SERVICE MANUAL

Embroidery Machine

ESP9000

(15 needles)

How to Use this Service Manu

al

1.This service manual applies to the ESP9000.

Model names are indicated only for sections equipped with each model.

2.Refer to the section on TROUBLESHOOTING first.

Trouble often results from two or more causes. The TROUBLESHOOTING

section indicates the correct order and method of troubleshooting. When

need arises to repair the embroidery machine in reference to this Service

Manual, refer to TROUBLESHOOTING first. Then, refer to ADJUSTMENT or

REPLACEMENT as suggested.

3.Only the critical instructions are given.

When a component must be removed for troubleshooting, adjustment or

replacement, the Service manual explains how to remove other components

before the component in question can be removed.

However, the manual does not explain how the other components are fitted,

unless such information is necessary for technical reasons, when adjustment

or replacement is completed.

Inspection & Repairs

1.When parts need to be replaced, use only parts certified by Aishin Seiki Co.,

Ltd., to ensure machine performance.

2.To prevent any accident from occurring, be sure to turn the power OFF

before repair.

CONTENTS

1.

SPECIFICATIONS

...............................................................................................................

.....................1

2.

TROUBLESHOOTING

............................................................................................

.......................

2

2-1 The power supply does not turn

on........................................................................................2

2-2 An error message is displayed ”Check ! SEWING

MOTOR”........................................3

2-3 An error message is displayed “Check ! X

MOTOR”......................................................4

2-4 An error message is displayed ” Check ! Y

MOTOR”.....................................................5

2-5 An error message is displayed ”NEEDLE CASE

ERROR” ............................................6

2-6 Holder does not return to stroke center after home position

return......................7

2-7 Thread comes off

needle.............................................................................................................8

2-8 Skips

stitches..................................................................................................................................

..9

2-9 Needle thread

breaks...................................................................................................................10

2-10 Bobbin thread

breaks...................................................................................................................12

2-11 Needle

breaks..................................................................................................................................1

3

2-12 Thread wiper hook does not

operate....................................................................................14

2-13 Thread trimming

fails....................................................................................................................15

2-14

Puckering...............................................................................................................................

............16

2-15 Improper

tension............................................................................................................................17

2-16 Jump function does not

work...................................................................................................18

2-17 An error message is displayed “THREAD

BREAK” .......................................................19

2-18 Stitch registration slips

out.......................................................................................................20

3.ADJUSTMENT OF MAIN COMPONEN

TS

..................................21

3-1 Timing of the needle and the rotary

hook...........................................................................21

3-2 Position of the hook

support....................................................................................................23

3-3 Standby position of thread

catcher.......................................................................................24

3-4 Blade

pressure................................................................................................................................

25

3-5 Picker

position................................................................................................................................2

7

3-6 Position of the thread wiper

hook..........................................................................................28

3-7 Adjustment of the jump motor

position...............................................................................29

3-8 Tension of drive belts A &

C....................................................................................................30

3-9 Tension of deceleration belts B, D,

E...................................................................................31

3-10 Limit

sensor....................................................................................................................................

..32

3-11 Thread

sensor.................................................................................................................................3

4

3-12 Power

box.........................................................................................................................................

35

4.REPLACEMENT OF MAIN COMPON

ENTS

..........................36

4-1 Rotary

hook.......................................................................................................................................

36

4-2 Thread

cutter...................................................................................................................................3

7

4-3 Thread

catcher................................................................................................................................3

8

4-4 Needle

bar.........................................................................................................................................

.39

4-5 Needle bar

reciprocator...............................................................................................................41

4-6 Thread change

motor...................................................................................................................43

4-7 Power supply

board.......................................................................................................................44

4-8 Power circuit

board........................................................................................................................45

4-9 Jump

motor.....................................................................................................................................

..46

4-10 Main circuit

board...........................................................................................................................47

4-11 Operation box

assembly...............................................................................................................48

4-12 Upper shaft

sensor.........................................................................................................................49

4-13 Sewing machine

motor..................................................................................................................50

4-14 X

motor.....................................................................................................................................

...........51

4-15 Y

motor.....................................................................................................................................

...........52

4-16 Thread wiper

motor........................................................................................................................53

4-17 Thread

sensor...................................................................................................................................

54

4-18 Operation control circuit

board................................................................................................55

4. REPLACEMTNT OF MAIN COMPONENTS

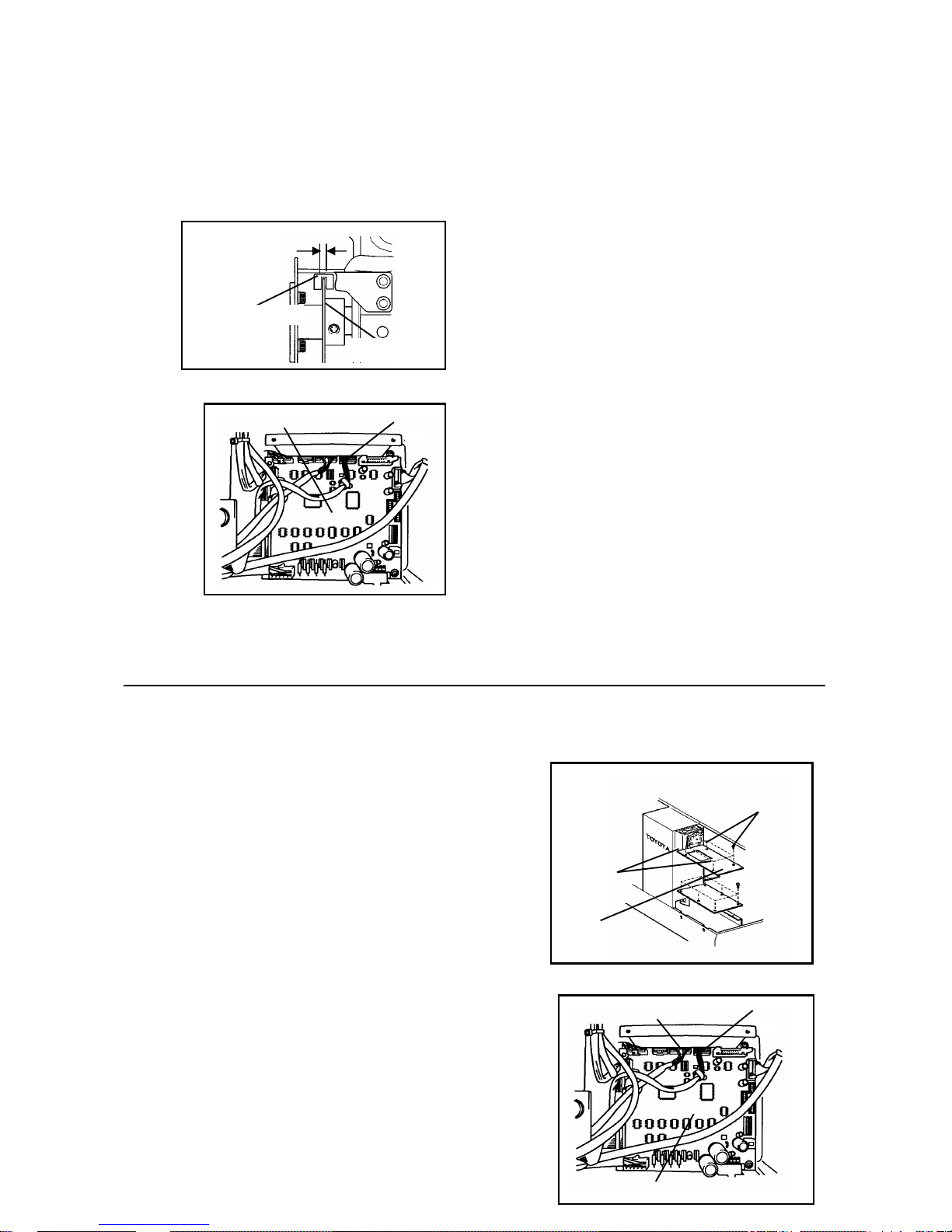

4-9. Jump motor

[Removal]

(1) Remove the needle case.

[Please refer to 『“ 4-5. Needle bar

reciprocator” 』 on page 41]

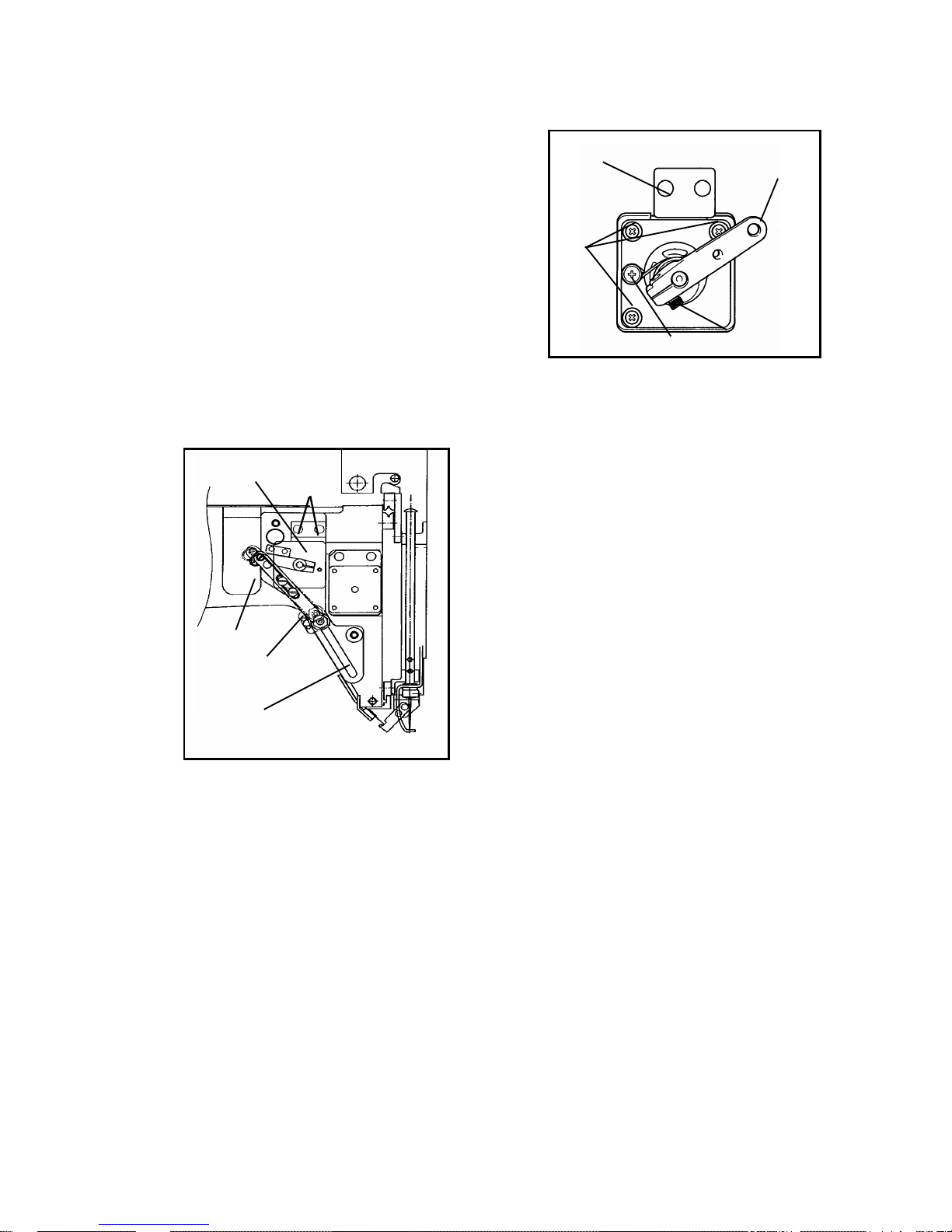

(2) Remove five set screws (a) and the arm

front cover L. (Fig.1)

(3) Remove each setting screws and the

thread stand plate, bobbin winder base

and rear cover. (Fig.2)

(4) Cut the cable tie and remove the relay

harness.

(5) Remove two setting screws (b) and the

jump motor set. (Fig.3)

(6) Loosen the setting screws (c) and

remove the jump lever holder. (Fig.4)

(7) Remove four setting screws (d) and the

jump motor. (Fig.4)

[Installation]

(1) Install the jump motor with four setting

screws (d). (Fig.4)

(2) Hang the jump lever return spring on

the jump lever holder and pull down the

spring as low as possible so that the

spring will not be located on the jump

positioning collar. (Fig.4)

(3) Tighten the setting screw (c) and check

that the jump lever holder returns with

the spring and stops with the stopper.

(Fig.4)

(4) Install the jump motor set with two

setting screws (b). Adjust the clearance

between the jump lever and the needle

reciprocator at 0.5 mm by moving the

jump motor right and left.

(5) Connect the relay harness, bundle the

cord with cable tie and install the thread

stand plate, bobbin winder base and

rear cover.

(6) Install the needle case.

FIG.1

FIG.2

FIG.3

(a)

Thread stand plate

R

ear cover

Bobbin winder base

(b)

Jump motor set

Jump lever return spring

Jump positioning

collar

Stopper

(d)

(d)

(c)

Jump lever holder

-46-

FIG.4

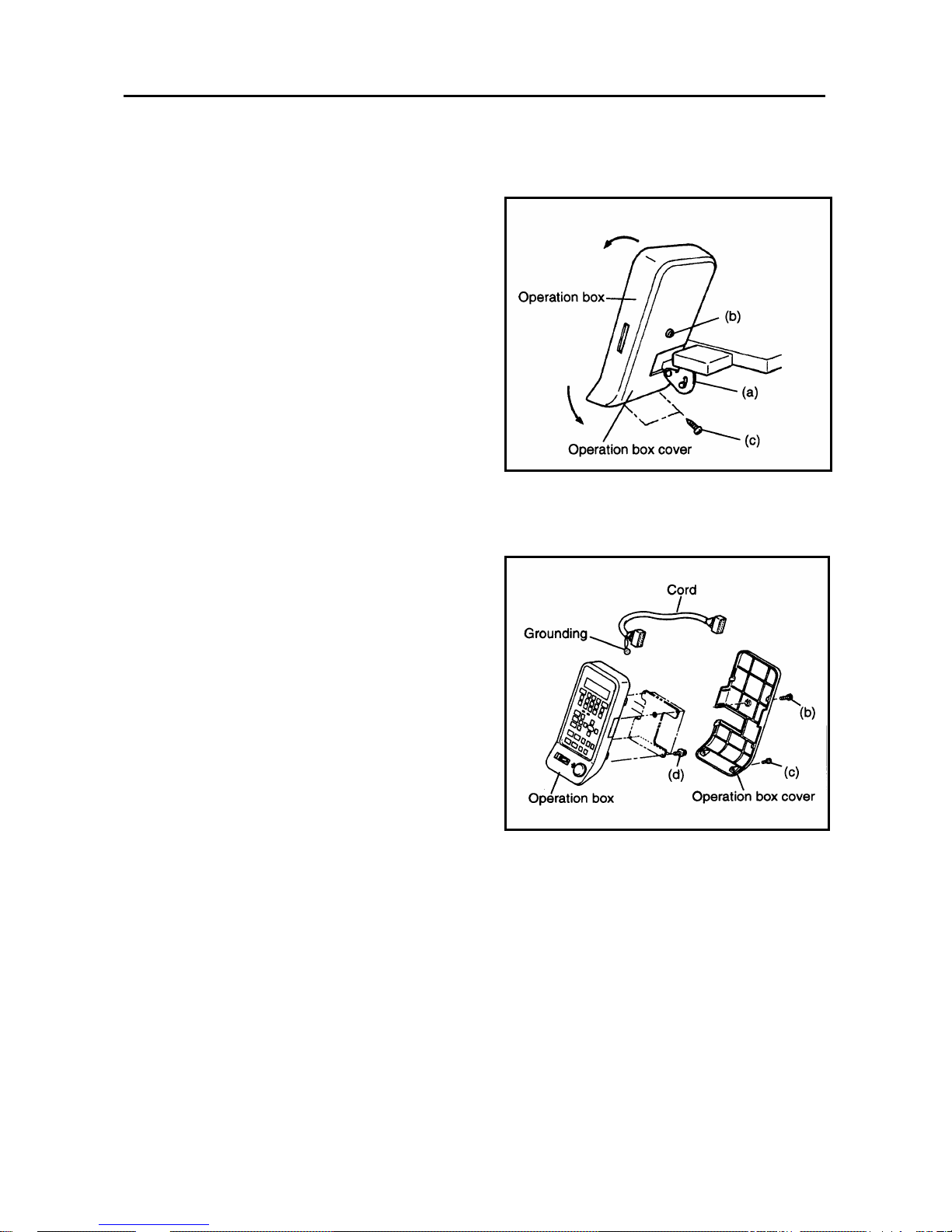

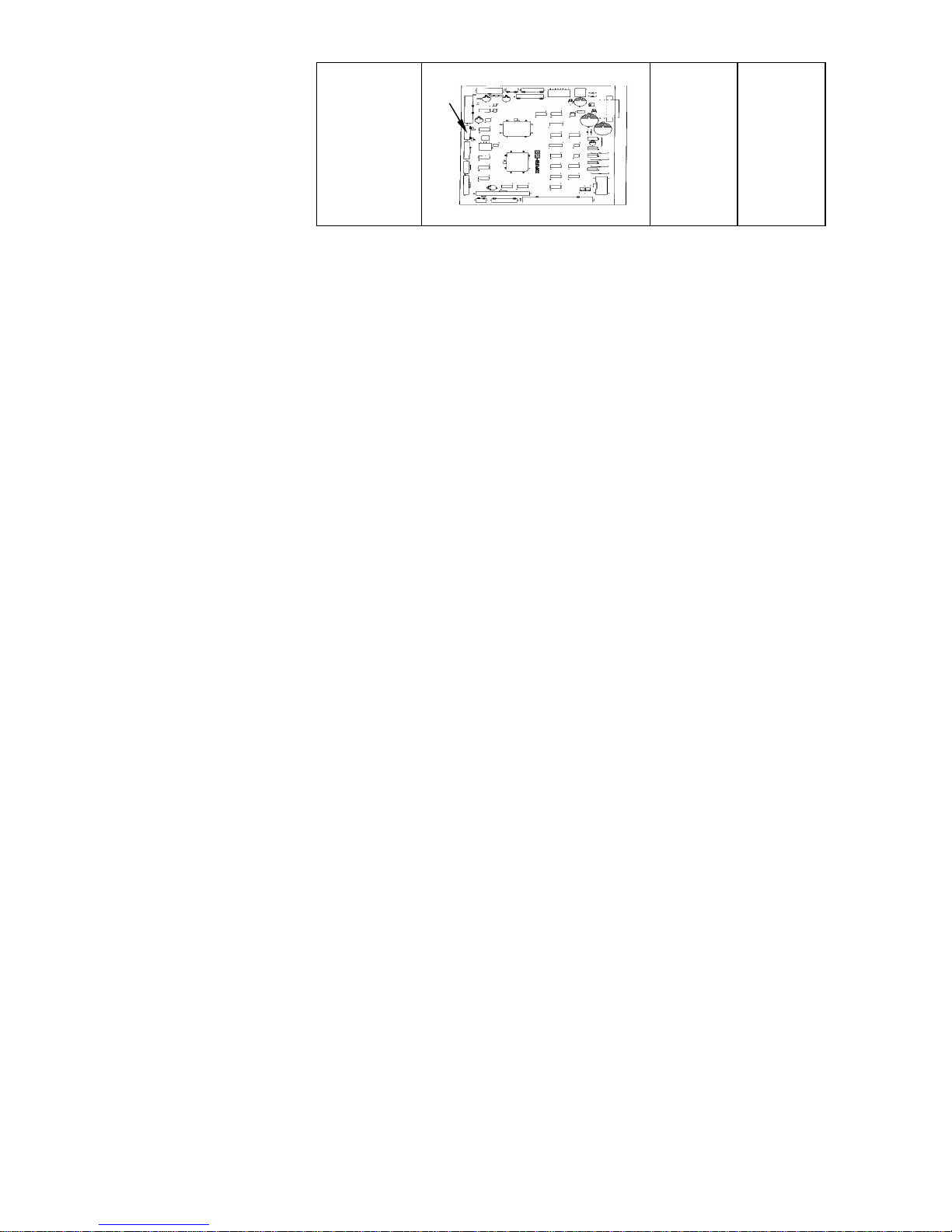

4-10. Main circuit board

[Removal]

(1) Remove two setting screws (a) and the

table set. (Fig.1)

(2) Remove four set screws (b) and the

base cover rear R. (Fig. 1)

(3) Loosen two setting screws (c), remove

other two set screws (d), move the

case cover upper upwards, disconnect

the connector CN2 and remove the

case cover upper. (Fig.2)

(4) Disconnect all the connectors. (Fig.3)

(5) Remove two setting screws (e) and

remove the main circuit board by

holding the plastic spacer with pliers.

[Installation]

Attached in the reverse procedure of

removal

FIG.1

FIG.2

4.REPLACEMENT OF MAIN COMPONENTS

(b)

Base cover

rear R

Table set

(a)

(d)

(c)

Case cove

r

upper

Main circuit board

(e)

CN2

-47-

FIG.3

-48-

4.REPLACEMENT OF MAIN COMPONENTS

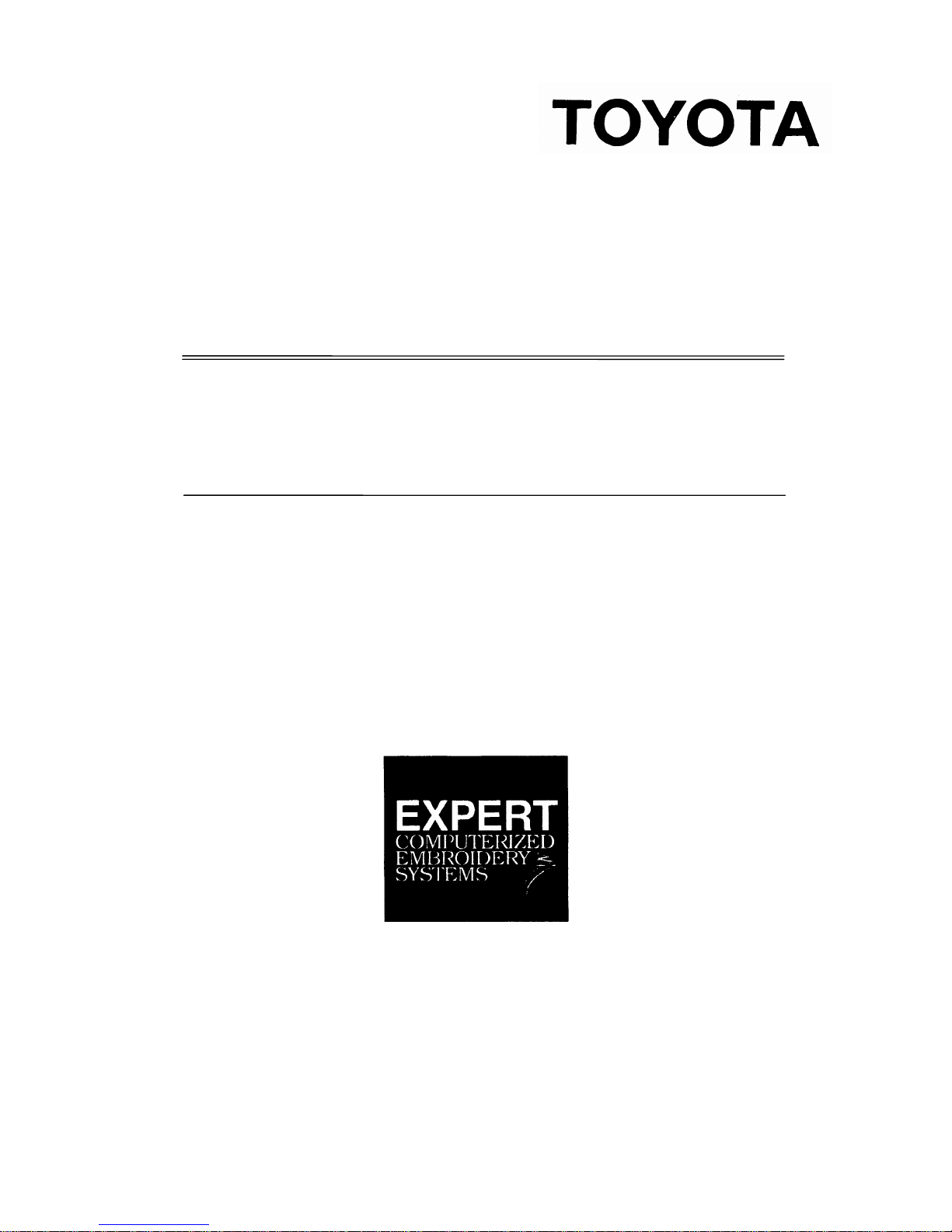

4-11. Operation box assembly

[Removal]

(1) Loosen retaining screw (a) and rotate

the operation box in the direction of the

arrow to set the box in the upright

position (Fig.1).

(2) Remove retaining screw (b) and two

retaining screws (c) and the operation

box cover (Fig.1).

(3) Remove four retaining screws (d).

Unplug the cord and remove the

operation box (Fig.2).

[Installation]

(1) Plug in the cord.

(2) Secure the operation box to the

bracket with four retaining screws (d).

One of these screws is for grounding

(Fig.2).

(3) Mount the operation box cover with

retaining screw (b) and two retaining

screws (c) (Fig.1).

(4) Rotate the operation box to set it at

the desired angle for easy operation

and secure it with retaining screw (a)

(Fig.1).

FIG.1

FIG.2

-49-

4-12. Upper shaft sensor

[Removal]

(1) Remove two setting screws (a) and the

bobbin winder base set. (Fig.1)

(2) Loosen four setting screws (b) and

remove the rear cover. (Fig.1)

(3) Remove two setting screws (c) and the

upper shaft sensor set. Then remove

two setting screws (d) and the upper

shaft sensor. (Figs.1, 2)

(4) Remove four setting screws and the

base cover rear L. (Fig.1)

(5) Loosen two setting screws, remove

other two setting screws, move the

case cover upper upwards, disconnect

the connector CN3 and cut the cable

tie and then remove the upper shaft

sensor. (Refer to Fig.2 on page 47)

[Installation]

(1) Install the upper shaft sensor on the

sensor base with two setting screws (d).

(Fig.3)

(2) Insert the connector of the upper shaft

sensor in CN3 on the main circuit board.

(Fig.5)

(3) Fix the upper shaft sensor set with two

setting screws (c) in the position where

the center of the sensor comes to the

center of the rotation detecting plate.

(Figs.2, 4)

(4) Bundle the cords with cable tie.

(5) Set the DS1-1 on and turn the power

on. Rotate the hand wheel to move the

needle bar to the bottom dead center.

Check that the LCD display shows the

needle position at 180°.

Note: In case the LCD display does not

show 180 ° , loosen the set screw,

adjust the position of the detecting

plate and fix it. (Fig.1)

(6) Install the case cover upper, base

cover rear L, rear cover and bobbin

winder base set.

FIG.1

FIG.2

4.REPLACEMENT OF MAIN COMPONENTS

(c)

Upper shaft sensor set

Upper shaft sensor

(a)

R

ear cover

(b)

(b)

B

ase cover

Rear L

Bobbin winder base set

-50-

FIG.3

FIG.4

FIG.5

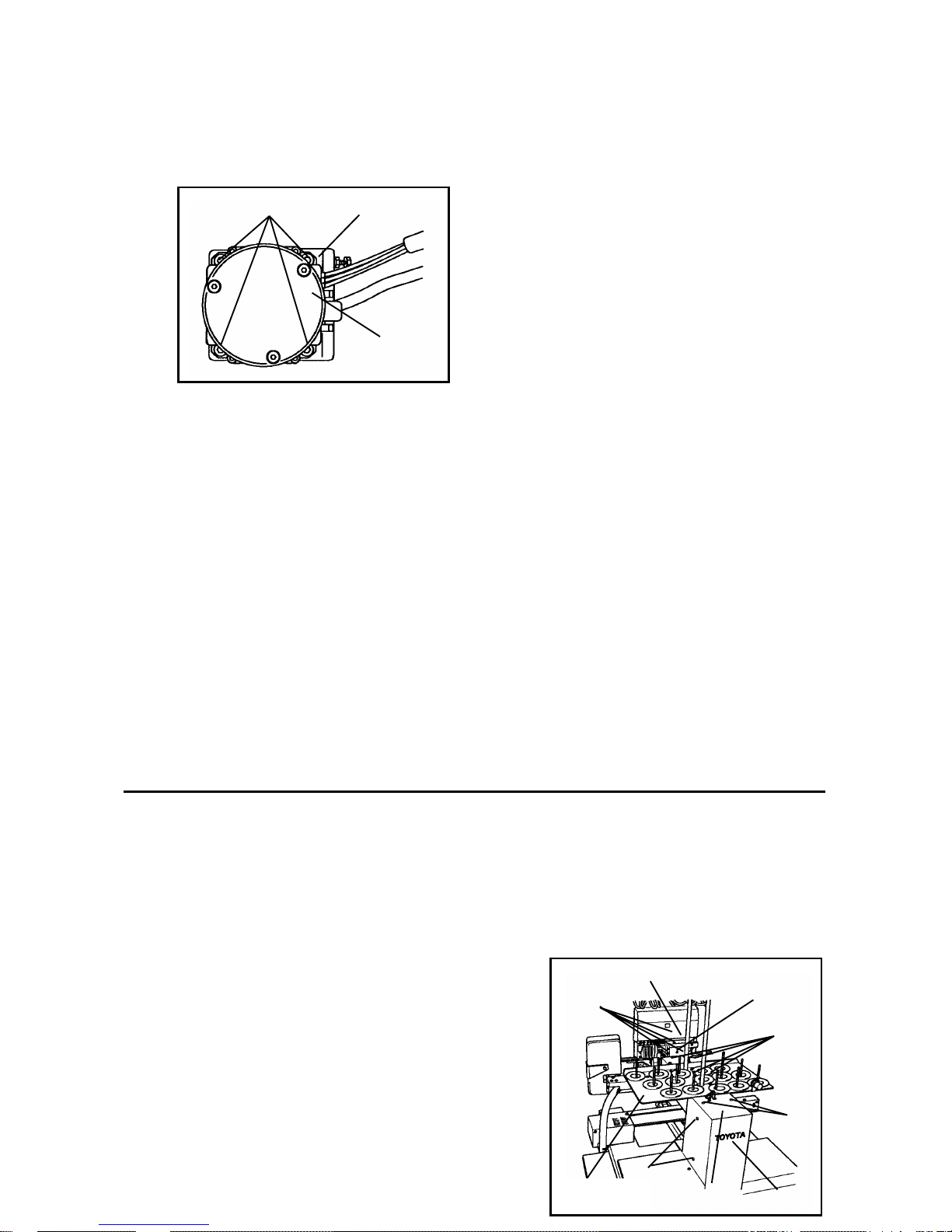

4-13. Sewing machine motor

[Removal]

(1) Remove the rear cover and base cover

rear R.L.

(2) Loosen two set screws (a), remove

other two set screws (b), move the

case cover upper, disconnect CN5 of

the main circuit board and CN3 of the

power circuit board and cut the cable

tie. (Figs.1, 2)

(3) Loosen two setting screws (c), which

are located on the motor side of the

lower shaft joint. (Fig.1)

(4) Remove four setting screws (d) and the

sewing machine motor. (Fig.4)

[Installation]

(1) Two set surfaces of the sewing

machine motor shaft and two setting

screws (c) of the lower shaft joint are

aligned and insert the sewing machine

motor.

(2) Fix the sewing machine motor with four

setting screws (d). (Fig.4)

Center

(3) Insert two setting screws (c) of the

lower shaft joint gradually, locate them

vertically to the setting points and

tighten them.

Upper shaft sensor

Detecting plate

(4) Insert two connectors and bundle the

cords with the cable tie.

(5) Install case cover upper with four

setting screws (a) and (b). (Fig.1)

CN3

Main circuit board

(6) Install the base cover rear R.L. and the

rear cover.

FIG.1

4.REPLACEMENT OF MAIN COMPONENTS

(b)

(a)

Case cove

r

upper

CN3

CN5

-51-

Main circuit board

FIG.2

FIG.3

FIG.4

4-14. X motor

[Removal]

(1) Remove two setting screws (a) and

motor cover. (Fig.1).

(2) Loosen the nut and remove the

setting screw (b). (Fig.2)

(3) Disconnect the connectors. Remove

two setting screws (c) and the X

motor. (Fig.2)

(4) Remove four setting screws (d) and X

motor from the bracket. (Fig.2)

[Installation]

Power circuit board

Lower shat joint

(1) Mount the X motor to the motor base

with four setting screws (d) (Fig.2).

Sewing machine

motor

(c)

(2) Set the X motor gear to the belt and

temporarily secure the motor base to

the X base B with two setting screws

(c) (Fig.2).

Arm bed

(3) Adjust the belt tension by setting

screw (b) and firmly tighten two

setting screws (c), then tighten the

nut. (Figs.2, 3)

Power circuit board

Note: Check the tension, after tighting

screws (c).

(4) Insert the connector.

(d)

Sewing machine

motor

4.REPLACEMENT OF MAIN COMPONENTS

(a)

Motor cover

-52-

FIG.1

FIG.2

X base B

(d)

Nut

(b)

4-15. Y motor

[Removal]

(1) Remove four set screws (a) and the

base cover rear R. (Fig.1)

(2) Remove two setting screws (b) and the

fan set. (Fig.2)

(3) Remove the Y pulley box adjusting

screw (c) and nut (d) and loosen

setting screw (e) and nut (f). (Fig.2)

4.REPLACEMENT OF MAIN COMPONENTS

(c)

X motor

Motor base

-53-

(4) Disconnect the connector, remove two

set screws (g) and Y motor bracket set.

(Fig.3)

(5) Remove four setting screws (h) and the

Y motor. (Fig.4)

[Installation]

(1) Mount the Y motor to its bracket with

four setting screws (h). (Fig.4)

(2) Set the Y motor gear to the belt and

temporarily secure them with two

setting screws (g). (Fig.3)

(3) Adjust the belt tension with setting

screw (e), and then firmly tighten with

two setting screws (g) and nut (f).

(Fig.3)

Note: Check the tension, after tighting

screws (g).

(4) Insert the Y pulley box adjusting

screw (c) into the backmost position

and tighten the nut (d). (Fig.3)

(5) Mount the fan set with two setting

screws (b). (Fig. 2)

(6) Insert the connector.

FIG.1

FIG.2

Base cover

rear R

(a)

Fan set

(b)

Y motor bracket set

(g)

(d)

(f)

(c)

(e)

-54-

FIG.3

FIG.4

4-16. Thread wiper motor

[Removal]

(1) Remove the each setting screws (a)

and the change cover, the relay circuit

board cover, the thread stand plate,

the bobbin base and the rear cover.

(Fig.1)

(2) Cut a cable tie and remove the relay

connector.

(3) Remove the setting screw (b) and two

setting screws (c), and the thread

wiper motor. (Fig.1)

(4) Remove the setting screw (d) and (e),

and the upper thread hook lever.

(Fig.3)

(5) Remove the three setting screws (f)

and the motor base.(Fig.3)

Note: Be sure to insert the small

washer that is contained in each

setting screws of (3) and (4) sections.

Y motor bracket

(h)

[Installation]

Y moto

r

(1) Attached in the reverse procedure of

removal

Note: Set the vertical position of the

upper thread hook lever slightly

upward, and make sure that the

connecting rod plate has a little play.

(2) After attaching, check the distance A

from the needle center to the thread

wiper hook tip. [Please refer to 『“3-6

Position of the thread wiper hook.” 』

on page 28 ]

(3) If the distance A differs from that

specified, loosen two setting screw (c)

and adjust by moving the thread wiper

motor base up/down.

4.REPLACEMENT OF MAIN COMPONENTS

Change cover

Relay circuit

board cover

(a)

(a)

(a)

(a)

-55-

Thread stand

plate

Bobbin winder

base

Rear cover

FIG.1

FIG.2

Motor base

Upper thread

hook leve

r

(f)

(d)

(e)

Thread wiper

motor base

(c)

FIG.3

(b)

Thread wipe

r

hook base

Connecting

rod plate

-56-

4.REPLACEMENT OF MAIN COMPONENTS

4-17. Thread sensor

[Removal]

(1) Remove the two each setting screws

(a), then remove the change cover and

relay circuit board cover. (Fig.1)

(2) Remove the connector CN2.

(3) Remove the tension base cover.

(Fig.1)

(4) Raised the connector upwards and

disconnect it.

(5) Cut the cable tie, remove the two

setting screws (b) then remove the

sensor arm. (Fig.4)

(6) Extract the thread sensor base from

the thread sensor rail; remove the

setting screw (c) and the thread

sensor board. (Figs.3, 4)

[Installation]

(1) Attach the sensor board with the

setting screw (c). (Fig. 4)

(2) Put the code of thread sensor base

upwards into the thread sensor rail.

(Fig. 3)

(3) Putting a sensor arm into the slot of

the thread sensor base and secure it

with two setting screws (b). (Fig.2)

Note: At this time, check the sensor

position.

[Please refer to 『 “ 3-11. Thread

sensor” 』 on page 34]

(4) Secure the cord with a cable tie and

insert the connector.

Note: The blue field of a code is

turned and inserted in a spool side. At

this time, check the connector

connection by pulling a code with

hand.

(5) Mount the relay circuit board cover,

change cover and tension base cover.

Tension base cover

(a)

Change

cover

Relay circuit board cove

r

FIG.1

FIG.2

(b)

Sensor arm

Thread sensor rail

Thread sensor base

FIG.3

(c)

Sensor board

FIG.4

-57-

4-18. Operation control circuit board

[Removal]

(1) Remove four setting screws (a) and

the base cover rear R. (Fig.1)

(2) Loosen the two setting screws (b),

remove the two setting screws (c) and

disconnect connectors CN12 and CN7,

then remove the case cover upper.

(Fig.2,3)

(3) Remove the two setting screws (d) and

the resin spacers, then remove the

console board (Fig.4).

[Installation]

Attached in the reverse procedure of

removal.

4.REPLACEMENT OF MAIN COMPONENTS

FIG.1

FIG.2

(a)

Base cover

rear R

(c)

(b)

Case cover

upper

CN12

CN7

FIG.3

(d)

Console board

-58-

FIG.4

-59-

1.SPECIFICATIONS

1.SPECIFICATIONS

ESP9000

No Item Specifications

1 Type of stitch

Lock stitch type sewing machine (for automatic embroidery

only)

2 Rotary hook Vertical 2 revolution type (eccentric)

3 Thread take-up lever Cam take-up lever

4 Needle bar stroke 50 ± 0.2 mm

5 Number of needles 15 (auto changing)

6 Applicable needles Organ DB×K5Z #11

7 Presser foot Needle bar linked driving system (with noise

reduction mechanism)

8 Bobbin thread winding Semi-auto winding (auto return, also stop)

9 Thread trimming method Horizontal reciprocation (motor drive)

10 Thread wiper Motor drive sliding type (with thread retaining

mechanism)

11 Picker method Picking at start, end of sewing and cutting thread

12 Stitch speed 1,200spm maximum (800spm standard)

13 Embroidery area 360 mm long × 500 mm wide

14 Embroidery control and

indication

Touch switch control with LED/LED displays

15 Stitch memory 280,000 stitches

16 Memory back-up Memory saved during operation and after power off;

kept for 4 weeks

17 Weight 80 ± 1kg (without table)

18 Machine oil High grease NX 2, molybdenum grease NO 2, SF oil

(multi-grade)

19 Drive motor AC servo motor (machine revolution)

20 Control motor AC servo motor (X axis, Y axis)

21 Needle thread failure detection Rotary detection system (photo sensor)

-1-

22 Power supply and consumption 100~120/200~240VAC, 50/60Hz, 220W

23 Dimensions 835(H) x 745(W) x 740(D)

-2-

2.TROUBLESHOOTING

2.TROUBLESHOOTING

2-1 The power supply does not

turn on

・ Power cord may be unplugged (AC power

cord).

・ Cable from the power box to the embroidery

machine may be disconnected (DC power

cord).

Main circuit board

-2-

Item Method Standard Action

Fuse

(outside)

250V6.3

A,without

fusion

Replace

fuse.

5V power

supply

Take out fuse and inspect it

visually

Check the voltage across ①

and ⑦with a circuit tester.

5.0to5.2V

when

turned on

Adjust or

replace

the

power

box. See

P.44.

Connection

of

connector

CN 12

Must be

connecte

d

correctly

Connect

the cable

correctly or

replace the

main circuit

board See

.47. P

Connection

of

connector

CN 7

Must be

connecte

d

correctly

Connect

the cable

correctly

or

replace

the main

circuit

board.

See

.55. P

CN12

CN7

Connection

of

connector

CN 3

Remove

the cover

and

inspect

connectio

n

visually

Must be

connecte

d

correctly

Connect

correctly

or

replace

defective

connectors.

See P48.

-3-

2.TROUBLESHOOTING

・ Upper shaft torque may be too large

・ Needle may be interfering with the embroidery

hoop.

・ Thread may be stuck.

Item Method Standard Action

24V power

supply

Check the voltage across⑤

and ⑪ with a circuit tester

hile shorting⑧to⑨. w

24.0 to

24.5V

Replace

See

P.44.

Connector

connection

Must be

connecte

d

correctly

Connect

correctly

Resistance

Check connector visually.

Disconnect the power

connector, and check the

resistance between ①and②,①

and③,②and③ with a circuit

tester.

0.2 to 0.6

Ω

Replace.

See

P.50.

Connection

of

connector

CN 3

Check the connector

visually.

Must be

connecte

d

correctly

Connect

correctly

or

replace

See

P.45.

CN3

Operation panel

“Check! SEWING

MOTOR ”

2-2 An error message is

displayed

-4-

Connection

of

connector

CN 3

Must be

connecte

d

correctly

Connect

the cable

correctly

or replace

the main

the circuit

board.

See P.47.

CN3

-5-