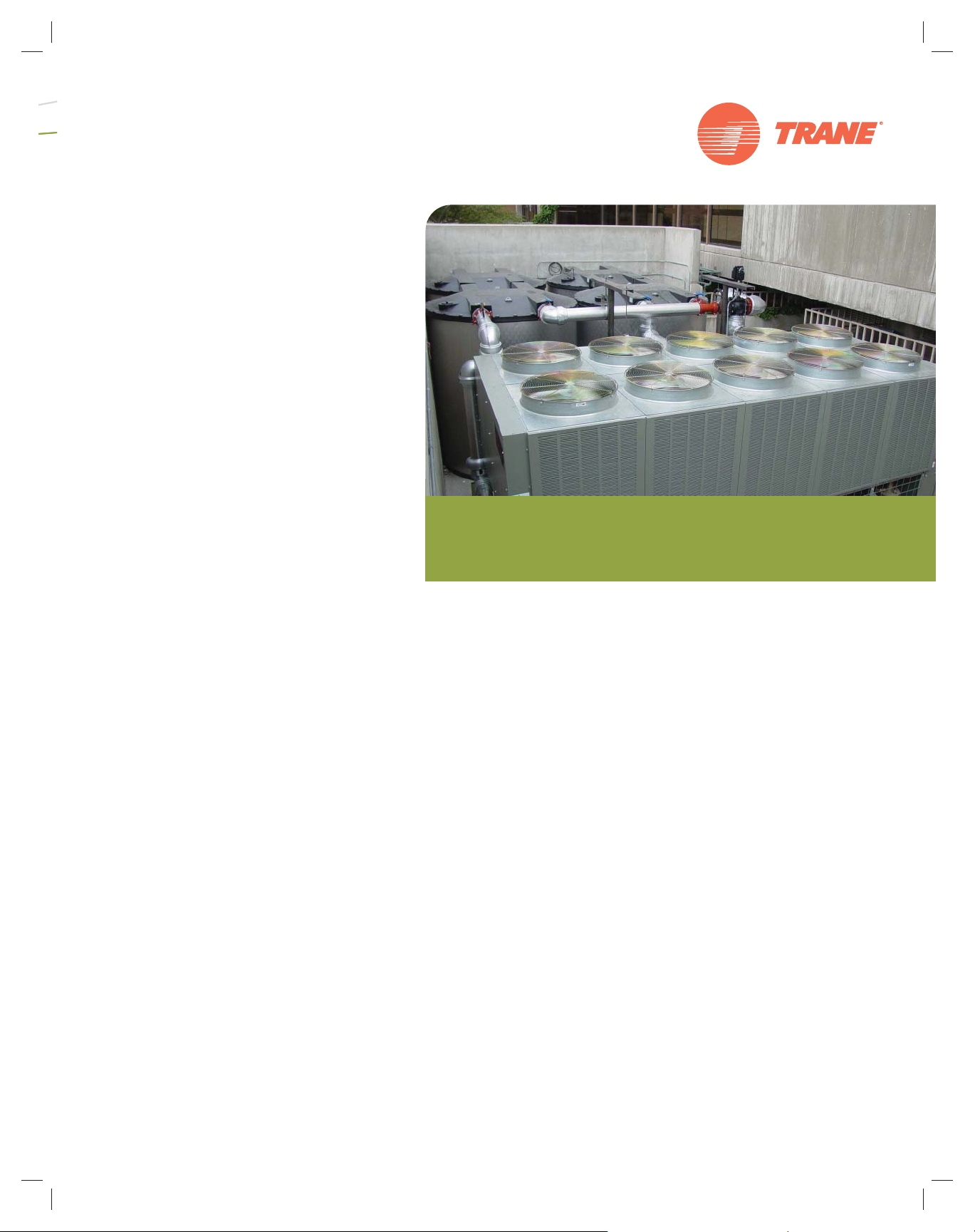

3 Air-cooled scroll chiller

On-site test

facility ensures

reliability and

performance

verification

Page 3

• Performance modeling and verifi cation, both

during design and for the life of the chiller

• FEA analysis confi rms the unit structure

can withstand shipping, rigging and

operational activity

• Electrical testing with destructive testing for

short circuit withstand rating

To minimize leaks, Trane improved the coil

structure stability by strengthening the coil frame

and changing the construction method. Now we

use a single copper tube for two passes through

the coil to reduce braze joints on one side of the

coil, eliminating up to 60 joints. Furthermore,

the new construction method ensures all

coils are square, so the coil components

are better aligned.

Trane reduces energy costs by incorporating an ice storage system

design that uses ice made at night, when energy demand and cost are

lowest, to cool the building during the day.

Factory installed reliability

We offer several factory-installed features

that further reduce energy consumption, add

redundancy for mission-critical operations and

reduce jobsite installation time — when every

day counts.

A factory-installed pump package, designed

specifi cally for this unit, comes pre-wired and

factory-tested. The dual pump setup provides

built-in redundancy and the standard inverter

delivers added pump energy savings.

With the factory-installed buffer tank, you can

install the chiller in applications with less than a

three minute water loop and still reliably maintain

precise temperature control.

The fl ow switch and water strainer are also

factory installed as standard, reducing jobsite

installation requirements and ensuring

reliable operation.

Low life cycle costs

Trane engineers, using some of the best analytic

approaches and tools in the industry, can fi nd

ways to reduce your energy usage by optimizing

energy effi ciency and performance at every point

within your system. We design systems tailored

for your specifi c application. For example, using

partial heat recovery, the heat rejected from

the condenser while cooling the building can

be redirected through a factory-installed heat

exchanger on the chiller to provide heat for

VAV reheat coils. This provides more effi cient

dehumidifi cation in commercial buildings,

or for pre-heating laundry or pool water in

lodging applications.

Another energy saving strategy is making

ice wherever energy costs are less expensive,

and then using it for cooling during the day.

Ice storage can be used in many applications

including: K-12 schools, government jobs and

industrial processes.

4

Page 4

Air-cooled scroll chiller

Model CGAM (20-130 Ton)

5 Air-cooled scroll chiller

Page 5

Compressor—facilitates full- and part-load effi ciencies that exceed

ASHRAE 90.1- 2004 by 6-8%

Fans—quiet fan design is standard, 5–8 db lower than current models,

with attenuation options for applications requiring ultra-quiet operation.

Integration—pump package and buffer tank are pre-wired and tested

in the factory.

Heat recovery—can provide 140°F (60°C) water for use in

dehumidifi cation or other applications, such as pre-heating laundry

or pool water.

Reliability—water strainer and fl ow switch are factory installed in the

most optimum location; increased coil structure strength and reduced

brazed joints minimize leaks.

Controls—CH530 improved fan staging logic for low ambient starting

capability; Adaptive Controls™ are standard to maintain operation in

adverse conditions.

Durability—powder-coated components and optional coated coils

minimize corrosion.

Serviceability—major components are positioned for easy access.

The unit structure is designed to rig pump up for easy seal changes.

5

6

Page 6

Controls for reliability, efficiency and system monitoring

Trane unit controls and building automation

solutions leverage our applications expertise

to meet your critical requirements. Adaptive

Control™ algorithms embedded in the factory-

mounted CH530 controller on the CGAM chiller

use Trane proprietary strategies to respond to

normal, extreme or adverse conditions.

The sophisticated algorithms intelligently

maximize uptime while protecting equipment

from damage.

The chiller manages time-of-day scheduling

for small offi ce buildings or schools without a

building automation system. If an integrated

pump package is included, the chiller even

controls pumps as needed. For larger enterprise-

wide projects, a Tracer ES™ building automation

system monitors and manages all chillers

within the enterprise.

Energy effi ciency is more important than ever. A

CH530 controller optimizes the CGAM chiller’s

energy consumption. New sensing technology

improves control of the electronic expansion

valve, further raising effi ciency. Tracer Summit™

building automation provides system and

building-wide energy optimization.

Building staff easily and quickly monitor

operating conditions at the chiller, on site or

remotely over the Web. Internet access solutions

can be tailored to facility needs. The CH530

controller improves usability over the previous

generation and the Tracer building automation

human interface is grounded in user-centered

design principles. It provides operators with

consolidated reports of needed data to keep

all systems running at maximum effi ciency.

Recognizing integration to legacy BAS is

sometimes a requirement, Trane actively supports

open standard protocols. The CGAM controller

integrates easily via LonTalk® or BACnet®.

Expert services for the life

of the building

Trane Building Services helps you improve

energy effi ciency, reduce operating costs and

enhance the performance of your equipment—

making your building work better for life.

The CGAM chiller is available with the Trane Elite

Start™ suite of services to make sure your system

operates as designed from day one. Factory

start-up services will help your system perform to

specifi cations upon installation.

7 Air-cooled scroll chiller

Not only do Trane CGAM air-cooled chillers

deliver the lowest noise levels and highest

efficiencies in their class, but they can be

applied with Trane fan coil units or airhandlers to improve indoor air quality—

helping achieve LEED performance.

Page 7

Trane recommends the following Elite

Start services:

• In-Warranty Support—oil analysis, diagnostic

reporting and monitoring keep equipment

operation at peak performance during the fi rst

year of operation.

• Extended Warranty—covers parts and labor

associated with any equipment failure.

• Service Agreements—scheduled inspections

for preventive and proactive maintenance

ensure long-term reliability, effi ciency

and performance.

Making service better

We take full advantage of the vast wealth of

knowledge available to us through our service

professionals by including them in our early

design efforts. As a result the Trane CGAM chiller

has many valuable service improvements:

Tracer Summit can manage chiller sequencing and load sensing for

optimum control on site or over the Web.

To help ensure that the building performance

is meeting your business needs, our service

professionals tap into a global network of proven

best practices, Trane proprietary technology and

industry-leading expertise.

• All major serviceable components are very

close to the edge of the unit, making it safer

and easier to service. The unit has quick and

easy-to-reach service valves, water strainer

and water piping connections.

• The factory-installed pump package is designed

to be serviced in place, including pump seal

changes. Simply lift the pump within the chiller

structure to replace the seal.

• The high pressure transducer and temperature

sensor mountings enable troubleshooting and

replacement without refrigerant handling.

• Separate access to the low voltage control

panel makes the chiller easier to service.

We continually train our technicians and provide

on-demand access to all the latest resources

to make maintenance decisions that will fi ne-

tune your entire system, in order to achieve the

highest level of performance.

No service provider is more qualifi ed to deliver

the cost savings and performance assurance

you demand from your Trane equipment. Trane

sales and service professionals are better able

to customize creative solutions that will better

meet your specifi c maintenance, budget and

operational requirements. To minimize any

downtime, the Trane nationwide network of

HVAC Parts and Supply stores—with access to

over 300,000 items—ensures you can get the

part you need when you need it.

8

Page 8

The results you’ve come to expect

Take advantage of all the benefi ts of the Trane

CGAM air-cooled chiller. Contact your local Trane

account manager to learn more about how you

can increase your effi ciency without sacrifi cing

quiet operation, enjoy low life cycle costs and

gain the peace of mind a Trane chiller provides.

How do you know?

There are hundreds of possible system designs

and chiller confi gurations, and thousands of

possible chiller system effi ciency levels.

How do you narrow the choices and determine

the right HVAC system design choice for your

building investment?

Whether you are calculating energy effi ciency to

determine eligibility for LEED credits, earn tax

deductions, or select the HVAC system with the

lowest operating costs, Trane can help.

The System Analyzer™ helps estimate building

loads and performs preliminary energy and

economic analyses of virtually any building,

system and equipment combination.

For LEED certifi cation, TRACE™ 700 (Trane Air

Conditioning Economics) software helps analyze

the energy and economic effects of virtually

any system confi guration by allowing users to

manipulate a wide range of variables to create

a detailed energy usage profi le for the specifi c

building. Unlike overly simplifi ed spreadsheet-

based energy analysis, TRACE 700 software

accurately compares the impact of building

alternatives, such as architectural features,

HVAC systems and other economic options, to

provide true lifecycle, cost-based decisions.

Your local Trane

account manager can

help you find the

CGAM chiller to meet

your needs.

Ingersoll Rand (NYSE:IR) is a world leader in creating and sustaining safe, comfortable and effi cient environments in commercial, residential and

industrial markets. Our people and our family of brands—including Club Car®, Hussmann®, Ingersoll Rand®, Schlage®, Thermo King® and Trane®—work

together to enhance the quality and comfort of air in homes and buildings, transport and protect food and perishables, secure homes and commercial

properties, and increase industrial productivity and effi ciency. We are a $13 billion global business committed to sustainable business practices within

our company and for our customers.

© 2010 Trane All rights reserved

CG-SLB017-EN October 01, 2010 ingersollrand.com

Produced on post-consumer recycled paper, using

environmentally friendly print practices that reduce waste.

Loading...

Loading...