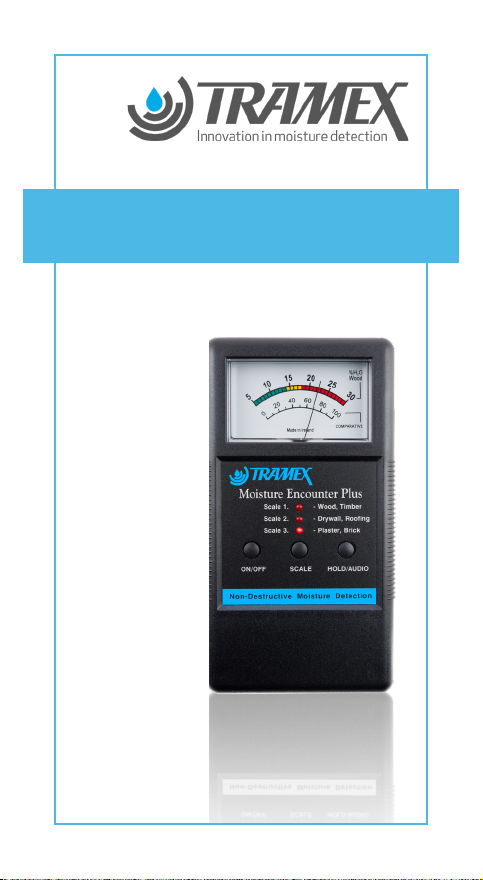

user guide

MEP

moisture encounter

plus

MEP USER GUIDE

TABLE OF CONTENTS

Introduction............................................................................................2

Instrument Features.....................................................................3-4

Operating Instructions.................................................................5-7

Working With your Moisture Encounter: Scale 1........7-15

Testing wood and wood products......................................7-9

Relative humidity and moisture content.........................10

Wood Flooring............... ...............................................................11

Notes on Specific Gravity (SG).............................................12

How to use the Wood SG Tables...........................................13

Wood SG Table, 5% to 17% meter reading...................14

Wood SG Table, 18% to 30% meter reading................15

Working With your Moisture Encounter: Scale 2.....16-18

Testing built-up roofing ..........................................................16

Testing drywall.............................................................................17

Testing on ceramic tiles, wall & floor coverings..17-18

Working With your Moisture Encounter: Scale 3....19-20

Testing plaster and brick................................................19-20

Limitations..........................................................................................20

Calibration...................................................................................20-21

Warranty.......................................................................................21-22

Product Development...................................................................23

Safety....................................................................................................23

1

MEP USER GUIDE

INTRODUCTION

Thank you for selecting the MEP - Moisture

Encounter Plus from Tramex.

The Moisture Encounter Plus is a patented

instrument, which enables non-invasive moisture

measurement and detection in a wide range of

building materials. The instrument operates on the

principle that the electrical impedance of a material

varies in proportion to its moisture content.

To measure/detect moisture, the two co-planar

conductive rubber electrodes mounted on the base

of the instrument case are lightly pressed onto the

wood or material sample. The instrument measures

the electrical impedance of the sample by creating a

low frequency alternating electric field between the

electrodes. This field penetrates the material under

test to a depth of approximately 30 mm (1¼ inches).

The very small alternating current flowing through

the field is inversely proportional to the impedance

of the material. The instrument detects this current,

determines its amplitude and, after processing,

drives the pointer of the moving coil meter to the

computed moisture value.

Transmit Electrode

Receive Electrode

Alternating Electric Field

2

MEP USER GUIDE

As there is a wide variation in the nominal electrical

impedance of different material types, the instrument

is provided with three selectable scales which are

optimized for testing (1) Wood, Timber (2) Drywall,

Roofing and (3) Plaster, Brick. By selection of an

appropriate scale, the instrument can also be used for

the detection and location of elevated moisture in or

behind a range of covering materials such as wall, floor,

and ceiling tiles, siding, carpet, ceramic tiles and

laminated floor coverings.

INSTRUMENT FEATURES

Your Moisture Encounter Plus employs advanced

analogue and digital technology to enable the

incorporation of many new features, which greatly

extend the capability of the instrument.

• Three simple pushbutton controls, ON/OFF,

SCALE and HOLD/AUDIO.

• Non-destructive moisture readings taken in

wood from 5% to 30% are displayed on a moving

coil meter with linear scale.

• Audio signal sounds when meter indicates high

reading.

• Comparative readings between zero and 100 can

be taken in or through drywall, ceramic tile,

carpet, floor coverings, roofing, plaster, and

other materials such as brick and cement block.

The meter scale is also color coded to assist in

identifying areas of wet and dry.

• Automatic supply timeout (10 minutes)

conserves battery life.

3

MEP USER GUIDE

• Supply timeout is automatically extended if a

change in meter reading is detected or if any

button is pressed.

• 10 second bleep warning on instrument sounder

prior to end of supply timeout period.

• Last used scale is memorized at supply timeout

and automatically selected next time ON/OFF

button is pressed.

• Three LEDs (light emitting diodes) show selected

scale, indicate if HOLD/AUDIO selected and

provide warning of battery nearing end of useful

life.

• HOLD/AUDIO button freezes moving coil meter,

which facilitates readings taken out-of-sight.

• If HOLD/AUDIO was selected prior to supply

timeout, the frozen meter reading is digitally

memorized and restored next time ON/OFF is

selected.

If the battery voltage is getting low, the three

LEDs will flash sequentially for a short period.

The instrument will continue to operate for

some time but it is recommended that the

PP3 (9 volt) battery be changed as soon as

convenient.

4

MEP USER GUIDE

OPERATING INSTRUCTIONS

The instrument face with brief notes on the push button

controls and LED indicators is shown below.

84mm

1

2

54

3

1 = Moving coil meter.

2 = LED Indicators.

3 = Scale Select button.

4 = Power ON/OFF button.

5 = Hold button.

154mm

5

MEP USER GUIDE

OPERATING INSTRUCTIONS

1. Press the ON/OFF button to power up. The LED

for the last used scale will light.

2. To change scale, press/release the SCALE button

until the LED opposite the required scale lights.

3. Hold your Moisture Encounter Plus directly on the

material being tested ensuring both conductive

rubber electrodes are fully in contact with the

surface.

4. For wood or wood products read the moisture

content from the upper line (Wood) of the meter

dial which is marked from 5% to 30%. Audio signal will sound when meter indicates high reading.

5. To turn audio signal on or off, press HOLD/AUDIO

button twice in quick succession.

6. For drywall, felt roofing, plaster or brick comparative (Relative) readings are taken from the lower

line on the meter dial, which is marked from 0 to

100.

7. The instrument will automatically power-off after

ten minutes if no button is pressed or if no change

in meter reading is detected. If a button is pressed

or the meter reading changes, the power-off will

be extended for a further ten minutes.

6

MEP USER GUIDE

8. To freeze readings press the HOLD/AUDIO button once. While on Hold, the LED for the selected

scale will flash slowly. This facility is extremely

useful if readings are being taken in areas where

it is difficult to see the instrument dial. To remove

freeze, press the HOLD/AUDIO button again.

WORKING WITH YOUR MOISTURE ENCOUNTER:

Scale 1

Testing wood and wood products

a. When testing wood, power-on, select Scale 1 and

press the rubber electrodes directly to the surface. Read the moisture percentage from the top

line of the analog dial where calibration is marked

from 5% to 30%. If switched on, the audio signal

will sound when readings are above 18%.

b. If possible, always take readings with the length

of the instrument parallel to the direction of the

wood grain.

c. Calibration tests were carried out by Forbairt,

the Irish Institute for Industrial Research and

Standards, and are based on Douglas fir, which

has a published specific gravity (SG) of 0.50. For

wood having an SG other than 0.50 see “Notes on

Specific Gravity” and “How to use the Wood SG

Adjustment Tables” on page 13.

7

MEP USER GUIDE

d. Acceptable levels of moisture content depend on

climatic conditions and we advise you check the

levels acceptable in your area. The table on page

10 shows the approximate relationship between

the ambient relative humidity and equilibrium

moisture content in woods.

e. As a rule of thumb and depending on climatic con-

ditions, exterior wood is generally considered safe

for painting when the moisture content is 14% or

below. Wood below 10% is generally considered

suitable for painting indoors. (Always check coating manufacturers recommendations).

f. The following moisture content levels are often

quoted in the wood industry and should be used as

a guide only. Please contact industry associations

and manufacturers for their specifications.

• Furniture: 5% to 6% when used in locations of low

relative humidity and up to 10% to 11% may be

acceptable where the relative humidity is higher.

• Indoors wood: 6% in low humidity areas. Up to

12% in higher humidity locations.

• Exterior wood: 10% to 15% depending on local

humidity levels.

• Generally, wood moisture content in excess of

23% - 25% is susceptible to rot.

8

MEP USER GUIDE

• Wood moisture content in excess of 18% - 20%

may provide an environment for termite and

wood-boring insects to thrive and multiply. Wood

at these high levels can also support mold and

biological growth.

• Wood at 28% moisture content is considered to

have reached fiber saturation point.

g. Avoid taking readings on wood from the top of a

stack stored outside as these may be affected by

surface moisture from recent rain.

h. When taking readings in chemically treated

wood, it is advisable to allow for possible effects

that the treatment may have on readings.

Depth of field penetration

Depending on the density of the material being

tested, the instrument field can penetrate

approximately 30mm (1¼ inches) below the

surface. When testing thin materials such as

wood veneers it is recommended that they are

stacked to at least that thickness.

9

MEP USER GUIDE

Relative humidity and moisture content

The table below shows the approximate relationship

between relative humidity and equilibrium moisture

content of some woods. (These figures are approximate values at a temperature of 70º F, and may vary

for different species.)

Relative Humidity

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Wood MC %

3 to 5

5 to 6

6 to 8

8 to 9

9 to 11

11 to 13

13 to 15

16 to 19

20 to 22

25+

10

MEP USER GUIDE

Wood Flooring

a. Excess moisture in wood flooring or concrete sub-

floors can cause major problems.

b. For instance, if installed with excess moisture,

the wood can subsequently shrink leading to job

failure.

c. If a wood floor (solid, laminated or engineered) is

installed above wet concrete the wood can absorb

moisture emitting from the concrete causing the

wood to swell and buckle and even cause structural damage to the building.

d. When vinyl or other impervious coverings are

applied over wet concrete, the result can be failure

of the adhesive and blistering of the surface.

Your Moisture Encounter Plus can be used to measure

the moisture content of the wood floor to ensure it

meets specification. Likewise it can be used to check,

on a qualitative basis, through the floor covering, to

identify elevated moisture in the substrate.

Adhesives

The presence of different species, treatments,

adhesives, etc., within products such as plywood,

particleboard, OSB (oriented strand board),

laminated and engineered woods will affect

measurements. If in doubt please contact us and, if

you wish, we can work with you in developing your

own calibration for a specific product.

11

MEP USER GUIDE

Density SG at 12% MC

Exceptionally Heavy

0.90 or More

Concrete

Your Moisture Encounter Plus is not calibrated for

concrete. The Tramex Concrete Encounter instrument is specifically designed for concrete flooring

and is recommended where quantitative measurements are required. However a useful indication of

the moisture condition of a concrete or sub floor can

be obtained with the Moisture

Encounter Plus set on the wall/brick mode.

Comparative readings can also be obtained through

coverings such as vinyl, carpet and laminated wood

flooring by using the drywall scale.

Notes on Specific Gravity (SG)

The SG of wood varies between species and this has an

effect on moisture meter readings. The Moisture

Encounter Plus calibration is based on wood having an SG

of 0.50. Wood is normally categorised as follows:

Exceptionally Light

Light

Medium

Heavy

12

0.30 or Less

0.30 to 0.45

0.45 to 0.65

0.65 to 0.90

MEP USER GUIDE

How to use the Wood SG tables

When testing wood, which does not have an SG of 0.50,

the meter reading can be adjusted by referring to the tables shown on pages 14 and 15. For example, if the wood

being tested has an SG of 0.70 and the meter reading

is 17% (top row of table) then the adjusted moisture

content reading can be found where the 0.70 SG row

intersects with 17% meter reading column. For this

example the adjusted moisture content would be 13%.

13

Wood S.G. Table, 5% to 17% meter reading

0.90

334455679999 10

WOOD SPECIFIC GRAVITY ADJUSTMENT TABLE (5 to 17%)

Meter

56789 10 11 12 13 14 15 16 17

Reading

Specific

Gravity

0.30

0.32

0.34

0.36

0.38

0.40

0.42

0.44

0.46

0.48

0.50

0.52

0.54

0.56

0.58

0.60

0.62

0.64

0.66

0.68

0.70

0.72

0.74

0.76

0.78

0.80

0.82

0.84

0.86

0.88

ADJUSTED/CORRECTED MOISTURE CONTENT

8 9 10 12 13 14 15 16 17 19 20 21 22

9 10 12 13 14 15 16 17 18 20 21 22

8

789 11 12 13 14 15 16 17 19 20 21

789 11 12 13 14 15 16 17 18 19 21

789 11 12 12 13 14 16 16 18 19 20

6789 11 12 13 14 15 16 17 18 20

6789 11 11 12 13 15 15 17 18 19

6789 10 11 12 13 14 15 16 17 19

5678 10 11 12 13 14 15 16 17 18

56789 10 11 12 13 14 15 16 17

56789 10 11 12 13 14 15 16 17

567899 11 11 12 13 14 15 17

457789 10 11 12 13 14 15 16

456788 10 11 12 13 13 15 16

4567889 10 11 12 13 14 15

4567889 10 11 12 13 14 15

4567889 10 11 12 13 14 15

4467889 10 11 12 13 14 15

4456789 10 11 11 12 13 14

44567789 10 11 12 13 14

34567789 10 11 11 12 13

33567789 10 11 11 12 13

33567789 10 11 11 12 13

33456678 10 11 11 11 12

33456678 10 11 11 11 12

334566789 10 10 11 12

334566789 10 10 10 11

334566789 10 10 10 11

334566789 10 10 10 11

334566789 10 10 10 11

MEP USER GUIDE

14

Wood S.G. Table, 18% to 30% meter reading

0.90

12 12 12 12 12 13 14 14 15 15 16 16 17

WOOD SPECIFIC GRAVITY ADJUSTMENT TABLE (18 to 30%)

Meter

18 19 20 21 22 23 24 25 26 27 28 29 30

Reading

Specific

Gravity

0.30

0.32

0.34

0.36

0.38

0.40

0.42

0.44

0.46

0.48

0.50

0.52

0.54

0.56

0.58

0.60

0.62

0.64

0.66

0.68

0.70

0.72

0.74

0.76

0.78

0.80

0.82

0.84

0.86

0.88

ADJUSTED/CORRECTED MOISTURE CONTENT

23 25 26 27 28 29 31 32 33 34 35 37 38

24 25 27 28 29 30 31 32 33 34 36 37

23

22 24 24 26 27 28 29 31 31 32 33 35 36

22 23 24 25 27 28 29 30 30 31 32 34 35

21 23 23 24 26 27 29 30 30 30 32 34 35

21 22 23 24 26 27 28 29 29 30 31 33 34

20 21 22 23 25 26 27 28 28 29 31 32 33

20 20 21 22 24 25 26 27 28 28 30 31 32

19 20 21 22 23 24 24 26 27 28 29 30 31

18 19 20 21 22 23 24 25 27 27 28 29 30

18 19 20 21 22 23 24 25 26 27 28 29 30

17 18 19 20 21 22 23 24 25 26 27 28 29

17 18 18 19 20 21 22 23 24 25 26 27 28

16 17 17 18 19 20 21 22 22 23 25 26 27

16 17 17 18 18 19 20 21 21 22 24 24 25

15 16 16 17 18 19 19 20 20 21 23 23 24

15 16 16 17 18 19 19 20 20 21 22 23

15 15 15 16 17 18 18 19 20 20 21 22 23

14 15 15 16 17 18 18 19 19 19 20 21 22

14 14 14 15 16 16 17 18 18 19 20 21 21

14 14 14 15 16 16 17 17 18 18 19 20 20

14 14 14 15 16 16 17 17 18 18 19 20 20

13 14 14 14 15 15 16 16 17 18 19 19 20

13 13 13 14 15 15 16 16 17 18 18 19 19

13 13 13 14 15 15 16 16 17 17 18 18 18

13 13 13 13 14 15 15 16 16 17 17 18 18

12 12 12 13 14 14 14 15 16 16 17 17 18

12 12 12 13 14 14 14 15 16 16 17 17 17

12 12 12 13 14 14 14 14 15 16 16 17 17

12 12 12 13 14 14 14 14 15 15 16 17 17

MEP USER GUIDE

23

15

MEP USER GUIDE

WORKING WITH YOUR MOISTURE ENCOUNTER:

Scale 2

Testing built-up roofing

a. The presence of moisture in built-up roofs

covered with multi-ply roofing felt, PVC, modified

bitumen (torch-on) or other membranes, can cause

blistering and splitting of the roof surfacing. In

addition moisture can cause considerable damage

to the contents and fabric of the building as well

as heat loss through wet insulation. Your Moisture

Encounter Plus can be used to confirm a new roof

has been installed dry.

b. When the waterproofing membrane develops a

leak, the water can travel within the built-up-roof

structure and enter the building some distance

away. Testing the membrane surface and comparing the dry areas with areas where moisture is

present below the surface can assist in tracing

such a leak to its source.

c. As there are many different types and thickness

sizes of roofing membranes, it is not possible

to give a calibrated percentage measurement.

Instead, the comparative scale, marked 0 to 100,

is used for checking the difference between wet

and dry.

16

MEP USER GUIDE

d. If gravel surfacing is present, this should be

removed to ensure your Moisture Encounter Plus

comes into direct contact with the surface of the

membrane.

e. It is recommended that a core be cut to determine

the depth and extent of the moisture before carrying out roof repairs. Alternatively, the area can

be checked with a Tramex Professional resistance

type moisture meter with insulated pins.

Testing Drywall user guide

Because of its deep signal penetration, your Moisture

Encounter Plus can identify excess moisture within and

behind drywall. It can also identify excess moisture behind ceramic tile and other wall coverings. As calibration

is not practical on this type of construction, readings

should be taken from the comparative scale (0 to 100)

on the meter dial.

Testing on ceramic tiles and other wall and floor

coverings

Your Moisture Encounter Plus can be used to detect and

identify areas of elevated moisture within or behind

most types of wall and floor coverings. For example the

Moisture Encounter Plus can detect elevated moisture

behind most types of ceramic tiles.

17

MEP USER GUIDE

Excess moisture trapped behind covering materials

such as ceramic tiles, carpet, wall coverings etc can

cause major problems. For instance, excess moisture

behind ceramic tiles on drywall or other substrates can

cause decay, delamination and mold growth, the longer

these problems go undetected the worse the problem

can get eventually leading to system failure.

As calibration is not practical because of the variation in

composition of these types of construction, tests

should be carried out on a comparative basis selecting

the most appropriate scale, and readings should be

taken from the 0 to 100 comparative scale on the meter

dial.

18

MEP USER GUIDE

WORKING WITH YOUR MOISTURE ENCOUNTER:

Scale 3

Testing plaster or brick

a. Your Moisture Encounter Plus gives qualitative

(relative) reading on walls, plaster, brick, drywall

and block. Make sure the appropriate wall scale

is used i.e. Scale 2 for drywall and Scale 3 for

plaster or brick. Always press the electrodes

firmly against the surface.

b. The moisture profile of a wall can be determined

by sliding your Moisture Encounter Plus across

the surface where it will read through most

paints, vinyl, wall coverings and even ceramic

tiles.

c. The Moisture Encounter Plus will help identify

the different levels of moisture even if not

apparent on the surface. Moisture can often be

trapped behind drywall and wall covering.

d. Rising damp and moisture migration from leaks

anddefective, or non-existent, vapor barriers can

be identified and profiled and often its source

identified by sliding the instrument across the

wall surface.

e. Water damage following flooding or fire fighting

can be checked and the drying out and de-humidification process can be monitored.

19

MEP USER GUIDE

Acceptably Dry Plaster or Brick

Your Moisture Encounter Plus will give low readings when the plaster or brick is acceptably dry.

Due to the hygroscopic nature of these materials, moisture values are affected by ambient

humidity and thus can vary according to climatic

conditions. We recommend you satisfy yourself

as to what is ‘acceptably dry’ in your area, and use

the instrument to compare these with areas that

are unacceptable.

Limitations

The Moisture Encounter Plus will not detect or measure

moisture through any electrically conductive materials

including metal sheeting or cladding, black EPDM roofing, butyl roofing, aluminum siding or wet surfaces.

Calibration

For regular on-site assessment of your MEP in moisture

measurement mode, a calibration-check box is available

from the suppliers of your MEP. Should it be found that

readings are outside the set tolerances, it is recommended that the MEP be returned for re-calibration.

Calibration adjustments should not be carried out by

anyone other than Tramex or their authorised service

provider who will issue a calibration certificate on

completion.

20

MEP USER GUIDE

Requirements for quality management and validation procedures, such as ISO 9001, have increased

the need for regulation and verification of measuring

and test instruments. It is therefore recommended

that calibration of the MEP should be checked and

certified in accordance with the standards and/or

protocols laid down by your industry (usually on an

annual basis) by an authorized test provider. The name

of your nearest test provider and estimate of cost is

available on request.

Warranty

Tramex warrants that this instrument will be free

from defects and faulty workmanship for a period

of one year from date of first purchase. If a fault

develops during the warranty period, Tramex will, at

its absolute discretion, either repair the defective

product without charge for the parts and labour, or

will provide a replacement in exchange for the defective product returned to Tramex Ltd

This warranty shall not apply to any defect, failure

or damage caused by improper use or improper or

inadequate maintenance and care.

21

MEP USER GUIDE

In no event shall Tramex, its agents or distributors be

liable to the customer or any other person, company or

organisation for any special, indirect, or consequential

loss or damage of any type whatsoever (including, without limitation, loss of business, revenue, profits, data,

savings or goodwill), whether occasioned by the act,

breach, omission, default, or negligence of Tramex Ltd.,

whether or not foreseeable, arising howsoever out of or

in connection with the sale of this product including arising out of breach of contract, tort, misrepresentation

or arising from statute or indemnity. Without prejudice

to the above, all other warranties, representations and

conditions whether made orally or implied by circumstances, custom, contract, equity, statute or common

law are hereby excluded, including all terms implied by

Section 13, 14 and 15 of the Sale of Goods Act 1893,

and Sale of Goods and Supply of Services Act 1980.

Warranty claims

A defective product should be returned shipping pre

paid, with full description of defect to your supplier or to

Tramex at address shown on the back of this guide.

22

MEP USER GUIDE

Product development

It is the policy of Tramex to continually improve and

update all its products. We therefore reserve the right

to alter the specification or design of this instrument

without prior notice.

Safety

This User Guide does not purport to address the

safety concerns, if any, associated with this instrument or its use. It is the responsibility of the user of

this instrument to establish appropriate safety and

health practices and determine the applicability of

regulatory limitations prior to use.

23

www.tramexmeters.com

FIND US ON:

Tramex Ltd.

Unit F, Glencormack Business Park, Kilmacanogue,

County Wicklow, Ireland.

Email:sales@tramexmeters.com

USA (toll free) & Canada:

Tel: 1800-234-5849

EU & Rest Of World:

Tel:+353 1 681 4450

Loading...

Loading...