Trane Air-Cooled Helical Rotary Liquid Chillers Installation and Maintenance Manual

Installation, Operation,

and Maintenance

Series R®Air-Cooled

Helical Rotary Liquid Chillers

SAFETY WARNING

Only qualified personnel should install and service the equipment.The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury.When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

January 2015

RTAC-SVX01M-EN

Introduction

Read this manual thoroughlybefore operating or servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required.Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards.To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situationthat could resultin

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

© 2015Trane All rights reserved RTAC-SVX01M-EN

Factory Warranty Information

Compliance with the following is required to preserve the

factory warranty:

All Unit Installations

Startup MUST be performed by Trane, or an authorized

agent of Trane, to VALIDATE this WARRANTY. Contractor

must provide a two-week startup notification to Trane (or

an agent of Trane specifically authorized to perform

startup).

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

Introduction

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

RTAC-SVX01M-EN (30 Jan 2015)

• Correction to Model Number digit 5-7.

• Addition of seismic isolator option.

• Removal of duplicated information found in other

locations

• Removal of detailed communication system

information

(nameplate, catalog, submittal).

found in controls documents.

RTAC-SVX01M-EN 3

Table of Contents

Introduction ............................. 2

Table of Contents ........................ 4

Model Number Description ............... 6

Outdoor Unit Nameplate ............... 6

Compressor Nameplate ................ 6

Unit Model Number .................... 7

Compressor Model Number ............ 8

Compressor Serial Number ............. 8

General Data ............................ 9

Unit Description ....................... 9

Accessory/Option Information ........... 9

Isolator Shipping Location ............. 9

Pre-installation ......................... 20

Unit Inspection ..................... 20

Inspection Checklist ................. 20

Storage ........................... 20

Installation Responsibilities ........... 20

General ............................. 20

Dimensions and Weights ................ 21

Dimensions .......................... 21

Clearances ........................... 21

Weights ............................. 24

Non-Seismically Rated Units .......... 24

Seismically Rated Unit Weights ....... 26

Remote Evaporator Unit Weights ...... 27

Installation - Mechanical ................ 28

Location Requirements ................ 28

Noise Considerations ................ 28

Foundation ........................ 28

Clearances ......................... 28

Rigging .............................. 28

Lifting Procedure ................... 28

Isolation and Sound Emission .......... 34

Mounting and Leveling ................ 34

Unit Isolation ........................ 34

Elastomeric Isolators

(Optional for units without seismic rating) 34

Unit Isolation for Seismically Rated Units 35

Isolator Selection and Mounting

Locations ...........................37

Drainage .............................47

Evaporator Water Piping ...............47

Entering Chilled Water Piping ..........48

Leaving Chilled Water Piping ..........48

Evaporator Drain ....................48

Evaporator Flow Switch ..............48

Water Pressure Gauges ................52

Water Pressure Relief Valves ............52

Freeze Avoidance ......................53

Low Evaporator Refrigerant Cutout, Glycol

Recommendations

Procedure ..........................54

Specials ............................54

.....................54

Installation - Mechanical

Remote Evaporator Option

...............56

System Configuration and Interconnecting

Refrigerant Piping

.....................56

Line Sizing ............................60

Liquid Line Sizing Steps ..............60

Suction Line Sizing Steps .............61

Suction Accumulator Sizing ...........61

Piping Installation Procedures ...........62

Refrigerant Sensors ....................62

Refrigerant Pressure Relief Valve Venting .62

Leak Test and Evacuation ...............63

Refrigerant and Additional Oil Charge ....64

Refrigerant Charge Determination ......64

Oil Charge Determination .............64

Installation - Electrical ....................65

General Recommendations .............65

Installer-Supplied Components ..........66

Power Supply Wiring .................66

Control Power Supply ..................67

Heater Power Supply and Convenience

Outlet (Packaged Units Only) ..........67

Interconnecting Wiring .................68

Chilled Water Pump Control ...........68

Alarm and Status Relay Outputs

4 RTAC-SVX01M-EN

Table of Contents

(Programmable Relays) ............... 68

Relay Assignments Using TechView .... 69

Low Voltage Wiring ................... 69

Emergency Stop .................... 69

External Auto/Stop .................. 70

External Circuit Lockout – Circuit #1 and #2

70

Ice Building Option .................. 70

External Chilled Water Setpoint

(ECWS) Option ..................... 70

External Current Limit Setpoint

(ECLS) Option ...................... 71

Chilled Water Reset (CWR) ........... 71

Communications Interface Options ..... 72

Tracer Communications Interface

Option ............................ 72

LonTalk™ Interface (LCI-C) ........... 72

Operating Principles .................... 73

Refrigeration Cycle ................... 73

Refrigerant R-134a .................... 73

Compressor .......................... 73

Condenser and Subcooler ............. 74

Expansion Valve ...................... 74

Evaporator ........................... 74

Oil System ........................... 74

Controls Interface ....................... 75

Overview ............................ 75

Controls Interface ..................... 75

DynaView Display .................... 75

Key Functions ...................... 75

Display Screens .................... 76

Modes Screen ...................... 77

Chiller Screen ...................... 81

Compressor Screen ................. 81

Refrigerant Screen .................. 81

Setpoint Screen .................... 82

Diagnostic Screen .................. 83

Power-Up ......................... 83

Display Formats ...................... 83

Units ............................. 83

Languages ......................... 83

TechView .............................83

Unit View ..........................85

Compressor Service View .............85

Status View .........................85

Setpoint View .......................85

Diagnostics View ....................86

Configuration View ..................86

Software View ......................89

Binding View .......................89

Replacing or Adding Devices ..........89

Pre-Start Checkout .......................92

Start-Up and Shutdown ..................93

Unit Start-Up .........................93

Temporary Shutdown and Restart .......94

Extended Shutdown Procedure ..........94

Seasonal Unit Start-Up Procedure .......95

System Restart After Extended Shutdown 95

Sequence of Operation .................96

Maintenance ...........................100

Weekly ..............................100

Monthly .............................100

Annual ..............................100

Refrigerant and Oil Charge Management 100

Lubrication System ...................101

Oil Sump Level Check ...............101

Condenser Maintenance ...............101

Condenser Coil Cleaning .............101

Travel Restraint ......................102

Diagnostics ............................103

Legend to Diagnostics Table ...........103

Starter Diagnostics ...................103

Main Processor Diagnostics ............108

Communication Diagnostics ...........116

Main Processor Boot Messages

and Diagnostics

......................121

Unit Wiring ............................122

Log and Check Sheet ...................124

RTAC-SVX01M-EN 5

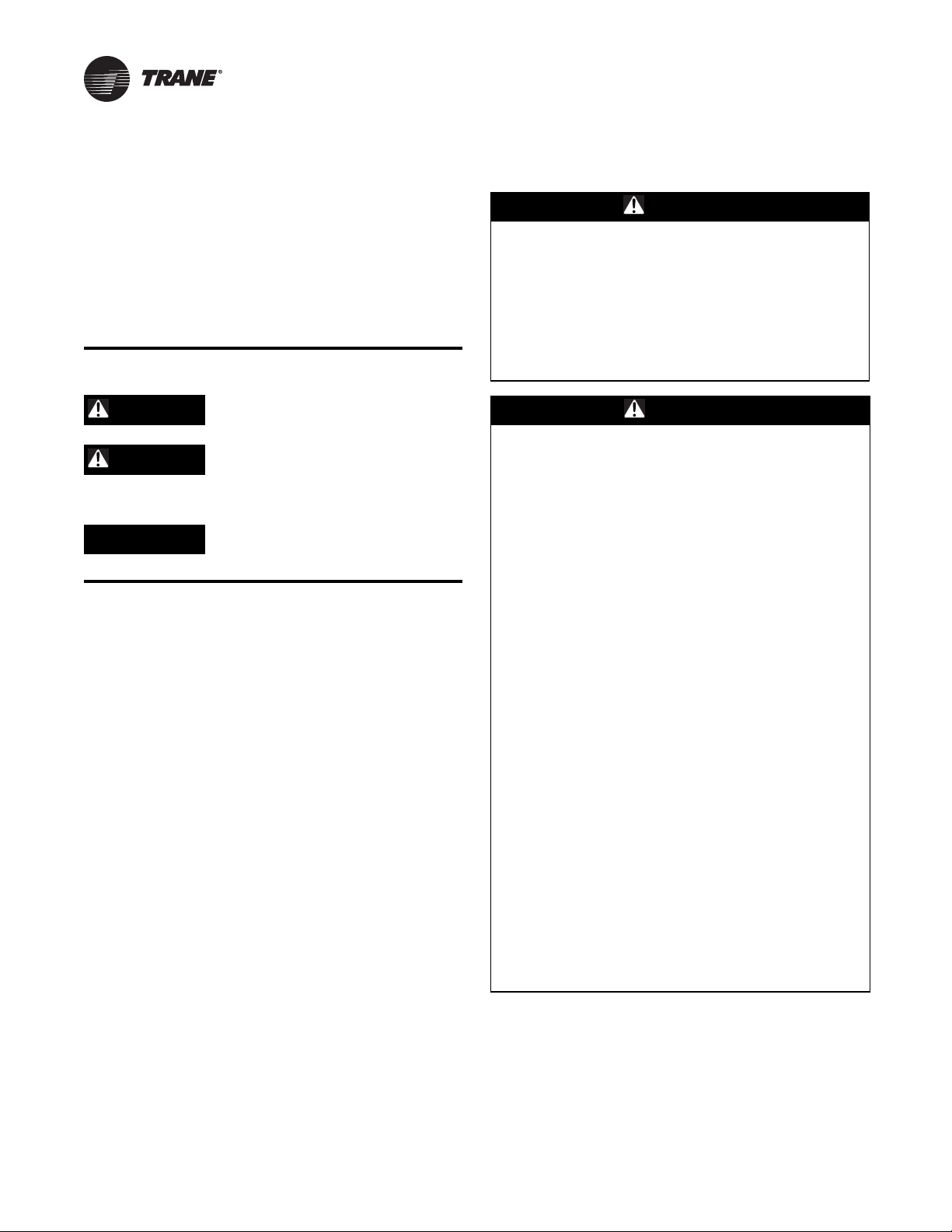

Model Number Description

Nameplates

The RTAC outdoor unit nameplates are applied to the

exterior of the Control Panel. A compressor nameplate is

located on each compressor.When the unit arrives, if unit

is not covered with atarp, compare all nameplate datawith

ordering, submittal, and shipping information.

Outdoor Unit Nameplate

See Figure 1, p. 6 for a typical unit nameplate.Theoutdoor

unit nameplate provides the following information:

• Unit model and size description.

• Unit serial number.

• Identifies unit electrical requirements.

• Lists correct operating charges of R-134a and

refrigerant oil (Trane OIL00048).

• Lists unit test pressures.

• Identifies installation, operation and maintenance and

service data literature (Pueblo).

• Lists drawing numbers for unit wiring diagrams

(Pueblo).

Model Number Coding System

The model numbers for the unit and the compressor are

composed of numbers and letters that represent features

of the equipment.Shown in the followingtable is a sample

of typical unit model number and the coding system for

each.

Each position, or group of positions, in the model number

is used to represent a feature. For example, in the first

table, position 08 of the unit model number, UnitVoltage,

contains the number“4”.A 4 in this position means that the

unit voltage is 460/60/3.

Unit Model Number. An example of a typical unit

model number (M/N) is:

RTAC 350A UA0N NAFN N1NX 1TEN NN0N N01N

Model number digits are selected and assigned in

accordance with the definitions as listed in “Unit Model

Number,” p. 7.

Compressor Nameplate

The compressor nameplate provides following

information:

• Compressor model number. See “Compressor Model

Number,” p. 8.

• Compressor serial number. See“Compressor Serial

Number,” p. 8.

• Compressor electrical characteristics.

• Utilization range.

• Recommended refrigerant.

Figure 1. Typical unit nameplate

6 RTAC-SVX01M-EN

Model Number Descriptions

Unit Model Number

Digits 1, 2 - Unit Model

RT = Rotary chiller

Digit 3 - Unit Type

A = Air-cooled

Digit4-Development Sequence

C = Development sequence

Digits 5,6&7-Nominal

Capacity

120 = 120 Nominal tons

130 = 130 Nominal tons

140 = 140 Nominal tons

155 = 155 Nominal tons

170 = 170 Nominal tons

185 = 185 Nominal tons

200 = 200 Nominal tons

225 = 225 Nominal tons

250 = 250 Nominal tons

275 = 275 Nominal tons

300 = 300 Nominal tons

350 = 350 Nominal tons

375 = 375 Nominal tons

400 = 400 Nominal tons

450 = 450 Nominal tons

500 = 500 Nominal tons

Digit 8 - Unit Voltage

A = 200/60/3

C = 230/60/3

J = 380/60/3

D = 400/50/3

4 = 460/60/3

5 = 575/60/3

Digit 9 - Manufacturing

Location

U = Water Chiller Business Unit,

Pueblo, CO USA

Digits 10, 11 - Design Sequence

XX = Factory Input

Digit 12 - Unit Basic

Configuration

N = Standard efficiency/performance

H = High efficiency/performance

A = Extra efficiency/performance

Digit 13 - Agency Listing

N = No agency listing

U = C/UL listing

S = Seismic rated - IBC and OSHPD

R = C/UL listed and seismic rated

Digit 14 - Pressure Vessel Code

A = ASME pressure vessel code

C = Canadian code

D = Australian code

L = Chinese code

Digit 15 - Evaporator

Application

F = Standard (40-60 F) leaving temp

G = Low (Less than 40 F) leaving

temp

R = Remote (40-60 F) leaving temp

Digit 16 - Evaporator

Configuration

N = 2 pass, 0.75” insulation

P = 3 pass, 0.75” insulation

Q = 2 pass, 1.25” insulation

R = 3 pass, 1.25” insulation

Digit 17 - Condenser

Application

N = Standard ambient (25-115°F)

H = High ambient (25-125°F)

L = Low ambient (0-115°F)

W = Wide ambient (0-125°F)

Digit 18 - Condenser Fin

Material

1 = Standard aluminum slit fins

2 = Copper fins

4 = CompleteCoat™ epoxy coated

fins

Digit 19 - Condenser Fan/Motor

Configuration

T = STD fans with TEAO motors

W = Low noise fans

Digit 20 - Compressor Motor

Starter Type

X = Across-the-line

Y = Wye-delta closed transition

Digit 21 - Incoming Power Line

Connection

1 = Single point power connection

2 = Dual point power connection

Digit 22 - Power Line

Connection Type

T = Terminal block connection

D = Non-fused disconnect switch(es)

C = Circuit breaker(s)

Digit 23 - Unit Operator

Interface

D = DynaView operator interface

Digit 24 - Remote Operator

Interface

N = No remote interface

C = Tracer™ Comm 3 interface

B = BACnet®interface

L = LonTalk®compatible (LCI-C)

interface

Digit 25 - Control Input

Accessories/Options

N = No remote inputs

R = Ext. evaporator leaving water

setpoint

C = Ext. current limit setpoint

B = Ext. leaving water and current

limit setpoint

Digit 26 - Control Output

Accessories/Options

N = No output options

A = Alarm relay outputs

C = Ice making I/O

D = Alarm relay outputs and ice

making I/O

Digit 27 - Electrical Protection

Options

0 = No short circuit rating

5 = Default short circuit rating

6 = High amp short circuit rating

Digit 28 - Flow Switch

T = Factory installed flow switch -

water

U = Factory installed flow switch

glycol

Digit 29 - Control Panel

Accessories

N = No convenience outlet

A = 15A 115V convenience outlet

(60Hz)

Digit 30 - Service Valves

1 = With suction service valves

Digit 31 - Compressor Sound

Attenuation Option

0 = No compressor sound

attenuation

1 = Factory installed compressor

sound attenuation

Digit 32 - Appearance Options

N = No appearance options

A = Architectural louvered panels

C = Half louvers

Digit 33 - Installation

Accessories

N = No installation accessories

F = Flange kit for water connections

R = Neoprene in shear unit isolators

G = Neoprene isolators and flange kit

E = Seismic elastomeric isolation

pads

S = Seismic spring isolators

RTAC-SVX01M-EN 7

Model Number Descriptions

Digit 34 - FactoryTesting

Options

0 = Standard functional test

C = Customer-witnessed

performance

test with report

C = Customer-witnessed

performance

test plus Rapid Restart test

E = Non-witnessed performance test

with report

Digit 35 — Control, Label &

Literature

C = Spanish

E = English

F = French

Digit 36 — Special Order

X = Standard unit configuration

S = Unit has special order feature

Digit 37 — Safety Devices

N = Standard

Compressor Model Number

Digits 1-3 — Compressor Family

CHH= Positive displacement,

refrigerant, helical rotary,

hermetic compressor

Digit 4— Compressor Type

T = GP2+

Digit 5

0 = All compressors

Digit 6 — Frame Size

K = K Frame

L = L Frame

M = M Frame

N = N Frame

Digit 7 — Compressor Capacity

3 = GP2+ Smaller capacity (minor)

4 = GP2+ Larger capacity (major)

Compressor Serial Number

Digits 1-2 — Year

YY = Last two digits of year of

manufacture

Digits 3-4 — Week

WW= Week of build, from 00 to 52

Digit 5 — Day

1 = Monday

2 = Tuesday

3 = Wednesday

4 = Thursday

5 = Friday

6 = Saturday

7 = sunday

Digits 6-8 — Coded Time Stamp

TTT = Used to ensure uniqueness of

serial number

Digit 9 — Assembly Line

L = Varies with facility

Digit 10— Build Location

A = Monterrey

8 RTAC-SVX01M-EN

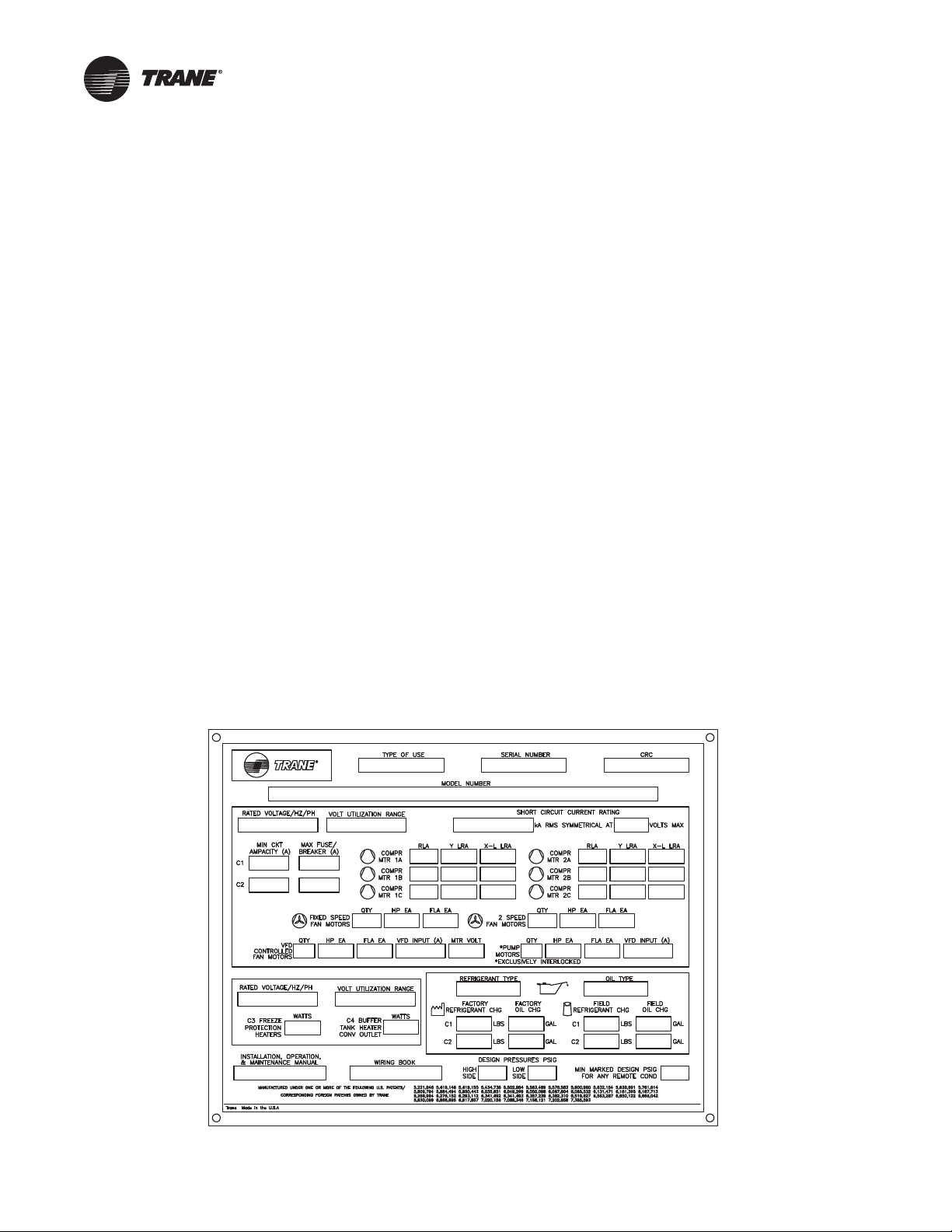

General Data

Unit Description

The 140 - 500 ton Model RTAC unitsare helical-rotary type,

air-cooled liquid chillers designed for installation

outdoors.The compressor circuits are completely

assembled, hermetic packages that are factory-piped,

wired, leak-tested, dehydrated, and tested for proper

control operation before shipment.

Chilled water inlet and outlet openings are covered for

shipment. Each compressor has a separate compressor

motor starter.The RTAC series featuresTrane’s exclusive

Adaptive Control ™ logic, which monitors the control

variables that govern the operation of the chiller unit.

Adaptive Control logic can adjust capacity variables to

avoid chiller shutdown when necessary, and keep

producing chilled water. The units feature two

independent refrigerant circuits. Compressor unloaders

are solenoid actuated and oil pressure operated. Each

refrigerant circuit is provided with filter, sight glass,

electronic expansion valve, and charging valves.The

shell-and-tube type evaporator is manufactured in

accordance with ASME standards or other international

codes. Each evaporator is fully insulated and is equipped

with water drain and vent connections. Packaged units

have heat tape protection to - 20°F (-28.9°C) as standard.

As an option, a convenience outlet can be supplied.

Note: Packaged units are factory charged with refrigerant

and oil.

Figure 2. Typical RTAC packaged unit and components

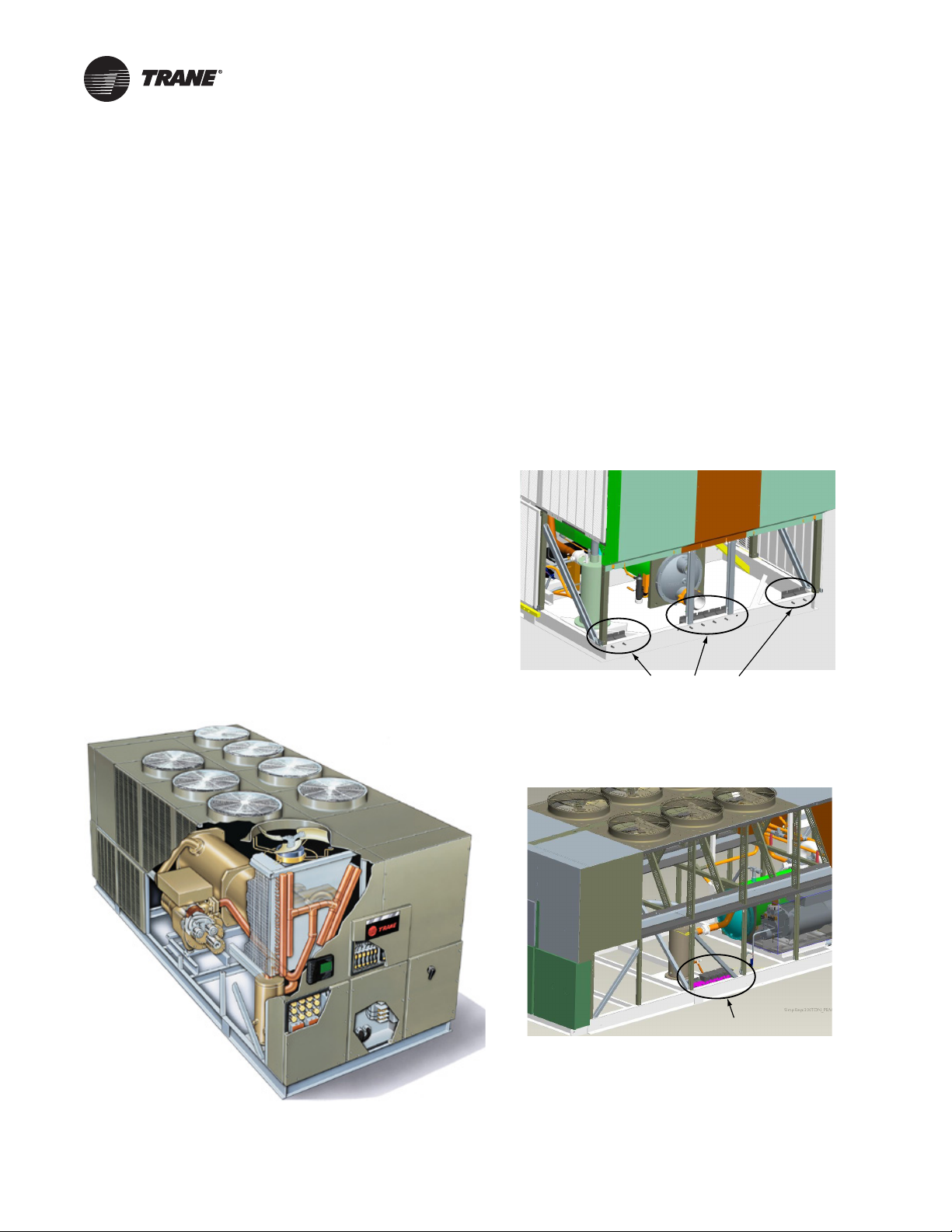

Accessory/Option Information

Check all the accessories and loose parts which are

shipped with the unit against the shipping list. Included in

these items will be water vessel drain plugs, rigging and

electrical diagrams, and service literature, which are

placed inside the control panel and/or starter panel for

shipment.

Isolator Shipping Location

If optional neopreneisolators (model number digit 33) are

ordered with unit, they are shipped mounted on the unit.

See Figure 3 and Figure 4.

Figure 3. Isolator shipping locations 140-250T units

Neoprene Isolator Shipping Location

Figure 4. Isolator shipping locations 275-500T units

Neoprene Isolator Shipping Location

RTAC-SVX01M-EN 9

General Data

Table 1. General Data - 60 hz units - standard efficiency - IP

Size 140 155 170 185 200 225 250 275 300 350 400 450 500

Compressor

Quantity # 2 2 2 2 2 2 2 3 33444

Nominal size

@60Hz

(tons) 70/70 85/70 85/85

100/

85

100/

100

120/

100

120/

120

Evaporator

Water storage (gal) 29 32 34 36 40 39 43 62 67 72 83 86 91

2 pass arrangement

Min flow (gpm) 193 214 202 217 241 217 241 309 339 375 404 422 461

Max flow (gpm) 709 785 741 796 883 796 883 1134 1243 1374 1483 1548 1690

Water conn (NPS-in) 4 4 6 6 6 6 6 8 88888

3 pass arrangement

Min flow (gpm) 129 143 135 145 161 145 161 206 226 250 270 282 307

Max flow (gpm) 473 523 494 531 589 531 589 756 829 916 989 1032 1127

Water conn (NPS-in) 3.5 3.5 4 4 4 4 4 6 66888

Condenser

Qty of coils # 4 4 4 4 4 4 4 8 88888

156/

180/

180/

216/

216/

252/

Coil length (in)

Coil height (in) 42 42 42 42 42 42 42 42 42 42 42 42 42

(mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

# of rows # 3 3 3 3 3 3 3 3 33333

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192

156

156

180

180

216

216

252/

252

Fan

Quantity # 4/4 5/4 5/5 6/5 6/6 7/6 7/7 10/6 12/6 14/6 12/12 14/12 14/14

Diameter (in) 30.0 30.0 30.0 30.0 30.0 30.0 30.0 30.0 30.0 30.0 30.0 30.0 30.0

Air flow per fan (cfm) 9625 9394 9209 9209 9209 9210 9210 9209 9209 9208 9209 9210 9214

Power/motor (hp) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Fan speed (rpm) 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140

Tip speed (Ft/min) 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954

General Unit

# Refrig ckts # 2 2 2 2 2 2 2 2 22222

% min load % 15 15 15 15 15 15 15 15 15 15 15 15 15

165/

175/

175/

215/

215/

225/

Refrigerant charge (lb)

Oil charge (gal)

Min ambient-std (°F) 25 25 25 25 25 25 25 25 25 25 25 25 25

Min ambient-low (°F) 0 0 0 0 0 0 0 0 00000

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

165

1.3/

1.3

165

1.3/

1.3

175

1.3/

1.3

210

1.9/

1.3

215

1.9/

1.9

215

1.9/

1.9

225/

225

1.9/

1.9

Screw

85-85/

Fin and tube

Direct drive propeller

4.2/1.9 4.6/2.9 4.6/1.9 4.6/4.6 4.6/4.6 4.6/4.6

100

Flooded

180/

108

HFC-134a

365/

200

100-100/

216/108 252/108 216/216 252/216 252/252

415/200 460/200 415/415 460/415 460/460

100

120-120/

100

100-100/

100-100

120-120/

100-100

120-120/

120-120

10 RTAC-SVX01M-EN

General Data

Table 2. General Data - 60 hz units - high efficiency - IP

Size 140 155 170 185 200 225 250 275 300 350 400

Compressor

Quantity # 22222223344

Nominal size

@60Hz

(tons) 70/70 85/70 85/85 100/85 100/100 120/100 120/120

Evaporator

Water storage (gal) 34 36 40 39 43 43 43 72 72 83 91

2 pass arrangement

Min flow (gpm) 202 217 241 217 241 241 241 375 375 404 461

Max flow (gpm) 741 796 883 796 883 883 883 1374 1374 1483 1690

Water conn (NPS-in) 66666668888

3 pass arrangement

Min flow (gpm) 135 145 161 145 161 161 161 250 250 270 307

Max flow (gpm) 494 531 589 531 589 589 589 916 916 989 1127

Water conn (NPS-in) 44444446688

Condenser

Qty of coils # 44444888888

Coil length (in) 180/180 216/180 216/216 252/216 252/252 144/144 144/144 216/144 252/144 216/216 252/252

Coil height (in) 42 42 42 42 42 42 42 42 42 42 42

Number of rows # 33333333333

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192

Fan

Quantity # 5/5 6/5 6/6 7/6 7/7 8/6 8/8 12/6 14/6 12/12 14/14

Diameter (in) 30 30 30 30 30 30 30 30 30 30 30

Air flow/fan (cfm) 9199 9199 9199 9200 9201 9783 9203 9652 9605 9199 9201

Power/motor (hp) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Fan speed (rpm) 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140

Tip speed (Ft/Min) 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954

General unit

# Refrig ckts # 22222222222

% min load % 15 15 15 15 15 15 15 15 15 15 15

Refrigerant charge (lb) 175/175 215/205 215/215 225/215 225/225 235/235 235/235 415/200 460/200 415/415 460/460

Oil charge (gal) 1.3/1.3 1.3/1.3 1.3/1.3 1.9/1.3 1.9/1.9 1.9/1.9 1.9/1.9

Min ambient-std (°F) 25 25 25 25 25 25 25 25 25 25 25

Min ambient-low (°F) 00000000000

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

Screw

Flooded

Fin and tube

Direct drive propeller

HFC-134a

85-85/

100

2.1-2.1/

1.9

100-100/

100

2.3-2.3/

1.9

85-85/

85/85

2.1-2.1/

2.1-2.1

100-100/

100-100

2.3-2.3/

2.3-2.3

RTAC-SVX01M-EN 11

General Data

Table 3. General Data - 60 hz units - extra efficiency - IP

Size 140 155 170 185 200 250 275 300 350

Compressor

Quantity # 2 2 2 2 2 3 3 4 4

Nominal size

@60Hz

(tons) 70/70 85/70 85/85 100/85 100/100 70-70/85 85-85/85

Evaporator

Water storage (gal) 40 39 43 43 43 72 72 83 91

2 pass arrangement

Min flow (gpm) 241 217 241 241 241 375 375 404 461

Max flow (gpm) 883 796 883 883 883 1374 1374 1483 1690

Water conn (NPS-in) 6 6 6 6 6 8 8 8 8

3 pass arrangement

Min flow (gpm) 161 145 161 161 161 250 250 270 307

Max flow (gpm) 589 531 589 589 589 916 916 989 1127

Water conn (NPS-in) 4 4 4 4 4 6 6 8 8

Condenser

Qty of coils # 4 4 4 8 8 8 8 8 8

Coil length (in) 216/216 252/216 252/252 144/144 144/144 216/144 252/144 216/216 252/252

Coil height (in) 42 42 42 42 42 42 42 42 42

Number of rows # 3 3 3 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192

Fan

Quantity # 6/6 7/6 7/7 8/6 8/8 12/6 14/6 12/12 14/14

Diameter (in) 30 30 30 30 30 30 30 30 30

Air flow/fan (cfm) 9199 9200 9201 9783 9203 9652 9605 9199 9201

Power/motor (hp) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Fan speed (rpm) 1140 1140 1140 1140 1140 1140 1140 1140 1140

Tip speed (Ft/Min) 8954 8954 8954 8954 8954 8954 8954 8954 8954

General unit

# Refrig ckts # 2 2 2 2 2 2 2 2 2

% min load % 15 15 15 15 15 15 15 15 15

Refrigerant charge (lb) 215/215 225/215 225/225 235/235 235/235 415/200 460/200 415/415 460/460

Oil charge (gal) 1.3/1.3 1.9/1.3 1.9/1.9 1.9/1.9 1.9/1.9 2.1-2.1/1.9 2.1-2.1/1.9

Min ambient-std (°F) 25 25 25 25 25 25 25 25 25

Min ambient-low (°F) 0 0 0 0 0 0 0 0 0

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

Screw

Flooded

Fin and tube

Direct drive propeller

HFC-134a

70-70/

70-70

2.1-2.1/

2.1-2.1

85-85/

85-85

2.1-2.1/

2.1-2.1

12 RTAC-SVX01M-EN

General Data

Table 4. General Data - 60 hz units - standard efficiency - SI

Size 140 155 170 185 200 225 250 275 300 350 400 450 500

Compressor

Quantity # 2 2 2 2 2 2 2 3 3 3 4 4 4

Nominal size

(tons) @60Hz

70/70 85/70 85/85 100/85

100/

100

120/

100

Evaporator

Water storage (L) 110.0 121 129 136 151 148 163 235 254 273 314 326 344

2 pass arrangement

Min flow (L/s) 12 14 13 14 15 14 15 19 21 24 25 27 29

Max flow (L/s) 45 50 47 50 56 50 56 72 78 87 94 98 107

Water conn (NPS-in) 4 4 6 6 6 6 6 8 8 8 8 8 8

3 pass arrangement

Min flow (L/s) 8 9 9 9 10 9 10 13 14 16 17 18 19

Max flow (L/s) 30 33 31 34 37 34 37 48 52 58 62 65 71

Water conn (NPS-in) 3.5 3.5 4 4 4 4 4 6 6 6 8 8 8

Condenser

Qty of coils # 4 4 4 4 4 4 4 8 8 8 8 8 8

3962/

4572/

4572/

5486/

5486/

Coil length (mm)

Coil height (mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

# of rows # 3 3 3 3 3 3 3 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192

3962

3962

4572

4572

5486

6400/

5486

Fan

Quantity # 4/4 5/4 5/5 6/5 6/6 7/6 7/7 10/6 12/6 14/6 12/12 14/12 14/14

Diameter (mm) 726.0 726.0 726.0 726.0 726.0 726.0 726.0 726.0 726.0 726.0 726.0 726.0 726.0

Air flow per fan (m³/hr) 16351 15958 15644 15644 15644 15646 15647 15644 15645 15642 15645 15646 15653

Power/motor (kW) 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12

Fan speed (rps) 19 19 19 19 19 19 19 19 19 19 19 19 19

Tip speed M/S 45 45 45 45 45 45 45 45 45 45 45 45 45

General Unit

# Refrig ckts # 2 2 2 2 2 2 2 2 2 2 2 2 2

% min load % 15 15 15 15 15 15 15 15 15 15 15 15 15

Refrigerant

charge

Oil charge (L) 5/5 5/5 5/5 7/5 7/7 7/7 7/7 8-8/7 9-9/11 9-9/11 9-9/9-9 9-9/9-9 9-9/9-9

Min ambient-std (°C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

Min ambient-low (°C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

(kg) 75/75 79/75 79/79 98/95 98/98 102/98

Screw

120/

85-85/

100

4572/

2743

100-100/

5486/

2743

120

Flooded

Fin and tube

6400/

6400

Direct drive propeller

HFC-134a

102/

166/91 188/91 209/91 188/188 209/188 209/209

102

100

120-120/

100

6400/

2743

100-100/

100-100

5486/

5486

120-120/

100-100

6400/

5486

120-120/

120-120

6400/

6400

RTAC-SVX01M-EN 13

General Data

Table 5. General Data - 60 hz units - high efficiency - SI

Size 140 155 170 185 200 225 250 275 300 350 400

Compressor

Quantity # 2222222444 4

Nominal size

@60Hz

(tons) 70/70 85/70 85/85 100/85 100/100 70-70/85 85-85/85

Evaporator

Water storage (L) 129 136 151 148 163 163 163 273 273 314 344

2 Pass arrangement

Min flow (L/s) 13 14 15 14 15 15 15 24 24 25 29

Max flow (L/s) 47 50 56 50 56 56 56 87 87 94 107

Water conn (NPS-in) 6666666888 8

3 Pass arrangement

Min flow (L/s) 9 9 10 9 10 10 10 16 16 17 19

Max flow (L/s) 31 34 37 34 37 37 37 58 58 62 71

Water conn (NPS-in) 4444444668 8

Condenser

Qty of coils # 4444488888 8

Coil length (mm)

Coil height (mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

Number of rows # 3333333333 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192

4572/

4572

5486/

4572

5486/

5486

6400/

5486

6400/

6400

Fan

Quantity # 5/5 6/5 6/6 7/6 7/7 8/6 8/8 12/6 14/6 12/12 14/14

Diameter (mm) 762 762 762 762 762 762 762 762 762 762 762

Air per fan (m³/hr) 15628 15628 15628 15629 15631 16619 15634 16397 16317 15628 15631

Power/motor (kW) 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12

Fan speed (rps) 19 19 19 19 19 19 19 19 19 19 19

Tip speed M/S 45 45 45 45 45 45 45 45 45 45 45

General unit

# refrig ckts # 2222222222 2

% min load % 15 15 15 15 15 15 15 15 15 15 15

Refrig charge (kg) 79/79 98/93 98/98 102/98 102/102 107/107 107/107 188/91 209/91 188/188 209/209

Oil charge (L) 5/5 5/5 5/5 7/5 7/7 7/7 7/7 8-8/7 9-9/7 8-8/8-8 9-9/9-9

Min ambient-std (°C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

Min ambient-low (°C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

Screw

Flooded

Fin and tube

3657/

3657

Direct drive propeller

HFC-134a

3657/

3657

70-70/

70-70

5486/

3657

85-85/

85-85

6400/

3657

85-85/

85/85

5486/

5486

100-100/

100-100

6400/

6400

14 RTAC-SVX01M-EN

General Data

Table 6. General Data - 60 hz units - extra efficiency - SI

Size 140 155 170 185 200 250 275 300 350

Compressor

Quantity # 22222334 4

Nominal size

@60Hz

Evaporator

Water storage (L) 151 148 163 163 163 273 273 314 344

2 Pass arrangement

Min flow (L/s) 15 14 15 15 15 24 24 25 29

Max flow (L/s) 56 50 56 56 56 87 87 94 107

Water conn (NPS-in) 66666888 8

3 Pass arrangement

Min flow (L/s) 10 9 10 10 10 16 16 17 19

Max flow (L/s) 37 34 37 37 37 58 58 62 71

Water conn (NPS-in) 44444668 8

Condenser

Qty of coils # 44488888 8

Coil length (mm) 5486/5486 6400/5486 6400/6400 3657/3657 4572/2743 5486/3657 6400/3657 5486/5486 6400/6400

Coil height (mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067

Number of rows # 33333333 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192

Fan

Quantity # 6/6 7/6 7/7 8/6 8/8 12/6 14/6 12/12 14/14

Diameter (mm) 762 762 762 762 762 762 762 762 762

Air per fan (m³/hr) 15628 15629 15631 16619 15634 16397 16317 15628 15631

Power/motor (kW) 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12

Fan speed (rps) 19 19 19 19 19 19 19 19 19

Tip speed M/S 45 45 45 45 45 45 45 45 45

General unit

# refrig ckts # 22222222 2

% min load % 15 15 15 15 15 15 15 15 15

Refrig charge (kg) 98/98 102/98 102/102 107/107 107/107 188/91 209/91 188/188 209/209

Oil charge (L) 5/5 7/5 7/7 7/7 7/7 8-8/7 8-8/7 8-8/8-8 8-8/8-8

Min ambient-std (°C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

Min ambient-low (°C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

(tons) 85/85 100/85 100/100 120/100 120/120 85-85/100

Flooded

Fin and tube

Direct drive propeller

HFC-134a

100-100/

100

85-85/85/85100-100/

100-100

RTAC-SVX01M-EN 15

General Data

Table 7. General Data - 50 hz units - standard efficiency - IP

Size 140 155 170 185 200 250 275 300 350 375 400

Compressor

Quantity # 2 2 2 2 2 3 3 3 4 4 4

Nominal

size@50Hz

(tons) 70/70 85/70 85/85 100/85 100/100

Evaporator

Water storage (gal) 29 32 34 36 40 56 62 67 75 79 83

2 pass arrangement

Min flow (gpm) 193 214 202 217 241 265 309 339 351 381 404

Max flow (gpm) 709 785 741 796 883 970 1134 1243 1287 1396 1483

Water conn (NPS-in) 4 4 6 6 6 8 8 8 8 8 8

3 pass arrangement

Min flow (gpm) 129 143 135 145 161 176 206 226 234 254 270

Max flow (gpm) 473 523 494 531 589 647 756 829 858 930 989

Water conn (NPS-in) 3.5 3.5 4 4 4 6 6 6 8 8 8

Condenser

Qty of coils # 4 4 4 4 4 8 8 8 8 8 8

Coil length (in) 156/156 180/156 180/180 216/180 216/216 156/108 180/108 216/108 180/180 216/180 216/216

Coil height (in) 42 42 42 42 42 42 42 42 42 42 42

Number of rows # 3 3 3 3 3 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192

Fan

Quantity # 4/4 5/4 5/5 6/5 6/5 8/6 10/6 12/6 10/10 12/10 12/12

Diameter (in) 30 30 30 30 30 30 30 30 30 30 30

Air flow per fan (cfm) 7918 7723 7567 7567 7567 7764 7566 7567 7567 7567 7567

Power per motor (hp) 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Fan speed (rpm) 950 950 950 950 950 950 950 950 950 950 950

Tip speed (Ft/min) 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461

General unit

# refrig ckts # 2 2 2 2 2 2 2 2 2 2 2

% min load % 15 15 15 15 15 15 15 15 15 15 15

Refrig charge (lb) 175/175 215/205 215/215 225/215 225/225 235/235 235/235 415/200 460/200 415/415 460/460

Oil charge (gal) 1.3/1.3 1.3/1.3 1.3/1.3 1.9/1.3 1.9/1.9

Min ambient-std (°F) 25 25 25 25 25 25 25 25 25 25 25

Min ambient-low (°F) 0 0 0 0 0 0 0 0 0 0 0

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

Screw

70-70 /

Flooded

Fin and tube

Direct drive propeller

HFC-134a

2.1-2.1/

100

1.9

85-85 /

100

2.1-2.1/

1.9

100-100/

100

2.3-2.3/

1.9

85-85/

85-85

2.1-2.1/

2.1-2.1

100-100/

85-85

2.3-2.3/

2.1-2.1

100-100/

100-100

2.3-2.3/

2.3-2.3

16 RTAC-SVX01M-EN

General Data

Table 8. General Data - 50 hz units - high efficiency - IP

Size 120 130 140 155 170 185 200 250 275 300 350 375 400

Compressor

Quantity # 2 2 2 2 2 2 2 3 3 3 4 4 4

Nominal

size@50Hz

(tons) 60/60 70/60 70/70 85/70 85/85 100/85

100/

100

Evaporator

Water storage (gal) 29 32 34 36 40 39 43 67 72 72 83 86 91

2 pass arrangement

Min flow (gpm) 193 214 202 217 241 217 241 339 375 375 404 422 461

Max flow (gpm) 709 785 741 796 883 796 883 1243 1374 1374 1483 1548 1690

Water conn (NPS-in) 4 4 6 6 6 6 6 8 8 8 8 8 8

3 pass arrangement

Min flow (gpm) 129 143 135 145 161 145 161 226 250 250 270 282 307

Max flow (gpm) 473 523 494 531 589 531 589 829 916 916 989 1032 1127

Water conn (NPS-in) 3.5 3.5 4 4 4 4 4 6 6 6 8 8 8

Condenser

Qty of coils # 4 4 4 4 4 4 4 8 8 8 8 8 8

156/

180/

180/

216/

216/

252/

Coil length (in)

Coil height (in) 42 42 42 42 42 42 42 42 42 42 42 42 42

Number of rows # 3 3 3 3 3 3 3 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192

156

156

180

180

216

216

252/

252

Fan

Quantity # 4/4 5/4 5/5 6/5 6/6 7/6 7/7 10/6 12/6 14/6 12/12 14/12 14/14

Diameter (in) 30 30 30 30 30 30 30 30 30 30 30 30 30

Air flow per fan (cfm) 62484 68819 7558 7557 7557 7558 7559 7561 7943 7906 7557 7490 7559

Power/motor (hp) 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Fan speed (rpm) 950 950 950 950 950 950 950 950 950 950 950 950 950

Tip speed (Ft/min) 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461

General unit

# refrig ckts # 2 2 2 2 2 2 2 2 2 2 2 2 2

% min load % 15 15 15 15 15 15 15 15 15 15 15 15 15

165/

175/

175/

215/

215/

225/

Refrig charge (lb)

Oil charge (gal) 1.3/1.3 1.3/1.3 1.3/1.3 1.3/1.3 1.3/1.3 1.9/1.3 1.9/1.9

Min ambient-std (°F) 25 25 25 25 25 25 25 25 25 25 25 25 25

Min ambient-low (°F) 0 0 0 0 0 0 0 0 0 0 0 0 0

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

165

165

175

205

215

215

225/

225

Screw

70-70 /

180/108 216/144 252/144 216/216 252/216 252/252

Direct drive propeller

365/200

2.1-2.1/

85-85 /

100

1.9

100

Flooded

Fin and tube

HFC-134a

415/

200

2.1-2.1/

1.9

100-100/

100

460/

200

2.3-2.3/

1.9

85-85 /

85-85

415/

415

2.1-2.1/

2.1-2.1

100-100/

85-85

460/

415

2.3-2.3/

2.3-2.3

100-100/

100-100

460/

460

2.3-2.3/

2.3-2.3

RTAC-SVX01M-EN 17

General Data

Table 9. General Data - 50 hz units - standard efficiency - SI

Size 140 155 170 185 200 250 275 300 350 375 400

Compressor

Quantity # 222223334 4 4

Nominal

size@50Hz

(tons) 70/70 85/70 85/85 100/85 100/100

Evaporator

Water storage (L) 110 121 129 136 151 212 235 254 284 299 314

2 pass arrangement

Min flow (L/s) 12 14 13 14 15 17 19 21 22 24 25

Max flow (L/s) 45 50 47 50 56 61 72 78 81 88 94

Water conn (NPS-in) 446668888 8 8

3 pass arrangement

Min flow (L/s) 899910111314151617

Max flow (L/s) 30 33 31 34 37 41 48 52 54 59 62

Water conn (NPS-in) 3.5 3.5 4446668 8 8

Condenser

Qty of coils # 444448888 8 8

Coil length (mm)

Coil height (mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

Number of rows # 333333333 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192

3962/

3962

4572/

3962

4572/

4572

5486/

4572

5486/

5486

Fan

Quantity # 4/4 5/4 5/5 6/5 6/6 8/6 10/6 12/6 10/10 12/10 12/12

Diameter (mm) 762 762 762 762 762 762 762 762 762 762 762

Air flow per fan (m³/hr) 13452 13120 12855 12855 12855 13190 12853 12856 12854 12855 12855

Power per motor (kW) .74 .74 .74 .74 .74 .74 .74 .74 .74 .74 .74

Fan speed (rps) 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8

Tip speed M/S 38 38 38 38 38 38 38 38 38 38 38

General unit

# refrig ckts # 222222222 2 2

% min load % 15 15 15 15 15 15 15 15 15 15 15

Refrig charge (kg) 79/79 98/93 98/98 102/98 102/102 107/107 107/107 188/91 209/91 188/188 209/209

Oil charge (L) 5/5 5/5 5/5 7/5 7/7 8-8/7 8-8/7 8-8/7 8-8/8-8 9-9/8-8 9-9/9-9

Min ambient-std (°C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

Min ambient-low (°C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

Screw

70-70 /

100

Flooded

Fin and tube

3962/

2743

Direct drive propeller

HFC-134a

85-85 /

100

4572/

2743

100-100/

100

5486/

2743

85-85/

85-85

4572/

4572

100-100/

85-85

5486/

4572

100-100/

100-100

5486/

5486

18 RTAC-SVX01M-EN

General Data

Table 10. General Data - 50 hz units - high efficiency - SI

Size 120 130 140 155 170 185 200 250 275 300 350 375 400

Compressor

Quantity # 2 2 2 2 2 2 2 3 3 3 4 4 4

Nominal

size@50Hz

(tons) 60/60 70/60 70/70 85/70 85/85 100/85

Evaporator

Water storage (L) 110 121 129 136 151 148 163 254 273 273 314 326 344

2 pass arrangement

Min flow (L/s) 12 14 13 14 15 14 15 21 24 24 25 27 29

Max flow (L/s) 45 50 47 50 56 50 56 78 87 87 94 98 107

Water conn (NPS-in) 4 4 6 6 6 6 6 8 8 8 8 8 8

3 pass arrangement

Min flow (L/s) 8 9 9 9 10 9 10 14 16 16 17 18 19

Max flow (L/s) 30 33 31 34 37 34 37 52 58 58 62 65 71

Water conn (NPS-in) 3.5 3.5 4 4 4 4 4 6 6 6 8 8 8

Condenser

Qty of coils # 4 4 4 4 4 4 4 8 8 8 8 8 8

3962/

4572/

4572/

5486/

5486/

Coil length (mm)

Coil height (mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

Number of rows # 3 3 3 3 3 3 3 3 3 3 3 3 3

Fins per foot (fpf) 192 192 192 192 192 192 192 192 192 192 192 192 192

3962

3962

4572

4572

5486

6400/

5486

Fan

Quantity # 4/4 5/4 5/5 6/5 6/6 7/6 7/7 10/6 12/6 14/6 12/12 14/12 14/14

Diameter (mm) 762 762 762 762 762 762 762 762 762 762 762 762 762

Air flow per fan (m?/hr) 62484 68819 12839 12839 12839 12840 12842 12844 13493 13430 12838 12724 12841

Power/motor (kW) .74 .74 .74 .74 .74 .74 .74 .74 .74 .74 .74 .74 .74

Fan speed (rps) 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8

Tip speed M/S 38 38 38 38 38 38 38 38 38 38 38 38 38

General unit

# refrig ckts # 2 2 2 2 2 2 2 2 2 2 2 2 2

% min load % 15 15 15 15 15 15 15 15 15 15 15 15 15

Refrig charge (kg) 75/75 79/75 79/79 98/93 98/98 102/95

Oil charge (L) 5/5 5/5 5/5 5/5 5/5 7/5 7/7

Min ambient-std (°C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

Min ambient-low (°C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

1. Data containing information on two circuits is shown as follows: ckt 1/ ckt 2.

2. Minimum start-up/operating ambient is based on a 5 mph wind across the condenser.

3. RTAC units must only operate with refrigerant R-134a and Trane Oil 00048.

Screw

100/

70-70 /

100

Flooded

Fin and tube

6400/

6400

Direct drive propeller

HFC-134a

102/

102

85-85 /

100

4572/

2743

166/91 188/91

8-8/78-8/78-8/

100

5486/

3657

100-100/

100

6400/

3657

209/91 188/

7

85-85 /

85-85

5486/

5486

188

8-8/

8-8

100-100/

85-85

6400/

5486

209/

188

9-9/

9-9

100-100/

100-100

6400/

6400

209/

209

9-9

9-9

RTAC-SVX01M-EN 19

Pre-installation

Unit Inspection

When unit is delivered, verify it is the correct unit and is

properly equipped.

If unit is covered with optional tarp, confirm unit was

ordered with a tarp. Inspect tarp for any visible damage.

If unit does not have optional tarp, compare information

on unit nameplate with ordering and submittal

information. Inspect all exterior components for visible

damage.

Report any apparent damage or material shortage to

carrier and make a “unit damage” notation on carrier’s

delivery receipt. Specify extent and type of damage found

and notifyTrane Sales Office. Do not proceed with

installation of a damaged unit without sales office

approval.

Inspection Checklist

To protect against loss due to damage in transit, complete

this checklist upon receipt of unit.

• Inspect the individual pieces of the shipment before

accepting the unit. Check for obvious damage to the

unit or packing material.

• Inspect the unit for concealed damage as soon as

possible after delivery and before it is stored.

Concealed damage must be reported within 15 days.

• If concealed damage is discovered, stop unpacking the

shipment. Do not remove damaged material from the

receiving location.Take photos of the damage, if

possible.The owner must provide reasonable

evidence that the damage did not occur after delivery.

• Notify the carrier’s terminal of the damage

immediately, by phone and by mail. Request an

immediate, joint inspection of the damage with the

carrier and the consignee.

NotifyTrane sales representative and arrange for repair.

Do not repairunit until damage is inspected bythe carrier’s

representative.

• Install unit on a flat foundation, level (within 1/4” [6

mm] across the length and width of the unit), and

strong enough to support unit loading.

• Install unit per the instructions contained in the

Installation-Mechanical and Installation-Electrical

sections of this manual.

• Install any optional sensors and make electrical

connections at the CH530.

• Where specified, provide and install valves in water

piping upstream and downstream of evaporator water

connections to isolate evaporator for maintenance,

and to balance/trim system.

• Furnish and install pressure gauges in inlet and outlet

piping of the evaporator.

• Furnish and install a drain valve to the bottom of the

evaporator waterbox.

• Supply and install a vent cock to the top of the

evaporator waterbox.

• Furnish and install strainers ahead of all pumps and

automatic modulating valves, and at inlet of

evaporator.

• Provide and install field wiring.

• Install heat tapeand insulate thechilledwater lines and

any other portions of the system, as required, to

prevent sweating under normal operating conditions

or freezing during low ambient temperature

conditions.

• Install evaporator drain plug.The plug ships in unit

control panel.

• Start unit under supervision of a qualified service

technician.

General

Report any damage incurred during handling or

installation to theTrane sales office immediately.

Storage

Extended storage of outdoor unit prior to installation

requires these precautionary measures:

• Store the outdoor unit in a secure area.

• At least every three months (quarterly), check the

pressure in the refrigerant circuits to verify that the

refrigerant charge is intact. If it is not, contact a

qualified service organization and the appropriate

Trane sales office.

• Close the discharge and liquid line isolation valves.

Installation Responsibilities

Generally, the contractor must do the following when

installing an RTAC unit:

20 RTAC-SVX01M-EN

Dimensions and Weights

Dimensions

See unit submittals for specificunit dimensions and water

connection locations.

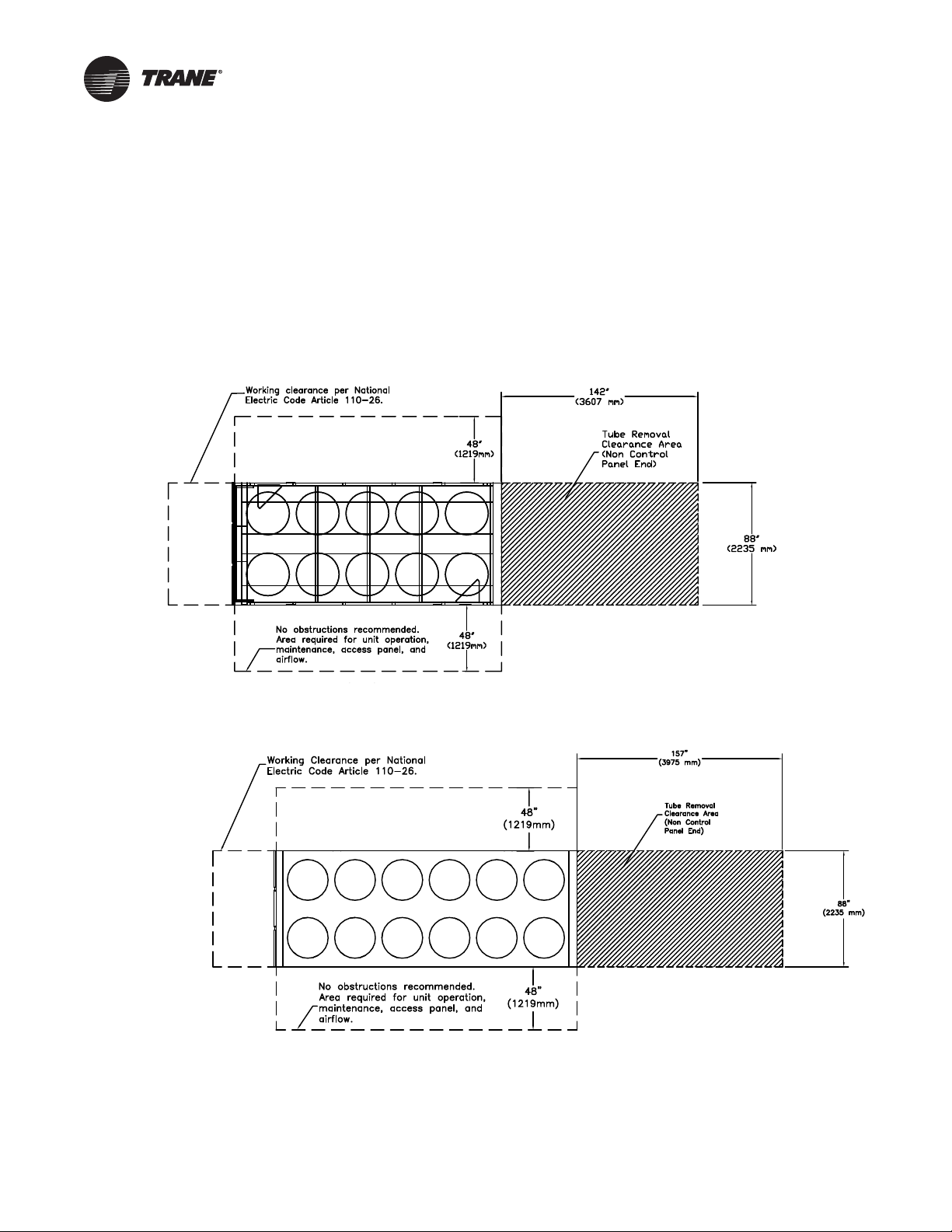

Clearances

Provideenough space aroundthe outdoor unit to allowthe

installation and maintenance personnel unrestricted

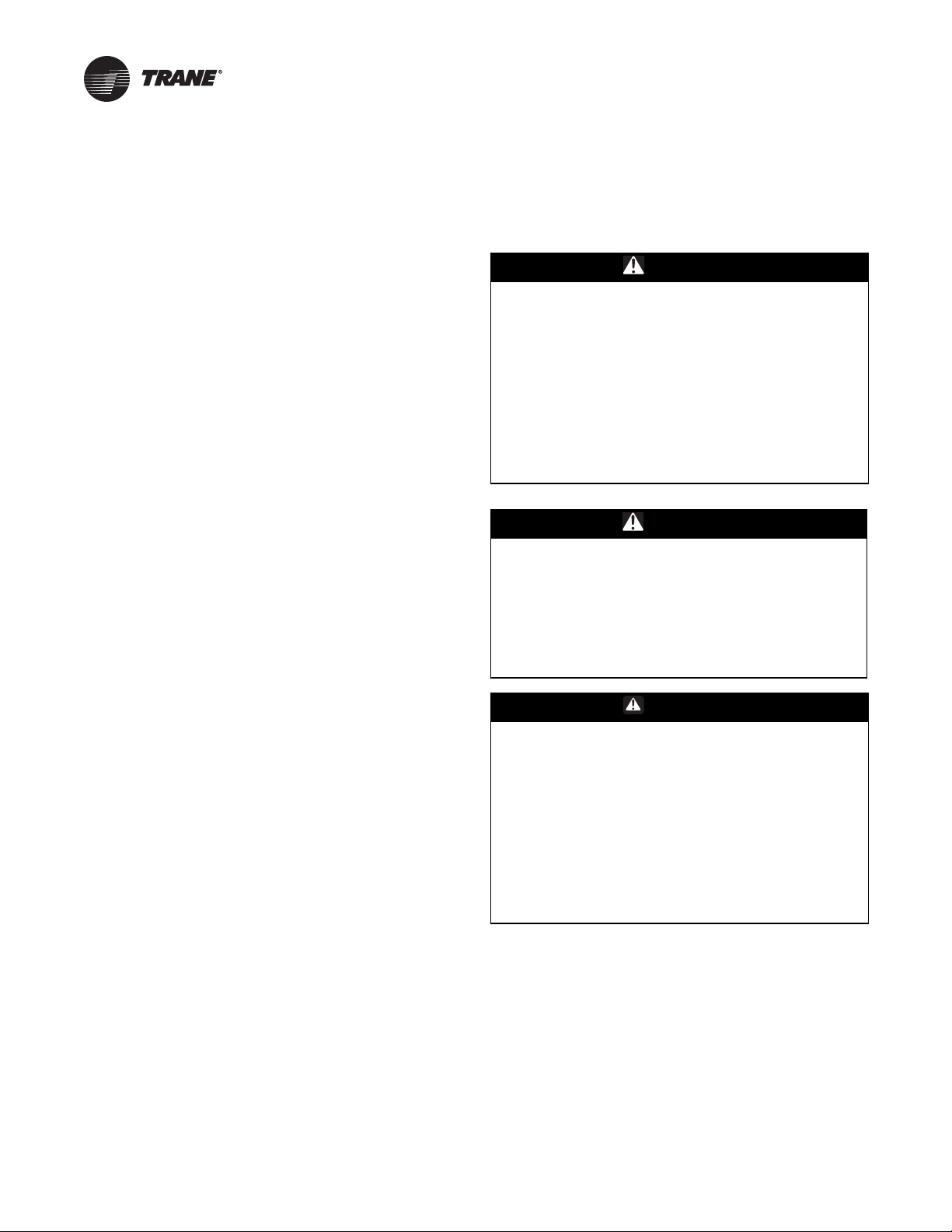

Figure 5. Recommended unit clearance — 15 foot bases

access to allservice points. Refer to submittal drawings for

the unit dimensions. A minimum of 4 feet (1.2 m) is

recommended for compressor service. Provide sufficient

clearance for the opening of control panel doors. See

Figure 5, p. 21 through Figure 9, p. 23 for minimum

clearances. In all cases, local codes which require

additional clearances will take precedence over these

recommendations.

Figure 6. Recommended unit clearances 18-21 foot bases

RTAC-SVX01M-EN 21

Dimensions and Weights

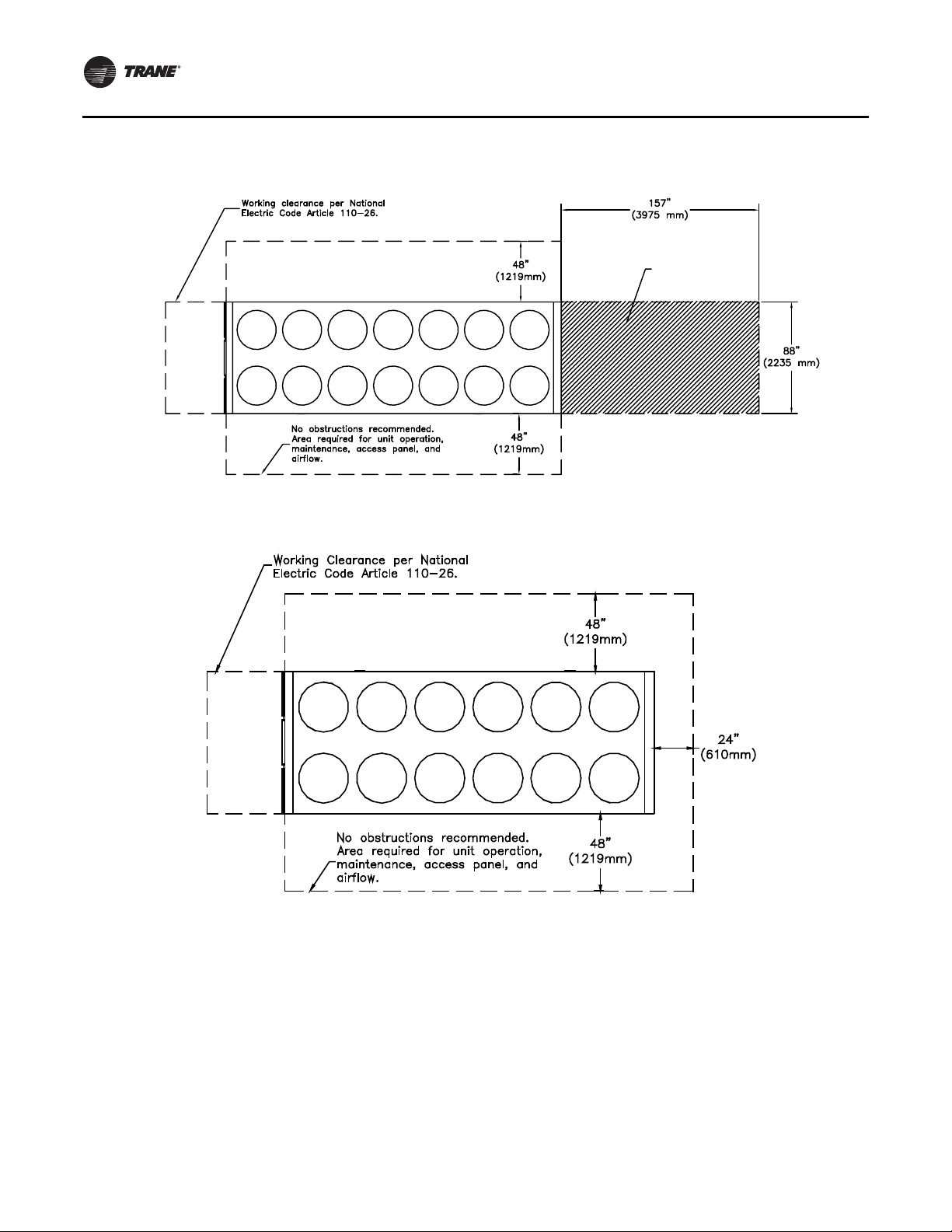

Figure 7. Recommended unit clearances 30-45 foot bases

Figure 8. Recommended remote evaporator unit clearances — 15-30 foot bases

Tube Removal

Clearance Area

(Non DynaView

Control Panel End)

22 RTAC-SVX01M-EN

Figure 9. Recommended evaporator clearance

148”

(3760 mm)

Unobstructed flow of condenser air is essential to

maintain chiller capacity and operating efficiency. When

determining unit placement, give careful consideration to

assuring a sufficient flow of air across the condenser heat

transfer surface.Two detrimental conditions are possible

and must be avoided if optimum performance is to be

achieved: warm air recirculation and coil starvation.

Warm air recirculationoccurs when discharge air from the

condenser fans is recycled back to the condenser coilinlet.

Coil starvation occurs when free airflow to (or from) the

condenser is restricted.

Both warm air recirculation and coil starvation cause

reduction in unit efficiency and capacity due to the

increased head pressures.

Debris, trash, supplies etc. should not be allowed to

accumulate in the vicinity ofthe unit. Supply air movement

may draw debris into the condenser coil, blocking spaces

between coil fins and causing coil starvation. Special

consideration should be given to low ambient units.

Condenser coils and fan discharge must be kept free of

snow or other obstructions to permit adequate airflow for

satisfactory unit operation.

In situations where equipment must be installed with less

clearance than recommended, such as frequently occurs

in retrofit and rooftop applications, restricted airflow is

common.The Main Processor will direct the unit to make

as much chilled water aspossible given theactual installed

conditions. Consult yourTrane sales engineer for more

details.

Note: If the outdoor unit configuration requires a

variance to the clearance dimensions, contact your

Trane Sales Office Representative. Also refer to

Trane Engineering Bulletins for application

information on RTAC chillers.

Dimensions and Weights

RTAC-SVX01M-EN 23

Dimensions and Weights

Weights

Non-Seismically Rated Units

Table 11. Weight - packaged units - 60 Hz - aluminum or CompleteCoat coils

Unit

Size

(tons)

140

155

170

185

200

225

250

275

300

350

400

450

500

1. Operating weight includes refrigerant and water.

2. Shipping weight includes refrigerant.

3. All weights +/- 3%.

10832 4913 11146 5056 10859 4926 11160 5062 12171 5521 12585 5708

10910 4949 11146 5056 12114 5495 12445 5645 13984 6343 14293 6483

10877 4934 11218 5088 12171 5521 12585 5708 14454 6556 14721 6677

12479 5660 12899 5851 13984 6343 14293 6483 15915 7219 16413 7445

12884 5844 13193 5984 14454 6556 14721 6677 16016 7265 16413 7445

14635 6638 14966 6788 15915 7219 16413 7445 n/a

14916 6766 15191 6890 16016 7265 16413 7445 20476 9288 21048 9547

19025 8630 19685 8929 20393 9250 21048 9547 21667 9828 22160 10052

20699 9389 21214 9622 21667 9828 22160 10052 24073 10919 24700 11204

21550 9775 22005 9981 24073 10919 24700 11204 27136 12309 27750 12587

25409 11525 25854 11727 27136 12309 27750 12587 n/a

26816 12163 27393 12425 n/a n/a

27136 12309 27912 12661 n/a n/a

Standard Efficiency High Efficiency Extra Efficiency

Shipping Operating Shipping Operating Shipping Operating

lb kg lb kg lb kg lb kg lb kg lb kg

Table 12. Weight - packaged units - 60 Hz - copper coils

Unit

Size

(tons)

140

155

170

185

200

225

250

275

300

350

400

450

500

1. Operating weight includes refrigerant and water.

2. Shipping weight includes refrigerant.

3. All weights +/- 3%.

Standard Efficiency High Efficiency Extra Efficiency

Shipping Operating Shipping Operating Shipping Operating

lb kg lb kg lb kg lb kg lb kg lb kg

13407 6081 13734 6230 13426 6090 13734 6230 15590 7071 15998 7257

13420 6087 13734 6230 15647 7097 15854 7191 18250 8278 18613 8443

13442 6097 13733 6229 15590 7071 15998 7257 18701 8483 18958 8599

15870 7198 16253 7372 18250 8278 18613 8443 20794 9432 21290 9657

16304 7395 16630 7543 18701 8483 18958 8599 20881 9471 21290 9657

18739 8500 18156 8235 20794 9432 21290 9657 n/a

18905 8575 19223 8719 20881 9471 21290 9657 26017 11801 26558 12046

23905 10843 24608 11162 26017 11801 26558 12046 27660 12546 28182 12783

26039 11811 26580 12056 27660 12546 28182 12783 30848 13992 31431 14257

27395 12426 27920 12664 30848 13992 31431 14257 35166 15951 35688 16188

32216 14613 32723 14843 35014 15882 35688 16188 n/a

32682 14824 33178 15049 n/a n/a

35014 15882 35787 16233 n/a n/a

24 RTAC-SVX01M-EN

Table 13. Weight - packaged units - 50 Hz - aluminum or CompleteCoat coils

Dimensions and Weights

Unit

Size

(tons)

Shipping Operating Shipping Operating

lb kg lb kg lb kg lb kg

120

130

140

155

170

185

200

250

275

300

350

375

400

1. Operating weight includes refrigerant and water.

2. Shipping weight includes refrigerant.

3. All weights +/- 3%.

10844 4919 11146 5056 10871 4931 11160 5062

11131 5049 11397 5170 12466 5654 12786 5800

11426 5183 11632 5276 12742 5780 12990 5892

12797 5805 13111 5947 14383 6524 14754 6692

12962 5879 13304 6035 14516 6584 14967 6789

18051 8188 19186 8703 19176 8698 20483 9291

19715 8943 20240 9181 21944 9954 21532 9767

20242 9182 21027 9538 22272 10102 22185 10063

23231 10537 23799 10795 24924 11305 25812 11708

24360 11049 25213 11436 26298 11929 26963 12230

25222 11440 25854 11727 27120 12301 27751 12588

Standard Efficiency High Efficiency

n/a 10832 4913 11146 5056

n/a 10910 4949 11146 5056

Table 14. Weight - packaged units - 50 Hz - copper coils

Unit

Size

(tons)

Shipping Operating Shipping Operating

lb kg lb kg lb kg lb kg

120

130

140

155

170

185

200

250

275

300

350

375

400

1. Operating weight includes refrigerant and water.

2. Shipping weight includes refrigerant.

3. All weights +/- 3%.

13417 6086 13734 6230 13446 6099 13734 6230

13851 6283 13962 6333 15772 7154 16192 7345

13856 6285 14366 6516 16162 7331 17421 7902

16216 7355 16463 7467 18570 8423 18979 8609

16381 7430 16721 7584 18833 8542 19223 8719

22058 10005 21837 9905 24015 10893 24056 10912

24584 11151 25095 11383 26617 12073 27135 12308

25893 11745 26336 11946 27617 12527 28182 12783

29084 13192 29527 13393 32037 14532 32712 14838

30432 13804 30971 14048 32463 14725 32971 14955

32112 14566 32787 14872 34982 15867 35525 16114

Standard Efficiency High Efficiency

n/a 13407 6081 13734 6230

n/a 13426 6090 13734 6230

RTAC-SVX01M-EN 25

Dimensions and Weights

Seismically Rated Unit Weights

Table 15. Weight - seismically rated - packaged units - 60 Hz - aluminum or CompleteCoat coils

Unit

Size

(tons)

140

155

170

185

200

225

250

275

300

350

400

450

500

1. Operating weight includes refrigerant and water.

2. Shipping weight includes refrigerant.

3. All weights +/- 3%.

11374 5159 11646 5283 11402 5172 11711 5312 12780 5797 13185 5981

11456 5196 11703 5308 12720 5770 13067 5927 14683 6660 15021 6813

11421 5180 11779 5343 12780 5797 13214 5994 15177 6884 15433 7000

13103 5943 13544 6143 14683 6660 15008 6807 16711 7580 17234 7817

13528 6136 13853 6284 15177 6884 15457 7011 16817 7628 17234 7817

15367 6970 15714 7128 16711 7580 17234 7817 n/a

15662 7104 15951 7235 16817 7628 17234 7817 21500 9752 22100 10025

19976 9061 20669 9375 21413 9713 22100 10025 22750 10319 23268 10554

21734 9858 22275 10104 22750 10319 23268 10554 25277 11465 25935 11764

22628 10264 23105 10480 25277 11465 25935 11764 28493 12924 29138 13216

26679 12102 27147 12313 28493 12924 29138 13216 n/a

28157 12772 28763 13046 n/a n/a

28493 12924 29308 13294 n/a n/a

Standard Efficiency High Efficiency Extra Efficiency

Shipping Operating Shipping Operating Shipping Operating

lb kg lb kg lb kg lb kg lb kg lb kg

26 RTAC-SVX01M-EN

Remote Evaporator Unit Weights

Table 16. Weights - condensing unit - 60 Hz

Dimensions and Weights

Unit

Size

(tons)

140

155

170

185

200

225

250

140

155

170

185

200

225

250

1. Operating weight includes refrigerant and water.

2. Shipping weight includes nitrogen holding charge.

3. All weights +/- 3%.

Shipping Operating Shipping Operating

lb kg lb kg lb kg lb kg

8359 3792 8624 3912 8292 3761 8624 3912

8299 3764 8624 3912 9460 4291 9931 4505

8304 3767 8624 3912 10610 4813 9944 4510

10944 4964 10226 4638 11060 5017 11512 5222

11179 5071 10625 4819 11443 5190 11886 5391

11531 5230 11997 5442 ---11623 5272 12126 5500 ----

10956 4970 11200 5080 10751 4877 11200 5080

10973 4977 11200 5080 12916 5859 13340 6051

10877 4934 11200 5080 13451 6101 13375 6067

13610 6173 13645 6189 15326 6952 15778 7157

13665 6198 14048 6372 15707 7125 16148 7325

15795 7164 16252 7372 ---15888 7207 16386 7433 ----

Standard Efficiency High Efficiency

Aluminum or CompleteCoat™ coils

Copper Coils

Table 17. Weights - remote evaporator - 60 Hz

Nominal

Tonnage

140

155

170

185

200

225

250

1. Operating weight includes refrigerant and water.

2. Shipping weight includes nitrogen holding charge.

3. All weights +/- 3%.

Shipping

Weight (lb)

2486 1128 2730 1238 2528 1147 2805 1272

2525 1145 2790 1266 2556 1159 2850 1293

2528 1147 2805 1272 2600 1179 2920 1325

2556 1159 2850 1293 2797 1269 3114 1413

2600 1179 2920 1325 2846 1291 3192 1448

2797 1269 3114 1413 ----

2846 1291 3192 1448 ----

Standard Efficiency High Efficiency

Shipping

Weight (kg)

Operating

Weight (lb)

Operating

Weight (kg)

Shipping

Weight (lb)

Shipping

Weight (kg)

Operating

Weight (lb)

Operating

Weight (kg)

RTAC-SVX01M-EN 27

Installation - Mechanical

Location Requirements

Noise Considerations

Locate outdoor unit away from sound sensitive areas. If

required, install rubber vibration isolators in all water

piping and use flexible electrical conduit. Consult an

acoustical engineer for critical applications. Also refer to

Trane Engineering Bulletinsfor application informationon

RTAC chillers.

Foundation

A base or foundationis notrequired if unit location islevel

and strong enough to support unit’s operating weight as

listed in “General Data,” p. 9, Table 1, p. 10 through

Table 10, p. 19. Provide rigid, non-warping mounting pads

or concrete foundation of sufficient strength and mass to

support unit operating weight (including piping, and full

operating charges of refrigerant, oil and water). Once in

place, outdoor unit must be level within 1/ 4" (6 mm) over

its length and width.

Trane Company is not responsible for equipment

problems resulting from an improperly designed or

constructed foundation.

Note: To allow for cleaning under the condensing coil, it

is recommended that an opening be left between

the unit base and the concrete pad.

Clearances

Provideenough space aroundthe outdoor unit to allowthe

installation and maintenance personnel unrestricted

access to allservice points. Referto submittal drawings for

the unit dimensions. A minimum of 4 feet (1.2 m) is

recommended for compressor service. Provide sufficient

clearance for the opening of control panel doors. See

Figure 5, p. 21 through Figure 9, p. 23 in “Dimensions and

Weights,” p. 21 for minimum clearances. In all cases, local

codes which require additional clearances will take

precedence over these recommendations.

Rigging

Lifting Procedure

WARNING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in unit dropping and

possibly crushing operator/technician which could

result in death or serious injury and possible

equipment or property-only damage.

WARNING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

Important: Do not fork lift unit.

See Table 18, p. 30 through Table 22, p. 32 for lifting

weights and Table 23, p. 33 andTable 24, p. 33 for center of

gravity (CG) dimensions.

28 RTAC-SVX01M-EN

Rigging

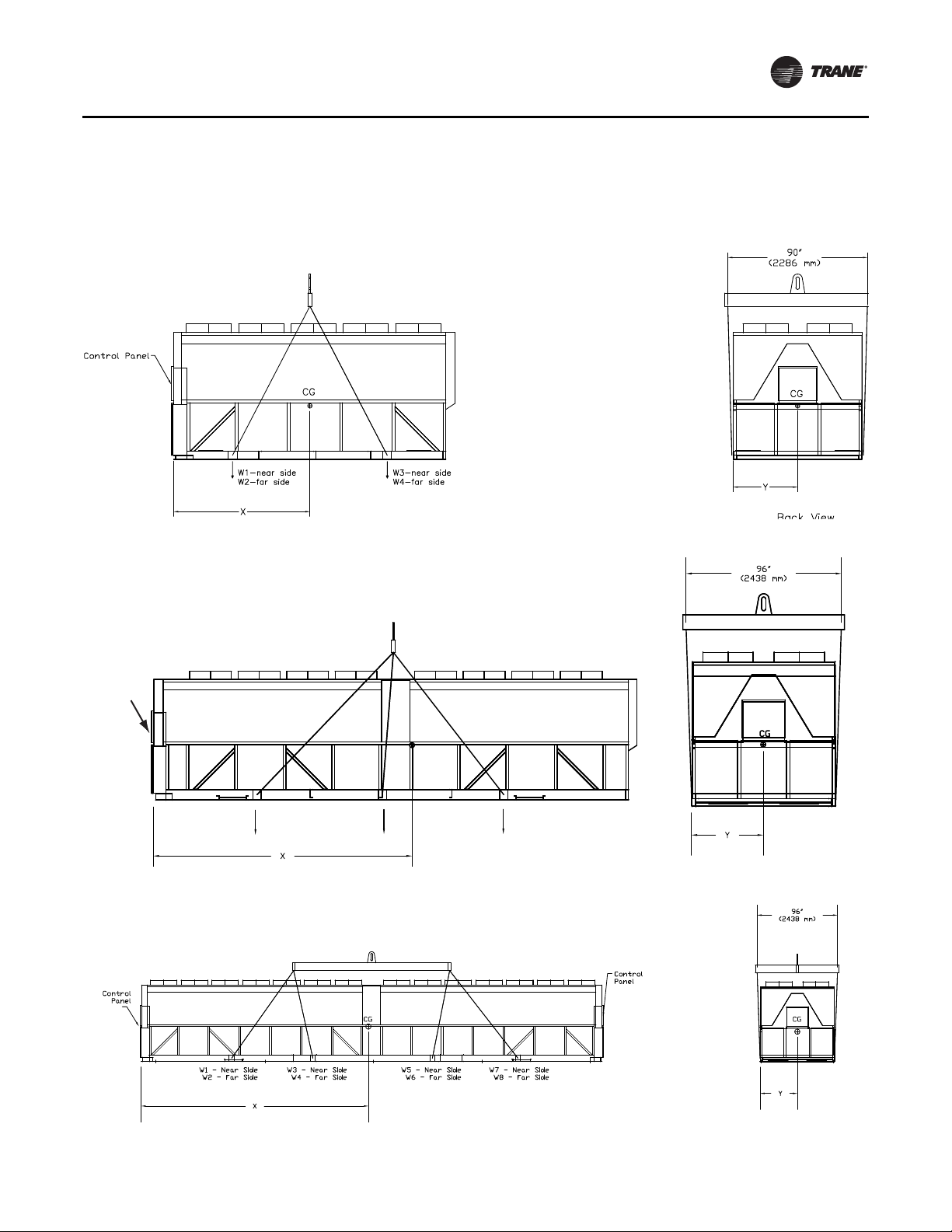

See Figure 10 through Figure 12, p. 29 for lifting point

references, Table 19 through Table 21 for lifting weights,

and unit submittals lift point dimensions.

Figure 10. Lifting the unit (packaged and remote) 15-21 foot base

Figure 11. Lifting the unit (packaged and remote) 30-36 foot base

Installation - Mechanical

Control Panel

W1 - near side

W2 - far side

W3 - near side

W4 - far side

Figure 12. Lifting the unit (packaged and remote) 39-45 foot base

W5 - near side

W6 - far side

RTAC-SVX01M-EN 29

Installation - Mechanical

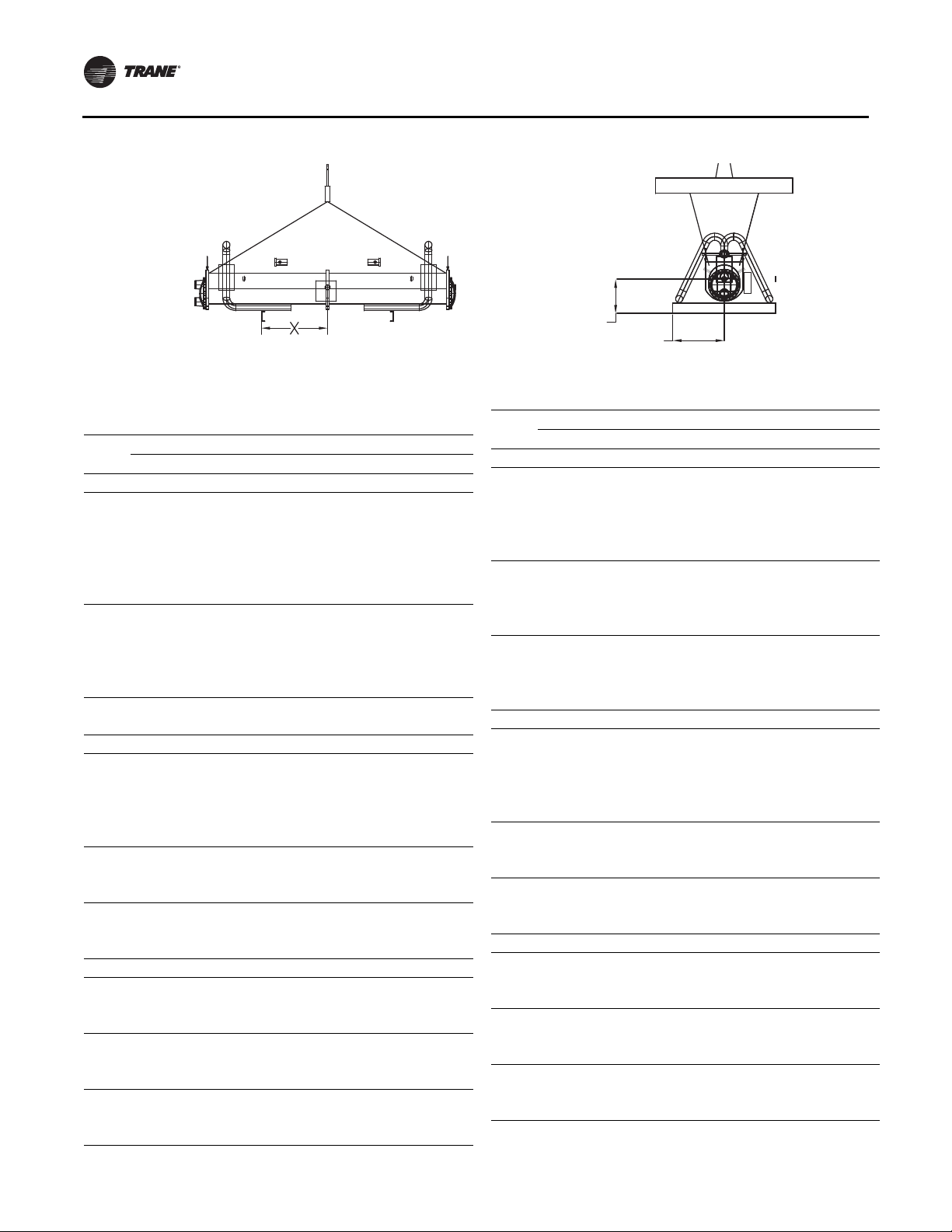

Figure 13. Lifting the remote evap

W1 - Near Side

W2 - Far Side

SIDE VIEW

Lifting Weights Tables

Table 18. Lifting weights (lbs) - packaged units - 60 Hz

Size

(tons)

W1 W2 W3 W4 W5 W6 W7 W8

Aluminum Coils - Standard Efficiency

140 2443 2814 2622 2953 - - - -

155 2446 2881 2627 2956 - - - -

170 2447 2831 2633 2966 - - - -

185 3244 3584 2656 2995 - - - -

200 3285 3701 2741 3157 - - - -

225 3943 4177 3183 3332 - - - -

250 3657 4167 3518 3574 - - - -

275 3376 2957 3372 2975 3377 2968 - -

300 3470 3099 3640 3258 3814 3418 - -

350 3389 3023 3787 3382 4187 3782 - -

400 3448 3315 3226 3205 3123 3102 3026 2964

450 3440 3419 3324 3303 3154 3133 3032 4011

500 3373 3299 3405 3331 3452 3378 3486 3412

Aluminum Coils - High Efficiency

140 2446 2820 2630 2963 - - - -

155 3114 3508 2549 2943 - - - -

170 3124 3524 2561 2962 - - - -

185 3469 4059 2933 3523 - - - -

200 3657 4139 3135 3523 - - - -

225 2581 2904 2489 2812 2400 2729 - -

250 2607 2904 2518 2825 2433 2729 - -

275 3272 2884 3592 3204 3915 3526 - -

300 2974 2647 2911 2584 2801 2514 2785 2451

350 2936 2876 3003 2943 3075 3015 3143 3082

400 3373 3299 3405 3331 3452 3378 3486 3412

Aluminum Coils - Extra Efficiency

140 3124 3524 2561 2962 - - - -

155 3469 4059 2933 3523 - - - -

170 3657 4139 3135 3523 - - - -

185 2581 2904 2489 2812 2400 2729 - -

200 2607 2904 2518 2825 2433 2729 - -

250 3272 2884 3592 3204 3998 3526 - -

275 2974 2647 2911 2584 2801 2514 2785 2451

300 2936 2876 3003 2943 3075 3015 3143 3082

350 3373 3299 3405 3331 3452 3378 3486 3412

Lifting Location

W3 - Near Side

W4 - Far Side

25”

(625mm)

30”

(762mm)

END VIEW

Table 18. Lifting weights (lbs) - packaged units - 60 Hz

Size

(tons)

W1 W2 W3 W4 W5 W6 W7 W8

Copper Coils - Standard Efficiency

140 2916 3405 3346 3740 - - - -

155 2919 3405 3352 3744 - - - -

170 2920 3412 3357 3753 - - - -

185 3991 4450 3500 3929 - - - -

200 4032 4567 3585 4120 - - - -

225 4593 5261 4101 4784 - - - -

250 4639 5261 4149 4856 - - - -

275 4319 3898 4170 3772 4078 3668 - -

300 4513 3980 4552 4169 4618 4207 - -

350 4289 3892 4769 4363 5244 4838 - -

400 4220 4198 4100 4078 3975 3953 3857 3835

450 4549 4526 4290 4268 3909 3887 3638 3615

500 4369 4293 4395 4319 4434 4358 4461 4385

Copper Coils - High Efficiency

140 2919 3410 3354 3743 - - - -

155 3973 4374 3393 3907 - - - -

170 3870 4390 3405 3925 - - - -

185 4404 5144 3981 4721 - - - -

200 4593 5223 4101 4784 - - - -

225 3189 3625 3247 3685 3303 3745 - -

250 3214 3625 3276 3685 3336 3745 - -

275 4235 3898 4522 4132 4810 4420 - -

300 3818 3527 3708 3379 3545 3216 3398 3069

350 4054 4035 3930 3911 3800 3781 3678 3659

400 4369 4293 4395 4319 4434 4358 4461 4385

Copper Coils - Extra Efficiency

140 3870 4390 3405 3925 - - - -

155 4404 5144 3981 4721 - - - -

170 4593 5223 4101 4784 - - - -

185 3189 3625 3247 3685 3303 3745 - -

200 3214 3625 3276 3685 3336 3745 - -

250 4235 3898 4522 4132 4810 4420 - -

275 3818 3527 3708 3379 3545 3216 3398 3069

300 4054 4035 3930 3911 3800 3781 3678 3659

350 4521 4293 4395 4319 4434 4358 4461 4385

Lifting Location

30 RTAC-SVX01M-EN

Loading...

Loading...