Trane BAYECON103AA, BAYECON103AB, BAYECON104AA, BAYRLAY006A, BAYECON104AB Installer's Manual

Page 1

Installer’s Guide

Down Discharge Economizer and Rain Hood

Model: Used with:

BAYECON103AA/AB 4WCZ6, 4YCZ6, & 4DCZ6036

BAYECON104AA/AB 4WCZ6, 4YCZ6, & 4DCZ6048-060

BAYRLAY006A (Required with 4WCZ6 & 4DCZ6 models)

WARNING: HAZARDOUS VOLTAGE - DISCONNECT POWER BEFORE SERVICING

!

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT ― This document is customer property and is to

remain with this unit. Please return to service information pack upon

completion of work

General

The economizer is a multi-damper design. It is installed in the

return air stream and is connected to the unit low voltage supply

through wire leads. The economizer is fully accessible

through the Coil access panel.

Important: After the Economizer installation you must

install an air lter rack ordered separately. Use:

BAYFLTR101B for 4WCZ6, 4YCZ6, 4DCZ6036

BAYFLTR201B for 4WCZ6, 4YCZ6, 4DCZ6048-060.

When the economizer is installed in 4WCZ6 & 4DCZ6 models,

relay accessory kit BAYRLAY006A is required. Refer to Figure 13

on page 9 to make your relay wiring connections in the Control

Box.

IMPORTANT: In order to maintain a specic minimum fresh

air cfm during each mode of operation, you must order and

install a BAYOSAC001 (outside air control) accessory.

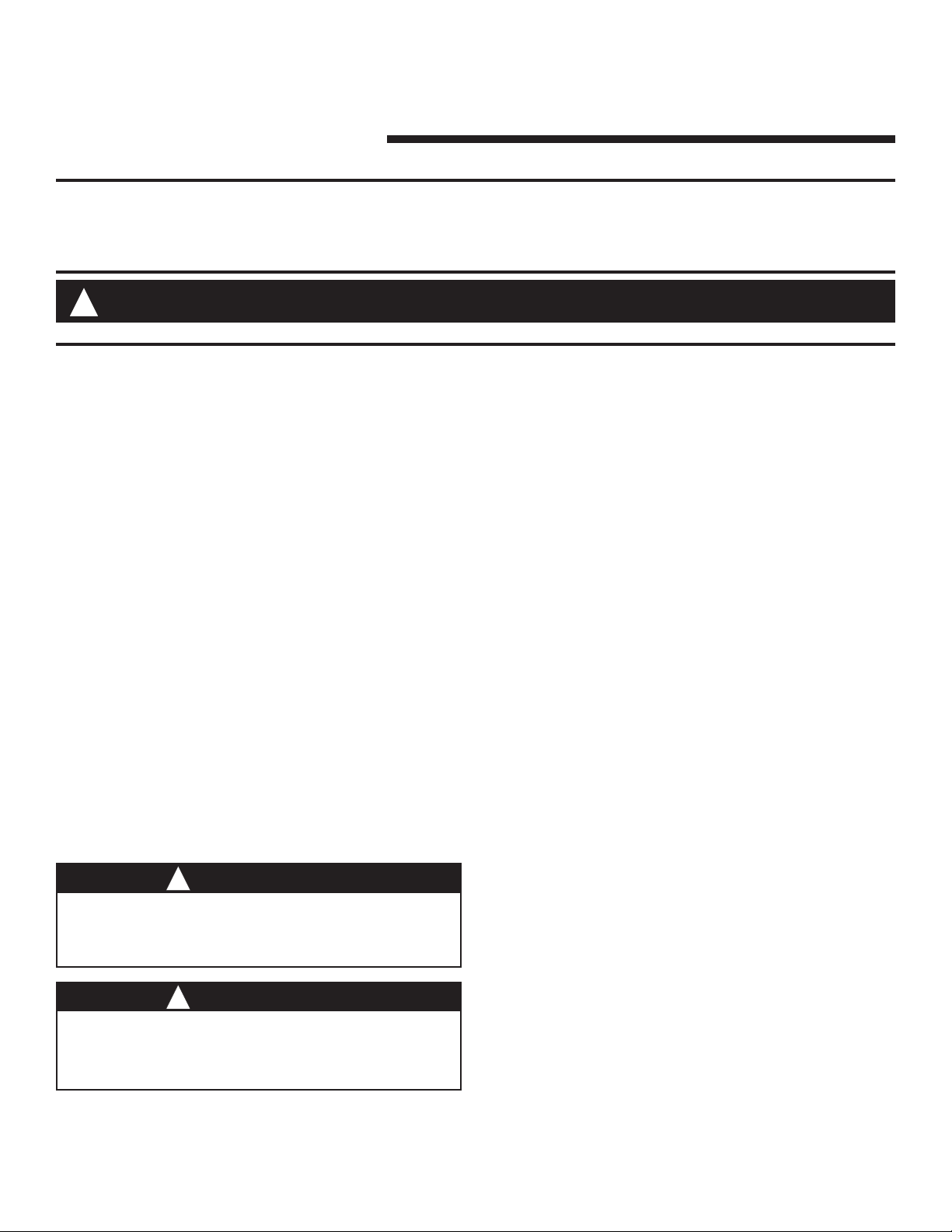

Identify Economizer Kit Contents

Refer to Figures 1 & 2 on page 3 to identify the kit contents.

Inspect Contents

You must report damage and make claims to the transportation company

immediately. Report missing parts to your supplier immediately and

replace with authorized parts only.

WARNING

!

ELECTRICAL SHOCK HAZARD

Open and lock out all unit disconnects prior to accessory

installation or unit maintenance, to prevent injury or death

from electrical shock or contact with moving parts.

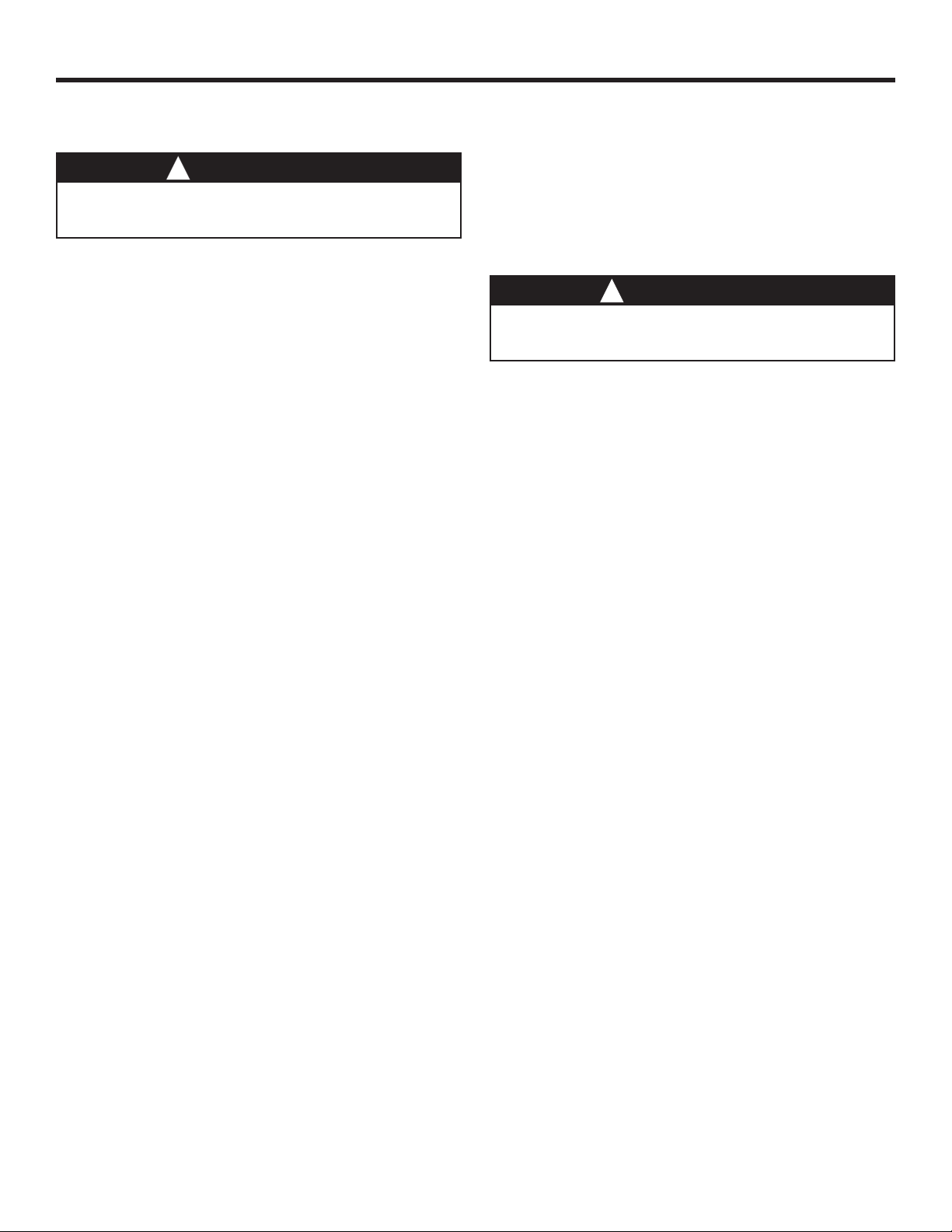

Install Economizer Kit

1. Remove Power

Disconnect and verify that power is off.

2. Remove Access Panels

Remove these four (4) access panels (see Figure 3, page 3):

• Control/Heat access panel

• Blower access panel

• Coil access panel

• Downow Return Air panel

3. BAYRLAY006A Installation (Required

for 4WCZ6 & 4DCZ6 units only, 4YCZ6

units skip to step 4)

1. Remove wire harness that came attached to the BAYECON

Logic Module being installed.

IMPORTANT: Do NOT remove the resistors from the

Logic Module. Also, Do NOT remove the YL & YL/BK

wires connected to SO and + on the Logic Module

2. Locate the ICMC Board in the upper left hand corner of the

unit control box and the DFC board in the upper center of

the unit control box. See Figure 8, page 6.

3. Using the existing holes in the back of the unit control box,

mount the relay bracket assembly using the 2 screws

supplied with the BAYRLAY0006A Kit. See Figure 8, page

6.

4. Route the BAYRLAY006A wire harness attached to the

relays to the logic module as shown in Figure 11 on page 7.

5. Connect the BAYRLAY006A to the economizer Logic

Module and make the eld connections as shown in Figure 13

on page 9.

18-HE85D1-4

WARNING

!

SAFETY HAZARD

Do not remove end covers from economizer actuator; the

spring-return assembly may release and cause personal

injury.

1

Page 2

INSTALLER’S GUIDE

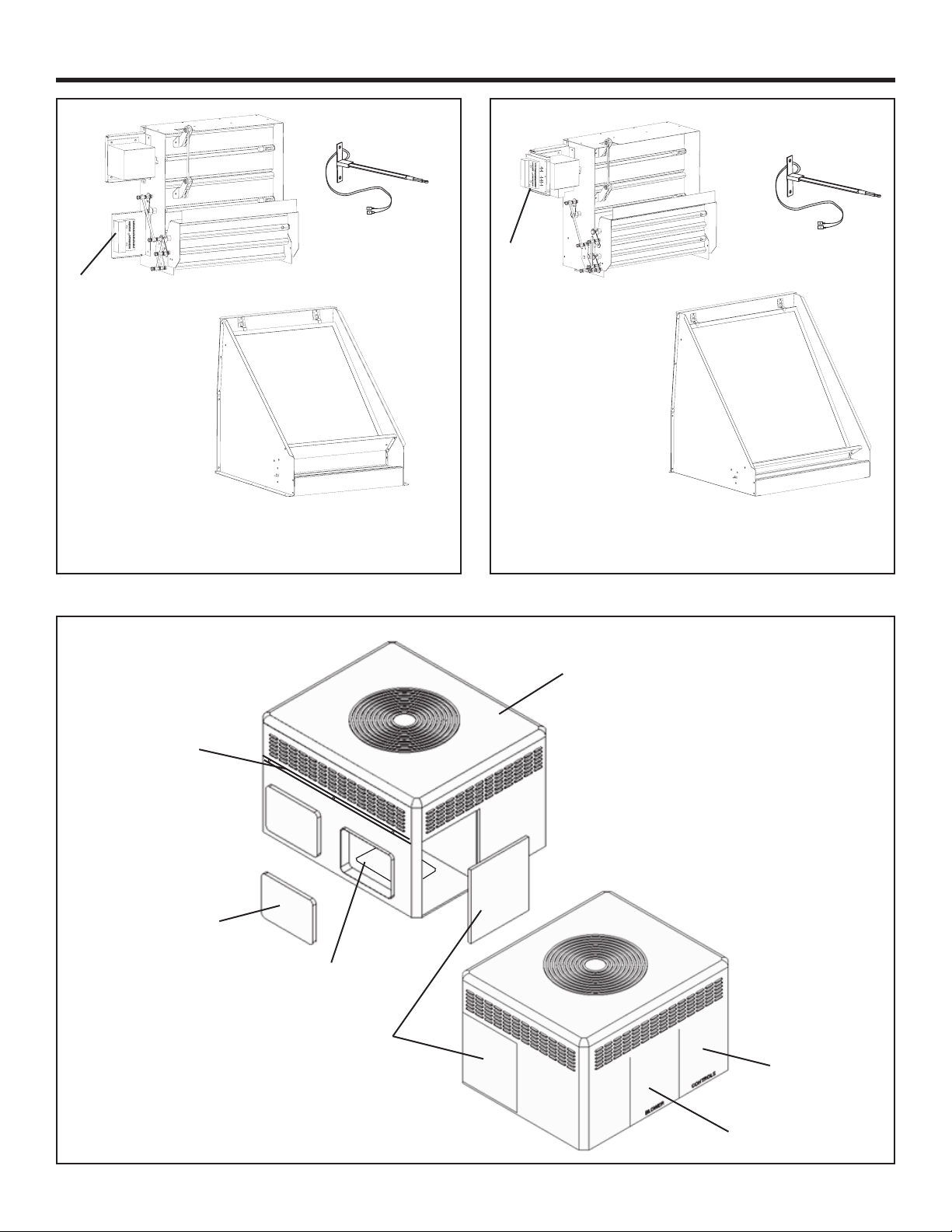

4. Install Economizer Assembly

NOTE: You must install the lter rack per the instructions

provided with the lter rack after you install the economizer.

CAUTION

!

Use care when inserting the economizer in the return

air compartment, to prevent damaging the foil faced

insulation.

1. The economizer ships with the return air damper folded

up to allow the assembly to t through the Coil opening

in the side of the unit. Insert the economizer assembly into the

unit through the Coil access panel opening. See Figure 4 on

page 4.

2. Swing the return air damper section down so that it rests

on the bottom of the unit. The economizer will sit completely

over the return air opening in the bottom of the unit. See

Figure 5 on page 4. Screw the economizer assembly together

with one assembly screw in the side of the economizer. Check

the linkage rod between the return air dampers to make sure it

is tight.

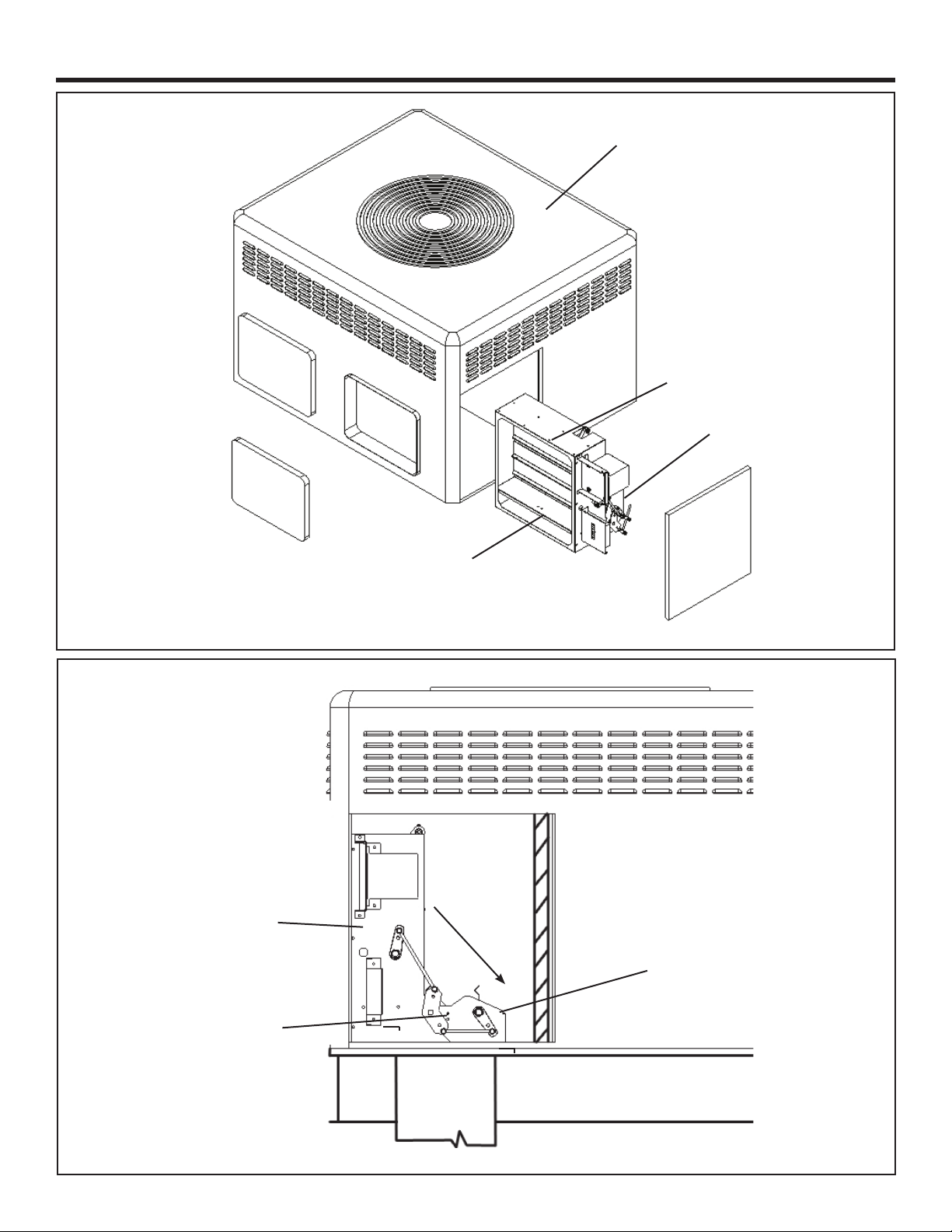

3. Insert 2 screws through the holes in the front face of the

unit and into the matching attachment holes in the economizer

assembly. See Figure 6 on page 5.

4. Insert a screw through the pre-punched hole in the side

ange of the return air damper and into the mating hole

in the economizer assembly and tighten. See Figure 5 on page

4.

8. Complete Installation (4WCZ6, 4DCZ6, 4YCZ6)

1. In the Control Box, locate the ICMC Board in the upper left hand

corner of the Control Box. Find the YL/RD and YL wires in the 12

pin connector. Leaving enough length of these wires so that the

ends going to the ICMC Board can be stripped, cut these wires in

two. Strip the cut end of the wires going to the ICMC Board and

connect to economizer wires as per hookup diagrams on pages 8

and 9. Cap the ends of the Yellow and Yellow/Red wires not

being hooked up. Secure all wires with wire ties so that there is no

interference with any moving parts in the unit.

CAUTION

!

Be certain to cap the ends of the cut YL/RD and YL wires

that are not being connected to an accessory or the unit to

reduce the risk of a short.

2. In the Control Box, complete the wiring connections per the

appropriate wiring diagram on pages 8 and 9. Secure all wires so

that there is no interference with any moving parts in the unit.

3. Power the economizer and run the checkout procedure on page

10. Make desired adjustments to the controller setting the

minimum occupied damper position, the outside air setting (if

enthalpy control used).

4. Replace the unit Coil access panel, the Blower access panel, and

the Control/Heat access panel.

5. Install Rain Hood Assembly

1. Locate the rainhood assembly, which includes the relief damper

and the mist eliminator. The back of the hood side mating anges

need to be gasketed (gaskets included in kit). Loosen the right two

(2) screws on the unit’s top sealing ange above the economizer.

See Figure 7 on page 5.

2. Slide the top ange of the hood underneath the unit’s top sealing

ange. Drive two self tapping screws into the keyhole openings on

the side anges of the hood. Tighten the two (2) screws on the top

sealing ange and the screws on the hood side anges. See

Figures 7 and 9.

6. Mount Mixed Air Sensor

1. Mount the Mixed Air sensor (with wiring) to the left Blower

partition using two sheetmetal screws. See Figure 10, page 7. The

male tabs on the Yellow and Yellow/Black wires will connect to

the Economizer wiring harness in a later step.

2. Enthalpy SensorIf used, install this option at this time per

instructions provided in the sensor kit.

7. Route Main Wiring

1. From the Economizer assembly, pass the wire harness through the

coil grommet. See Figure 11 (view A) on page 7. Continue routing

the harness behind the Compressor compartment and into the

Blower compartment.

2. Continue routing the remaining harness through the grommet in

the Control Box partition and into the Control Box.

2

Page 3

INSTALLER’S GUIDE

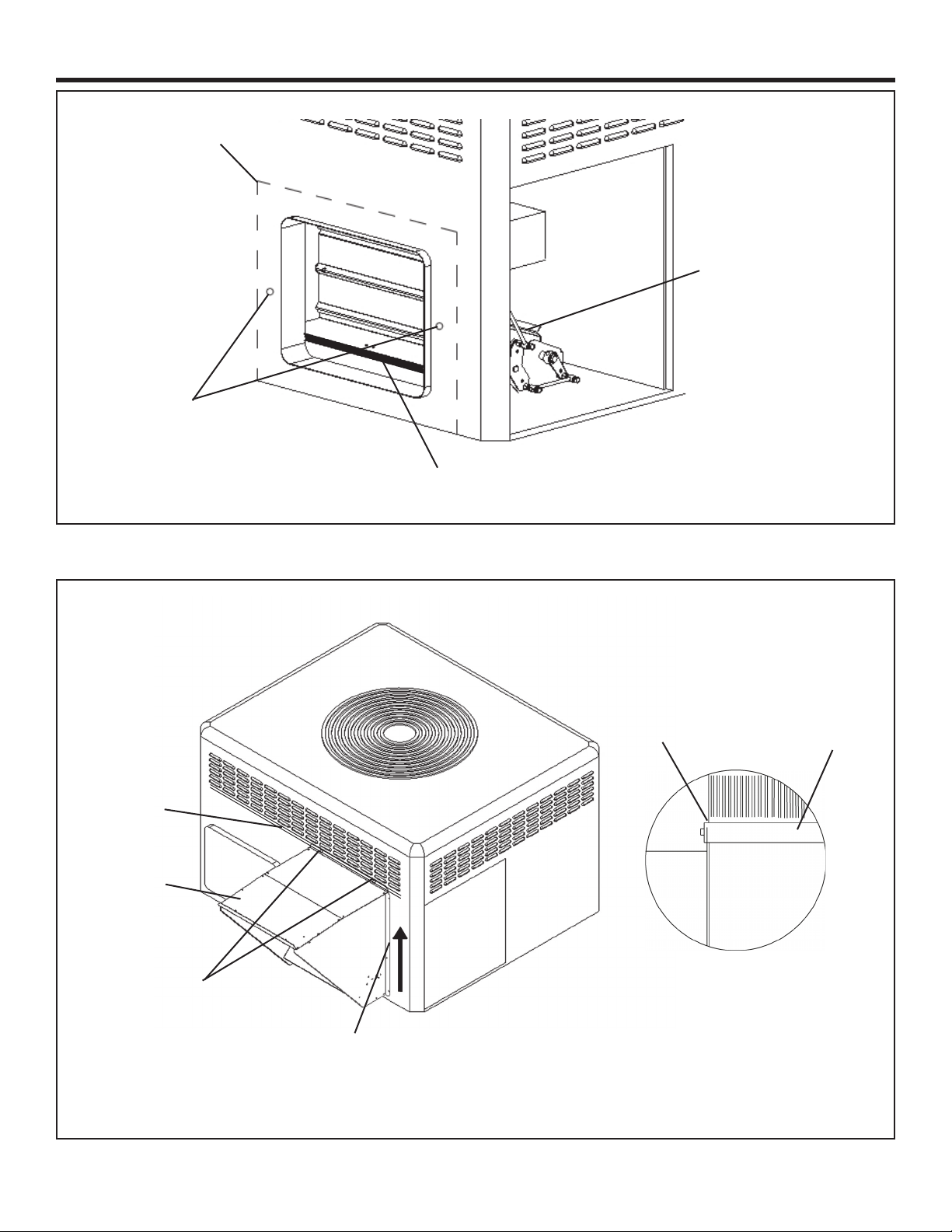

Mixed Air Sensor

Logic

Module

Return Air Damper

Flange Screw and

two (2) Mixed Air

Sensor

Sheetmetal Screws

(not shown)

Figure 1. BAYECON103AA/AB Economizer Kit Components

Economizer Assembly

Mist

Eliminator

(Filter)

Rainhood Assembly

4WCZ6, 4YCZ6, & 4DCZ6036

Logic

Module

Economizer Assembly

Return Air Damper

Flange Screw and

two (2) Mixed Air

Sensor

Sheetmetal Screws

(not shown)

Rainhood Assembly

Figure 2. BAYECON104AA/AB Economizer Kit Components

4WCZ6, 4YCZ6, & 4DCZ6048-060

4WCZ6, 4YCZ6, or 4DCZ6 Unit

Mixed Air Sensor

Mist

Eliminator

(Filter)

Top Sealing

Flange

Horizontal

Return Air

Panel

Down Flow

Return Air

Panel

Coils Access

Panel

Control Box

Access Panel

Blower Access Panel

Figure 3. Remove Panels

3

Page 4

INSTALLER’S GUIDE

4WCZ6, 4YCZ6, or 4DCZ6 Unit

Insert economizer

in folded shipping

position

Economizer

actuator and

Logic Module

Economizer

Dry bulb outside air

temperature sensor

Figure 4. Insert Economizer in Shipping Position

1.) Swing

Down

Return Air

Damper

Return Air Damper

2.) Insert Assembly

Screw

Figure 5. Swing Down and Set Economizer Return Damper

4

Page 5

Economizer outline

Install two (2)

screws into holes.

Leave extended

from unit 1/2”

INSTALLER’S GUIDE

Economizer and

Return Air Damper

Apply gasket between damper assembly and hood

Figure 6. Start Economizer’s Front Mounting Screws

Unit’s top sealing

ange

Economizer Rain

Hood

1. Loosen the two

(2) screws to allow

hood to slide under

top sealing ange of

the unit.

2. Drive six (6) self

tapping screws into

the keyhole openings

on each side of hood

anges.

3. Tighten the two

(2) top screws and

the two (2) side

screws

Figure 7. Mounting Rain Hood

Top ange of hood

slides under HVAC

unit’s top sealing

ange

Hood

HVAC unit’s top

sealing ange

HVAC unit

Detail

5

Page 6

INSTALLER’S GUIDE

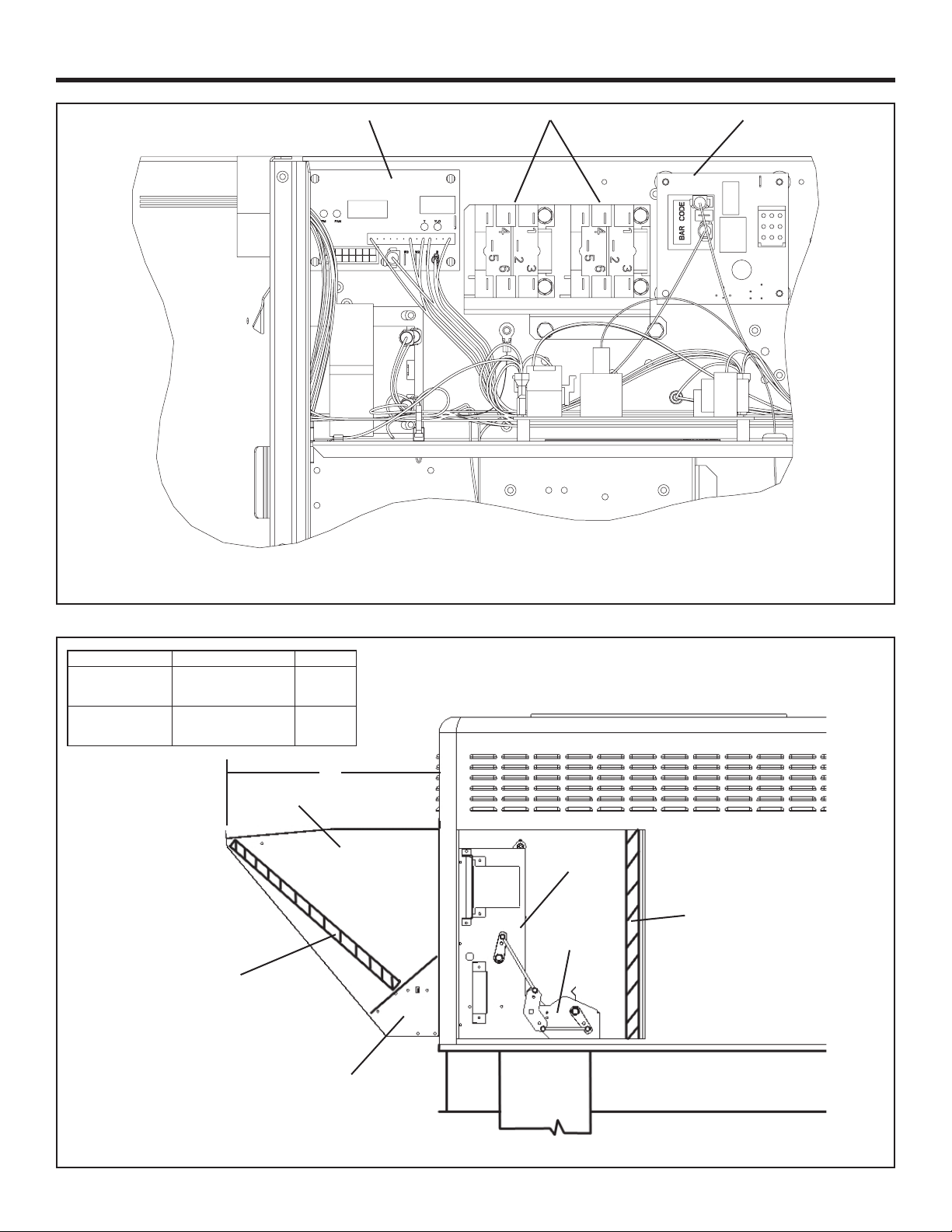

ICMC Board Relays

DFC

Economizer Unit Application Models A

BAYECON103AA/AB

BAYECON104AA/AB

4WCZ6036A

4DCZ6036A

4YCZ6036A

4WCZ6048-060A

4DCZ6048-060A

4YCZ6048-060A

Economizer Rain

Hood

Mist Eliminator

(lter)

Figure 8. Mount BAYRLAY006A

20 1/8”

24 3/8”

A

Outside air

dampers

Return air

dampers

Required lter kit,

order separately

Relief Damper

Return Duct

Roofcurb

Figure 9. Rain Hood, Economizer, and Filter

6

Page 7

1.80”

INSTALLER’S GUIDE

2.82”

View ‘A’ Approximate

Mounting Dimensions

1.) From economizer

assembly, pass wire

harness through coil

Grommet. See View A.

See View ‘A’

Mount the Mixed Air

Sensor to the partition

using two (2) sheetmetal

screws. See view A for

approximate positioning

Figure 10. Mount Mixed Air Sensor in Blower Compartment

2.) Continue routing

behind compressor

compartment and into

Blower Compartment.

3.) Pull the two (2) Mixed Air

Sensor wires (with female quick

connects) from the harness and

route down near the Mixed Air

Sensor. Connect to sensor

pigtail wire leads.

4.) Continue Routing the

Remaining Harness

Through the Grommet

and into the Control Box.

Location of

Mixed Air Sensor

Figure 11. Main Wire Harness Routing

Coil Grommet

View A

Coil Grommet Location

7

Page 8

INSTALLER’S GUIDE

A

A

A

A

Wiring Diagram for Economizer Using a Honeywell W7459 Logic

Figure 12. 4YCZ6 Economizer Connection Diagram

IMPORTANT-Retain this wiring diagram; please return this document to service information pack upon completion of work.

8

Page 9

INSTALLER’S GUIDE

Wiring Diagram for Economizer Using a Honeywell W7459 Logic

AAA

A

Figure 13. 4WCZ6 & 4DCZ6 Economizer Connection Diagram

IMPORTANT-Retain this wiring diagram; please return this document to service information pack upon completion of work.

9

Page 10

INSTALLER’S GUIDE

Wiring Diagram for Economizer Using a Honeywell W7212 Logic

A

A

A

A

Figure 14. 4WCZ6 & 4DCZ6 Economizer Connection Diagram

IMPORTANT-Retain this wiring diagram; please return this document to service information pack upon completion of work.

10

Page 11

INSTALLER’S GUIDE

Wiring Diagram for Economizer Using a Honeywell W7212 Logic

A

A

A

A

Figure 15. 4YCZ6 Economizer Connection Diagram

IMPORTANT-Retain this wiring diagram; please return this document to service information pack upon completion of work.

11

Page 12

INSTALLER’S GUIDE

12

85

100

105

110

(43)

0

(43)

1

HIGH LIMIT CURVE FOR W7459D.

Sequence Of Operation

NOTE: A (G) signal is required for the economizer to operate. As

shipped, the economizer will not operate when there is a signal for

Heating Modes utilizing gas heat.

Fan Only (G): When the thermostat sends a signal for fan only (G),

the economizer will open to the minimum position setting regardless

of the outdoor air conditions and the indoor blower will operate at

approximately 50% airow.

Heating (W1), (W2), (Y1, Y2 on Heat Pump or Dual Fuel

Models): When the thermostat sends a signal for auxiliary heat (G)

+ (W1) or rst stage heat (G) + (Y1,Y2), the economizer will open

to the minimum position setting. When the ambient temperature may

be below 70F, the economizer will not fully open to the economizing

position, when there is a signal for heat. In order to receive fresh air

and open the dampers to the minimum position setting, you must

provide a G signal to the unit from the thermostat or comfort control

being used.

FREE COOLING NOT AVAILABLE: When the outdoor air

conditions are not sufcient for “Free Cooling” the Economizer will

open to the minimum position setting only and the unit will

function.

FREE COOLING AVAILABLE:

1st Stage Cooling (Y1) + (O for Heat Pumps and Dual Fuel

models): When outdoor air conditions are sufcient for “Free

Cooling” and the thermostat sends a signal for 1st stage cooling (G) +

(Y1) + (O for Heat Pumps and Dual Fuel models), the economizer

will modulate accordingly and the indoor blower will run at

approximately 70% airow.

2nd Stage Cooling (Y1) + (Y2) + (O for Heat Pumps and Dual

Fuel models): When outdoor air conditions are sufcient for “Free

Cooling” and the thermostat sends a signal for 2nd stage cooling (G) +

(Y1) + (Y2) + (O for Heat Pumps and Dual Fuel models), the

economizer will modulate accordingly, the compressor will operate

on low speed, and the indoor blower will operate at 100% airow.

Unit “OFF” Mode

When the economizer is not receiving a 24V signal to the TR

terminal, or if power is disconnected to the unit, the dampers will be

fully closed to the outside air and fully open to the return air.

NOTE: Free Cooling refers to the process of circulating

unconditioned outside air, without operating the compressor, to cool

the structure.

5A. CHECKOUT - For Units using a Honeywell

W7459 Control, Only.

Operate the motor through its complete open-close stroke. Check

for proper operation, making sure that the linkage does not bind

and that the motor travels smoothly throughout its fully open

and closed position. Table 1 describes how to drive the motor to

the full open and full closed positions (power connected). Make

necessary minor adjustments until desired operation is obtained,

and tighten all nuts and set screws. This motor checkout ensures

that:

1. The motor operates the load.

2. The motor responds properly to the controller.

3. There is no binding of the linkage or motor stalling at any

point of travel.

If motor does not operate properly, check for proper voltage or

mechanical binding in linkage or damper.

If questions arise regarding this product, contact your distributor

or representative.

Single enthalpy: The enthalpy

changeover set point is set to return

the outdoor air damper to minimum

position when the enthalpy rises above

its set point. The enthalpy set point

scale markings, located on W7459, are

A,B,C,D; see table for the corresponding

control point. The factory-installed R4

CONTROL

CURVE

A 73 (23)

B 70 (21)

C 67 (19)

D 63 (17)

CONTROL POINT

APPROX. F (C)

AT 50% RH

44 46

(29)90(32)95(35)

80

(27)

75

(24)

(38)

(41)

WHITE 620-ohm jumper must be in place

across terminals + and SR.

ENTHALPY—BTU PER POUND DRY AIR

55

(13)

50

C

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

35

(2)

35

(2)

APPROXIMATE DRY BULB TEMPERATURE— F ( C)

(10)

45

D

(7)

40

(4)

40

45

50

(4)

55

(7)

(10)

(13)

70

(21)

100

90

65

80

(18)

60

(16)

A

B

60

(16)

70

60

C

D

65

70

75

(18)

(21)

(24)

(27)

50

A

B

80

85

(29)90(32)95(35)

40

1

RELATIVE HUMIDITY (%)

30

20

10

105

11

100

(41)

(38)

M11681

12

Figure 16. Single Enthalpy Changeover Set Point

Page 13

INSTALLER’S GUIDE

Table 1. Motor Operation Checkout - W7459 Control Only

MODEL DRIVE MOTOR OPEN DRIVE MOTOR CLOSED SPRING RETURN

M7415 Power to TR and TR1, jumper T and T1

Table 2. Enthalpy Checkout Procedure - W7459 Control

Checkout Procedure Response

A 1. Disconnect power at TR and TR1.

2. Disconnect jumper P to P1.

3. Jumper TR to 1.

4. Jumper T1 to T.

5. If connected, remove C7400 Solid State Enthalpy Sensor from terminals S0 and +. Ensure factory-installed 620 ohm resistor is connected to terminals Sr and +.

6. Apply power (24Vac) to terminals TR and TR1

B 1. Disconnect factory-installed 620 ohm resistor from terminals Sr and

+

C 1. To simulate high and low enthalpy (single enthalpy sensor) re-

connect factory-installed 620 ohm resistor from terminals Sr and +.

Connect 1.2K ohm 4074EJM Checkout Resistor across terminals So

and +.

2. Turn enthalpy setpoint potentiometer to "A".

3. Turn enthalpy setpoint potentiometer to "D".

4. Disconnect the 1.2K ohm checkout resistor

D 1. To verify sensor operation, reconnect the + lead of the outdoor

enthalpy sensor to the + terminal of W7459.

2. Connect a DC multimeter between terminal So of the W7459A and

terminal S of the enthalpy sensor. See Fig. 17 (positive meter lead to

terminal S of the enthalpy sensor).

3. When using differential enthalpy, check the return air enthalpy

sensor by connecting a DC multimeter between terminal Sr of the

W7459A and terminal S of the return air enthalpy sensor. (positive

meter lead to terminal S of the enthalpy sensor).

Disconnect jumper at T or T1 and

disconnect P or P1, if connected

LED is off.

Motor is in closed position.

LED turns on, motor drives toward open.

―

LED turns on, indicating low enthalpy.

Motor drives toward open.

LED turns off, indicating high enthalpy.

Motor drives toward closed.

―

―

Multimeter indication is between 3 and 25 mA if

sensor is operating properly.

If multimeter indicates zero, the sensor may be

wired backward.

Multimeter indication is between 3 and 25 mA if

sensor is operating properly.

If multimeter indicates zero, the sensor may be

wired backward.

Disconnect power at TR and TR1

13

Page 14

INSTALLER’S GUIDE

OUTDOOR AIR IS SUITABLE

IS PRESENT ONLY ON W7459A,D MODELS.

Location of Enthalpy Set Point, Minimum Position and LED Meter Location for Checkout and Troubleshooting

14

MINIMUM DAMPER POSITION ADJUSTMENT

1

Table 3. Temp vs. OHM Values for MAS (Mixed Air Sensor)

Temp F Temp C R(K OHMS) DC Volts

33.8 1 9.576 3.910

35.6 2 9.092 3.882

37.4 3 8.636 3.894

39.2 4 8.204 3.863

41.0 5 7.796 3.829

42.8 6 7.412 3.790

44.6 7 7.048 3.749

46.4 8 6.705 3.713

48.2 9 6.380 3.674

50.0 10 6.073 3.634

51.8 11 5.782 3.590

53.6 12 5.507 3.550

55.4 13 5.247 3.507

57.2 14 5.000 3.420

59.0 15 4.767 3.373

60.8 16 4.545 3.328

62.6 17 4.335 3.283

64.4 18 4.136 3.239

66.2 19 3.948 3.180

68.0 20 3.769 3.157

69.8 21 3.599 3.118

71.6 22 3.437 3.080

73.4 23 3.284 3.034

75.2 24 3.138 3.007

77.0 25 3.000 2.971

78.8 26 2.869 2.932

80.6 27 2.744 2.896

82.4 28 2.625 2.860

84.2 29 2.512 2.824

86.0 30 2.404 2.787

87.8 31 2.301 2.750

89.6 32 2.204 2.714

91.4 33 2.111 2.676

93.2 34 2.023 2.639

95.0 35 1.938 2.600

96.8 36 1.858 2.561

98.6 37 1.781 2.526

100.4 38 1.708 2.484

ENTHALPY

CHANGEOVER

SETPOINT

MINIMUM

DAMPER

POSITION

1

SETTING

LED LIGHTS

WHEN OUTDOOR

AIR IS SUITABLE

FOR FREE COOLING

M9098B

W7459

BC

A

INSERT DC MILLIAMMETER BETWEEN SO AND S FOR CHECKOUT

1

2

MULTIMETER

AND TROUBLESHOOTING.

JUMPER USED FOR SINGLE ENTHALPY CONTROL.

Figure 17. Enthalpy LEDs and Checkout

Temp vs. OHM for MAS (Mixed Air Sensor)

TR1

TR

S

O

D

S

R

+

+

2

620 OHM

JUMPER

LED LIGHTS WHEN

FOR FREE COOLING

ENTHALPY CHANGEOVER

SETPOINT

+

1

S

+

C7400

DC

MULTIMETER

MILLIMETER

M9097

Page 15

INSTALLER’S GUIDE

M20612

DC VOL

W7212

AQ1 FOR

5B. CHECKOUT - For Units with a Honeywell W7212 Control, Only. See 5A for W7459

CHECKOUT AND

TROUBLESHOOTING

Checkout requires a 9V battery, 620 ohm, 1.2K ohm, 5.6K ohm,

and 6.8K ohm resistors. Use Table 4 and Fig. 18 for checkout.

CAUTION

!

Equipment Damage Hazard.

Excessive force can damage potentiometer

controls.

Use a small screwdriver when adjusting enthalpy

changeover and minimum damper position controls.

EXH

DCV

Free

Cool

EXH

Set

10V

2V

Min

Pos

Open

DCV

Max

2V

10V

DCV

Set

2V

10V

B

C

A

D

N1

N

P1

P

T1

1

TMETER

T

+

AQ1

AQ

S

C7400

+

2

1

INSERT DC VOLTMETER BETWEEN AQ AND

CHECKOUT AND TROUBLESHOOTING.

2

JUMPER USED FOR SINGLE ENTHALPY CONTROL.

SO+

SO

SR+

SR

620 OHM RESISTOR

Fig. 18. Meter location for checkout and

troubleshooting (W7212 shown).

Table 4. Checkout for W7212, W7213, W7214 Economizer Connected to Honeywell Actuator

Step Checkout Procedure Proper Response

1. CHECKOUT PREPARATION FOR ECONOMIZING ONLY

Disconnect power at TR and TR1 All LED are off; Exhaust Fan contacts are open

Disconnect devices at P and P1

Jumper P to P1 (defaults to on board MIN POS potentiometer).

Place 5.6K ohm resistor across T and T1 (Blue sleeve-provides input to

economizer that the MAT is between 50-55F).

Jumper TR to 1 (call for cooling from the thermostat).

W7212 only jumper TR to N (places economizer in occupied mode).

If connected, remove C7400 Enthalpy Sensor from terminals SO and +.

Connect 1.2K ohm, from 4074EJM Checkout Resistor kit, (purple sleeve)

across terminals SO and + (makes OA enthalpy high).

Place 620 ohm resistor (white sleeve) across SR and + (makes return

enthalpy lower than OA).

Set MIN POS and DCV MAX potentiometers fully CCW.

Turn DCV setpoint potentiometer mid position (this sets the DCV

ventilation at approximately 1000 ppm).

Turn exhaust potentiometer to mid position (motor will be approximately

50% open when the exhaust fan contacts make).

Set enthalpy potentiometer to D.

W7214 only Jumper TR to O.

Apply power (24 Vac) to terminals TR and TR1

15

Page 16

INSTALLER’S GUIDE

Table 4. Checkout for W7212, W7213, W7214 Economizer Connected to Honeywell Actuator (Cont.)

Step Checkout Procedure Proper Response

2. DIFFERENTIAL ENTHALPY

Execute stop one, Checkout Preparation.

Turn DCV MAX to mid position.

Place 620 ohm resistor across SO and + (white sleeve resistor

makes OA enthalpy low).

Place 1.2K ohm resistor across SR and + (purple sleeve resistor

makes RA enthalpy high).

Remove 620 ohm resistor from SO and +. Free cool LED turn off; motor drives closed

3. SINGLE ENTHALPY

Execute stop one, Checkout Preparation.

Turn DCV MAX to mid position.

Set enthalpy potentiometer to A (fully CCW). Free cool LED turns on; motor drives to approximately 45

Set enthalpy potentiometer to D or E for W7212C (fully CW). Free cool LED turns off; motor drives closed.

4. DCV AND EXHAUST

Execute step one, Checkout Preparation.

LED for both DCV and Exhaust should be off.

Turn DCV MAX to mid position. Motor drives to mid position, 45 degrees open.

Turn MIN POS fully CW. Motor drives fully open.

Turn MIN POS and DCV MAX to fully CCW. Motor drives closed.

Turn DCV MAX to mid position.

Connect 9V battery positive to AQ and negative to AQ1.

Remove jumper from N terminal (economizer goes into not occupied mode).

Adjust DCV MAX towards CW. Motor will move to position set by DCV MAX pot.

Adjust DCV MAX to fully CCW. Motor will drive closed.

Reconnect jumper to N terminal.

Adjust DCV MAX and MIN POS pots. Motor will drive to the most open position of the pots.

Adjust DCV MAX and MIN POS pots to fully CCW.

Remove power from N terminal adjust MIN POS towards CW. Motor should not move.

Adjust DCV MAX towards CW. Motor will move to position set by DCV MAX pot.

5. MINIMUM AND MAXIMUM POSITION

Execute stop one, Checkout Preparation.

Connect 9V battery positive to AQ and negative to AQ1. Adjust

DCV MAX potentiometer to mid position.

Turn DCV maximum position potentiometer to fully CCW. Actuator drives fully closed.

Turn minimum position potentiometer to midpoint. Actuator drives to 45 degrees open.

Turn minimum position potentiometer fully CW. Actuator drives fully open.

Turn MIN POS to fully CCW. Actuator drives fully closed.

W7212: Remove jumper from TR and N. Actuator drives fully closed.

W7214: Jumper TR to O.

6. MIXED AIR INPUT

Execute stop one, Checkout Preparation.

Turn DCV MAX to mid position; set enthalpy potentiometer to A. Free cool LED turns on.

Remove 5.6K ohm resistor (green sleeve) and place jumper from

T and T1.

Remove jumper from T and T1 and leave open. Actuator drives fully closed.

16

―

Free cool LED turn on; motor drives to approximately 45

degrees (half) open.

―

degrees (half) open.

―

LED for both DCV and Exhaust turn on.

Actuator drives to 45 degrees open.

Motor remains at 45 degrees open.

―

DCV LED turns on. Actuator drives to 45 degrees open.

―

Actuator drives to 45 degrees open.

Actuator drives to 45 degrees open.

Page 17

INSTALLER’S GUIDE

17

Page 18

INSTALLER’S GUIDE

Trane

6200 Troup Highway

Tyler, TX 75707-9010 © 2010 Trane

18

The manufacturer has a policy of continuous product and

product data improvement. It reserves the right to change

design and specication without notice.

Loading...

Loading...