INSTALLER'S GUIDE

▲

WARNING

!

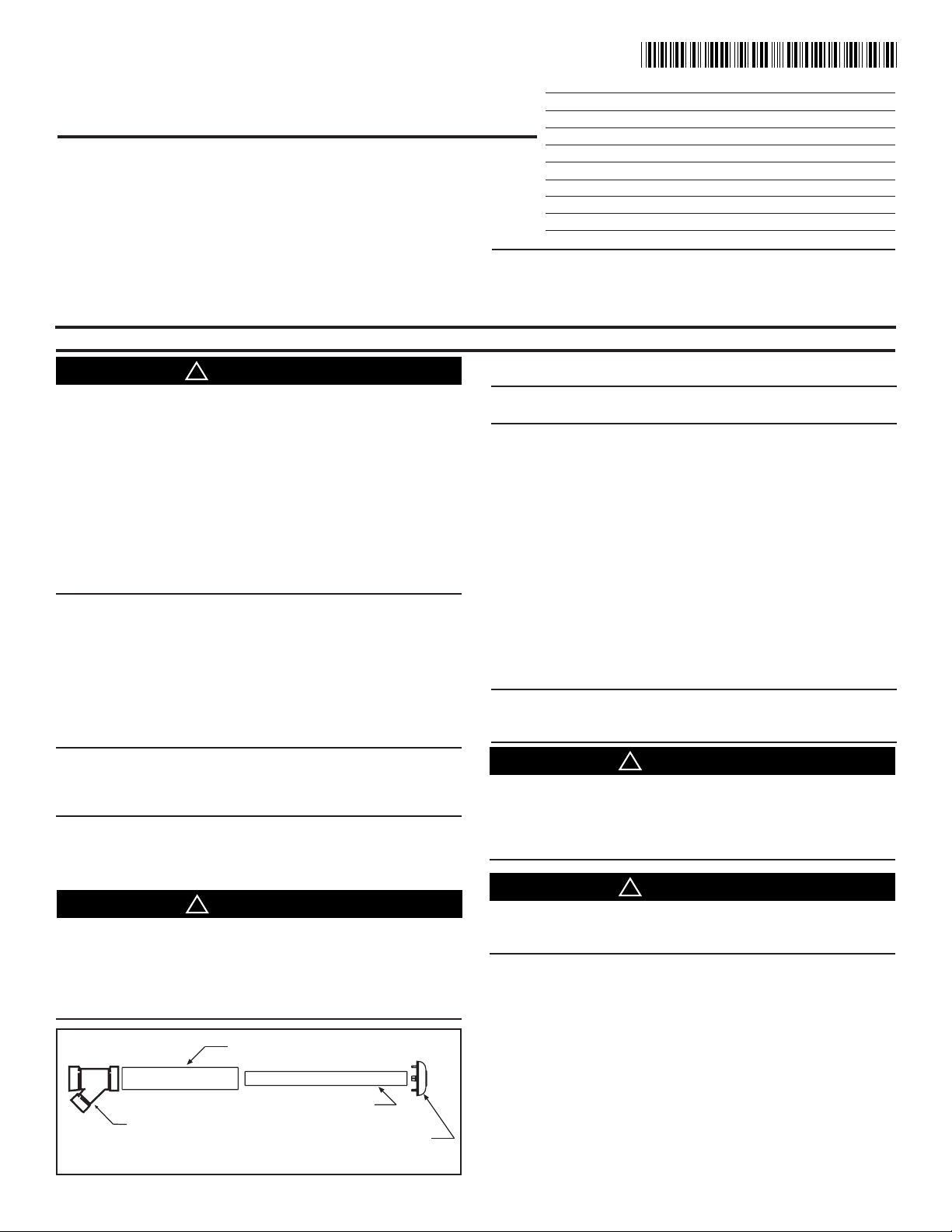

RAIN CAP

4" SDR-26 PIPE

2-1/2" SDR-26 PIPE

WYE- CONCENTRIC FITTING

▲

WARNING

!

▲

WARNING

!

▲

WARNING

!

ALL phases of this installation must comply with

NATIONAL, STATE AND LOCAL CODES.

Model:

BAYAIR30AVENTA

Concentric Vent Kit for

Condensing Furnaces and Boilers

For use with *UH, *DH, M95, *UY, *DY, *UX, *DX,

*UC, *DC model Furnaces and TGCW130A90M0A

and TGXWW130A90M0A boilers

* may be A or T or C

IMPORTANT — This Document is customer proper ty and is to remain with this unit. Please return to service information pack upon completion of work.

NOTE:

Canada requires that all Category IV heating appliances use

venting material that meets ULC S636. This kit does not meet

these requirements and cannot be used.

DO NOT APPLY TO A NON-CONDENSING FURNACE.

Library

Product Section

Product

Model

Literature Type

Sequence

Date

File No.

Supersedes

18-CH34D1-7

Service Literature

Unitary

Unitary Accessories

Vents

Installer's Guide

02/12

18-CH34D1-7

18-CH34D1-56

0

INSTALLATION OR REPAIRS MADE BY UNQUALIFIED

PERSONS CAN RESULT IN HAZARDS TO YOU AND OTHERS. INSTALLATION MUST CONFORM WITH LOCAL CODES

OR, IN THE ABSENCE OF LOCAL CODES, WITH CODES OF

THE COUNTRY HAVING JURISDICTION. THE INFORMATION

CONTAINED IN THESE INSTRUCTIONS IS INTENDED FOR

USE BY A QUALIFIED SERVICE TECHNICIAN FAMILIAR WITH

SAFETY PROCEDURES AND EQUIPPED WITH THE PROPER

TOOLS AND TEST INSTRUMENTS. FAILURE TO CAREFULLLY READ AND FOLLOW ALL INSTRUCTIONS IN THESE

INSTRUCTIONS CAN RESULT IN FURNACE OR BOILER

MALFUNCTION, PROPERTY DAMAGE, PERSONAL INJURY

AND/ OR DEATH.

NOTE: Codes and local utility requirements governing the

installation of gas fired equipment, wiring, plumbing, and

flue connections must be adhered to. In the absence of local

codes, the installation must conform with the Nation Fuel

Gas Code ANSI Z223.1 "latest edition", or CAN/ CGA B149

Installation Codes. The latest code may be obtained from the

American Gas Association Laboratories 400 N. Capitol St.

NW, Washington D.C. 20001, 1-800-699-9277 or www.aga.

com

NOTE: Read the Installer's Guide before starting the installation. Refer to the Furnace or boiler Installer's Guide for

equivalent vent lengths. The BAYAIR30AVENTA is 5 equivalent feet.

INTRODUCTION

This Installer's Guide covers installation of the concentric vent

kit on all gas fired direct vent condensing furnaces.

NOTE: If these instructions differ from those packaged with

the furnace or boiler, follow these instructions.

DESCRIPTION AND USAGE

Kit Contents:

1 — Rain cap

1 — 4" Diameter SDR-26 Pipe, 23.75" Long

1 — 21/2" Diameter SDR-26 Pipe, 33.12"

1 — Wye concentric Fitting

Only one vent kit per each furnace or boiler is allowed.

Vent kit is for 2, 2-1/2 or 3 in. diameter pipe systems, (See

Figures 3, 4, 5, and 6 for the different applications.) Both

the combustion air and vent pipes must attach to the vent

kit. The vent kit must terminate outside of the structure and

should be installed vertically as shown in Figures 3 and 4, or

horizontal as shown in Figures 5 and 6.

NOTE: The roof vent location is preferred since it is less

susceptible to damage, has reduced chances to intake contaminants, and vent vapors are less visible.

THIS VENT KIT IS ONLY TO BE USED FOR VENTING CATEGORY IV FURNACES AND CONDENSING BOILERS. DO

NOT USE TO VENT CATEGORY I, II OR III VENT FURNACES

OR BOILERS. FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN FIRE, PERSONAL INJURY OR DEATH.

INSTALLING AND SERVICING HEATING EQUIPMENT CAN

BE HAZARDOUS DUE TO GAS AND ELECTRICAL COMPONENTS. ONLY TRAINED PERSONNEL SHOULD INSTALL OR

SERVICE HEATING EQUIPMENT. FAILURE TO FOLLOW THIS

WARNING CAN RESULT IN PRODUCT DAMAGE, PERSONAL

INJURY AND/OR DEATH.

1

© 2012 Trane All Rights reserved

CONCENTRIC VENT KIT

DISCONNECT POWER SUPPLY BEFORE BEGINNING INSTALLATION TO PREVENT PERSONAL INJURY OR DEATH

FROM ELECTRICAL SHOCK AND EQUIPMENT DAMAGE.

Field supplied pipe and fittings are required to complete the

installation.

The combustion air and vent pipe and fittings must conform to

American National Standards Institute (ANSI) and American

Society for Testing and Materials (ASTM) standards D1785

(schedule-40 PVC), D2665 (PVC-DWV), D2441 (SDR-21 and

SDR-26 PVC), D2661 (ABS-DWV), or F628 (schedule-40 ABS).

Pipe cement and primer must conform to ASTM standards D2564

(PVC) or D2235 (ABS). In Canada, construct all combustion air

and vent pipes for this unit of CSA or ULC certified schedule-40

PVC/ABS-DWV pipe and pipe cement.

INSTALLER'S GUIDE

MAINTAIN 12 IN.

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SNOW

LEVEL. MAXIMUM OF

24 IN. ABOVE ROOF.

VENT

COMBUSTION

AIR

REMOVE RIBS

FROM CAP

4.5" DIA

35.2" (typ.)

3" DIA PVC

VENT/EXHAUST

3" DIA PVC INTAKE/

COMBUSTION AIR

MAY BE

LENGTHENED TO 60" MAXIMUM

WITH FIELD REPLACEMENT PIPING.

DO NOT EXTEND MAIN BODY PIPES

WITH PIPE COUPLINGS.

MAIN BODY PIPES

21.125" (typ)

▲

WARNING

!

▲

CAUTION

!

▲

WARNING

!

▲

WARNING

!

2 3

CONCENTRIC VENT KIT ASSEMBLED

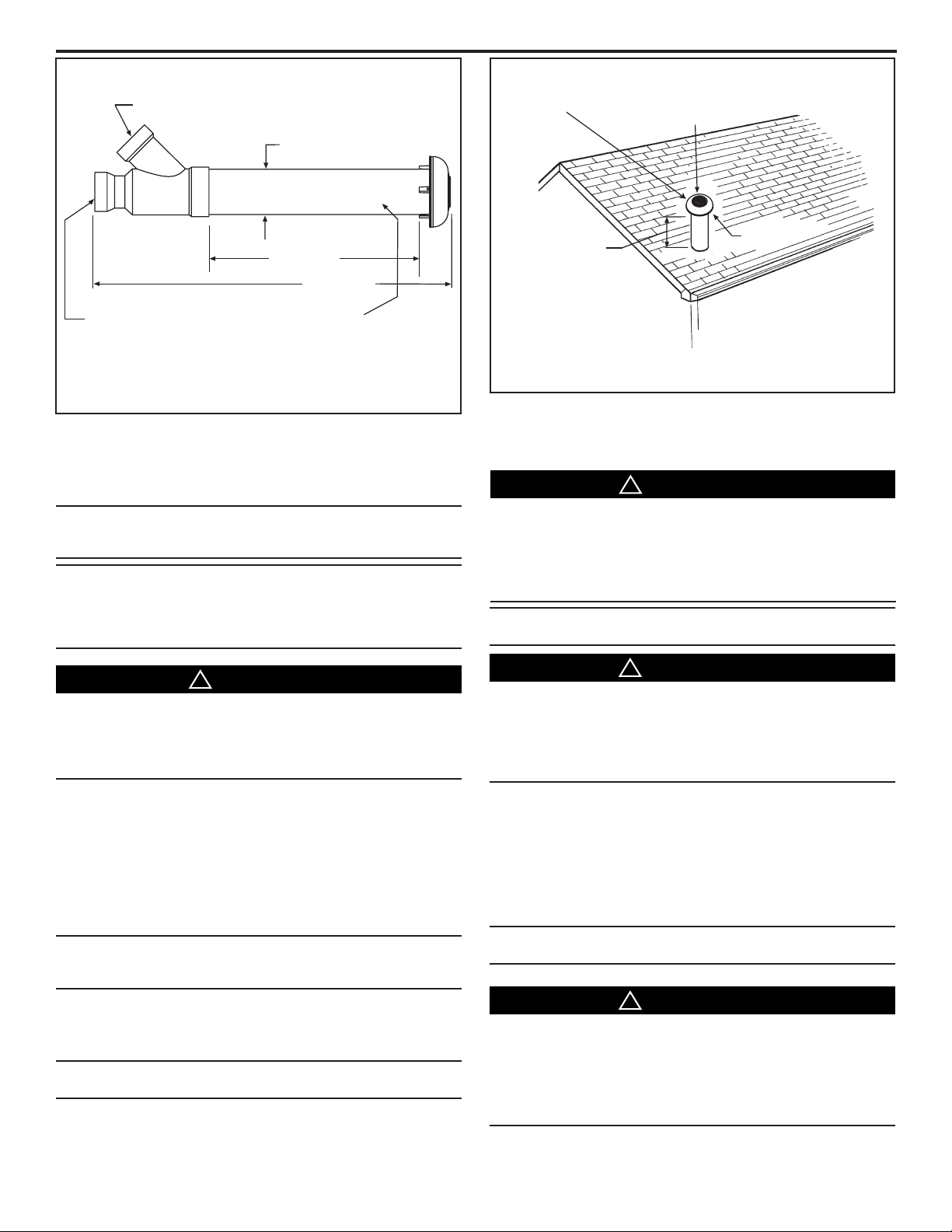

INSTALLATION - ROOF TERMINATION (SEE FIG. 3)

1. Determine best location for termination kit.

2. Cut one hole (5 in. diameter) for vent kit.

6. Remove ribs from rain cap. Install the rain cap and the

CONCENTRIC VENT

ROOF TOP APPLICATION

small diameter pipe assembly in the Wye fitting and pipe

assembly. Ensure that the small diameter pipe is cemented

and bottomed into the Wye fitting.

NOTE: Ensure termination height is above the roof surface

or anticipated snow level (1 ft. in USA or 1 1/2 ft. in Canada)

as shown in Figure 4.

NOTE: If assembly is too short to meet the height requirement, the two pipes supplied in the kit may be replaced by

using same diameter, field supplied SDR-26 PVC (ASTM

D2241) pipe. Do not extend the 4" pipe (24" as shipped) to

more than 60 in. (See Figure 2).

DO NOT USE FIELD SUPPLIED COUPLINGS TO EXTEND

MAIN BODY PIPES (4" AND 2-1/2" PIPES). AIRFLOW RESTRICTION WILL OCCUR AND THE FURNACE OR BOILER

PRESSURE SWITCH MAY CAUSE INTERMITTENT OPERATION.

3. Partially assemble the vent kit. Clean the pipe ends and

adjoining sockets with PVC primer (ASTM F-656) and

cement using PVC cement (ASTM D-256).

a. Cement the Wye concentric fitting to larger diameter kit

pipe. (See Figure 1)

b. Cement the rain cap to smaller diameter kit pipe. (See

Figure 1)

NOTE: Instead of cementing the smaller pipe to the rain cap,

RTV silicon sealant may be used to permit future field disassembly for cleaning

4. Install Wye fitting and pipe assembly from the inside through

structure's hole. Install field supplied roof boot/ flashing.

NOTE: Do not allow insulation or other materials to accumulate inside pipe assembly when installing through hole.

5. Secure assembly to roof structure as shown in Figure 4 using

field supplied metal strapping or equivalent support material.

FAILURE TO REMOVE RIBS FROM RAIN CAP FOR VERTICAL VENT KIT INSTALLATIONS MAY CAUSE ICE OR SNOW

TO FORM ON THE RAIN CAP, LEADING TO AN INOPERABLE

FURNACE. FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

NOTE: Kit supplied stainless steel screw will be used to secure the rain cap to the pipe.

DRILL A PILOT HOLE IN THE VENT PIPE FOR THE SCREW

SIZE BEING USED. FAILURE TO DRILL ADEQUATE HOLES

MAY CAUSE CRACKING OF THE PVC COMPONENTS, ALLOWING FLUE GASES TO BE RECIRCULATED. FAILURE TO

FOLLOW THIS WARNING COULD RESULT IN PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

7. Cement the furnace or boiler combustion air and vent pipes

to the concentric vent termination assembly. See Figure 4

for proper pipe attachment.

8. CHECKOUT: Operate the furnace or boiler to make sure ALL

pipe joints are fastened and sealed to prevent the escape of

combustion products into the building.

NOTE: Two or more installations require a minimum separation distance of approximately one inch between vent kits.

DO NOT OPERATE THE FURNACE OR BOILER WITHOUT

THE RAIN CAP IN PLACE AS RECIRCULATION OF COMBUSTION PRODUCTS MAY OCCUR. WATER MAY ALSO COLLECT

INSIDE THE LARGER COMBUSTION AIR PIPE AND FLOW

TO THE BURNER ENCLOSURE. FAILURE TO FOLLOW THIS

WARNING COULD RESULT IN PRODUCT DAMAGE OR IMPROPER OPERATION, PERSONAL INJURY OR DEATH

Pub. No. 18-CH34D1-7Page 2

INSTALLER'S GUIDE

REMOVE RIBS

FROM CAP

COMBUSTION

AIR

ROOF BOOT

(FIELD SUPPLIED)

COMBUSTION

AIR

VENT

ELBOW

(FIELD SUPPLIED)

MAINTAIN 12 IN.

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SNOW

LEVEL. MAXIMUM OF

24 IN. ABOVE ROOF

SUPPORT

(FIELD SUPPLIED)

VENT

4

CONCENTRIC VENT

ROOF INSTALLATION

INSTALLATION -SIDE WALL VENT (SEE FIGURE 5)

1. Determine the best location for the vent kit.

NOTE: Consider the following when determining the vent kit

location:

A. Vent kit positioned where the vent vapors will not damage

planting/ shrubs or air conditioning equipment or building

structure.

B. Vent kit positioned so it will not be affected by wind eddy

that may allow recirculation of combustion products, or airborne leaves, or light snow.

C. Vent kit positioned where it will not get damaged or be

subjected to foreign objects, such as stones, balls, etc.

D. Vent kit positioned where the vent vapors will not be objectionable.

5

CONCENTRIC VENT

SIDE WALL

NOTE: To prevent the possiblility of condenate freeze-up, do

not install vent kits one above the other.

NOTE: FLUE GAS DEGRADATION

The moisture content of the flue gas may have a detrimental

effect on some building materials. This can be avoided by

using the roof or chimney venting option. When wall venting

is used on any surface that can be affected by this moisture,

it is recommended that a corrosion resistance shield (24

inches square) be used behind the Vent Terminal. This shield

can be made of wood, plastic, sheet metal, etc. Also, silicone

caulk all cracks, seams, and joints within 3 feet of the Vent

Terminal.

2. Cut 1 hole (5 in. diameter) for Vent kit.

3. Partially assemble the vent kit. Clean the pipe ends and

adjoining sockets with PVC primer (ASTM F-656) and

cement using PVC cement (ASTM D-256).

a. Cement the Wye concentric fitting to larger diameter kit

pipe. (See Figure 1)

b. Cement the rain cap to smaller diameter kit pipe. (See

Figure 1)

4. Install Wye concentric fitting and pipe assembly through

structure's hole.

NOTE: Kit supplied stainless steel screw will be used to

secure the rain cap to the pipe.

7. Cement furnace or boiler combustion air and vent pipes to

8. CHECKOUT: Operate the furnace or boiler to make sure ALL

NOTE: Two or more installations require a minimum separation distance of approximately one inch between vent kits.

concentric vent assembly. See Figure 6 for proper pipe attachment.

pipe joints have fastened and sealed to prevent the escape

of combustion products into the building.

6

CONCENTRIC VENT

SIDE WALL INSTALLATION

Pub. No. 18-CH34D1-7 Page 3

INSTALLER'S GUIDE

▲

WARNING

!

▲

CAUTION

!

NOTE: Do not allow insulation or other materials to accumulate inside pipe assembly when installing through hole.

DO NOT USE FIELD SUPPLIED COUPLINGS TO EXTEND

MAIN BODY PIPES (4" AND 2-1/2" PIPES). AIRFLOW RESTRICTION WILL OCCUR AND THE FURNACE OR BOILER

PRESSURE SWITCH MAY CAUSE INTERMITTENT OPERATION.

5. Install rain cap and small diameter pipe assembly in Wye

concentric fitting and large pipe assembly. Ensure small

diameter pipe is bottomed and cemented in Wye concentric

fitting.

DRILL A PILOT HOLE IN THE VENT PIPE FOR THE SCREW

SIZE BEING USED. FAILURE TO DRILL ADEQUATE HOLES

MAY CAUSE CRACKING OF THE PVC COMPONENTS, ALLOWING FLUE GASES TO BE RECIRCULATED. FAILURE TO

FOLLOW THIS WARNING COULD RESULT IN PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

6. Secure assembly to structure as shown in Figure 6 using field

supplied metal strapping or equivalent support material.

NOTE: Ensure termination location clearance dimensions

as shown in Figure 5. Do not locate the vent cap directly to

the wall surface. A distance of 1" ± 1/2" is required to prevent

water accumulating between the vent fins.

NOTE: If assembly needs to be extended to allow side wall

thickness requirement, the two pipes supplied in the kit may

be replaced by using same diameter, field supplied SDR-26

PVC (D2241) pipe. Do not extend the 4" pipe (24" as shipped)

to more than 60 in. (See Figure 2). The 4" pipe may be shortened to 14" minimum.

IMPORTANT:

The Commonwealth of Massachusetts requires compliance

with regulation 248 CMR 4.00 and 5.00 for installation of

through – the – wall vented gas appliances as follows:

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where the side

wall exhaust vent termination is less than seven (7) feet above

finished grade in the area of the venting, including but not

limited to decks and porches, the following requirements shall

be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing

plumber or gasfitter shall observe that a hard wired carbon

monoxide detector with an alarm and battery back-up is

installed on the floor level where the gas equipment is to

be installed. In addition, the installing plumber or gasfitter

shall observe that a battery operated or hard wired carbon

monoxide detector with an alarm is installed on each

additional level of the dwelling, building or structure served

by the side wall horizontal vented gas fueled equipment. It

shall be the responsibility of the property owner to secure the

services of qualified licensed professionals for the installation

of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or an

attic, the hard wired carbon monoxide detector with alarm

and battery back-up may be installed on the next adjacent

floor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation, the

owner shall have a period of thirty (30) days to comply with

the above requirements; provided, however, that during said

thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each

carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building at a

minimum height of eight (8) feet above grade directly in line

with the exhaust vent terminal for the horizontally vented

gas fueled heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch in size,

“GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment shall not

approve the installation unless, upon inspection, the inspector

observes carbon monoxide detectors and signage installed

in accordance with the provisions of 248 CMR 5.08(2)(a)1

through 4.

This appliance requires a special venting system. If

BAYAIR30AVENTA or BAYVENT200B are used, a copy of

the installation instructions for the kit shall remain with the

appliance or equipment at the completion of installation. The

venting system installation instructions can be obtained from

the manufacturer by writing to the following address:

Residential Systems

6200 Troup Highway

Tyler, TX 75707

Attention: Manager of Field Operations Excellence

Trane

6200 Troup Highway

Tyler, TX 75707

For more information contact

your local dealer (distributor)

Since the manufacturer has a policy of continuous product and product data improvement, it

reserves the right to change specifications and design without notice.

Pub. No. 18-CH34D1-7Page 4

Loading...

Loading...