Page 1

®

Hardware Installation

Tracker™ Version 12

Building Automation System

BMTK-SVN01D-EN

Page 2

Page 3

®

Hardware Installation

Tracker™ Version 12

Building Automation System

BMTK-SVN01D-EN

February 2004

Page 4

Page 5

®

Tracker Version 12 Building Automation System Hardware Installation

This guide and the information in it are the property of American Standard Inc. and may not be used or reproduced in whole or in part,

without the written permission of American Standard Inc. Since Trane has a policy of continuous product improvement, it reserves the

right to change design and specification without notice.

Use of the software contained in this package is provided under a software license agreement. Unauthorized use of the software or

related materials discussed in this guide can result in civil damages and criminal penalties. The terms of this license are included with

the compact disk. Please read them thoroughly.

Although Trane has tested the hardware and software described in this guide, no guarantee is offered that the hardware and software

are error free.

Trane reserves the right to revise this publication at any time and to make changes to its content without obligation to notify any person of such revision or change.

Trane may have patents or patent applications covering items in this publication. By providing this document, Trane does not imply

giving license to these patents.

The following are trademarks or registered trademarks of Trane: Tracer, Tracker, Trane, Precedent, Rover, VariTrac, Vari-

®

™

™

Trane, and Voyager.

The following are trademarks or registered trademarks of their respective companies or organizations: LonMark, LonTalk,

®

and Neuron from Echelon Corporation; ReliaTel from Tone Software Corporation.

Printed in the U.S.A.

© 2004 American Standard Inc. All rights reserved.

BMTK-SVN01D-EN

Page 6

NOTICE:

Warnings and Cautions appear at appropriate sections throughout this manual. Read these carefully:

WARNING

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

CAUTION

Indicates a situation that may result in equipment or property-damage-only accidents.

®

The following format and symbol conventions appear at appropriate sections throughout this manual:

IMPORTANT

Alerts installer, servicer, or operator to potential actions that could cause the product or system to

operate improperly but will not likely result in potential for damage.

Note:

A note may be used to make the reader aware of useful information, to clarify a point, or to describe

options or alternatives.

◆ This symbol precedes a procedure that consists of only a single step.

BMTK-SVN01D-EN

Page 7

Contents

Chapter 1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Termination module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Main module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Display module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Model numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tracker controller specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

UCM maximum capacities for Tracker models 12 and 24 . . . . . . . . . . 10

UCM maximum capacities for Tracker model WSHP . . . . . . . . . . . . . . .11

Before installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Verify the shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inspect for shipping damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Store unused components until needed . . . . . . . . . . . . . . . . . . . . . 12

After installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FCC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2 Termination module mounting . . . . . . . . . . . . . . 15

Select a location for the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Verify location conformance to controller specifications . . . . . . . . 15

Verify location conformance to controller dimensions and

clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Verify location conformance to optimal touch screen viewing

angles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mount the termination module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Securing the termination module to a wall . . . . . . . . . . . . . . . . . . . 20

Securing the termination module to a conduit box . . . . . . . . . . . . 20

Installing electrical conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3 Termination board wiring . . . . . . . . . . . . . . . . . . . 23

Wire 24 Vac power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wire optional inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wire the alarm relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wire the priority shutdown device . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wire the utility pulse meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wire the thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

BMTK-SVN01D-EN i

Page 8

Contents

Wire the UCMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Wire specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

UCM wiring configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Termination resistor placement for Comm5 links . . . . . . . . . . . . . . 34

Wire supported UCMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Requirements for repeaters on Comm5 communication links . . . 37

Chapter 4 Main module mounting . . . . . . . . . . . . . . . . . . . . 41

Chapter 5 Display module mounting. . . . . . . . . . . . . . . . . . . 43

Chapter 6 PC workstation wiring. . . . . . . . . . . . . . . . . . . . . . 47

Verify PC workstation specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Direct connection to PC workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Modem connection to PC workstation . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Ethernet connection to PC workstation . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Connecting over an existing LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Connecting through a hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Connecting with one cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chapter 7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Service pin buttons and jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Symptom/action troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 8 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cleaning the touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Calibrating the touch screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix A Installation checklists . . . . . . . . . . . . . . . . . . . . . . 65

Appendix B Declaration of Conformity. . . . . . . . . . . . . . . . . . . 73

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

ii BMTK-SVN01D-EN

Page 9

®

Chapter 1

Overview

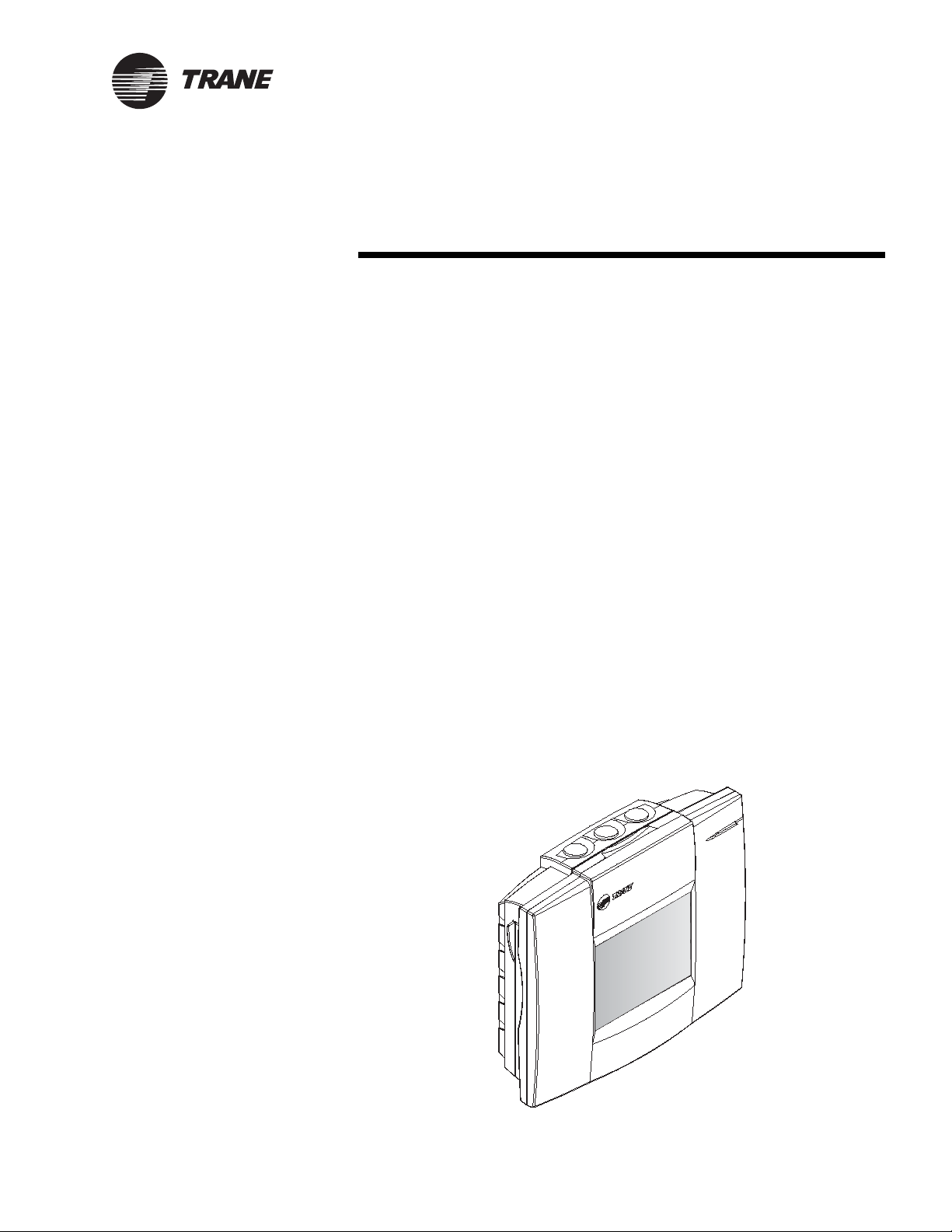

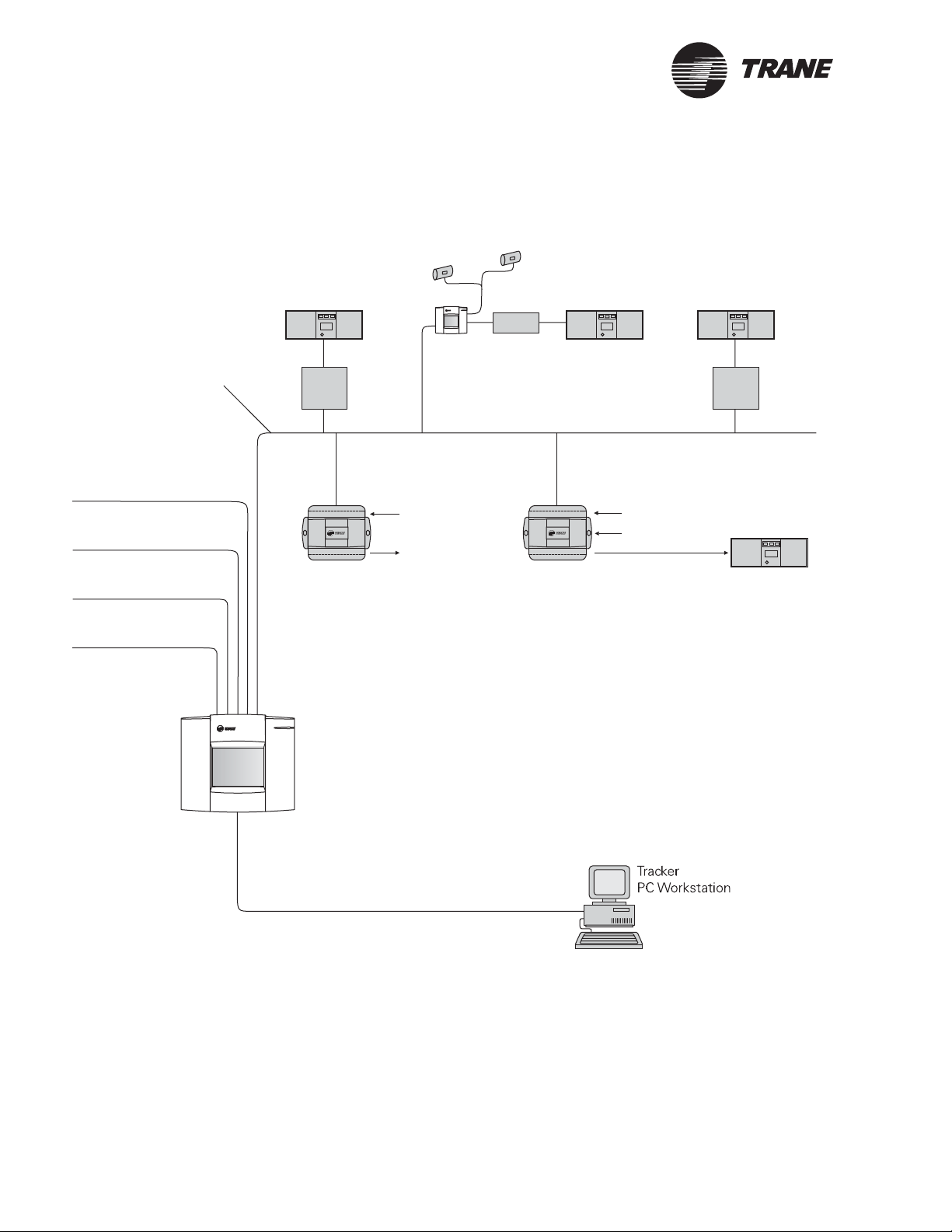

The Tracker building automation system (BAS) is an energy management

system for small- to medium-size buildings. The Tracker BAS controls

heating, ventilating, and air conditioning (HVAC) equipment. It consists

of a Tracker controller (Figure 1) and an optional PC workstation.

The Tracker BAS can be operated by using either a Tracker controller or a

PC workstation that is running Tracker PC Workstation software. A

visual interface enables an operator to set up and change HVAC

operating parameters and to collect and display building information.

The Tracker PC Workstation software allows a PC to be connected to the

Tracker controller directly with a prescribed adapter and cable, locally

over a standard Ethernet local area network (LAN) connection, or

remotely with a modem and standard phone line.

The Tracker BAS supports Comm5 communications architecture, which

is the Trane implementation of LonTalk

(Figure 2 on page 2 and Figure 3 on page 3) that includes HVAC and

other comfort-related equipment, such as Trane VariTrac zoning systems;

zoning controls; unit control modules (UCMs), which control and monitor

other HVAC equipment; Tracer LCI-V (LonTalk

interfaces for Voyager rooftop controls); Tracer LCI-R (LonTalk

communication interfaces for ReliaTel rooftop controls); external input/

output (I/O) devices, which help to monitor and control specific areas or

devices; and miscellaneous equipment such as sensors, lights, and fans.

®

protocol. It resides on a network

®

communication

®

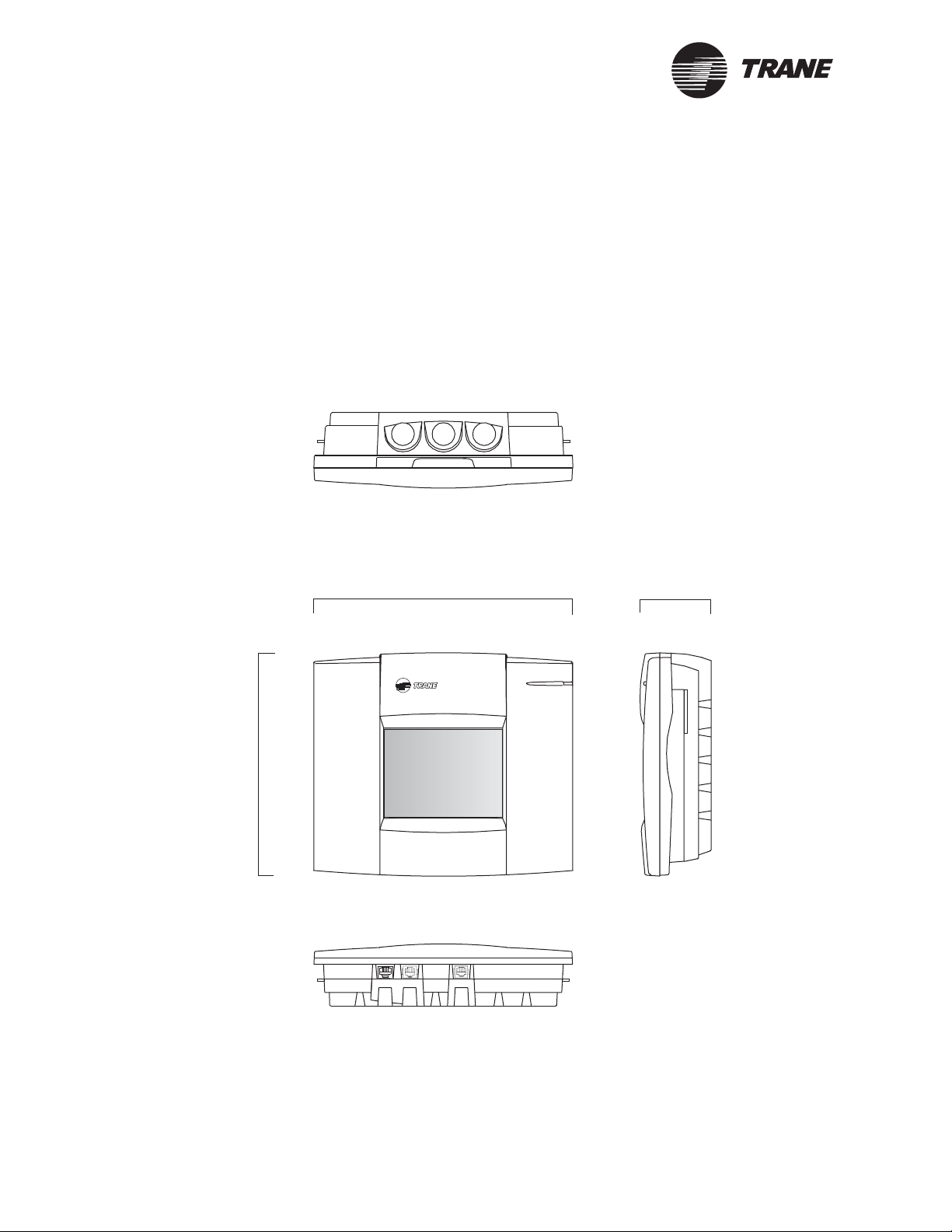

Figure 1. Tracker controller

BMTK-SVN01D-EN 1

Page 10

Chapter 1 Overview

Figure 2. Example Tracker building automation system (models 12 and 24) on a network

VariTrac or VariTrane

zone dampers

®

Interconnecting wiring

(Comm5 link): single, twisted

pair, shielded wire for twoway communication.

Utility pulse meter input

Outdoor air

temperature sensor input

Priority shutdown

contact input

Alarm relay output

Voyager constant

volume rooftop

Tracer

LCI-V

Tracer MP503

I/O module

Tracker

controller

VariTrac central

control panel

Universal inputs

Binary outputs

Voyager rooftop

TCI-V

Tracer ZN517

unitary controller

Precedent rooftop

with ReliaTel controls

Tracer

LCI-R

Analog inputs

Binary inputs

Binary outputs

Generic rooftop

Direct, dial-in (modem),

or Ethernet connection

2 BMTK-SVN01D-EN

Page 11

®

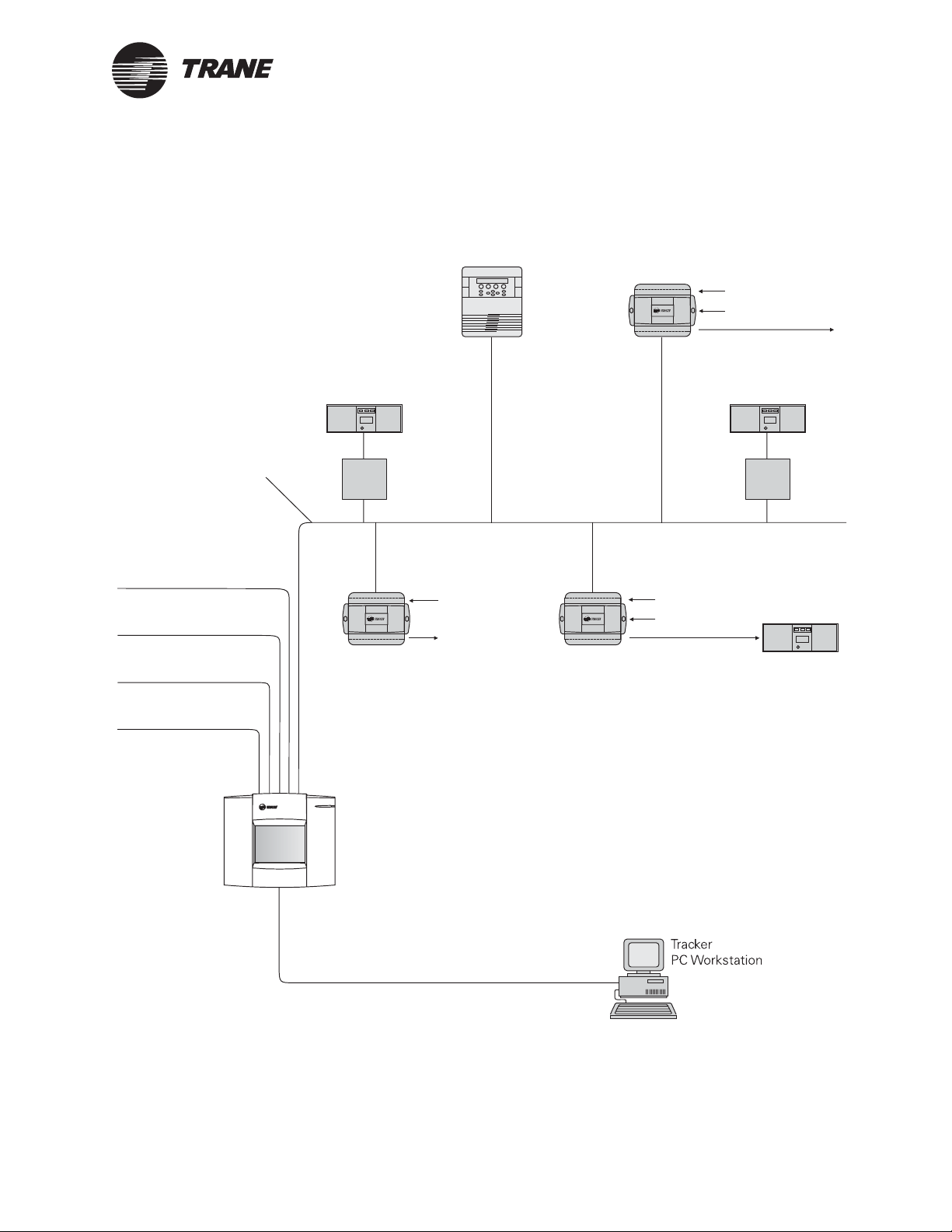

Figure 3. Example building automation system (water-source heat pump) on a network

Tracer loop controller

(for water-source

pump)heat

Tracer ZN510, ZN511, or

ZN524 controller

Analog inputs

Binary inputs

Binary outputs

Overview

Interconnecting wiring

(Comm5 link): single, twisted

pair, shielded wire for twoway communication.

Utility pulse meter input

Outdoor air

temperature sensor input

Priority shutdown

contact input

Alarm relay output

Voyager constant

volume rooftop

Tracer

LCI-V

Tracer MP503

I/O module

Tracker

controller

Universal inputs

Binary outputs

Tracer ZN517

unitary controller

Precedent rooftop

with ReliaTel controls

Tracer

LCI-R

Analog inputs

Binary inputs

Binary outputs

Generic rooftop

Direct, dial-in (modem),

or Ethernet connection

BMTK-SVN01D-EN 3

Page 12

Chapter 1 Overview

®

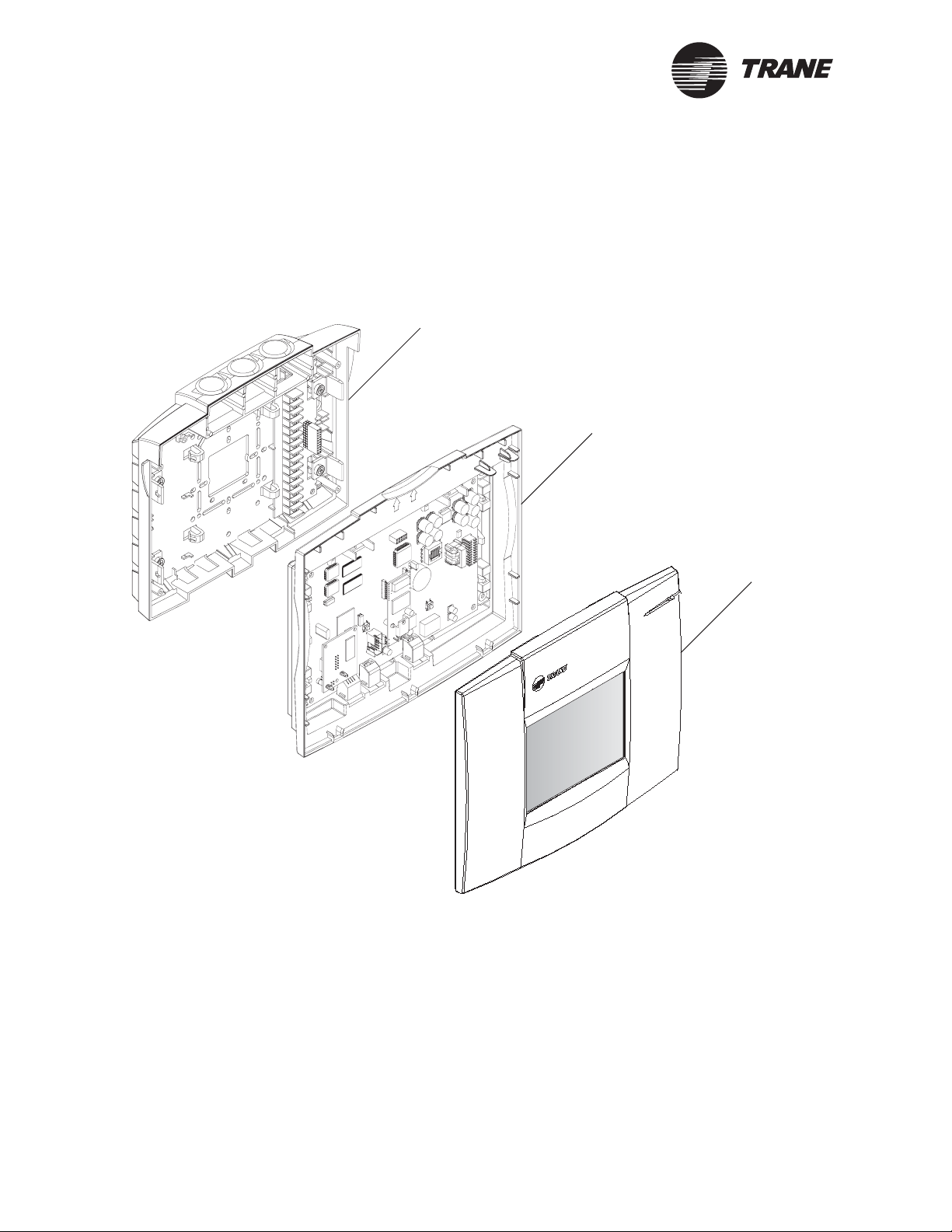

Controller components

The controller consists of a termination module, main module, and

display module (Figure 4).

Figure 4. Tracker controller components

Termination module

Main module

Display module

4 BMTK-SVN01D-EN

Page 13

Controller components

®

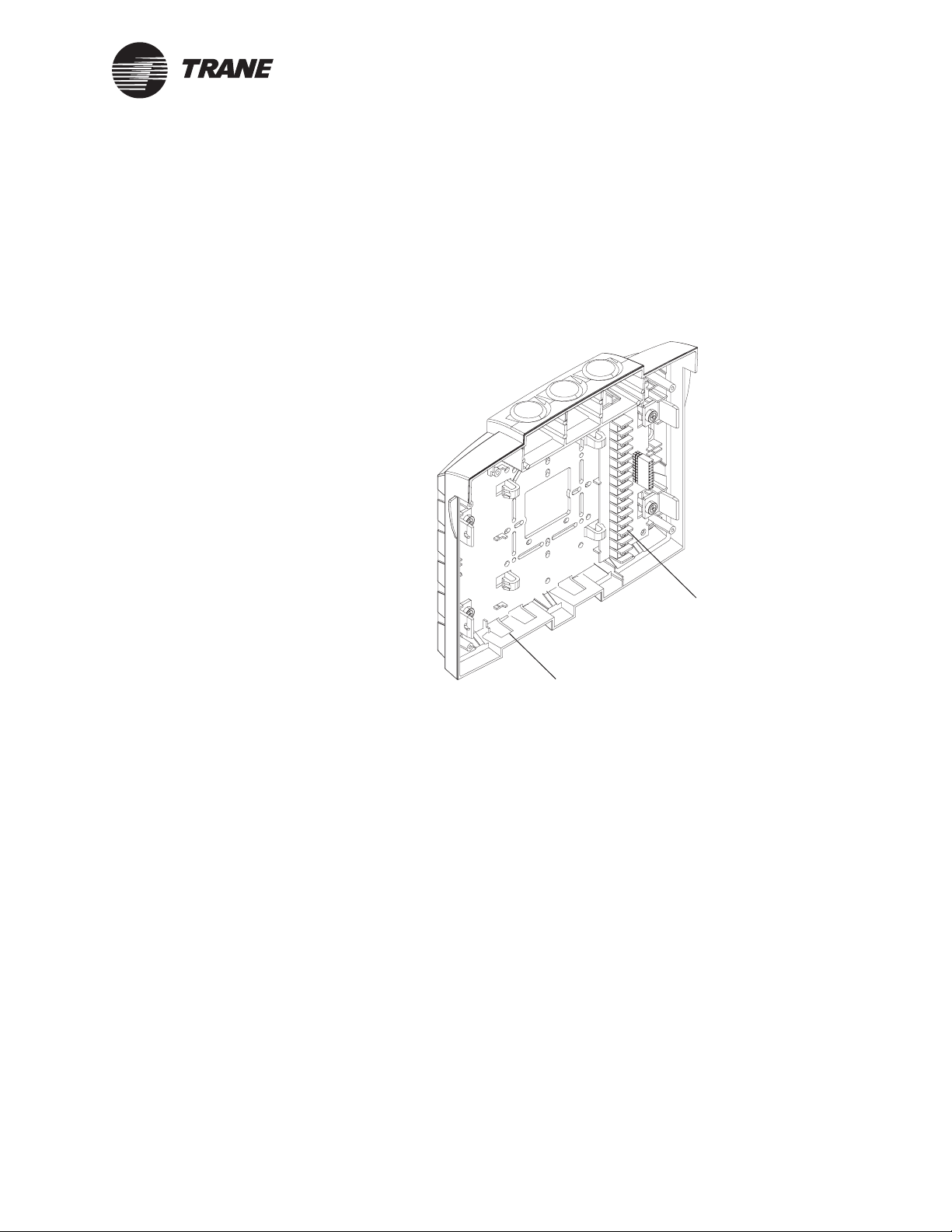

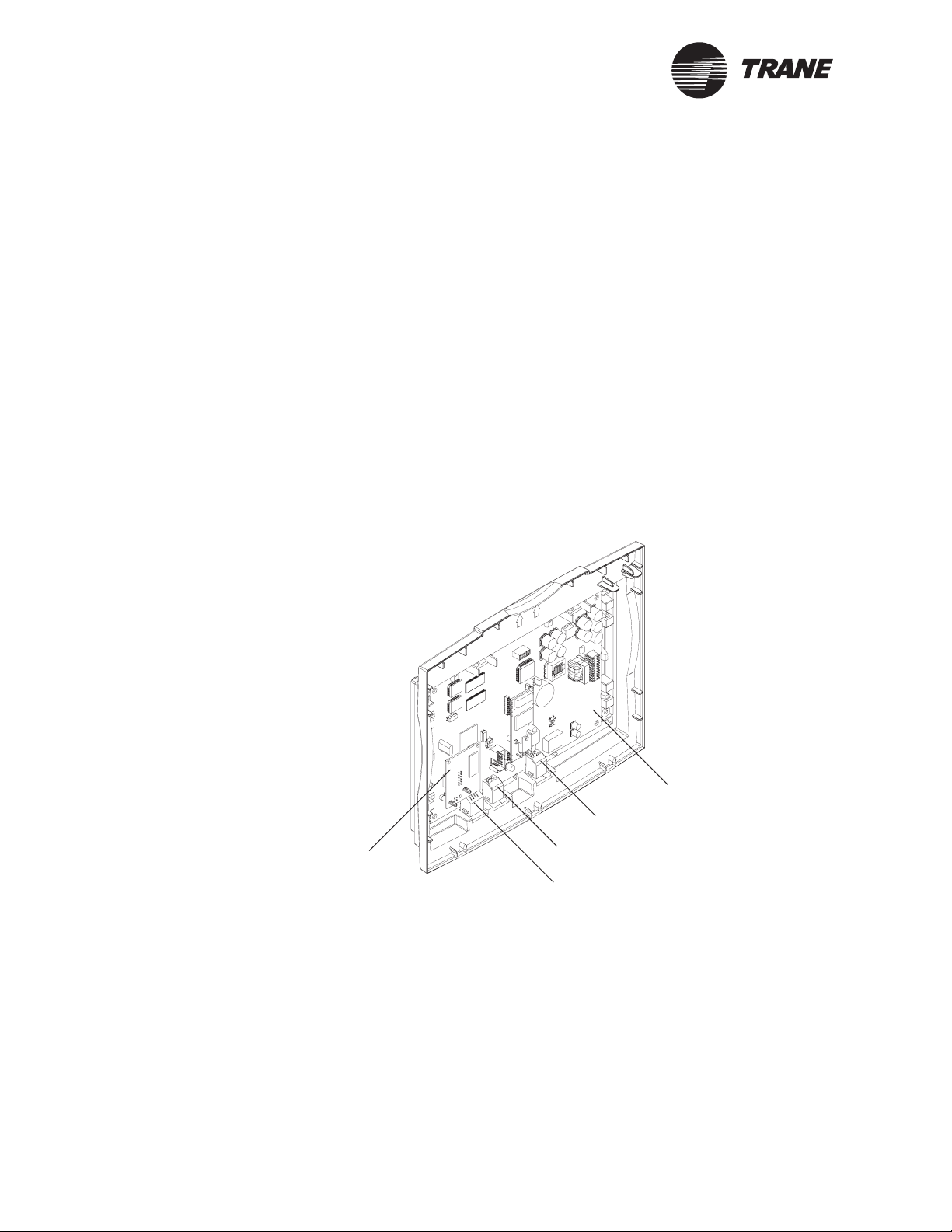

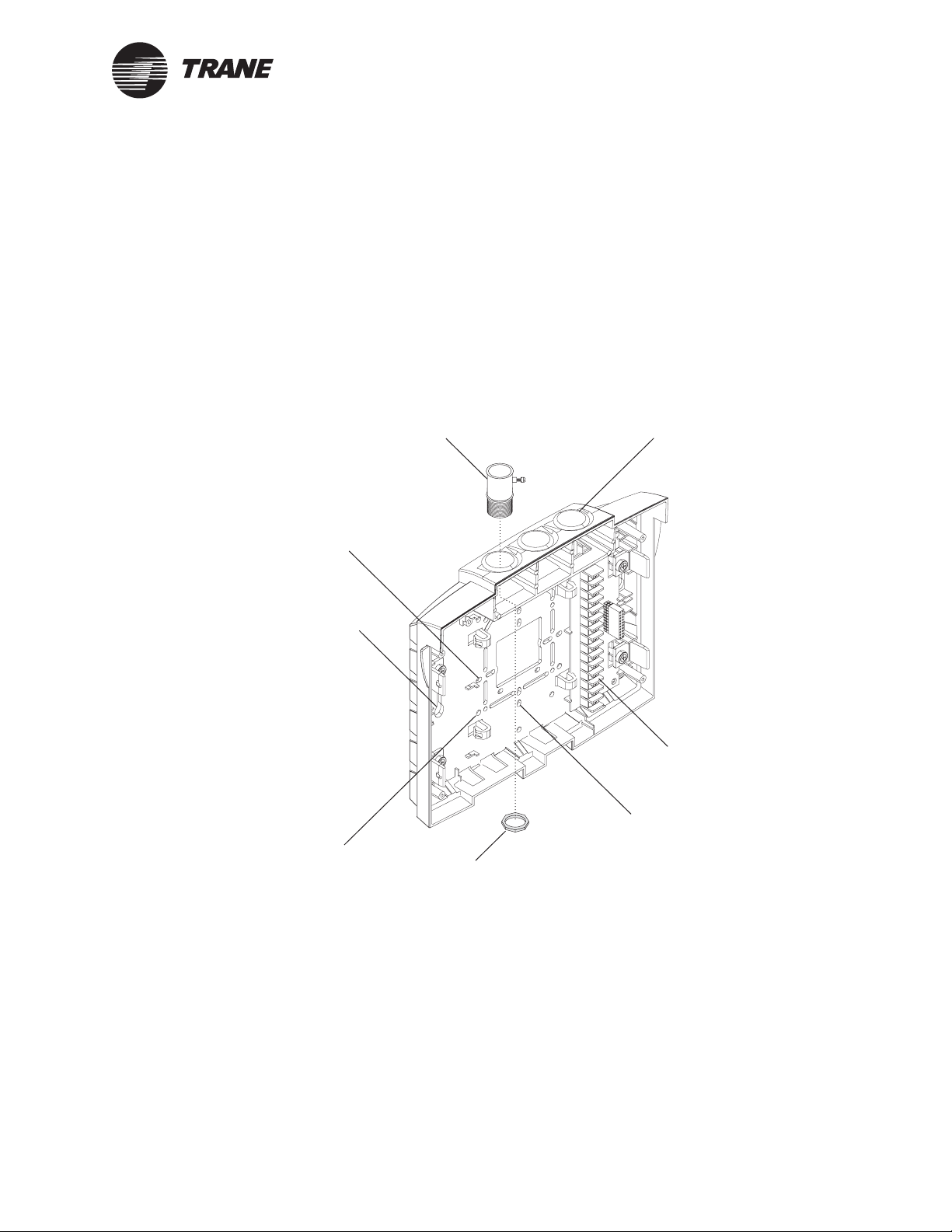

Termination module

The termination module (Figure 5) is a housing that provides a

termination board and cable access for power, communications, and

system input connections. Mounting holes enable it to be mounted on a

wall or a recessed conduit box. The termination board accepts connections

for power, communications, and system inputs.

Figure 5. Termination module

Cable access

(three places)

Termination

board

BMTK-SVN01D-EN 5

Page 14

Chapter 1 Overview

®

Main module

The main module (Figure 6) is a housing that contains the main logic

board and the Ethernet board. The main module can be “hot swapped”: it

can be removed and installed without removing power from the

termination module. When the main module is installed onto a powered

termination module, it receives power and begins to operate

automatically.

The main logic board provides an Ethernet LAN port, a PC interface port,

and a modem port. It provides an internal interface to termination

module I/O. It also provides Comm5 communication, 24 VAC power,

alarm, and communication indicators. It communicates and exchanges

data with the devices wired to the termination module. It also

communicates with the display module.

The Ethernet board provides two LED indicators. One shows that an

Ethernet link is detected; the other shows that there is serial traffic

between the Ethernet board and the main logic board.

Figure 6. Main module

Ethernet

board

Main logic board

Modem port

PC interface port

Ethernet LAN port

6 BMTK-SVN01D-EN

Page 15

Controller components

®

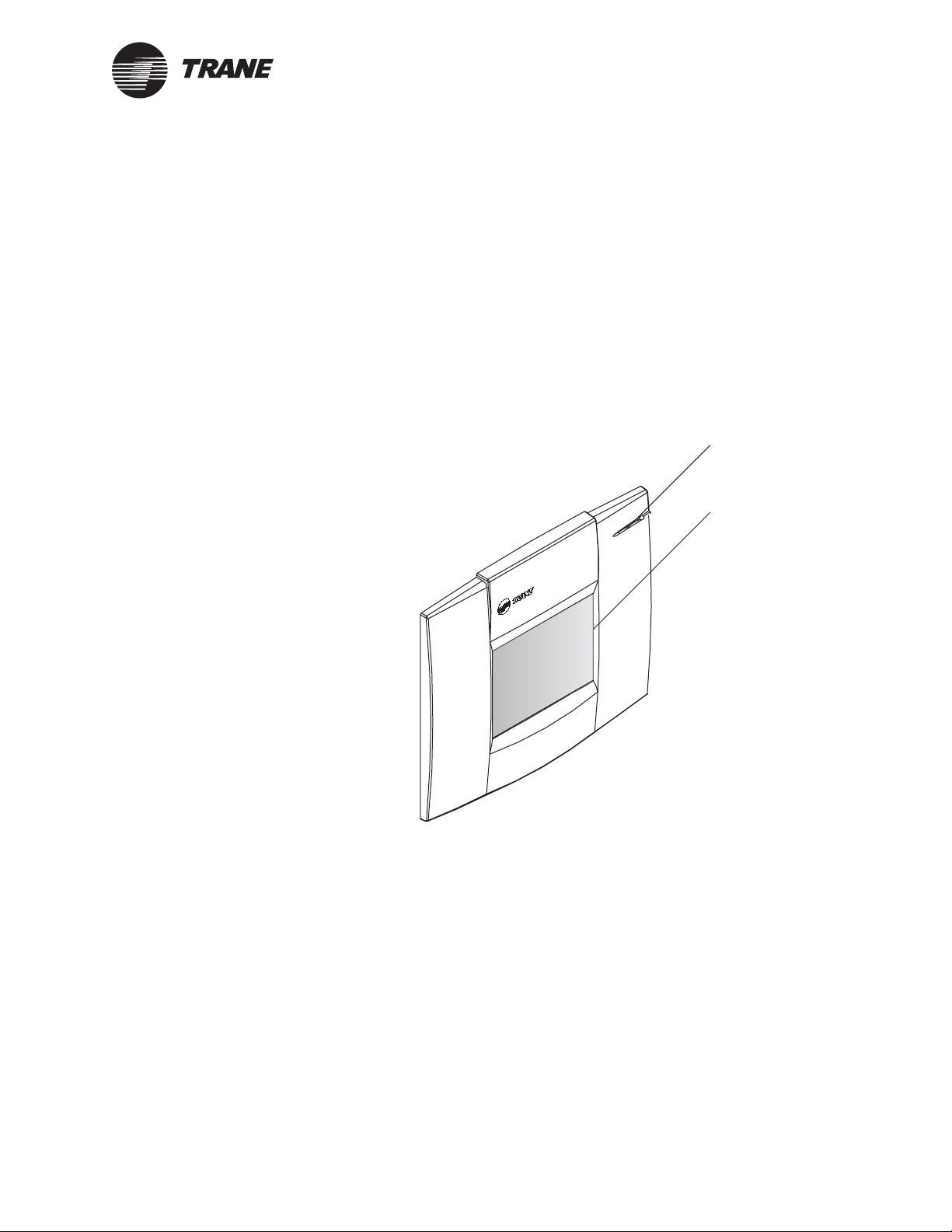

Display module

The display module (Figure 7) is a housing that contains a printed circuit

board, liquid crystal display (LCD) touch screen, and an alarm LED. The

printed circuit board supports the LCD touch screen and the alarm LED.

The touch screen provides the operator access to the user interface

program.

The display module can be “hot swapped:” it can be removed and installed

without removing power from the main module. When the display module

is installed onto a powered main module, it receives power and begins to

operate automatically.

Figure 7. Display module

Alarm LED

LCD touch screen

BMTK-SVN01D-EN 7

Page 16

Chapter 1 Overview

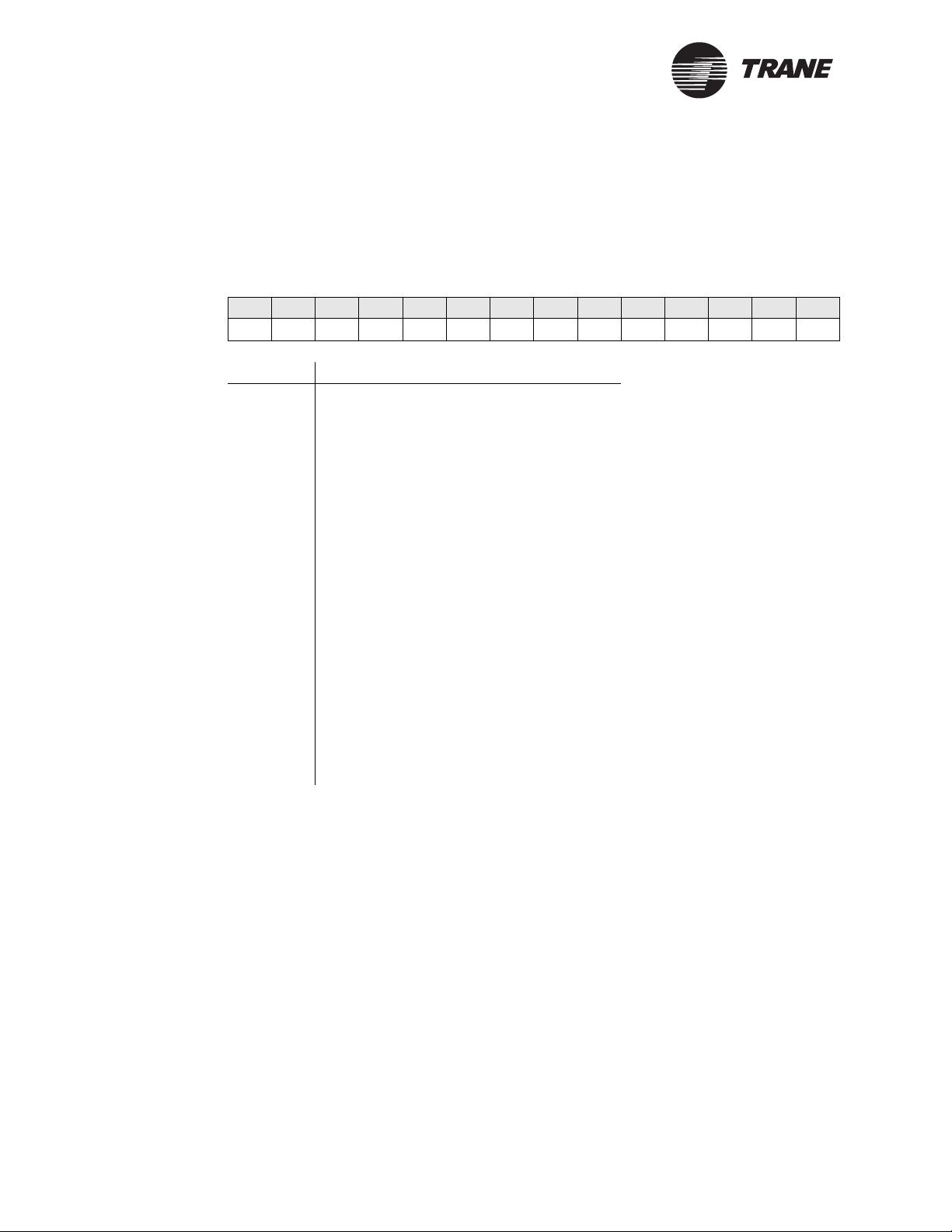

Model numbers

Each controller is identified by a model number that provides information

about the controller (Figure 8).

Figure 8. Model number definition

Digit number 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Model number B M T K 0 0 0 A A 0 A x 1 0

Digit Description

1–2 BM = Building management

3–4 TK = Tracker

5–7 Customer ID:

000 = Customer sales office (CSO)

KBB = Independent wholesale distributor (IWD)

8 A = 24 Vac, 50/60 Hz

9 Ethernet option

A = Modem with no Ethernet LAN option

B = Modem with Ethernet LAN option

10–11 0A = Design sequence

12 Model/software options:

1 = Model 12

2 = Model 24

3 = N/A

4 = N/A

5 = WSHP (water-source heat pump)

6 = N/A

13 Display options:

1 = LCD touch screen

14 Language options:

0 = English

®

8 BMTK-SVN01D-EN

Page 17

Tracker controller specifications

®

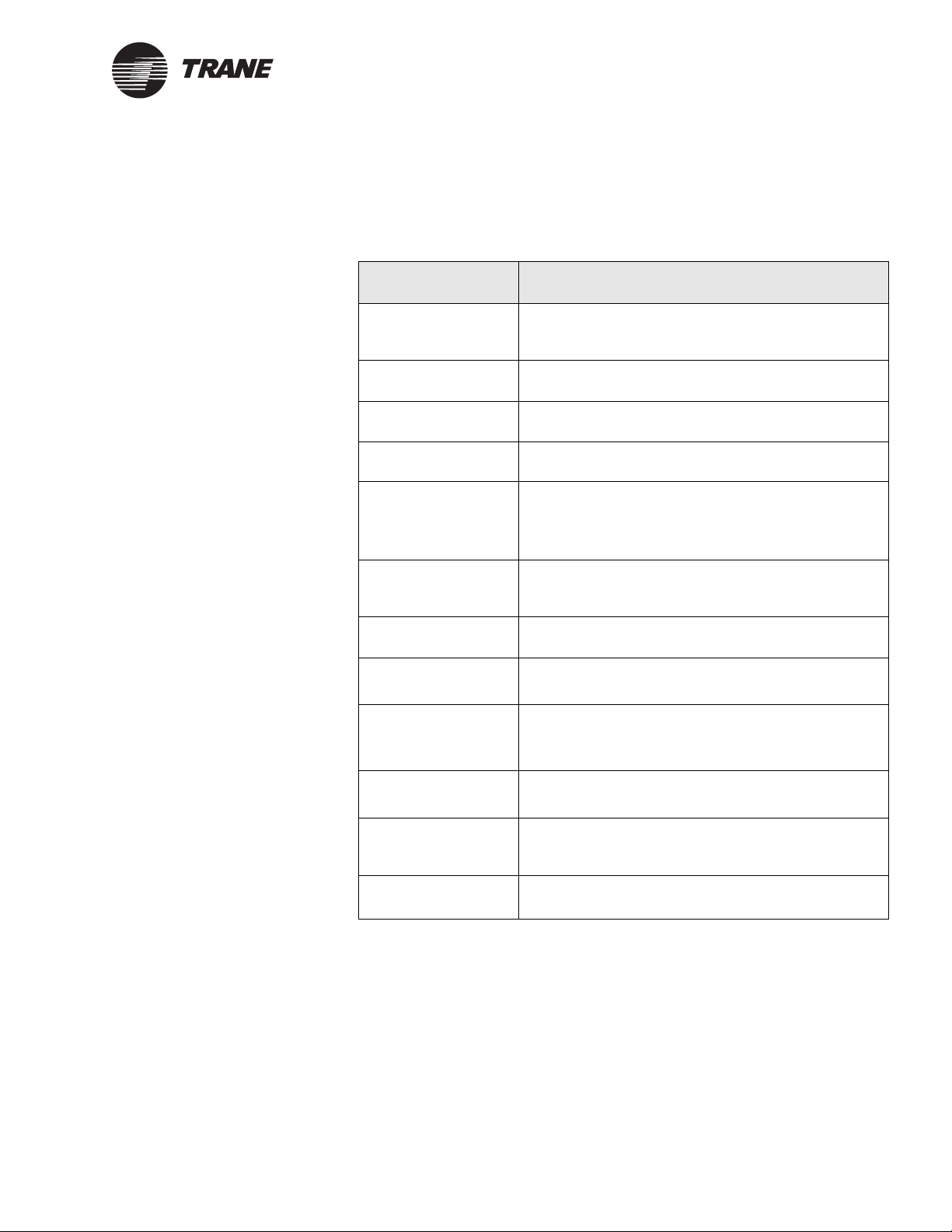

Tracker controller specifications

Table 1 shows the specifications for the Tracker controller.

Table 1. Tracker Controller specifications

Specification Description

Power 24 Vac nominal (19 Vac to 30 Vac),

50/60 Hz, 1 phase 40 VA minimum,

UL Class 2 transformer required

Operating environment

Storage environment From –40°F to 185°F (–40°C to 85°C)

Cabinet NEMA 1 resin enclosure—plenum rated

Mounting Flat wall surface with one of the following recessed

Dimensions Height: 8.75 in. (22.38 cm)

Weight 2.5 lb (1.13 kg)

From 32°F to 122°F (0°C to 50°C)

10% to 90% relative humidity, non-condensing

5% to 95% relative humidity, non-condensing

conduit boxes:

2 in. × 4 in. (5.08 cm × 10.15 cm)

4 in. × 4 in. (10.15 cm × 10.15 cm)

Width: 10.25 in. (26.04 cm)

Depth: 2.75 in. (6.99 cm)

Analog input

• Thermistor

Binary inputs

• Utility pulse meter

• Priority shutdown

Binary output

• Alarm relay

Memory backup At power loss, the system backs up memory and

Approvals See Appendix B, Declaration of Conformity.

10 k Ω at 77°F (25°C)

From –50°F to 200°F (–46°C to 93°C)

User-supplied dry contacts only. Tracker-supplied

voltage of 12 Vdc nominal (10 Vdc to 14 Vdc) at

12 mA nominal (10 mA to 14 mA).

Tracker-supplied single-pole single-throw (SPST) dry

contact rated at 24 Vac, 0.5 A maximum

stores all data for seven days. After seven days,

trends and alarms are not retained.

BMTK-SVN01D-EN 9

Page 18

Chapter 1 Overview

UCM maximum capacities for Tracker models 12 and 24

The Tracker model 12 and 24 controllers can control and monitor specific

types and numbers of Trane unit control modules (UCMs) as specified in

this topic. The supported UCMs are as follows:

• HVAC controllers that conform to the LonMark

troller (SCC) profile: the primary controller options are the Voyager

rooftop with a Tracer LCI-V, Precedent rooftop with ReliaTel controls

and a Tracer LCI-R, and Tracer ZN517 unitary controller. Other controllers are limited to the Tracer ZN510, ZN511, and ZN524.

• VariTrac central control panels (CCPs) with a TCI-V.

• Tracer MP503 I/O module.

Table 2 shows the maximum number of each UCM type that can be linked

to each Tracker controller model. Any combination of the specified UCMs

may be used in aggregate if they do not exceed the maximum. (For

example: A fully loaded Tracker 24 controller can control 24 SCC devices,

10 VariTrac CCPs, and 4 Tracer MP503 I/O modules.)

®

Space Comfort Con-

®

Trane VariTrac CCP is the main controller for either a changeover

The

bypass system configuration or a delivered variable air volume (VAV)

system configuration. Any combination of CCP configurations may be

used in aggregate, as long as they do not exceed the maximum.

Note:

• Each VariTrac CCP configured for changeover bypass can

control 1 HVAC device and up to 24 VAV UCMs.

• Each VariTrac CCP configured for delivered VAV can con-

trol 1 HVAC device and up to 32 VAV UCMs.

• See repeater information, “Requirements for repeaters on

Comm5 communication links” on page 37.

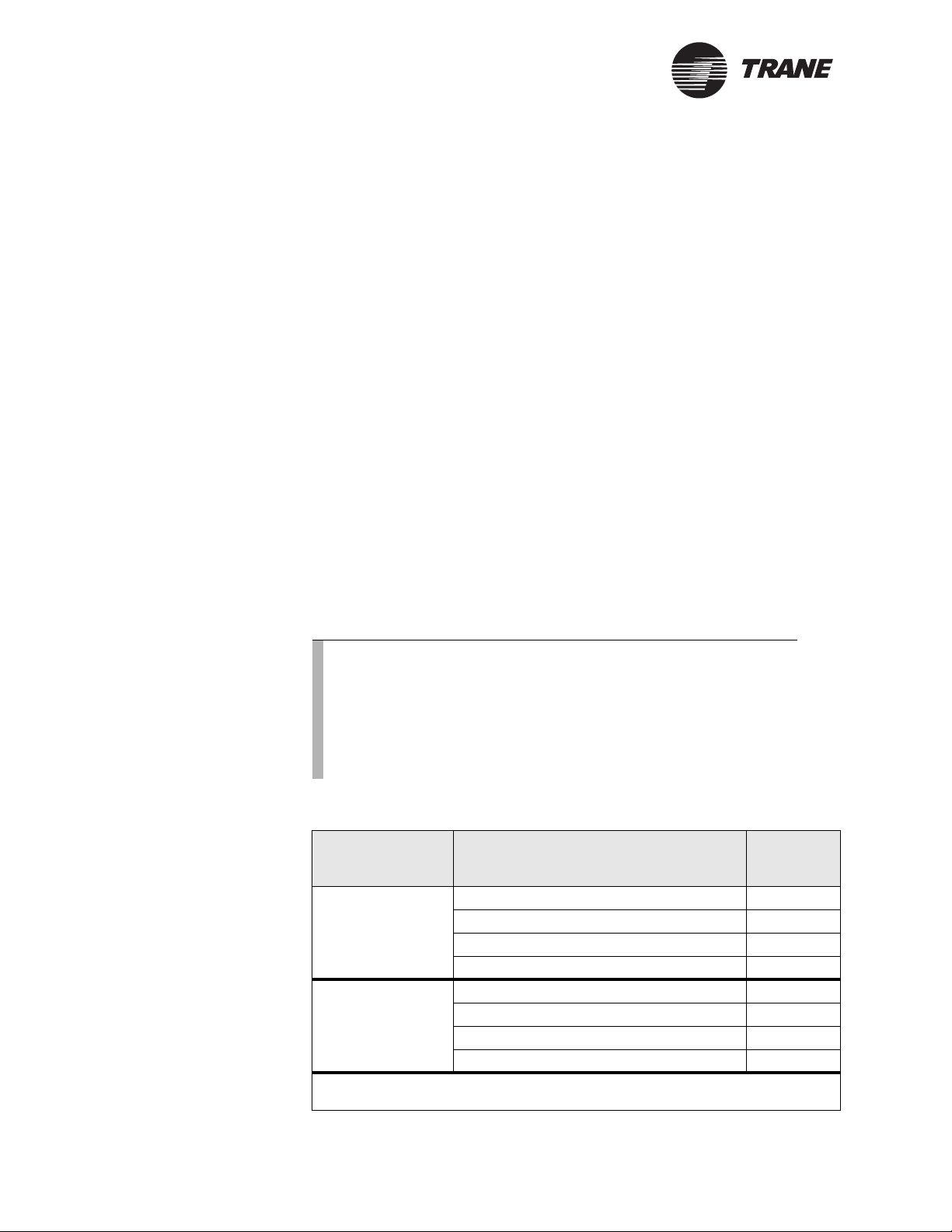

Table 2. Tracker controller models 12 and 24 UCM capacities

Tr a ck e r m o d e l UCM type

24 SCC* 24

Trane VariTrac CCP 10

Tracer MP503 I/O module 4

To t al maximum UCMs supported 38

12 SCC* 12

Trane VariTrac CCP 5

Tracer MP503 I/O module 4

To t al maximum UCMs supported 21

* SCCS supported by Tracker are limited to Voyager rooftops, Precedent rooftops with

ReliaTel controls, Tracer ZN517, ZN510, ZN511, and ZN524.

Maximum

UCMs

10 BMTK-SVN01D-EN

Page 19

UCM maximum capacities for Tracker model WSHP

®

UCM maximum capacities for Tracker

model WSHP

The Tracker model WSHP controller can control and monitor specific

types and numbers of Trane unit control modules (UCMs) as specified in

this topic. The supported UCMs are as follows:

• Space Comfort Controllers (SCCs): the primary controller options are

the Tracer ZN510, ZN511, and ZN524. Other controllers are limited

to Voyager rooftops with a Tracer LCI-V, Precedent rooftops with ReliaTel controls and a Tracer LCI-R, and Tracer ZN517 unitary controllers

• Tracer loop controller (TLC)

• Tracer MP503 I/O module

Table 3 shows the maximum number of each UCM type that can be linked

to each Tracker controller model. Any combination of the specified UCMs

may be used in aggregate if they do not exceed the maximum. (For

example: As the table shows, a fully loaded Tracker WSHP controller can

control 100 SCC devices, 1 Tracer loop controller (TLC), and 4 Tracer

MP503 I/O modules.)

Note:

See repeater information, “Requirements for repeaters on

Comm5 communication links” on page 37.

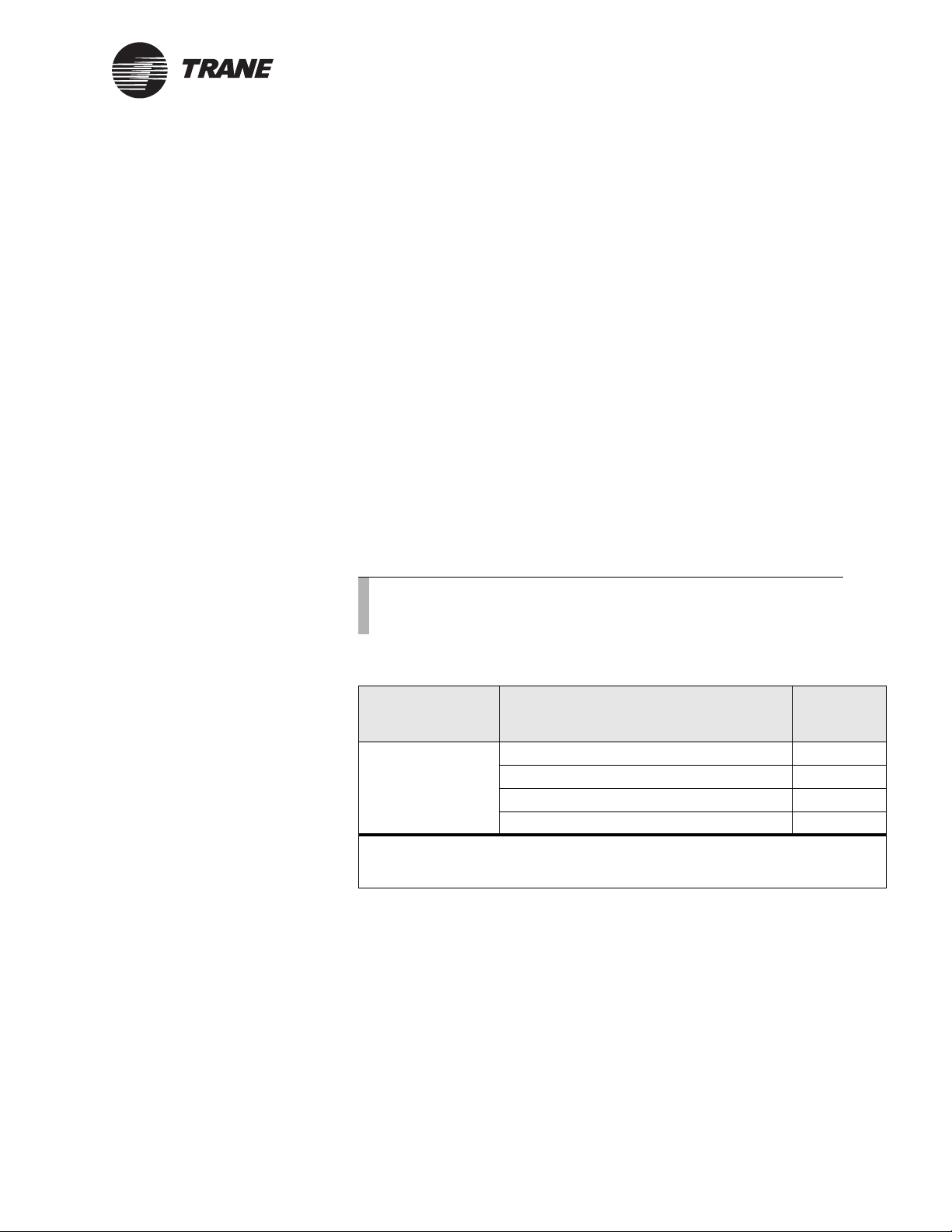

Table 3. Tracker controller model WSHP UCM capacities

Tr a ck e r m o d e l UCM type

WSHP SCC* 100

TLC** 1

Tracer MP503 I/O module 4

To t al maximum UCMs supported 105

* SCCS supported by Tracker are limited to Tracer ZN510, ZN511,and ZN524; Voyager

rooftops; Precedent rooftops with ReliaTel controls; and Tracer ZN517.

** The TLC is mandatory and must be present to enable SCC compressor operation.

Maximum

UCMs

IMPORTANT

SCC compressor operation will be enabled only when a TLC is communicating with the Tracker panel.

BMTK-SVN01D-EN 11

Page 20

Chapter 1 Overview

®

Before installation

Before beginning to install the Tracker controller, make sure that you

have all the necessary controller components and that they are

undamaged. Also, take steps to protect components until they are needed.

IMPORTANT

Before you install the Tracker hardware, review this guide and other

Tracker support literature and create an installation plan.

Verify the shipment

When the shipment arrives at the job site, carefully unpack the carton.

Even though outgoing orders are thoroughly reviewed before leaving the

factory, compare the items in the shipment with the shipping

authorization paper and verify that all items are present.

Verify that the controller model received is the model that you ordered

and write down the model number for use later.

Note:

Contact your sales office to order additional Tracker literature,

if needed.

Inspect for shipping damage

Inspect the items in the shipment to verify that no shipping damage or

loss occurred. If your inspection reveals damage or material shortage:

• Make the appropriate notation on the carrier delivery receipt.

• Immediately file a claim with the carrier, specifying the extent and

type of damage and/or shortage found.

• Notify the appropriate Trane representative.

Store unused components until needed

CAUTION

Avoid Equipment Damage!

Store all Tracker components off-site until most or all of the building

construction is complete. Failure to do so could result in damage to

components.

The termination module is shipped detached from the main module and

display module assembly. To protect the controller from damage, Trane

recommends storing the main module and display module assembly away

from the construction and/or installation site to prevent it from being

damaged or lost. Verify that the storage site conforms to the specifications

shown in Table 1 on page 9.

12 BMTK-SVN01D-EN

Page 21

®

After installation

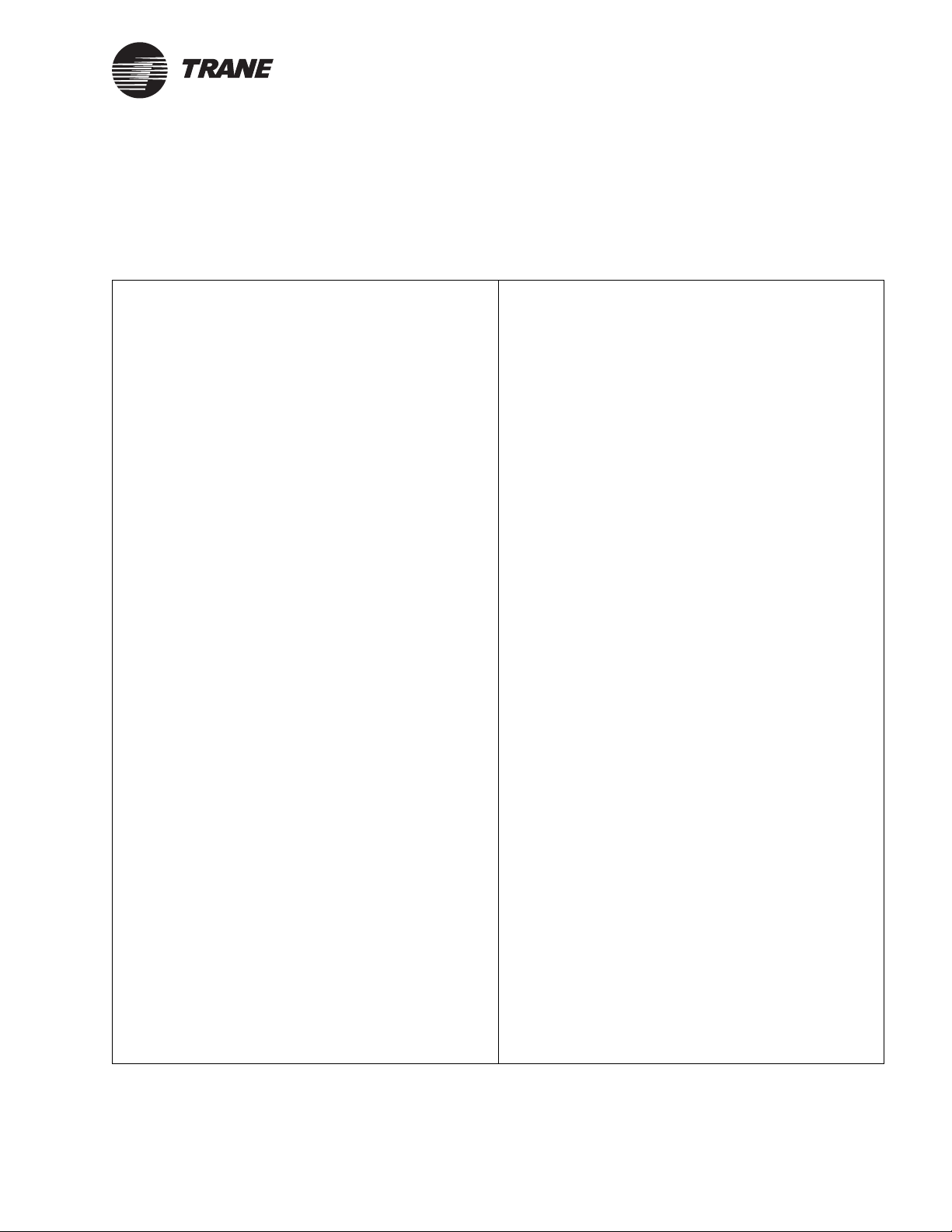

After installing the Tracker hardware, use the post-installation checklist

(Table 4) to verify that all installation procedures were completed.

Table 4. Tracker controller post-installation checklist

After installation

Inspect shipment upon receipt

_____ Verify that the shipment is complete.

_____ Inspect the controller and accessories to verify that

there has been no shipping damage or loss.

_____ File a damage claim with the carrier, if necessary.

_____ Verify that the controller received is the one that

was ordered.

_____ Write down the controller model number for use

later.

Verify termination module mounting

_____ Verify that the controller is in a safe indoor

environment.

_____ Verify that the location enables appropriate

personnel to access the controller.

_____ Verify that the controller is mounted securely with

recommended fasteners and screws.

_____ Verify that the installation conforms to controller

dimensions, recommended clearances, and

viewing angles.

Verify 24 Vac power wiring

_____ Verify that the power wiring complies with

applicable codes.

_____ Verify the 24 Vac power connection to the

controller termination Block TB1.

_____ Check the power wiring for shorts and improper

grounds.

_____ If using conduit connections, make sure separate

conduits are used for power and communications.

_____ Inspect the controller printed circuit card for

damage.

Verify input and output wiring

_____ Verify that wiring complies with specifications.

_____ Inspect all binary and analog terminations at TB1.

Verify communication wiring

_____ Verify that wiring complies with specifications.

_____ Inspect communication wiring between devices.

_____ Verify that all connections are properly shielded.

Verify wire terminations with a voltmeter

_____ Verify that the tests detailed in Table 18 on page 70

provide acceptable values.

Verify main module installation

_____ Verify that the main module is snapped in tightly

against the termination module.

_____ Verify that there is LED5 (HRT) activity.

Verify display module installation

_____ Verify that the display module is snapped in tightly

against the main module.

_____ Verify that the touch screen illuminates when

touched.

Verify direct and modem communication wiring

_____ Verify that the recommended cable is used for a

direct PC connection.

_____ Verify that the recommended adapter is used for

the direct connection cable.

_____ Verify that the direct connection cable is connected

to the correct Tracker port.

_____ Verify that the phone cable is connected to the

correct Tracker port.

Verify Ethernet communication wiring

_____ Verify that the recommended cable is used for the

connection.

_____ Verify that the Ethernet connection cable is

connected to the correct Tracker port.

BMTK-SVN01D-EN 13

Page 22

Chapter 1 Overview

®

FCC compliance

The Tracker controller generates, uses, and radiates radio frequency

energy and if not installed and used in accordance with the instruction

manual, may cause interference to radio and television reception. The

Tracker controller has been tested and found to comply with the limits for

a Class A computing device in accordance with the specifications in

Subpart J of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference in a commercial

installation.

There is no guarantee that interference will not occur in a particular

installation. If the Tracker controller does cause interference, consult a

radio or television technician for suggestions to correct the problem. Also,

the booklet How to Identify and Resolve Radio-TV Interference Problems

is available from the U.S. Government Printing Office, Washington DC

20402. Order stock number 004-000-00345-4.

14 BMTK-SVN01D-EN

Page 23

®

Chapter 2

Termination module mounting

After unpacking and inspecting the shipment, mount the termination

module. The mounting process for the termination module consists of

selecting a location and mounting the module. This chapter provides

information and procedures that enable you to mount the termination

module.

Select a location for the controller

When selecting a location for the Tracker controller:

• Select a location that is in a clean, non-corrosive, indoor environment.

The controller is only intended for indoor installation.

• Consider both security and control wire lengths when making the

selection.

• Select a location that limits controller access to operating and service

personnel.

• Select a location that conforms to the operating environment

described in Table 1 on page 9. The recommended operating environment will extend the life of the electronic components. Verify that the

location does not subject the controller to extreme operating conditions (including excessive vibration).

CAUTION

Avoid Equipment Damage!

Install the Tracker controller out of direct sunlight. Failure to do so may

cause overheating, which could result in equipment damage.

IMPORTANT

Do not install the Tracker controller near high-power radio signals, electrical switching gear, power buses, large motors, or other sources of

electrical noise. The electrical interference may lead to control malfunctions.

Verify location conformance to controller specifications

Verify that the selected location conforms to the applicable controller

specifications listed in Table 1 on page 9.

BMTK-SVN01D-EN 15

Page 24

Chapter 2 Termination module mounting

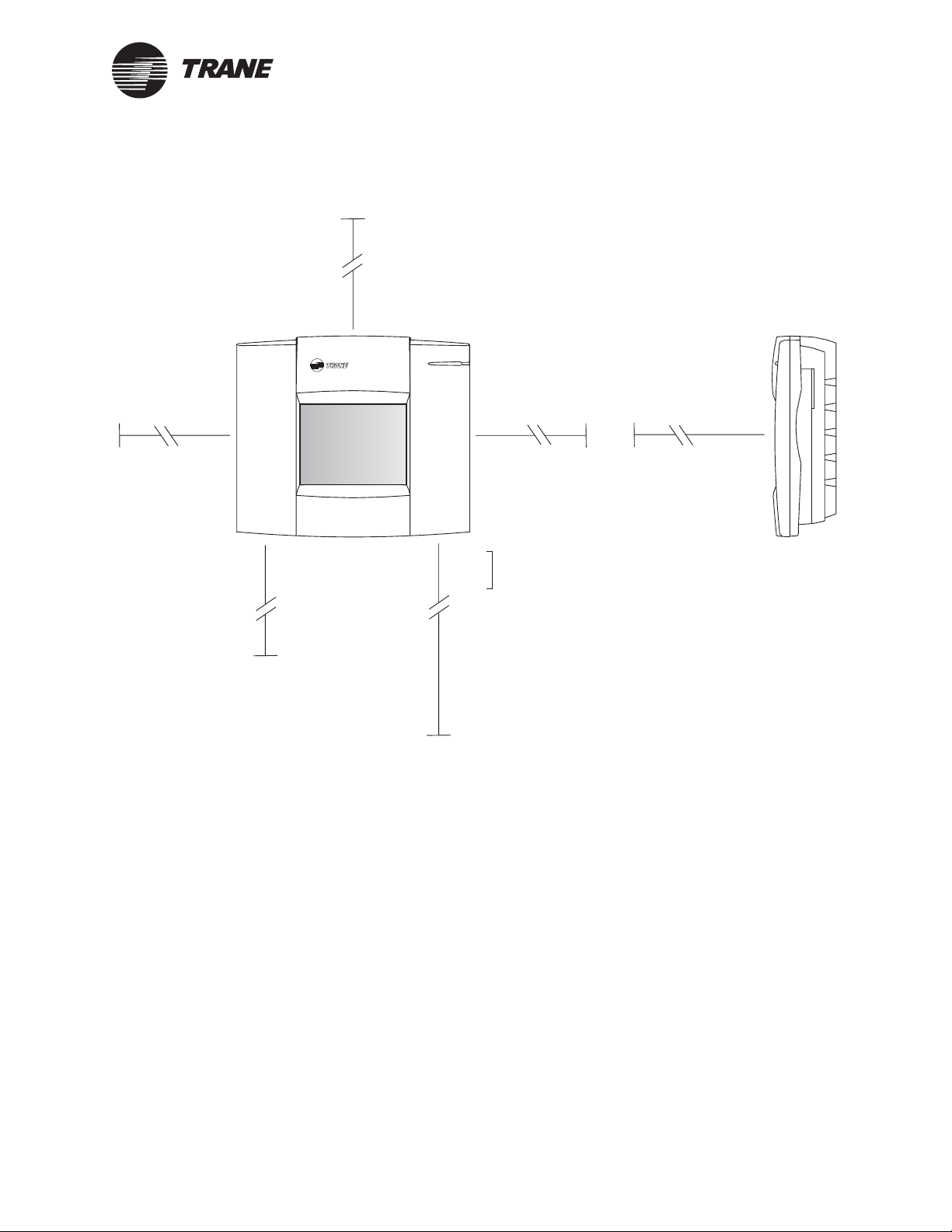

Verify location conformance to controller dimensions and clearances

Verify that the selected location provides enough space to accommodate

the controller (Figure 9) and its minimum clearances (Figure 10 on

page 17):

• The top clearance allows for ventilation and conduit entry.

• The bottom clearance allows for PC cable interface clearance.

• The front clearance allows for operation and service access.

Figure 9. Dimensions

®

8.75 in.

(22.38 cm)

Top view

10.25 in.

(26.04 cm)

Front view

2.75 in.

(6.99 cm)

Side view

Bottom view

16 BMTK-SVN01D-EN

Page 25

®

Figure 10. Minimum clearances

Select a location for the controller

12 in.

(30 cm)

12 in.

(30 cm)

12 in.

(30 cm)

54 in.

(1.4 m)

12 in.

(30 cm)

Distance

to floor

36 in.

(91 cm)

Front

Back

BMTK-SVN01D-EN 17

Page 26

Chapter 2 Termination module mounting

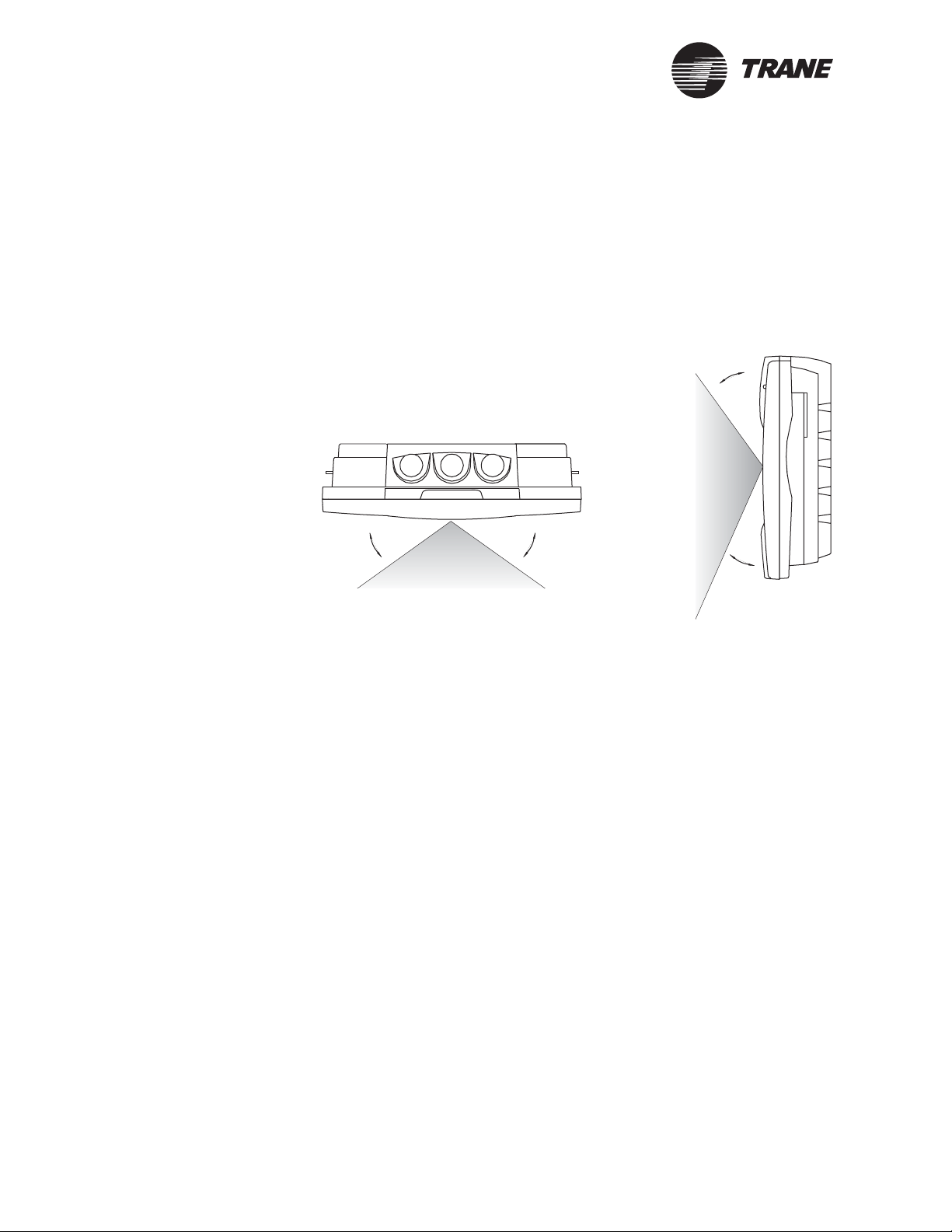

Verify location conformance to optimal touch screen viewing angles

Verify that the height and location enable the user to view the touch

screen at the optimal viewing angles (Figure 11).

Figure 11. Optimal touch screen viewing angles

Top view

40

o

®

Side view

40

o

40

o

25

o

18 BMTK-SVN01D-EN

Page 27

®

Mount the termination module

After selecting a suitable location for the Tracker controller, mount the

termination module. Mounting consists of securing the termination

module to a wall or a 2 in. × 4 in. recessed conduit box (mounted vertically

or horizontally) or a 4 in. × 4 in. recessed conduit box (several European

electrical box sizes are also usable) and installing electrical conduit

(optional). Figure 12 shows the conduit access and mounting holes on the

termination module.

Figure 12. Termination module conduit access and mounting holes

Conduit connector

Holes for mounting on a 2 in. x 4 in.

conduit box horizontally

(left and right)

Mount the termination module

Conduit access

(three places)

Two holes for mounting on a wall

(one on each side)

Holes for mounting on a

4 in. x 4 in. conduit box

(four corners)

Jamb nut

(attaches to

conduit connector)

Termination board

Holes for mounting on a 2 in. x 4 in.

conduit box vertically

(top and bottom)

BMTK-SVN01D-EN 19

Page 28

Chapter 2 Termination module mounting

Securing the termination module to a wall

1. Mark the location of the two mounting holes on the wall.

2. Set the termination module aside and drill mounting holes.

3. Secure the termination module to the wall with the supplied hardware (#10 × 1 in. screw with plastic anchor).

Securing the termination module to a conduit box

1. Remove the screws from the conduit box.

2. Line up the conduit box screw holes on the termination module

(Figure 12 on page 19) with the screw holes on the conduit box.

3. Install the screws.

Note:

When mounting the termination module to a 4 in. × 4 in.

conduit box, removing the plastic cover over the box will

provide easier access. Do not attempt to break away excess

plastic. Instead, use a hack saw blade and carefully cut away

the plastic.

®

20 BMTK-SVN01D-EN

Page 29

Mount the termination module

®

Installing electrical conduit

Use the conduit openings on the top of the Tracker termination module to

supply power or communication wires to the controller.

If the controller is mounted on a wall, you must use electrical conduit. If

the controller is mounted to a conduit box through which power, input/

output, and communications are supplied, you do not need to use

electrical conduit.

IMPORTANT

The 24 Vac wire conduit may not contain input/output or communication wires. Failure to comply will cause the Tracker controller to malfunction due to electrical noise.

7

1. Remove one of the

mination module (Figure 13).

2. Install

1

/2 in. (12 mm) conduit connector (Figure 12 on page 19) in

opening.

3. Install the conduit jamb nut on the conduit connector threads and

tighten it to secure the connector to the Tracker panel.

/8 in. (22 mm) diameter plugs at the top of the ter-

Figure 13. Electrical conduit installation

3.0 in.

(7.62 cm)

1.5 in.

(3.81 cm)

Termination module top view

ø 7/8 in.

(ø 22 mm)

0.75 in.

(2.02 cm)

BMTK-SVN01D-EN 21

Page 30

Chapter 2 Termination module mounting

®

22 BMTK-SVN01D-EN

Page 31

®

Chapter 3

Termination board wiring

After mounting the termination module, wire the termination board. The

wiring process consists of wiring the termination board to 24 Vac power,

inputs, outputs, and UCMs. This chapter provides information and

procedures that enable you to wire the termination board. Figure 14 on

page 24 shows all field wiring connections.

Refer to the required and optional supply checklists in Appendix A

(Table 15 and Table 16 on page 65) to verify that you have the materials

required to wire the Tracker controller. When termination board wiring is

complete, use the termination module post-installation checklist in

Appendix A (Table 18 on page 70) to verify the wiring.

BMTK-SVN01D-EN 23

Page 32

Chapter 3 Termination board wiring

Figure 14. Tracker field wiring connections

®

Line voltage

Line voltage

24 Vac

LOAD

1

2

3

4

5

6

7

8

9

10

11

24VAC

ALARM

RELAY

PRIORITY

SHUTDOWN

METER

INPUT

THERMISTOR

1

2

3

4

4

12

Comm5 deviceComm5 device

AA

BB

Comm5

link

AA

BB

Comm5

link

13

14

COMM

5

15

Splice

Legend

=

Transformer

Thermistor device per

=

Trane specifications

=

Termination resistor

Figure Notes:

1 All customer wiring must be in accordance with national, state, and local electrical codes.

2 Trane recommends a dedicated transformer for 24 Vac power.

3 Alarm relay circuit must not exceed 24 Vac, 1 A.

4 Do not apply voltage to the priority shutdown inputs.

5 Example of Comm5 communication link wiring. See product-specific literature for Comm5 wire connection details.

Twisted pair, shielded wire

=

per Trane specifications

=

Shield termination

=

Contact points

=

Earth ground

Shield ground

=

=

Figure note

24 BMTK-SVN01D-EN

Page 33

®

Wire 24 Vac power

After the termination module is mounted in the selected location, wire

24 Vac power to the termination board. Table 5 shows the specifications

for power wiring.

Table 5. Power wiring specifications

Wire 24 Vac power

24 Vac power

terminals

24 Vac

TB1-1, TB1-2,

Earth ground TB1-3

Description Wire specifications

Power input

24 Vac nominal (19–30 Vac), 50/60 Hz,

1 phase 40 VA minimum, class 2

transformer required

IMPORTANT

The 24 Vac wire conduit may not contain input/output or communication wires. Failure to comply may cause the Tracker controller to malfunction due to electrical noise.

1. Route input wires into the termination module through the conduit

box or any of the conduit access openings designated for input and

communication wiring (Figure 12 on page 19).

2. Wire the two 24 Vac power input wires and the ground wire to the

controller 24 VAC terminals (Figure 14 on page 24).

2

Trane recommends 18 AWG (1.02 mm

metal conduit.

Low voltage (24 Vac) wire must comply with

National Electrical Code (NEC) and federal, state,

and local electrical codes.

) wire and

BMTK-SVN01D-EN 25

Page 34

Chapter 3 Termination board wiring

Wire optional inputs and outputs

The Tracker controller provides input and output terminals as follows:

• Input for an optional priority shutdown device

• Input for an optional utility pulse meter

• Input for an optional outdoor air temperature sensor

• Output terminal for an optional alarm relay

Refer to Table 6 for input and output wire specifications, and to the

termination board wiring diagram in Figure 14 on page 24 for wiring all

inputs and outputs.

Table 6. Input and output wire specifications

®

Input and output

terminals

Alarm relay output

TB1-4, TB1-5

Priority shutdown

device input

TB1-6, TB1-7

Utility pulse meter

input

TB1-8, TB1-9

Thermistor input

TB1-10, TB1-11,

shield ground TB1-12

* All field-installed binary wiring is low voltage and must comply with National Electrical Code (NEC) and federal, state, and

local electrical codes.

† Alarm relay wires and 24 Vac wires may reside in the same conduit.

‡ Do not run input wires and ac power wires together in the same conduit or wire bundle.

Binary output

Dry contact

Operating range: 24 V, 1 A

maximum

Binary input

Operating range:

12 Vdc nominal

(10 Vdc to 14 Vdc) at

12 mA nominal

(10 mA to 14 mA)

< 50 Ω = switch closed

> 1000 Ω = switch open

Analog input for an outdoor air

temperature sensor

Operating range:

From –50ºF to 200ºF

(–46ºC to 93ºC)

Thermistor, 10 kΩ at 77°F (25°C)

Description Wire specifications

Trane recommends 18 AWG (1.02 mm

conduit.

Maximum length = 1000 ft (305 m) *†

Trane recommends 18—22 AWG (1.02 mm

wire and metal conduit.

Maximum length = 1000 ft (305 m) *‡

Shielded wire, 18—22 AWG (1.02 mm

twisted pair

Maximum length = 300 ft (91 m) *‡

2

) wire and metal

2

—0.643mm2)

2

—0.643mm2)

26 BMTK-SVN01D-EN

Page 35

Wire optional inputs and outputs

®

Wire the alarm relay

Wire the alarm relay to the termination board output.

CAUTION

Avoid Equipment Damage!

Use a dedicated power transformer for this output. Failure to do so will

damage the main module, if the alarm output is powered from the

Tracker 24 Vac input (TB-1 and TB-2) and the circuit shorts to ground.

1. Route input wires into the termination module through a conduit

opening (Figure 12 on page 19) or the conduit box.

2. Connect the wires to the ALARM RELAY terminals on the termination board (Figure 14 on page 24).

3. Connect the other end of the wires to the customer-supplied power

supply and load.

Wire the priority shutdown device

Wire the priority shutdown device to the termination board input.

1. Route input wires into the termination module through a conduit

opening (Figure 12 on page 19) or the conduit box.

2. Connect the wires to the PRIORITY SHUTDOWN terminals on the

termination board (Figure 14 on page 24).

3. Connect the other end of the wires to the contacts of the priority shutdown device.

BMTK-SVN01D-EN 27

Page 36

Chapter 3 Termination board wiring

Wire the utility pulse meter

Wire the utility pulse meter to the termination board input.

1. Route input wires into the termination module through a conduit

2. Connect the wires to the METER INPUT terminals on the termina-

3. Connect the other end of the wires to the pulsed-output contacts of

Wire the thermistor

The thermistor input is for a Trane outdoor air temperature sensor only.

The input cannot be used for any other purpose. Using wire that meets

the specifications listed in Table 6 on page 26, wire the thermistor to the

termination board input.

1. Route input wires into the termination module through a conduit

2. Connect the wires to the THERMISTOR terminals on the termination

®

opening (Figure 12 on page 19) or the conduit box.

tion board (Figure 14 on page 24).

the electrical meter.

opening (Figure 12 on page 19) or the conduit box.

board (Figure 14 on page 24).

3. Connect the shield to the ground terminal.

Note:

The thermistor input is not polarity sensitive.

4. Connect the other end of the wires to the thermistor device.

IMPORTANT

Tape the shield at the sensor. Any connection between the shield and

ground will cause a malfunction.

28 BMTK-SVN01D-EN

Page 37

Wire the UCMs

®

Wire the UCMs

The Comm5 communication link connects unit control modules (UCMs)

to the Tracker termination module. Each controller has one Comm5

communication link. This topic includes information and procedures for

wiring a UCM to a termination module:

Note:

Do not exceed the maximum number of UCMs that can

communicate on a Tracker controller (see “UCM maximum

capacities for Tracker models 12 and 24” on page 10 for details).

Wire specifications

Tracker Comm5 communication-link and sensor wiring is low-voltage

Class 2 wire and must be field-supplied and installed in compliance with

NEC and local codes. To prevent electrical noise interference, all wiring

must comply with requirements outlined in this topic for wire selection

and link-wiring topology.

Trane recommends that you use Level 4 (Echelon) shielded cable for the

Tracker communication link wiring between the Tracker and the Comm5

UCMs to which it communicates. Trane also recommends that you use it

for communication wiring between the VariTrac CCP and its associated

VariTrac or VariTrane UCMs, and for sensor wiring to these devices.

Level 4 cable is available in shielded, plenum and non-plenum versions.

Level 4 cable is available from Trane-approved suppliers as well as other

suppliers. Table 7 on page 30 shows the Trane approved suppliers;

Table 8 on page 31 provides the specifications for Level 4 compliant

cables.

BMTK-SVN01D-EN 29

Page 38

Chapter 3 Termination board wiring

Table 7. Trane-approved wire suppliers

®

Supplier Cable type

Connect-Air International

Phone: 1-800-247-1978

FAX: 1-253-813-5699

Level 4

22 AWG

(0.643mm2)

Number of

pairs

Details

1 Shielded plenum

UL type CMP

Catalog

number

W221P-2002

Web: www.connect-air.com

Windy City Wire

Phone: 1-800-379-1191

FAX: 1-708-493-1380

Level 4

22 AWG

(0.643mm

Level 4

22 AWG

(0.643mm

2

)

2

)

1 Shielded non-plenum

UL type CM

1 Shielded plenum

UL type CMP

W221P-1003

106500

Web: www.smartwire.com

Level 4

22 AWG

(0.643mm

Category 4 cable is not the same as Level 4 cable and should not be used. The Echelon Level 4 cable specification was originally

defined by the National Electrical Manufacturers Association (NEMA) and differs from the Category 4 specification proposed

by the Electronic Industries Association/Telecommunications Industry Association (EIA/TIA).

2

)

1 Shielded non-plenum

UL type CM

10760 0

30 BMTK-SVN01D-EN

Page 39

Wire the UCMs

®

Table 8. Specifications for Echelon Level 4 compliant cables

Specification Valu e

dc resistance

(Maximum resistance of a single

copper conductor regardless of

whether or not it is solid or

stranded and regardless of

whether or not it is metal coated.)

dc resistance unbalance (maximum)

Mutual capacitance of a pair

(maximum)

Pair-to-ground unbalance (maximum)

Characteristic impedance 772 kHz

1.0 M H z

4.0 MHz

8.0 MHz

10.0 MHz

16.0 MHz

20.0 MHz

Attenuation (maximum dB/1000

feet at 20°C)

772 kHz 4.5 dB/1000 feet at 20°C

1.0 MHz 5.5 dB/1000 feet at 20°C

4.0 MHz 11.0 dB/1000 feet at 20°C

8.0 MHz 15.0 dB/1000 feet at 20°C

10.0 MHz 17.0 dB/1000 feet at 20°C

16.0 MHz 22.0 dB/1000 feet at 20°C

20.0 MHz 24.0 dB/1000 feet at 20°C

Worst-pair near-end crosstalk

(minimum)

(Values shown are for information

only. The minimum NEXT coupling loss for any pair combination at room temperature is to be

greater than the value determined

using the formula NEXT

)>NEXT(0.772)-15

(F

MHz

log10

(F

772 kHz 58 dB

1.0 M H z 56 d B

4.0 MHz 47 dB

8.0 MHz 42 dB

10.0 MHz 41 dB

16.0 MHz 38 dB

/

20.0 MHz 36 dB

MHz

0.72) for all frequencies in the

range of 0.772 MHz–20 MHz for a

length of 1000 feet.)

dc resistance unbalance (maximum)

Ω/1000 feet at 20°C

18.0

5%

17 pF/foot

1000 pF/foot/1000 feet

102

Ω ± 15%

100

Ω ± 15%

Ω ± 15%

100

Ω ± 15%

100

100

Ω ± 15%

Ω ± 15%

100

Ω ± 15%

100

5%

BMTK-SVN01D-EN 31

Page 40

Chapter 3 Termination board wiring

UCM wiring configurations

The Tracker UCM Comm5 communication-link wiring must be installed

in a daisy-chain configuration (Figure 15 on page 32 and Figure 16 on

page 33).

Figure 15. Daisy-chain configuration for UCM communication-link

wiring (preferred configuration)

®

Tracker

Controller

Trane UCM

Figure Note:

Maximum wire length for daisy-chained wiring is 4593 ft (1400 m).

Trane UCM

Trane UCM

32 BMTK-SVN01D-EN

Page 41

Wire the UCMs

®

Figure 16. Daisy-chain configuration for UCM communication-link wiring with Tracker controller in

middle of link

Tracker

Controller

Trane UCM

Trane UCM

Trane UCM

Trane UCM

Trane UCM

Trane UCM

Figure Note:

• Maximum wire length for daisy-chained wiring is 4593 ft (1400 m) unless a Comm5 repeater is used.

BMTK-SVN01D-EN 33

Page 42

Chapter 3 Termination board wiring

Termination resistor placement for Comm5 links

Install one 105 Ω resistor across the communication link terminals of the

device at the beginning of the daisy chain, which is typically a Tracker

controller. Then install a second 105 Ω resistor across the communication

terminals at the last UCM on each link. See Figure 17 on page 35 for an

example of a link that begins with a Tracker controller. See Figure 18 on

page 36 for an example of a link that does not begin with a Tracker

controller.

IMPORTANT

For maximum performance of the Comm5 link, use the 105 Ω resistors

that are included with the Tracker controller. If they are not available, as

a second choice, use a 100 Ω, ¼ W, 5% tolerance resistor, or as a third

choice, a 110 Ω, ¼ W, 5% tolerance resistor. Failure to comply may cause

the controller to malfunction.

®

Note:

If, after installation, the link is extended to add more UCMs,

the resistor must be relocated to the new last UCM on the link.

The resistor value can be determined by reading its color bands. Table 9

provide the resistor color coding.

Table 9. Resistor color band table

To l e r a n c e Color sequence

105

Ω ± 1% tolerance

100

Ω ± 5% tolerance

11 0

Ω ± 5% tolerance

Brown, black, green, brown

Brown, black, brown, gold

Brown, brown, brown, gold

If a repeater is used, each link of the configuration that is created by the

repeater requires termination resistors (see “Requirements for repeaters

on Comm5 communication links” on page 37).

Create a set of as-built drawings or a map of the communication wire

layout during installation. Ensure that sketches of the communication

layout show the placement of the termination resistors.

34 BMTK-SVN01D-EN

Page 43

®

Figure 17. Daisy-chain termination resistor placement

Wire the UCMs

Tracker

termination board TB1

Legend

Twisted pair, shielded wire

=

per Trane specifications

=

Shield ground

=

Termination resistor

=

Shield termination

=

Figure note

1

2

3

4

5

6

7

(Last device on the link)

8

9

Comm5 device

AAAABBBB

Comm5 device

10

11

12

13

1

2

Splice

3

1

14

COMM

15

Figure Notes:

1105 Ω termination resistor

2 Shield must be cut back and taped at last unit controller.

3 A continuous shield is required. At each unit controller, splice shield wire and tape back to prevent

grounding.

BMTK-SVN01D-EN 35

Page 44

Chapter 3 Termination board wiring

Figure 18. Termination resistor placement with a Tracker controller in the middle of the link

Tracker

termination boardTB1

1

Legend

Twisted pair, shielded wire

=

per Trane specifications

=

Shield ground

=

Termination resistor

=

Shield termination

=

Figure note

2

3

4

5

6

7

®

(Last device on the link)

Comm5 device

A

B

1

2

(Last device on the link)

Comm5 device

A

B

1

8

9

Comm5 device

A

B

A

B

A

B

10

11

12

13

COMM

14

15

Splice

3

Comm5 device

A

B

A

B

A

B

2

Splice

3

Figure Notes:

1105 Ω termination resistor

2 Shield must be cut back and taped at last unit controller of each link.

3 A continuous shield is required. At each unit controller, splice shield wire and tape back to prevent

grounding.

36 BMTK-SVN01D-EN

Page 45

Wire the UCMs

®

Wire supported UCMs

Wire the supported UCMs to the Tracker termination board. When

installing communication wire:

• Keep the polarity consistent throughout the site. Although Comm5 is

not polarity sensitive, consistency will improve serviceability.

• Strip away a maximum of 2 inches (50 mm) of the outer conductor

and foil shield when splicing or terminating shielded wire.

IMPORTANT

Use extreme care when stripping away the outer conductor and foil

shield. Be careful not to nick the insulating jacket of the two conductors. A nick in the insulating jacket will cause communication problems.

Wire the UCMs as follows:

1. Install termination resistors in the correct locations.

2. Route input wires into the termination module through the conduit

box or any of the conduit openings designated for input and communication wiring (Figure 12 on page 19).

3. Connect the wires to the COMM terminals on the termination board

(Figure 14 on page 24).

4. Connect the shield to the ground terminal.

5. Connect the other end of the wires to the UCMs, as necessary.

Requirements for repeaters on Comm5 communication links

The Comm5 communication link repeater is a device that repeats and

regenerates the signal on a Comm5 link in order to enhance signal

quality or extend the length of the run. The Comm5 link goes from the

Tracker controller to the UCMs to the repeater. A second link segment

extends from the other side of the repeater to the rest of the devices. The

configuration on either side of the repeater must be a daisy-chain

configuration. Both link segments require termination.

A link repeater is required when:

• The total wire length is greater than the maximum wire run length of

4593 ft (1400 m) for a daisy-chain configuration.

• More than 60 devices are connected to a link. This total does not

include the Tracker controller, the link repeater, and the possible use

of the Rover service tool on the same link.

The link repeater has several limitations:

• Only one link repeater can be used on a link.

• The use of a repeater doubles the maximum allowable wire length.

For example, when a repeater is used with a daisy-chain configuration, the total wire length can be 9186 ft (2800 m) (with half the wire

length on either side of the repeater).

BMTK-SVN01D-EN 37

Page 46

Chapter 3 Termination board wiring

• The link repeater is limited to 60 devices on either side of the link

• The link repeater requires an earth ground. The installer should be

Recommended shield connections are shown in Figure 19. Figure 20 on

page 39 shows a daisy-chain repeater connection. Follow these guidelines

when using a repeater:

• Reference the installation information that comes with the link

• Connect the shield-drain wires entering the repeater to a terminal

• Connect the shield-drain wires leaving the repeater to the repeater

Figure 19. Connecting communication link shield wiring to repeater

®

(120 devices total).

aware of this before making power connections.

repeater (Comm5 repeater installation, 3270 3285).

marked with a capacitor symbol. The entering shield-drain wire must

be connected to earth ground at the Tracker controller.

terminal marked with an earth ground symbol.

24 Vac

Transformer

Earth ground

Entering shield. Continuous run, typically

starting at the Tracker controller.

Leaving shield. Must be connected to the earth ground

terminal on the repeater and terminated (insulated from

ground) at the last UCM.

Legend

=

Transformer

Link Repeater

24 VAC

1

2

3

Comm

4

5

6

Comm

7

8

9

=

Earth ground

Twisted pair, shielded wire

=

per Trane specifications

38 BMTK-SVN01D-EN

=

Shield ground

Page 47

®

Figure 20. Comm5 daisy-chain repeater connection

Wire the UCMs

Comm5 device

Comm5 device

AABB

AABB

Tracker

termination boardTB1

13

1

14

COMM

15

SpliceSplice

33

Link repeater

24 VAC

1

2

3

1

Comm

4

5

6

1

Comm

7

(Last device on the link)

Comm5 device

1

2

Legend

Twisted pair, shielded wire

=

per Trane specifications

=

Shield ground

=

Termination resistor

Comm5 device

AAAABBBB

Splice

=

Shield termination

Figure note

=

3

Figure Notes:

1105 Ω

termination resistor

2 Shield must be cut back and taped

3 A continuous shield is required. At each

controller, splice shield wire and tape back to

prevent grounding.

8

9

BMTK-SVN01D-EN 39

Page 48

Chapter 3 Termination board wiring

®

40 BMTK-SVN01D-EN

Page 49

®

Chapter 4

Main module mounting

After mounting and wiring the termination module, attach the main

.

module to the termination module

procedures that enable you to mount the main module.

Note:

The Tracker controller ships with the display module

assembled to the main module. If those two modules are

assembled, performing this procedure also mounts the display

module.

Note:

It is not necessary to turn off 24 Vac power to the Tracker

controller prior to mounting or removing the main module.

1. Verify that all wires on the termination module are securely fastened

in place.

2. Carefully line up the alignment pins on the termination module with

the back side of the main module (Figure 21 on page 42).

This chapter provides information and

CAUTION

Avoid Equipment Damage!

Do not use excessive force when mounting the module. If the module

does not snap easily into place, slightly reposition it on the alignment

pins. Failure to comply may cause damage to the module.

3. Firmly push the main module onto the termination module until it

snaps into place. If 24 Vac power is applied, the main module will

start. If the display module is not assembled to the main module, you

will see the LEDs on the main module flash on and off after a few seconds. If the display module is assembled to the main module, it will

turn on and display information.

BMTK-SVN01D-EN 41

Page 50

Chapter 4 Main module mounting

Figure 21. Main module mounting

Alignment pin

(four places)

®

Termination module

Main module

42 BMTK-SVN01D-EN

Page 51

®

Chapter 5

Display module mounting

After mounting the main module, attach the display module to the main

.

module

you to mount the display module.

1. Tilt the top of the display module about 30 degrees toward you.

2. Line up the three tabs on the bottom of the display module with the

3. Starting with the center tab, insert the tabs into the slots.

This chapter provides information and procedures that enable

Note:

The Tracker controller ships with the display module

assembled to the main module. If those two modules are

assembled, you need only to perform the main module

mounting procedure (Chapter 4, “Main module mounting”).

Note:

It is not necessary to turn off 24 Vac power to the Tracker

controller prior to mounting or removing the display module.

slots on the bottom of the main module (Figure 22 on page 44).

CAUTION

Avoid Equipment Damage!

Do not use excessive force when mounting the module. If the module

does not snap easily into place, slightly reposition it on the alignment

pins. Failure to comply may cause damage to the module.

4. Push the top of the display module toward the main module until it

snaps into place while making sure that the tabs on the display module engage the slots on the main module (Figure 23 on page 45). If 24

Vac power is applied to the Tracker controller, the display module will

turn on and display information.

BMTK-SVN01D-EN 43

Page 52

Chapter 5 Display module mounting

Figure 22. Tab and slot alignment

®

44 BMTK-SVN01D-EN

Page 53

®

Figure 23. Display module engagement

Display module mounting

BMTK-SVN01D-EN 45

Page 54

Chapter 5 Display module mounting

®

46 BMTK-SVN01D-EN

Page 55

®

Chapter 6

PC workstation wiring

The Tracker controller connects to a PC workstation with a direct

connection cable, an internal modem, or an Ethernet connection.

Verify PC workstation specifications

Verify that the PC conforms to the minimum specifications listed on the

insert in the CD jewel case and that the Tracker PC workstation software

is installed.

Direct connection to PC workstation

To make an EIA-232 direct connection between the controller and a PC

workstation, you need an RJ-12 cable and an adaptor matched to the

serial port connector on the PC workstation (Table 10).

Table 10. Cable and adapter specifications for direct connection

Description Trane part number

RJ-12 interface cable 3591 4260

9-pin female modular adapter 3591 4262

25-pin female modular adapter 3591 4263

The cable and adapter are not shipped with the Tracker controller and

must be purchased separately.

BMTK-SVN01D-EN 47

Page 56

Chapter 6 PC workstation wiring

®

IMPORTANT

Do not use a standard phone cable for a direct connection. The RJ-12

cable is a 6-wire straight-through cable. Failure to comply will cause the

Tracker controller to malfunction.

IMPORTANT

The maximum allowable length of the RJ-12 cable is 50 ft (15 m). Failure

to comply may cause the Tracker controller to malfunction.

1. Locate the RJ-12 cable and the appropriate adapter.

2. Connect the RJ-12 cable to the RJ-12 port on the bottom side of the

controller (Figure 24).

3. Connect the other end of the RJ-12 cable to a 9-pin or 25-pin adapter,

as appropriate (Figure 25 on page 49).

4. Connect the adaptor to the appropriate serial port on the PC workstation.

Figure 24. Tracker communication ports

LAN RJ-45 port

(Ethernet connection)

RJ-12 port

(PC direct connection)

RJ-11 port

(modem connection to

standard telephone line)

48 BMTK-SVN01D-EN

Page 57

®

Figure 25. Tracker direct connection to a PC workstation

RJ-45

LAN port

for future Ethernet

connection

(bottom side)

Connect RJ-12 to

9-pin female

adapter

RJ-12 port for PC

direct connection

(bottom side)

Direct connection to PC workstation

To PC workstation

serial port

RJ-12 cable

Connect RJ-12 to

25-pin female

adapter

BMTK-SVN01D-EN 49

Page 58

Chapter 6 PC workstation wiring

®

Modem connection to PC workstation

To make a modem connection between the controller and a PC

workstation, you need an RJ-11 cable (standard telephone cable).

Note:

The Trane Company reserves the right to support only selected

modems for the Tracker PC workstation. This ensures proper

operation of the Tracker software and makes troubleshooting

easier, if a communication failure occurs.

Modem specifications are subject to change. For a current list of

specified modems, contact your local Trane office.

1. Connect a RJ-11 cable (standard telephone cable) into the RJ-11 port

on the bottom side of the controller (Figure 24 on page 48).

2. Connect the other end of the cable to a phone jack, a port on an external modem, or the PC workstation modem port (Figure 26 on

page 51). The incoming modem port is typically labeled “Line” or

“Line in.”

Note:

Use the Tracker software to set the communication port that

the modem will use.

50 BMTK-SVN01D-EN

Page 59

®

Figure 26. Tracker modem connection to a PC workstation

Modem connection to PC workstation

Phone jack

RJ-11 modem

(back)

port

RJ-11 modem

(bottom side)

RJ-11 cable

port

BMTK-SVN01D-EN 51

Page 60

Chapter 6 PC workstation wiring

®

Ethernet connection to PC workstation

Connecting over an existing LAN

To make an Ethernet LAN connection between the Tracker controller and

a Tracker PC Workstation through an existing customer LAN, you need

two CAT 5 patch cables.

1. Connect one end of the first CAT 5 patch cable to the RJ-45 Ethernet

port on the bottom side of the Tracker controller (Figure 27 on

page 52).

2. Connect the other end of the cable to an RJ-45 Ethernet wall jack

near the controller.

3. Connect one end of the second CAT 5 patch cable to an RJ-45 Ethernet wall jack near the Tracker PC Workstation.

4. Connect the other end of the cable to the RJ-45 Ethernet port on the

PC workstation.

Figure 27. Tracker Ethernet LAN connection to a PC workstation over an existing LAN

Tracker

Controller

RJ-45

Ethernet

LAN jack

CAT 5

patch cable

RJ-45 Ethernet

LAN (bottom side)port

Existing LAN

RJ-45

Ethernet

LAN jack

CAT 5

patch cable

RJ-45 Ethernet

LAN (back)port

52 BMTK-SVN01D-EN

Page 61

Ethernet connection to PC workstation

®

Connecting through a hub

To make an Ethernet connection between the Tracker controller and a

Tracker PC Workstation through a hub, you need two CAT 5 patch cables.

1. Connect one end of the first CAT 5 patch cable to the RJ-45 Ethernet

port on the bottom side of the Tracker controller (Figure 27 on

page 52).

2. Connect the other end of the cable to an RJ-45 Ethernet port on the

hub.

3. Connect one end of the second CAT 5 patch cable to an RJ-45 Ethernet port on the hub.

4. Connect the other end of the cable to the RJ-45 Ethernet port on the

Tracker PC Workstation.

Figure 28. Tracker Ethernet LAN connection to a PC workstation through a hub

Tracker

Controller

Tracker

PC Workstation

RJ-45 Ethernet

LAN (back)port

RJ-45

Ethernet

LAN jack

CAT 5

patch cable

RJ-45

Ethernet

LAN jack

Hub

RJ-45 Ethernet

LAN (bottom side)port

CAT 5

patch cable

BMTK-SVN01D-EN 53

Page 62

Chapter 6 PC workstation wiring

Connecting with one cable

To make an Ethernet connection between the Tracker controller and a

Tracker PC Workstation using one cable, you need one CAT 5 crossover

cable.

1. Connect one end of the CAT 5 crossover cable to the RJ-45 Ethernet

LAN port on the bottom side of the Tracker controller (Figure 29).

2. Connect the other end of the cable to the RJ-45 Ethernet LAN port on

the Tracker PC Workstation.

Figure 29. Tracker Ethernet LAN connection to a PC workstation with one cable

Tracker

Controller

®

RJ-45 Ethernet

LAN (back)port

CAT 5

crossover cable

RJ-45 Ethernet

LAN (bottom side)port

54 BMTK-SVN01D-EN

Page 63

®

Chapter 7

Troubleshooting

Troubleshooting components

Light-emitting diodes (LEDs) and service pin buttons are used for

troubleshooting the Tracker system.

LEDs

The LEDs on the Tracker controller main logic board and display module

show central processing unit (CPU) status and traffic on the Comm5

communication link, the Ethernet module, and the EIA-232 connection.

Figure 30 shows the location of the main logic board LEDs; Table 11 on

page 57 provides a description of them. Figure 30 shows the location of

the Ethernet module LEDs; Table 11 on page 57 provides a description of

them. Figure 7 on page 7 shows the location of the alarm LED on the

display module; Table 12 on page 57 provides a description of it.

Service pin buttons and jumper

Table 13 on page 58 describes the service pin buttons that are located on

the main logic board. They are used for rebooting the controller and for

Neuron identification. The table also describes the jumper that is on the

main logic board.

BMTK-SVN01D-EN 55

Page 64

Chapter 7 Troubleshooting

Figure 30. Tracker controller main logic board component location

HI TX

LED6

J1

HRT

LED5

BOP

LED3

S1

LED4

PC RX

LED7 LED8

CODE

PC TX

SERVICE

COMM

LED2

LED9

S2

®

Ethernet

board

Left

LED

Right

LED

56 BMTK-SVN01D-EN

Page 65

®

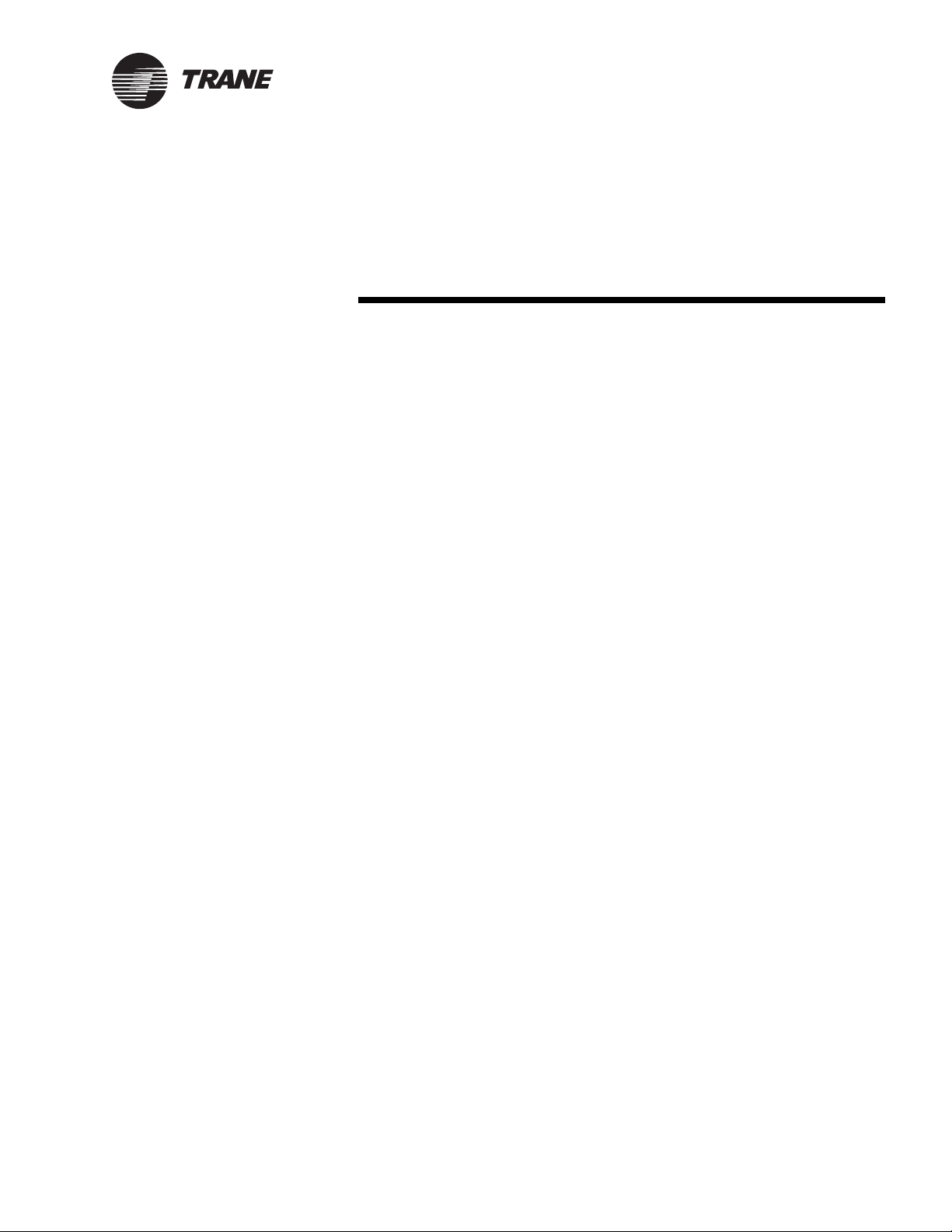

Table 11. Tracker main logic board LEDs

Troubleshooting components

LED name

LED

number

Color Description

HI TX LED6 Green Flashes when the main module attempts to communicate with the display

module. The main module attempts to communicate with the display module

even when the display module is not installed. With no display module installed,

the LED flashes every two seconds.

HRT LED5 Green Shows the status (heart beat) of the CPU. This LED is on continuously while the

controller boots up. It flashes to show processor activity.

CODE LED4 Red Shows the status of the controller operating code. This LED is on continuously

while the controller is booting up and/or whenever the controller needs operating code.

Note: Code can be downloaded to the Tracker controller with the use of the Tracker PC software

if this LED is on.

PC RX LED7 Green Shows that EIA-232 traffic is on the PC port. This LED is normally off. Flashes

when the controller receives data from the PC.

PC TX LED8 Green Shows that EIA-232 traffic is on the PC port. This LED is normally off. Flashes

when the controller transmits data to the PC.

BOP LED3 Red Flashes when the controller binary output relay is energized and when an

appropriate alarm condition exists.

SERVICE LED9 Red Shows that Comm5 service is required. This LED is normally off. LED is on

continuously to show that controller hardware is defective. LED is on

continuously to show that the Service pin button (SW2) was pressed. Flashes to

show that the controller must be rebooted.

COMM LED2 Yellow Shows that network traffic is on the Comm5 link. Flashes when the controller

receives data from a Comm5 device.

Left LED None Green Shows that an Ethernet link is detected.

Right LED None Green Shows that there is serial traffic between the Ethernet module and the Tracker

main logic board.

Table 12. Alarm LED

State Color Description

Normal Green LED is on continuously when the controller is operating normally and has received

no alarms of the appropriate severity.

Alarm Red Flashes when the controller receives an alarm of the appropriate severity. To

acknowledge the alarm and turn off the LED, press the Alarm function button

displayed on the user interface home screen.

BMTK-SVN01D-EN 57

Page 66

Chapter 7 Troubleshooting

Table 13. Main logic board service pin buttons and jumper

Service pin buttons/jumper Function

S1 This service pin is the reset button. Pressing S1 reboots the controller. It starts the

same operation as does rebooting the controller from either the controller or the PC

software. All RAM data is permanently lost.

Note: Before pressing this button, attempt to restart the controller by cycling power; this method

retains the RAM image.

S2 Momentarily pressing this service pin button causes the controller to broadcast

Neuron ID and Program ID. This action also turns on LED9.

J1 This jumper is for factory use only. It must always remain in place. If removed, the

backup capacitor will not charge and data may be lost if power is lost.

®

58 BMTK-SVN01D-EN

Page 67

®

Symptom/action troubleshooting

Table 14 provides a list of symptoms that indicate a problem in the Tracker system.

For each symptom, the table provides on e or more actions that yo u can perfo rm in an

attempt to resolve the problem.

Table 14. Symptom/action troubleshooting

Symptom Action

Symptom/action troubleshooting

Tracker controller does not

communicate by modem.

Tracker controller does not

communicate by EIA-232

port.

Tracker controller did not

discover UCMs when initially started.

Touch screen beeps when

touched but does not

progress to the next screen.

Touch-screen back light and

contrast is out of adjustment.

Tracker I/O status is wrong.

• Verify that the telephone cable is connected to the PC modem port (Figure 24 on

page 48).

• Verify that the phone line is an analog line (not digital).

• Perform the modem self-test procedure from the display module.

Note: The modem is an integral component of the main module and is not field replaceable.

Replacement of the modem requires replacement of the main module.

• Verify that the cable is connected to the PC direct connect port (Figure 24 on

page 48).

• Verify that the proper cable is used. (Refer to Table 10 on page 47.)

• Verify that the PC workstation is using the Tracker controller software; other com-

munications software will not work.

• Look for activity on the PC RX LED (Figure 30 on page 56).

When the controller is initially powered up, it automatically discovers all communicating UCMs of the proper type and installs them into its database. The discovery

process takes several minutes, depending on how many UCMs are installed on the

communication link.

After the controller has built its database after the initial power up, the controller no

longer automatically discovers UCMs. If you want to initiate the discovery process,

you must do so manually. Initiate the discovery process when a new UCM is added

to the system or an existing UCM is replaced.

• Verify proper wiring of the Comm5 communication link. (UCMs can be discov-

ered only if Comm5 communication has been established.)

• Wait at least 5 minutes for the controller to discover the UCMs.

Note: You can press the service pin button on a UCM at any time to check if it is communicating

with the controller. Pressing the service pin button causes the UCM status LED to flash on and off

(known as “winking”), if the controller is communicating with that UCM.

Touch screen is out of calibration.

• Perform the procedures for calibrating the touch screen in Tracker Building Auto-

mation System Controller Operations guide (BMT-SVU01A-EN).

• Perform the adjust brightness and contrast procedure from the display module.

• Verify electrical connection using the post-installation checklist (Table 18 on

page 70).

• Verify I/O status as indicated on home display on the display module.

• Display Tracker I/O status self test from display module.

BMTK-SVN01D-EN 59

Page 68

Chapter 7 Troubleshooting

Table 14. Symptom/action troubleshooting (Continued)

Symptom Action

®

Tracker alarm output is not

working as expected.

Tracker controller will not

communicate with its

UCMs.

Tracker processor is locked

up.

Alarm LED on the display is

flashing red.

Tracker controller is annunciating an alarm.

Display module is not illuminated.

Display module does not

respond to the touch.

• Confirm proper wiring of the alarm relay output. Consult the post-installation

checklist (Table 18 on page 70) for details.

• Initiate the BOP self test from the display module.

Note: The binary output is for alarm notification only. There must be an unacknowledged alarm

present of the proper severity to actuate the alarm output.

• Look for wiring problems (shorts or opens, for example) that develop when wire