Page 1

18-HE39D9-6

Installer’s Guide

Horizontal Economizer & Rain Hood

Model:

BAYECON200A

BAYECON201A

BAYRLAY004A

WARNING:

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit. Please return to service

information pack upon completion of work.

General

The economizer is a multi-damper design. It inserts into the

return air stream and is connected to the unit low voltage

supply through wire leads. The economizer is fully accessible through an access panel.

Important: The Economizer installation requires that you first

install an air filter rack ordered separately. Use:

BAYFLTR101A for 2/4YC*, WC*, TC*, DC* *018-3036A

BAYFLTR201A for 2/4YC*, WC*, TC*, DC* *042-3060A.

When the economizer is installed in WC* models, relay

accessory kit BAYRLAY004A is required. Refer to the drawing

on page 6 to make your relay wiring connections in the Control

Box.

Identify Economizer Kit Contents

Refer to Figure 2 on page 3 to identify the kit contents.

Inspect Contents

You must report damage and make claims to the transportation company immediately. Report missing parts to your

supplier immediately and replace with authorized parts

only.

!

ELECTRIC SHOCK HAZARD

OPEN AND LOCK OUT ALL UNIT DISCONNECTS PRIOR

TO ACCESSORY INSTALLATION OR UNIT MAINTENANCE,

TO PREVENT INJURY OR DEATH FROM ELECTRICAL

SHOCK OR CONTACT WITH MOVING PARTS.

!

SAFETY HAZARD

DO NOT REMOVE END COVERS FROM ECONOMIZER ACTUATOR; THE SPRING-RETURN ASSEMBLY MAY RELEASE

AND CAUSE PERSONAL INJURY.

Used with:

2/4TC*,WC*,YC*,DC* *018-036A

2/4TC*,WC*,YC*,DC* *042-060A

(Required with WC* models)

HAZARDOUS VOLTAGE - DISCONNECT POWER BEFORE SERVICING

Install Economizer Kit

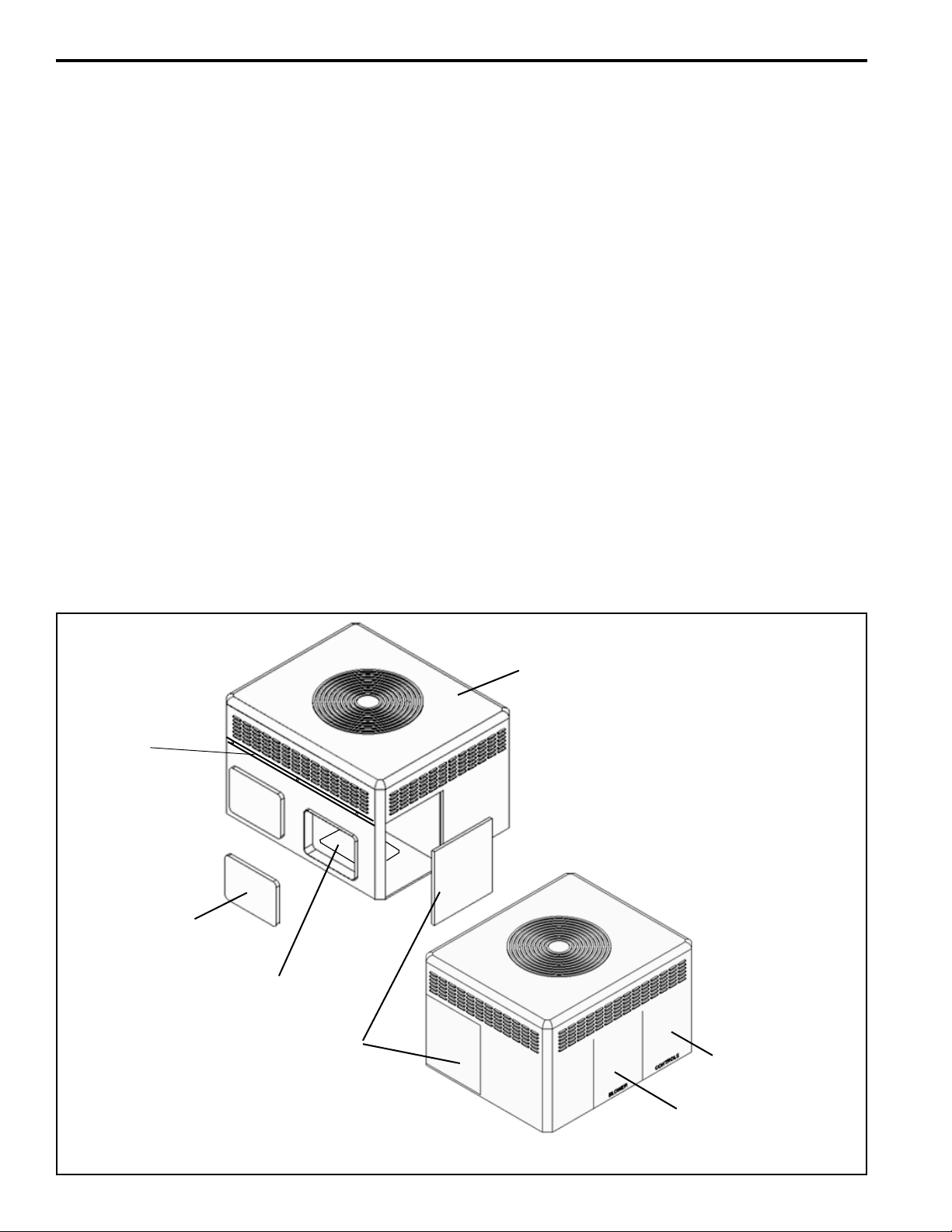

1. Remove the unit economizer/filter access panel, the

evaporator coil and blower access panel, and the electri

cal control box access panel, see Figure 1 on page 2.

2. Filter frame must be installed prior to economizer installa-

tion.

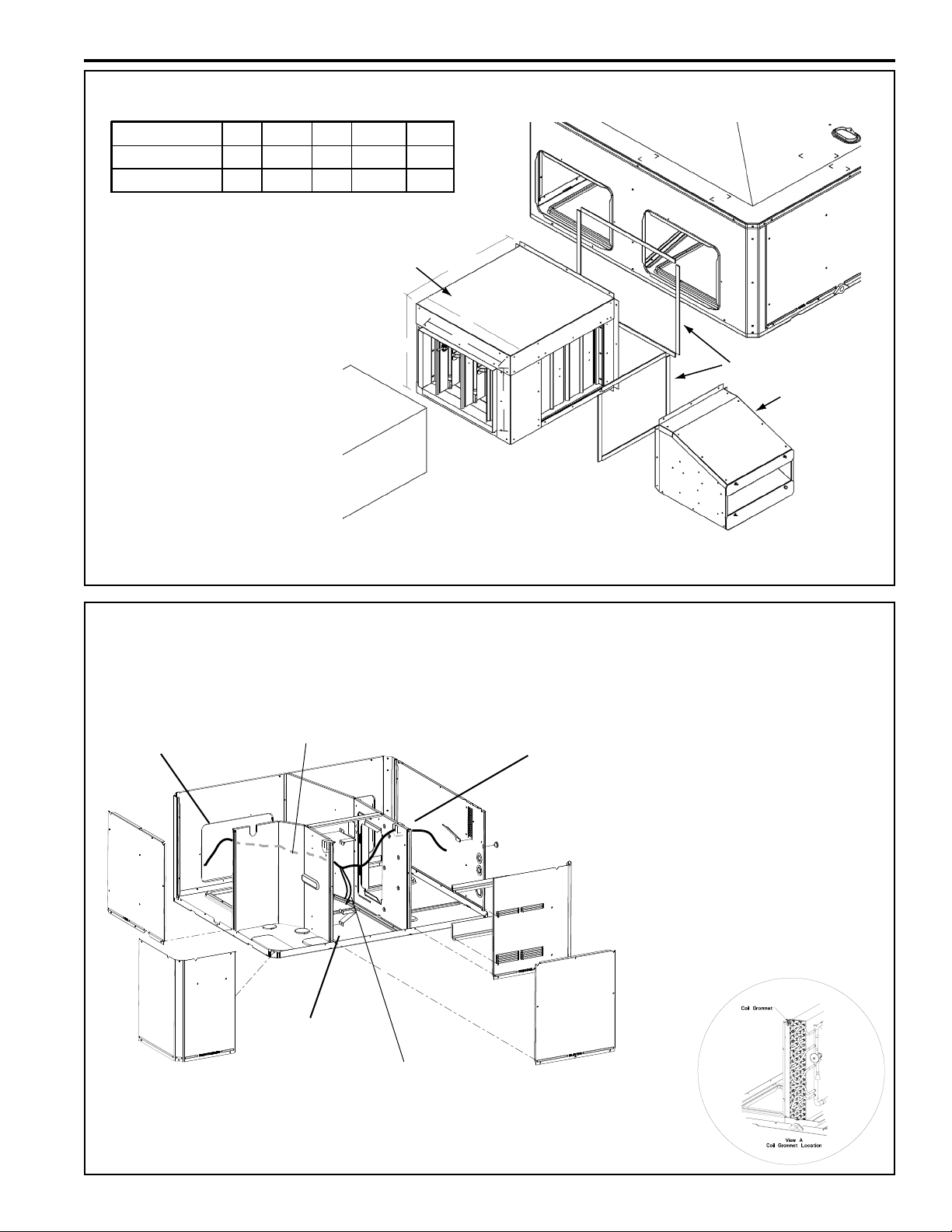

3. Apply two gaskets to horizontal economizer mounting

flanges. See Figure 2 on page 3.

4a. Small Cabinet - BAYECON200A

(TC*,WC*,YC*,DC* *018A to 3036A)

Set the horizontal economizer over the horizontal return

air opening on the unit. The notches in the bottom

flange of the economizer clear the two existing screws

below the return air opening of the unit.

4b. Medium Cabinet Only - - BAYECON201A

(TC*,WC*,YC*,DC* *042A to 3060A)

Apply a gasket to the economizer and slide the top

flange of the economizer under the lip between the top

and bottom sections of the unit. Mate the notches on

WARNING

WARNING

the top flange of the economizer with the existing screws

between the top and bottom sections of the unit. The

notches on the bottom flange of the economizer clear

the two existing screws below the return air opening of

the unit.

CAUTION

!

Use care when inserting the economizer in the return air

compartment, to prevent damaging the foil faced insulation.

Page 2

INSTALLER’S GUIDE

5. Drill three (3) 9/64” holes through the mating holes in

the top flange of economizer and into the unit. Then,

drive three (3) #10 sheet metal screws to secure the top.

6. Drill three (3) 9/64” engagement holes on each side of the

economizer. Then, drive three (3) #10 sheet metal screws

into each side of the economizer to the unit.

7.

Mount the Mixed Air sensor to the left Blower partition

using two sheetmetal screw. See Figure 4, page 4. The 2 yellow

wires will connect to the Economizer wiring harness in a later step.

Install any economizer options (enthalpy sensor or CO2 sensor)

at this time per instructions provided with the sensor.

8. Apply a gasket to the Rain Hood flanges. See Figure 2.

9. Place the Rain Hood over the horizontal return air opening

of the economizer. See Figure 2. Use the #10 sheet metal

screws provided to attach the hood to the economizer.

10.

Route the main wiring harness. From the Economizer assembly,

route the main wiring harness to the Mixed Air sensor and to the

Control Box. See Figure 3.

11. Connect the two (2) Mixed Air Sensor wires (pulled from harness)

to the mating pigtail wires (with Stake-Ons) from the Mixed Air

Sensor.

12. In the Control Box, complete the wiring connections per the wiring

diagram on page 5. Secure all wires with wire ties so that there

is no interference with any moving parts in the unit.

IMPORTANT - When the economizer is installed in heat

pump models (WC*), a relay accessory kit

(BAYRLAY004A) is required. Mount relay accessory kit

in unit control box as illustrated on page 6.

13. Attach the return duct to the economizer.

14. Power the economizer and run the checkout procedure on page

7. Make desired adjustments to the controller: set the minimum

occupied damper position, set the outside air (if enthalpy used),

and the IAQ sensor (if used).

15. Replace the unit Coil access panel, the Blower access panel, and the

Control Box access panel.

Top Sealing

Flange

Horizontal

Return Air

Panel

Down Flow

Return Air

Panel

TC, WC, or

YC Unit

Coil Access

Panel

Control Box Access

Panel

Blower Access Panel

Page 2

Figure 1. Remove Panels

Page 3

Horizontal Economizer Assembly

Economizer A B C D E

BAYECON200AA 22" 20" 16-7/8" 15-11/16 11-11/16

BAYECON201AA 26" 22-21/32" 19" 17-11/16 14-11/16

INSTALLER’S GUIDE

NOTE: BAYECON200A economizer only contains two clearance notches in the top flange.

1.) From

EconomizerAssembly,

Pass Wire Harness

Through Coil Grommet. See View A.

Economizer

A

B

C

Duct

D

E

Figure 2. Apply Two Gaskets to Mounting Flanges

2.) Continue Routing

Behind Compressor

Compartment and into

Blower Compartment.

4.) Continue Routing the

Remaining Harness

Through the Grommet

and into the Control Box.

Gaskets (2)

Rain Hood

Location of

Mixed Air Sensor

3.) Pull the 2 Mixed Air Sensor

Wires (with Stake-Ons) from the

Harness and Route Down Near

the Mixed Air Sensor.

Figure 3. Main Wire Harness Routing

Page 3

Page 4

INSTALLER’S GUIDE

1.80"

2.82"

See View ‘A’

View ‘A’ Approximate

Mounting Dimension

Figure 4. Mount Mixed Air Sensor in Blower Compartment

Mount the Mixed Air

Sensor to the partition

using two sheetmetal

screws. See View A

for approximate

positioning.

Page 4

Page 5

INSTALLER’S GUIDE

Figure 5. TC*/YC* Economizer Connection Diagram

Page 5

Page 6

INSTALLER’S GUIDE

Page 6

Figure 6. WC* Economizer Connection Diagram

Page 7

INSTALLER’S GUIDE

CONTROL

CURVE

A

B

C

D

CONTROL POINT

APPROX. F ( C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

44 46

90

100

80

70

60

50

40

30

20

10

ENTHALPY—BTU PER POUND DRY AIR

85

(29)90(32)95(35)

100

(38)

105

(41)

110

(43)

35

(2)

35

(2)

40

(4)

40

(4)

105

(41)

110

(43)

45

(7)

45

(7)

50

(10)

50

(10)

55

(13)

55

(13)

60

(16)

60

(16)

65

(18)

65

(18)

70

(21)

70

(21)

75

(24)

75

(24)

80

(27)

80

(27)

85

(29)90(32)95(35)

100

(38)

APPROXIMATE DRY BULB TEMPERATURE— F ( C)

A

A

B

B

C

C

D

D

M11681

RELATIVE HUMIDITY (%)

1

1

HIGH LIMIT CURVE FOR W7459D.

Checkout

Operate the motor through its complete open-close

stroke. If necessary, release one of the previously

tightened linkage connections to prevent damage.

Check for proper operation, making sure that the

linkage does not bind and that the motor travels

smoothly throughout its fully open and closed position. Table 1 describes how to drive motors full open

and closed (power connected). If there is excess

length of linkage rod, cut it to size. Make necessary

minor adjustments until desired operation is obtained, and tighten all nuts and set screws. This

motor checkout ensures that:

Table 1. Motor Operation Checkout

MODEL DRIVE MOTOR OPEN DRIVE MOTOR CLOSED SPRING RETURN

M7415 Power to TR and TR1, jumper T and T1.

Disconnect jumper at T or T1 and

disconnect P or P1,if connected.

1. The motor operates the load.

2. The motor responds properly to the controller.

3. There is no binding of the linkage or motor

stalling at any point of travel.

If motor does not operate properly, check for

proper voltage or mechanical binding in linkage or

damper.

If questions arise regarding this product, contact

your distributor or representative.

Disconnect power at TR and TR1.

Single enthalpy: The enthalpy

changeover set point is set to return the

outdoor air damper to minimum position when the enthalpy rises above its

set point. The enthalpy set point scale

markings, located on W7459, are

A,B,C,D; see table for the corresponding control point. The factory-installed

R4 WHITE 620-ohm jumper must be in

place across terminals + and SR.

Figure 7. SINGLE ENTHALPY CHANGEOVER SET POINT

Page 7

Page 8

INSTALLER’S GUIDE

Checkout Procedure Response

A

1. Disconnect power at TR and TR1.

2. Disconnect jumper P to P1.

3. Jumper TR to 1.

4. Jumper T1 to T.

5. If connected, remove C7400 Solid State Enthalpy Sensor

from teminals S0 and +. Ensure factory-installed 620 ohm

resistor is connected to terminals Sr and +.

6. Apply power (24Vac) to terminals TR and TR1

B

1. Disconnect factory-installed 620 ohm resistor from

terminals Sr and +.

C 1. To simulate high and low enthalpy (single enthalpy

sensor) reconnect factory-installed 620 ohm resistor from

termonals Sr and +. Connect 1.2K ohm 4074EJM Checkout

Resistor across terminals So and +.

2. Turn enthalpy setpoint potentiometer to "A".

3. Turn enthalpy setpoint potentiometer to "D".

4. Disconnect the 1.2 K ohm checkout resistor.

D

1. To verify sensor operation, reconnect the + lead of the

outdoor enthalpy sensor to the + terminal of W7459.

2 Connect a DC millimeter between terminal So of the

W7459A and terminal S of the enthalpy sensor. See Fig. 10

(positive meter lead to terminal S of the enthalpy sensor).

3. When using differential enthalpy, check the return air

enthalpy sensor by connecting a DC millimeter between

terminal Sr of the W7459A and terminal S of the return air

enthalpy sensor. (positve meter lead to terminal S of the

enthalpy sensor).

Table 2. Enthalpy Checkout Procedure

LED is off.

Motor is in closed position.

Led turns on, motor drives toward open.

__

LED turns on, indicating low enthalpy.

Motor drives toward open.

LED turns off, indicating high enthalpy.

Motor drives toward closed.

__

__

Millimeter indication is between 3 and 25

mA if sensor is operating properly.

If millimeter indicates zero, the sensor may

be wired backward.

Millimeter indication is between 3 and 25

mA if sensor is operating properly.

If millimeter indicates zero, the sensor may

be wired backward.

Location of Enthalpy Set Point, Minimum Position

and LED

Trane

6200 Troup Highway

Tyler, TX 75707-9010

Page 8

ENTHALPY

CHANGEOVER

SETPOINT

LED LIGHTS

WHEN OUTDOOR

AIR IS SUITABLE

FOR FREE COOLING

MINIMUM DAMPER POSITION ADJUSTMENT

1

IS PRESENT ONLY ON W7459A,D MODELS.

Figure 8. Enthalpy LEDs and Checkout

© 2008 Trane All rights reserved

1

MINIMUM

DAMPER

POSITION

SETTING

M9098B

Meter Location for Checkout and Troubleshooting

W7459

INSERT DC MILLIMETER BETWEEN SO AND S FOR CHECKOUT

1

AND TROUBLESHOOTING.

2

JUMPER USED FOR SINGLE ENTHALPY CONTROL.

The manufacturer has a policy of continuous product and

product data improvement. It reserves the right to

change design and specification without notice.

BC

A

TR

S

O

D

S

R

TR1

+

+

620 OHM

JUMPER

ENTHALPY CHANGEOVER

SETPOINT

2

LED LIGHTS WHEN

OUTDOOR AIR IS SUITABLE

FOR FREE COOLING

1

+

DC

MILLIMETER

+

S

C7400

M9097

Loading...

Loading...