Trane CGAF 100 SE, CGAF 90 SE, CGAF 130 SE, CGAF 150 SE, CGAF 140 SE Installation Operation & Maintenance

...Page 1

Installation

Operation

Maintenance

CGAF / CXAF

Air-cooled Scroll Chillers and Heat Pumps

260 - 670 kW

CG-SVX039B-GB

Original instructions

Page 2

Table of Contents

General Information ............................................................................................................... 3

Unit Description ...................................................................................................................... 5

Unit Model Number ............................................................................................................... 6

Pre-Installation ........................................................................................................................ 8

General Data ......................................................................................................................... 10

Table 1 – General data CGAF 090-190 standard efficiency ...........................................................................................................................10

Table 2 – General data CGAF 080-190 high efficiency ..................................................................................................................................13

Table 3 – General data CGAF 080-190 extra efficiency .................................................................................................................................16

Table 4 – General data CGAF 090-150 standard efficiency (shell & tube) ...................................................................................................18

Table 5 – General data CXAF 080-190 standard efficiency ...........................................................................................................................21

Table 6 – General data CXAF 080-190 high efficiency ...................................................................................................................................24

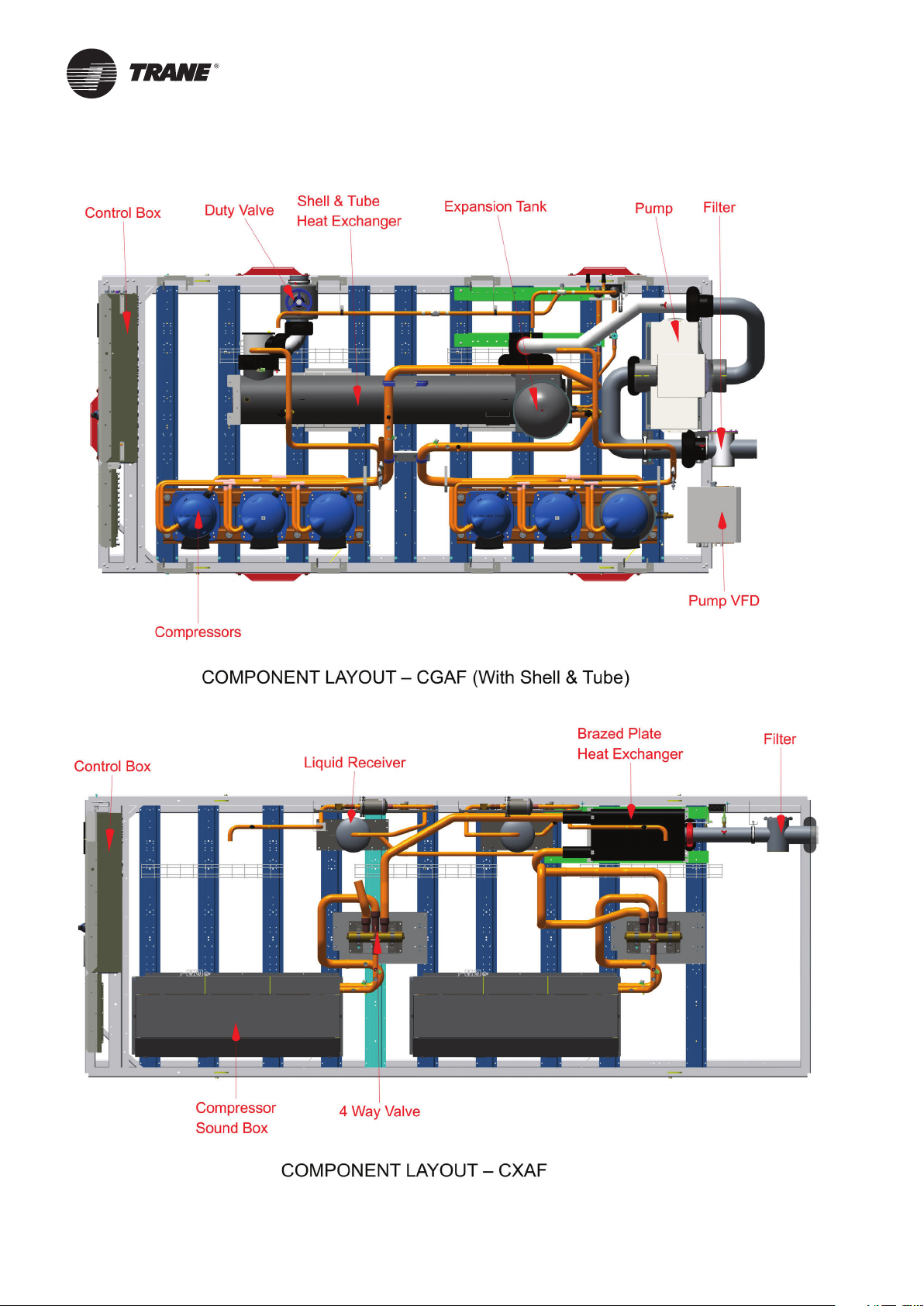

Typical CGAF / CXAF Components location ...................................................................... 27

Installation Requirements ................................................................................................... 29

Evaporator Piping ................................................................................................................. 31

Installation Mechanical ........................................................................................................ 34

Schematic pump package .................................................................................................... 35

Evaporator Waterside ........................................................................................................... 37

General Electrical Recommendations ................................................................................. 40

Installer-Supplied Components ........................................................................................... 42

Operating Principles ............................................................................................................. 43

Operating Map ...................................................................................................................... 47

Total Heat Recovery (THR) Optional .................................................................................. 48

Table 7 – General data Total Heat Recovery (THR) CGAF 080-190 ................................................................................................................48

Table 9 – Refrigerant Charge (THR Option) CGAF 080-190 ...........................................................................................................................50

Partial Heat Recovery Optional .......................................................................................... 51

Table 10/11/12 – General data for Partial Heat Recovery CGAF 080-190 SE/HE/XE .....................................................................................52

Optional Free-Cooling .......................................................................................................... 53

Table 13 – General data Free Cooling Option 080-190 ..................................................................................................................................53

Controls / Tracer TD7 Operator Interface............................................................................. 60

Pre-Start Checkout ............................................................................................................... 61

Unit Start Up Procedures ..................................................................................................... 63

Periodic Maintenance ........................................................................................................... 65

Compressor Service Information ........................................................................................ 68

Condenser Coils MCHE Maintenance ................................................................................. 70

Integrated Pump Maintenance ............................................................................................ 71

BPHE Evaporator Maintenance ........................................................................................... 72

Log Check Sheet ................................................................................................................... 73

Recommended service routine frequencies ....................................................................... 74

Additional services ............................................................................................................... 75

2 © 2019 Trane

CG-SVX039B-GB

Page 3

General Information

Foreword

These instructions are given as a guide to good practice

in the installation, start-up, operation, and maintenance

by the user, of Trane CGAF - Chillers and CXAF – Heat

Pumps manufactured in France.

A separate manual is available for the use and

maintenance of the unit’s control, Tracer™ UC800. They

do not contain full service procedures necessary for the

continued successful operation of this equipment. The

services of a qualified technician should be employed

through the medium of a maintenance contract with a

reputable service company. Read this manual thoroughly

before unit start-up.

Note: All the Chiller / Heat Pump Units are assembled,

pressure tested, dehydrated, charged and tested in

accordance with factory standard before shipment.

Warnings and Cautions

Warnings and Cautions appear at appropriate sections

throughout this manual. Your personal safety and the

proper operation of this machine require that you follow

them carefully. The constructor assumes no liability

for installations or servicing performed by unqualified

personnel.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

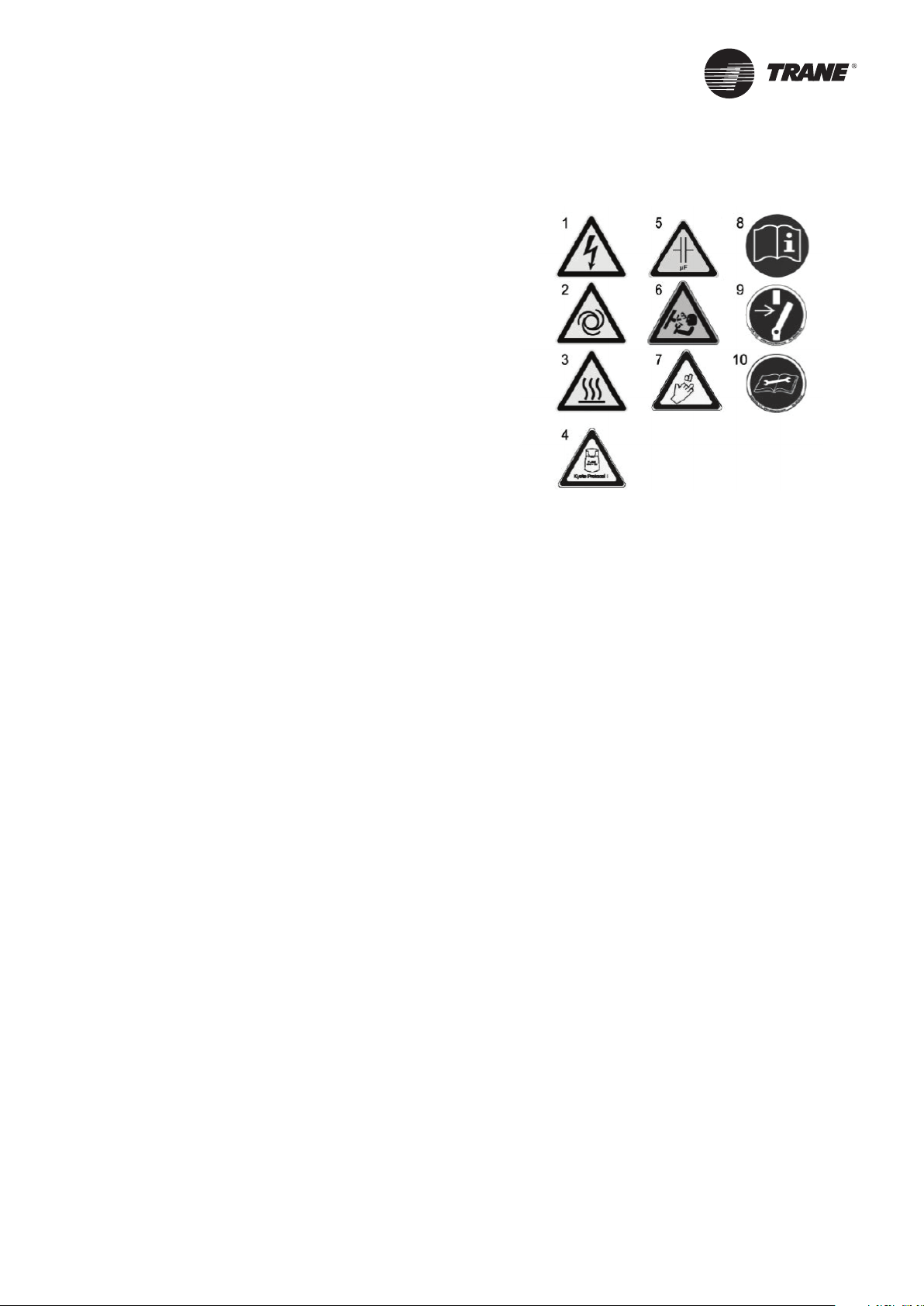

Figure 1 – Warning pictograms

1 = Risk that unit is powered up

2 = Risk hazard due to fan rotation

3 = Risk hazard of burns on compressors or refrigeration

piping

4 = Unit contains refrigerant gas. See specific warnings.

5 = Risk of residual voltage when speed drive, capacitor or

softstarter options are present

6 = Unit under pressure

7 = Risk to cut, particularly on heat exchanger fins

8 = Read instructions before installation

9 = Disconnect all electric power before servicing

10 = Read technical instructions

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices or for equipment or property-damage-only

accidents.

Safety Recommendations

To avoid death, injury, equipment or property damage,

the following recommendations should be observed

during maintenance and service visits:

1. The maximum allowable pressures for system

leak testing on low and high pressure side are

given in the chapter “Installation”. Ensure that the

pressures are within the specified limits by using

appropriate devices.

2. Disconnect all power supplies before the start of

any service activity on the unit.

3. Service work on the refrigeration system and the

electrical system should be carried out only by

qualified and experienced personnel.

4. To avoid any risk, it is recommended to place the

unit on an area with limited access.

The following pictograms can be found on the unit. Take

necessary precautions to avoid damage and injury.

Reception

On arrival,

• Inspect the unit before signing the delivery note.

• Specify any visible damage on the delivery note.

• Notify the local TRANE sales office at the same time.

Note: The delivery note must be clearly signed after

inspection and countersigned by the driver.

Also send a registered letter of protest to the last carrier

of the goods within 7 days of delivery.

Concealed damage also shall be notified by a registered

letter of protest to the last carrier of the goods within 7

days of delivery. Notify the local TRANE sales office at

the same time.

Important notice: No shipping claims will be accepted

by TRANE if the above mentioned procedure is not

respected.

For more information, refer to the general sales

conditions of your local TRANE sales office.

Note: For unit’s delivered in France, scheduled time for

unit inspection and notifying through registered letter in

case of visible and concealed damage is only 72 hours.

CG-SVX039B-GB

3

Page 4

General Information

Loose Parts Inventory

Check all the accessories and loose parts that are

shipped with the unit against the shipping list. Included

in these items will be the water vessel drain plugs,

rigging and electrical diagrams, service literature,

which are placed inside the control panel and/or starter

panel for shipment. If optional elastomeric isolators

are ordered with the unit they are shipped mounted on

the horizontal support frame of the chiller / heat pump.

The isolators’ location and distribution weight diagram

is placed with the service literature inside the starter/

control panel.

Warranty

Warranty is based on the general terms and conditions

of the manufacturer. The warranty is void if the

equipment is repaired or modified without the written

approval of the manufacturer, if the operating limits are

exceeded or if the control system or the electrical wiring

is modified. Damage due to misuse, lack of maintenance

or failure to comply with the manufacturer’s instructions

or recommendations is not covered by the warranty

obligation. If the user does not conform to the rules of

this manual, it may entail cancellation of warranty and

liabilities by the manufacturer.

Startup MUST be performed by Trane, or an authorized

agent of Trane, to VALIDATE this WARRANTY.

Training

To assist you in obtaining the best use of it and

maintaining it in perfect operating condition over a long

period of time, the manufacturer has at your disposal

a refrigeration and air conditioning service school. The

principal aim of this is to give operators and technicians

a better knowledge of the equipment they are using,

or that is under their charge. Emphasis is particularly

given to the importance of periodic checks on the

unit operating parameters as well as on preventive

maintenance, which reduces the cost of owning the unit

by avoiding serious and costly breakdown.

Refrigerant

The refrigerant provided by the manufacturer meets

all the requirements of our units. When using recycled

or reprocessed refrigerant, it is advisable to ensure its

quality is equivalent to that of a new refrigerant. For

this, it is necessary to have a precise analysis made by

a specialized laboratory. If this condition is not respected,

the manufacturer warranty could be cancelled.

Maintenance contract

It is strongly recommended that you sign a maintenance

contract with your local Service Agency.

This contract provides regular maintenance of your

installation by a specialist in our equipment. Regular

maintenance ensures that any malfunction is detected

and corrected in good time and minimizes the possibility

that serious damage will occur. Finally, regular

maintenance ensures the maximum operating life of

your equipment. We would remind you that failure to

respect these installation and maintenance instructions

may result in immediate cancellation of the warranty.

4

CG-SVX039B-GB

Page 5

Sintesis Advantage Chillers CGAF and Heat pumps

CXAF are air cooled scroll compressor units designed

for outdoor Installation. The CGAF units are cooling only

units and CXAF units are reversible and can work in

cooling and heating mode.

The units have two independent refrigerant circuits, two

or three compressors per circuit. Units are packaged

with an evaporator and condenser.

Each Unit is completely assembled, hermetic packaged,

refrigerant circuit factory piped, electrical components

wired, leak tested, dehydrated, charged and tested.

The chilled water inlet and outlet openings are covered

for shipment.

Units feature Trane’s exclusive Tracer UC800 Control

logic and controls. It monitors the control variables

that govern the operation of the unit. Control logic can

correct these variables, when necessary, to optimize

operational efficiencies, avoid unit shut down, and keep

producing chilled or hot Water.

These units comes with various options and can be

customized depending on Capacity, efficiencies, acoustic

levels, applications requirements at the time of order

placement.

Unit received and its options can be cross-checked with

the serial and model number provided in unit name

plate and description provided under unit model number

description provided in manual.

Unit Description

Nameplates

The CGAF / CXAF outdoor unit nameplates are applied

to the exterior of the control panel. A compressor

nameplate is located on each compressor.

Unit Nameplate

The unit nameplate provides the following information:

• Unit model and size description

• Unit serial number

• Identifies unit electrical requirements

• Lists correct operating charges of refrigerant and

refrigerant oil

• Lists unit test pressures

Compressor Nameplate

The compressor nameplate provides following

information:

• Compressor model number.

• Compressor serial number.

• Compressor electrical characteristics.

• Utilization range.

• Recommended refrigerant.

CG-SVX039B-GB

5

Page 6

Unit Model Number Description

Digit 1, 2, 3, 4 – Unit model

CGAF = Air-Cooled Scroll – Chiller

CXAF = Air-Cooled Scroll – Heat Pump

Digit 5-7 – Unit Nominal Tonnage

080 = 80 Tons

090 = 90 Tons

100 = 100 Tons

110 = 110 Tons

130 = 130 Tons

140 = 140 Tons

150 = 150 Tons

165 = 165 Tons

180 = 180 Tons

190 = 190 Tons

Digit 8 – Unit voltage

D = 400V/50Hz/3ph

G = 400V/50Hz/3ph Compatible with IT Neutral

Digit 9 – Manufacturing Location

E = Europe

Digit 10, 11 – Design sequence

** = Factory assigned

Digit 12 – Efficiency

N = Standard Efficiency

H = High Efficiency

A = Extra Efficiency

Digit 13 – Agency listing

C = CE Marking

Digit 14 – Pressure vessel code

2 = PED (Pressure equipment directive)

Digit 15 – Acoustic level

X = Standard noise (SN)

L = Low noise (LN)

E = Extra Low Noise (XLN)

Digit 16 – Unit Application

X = Standard Ambient [-10°C; +46°C]

L = Low Ambient [-20°C; +46°C]

H = High Ambient [-10°C; +52°C]

D = Wide Ambient [-20°C; + 52°C]

1 = Comfort application, cooling mode [10°C; 46°C] and

heating mode [-15°C; 20°C]

3 = Process application, cooling mode [-20°C; 46°C]

Heating mode [-15°C; 35°C]

Digit 17 – Relief valve option

W = Without

Digit 20 – Evaporator Configurations

B = Brazed plate heat exchanger

T = Shell & Tube heat exchanger

Digit 21 – Thermal Insulation

N = Standard

Digit 22 – Condenser Coating

N = Aluminum Micro Channel

C = E-Coated Micro Channel

B = Aluminum Fin w/o slit

E = Epoxy Coated Aluminum Fin

Digit 23 – Heat Recovery

X = No Heat Recovery

P = Partial Heat Recovery

T = Total Heat Recovery (full equipment)

Digit 24 – Hydraulic module

X = Pump signal On/Off

1 = Dual pump standard pressure

2 = Single pump standard pressure

3 = Dual pump high pressure

4 = Single pump high pressure

Digit 25 – Free Cooling

X = No Free Cooling

F = Total Free-Cooling Direct

H = Total Free-Cooling Glycol free

Digit 26 – Disconnect switch

B = With circuit breaker

Digit 27 – Under/Over Voltage

X = None

1 = Included

2 = Included with ground fault protection

Digit 28 – Human Interface language

C = Spanish

D = German

E = English

F = French

H = Dutch

I = Italian

M = Swedish

P = Polish

R = Russian

T = Czech

U = Greek

V = Portuguese

2 = Romanian

6 = Hungarian

8 = Turkish

Digit 18 – Water connection

X = Grooved pipe connection

W = Grooved pipe + welded coupling

2 = Grooved pipe with coupling and Flange adapter

Digit 19 – Evaporator Application

N = Standard cooling [4°C; 20°C]

P = Low Temperature process [-12°C; 4°C]

C = Ice Making [-7°C; 20°C] with hardwired interface

6

Digit 29 – Smart com protocol

X = None

B = BACnet interface

M = Modbus interface

L = LonTalk interface

Digit 30 – Communication customer

X = None

A = External set point & capacity outputs

CG-SVX039B-GB

Page 7

Unit Model Number Description

Digit 31 – Flow switch

X = None

F = Field installed flow switch

Digit 32 – Electrical Panel Protection

X = Enclosure with deadfront protection

1 = Enclosure with IP 20 internal protection

Digit 33 – Master Slave

X = Without

A = With

Digit 34 – Unit User Interface

L = Standard, Local UI supplied (TD7)

Digit 35 – Energy meter

X = No energy meter

M = Energy meter installed

Digit 36 – Mini Chiller Plant Control

X = No Mini PC

Digit 37 – Variable Primary Flow

X = Constant speed pump (no AFD)

A = Pump flow controlled by 3 ways Duty Valve

F = Constant Speed Pump -AFD Adjustment

T = Variable Speed Pump - Constant delta T

Digit 38 – Open for future use = X

Z = Slovenian

2 = Romanian

3 = Serbian

4 = Slovak

5 = Croatian

6 = Hungarian

8 = Turkish

Digit 44 – Shipping package

X = Standard protection

A = Containerization package

Digit 45 – Refrigerant

X = None

A = R410A Factory full Refrigerant charge

8 = R410A Factory Refrigerant Pre-Charge

Digit 46 – Isolator Valve per Manifold Compressor

X = None

Digit 47 – Power Factor Correction Capacitors

A = With

X = None

Digit 48 – Open for future use = X

Digit 49 – Freeze Protection (Factory Installed)

X = None

2 = With freeze protection

Digit 39 – Open for future use = X

Digit 40 – Power socket

X = None

P = Included (230V - 100W)

Digit 41 – Factory tests

X = No final performances test

B = Visual inspection with customer

E = Performance test without customer

Digit 42 – Installation accessory

X = None

1 = Neoprene Isolators

4 = Neoprene pads

Digit 43 – Literature language

B = Bulgarian

C = Spanish

D = German

E = English

F = French

H = Dutch

I = Italian

K = Finnish

L = Danish

M = Swedish

N = Norwegian

P = Polish

R = Russian

T = Czech

U = Greek

V = Portuguese

Digit 50 – Buffer Tank

X = No Tank

1 = With Tank

Digit 51 – Water Strainer

X = No strainer

A = Factory installed strainer

Digit 52 – Louvered panels

X = None

Digit 53 – Open for future use = X

Digit 54 – Starter type

A = Across the line starter/Direct On Line

B = Soft starter

Digit 55 – Annunciation Relay

X = None

A = With

Digit 56 – Fan type

1 = AC fan

2 = EC fan

3 = EC with Axitop

Digit 57 – Night Noise Setback (NNSB)

X = Without

1 = With NNSB

Digit 58 – Design special

X = Standard

S = Special requirement

CG-SVX039B-GB

7

Page 8

Pre-Installation

Inspection checklist

When the unit is delivered, verify that it is the correct

unit and that it is properly equipped. Compare the

information which appears on the unit nameplate with

the ordering and submittal information.

Inspect all exterior components for visible damage.

Report any apparent damage or material shortage to

the carrier and make a “unit damage” notation on the

carrier’s delivery receipt. Specify the extent and type of

damage found and notify the appropriate Trane Sales

Office. Do not proceed with installation of a damaged

unit without sales office approval.

Mandatory Start-up Checklist

This checklist is not intended to be a substitution for

the contractor’s installation instruction. This checklist is

intended to be a guide for the Trane technician just prior

to unit ‘start-up’. Many of the recommended checks and

actions could expose the technician to electrical and

mechanical hazards. Refer to the appropriate sections in

the unit manual for appropriate procedures, component

specifications and safety instructions.

Except where noted; it is implied that the technician is to

use this checklist for inspection / verification of prior task

completed by the general contractor at installation.

1. Unit clearances adequate for service and to avoid

air recirculation, etc

2. Unit exterior inspected. CGAF / CXAF condenser

coil will not be obstructed at any time by snow or

ice during winter conditions

3. Unit properly grounded

4. Crankcase heaters working for 24 hours prior to

arrival of Trane technician performing start up

5. Correct voltage supplied to unit and electric

heaters (imbalance not to exceed 2%)

6. Unit power phasing (A-B-C sequence) proper for

compressor rotation

7. Copper power wiring meets sizing requirement in

job submittal

8. All automation and remote controls installed/

wired

9. All wiring connections tight

10. Prove chilled water side Interlock and

Interconnecting

11. Wiring Interlock and externals (chilled water

pump)

12. Field installed control wiring landed on correct

terminals (external start/stop, emergency stop,

chilled water reset…)

13. Verify all refrigerant and oil valves are open/back

seated

14. Compressor oil levels (1/2 -3/4 high in glass)

proper

15. Verify chilled water strainer is clean and free of

debris and evaporator chilled water circuits are

filled

16. A pressure switch device to detect lack of water

is not included in the pump package. Installation

of this type of device is highly recommended to

avoid sealing damage due to operation of pump

without enough water

1 7. Close the fused-disconnect switches that supplies

power to the chilled water pump starter

18. Start the chilled water pump to begin circulation

of the water. Inspect piping for leaks and repair

as necessary. Check the physical presence of the

water pressure switch

19. With water circulating through the system, adjust

water flow and check water pressure drop through

evaporator

20. Return chilled water pump to auto

21. Verify all the chiller controller Menu Items

22. All panels/doors secured prior to start-up

23. All coil fins inspected and straightened

24. Rotate fans before starting unit to inspect for

potential audible and visual signs of rubbing.

Start unit

25. Press AUTO key. The unit will start if the chiller

control calls for cooling and the safety interlocks

are closed

26. Check the evaporator and the condenser

refrigerant pressure on the chiller controller

27. Confirm Superheat and sub-cooling values are

normal

28. Compressor operation normal and within

amperage rating

29. Operating log completed

30. Press stop key

31. Inspect fans again after being under load to

ensure no signs or rubbing exist

32. Verify the chilled water pump runs for at least

1 minute (possibility to configure maxi 10 mn)

after the chiller is commanded to stop (for normal

chilled water systems)

Unit storage

If the chiller is to be stored for more than one month

prior to installation, observe the following precautions:

• Store the unit in a secured area, to avoid intentional

damages.

• Close the suction, discharge and liquid-line isolation

valves.

• Store the chiller in a dry, vibration-free, secure area.

• At least every three months, attach a gauge and

manually check the pressure in the refrigerant circuit.

• If the refrigerant pressure is below 13 bar at 20°C

(or 10 bar at 10°C), call a qualified service organization

and the appropriate Trane sales office.

Note: If the unit is stored before servicing near a

construction site it is highly recommended to protect

micro channel coils from any concrete and iron element.

Failure to do so may considerably reduce reliability of

the unit.

8

CG-SVX039B-GB

Page 9

Pre-Installation

Installation requirements and contractor responsibilities

A list of the contractor responsibilities typically associated with the unit installation process is provided.

Type of requirement

Foundation • Meet foundation requirements

Rigging

Isolation

Electrical

Water piping

Insulation • Insulation • Insulation (Piping)

Water piping connection elements • Grooved pipe

Trane-supplied

Trane-installed

• Disconnect

Switch

• Unit mounted

starter

• Flow Switch

• Water Strainer

(Optional)

Trane-supplied

Field-installed

• Neoprene Pads

• Isolators

(Optional)

• Grooved pipe

couplings (or)

Flanged Adopters

Field-supplied

Field-installed

• Safety chains

• Clevis connectors

• Lifting beams

• Neoprene Pads

• Isolators (Customer Supplied)

• Wiring sizes per submittals and local codes and

regulations

• Terminal lugs

• Ground connection(s)

• BAS Wiring (optional)

• Control voltage wiring

• Chilled water pump contactor and wiring

including interlock

• Option relays and wiring

• Taps for thermometers and gauges

• Thermometers

• Water ow pressure gauges

• Isolation and balancing valves in water piping

• Vents and drains

• Pressure relief valves

• Pressure switch device to detect lack of water

CG-SVX039B-GB

9

Page 10

General Data

Table 1 – General data CGAF 090-190 Standard Efficiency

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

90 100 110 130 140 150 165 180 190

SE SE SE SE SE SE SE SE SE

Net Cooling Capacity (1) (kW) 318 351 391 431 473 519 558 621 661

Net Total Power input (1) (kW) 105 120 138 157 160 183 202 211 230

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15 15 15 15

Power Cable Cross Section (max) mm² 1*240 1*240 1*240 1*240 2*300 2*300 2*300 2*300 2*300

Disconnect switch size (A) 400 400 500 500 630 630 630 800 800

Digit 56=1

Maximum Power input (kW) 142.6 162.2 176.0 189.9 221.9 241.5 255.4 272.1 286.0

Max. amps (A) 237.8 270.0 292.1 314.2 368.9 401.1 423.2 451.2 473.3

Unit start up amps (w/o soft starter digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

Displacement power factor (dpf) 0.87 0.87 0.87 0.87 0.87 0.87 0.87 0.87 0.87

Digit 56=2 or Digit 56=3

Maximum Power input (kW) 145.7 165.2 179.1 193.0 226.0 245.6 259.5 277.2 291.1

Max. amps (A) 238.4 270.6 292.7 314.8 369.7 401.9 424.0 452.2 474.3

Unit start up amps (w/o soft starter Digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

Displacement power factor (dpf) 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.89

Compressor

Compressor Number per Circuit # 2 2 2 2 3 3 3 3 3

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit 1 / Circuit 2

Max Comp Power input Circuit 1 / Circuit 2 kW

Rated Amps Circuit 1 / Circuit 2

(Digit 56=1) (4)

Rated Amps Circuit 1 / Circuit 2

(Digit 56=2 or Digit 56=3) (4)

Locked Rotor Amps Circuit 1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit 1 / Circuit 2 (W) 112/112 112/112 112/112 112/112 168/168 168/168 168/168 168/168 168/168

Evaporator

Quantity # 1 1 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model

Evaporator Water Content volume (l) 31.0 35.7 40.4 48.6 48.6 56.7 64.9 73.1 81.3

Nominal water connection size

(Grooved coupling) - Without HYM

Nominal water connection size

(Grooved coupling) - With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 123 115 98 92 142 137 124 164 155

Motor Power (kW) 5.5 5.5 7.5 7.5 7.5 7.5 11.0 11.0 11.0

Rated Amps (A) 11.0 11.0 14.4 14.4 14.4 14.4 20.8 20.8 20.8

Single pump - High head pressure option

Max available Head Pressure (kPa) 251 247 234 232 249 252 245 234 226

Motor Power (kW) 11.0 11.0 11.0 11.0 15.0 15.0 15.0 15.0 15.0

Rated Amps (A) 20.8 20.8 20.8 20.8 28.0 28.0 28.0 28.0 28.0

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 123 115 98 92 142 137 124 164 155

Motor Power (kW) 5.5 5.5 7.5 7.5 7.5 7.5 11.0 11.0 11.0

Rated Amps (A) 11.0 11.0 14.4 14.4 14.4 14.4 20.8 20.8 20.8

(A) 495.1 527.3 631.4 653.5 626.3 658.5 762.5 790.4 812.6

(A) 367.1 399.3 466.2 488.3 498.3 530.5 597.3 625.2 647.4

(A) 495.7 527.9 632.0 654.1 627.1 659.3 763.3 791.4 813.6

367.7 399.9 466.8 488.9 499.1 531.3 598.1 626.2 648.4

25+30/

25+30

28.4+38.2/

28.4+38.2

35.4+46.0/

(A)

35.4+46.0

35.1+45.5/

35.1+45.5

260+320/

260+320

DFX650x106 DFX650x122 DFX650x138 DFX650x166 DFX650x166 DFX650x194 DFX650x222 DFX650x250 DFX650x278

(in) (mm)

(in) (mm)

4" -

114.3

4" -

114.3

30+30/

30+30

38.2+38.2/

38.2+38.2

47.0+47.0/

47.0+47.0

46.5+46.5/

46.5+46.5

320+320/

320+320

4" -

114.3

4" -

114.3

30+40/

30+40

38.2+45.2/

38.2+45.2

48.3+59.8/

48.3+59.8

47.7+59.0/

47.7+59.0

320+413/

320+413

4" -

114.3

4" -

114.3

40+40/

40+40

45.2+45.2/

45.2+45.2

61.7+61.7/

61.7+61.7

60.7+60.7/

60.7+60.7

413+413/

413+413

4" -

114.3

4" -

114.3

25+30+30/

25+30+30

28.4+38.2+38.2/

28.4+38.2+38.2

35.5+48.1+48.1/

35.5+48.1+48.1

35.1+47.5+47.5/

35.1+47.5+47.5

260+320+320/

260+320+320

5" -

139.7

5" -

139.7

30+30+30/

30+30+30

38.2+38.2+38.2/

38.2+38.2+38.2

48.2+48.2+48.2/

48.2+48.2+48.2

47.5+47.5+47.5/

47.5+47.5+47.5

320+320+320/

320+320+320

5" -

139.7

5" -

139.7

30+30+40/

30+30+40

38.2+38.2+45.2/

38.2+38.2+45.2

49.2+49.2+61.0/

49.2+49.2+61.0

48.5+48.5+60.1/

48.5+48.5+60.1

320+320+413/

320+320+413

5" -

139.7

5" -

139.7

30+40+40/

30+40+40

38.2+45.2+45.2/

38.2+45.2+45.2

47.6+59.0+59.0/

47.6+59.0+59.0

47.1+58.2+58.2/

47.1+58.2+58.2

320+413+413/

320+413+413

5" -

139.7

5" -

139.7

40+40+40/

40+40+40

45.2+45.2+45.2/

45.2+45.2+45.2

60.1+60.1+60.1/

60.1+60.1+60.1

59.2+59.2+59.2/

59.2+59.2+59.2

413+413+413/

413+413+413

5" -

139.7

5" -

139.7

10

CG-SVX039B-GB

Page 11

General Data

Table 1 – General data CGAF 090-190 Standard Efficiency (continued)

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

90 100 110 130 140 150 165 180 190

SE SE SE SE SE SE SE SE SE

Twin pump - High head pressure option

Max available Head Pressure (kPa) 251 247 234 232 249 252 245 234 226

Motor Power (kW) 11.0 11.0 11.0 11.0 15.0 15.0 15.0 15.0 15.0

Rated Amps (A) 20.8 20.8 20.8 20.8 28.0 28.0 28.0 28.0 28.0

Expansion Tank Volume (l) 50 50 50 50 50 50 50 50 50

Max User water loop Volume for factory

mounted expansion tank (1)

Optional water Buffer tank volume (l) 607 607 607 607 777 777 777 777 777

Antifreeze Heater without pump package

and without buffer tank

Antifreeze Heater with pump package and

without buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

Antifreeze Heater with pump package and

with buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 6 6 6 6 8 8 8 10 10

Face area per circuit (m²) 8.88 8.88 8.88 8.88 11.84 11.84 11.84 14.80 14.80

Condenser Fan

Quantity # 6 6 6 6 8 8 8 10 10

Diameter (mm) 800

Fan / motor Type Propeller fan : Fixed speed AC motor / Variable speed EC motor

Digit 56=1

Fan / motor Type Fixed speed AC motor

Airow per fan m3/h 15859 15778 15680 15580 15686 15684 15609 15730 15670

Max Power Input per Motor Kw 1.44 1.44 1.44 1.44 1.44 1.44 1.44 1.44 1.44

Max Amps per Motor A 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9

Motor RPM (rpm) 900 900 900 900 900 900 900 900 900

Digit 56=2 or Digit 56 =3

Fan / motor Type Variable speed EC motor

Airow per fan m3/h 17411 17331 17235 17136 17240 17239 17165 17283 17225

Max Power Input per Motor Kw 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95

Max Amps per Motor A 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0

Motor RPM (SN - Digit 15=X or LN Digit 15=L and Digit 56=2)

Motor RPM (XLN - Digit 15=E and

Digit 56=2)

Motor RPM (SN - Digit 15=X or LN Digit 15=L and Digit 56=3)

Motor RPM (XLN - Digit 15=E and

Digit 56=3)

Dimensions

Unit Length (mm) 3395 3395 3395 3395 4520 4520 4520 5645 5645

Unit Width (mm) 2200 2200 2200 2200 2200 2200 2200 2200 2200

Std Unit Height (mm) 2526 2526 2526 2526 2526 2526 2526 2526 2526

Axitop EC Fan Unit - (Additional height

conguration)

Pump Package Option - (Additional length

conguration)

(l) 1750 1750 1750 1750 1750 1750 1750 1750 1750

(W) 360 420 420 420 540 640 640 640 640

1000 /

(W)

1060

1880 /

(W)

1940

(rpm) 850 850 860 920 860 900 940 890 920

840 840 840 840 840 840 840 840 840

850 850 880 940 860 920 960 900 940

800 800 800 800 800 800 800 800 800

(mm) +146 +146 +146 +146 +146 +146 +146 +146 +146

(mm) +425 +425 +425 +425 +370 +370 +370 +370 +370

1060 /

1120

1940 /

2000

1060 /

1120

1940 /

2000

1060 /

1120

1940 /

2000

1240 /

1300

2690 /

2750

1340 /

1400

2790 /

2850

1340 /

1400

2790 /

2850

1340 /

1400

2790 /

2850

1340 /

1400

2790 /

2850

CG-SVX039B-GB

11

Page 12

General Data

Table 1 – General data CGAF 090-190 Standard Efficiency (continued)

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

90 100 110 130 140 150 165 180 190

SE SE SE SE SE SE SE SE SE

Weights

Shipping Weight (3) (kg) 2085 2195 2260 2325 2835 3010 3075 3440 3515

Operating Weight (3) (kg) 2145 2260 2330 2400 2915 3100 3175 3550 3630

Option Additional shipping weight

Single pump - Standard head pressure (kg) 215 220 225 225 230 230 295 310 305

Single pump - High head pressure (kg) 260 265 265 260 305 305 305 320 320

Twin pump - Standard head pressure (kg) 300 305 325 320 325 325 440 450 450

Twin pump - High head pressure (kg) 385 390 385 385 460 460 465 480 475

Axitop option (kg) 60 60 60 60 80 80 80 100 100

XLN option (kg) 115 115 115 115 150 150 150 150 150

Pump VFD option (kg) 70 70 70 70 70 70 70 70 70

Partial heat recovery option

(Digit 19 = N)

Partial heat recovery option

(Digit 19 = P)

Water Buffer tank option (kg) 250 250 250 250 330 330 330 330 330

System data

Nb of refrigerant circuit # 2 2 2 2 2 2 2 2 2

Minimum cooling load % (6) % 23 25 21 25 15 17 15 14 17

Standard/Partial Heat Recovery Unit

R410A refrigerant charge

Circuit 1 / Circuit 2

Oil charge Circuit 1 / Circuit 2 (l)

POE Oil type OIL058E / OIL057E

(kg) 45.00 45.00 65.00 65.00 75.00 75.00 75.00 75.00 75.00

(kg) 45.00 45.00 45.00 45.00 75.00 75.00 75.00 75.00 75.00

(kg) 18 / 18 19 / 19

13.4 /

13.4

13.4 /

13.4

19.5 /

19.5

13.4 /

13.4

20.5 /

20.5

13.4 /

13.4

30 / 30 32 / 32 33 / 33 38 / 38 39 / 38

23.1 /

22.1

23.1 /

23.1

23.1 /

23.1

23.1 /

23.1

23.1 /

23.1

(1) Indicative performance at Evaporator water temperature : 12°C / 7°C - Condenser air temperature 35°C - for detailed performances, on a given unit,

consult Order Write Up.

(2) Under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

12

CG-SVX039B-GB

Page 13

General Data

Table 2 – General data CGAF 080-190 High Efficiency

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

80 90 100 110 130 140 150 165 180 190

HE HE HE HE HE HE HE HE HE HE

Net Cooling Capacity (1) (kW) 293 334 371 416 459 498 548 587 641 682

Net Total Power input (1) (kW) 90 102 115 132 149 155 176 193 205 222

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15 15 15 15 15

Power Cable Cross Section (max) mm² 1*240 1*240 1*240 1*240 1*240 2*240 2*300 2*300 2*300 2*300

Disconnect switch size (A) 315 400 400 500 500 630 630 630 800 800

Digit 56=1

Maximum Power input (kW) 123.0 145.5 165.0 178.9 192.8 224.8 244.4 258.3 275.0 288.9

Max. amps (A) 205.6 243.6 275.8 297.9 320.0 374.7 406.9 429.0 457.0 479.1

Unit start up amps (w/o soft starter Digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

Displacement power factor (dpf) 0.86 0.86 0.86 0.87 0.87 0.87 0.87 0.87 0.87 0.87

Digit 56=2

Maximum Power input (kW) 126.1 149.6 169.1 183.0 196.9 229.9 249.5 263.4 281.1 295.0

Max. amps (A) 206.2 244.4 276.6 298.7 320.8 375.7 407.9 430.0 458.2 480.3

Unit start up amps (w/o soft starter Digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

Power factor 0.88 0.88 0.88 0.88 0.89 0.88 0.88 0.88 0.89 0.89

Compressor

Compressor Number per Circuit # 2 2 2 2 2 3 3 3 3 3

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit 1 / Circuit 2

Max Comp Power input Circuit 1 / Circuit 2 kW

Rated Amps Circuit 1 / Circuit 2

(Digit 56=1) (4)

Rated Amps Circuit 1 / Circuit 2

(Digit 56=2) (4)

Locked Rotor Amps Circuit 1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit 1 / Circuit 2 (W) 112/112 112/112 112/112 112/112 112/112 168/168 168/168 168/168 168/168 168/168

Evaporator

Quantity # 1 1 1 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model

Evaporator Water Content volume (l) 40.4 40.4 48.6 56.7 64.9 73.1 81.3 81.3 81.3 86.0

Nominal water connection size (Grooved

coupling) - Without HYM

Nominal water connection size (Grooved

coupling) - With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 155 136 119 103 92 146 134 122 161 149

Motor Power (kW) 5.5 5.5 5.5 7.5 7.5 7.5 7.5 11.0 11.0 11.0

Rated Amps (A) 11.0 11.0 11.0 14.4 14.4 14.4 14.4 20.8 20.8 20.8

Single pump - High head pressure option

Max available Head Pressure (kPa) 280 266 254 242 237 257 253 249 231 220

Motor Power (kW) 11.0 11.0 11.0 11.0 11.0 15.0 15.0 15.0 15.0 15.0

Rated Amps (A) 20.8 20.8 20.8 20.8 20.8 28.0 28.0 28.0 28.0 28.0

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 155 136 119 103 92 146 134 122 161 149

Motor Power (kW) 5.5 5.5 5.5 7.5 7.5 7.5 7.5 11.0 11.0 11.0

Rated Amps (A) 11.0 11.0 11.0 14.4 14.4 14.4 14.4 20.8 20.8 20.8

(A) 419.0 500.9 533.1 637.2 659.3 632.1 664.3 768.3 796.2 818.4

(A) 315.0 372.9 405.1 472.0 494.1 504.1 536.3 603.1 631.0 653.2

(A) 419.6 501.7 533.9 638.0 660.1 633.1 665.3 769.3 797.4 819.6

315.6 373.7 405.9 472.8 494.9 505.1 537.3 604.1 632.2 654.4

(A)

(in) -

(mm)

(in) -

(mm)

25+25/

25+25

28.4+28.4/

28.4+28.4

34.9+34.9/

34.9+34.9

34.6+34.6/

34.6+34.6

260+260/

260+260

DFX650

x138

4" -

114.3

4" -

114.3

25+30/

25+30

28.4+38.2/

28.4+38.2

34.1+44.3/

34.1+44.3

34.0+44.1/

34.0+44.1

260+320/

260+320

DFX650

x138

4" -

114.3

4" -

114.3

30+30/

30+30

38.2+38.2/

38.2+38.2

44.9+44.9/

44.9+44.9

44.6+44.6/

44.6+44.6

320+320/

320+320

DFX650

x166

4" -

114.3

4" -

114.3

30+40/

30+40

38.2+45.2/

38.2+45.2

45.9+56.6/

45.9+56.6

45.4+56.1/

45.4+56.1

320+413/

320+413

DFX650

x194

4" -

114.3

4" -

114.3

40+40/

40+40

45.2+45.2/

45.2+45.2

57.9+57.9/

57.9+57.9

57.3+57.3/

57.3+57.3

413+413/

413+413

DFX650

x222

4” -

114.3

4” -

114.3

25+30+30/

25+30+30

28.4+38.2+38.2/

28.4+38.2+38.2

34.4+46.2+46.2/

34.4+46.2+46.2

34.2+45.8+45.8/

34.2+45.8+45.8

260+320+320/

260+320+320

DFX650

x250

5" -

139.7

5" -

139.7

30+30+30/

30+30+30

38.2+38.2+38.2/

38.2+38.2+38.2

46.2+46.2+46.2/

46.2+46.2+46.2

45.8+45.8+45.8/

45.8+45.8+45.8

320+320+320/

320+320+320

DFX650

x278

5" -

139.7

5" -

139.7

30+30+40/

30+30+40

38.2+38.2+45.2/

38.2+38.2+45.2

47.0+47.0+58.1/

47.0+47.0+58.1

46.4+46.4+57.4/

46.4+46.4+57.4

320+320+413/

320+320/

413

DFX650

x278

5" -

139.7

5" -

139.7

30+40+40/

30+40+40

38.2+45.2+45.2/

38.2+45.2+45.2

46.1+56.9+56.9/

46.1+56.9+56.9

45.6+56.3+56.3/

45.6+56.3+56.3

320+413+413/

320+413+413

DFX650

x278

5" -

139.7

5" -

139.7

40+40+40/

40+40+40

45.2+45.2+45.2/

45.2+45.2+45.2

57.7+57.7+57.7/

57.7+57.7+57.7

57.1+57.1+57.1/

57.1+57.1+57.1

413+413+413/

413+413+413

DFX650

x294

5" -

139.7

5" -

139.7

CG-SVX039B-GB

13

Page 14

General Data

Table 2 – General data CGAF 080-190 High Efficiency (continued)

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

80 90 100 110 130 140 150 165 180 190

HE HE HE HE HE HE HE HE HE HE

Twin pump - High head pressure option

Max available Head Pressure (kPa) 280 266 254 242 237 257 253 249 231 220

Motor Power (kW) 11.0 11.0 11.0 11.0 11.0 15.0 15.0 15.0 15.0 15.0

Rated Amps (A) 20.8 20.8 20.8 20.8 20.8 28.0 28.0 28.0 28.0 28.0

Expansion Tank Volume (l) 50 50 50 50 50 50 50 50 50 50

Max User water loop Volume for factory

mounted expansion tank (1)

Optional water Buffer tank volume (l) 607 607 607 607 607 777 777 777 777 777

Antifreeze Heater without pump package

and without buffer tank

Antifreeze Heater with pump package and

without buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

Antifreeze Heater with pump package and

with buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 6 8 8 8 8 10 10 10 12 12

Face area per circuit (m²) 8.88 11.84 11.84 11.84 11.84 14.80 14.80 14.80 17.76 17.76

Condenser Fan

Quantity # 6 8 8 8 8 10 10 10 12 12

Diameter (mm) 800

Fan / motor Type Propeller fan : Fixed speed AC motor / Variable speed EC motor

Digit 56=1

Fan / motor Type Fixed speed AC motor

Airow per fan m3/h 15925 16020 15956 15879 15803 15840 15839 15782 15858 15809

Max Power Input per Motor Kw 1.44 1.44 1.44 1.44 1.44 1.44 1.44 1.44 1.44 1.44

Max Amps per Motor A 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9

Motor RPM (rpm) 900 900 900 900 900 900 900 900 900 900

Digit 56=2

Fan / motor Type Variable speed EC motor

Airow per fan

(SN - Digit 15=X or LN - Digit 15=L)

Airow per fan (XLN - Digit 15=E) m3/h 17360 17453 17390 17315 17240 17276 17276 17220 17294 17246

Max Power Input per Motor Kw 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95

Max Amps per Motor A 3 3 3 3 3 3 3 3 3 3

Motor RPM (SN - Digit 15=X or LN Digit 15=L)

Motor RPM (XLN - Digit 15=E) 840 840 840 840 840 840 840 840 840 840

Dimensions

Unit Length (mm) 3395 4520 4520 4520 4520 5645 5645 5645 6770 6770

Unit Width (mm) 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200

Std Unit Height (mm) 2526 2526 2526 2526 2526 2526 2526 2526 2526 2526

Axitop EC Fan Unit - (Additional height

conguration)

Pump Package Option - (Additional length

conguration)

Weights

Shipping Weight (3) (kg) 2015 2410 2540 2615 2675 3205 3385 3425 3790 3855

Operating Weight (3) (kg) 2085 2480 2615 2700 2770 3315 3500 3540 3910 3975

Option Additional shipping weight

Single pump - Standard head pressure (kg) 215 230 225 235 235 245 240 305 330 325

Single pump - High head pressure (kg) 265 275 270 270 270 320 315 315 340 340

Twin pump - Standard head pressure (kg) 305 315 315 335 335 345 340 450 475 470

Twin pump - High head pressure (kg) 385 400 395 395 395 480 475 475 500 495

XLN option (kg) 115 115 115 115 115 150 150 150 150 150

Pump VFD option (kg) 70 70 70 70 70 70 70 70 70 70

(l) 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750

(W) 420 420 420 520 520 640 640 640 640 640

1060 /

(W)

1120

1940 /

(W)

2000

(rpm) 850 850 850 860 920 860 900 940 890 920

(mm) +146 +146 +146 +146 +146 +146 +146 +146 +146 +146

(mm) +425 +425 +425 +425 +425 +370 +370

1060 /

1120

1940 /

2000

1060 /

1120

1940 /

2000

1160 /

1220

2040 /

2100

1160 /

1220

2040 /

2100

1340 /

1400

2790 /

2850

1340 /

1400

2790 /

2850

1340 /

1400

2790 /

2850

+370 +370 +370

1340 /

1400

2790 /

2850

1340 /

1400

2790 /

2850

14

CG-SVX039B-GB

Page 15

General Data

Table 2 – General data CGAF 080-190 High Efficiency (continued)

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

80 90 100 110 130 140 150 165 180 190

HE HE HE HE HE HE HE HE HE HE

Partial heat recovery option

(Digit 19 = N) / (Digit 19 = P)

Water Buffer tank option (kg) 250 250 250 250 250 330 330 330 330 330

System data

Nb of refrigerant circuit # 2 2 2 2 2 2 2 2 2 2

Minimum cooling load % (6) % 25 23 25 21 25 15 17 15 14 17

Standard/Partial Heat Recovery Unit

R410A refrigerant charge

Circuit 1 / Circuit 2

Oil charge Circuit 1 / Circuit 2 (l)

POE Oil type OIL058E / OIL057E

(1) Indicative performance at Evaporator water temperature: 12°C / 7°C - Condenser air temperature 35°C - for detailed performances, on a given unit, consult

Order Write Up.

(2) Under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

(kg)

(kg)

45.00 /

45.00

22.0 /

22.0

13.4 /

13.4

45.00 /

45.00

27.5 /

27.5

13.4 /

13.4

45.00 /

45.00

27.5 /

27.5

13.4 /

13.4

65.00 /

45.00

28.5 /

28.5

13.4 /

13.4

65.00 /

45.00

29 / 29 39 / 39 39 / 39 39 / 39 43 / 43

13.4 /

13.4

75.00 /

75.00

23.1 /

22.1

75.00 /

75.00

23.1 /

23.1

75.00 /

75.00

23.1 /

23.1

75.00 /

75.00

23.1 /

23.1

75.00 /

75.00

43.5 /

43.5

23.1 /

23.1

CG-SVX039B-GB

15

Page 16

General Data

Table 3 – General data CGAF 080-190 Extra Efficiency

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

80 90 100 110 130 140 150 165 180 190

XE XE XE XE XE XE XE XE XE XE

Net Cooling Capacity (1) (kW) 295 335 373 419 464 502 553 593 647 689

Net Total Power input (1) (kW) 87 99 112 128 145 151 172 188 200 216

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15 15 15 15 15

Power Cable Cross Section (max) mm21*240 1*240 1*240 1*240 1*240 2*300 2*300 2*300 2*300 2*300

Disconnect switch size (A) 315 400 400 500 500 630 630 630 800 800

Maximum Power input (kW) 126.1 149.6 169.1 183.0 196.9 229.9 249.5 263.4 281.1 295.0

Unit rated amps (A) 206.2 244.4 276.6 298.7 320.8 375.7 407.9 430.0 458.2 480.3

Unit start up amps

(w/o soft starter - Digit 54=A) (4)

Unit start up amps

(with soft starter - Digit 54=B) (4)

Displacement power factor (dpf) 0.88 0.88 0.88 0.88 0.89 0.88 0.88 0.88 0.89 0.89

Compressor

Compressor Number per Circuit # 2 2 2 2 2 3 3 3 3 3

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit 1 / Circuit 2

Max Comp Power input Circuit 1 / Circuit 2 kW

Rated Amps Circuit 1 / Circuit 2 (4) (A)

Locked Rotor Amps Circuit 1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit 1 / Circuit 2 (W) 112/112 112/112 112/112 112/112 112/112 168/168 168/168 168/168 168/168 168/168

Evaporator

Quantity # 1 1 1 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model

Evaporator Water Content volume (l) 40.4 40.4 48.6 56.7 64.9 73.1 81.3 81.3 81.3 86.0

Nominal water connection size (Grooved

coupling) - Without HYM

Nominal water connection size (Grooved

coupling) - With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 155 136

Motor Power (kW) 5.5 5.5 5.5 7.5 7.5 7.5 7.5 11.0 11.0 11.0

Rated Amps (A) 11.0 11.0 11.0 14.4 14.4 14.4 14.4 20.8 20.8 20.8

Single pump - High head pressure option

Max available Head Pressure (kPa) 280 266 254 241 232 252 257 245 229 218

Motor Power (kW) 11.0 11.0 11.0 11.0 11.0 15.0 15.0 15.0 15.0 15.0

Rated Amps (A) 20.8 20.8 20.8 20.8 20.8 28.0 28.0 28.0 28.0 28.0

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 155 136 119 102 87 141 137 115 159 146

Motor Power (kW) 5.5 5.5 5.5 7.5 7.5 7.5 7.5 11.0 11.0 11.0

Rated Amps (A) 11.0 11.0 11.0 14.4 14.4 14.4 14.4 20.8 20.8 20.8

Twin pump - High head pressure option

Max available Head Pressure (kPa) 280 266 254 241 232 252 257 245 229 218

Motor Power (kW) 11.0 11.0 11.0 11.0 11.0 15.0 15.0 15.0 15.0 15.0

Rated Amps (A) 20.8 20.8 20.8 20.8 20.8 28.0 28.0 28.0 28.0 28.0

Expansion Tank Volume (l) 50 50 50 50 50 50 50 50 50 50

Max User water loop Volume for factory

mounted expansion tank (1)

Optional water Buffer tank volume (l) 607 607 607 607 607 777 777 777 777 777

Antifreeze Heater without pump package

and without buffer tank

Antifreeze Heater with pump package and

without buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

(A) 419.6 501.7 533.9 638.0 660.1 633.1 665.3 769.3 797.4 819.6

315.6 373.7 405.9 472.8 494.9 505.1 537.3 604.1 632.2 654.4

(in) -

(mm)

(in) -

(mm)

25+25/

25+25

28.4+28.4/

28.4+28.4

34.6+34.6/

34.6+34.6

260+260/

260+260

DFX650

x138

4" -

114.3

4" -

114.3

25+30/

25+30

28.4+38.2/

28.4+38.2

33.9+44.1/

33.9+44.1

260+320/

260+320

DFX650

x138

4" -

114.3

4" -

114.3

30+30/

30+30

38.2+38.2/

38.2+38.2

44.6+44.6/

44.6+44.6

320+320/

320+320

DFX650

x166

4" -

114.3

4" -

114.3

30+40/

30+40

38.2+45.2/

38.2+45.2

45.4+56.1/

45.4+56.1

320+413/

320+413

DFX650

x194

4" -

114.3

4" -

114.3

40+40/

40+40

45.2+45.2/

45.2+45.2

57.2+57.2/

57.2+57.2

413+413/

413+413

DFX650

x222

4” -

114.3

4” -

114.3

25+30+30/

25+30+30

28.4+38.2+38.2/

28.4+38.2+38.2

34.2+45.7+45.7/

34.2+45.7+45.7

260+320+320/

260+320+320

DFX650

x250

5" -

139.7

5" -

139.7

30+30+30/

30+30+30

38.2+38.2+38.2/

38.2+38.2+38.2

45.7+45.7+45.7/

45.7+45.7+45.7

320+320+320/

320+320+320

DFX650

x278

5" -

139.7

5" -

139.7

30+30+40/

30+30+40

38.2+38.2+45.2/

38.2+38.2+45.2

46.4+46.4+57.3/

46.4+46.4+57.3

320+320+413/

320+320/413

DFX650

x278

5" -

139.7

5" -

139.7

30+40+40/

30+40+40

38.2+45.2+45.2/

38.2+45.2+45.2

45.6+56.3+56.3/

45.6+56.3+56.3

320+413+413/

320+413+413

DFX650

x278

5" -

139.7

5" -

139.7

119 102 87 141 137 115 159 146

(l) 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750

(W) 420 420 420 520 520 640 640 640 640 640

(W)

1060 /

1120

1060 /

1120

1060 /

1120

1160 /

1220

1160 /

1220

1340 /

1400

1340 /

1400

1340 /

1400

1340 /

1400

40+40+40/

40+40+40

45.2+45.2+45.2/

45.2+45.2+45.2

57.0+57.0+57.0/

57.0+57.0+57.0

413+413+413/

413+413+413

DFX650

x294

5" -

139.7

5" -

139.7

1340 /

1400

16

CG-SVX039B-GB

Page 17

General Data

Table 3 – General data CGAF 080-190 Extra Efficiency (continued)

CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF CGAF

80 90 100 110 130 140 150 165 180 190

XE XE XE XE XE XE XE XE XE XE

Antifreeze Heater with pump package and

with buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 6 8 8 8 8 10 10 10 12 12

Face area per circuit (m²) 8.88 11.84 11.84 11.84 11.84 14.80 14.80 14.80 17.76 17.76

Condenser Fan

Quantity # 6 8 8 8 8 10 10 10 12 12

Diameter (mm) 800

Fan / motor Type Propeller fan : Variable speed EC motor

Airow per fan m3/h 17476 17569 17506 17430 17355 17392 17391 17335 17410 17362

Max Power Input per Motor Kw 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95

Max Amps per Motor A 3 3 3 3 3 3 3 3 3 3

Motor RPM (SN - Digit 15=X or LN Digit 15=L)

Motor RPM (XLN - Digit 15=E) (rpm) 800 800 800 800 800 800 800 800 800 800

Dimensions

Unit Length (mm) 3395 4520 4520 4520 4520 5645 5645 5645 6770 6770

Unit Width (mm) 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200

Std Unit Height (mm) 2526 2526 2526 2526 2526 2526 2526 2526 2526 2526

Axitop EC Fan Unit - (Additional height

conguration)

Pump Package Option - (Additional length

conguration)

Weights

Shipping Weight (3) (kg) 2075 2490 2620 2695 2755 3305 3485 3525 3910 3975

Operating Weight (3) (kg) 2145 2560 2695 2780 2850 3415 3600 3640 4030 4095

Option Additional shipping weight

Single pump - Standard head pressure (kg) 215 230 225 235 235 245 240 305 330 325

Single pump - High head pressure (kg) 265 275 270 270 270 320 315 315 340 340

Twin pump - Standard head pressure (kg) 305 315 315 335 335 345 340 450 475 470

Twin pump - High head pressure (kg) 385 400 395 395 395 480 475 475 500 495

XLN option (kg) 115 115 115 115 115 150 150 150 150 150

Pump VFD option (kg) 70 70 70 70 70 70 70 70 70 70

Partial heat recovery option

(Digit 19 = N)

Partial heat recovery option

(Digit 19 = P)

Water Buffer tank option (kg) 250 250 250 250 250 330 330 330 330 330

System data

Nb of refrigerant circuit # 2 2 2 2 2 2 2 2 2 2

Minimum cooling load % (6) % 25 23 25 21 25 15 17 15 14 17

Standard/Partial Heat Recovery Unit

R410A refrigerant charge

Circuit 1 / Circuit 2

Oil charge Circuit 1 / Circuit 2 (l)

POE Oil type OIL058E / OIL057E

1940/

(W)

2000

(rpm) 850 850 850 880 940 860 920 960 900 940

(mm) +146 +146 +146 +146 +146 +146 +146 +146 +146 +146

(mm) +425 +425 +425 +425 +425 +370 +370 +370 +370 +370

(kg) 45.00 45.00 45.00 65.00 65.00 75.00 75.00 75.00 75.00 75.00

45.00 45.00 45.00 45.00 45.00 75.00 75.00 75.00 75.00 75.00

22.0 /

(kg)

22.0

13.4 /

13.4

1940/

2000

27.4 /

27.4

13.4 /

13.4

1940/

2000

27.6 /

27.6

13.4 /

13.4

1940/

2000

28.4 /

28.4

13.4 /

13.4

2040/

2100

29.4 /

29.4

13.4 /

13.4

2040/

2100

39.0 /

39.0

23.1 /

22.1

2790/

2850

39.0 /

39.0

23.1 /

23.1

2790/

2850

39.0 /

39.0

23.1 /

23.1

2790/

2850

43.0 /

43.0

23.1 /

23.1

2790/

2850

43.5 /

43.5

23.1 /

23.1

(1) Indicative performance at Evaporator water temperature: 12°C / 7°C - Condenser air temperature 35°C - for detailed performances, on a given unit,

consult Order Write Up.

(2) Under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

CG-SVX039B-GB

17

Page 18

General Data

Table 4 – General data CGAF 090-150 Standard Efficiency – Shell & Tube

CGAF CGAF CGAF CGAF CGAF CGAF

90 100 110 130 140 150

SE SE SE SE SE SE

Net Cooling Capacity (1) (kW) 319 349 384 418 483 510

Net Total Power input in cooling (1) (kW) 105 120 139 159 168 184

Unit electrical data (1) (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15

Power Cable Cross Section (max) mm

Disconnect switch size (A) 400 400 500 500 630 630

Digit 56=1

Maximum Power input (kW) 154.6 174.2 188.1 201.9 228.2 257.5

Unit rated amps (A) 258.8 291.0 313.1 335.2 381.0 429.3

Unit start up amps (w/o soft starter digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

Displacement power factor (dpf) 0.87 0.87 0.87 0.87 0.87 0.87

Digit 56=2 or Digit 56=3

Maximum Power input (kW) 156.7 176.2 190.1 204.0 231.2 260.6

Max. amps (A) 259.4 291.4 313.5 335.6 381.6 430.0

Unit start up amps (w/o soft starter Digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

Displacement power factor (dpf) 0.88 0.88 0.88 0.88 0.88 0.88

Compressor

Compressor Number per Circuit # 2 2 2 2 3 3

Type Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit 1 / Circuit 2

Max Comp Power input Circuit 1 / Circuit 2 kW

Rated Amps Circuit 1 / Circuit 2

(Digit 56=1) (4)

Rated Amps Circuit 1 / Circuit 2

(Digit 56=2 or Digit 56=3) (4)

Locked Rotor Amps Circuit 1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit 1 / Circuit 2 (W) 112/112 112/112 112/112 112/112 168/168 168/168

Evaporator

Quantity # 1 1 1 1 1 1

Type Shell & Tube Heat exchanger

Evaporator model 3511 3511 3511 3511 3519 3519

Evaporator Water Content volume (l) -- -- -- -- -- --

Unit Connections

Without pump package and no strainer

Inlet / Outlet 8" / 8" 8" / 8" 8" / 8" 8" / 8" 8" / 8" 8" / 8"

Without pump package but strainer

Inlet / Outlet 4" / 8" 4" / 8" 4" / 8" 4" / 8" 5" / 8" 5" / 8"

With pump package but no balance valve

Inlet / Outlet 4" / 8" 4" / 8" 4" / 8" 4" / 8" 5" / 8" 5" / 8"

With pump package and balance valve

Inlet / Outlet 4" / 4" 4" / 4" 4" / 4" 4" / 4" 5" / 5" 5" / 5"

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 124 109 147 130 122 107

Motor Power (kW) 5.5 5.5 7.5 7.5 7.5 7.5

Rated Amps (A) 11 11 14.4 14.4 14.4 14.4

Single pump - High head pressure option

Max available Head Pressure (kPa) 254 242 223 205 234 224

Motor Power (kW) 11 11 11 11 15 15

Rated Amps (A) 20.8 20.8 20.8 20.8 28 28

2

1*240 1*240 1*240 1*240 2*300 2*300

(A) 516.1 548.3 652.4 674.5 638.4 686.7

(A) 388.1 420.3 487.2 509.3 510.4 558.7

(A) 516.5 548.7 652.8 674.9 639.0 687.3

388.5 420.7 487.6 509.7 511.0 559.3

(A)

25+30/

25+30

28.4+38.2/

28.4+38.2

35.4+46.0/

35.4+46.0

35.1+45.5/

35.1+45.5

260+320/

260+320

30+30/

30+30

38.2+38.2/

38.2+38.2

47.0+47.0/

47.0+47.0

46.5+46.5/

46.5+46.5

320+320/

320+320

30+40/

30+40

38.2+45.2/

38.2+45.2

48.3+59.8/

48.3+59.8

47.7+59.0/

47.7+59.0

320+413/

320+413

40+40/

40+40

45.2+45.2/

45.2+45.2

61.7+61.7/

61.7+61.7

60.7+60.7/

60.7+60.7

413+413/

413+413

25+30+30/

25+30+30

28.4+38.2+38.2/

28.4+38.2+38.2

35.5+48.1+48.1/

35.5+48.1+48.1

35.1+47.5+47.5/

35.1+47.5+47.5

260+320+320/

260+320+320

30+30+30/

30+30+30

38.2+38.2+38.2/

38.2+38.2+38.2

48.2+48.2+48.2/

48.2+48.2+48.2

47.5+47.5+47.5/

47.5+47.5+47.5

320+320+320/

320+320+320

18

CG-SVX039B-GB

Page 19

General Data

Table 4 – General data CGAF 090-150 Standard Efficiency – Shell & Tube (continued)

CGAF CGAF CGAF CGAF CGAF CGAF

90 100 110 130 140 150

SE SE SE SE SE SE

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 124 109 147 130 122 107

Motor Power (kW) 5.5 5.5 7.5 7.5 7.5 7.5

Rated Amps (A) 11 11 14.4 14.4 14.4 14.4

Twin pump - High head pressure option

Max available Head Pressure (kPa) 254 242 223 205 234 224

Motor Power (kW) 11 11 11 11 15 15

Rated Amps (A) 20.8 20.8 20.8 20.8 28 28

Expansion Tank Volume (l) 50 50 50 50 50 50

Max User water loop Volume for factory

mounted expansion tank (1)

Antifreeze Heater without pump package

Without lter option (digit 51=X) (W) 200 200 200 200 200 200

With lter option (digit 50=A) (W) 320 320 320 320 440 440

Antifreeze Heater with single pump package

With balance valve (Digit 37=A) (W) 1160 1160 1160 1160 1340 1340

Without balance valve (Digit 37=X) (W) 900 900 900 900 1020 1020

Antifreeze Heater with dual pump package

With balance valve (Digit 37=A) (W) 1220 1220 1220 1220 1140 1140

Without balance valve (Digit 37=X) (W) 960 960 960 960 1080 1080

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 6 6 6 6 8 8

Face area per circuit (m²) 8.88 8.88 8.88 8.88 11.84 11.84

Condenser Fan

Quantity # 6 6 6 6 8 8

Diameter (mm) 800

Fan / motor Type

Digit 56=1

Fan / motor Type Fixed speed AC motor

Airow per fan m3/h 15859 15778 15680 15580 15686 15684

Max Power Input per Motor Kw 1.44 1.44 1.44 1.44 1.44 1.44

Max Amps per Motor A 2.9 2.9 2.9 2.9 2.9 2.9

Motor RPM (rpm) 900 900 900 900 900 900

Digit 56=2

Fan / motor Type Variable speed EC motor

Airow per fan m3/h 17295 17215 17120 17021 17125 17124

Max Power Input per Motor Kw 1.95 1.95 1.95 1.95 1.95 1.95

Max Amps per Motor A 3.0 3.0 3.0 3.0 3.0 3.0

Motor RPM (rpm) 840 840 840 840 840 840

Digit 56 = 3

Fan / motor Type Variable speed EC motor with Axitop

Airow per fan m3/h 17411 17331 17235 17136 17240 17239

Max Power Input per Motor Kw 1.95 1.95 1.95 1.95 1.95 1.95

Max Amps per Motor A 3 3 3 3 3 3

Motor RPM (rpm) 800 840 840 840 840 840

Dimensions

Unit Length (mm) 3395 3395 3395 3395 4520 4520

Unit Width (mm) 2200 2200 2200 2200 2200 2200

Std Unit Height (mm) 2526 2526 2526 2526 2526 2526

Axitop EC Fan Unit - (Additional height

conguration)

Pump Package Option - (Additional length

conguration)

(l) 1750 1750 1750 1750 1750 1750

Propeller fan : Fixed speed AC motor / Variable speed EC motor / Variable speed EC

motor with Axitop

(mm) +146 +146 +146 +146 +146 +146

(mm) +425 +426 +427 +428 +370 +370

CG-SVX039B-GB

19

Page 20

General Data

Table 4 – General data CGAF 090-150 Standard Efficiency – Shell & Tube (continued)

CGAF CGAF CGAF CGAF CGAF CGAF

90 100 110 130 140 150

SE SE SE SE SE SE

Weights

Shipping Weight (3) (kg) 2375 2475 2525 2555 3235 3380

Operating Weight (3) (kg) 2470 2570 2620 2650 3379 3524

Standard/Partial Heat Recovery Unit

R410A refrigerant charge

Circuit 1 / Circuit 2

Oil charge Circuit 1 / Circuit 2 (l) 12.8 / 12.8 12.8 / 12.8 12.8 / 12.8 12.8 / 12.8 23.1 / 23.1 23.1 / 23.1

POE Oil type OIL058E / OIL057E

(1) Indicative performance at Evaporator water temperature: 12°C / 7°C - Condenser air temperature 35°C - for detailed performances, on a given unit,

consult Order Write Up.

(2) Under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

(kg) 20 / 20 20 / 20 20 / 20 20 / 20 30 / 30 30 / 30

20

CG-SVX039B-GB

Page 21

General Data

Table 5 – General data CXAF 080-190 Standard Efficiency

CXAF CXAF CXAF CXAF CXAF CXAF CXAF CXAF CXAF CXAF

080 090 100 110 130 140 150 165 180 190

SE SE SE SE SE SE SE SE SE SE

Net Cooling / Heating Capacity (1) (kW)

278 /

276

Net Total Power input (1) (kW) 87 102 117 133 151 164 179 196 209 225

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15 15 15 15 15

Power Cable Cross Section (max) mm² 1*240 1*240 1*240 1*240 1*240 1*240 2*300 2*300 2*300 2*300

Disconnect switch size (A) 315 400 400 400 500 500 630 630 630 800

Digit 56=1

Maximum Power input (kW) 122 141 161 179 193 225 244 258 275 289

Max. amps (A) 154 175 201 223 252 274 300 329 347 375

Unit start up amps (w/o soft starter Digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

(A) 419 495 528 637 659 632 664 768 796 818

(A) 315 367 400 472 494 504 536 603 631 653

Displacement power factor (dpf) 0.84 0.84 0.84 0.86 0.86 0.86 0.86 0.85 0.86 0.86

Digit 56=2 or Digit 56 =3

Maximum Power input (kW) 130 150 169 183 197 230 249 263 281 295

Unit rated amps (A) 153 173 196 223 250 272 298 326 342 369

Unit start up amps (w/o soft starter Digit 54=A) (4)

Unit start up amps (with soft starter Digit 54=B) (4)

(A) 426 502 534 638 660 633 665 769 797 820

322 374 406 473 495 505 537 604 632 654

Displacement power factor (dpf) 0.83 0.84 0.85 0.86 0.86 0.86 0.86 0.86 0.87 0.87

Compressor

Compressor Number per Circuit # 2 2 2 2 2 3 3 3 3 3

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

(A)

25+25/

25+25

28.4+28.4/

28.4+28.4

35.4+35.4/

35.4+35.4

35.1+35.1/

35.1+35.1

260+260/

260+260

Model Circuit 1 / Circuit 2

Max Comp Power input Circuit 1 / Circuit 2 kW

Rated Amps Circuit 1 / Circuit 2

(Digit 56=1) (4)

Rated Amps Circuit 1 / Circuit 2

(Digit 56=2 or Digit 56=3) (4)

Locked Rotor Amps Circuit 1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit 1 / Circuit 2 (W) 112/112 112/112 112/112 112/112 112/112 168/168 168/168 168/168 168/168 168/168

Evaporator

Quantity # 1 1 1 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model

DFX650

x138

Evaporator Water Content volume (l) 40.4 40.4 48.6 56.7 64.9 73.1 81.3 81.3 81.3 86

Nominal water connection size (Grooved

coupling) - Without HYM

Nominal water connection size (Grooved

coupling) - With HYM

(in) -

(mm)

(in) -

(mm)

4" -

114.3

4" -

114.3

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 153 141 137 166 157 141 143 182 163 154

Motor Power (kW) 5.5 5.5 5.5 7.5 7.5 7.5 7.5 11 11 11

Rated Amps (A) 11 11 11 14.4 14.4 14.4 14.4 20.8 20.8 20.8

Single pump - High head pressure option

Max available Head Pressure (kPa) 266 254 252 242 232 252 258 249 230 221

Motor Power (kW) 11 11 11 11 11 15 15 15 15 15

Rated Amps (A) 20.8 20.8 20.8 20.8 20.8 28 28 28 28 28

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 153 141 137 166 157 141 143 182 163 154

Motor Power (kW) 5.5 5.5 5.5 7.5 7.5 7.5 7.5 11 11 11

Rated Amps (A) 11 11 11 14.4 14.4 14.4 14.4 20.8 20.8 20.8

306 /

313

25+30/

25+30

28.4+38.2/

28.4+38.2

35.4+46.0/

35.4+46.0

35.1+45.5/

35.1+45.5

260+320/

260+320

DFX650

x138

4" -

114.3

4" -

114.3

338 /

343

30+30/

30+30

38.2+38.2/

38.2+38.2

47.0+47.0/

47.0+47.0

46.5+46.5/

46.5+46.5

320+320/

320+320

DFX650

x166

4" -

114.3

4" -

114.3

384 /

389

30+40/

30+40

38.2+45.2/

38.2+45.2

48.3+59.8/

48.3+59.8

47.7+59.0/

47.7+59.0

320+413/

320+413

DFX650

x194

4" -

114.3

4" -

114.3

421 /

421

40+40/

40+40

45.2+45.2/

45.2+45.2

61.7+61.7/

61.7+61.7

60.7+60.7/

60.7+60.7

413+413/

413+413

DFX650

x222

4” -

114.3

4” -

114.3

467 /

481

25+30+30/

25+30+30

28.4+38.2+38.2/

28.4+38.2+38.2

35.5+48.1+48.1/

35.5+48.1+48.1

35.1+47.5+47.5/

35.1+47.5+47.5

260+320+320/

260+320+320

DFX650

x250

5" -

139.7

5" -

139.7

496 /

508

30+30+30/

30+30+30

38.2+38.2+38.2/

38.2+38.2+38.2

48.2+48.2+48.2/

48.2+48.2+48.2

47.5+47.5+47.5/

47.5+47.5+47.5

320+320+320/

320+320+320

DFX650

x278

5" -

139.7

5" -

139.7

527 /

538

30+30+40/

30+30+40

38.2+38.2+45.2/

38.2+38.2+45.2

49.2+49.2+61.0/

49.2+49.2+61.0

48.5+48.5+60.1/

48.5+48.5+60.1

320+320+413/

320+320/413

DFX650

x278

5" -

139.7

5" -

139.7

585 /

599

30+40+40/

30+40+40

38.2+45.2+45.2/

38.2+45.2+45.2

47.6+59.0+59.0/

47.6+59.0+59.0

47.1+58.2+58.2/

47.1+58.2+58.2

320+413+413/

320+413+413

DFX650

x278

5" -

139.7

5" -

139.7

619 /

631

40+40+40/

40+40+40

45.2+45.2+45.2/

45.2+45.2+45.2

60.1+60.1+60.1/

60.1+60.1+60.1

59.2+59.2+59.2/

59.2+59.2+59.2

413+413+413/

413+413+413

DFX650

x294

5" -

139.7

5" -

139.7

CG-SVX039B-GB

21

Page 22

General Data

Table 5 – General data CXAF 080-190 Standard Efficiency (continued)

CXAF CXAF CXAF CXAF CXAF CXAF CXAF CXAF CXAF CXAF

080 090 100 110 130 140 150 165 180 190

SE SE SE SE SE SE SE SE SE SE

Twin pump - High head pressure option

Max available Head Pressure (kPa) 266 254 252 242 232 252 258 249 230 221

Motor Power (kW) 11 11 11 11 11 15 15 15 15 15

Rated Amps (A) 20.8 20.8 20.8 20.8 20.8 28 28 28 28 28

Expansion Tank Volume (l) 50 50 50 50 50 50 50 50 50 50

Max User water loop Volume for factory

mounted expansion tank (1)

Optional water Buffer tank volume (l) 607 607 607 607 607 777 777 777 777 777

Antifreeze Heater without pump package

and without buffer tank

Antifreeze Heater with pump package and

without buffer tank

(Single Water Pump digit 24=2 or 4 / Dual

Water Pump digit 24=1 or 3)

Antifreeze Heater with pump package and

with buffer tank