Page 1

TOYOTA COMPUTERIZED EMBROIDERY SYSTEM

INSTRUCTION MANUAL

Before using the embroidery machine, please read through this manual

carefully for proper use of the machine.

After reading the manual, keep it at a safe place near the machine so

that you can consult it whenever it is necessary.

When you turn over the machine to somebody, make sure to attach this

manual to the machine.

Since this is a business use machine, it should be operated by operators

who are well versed in the basic operations.

Page 2

Page 3

CONTENTS

SAFETY PRECAUTIONS (Make sure to read the following before use) - - - - - - - - - - - - - - - - 4

PART NAMES

CHECKING THE PARTS - - - - - - - - - - - - - - - - - - - - - - - 8

ACCESSORIES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

AMC335: FLOPPY DISK DRIVE

(TO BE PURCHASED SEPARATELY) - - - - - - - - - - - - 10

PREPARATION

ASSEMBLING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

CARRYING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

WIRING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

CONNECTING THE FDD (FLOPPY DISK DRIVE)

(TO BE PURCHASED SEPARATELY) - - - - - - - - - - - - 17

SETTING THE UPPER THREAD - - - - - - - - - - - - - - - - 18

UPPER THREAD SETTING PROCEDURE - - - - - - - - - 18

OPERATION PROCEDURE

《OPERATION BASICS》

STARTING AND STOPPING THE MACHINE - - - - - - - 27

STEPS TO START EMBRODIERY - - - - - - - - - - - - - - - 28

SCREENS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

《FUNCTION MENU》

CHANGING DISPLAY - - - - - - - - - - - - - - - - - - - - - - - - 36

THREAD BREAKAGE SENSOR - - - - - - - - - - - - - - - - - 37

BOBBIN COUNTER (SET) - - - - - - - - - - - - - - - - - - - - - 38

BOBBIN COUNTER (COUNTER) - - - - - - - - - - - - - - - - 39

LOCK STITCH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

SATIN ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - 41

SLOW START - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

TRIMMING IN JUMP - - - - - - - - - - - - - - - - - - - - - - - - - 43

JUMP LENGTH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

TRIMMING LENGTH - - - - - - - - - - - - - - - - - - - - - - - - - 45

TRIMMING TIMING - - - - - - - - - - - - - - - - - - - - - - - - - - 46

COMMUNICATION SPEED - - - - - - - - - - - - - - - - - - - - 47

《HOOP MENU》

HOOP MODE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

INITIALIZATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

START POINT RETURN MODE - - - - - - - - - - - - - - - - - 53

MANUAL SPEED - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

HOOP TIMING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

OFFSET - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

《EDIT》

DESIGN ROTATION - - - - - - - - - - - - - - - - - - - - - - - - - 57

MIRROR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

DESIGN REPEAT - - - - - - - - - - - - - - - - - - - - - - - - - - - 59

EMBROIDERY MACHINE - - - - - - - - - - - - - - - - - - - - - 11

OPERATION PANEL BOX - - - - - - - - - - - - - - - - - - - - - 12

DIP SWITCHES - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

SETTING THE UNDER THREAD - - - - - - - - - - - - - - - - 20

SETTING THE FABRIC ON THE HOOP - - - - - - - - - - - 21

SETTING THE HOOP TO

THE EMBROIDERY MACHINE - - - - - - - - - - - - - - - - - - 22

ATTACHING THE TABLE - - - - - - - - - - - - - - - - - - - - - 23

WINDING THE UNDER THREAD - - - - - - - - - - - - - - - - 24

CHECKUPS BEFORE STARTING OPERATION - - - - - 25

CHECKING THE EMBROIDERY HEAD - - - - - - - - - - - 26

《COLOR CHANGE SETTING》

COLOR CHANGE MODE - - - - - - - - - - - - - - - - - - - - - - 58

NEEDLE BAR SETTING (INPUTTING) - - - - - - - - - - - - 59

NEEDLE BAR SETTING (CHANGE) - - - - - - - - - - - - - - 60

PAUSE SETTING - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

《DATA SET MENU》

DATA INPUT (FLOPPY DISK) - - - - - - - - - - - - - - - - - - 62

DATA INPUT (SERIAL) - - - - - - - - - - - - - - - - - - - - - - - 64

DATA SELECT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

DATA DELETION - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

MEMORY MODE - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

MEMORY INITIALIZATION - - - - - - - - - - - - - - - - - - - - 69

《MANUAL OPERATION》

COLOR CHANGE - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

START POINT RETURN MODE - - - - - - - - - - - - - - - - - 71

TRACE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 72

OFFSET (POSITION SETTING) - - - - - - - - - - - - - - - - - 73

OFFSET (HOOP TRAVELING) - - - - - - - - - - - - - - - - - - 74

TRIMMING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

HOOP FORWARD/BACK (TRAVEL UNITS) - - - - - - - - 76

HOOP FORWARD/BACK (n-STITCH FEED) - - - - - - - - 77

HOOP FORWARD - - - - - - - - - - - - - - - - - - - - - - - - - - - 78

HOOP BACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

《OUTLINE OF FUNCTIONS》

ROTATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

MIRROR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

REPEAT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

OFFSET - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 82

SATIN ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - 84

TRACE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

SAFETY

PRECAUTIONS

PART

NAMES

PREPARATION

OPERATION

PROCEDURE

TROUBLESHOOTING AND MAINTENANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 86

DAILY MAINTENANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -86

PROGRAM INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -90

IF MACHINE OPERATION IS INTERRUPTED - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -95

IF MACHINE STOPS DUE TO OCCURRENCE OF A TROUBLE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -98

SPECIFICATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

INDEX - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 100

TROUBLESHOOTING

AND MAINTENANCE

SPECIFICATION

INDEX

Page 4

SAFETY PRECAUTIONS (Make sure to read the following before use)

Safety precautions are provided to prevent risks and losses which could result from incorrect

handling.

SAFETY

Please read carefully and comply strictly with them.

PRECAUTIONS

Meaning of " DANGER", " WARNING" and " CAUTION"

DANGER

!

WARNING

!

CAUTION

!

Meaning of Pictographs

! ! !

Indicates there could be imminent risk of situation resulting in fatal or serious injury

from incorrect handling.

Indicates there could be possible accident of fatal or serious injury resulting from

incorrect handling.

Indicates incorrect handling could cause physical injury or damage on goods.

Prohibition of touching

Prohibited action

Mandatory action

Disconnection of the power cord plug from receptacle

Caution on finger injury

Caution on high temperature

Caution on electric shock

4

Page 5

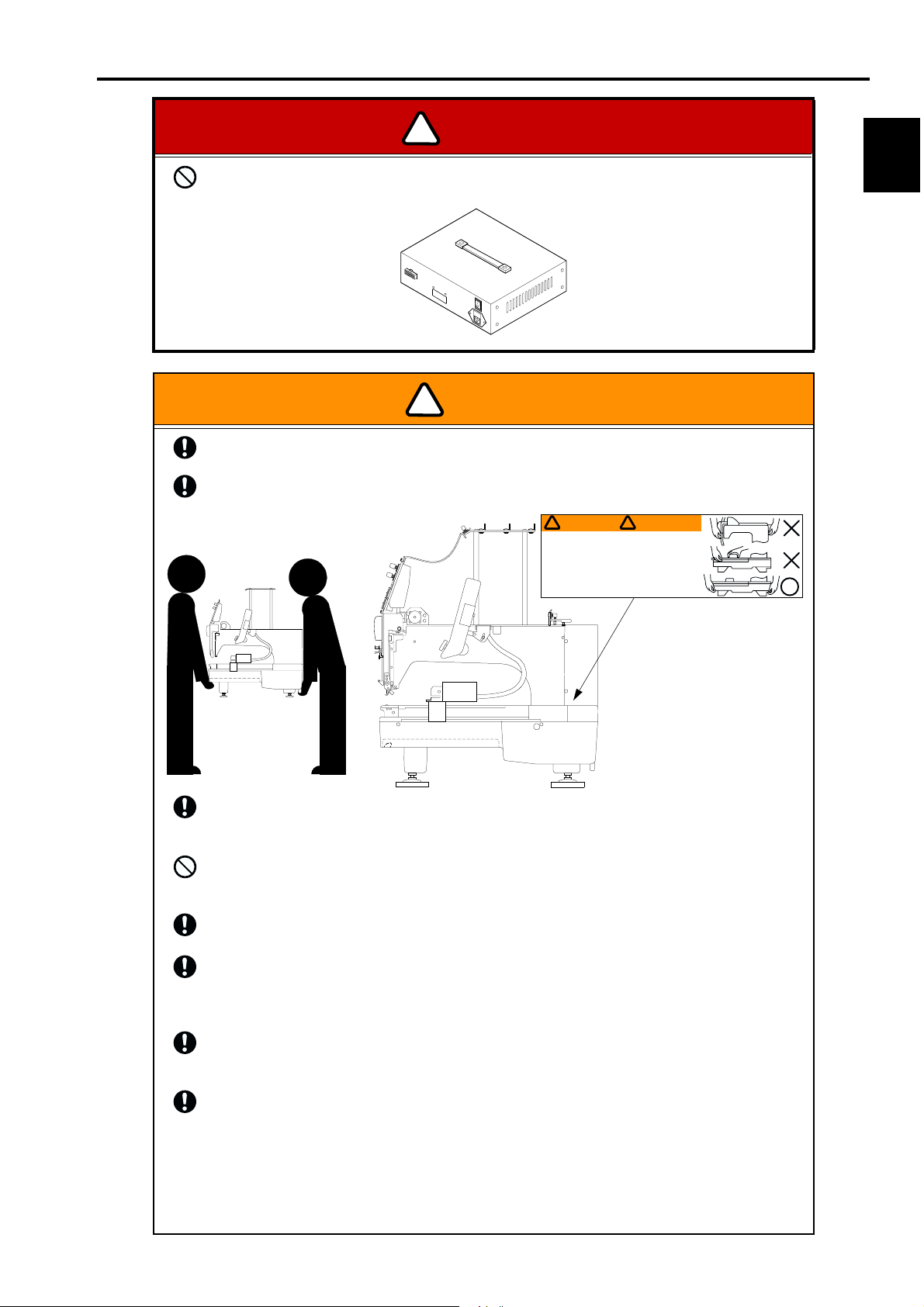

DANGER

!

Do not open the power supply box.

Otherwise, you may sustain electric shock.

WARNING

!

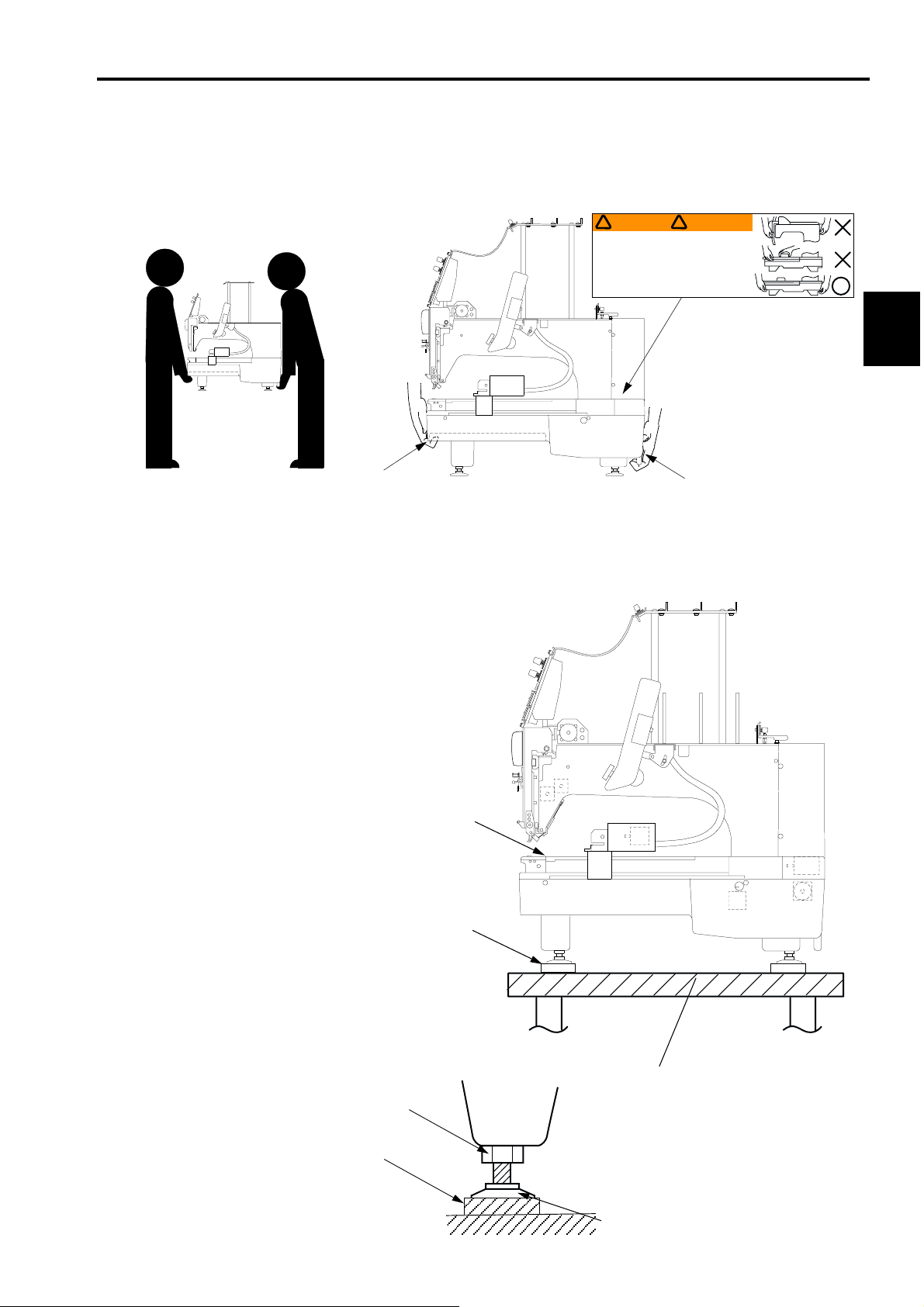

Carry the machine by two or more persons.

Falling the machine may cause injury as well as breakdown of the machine.

When carrying the machine, hold the machine at the positions specified by the label.

Falling the machine may cause injury as well as breakdown of the machine.

WARNI NG

!

CARRYING

Carry the machine with

at least t wo people.

DO NOT hold it by parts

other than those specified.

Dropping may cause bodily

injury and will damage

the machine.

ATTENTION

!

Il faut être au moins 2personnes

pour porter la machine.

Ne pas tenir la machine par

une autre partie que celle

indiquées.

Une chute peut vous blesser

et endommager la machine.

SAFETY

PRECAUTIONS

SAFETY

PRECAUTIONS

When installing the machine, make sure to place it on the attached vibration-preventive rubbers

(H).

Falling the machine may cause injury as well as breakdown of the machine.

Do not damage, modify, heat or apply undue force to the power cords and other connection

cables.

Otherwise the cables may be damaged causing fire and electric shock.

Insert the power cord plug fully.

Incomplete insertion could cause fire or electric shock.

Keep away electric and electronic units from water and oils.

Exposure them to water or oils leads to short circuits, causing fire and electric shock.

If water or oils enter the electric/electronic units, shut off the power by the power switch, shut off

the source of power supply and contact your TOYOTA dealer.

When disconnecting the power cord from the receptacle, pull the cord while holding the plug.

Pulling the power cord by holding the cord may damage the cord and the plug, causing fire and

electric shock.

The machine must be switched off at the mains switch on the power supply or by unplugging it

from the incoming mains supply, when:

• Sewing implements (thread, needle, bobbin, etc) have to be replaced or adjusted

• Threading a needle, bobbin, etc

• If the workplace is left unattended

• Maintenance work has to be performed

5

FD07

Page 6

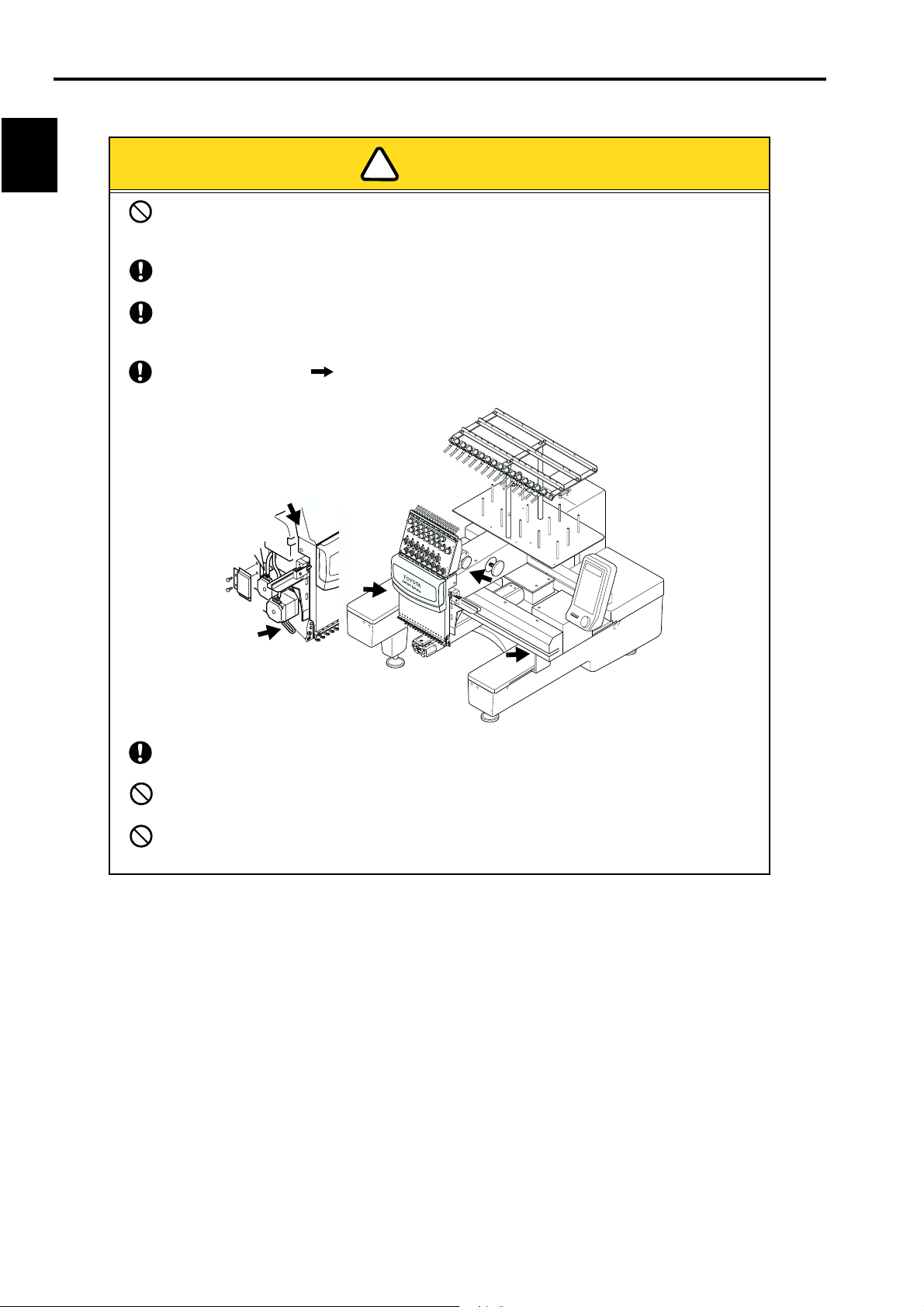

CAUTION

SAFETY

PRECAUTIONS

Do not use the machine in areas where strong electric field or magnetic field is generated by a

high-power high-frequency motor generator or high-frequency welder.

Otherwise the machine will malfunction to cause injury or machine trouble.

Place the machine on a sturdy base.

Otherwise the machine may fall to cause injury or machine trouble.

Ground the grounding wire of the power cord.

There is the danger of electric shock due to leak current if the machine is used without

grounding.

Do not touch the parts ( ) of the machine that move during embroidery.

Otherwise you will sustain injury.

!

SAFETY

PRECAUTIONS

Take care to attire properly for operations of the embroidery machine.

You could get hurt if you wear clothes likely being arrested by the embroidery machine.

Do not step on the embroidery machine.

Otherwise you will sustain injury.

Do not operate the machine without the take-up lever guard or the covers of the moving parts.

Otherwise you will sustain injury.

6

Page 7

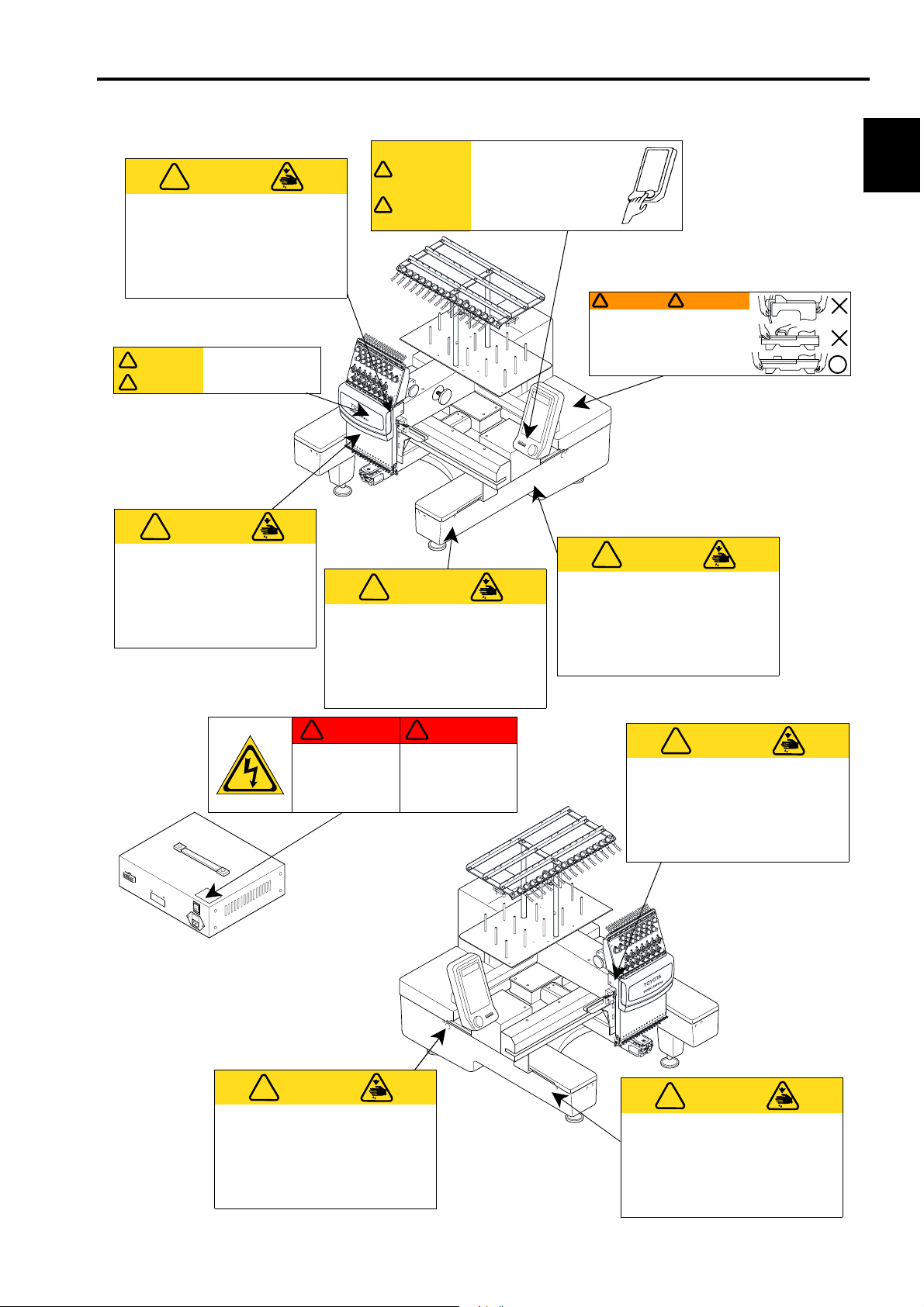

Positions and Contents of the Warning Labels

For abnormal conditions.

CAUTION

!

CAUTION

!

ATTENTION

ATTENTION

Cover must be closed

during operation.

Le couvercle doit être

fermé durant l’utilisation.

Fingers might be injured.

Do not put your hand on hoop while in motion.

Do not put your finger or hand inside thread

tension cover or guard cover.

Les doigts peuvent être blessés.

Ne pas mettre la main sur le cercle à broder quand il

est en mouvement.

Ne pas mettre les doigts ou la main dans le couvercle

du système de tension ou le couvercle de protection.

!

CAUTION

ATTENTI ON

!

Do not operate without finger guard and

safety dev ices. Before thre ading, changing

bobbin and needle, cleaning etc. Switch

off main s witch.

Ne pas travailler sans protection aux

doigts et aux mains et sans dispositif

de sécurité. Avant d’enfiler, changer de

canette ou d’aiguilles, nettoyer. Eteindre

la machine.

CAUTION

!

EMERGENCY

ATTENTION

!

CAUTION

!

Fingers migh t be injured.

Do not put your hand on hoop while in motion.

Do not put your finger or hand inside thread

tension cover or guard cover.

Les doigts peuvent être blessés.

Ne pas mettre la main sur le cercle à broder quand il

est en mouvement.

Ne pas mettre les doigts ou la main dans le couvercle

du système de tension ou le couvercle de protection.

ATTENTION

Immediately press the emergency suspension switch to

stop the embr oidering mac hine.

En cas de conditions anormales,

pousser immédiatement sur

le bouton d’arrêt d’urgence pour

stopper la brodeuse.

WARNING

!

CARRYING

Carry the machine with

at least two people.

DO NOT hold it by parts

other than those specified.

Dropping may cause bodily

injury and will damage

the machine.

CAUTION

!

Fingers might be injured.

Do not put your hand on hoop while in motion.

Do not put your finger or hand inside thread

tension cover or guard cover.

Les doigts peuvent être blessés.

Ne pas mettre la main sur le cercle à broder quand il

est en mouvement.

Ne pas mettre les doigts ou la main dans le couvercle

du système de tension ou le couvercle de protection.

ATTENTION

ATTENTION

!

Il faut être au moins 2personnes

pour porter la machine.

Ne pas tenir la machine par

une autre partie que celle

indiquées.

Une chute peut vous blesser

et endommager la machine.

SAFETY

PRECAUTIONS

SAFETY

PRECAUTIONS

DANGER

!

Risk of

electric shock

Don’t open

this cover.

CAUTION

!

Fingers might be injured.

Do not put your hand on hoop while in motion.

Do not put you r finger or ha nd inside thr ead

tension cover or guard cover.

Les doigts peuvent être blessés.

Ne pas mettre la main sur le cercle à broder quand il

est en mouvement.

Ne pas mettre les doigts ou la main dans le couver cle

du système de tension ou le couvercle de protection.

ATTENTION

!

Risque dechoc

électrique.

Ne pas ouvrir

ce couvercle.

ATT E NTI ON

CAUTION

!

Fingers might be injured.

Do not put your hand on hoop while in motion.

Do not put your finger or hand inside thread

tension cover or guard cover.

Les doigts peuvent être blessés.

Ne pas mettre la main sur le cercle à broder quand il

est en mouvement.

Ne pas mettre les doigts ou la main dans le couvercle

du système de tension ou le couvercle de protection.

Fingers might be injured.

Do not put your hand on hoop w hile in motion.

Do not put your finger or hand inside thread

tension cover or guard cover.

Les doigts peuvent être blessés.

Ne pas mettre la main sur le cercle à broder quand il

est en mouvement.

Ne pas mettre les doigts ou la main dans l e couvercle

du système de tension ou le couvercle de protection.

ATTENTION

CAUTION

!

ATTENTION

7

FD07

Page 8

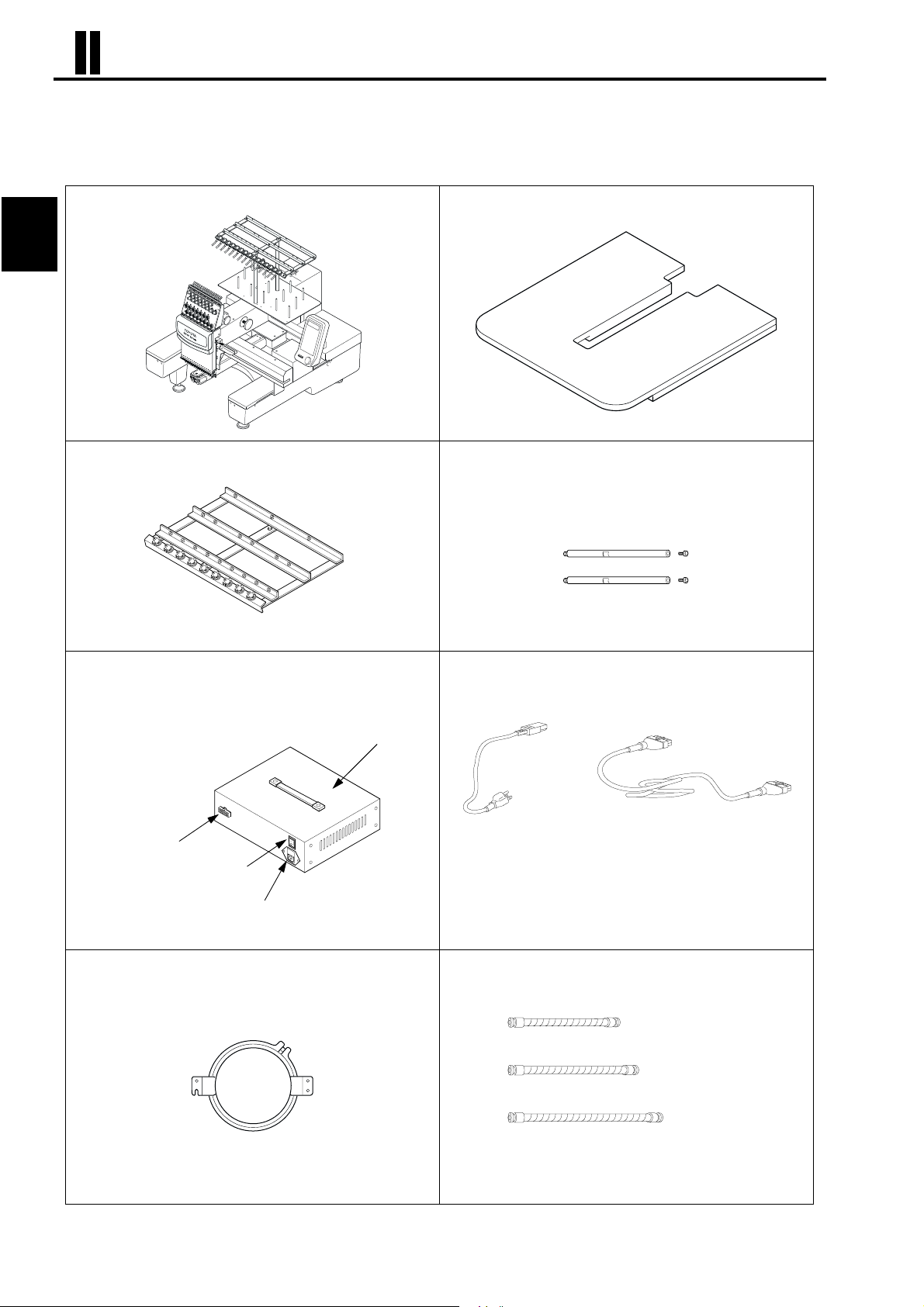

PART NAMES

CHECKING THE PARTS

After unpacking the machine, check to be sure that all of the items below have been delivered.

● Embroidery machine (1 set) ● Table (1 pc.)

PART

NAMES

● Thread guide (1 pc.)

● Power supply box (1 pc.)

DC power supply connector

Power switch

AC power supply connector

● Thread stand shaft and hexagon socket head cap

screw (2 pcs. each)

● Power cord

AC power cord (1 pc.) DC power cord (1 pc.)

Cover

* An additional AC power cord and plug for 250 V

are included only for USA/Canada spec.

● Embroidery hoop (1 pc.) ● Spiral tube

<Tubular frame>

Small

Medium

Large

8

- - - - - - - - - - (5 pcs.)

- - - - - - - - - - (4 pcs.)

- - - - - - - - - - (6 pcs.)

Page 9

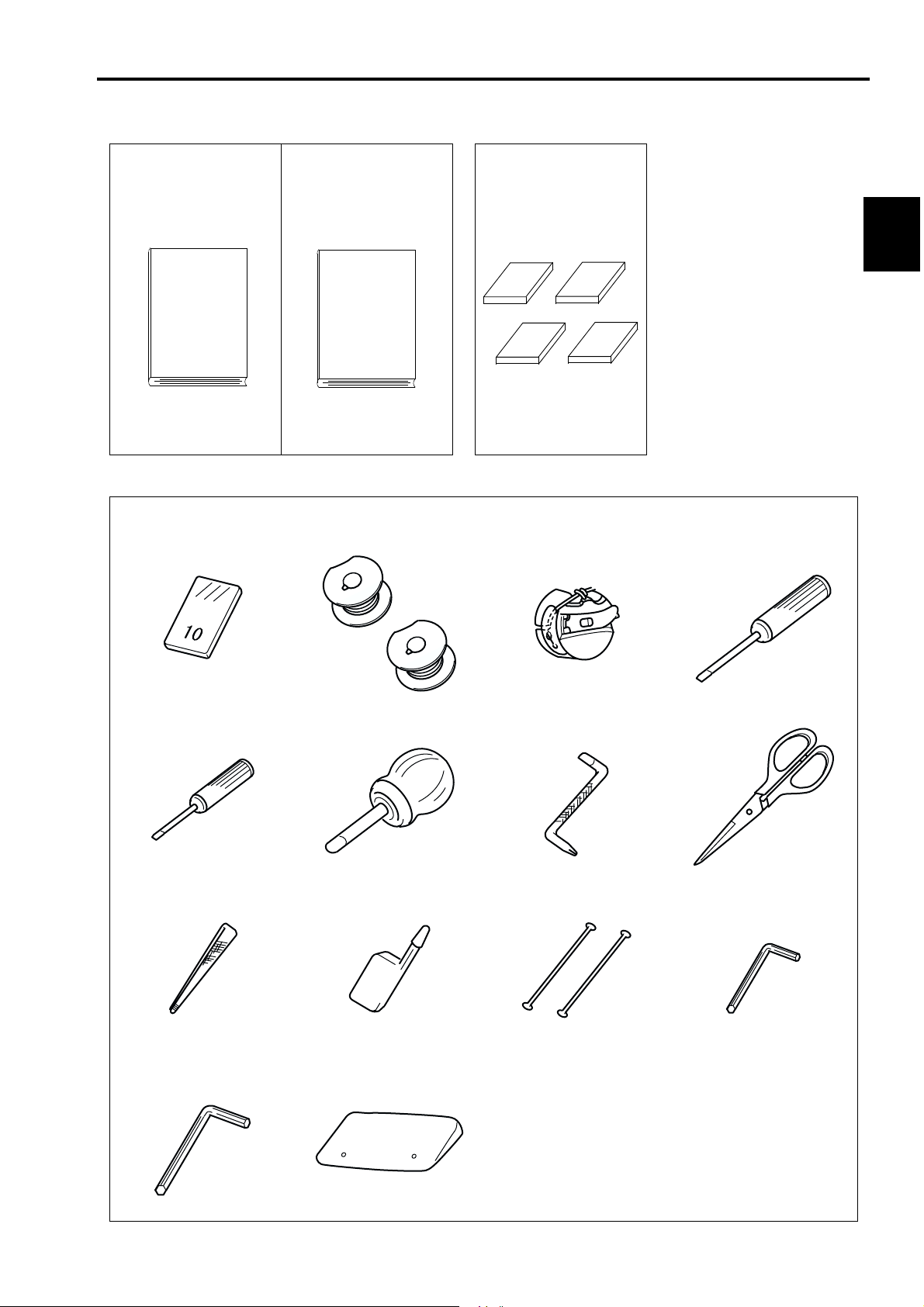

ACCESSORIES

● Instruction manual

(1 copy)

● Parts catalogue

(1 copy)

● Vibration-preventive

rubber (H)

(This book)

NAMES

PART

INSTRUCTION

MANUAL

PART S

CATALOGUE

* We reserve the right to

change the contents of this

instruction manual without

prior notice.

PART

NAMES

● Too ls

(1) Needle (#11) 10 pcs.

(2) Aluminum bobbin 2 pcs. (3) Bobbin case 1 pc. (4) Minus screwdriver (large)

1 pc.

(5) Minus screwdriver (small)

1 pc.

(9) Small pincers 1 pc. (10) Oiler 1 pc.

(13) Allen wrench (4 mm)

1 pc.

(6) Offset screwdriver

1 pc.

(14) Tool bag 1 pc.

(7) L-shaped screwdriver

(plus/minus) 1 pc.

(11) Threader

2 pcs. (12) L wrench (3 mm)

(8) Scissors

1 pc.

1 pc.

9

Page 10

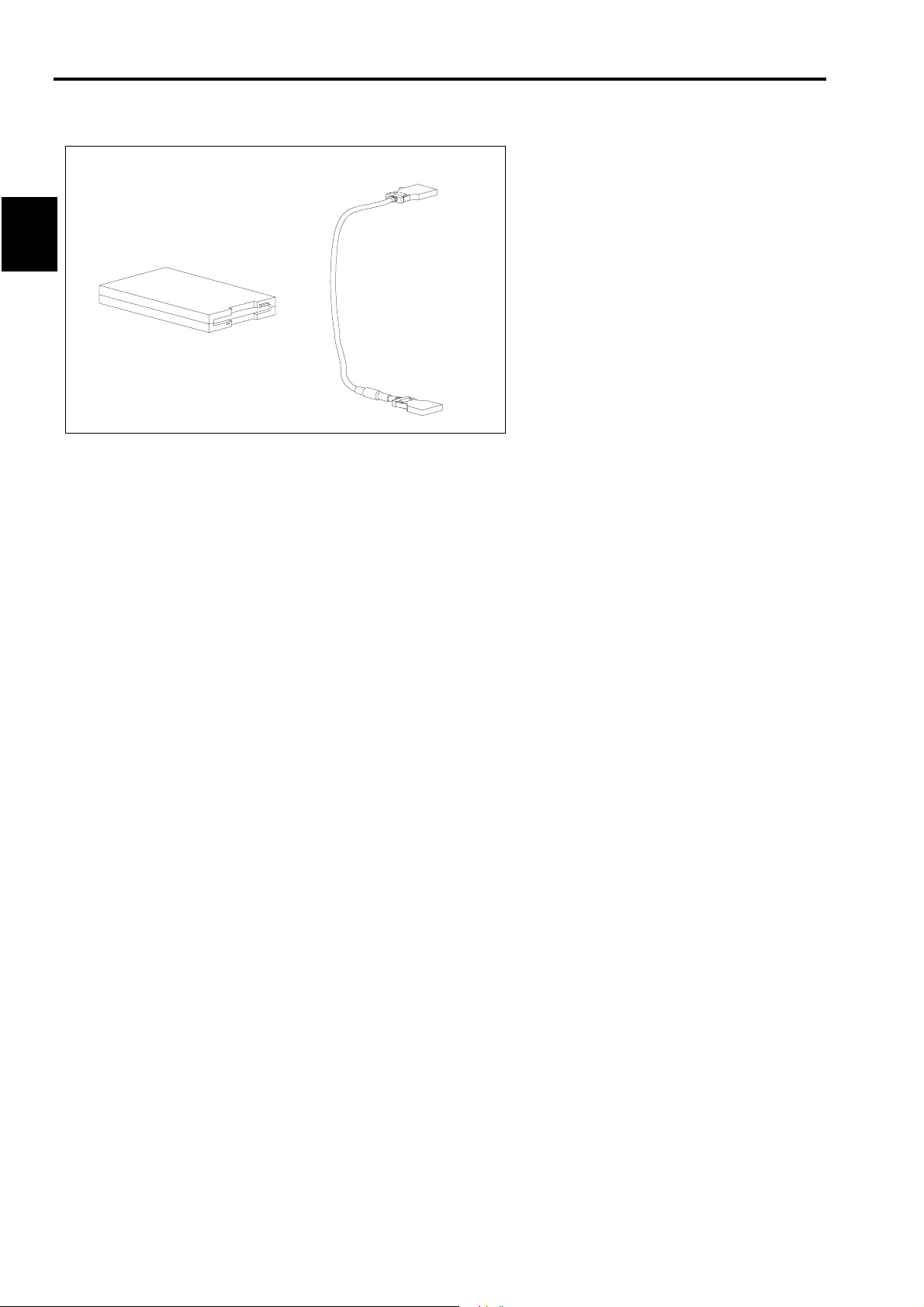

AMC335: FLOPPY DISK DRIVE (TO BE PURCHASED SEPARATELY)

● FDD (floppy disk drive) and FDD connection cable

PART

NAMES

Various kinds of embroidery hoop are available.

Consult your TOYOTA dealer for details.

10

Page 11

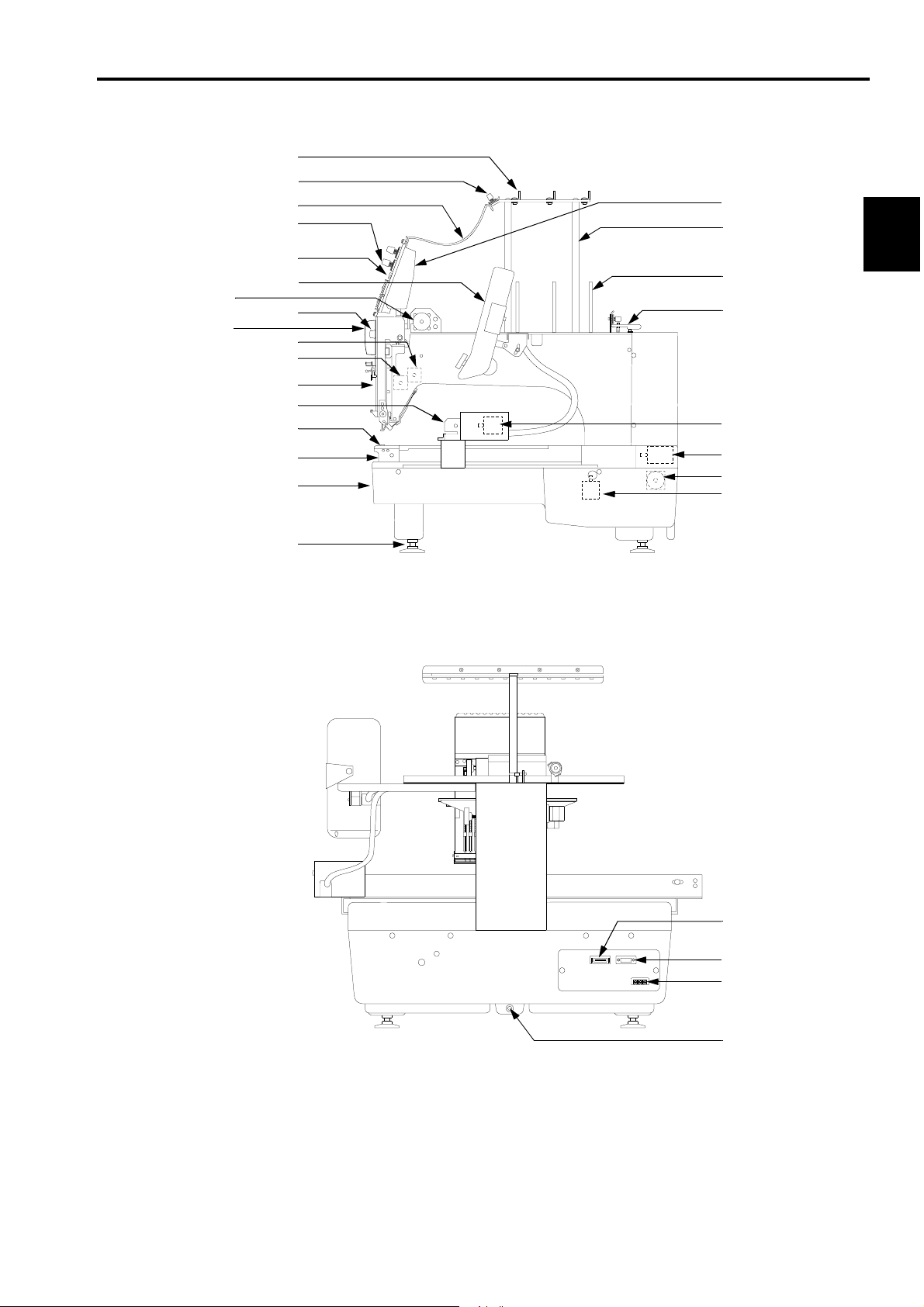

EMBROIDERY MACHINE

Thread guide

Sub thread tension regulator

NAMES

PART

Thread tension regulator

Operation panel box

(For details, refer to Page 12.)

Color change motor

Thread take-up cover

X/Y-axis drive system

Spiral tube

Tension base

Take-up lever

Thread hook motor

Jump motor

Needle bar case

Needle plate

Table

Base

Adjuster foot

Tension base cover

Thread stand shaft

Thread stand stud

Under thread winder

X-axis drive motor

Main shaft motor

Y-axis drive motor

Thread trimming motor

PART

NAMES

11

FDD connection port

Serial connector

Power supply

connector

Drain port

Page 12

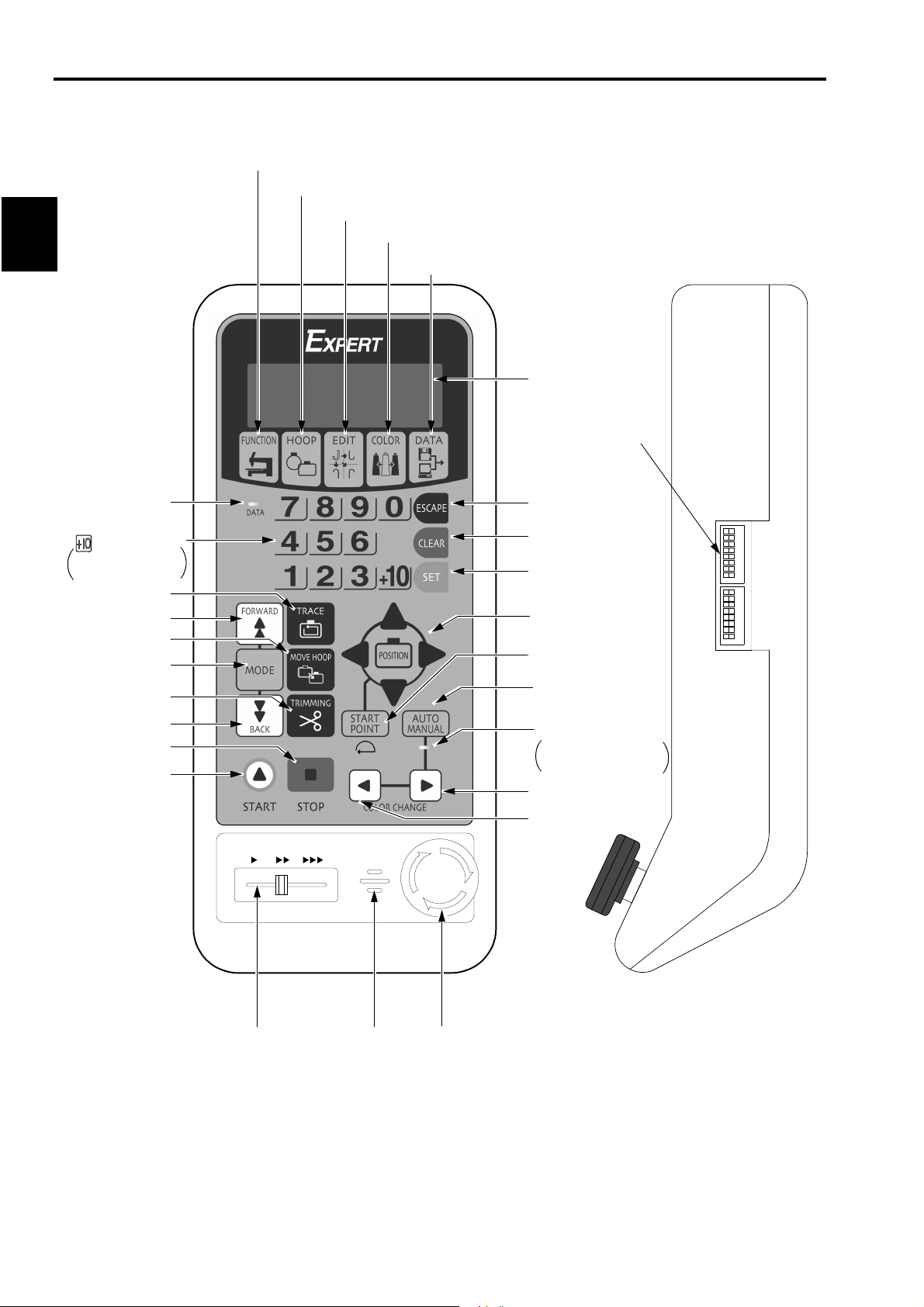

OPERATION PANEL BOX

PART

NAMES

Function menu key

Hoop menu key

Edit key

Color change key

Data set menu key

LCD screen

DIP switches

(For details, refer to

Page 13.)

Ten keys

LED

(numeric keys)

:Used for a

needle bar number

of 10 or larger

Trace key

Hoop forward key

Offset key

Forward/Back

unit selection key

Thread trimming

key

Hoop back key

Stop key

Start ke y

スピード

SLOW FAST

SPEED

非常停止

EMERGENCY STOP

Escape key

Clear key

Set key

Hoop travel key

Start point return key

Color change mode

(automatic/manual) key

Manual lamp

Lights when manual

color change is

selected.

Needle bar case

right-slide key

Needle bar case

left-slide key

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

FD07

Speed adjusting switch Buzzer Emergency stop switch

12

Page 13

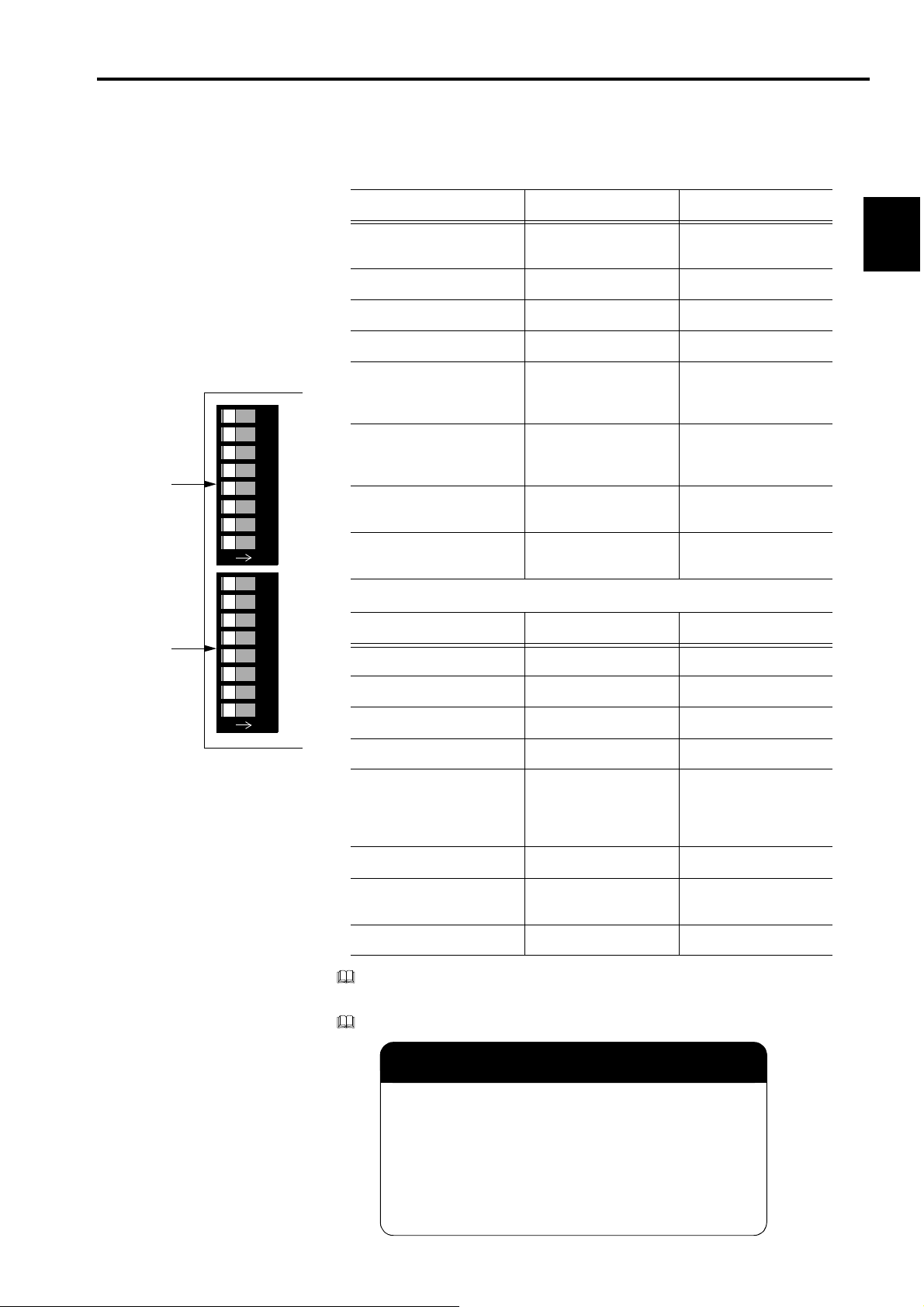

DIP SWITCHES

DIP switch ON or OFF is set as follows:

DSW 2

NAMES

PART

DSW2

1 2 3 4 5 6 7 8

ON

No. Function OFF ON

8 PC connection *Standard

7 Not used *Select OFF. −

6 Not used *Select OFF. −

5 Not used *Select OFF. −

Satin stitch width

4

adjustment

Satin stitch adjust-

3

ment mode selection

Program install

2

device selection

1 Installation mode *Normal mode

*Adjustment for stitch

width of 1.5 mm or

larger

*Collective adjustment

for X- and Y-axis

*FD PC

Two-way communications

Adjustment for stitch

width of 0.6 mm or larger

Independent adjustment for X- and Y-axis

Installation mode if

DSW1-1 is ON.

PART

NAMES

DSW 1

No. Function OFF ON

DSW1

8 Start-up speed *Standard High speed

1 2 3 4 5 6 7 8

ON

7 Not used *Select OFF. −

6 Not used *Select OFF. −

5 Not used *Select OFF. −

Hoop travel direction: Arrow symbols

4

and actual travel

direction

3 Buzzer sounds *10 times 1 time

Language in LCD

2

display

1 Test mode *Normal operation Test mode

After changing the setting of a DIP switch, turn the power switch off once and then

turn it back on.

*Same direction as indi-

cated by the arrow

symbol

*English Japanese

Opposite to the direction

indicated by the arrow

symbol

*: Factory-setting made before shipping

Access to the Embroidery Information

In the test mode, you can access to the following

information:

● Accumulated number of embroidered pieces of cloth

● Accumulated number of stitches

● Accumulated number of error displays and others

Consult your TOYOTA dealer for more details.

FD07

13

Page 14

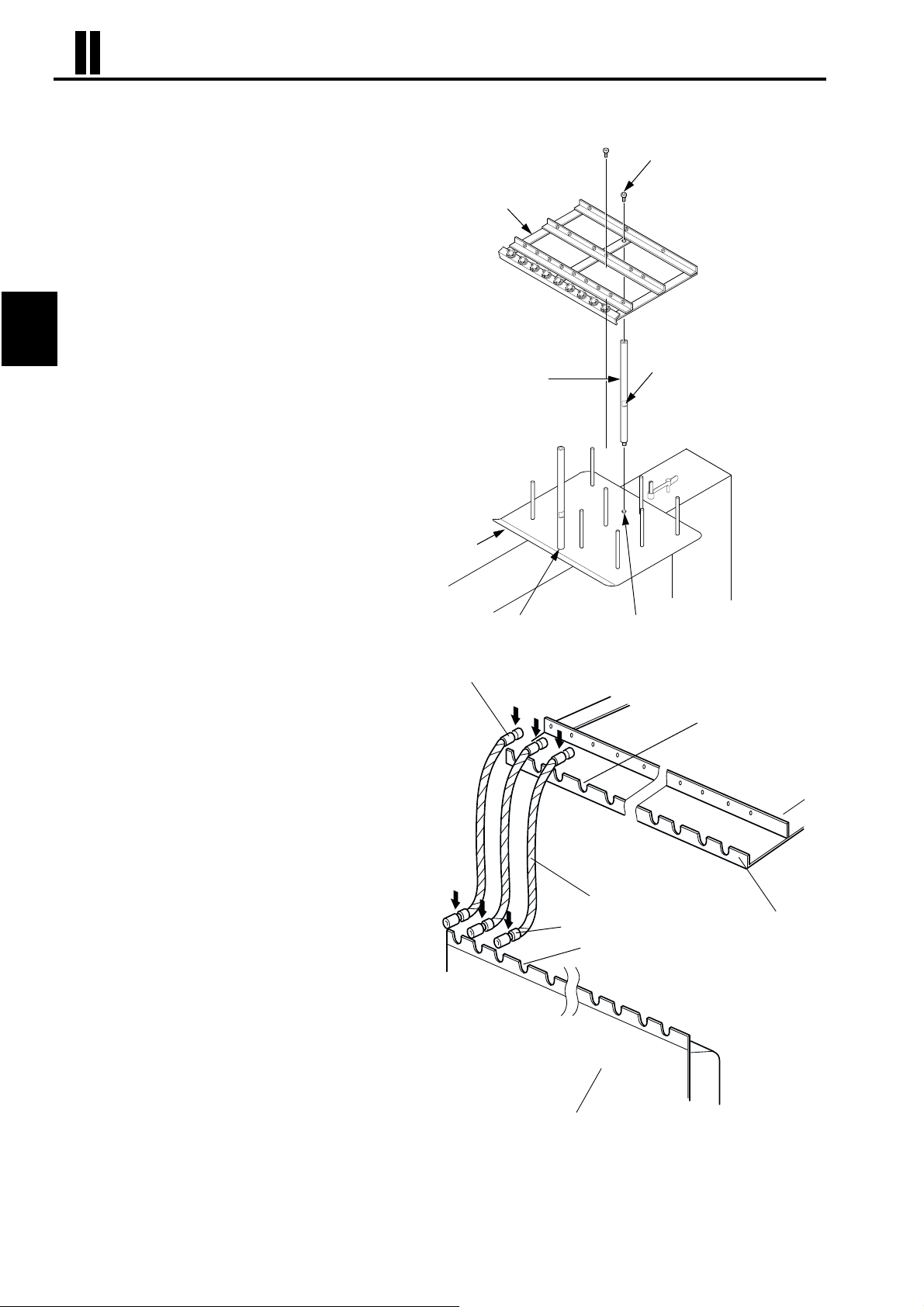

PREPARATION

ASSEMBLING

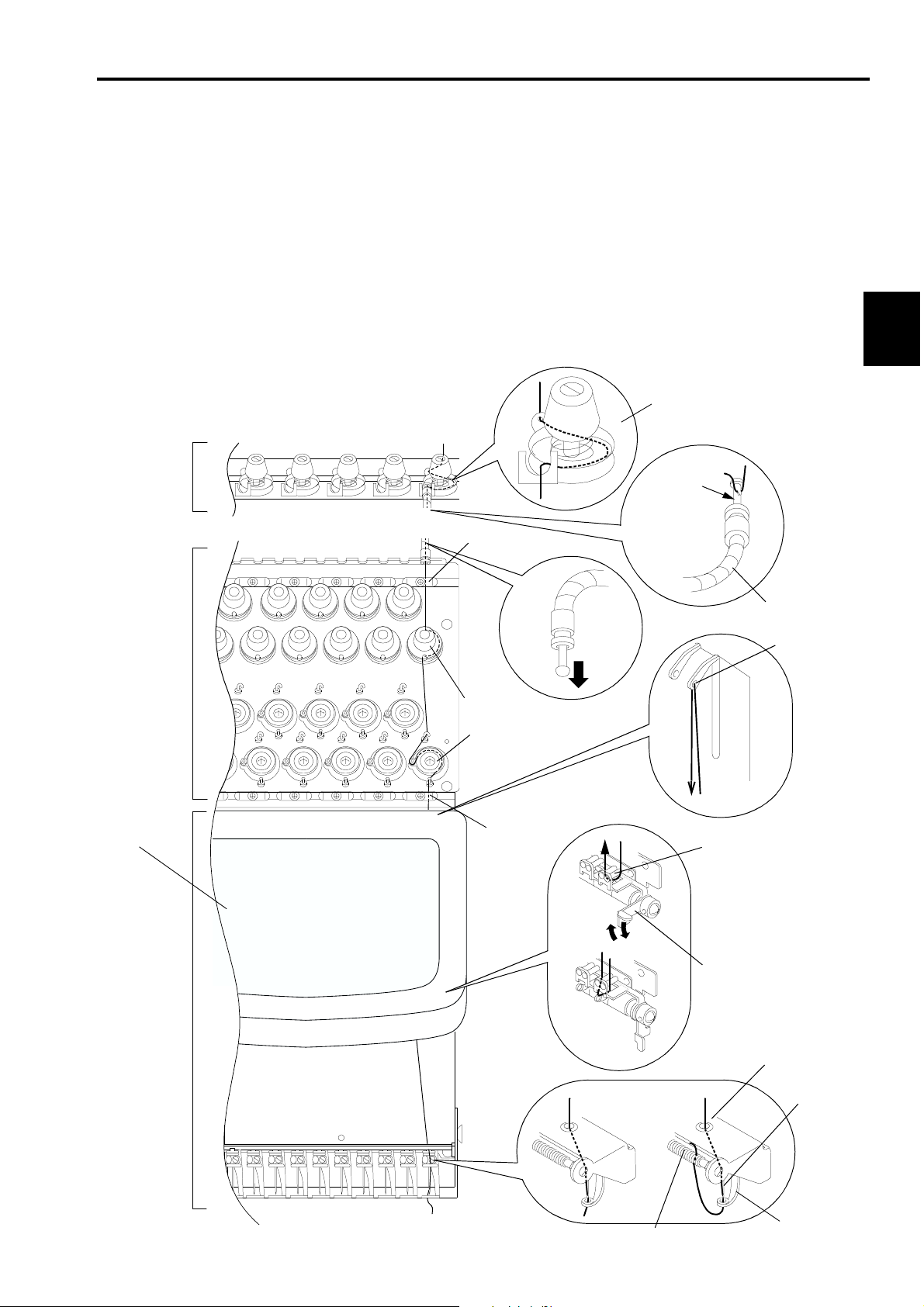

● Attaching the thread guide

1. Stand the thread stand shafts (1) (2 pcs. in

total) on the thread stand plate (2) perpendicular to it by screwing in the shaft at positions A

and B on the plate (2). Securely tighten the

thread stand shafts (1) by the spanner set on

the flats at the middle of the thread stand shaft

(1) to fix them on the thread stand plate (2).

2. Place the thread guide (4) on top ends of two

thread stand shafts (1), and align the two holes

PREPARATION

at the center of the thread guide (4) with the

thread stand shafts (1). Insert then hexagon

socket head cap screws (5) in the holes and

securely tighten the screws to lock the guide

and the shafts.

Thread guide (4)

Thread stand shaft (1)

Thread stand

plate (2)

Hexagon socket head

cap screw (2 pcs.) (5)

Flats

● Mounting the spiral tubes

1. Place the joint on the one end of spiral tube

(large) in the U-shaped slot on the thread guide

and fix it in the slot by pressing in the arrow

direction. Set and fix the joint on the other end

of spiral tube in the U-shaped slot on the tension base in the same way. Repeat the same

steps on the U-shaped slots as numbered (1) to

(3) and (13) to (15) in the figure shown at right.

Spiral tube (large): No. 1 to No. 3/

No. 13 to No. 15

2. In the similar manner, fit the spiral tube B

(medium) into the U-shaped slots.

Spiral tube (medium): No. 4, No. 5,

No. 11 and No. 12

3. In the similar manner, fit the spiral tube

(small) into the U-shaped slots.

Spiral tube (small): No. 6 to No. 10

Tube joint

(1)

(2)

A B

(1)

(2)

(3)

(4)

Tube joint

(3)

(4)

(5)

(12)

(5)

(12)

Spiral tube (large)

U-shaped slots

(13)

(14)

(15)

U-shaped slots

(13)

(14)

(15)

Thread guide

14

Tension base

Page 15

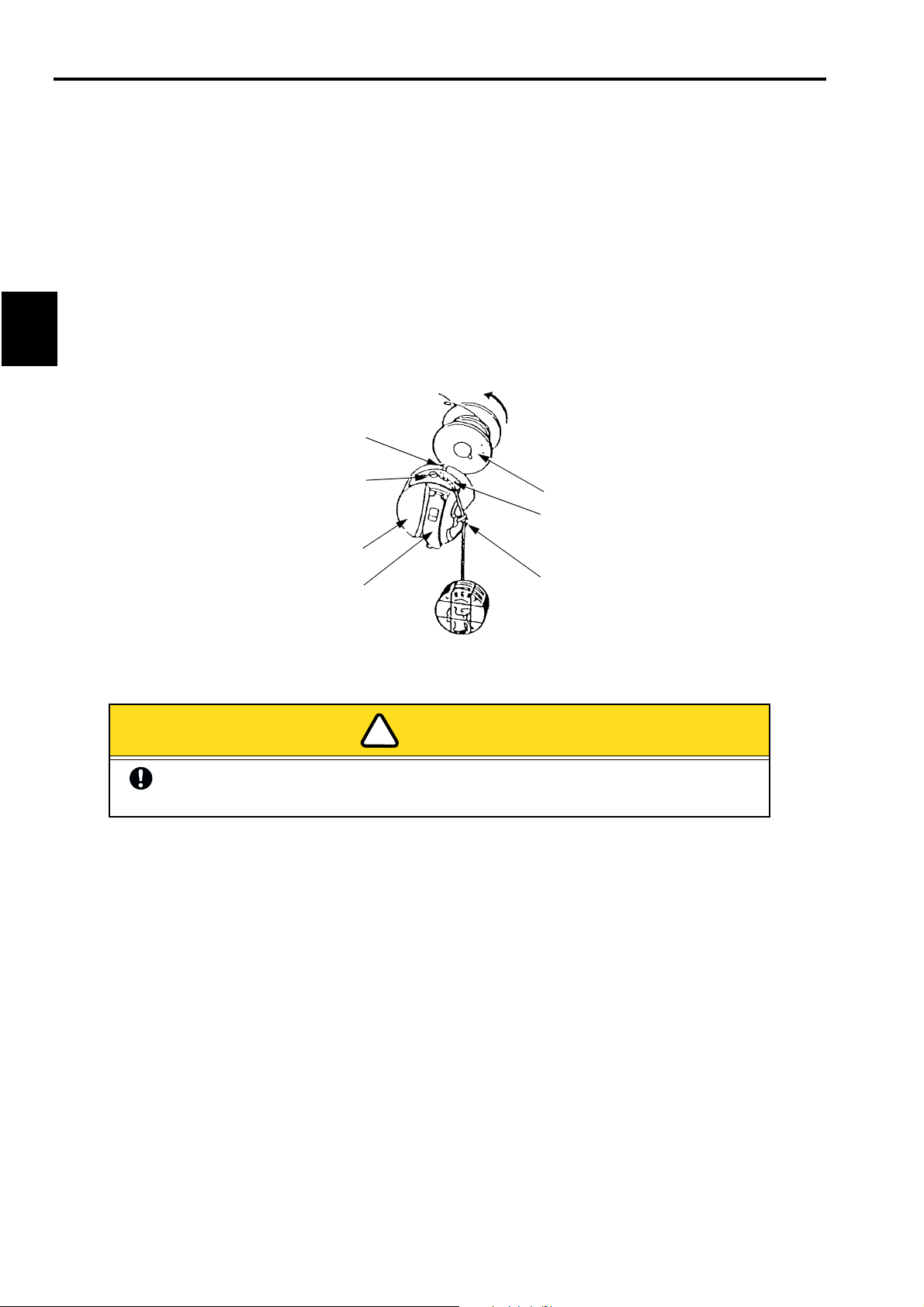

CARRYING

As shown in the illustration below, hold the machine at the positions indicated in the label by two or more persons to carry the machine.

Machine holding position

(indicated in the label)

INSTALLATION

Place the embroidery machine on a rugged base so that the table will be level.

At this time, make sure to place attached vibration-preventive rubbers (H)

under the adjuster foot (1). The rubbers will effectively prevent the machine

from moving on the table or vibrating.

If the machine is not stable or it is not level, adjust the level of

the machine after loosening the nut (2) (4 places) of the adjuster

foot (1). After adjusting the machine level, tighten the nut (2) to

lock the adjuster foot.

WARNING

!

CARRYING

Carry the machine with

at least two people.

DO NOT hold it by parts

other than those specified.

Dropping may cause bodily

injury and will damage

the machine.

ATTENTION

!

Il faut être au moins 2personnes

pour porter la machine.

Ne pas tenir la machine par

une autre partie que celle

indiquées.

Une chute peut vous blesser

et endommager la machine.

Machine holding position

(indicated in the label)

PREPARATION

Table top face

Vibration-preventive rubber (H)

Nut (2)

Vibration-preventive rubber (H)

Base (must be level)

Adjuster foot (1)

15

Page 16

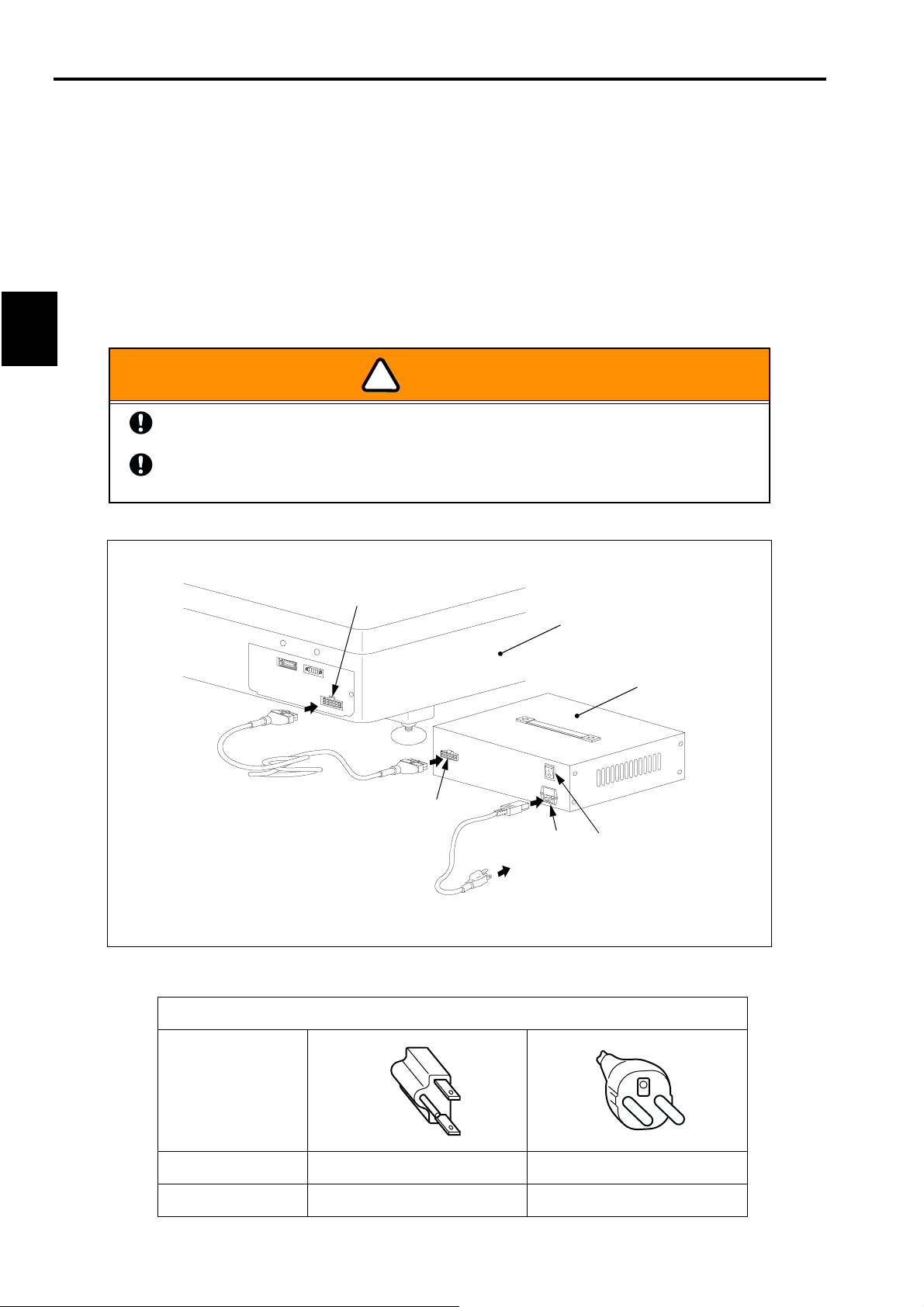

WIRING

1. Make sure that the power switch (2) of the power supply box (1) is OFF.

2. Insert the plug (4) of the DC power cord (3) securely into the power supply connector (5) of the embroidery

machine.

3. Insert the other plug (6) of the DC power cord (3) securely into the DC power supply connector (7) of the power

supply box (1).

4. Insert the plug (9) of the AC power cord (8) securely into the AC power supply connector (10) of the power supply

box.

5. Insert the plug (11) at the other end of the AC power cord (8) securely into the single-phase 100 to 240 V power

supply.

PREPARATION

WARNING

!

PREPARATION

Connect the earth wire of the AC power cord to the earth terminal

It could cause electric shock unless the machine is grounded properly.

The mains plug must be accessible after it is connected to the supply socket, so that it can easily

be disconnected in an emergency.

(5)

Embroidery machine

Power supply box (1)

(4)

DC power cord (3)

AC power cord (8)

(6)

(7)

(9)

(10)

Power switch (2)

AC power source

(to the receptacle with earth terminal)

(11)

(Switch: OFF position)

Types of AC Power Cord

Plug

Spec. USA and Canada EU

Voltage Rating 125 V 250 V

16

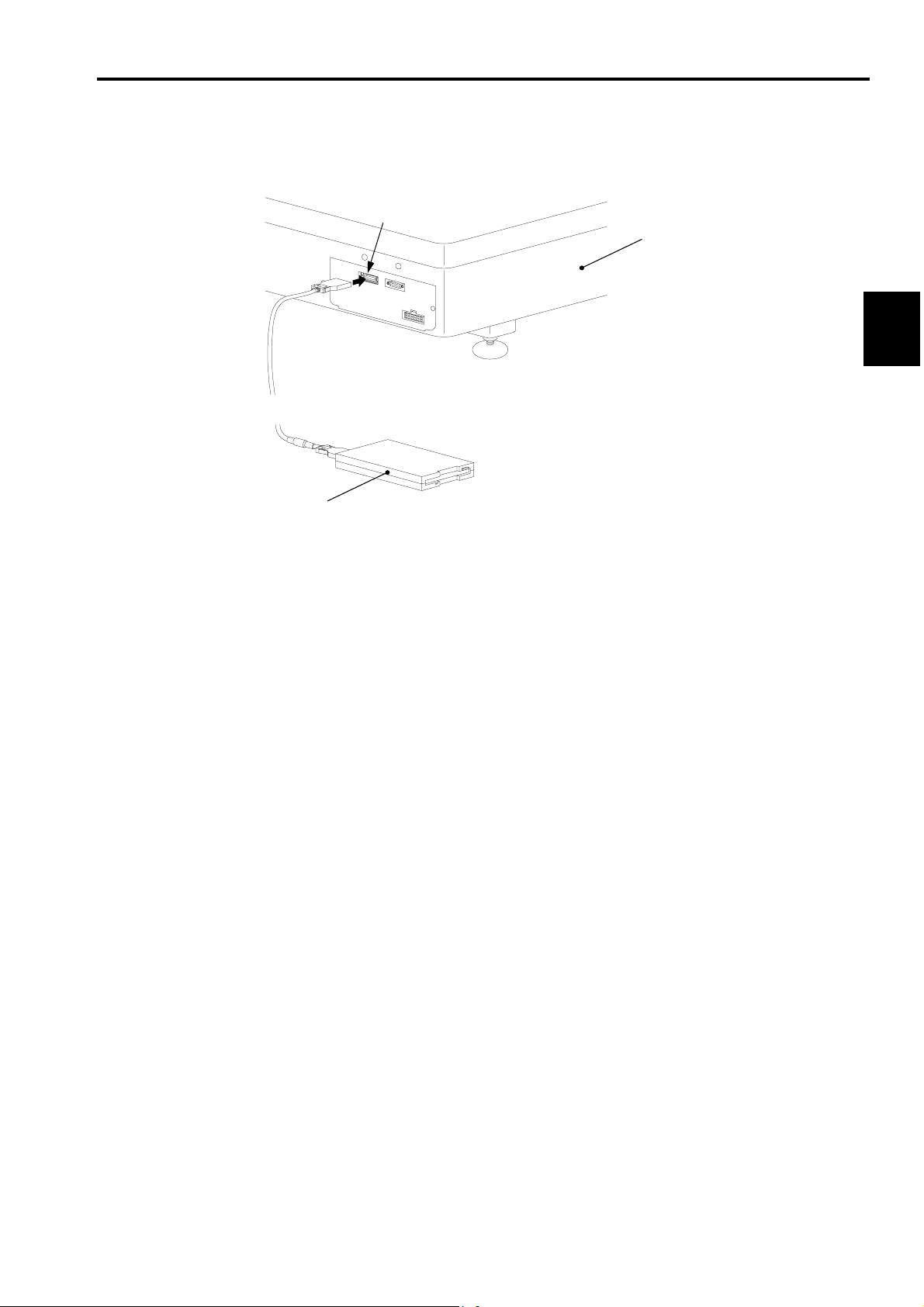

Page 17

CONNECTING THE FDD (FLOPPY DISK DRIVE) (TO BE PURCHASED SEPARATELY)

1. Insert the plug (2) of the FDD connection cable (1) securely into the FDD connector (3).

2. Insert the plug (4) at the other end of the FDD connection cable (1) securely into the connector of the FDD.

(3)

Embroidery machine

(2)

FDD connection cable (1)

(4)

FDD

PREPARATION

17

Page 18

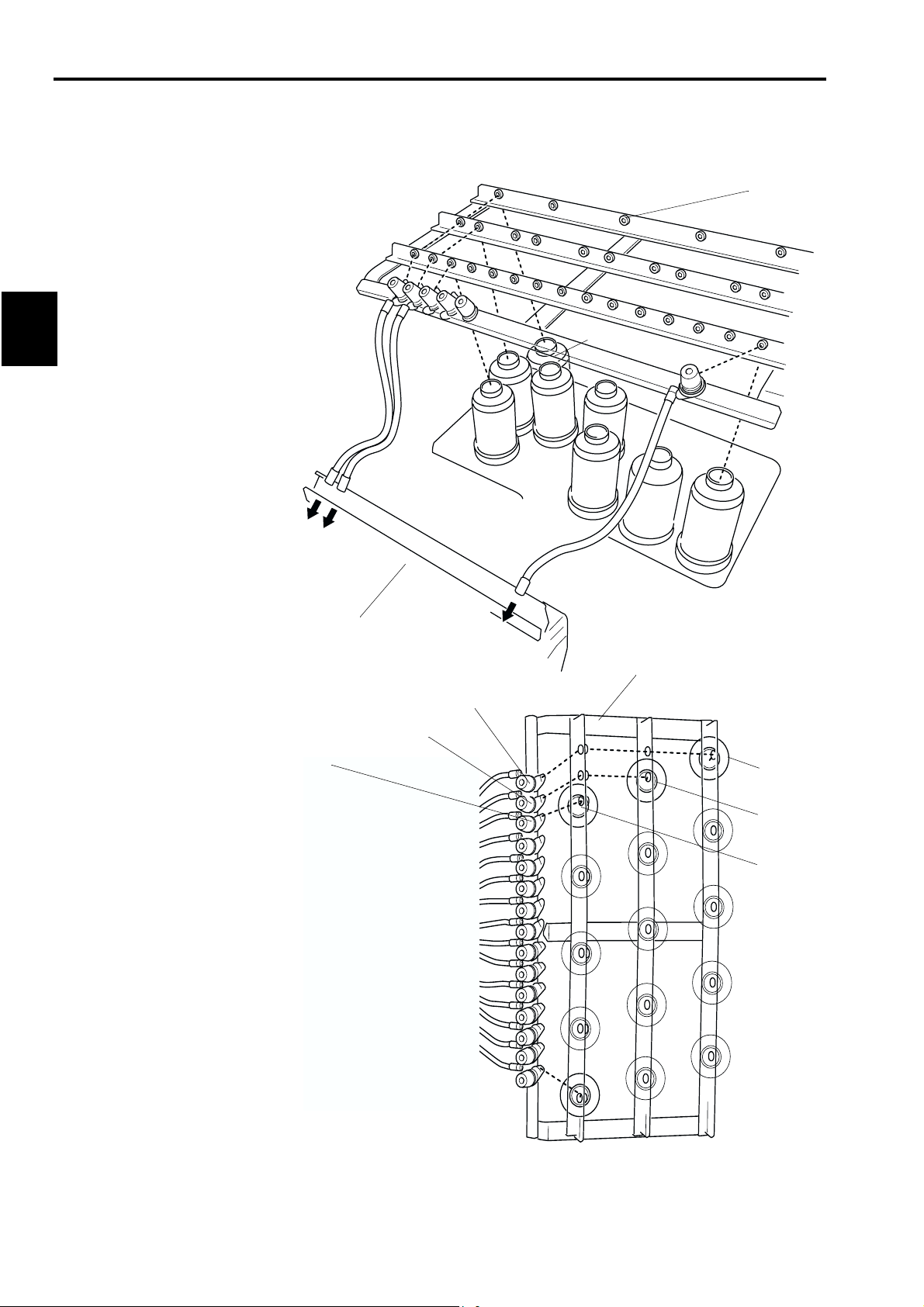

SETTING THE UPPER THREAD

Upper Thread Setting

Procedure

1. Pass the thread from the

spool (1) through the hole

on the thread guide (1)

just above the spool (1)

and further pass it through

thread guides at the middle and front rows.

2. Pass next the thread

through the sub thread

PREPARATION

tension regulator (1).

3. For spools (4), (7), (10)

and (13), set the thread in

the same manner up to

the sub thread tension

regulators of the same

number.

4. Pass the thread from the

spool (2), at the middle

row, through the hole on

the thread guide (2) just

above the spool (2) and

further pass it through the

thread guide at the front

row.

5. Pass the thread through

the sub thread tension

regulator (2).

6. For spools (5), (8), (11)

and (14), set the thread in

the same manner up to

the sub thread tension

regulators of the same

number.

7. Pass the thread from the

spool (3), at the front row,

through the hole on the

thread guide (3) just above

the spool (3).

8. Pass next the thread

directly through the sub

thread tension regulator

(3).

9. For spools (6), (9), (12)

and (15), set the thread in

the same manner up to

the sub thread tension

regulators of the same

number.

Fig. A Passing the Upper Thread:

Spool to Thread Guide

Tension base

Sub thread tension regulator (1)

Sub thread tension regulator (2)

Sub thread tension regulator (3)

(2)

(1)

(3)

(5)

(4)

(6)

(8)

(9)

Spool (1)

(6)

(9)

(12)

(15)

(7)

(12)

Thread guide

(11)

(5)

(8)

(11)

(14)

Thread guide

(10)

(13)

(14)

(15)

PREPARATION

Rear rowMiddle rowFront row

Spool (1)

Spool (2)

(4)

Spool (3)

(7)

(10)

(13)

18

Page 19

10. Run the thread from the sub thread tension regulator (15) through the spiral tube (15).

11. Run the thread further through the thread guide (15)-1, thread tension regulator (15) rotary sensor (15) and thread

guide (15)-2.

12. Open next the needle bar case cover.

13. Raise the thread holder lever (GL), hook the upper thread on the thread holder (15) from right to bottom and pass

the thread through the hole of take-up lever (15) at the top.

14. After that, run the thread down and through the thread guide (15)-3, then through the hole of the needle (15) and

finally through the hole in the presser foot (15).

15. Hook next the thread end on the thread holding spring.

16. Set the thread of spools (14) to (1) in the same manner. Finally, push down the thread holder lever (GL) down to

finish the setting of upper thread.

Fig. B Passing the Upper Thread:

Thread Guide to Needle

Sub thread tension regulator (15)

PREPARATION

Thread guide

Tension base

Needle bar

case cover

Threader

Thread guide (15)-1

Spiral tube (15)

Take-up lever (15)

Thread tension

regulator (15)

Rotary sensor (15)

Thread guide (15)-2

Thread holder (15)

TOYOTA

EXPERT ESP9000

Needle bar

case

19

Thread holder spring

Thread holder lever

Thread guide (15)-3

Needle (15)

Presser foot (15)

(GL)

Page 20

SETTING THE UNDER THREAD

1. Orient the bobbin (1) with its thread facing in the direction, specified by the arrow symbol, and put it in the bobbin

case (2).

2. Route the thread through the thread groove (3) in the bobbin case, under the thread tension spring (4) and the

thread guard (5).

3. Raise the "lever" (6) on the bobbin case and then install it in the rotary hook.

NOTE: The standard under thread tension is 25 to 30 g (0.25 to 0.3 N) for the carbonized yarn #120.

The thread tension can be adjusted with the tension adjusting screw of the bobbin case. Turning the screw

clockwise tightens the thread and turning it counterclockwise loosens the thread tension.

For adjustment, suspend three 25-cent coins from the bobbin case by taping them to the thread as shown in

PREPARATION

the illustration below. If thread is pulled out slightly when the bobbin case is gently shaken up and down, the

thread tension is between 25 and 30 g (0.25 and 0.3 N).

Thread groove (3)

PREPARATION

Tension adjusting screw

Bobbin case (2)

Lever (6)

CAUTION

!

Before setting or removing the bobbin, be sure to turn OFF the power switch.

Otherwise, the embroidery machine may start causing injury of operators.

Bobbin (1)

Tension spring (4)

Thread guard (5)

20

Page 21

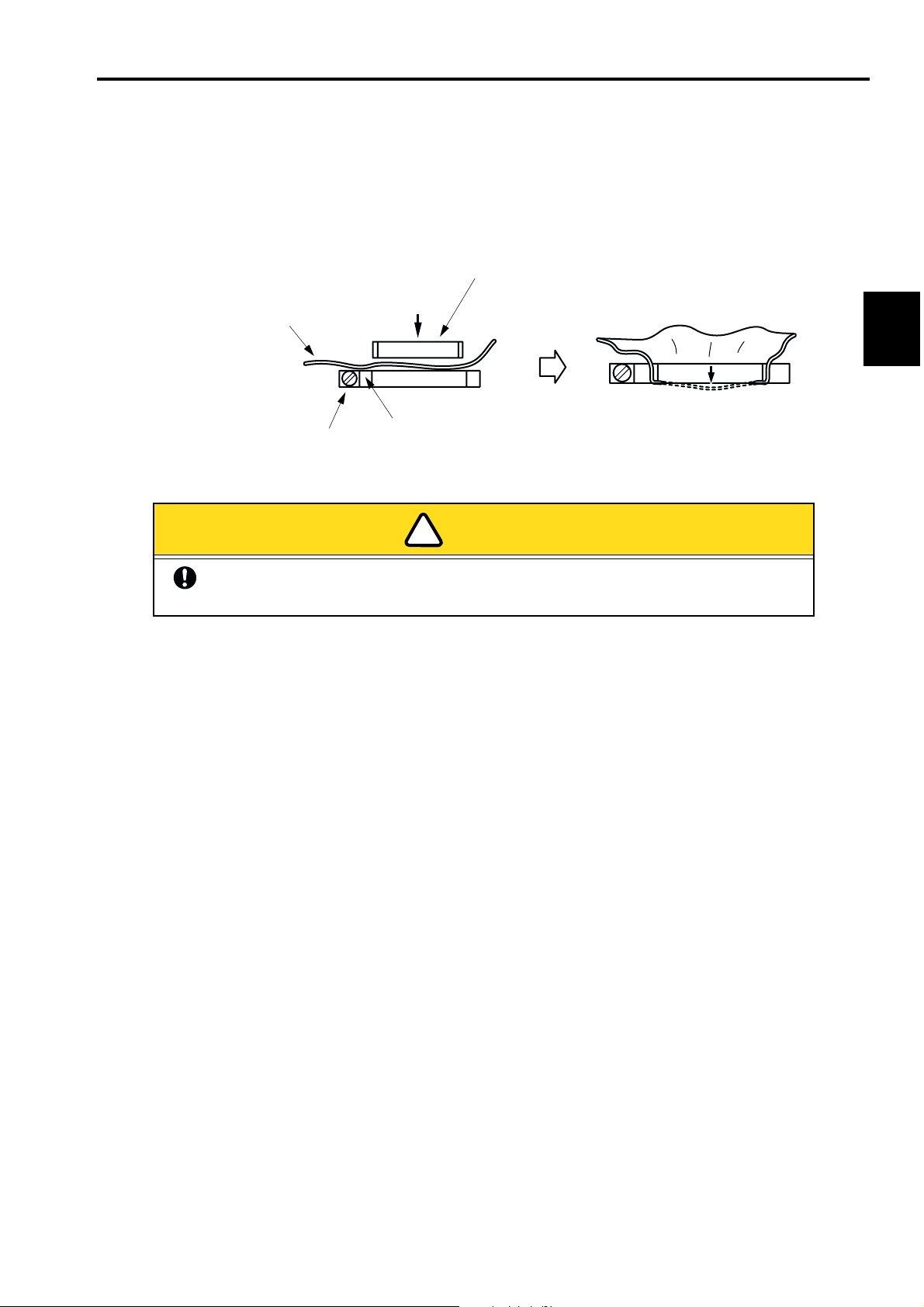

SETTING THE FABRIC ON THE HOOP

1. Place the fabric (2) on the outer hoop (1) and press the inner hoop (3) into the outer hoop (1).

If the inner hoop (3) cannot be pressed into the outer hoop (1) smoothly, loosen the hoop set screw (4).

2. Check if the fabric is correctly set in the hoop by pressing the center of the fabric gently with the finger as shown

in the illustration below. The fabric should be stretched so that it returns to the state as before when the finger is

released.

Inner hoop (3)

Fabric (2)

(Checking the setting of fabric)

Embroidery hoop set screw (4)

Outer hoop (1)

!

CAUTION

PREPARATION

Make sure there is no hard item such as a button in the embroidery range.

Otherwise, the needle may be broken causing injury of operators.

21

Page 22

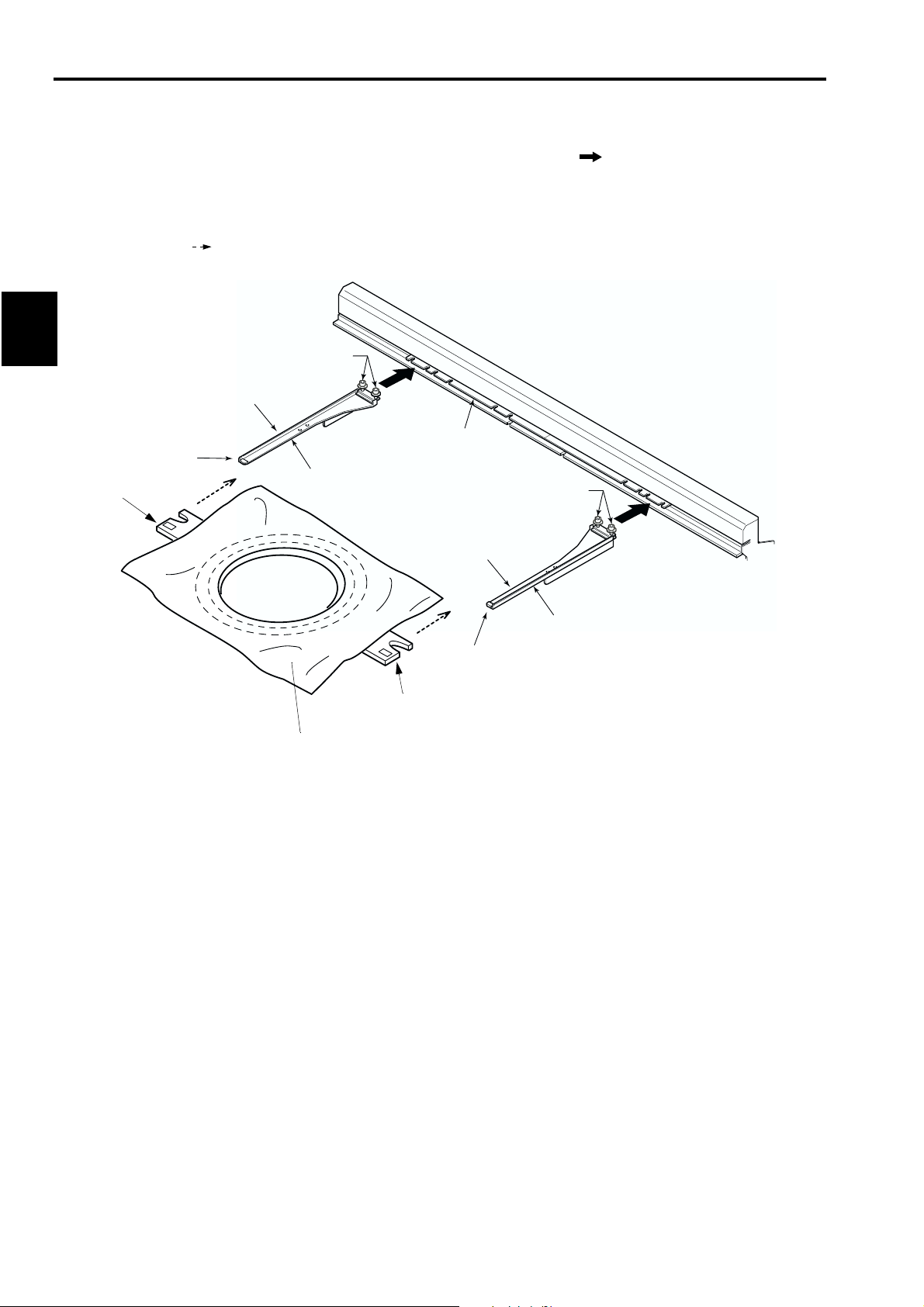

SETTING THE HOOP TO THE EMBROIDERY MACHINE

1. Attach two holder bases (1) to the joint plate (2) in the direction indicated by symbol and secure them in place

with screws (3).

Determine the holder base (1) attaching position meeting the size of the hoop.

2. Insert the right and left metallic tabs of the embroidery hoop set in the sections A and B in the direction of dashed

line arrows and fix the tabs by engaging the hoop presser springs (4) of the holder bases (1) in the tabs.

PREPARATION

Right hoop metallic tab

Screw (3)

Hoop presser spring (4)

A

Holder base (1)

Embroidery hoop set

PREPARATION

Joint plate (2)

Screw (3)

Hoop presser spring (4)

Holder base (1)

B

Left hoop metallic tab

22

Page 23

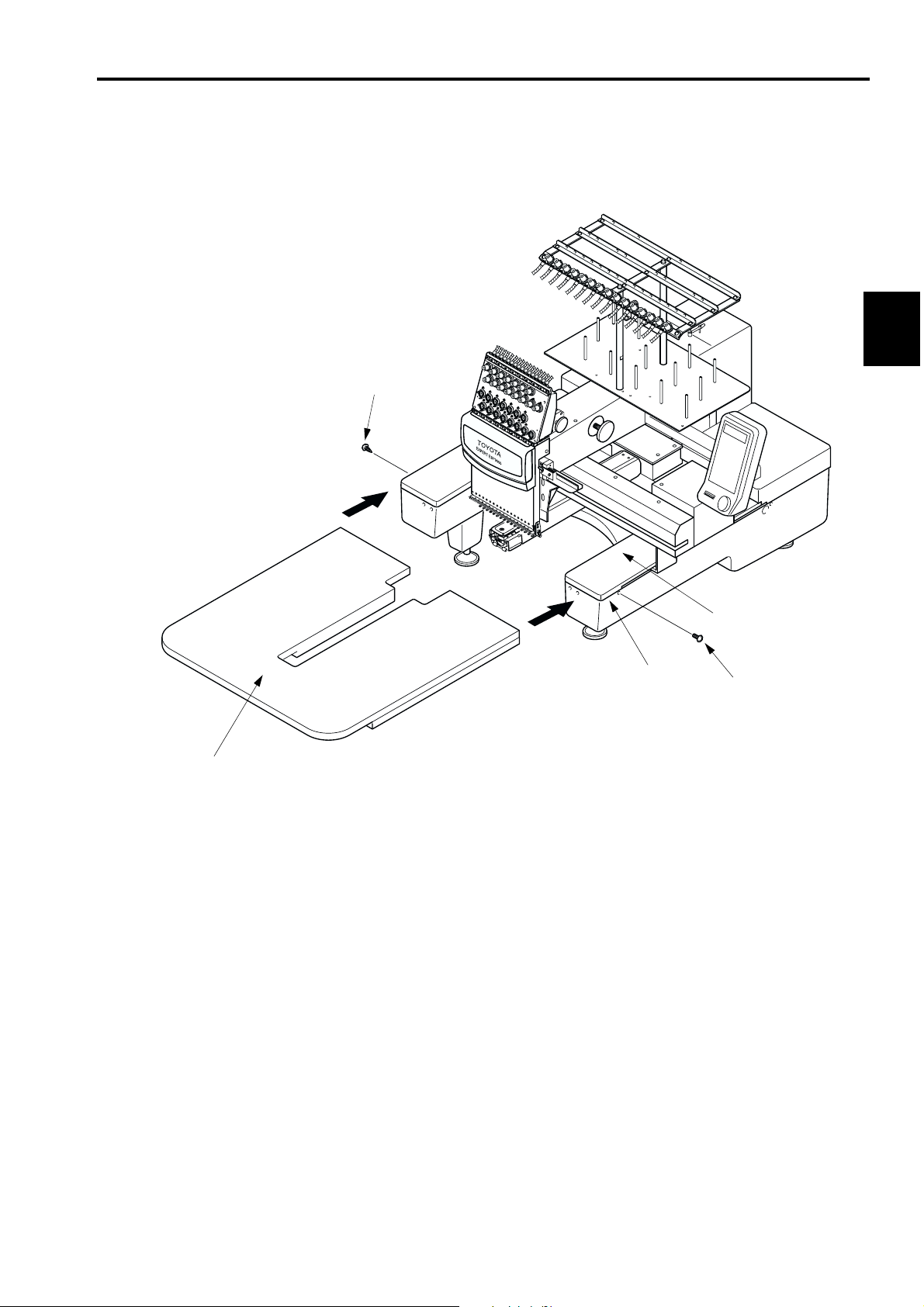

ATTACHING THE TABLE

1. Push in the table (1) till it hits the bottom with care to maintain equally at both right and left of top of the base cover

(2) on the embroidery machine.

2. Tighten the right and left fixing screws (3). This completes the attaching of the table.

Fixing screw (3)

PREPARATION

Base

Table (1)

DIP SWITCH SETTING

Set DSW1-2 at ON to change the LCD indicator on the operation panel box to the display in Japanese.

Base cover (2)

Fixing screw (3)

23

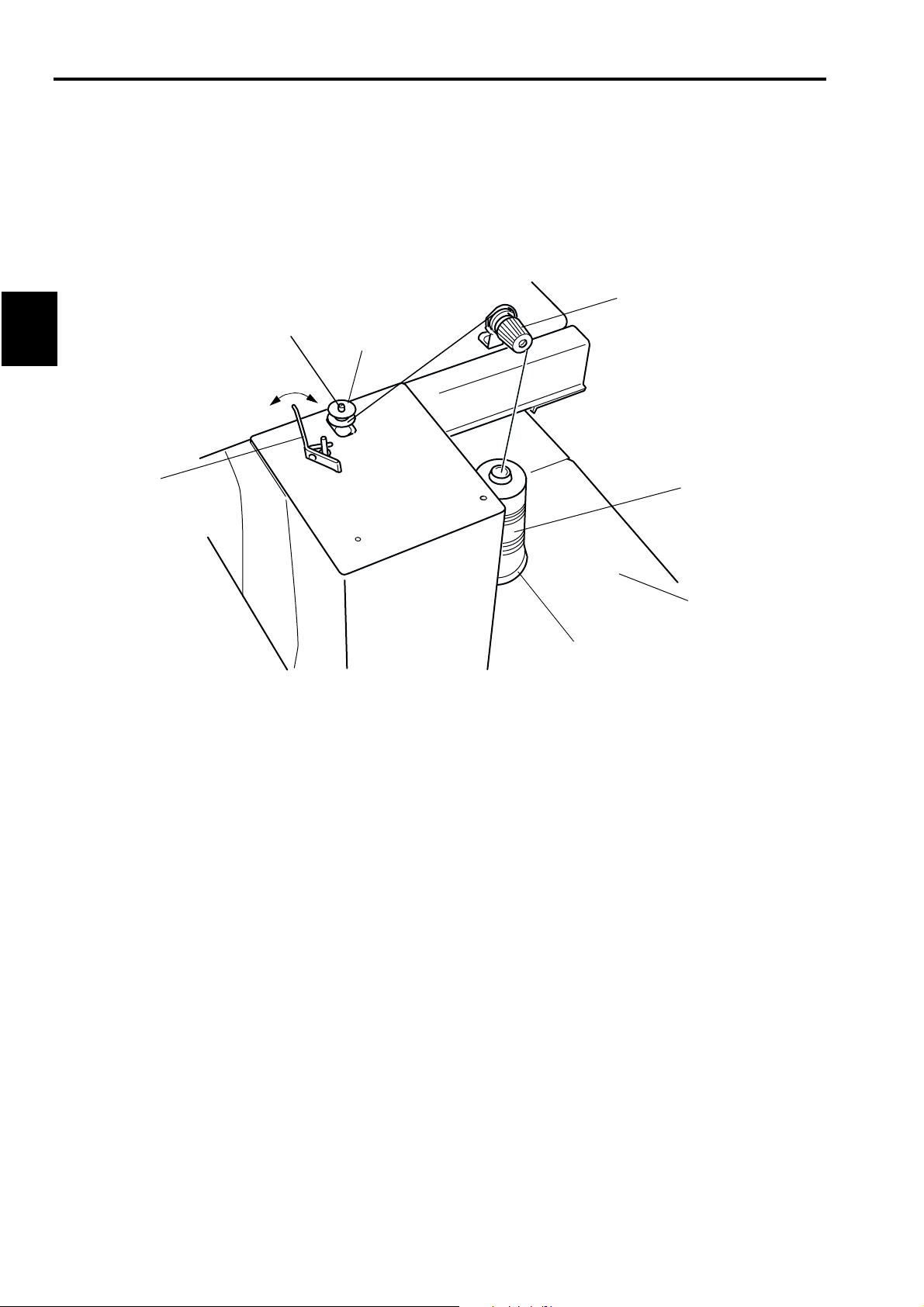

Page 24

WINDING THE UNDER THREAD

1. Set a bobbin (2) on the under thread winding shaft (1).

2. Place the spool (3) on the spool stand on the cover, pass the thread end through the thread tension regulator

guide (4) and wind the thread round the bobbin (2).

3. Press the thread winder lever (5) to the right so that it touches the inner face of the bobbin (2).

4. Thread is wound on the bobbin as the machine operates and the lever automatically returns back (turning to the

left) when a certain amount of thread is wound on the bobbin to stop winding of the under thread.

Thread tension

regulator guide (4)

Under thread winding shaft (1)

Bobbin (2)

PREPARATION

PREPARATION

Thread winder lever (5)

Spool stand

Spool (3)

Cover

Under thread may be used up during embroidery. In this case, set the under thread in the same manner as

explained above.

24

Page 25

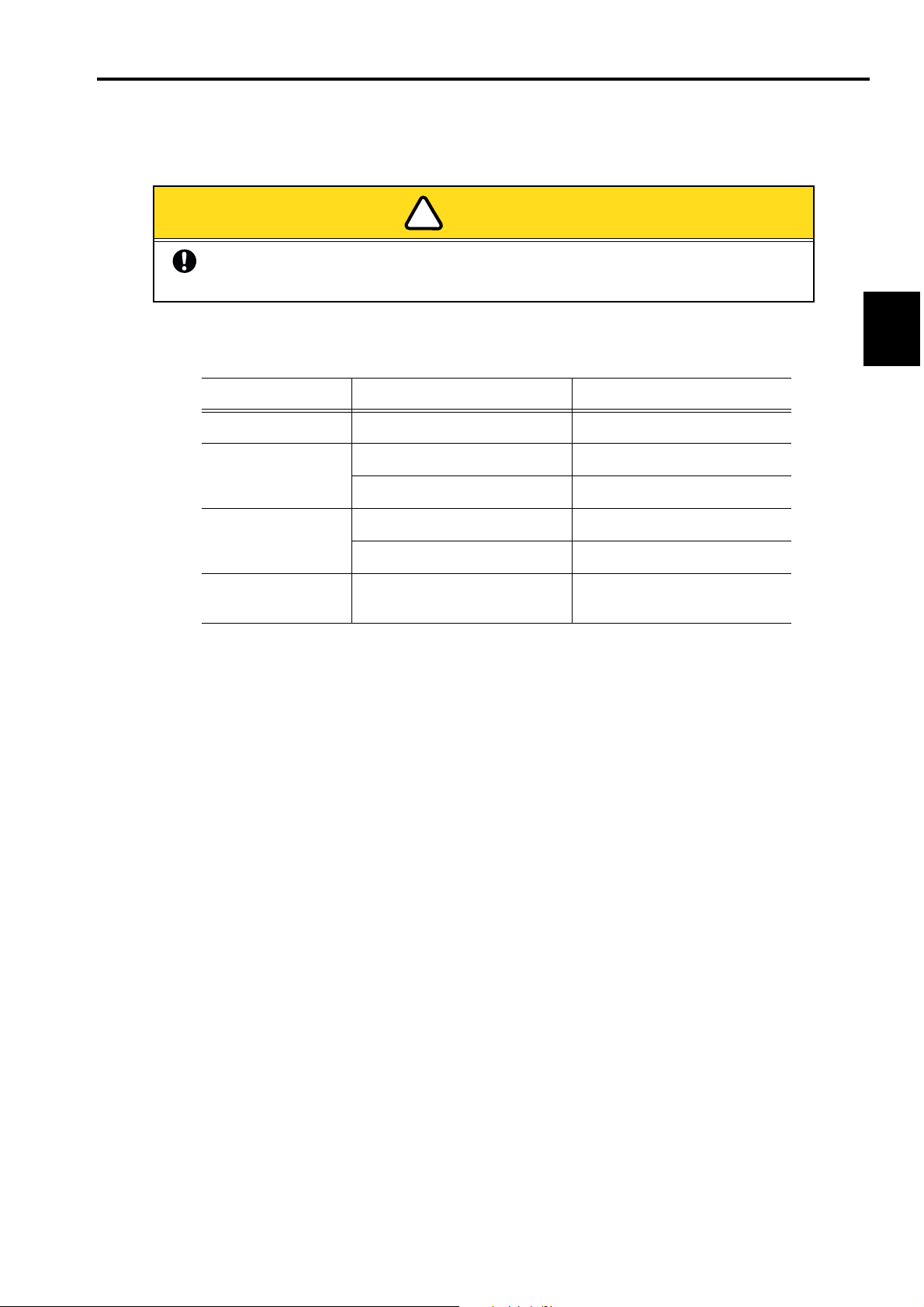

CHECKUPS BEFORE STARTING OPERATION

Before starting the machine, carry out checkups as indicated below.

CAUTION

!

Turn the main switch OFF before checking the machine prior to starting the operation.

If you check the machine without turning the main switch OFF, you could sustain injury.

Check Point Description Action

Covers Check for disengagement. Install if disengaged.

Check for disengagement. Set if disengaged.

Thread

Check for breakage. Set if broken.

Check for bend. Replace if bent.

Needle

Check for breakage. Replace if broken.

PREPARATION

Rotary hook rail

Check if appropriate amount of

oil applied.

Lubricate as required.

FD07

25

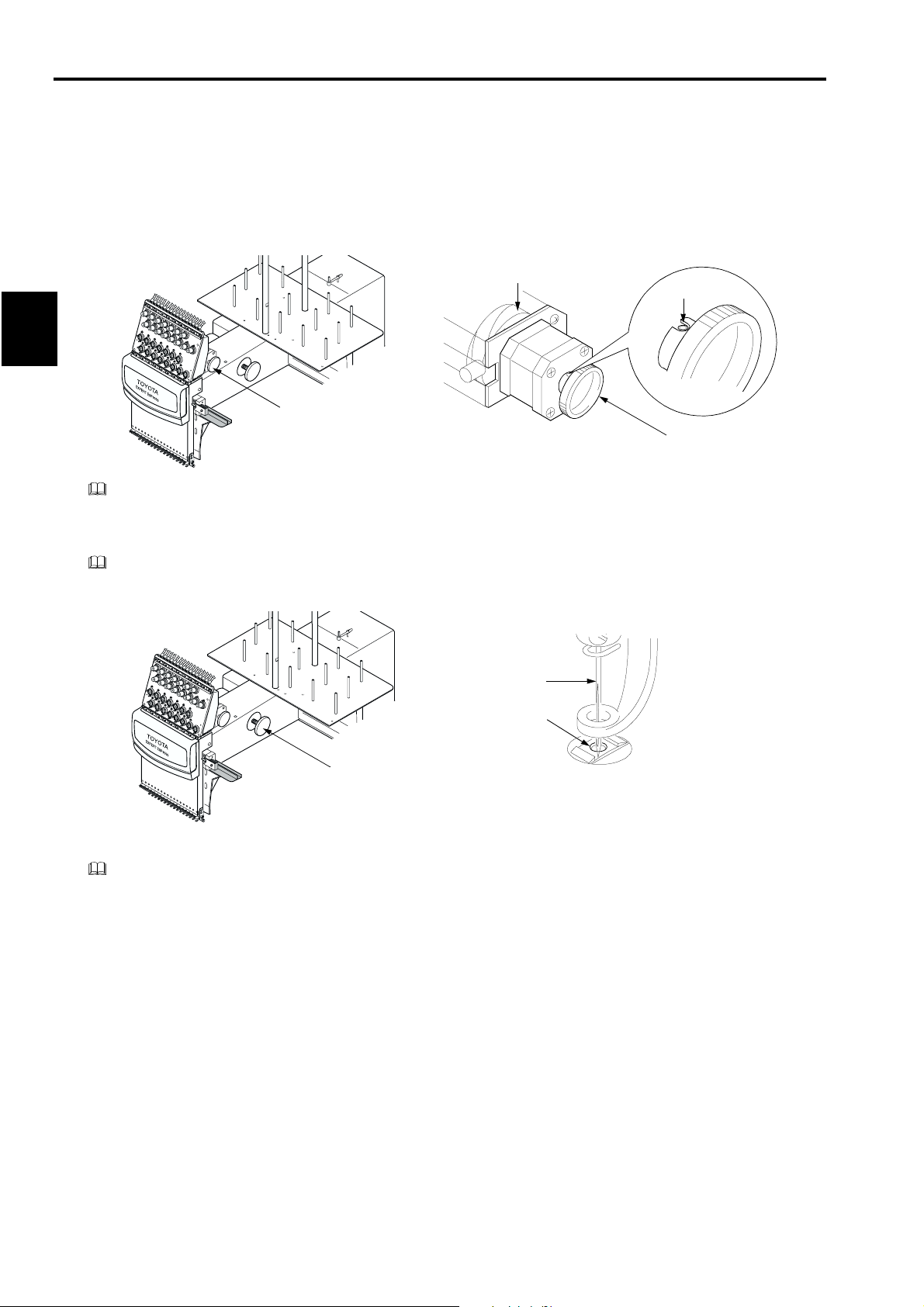

Page 26

CHECKING THE EMBROIDERY HEAD

Check of the Color Change Device and Set Screw

The color change device selects needle bars. The machine will fail to operate if the color change cam is off the predetermined position (set screw is positioned right above or right below).

1. Turn the handle of the color change device to bring the set screw to the top position.

Color change cam will be set at the fixed position.

Color change cam

PREPARATION

Color change device

When the set screw of the handle is at the top position, an odd-numbered needle bar is selected.

Check of Needle Lowered Position

Check the needle lowered position only after checking the set screw position.

1. Turn the main shaft handle counterclockwise while pressing it against the arm.

2. When the needle enters the needle hole, check the needle location.

Needle hole

Set screw

PREPARATION

Handle

Needle

Handle

3. Make sure that the needle is located at the center of the needle hole.

If the needle is not positioned at the center, the needle could be bent. Replace it if necessary.

FD07

26

Page 27

OPERATION PROCEDURE

《《《《OPERATION BASICS》》》》

STARTING AND STOPPING THE MACHINE

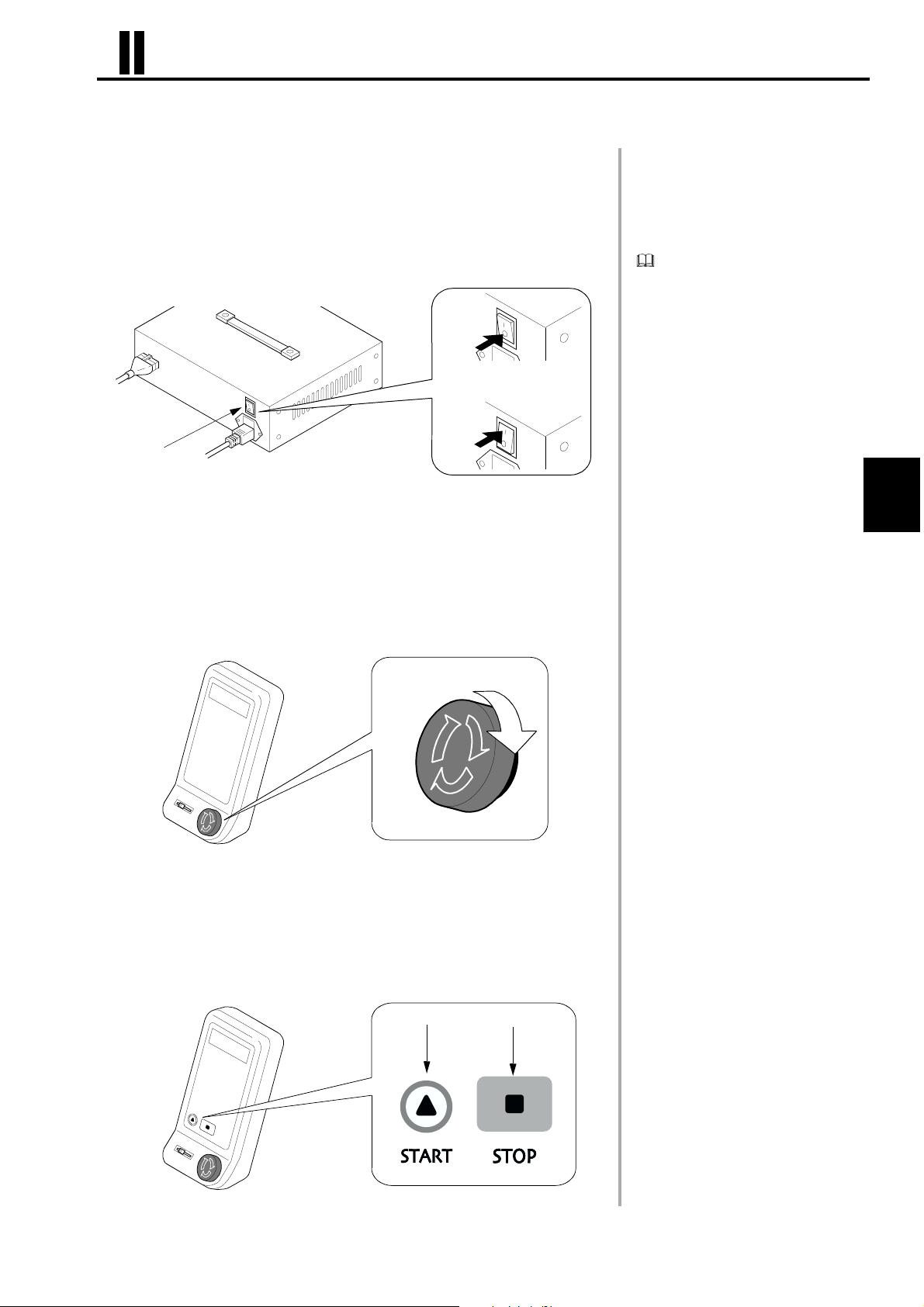

Power Switch

The power switch is provided on the power supply box.

Press the power switch at "O" side to turn the power OFF or at "I" to turn the

power ON.

OFF

ON

Power switch

When reapplying the power, turn

the switch OFF and then turn it

back ON after several seconds.

EMERGENCY STOP Switch

Use the EMERGENCY STOP switch to stop the machine in an emergency.

When the EMERGENCY STOP switch is pressed, the main shaft stops rotating

and the EMERGENCY STOP switch is locked in the pressed state.

Turn the switch in the arrow direction to release the lock.

START and STOP Keys

The START key, when pressed, starts machine operation and the STOP key,

when pressed, stops the machine.

The needle bar stops at the upper dead point when the STOP key is pressed.

OPERATION

PROCEDURE

FD07

START key STOP key

27

Page 28

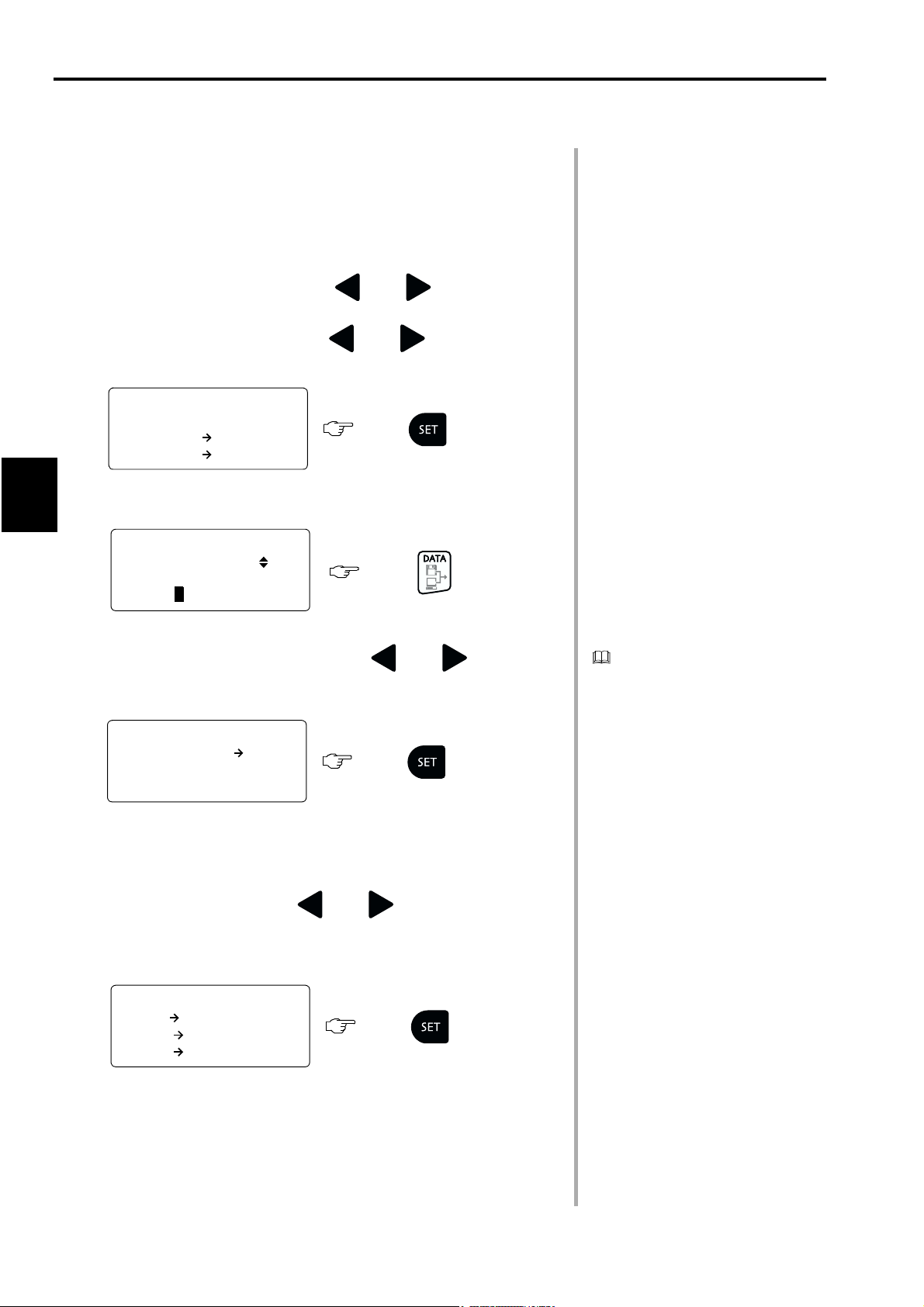

STEPS TO START EMBRODIERY

Example: To input the hoop data using the flat hoop from FDD

(floppy disk drive) (to be purchased separately)

1 Turn ON the power switch at the power supply box.

2 Select "FLAT" for "HOOP" using and (hoop travel keys).

3 Select "ON" for "INITIAL" using and (hoop travel keys).

4 Press the SET key.

** ESP9000 series **

HOOP FLAT

INITIAL ON <D>

5 The screen displays "EMB START". Press the DATA set menu key.

PROCEDURE

OPERATION

***** EMB START ****

AISIN 123.10O 1

0/ 1027

0 1 / 1 5: 23-456789A<D>

1

Press .

Press .

6 For "INPUT DATA", select "335" using and (hoop travel

keys).

7 Press the SET key.

***** DATA MENU ****

1 .INPUT DATA 335

2.SELECT DATA

Press .

3.DELETE DATA

8 Set the floppy disk in which the hoop data is stored to the FDD.

9 Select the hoop data using and (hoop travel keys).

Example: AISIN123

10 Press the SET key.

**** SELECT FILE ***

1 AISIN123.10O

STITCH 1 071 3 ST

Press .

MEMORY 1 80876 ST

"335" is a model name of FDD.

28

Page 29

11 Input the needle numbers in the order of needle change using the

numeric keys.

12 Press the SET key.

*** COLOR CHANGE ***

MODE AUTO

Press .

0 1 /04:

13 The screen will display the information as shown below when the

hoop data setting is completed.

***** EMB START ****

AISIN 123.10O 1

0/ 2451

0 1 /04: 573 <D>

B

14 Set the fabric in the embroidery hoop.

15 Set the embroidery hoop in the embroidery machine.

16 Set the upper and under threads.

17 Press the TRACE key to check if the range of embroidery fits the size

and position of the embroidery hoop.

18 If the hoop position does not fit the range of embroidery, adjust the

position of the hoop using the hoop travel keys and repeat step 17

again.

If the hoop size does not fit the range of embroidery, change the hoop

(to be purchased separately) to the one that fits the range of

embroidery.

Various kinds of setting can be

made after completing the setting

of hoop data.

OPERATION

PROCEDURE

FD07

19 After confirming that the hoop is set in the correct position, press the

START key.

Embroidering starts up.

29

Page 30

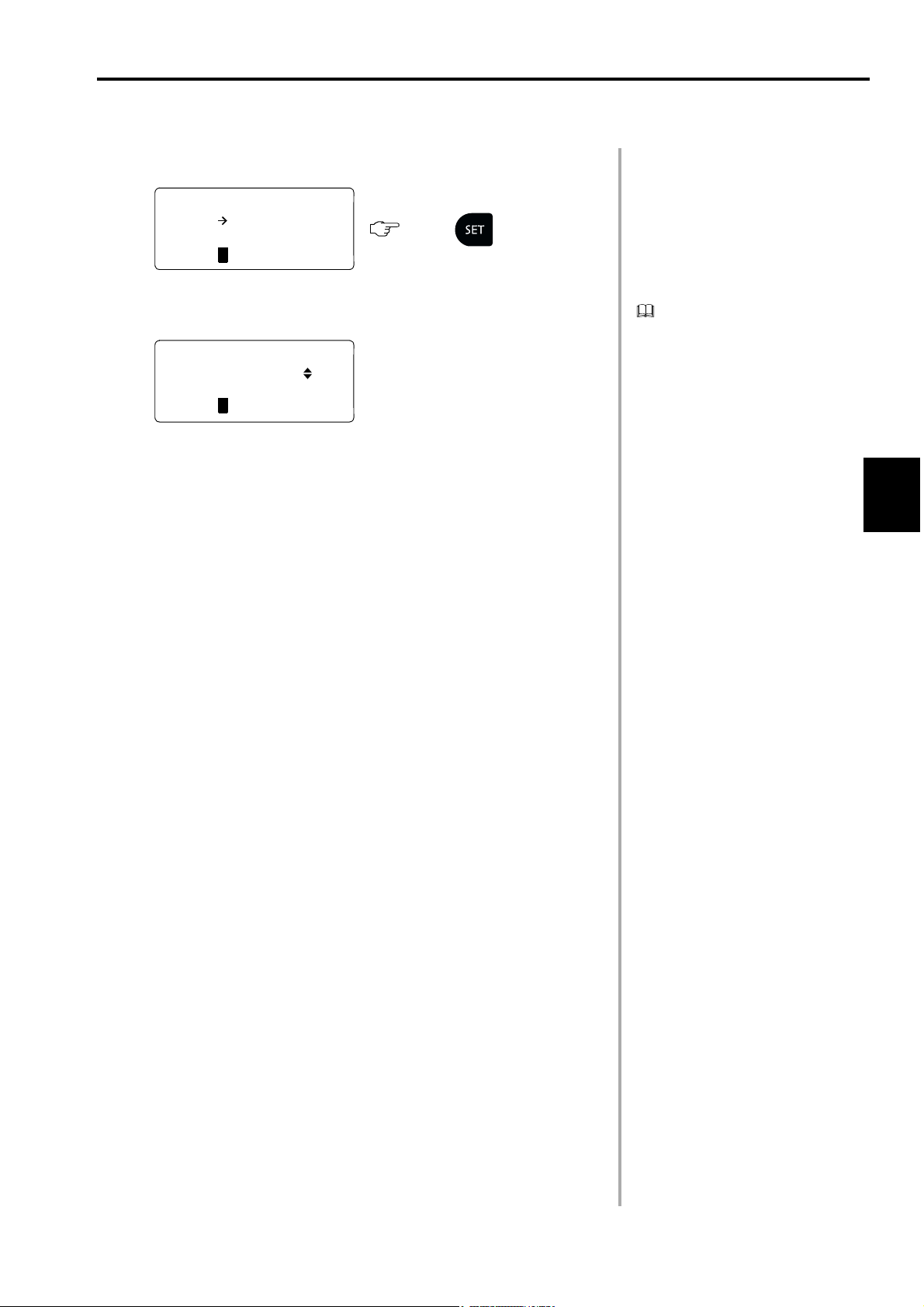

SCREENS

The LCD screen displays variety of information to navigate the operation.

The information displayed on the LCD screen is briefly explained below.

● Basic Menu

1

Hoop mode (FLAT / CAP / SLEEVE)

OPERATION

PROCEDURE

Change the selection with the hoop travel keys and .

2

Start point return motion and initializing at the power switch

"ON" (ON: Operated / OFF: Not)

Power ON

Change the selection with the hoop travel keys and .

* In automatic color change mode:

Use to change the color change mode between

automatic and manual.

1

File name

2

Forward/Back travel unit (1/10/100/C/n-ST)

3

Present number of stitches / Total number of stitches

4

Present step / Total number of steps:

Needle bar numbers in the order of color change

* In manual color change mode:

Use to change the color change mode between auto-

At the Start of Embroidery

matic and manual.

1

Needle bar No.

** ESP9000 series **

HOOP FLAT

INITIAL ON <D>

1

***** EMB START ****

AISIN 123.10O 1

0/ 1027

0 1 / 1 5: 23-456789A<D>

4

1

***** EMB START ****

AISIN 123.10O 1

0/ 1027

0 1 / 1 5: NO.2

1

2

2

3

1

Change the selection with the hoop travel keys and .

1

Present number of stitches / Total number of stitches (ST)

Present number of stitches / Maximum speed (RPM)

Set for "1. DISPLAY" of FUNCTION MENU (Machine Setting).

During Embroidering

1

Stop due to pause code

Insert "-" : Pause in the needle bar setting.

1

Needle bar No.

During Machine Stop

If "MANUAL" is selected for color change, the machine stops at

each color change operation.

*** EMBROIDERING ***

AISIN 123.10O 1

1

66/ 900 rpm

0 1 / 1 5: 23-456789A<D>

1

***** EMB PAUSE ****

AISIN 123.10O 1

159/ 1 027

0 1 / 1 5:1 23 456789A<D>

-

1

***** EMB PAUSE ****

AISIN 123.10O 1

1 59/ 1 027

0 1 / 1 5: NO.4

1

FD07FD07

30

Page 31

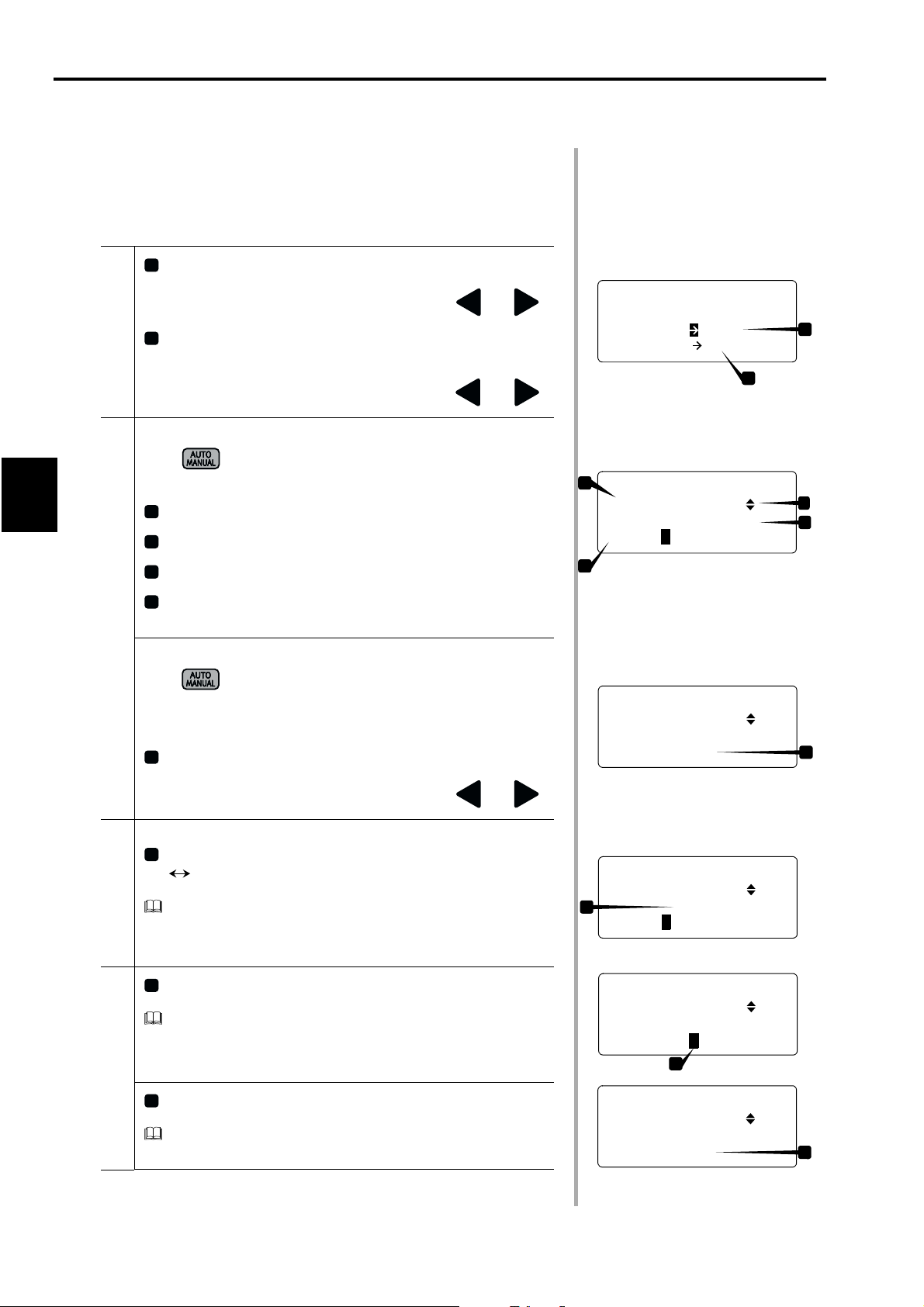

● Function Menu: Pressing in "EMB START" mode.

1

Stitch / RPM

Change the selection with the hoop travel keys and .

2

Thread breakage sensor (OFF / 1 - 5)

Change the selection with the hoop travel keys and .

3

Press the SET key to set the bobbin counter.

* Bobbin counter setting

a

Counter data (Actual accumrated value): Max. 999999

stitches

(Can be cleared)

b

Preset data (Preset accumrated value): Max. 999999

stitches by Numeric keys

4

Lock stitch (So: Yes at start / S-: No at start; Eo : Yes at end /

E-: No at end)

Change the selection with the hoop travel keys and .

5

Satin stitch adjustment

Machine Setting

(-: No adjustment / 1 - 5: Adjustment in 0.1 mm units)

Change the selection with the hoop travel keys and .

6

Slow start (2 - 9 stitches)

1

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

**** BOBBIN CNT ****

COUNTER 1 278 ST

PRESET 30000 ST

*** FUNCTION MENU **

4.LOCK ST. So Eo

5.SATIN ADJ. 2

6.SLOW START 2 ST

2

3

a

b

OPERATION

PROCEDURE

4

5

6

Change the selection with the hoop travel keys and .

7

Trimming in jump (0 - 9 stitches)

Change the selection with the hoop travel keys and .

8

Jump length (OFF / 4.0 - 9.9 mm)

Change the selection with the hoop travel keys and .

9

Trimming length (1 - 17)

Change the selection with the hoop travel keys and .

A

Trimming timing (–10 - +10)

Change the selection with the hoop travel keys and .

B

Communication speed (9600 / 19200 / 38400)

Change the selection with the hoop travel keys and .

Machine Setting

C

Machine No. (0 - 3)

Change the selection with the hoop travel keys and .

*** FUNCTION MENU **

7.TRIM JUMP 3 ST

8.JUMP LNGTH 6.0mm

9.TRIM LNGTH 3

*** FUNCTION MENU **

A.TRIM TMNG +0

B.COM SPEED *38400

C.MACHINE *1

7

8

9

A

B

C

FD07

31

Page 32

OPERATION

PROCEDURE

● Hoop Menu: Pressing in "EMB START" mode.

1

Hoop type (FLAT / CAP / SLEEVE)

Change the selection with the hoop travel keys and .

2

Initialization (ON / OFF)

Change the selection with the hoop travel keys and .

3

Start point return after embroidering (AUTO / MANUAL)

Change the selection with the hoop travel keys and .

4

Hoop travel speeds (1 - 3) in the manual mode

Frame Setting

Change the selection with the hoop travel keys and .

5

Hoop drive start timing (AUTO / 250

° )

Change the selection with the hoop travel keys and .

6

Offset at the completion of embroidering (AUTO / MANUAL)

***** HOOP MENU ****

1 HOOP *FLAT

.

2.INITIALIZE ON

3.START PNT AUTO

***** HOOP MENU ****

.

4 MANUAL SPD 1

5.HOOP TMNG AUTO

6.OFFSET AUTO

1

2

3

4

5

6

Change the selection with the hoop travel keys and .

● Edit Menu: Pressing in "EMB START" mode.

1

Rotation (90° units)

Change the selection with the hoop travel keys and .

2

Mirror (OFF / X (X-axis mirror) / Y (Y-axis mirror))

Change the selection with the hoop travel keys and .

3

Repeat

* Repeat setting

a

Data Setting

Direction of repeat (HORIZONTAL / VERTICAL)

Change the selection with the hoop travel keys and .

b

Number of repetition times (01 - 99)

***** EDIT MENU ****

.

1 ROTATE 270

2.MIRROR

×

3.REPEAT [SET]

** REPEAT SETTING **

DIR HORIZONTAL

TIMES 03

SPACE 255 mm

1

2

3

a

b

c

FD07

Change the selection with the hoop travel keys and .

c

Repeat space (0 - 255 mm)

Change the selection with the hoop travel keys and .

32

Page 33

● Data Set Menu: Pressing in "EMB START" mode.

1

Data input device (PC: Serial port / 335: FDD)

Select with the hoop travel keys and , and confirm

the selection by pressing the SET key .

***** DATA MENU ****

.

1 INPUT DATA PC

2.SELECT DATA

3.DELETE DATA

1

*Input from PC

a

Label name

b

Available memory size

Data Input

*Input from 335 (floppy disk drive)

c

Design No. Design name

Change the selection with the hoop travel keys and .

Number of stitches of FD stored design

d

e

Available memory size

2

Memory-stored design selection (Data selection)

When the SET key is pressed

a

Memory No. / Number of registered designs

Design name

Change the selection with the hoop travel keys and .

Selecting Design

b

Number of stitches of memory stored design

c

Available memory size

*** INPUT THRU PC **

NUMBER 01

NAME DATA 01

MEMORY 280576 ST

c

**** SELECT FILE ***

0 1 /03 AISIN 123.10O

STITCH 1 071 3 ST

MEMORY 1 80876 ST

***** DATA MENU ****

1 .INPUT DATA PC

2 SELECT DATA

.

3.DELETE DATA

a

**** SELECT DATA ****

0 1 /03 AISIN 123.10O

STITCH 1 071 3 ST

MEMORY 1 80876 ST

a

b

d

e

OPERATION

PROCEDURE

2

b

c

FD07

33

Page 34

3

Memory-stored design deletion

When the SET key is pressed

*Selecting the design

a

Memory No. / Number of registered designs

Design name

Change the selection with the CLEAR key after

pressing the hoop travel key and .

b

Number of stitches of memory stored design

Deleting Design

c

Available memory size

*Confirmation for deletion

a

Press the SET key when Y (yes) or the ESCAPE

***** DATA MENU ****

1 .INPUT DATA PC

2.SELECT DATA

.

3 DELETE DATA

a

**** DELETE DATA ***

0 1 /03 AISIN 123.10O

STITCH 1 071 3 ST

MEMORY 1 80876 ST

**** DELETE DATA ***

DELETE OK ?

a

[Y=SET,N=ESC]

3

b

c

OPERATION

PROCEDURE

key when N (no).

4

Design input mode

When the SET key is pressed

a

Mode selection (SINGLE / MULTI)

Change the selection with the hoop travel keys and .

Input Mode

SINGLE: Embroidery is possible without storing the design in

MULTI: Design is input to memory.

3

45

Memory initialization

memory

When the SET key is pressed

a

Press the SET key when Y (yes) or the ESCAPE

key when N (no).

Memory Initialization

***** DATA MENU ****

2.SELECT DATA

3.DELETE DATA

.

4 MEMORY MODE

**** MEMORY MODE ***

MEMORY MULTI

***** DATA MENU ****

3.DELETE DATA

4.MEMORY MODE

.

5 INITIAL MEMORY

** INITIAL MEMORY **

DELETE ALL DATA OK ?

a

[Y=SET, N=ESC]

4

5

34

Page 35

● Color Change Setting: Pressing in "EMB START" mode.

*In automatic color change mode

1

Color change mode (AUTO / MANUAL)

Press the color change mode key to select.

The lamp lights if manual mode is set.

2

Present step / Total number of steps: Color change sequence

Select with the hoop travel keys and and ten keys.

"-" : Pause may be inserted by .

a

Needle bar operation is suspended temporarily.

Needle Bar Selection

*In manual color change mode

1

Color change mode (AUTO / MANUAL)

Press the color change mode key to select.

2

Present step / Total number of steps:

Present needle bar No.

*** COLOR CHANGE ***

MODE AUTO

0 1 / 1 5: 23456789ABCDE

1

*** COLOR CHANGE ***

MODE AUTO

STOP

04/1 5:1 23- 56789ABCD

4

*** COLOR CHANGE ***

MODE MANUAL

0 1 / 1 5: NO.7

1

2

a

OPERATION

PROCEDURE

1

2

FD07

35

Page 36

《《《《FUNCTION MENU》》》》

CHANGING DISPLAY

Sets the information to be displayed during embroidering - number of stitches

or main shaft speed

[*1]

.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

6/ 1027

0 1 / 1 5: 23456789AB<D>

1

Press .

2 Select the desired display mode.

Select "ST: stitch" or "rpm: number

of revolutions" for "DISPLAY" using

the following keys:

and (hoop travel keys)

OPERATION

PROCEDURE

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Press [SET] to confirm the selection.

*** FUNCTION MENU **

.

1 DISPLAY rpm

2.THRED SNS 2

Press .

3.BOBBIN CNT [SET]

DISPLAY: ST / rpm

Total number of stitches of the design

data set for embroidery

6/ 1 027

Present main shaft speed

6/ 240 rpm

4 End of operation

***** EMB START ****

AISIN123.10O 1

6/ 1027

0 1 / 1 5: 23456789AB<D>

1

FD07

*1: Even if you select "rpm", the number of stitches of the design data set for embroidery is displayed while the machine stops.

36

Page 37

THREAD BREAK SENSOR

Sets the thread break detection sensing level.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Select "2. THRED SNS" (thread break detection sensor).

Press .

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS OFF

3.BOBBIN CNT [SET]

3 Select the desired setting.

*** FUNCTION MENU **

1 .DISPLAY ST

2 THRED SNS OFF

.

3.BOBBIN CNT [SET]

4 Press [SET] to confirm the setting.

*** FUNCTION MENU **

1 .DISPLAY ST

2 THRED SNS 3

.

3.BOBBIN CNT [SET]

5 End of operation

Move the cursor using (hoop

travel key).

Select "OFF", "1", "2", "3", "4" or "5"

for "THRED SENS" using the following keys:

and (hoop travel keys)

Press .

Setting: OFF / 1 / 2 / 3 / 4 / 5

- OFF: Does not detect break of

thread.

- 1 - 5: Detects break of thread at

the set number of

stitches.

∗ Sensitivity gets higher when a

smaller number is set.

OPERATION

PROCEDURE

FD07

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

37

Page 38

BOBBIN COUNTER (SET)

Sets the number of stitches for stopping the machine automatically.

When the counted number of stitches reaches the preset number, the machine

stops automatically.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Select "3. BOBBIN CNT" (bobbin counter).

Press .

Determine the number of stitches

to be set for bobbin counter so that

the machine will stop before lower

thread is used up.

OPERATION

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

PROCEDURE

3 Press [SET] to confirm the selection.

*** FUNCTION MENU **

1 .DISPLAY ST

2.THRED SNS 2

.

3 BOBBIN CNT [SET]

4 Select "PRESET".

**** BOBBIN CNT ****

COUNTER 0 ST

PRESET 0 ST

5 Input the preset number of stitches.

**** BOBBIN CNT ****

COUNTER 0 ST

PRESET 0 ST

6 Press [SET] to confirm your input.

**** BOBBIN CNT ****

COUNTER 0 ST

PRESET 30000 ST

7 End of operation

Move the cursor using (hoop

travel key).

Press .

Move the cursor using (hoop

travel key).

7890

456

123

Input the preset number using the

numeric keys.

Press .

If you make a mistake, clear the

value you have input by pressing

the CLEAR key and then input the

correct value again.

When the number of stitches set

by the counter is reached, the

machine automatically stops, by

buzzer sounds and the message

below is displayed.

LOWER THREAD RUN OUT

Press the STOP key to reset the

alarm message, and then perform

the necessary work to restore

operation.

FD07

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

38

Page 39

BOBBIN COUNTER (COUNTER)

Clears the counted number of stitches

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Select "3. BOBBIN CNT" (bobbin counter).

[*1]

.

Press .

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Press [SET] to confirm the selection.

*** FUNCTION MENU **

1 .DISPLAY ST

2.THRED SNS 2

.

3 BOBBIN CNT [SET]

4 Clear the COUNTER data.

**** BOBBIN CNT ****

COUNTER 1278 ST

PRESET 30000 ST

5 Press [SET] to confirm the operation.

**** BOBBIN CNT ****

COUNTER 0 ST

PRESET 30000 ST

Move the cursor using (hoop

travel key).

Press .

Press .

Press .

PRESET data can also be cleared

by pressing the CLEAR key after

selecting the SET key for BOBBIN

CNT.

OPERATION

PROCEDURE

FD07

6 End of operation

***** EMB START ****

AISIN1 23.1 0O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

*1: The bobbin counter (COUNTER) functions only when the PRESET data is set.

1

39

Page 40

LOCK STITCH

Sets "lock stitch" at the start and end of sewing.

1 Change the display to FUNCTION MENU.

2 Change the displayed items.

3 Select the setting.

PROCEDURE

OPERATION

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

*** FUNCTION MENU **

4 LOCK ST. So Eo

.

5.SATIN ADJ. OFF

6.SLOW START 2 ST

Press .

Press .

Select the setting using the following

keys:

and (hoop travel keys)

:So / S-

:Eo / E-

So: Lock stitch at the start of

sewing

Eo: Lock stitch at the start of

sewing

S-, E-: No lock stitching

4 Press [SET] to confirm the setting.

*** FUNCTION MENU **

.

4 LOCK ST. S- Eo

5.SATIN ADJ. OFF

6.SLOW START 2 ST

5 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Lock stitch: Back and forth stitch-

ing by one stitch

Press .

FD07

40

Page 41

SATIN ADJUSTMENT

Sets adjustment of satin stitch width.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Change the displayed items.

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Select "4. SATIN ADJ." (satin stitch width adjustment).

Press .

Press .

*** FUNCTION MENU **

4 LOCK ST. So Eo

.

5.SATIN ADJ. OFF

6.SLOW START 2 ST

4 Select the setting.

*** FUNCTION MENU **

4.LOCK ST. So Eo

5 SATIN ADJ. OFF

.

6.SLOW START 2 ST

5 Press [SET] to confirm the setting.

*** FUNCTION MENU **

4.LOCK ST. So Eo

.

5 SATIN ADJ. 1

6.SLOW START 2 ST

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Move the cursor using (hoop

travel key).

Select "OFF" "1", "2", "3", "4" or "5" of

SATIN AJD. using the following keys:

and (hoop travel keys)

Press .

Setting: OFF / 1 / 2 / 3 / 4 / 5

- OFF: Satin stitch width is not

adjusted.

- 1 - 5: 0.1 - 0.5 mm

Satin stitch width is extended on

both sides by the set adjustment

amount.

OPERATION

PROCEDURE

FD07

41

Page 42

SLOW START

Sets the number of main shaft rotations for which the main shaft rotates at a

slow speed when starting sewing after thread trimming.

1 Change the display to FUNCTION MENU.

2 Change the displayed items.

3 Select "5. SLOW START" (slow start).

PROCEDURE

OPERATION

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

*** FUNCTION MENU **

.

4 LOCK ST. So Eo

5.SATIN ADJ. OFF

6.SLOW START 2 ST

Press .

Press .

Move the cursor using (hoop

travel key).

4 Select the setting.

*** FUNCTION MENU **

4.LOCK ST. So Eo

5.SATIN ADJ. OFF

.

6 SLOW START 2 ST

5 Press [SET] to confirm the setting.

*** FUNCTION MENU **

4.LOCK ST. So Eo

5.SATIN ADJ. OFF

.

6 SLOW START 2 ST

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Select "2"... or "9"using the following

keys:

and (hoop travel keys)

Press .

Setting: 2 - 9 stitches

The number of stitches for slow

start

FD07

42

Page 43

TRIMMING IN JUMP

Inserts thread trimming to stitches of consecutive jumps.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Change the displayed items.

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Select the setting.

*** FUNCTION MENU **

7 TRIM JUMP 3 ST

.

8.JUMP LNGTH 6.0mm

9.TRIM LNGTH 3

Press .

Press the FUNCTION menu key two

times.

Select "0", "1"... or "9" using the following keys:

and (hoop travel keys)

Thread is trimmed using the continuous jump signals.

Setting: 0 / 1 / 2 / ... / 8 / 9 (ST)

- 0: Does not insert.

Keep pressing or , and the

value changes quickly.

OPERATION

PROCEDURE

4 Press [SET] to confirm the setting.

*** FUNCTION MENU **

.

7 TRIM JUMP 3 ST

8.JUMP LNGTH 6.0mm

9.TRIM LNGTH 3

5 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Press .

When the number of jump signals

appearing in succession reaches

the set value, thread trimming is

inserted.

FD07

43

Page 44

JUMP LENGTH

Sets the condition (length) for converting stitches into jump. Stitches longer

than the set length are converted into jump.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

2 Change the displayed items.

*** FUNCTION MENU **

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Select "8. JUMP LNGTH" (length of stitch).

PROCEDURE

OPERATION

*** FUNCTION MENU **

7 TRIM JUMP 3 ST

8.JUMP LNGTH 6.0mm

9.TRIM LNGTH 3

Press .

1

.

Press the FUNCTION menu key

twice.

.

Move the cursor using (hoop

travel key).

4 Select the setting.

*** FUNCTION MENU **

7.TRIM JUMP 3 ST

8 JUMP LNGTH 6.0mm

.

9.TRIM LNGTH 3

5 Press [SET] to confirm the setting.

*** FUNCTION MENU **

7.TRIM JUMP 3 ST

.

8 JUMP LNGTH 6.0mm

9.TRIM LNGTH 3

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Select "OFF", "4.0"... or "9.9" using

the following keys:

and (hoop travel keys)

Press .

Setting: OFF, 4.0 ... 9.9 (ST)

- OFF: Does not insert.

Keep pressing or , and the

value changes quickly.

FD07

44

Page 45

TRIMMING LENGTH

Sets the length of thread to be trimmed.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

2 Change the displayed items.

*** FUNCTION MENU **

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Select "9. TRIM LNGTH" (trimming length).

1

.

Press .

Press the FUNCTION menu key

twice.

*** FUNCTION MENU **

7 TRIM JUMP 3 ST

.

8.JUMP LNGTH 6.0mm

9.TRIM LNGTH 3

4 Select the setting.

*** FUNCTION MENU **

7.TRIM JUMP 3 ST

8.JUMP LNGTH 6.0mm

.

9 TRIM LNGTH 3

5 Press [SET] to confirm the setting.

*** FUNCTION MENU **

7.TRIM JUMP 3 ST

8.JUMP LNGTH 6.0mm

.

9 TRIM LNGTH 3

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Move the cursor using (hoop

travel key).

Select "1"... or "17" using the following keys:

and (hoop travel keys)

Press .

OPERATION

PROCEDURE

Setting: 1 / 2 / 3 / ... / 17

Shorter

1817

A smaller number sets a shorter

thread trimming length and a

larger number sets a longer thread

trimming length.

Longer

FD07

45

Page 46

TRIMMING TIMING

Adjusts the timing for starting trimming.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

2 Change the displayed items.

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Select the setting.

OPERATION

PROCEDURE

*** FUNCTION MENU **

A TRIM TMNG + 3

.

B.COM SPEED 9600

C.MACHINE 1

Press .

1

Press the FUNCTION menu key three

times.

Setting: -10 / ... / -1 / 0 / +1 / ... /

Select "-10"... or "+10" using the following keys:

and (hoop travel keys)

+10

Earlier

-10 0 +10

Adjust the timing meeting the

thread length after trimming the

kind of thread being used.

Later

4 Press [SET] to confirm the setting.

*** FUNCTION MENU **

.

A TRIM TMNG + 3

B.COM SPEED 9600

C.MACHINE 1

5 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Press .

FD07

46

Page 47

COMMUNICATION SPEED

Sets data transmission speed (bps) for serial communication.

1 Change the display to FUNCTION MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Change the displayed items.

*** FUNCTION MENU **

.

1 DISPLAY ST

2.THRED SNS 2

3.BOBBIN CNT [SET]

3 Select "B. COM SPEED" (communication speed).

Press .

Press the FUNCTION menu key three

times.

*** FUNCTION MENU **

A TRIM TMNG + 0

.

B.COM SPEED 38400

C.MACHINE 1

4 Select the setting.

*** FUNCTION MENU **

A.TRIM TMNG + 0

B COM SPEED 38400

.

C.MACHINE 1

5 Press [SET] to confirm the setting.

*** FUNCTION MENU **

A.TRIM TMNG + 0

B COM SPEED 38400

.

C.MACHINE 1

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Move the cursor using (hoop

travel key).

Select "9600", "19200" or "38400"

(bps) according to the transmission

speed on the P/C at the transmitting

side using the following keys:

and (hoop travel keys)

Press .

OPERATION

PROCEDURE

FD07

47

Page 48

《《《《HOOP MENU》》》》

HOOP MODE

Sets the embroidery hoop type - flat / cap / sleeve.

1 Change the display to HOOP MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

1

.

.

OPERATION

0 1 / 1 5: 23456789AB<D>

2 Select the type of embroidery hoop.

***** HOOP MENU ****

1 HOOP CAP

2.INITIALIZE ON

3.START PNT AUTO

PROCEDURE

3 Press [SET] to confirm the selection.

***** HOOP MENU ****

1 HOOP CAP

2.INITIALIZE ON

3.START PNT AUTO

Press .

Select "FLAT", "CAP" or "SLEEVE"

using the following keys:

and (hoop travel keys)

Press .

Setting: FLAT / CAP / SLEEVE

4 End of operation

** ESP9000 series **

HOOP CAP

INITIALIZE ON

The screen returns to the start-up

screen (the initial screen displayed

when the power is turned ON)

when the hoop mode is set.

Press the SET key to display the

EMB START screen.

48

Page 49

INITIALIZATION

Sets if initial point is searched for when the power is turned ON.

1 Change the display to HOOP MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Select "2. INITIALIZE" (initialization).

Press .

***** HOOP MENU ****

.

1 HOOP FLAT

2.INITIALIZE ON

3.START PNT MANUAL

3 Select the setting.

***** HOOP MENU ****

1 .HOOP FLAT

2 INITIALIZE ON

.

3.START PNT MANUAL

4 Press [SET] to confirm the selection.

***** HOOP MENU ****

1 .HOOP FLAT

2 INITIALIZE ON

.

3.START PNT MANUAL

5 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Move the cursor using (hoop

travel key).

Select "ON" or "OFF" using the

following keys:

and (hoop travel keys)

Press .

Setting: ON / OFF

- ON: When the SET key is

pressed after turning the

power ON, the hoop automatically travels to the start

point.

- OFF: The hoop does not travel

automatically.

OPERATION

PROCEDURE

FD07

49

Page 50

START POINT RETURN MODE

Sets the mode (automatic/manual) to move the hoop to the start point when the

power is turned ON.

1 Change the display to HOOP MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Select "3. START PNT" (start point return mode).

Press .

OPERATION

***** HOOP MENU ****

.

1 HOOP FLAT

2.INITIALIZE ON

3.START PNT MANUAL

3 Select the setting.

PROCEDURE

***** HOOP MENU ****

1 .HOOP FLAT

2.INITIALIZE ON

.

3 START PNT MANUAL

4 Press [SET] to confirm the selection.

***** HOOP MENU ****

1 .HOOP FLAT

2.INITIALIZE ON

3 START PNT AUTO

.

5 End of operation

Move the cursor using (hoop

travel key).

Select "AUTO" or "MANUAL" using

the following keys:

and (hoop travel keys)

Press .

Setting: AUTO / MANUAL

- AUTO: The hoop automatically

travels to the start point

at the completion of

embroidery.

- MANUAL: The hoop stops at the

position where embroidery is completed. To

return the hoop to the

start point, press the

start point return key.

FD07

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

50

Page 51

MANUAL SPEED

Sets hoop travel speed.

1 Change the display to HOOP MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

2 Change the displayed items.

***** HOOP MENU ****

1 HOOP FLAT

2.INITIALIZE ON

3.START PNT MANUAL

3 Select the setting.

***** HOOP MENU ****

4 MANUAL SPD 3

5.HOOP TMNG AUTO

6.OFFSET AUTO

1

.

.

Press .

Press .

Select "1", "2" or "3" using the following keys:

and (hoop travel keys)

Setting: 1 / 2 / 3

123

High speed

Medium

speed

Low speed

OPERATION

PROCEDURE

4 Press [SET] to confirm the selection.

***** HOOP MENU ****

.

4 MANUAL SPD 3

5.HOOP TMNG AUTO

6.OFFSET AUTO

5 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Press .

FD07

51

Page 52

HOOP TIMING

Sets the hoop drive start timing.

1 Change the display to HOOP MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

2 Change the displayed items.

***** HOOP MENU ****

.

1 HOOP FLAT

2.INITIALIZE ON

3.START PNT MANUAL

3 Select "5. HOOP TMNG" (hoop drive start timing).

Press .

Press .

OPERATION

PROCEDURE

***** HOOP MENU ****

.

4 MANUAL SPD 1

5.HOOP TMNG AUTO

6.OFFSET MANUAL

4 Select the setting.

***** HOOP MENU ****

4.MANUAL SPD 1

.

5 HOOP TMNG AUTO

6.OFFSET MANUAL

5 Press [SET] to confirm the selection.

***** HOOP MENU ****

4.MANUAL SPD 1

.

5 HOOP TMNG 250

6.OFFSET 2

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Move the cursor using (hoop

travel key).

Setting: AUTO / 250°

Select "AUTO" or "250°"

using

the following keys:

and (hoop travel keys)

°

Press .

- AUTO: Automatically adjusted

- 250°: The hoop drive starts

always at 250°.

FD07

52

Page 53

OFFSET

Sets if the hoop automatically travels to the offset position.

1 Change the display to HOOP MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Press .

2 Change the displayed items.

***** HOOP MENU ****

.

1 HOOP FLAT

2.INITIALIZE ON

Press .

3.START PNT MANUAL

3 Select "6. OFFSET" (hoop offset).

***** HOOP MENU ****

4.MANUAL SPD 1

.

5 HOOP TMNG AUTO

Move the cursor using (hoop

travel key).

6.OFFSET AUTO

For details of offset, refer to Pages

73 and 74.

OPERATION

PROCEDURE

4 Select the setting.

***** HOOP MENU ****

4.MANUAL SPD 1

5.HOOP TMNG AUTO

6 OFFSET AUTO

.

5 Press [SET] to confirm the selection.

***** HOOP MENU ****

4.MANUAL SPD 1

5.HOOP TMNG AUTO

.

6 OFFSET MANUAL

6 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Select "AUTO" or "MANUAL" using

the following keys:

and (hoop travel keys)

Press .

Setting: AUTO / MANUAL

- AUTO: The hoop travels automatically to the offset

position upon completion of embroidering.

- MANUAL: The hoop does not

travel automatically.

When OFFSET is

pressed, the hoop

automatically travels

to the preset offset

position.

FD07

53

Page 54

《《《《EDIT》》》》

DESIGN ROTATION

Sets the angle through which the input design data is rotated.

1 Change the display to EDIT MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

2 Select the angle.

***** EDIT MENU ****

.

1 ROTATE 0

2.MIRROR OFF

3.REPEAT [SET]

3 Press [SET] to confirm the setting.

OPERATION

PROCEDURE

***** EDIT MENU ****

.

1 ROTATE 1 80

2.MIRROR OFF

3.REPEAT [SET]

For details of design rotation, refer

to Page 80.

Press .

1

Select "0°", "90°", "180°" or "270°"

using the following keys:

and (hoop travel keys)

Press .

Rotation angle can be set in 90°

units.

To edit the design data continuously, move the cursor to "MIRROR" or "REPEAT" using

(hoop travel key) and input the

data for "MIRROR" or "REPEAT"

before pressing the SET key.

4 End of operation

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

FD07

54

Page 55

MIRROR

Sets the axis of symmetry for reversing the design data.

1 Change the display to EDIT MENU.

***** EMB START ****

AISIN123.10O 1

0/ 1027

0 1 / 1 5: 23456789AB<D>

1

Press .

2 Select "2. MIRROR" (reversal of design data).

***** EDIT MENU ****

.

1 ROTATE 0

2.MIRROR OFF

Move the cursor using (hoop

travel key).

3.REPEAT [SET]

3 Select the axis as the base line for reversing the design data.

***** EDIT MENU ****

1 .ROTATE 0

.

2 MIRROR OFF

3.REPEAT [SET]

Select "OFF", "X", "Y" or "XY" using

the following keys:

and (hoop travel keys)

For details of mirror, refer to

Page 80.

Data is reversed symmetrically

around the X-/Y-axis.

Y

Reversal around

the Y-axis

OPERATION

PROCEDURE

4 Press [SET] to confirm the selection.

***** EDIT MENU ****

1 .ROTATE 0