Page 1

Product Catalog

Air-Cooled Scroll Chillers

Model CGAM - Made in USA

20-130 NominalTons (50 Hz and 60 Hz)

February 2015

CG-PRC017H-EN

Page 2

Introduction

Design and manufacturing excellence makesTrane a leader in the air-cooled chiller market place.

This tradition of using excellence to meet market demands is illustrated with the newTrane 20-130

ton nominal air-cooled chiller.The introduction of this next-generation chiller is an exciting step

forward in energy-efficiency,sound, reliability,ease of serviceability, control precision, application

versatility, and operational cost-effectiveness.The new chiller is designed to deliver provenTrane

performance based on the redesign of a European model that has been a market leader, plus all

the benefits of new heat transfer and fan designs, as well as, low-speed, direct-drive scroll

compressors.

Important Design Advances and New Features

• Higher full-load and part-load energy efficiency that exceeds ASHRAE 90.1 and reduces

• Significantly lower noise levels than other scroll compressor chillers.

• HFC-410A optimized design.

• Flow switch and water strainer are factory installed in the optimum locations for seamless

• Trane CH530™ with Adaptive Controls™ have improved fan algorithms for more reliable

• Single chiller time of day scheduling communication for easier control of small jobs.

• Easily integrated with existing BAS via BACnet™ or LonTalk™ communication interface.

• All major service components are close to the unit edge for safe and easy maintenance.

• The chiller is designed for easy serviceability with input from our extended experience in

operating costs.

operation and reduced chiller installation and maintenance time.

operation at extreme conditions.

design, testing and field operation.

Copyright

This document and the information in it are the property ofTrane, and may not be used or

reproduced in whole or in part without written permission.Trane reserves the right to revise this

publication at any time, and to make changes to its content without obligation to notify any person

of such revision or change.

Trademarks

All trademarks referenced in this document are the trademarks of their respective owners.

Revision History

CG-PRC017H-EN (23 Feb 2015)

Added high efficiency option.

© 2015Trane All rights reserved CG-PRC017H-EN

Page 3

Table of Contents

Table of Contents ..................................................3

Features and Benefits ..............................................4

Application Considerations ..........................................6

Model Number Descriptions ........................................13

General Data .....................................................15

Performance Data ................................................23

Controls ........................................................ 31

Electrical ........................................................35

Electrical Connections .............................................40

Dimensions ......................................................44

Weights .........................................................57

Mechanical Specifications ..........................................59

CG-PRC017H-EN 3

Page 4

Features and Benefits

Reliability

• Years of laboratory testing, including running the chiller at extreme operating conditions, have

resulted in optimized compressor and chiller systems reliability by confirming a robust design

and verifying quality each step of the way.

• Direct-drive, low-speed scroll compressors with fewer moving parts provide maximum

efficiency, highreliability, and low maintenance requirements. Suction gas-cooledmotor stays

at a uniformly low temperature for long motor life.

• The third generation microprocessor control system provides improved control capabilities

with Adaptive Control™ to keep the unit operating even in adverse conditions. Advanced

microelectronics protect both the compressor and the motor from typical electrical fault

conditions like thermal overload and phase rotation.

• Standard factory-installed water strainer helps prevent system debris from affecting unit flow

or heat transfer.

• Flow switch is factory-installed at the optimum location in the piping for reduced chiller

installation cost and superior flow sensing, reducing the potential for nuisance trips.

• Exceptionally rigid condenser coil structure is manufactured with hairpin tubes which halves

the number of braze joints significantly reducing the potential for leaks.

• Innovative condenser pressure integrated fan control algorithms and variable frequency drive

on circuits’ lead fans provides more reliable operation at extreme temperature conditions.

Life Cycle Cost-Effectiveness

• Industry leading full- and part-load efficiency

• Electronic expansion valve and high speed suction temperature sensor enables tight chilled

water temperature control and lowsuperheat, resulting in more efficient full-load and part-load

operation than previously available.

• Partial heat recovery available to save energy on pre-heat or reheat applications.

• Pump package features standard variable speed drive on the pump motors eliminating the

need for energy sapping chilled water system triple duty or balancing valves. Additionally,

system commissioning and flexibility is greatly enhanced. Chilled water supply reliability is

increased with the dual pump design, due to standard failure/recovery functionality.

Application Versatility

• Industrial/low temperature process cooling - Excellent operating temperature range and

precise control capabilities enable tight control.

• Ice/thermal storage - Utilities and owners benefit from reduced cooling energy cost.The

chiller’s dual setpoint control and industry leading ice energy storage efficiency assures reliable

operation and superior system efficiencyTrane’s partnership with CALMAC, brings a proven

track record of successful installations across many markets; from churches and schools to sky

scrapers and office buildings.

• Partialheat recovery -Anoptional factory-installedheat exchanger provides hot water for many

needs; water preheat and reheatfor enhanced system humidity control are justtwo.This option

reduces operating costs associated with boilers/domestic hot water.

4 CG-PRC017H-EN

Page 5

Simple, Economical Installation

• Standard sound levels are roughly 5-8 dBa less than the previousTrane air-cooled models,

perfect for applying outdoor HVAC equipment in neighborhoods, such as K-12 schools.

• System integration available with LonTalk®or BACnet®through a single twisted-pair wire for

a less expensive translation to an existing building automation system.

• Powder-coated paint provides superior durability, corrosion protection, and is less likely to be

damaged while rigging/lifting/installing the chiller.

• Factory commissioned unit-mounted starter reduces overall job cost and improves system

reliability by eliminating job site design, installation and labor coordination requirements.

Precision Control

• Easily integrated with existing BAS via BACnet or LonTalk communication interfaces.

• Microprocessor-basedTrane CH530 controls monitor and maintain optimal operation of the

chiller and its associated sensors, actuators, relays, and switches, all of which are factoryinstalled and tested prior to shipping.

• Adaptive Control maintains chiller operation under adverse conditions, when many other

chillers might simply shut down. Operating conditions that are compensated for include high

condensing pressure and low suction pressure.

• Advanced microprocessor controls enable variable primary flow applications providingchilled

water temperature control accuracy of ±2°F (1.1°C) for flow changesupto 10 percent per minute,

plus handling of flow changes up to 30 percent per minute with continuous operation.

• Easy-to-use operator interface displays all operating and safety messages, with complete

diagnostics information, on a highly readable panel with a scrolling touch-screen display.

Status and diagnosticmessages are in plain language - no codes to interpret - and areavailable

in 20 languages.

Features and Benefits

Improved Serviceability

• All major serviceable components are close to the edge. Service shutoff valves and water

strainer are conveniently located to enable easy service.

• Waterpiping connections are factory piped tothe edge of the unit to make installation safer and

faster.

• Electronic expansion valve designed so controls can be removed and serviced without

refrigerant handling.

• The optional pump package is designed to be serviced in place.The unit structure includes a

rigging point for pump servicing, making inspection, cleaning and pump seal changes easier.

• High pressure transducer and temperature sensors mountings enable troubleshooting and

replacement without removing refrigerant charge, greatly improving serviceability over the life

of the unit.

• Dead front panel construction provides for enhanced service technician safety.

CG-PRC017H-EN 5

Page 6

Application Considerations

Certain application constraints should be considered when sizing, selecting and installingTrane

CGAM chillers. Unit and system reliability is often dependent upon proper and complete

compliance with these considerations.Wheretheapplicationvariesfromthe guidelines presented,

it should be reviewed with your localTrane account manager.

Note: The terms water and solution are used interchangeably in the following paragraphs.

Unit Sizing

Unit capacities are listed in the Performance Data section. Intentionally over-sizing a unit to assure

adequate capacity is not recommended. Erratic system operation and excessive compressor

cycling are often a direct result ofan oversized chiller. In addition, an oversized unit is usually more

expensive to purchase, install, and operate. If over sizing is desired consider using two smaller

units.

WaterTreatment

The use of untreated or improperly treated water in chillers may result in scaling, erosion,

corrosion, and algae or slime buildup.This will adversely affect heat transfer between the water

and system components. Proper water treatment must be determined locally and depends on the

type of system and local water characteristics.

Neither salt nor brackish water is recommend for use inTrane air-cooled CGAM chillers. Use of

either will lead toa shortenedlife.Trane encourages the employment of a qualifiedwater treatment

specialist, familiar with local water conditions, to assist in the establishment of a proper water

treatment program.

Foreign matter in the chilled water system can also increase pressure drop and, consequently,

reduce water flow. For this reason it is important to thoroughly flush all water piping to the unit

before making the final piping connections to the unit.

The capacities give in the Performance Data section of this catalog are based on water with a

fouling factor of 0.0001°F·ft²·h/Btu (in accordance withAHRI550/590).For capacities at other fouling

factors, see Performance Selection Software.

Effect of Altitude on Capacity

Chiller capacities given in the Performance Data section are based upon application at sea level.

At elevations substantially above sea level, the decreased air density will decrease condenser

capacity and, therefore, unit capacity and efficiency.

Ambient Limitations

Trane chillers are designed for year-round operation over a range of ambient temperatures.The air-

cooled model CGAM chiller will operate in ambient temperatures of 32°F to 125°F (0°C to 52°C) for

high ambient or 0°F to 125°F (-18°C to 52°C) for wide ambient. Operation down to 0°F requires the

use of variable speed fans to modulate and maintain system differential pressure.

The minimum ambient temperatures are based on still conditions (winds not exceeding five mph).

Greater wind velocities will result in a drop in head pressure, therefore increasing the minimum

starting and operating ambient temperature.TheAdaptive Control™ microprocessor will attempt

to keep the chiller on-line when high or low ambient conditions exist, making every effort to avoid

nuisance trip-outs and provide the maximum allowable tonnage.

6 CG-PRC017H-EN

Page 7

Water Flow Limits

The minimum water flow rates are given in the General Data section of this catalog. Evaporator

flow rates below the tabulated values will result in laminar flow causing freeze-up problems,

scaling, stratification and poor control.The maximum evaporator water flow rate is also given.

Flow rates exceeding those listed may result in very high pressure drop across the evaporator.

Flow Rates Out of Range

Many process cooling jobs require flow rates that cannot be met with the minimum and maximum

published values within the CGAM evaporator. A simple piping change can alleviate this problem.

For example: a plastic injection molding process requires 80 gpm (5.0 l/s) of 50°F (10°C) water and

returns that water at 60°F (15.6°C).The selected chiller can operate at these temperatures, but has

a minimum flow rate of 106 gpm (6.6 l/s).The system layout in Figure 1 can satisfy the process.

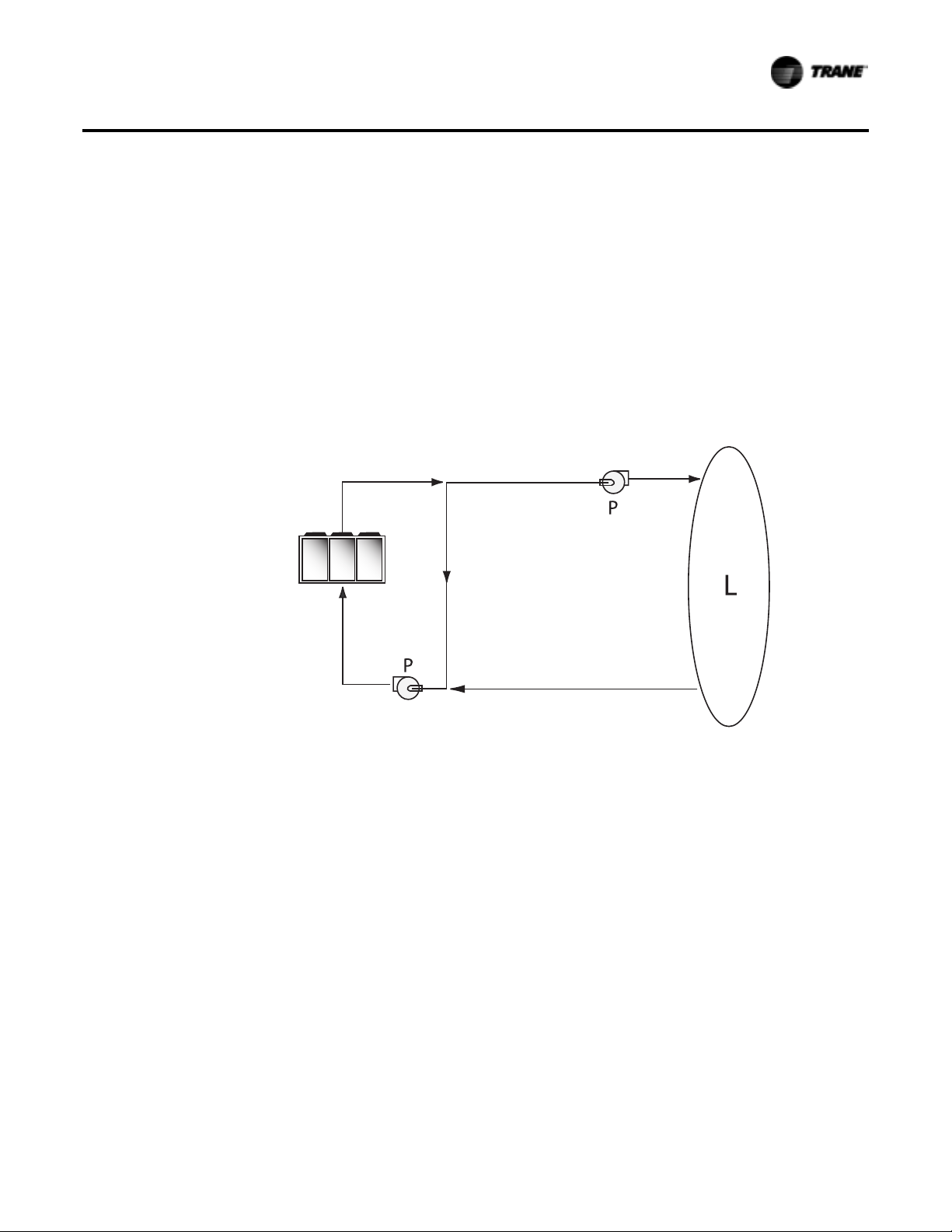

Figure 1. Flow rate out of range systems solution

50°F (10°C)

112 gpm (7 l/s)

Application Considerations

50°F (10°C)

80 gpm (5 l/s)

50°F (10°C)

32 gpm (2 l/s)

57°F (14°C)

112 gpm (7 l/s)

Flow Proving

Trane provides a factory-installed water flow switch monitored by CH530 which protects the chiller

from operating in loss of flow conditions.

Variable Flow in the Evaporator

An attractive chilled water system option may be a Variable Primary Flow (VPF) system. VPF

systems present building owners with several cost-saving benefits when compared with Primary/

Secondary chilled water systems.The most obvious cost savings results from eliminating the

constant volume chiller pump(s), which in turn eliminates the related expenses of the associated

piping connections (material, labor), and electrical service and switch gear. In addition to the

installed cost advantage building owners often cite pump related energy savings as the reasons

that prompted them to select a VPF system.

The CGAM has the capability to handle variable evaporator flow without losing leaving water

temperature control.The microprocessor and capacity control algorithms are designed to take a

10 percent change in water flow rate per minute while maintaining a ±2°F (1.1°C) leaving water

temperature control accuracy.The chiller tolerates up to 30 percent per minute waterflow variation

as long as the flow is equal or above the minimum flow rate requirement.

With the help of a software analysis tool such as System Analyzer™, DOE-2 orTRACE™, you can

determine whether the anticipated energy savings justify the use of variable primary flow in a

particular application. Existing constant flow chilled water systems may be relatively easily

converted to VPF and benefit greatly from the inherent efficiency advantages.

60°F (15.6°C)

80 gpm (5 l/s)

CG-PRC017H-EN 7

Page 8

Application Considerations

WaterTemperature

Leaving Water Temperature Limits

Trane CGAM chillers have three distinct leaving water categories:

• standard, with a leaving solution range of 42 to 65°F (5.5 to 18°C)

• low temperature process cooling, with leaving solution range of 10 to 65°F (-12 to 18°C)

• ice-making, with leaving solution range of 20 to 65°F (-7 to 18°C)

Since leaving solution temperature below 42°F (5.5°C) results in suction temperature at or below

the freezing point of water, a glycol solution is required for all low temperature and ice-making

machines. Ice making control includes dual setpoint controls and safeties for ice making and

standard cooling capabilities. Consult your localTrane account manager for applications or

selections involving low temperature or ice making machines.

The maximum water temperature that can be circulated through the CGAM evaporator when the

unit is not operating is 125°F (51.7°C). Evaporator damage may result above this temperature.

Leaving Water Temperature Out of Range

Similar to the flow rate limitations above, many process cooling jobs require temperature ranges

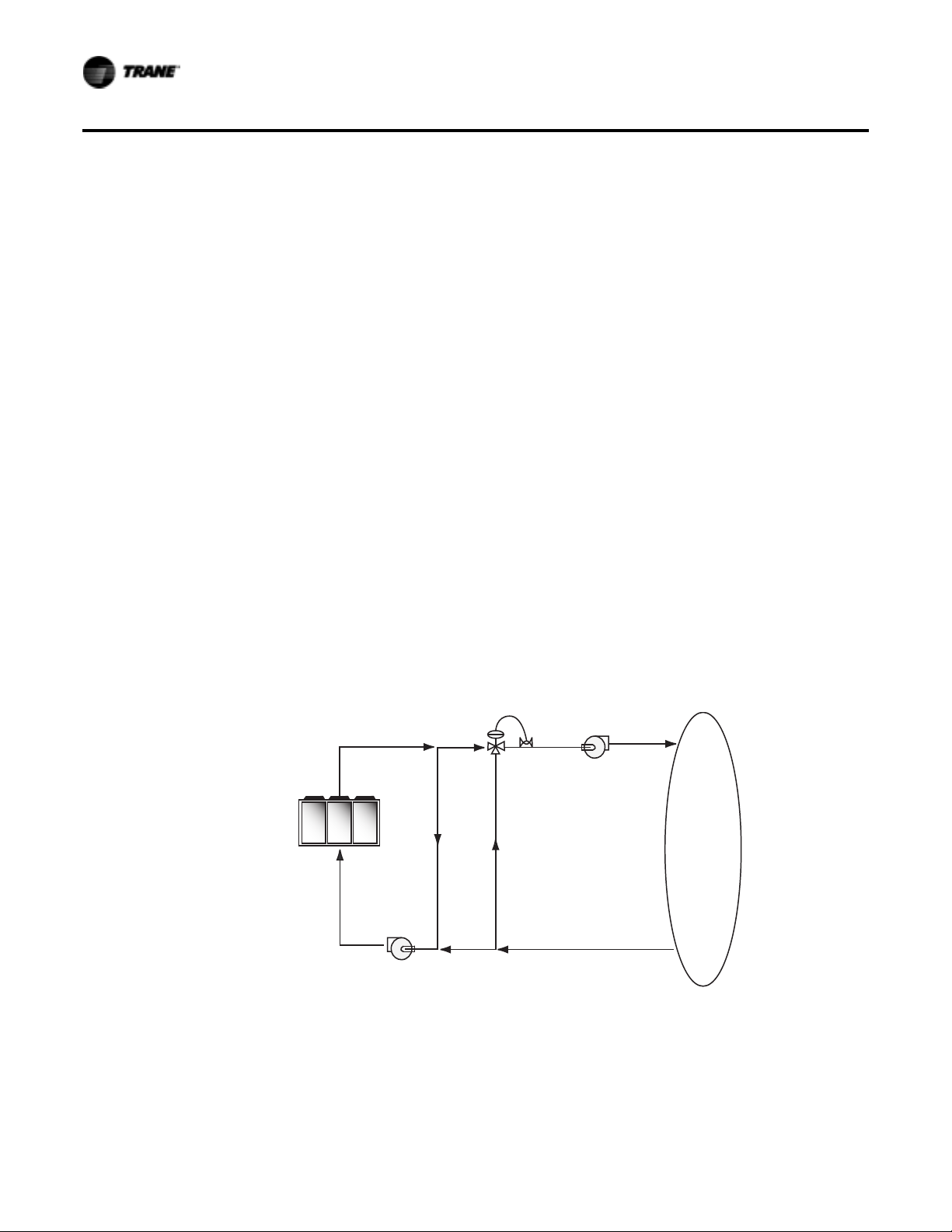

that are outside the allowable minimum and maximum operating values for the chiller. Figure 2

below shows a simple example of a mixed water piping arrangement change that can permit

reliable chiller operation while meeting such cooling conditions. For example, a laboratory load

requires 238 gpm (5 l/s) of water entering the process at 86°F (30°C) and returning at 95°F (35°C).

The chiller’s maximum leaving chilled water temperature of 65°F (15.6°C) prevents direct supply to

the load. In the example shown, both the chiller and process flow rates are equal, however, this is

not necessary. For example, if the chiller had a higher flow rate, there would simply be more water

bypassing and mixing with warm water returning to the chiller.

Figure 2. Temperature out of range system solution

59°F (15°C)

238 gpm (15 l/s)

68°F (20°C)

238 gpm (15 l/s)

Supply WaterTemperature Drop

The cataloged performance datafor theTraneCGAM chiller is based ona chilled water temperature

drop of 10°F (6°C) for I-P data and 9°F (5°C) for SI data. Full load chilled water temperature drops

from 6 to 18°F (3.3 to 10°C) may be used as long as minimum and maximum water temperature

and minimum and maximum flow rates are not violated.Temperature drops outside this range at

full load conditions are beyond the optimum range for control and may adversely affect the

59°F (15°C)

60 gpm (3.8 l/s)

59°F

(15°C)

178 gpm

(11.2 l/s)

P

95°F (35°C)

60 gpm (3.8 l/s)

95°F

(35°C)

178 gpm

(11.2 l/s)

86°F (30°C)

238 gpm

(15 l/s)

P

L

95°F (35°C)

238 gpm (15 l/s)

8 CG-PRC017H-EN

Page 9

microcomputer’s ability to maintain an acceptable supply water temperature range. Furthermore,

full load temperature drops of less than 6°F (3.3°C) may result in inadequate refrigerant superheat

which is critical to long term efficient and reliable operation. Sufficient superheat is always a

primary concern in any refrigerant system and is especially important in a packaged chiller where

the evaporator is closely coupled to the compressor.

Typical Water Piping

All building water piping must be flushed prior to making final connections to the chiller.To reduce

heat loss and prevent condensation,insulation should be applied.Expansion tanks are alsousually

required so that chilled water volume changes can be accommodated.

Avoidance of Short Water Loops

Adequate chilled water system water volume is an important system design parameter because it

provides for stable chilled water temperature control and helps limit unacceptable short cycling of

chiller compressors.

The chiller’s temperature control sensor is located in the supply (outlet) water connection or pipe.

This location allows the building to act as a buffer to slow the rate of change of the system water

temperature. If there is nota sufficient volume of water in the systemto provide an adequatebuffer,

temperature control can suffer, resulting in erratic system operation and excessive compressor

cycling.

Typically, a two-minute water loop circulation time is sufficient to prevent short water loop issues.

Therefore, as a guideline, ensure the volume of water in the chilled water loop equals or exceeds

two times the evaporator flow rate. For systems with a rapidly changing load profile the amount

of volume should be increased.

If the installed system volume does not meet the above recommendations, the following items

should be given careful consideration to increase the volume of water in thesystem and,therefore,

reduce the rate of change of the return water temperature.

• A volume buffer tank located in the return water piping.

• Larger system supply and return header piping (which also reduces system pressure drop and

pump energy use).

Application Considerations

Minimum water volume for a process application

If a chiller is attached to an on/off load such as a process load, it may be difficult for the controller

to respond quickly enough to the very rapid change in return solution temperature if the system

has only the minimum water volume recommended. Such systems may cause chiller low

temperature safety trips or in the extreme case evaporator freezing. In this case, it may be

necessary to add or increase the size of the mixing tank in the return line.

Multiple Unit Operation

Whenever two or more units are used on one chilled water loop,Trane recommends that their

operation be coordinated with a higher level system controller for best system efficiency and

reliability.The TraneTracer system has advanced chilled plant control capabilities designed to

provide such operation.

Ice Storage Operation

An ice storage system uses the chiller to make ice at night when utilities generate electricity more

efficiently and charge less for electricity with lower demand and energy charges.The stored ice

reduces or even replaces mechanical cooling during the day when utility rates are at their highest.

This reduced need for cooling results in significant utility cost savings and source energy savings.

CG-PRC017H-EN 9

Page 10

Application Considerations

Another advantage of an ice storage system is its ability to eliminate chiller over sizing. A

“rightsized” chiller plant with ice storage operates more efficiently with smaller support equipment

while lowering the connected load and reducing operating costs. Best of all this system still

provides a capacity safety factor and redundancy by building it into the ice storage capacity for

practically no cost compared to over sized systems.

TheTrane air-cooled chiller is uniquely suited to low temperature applications like ice storage

because of the ambient relief experienced at night. Chiller ice making efficiencies are typically

similar to or even better than standard cooling daytime efficiencies as a result of night-time drybulb ambient relief.

Standard smart control strategies for ice storage systems are another advantage of the CGAM

chiller.The dual mode control functionality are integrated right into the chiller.TraneTracer

building management systems can measure demand and receive pricing signals from the utility

and decide when to use the stored cooling and when to use the chiller.

Partial Heat Recovery Operation

Partial heat recovery is designed to salvage a portion of the heat that is normally rejected to the

atmosphere through the air-cooled condenser coil and put it to beneficial use.With the addition of

a heat recovery cycle, heat removed from the building cooling load can be transferred to a preheat

application. Keep in mind that the heat recovery cycle is only possible if a cooling load exists to act

as a heat source.

To provide a heat recovery cycle, a supplemental heat exchanger is mounted in series to the air-

cooled condenser.The supplemental heat exchanger is piped into a preheat circuit. During the heat

recovery cycle, the unit operates just as it does in the cooling-only mode except that a portion of

the cooling load heat is rejected to the water heating circuit rather than to the air through the aircooled condenser. Water circulated through the heat recovery heat exchanger by the pumps

absorbs cooling load heat from the compressed refrigerant gas discharged by the compressors.

The heated water is then used to satisfy heating requirements.

Partial heat recovery can be used in applications where hot water is needed for use in kitchens,

lavatories, etc. It is comparatively smaller in size and its heating capacity is not controlled.The

partial heat recovery heat exchanger cannot operate alone without a load on the chiller.

The partial heat recovery heat exchanger can get up to 157°F (69.4°C) leaving temperature. For

more information see the Performance Selection Program.

Unit Placement

SettingThe Unit

A base or foundation is not required if the selected unit location is level and strong enough to

support the unit’s operating weight (see “Weights” section of this catalog).

For a detailed discussion of base and foundation construction, refer to the sound engineering

bulletin or the unit IOM. Manuals are available through the localTrane office.

HVAC equipment must be located to minimize sound and vibration transmission to the occupied

spaces of the building structure it serves. If the equipment must be located in close proximity to

a building, it should be placed next to an unoccupied space such as a storage room, mechanical

room, etc. It is not recommended to locate the equipment near occupied, sound sensitive areas of

the building or near windows. Locating the equipment away from structures will also prevent

sound reflection, which can increase sound levels at property lines or other sensitive points.

10 CG-PRC017H-EN

Page 11

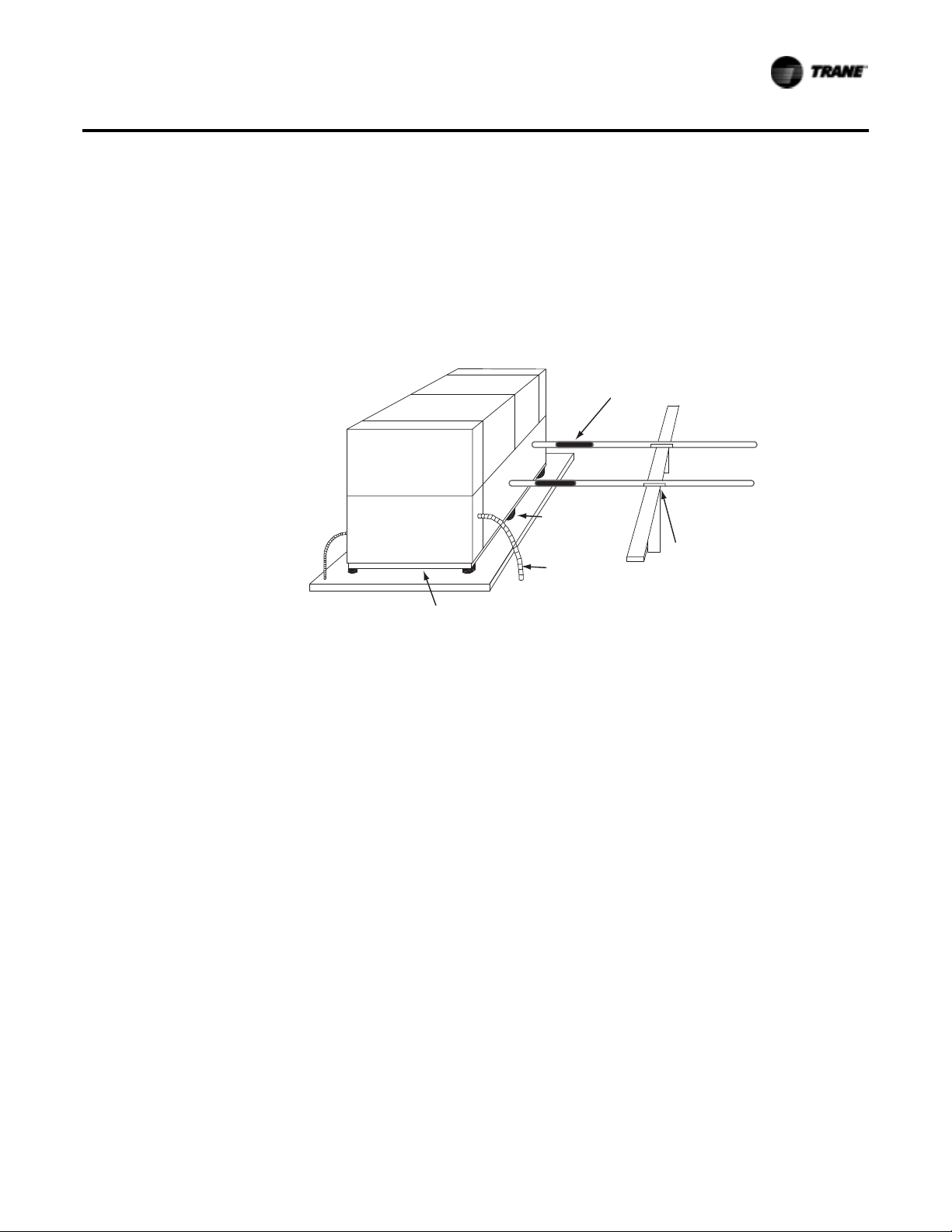

Isolation and Sound Emission

Structurally transmitted sound can be reduced by elastomeric vibration eliminators. Elastomeric

isolators are generally effective in reducing vibratory noise generated by compressors, and

therefore, are recommended for sound sensitive installations. An acoustical engineer should

always be consulted on critical applications.

Figure 3. Installation example

Application Considerations

Piping isolation

Servicing

Chilled water piping

supported.should be

Isolators

Isolators

Flexible electrical

conduit

Concrete base

For maximum isolation effect, water lines and electrical conduit should also be isolated.Wall

sleeves and rubber isolated piping hangers can be used to reduce the sound transmitted through

water piping.To reduce the sound transmitted through electrical conduit, use flexible electrical

conduit.

Local codes on sound emissions should always be considered. Since the environment in which a

sound source is located affects sound pressure, unitplacement must be carefullyevaluated. Sound

power levels for chillers are available on request.

Adequate clearance for evaporator and compressor servicing should be provided. Recommended

minimum space envelopes for servicing are located in the dimensional data section and can serve

as a guideline for providing adequate clearance.The minimum space envelopes also allow for

control panel door swing and routine maintenance requirements. Local code requirements may

take precedence.

CG-PRC017H-EN 11

Page 12

Application Considerations

Unit Location

General

Unobstructed flow of condenser air is essential to maintain chiller capacity and operating

efficiency. When determining unit placement, careful consideration must be given to assure a

sufficient flow of air across the condenser heat transfer surface.Two detrimental conditions are

possible and must be avoided: warm air recirculation and coil starvation. Air recirculation occurs

when discharge air from the condenser fans is recycled back to the condenser coil inlet. Coil

starvation occurs when free airflow to the condenser is restricted.

Condenser coils and fan discharge must be kept free of snow or other obstructions to permit

adequate airflow for satisfactory unit operation. Debris, trash, supplies, etc., should not be allowed

to accumulate in the vicinity of the air-cooled chiller. Supply air movement may draw debris into

the condenser coil, blocking spaces between coil fins and causing coil starvation.

Both warm air recirculation and coil starvation cause reductions in unit efficiency and capacity

because of the higher head pressures associated with them.The air-cooled CGAM chiller offers an

advantage over competitive equipment in these situations. Operation is minimally affected in

many restricted air flow situations due to its advanced Adaptive Control™ microprocessor which

has the ability to understand the operating environment of the chiller and adapt to it by first

optimizing its performance and then staying on line through abnormal conditions. For example,

high ambient temperatures combined with a restricted air flow situation will generally not cause

the air-cooled model CGAMchiller to shut down. Otherchillers would typically shutdown on ahigh

pressure nuisance cut-out in these conditions.

Cross winds, those perpendicular to the condenser, tend to aid efficient operation in warmer

ambient conditions. However, they tend to be detrimental to operation in lower ambients due to

the accompanying loss of adequate head pressure. Special consideration should be given to low

ambient units. As a result, it is advisable to protect air-cooled chillers from continuous direct winds

exceeding 10 mph (4.5 m/s) in low ambient conditions.

The recommended lateral clearances are depicted in the close spacing engineering bulletin

available from your local office.

Provide Sufficient Unit-to-Unit Clearance

Units should be separated from each other by sufficient distance to prevent warm air recirculation

or coil starvation. Doubling the recommended single unit air-cooled chiller clearances will

generally prove to be adequate.

Walled Enclosure Installations

When the unit is placed in an enclosure or small depression, the top of the surrounding walls

should be no higher than the top of the fans.The chiller should be completely open above the fan

deck.There should be no roof or structure covering the top of the chiller. Ducting individual fans

is not recommended.

12 CG-PRC017H-EN

Page 13

Model Number Descriptions

Digits 1-4— Chiller Model

CGAM= Air-Cooled Scroll Packaged

Chiller

Digits 5-7— Unit Nominal Ton

020 = 20Tons

026 = 26Tons

030 = 30Tons

035 = 35Tons

040 = 40Tons

052 = 52Tons

060 = 60Tons

070 = 70Tons

080 = 80Tons

090 = 90Tons

100 = 10 0Ton s

110 = 11 0 T o n s

120 = 120 Tons

130 = 130 Tons

Digit 8— Unit Voltage

A = 208Volt 60 Hz 3 Phase

B = 230 Volt 60 Hz 3 Phase

D = 380 Volt 60 Hz 3 Phase

E = 400 Volt 50 Hz 3 Phase

F = 460 Volt 60 Hz 3 Phase

G = 575 Volt 60 Hz 3 Phase

Digit 9— Manufacturing Plant

2 = Pueblo, USA

Digits 10-11— Design Sequence

** = Factory/ABU Assigned

Digit 12— Unit Type

2 = High Efficiency

3 = Extra Efficiency

Digit 13— Agency Listing

X = No Agency Listing

A = UL Listed to U.S. and

Canadian Safety Standard

Digit 14— Pressure Vessel Code

X = No Pressure VesselCode

Digit 15— Unit Application

B = High Ambient (32-125°F/0-52°C)

D = Wide Ambient

(0-125°F/-18-52°C)

Digit 16— Refrigerant Isolation

Valves

2 = Refrigerant Isolation Valves

(Discharge Valve)

Digit 17— Seismically Rated

A = Not Seismically Rated Unit

B = IBC Seismically Rated Unit

C = OSHPD Seismically Rated Unit

Digit 18— Freeze Protection

(Factor-Installed Only)

X = Without Freeze Protection

1 = With Freeze Protection

(ExternalT-Stat Control)

Digit 19— Insulation

A = Factory Insulation - All Cold Parts

B = Insulation for High Humidity/

Low EvapTemp

Digit 20— Factory Charge

1 = Full Factory Refrigerant Charge

(HFC R-410A)

2 = Nitrogen Charge

Digit 21— Evaporator

Application

A = Standard Cooling

(42 to 65°F/5.5 to 18°C)

B = Low Temperature Processing

(lower than 42°F/5.5°C)

C = Ice-Making - Hardwired Interface

(20 to 65°F/-7 to 18°C)

Digit 22— Water Connections

1 = Grooved Pipe Connection

Digit 23— Condenser Fin

Material

A = Lanced Aluminum Fins

C = Non-Lanced Copper Fins

D = Lanced Aluminum Fins

w/ CompleteCoat™

Digit 24— Condenser Heat

Recovery

X = No Heat Recovery

1 = Partial Heat Recovery with

Fan Control

Digit 25— Not Used

X

Digit 26— Starter Type

A = Across the Line Starter/

Direct on Line

Digit 27— Incoming Power Line

Connection

1 = Single Point Power Connection

Digit 28— Power Line

Connection Type

A = Terminal Block

C = Circuit Breaker

D = Circuit Breaker with High Fault

Rated Control Panel

Digit 29— Enclosure Type

1 = Water Tight (per UL 1995

Standard)

Digit 30— Unit Operator

Interface

A = Dyna-View/English

Digit 31— Remote Interface

(Digital Comm)

X = No Remote Digital

Communication

2 = LonTalk®/Tracer Summit Interface

3 = Time of Day Scheduling

4 = BACNet®Interface

Digit 32— External Chilled/Hot

Water and Current Demand Limit

Setpoint

X = No External Chilled Water

Setpoint

A = External Chilled Water and

Demand Limit Setpoint 4-20mA

B = External Chilled Water and

Demand Limit Setpoint 2-10Vdc

Digit 33— Percent Capacity

X = Without % Capacity

1 = With % Capacity

Digit 34— Programmable Relays

X = No Programmable Relays

A = Programmable Relays

Digit 35— Pump Type

X = No Pumps and No Contactors

8 = Dual High Head Pump

Digit 36— Pump Flow Control

X = No Pump Control

B = Pump Flow Controlled by

Variable Speed Drive

Digit 37— Buffer Tank

X = No BufferTank

1 = With Buffer Tank

Digit 38— Short Circuit Rating

X = No Short Circuit Rating

A = Default A Short Circuit Rating

B = High A Short Circuit Rating

Digit 39— Installation

Accessories

X = No Installation Accessories

1 = Elastomeric Isolators

3 = Seismically Rated Isolators

Digit 40— Water Strainer

A = With Water Strainer Factory

Installed

Digit 41— Sound Attenuator

Package

3 = Super Quiet

5 = Comprehensive Acoustic

Package

Digit 42— Appearance Options

X = No Appearance Options

A = Architectural Louvered Panels

B = Half Louvers

CG-PRC017H-EN 13

Page 14

Model Number Descriptions

Digit 43— Exterior Finish

1 = Standard Paint

Digit 44— Label, Literature

Language

B = Spanish

D = English

E = French and English

Digit 45— Phase Reversal

Protection

1 = Phase Reversal Protection

Digit 46— Shipping Package

X = No Skid (Standard)

A = Unit Containerization Package

Digit 47— PerformanceTest

Options

X = No PerformanceTest

2 = 1 Point Test with Report

3 = Witness Test with Report

Digit 48— Flow Switch Set Point

C = Flow Switch Set Point 15

F = Flow Switch Set Point 35

H = Flow Switch Set Point 45

L = Flow Switch Set Point 60

Digit 49— Not Used

X

Digit 50— Specials

X = None

S = Special

Note: If a digit is not defined it may be

held for future use.

14 CG-PRC017H-EN

Page 15

General Data

Table 1. General data - 60 Hz - high efficiency - IP

Size 20 26 30 35 40 52 60 70 80 90 100 110 120 130

Compressor

Number # 2 2 2 2 4 4 4 4 4 4 4 4 4 6

25-5075-100

20+20

+25

15-3146-62-

81-100

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20 20+20 20+25 25+25 25+30 30+30

Evaporator

Water storage (gal) 1.4 2.2 2.2 3.2 2.4 4.1 5.0 7.5 7.0 9.0 10.3 11.5 11.5 12.3

Min. flow (gpm) 30 38 42 50 57 74 84 100 115 129 145 157 170 184

Max. flow (gpm) 69 89 100 117 136 176 201 238 275 307 346 375 407 440

Water connection (in) 2 2.5 2.5 2.5 3 3 3 3 4 4 4 4 4 4

Condenser

Quantity of coils # 1 1 1 1 2 2 2 2 4 4 4 4 4 4

Coil length (in) 91 91 127 127 91 91 127 127 121 121 144 144 144 180

Coil height (in) 68 68 68 68 68 68 68 68 42 42 42 42 42 42

Number of rows # 2 2 2 2 2 2 2 2 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192 192

Fan

Quantity # 2 2 3 3 4 4 6 6 6 6 8 8 8 10

Diameter (in) 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8

Airflow per fan (cfm) 9413 9420 9168 9173 9413 9420 9168 9173 9470 9472 9094 9096 9098 9094

Power per motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 840 840 840 840 840 840 840 840 840 840 840 840 840 840

Tip speed (ft/min) 6333 6333 6333 6333 6333 6333 6333 6333 6333 6333 6333 6333 6333 6333

General Unit

Refrig circuits # 1 1 1 1 2 2 2 2 2 2 2 2 2 2

25-50-

25-50-

25-50-

21-43-

25-50-

22-44-

25-50-

Capacity steps % 50-100 50-100 50-100 43-100

Refrig charge/circuit ¹ (lbs) 32 34 44 48 32 32 44 48 74 78 90 91.5 86 112

Oil charge/circuit¹ (gal) 1.7 1.7 1.9 3.5 1.7 1.7 1.9 3.5 3.5 3.5 3.5 3.7 3.8 5.8

Min ambient - wide (°F) 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Min ambient - high (°F) 32 32 32 32 32 32 32 32 32 32 32 32 32 32

75-100

75-100

75-100

71-100

75-100

72-100

75-100

23-4573-100

Pump Package

Avail head pressure² (ft H2O) 78.2 77.7 71.1 67.6 67.1 58.6 76.7 63.5 82.0 78.1 69.0 61.9 71.3 62.2

Power (HP) 5 5 5 5 5 5 7.5 7.5 10 10 10 10 15 15

Expansion tank

volume

Buffer tank volume (gal) 140 140 140 140 140 140 140 140 152 152 195 195 195 195

(gal) 5 5 5 5 5 5 5 5 6 6 6 6 6 6

Partial Heat Recovery

Water storage/circuit¹ (gal) 0.02 0.02 0.02 0.03 0.02 0.02 0.02 0.03 0.03 0.04 0.04 0.04 0.06 0.06

Max flow (gpm) 39 39 39 39 78 78 78 78 127 127 127 127 127 127

Water connection (in) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 2.5 2.5 2.5 2.5 2.5 2.5

1. Data shown for circuit one only. The second circuits always matches.

2. Pump available head pressure is based on: 44/54°F evaporator with water, .0001 hr-ft²-°F/Btu, 95°F ambient and 0 ft elevation.

CG-PRC017H-EN 15

Page 16

General Data

Table 2. General data - 60 Hz - high efficiency - SI

Size 20 26 30 35 40 52 60 70 80 90 100 110 120 130

Compressor

Number # 22224444444446

25-5075-100

20+20

+25

15-3146-62-

81-100

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20 20+20 20+25 25+25 25+30 30+30

Evaporator

Water storage (l) 5.3 8.3 8.3 12.1 9.1 15.5 18.9 28.4 26.5 34.1 39.0 43.5 43.5 46.6

Min. flow (l/s) 1.8 2.3 2.6 3.1 3.6 4.6 5.3 6.3 7.2 8.1 9.1 9.9 10.7 11.6

Max. flow (l/s) 4.4 5.6 6.3 7.4 8.6 11.1 12.7 15.1 17.4 19.4 21.9 23.7 25.7 27.8

Water connection (mm) 50.8 63.5 63.5 63.5 76.2 76.2 76.2 76.2 101.6 101.6 101.6 101.6 101.6 101.6

Condenser

Qty of coils # 11112222444444

Coil length (mm) 2311 2311 3226 3226 2311 2311 3226 3226 3073 3073 3658 3658 3658 4572

Coil height (mm) 1727 1727 1727 1727 1727 1727 1727 1727 1067 1067 1067 1067 1067 1067

Number of rows # 22222222333333

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192 192

Fan

Quantity # 223344664688810

Diameter (mm) 732 732 732 732 732 732 732 732 732 732 732 732 732 732

Airflow per fan

Power per motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 840 840 840 840 840 840 840 840 840 840 840 840 840 840

Tip speed (m/s) 32 32 32 32 32 32 32 32 32 32 32 32 32 32

(m³/

15993 16005 15577 15585 15993 16005 15577 15585 16090 16093 15451 15454 15458 15451

h)

General Unit

Refrig circuits # 11112222222222

25-50-

25-50-

25-50-

21-43-

25-50-

22-44-

25-50-

Capacity steps % 50-100 50-100 50-100 43-100

Refrig charge/circuit¹ (kg) 14.5 15.4 20 21.8 14.5 14.5 20 21.8 33.6 35.4 40.8 41.5 39.0 50.8

Oil charge /circuit¹ (l) 6.6 6.6 7.2 13.4 6.6 6.6 7.2 13.4 13.4 13.4 13.4 13.9 14.4 22.0

Min ambient - wide (°C) -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18

Min ambient - high (°C) 00000000000000

75-100

75-100

75-100

71-100

75-100

72-100

75-100

23-4573-100

Pump Package

Avail head pressure² (kPa) 233.7 232.3 212.6 202.1 200.6 175.0 229.2 189.7 245.1 233.3 206.3 185.0 213.1 185.8

Power (HP) 5555557.57.5101010101515

Expansion tank

volume

Buffer tank volume (l) 530 530 530 530 530 530 530 530 575 575 727 727 727 727

(l) 18.9 18.9 18.9 18.9 18.9 18.9 18.9 18.9 22.7 22.7 22.7 22.7 22.7 22.7

Partial Heat Recovery

Water storage/circuit¹ (l) 0.07 0.09 0.09 0.11 0.07 0.09 0.09 0.11 0.12 0.16 0.16 0.16 0.21 0.21

Max flow (l/s) 2.5 2.5 2.5 2.5 5.0 5.0 5.0 5.0 8.0 8.0 8.0 8.0 8.0 8.0

Water connection (mm) 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 63.5 63.5 63.5 63.5 63.5 63.5

1. Data shown for circuit one only. The second circuit always matches.

2. Pump available head pressure is based on: 6.7/12.2°C evaporator with water, .01761 m²°C/kW, 35°C ambient and 0 m elevation.

16 CG-PRC017H-EN

Page 17

General Data

Table 3. General data - 50 Hz - high efficiency - IP

Size 20 26 30 35 40 52 60 70 80 90 100 110 120

Compressor

Number # 2 2 2 2444444444

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20 20+20 20+25 25+25 25+30 30+30

Evaporator

Water storage (gal) 1.4 2.2 2.2 3.2 2.4 4.1 5.0 7.5 7.0 9.0 10.3 11.5 11.5

Min. flow (gpm) 25 32 36 41 48 62 71 83 97 109 123 133 142

Max. flow (gpm) 59 75 85 98 115 149 170 199 234 262 296 319 341

Water connection (in) 2 2.5 2.5 2.5 3 3 3 3 4 4 4 4 4

Condenser

Quantity of coils # 1 1 1 1222244444

Coil length (in) 91 91 127 127 91 91 127 127 121 121 144 144 144

Coil height (in) 68 68 68 68 68 68 68 68 42 42 42 42 42

Number of rows # 2 2 2 2222233333

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192

Fan

Quantity # 2 2 3 3446666888

Diameter (in) 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8

Airflow/fan (cfm) 7796 7783 7587 7590 7795 7801 7587 7590 7827 7829 7503 7505 7506

Power/motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 700 700 700 700 700 700 700 700 700 700 700 700 700

Tip speed

General Unit

Refrig circuits # 1 1 1 1222222222

Capacity steps % 50-100 50-100 50-100 43-100

Refrig charge/circuit¹ (lbs) 34 34 44 48 32 32 44 48 74 78 82 86 84

Oil charge/circuit¹ (gal) 1.7 1.7 1.9 3.5 1.7 1.7 1.9 3.5 3.5 3.5 3.5 3.7 3.8

Min ambient - wide (°F) 0 0 0 0000000000

Min ambient - high (°F) 32 32 32 32 32 32 32 32 32 32 32 32 32

Partial Heat Recovery

Water storage/circuit¹ (gal) 0.02 0.02 0.02 .02 0.02 0.02 0.02 0.02 0.03 0.03 0.03 0.04 0.04

Max flow (gpm) 39 39 39 39 78 78 78 78 127 127 127 127 127

Water connection (in) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 2.5 2.5 2.5 2.5 2.5

1. Data shown for circuit one only. The second circuits always matches.

(ft/

5278 5278 5278 5278 5278 5278 5278 5278 5278 5278 5278 5278 5278

min)

25-5075-100

25-50-

75-100

25-5075-100

21-4371-100

25-5075-100

22-4472-100

25-5075-100

23-45-

73-100

25-5075-100

CG-PRC017H-EN 17

Page 18

General Data

Table 4. General data - 50 Hz - high efficiency - SI

Size 20 26 30 35 40 52 60 70 80 90 100 110 120

Compressor

Number # 2 2 2 2444444444

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20 20+20 20+25 25+25 25+30 30+30

Evaporator

Water storage (l) 5.3 8.3 8.3 12.1 9.1 15.5 18.9 28.4 26.5 34.1 39.0 43.5 43.5

Min. flow (l/s) 1.6 2.0 2.2 2.6 3.0 3.9 4.4 5.2 6.1 6.8 7.7 8.3 8.9

Max. flow (l/s) 3.7 4.8 5.4 6.2 7.3 9.4 10.8 12.6 14.8 16.5 18.7 20.2 21.6

Water connection (mm) 50.8 63.5 63.5 63.5 76.2 76.2 76.2 76.2 101.6 101.6 101.6 101.6 101.6

Condenser

Quantity of coils # 1 1 1 1222244444

Coil length (mm) 2311 2311 3226 3226 2311 2311 3226 3226 3073 3073 3658 3658 3658

Coil height (mm) 1727 1727 1727 1727 1727 1727 1727 1727 1067 1067 1067 1067 1067

Number of rows # 2 2 2 2222233333

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192

Fan

Quantity # 2 2 3 3446666888

Diameter (mm) 732 732 732 732 732 732 732 732 732 732 732 732 732

Airflow/fan

Power/motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 700 700 700 700 700 700 700 700 700 700 700 700 700

Tip speed (m/s) 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8

General Unit

Refrig circuits # 1 1 1 1222222222

Capacity steps % 50-100 50-100 50-100 43-100

Refrig charge/circuit¹ (kg) 15.4 15.4 20 21.8 14.5 14.5 20 21.8 33.6 35.4 37.2 39.0 38.1

Oil charge/circuit ¹ (l) 6.6 6.6 7.2 13.4 6.6 6.6 7.2 13.4 13.4 13.4 13.4 13.9 14.4

Min ambient - wide (°C) -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18

Min ambient - high (°C) 0 0 0 0000000000

Partial Heat Recovery

Water storage/circuit¹ (l) 0.07 0.07 0.09 0.09 0.07 0.07 0.09 0.09 0.12 0.12 0.12 0.16 0.16

Max flow (l/s) 2.5 2.5 2.5 2.5 5.0 5.0 5.0 5.0 8.0 8.0 8.0 8.0 8.0

Water connection (mm) 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 63.5 63.5 63.5 63.5 63.5

1. Data shown for circuit one only. The second circuit always matches.

(m³/

13245 13223 12890 12895 13244 13254 12890 12895 13298 13302 12748 12751 12753

h)

25-5075-100

25-5075-100

25-5075-100

21-4371-100

25-5075-100

22-4472-100

25-5075-100

23-4573-100

25-5075-100

18 CG-PRC017H-EN

Page 19

General Data

Table 5. General data - 60 Hz - extra efficiency - IP

Size 20 26 30 35 40 52 60 70

Compressor

Number # 2 2 2 2 4 4 4 4

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20

Evaporator

Water storage (gal) 1.4 2.2 2.2 3.2 2.4 4.1 5.0 7.5

Min. flow (gpm) 30 38 42 50 57 74 84 100

Max. flow (gpm) 69 89 100 117 136 176 201 238

Water connection (in) 2 2.5 2.5 2.5 3 3 3 3

Condenser

Quantity of coils # 1 1 1 1 2 2 2 2

Coil length (in) 91 91 127 127 91 91 127 127

Coil height (in) 68 68 68 68 68 68 68 68

Number of rows # 3 3 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192

Fan

Quantity # 2 2 3 3 4 4 6 6

Diameter (in) 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8

Airflow per fan (cfm) 9413 9420 9168 9173 9413 9420 9168 9173

Power per motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 840 840 840 840 840 840 840 840

Tip speed (ft/min) 6333 6333 6333 6333 6333 6333 6333 6333

General Unit

Refrig circuits # 1 1 1 1 2 2 2 2

Capacity steps % 50-100 50-100 50-100 43-100 25-50-75-100 25-50-75-100 25-50-75-100 21-43-71-100

Refrig charge/circuit ¹ (lbs) 45 48 68 68 42 42 66 62

Oil charge/circuit¹ (gal) 1.7 1.7 1.9 3.5 1.7 1.7 1.9 3.5

Min ambient - wide (°F) 0 0 0 0 0 0 0 0

Min ambient - high (°F) 32 32 32 32 32 32 32 32

Pump Package

Avail head pressure² (ft H2O) 78.2 77.7 71.1 67.6 67.1 58.6 76.7 63.5

Power (HP) 5 5 5 5 5 5 7.5 7.5

Expansion tank

volume

Buffer tank volume (gal) 140 140 140 140 140 140 140 140

Partial Heat Recovery

Water storage/circuit¹ (gal) 0.02 0.02 0.02 0.03 0.02 0.02 0.02 0.03

Max flow (gpm) 39 39 39 39 78 78 78 78

Water connection (in) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

1. Data shown for circuit one only. The second circuits always matches.

2. Pump available head pressure is based on: 44/54°F evaporator with water, .0001 hr-ft²-°F/Btu, 95°F ambient and 0 ft elevation.

(gal) 5 5 5 5 5 5 5 5

CG-PRC017H-EN 19

Page 20

General Data

Table 6. General data - 60 Hz - extra efficiency - SI

Size 20 26 30 35 40 52 60 70

Compressor

Number # 2222 4444

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20

Evaporator

Water storage (l) 5.3 8.3 8.3 12.1 9.1 15.5 18.9 28.4

Min. flow (l/s) 1.8 2.3 2.6 3.1 3.6 4.6 5.3 6.3

Max. flow (l/s) 4.4 5.6 6.3 7.4 8.6 11.1 12.7 15.1

Water connection (mm) 50.8 63.5 63.5 63.5 76.2 76.2 76.2 76.2

Condenser

Qty of coils # 1111 2222

Coil length (mm) 2311 2311 3226 3226 2311 2311 3226 3226

Coil height (mm) 1727 1727 1727 1727 1727 1727 1727 1727

Number of rows # 3333 3333

Fins per foot (fpf) 192 192 192 192 192 192 192 192

Fan

Quantity # 2233 4466

Diameter (mm) 732 732 732 732 732 732 732 732

Airflow per fan

Power per motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 840 840 840 840 840 840 840 840

Tip speed (m/s) 32 32 32 32 32 32 32 32

General Unit

Refrig circuits # 1111 2222

Capacity steps % 50-100 50-100 50-100 43-100 25-50-75-100 25-50-75-100 25-50-75-100 21-43-71-100

Refrig charge/circuit¹ (kg) 20.3 21.6 30.7 30.7 18.9 18.9 29.8 28.3

Oil charge /circuit¹ (l) 6.6 6.6 7.2 13.4 6.6 6.6 7.2 13.4

Min ambient - wide (°C) -18 -18 -18 -18 -18 -18 -18 -18

Min ambient - high (°C) 0000 0000

Pump Package

Avail head pressure² (kPa) 233.7 232.3 212.6 202.1 200.6 175.0 229.2 189.7

Expansion tank

volume

Buffer tank volume (l) 530 530 530 530 530 530 530 530

Partial Heat Recovery

Water storage/circuit¹ (l) 0.07 0.09 0.09 0.11 0.07 0.09 0.09 0.11

Max flow (l/s) 2.5 2.5 2.5 2.5 5.0 5.0 5.0 5.0

Water connection (mm) 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1

1. Data shown for circuit one only. The second circuit always matches.

2. Pump available head pressure is based on: 6.7/12.2°C evaporator with water, .01761 m²°C/kW, 35°C ambient and 0 m elevation.

(m³/

15993 16005 15577 15585 15993 16005 15577 15585

h)

Power (HP) 5555 5 5 7.5 7.5

(l) 18.9 18.9 18.9 18.9 18.9 18.9 18.9 18.9

20 CG-PRC017H-EN

Page 21

General Data

Table 7. General data - 50 Hz - extra efficiency - IP

Size 20 26 30 35 40 52 60 70

Compressor

Number # 2 2 2 2 4444

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20

Evaporator

Water storage (gal) 1.4 2.2 2.2 3.2 2.4 4.1 5.0 7.5

Min. flow (gpm) 25 32 36 41 48 62 71 83

Max. flow (gpm) 59 75 85 98 115 149 170 199

Water connection (in) 2 2.5 2.5 2.5 3333

Condenser

Quantity of coils # 1 1 1 1 2222

Coil length (in) 91 91 127 127 91 91 127 127

Coil height (in) 68 68 68 68 68 68 68 68

Number of rows # 2 2 2 2 2222

Fins per foot (fpf) 192 192 192 192 192 192 192 192

Fan

Quantity # 2 2 3 3 4466

Diameter (in) 28.8 28.8 28.8 28.8 28.8 28.8 28.8 28.8

Airflow/fan (cfm) 7796 7783 7587 7590 7795 7801 7587 7590

Power/motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 700 700 700 700 700 700 700 700

Tip speed (ft/min) 5278 5278 5278 5278 5278 5278 5278 5278

General Unit

Refrig circuits # 1 1 1 1 2222

Capacity steps % 50-100 50-100 50-100 43-100 25-50-75-100 25-50-75-100 25-50-75-100 21-43-71-100

Refrig charge/circuit¹ (lbs) 48 48 68 68 42 42 62 62

Oil charge/circuit¹ (gal) 1.7 1.7 1.9 3.5 1.7 1.7 1.9 3.5

Min ambient - wide (°F) 0 0 0 0 0000

Min ambient - high (°F) 32 32 32 32 32 32 32 32

Partial Heat Recovery

Water storage/circuit¹ (gal) 0.02 0.02 0.02 .02 0.02 0.02 0.02 0.02

Max flow (gpm) 39 39 39 39 78 78 78 78

Water connection (in) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

1. Data shown for circuit one only. The second circuits always matches.

CG-PRC017H-EN 21

Page 22

General Data

Table 8. General data - 50 Hz - extra efficiency - SI

Size 20 26 30 35 40 52 60 70

Compressor

Number # 2 2 2 2 4 4 4 4

Tonnage/circuit¹ 10+10 13+13 15+15 15+20 10+10 13+13 15+15 15+20

Evaporator

Water storage (l) 5.3 8.3 8.3 12.1 9.1 15.5 18.9 28.4

Min. flow (l/s) 1.6 2.0 2.2 2.6 3.0 3.9 4.4 5.2

Max. flow (l/s) 3.7 4.8 5.4 6.2 7.3 9.4 10.8 12.6

Water connection (mm) 50.8 63.5 63.5 63.5 76.2 76.2 76.2 76.2

Condenser

Quantity of coils # 1 1 1 1 2 2 2 2

Coil length (mm) 2311 2311 3226 3226 2311 2311 3226 3226

Coil height (mm) 1727 1727 1727 1727 1727 1727 1727 1727

Number of rows # 2 2 2 2 2 2 2 2

Fins per foot (fpf) 192 192 192 192 192 192 192 192

Fan

Quantity # 2 2 3 3 4 4 6 6

Diameter (mm) 732 732 732 732 732 732 732 732

Airflow/fan (m³/h) 13245 13223 12890 12895 13244 13254 12890 12895

Power/motor (HP) 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

Motor RPM (rpm) 700 700 700 700 700 700 700 700

Tip speed (m/s) 26.8 26.8 26.8 26.8 26.8 26.8 26.8 26.8

General Unit

Refrig circuits # 1 1 1 1 2 2 2 2

Capacity steps % 50-100 50-100 50-100 43-100 25-50-75-100 25-50-75-100 25-50-75-100 21-43-71-100

Refrig charge/circuit¹ (kg) 21.6 21.6 30.7 30.7 18.9 18.9 28.3 28.3

Oil charge/circuit ¹ (l) 6.6 6.6 7.2 13.4 6.6 6.6 7.2 13.4

Min ambient - wide (°C) -18 -18 -18 -18 -18 -18 -18 -18

Min ambient - high (°C) 0 0 0 0 0 0 0 0

Partial Heat Recovery

Water storage/circuit¹ (l) 0.07 0.07 0.09 0.09 0.07 0.07 0.09 0.09

Max flow (l/s) 2.5 2.5 2.5 2.5 5.0 5.0 5.0 5.0

Water connection (mm) 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1

1. Data shown for circuit one only. The second circuit always matches.

22 CG-PRC017H-EN

Page 23

Performance Data

Table 9. Performance data - 60 Hz - I-P units

Evaporator

Leaving

Temperature

(°F)

42

44

Unit

Size Tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

Condenser Ambient Temperature (°F)

85 95 105 115

kW

Input EER Tons

20.1 20.8 11.6 18.9 22.7 10 17.7 24.7 8.6 16.3 27 7.2

25.9 27.3 11.4 24.3 29.9 9.7 22.5 32.8 8.2 20.7 35.8 6.9

29 30.2 11.5 27.2 33.2 9.9 25.4 36.5 8.3 23.4 40 7

34.1 36 11.4 32 39.5 9.7 29.7 43.4 8.2 27.4 47.6 6.9

39.1 41.6 11.3 36.9 45.4 9.8 34.4 49.6 8.3 31.7 54.2 7

51.3 54.8 11.2 47.9 60 9.6 44.4 65.8 8.1 40.7 71.9 6.8

58.9 60.6 11.7 55.2 66.5 10 51.3 73.1 8.4 47.3 80.1 7.1

70 73 11.5 65.4 80.1 9.8 60.6 87.8 8.3 55.8 96 7

80.5 80.9 11.9 75.6 89.2 10.2 70.3 98.3 8.6 64.8 108.1 7.2

90.3 93.1 11.6 84.5 102.1 9.9 78.4 111.9 8.4 72 122.4 7.1

101.9 103.9 11.8 95.6 113.5 10.1 88.8 124 8.6 81.7 135.3 7.2

110.7 116.2 11.4 103.6 126.9 9.8 96.1 138.4 8.3 88.3 150.8 7

119.9 128.4 11.2 112.1 140.1 9.6 103.8 152.7 8.2 95.2 166.2 6.9

130 132.6 11.8 121.9 145.5 10.1 113.3 159.7 8.5 104.3 174.8 7.2

20.8 21 11.9 19.6 22.9 10.3 18.3 24.9 8.8 16.9 27.2 7.4

26.8 27.6 11.7 25.1 30.2 10 23.2 33 8.4 21.3 36.1 7.1

30 30.4 11.8 28.2 33.4 10.1 26.3 36.7 8.6 24.3 40.2 7.2

35.3 36.3 11.7 33.1 39.8 10 30.7 43.7 8.4 28.3 47.9 7.1

40.6 42 11.6 38.2 45.8 10 35.6 50 8.6 32.9 54.6 7.2

53 55.4 11.5 49.5 60.6 9.8 45.9 66.3 8.3 42 72.5 7

61 61.1 12 57.2 67.1 10.2 53.1 73.6 8.7 49 80.5 7.3

72.4 73.8 11.8 67.7 80.8 10.1 62.7 88.5 8.5 57.7 96.7 7.2

83.3 81.6 12.2 78.2 89.9 10.4 72.7 99 8.8 67.1 108.8 7.4

93.3 94 11.9 87.4 103 10.2 81 112.8 8.6 74.5 123.2 7.3

105.5 104.8 12.1 98.9 114.4 10.4 91.9 124.9 8.8 84.5 136.1 7.5

114.4 117.3 11.7 107.1 128 10 99.3 139.5 8.5 91.3 151.8 7.2

123.9 129.6 11.5 115.8 141.3 9.8 107.2 154 8.4 98.5 167.4 7.1

134.4 133.9 12 126.1 146.8 10.3 117.1 160.9 8.7 107.9 176 7.4

kW

Input EER Tons

kW

Input EER Tons

kW

Input EER

CG-PRC017H-EN 23

Page 24

Performance Data

Table 9. Performance data - 60 Hz - I-P units

Evaporator

Leaving

Temperature

(°F)

46

48

Unit

Size Tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

Condenser Ambient Temperature (°F)

85 95 105 115

kW

Input EER Tons

21.5 21.2 12.2 20.3 23.1 10.6 18.9 25.1 9 17.5 27.4 7.6

27.6 27.9 11.9 25.9 30.4 10.2 24 33.3 8.6 22 36.3 7.3

31 30.6 12.2 29.1 33.6 10.4 27.2 36.9 8.8 25.1 40.4 7.5

36.4 36.6 11.9 34.2 40.2 10.2 31.8 44 8.7 29.3 48.2 7.3

42 42.4 11.9 39.6 46.2 10.3 36.9 50.4 8.8 34.1 55 7.4

54.7 56 11.7 51.1 61.2 10 47.4 66.9 8.5 43.4 73 7.1

63.1 61.6 12.3 59.2 67.6 10.5 55 74.1 8.9 50.8 81 7.5

74.8 74.5 12.1 70 81.6 10.3 64.9 89.2 8.7 59.7 97.4 7.4

86.1 82.4 12.5 80.8 90.7 10.7 75.2 99.8 9 69.3 109.6 7.6

96.4 94.9 12.2 90.3 103.9 10.4 83.7 113.7 8.8 77 124.1 7.4

109.1 105.7 12.4 102.3 115.3 10.6 95 125.8 9.1 87.4 137 7.7

118.3 118.4 12 110.7 129.1 10.3 102.6 140.6 8.8 94.4 152.9 7.4

127.9 130.9 11.7 119.6 142.6 10.1 110.7 155.2 8.6 101.7 168.6 7.2

138.9 135.1 12.3 130.2 148 10.6 121 162.1 9 111.5 177.2 7.6

22.2 21.4 12.5 20.9 23.3 10.8 19.5 25.3 9.3 18 27.6 7.8

28.5 28.1 12.2 26.7 30.7 10.4 24.7 33.6 8.8 22.7 36.6 7.5

32 30.9 12.5 30.1 33.9 10.7 28.1 37.1 9.1 26 40.6 7.7

37.6 37 12.2 35.3 40.5 10.4 32.8 44.4 8.9 30.3 48.5 7.5

43.5 42.9 12.2 41 46.7 10.5 38.2 50.8 9 35.3 55.4 7.6

56.5 56.6 12 52.8 61.8 10.2 48.9 67.5 8.7 44.8 73.5 7.3

65.3 62.2 12.6 61.2 68.1 10.8 56.9 74.6 9.2 52.6 81.5 7.7

77.3 75.3 12.3 72.3 82.3 10.5 67 89.9 8.9 61.7 98 7.6

88.9 83.1 12.8 83.5 91.5 11 77.7 100.6 9.3 71.6 110.3 7.8

99.6 95.8 12.5 93.2 104.8 10.7 86.4 114.6 9 79.5 124.9 7.6

112.7 106.6 12.7 105.7 116.2 10.9 98.1 126.7 9.3 90.4 137.8 7.9

122.1 119.5 12.3 114.3 130.2 10.5 106 141.7 9 97.5 153.9 7.6

132 132.2 12 123.4 143.9 10.3 114.3 156.5 8.8 105 169.7 7.4

143.4 136.3 12.6 134.5 149.3 10.8 125 163.3 9.2 115.2 178.4 7.8

kW

Input EER Tons

kW

Input EER Tons

kW

Input EER

24 CG-PRC017H-EN

Page 25

Table 9. Performance data - 60 Hz - I-P units

Performance Data

Evaporator

Leaving

Temperature

(°F)

50

1. Rated in accordance with AHRI Standard 550/590 based on sea level altitude, evaporator fouling factor of 0.00010°F·ft²h/Btu, evaporator temperature

drop of 10°F and 380/460/575 voltage.

2. kW input is for compressors only.

3. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include: compressors, condenser fans, and control power.

4. Interpolation between points is permissible. Extrapolation is not permitted.

5. Performance based on TOPSS™ version 137. Consult Trane representative for performance at temperatures outside of the ranges shown.

Unit

Size Tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

23 21.6 12.8 21.6 23.5 11.1 20.2 25.5 9.5 18.6 27.8 8.1

29.4 28.4 12.4 27.5 31 10.6 25.5 33.8 9 23.4 36.8 7.6

33.1 31.1 12.8 31.1 34.1 10.9 29 37.4 9.3 26.8 40.9 7.9

38.8 37.3 12.5 36.4 40.8 10.7 33.9 44.7 9.1 31.3 48.8 7.7

45 43.3 12.5 42.4 47.1 10.8 39.6 51.3 9.3 36.5 55.8 7.9

58.2 57.2 12.2 54.4 62.4 10.5 50.4 68 8.9 46.3 74 7.5

67.4 62.7 12.9 63.3 68.7 11.1 58.9 75.1 9.4 54.4 81.9 8

79.8 76 12.6 74.6 83 10.8 69.2 90.6 9.2 63.8 98.7 7.7

91.8 83.9 13.1 86.2 92.2 11.2 80.2 101.3 9.5 74 111.1 8

102.7 96.7 12.7 96.1 105.7 10.9 89.1 115.5 9.3 82 125.7 7.8

116.3 107.5 13 109.1 117.1 11.2 101.3 127.5 9.5 93.3 138.6 8.1

126 120.7 12.5 117.9 131.3 10.8 109.4 142.7 9.2 100.6 154.9 7.8

136.1 133.5 12.2 127.2 145.2 10.5 117.8 157.7 9 108.3 170.9 7.6

148 137.6 12.9 138.7 150.5 11.1 129 164.5 9.4 118.9 179.5 8

85 95 105 115

kW

Input EER Tons

Condenser Ambient Temperature (°F)

kW

Input EER Tons

kW

Input EER Tons

kW

Input EER

Table 10. Part load performance - 60 Hz - I-P units

IPLV 100% 75% 50% 25%

Unit

Size

20 tons 14.2

26 tons 15.1

30 tons 15.0

35 tons 15.2

40 tons 13.8

52 tons 15.1

60 tons 15.3

70 tons 15.6

80 tons 15.6

90 tons 15.8

100 tons 15.4

110 tons 15.3

120 tons 15.4

130 tons 16.6

1. IPLV values are rated in accordance with AHRI Standard 550/590.

2. EER and IPLV values include compressors, condenser fans, and control kW.

3. Performance is based on 380/460/575 voltage TOPSS version 137.

EER Tons

19.6 22.9 10.3 14.7 13.7 12.9 9.8 8.0 14.7 4.9 3.5 16.7

25.1 30.2 10.0 18.8 16.8 13.4 12.5 9.3 16.1 6.3 4.4 17.2

28.2 33.4 10.1 21.1 19.0 13.3 14.1 10.5 16.2 7.1 4.9 17.2

33.1 39.8 10.0 24.8 22.6 13.1 16.5 11.9 16.7 8.3 5.6 17.6

38.2 45.8 10.0 28.7 27.6 12.5 19.1 15.9 14.4 9.6 7.0 16.4

49.5 60.6 9.8 37.2 33.6 13.3 24.8 18.2 16.4 12.4 8.6 17.3

57.2 67.1 10.2 42.9 38.3 13.4 28.6 20.6 16.6 14.3 9.8 17.6

67.7 80.8 10.1 50.8 46.1 13.2 33.8 23.6 17.2 16.9 11.1 18.3

78.2 89.9 10.4 58.6 50.7 13.9 39.1 27.2 17.3 19.5 14.4 16.3

87.4 103.0 10.2 65.5 57.8 13.6 43.7 29.5 17.8 21.8 15.5 16.9

98.9 114.4 10.4 74.2 65.6 13.6 49.5 35.7 16.6 24.7 16.5 18.0

107.1 128.0 10.0 80.3 72.9 13.2 53.6 38.5 16.7 26.8 17.7 18.2

115.8 141.3 9.8 86.8 78.1 13.3 57.9 41.6 16.7 29.0 19.4 17.9

126.1 146.8 10.3 94.5 79.0 14.4 63.0 42.6 17.8 31.5 18.6 20.3

kW

input EER Tons

kW

input EER Tons

kW

input EER Tons

kW

input EER

CG-PRC017H-EN 25

Page 26

Performance Data

Table 11. Performance data - 60 Hz - SI units

Evaporator

Leaving

Temperature

(°C)

7

9

1. Rated in accordance with AHRI Standard 550/590, based on sea level altitude, evaporator fouling factor of 0.01761 m²-°C/kW, evaporator temperature

drop of 5°C and 380/460/575 voltage.

2. COP = Coefficient of Performance. Power inputs include: compressors, condenser fans, and control power.

3. kW input is for compressors only.

4. Interpolation between points is permissible. Extrapolation is not permitted.

5. Performance based on TOPSS™ version 137. Consult Trane representative for performance at temperatures outside of the ranges shown.

Unit

Size

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

130 tons

kW

Cooling

73.13 21.2 3.46 69.27 22.9 3.02 65.05 24.8 2.64 60.83 26.8 2.26

94.23 27.9 3.37 88.6 30.2 2.93 82.98 32.8 2.52 77 35.5 2.17

105.48 30.7 3.43 99.85 33.4 2.99 93.53 36.4 2.58 87.2 39.5 2.2

124.11 36.7 3.37 117.08 39.9 2.93 109.7 43.4 2.52 101.96 47.1 2.17

142.75 42.4 3.37 135.37 45.9 2.96 127.28 49.6 2.55 118.49 53.7 2.2

186.35 56 3.34 175.45 60.7 2.9 163.49 65.9 2.49 151.54 71.3 2.14

214.48 61.8 3.49 202.52 67.2 3.02 189.51 73 2.61 176.5 79.2 2.23

254.56 74.6 3.43 239.79 81 2.96 223.97 87.8 2.55 207.8 95.2 2.2

292.88 82.6 3.54 276.71 90.1 3.08 259.48 98.3 2.64 241.55 107 2.26

328.39 95 3.46 309.41 103.2 2.99 289.02 112 2.58 268.27 121.3 2.23

371.29 105.9 3.51 350.19 114.6 3.05 328.04 124 2.64 304.49 134 2.28

402.58 118.6 3.4 379.38 128.2 2.96 354.41 138.5 2.55 329.1 149.5 2.2

435.63 131 3.31 409.97 141.6 2.9 382.54 152.9 2.49 354.76 164.9 2.14

472.9 135.3 3.49 446.18 147 3.05 418.05 159.7 2.61 388.52 173.2 2.26

77.7 21.6 3.6 73.48 23.3 3.16 69.27 25.1 2.75 64.34 27.1 2.37

99.5 28.4 3.51 93.88 30.7 3.05 87.55 33.3 2.64 81.22 36 2.26

111.81 31.1 3.6 105.83 33.9 3.13 99.5 36.8 2.69 92.82 39.9 2.31

131.5 37.3 3.51 124.11 40.5 3.05 116.03 44 2.64 108.29 47.6 2.28

152.24 43.2 3.51 144.16 46.7 3.08 135.37 50.4 2.69 126.22 54.5 2.31

197.25 57.1 3.46 185.64 61.8 2.99 173.34 66.9 2.58 160.68 72.3 2.23

228.19 62.7 3.63 215.18 68.1 3.16 201.82 73.9 2.72 188.11 80.1 2.34

270.03 76 3.54 254.21 82.3 3.08 237.68 89.1 2.67 220.8 96.4 2.28

310.81 83.9 3.69 293.59 91.5 3.22 275.3 99.6 2.75 256.32 108.3 2.37

347.73 96.7 3.6 327.69 104.8 3.13 306.24 113.6 2.69 284.44 122.8 2.31

393.79 107.5 3.66 371.64 116.2 3.19 347.73 125.6 2.78 323.47 135.5 2.37

426.49 120.6 3.54 401.88 130.2 3.08 375.51 140.5 2.67 348.79 151.4 2.31

461.3 133.3 3.46 433.87 143.9 3.02 405.04 155.2 2.61 375.86 167 2.26

501.03 137.6 3.63 472.9 149.2 3.16 443.02 161.9 2.72 412.08 175.3 2.34

30 35 40 45

kW

Input COP

Condenser Ambient Temperature (°C)

kW

Cooling

kW

Input COP

kW

Cooling

kW

Input COP

kW

Cooling

kW

Input COP

26 CG-PRC017H-EN

Page 27

Table 12. Performance data - 50 Hz - I-P units

Performance Data

Evaporator

Leaving

Temperature

(°F)

42

44

46

Unit

Size Tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

Condenser Ambient Temperature (°F)

85 95 105 115

kW

Input EER Tons

17.1 16.4 12.5 16.1 18 10.7 15 19.8 9.1 13.8 21.8 7.6

21.9 21.6 12.1 20.5 23.9 10.3 18.9 26.4 8.6 17.3 29.1 7.1

24.7 24.4 12.2 23.2 26.9 10.4 21.5 29.7 8.7 19.8 32.7 7.3

28.6 28.9 11.9 26.8 32 10.1 24.9 35.4 8.4 22.8 39.1 7

33.1 32.7 12.1 31.1 36 10.4 29 39.6 8.8 26.7 43.5 7.4

43.2 43.3 12 40.3 47.9 10.1 37.2 52.9 8.4 34 58.3 7

49.6 49 12.1 46.4 54 10.3 43.1 59.6 8.7 39.5 65.8 7.2

58.3 58.2 12 54.5 64.3 10.2 50.4 71 8.5 46.1 78.3 7.1

68.1 65.4 12.5 63.8 72.6 10.5 59.2 80.6 8.8 54.4 89.2 7.3

76.6 75.1 12.2 71.6 82.9 10.4 66.2 91.3 8.7 60.6 100.3 7.3

86.6 83.9 12.4 81.1 92.2 10.6 75.1 101.2 8.9 68.8 110.9 7.5

93.7 92 12.2 87.6 101.1 10.4 81.1 110.9 8.8 74.2 121.3 7.3

100.2 101.2 11.9 93.6 111.2 10.1 86.5 121.8 8.5 79.2 133.1 7.1

17.7 16.6 12.8 16.6 18.2 11 15.5 20 9.3 14.3 21.9 7.8

22.6 21.9 12.4 21.2 24.1 10.5 19.6 26.6 8.8 17.9 29.3 7.3

25.6 24.5 12.5 24 27 10.7 22.3 29.8 9 20.5 32.9 7.5

29.6 29.2 12.2 27.8 32.2 10.3 25.7 35.6 8.7 23.7 39.3 7.2

34.3 33 12.5 32.3 36.3 10.7 30 39.9 9 27.7 43.8 7.6

44.6 43.8 12.2 41.7 48.3 10.3 38.5 53.3 8.7 35.2 58.7 7.2

51.4 49.4 12.5 48.1 54.4 10.6 44.7 60 8.9 41 66.1 7.4

60.4 58.7 12.3 56.4 64.8 10.4 52.2 71.5 8.8 47.8 78.7 7.3

70.5 66 12.8 66.1 73.2 10.8 61.3 81.2 9.1 56.4 89.8 7.5

79.2 75.8 12.5 74 83.6 10.6 68.5 92 8.9 62.7 101 7.5

89.6 84.6 12.7 83.9 92.9 10.8 77.8 101.9 9.2 71.3 111.5 7.7

96.9 92.9 12.5 90.6 101.9 10.7 83.9 111.7 9 76.8 122.1 7.5

103.6 102.3 12.2 96.7 112.2 10.3 89.4 122.8 8.7 81.9 134.1 7.3

18.3 16.7 13.2 17.2 18.3 11.3 16 20.1 9.6 14.8 22.1 8

23.4 22.1 12.7 21.9 24.3 10.8 20.2 26.8 9 18.5 29.5 7.5

26.5 24.7 12.9 24.8 27.2 11 23.1 30 9.2 21.3 33 7.7

30.6 29.4 12.5 28.7 32.5 10.6 26.6 35.9 8.9 24.5 39.5 7.4

35.6 33.3 12.8 33.4 36.6 11 31.1 40.2 9.3 28.7 44.1 7.8

46.1 44.3 12.5 43.1 48.8 10.6 39.8 53.8 8.9 36.3 59.1 7.4

53.2 49.8 12.8 49.9 54.8 10.9 46.3 60.4 9.2 42.5 66.5 7.7

62.5 59.3 12.6 58.4 65.3 10.7 54 72 9 49.5 79.2 7.5

73 66.6 13.2 68.4 73.8 11.1 63.5 81.7 9.3 58.4 90.3 7.8

81.9 76.5 12.8 76.5 84.3 10.9 70.8 92.7 9.2 64.9 101.6 7.7

92.7 85.3 13 86.8 93.6 11.1 80.5 102.6 9.4 73.8 112.2 7.9

100.2 93.8 12.8 93.7 102.8 10.9 86.7 112.6 9.2 79.4 122.9 7.8

107 103.3 12.4 99.9 113.3 10.6 92.4 123.9 8.9 84.7 135 7.5

kW

Input EER Tons

kW

Input EER Tons

kW

Input EER

CG-PRC017H-EN 27

Page 28

Performance Data

Table 12. Performance data - 50 Hz - I-P units

Evaporator

Leaving

Temperature

(°F)

48

50

1. Rated in accordance with AHRI Standard 550/590 based on sea level altitude, evaporator fouling factor of 0.00010°F·ft²h/Btu, and evaporator temperature drop of 10°F.

2. kW input is for compressors only.

3. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include: compressors, condenser fans, and control power.

4. Interpolation between points is permissible. Extrapolation is not permitted.

5. Performance based on TOPSS™ version 137.Consult Trane representative for performance at temperatures outside of the ranges shown.

Unit

Size Tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

19 16.9 13.5 17.8 18.5 11.6 16.6 20.3 9.8 15.3 22.2 8.2

24.1 22.3 13 22.6 24.6 11 20.9 27.1 9.2 19.1 29.7 7.7

27.4 24.9 13.2 25.7 27.4 11.3 23.9 30.2 9.5 22 33.2 8

31.7 29.7 12.8 29.7 32.7 10.9 27.5 36.1 9.2 25.3 39.8 7.6

36.9 33.7 13.1 34.6 36.9 11.3 32.3 40.5 9.5 29.7 44.4 8

47.7 44.8 12.8 44.5 49.3 10.8 41.1 54.2 9.1 37.6 59.5 7.6

55.1 50.2 13.2 51.6 55.2 11.2 47.9 60.8 9.5 44.1 66.8 7.9

64.6 59.8 13 60.3 65.9 11 55.8 72.5 9.2 51.2 79.7 7.7

75.5 67.2 13.5 70.7 74.4 11.4 65.6 82.3 9.6 60.4 90.9 8

84.6 77.2 13.2 79.1 85 11.2 73.2 93.4 9.4 67.1 102.3 7.9

95.8 86 13.4 89.8 94.3 11.4 83.2 103.3 9.7 76.3 112.9 8.1

103.5 94.6 13.1 96.7 103.7 11.2 89.5 113.5 9.5 82.1 123.8 8

110.4 104.4 12.7 103.1 114.3 10.8 95.3 124.9 9.2 87.4 136 7.7

19.6 17 13.8 18.4 18.6 11.8 17.1 20.4 10.1 15.8 22.4 8.5

24.9 22.6 13.2 23.3 24.8 11.2 21.5 27.3 9.5 19.7 29.9 7.9

28.3 25 13.5 26.5 27.6 11.6 24.7 30.3 9.8 22.8 33.4 8.2

32.7 29.9 13.1 30.6 33 11.1 28.4 36.3 9.4 26.2 40 7.9

38.2 34 13.5 35.9 37.3 11.5 33.4 40.9 9.8 30.8 44.8 8.3

49.2 45.3 13 45.9 49.8 11.1 42.4 54.7 9.3 38.8 60 7.8

57 50.6 13.5 53.4 55.6 11.5 49.6 61.2 9.7 45.6 67.2 8.1

66.7 60.4 13.3 62.3 66.4 11.3 57.7 73.1 9.5 53 80.2 7.9

78 67.8 13.8 73 75 11.7 67.8 82.9 9.8 62.4 91.4 8.2

87.3 77.9 13.5 81.6 85.7 11.4 75.5 94.1 9.6 69.3 102.9 8.1

99 86.7 13.7 92.7 95 11.7 85.9 104 9.9 78.9 113.6 8.3

106.8 95.5 13.4 99.8 104.6 11.5 92.4 114.3 9.7 84.8 124.6 8.2

113.9 105.5 13 106.3 115.4 11.1 98.3 126 9.4 90.2 137 7.9

85 95 105 115

kW

Input EER Tons

Condenser Ambient Temperature (°F)

kW

Input EER Tons

kW

Input EER Tons

kW

Input EER

28 CG-PRC017H-EN

Page 29

Table 13. Part load performance - 50 Hz - I-P units

IPLV 100% 75% 50% 25%

Unit

Size

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

1. IPLV values are rated in accordance with AHRI Standard 550/590.

2. EER and IPLV values include compressors, condenser fans, and control kW.

3. Performance is based on 400 voltage 50 Hz TOPSS™ version 137.

EER Tons

16.1 16.6 18.2 11.0 12.5 10.6 14.2 8.3 5.8 17.3 4.2 2.7 18.6

16.4 21.2 24.1 10.5 15.9 13.2 14.5 10.6 7.1 17.8 5.3 3.4 18.5

16.1 24.0 27.0 10.7 18.0 15.4 14.1 12.0 8.1 17.8 6.0 4.2 17.3

16.2 27.8 32.2 10.3 20.8 18.2 13.7 13.9 9.2 18.2 6.9 4.8 17.5

15.3 32.3 36.3 10.7 24.2 21.3 13.6 16.1 11.9 16.3 8.1 5.4 18.0

16.4 41.7 48.3 10.3 31.3 26.3 14.2 20.8 13.9 17.9 10.4 6.7 18.6

15.7 48.1 54.4 10.6 36.1 31.1 13.9 24.1 16.9 17.1 12.0 8.3 17.4

16.5 56.4 64.8 10.4 42.3 36.7 13.8 28.2 18.2 18.6 14.1 9.3 18.3

16.6 66.1 73.2 10.8 49.5 40.5 14.7 33.0 21.3 18.6 16.5 11.8 16.8

16.9 74.0 83.6 10.6 55.5 46.2 14.4 37.0 23.1 19.2 18.5 12.7 17.4

16.4 83.9 92.9 10.8 63.0 52.5 14.4 42.0 28.2 17.9 21.0 13.4 18.8

16.5 90.6 101.9 10.7 68.0 57.4 14.2 45.3 30.0 18.1 22.6 14.2 19.2

16.8 96.7 112.2 10.3 72.5 60.8 14.3 48.4 31.3 18.5 24.2 14.7 19.7

kW

input EER Tons

kW

input EER Tons

Performance Data

kW

input EER Tons

kW

input EER

CG-PRC017H-EN 29

Page 30

Performance Data

Table 14. Performance data - 50 Hz - SI units

Evaporator

Leaving

Temperature

(°C)

7

9

1. Rated in accordance with AHRI Standard 550/590, based on sea level altitude, evaporator fouling factor of 0.01761 m²-°C/kW, and evaporator temperature

drop of 5°C.

2. COP = Coefficient of Performance. Power inputs include: compressors, condenser fans, and control power.

3. kW input is for compressors only.

4. Interpolation between points is permissible. Extrapolation is not permitted.

5. Performance based on TOPSS™ version 137. Consult Trane representative for performance at temperatures outside of the ranges shown.

Unit

Size

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

20 tons

26 tons

30 tons

35 tons

40 tons

52 tons

60 tons

70 tons

80 tons

90 tons

100 tons

110 tons

120 tons

kW

Cooling

62.23 16.7 3.72 59.07 18.2 3.22 55.2 19.8 2.78 51.33 21.6 2.37

79.46 22.1 3.6 74.89 24.2 3.1 69.97 26.4 2.64 64.69 28.8 2.23

90.01 24.8 3.63 85.09 27.1 3.13 79.46 29.6 2.69 73.84 32.3 2.28

104.07 29.5 3.51 98.1 32.3 3.05 91.77 35.3 2.61 85.09 38.6 2.2

120.95 33.4 3.6 114.27 36.3 3.13 107.24 39.6 2.69 99.85 43.1 2.31

157.17 44.3 3.54 147.67 48.4 3.05 137.48 52.9 2.61 126.93 57.7 2.2

180.72 50 3.63 170.53 54.5 3.13 159.63 59.5 2.67 148.02 64.9 2.28

212.37 59.4 3.57 199.71 64.9 3.08 186.35 70.9 2.64 172.64 77.4 2.23

248.23 66.8 3.72 233.81 73.3 3.19 218.7 80.5 2.72 203.22 88.1 2.31

278.82 76.7 3.63 261.94 83.7 3.13 244.36 91.3 2.67 226.43 99.3 2.28

315.39 85.5 3.69 297.1 93 3.19 277.76 101.1 2.75 257.02 109.7 2.34

341.05 93.9 3.63 321.01 102.1 3.13 299.21 110.9 2.69 277.06 120.2 2.31

364.26 103.4 3.51 342.46 112.4 3.05 319.25 122 2.61 295.34 132 2.23

66.1 17 3.9 62.58 18.5 3.4 58.72 20.1 2.93 54.5 21.8 2.49

84.38 22.5 3.75 79.11 24.6 3.22 73.84 26.8 2.75 68.21 29.2 2.34

95.64 25.1 3.81 90.36 27.4 3.31 84.74 29.9 2.84 78.76 32.6 2.4

110.75 30 3.69 104.43 32.7 3.19 97.39 35.7 2.72 90.71 39 2.31

128.69 34 3.78 121.65 36.9 3.31 114.27 40.2 2.84 106.18 43.6 2.43

166.66 45.2 3.69 156.46 49.3 3.16 145.56 53.7 2.72 134.66 58.5 2.31

192.68 50.6 3.81 181.43 55.2 3.28 169.82 60.2 2.81 157.87 65.6 2.4

225.73 60.4 3.75 212.01 65.9 3.22 197.95 71.8 2.75 183.54 78.3 2.34

263.7 67.9 3.9 248.58 74.4 3.34 232.41 81.5 2.84 215.88 89.1 2.43

295.7 77.9 3.78 278.12 85 3.28 259.48 92.5 2.81 240.14 100.5 2.4

335.07 86.8 3.87 315.74 94.3 3.34 294.99 102.4 2.87 273.19 110.9 2.46