88

SERVICE MANUAL

Pallet Trucks

8HBW30

8HBE40

8HBC40

36,001 and up

36,001 and up

36,001 and up

8HBE30

8HBC30

8TB50

36,001 and up

36,001 and up

36,001 and up

00700-CL398-07, Issued: 9 August 2007

Toyota Pallet Truck Service Manual Table of Contents

Table of Contents

How To Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Map of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Abbreviations & Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

START Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Battery Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Jacking Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Tie-Down for Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Welding Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Static Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Truck Model Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Vehicle Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Maximum Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

General System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Planned Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Initial 90 Day/250 Deadman Hours (HD) Maintenance . . . . . . . . . . . 4-3

Every 180 Days or 500 Deadman Hours . . . . . . . . . . . . . . . . . . . . . . 4-4

Every 360 Days or 2000 Deadman Hours (HD) . . . . . . . . . . . . . . . . . 4-6

Grease Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

How to Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Electrical Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . 5-3

DC Electric Motor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

AC Electric Motor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Hydraulic Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . 5-10

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

List of Electrical Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Operator Display and Programming . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Service Input/Output Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Traction Power Amplifier LED Diagnostics . . . . . . . . . . . . . . . . . . . . 5-26

Traction Power Amplifier Flash Codes . . . . . . . . . . . . . . . . . . . . . . . 5-27

Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Caution and Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Symptom Tables: Lift/Lower System . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Symptom Tables: Travel (Forward/Reverse) System . . . . . . . . . . . . . 5-59

Symptom Tables: Wiring System . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

Pinout Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

Component Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

List of Component Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Component Locator Photos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Tractor Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

00700-CL398-07, Issued: 9 August 2007 i

Table of Contents Toyota Pallet Truck Service Manual

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Switches (General) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Key Switch (SW1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Brake (Deadman) Switch (SW2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Lift-Limit Switch (SW8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Grab Rail Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Hydraulic Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Jog Pick Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Traction Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

AMP Harness/Traction Power Amplifier Connector . . . . . . . . . . . . . 6-27

Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Control Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Control Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Motors, General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Traction Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

AC Motor Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Drive Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-60

Casters (Torsion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63

Casters (Spring-Loaded) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-65

Load Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-69

Pallet Entry Sliders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-72

Fork Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-73

Hydraulic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-75

Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-76

Adjusting Hydraulic Pump Relief Valve Pressure . . . . . . . . . . . . . . . 6-77

Hydraulic Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-79

Hydraulic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-85

Lift Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-89

Cold Storage Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-91

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Lubrication Equivalency Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Torque Chart - Standard (Ferrous) . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Torque Chart - Standard (Brass) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Torque Chart - Metric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Torque Chart - Thread-Forming Screws . . . . . . . . . . . . . . . . . . . . . . . A-6

Decimal Equivalent Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Standard/Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

ii 00700-CL398-07, Issued: 9 August 2007

Toyota Pallet Truck Service Manual How To Use This Manual

Section 1. How To Use This Manual

00700-CL398-07, Issued: 9 August 2007 1-1

Toyota Pallet Truck Service Manual

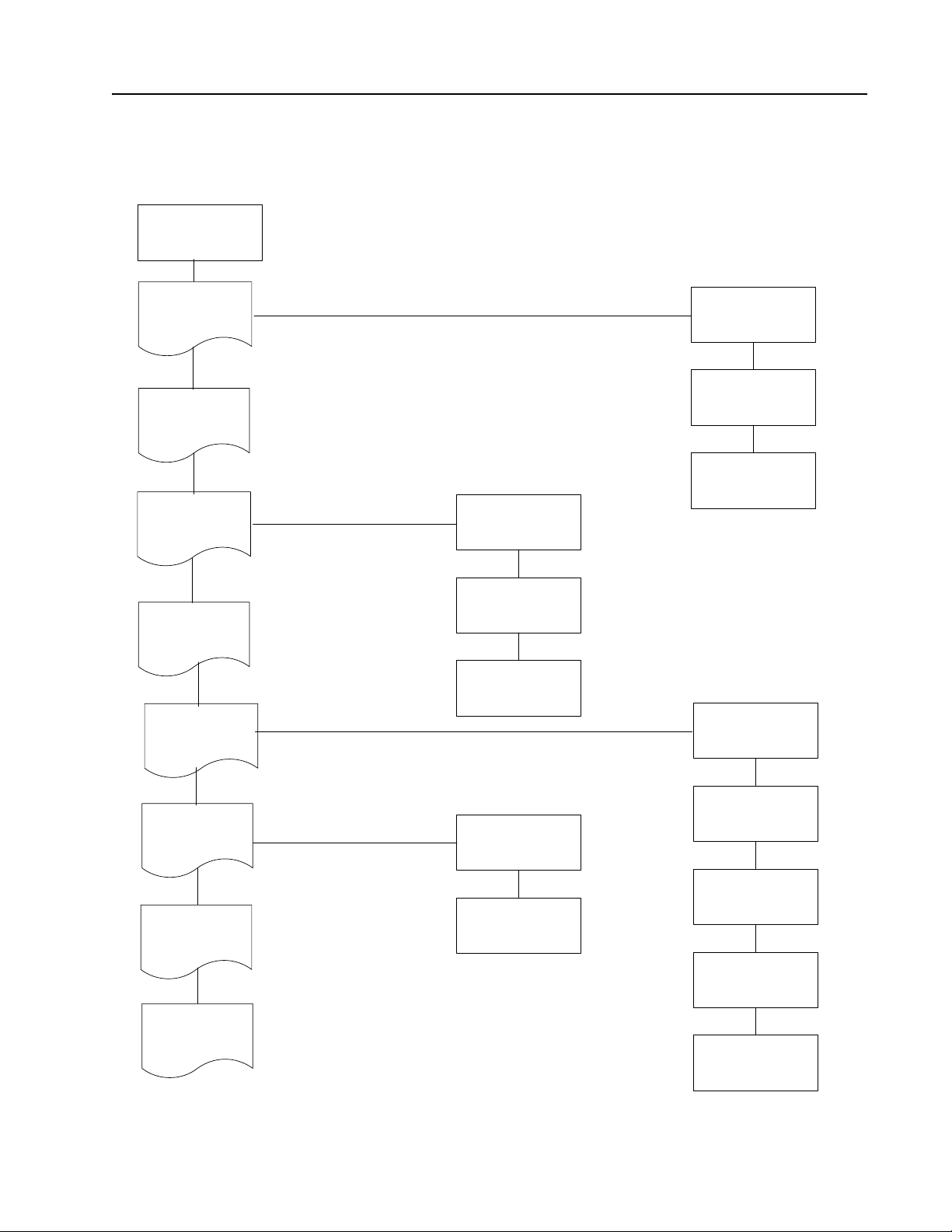

Map of the Manual

Table of Contents

and Page

Revision Record

How to Use This

Manual

Safety

Map of the Manual

Manual Design

Start Page

Systems

Overview

Scheduled

Maintenance

Trouble-

Shooting

Component

Procedures

Appendix

Vehicle

Specifications

General System

Data

Theory of

Operations

Alphabetical List

of Component

Procedures

Component

Locator Photos

Electrical &

Hydraulic T.S.

Guidelines

Definitions

Control Handle

Display &

Programming

Fault Codes &

Caution & Error

Codes

Index

Troubleshooting

Charts and

Symptom Tables

1Map.wmf

00700-CL398-07 Issued: 9 August 2007 1-2

Toyota Pallet Truck Service Manual How To Use This Manual

Manual Design

Manual Design

The Toyota Pallet Truck Service Manual is

designed with the following objectives in mind:

• Provide technical coverage for expected

levels of user expertise

• Anticipate your needs and reduce your

decisions regarding maintenance

• Reduce page flipping thru a “one-stop

shopping” approach

The two-line running page header at the top of

each page tells you:

• Name of the manual (Toyota Pallet Truck

Service Manual)

• Current section title

(for example, this page How to Use This

Manual)

• Current topic

(for example, this page Manual Design)

We suggest you get in the habit of turning to the

START page first when you use this manual.

•The START page asks a few questions to

guide you to the correct section.

How to Use This Manual explains the manual

format and contains the START page.

Safety explains warning and caution notes,

general safety rules and safety rules for

batteries, static, jacking, and welding.

• The section “Caution and Error Codes”

on page 5-33 defines the various codes

displayed on the operator display.

•The chart “TS1: START

TROUBLESHOOTING” on page 5-29 will

guide you to the symptom chart you need.

• When you’re familiar with the symptoms

listed, you may simply look up the

symptom from the “Troubleshooting” on

page 5-29.

• As you work with a troubleshooting chart,

code, or table, you may be instructed to

test various electrical connector pins. The

pinout matrix chart lists information on

functions and normal voltages of terminals

and harness connector pins. See “Pinout

Matrix” on page 5-69.

• When you complete a troubleshooting

procedure, perform the steps in the

“END1: End of Troubleshooting

Procedure” on page 5-31.

Component Procedures gives step-by-step

procedures for testing, removal, installation,

and adjustment of individual truck

components. Components are listed in an order

that considers:

• Frequency of attention

• Physical attachment (for example, remove

the brake before the traction motor)

• Functional relation (for example, traction

motor and drive unit components are

grouped together)

Systems Overview includes truck

specifications and theory of operation

information.

Planned Maintenance outlines the

recommended schedule of preventive services to

keep your truck working most efficiently.

Troubleshooting is a set of fault, caution, and

error codes, charts and tables designed to take

you from a symptom to a specific sequence of

actions in order to isolate a failing component.

•The chart “Traction Power Amplifier

Flash Codes” on page 5-27 will guide you

thru the flash codes displayed on the

LED’s installed on the TA.

To find a component procedure, you may use

one of three methods:

• Look up the component name in the “List

of Component Procedures” on page 6-2.

• Find the component in the “Component

Locator Photos” on page 6-5.

• Look up component name in the “Index”.

Appendix contains reference information such

as torque values, lubricants, and schematics.

Index lists subjects alphabetically.

00700-CL398-07, Issued: 9 August 2007 1-3

How To Use This Manual Toyo ta Pallet Truck Service Manual

Abbreviations & Symbols

Abbreviations &

Symbols

These abbreviations, acronyms and symbols are used in this manual.

Term/Symbol Definition Term/Symbol Definition

AAmpere

AC Alternating Current

amp Ampere or amplifier

ANSI American National Standards

Institute

approx approximately

aux auxiliary

AWG American Wire Gauge

BSOC Battery State-of-Charge

CAN Controller Area Network

CCW counterclockwise

cm centimeter

COP Computer Operating Program

CV checkvalve

CW clockwise

DC Direct Current

DGND digital ground

EE UL Electric Truck Type

Certification Rating where

electrical equipment is completely

enclosed

ESD Electrostatic Discharge

ETAC Electronic Tiller Arm Control (See

Vehicle Manager)

ft. foot or feet

gal. gallon or gallons

Gnd ground

km/hr kilometers per hour

kPa kilo Pascal

lb. pound or pounds

LED Light Emitting Diode

L/H Load Holding

L/L Lift/Lower

mA milliampere

mm millimeter

mph miles per hour

ms millisecond(s)

N/A Not Applicable or Not Available

N•m newton meter

OD Operator’s Display

OSHA Occupational Safety and Health

Administration

oz. ounce

pot potentiometer

psi pounds per square inch

PWM Pulse Width Modulation

P/N Part Number

RAM Random Access Memory

RCFP Relay Control Fuse Panel

ROM Read Only Memo ry

RPM Revolutions per Minute

R/R Remove and Replace

HD hours on deadman

in. inch or inches

kg kilogram(s)

SOL Solenoid

spec specification

SPI Service Port Interface

1-4 00700-CL398-07, Issued: 9 August 2007

Toyota Pallet Truck Service Manual How To Use This Manual

Abbreviations & Symbols

Term/Symbol Definition

TPA Traction Power Amplifier

temp Temperature

TM Traction Motor

TS troubleshoot

UL Underwriters Laboratories, Inc.

V Volt or Volts

VAC Volts Alternating Current

VDC Volts Direct Current

VM Vehicle Manager (ETAC)

wrt with respect to

@at

™ trademark

© copyright

+ plus or positive

– mi nus or negative

± plus or minus

° degrees

°F degrees Fahrenheit

°C degrees Celsius

< less than

> greater than

% percent

= equals

00700-CL398-07, Issued: 9 August 2007 1-5

Toyota Pallet Truck Service Manual How To Use This Manual

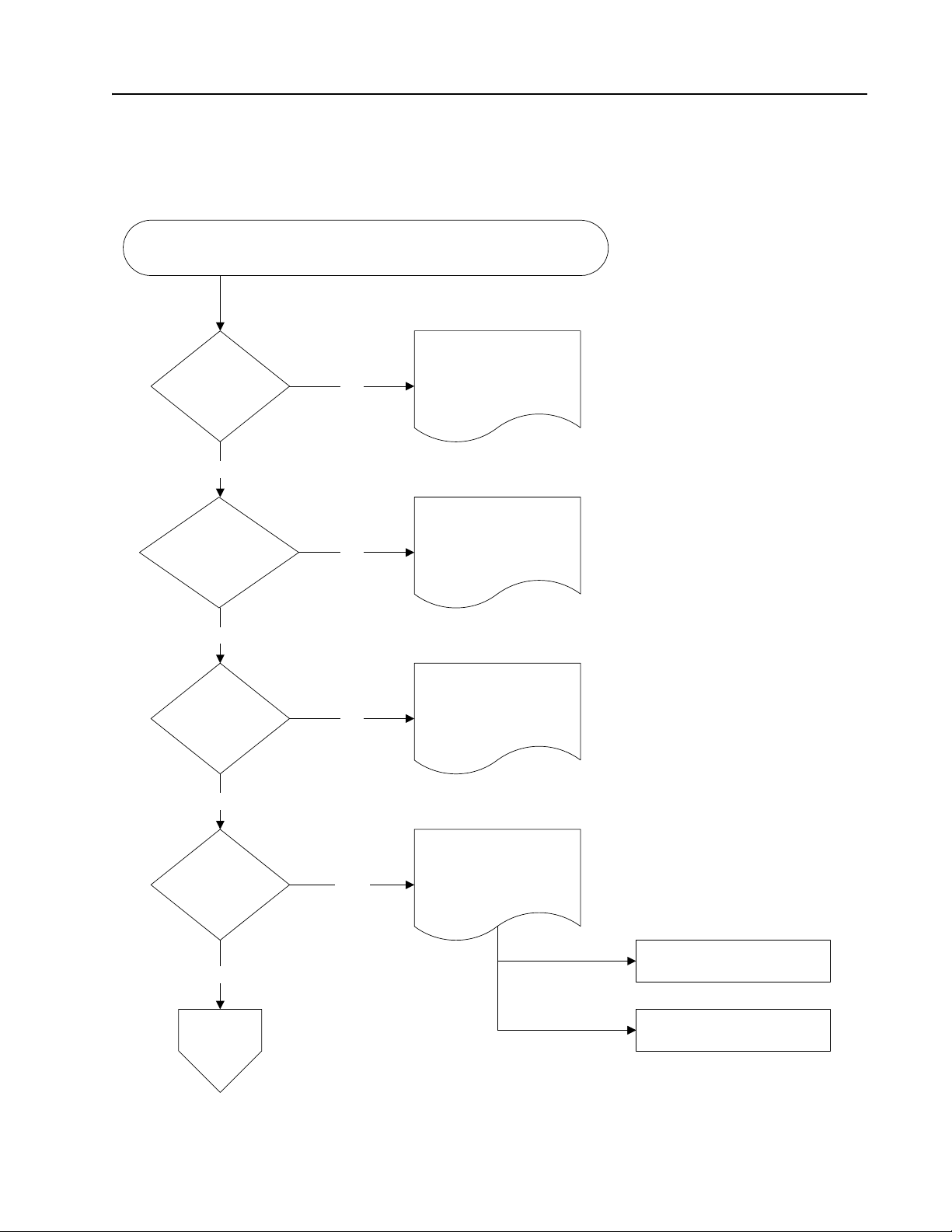

START Page

Section 1. How To Use This Manual

START Page

START: Why are you here?

Go to Section 2

To review safety

precautions?

No

Yes

"Safety"

To examine

specifications or

theory of

operations?

No

To do scheduled

maintenance?

No

To troubleshoot

a problem?

No

Yes

Yes

Yes

Go to Section 3

"Systems Overview"

Go to Section 4

"Scheduled Maintenance"

Go to Section 5

"Troubleshooting"

List of Caution and Error

Codes

Go to Chart

START-2

START Troubleshooting

1Startpg1.wmf

00700-CL398-07, Issued: 9 August 2007 1-7

How To Use This Manual Toyo ta Pallet Truck Service Manual

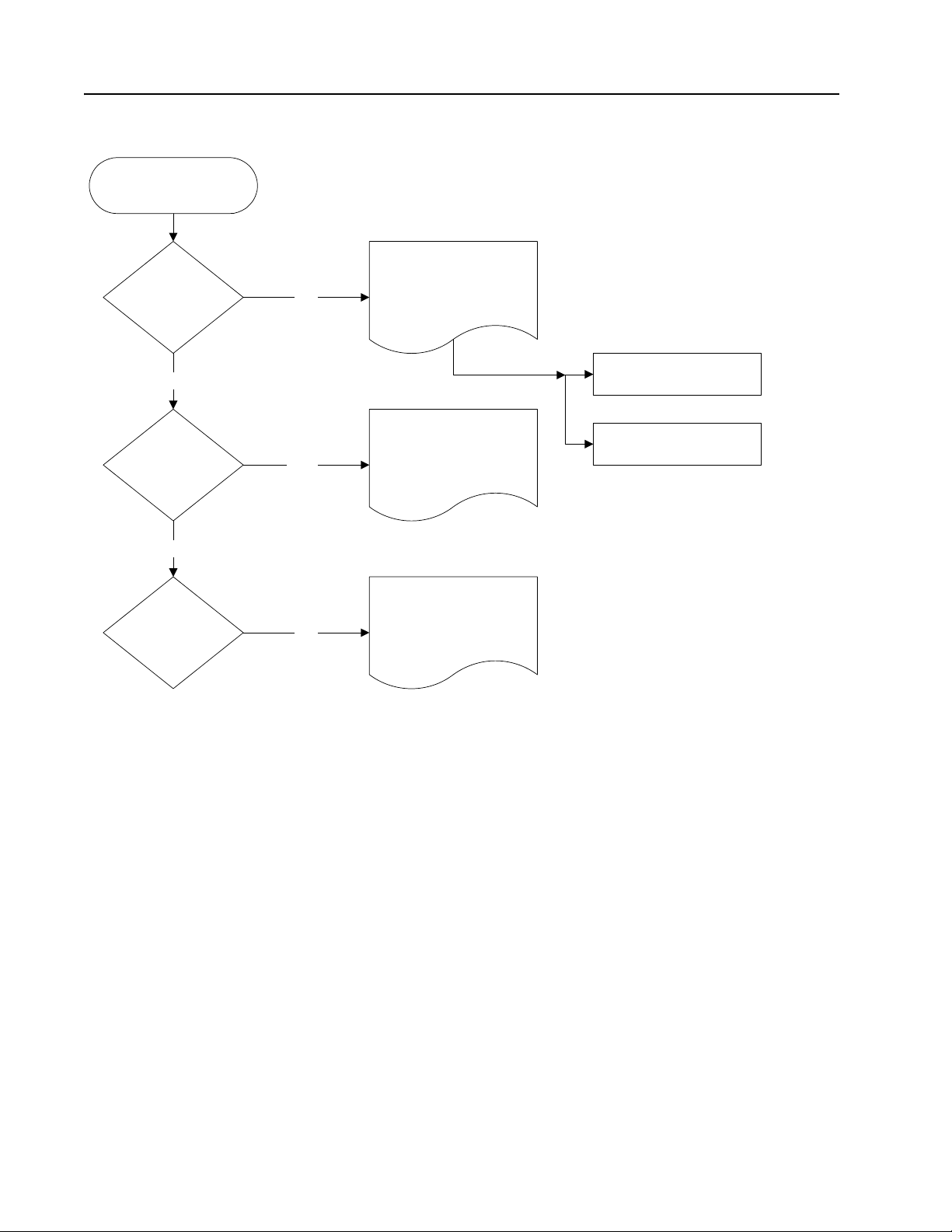

START Page

START-2

To test,

inspect, adjust,

remove/install a

component?

No

To find general

reference

information?

No

To locate

an object or

procedure by

name?

Yes

Yes

Yes

Go to Section 6

"Component Procedures"

Go to the

"Appendix"

Go to the Index

Alphabetical List of

Component Procedures

Component Locator

1Startpg2.wmf

1-8 00700-CL398-07, Issued: 9 August 2007

Toyota Pallet Truck Service Manual Safety

Section 2. Safety

00700-CL398-07, Issued: 9 August 2007 2-1

Safety Toyot a Pallet Truck Service Manual

Definitions

Definitions

In this manual, you will see two kinds of safety

reminders:

A warning specifies a potentially

hazardous situation that, if not

prevented, could result in death or

serious injury.

A caution specifies a potentially

hazardous situation that, if not avoided,

could result in minor or moderate injury

or in damage to the lift truck or nearby

objects. A caution can also alert against

unsafe practices.

2-2 00700-CL398-07, Issued: 9 August 2007

Toyota Pallet Truck Service Manual Safety

General Safety

General Safety

Do not operate or work on this truck unless you

are trained, qualified and authorized to do so,

and have read the Owner/Operator Manual.

2

Know the truck’s controls and what they do.

Operate this truck only from the operator’s

position.

2O-7.eps

Before working on this truck, always turn the

key switch to OFF and disconnect the truck’s

battery connector (unless this manual tells you

otherwise).

2

Do not operate this truck if it needs repair or if

it is in any way unsafe.

2O-6.eps

2S-1.eps

Do not wear watches, rings, or jewelry when

working on this truck.

21864 067.eps

00700-CL398-07, Issued: 9 August 2007 2-3

Safety Toyot a Pallet Truck Service Manual

General Safety

Obey the scheduled lubrication, maintenance,

and inspection steps.

2Schedmnt.eps

Obey exactly the safety and repair instructions

in this manual. Do not take “shortcuts.”

2

Do not use an open flame near the truck.

Clean up any hydraulic fluid, oil, or grease that

has leaked or spilled on the floor.

2Spills.eps

Always park this truck indoors.

2O-63.eps

Do not park this truck in a cold storage area

overnight.

223L6S012.eps

Do not use gasoline or other flammable liquids

Do not wash this truck with a hose.

2

for cleaning parts.

2

2

2-4 00700-CL398-07, Issued: 9 August 2007

Loading...

Loading...