Page 1

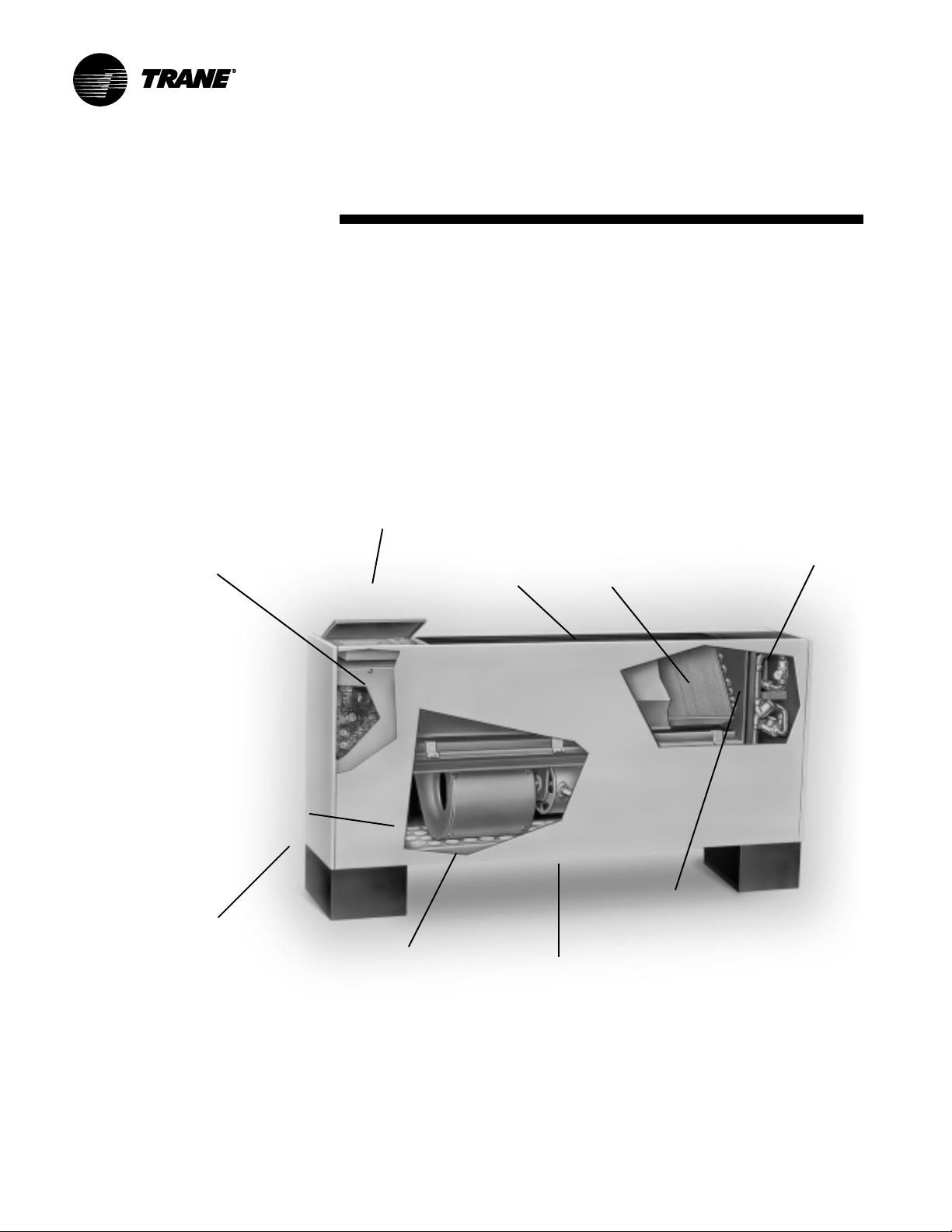

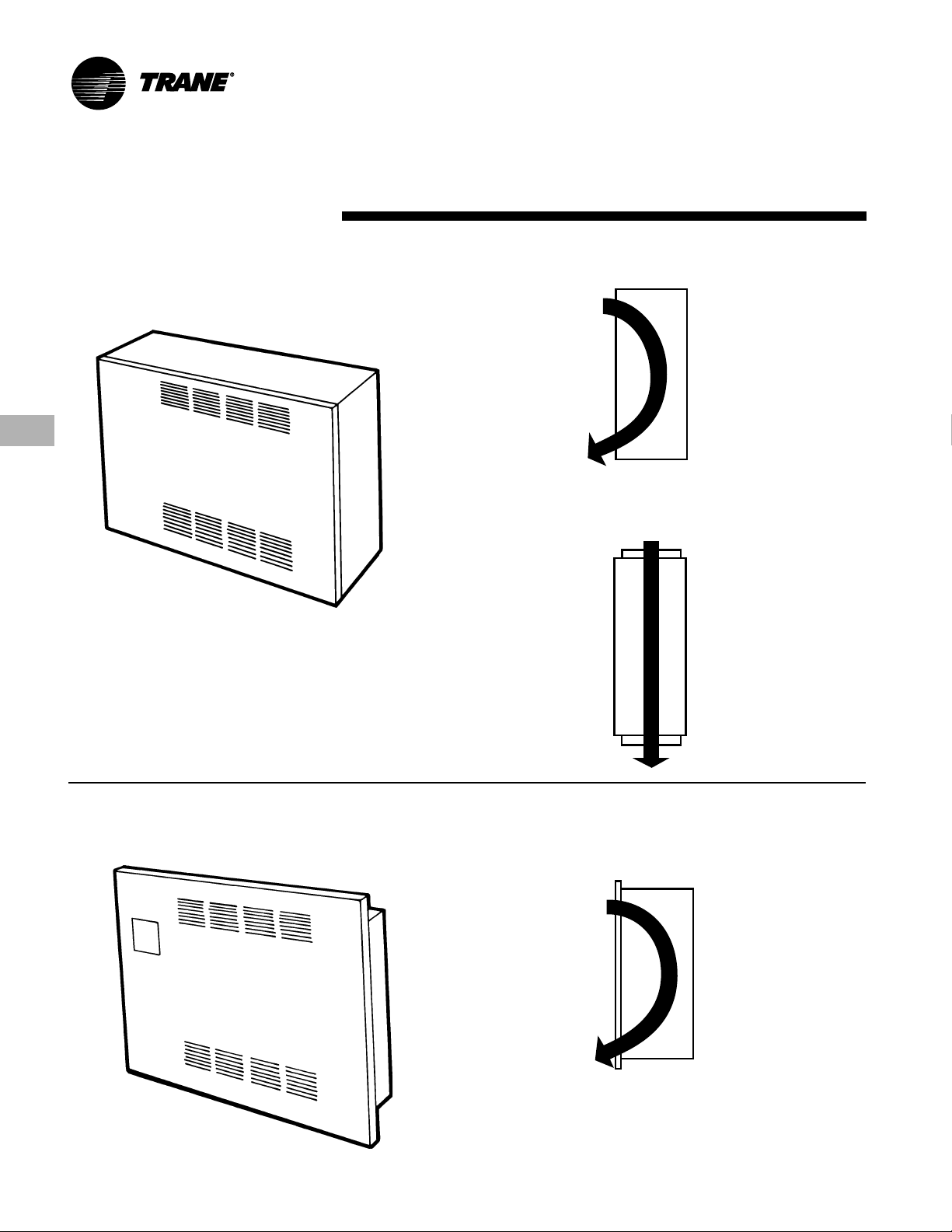

Force–Flo™ Cabinet Heater

Air Terminal Devices

Horizontal and Vertical

Sizes 02-12

December 2000

CAB-PRC001-EN

Page 2

It isn’t just a fan and a coil…

The Trane Company has redesigned the traditional cabinet heater to lead the indus-

try in:

• indoor air quality (IAQ) features

• easy installation and maintenance

• high quality and durability

• advanced controls

Factory installed

and tested controls

Easy to remove fan assembly

16-gauge steel construction

Smaller unit footprint

Easy filter access

without front panel

removal

Quiet operation

Two, three or

four-row coils

Cleanable closedcell insulation

(non-fiberglass)

Fresh air damper for

ventilation

Factory assembled,

installed and tested

piping package

©American Standard Inc. 2000 CAB-PRC001-EN

Page 3

Contents

Introduction 2

Features and Benefits 4

Selection Procedure 5

Model Number Description 5

General Data 7

Performance Data 18

Hot Water Coils 19

Steam Coils 22

Controls 24

Electrical Data 30

Dimensions and Weights 34

Mechanical Specifications 50

Options 52

CAB-PRC001-EN 3

Page 4

Features and Benefits

The Force–Flo™ cabinet heater meets the

standards of today’s market, as well as

the anticipated needs of tomorrow’s

market. The tradition that company

founder Reuben Trane began in 1913

continues with the latest generation of

cabinet heaters from Trane.

The Force–Flo cabinet heater is the leader

in these key areas:

• Indoor Air Quality (IAQ)

• Controls

• Flexibility

• Quality

• Serviceability

Today’s HVAC market is concerned with

issues such as indoor air quality (IAQ)

and CFCs that demand a change in HVAC

products. In addition, renovation has

overtaken new construction in the

cabinet heater market—demanding a

design that caters to renovation issues.

Trane is concerned with these issues,

too. That’s why we designed the Force–

Flo cabinet heater as an integral part of

the company’s system solutions with

standard IAQ-related features that fully

comply with ASHRAE 62.

IAQ Design

• Closed-cell insulation is standard on all

units to help prevent fiberglass in the

airstream.

• Easy filter access encourages frequent

changing.

• Force–flo cabinet heaters have a blowthru design.

Controls

• All controls are factory-mounted and

tested to minimize field setup.

• Controls are wired with a 24 VAC

transformer to keep only a single

source power connection requirement

to the unit.

• All wall-mounted zone sensors require

only low voltage control wiring from

the device to the unit control box. (No

line voltage.)

• The Tracer

the latest in control technology with the

ZN.010, ZN.510, and ZN.520 controllers.

• The random start-up feature helps

reduce electrical demand peaks by

randomly staggering multiple units at

start-up.

• Occupied/unoccupied operation allows

the controller to utilize unoccupied

temperature setpoints for energy

savings.

• Warm-up energy feature is standard

with Trane controls.

• Continuous fan or fan cycling is available with ZN.010 or ZN.510.

• Monitor unit operation using Tracer

Summit building management system

with ZN.510 or ZN.520.

• To customize unit control, Tracer

Summit or Rover

field modification of ZN.510 and ZN.520

default settings. For ZN.010, use Rover

to field modify default settings.

• Maximize cabinet heater system

efficiency with modulating valves on

units with ZN.520.

Flexibility

• Two, three, and four-row hot water coils

allow greater design flexibility. Steam

distributing or electric heat coils are

also available.

• Fan motors are available for either high

static (0.4-inch external static pressure)

or free discharge applications.

• Piping is factory assembled, mounted

and tested. Units are also available

without piping.

• Factory piping options include intercon-

®

controls family introduces

™

software will allow

®

necting piping, control valves, and end

valves. Deluxe piping also has unions

and a strainer.

• Control options range from a simple fan

speed switch to a DDC controller that

can tie into a Tracer Summit

automation system.

• The extended end pocket option adds 8inches (20 cm) to the piping end of

cabinet style units.

• Slope-top vertical cabinet units are an

excellent application for school and

dormitories to prevent items from

being placed on top of the units.

• Vertical wall hung units are used in

vestibules, bathrooms, stairwells, or

other applications when the unit cannot

be installed on the floor

• Inverted unit models allow heating to

circulate from the bottom of the unit.

Quality

• Coils and piping packages are air and

leak-tested before mounting on the

unit.

• Coil piping connections are also air and

leak-tested after mounting on the unit.

• All control end devices and moving

components (fans and motors) are

computer-tested after units are

complete.

Serviceability

• Filters are easily removable and

changed without removing the front

panel on vertical cabinet units.

• Motors are easy to disconnect from the

fan board, allowing easy service.

• The manual output test function is an

invaluable troubleshooting tool. By

simply pressing the test button on the

®

ZN.510, ZN.520, or ZN.010;

Tracer

service personnel can manually

exercise outputs in a pre-defined

sequence.

®

building

CAB-PRC001-EN4

Page 5

Selection

Model Number

Procedure

Description

Force–Flo Cabinet Heater Model Number Description

Following is a complete description of the cabinet heater model number. Each digit in the model number has a corresponding

code that identifies specific unit options.

FF B B 020 1 C M0 A 0 G 1 0 A A 2 M 000 0 0 1 0 0 0 A A 000 000 0 0 0 0 0 0 0

1 5 10 15 20 25 30 35 40 44

Digits 1, 2 — Unit Type

FF = Force–Flo

Digit 3 — Cabinet Type

A = Vertical Concealed

B = Vertical Cabinet

C = Horizontal Concealed

D = Horizontal Cabinet

E = Horizontal Recessed

H = Vertical Recessed

J = Vertical Cabinet Slope Top

M = Inverted Vertical Cabinet

N = Inverted Vertical Recessed

Digit 4 — Development Sequence “B”

Digits 5, 6, 7 — Unit Size

020 040 080

030 060 100

120

Digit 8 — Unit Voltage

1 = 115/60/1 6 = 230/60/3

2 = 208/60/1 7 = 480/60/3

3 = 277/60/1 8 = 110-120/50/1

4 = 230/60/1 9 = 220-240/50/1

5 = 208/60/3 A = 220-240/50/3

B = 380-415/50/3

Digit 9 — Piping System/Placement

A = No piping, RH

B = No piping, LH

E = No piping, RH,Extended End Pocket

F = No piping, LH, Extended End Pocket

J = With piping package, RH

K = With piping package, LH

L = With piping package, RH, Extended

End Pocket

M= With piping package, LH, Extended

End Pocket

Digits 10, 11 — Design Sequence “M0”

Digit 12 — Inlets

A = Front Toe Space

B = Front Bar Grille

C = Front Stamped Louver

D = Bottom Stamped Louver

E = Bottom Toe Space

F = Back Duct Collar

G = Back Open Return

H = Back Stamped Louver

J = Top Duct Collar

Digit 13 — Fresh Air Damper

0 = None

A = Manual, Bottom Opening

B = Manual, Back Opening

C = Manual, Top Opening

K = No Damper, Bottom Opening

L = No Damper, Back Opening

M= No Damper, Top Opening

Digit 14 — Outlets

A = Front Duct Collar

B = Front Bar Grille

C = Front Stamped Louver

D = Front Quad Grille

E = Bottom Duct Collar

F = Bottom Stamped Louver

G = Top Quad Grille

H = Top Bar Grille

J = Top Duct Collar

Digit 15 — Color

0 = No Paint (Concealed Units Only)

1 = Deluxe Beige 4 = Driftwood Grey

2 = Soft Dove 5 = Stone Grey

3 = Cameo White 6 = Rose Mauve

Digit 16 —

0 = None

B = Keylock Access Door

C = Keylock Panel and Access Door

D = Leveling Feet

F=

G = Keylock Panel and Access Door with

Digit 17 — Motor

A = Free Discharge

B = High Static

Digit 18 — Coil

A = 2 Row Hot Water

B = 3 Row Hot Water

C = 4 Row Hot Water

N = Electric Heat, Single Stage

U = Electric Heat, Two Stage

V = Electric Heat, Low kw, One Stage

W = Steam Distributing

Digit 19 — Coil Series

1 = 108 fpf (steam only)

2 = 144 fpf (hot water only)

Tamperproof Locks/Leveling

Feet

Keylock Access Door with Leveling

Feet

Leveling Feet

Digit 20 — Coil Air Vent

A = Automatic Air Vent

M= Manual Air Vent

Digits 21, 22, 23 — Electric Heat kW

(208V Derate)

000 = No Electric Heat

010 = 1.0 kW (0.75 kW)

020 = 2.0 kW (1.5 kW)

030 = 3.0 kW (2.3 kW)

045 = 4.5 kW (3.3 kW)

060 = 6.0 kW (4.5 kW)

075 = 7.5 kW (5.7 kW)

090 = 9.0 kW (6.6 kW)

100 = 10.0 kW

105 = 10.5 kW (7.9 kW)

110 = 11.0 kW (9.0 kW)

120 = 12.0 kW

135 = 13.5 kW (10.2 kW)

150 = 15.0 kW

180 = 18.0 kW (13.5 kW)

200 = 20.0 kW (15.0 kW)

Digit 24 —Not Used

Digit 25 — Disconnect Switch

0 = None

D = Disconnect Switch

Digit 26 — Filter

0 = None

1 = 1” Throwaway Filter

2 = 1” Throwaway Pleated Media Filter

3 = 1” Throwaway + (1) Extra

4=

1” Throwaway Pleated Media + (1)

5 = 1” Throwaway + (2) Extras

6 = 1” Throwaway Pleated Media +

7 = 1” Throwaway + (3) Extras

8 = 1” Throwaway Pleated Media +

Extra

(2) Extras

(3) Extras

CAB-PRC001-EN 5

Page 6

Selection

Model Number

Procedure

Digit 27 — Main Control Valve

0 = None

A = 2-Way, 2-Position, NO (25 psig)

B = 3-Way, 2-Position, NO (30 psig)

C = 2-Way, 2-Position, NC (25 psig)

D = 3-Way, 2-Position, NC (15 psig)

E = 2-Way, 2-Position, NO (50 psig)

F = 3-Way, 2-Position, NO (50 psig)

G = 2-Way, 2-Position, NC (50 psig)

H = 3-Way, 2-Position, NC (50 psig)

J = 2-Way, Modulating, 0.7 Cv (50 psig)*

K = 3-Way, Modulating, 0.7 Cv (50 psig)*

L = 2-Way, Modulating, 1.5 Cv (50 psig)*

M= 3-Way, Modulating, 1.5 Cv (50 psig)*

N = 2-Way, Modulating, 2.5 Cv (50 psig)*

P = 3-Way, Modulating, 2.5 Cv (50 psig)*

Q = 2-Way, Modulating, 4.0 Cv (50 psig)*

R = 3-Way, Modulating, 4.0 Cv (50 psig)*

X = Field-supplied, NO

Y = Field-supplied, NC

Z = Field-Supplied 3-Wire Modulating

Digit 28 — Not Used

0 = None

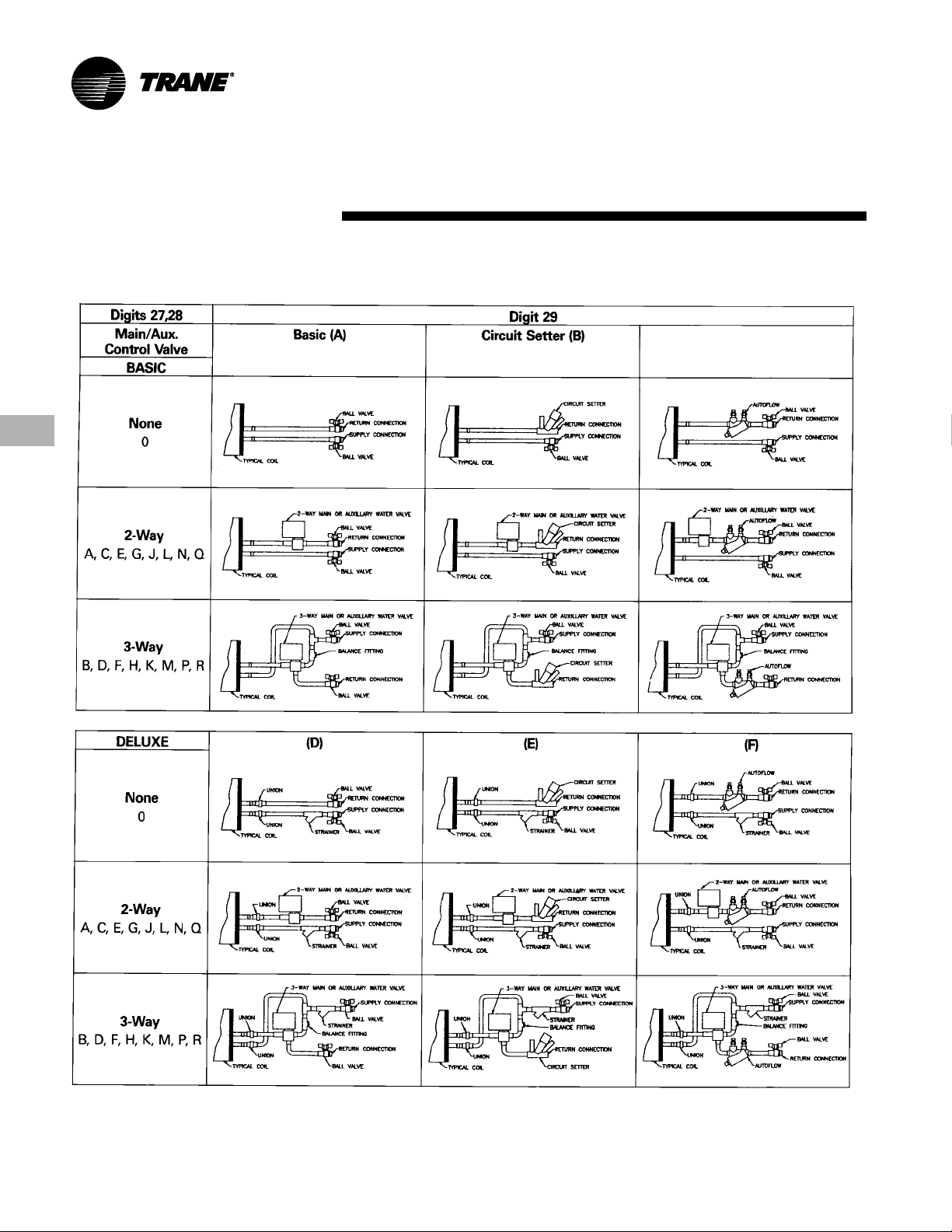

Digit 29 — Piping Packages

0 = None

A = Basic Ball Valve Supply and Return

B = Basic Ball Valve Supply/Manual

Circuit Setter

C = Basic Ball Valve Supply and Return

with Auto Circuit Setter

D = Deluxe Ball Valve Supply and Return

E = Deluxe Ball Valve Supply/Manual

Circuit Setter

F = Deluxe Ball Valve Supply and Return

with Auto Circuit Setter

Digit 30 — Control Type

A = Fan Speed Switch

E = Tracer ZN.010

F = Tracer ZN.510

G = Tracer ZN.520

Description

Digit 32 —Not Used

0 = None

Digits 33, 34 —Future Control Functions

0 = None

Digit 35 — Control Function #3

0 = None

Digit 36 — Control Function #4

0 = None

Digit 37 — Control Function #5

0 = None

2 = Fan Status Sensor

Digit 38 — Control Function 6

0 = None

2 = Filter Status Sensor

Digit 39 —

Falsebacks

0 = None

A=5/8” Standard Recessed Panel

B = 2” Projection Panel

C = 2.5” Projection Panel

D= 3” Projection Panel L = 2”Falseback

E = 3.5” Projection Panel M= 3” Falseback

F = 4” Projection Panel N = 4” Falseback

G = 4.5” Projection

Panel P = 5” Falseback

H= 5” Projection Panel Q =6” Falseback

J = 5.5” Projection Panel R = 7” Falseback

K = 6” Projection Panel T = 8” Falseback

Digit 40 — Main Autoflow GPM

A = 0.5 G = 3.0 N = 7.0

B = 0.75 H = 3.5 P = 8.0

C = 1.0 J = 4.0 Q = 9.0

D = 1.5 K = 4.5 R = 10.0

E = 2.0 L = 5.0 T = 11.0

F = 2.5 M = 6.0 U = 12.0

Projection Panels and

(Vertical Recessed Units Only)

Digit 31 — Control Option

D = Unit Mounted Fan Speed Switch

K = Wall Mounted Fan Speed Switch

V = Unit Mounted Fan Speed Switch w/

Setpoint Dial

W = Wall Mounted Fan Speed Switch w/

Setpoint Dial

X = Unit Mounted Fan Speed Switch w/

Wall Mounted Setpoint Dial

Y = Unit Mounted Fan Speed Switch &

Wall Mounted Setpoint Dial W/ Comm.

Z = Unit Mounted Fan Speed Switch,

On/Cancel, Setpoint Dial W/ Comm.

1 = Wall Mounted On/Cancel W/ Comm.

2 = Wall Mounted Fan Speed Switch,

Setpoint Dial, On/Cancel W/ Comm.

Note: Please contact your local Trane sales representative for buildable digit combinations.

Digit 41 — Not Used

Digit 42 — Subbases

0 = None

A = 2” Subbase D = 5” Subbase

B = 3” Subbase E = 6” Subbase

C = 4” Subbase F = 7” Subbase

Digit 43 — Recessed Flange

0 = None

A = Recessed Flange

Digit 44 — Wall Boxes

0 = None

A = Anodized Wall Box

CAB-PRC001-EN6

Page 7

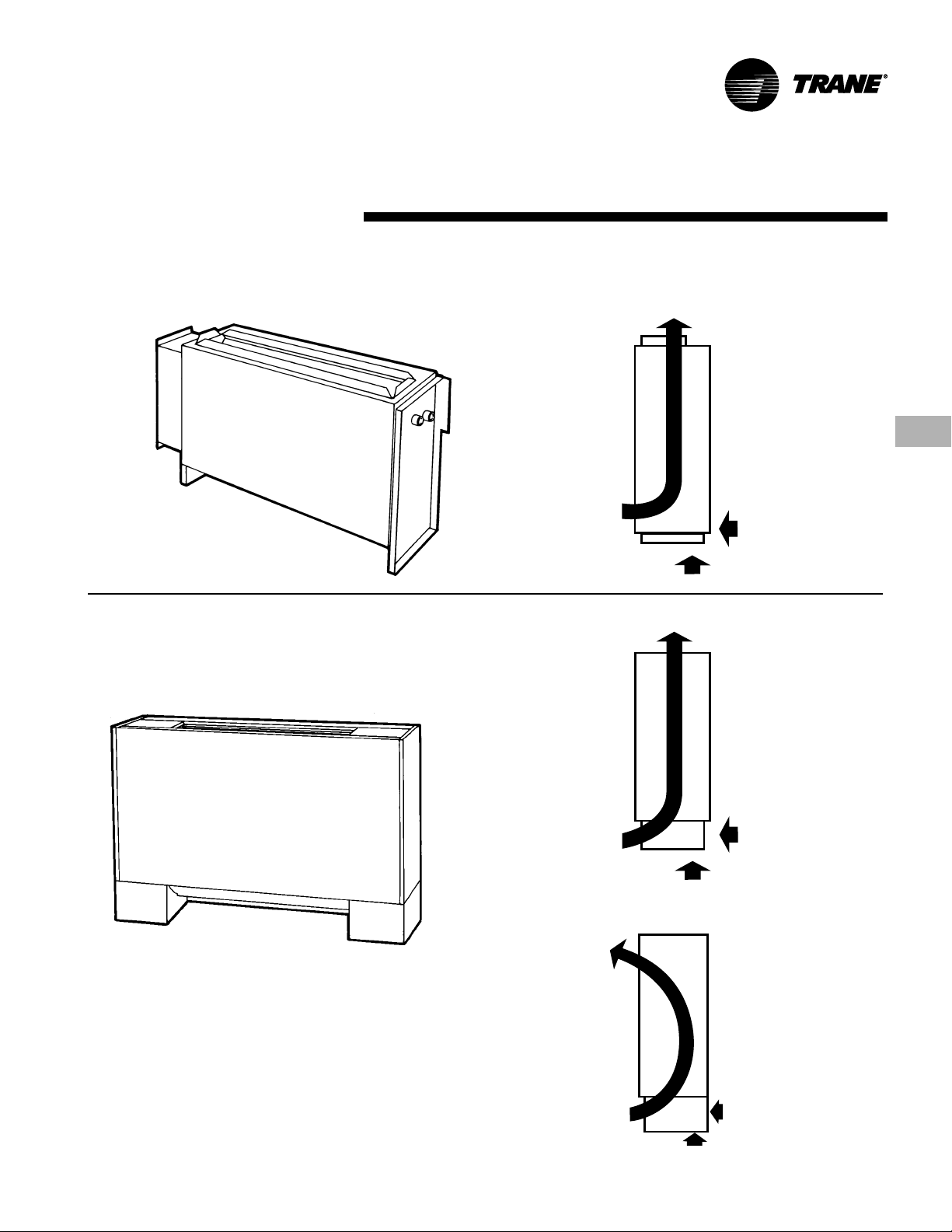

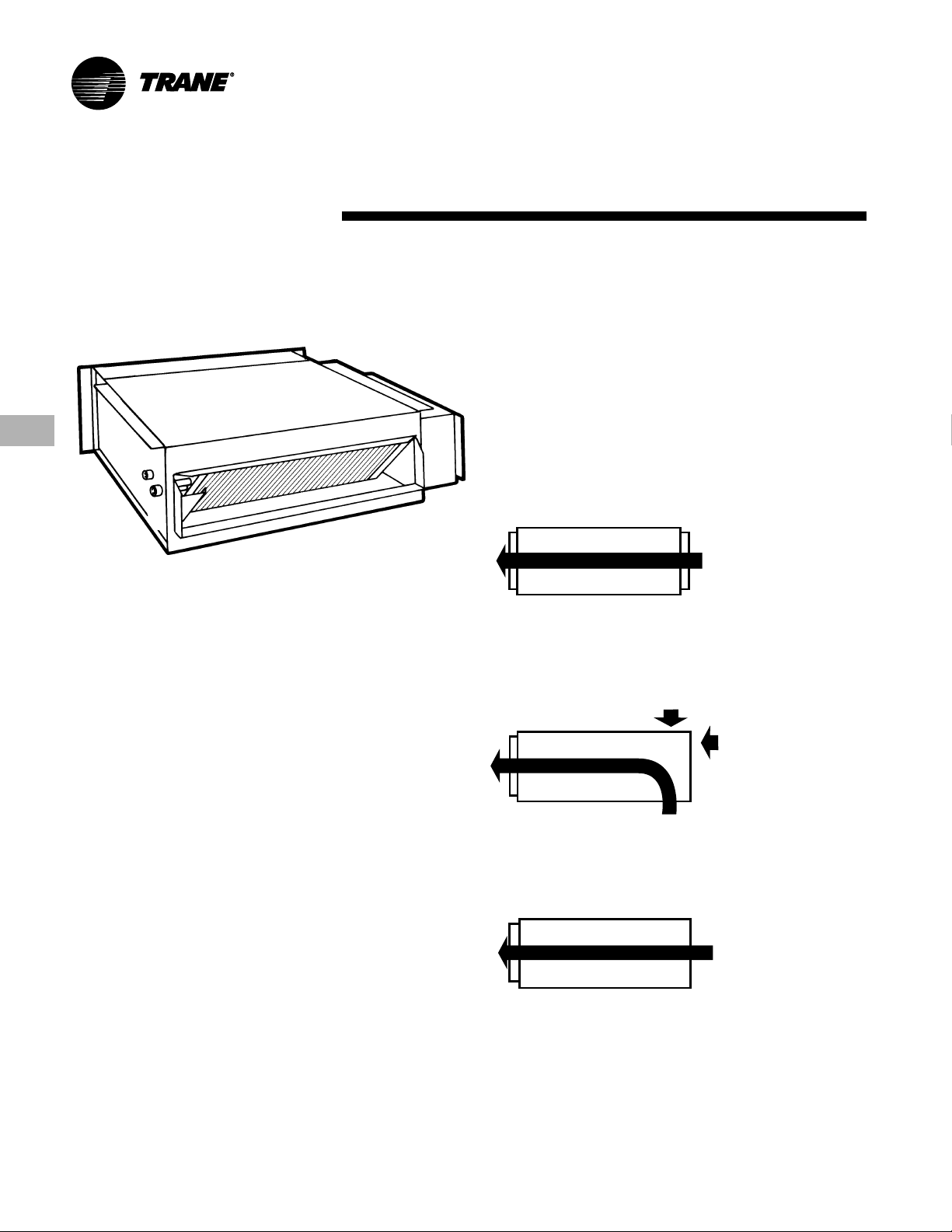

Unit

Model A

Vertical Concealed

Model B

Vertical Cabinet

General Data

Inlet

Front Toe Space

Configurations

Outlet

Top Duct Collar

Fresh Air

Bottom or Back

Outlet

Top Quad Grille, Top Bar Grille

Inlet

Front Toe Space,

Front Bar Grille

Outlet

Front Stamped Louver

Inlet

Front Toe Space,

Front Bar Grille

CAB-PRC001-EN 7

Fresh Air

Bottom or Back

Fresh Air

Bottom or Back

Page 8

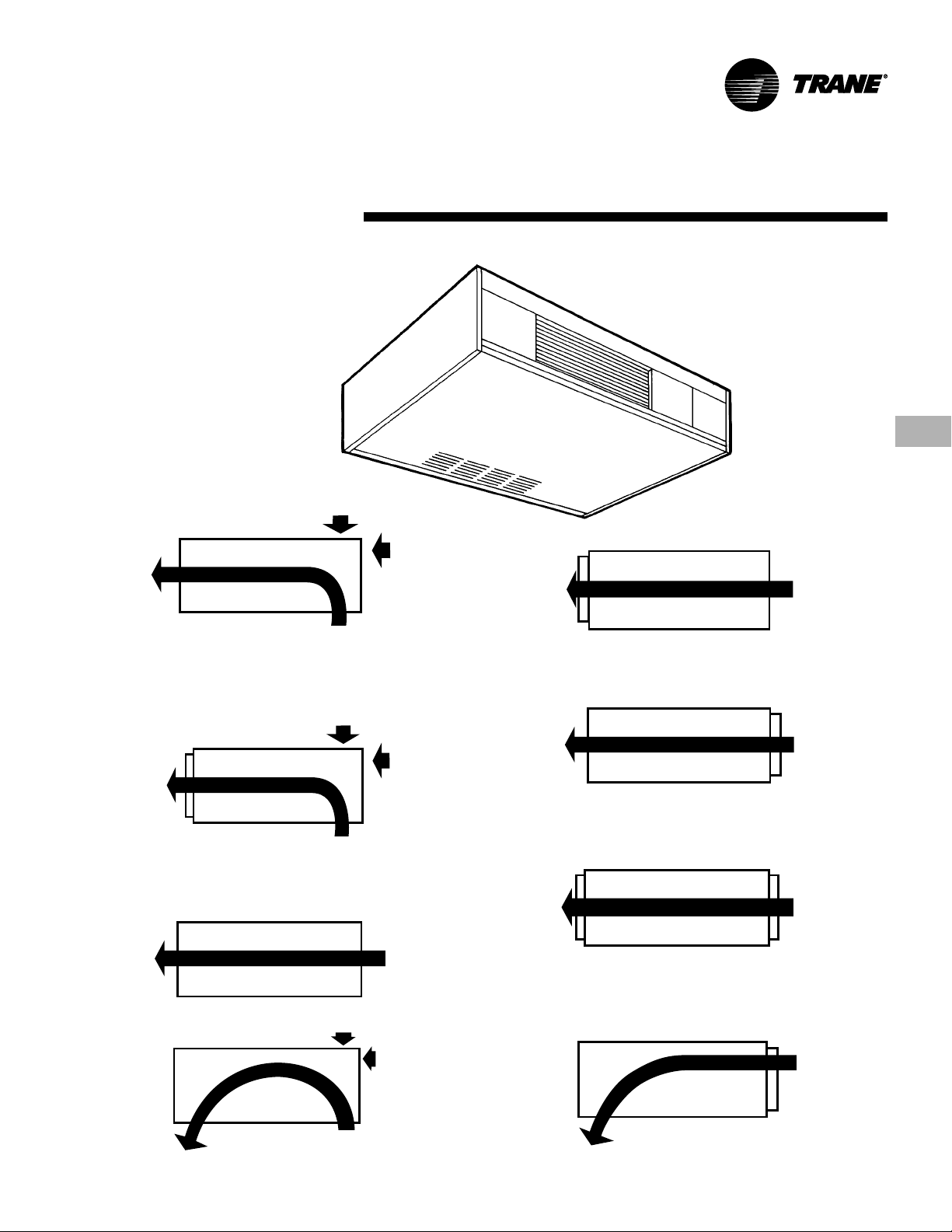

Unit

Model C

Horizontal Concealed

General Data

Outlet

Front Duct Collar

Configurations

Inlet

Back Duct Collar

Fresh Air

N/A

Outlet

Front Duct Collar

Outlet

Front Duct Collar

Fresh Air

Top or Back

Inlet

Bottom Toe Space

Inlet

Open Return

No Filter

Fresh Air

N/A

8

CAB-PRC001-EN

Page 9

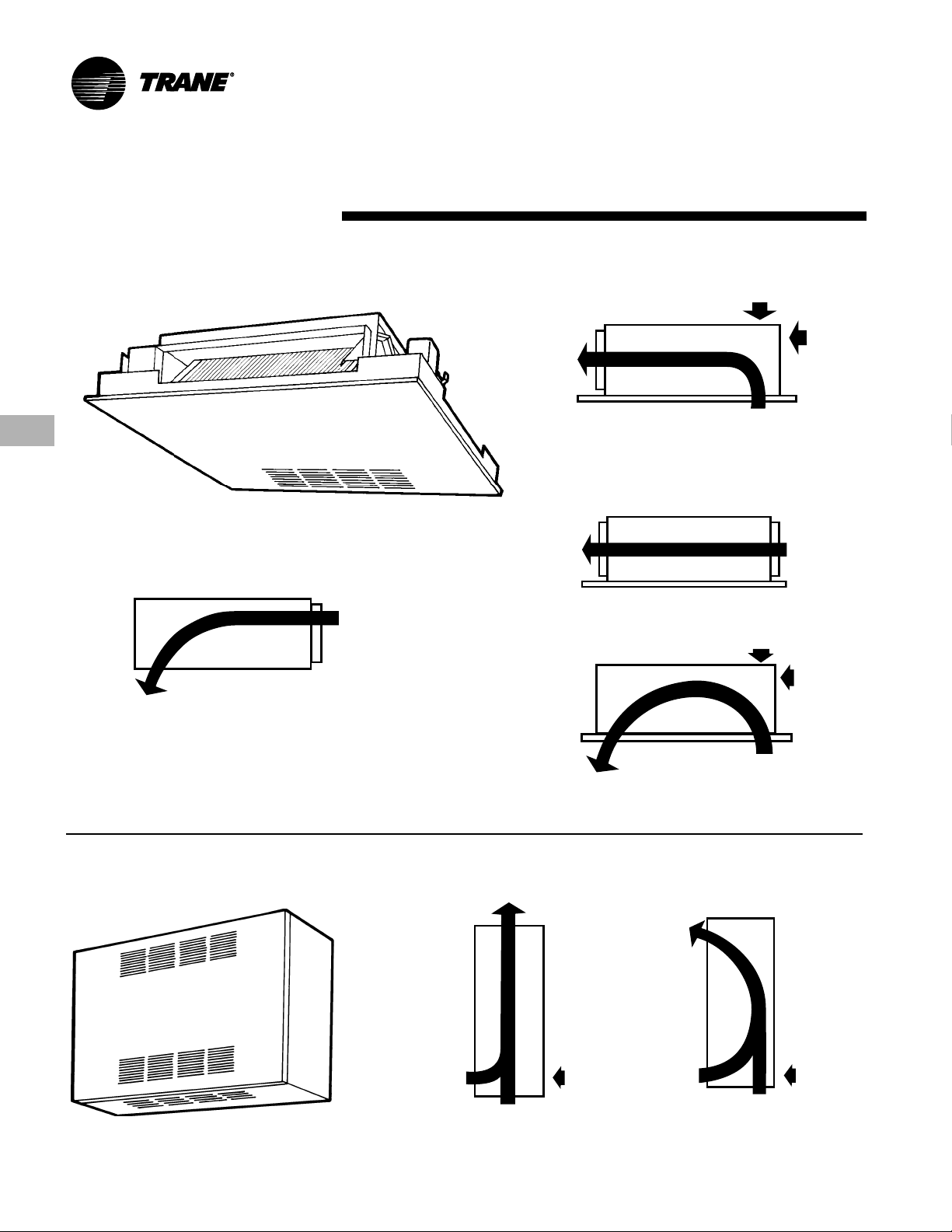

Unit

General Data

Configurations

Model D

Horizontal Cabinet

Fresh Air

Top or Back

Fresh Air

N/A

Inlet

Outlet

Front Quad

Grille, Front Bar Grille

Outlet

Front Duct Collar

Fresh Air

N/A

Outlet

Front Quad

Grille, Front Bar Grille

Outlet

Bottom

Stamped Louver

CAB-PRC001-EN 9

Inlet

Bottom Stamped

Louver

Fresh Air

Top or Back

Inlet

Bottom Stamped

Louver

Inlet

Back Stamped

Louver

Fresh Air

Top or Back

Inlet

Bottom Stamped

Louver

Outlet

Front Duct Collar

Fresh Air

N/A

Outlet

Front Quad Grille,

Front Bar Grille

Fresh Air

N/A

Outlet

Front Duct Collar

Fresh Air

N/A

Outlet

Bottom

Stamped Louver

Back Stamped

Louver

Inlet

Back Duct

Collar

Inlet

Back Duct

Collar

Inlet

Back Duct

Collar or

Stamped

Louver

Page 10

Unit

Model E

Horizontal Recessed

General Data

Outlet

Inlet

Back Duct

Collar

Front Duct Collar

Configurations

Outlet

Front Duct Collar

Fresh Air

Top or Back

Inlet

Bottom Stamped

Louver

Fresh Air

N/A

Inlet

Back Duct

Collar

Fresh Air

Top or Back

Outlet

Bottom Stamped

Louver

Model F

Vertical Wall Hung Cabinet

Outlet

Top Quad Grille or

Bar Grille

Inlet

Bottom & Front

Stamped Louver

Outlet

Bottom Stamped

Louver

Fresh Air

Back

Outlet

Front Stamped

Louver

Inlet

Bottom & Front

Stamped Louver

Inlet

Bottom Stamped

Louver

Fresh Air

Back

10

CAB-PRC001-EN

Page 11

Unit

Model H

Vertical Recessed

General Data

Inlet

Front Stamped Louver

Outlet

Front Stamped

Louver

Configurations

Outlet

Top Duct Collar

Fresh Air

Bottom or Back

Model J

Vertical Cabinet Slope Top

Inlet

Front Stamped Louver

Inlet

Front Toe Space,

Front Bar Grille

Fresh Air

Bottom or Back

Outlet

Top Quad Grille, Top Bar Grille

Fresh Air

Bottom or Back

CAB-PRC001-EN 11

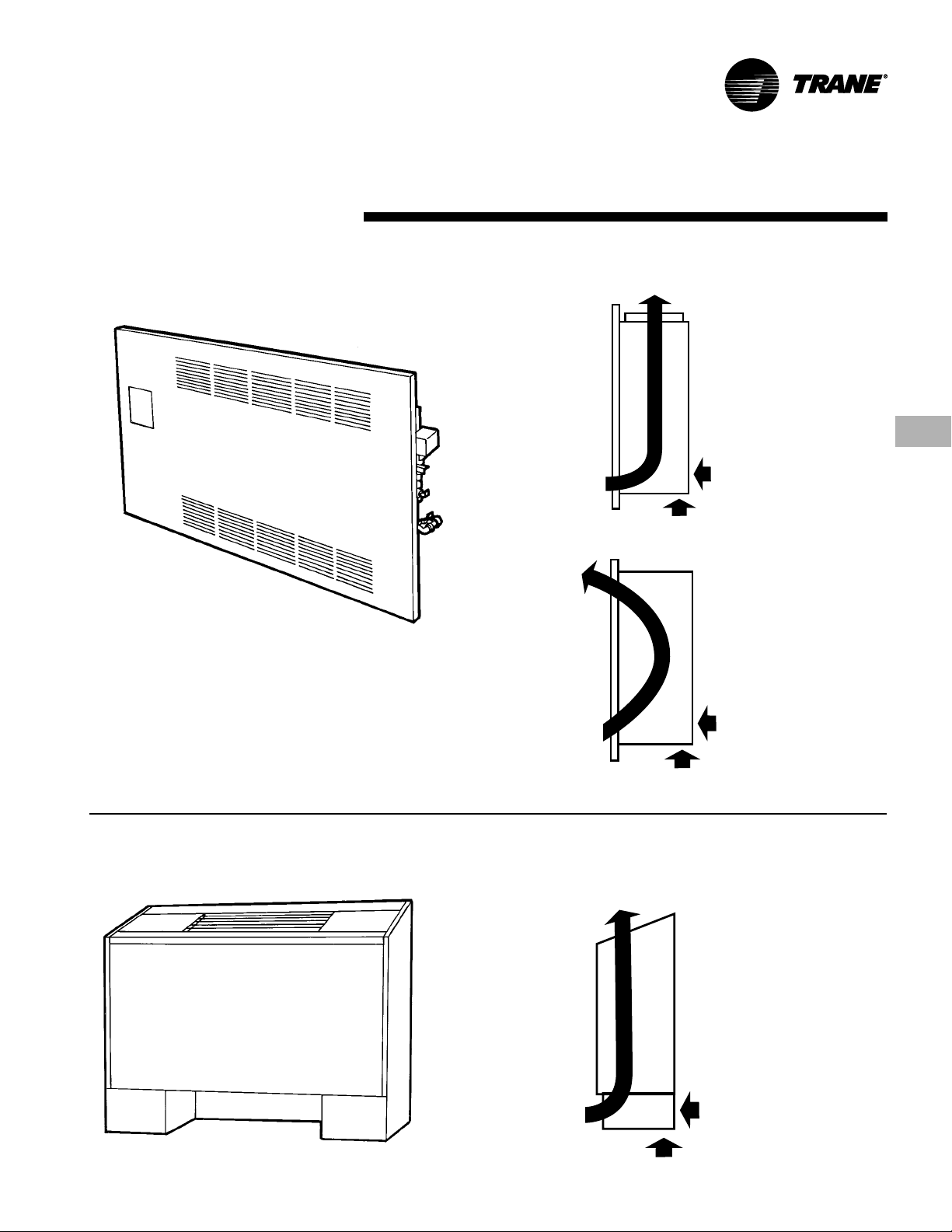

Page 12

General Data

Model M

Inverted Vertical Cabinet

Inlet

Front Stamped

Louver

Outlet

Front Stamped

Louver

Inlet

Top Duct

Collar

Outlet

Top Duct

Collar

Model N

Inverted Vertical Recessed

12

Inlet

Front Stamped

Louver

Outlet

Front Stamped

Louver

CAB-PRC001-EN

Page 13

General Data

Table GD-1. Force–Flo Cabinet Heater General Data

Unit Size 0 2 0 3 0 4 0 6 0 8 1 0 1 2

Coil Data

Face Area — Ft

LxDxH — In. (cm)

2-Row 15x1.7x8 15x1.7x8 20x1.7x8 29.5x1.7x8 38x1.7x8 57x1.7x8 57x1.7x8

3-Row 15x2.6x8 15x2.6x8 20x2.6x8 29.5x2.6x8 38x2.6x8 57x2.6x8 57x2.6x8

4-Row 15x3.5x8 15x3.5x8 20x3.5x8 29.5x3.5x8 38x3.5x8 57x3.5x8 57x3.5x8

Volume — Gal. (Liters)

1-Row (Heat) .06 (.23) .06 (.23) .08 (.30) .11 (.42) .14 (.53) .21 (.79) .21 (.79)

2-Row .12 (.45) .12 (.45) .15 (.57) .22 (.83) .28 (1.06) .42 (1.59) .42 (1.59)

3-Row .18 (.68) .18 (.68) .23 (.87) .33 (1.25) .42 (1.59) .62 (2.35) .62 (2.35)

4-Row .24 (.91) .24 (.91) .30 (1.14) .44 (1.67) .56 (2.12) .83 (3.14) .83 (3.14)

Fins/Ft (cm)

2-Row 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7)

3-Row 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7)

4-Row 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7) 144 (4.7)

Fan/Motor Data

Fan Quantity 1 1 1 2 2 3 3

Size — Dia” x Width” (cm) 6.31x4 6.31x6.5 6.31x7.5 6.31x6.5 6.31x7.5 (1) 6.31x7.5 6.31x7.5

Motor Quantity 1 1 1 1 1 2 2

Filter Data

1” (cm) TA and Pl. Media

Quantity 1 1 1 1 1 1 1

Size — In. (cm) 8

1” Fresh Air Filter (only on cabinet styles D, E, and H with bottom return and fresh air opening)

Quantity 1 1 1 1 1 1 1

Size — In. (cm) 5

(14 x 49) (14 x 49) (14 x 61) (14 x 85) (14 x 107) (14 x 156) (14 x 156)

2

(cm2) 0.8 (743) 0.8 (743) 1.1 (1020) 1.6 (1490) 2.1 (1950) 3.2 (2970) 3.2 (2970)

(38x4x20) (38x4x20) (51x4x20) (75x4x20) (97x4x20) (145x4x20) (145x4x20)

(38x7x20) (38x7x20) (51x7x20) (75x7x20) (97x7x20) (145x7x20) (145x7x20)

(38x9x20) (38x9x20) (51x9x20) (75x9x20) (97x9x20) (145x9x20) (145x9x20)

(16x10) (16x17) (16x19) (16x17) (16x19) (16x19) (16x19)

7

/8 x 191/8 87/8 x 191/8 87/8 x 241/8 87/8 x 335/8 87/8 x 421/8 87/8 x 611/8 87/8 x 611/8

(23x49) (23x49) (23x61) (23x85) (23x107) (23x155) (23x155)

1

/2 x 191/8 51/2 x 191/8 51/2 x 241/8 51/2 x 335/8 51/2 x 421/8 51/2 x 611/8 51/2 x 611/8

(2) 6.31x6.5

(16x6.5)

Table GD-2. Cabinet Heater Air Flow

Unit Size Coil 0.05 0.1 0.2 0.3 0.4

02 3R144 230 330 300 270 240

03 3R144 310 400 360 330 290

04 3R144 370 550 510 470 430

06 3R144 610 890 830 770 710

08 3R144 730 1000 930 870 800

10 3R144 1000 1400 1310 1210 1120

12 3R144 1080 1520 1420 1330 1220

Note: This is data is based on horizontal concealed model only, with duct inlet, duct outlet and no filter, dry coil, all voltages

except 208 V.

CAB-PRC001-EN 13

2R144 240 330 300 280 250

4R144 200 300 270 250 220

2R144 320 410 390 350 320

4R144 280 370 340 300 270

2R144 390 450 410 380 340

4R144 340 510 480 440 400

2R144 610 760 700 650 590

4R144 560 820 760 710 660

2R144 800 1020 960 890 820

4R144 680 940 870 810 750

2R144 980 1260 1180 1090 1010

4R144 930 1300 1220 1130 1040

2R144 1110 1430 1330 1240 1140

4R144 1000 1430 1340 1240 1150

FD Motor High Static Motor

ESP

Page 14

General Data

Electric Heat

Electric Heat

All Force-Flo™ cabinet heaters, except

inverted models M and N, are available

with electric heating coils as a standard

option.

Coil Construction

Electric heat coils are open wire type with

a nickel chromium element design.

Power Supply

Units have single-point power since the

electric heating elements operate on line

voltage. Electric heat is available as

208/60/1, 230/60/1, 277/60/1, 208/60/3, or

480/60/3. Electric heat coils operate on the

same voltage as the unit, except for units

with 480/60/3 electric heat. In this case, the

unit operates at 277/60/1, thus requiring a

4-wire supply. All fans and motors are

single phase. In addition, all control

options are 24-volt, utilizing a factoryinstalled transformer.

Power Supply Location

All electric heat cabinet heaters have a

terminal block for main power on the

unit’s right-hand side.

Control Type

Single-stage electric heat units are

controlled by any of the Tracer

control options. Two-stage electric heat is

controlled by the Tracer ZN.520 only. Both

®

ZN

control options use PWM (pulse-width

modulation) outputs to calculate the

electric heat output based on the capacity

request and the electric heat cycles per

hour. For example, if the electric heat

cycles per hour is configured for six

cycles (as Trane recommends) the

controller bases the output on or off time

on six 10-minute periods. If the capacity

request is 40%, the controller controls the

electric heat output on for approximately

four minutes each period.

Safety Features

• All Force-Flo units with standard electric

heat are UL listed.

• Units require only a single-point

electrical connection.

• All electric heating coils are interlocked

with the fan motor switch. Therefore,

electric heat operation is only possible

when the fan is running.

• Each unit has a transformer, eliminating

the need for field installation of a stepdown transformer.

• A unit mounted magnetic contactor(s) is

(are) supplied on all unit voltages.

• A high temperature cutout with automatic reset de-energizes the electric

heat in the event of an overheat condition.

14

CAB-PRC001-EN

Page 15

General Data

Piping Packages

Factory-Installed Piping

Packages

Force–Flo cabinet heaters have standard

piping packages available as a factory

built and installed option. Factory built

assures all piping packages are fully

tested under water for leaks and are built

within strict tolerances. Factory-installed

means that supply and return pipes are

the only field connections required. The

installer doesn’t have to sweat connect

piping packages onto coil connections in

a tight end pocket. Field connections are

brought to a point near the exterior of the

unit for easy access.

Piping Package Components

Force–Flo piping packages consist of a

variety of components for each application. The following section provides a

detailed description of the piping components. Following this section are additional illustrations and specifications.

Piping System/Placement

Factory piping packages are available

with right or left hand connections. A

simple coil connection (a unit without a

piping package) is also available in either

a right or left hand configuration for those

applications requiring field piping.

Interconnecting Piping

Interconnecting piping refers to the

copper piping which is attached to the

coil connections and all other components such as control valves, end valves,

etc. Piping is

extends near the unit exterior to one inlet

and one outlet connection.

Deluxe or Basic Piping Package

The basic piping package includes only

the main components of the piping

package: interconnecting piping, control

valves, and end valves.

The deluxe piping package also includes

a strainer on the entering water pipe and

unions at the coil connections along with

the basic components. The strainer body

is cast brass construction, with a stainless steel mesh strainer that is easily

removed for cleaning. The unions are

forged brass construction and close with

a minimum amount of effort.

1

/2” nominal OD copper and

End Valves

Each piping package includes a ball valve

for the entering water pipe and one of the

following end valves on the leaving water

pipe: ball valve, manual circuit setter, or

an auto circuit setter. These valves serve

as the field connection points on all

Force–Flo piping packages.

• Ball Valves

Ball valves, also known as stop or end

valves, allow the unit to be cut off for

service purposes. These valves have a

two-inch handle that rotates 90 degrees

to a fully open position. The valve body is

cast brass, and the ball is polished brass

with a Teflon seat. Ball valves are available

as end valves on both the entering and

leaving water pipes.

Manual Circuit Setter

In lieu of a ball valve on the leaving water

pipe, a manual circuit setter, also known

as a manual flow control valve, acts as

both a flow setting device and a stop

valve. This valve allows water flow

through the cabinet heater to be set

quickly and accurately.

The manual circuit setter includes

Schrader ports in the valve body. These

ports are used to measure the pressure

drop across the valve. This pressure drop

can be compared to factory supplied

curves that relate the pressure drop to a

specific flow rate. This valve also has a

memory stop so the correct setting can

be found quickly.

Auto Circuit Setter

An auto circuit setter is an automatic flow

control device available on the leaving

water pipe. The auto circuit setter

includes a cartridge within the valve body

that is sized to allow a specific flow rate

through the coil. This valve sets flow

through the coil without any action

required by a system piping balancer. The

auto circuit setter is available on the

leaving water pipe with a ball valve.

The auto circuit setter also includes two

P/T’s plugs in the valve body to allow

measurement of the pressure drop

temperature through the valve.

Control Valves

Piping packages are available with or

without control valves. All control valve

options are factory mounted and wired to

the Force–Flo unit controls.

• Two-Way/Two-Position Valves

These valves will either fully open or

close in response to a 24VAC signal from

the Trane controller. Control valves are

direct-acting valves. The control valve is

factory mounted in the leaving water pipe

downstream of the coil. Some means of

relieving pump head pressure should be

accounted for when two-way valves are

selected. Normally open or normally

closed valves are available.

• Three-Way/Two-Position Valves

These valves will either allow full water

flow through the coil or divert the flow

through a bypass line. The valves

respond to a 24VAC signal from the Trane

controller. Control valves are direct acting

valves. All three-way valve packages

include a balance fitting in the bypass line

to allow flow balancing in the bypass

position. Three-way valves are factory

mounted in the leaving water pipe

downstream of the coil. Normally open

or normally closed valves are available.

• Two-Way Modulating Valves

These valves modulate the water flow

through the coil in response to a signal

from the Trane controller. Modulating

valves are three-wire floating point equal

percentage valves, and are factory

mounted in the leaving water pipe

downstream of the coil.

• Three-Way Modulating Valves

These valves modulate the water flow

through the coil in response to a signal

from the Trane controller. Three-way

valves allow water that is directed

through the coil to mix with water that is

directed through the bypass line. This

mixture exits through the leaving water

pipe. Modulating valves are three-wire

floating point equal percentage valves,

and are factory mounted in the leaving

water pipe downstream of the coil.

CAB-PRC001-EN 15

Page 16

Piping Package Options

General Data

Piping Packages

Manual

Automatic Circuit Setter (C)

16

CAB-PRC001-EN

Page 17

General Data

Selecting the Correct

Modulating Valve Size

Modulating valves are available in any of

four port sizes. These four port sizes

relate to a Cv of 0.7, 1.5, 2.5 or 4.0, which

is the coefficient of flow. The coefficient of

flow is defined as the volume of water

flow through a control valve in the fully

open position with a 1 psig (6.895 kPa)

differential across the valve. It is calculated using the following formula:

Cv = Q/Square root ∆P where:

Cv = flow coefficient

Q = flow rate (GPM)

∆P = pressure drop across the valve or

coil (psig).

For good control, the valve Cv should be

approximately equal to the Cv of the

water coil.

Modulating Valve Selection Example

Assume a size 06 cabinet heater is

selected to operate at the following

conditions:

Vertical cabinet cabinet heater

Entering water temperature = 180 F (82 C)

Leaving water temperature = 150 F ( C)

EAT = 70 F (21 C)

The coil is selected as a four-row coil.

Select the best modulating valve size for

this unit.

1

Find the ∆P across the water coil. Refer to

the ARI performance table to determine

the ∆P across the water coil or use the

Trane Official Product Selection System,

TOPSS™, selection program. The water

pressure drop is found to be 5.7’ (17.0

kPa) of water at a flow rate of 3.59 gpm.

This converts to a pressure drop of 2.47

psig (1.0 feet of water = 0.4328 psig.)

2

Calculate the Cv of the water coil.

Cv = GPM/Square root ∆P.

Cv = 3.59/Square root 2.47

Cv = 2.29

Therefore, select the valve with the Cv of

2.5 since it is closest to the Cv of the

water coil. The following tables illustrate

possible valve selections at ARI conditions for horizontal concealed units with a

high static motor and vertical cabinet

units with a free discharge motor. For

other applications, use TOPSS to

determine the flowrate and make

calculations using the formulas above.

Table GD-3. Modulating Valve Selections for Horizontal Concealed Units, High Static Motor,

∆∆

70 F (21 C) EAT, 180 F (82 C) EWT, 30 F (-1 C)

Unit Coil Coil Valve

Size Coil GPM (L/s) WPD (kPa) Cv Cv

2-Row 1.19 (0.08) 6.0 (17.8) 0.74 0.7

02 3-Row 1.52 (.10) 13.8 (41.2) 0.62 0.7

4-Row 1.59 (.10) 3.8 (11.5) 1.24 1.5

2-Row 1.53 (.10) 10.3 (30.8) 0.72 0.7

03 3-Row 1.82 (.11) 4.3 (12.8) 1.33 1.5

4-Row 1.98 (.12) 6.2 (18.6) 1.21 1.5

2-Row 1.73 (.11) 3.3 (9.8) 1.45 1.5

04 3-Row 2.57 (.16) 9.1 (27.0) 1.29 1.5

4-Row 2.81 (.18) 13.4 (39.9) 1.17 1.5

2-Row 2.87 (.18) 9.9 (29.5) 1.39 1.5

06 3-Row 3.96 (.25) 5.9 (17.7) 2.48 2.5

4-Row 4.37 (.28) 8.2 (24.6) 2.32 2.5

2-Row 3.71 (.23) 4.7 (14.2) 2.60 2.5

08 3-Row 4.74 (.30) 9.1 (27.1) 2.39 2.5

4-Row 5.22 (.33) 12.7 (37.8) 2.23 2.5

2-Row 4.71 (.30) 8.1 (24.1) 2.52 2.5

10 3-Row 6.50 (.41) 18.1 (54.0) 2.32 2.5

4-Row 7.13 (.45) 25.3 (75.6) 2.15 2.5

2-Row 5.48 (.35) 11.4 (34.0) 2.47 2.5

12 3-Row 7.19 (.45) 14.5 (43.2) 2.87 2.5

4-Row 7.83 (.51) 10.5 (31.4) 3.67 4.0

Table GD-4. Modulating Valve Selections for Vertical Cabinet Units, Free Discharge Motor, 70

F (21 C) EAT, 180 F (82 C) EWT, 30 F (-1 C)

Unit Coil Coil Valve

Size Coil GPM (L/s) WPD (kPa) Cv Cv

2-Row 1.06 (.07) 4.8 (14.4) 0.74 0.7

02 3-Row 1.31 (.08) 10.5 (31.4) 0.61 0.7

4-Row 1.34 (.08) 2.8 (8.4) 1.22 1.5

2-Row 1.40 (.09) 8.8 (26.3) 0.72 0.7

03 3-Row 1.70 (.11) 3.8 (11.3) 1.33 1.5

4-Row 1.81 (.11) 5.3 (15.7) 1.20 1.5

2-Row 1.71 (.11) 3.2 (9.5) 1.45 1.5

04 3-Row 2.12 (.13) 6.4 (19.0) 1.27 1.5

4-Row 2.28 (.14) 9.1 (27.3) 1.15 1.5

2-Row 2.70 (.17) 8.9 (26.5) 1.38 1.5

06 3-Row 3.31 (.21) 4.2 (12.6) 2.46 2.5

4-Row 3.59 (.23) 5.7 (17.0) 2.29 2.5

2-Row 3.39 (.21) 4.0 (11.9) 2.58 2.5

08 3-Row 4.11 (.26) 6.9 (20.7) 2.38 2.5

4-Row 4.45 (.28) 9.4 (28.1) 2.21 2.5

2-Row 4.32 (.27) 6.8 (20.4) 2.52 2.5

10 3-Row 5.55 (.35) 13.4 (40.2) 2.30 2.5

4-Row 6.00 (.38) 18.3 (54.8) 2.13 2.5

2-Row 4.99 (.32) 9.6 (28.6) 2.45 2.5

12 3-Row 6.10 (.38) 10.5 (31.4) 2.86 2.5

4-Row 6.48 (.42) 7.3 (21.8) 3.65 4.0

T

∆

∆∆

∆∆

∆

T

∆∆

CAB-PRC001-EN 17

Page 18

Performance

Hot Water

Data

Coils

Force–Flo cabinet heater performance data is grouped based on performance. Unit

performance is impacted by the unit model and the airflow inlet and outlet configuration. Below is a table that summarizes the performance groups.

Table PD-1. Force Flo™ Performance Groupings

Group Unit Inlet Outlet

Description Model Style Style

Group 1 Horizontal Concealed (C) Back Duct Collar Front Duct Collar

Horizontal Cabinet (D) Back Duct Collar Front Duct Collar

Horizontal Recessed (E) Back Duct Collar Front Duct Collar

Group 2 Vertical Concealed (A) Front Toe Space Top Duct Collar

Vertical Cabinet (B) Front Toe Space Top Quad Grille

Horizontal Concealed (C) Bottom Toe Space Front Duct Collar

Horizontal Cabinet (D) Back Duct Collar Bottom Stamped Louver

Horizontal Recessed (E) Bottom Stamped Louver Front Duct Collar

Open Return Front Duct Collar

Front Bar Grille

Front Quad Grille

Top Bar Grille

Front Stamped Louver

Front Bar Grille Top Quad Grille

Top Bar Grille

Front Stamped Louver

Bottom Stamped Louver Front Quad Grille

Front Bar Grille

Front Duct Collar

Bottom Stamped Louver

Back Stamped Louver Front Quad Grille

Front Bar Grille

Front Duct Collar

Bottom Stamped Louver

Bottom Stamped Louver

Back Duct Collar Bottom Stamped Louver

Wall Hung Cabinet (F) Front Stamped Louver Top Quad Grille

Vertical Recessed (H) Front Stamped Louver Front Stamped Louver

Inverted Vertical Cabinet (M) Front Stamped Louver Front Stamped Louver

Top Duct Collar Bottom Duct Collar

Inverted Vertical Recessed (N) Front Stamped Louver Front Stamped Louver

Group 3 Vertical Slope Top (J) Front Toe Space Top Quad Grille

Front Bar Grille Top Quad Grille

Note:

For performance conditions other than ARI, use TOPSS™ (Trane Official Product Selection System) for Force Flo cabinet

heaters.

Top Bar Grille

Front Stamped Louver

Top Duct Collar

Bottom Duct Collar

Front Stamped Louver

Top Bar Grille

Top Bar Grille

CAB-PRC001-EN18

Page 19

Performance

Hot Water

Data

Coils

Heating performance is based on 70 F (21 C) entering air temperature, 180 F (82 C) entering hot water temperature with a 30 F (-1 C)

∆T. All performance measured on high speed tap, zero ESP, and a throwaway filter.

Table PD-2. Free Discharge Motor, Group 1

Unit CFM TMBH GPM WPD 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (L/s) (kPa) Watt Watt Watt

2 2 H 240 (113) 15.9 (4.7) 0.14 1.06 (0.07) 4.8 (14.4) 60 95 65

3 H 230 ( 108) 19.6 (5.7) 0.18 1.31(0.08) 10.5 (31.4) 6 0 95 65

4 H 210 (99) 20.1 (6.0) 0.18 1.34 (0.08) 2.8 (8.4) 6 0 95 65

3 2 H 318 (150) 21.0 (6.2) 0.19 1.40 (0.09) 8.8 (26.3) 70 80 83

3 H 314 (148) 25.6 (7.5) 0.23 1.70 (0.11) 3.8 (11.3) 85 89 101

4 H 284 (134) 27.1 (7.9) 0.25 1.81 (0.11) 5.3 (15.7) 85 89 101

4 2 H 388 (183) 25.6 (7.5) 0.23 1.71 (0.11) 3.2 (9.5) 9 5 96 10 4

3 H 374 (177) 31.8 (9.3) 0.29 2.12 (0.13) 6.4 (19.0) 1 00 10 7 106

4 H 350 (165) 34.2 (10.0) 0.31 2.28 (0.14) 9.1 (27.3) 100 107 106

6 2 H 611 (289) 40.6 (11.9) 0.37 2.70 (0.17) 8.9 (26.5) 1 10 15 4 165

3 H 608 (287) 49.7 (14.6) 0.45 3.31 (0.21) 4.2 (12.6) 125 130 124

4 H 565 (267) 53.8 (15.8) 0.49 3.59 (0.23) 5.7 (17.0) 125 130 124

8 2 H 790 (373) 50.9 (14.9) 0.46 3.39 (0.21) 4.0 (11.9) 1 35 15 0 159

3 H 731 (345) 61.6 (18.1) 0.56 4.11 (0.26) 6.9 (20.7) 120 123 133

4 H 688 (325) 66.8 (19.6) 0.61 4.45 (0.28) 9.4 (28.1) 120 123 133

1 0 2H 980 (463) 64.8 (19.0) 0.59 4.32 (0.27) 6.8 (20.4) 2 05 25 0 269

3 H 992 (468) 83.3 (24.4) 0.76 5.55 (0.35) 13.4 (40.2) 22 5 237 23 0

4 H 930 (439) 90.1 (26.4) 0.82 6.00 (0.38) 18.3 (54.8) 22 5 237 23 0

1 2 2H 1110 (524) 75.0 (22.0) 0.68 4.99 (0.32) 9.6 (28.6) 230 246 263

3 H 1082 (511) 91.5 (26.8) 0.83 6.10 (0.38) 10.5 (31.4) 220 230 239

4 H 1010 (477) 99.3 (28.5) 0.90 6.48 (0.42) 7.3 (21.8) 2 20 23 0 239

Heating

Table PD-3. Free Discharge Motor, Group 2

Unit CFM TMBH GPM WPD 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (L/s) (kPa) Watt Watt Watt

2 2 H 211 (100) 14.5 (4.3) 0.13 0.97 (0.06) 4.1 (12.3) 60 95 65

3 H 201 (95) 17.7 (5.2) 0.16 1.18 (0.07) 8.8 (26.2) 6 0 95 65

4 H 188 (89) 18.3 (5.4) 0.17 1.22 (0.08) 2.4 (7.1) 6 0 95 65

3 2 H 280 (132) 19.2 (5.6) 0.17 1.28 (0.08) 7.5 (22.4) 70 80 83

3 H 277 (131) 23.3 (6.8) 0.21 1.55 (0.10) 3.2 (9.5) 8 5 8 9 101

4 H 256 (121) 24.8 (7.3) 0.23 1.65 (0.10) 4.5 (13.4) 85 89 101

4 2 H 349 (165) 23.8 (7.0) 0.22 1.58 (0.10) 2.8 (8.3) 9 5 96 10 4

3 H 338 (159) 29.4 (8.6) 0.27 1.96 (0.12) 5.5 (16.5) 1 00 10 7 106

4 H 320 (151) 31.7 (9.3) 0.29 2.11 (0.13) 7.9 (23.7) 1 00 10 7 106

6 2 H 544 (257) 37.4 (11.0) 0.34 2.49 (0.16) 7.6 (22.8) 1 10 15 4 165

3 H 541 (255) 45.4 (13.3) 0.41 3.03 (0.19) 3.6 (10.6) 125 130 124

4 H 510 (241) 49.4 (14.5) 0.45 3.29 (0.21) 4.8 (14.5) 125 130 124

8 2 H 706 (331) 47.0 (13.8) 0.43 3.13 (0.20) 3.4 (10.2) 1 35 15 0 159

3 H 659 (311) 56.8 (16.7) 0.52 3.79 (0.24) 5.9 (17.8) 120 123 133

4 H 627 (296) 61.8 (18.1) 0.56 4.12 (0.26) 8.1 (24.3) 120 123 133

1 0 2H 879 (415) 60.0 (17.6) 0.55 4.00 (0.25) 5.9 (17.7) 2 05 25 0 269

3 H 886 (420) 76.4 (22.4) 0.69 5.09 (0.32) 11.4 (34.1) 22 5 237 23 0

4 H 840 (397) 82.8 (24.3) 0.75 5.52 (0.35) 15.7 (46.8) 22 5 237 23 0

1 2 2H 996 (470) 69.4 (20.3) 0.63 4.62 (0.29) 8.3 (24.7) 2 30 24 6 263

3 H 976 (461) 84.3 (24.8) 0.77 5.62 (0.35) 9.0 (26.8) 220 230 239

Note:

1. CFM = Cubic feet per minute

2. TMBH = Total capacity (MBH)

3. GPM = Gallons per minute

4. WPD = Water pressure drop (feet of water)

5. Q/ITD = MBH (kW)/(Entering water temperature - Entering air temperature) when DT and GPM (L/s) remain constant. To determine heating capacities at a different entering water

6. Medium and low speed capacities are approximately 80 percent and 60 percent respectively of the high speed capacity.

4 H 921 (435) 91.8 (26.4) 0.83 6.12 (0.39) 10.2 (30.5) 22 0 230 23 9

temperature or entering air temp, compute the new ITD and multiply it by the Q/ITD shown.

Heating

CAB-PRC001-EN 19

Page 20

Performance

Hot Water

Data

Coils

Heating performance is based on 70 F (21 C) entering air temperature, 180 F (82 C) entering hot water temperature with a 30 F (-1 C)

∆T. All performance measured on high speed tap, zero ESP, and a throwaway filter.

Table PD-4. Free Discharge Motor, Group 3

Unit CFM TMBH GPM WPD 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (L/s) (kPa) Watt Watt Watt

2 2 H 198 (93) 13.8 (4.1) 0.13 0.92 (0.06) 3.8 (11.3) 60 95 65

3 H 188 (90) 16.7 (4.9) 0.15 1.11 (0.07) 8.0 (23.8) 6 0 95 65

4 H 177 (84) 17.3 (5.1) 0.16 1.16 (0.07) 2.2 (6.4) 6 0 95 65

3 2 H 262 (124) 18.3 (5.4) 0.17 1.22 (0.08) 6.9 (20.6) 70 80 83

3 H 260 (123) 22.1 (6.5) 0.20 1.47 (0.09) 2.9 (8.7) 8 5 8 9 101

4 H 242 (114) 23.7 (6.9) 0.22 1.58 (0.10) 4.1 (12.3) 85 89 101

4 2 H 330 (156) 22.8 (6.7) 0.21 1.52 (0.10) 2.6 (7.7) 9 5 96 10 4

3 H 320 (151) 28.1 (8.2) 0.26 1.87 (0.12) 5.1 (15.2) 1 00 10 7 106

4 H 304 (144) 30.3 (8.9) 0.28 2.02 (0.13) 7.3 (21.9) 1 00 10 7 106

6 2 H 512 (242) 35.8 (10.5) 0.33 2.38 (0.15) 7.0 (21.0) 11 0 154 16 5

3 H 508 (240) 43.3 (12.7) 0.39 2.88 (0.18) 3.3 (9.7) 12 5 130 12 4

4 H 483 (228) 47.2 (13.8) 0.43 3.14 (0.20) 4.4 (13.3) 12 5 130 124

8 2 H 665 (314) 45.0 (13.2) 0.41 3.00 (0.19) 3.2 (9.4) 13 5 150 15 9

3 H 623 (294) 54.3 (15.9) 0.49 3.62 (0.23) 5.5 (16.3) 12 0 123 133

4 H 596 (282) 59.2 (17.3) 0.54 3.94 (0.25) 7.5 (22.4) 12 0 123 133

1 0 2H 829 (391) 57.5 (16.9) 0.52 3.83 (0.24) 5.5 (16.3) 2 05 25 0 269

3 H 835 (394) 72.9 (21.3) 0.66 4.86 (0.31) 10.5 (31.2) 225 237 230

4 H 796 (376) 79.0 (23.1) 0.72 5.26 (0.33) 14.4 (42.9) 225 237 230

1 2 2H 940 (444) 66.5 (19.5) 0.60 4.43 (0.28) 7.6 (22.8) 2 30 24 6 263

3 H 923 (436) 80.6 (23.6) 0.73 5.37 (0.34) 8.2 (24.6) 22 0 230 239

Note:

1. CFM = Cubic feet per minute

2. TMBH = Total capacity (MBH)

3. GPM = Gallons per minute

4. WPD = Water pressure drop (feet of water)

5. Q/ITD = MBH (kW)/(Entering water temperature - Entering air temperature) when DT and GPM (L/s) remain constant. To determine heating capacities at a different entering water

6. Medium and low speed capacities are approximately 80 percent and 60 percent respectively of the high speed capacity.

4 H 876 (413) 87.9 (25.8) 0.80 5.86 (0.37) 9.4 (28.2) 22 0 230 239

temperature or entering air temp, compute the new ITD and multiply it by the Q/ITD shown.

Heating

CAB-PRC001-EN20

Page 21

Performance

Hot Water

Data

Coils

Heating performance is based on 70 F (21 C) entering air temperature, 180 F (82 C) entering hot water temperature with a 30 F (-1 C)

∆T. All performance measured on high speed tap, zero ESP, and a throwaway filter.

Table PD-5. High Static Motor, Group 1

Unit CFM TMBH GPM WPD 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (L/s) (kPa) Watt Watt Watt

2 2 H 287 (135) 17.9 (5.3) 0.16 1.19 (0.08) 6.0 (17.8) 1 45 14 5 145

3 H 282 (133) 22.9 (6.7) 0.21 1.52 (0.10) 13.8 (41.2) 145 145 145

4 H 260 (123) 23.9 (7.0) 0.22 1.59 (0.10) 3.8 (11.5) 1 45 14 5 145

3 2 H 365 (172) 23.0 (6.7) 0.21 1.53 (0.10) 10.3 (30.8) 140 140 140

3 H 343 (162) 27.3 (8.0) 0.25 1.82 (0.11) 4.3 (12.8) 1 45 14 0 135

4 H 318 (150) 29.7 (8.7) 0.27 1.98 (0.12) 6.2 (18.6) 1 45 14 0 135

4 2 H 396 (187) 26.0 (7.6) 0.24 1.73 (0.11) 3.3 (9.8) 1 70 18 0 170

3 H 484 (228) 38.6 (11.3) 0.35 2.57 (0.16) 9.1 (27.0) 210 210 210

4 H 453 (214) 42.2 (12.4) 0.38 2.81 (0.18) 13.4 (39.9) 21 0 210 21 0

6 2 H 668 (315) 43.1 (12.6) 0.39 2.87 (0.18) 9.9 (29.5) 2 45 24 0 240

3 H 780 (368) 59.5 (17.4) 0.54 3.96 (0.25) 5.9 (17.7) 320 320 320

4 H 725 (342) 65.6 (19.2) 0.60 4.37 (0.28) 8.2 (24.6) 320 320 320

8 2 H 907 (428) 55.7 (16.3) 0.51 3.71 (0.23) 4.7 (14.2) 3 20 32 0 320

3 H 886 (418) 71.2 (20.9) 0.65 4.74 (0.30) 9.1 (27.1) 320 320 320

4 H 835 (394) 78.3 (22.9) 0.71 5.22 (0.33) 12.7 (37.8) 32 0 320 32 0

1 0 2H 1117 (527) 70.8 (20.7) 0.65 4.71 (0.30) 8.1 (24.1) 415 420 410

3 H 1230 (580) 97.6 (28.6) 0.89 6.50 (0.41) 18.1 (54.0) 530 530 530

4 H 1152 (544) 107.1 (31.4) 0.97 7.13 (0.45) 25.3 (75.6) 5 30 53 0 530

1 2 2H 1270 (600) 82.2 (24.1) 0.75 5.48 (0.35) 11.4 (34.0) 49 0 500 49 0

3 H 1350 (637) 108.0 (31.6) 0.98 7.19 (0.45) 14.5 (43.2) 5 30 53 0 530

4 H 1274 (601) 120.0 (35.2) 1.09 7.83 (0.51) 10.5 (31.4) 5 30 53 0 530

Heating

Table PD-6. High Static Motor, Group 2

Unit CFM TMBH GPM WPD 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (L/s) (kPa) Watt Watt Watt

2 2 H 256 (121) 16.6 (4.9) 0.15 1.11 (0.07) 5.2 (15.5) 1 45 14 5 145

3 H 250 (118) 20.9 (6.1) 0.19 1.39 (0.09) 11.8 (35.3) 145 145 145

4 H 234 (111) 22.0 (6.5) 0.20 1.47 (0.09) 3.3 (9.9) 145 14 5 145

3 2 H 330 (156) 21.5 (6.3) 0.20 1.43 (0.09) 9.2 (27.4) 1 40 14 0 140

3 H 309 (146) 25.3 (7.4) 0.23 1.68 (0.11) 3.7 (11.1) 1 45 14 0 135

4 H 290 (137) 27.6 (8.1) 0.25 1.84 (0.12) 5.4 (16.3) 1 45 14 0 135

4 2 H 367 (173) 24.6 (7.2) 0.22 1.64 (0.10) 3.0 (8.9) 1 70 18 0 170

3 H 440 (208) 36.0 (10.5) 0.33 2.40 (0.15) 8.0 (23.8) 210 210 210

4 H 416 (196) 39.5 (11.6) 0.36 2.63 (0.17) 11.8 (35.3) 21 0 210 21 0

6 2 H 610 (288) 40.5 (11.9) 0.37 2.70 (0.17) 8.8 (26.4) 2 45 24 0 240

3 H 704 (332) 55.3 (16.2) 0.50 3.68 (0.23) 5.2 (15.4) 320 320 320

4 H 662 (312) 61.1 (17.9) 0.56 4.07 (0.26) 7.2 (21.5) 320 320 320

8 2 H 834 (394) 52.7 (15.5) 0.48 3.51 (0.22) 4.3 (12.7) 3 20 32 0 320

3 H 815 (385) 66.9 (19.6) 0.61 4.46 (0.28) 8.1 (24.1) 320 320 320

4 H 775 (366) 73.7 (21.6) 0.67 4.91 (0.31) 11.3 (33.8) 32 0 320 32 0

1 0 2H 1029 (486) 67.0 (19.6) 0.61 4.46 (0.28) 7.3 (21.8) 415 420 410

3 H 1117 (527) 91.0 (26.7) 0.83 6.06 (0.38) 15.9 (47.4) 530 530 530

4 H 1057 (499) 100.0 (29.3) 0.91 6.66 (0.42) 22.3 (66.6) 5 30 53 0 530

1 2 2H 1175 (554) 78.0 (22.8) 0.71 5.19 (0.33) 10.3 (30.8) 49 0 500 49 0

3 H 1242 (586) 101.5 (29.8) 0.92 6.77 (0.43) 12.8 (38.4) 5 30 53 0 530

Note:

1. CFM = Cubic feet per minute

2. TMBH = Total capacity (MBH)

3. GPM = Gallons per minute

4. WPD = Water pressure drop (feet of water)

5. Q/ITD = MBH (kW)/(Entering water temperature - Entering air temperature) when DT and GPM (L/s) remain constant. To determine heating capacities at a different entering water

6. Medium and low speed capacities are approximately 80 percent and 60 percent respectively of the high speed capacity.

7. High static motors need the appropriate length of duct to prevent poor acoustical applications.

4 H 1181 (557) 113.0 (33.1) 1.03 7.53 (0.47) 14.9 (44.6) 5 30 53 0 530

temperature or entering air temp, compute the new ITD and multiply it by the Q/ITD shown.

Heating

CAB-PRC001-EN 21

Page 22

Performance

Steam

Data

Coils

Heating performance is based on 70 F (21 C) entering air temperature, 2 psig (14 kPa) and 5 psig (103 kPa) entering steam pressure.

All performance measured on high speed tap, zero ESP, with a throwaway filter.

Table PD-7. Free Discharge Motor, Group 1

Unit CFM TMBH TMBH 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (TkW) Q/ITD Watt Watt Watt

2 Steam 234 (110) 10.1 (2.9) 0.07 10.7 (3.1) 0.07 60 95 65

3 Steam 311 (147) 13.2 (3.9) 0.09 13.9 (4.1) 0.09 70 80 83

4 Steam 383 (181) 17.3 (5.1) 0.12 18.3 (5.4) 0.12 95 96 104

6 Steam 601 (284) 26.3 (7.7) 0.18 27.9 (8.2) 0.18 110 154 165

8 Steam 783 (370) 34.7 (10.2) 0.23 36.7 (10.8) 0.23 135 150 159

10 Steam 974 (460) 44.0 (12.9) 0.30 46.6 (13.7) 0.30 205 250 269

12 Steam 1104 (521) 51.1 (15.0) 0.34 54.2 (15.9) 0.35 230 246 263

Table PD-8. Free Discharge Motor, Group 2

Unit CFM TMBH TMBH 115V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (TkW) Q/ITD Watt Watt Watt

2 Steam 207 (98) 9.6 (2.8) 0.07 10.1 (3.0) 0.07 6 0 9 5 6 5

3 Steam 277 (130) 12.5 (3.7) 0.08 13.3 (3.9) 0.08 70 80 83

4 Steam 346 (163) 16.6 (4.9) 0.11 17.6 (5.1) 0.11 95 96 104

6 Steam 538 (254) 25.1 (7.4) 0.17 26.6 (7.8) 0.17 110 154 165

8 Steam 702 (331) 33.1 (9.7) 0.22 35.1 (10.3) 0.22 135 150 159

10 Steam 875 (413) 42.1 (12.3) 0.28 44.6 (13.1) 0.28 205 250 269

12 Steam 993 (469) 48.9 (14.3) 0.33 51.8 (15.2) 0.33 230 246 263

2 psig 5 psig

2 psig 5 psig

Table PD-9. Free Discharge Motor, Group 3

Unit CFM TMBH TMBH 115V 230V 277V

size Coil (L/s) (TkW) Q/ITD (TkW) Q/ITD Watt Watt Watt

2 Steam 195 (92) 9.3 (2.7) 0.06 9.9 (2.9) 0.06 6 0 9 5 6 5

3 Steam 259 (122) 12.2 (3.6) 0.08 12.9 (3.8) 0.08 70 80 83

4 Steam 328 (155) 16.2 (4.7) 0.11 17.1 (5.0) 0.11 95 96 104

6 Steam 507 (239) 24.5 (7.2) 0.16 26.0 (7.6) 0.17 110 154 165

8 Steam 662 (312) 32.3 (9.5) 0.22 34.3 (10.0) 0.22 135 150 159

10 Steam 827 (390) 41.1 (12.0) 0.28 43.6 (12.8) 0.28 205 250 269

12 Steam 938 (443) 47.7 (14.0) 0.32 50.6 (14.8) 0.32 230 246 263

Note:

Q/ITD = MBH (kW)/(Saturated Steam temperature - Entering air temperature) when DT and GPM remain constant. To determine heating capacities at a different saturated steam or

entering air temperature, compute the new ITD and multiply it by the Q/ITD shown.

2 psig 5 psig

CAB-PRC001-EN22

Page 23

Performance

Steam

Data

Coils

Heating performance is based on 70 F (21 C) entering air temperature, 2 psig (14 kPa) and 5 psig (103 kPa) entering steam pressure.

All performance measured on high speed tap, zero ESP, no filter.

Table PD-10. High Static Motor, Group 1

Unit CFM TMBH TMBH 11 5V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (TkW) Q/ITD Watt Watt Watt

2 Steam 208 (132) 10.8 (3.2) 0.07 11.5 (3.4) 0.07 145 145 145

3 Steam 358 (169) 13.9 (4.1) 0.09 14.7 (4.3) 0.09 140 140 140

4 Steam 393 (185) 17.5 (5.1) 0.12 18.5 (5.4) 0.12 170 180 170

6 Steam 658 (311) 27.3 (8.0) 0.18 28.9 (8.5) 0.18 245 240 240

8 Steam 901 (425) 36.7 (10.7) 0.25 38.9 (11.4) 0.25 320 320 320

10 Steam 1110 (524) 46.4 (13.6) 0.31 49.2 (14.4) 0.31 415 420 410

12 Steam 1264 (597) 54.0 (15.8) 0.36 57.2 (16.8) 0.36 490 500 490

Table PD-11. High Static Motor, Group 2

Unit CFM TMBH TMBH 11 5V 230V 277V

Size Coil (L/s) (TkW) Q/ITD (TkW) Q/ITD Watt Watt Watt

2 Steam 251 (119) 10.4 (3.0) 0.07 11.0 (3.2) 0.07 145 145 145

3 Steam 326 (154) 13.4 (3.9) 0.09 14.2 (4.2) 0.09 140 140 140

4 Steam 364 (172) 16.9 (5.0) 0.11 17.9 (5.3) 0.11 170 180 170

6 Steam 603 (285) 26.3 (7.7) 0.18 27.9 (8.2) 0.18 245 240 240

8 Steam 829 (392) 35.5 (10.4) 0.24 37.6 (11.0) 0.24 320 320 320

10 Steam 1024 (483) 44.9 (13.2) 0.30 47.6 (14.0) 0.30 415 420 410

12 Steam 1171 (553) 52.3 (15.3) 0.35 55.5 (16.3) 0.35 490 500 490

2 psig 5 psig

2 psig 5 psig

Table PD-12. Steam Properties

Steam Pressure PSIG (kPa) 2 (14) 5 (34) 10 (69) 15 (103)

Sat. Steam Temp. F (C) 219 (104) 227 (108) 239 (115) 250 (121)

Latent Heat — BTU/LB. (kJ/kg) 965 (2240) 960 (2230) 952 (2210) 945 (2200)

Note:

Q/ITD = MBH (kW)/(Saturated Steam temperature - Entering air temperature) when DT and GPM remain constant. To determine heating capacities at a different saturated steam or entering

air temperature, compute the new ITD and multiply it by the Q/ITD shown.steam pressure. All performance measured on high speed tap, zero ESP, with a throwaway filter.

CAB-PRC001-EN 23

Page 24

Fan Speed Switch

ZN.010 Control Board

ZN.510 Control Board

Controls

Control Options

Force–Flo cabinet heaters are available with four different control options:

• Manual three-speed fan switch

• Tracer ZN.010

• Tracer ZN.510

• Tracer ZN.520

Manual Fan Mode Switch

Model Number Digit 30 = A and Digit 31 = D or K

The manual fan mode switch is a four-position switch (off, high, medium, low) that

allows manual fan mode selection. The unit-mounted option (digit 31 = D) operates on

line voltage. The wall-mounted option (digit 31 = K) is low-voltage and has three 24 volt

relays using a factory-wired transformer and relays to control the fan motor.

Tracer® Controls

The Tracer family of controllers (ZN.010, ZN.510, and ZN.520) offer the combined

advantages of simple and dependable operation with the latest Trane-designed

controller. Standard control features include options normally available on more

elaborate control systems. All control options are available factory-configured or can

be field-configured using Rover

to the Trane publication,

Tracer ZN.010

Model Number Digit 30 = E

Tracer ZN.010 is a stand-alone microprocessor controller.

Tracer ZN.510

Model Number Digit 30 = F

ZN.510 can be used as either a stand-alone or communicating microprocessor

controller.

Tracer ZN.520

Model Number Digit 30 = G

The ZN.520 controller can be used in a stand-alone application or as part of a Trane

Integrated Comfort

In the stand-alone configuration, ZN.520 receives operation commands from the zone

sensor. The zone sensor module is capable of transmitting the following information to

the controller:

• Timed override on/cancel request

• Zone setpoint

• Current zone temperature

• Fan mode selection (off-auto-high-med-low)

For optimal system performance, Force–Flo units can be linked to an Integrated

Comfort™ System (ICS) building automation system controlled by Tracer Summit

The controller is connected directly to the Summit control panel via a twisted pair

communication wire, requiring no additional interface device (i.e., a command unit).

The Trane ICS system can monitor or override ZN.520 control points. This includes

such points as temperature and output positions.

™

Service Software

Rover

This windows-based software package option allows field service personnel to easily

monitor, save, download, and configure Tracer controllers through a communication

link from a portable computer. When connected to the communication link, Rover can

view any Tracer controller that is on the same communication link.

™

System (ICS).

™

service software. For more detailed information, refer

CNT-IOP-1 or CNT-IOP-2

.

®

.

CAB-PRC001-EN24

Page 25

Sequence of

Controls

Sequence of Operation

Fan Speed Switch

Off: Fan is turned off, two-position

damper option spring-returns closed.

High, Medium, Low: Fan runs continuously at the selected speed. The twoposition damper option opens to an

adjustable mechanical stop-position.

ZN.010 and ZN.510

Off: Fan is off; control valves and fresh air

damper option close.

Auto (Fan Cycling): Fan and fresh air

damper cycle with control valve option to

maintain setpoint temperature. In cooling

mode, the fan cycles from off to medium

and in heating mode it cycles from off to

low (factory default that can be fieldadjusted using Rover service software).

When heating is not required, the fan is

off and the fresh air damper option

closes. The fan can also be field-configured (using Rover) to run at a userdefined speed when the fan speed switch

is in the auto position.

Low, Medium, High (Continuous Fan): Fan

operates continuously while control valve

option cycles to maintain setpoint

Operation

temperature. Fresh air damper option is

open.

ZN.520

Off: Fan is off; control valve options and

fresh air damper options close.

:

Fan speed control in the auto

Auto

setting allows the modulating (three-wire

floating point) control valve option and

three-speed fan to work cooperatively to

meet precise capacity requirements,

while minimizing fan speed (motor/

energy/acoustics) and valve position

(pump energy). As the capacity requirement increases at low fan speed, the

water valve opens. When the low fan

speed capacity switch point is reached,

the fan switches to medium speed and

the water valve repositions to maintain an

equivalent capacity. The reverse sequence takes place with a decrease in

required capacity.

Low, Medium, High: The fan will run

continuously at the selected speed and

the valve option will cycle to meet

setpoint.

CAB-PRC001-EN 25

Page 26

General

Controls

Information

Table C-1. Controller Input/Output Summary

Binary Outputs

3-Speed Fan ===

2-Position Hydronic Valve ===

2-Position Fresh Air Damper ==

1-Stage Electric Heat ===

3-Wire Hydronic Valve =

2-Stage Electric Heat =

Generic ===

Binary Inputs

Occupancy ===

Generic Input ===

Analog Inputs

Zone Temperature ===

Setpoint ===

Fan Mode: Auto, High, Medium, Low ===

Entering Water ===

Discharge Air ===

Outside Air =

Generic =

Note: The generic input and output are for use with a Tracer Summit system only.

ZN.010 ZN.510 ZN.520

Table C-2. Controller Function Summary

Control Functions

Timed Override ===

Fan Cycling ==

Warm-Up ===

Data Sharing (Master/Slave) ==

Random Start ===

Staged Capacity (2-Stage Electric Supplementary) =

Other Functions

Manual Test ===

Maintenance Timer ===

Setpoint Limits ===

ZN.010 ZN.510 ZN.520

CAB-PRC001-EN26

Page 27

Zone Sensor

Zone Sensor Options

Zone sensors are available as either unit,

wall, or split-mounted options for design

flexibility. Cabinet heaters with the unitmounted zone sensor option include a

thermistor in the unit’s return air path.

Wall-mounted zone sensor options have

an internal thermistor. Zone sensors

operate on 24 VAC.

ZN.010

Controls

Options

Unit-mounted zone sensor: Digit 30 = E

and Digit 31 = V

ZN.510 and ZN.520

Unit-mounted zone sensor: Digit 30 = E

and Digit 31 = Z

Wall-mounted zone sensor: Digit 30 = E

and Digit 31 = W

Wall-mounted zone sensor: Digit 30 = E and

Digit 31 = 2

Split-mounted zone sensor, unit-mounted fan

mode and wall-mounted setpoint dial:

Digit 30 = E and Digit 31 = X

Split-mounted zone sensor, unit-mounted fan

mode and wall-mounted setpoint dial:

Digit 30 = E and Digit 31 = Y

CAB-PRC001-EN 27

Page 28

Controls

Features

Control Features

The following control functions are

standard features on units with Tracer

ZN.010, ZN.510, or ZN.520.

Occupied/Unoccupied Operation

The occupancy input utilizes a binary

switch (i.e. motion sensor, timeclock, etc.)

that allows the zone sensor to utilize it’s

unoccupied internal setpoints.

Random Start

This feature randomly staggers multiple

unit start-up to reduce electrical demand

spikes.

Warm-up

The two-position fresh air damper option

closes during the occupied mode when

the space temperature is three degrees or

more below the heating setpoint temperature. The damper remains closed

during warm-up until the space temperature is within two degrees of the heating

setpoint temperature.

Manual Output Test Function

This feature is an invaluable tool for

troubleshooting a unit. By simply

pressing the controller’s test button,

service personnel can manually exercise

outputs in a pre-defined sequence.

Peer to Peer Communication (ZN.510 and

ZN.520)

Peer to peer communication allows

multiple units in one space to share the

same zone sensor and provide simultaneous heating. The ZN.510 or ZN.520

controller can share information between

units on the same communication link

using a twisted pair wire in the field. Unit

configuration must be modified with

Rover service tool.

ZN.520 Additional Features

Fan Status

The ZN.520 controller monitors the fan

output status to determine if the fan is

operating.

Filter Maintenance Status

The controller has an adjustable timer

that indicates through Summit or Rover

when filter maintenance is necessary.

Filter maintenance status is based on

cumulative fan run hours.

Water Valve Override

Using Summit or Rover, the water valve

override function drives all water valves

in every unit fully open simultaneously.

This helps reduce the time required for

waterside balancing.

Cascade Control

The controller maintains discharge air

temperature using a cascade control

algorithm. The discharge air temperature

is based on the difference between the

space temperature and setpoint. Unit

capacity modulates to achieve the

discharge air temperature.

Interoperability

The ZN.520 controller can be used with a

Tracer Summit system or on other

control systems that suport LonTalk and

the SCC profile. For more information on

specific inputs and outputs, see the

Installation, Owner, and Maintenance

Manual, UNT-IOM-6

.

CAB-PRC001-EN28

Page 29

End Device

Control Valve

Two-Position Fresh Air Damper Actuator

Controls

End Device Options

All end device options are factoryinstalled and tested.

Two-Position Control Valves

Model Number Digits 27 and 28 = A - H

Two-position valve options are available

with either Tracer ZN.010, ZN.510, or

ZN.520. Valves are spring-return type,

sweat connections, and available as

normally open or closed. The valves

respond to a 24V signal and have

sweat connections. The two-way valve

option will either fully open or close. The

three-way valve option allows either full

water flow through the coil or diverts

waterflow through the bypass. If the

control valve loses power, the valve

returns to its de-energized position. All

control valve options are factory installed

in the leaving water piping downstream

of the hydronic coil. The valve actuator is

easily removable for service without

removing the valve body from piping.

Modulating Control Valves (ZN.520)

Model Number Digits 27 and 28 = J - R

1

/2-inch sweat connect valves are

These

three-wire floating point valves, equal

percentage type. Modulating valves are

available in four Cv sizes: 0.7, 1.5, 2.5, and

4.0. The valve responds to a 24V triac

signal from the controller, which determines the valve position by a control

algorithm. If the valve loses power, it

remains in the position that it was in

1

/2-inch

Options

when the power loss occurred. All

control valves are factory installed in the

leaving water piping downstream of the

hydronic coil.

Field-Supplied Valves

Model Number Digits 27 and 28 = X or Y

When using field-supplied valves, this

option allows the controller to be factoryconfigured for the normal position of the

field-supplied valve.

Note: The Trane Company does not

recommend wild coil applications.

Two-Position Fresh Air Damper Actuator

Model Number Digit 13 = D, E, or F

(Available with all control options except

ZN.520)

This damper actuator uses a 24V signal

and is factory-wired and mounted to the

damper assembly. It allows zero to 50%

fresh air. The damper will drive open to

an adjustable mechanical stop-position

whenever the fan is running during

occupied mode and will spring-return

closed when the fan turns off.

CAB-PRC001-EN 29

Page 30

Electrical Data

Minimum Circuit Ampacity

(MCA) and Maximum Fuse

Size (MFS) Calculations

Units with Electric Heat

HACR (heating, air conditioning, and

refrigeration) type circuit breakers are

required in the branch circuit wiring for all

units with electric heat. To compute MCA

and MFS, see Tables ED-2 through ED-5

on page 31 for motor FLAs and Tables

ED-6 through ED-8 on pages 32-33 for

electric heat amps.

Calculating electric heat amps:

Single stage, three phase =

heat kW * 1000/1.732/volts

Two stage, three phase =

total heat kW * 1000/1.732/volts

Note: Use 240V heat voltage for 230V

units.

Calculating MCA:

MCA = 1.25 * (heat amps + sum of all

motor FLAs)

Calculating MFS:

MFS = (2.25 * largest motor FLA) +

second motor FLA, size 10-12 units only +

heat amps

Use the closest larger fuse or HACR

circuit breaker above the MCA. Standard

fuse sizes are: 15, 20, 25, 30, 35, 40, 45,

50, 60 amps.

Electric heat MBH = heater kW * 3.413

Units Without Electric Heat

To compute MCA and MFS, see Tables

ED-2 through ED-5 on page 31 for motor

FLAs and Tables ED-6 through ED-8 on

pages 32-33 for electric heat amps.

Calculating MCA:

MCA = (1.25) x largest motor FLA +

second motor FLA, unit sizes 10-12 only

Calculating MFS:

MFS or HACR

amps for all units without electric heat.

1

HACR (heating, air-conditioning and

refrigeration) type circuit breakers are

required in the branch circuit wiring for

all size 10 and 12 units.

1

type circuit breaker = 15

Table ED-1. Decimal to Fractional HP (kW)

Conversion

Unit Size Decimal Fraction

02 .03

.07

03 .04

.05

.08

04 .05

.06

.10

.13

06 .07

.12

.16

.24

08 .12

.13

.24

10 .05 .07

.06 .12

.10 .16

.13 .24

12 .05 .12

.06 .13

.10 .24

.13 .24

Note:

Values for fractional HPs (kWs) are approximate values and

not necessarily the actual HP (kW).

1

/

30

1

/

15

1

/

25

1

/

20

1

/

12

1

/

20

1

/

16

1

/

10

1

/

8

1

/

15

1

/

8

1

/

6

1

/

4

1

/

8

1

/

8

1

/

4

1

1

/

/

20

15

1

1

/

/

16

8

1

1

/

/

10

6

1

1

/

/

8

4

1

1

/

/

20

8

1

1

/

/

16

8

1

1

/

/

10

4

1

1

/

/

8

4

30

CAB-PRC001-EN

Page 31

Electrical Data

Table ED-2. Free Discharge Motors on Units with Two-Row, Electric, or Steam Coils

FC FLA HP (kW) FLA HP (kW) FLA HP (kW) H M L

02 0.6 .03 (.02) 0.3 .03 (.02) 0.2 .03 (.02) 980 840 655

03 0.7 .04 (.02) 0.4 .04 (.02) 0.3 .04 (.02) 980 780 580

04 0.9 .05 (.04) 0.5 .05 (.04) 0.4 .05 (.04) 1050 780 580

06 1.2 .07 (.05) 0.6 .07 (.05) 0.5 .07 (.05) 1030 780 580

08 1.4 .12 (.09) 0.9 .12 (.09) 0.6 .12 (.09) 1080 800 600

10 0.9 1.2 .05 (.04) .07 (.05) 0.5 0.6 .05 (.04) .07 (.05) 0.4 0.5 .05 (.04) .07 (.05) 1050 780 580

12 0.9 1.4 .05 (.04) .12 (.09) 0.5 0.9 .05 (.04) .12 (.09) 0.4 0.6 .05 (.04) .12 (.09) 1050 780 580

Table ED-3. High Static Motors on Units with Two-Row, Electric, or Steam Coils

FC FLA HP (kW) FLA HP (kW) FLA HP (kW) H M L

02 1.1 .07 (.05) 0.6 .07 (.05) 0.5 .07 (.05) 1480 1110 865

03 1.4 .08 (.06) 0.7 .08 (.06) 0.6 .08 (.06) 1400 1175 860

04 1.6 .10 (.07) 0.8 .10 (.07) 0.7 .10 (.07) 1475 1315 1070

06 2.6 .16 (.12) 1.2 .16 (.12) 1.0 .16 (.12) 1400 1070 855

08 3.4 .24 (.18) 1.4 .24 (.18) 1.1 .24 (.18) 1475 1285 975

10 1.6 2.6 .10 (.07) .16 (.12) 0.8 1.2 .10 (.07) .16 (.12) 0.7 1.0 .10 (.07) .16 (.12) 1475 1315 1070

12 1.6 3.4 .10 (.07) .24 (.18) 0.5 0.9 .10 (.07) .24 (.18) 0.7 1.1 .10 (.12) .24 (.18) 1475 1315 1240

115 Volt 208-230 Volt 277-480 Volt RPM

1030 780 580

108 800 600

115 Volt 208-230 Volt 277- 480 Volt RPM

1400 1070 855

1475 1285 975

Table ED-4. Free Discharge Motors on Units with Three and Four-Row Coils

FC FLA HP (kW) FLA HP (kW) FLA HP (kW) H M L

02 0.6 .03 (.02) 0.3 .03 (.02) 0.2 .03 (.02) 980 840 655

03 0.8 .05 (.04) 0.5 .05 (.04) 0.4 .05 (.04) 1080 800 600

04 1.0 .06 (.04) 0.6 .06 (.04) 0.5 .06 (.04) 1080 800 600

06 1.4 .12 (.09) 0.9 .12 (.09) 0.6 .12 (.09) 1080 800 600

08 1.7 .13 (.10) 1.0 .13 (.10) 0.8 .13 (.10) 1080 800 600

10 1.0 1.4 .06 (.04) .12 (.09) 0.6 0.9 .06 (.04) .12 (.09) 0.5 0.6 .06 (.04) .12 (.09) 1080 800 600

12 1.0 1.7 .06 (.04) .13 (.10) 0.6 1.0 .06 (.04) .13 (.10) 0.5 0.8 .06 (.04) .13 (.10) 1080 800 600

115 Volt 208-230 Volt 277-480 Volt RPM

1080 800 600

1080 800 600

Table ED-5. High Static Motors on Units with Three and Four-Row Coils

FC FLA HP (kW) FLA HP (kW) FLA HP (kW) H M L

02 1.1 .07 (.05) 0.6 .07 (.05) 0.5 .07 (.05) 1480 1110 865

03 1.3 .08 (.06) 0.7 .08 (.06) 0.5 .08 (.06) 1500 1355 1110

04 2.1 .13 (.10) 0.9 .13 (.10) 0.7 .13 (.10) 1580 1375 1240

06 3.4 .24 (.18) 1.4 .24 (.18) 1.1 .24 (.18) 1475 1285 975

08 3.4 .24 (.18) 1.4 .24 (.18) 1.1 .24 (.18) 1475 1285 975

10 2.1 3.4 .13 (.10) .24 (.18) 0.9 1.4 .13 (.10) .24 (.18) 0.7 1.1 .13 (.10) .24 (.18) 1580 1375 1240

12 2.1 3.4 .13 (.10) .24 (.18) 0.9 1.4 .13 (.10) .24 (.18) 0.7 1.1 .13 (.10 ) .24 (.18) 1580 1375 1240

Note:

Actual rpm will vary with application and configuration.

115 Volt 208-230 Volt 277-480 Volt RPM

1475 1285 975

1475 1285 975

CAB-PRC001-EN 31

Page 32

Electrical Data

Table ED-6. Two-Stage Electric Heat (Digit 18 = U)

Unit 1st Stage Total Total

Size Volts Hz Ph Wires kW kW Amps/ph

02 277 60 1 2 1.0 3.0 10.9

03 277 60 1 2 2.0 6. 0 21.7

04 277 6 0 1 2 2. 5 7.5 27.1

06 277 60 1 2 4.5 10.5 38.0

08 277 60 1 2 6.0 13.5 48.8

10 277 60 1 2 8.0 18.0 65.0

12 277 60 1 2 9.0 20.0 72.3

Note: When both stages are on, the electric heat will operate only when fan is in high speed. All data based on

individual units.

208 1 2 0.75 2.25 10.9

240 1 2 1.0 3.0 12.5

208 3 3 0.75 2.25 6.3

240 3 3 1.0 3.0 7.3

480 3 4 1.0 3.0 3.7

208 1 2 1.5 4.5 21.7

240 1 2 2.0 6.0 25.0

208 3 3 1.5 4.5 12. 6

240 3 3 2.0 6.0 14.5

480 3 4 2.0 6.0 7.3

208 1 2 1.9 5. 7 27.5

240 1 2 2.5 7.5 31.3

208 3 3 1.9 5.7 15. 9

240 3 3 2.5 7.5 18.1

480 3 4 2.5 7.5 9.1

208 1 2 3.4 7.9 38.0

240 1 2 4.5 10.5 43.8

208 3 3 3.4 7.9 21.9

240 3 3 4.5 10.5 25.3

480 3 4 4.5 10.5 12.7

208 1 2 4.5 10.1 48.8

240 1 2 6.0 13.5 56.3

208 3 3 4.5 10.1 28.2

240 3 3 6.0 13.5 32.5

480 3 4 6.0 13.5 16.3

208 1 2 6.0 13.5 65.0

240 1 2 8.0 18.0 75.0

208 3 3 6.0 13.5 37.6

240 3 3 8.0 18.0 43.3

480 3 4 8.0 18.0 21.7

208 1 2 6.8 15.0 72.3

240 1 2 9.0 20.0 83.4

208 3 3 6.8 15.0 41.7

240 3 3 9.0 20.0 48.2

480 3 4 9.0 20.0 24.1

32

CAB-PRC001-EN

Page 33

Electrical Data

Table ED-7. Single-Stage, Max kW Electric Heat (Digit 18 = N)

Unit Heater Heater

Size Volts Hz Ph Wires kW Amps/ph

208 1 2 2.25 10.9

240 1 2 3.0 12.5

02 277 6 0 1 2 3.0 10.9

208 3 3 2.25 6.3

240 3 3 3.0 7.3

480 3 4 3.0 3.7

208 1 2 4.5 21.7

240 1 2 6.0 25.0

03 277 6 0 1 2 6.0 21.7

208 3 3 4.5 12.6

240 3 3 6.0 14.5

480 3 4 6.0 7.3

208 1 2 5.7 27.5

240 1 2 7.5 31.3

04 277 6 0 1 2 7.5 27.1

208 3 3 5.7 15.9

240 3 3 7.5 18.1

480 3 4 7.5 9.1

208 1 2 7.9 38.0

240 1 2 10.5 43.8

06 277 60 1 2 10.5 38.0

208 3 3 7.9 21.9

240 3 3 10.5 25.3

Note: All data based on individual units. Electric heat will operate only with fan at high speed.

480 3 4 10.5 12.7

Table ED-8. Single Stage, Low kW Electric Heat (Digit 18 = V)

Unit Size Voltage # Wires kW Amps/ph k W Amps/ph kW Amps/ph

02 208/60/1 2 0.75 3.7 1.5 7.3

0 3 208/60/1 2 2.25 10.9

0 4 208/60/1 2 2.25 10.9

0 6 208/60/1 2 2.25 10.9 3.3 15.9

0 8 208/60/1 2 2.25 10.9 3.3 15.9 4.5 21.7

1 0 208/60/1 2 2.25 10.9 3.3 15.9 5.7 27.5

1 2 208/60/1 2 2.25 10.9 3.3 15.9 6.6 31.8

Note: All data based on individual units. Electric heat will operate only with fan at high speed.

240/60/1 2 1.0 4.2 2.0 8.4

277/60/1 2 1.0 3.7 2.0 7.3

240/60/1 2 3.0 12.5

277/60/1 2 3.0 10.9

208/60/3 3 2.25 6.3

240/60/3 3 3.0 7.3

480/60/3 4 3.0 3.7

240/60/1 2 3.0 12.5

277/60/1 2 3.0 10.9

208/60/3 3 2.25 6.3

240/60/3 3 3.0 7.3

480/60/3 4 3.0 3.7

240/60/1 2 3.0 12.5 4.5 18.8

277/60/1 2 3.0 10.9 4.5 16.3

208/60/3 3 2.25 6.3 3.3 9.2

240/60/3 3 3.0 7.3 4.5 10.9

480/60/3 4 3.0 3.7 4.5 5.5

240/60/1 2 3.0 12.5 4.5 18.8 6.0 25.0

277/60/1 2 3.0 10.9 4.5 16.3 6.0 21.7

208/60/3 3 2.25 6.3 3.3 9.2 4.5 12.5

240/60/3 3 3.0 7.3 4.5 10.9 6.0 14.5

480/60/3 4 3.0 3.7 4.5 5.5 6.0 7.3

240/60/1 2 3.0 12.5 4.5 18.8 7.5 31.3

277/60/1 2 3.0 10.9 4.5 16.3 7.5 27.1

208/60/3 3 2.25 6.3 3.3 9.2 5.7 15.9

240/60/3 3 3.0 7.3 4.5 10.9 7.5 18.1

480/60/3 4 3.0 3.7 4.5 5.5 7.5 9.1

240/60/1 2 3.0 12.5 4.5 18.8 9.0 37.5

277/60/1 2 3.0 10.9 4.5 16.3 9.0 32.5

208/60/3 3 2.25 6.3 3.3 9.2 6.6 18.4

240/60/3 3 3.0 7.3 4.5 10.9 9.0 21.7

480/60/3 4 3.0 3.7 4.5 5.5 9.0 10.9

CAB-PRC001-EN 33

Page 34

Dimensions and Weights

Table DW-1. Operating Weights — lbs. (kg)

Unit Cabinet Concealed Recessed

Size Models Models Models

Table DW-2. Shipping Weights — lbs. (kg)

Unit Cabinet Concealed Recessed

Size Models Models Models

0 2 97 (44) 81 (37) 78 (35)

0 3 97 (44) 81 (37) 78 (35)

0 4 125 (57) 109 (49) 88 (40)

0 6 155 (70) 139 (63) 128 (58)

0 8 164 (74) 147 (67) 139 (63)

1 0 218 (99) 200 (91) 253 (115)

1 2 218 (99) 200 (91) 253 (115)

0 2 84 (38) 68 (31) 68 (31)

0 3 84 (38) 68 (31) 68 (31)

0 4 112 (51) 96 (44) 78 (35)

0 6 139 (63) 123 (56) 118 (54)

0 8 148 (67) 131 (59) 129 (59)

1 0 200 (91) 182 (83) 243 (110)

1 2 200 (91) 182 (83) 243 (110)

CAB-PRC001-EN34

Page 35

Dimensions

Vertical

Vertical Concealed, Model A

and Weights

Concealed

Vertical Concealed Unit Dimensions

Unit

Size 02-03 04 06 08 10-12

A2’-3 7/8” 2’-8 7/8” 3’-6 3/8” 4’-2 7/8” 5’-9 7/8”

B1’-9 5/16” 2’-2 5/16” 2’-11 13/16”3’-8 5/16” 5’-3 5/16”

C1’-10 13/16” 2’-3 13/16” 3’-1 5/16” 3’-9 13/16” 5’-4 13/16”

D1’-5 5/16” 1’-10 5/16” 2’-7 13/16” 3’-4 5/16” 4’-11 5/16”

E1’-7 5/16” 2’-0 5/16” 2’-9 13/16” 3’-6 5/16” 5’-1 5/16”

NOTE:1. Coil connections are always on the side opposite the control

box.

2. Coil connections are 5/8” O.D. sweat. See page 45 for locations.

3. All duct collar dimensions are to the outside of the collar.

4. See page 47 for fresh air opening dimensions.

CAB-PRC001-EN 35

Page 36

Dimensions

Vertical Cabinet, Model B

and Weights

Vertical Cabinet

Vertical Cabinet Unit Dimensions

Unit

Size 02-03 04 06 08 10-12

A2’-9 5/16” 3’-2 5/16” 3’-11 13/16”4’-8 5/16” 6’-3 5/16”

B1’-9 5/16” 2’-2 5/16” 2’-11 13/16”3’-8 5/16” 5’-3 5/16”

C7 5/8” 7 1/8” 8 7/8” 7 1/8” 7 5/8”

D1’-6” 2’-0” 2’-6” 3’-6” 5’-0”

E1’-7 5/16” 2’-0 5/16” 2’-9 13/16” 3’-6 5/16” 5’-1 5/16”