Toyota 8FGDU15-32, 8FGCU20-32 User Manual

ELECTRICAL SYSTEM TROUBLESHOOTING

8FG(D)U15-32, 8FGCU20-32

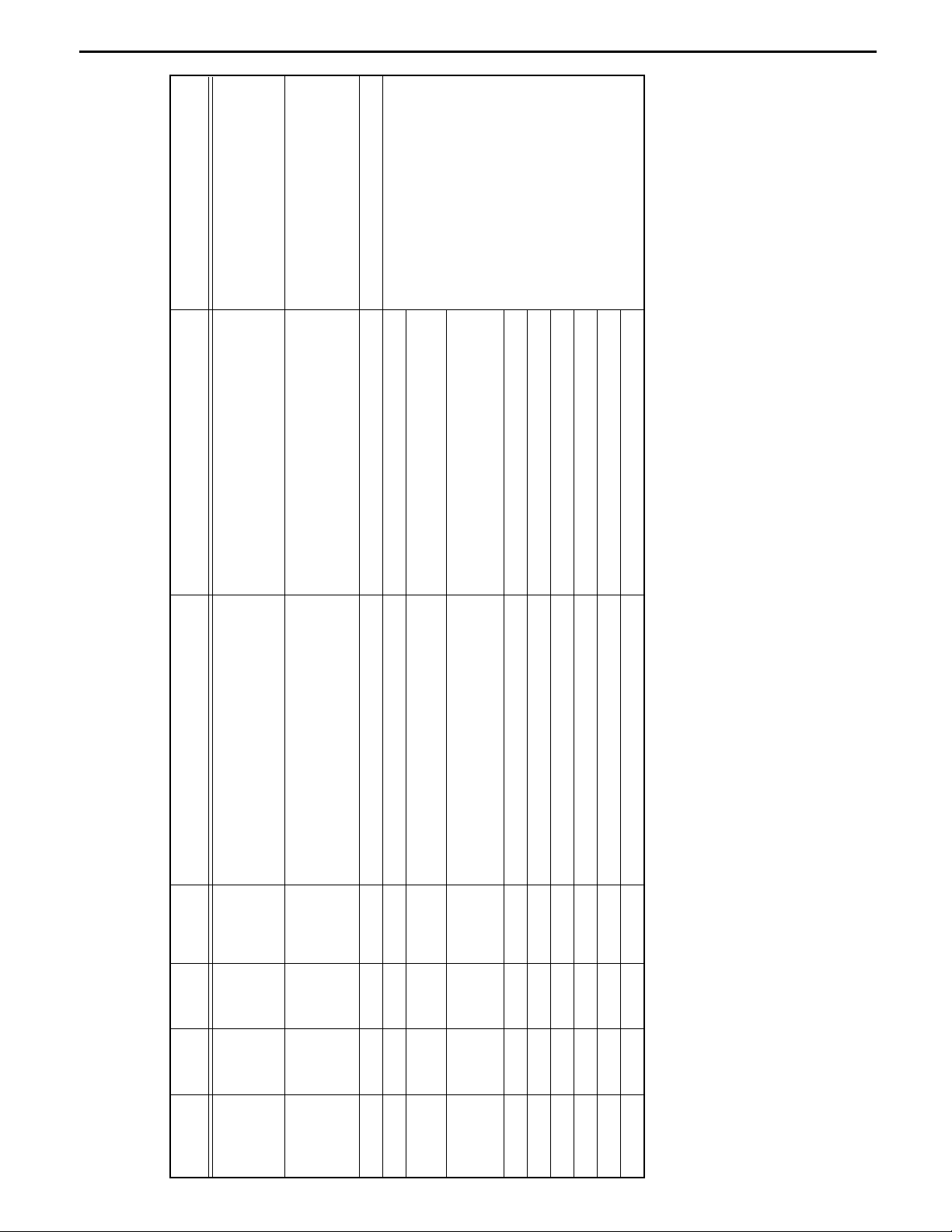

Page

BEFORE TROUBLESHOOTING..........................19-2

CONNECTOR HANDLING.......................................19-2

WIRE HARNESS AND CONNECTOR

INSPECTION PROCEDURE

..................................19-2

19-1

0

1

2

TROUBLESHOOTING..........................................19-4

BEFORE BEGINNING TROUBLESHOOTING

FOR THE 4Y-E ENGINE

DIAGNOSIS (SELF DIAGNOSIS FUNCTION) ............19-5

DIAGNOSIS DISPLAY METHOD..............................19-5

LIST OF DIAGNOSIS CODES..................................19-6

WARNING LIST ...................................................19-12

VIEWING RELATED PORTIONS............................19-13

ERROR CONFIRMATION DRIVE MODE .................19-13

TROUBLESHOOTING BY ERROR CODE...............19-14

TROUBLESHOOTING WHEN THERE IS

NO ERROR CODE

...........................................19-156

........................................19-4

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

E

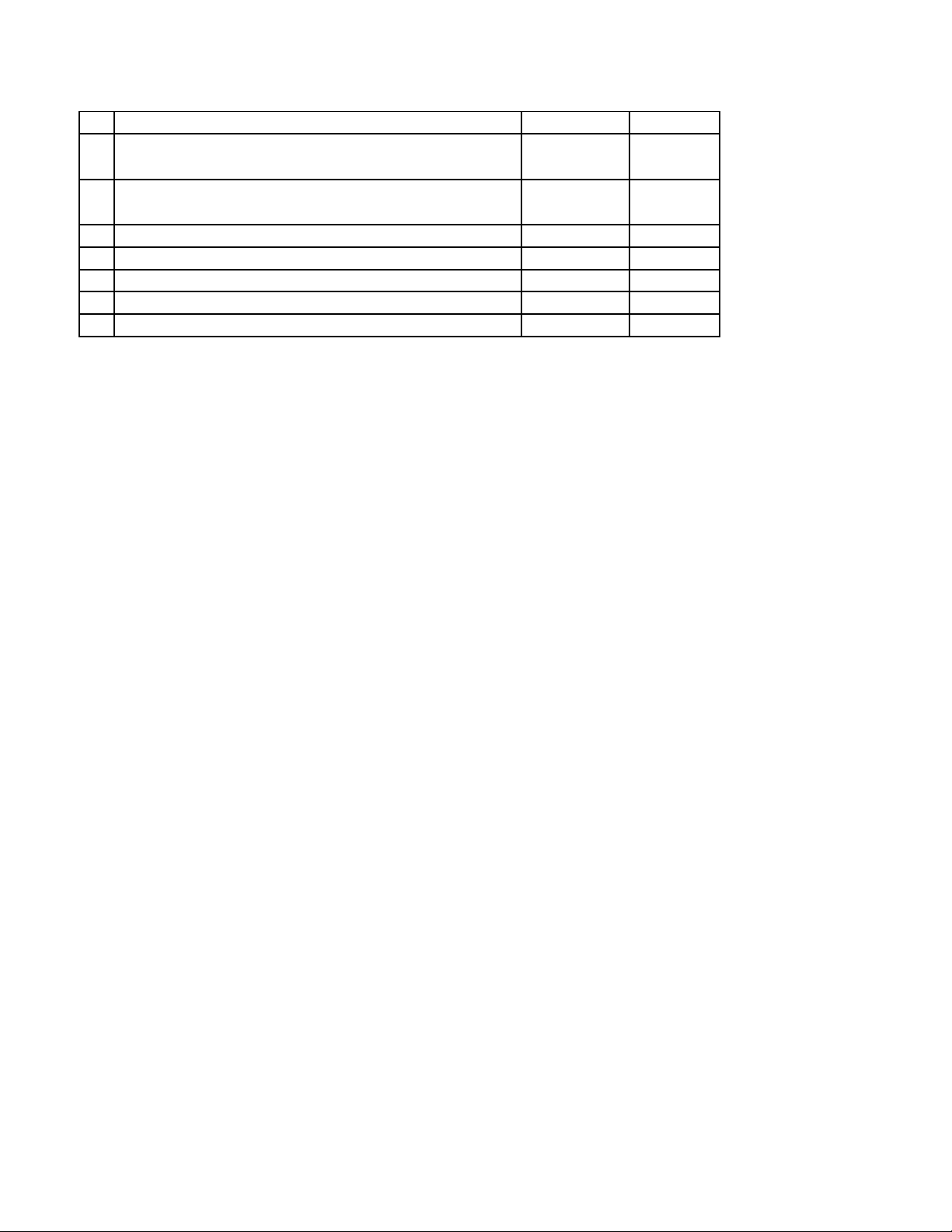

Service Manual Change History

Description Page # Date

Revised error code for change in terminal

1

esignation on seat switch from X1-1, X1-2 to 05Page not required foerror code A5-1 and turned

2

into memo page

3Added bookmarks all 3/31/13

4Added SIB CE07-008 197 3/31/13

5Added SIB CE08-005 195, 196 3/31/13

6Added SIB CE09-004 199 3/31/13

7Added SIB CE10-005 198 3/31/13

19-111 12/15/09

19-112 12/15/09

Service Information Buletin

1 SIB CC08-005 4Y ECS Controller Programming Change Chapter 19

2 SIB CE07-008 Error Code AD-1 and AD-7 Chapter 19

3 SIB CE09-004 A5, A5-1 or 1-1 Error Codes For OPSS Chapter 19

4 SIB CE10-003 Horn Relocation Chapter E2

5 SIB CE10-005 Main Wiring Harness Change (Error Code 73-1) Chapter 19

6 SIB CE11-001R Clamp Release Interlock (Mini Lever Units) Chapter 19, 14, E3

7 SIB CE11-003 Clamp Release Interlock (Standard Lever Units) Chapter 14, E3

8 SIB EN07-001 4Y Engine Ignition Timing Procedure Chapter 1.3-10

9 SIB EN08-001 Repair Manual (00700-X8880-71) Revision Embedded

10 SIB EN08-002 Repair Manual (00700-X8880-71) Revision Embedded

11 SIB EN09-001 Repair Manual (00700-X8880-71) Revision Embedded

12 SIB EN09-002 Repair Manual (00700-X8880-71) Revision Embedded

13 SIB EN10-001 Engine Block Heaters Chapter 1.2-4

14 SIB FS08-001 LPG Regulator Chapter 1.3-2

15 SIB HS07-003 Flow Regulator Replacement Parts Chapter 14

16 SIB MA07-001 Hourmeter Fuse Installation Chapter 0

17 SIB MA07-003 Transmission Oil Level Inspection Chapter 2 & 2.1

18 SIB MA07-004R Grease Specifications Chapter 0

19 SIB MA10-001 Overhead Guard Mounting Bolt Torque Chapter 9

20 SIB MA10-007 Oil Pressure Switch Chpater 0 & E3

21 SIB MA11-001 Service Hint For Greasing Rear Axle Beam Pivot Pin Chapter 0

22 SIB MA13-001 Exhaust Mounting Clamp with Rubber Bushing Inspection Chapter 0

23 SIB RA08-001 Updated Horn Pad Chapter 7

24 SIB ST07-001 Special Service Tools Chapter 17

25 SIB TR07-001 Transmission Control Valve Identification Chapter 2 & 2.1

26 SIB TR07-002 Propeller Shaft Cover Chapter 2 & 2.1

Technical News Brief

1 TNB 2007-03R1 Hydraulic Oil Change

2 TNB 2007-05 Transmission Knocking Noise At Idle

3 TNB 2007-06 LPG Regualtor Slow Path Tamper Resistant Cap

4 TNB 2007-11 Torque Specificaion Of Outer Mast Support Bolts

5 TNB 2008-07 Fuel Mixture Adjustment Procedure For The 4Y ECS Engine

6 TNB 2008-20 Gasoline Fuel System

7 TNB 2008-12 Installation of Fuel Line Fittings

8 TNB 2009-03 Suppliment to TNB 2008-07 For Adjusting VF (Voltage Fuel)

Hotline Tech Tips

1 HTT 2007-02

2 HTT 2007-03

3 HTT 2007-04

4 HTT 2007-05

5 HTT 2007-06

6 HTT 2007-07

7 HTT 2007-08

8 HTT 2007-09

9 HTT 2007-10

10 HTT 2007-11

Transmission Control Valve Identification; Proper Chasis Lubrication

Idle Surge/Hunt; Quick Facts; Rotten Egg/Ammonia Smell

Limiting Travel Speed; A5-1 Code

LPG Regulator Adjustment; Engine/Transmission "Knocking" Complaint

Troubleshooting Diesel Smoke; Multifunction Display

LPG Regulator Maintenance

Engine Surge

Propshaft Cover

Error Code 68-3; Flow Regulator Valve Parts Replacement

Wet Brake Option Hydraulic Oil; Error Code AD-1 And AD-7

11 HTT 2007-12

12 HTT 2008-01

13 HTT 2008-02

14 HTT 2008-03

15 HTT 2008-04

16 HTT 2008-05

17 HTT 2008-06

18 HTT 2008-07

19 HTT 2008-08

20 HTT 2008-09

21 HTT 2008-10

22 HTT 2008-11

23 HTT 2008-12

24 HTT 2009-01

25 HTT 2009-03

26 HTT 2009-06

27 HTT 2009-07

28 HTT 2009-08

29 HTT 2009-09

30 HTT 2009-10

31 HTT 2009-11

32 HTT 2010-01

33 HTT 2010-02

34 HTT 2010-03

35 HTT 2010-04

36 HTT 2010-05

37 HTT 2010-06

38 HTT 2010-07

39 HTT 2010-08

40 HTT 2010-09

41 HTT 2010-10

42 HTT 2010-11

43 HTT 2010-12

44 HTT 2011-01

45 HTT 2011-02

46 HTT 2011-03

47 HTT 2011-04

48 HTT 2011-05

49 HTT 2011-06

50 HTT 2011-07

51 HTT 2011-08

52 HTT 2011-09

53 HTT 2011-10

54 HTT 2011-11

55 HTT 2011-12

56 HTT 2012-01

Horn Pad Improvements; Correct Timing Mark On Crank Pulley

"L-OFF" Complaint

Error Code List; Rear Pillar Assist Relay Location; New Cab

Carriage Roller Replacement

Fuel Shut Off Valve Orientation On Gasoline And Dual Fuel Trucks

Driveability Issues Due To Dirty Throttle Body

Shift Interlock (Intelli-Shift) Adjustments; Overheat Trouble Shooting

LPG Tamper Resistant Cap

Cam Positions Sensor

SAS Matching; Transmission Repair

Seatbelt Interlock; Function Menu w/ Travel & Load Handling Option; Gas Tank Pressure

Accelerator Sensor Codes; LPG Filter Kit Service Parts

CNG Trucks Using The Analyzer; Extra Long Feeler Gauges for Mast Shimming Checks

Error Code 73-1, Or Missing Plug On New Harness

Load Sensor Wire Breakage; Dual Brake Pedal "Low Pedal" Complaint

Error Code OB-1

Horn Pad Improvements; Flow Regulator Update; Overheat Diagnostics

Engine Controller Version Identification

Identifying LPG Regulator 1st Valve Material; High Engine Idle Issues

Using the Engine Analyzer To Check The Engine Function

Error Codes Without An Hour Meter Reading; LPG Filter Kit PN

Reverse Polarity Damage Issues

Ignition Timing Value (IGT) Shown On Analyzer

Error Code 06-3; Error Code 01-5

To Throttle Valve Actuation And Error Code 06-3 E-THRO Fuse Location

Error Code AD-7 After Replacing The Main Harness

SAS Manual Lowering Valve Location; Flow Regulator W/ Part Numbers

SAS Code History Check Without The Analyzer

Clearing 01-1, 01-2, 01-3, 01-4, 01-5, 01-6 Codes After Making The Repair

Error Code 73-1 After Replacing The Main Harness

Hour Meter Diagnostics & Memory

Diagnosing Diesel Smoke

LPG Regulator Adjustment & Tar Draining: Idle Speed Adjustment

How To Read An O2 Sensor

Required Adjustments For New LP Regulator, And Installation Of Anti-Tamper Caps

Engine Analyzer Screen 1/10; Throttle Body Cleaning

Engine Analyzer Screen 2/10; Analyzer Speed Versus Displayed Speed

Engine Analyzer Screen 3/10

Engine Analyzer Screen 4/10

Engine Analyzer Screen 5/10

Engine Analyzer Screen 6/10

Engine Analyzer Screen 7/10

Engine Analyzer Screen 8/10

Engine Analyzer Screen 9/10

Engine Analyzer Screen 10/10

Error Code 09-1; LPG Filter Kit; Cold Soak Lack Of Travel

19-219-2

Electrical System Troubleshooting

Section 19

BEFORE TROUBLESHOOTING

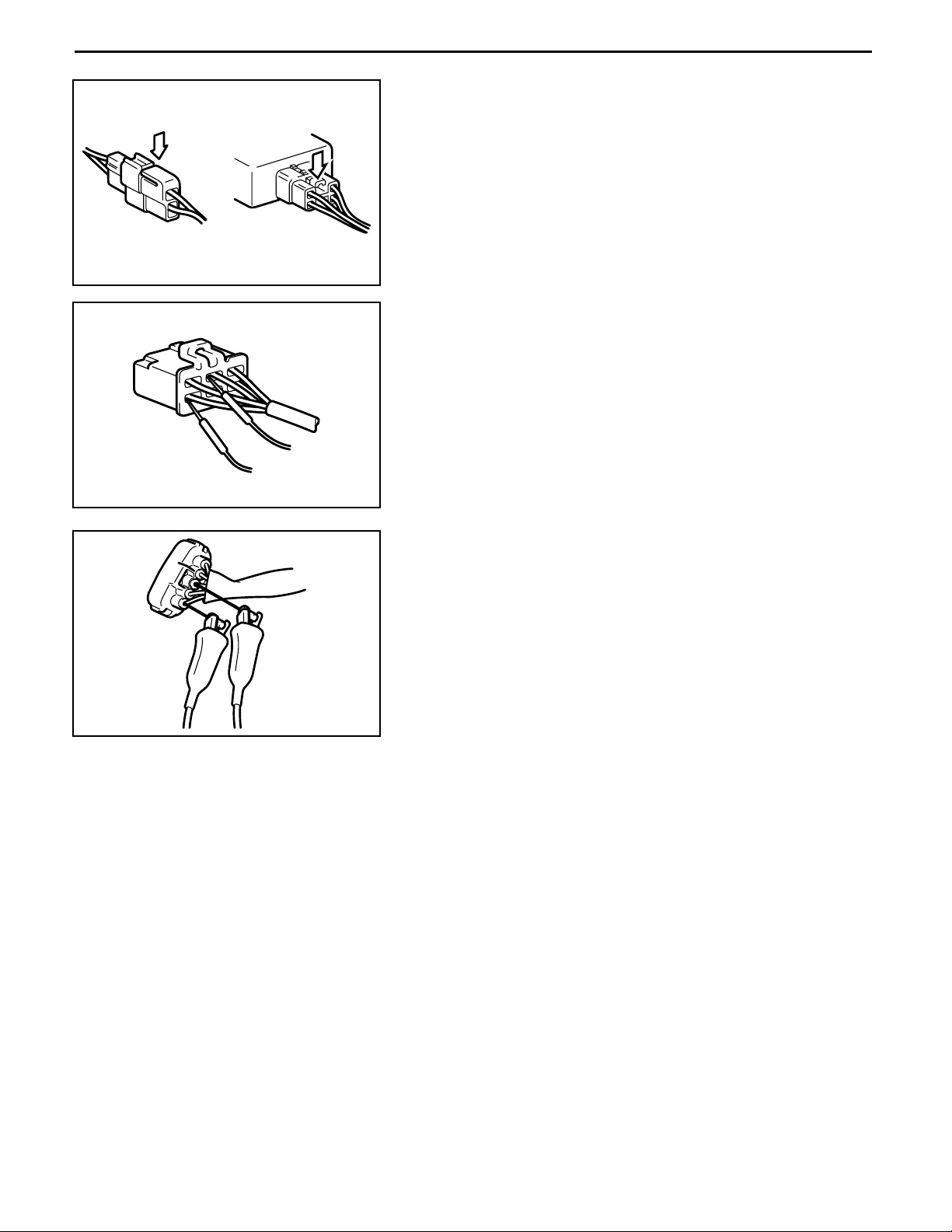

CONNECTOR HANDLING

1. Disconnect the battery plug before connecting or

disconnecting each connector or terminal.

2. When disconnecting a connector, do not pull the wire harness

but hold the connector itself and pull it after unlocking it.

To connect, push the connector fully until it is locked in

position.

3. Bring a tester probe into contact with a connector terminal from

the rear side of the connector (harness side).

4. If insertion from the rear side is impossible, as in the case of a

waterproof connector, bring the tester probe carefully into

contact with the terminal so as not to cause deformation of the

connector terminal.

5. Do not touch connector terminals directly with your hand.

6. When bringing tester probes into contact with terminals that

voltage is applied to prevent two tester probes from coming

into contact with each other.

WIRE HARNESS AND CONNECTOR

INSPECTION PROCEDURE

When any trouble occurs, first inspect the connectors and wire

harness of the related circuit according to the following procedure:

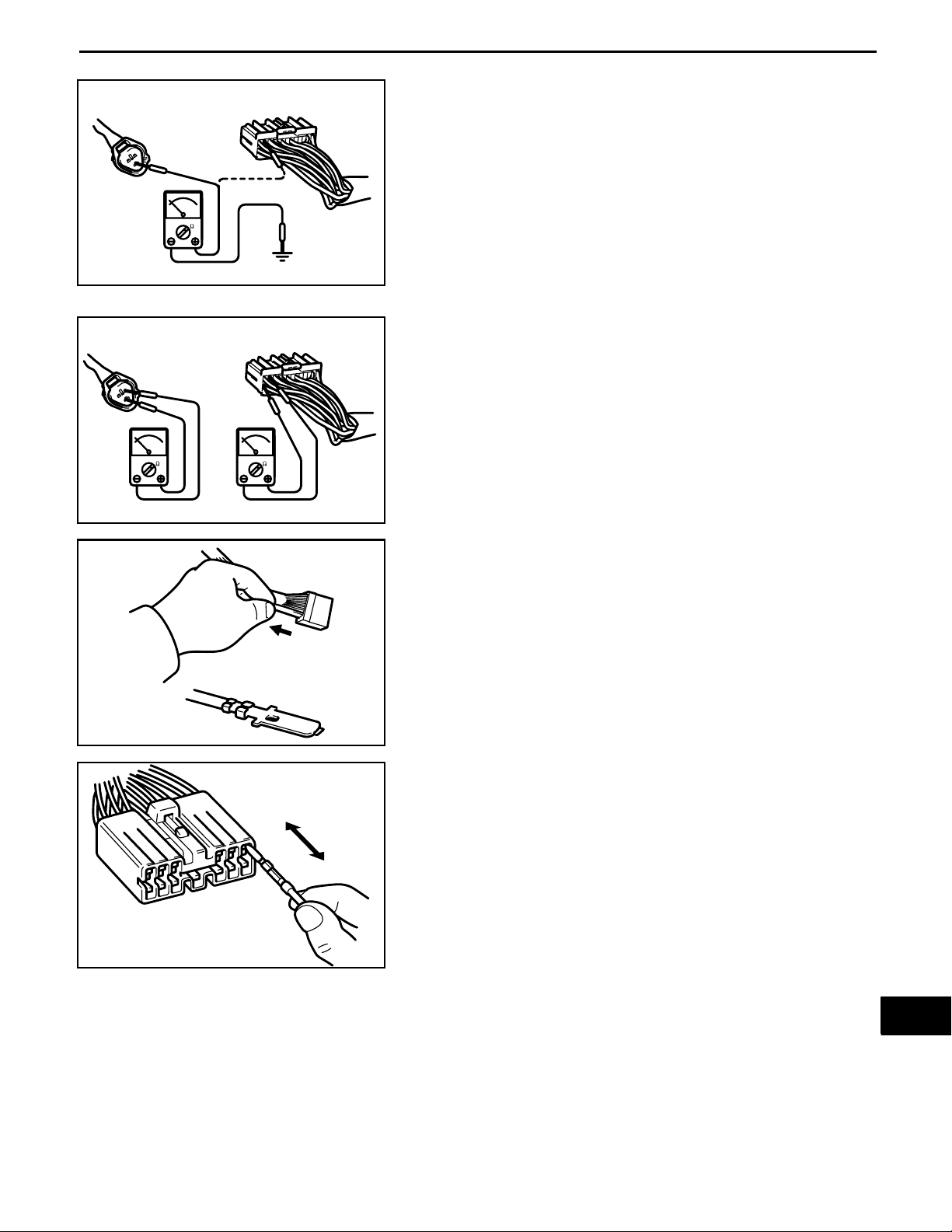

Continuity Inspection

1. Disconnect the connectors at both ends of the corresponding

harness.

2. Measure the resistance between corresponding terminals of

the connectors at both ends.

Standard: 10 Ω or less

Note:

• Measure while jiggling the wire harness up and down and

sideways.

• Open circuit at the wire harness occurs rarely partway

through a vehicle wiring but mostly at connectors. Inspect

especially the sensor connectors with sufficient care.

19-3

Electrical System Troubleshooting

Section 19

Short Circuit Check

1. Disconnect the connectors at both ends of the corresponding

harness.

2. Measure the resistance between the corresponding connector

terminal and frame. Be sure to inspect the connectors at both

ends.

0

Standard: 1 MΩ or above

Note:

Measure while jiggling the wire harness up and down and

sideways.

3. Measure the resistance between terminals of the

corresponding connector. Be sure to inspect the connectors at

both ends.

Standard: 1 MΩ or above

Note:

The wiring may short-circuit due to pinching by the body or

defective clamping.

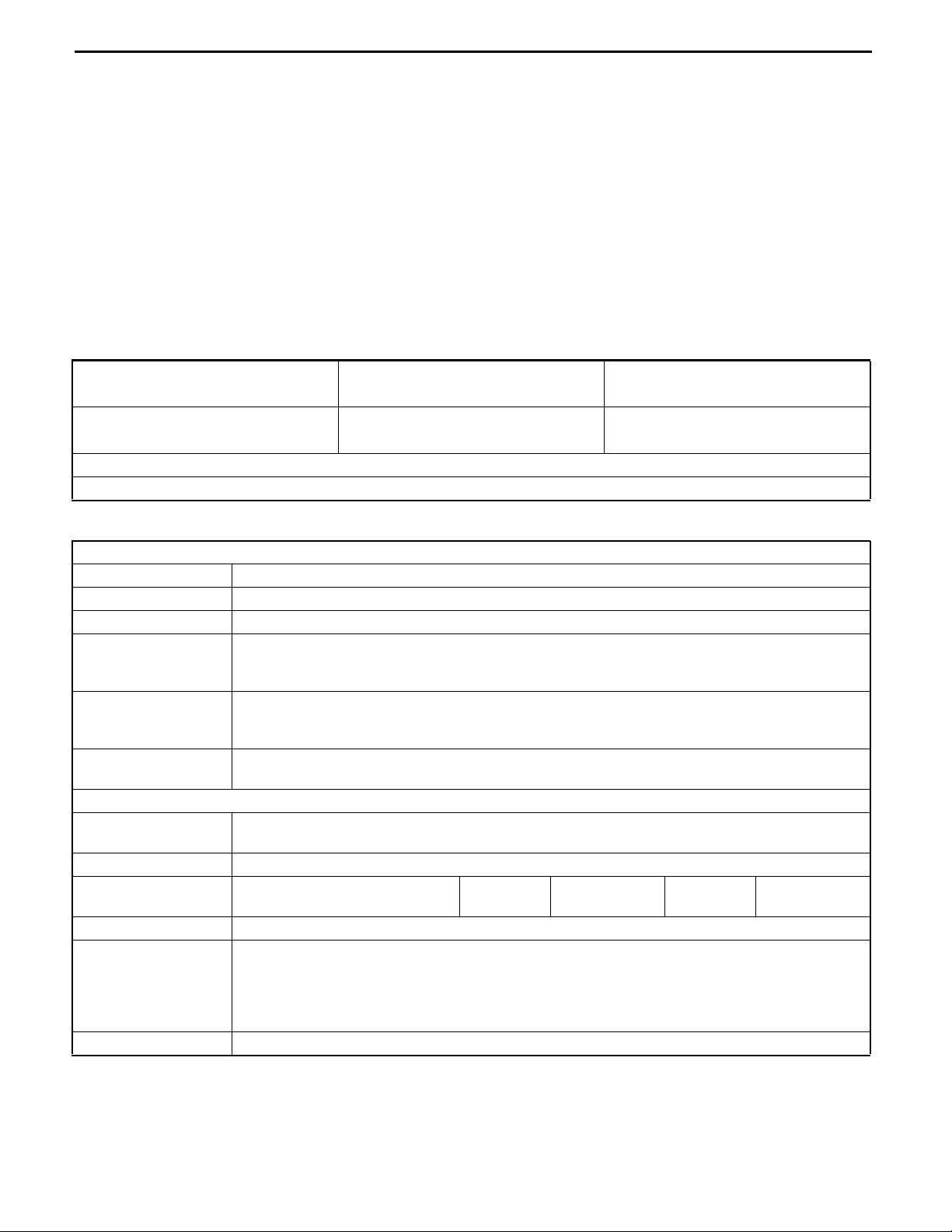

Visual and Contact Pressure Checks

1. Disconnect the connectors at both ends of the corresponding

harness.

2. Visually inspect that there is neither rust nor foreign matter

trapped at connector terminals.

3. Inspect that there is no looseness or damage at the crimped

portion. Also, lightly pull the wire harness from the connector to

check that it does not come off.

1

2

3

4

5

6

7

8

9

10

11

12

4. Insert a male terminal same as that of the connector terminal

to a female connector and check the drawing force.

Defective contact may exist at a terminal where the drawing

force is less than that of other terminals.

Note:

Even if there is rust or foreign matter trapped at the terminal,

or the contact pressure between male and female terminals is

low, abnormal contact condition may be changed to normal by

disconnecting and reconnecting the connector. In this case,

disconnect and reconnect the connector several times, and if

a fault occurs even once, then consider the terminal may have

a defective contact.

13

14

15

16

17

18

19

20

21

E

19-419-4

Electrical System Troubleshooting

Section 19

TROUBLESHOOTING

BEFORE BEGINNING TROUBLESHOOTING FOR THE 4Y-E ENGINE

It is extremely risky to begin troubleshooting for the 4Y engine on the basis of results only. It can lead to mistaken

corrective action, wasted time, and sometimes to an increase in abnormalities. Therefore, ask the customer about

detailed information on conditions around the time a problem occurred, based on the following.

Diagnostic Procedure

First, it is necessary to be informed of the "fault history and service history" for the vehicle, and then to gather definite

information about the fault occurence such as "when", "at what times", "in what places", "during what operations or

actions", "what happened afterwards", and “frequency of occurrence”.

Also, try to recreate the conditions for the fault occurence. (a. Recreation impossible b. Recreation possible: in what

condition?)

• General items

Customer name Date of delivery Date fault occurred / hour meter reading

Vehicle model Frame No. Engine No. (punched)

Fuel type

F Gasoline F LPG F Gasoline - LPG combination (Note LPG fuel company name: )

• Condition of the defect (Tick the items that apply)

Defect phenomena

1. Cannot start a. Does not crank b. Combustion does not start c. Incomplete combustion

2. Does not start well Poor cranking (when cold - when warm - at all times)

3. Poor idle a. Poor idle speed b. Unstable idle speed c. Hunting (regular fluctuation in speed)

a. Immediately after start-up (when cold - when warm) b. During deceleration c. After deceleration

4. Engine stalling

5. Defect operational

status

6. Other

Environment at the time of the defect's occurrence

The time when the fault

began to occur

Frequency of occurence a. Always b. Under certain conditions c. Sometimes

Weather

Temperature conditions Coolant: a. When cool b. When warm Temperature inside engine room: °C

Operation conditions

Lamps a. Lights constantly b. Lights occaisonally c. Does not light

d. Without sign e. After the engine has been running rough f. When steering

g. When handling materials h. Can be re-started immediately

a. Insufficient power output b. Hesitation

c. Surging (swaying forward and backward during acceleration) d. Knocking e. Backfiring f. After

firing

a. Excessive fuel consumption b. Excessive oil consumption c. Overheating d. Water or oil leaks

e. Abnormal noise f. Other ( )

a. Since the vehicle was new b. Recently (from around the following date (month and year): )

c. After being serviced

Sunny - cloudy - rain - snow thunderstorm

a. No relation b. When idling c. When revving d. When accelerating

e. When traveling at constant speed f. When decelerating g. When climbing a slope

h. During material handling operations When not loaded (when steering - when lifting - when tilting)

When loaded (load: appox. kg) (when steering - when lifting - when tilting)

i. Other (when using the inching brake - when steering - other)

Temperature

Approximately

°C

Humidity

Approximately

%

19-5

Electrical System Troubleshooting

Section 19

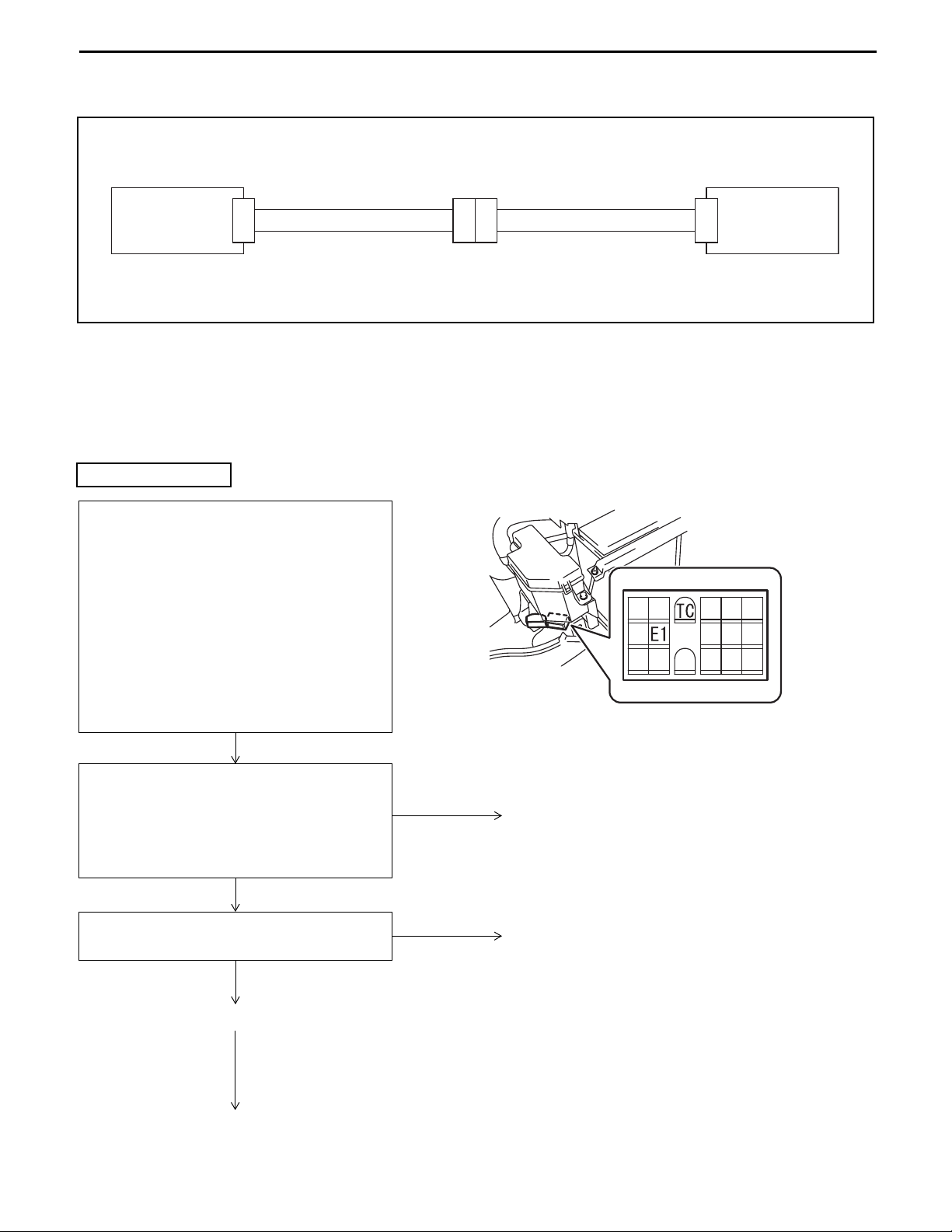

DIAGNOSIS (SELF DIAGNOSIS FUNCTION)

General

When the computer detects a problem in the system, the fault is indicated by lighting a warning lamp on the

combination meter and displaying an error code. And fail-safe functions are started automatically to stop the engine

or control the engine to a low speed.

0

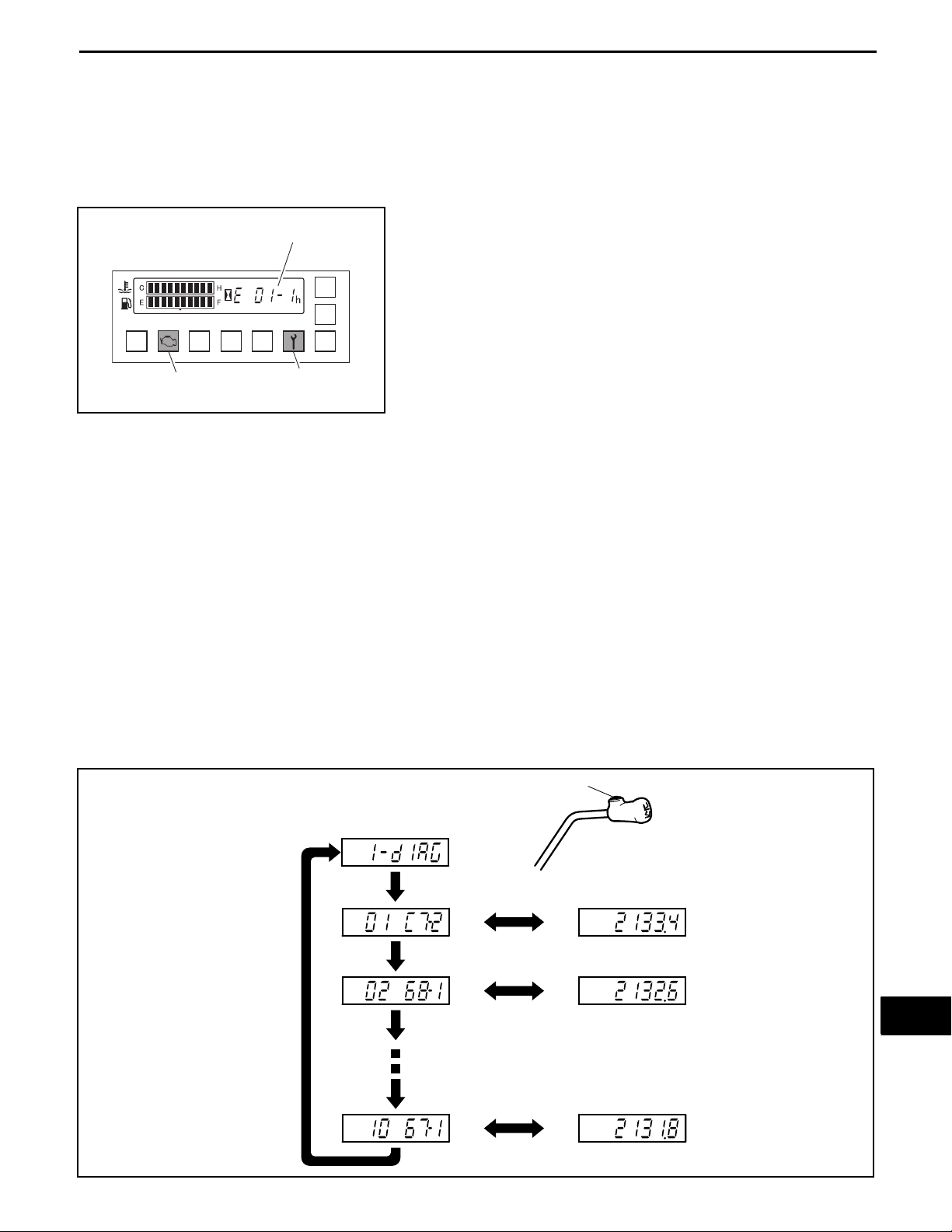

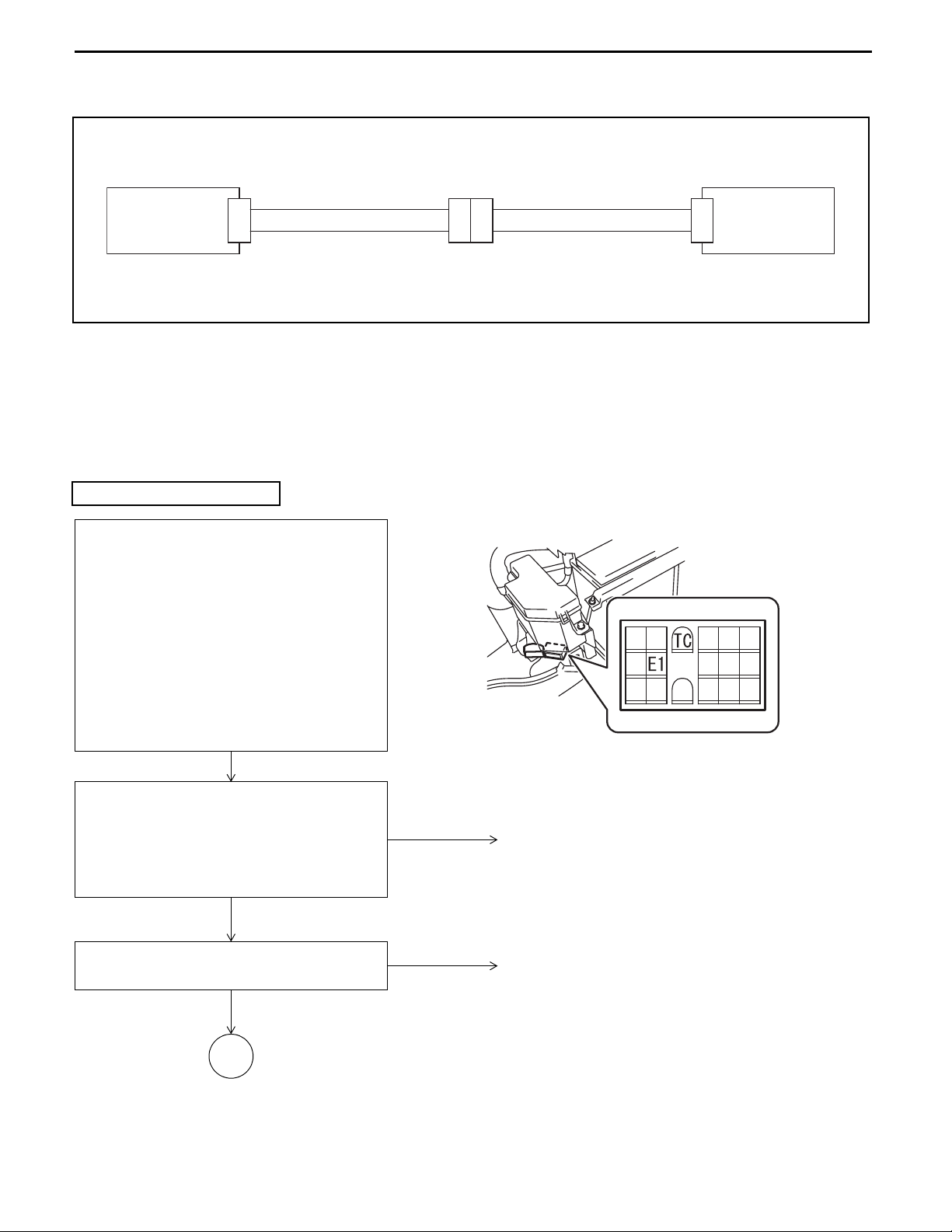

DIAGNOSIS DISPLAY METHOD

Error code display

An orange colored lamp lights

(Engine ECU only)

2. Diagnosis memory display method

To display the diagnosis memory display, there are a method using the hour meter and tilt lever, a method using

the optional display, and a method using a plug-in analyzer.

Here the display method using the hour meter and tilt lever is described.

(1) From the main menu, display the diagnosis memory menu. For how to display the main menu, refer to page

18-30.

(2) A diagnosis No. and error code are displayed each time the knob switch is pressed and released. Each

error code and the time at which it occurred are displayed alternately at 2 second intervals.

Note:

• The maximum number of error codes that can be stored is 10. The smaller the diagnosis No., the more

recent the error is.

• The stored time of an error code appearing just when the ignition key switch is turned ON may be stored

as 0.0.

Lamp blinks

1. Diagnosis display method

The diagnosis is displayed by means of an error code as

shown in the illustration to the left, and by the lights turning on.

When the ignition key switch is turned ON, the lamp lights

once to allow checking for the bulb, and then turns off again if

the status is normal.

With the ignition key switch ON, if an abnormality is detected

when the vehicle is stopped, travelling or performing meterials

handling operations, an error code is displayed and the lamps

turn on as a warning.

When this happens, stop the vehicle immediately and check

the error code.

1

2

3

4

5

6

7

8

9

10

11

12

(3) Connect the matching connector and turn the ignition key switch OFF.

Knob switch

Diagnosis memory menu

Press the knob switch to return it.

Switches automatically

every 2 seconds

13

14

15

16

17

18

19

20

21

E

19-6

Electrical System Troubleshooting

Section 19

Described

19-14

on page

19-18

The engine speed is unstable and it may stop.

19-27

The engine may have a problem at low

temperatures.

The engine may have a problem 19-29

19-31

The engine may have a problem at low

temperatures.

19-33

Limting speed of traveling and materials

handling due to limited engine power output

19-35

19-37

Limting speed of traveling and materials

handling due to limited engine power output

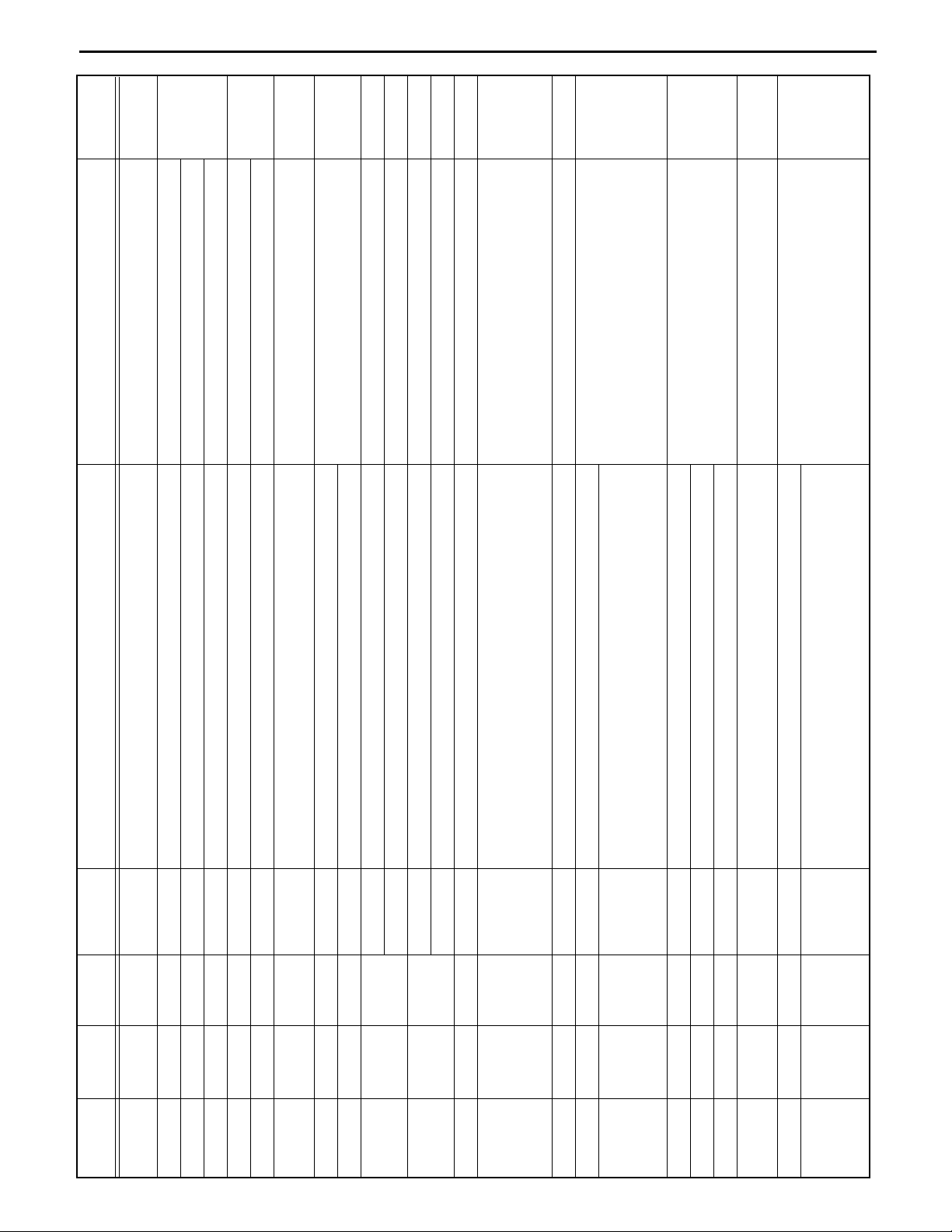

19-470A-2 0A-2 Blinking 4Y-ECS Fuel specification changeover switch error Display only

Error mode Phenomenon on vehicle

ECU

Detection

Spanner

lamp

Wrench

01-1 01-1 Blinking 4Y-ECS Fuel feedback control error (gasoline) rich

Indication

LIST OF DIAGNOSIS CODES

01-2 01-2 Blinking 4Y-ECS Fuel feedback control error (gasoline) lean

01-3 01-3 Blinking 4Y-ECS Fuel feedback control error (LPG/CNG) rich

01-4 01-4 Blinking 4Y-ECS Fuel feedback control error (LPG/CNG) lean

01-5 01-5 Blinking 4Y-ECS O2 sensor open abnormality The engine speed is unstable and it may stop. 19-23

01-6 01-6 Blinking 4Y-ECS O2 sensor heater open abnormality Display only 19-25

02-1 02-1 Blinking 4Y-ECS Intake temperature sensor open abnormality

02-2 02-2 Blinking 4Y-ECS Intake temperature sensor short abnormality

03-1 03-1 Blinking 4Y-ECS Intake pipe pressure sensor open abnormality

03-2 03-2 Blinking 4Y-ECS Intake pipe pressure sensor short abnormality

04-1 04-1 Blinking 4Y-ECS Coolant temperature sensor open abnormality

04-2 04-2 Blinking 4Y-ECS Coolant temperature sensor short abnormality

05-1 05-1 Blinking 4Y-ECS Throttle position sensor 1 open abnormality

05-2 05-2 Blinking 4Y-ECS Throttle position sensor 1 short abnormality

05-3 05-3 Blinking 4Y-ECS Throttle position sensor 2 open abnormality

05-4 05-4 Blinking 4Y-ECS Throttle position sensor 2 short abnormality

05-5 05-5 Blinking 4Y-ECS Throttle position sensor offset abnormality

05-6 05-6 Blinking 4Y-ECS Throttle position sensor out of range error

06-1 06-1 Blinking 4Y-ECS Throttle motor drive circuit open abnormality

06-2 06-2 Blinking 4Y-ECS Throttle motor drive circuit short abnormality

06-3 06-3 Blinking 4Y-ECS Throttle motor power supply circuit open abnormality

06-4 06-4 Blinking 4Y-ECS Throttle motor power supply circuit short abnormality

06-5 06-5 Blinking 4Y-ECS Throttle motor seizing abnormality 19-38

06-6 06-6 Blinking 4Y-ECS Electronic throttle system error 19-40

07-1 07-1 Blinking 4Y-ECS Air-fuel ratio motor open abnormality The engine speed is unstable and it may stop. 19-41

08-1 08-1 Blinking 4Y-ECS Low voltage (battery line open) error Display only 19-43

09-1 09-1 Blinking 4Y-ECS Ignition signal error The engine speed is unstable and it may stop. 19-44

0A-1 0A-1 Blinking 4Y-ECS Fuel specification determination signal error Display only

0A-3 0A-3 Blinking 4Y-ECS Fuel specification type unmatch Engine may stop

19-7

Electrical System Troubleshooting

Section 19

Described

on page

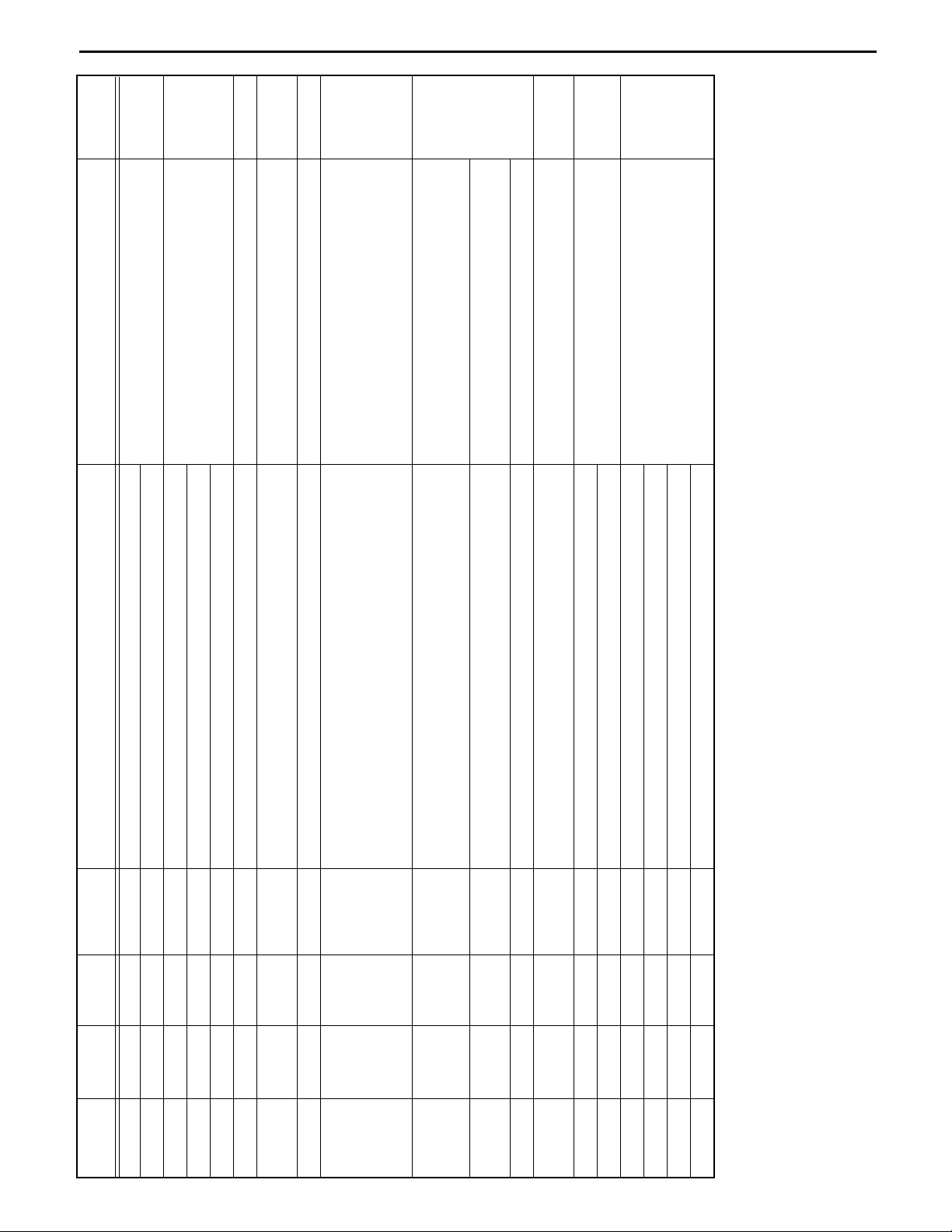

19-49

Limting speed of traveling and materials

handling due to limited engine power output

19-5013-2 13-2 Blinking ASC Motor relay contact point short abnormality Display only

19-52

19-55

Continuation of engine idling status after

acceleration off.

Continuation of engine idling status 19-58

19-67

Continuation of engine idling status

Maximum speed may be limited

Function of automatic idle speed increse during

lifting limited

19-69

Partial limitation of the rear wheel swing control

function.

Knob offest compensation stops

Partial limitation of the drive control function.

19-7152-2 52-2 Blinking SAS/OPS Yaw rate sensor VCC short abnormality

Partial limitation of the rear wheel swing control

function

19-73

Partial limitation of the rear wheel swing control

function

19-75

function

Partial limitation of mast control function

Limitation of the drive control function

Load indicator cannot display

Error mode Phenomenon on vehicle

ECU

Detection

Spanner

lamp

Wrench

Indication

13-1 13-1 Blinking ASC Motor relay contact point open abnormality Continuation of engine idling status

0A-4 0A-4 Blinking 4Y-ECS Engine specification determination error

13-3 13-3 Blinking ASC Motor relay open circuit or load short abnormality Continuation of engine idling status

15-1 15-1 Blinking ASC NMR switch open abnormality The engine may idle during full acceleration.

15-2 15-2 Blinking ASC NMR switch short abnormality Continuation of engine idling status

15-3 15-3 Blinking ASC Idle / NMR switch simultaneously ON error

16-1 16-1 Blinking ASC Idle switch open abnormality

16-2 16-2 Blinking ASC Idle switch short abnormality

ASC Engine speed sensor open abnormality Partial limitation of the drive control function. 19-65

4Y-ECS Cam angle sensor open abnormality Engine stop 19-61

18-1 18-1 Blinking

ASC Engine speed sensor GND short abnormality Partial limitation of the drive control function. 19-65

4Y-ECS Cam angle sensor open abnormality (on start up) Engine will not start 19-61

18-2 18-2 Blinking

18-3 18-3 Blinking 4Y-ECS Crank angle sensor open abnormality Display only 19-63

1F-1 ~ 8 1F-1 ~ 8 Blinking ASC CPU error

41-1 41-1 Blinking SAS/OPS Matching connector open abnormality Display only 19-68

51-1 51-1 Blinking SAS/OPS Speed sensor open abnormality The vehicle speed indicator shows 0 km/h

51-2 51-2 Blinking SAS/OPS Speed sensor GND short abnormality

52-1 52-1 Blinking SAS/OPS Yaw rate sensor open abnormality

52-3 52-3 Blinking SAS/OPS Yaw rate sensor neutral voltage error

54-1 54-1 Blinking SAS/OPS Swing lock solenoid open circuit or load short abnormality

61-2 61-2 Blinking SAS/OPS Load sensor VCC short abnormality

61-1 61-1 Blinking SAS/OPS Load sensor open abnormality Partial limitation of the rear wheel swing control

19-8

Electrical System Troubleshooting

Section 19

Described

on page

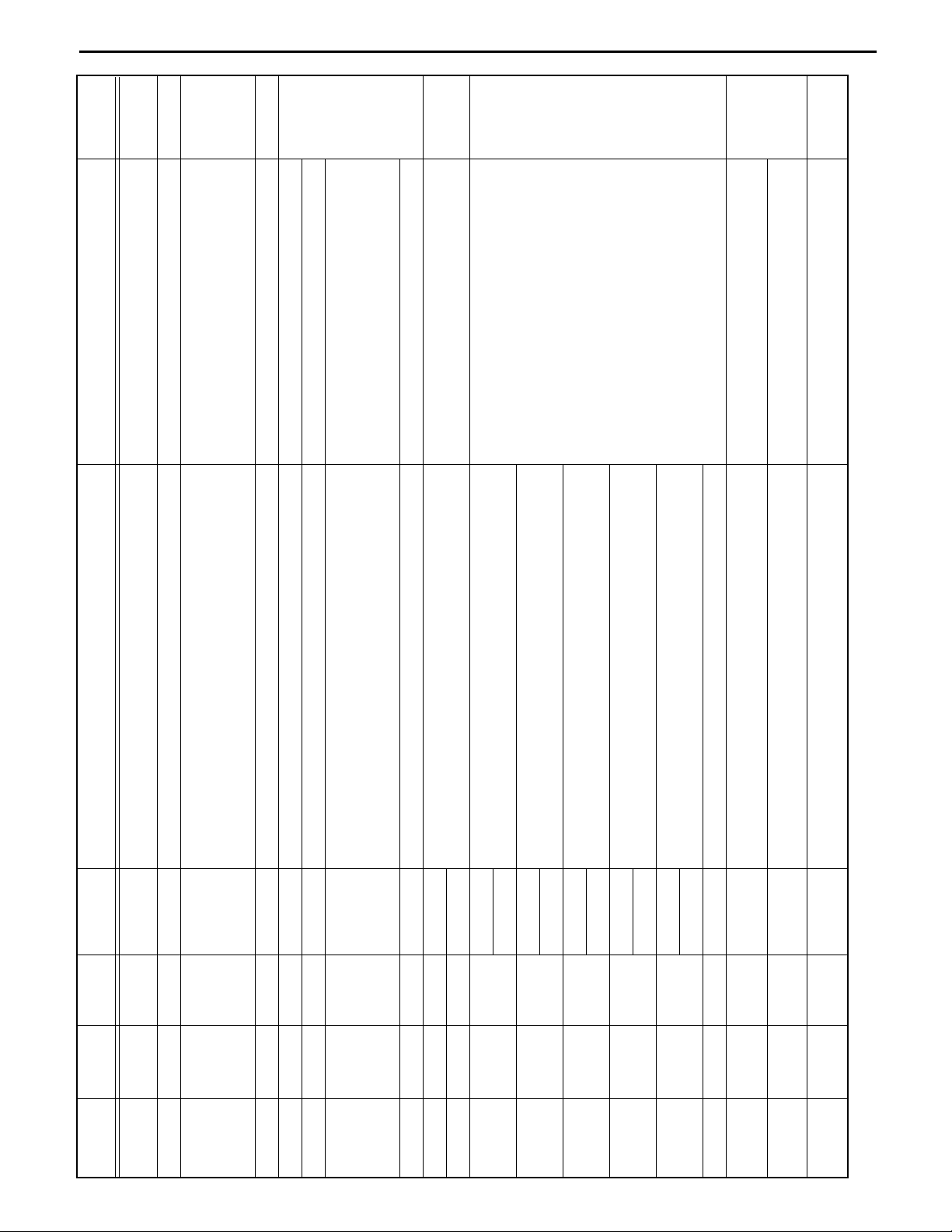

Partial limitation of mast control function 19-78

Partial limitation of mast control function 19-8163-2 63-2 Blinking SAS/OPS Tilt switch forward tilt SW short

19-86

Forward tilt may stop, backward tilt may go fully

back

19-89

Partial limitation of the rear wheel swing control

function

Partial limitation of mast control function

Limitation of the drive control function

19-92

Backward tilt may stop 19-95

Load indicator display is unsteady

Lowering may stop

Function of automatic idle speed increse during

lifting limited

Function of automatic idle speed increse during

lifting limited

Knob offest compensation stops 19-97

Knob offest compensation stops 19-100

Error mode Phenomenon on vehicle

ECU

Detection

Spanner

lamp

Wrench

Indication

62-1 62-1 Blinking SAS/OPS Tilt angle sensor open abnormality

62-2 62-2 Blinking SAS/OPS Tilt angle sensor VCC short abnormality

63-1 63-1 Blinking SAS/OPS Tilt switches simultaneously ON

63-3 63-3 Blinking SAS/OPS Tilt switch backward tilt SW short

64-1 64-1 Blinking SAS/OPS Lift lower lock solenoid open circuit or load short abnormality Lift lower may stop 19-84

65-1 65-1 Blinking SAS/OPS Tilt control solenoid open circuit or load short abnormality

66-1 66-1 Blinking SAS/OPS Outside matching value range for tilt angle error Partial limitation of mast control function 19-88

67-1 67-1 Blinking SAS/OPS Lifting height switch open abnormality

68-1 68-1 Blinking SAS/OPS Lift switch raise and lower simultaneously ON error

68-2 68-2 Blinking SAS/OPS Lift switch raise SW short abnormality

68-3 68-3 Blinking SAS/OPS Lift switch lower SW short abnormality Lowering may stop

Backward tilt lock solenoid open circuit or load short

abnormality

71-1 71-1 Blinking SAS/OPS Tire angle sensor open abnormality

69-1 69-1 Blinking SAS/OPS

71-2 71-2 Blinking SAS/OPS Tire angle sensor VCC short abnormality

72-1 72-1 Blinking SAS/OPS Steering-wheel angle sensor SS1 open abnormality

72-2 72-2 Blinking SAS/OPS Steering-wheel angle sensor SS2 open abnormality

72-3 72-3 Blinking SAS/OPS Steering-wheel angle sensor SSC open abnormality

72-4 72-4 Blinking SAS/OPS Steering-wheel angle sensors SS1 and SS2 open abnormality

19-9

Electrical System Troubleshooting

Section 19

Described

on page

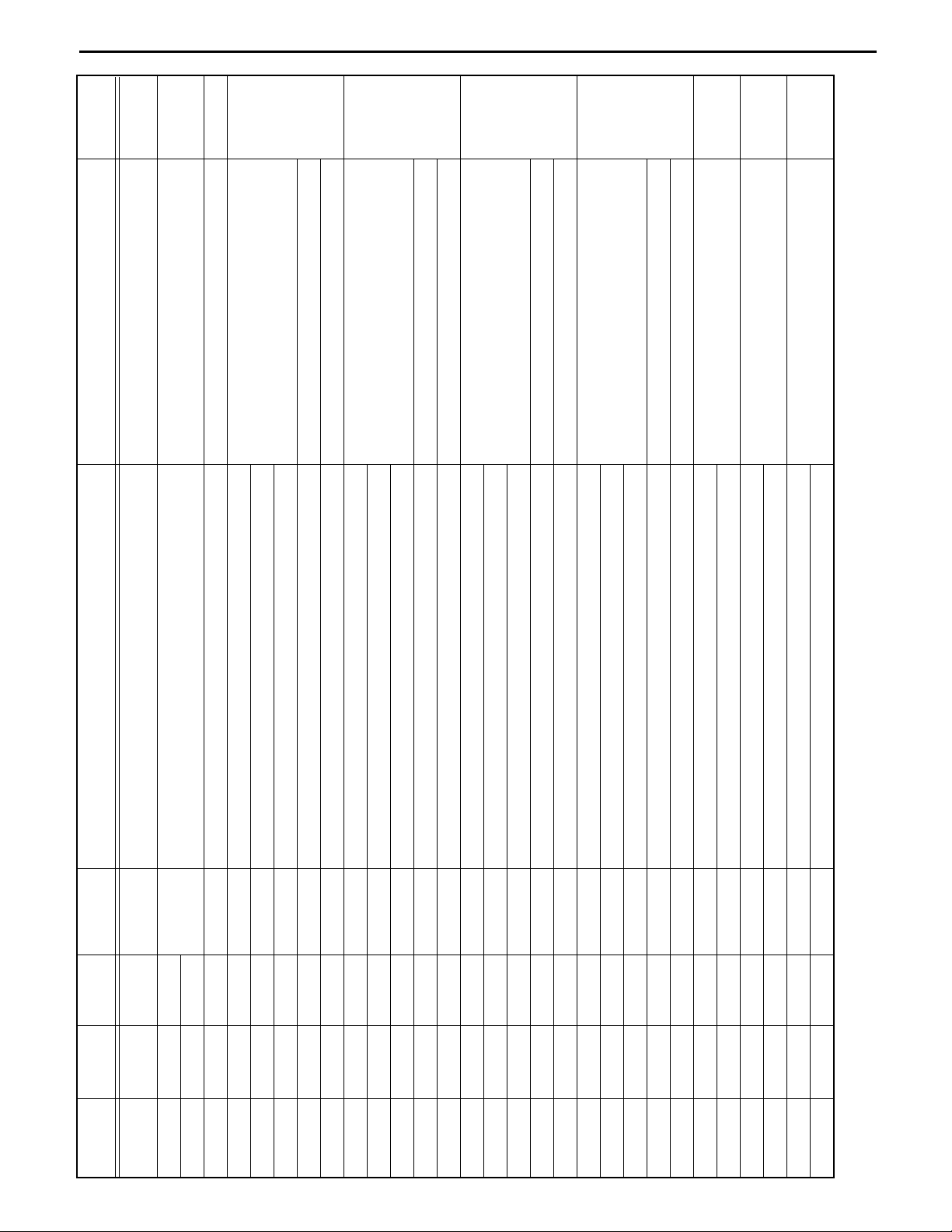

Knob offest compensation stops 19-108

19-111

Traveling and material handling possible even

after leaving the seat.

Parking brake reminder and release reminder

alarm partially disabled.

19-115

Limitation of the drive control function

Function of automatic idle speed increse during

lifting limited

Display warning function operation failure

19-123

Limting speed of traveling and materials

handling due to limited engine power output

Travel return to neutral operation disabled

Partial limitation of the drive control function.

19-126

Travelling may stop

Partial limitation of the drive control function.

19-129

Travelling and material handling enabled even

after leaving the seat.

Error mode Phenomenon on vehicle

ECU

Detection

Spanner

lamp

Wrench

Indication

Knob position compensation solenoid open circuit or load short

abnormality

73-1 73-1 Blinking SAS/OPS

CPU error Various control operations not stable 19-119

Accelerator sensor 1 open

4Y-ECS

74-1 74-1 Blinking SAS/OPS Outside matching value range for tire angle error Knob offest compensation stops 19-110

A5-1 A5-1 Blinking SAS/OPS Seat switch GND short abnormality

A7-1 A7-1 Blinking SAS/OPS Brake switch GND short abnormality Partial limitation of the drive control function 19-113

AD-1 AD-1 Blinking SAS/OPS CAN communication 4Y-ECS or ASC data reception error Partial limitation of the drive control function

AD-2 AD-2 Blinking 4Y-ECS CAN communication SAS/OPS data reception error Partial limitation of the drive control function

AD-7 AD-7 Blinking SAS/OPS CAN communication display data reception error

AD-8 AD-8 – Display CAN communication SAS/OPS data reception error Display not stable

AF-1 ~ 3 AF-1 ~ 3 On SAS/OPS

AF-4 ~ 8 AF-4 ~ 8 Blinking SAS/OPS

C4-1 C4-1 Blinking

ASC

4Y-ECS

Accelerator sensor 1 short

ASC

C4-2 C4-2 Blinking

4Y-ECS

Accelerator sensor 2 open

ASC

C4-3 C4-3 Blinking

4Y-ECS

Accelerator sensor 2 short

ASC

C4-4 C4-4 Blinking

4Y-ECS

Accelerator sensor offset abnormality

ASC

C4-5 C4-5 Blinking

Shift lever forward and reverse travel switches simultaneously

ON error

C4-6 C4-6 Blinking 4Y-ECS Accelerator sensor out of range error

C7-2 C7-2 Blinking SAS/OPS

C7-1 C7-1 Blinking SAS/OPS Shift lever forward and reverse travel switch open abnormality

Forward and reverse travel T/C relay open circuit or load short

abnormality

CA-1 CA-1 Blinking SAS/OPS

19-10

Electrical System Troubleshooting

Section 19

Described

on page

19-131

Travelling and material handling enabled even

after leaving the seat.

Lift stop

19-135

19-138

Tilt stop

19-141

Attachment 1 stop

19-144

Lever 2 stop

Lift may stop 19-147

Tilt may stop 19-149

Attachment 1 may stop 19-151

Error mode Phenomenon on vehicle

ECU

Detection

Spanner

lamp

Wrench

Meter SAS/OPS data reception error Display only 19-133

F1-1 – Blinking

EC-1 EC-1 Blinking SAS/OPS Unload solenoid open circuit or load short abnormality

Indication

F2-1 – Blinking

F4-1 ~ 8 F4-1 ~ 8 Blinking Display CPU error Display not stable 19-134

H1-1 H1-1 Blinking SAS/OPS Lift lever potentiometer open abnormality

H1-2 H1-2 Blinking SAS/OPS Lift lever potentiometer VCC short abnormality

H1-3 H1-3 Blinking SAS/OPS Lift lever potentiometer assembly error

H1-4 H1-4 Blinking SAS/OPS Lift lever potentiometer neutral abnormality Material handling disabled

H1-5 H1-5 Blinking SAS/OPS Lift lever potentiometer matching value abnormality Lift stop

H2-1 H2-1 Blinking SAS/OPS Tilt lever potentiometer open abnormality

H2-2 H2-2 Blinking SAS/OPS Tilt lever potentiometer VCC short abnormality

H2-3 H2-3 Blinking SAS/OPS Tilt lever potentiometer assembly error

H2-4 H2-4 Blinking SAS/OPS Tilt lever potentiometer neutral error abnormality Material handling disabled

H2-5 H2-5 Blinking SAS/OPS Tilt lever potentiometer matching error Tilt stop

H3-1 H3-1 Blinking SAS/OPS Attachment 1 lever potentiometer open abnormality

H3-2 H3-2 Blinking SAS/OPS Attachment 1 lever potentiometer VCC short abnormality

H3-3 H3-3 Blinking SAS/OPS Attachment 1 lever potentiometer combination error

H3-4 H3-4 Blinking SAS/OPS Attachment 1 lever potentiometer neutral abnormality Material handling disabled

H3-5 H3-5 Blinking SAS/OPS Attachment 1 lever potentiometer matching value abnormality Attachment 1 stop

H4-1 H4-1 Blinking SAS/OPS Attachment 2 lever potentiometer open abnormality

H4-2 H4-2 Blinking SAS/OPS Attachment 2 lever potentiometer VCC short abnormality

H4-3 H4-3 Blinking SAS/OPS Attachment 2 lever potentiometer combination error

H4-4 H4-4 Blinking SAS/OPS Attachment 2 lever potentiometer neutral abnormality Material handling disabled

H4-5 H4-5 Blinking SAS/OPS Attachment 2 lever potentiometer matching value abnormality Lever 2 stop

H5-1 H5-1 Blinking SAS/OPS Lift PUSH solenoid open abnormality

H5-2 H5-2 Blinking SAS/OPS Lift PULL solenoid open abnormality

H6-1 H6-1 Blinking SAS/OPS Tilt PUSH solenoid open abnormality

H6-2 H6-2 Blinking SAS/OPS Tilt PULL solenoid open abnormality

H7-1 H7-1 Blinking SAS/OPS Attachment 1 PUSH solenoid open abnormality

H7-2 H7-2 Blinking SAS/OPS Attachment 1 PULL solenoid open abnormality

Described

Electrical System Troubleshooting

Section 19

19-11

on page

Attachment 2 may stop 19-153

Error mode Phenomenon on vehicle

ECU

Detection

Spanner

lamp

Wrench

H8-1 H8-1 Blinking SAS/OPS Attachment 2 PUSH solenoid open abnormality

H8-2 H8-2 Blinking SAS/OPS Attachment 2 PULL solenoid open abnormality

HA-1 HA-1 Blinking SAS/OPS 3/4 way change relay GND short abnormality Attachment switching disabled 19-155

Indication

19-12

Electrical System Troubleshooting

Section 19

Use a battery of the specified

voltage

Carry out matching for each item

Overheat Leave the vehicle at idle for a while

Phenomenon on vehicle Content of warning Appropriate corrective action

Top speed and load lifting speed are limited.

(Only when OPT equipped)

ECU

Detection

lamp

Wrench

High battery voltage

Swing lock control is always locked

Knob offset occurrence

Material handling disabled (mini lever)

Material handling except lifting disabled

Auto leveling angle not matching

SAS/OPS NL load not matching

(NL: No-load)

Tilt disabled with the knob switch in the ON

position

Tilt operates to forward most tilt position

Tilt disabled with the knob switch in the ON

position

Water

WARNING LIST

Caution:

If the wrench lamp illuminates and the following phenomena occur on the vehicle without an error being displayed, it is not a fault. Take the

appropriate corrective action.

Indication Memory

OB-1 – 4Y-ECS

flashing

e gauge

temperatur

– – On SAS/OPS

– – On SAS/OPS Swing lock control is always locked Low battery voltage Charge or replace the battery

– – On SAS/OPS Tilt operates to forward most tilt position Forward tilt restriction angle not matching

– – On SAS/OPS

– – On SAS/OPS

– – On SAS/OPS Knob offset occurrence Tire angle not matching

– – On SAS/OPS Swing lock control disabled Swing leveling not matching

– – On SAS/OPS Lift stop Lift lever not matching

– – On SAS/OPS Tilt stop Tilt lever not matching

– – On SAS/OPS Attachment 1 stop Attachment 1 not matching

– – On SAS/OPS Attachment 2 stop Attachment 2 not matching

19-13

Electrical System Troubleshooting

Section 19

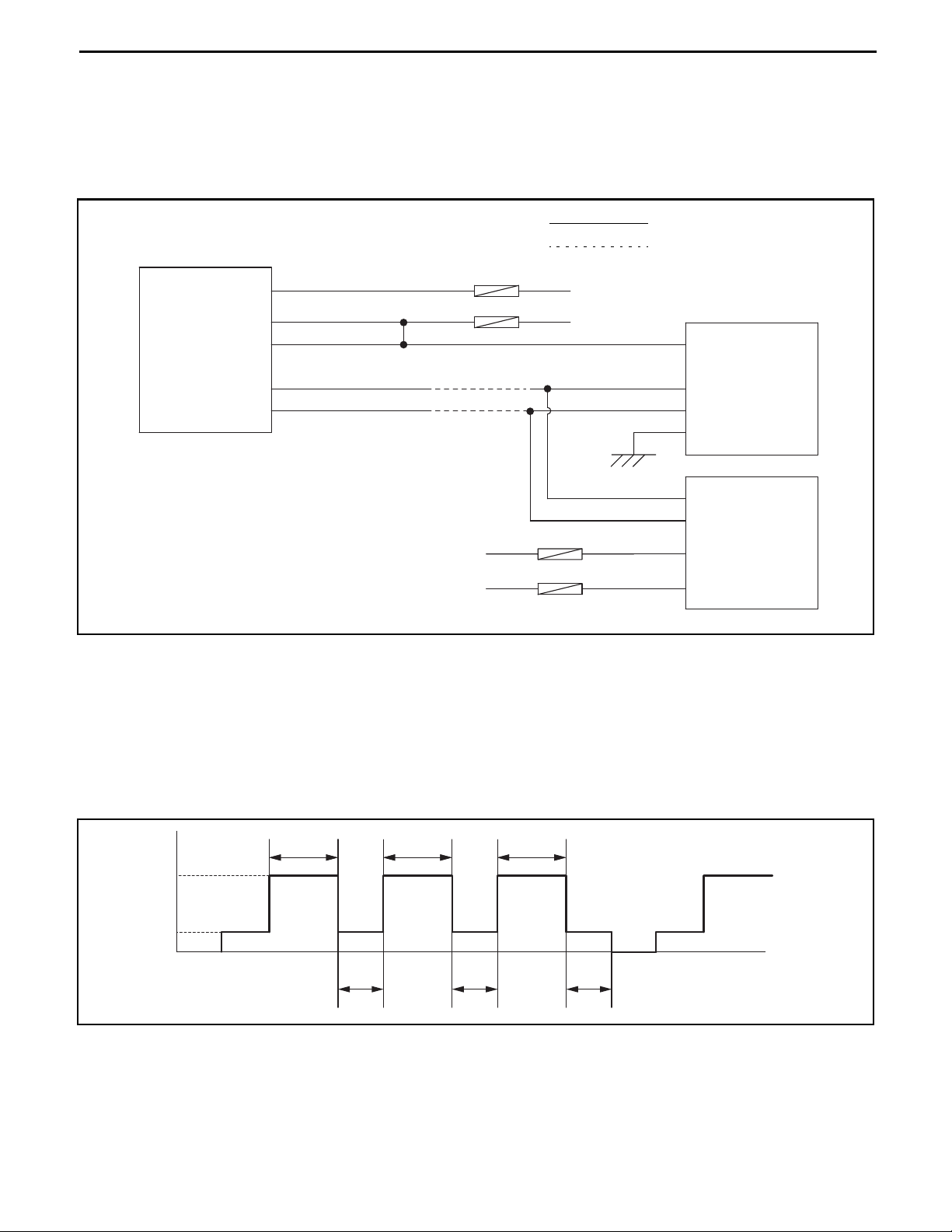

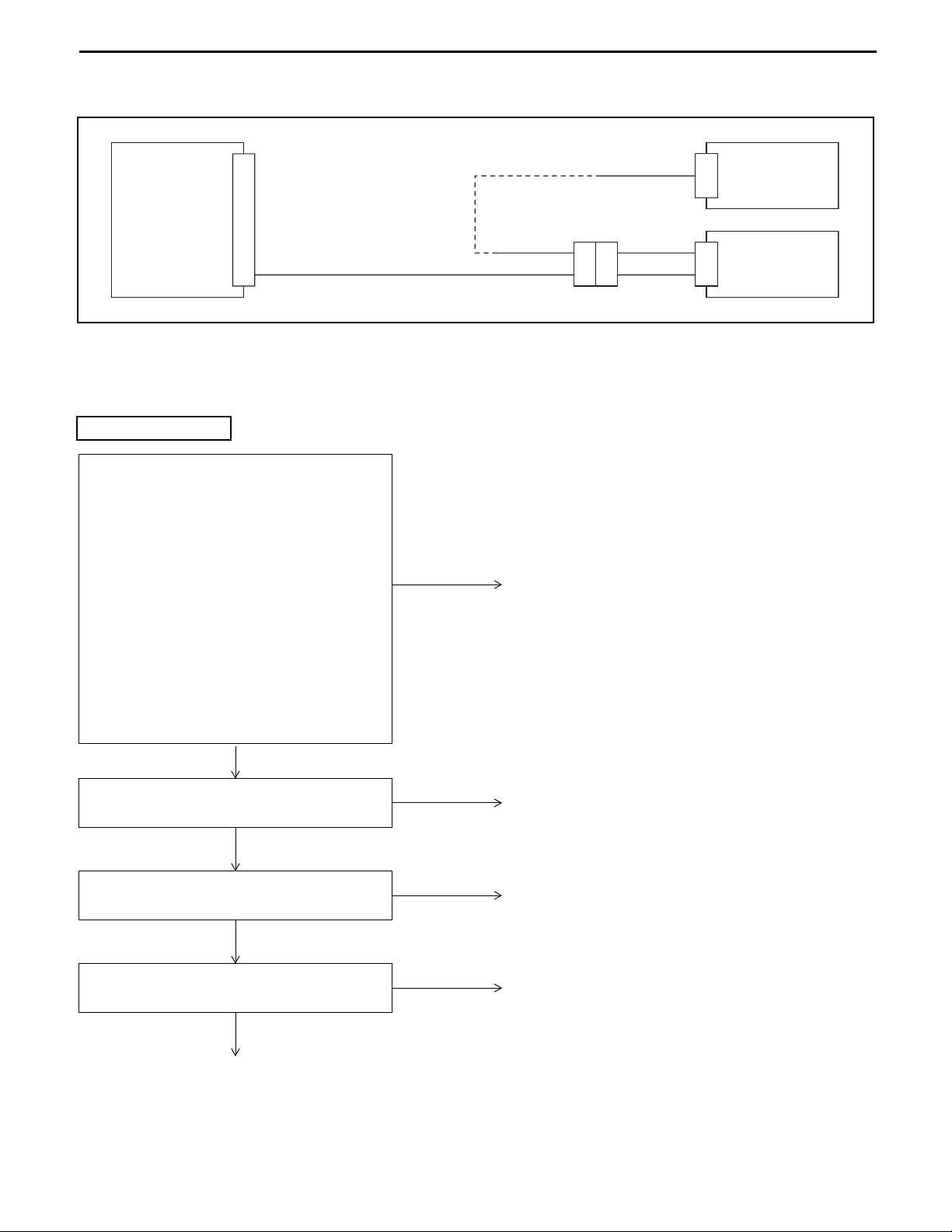

VIEWING RELATED PORTIONS

In the wiring diagrams for related portions, there are cases in which the parts are connected directly, and cases

where they are connected via a junction block or similar.

Refer below for how to identify wiring configuartions.

Example of a Related Portion

: Direct connection

A21

8 (BATT)

ECU-B

: Connection via a junction

ECU-IG

EFI

IGN

SAS/OPS

controller

1 (IG1)

2 (IG2)

A20

12 (CANH)

13 (CANL)

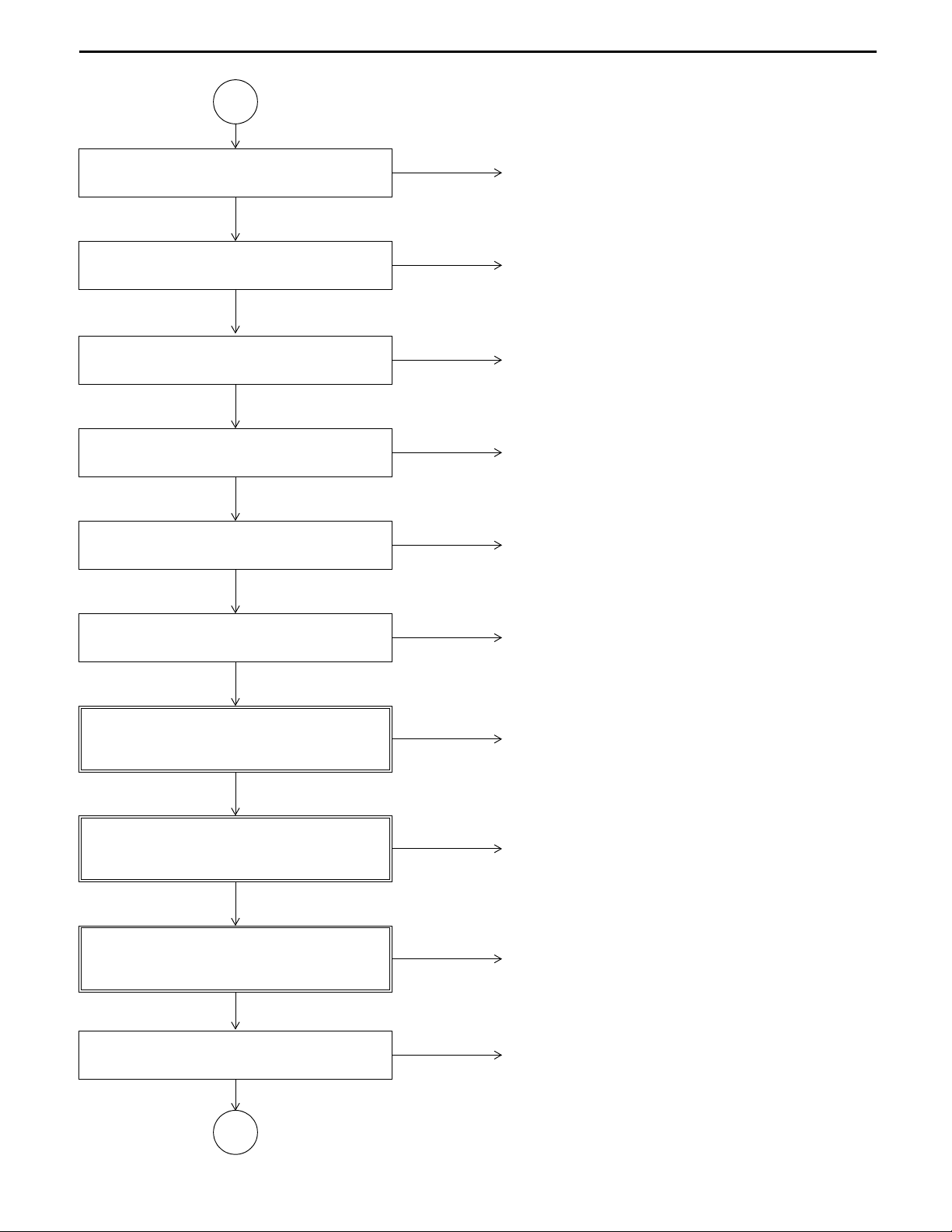

ERROR CONFIRMATION DRIVE MODE

c Turn the ignition key switch ON, start and completely warm up the engine.

d Fully depress the accelerator pedal for 3 to 5 minutes with the direction neutral.

e Release and leave the accelerator pedal (run the engine at idle) for 2 minutes.

f Repeat steps d and e 3 times.

g Turn the ignition key switch OFF (for 1 minute).

h Repeat steps c to g 3 times.

Q2

2 (IG)

5 (CANH)

6 (CANL)

3 (E1)

A36

28 (CAN+)

29 (CAN-)

3 (BATT)

9 (IGSW)

Multifunction

display

Engine

controller

Engine speed

NMR

Warmed up

Idle

IG

OFF

3 ~ 5 minutes 3 ~ 5 minutes 3 ~ 5 minutes

2 minutes 2 minutes 2 minutes

IG

OFF

time

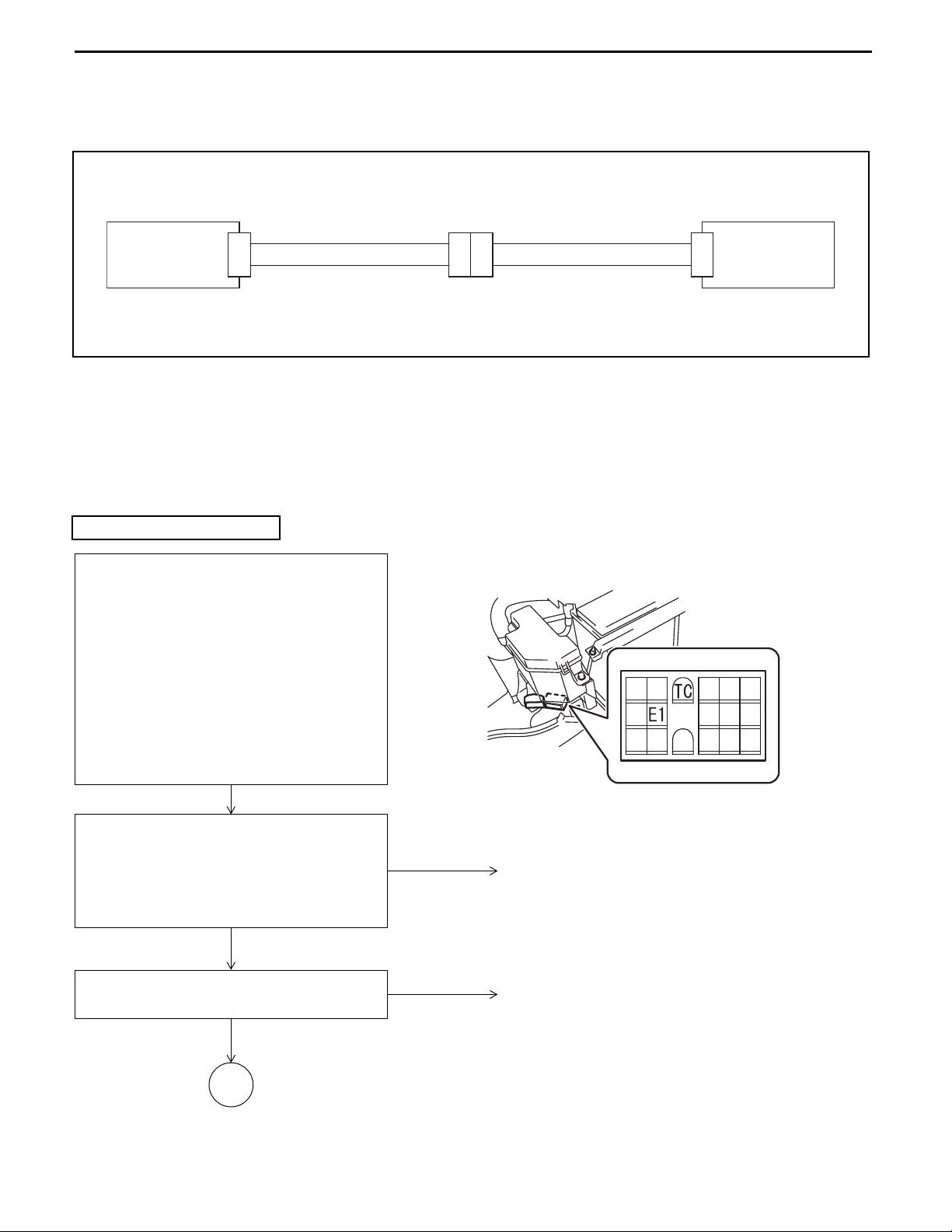

19-1419-14

Electrical System Troubleshooting

Section 19

TROUBLESHOOTING BY ERROR CODE

z Error codes 01-1, 01-2 (Fuel feedback control abnormality) (Gasoline)

Related portion

C1

O2 sensor

Engine

controller

A35

20 (OX) 3 (OX)

20 (OX) 4

21 (E11) 4 (E1)

AC2

REC

7

TAB

Probable cause

c Intake system defect g Fuel system defect

d Exhaust system defect h Harness defect

e Sensor defect i Engine controller defect

f Ignition defect

Caution:

When another error code is present repair the related parts first before carrying out the following.

Error codes 01-1 and 01-2

Disconnect the battery negative terminal (for

more than 10 seconds). Check the connection

status of C1, disconnect C1 and perform a visual

and contact pressure inspection of the

connector. Short circuit the service connector TC

terminal with the E1 terminal, and after

connecting C1 and the battery negative terminal

(on a combination vehicle, switch the fuel

changeover switch to gasoline), turn the ignition

key switch ON (engine stopped), depress the

accelerator pedal 5 times within 30 seconds

(fully open to fully closed), then start the engine

and check that the error has been cleared.

Service connector

Disconnect the battery negative terminal,

disconnect TC terminal - E1 terminal, connect

the battery negative terminal, start the engine,

and check whether the error occurs after

performing error confirmation drive mode (see

19-13).

Error

Inspection 1:

Inspect the air intake

OK

A

No error

NG

Connector contact defect

Intake system defect

Intake system connection defect

19-15

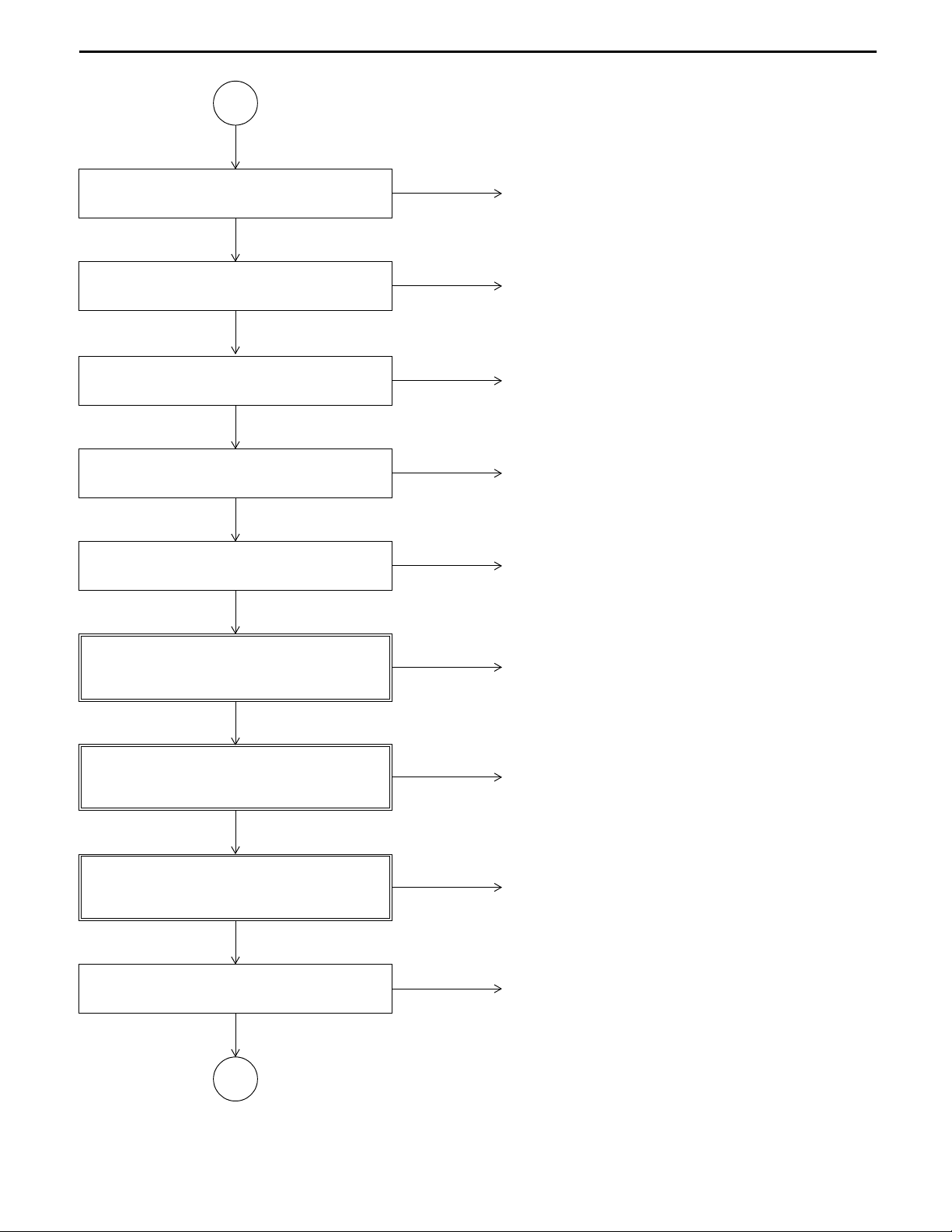

Electrical System Troubleshooting

Section 19

A

Exhaust gas leakage inspection

OK

Inspection 3:

Fuel leakage inspection

OK

Fuel pressure inspection

OK

Inspection 5:

Spark plug individual inspection

OK

Inspection 6:

Injector individual inspection

OK

NGInspection 2:

NG

NGInspection 4:

NG

NG

Exhaust system defect

Exhaust system

Fuel system defect

Fuel system connection defect

Pressure regulator defect

Fuel filter defect

Fuel pump defect

Spark plug defect

Injector defect

Inspection 7:

Intake pipe pressure sensor voltage inspection

ANL.: I/O ENGINE CTRL 3/10

OK

Inspection 8:

Intake temperature sensor voltage inspection

ANL.: I/O ENGINE CTRL 3/10

OK

Inspection 9:

Coolant temperature sensor voltage inspection

ANL.: I/O ENGINE CTRL 3/10

OK

Harness continuity and short circuit inspection

OK

B

NG

Intake pipe pressure sensor defect

NG

Intake temperature sensor defect

NG

Coolant temperature sensor defect

NGInspection 10:

Harness defect

19-1619-16

Electrical System Troubleshooting

Section 19

B

Inspection 11:

O2 sensor voltage inspection

ANL.:I/O ENGINE CTRL 9/10

NG

Inspection 12:

2 sensor voltage inspection

O

ANL.:I/O ENGINE CTRL 9/10

OK

O2 sensor defect

OK

NG

Connector contact defect

Engine controller defect

Inspection 1:

Inspect for air suction.

Start the engine and check whether air is being sucked in from the engine oil level gauge, oil filler cap, or PCV

hose etc.

Standard: There is no air being sucked in.

Check if there is air being sucked in from the intake system parts and connections between the air cleaner and

the cylinder head.

Standard: There is no air being sucked in.

Inspection 2:

Inspect for exhaust gas leakage.

Start the engine and check if there is any exhaust gas leakage from the exhaust system parts and connections

between the cylinder head and the catalytic muffler.

Standard: There is no exhaust gas leakage.

Inspection 3:

Inspect for fuel leakage.

Start the engine and check if there is any fuel leakage from the fuel system parts and connections between the

fuel pump and the injectors.

Standard: There is no fuel leakage.

Inspection 4:

Inspect the fuel pressure.

For the fuel pressure inspection, refer to the repair manual for the 4Y engine.

Inspection 5:

Carry out a spark plug individual inspection.

For the spark plug individual inspection, refer to the repair manual for the 4Y engine.

Inspection 6:

Carry out an injector individual inspection.

For the individual injector inspection, refer to the repair manual for the 4Y engine.

Inspection 7:

Electrical System Troubleshooting

Section 19

Inspect the intake pipe pressure sensor voltage.

Ignition key switch ON, engine stopped

Intake pipe pressure sensor voltage (I/O monitor: PIM)

Standard:

PIM

3.6 ± 0.3 V (100 ± 10 kPa (1 ± 0.1 kgf/cm

Inspection 8:

Inspect the intake temperature sensor voltage.

Ignition key switch ON, engine stopped

Intake temperature sensor voltage (I/O monitor: THA)

Standard:

THA

0.55 ± 0.15 V (80 ± 10°C) (reference value)

2.4 ± 0.6 V (20 ± 10°C)

Inspection 9:

Inspect the coolant temperature sensor voltage.

Start the engine, warm up completely (coolant temperature gauge: at 5-6 bars)

Coolant temperature sensor voltage (I/O monitor: THW)

2

) [14 ± 1.4 psi])

19-17

Standard:

THW

0.55 ± 0.15 V (80 ± 10°C)

2.4 ± 0.6 V (20 ± 10°C) (reference value)

Inspection 10:

Inspect for continuity and short circuiting of the harness.

Ignition key switch OFF, disconnect battery negative terminal, disconnect A35 and C1.

Standard:

A35-20 ~ C1-3 Continuity

A35-21 ~ C1-4 Continuity

A35-20 ~ Frame No continuity

Inspection 11:

Inspect the O

2 sensor output.

Connect A35 and C1, start the engine, warm up completely, set direction in neutral, fully open the accelerator

pedal

2 sensor voltage (I/O monitor: OX)

O

Standard:

OX 0.4 V or less and 0.5 V or more alternately output

Inspection 12:

Inspect the O

2 sensor output.

Disconnect C1, connect A35, start the engine, warm up completely, set direction in neutral, fully open the

accelerator pedal

2 sensor voltage (I/O monitor: OX)

O

Standard:

OX 0.2 V or less

19-1819-18

Electrical System Troubleshooting

Section 19

z Error codes 01-3, 01-4 (Fuel feedback control abnormality) (LPG/CNG)

Related portion

Engine

controller

A35

20 (OX) 4

20 (OX) 3 (OX)

21 (E11) 4 (E1)

AC2

REC

7

TAB

C1

O

2 sensor

Probable cause

c Intake system defect g Fuel system defect

d Exhaust system defect h Harness defect

e Sensor defect i Engine controller defect

f Ignition defect

Caution:

When another error code is occuring, repair the related parts first before carrying out the following.

Error codes 01-3 and 01-4

Disconnect the battery negative terminal (for

more than 10 seconds). Check the connection

status of C1, disconnect C1 and perform a visual

and contact pressure inspection of the

connector. Short circuit the service connector TC

terminal with the E1 terminal, and after

connecting C1 and the battery negative terminal

(on a combination vehicle, switch the fuel

changeover switch to gasoline), turn the ignition

key switch ON (engine stopped), depress the

accelerator pedal 5 times within 30 seconds

(fully open to fully closed), then start the engine

and check that the error has been cleared.

Service connector

Disconnect the battery negative terminal,

disconnect TC terminal - E1 terminal, connect

the battery negative terminal, start the engine,

and check whether the error occurs after

performing error confirmation drive mode (see

19-13).

Error

Inspection 1:

Inspect the air intake

OK

A

No error

NG

Connector contact defect

Intake system defect

Intake system connection defect

19-19

Electrical System Troubleshooting

Section 19

A

Exhaust gas leakage inspection

OK

Fuel leakage inspection

OK

Inspection 4:

Regulator primary pressure inspection

OK

Inspection 5:

Spark plug individual inspection

OK

Inspection 6:

Injector individual inspection

OK

NGInspection 2:

NGInspection 3:

NG

NG

NG

Exhaust system defect

Exhaust system connection defect

Fuel system defect

Fuel system connection defect

Regulator defect

Spark plug defect

Injector defect

Air-fuel ratio motor individual inspection

OK

Inspection 8:

Intake pipe pressure sensor voltage inspection

ANL.: I/O ENGINE CTRL 3/10

OK

Inspection 9:

Intake temperature sensor voltage inspection

ANL.: I/O ENGINE CTRL 3/10

OK

Inspection 10:

Water temperature sensor voltage inspection

ANL.: I/O ENGINE CTRL 3/10

OK

Harness continuity and short circuit inspection

NGInspection 7:

Air-fuel ratio motor defect

NG

Intake pipe pressure sensor defect

NG

Intake temperature sensor defect

NG

Water temperature sensor defect

NGInspection 11:

Harness defect

OK

B

19-2019-20

Electrical System Troubleshooting

Section 19

B

Inspection 12:

O2 sensor voltage inspection

ANL.:I/O ENGINE CTRL 9/10

NG

Inspection 13:

2 sensor voltage inspection

O

ANL.:I/O ENGINE CTRL 9/10

OK

O2 sensor defect

OK

NG

Connector contact defect

Engine controller defect

Inspection 1:

Inspect for air suction.

Start the engine and check whether air is being sucked in from the engine oil level gauge, oil filler cap, or PCV

hose etc.

Standard: There is no air being sucked in.

Check if there is air being sucked in from the intake system parts and connections between the air cleaner and

the regulator.

Standard: There is no air being sucked in.

Check if there is air being sucked in from the intake system parts and connections among the air cleaner hose,

the resonator, and the regulator.

Standard: There is no air being sucked in.

Inspection 2:

Inspect for exhaust gas leakage.

Start the engine and check if there is any exhaust gas leakage from the exhaust system parts and connections

between the cylinder head and the catalytic muffler.

Standard: There is no exhaust gas leakage.

Inspection 3:

Inspect for fuel leakage.

Start the engine and check if there is any fuel leakage from the fuel system parts and connections between the

fuel tank and the regulator.

Standard: There is no fuel leakage.

Check if there is fuel leakage from the fuel system parts and connections between the regulator and the LPG

adapter.

Standard: There is no fuel leakage.

Check if there is fuel leakage from the fuel system parts and connections between the regulator and the injector.

Standard: There is no fuel leakage.

Inspection 4:

Inspect the regulator primary pressure.

For the regulator primary pressure inspection, refer to the LPG repair manual.

Inspection 5:

Electrical System Troubleshooting

Section 19

Carry out a spark plug individual inspection.

For the spark plug individual inspection, refer to the repair manual for the 4Y engine.

Inspection 6:

Carry out an injector individual inspection.

For the individual injector inspection, refer to the repair manual for the 4Y engine.

Inspection 7:

Carry out an individual inspection of the air-fuel ratio motor.

For the individual air-fuel ratio motor inspection, refer to the LPG repair manual.

Inspection 8:

Inspect the intake pipe pressure sensor voltage.

Ignition key switch ON, engine stopped

Intake pipe pressure sensor voltage (I/O monitor: PIM)

Standard:

PIM

3.6 ± 0.3 V (100 ± 10 kPa (1 ± 0.1 kgf/cm

2

) [14 ± 1.4 psi])

19-21

Inspection 9:

Inspect the intake temperature sensor voltage.

Ignition key switch ON, engine stopped

Intake temperature sensor voltage (I/O monitor: THA)

Standard:

THA

0.55 ± 0.15 V (80 ± 10°C) (reference value)

2.4 ± 0.6 V (20 ± 10°C)

Inspection 10:

Inspect the coolant temperature sensor voltage.

Start the engine, warm up completely (coolant temperature gauge: 5-6 bars)

Coolant temperature sensor voltage (I/O monitor: THW)

Standard:

THW

0.55 ± 0.15 V (80 ± 10°C)

2.4 ± 0.6 V (20 ± 10°C) (reference value)

Inspection 11:

Inspect for continuity and short circuiting of the harness.

Ignition key switch OFF, disconnect A35 and C1

Standard:

A35-20 ~ C1-3 Continuity

A35-21 ~ C1-4 Continuity

A35-20 ~ Frame No continuity

19-2219-22

Electrical System Troubleshooting

Section 19

Inspection 12:

Inspect the O

2 sensor output.

Start the engine, warm up completely, put the direction in neutral, fully open the accelerator pedal

2 sensor voltage (I/O monitor: OX)

O

Standard:

OX 0.4 V or less and 0.5 V or more alternately output

Inspection 13:

Inspect the O

2 sensor output.

Start the engine, warm up completely, put the direction in neutral, fully open the accelerator pedal

2 sensor voltage (I/O monitor: OX)

O

Standard:

OX 0.2 V or less

z Error code 01-5 (O2 sensor open abnormality)

Electrical System Troubleshooting

Section 19

Related portion

19-23

Engine

controller

A35

20 (OX) 4

20 (OX) 3 (OX)

21 (E11) 4 (E1)

AC2

REC

7

TAB

C1

O

2 sensor

Probable cause

c O2 Sensor defect

d Harness defect

e Engine controller defect

Caution:

When another error code is present, repair the related parts first before carrying out the following.

Error code 01-5

Disconnect the battery negative terminal (for

more than 10 seconds). Check the connection

status of C1, disconnect C1 and perform a visual

and contact pressure inspection of the

connector. Short circuit the service connector TC

terminal with the E1 terminal, and after

connecting C1 and the battery negative terminal

(on a combination vehicle, switch the fuel

changeover switch to gasoline), turn the ignition

key switch ON (engine stopped), depress the

accelerator pedal 5 times within 30 seconds

(fully open to fully closed), then start the engine

and check that the error has been cleared.

Service connector

Disconnect the battery negative terminal,

disconnect TC terminal - E1 terminal, connect

the battery negative terminal, start the engine,

and check whether the error occurs after

performing error confirmation drive mode (see

19-13).

Error

Harness continuity and short circuit inspection

OK

2 sensor defect

O

If the error occurs even

after replacing the O

sensor

Engine controller defect

2

No error

NGInspection 1:

Connector contact defect

Harness defect

19-2419-24

Electrical System Troubleshooting

Section 19

Inspection 1:

Inspect for continuity and short circuiting of the harness.

Ignition key switch OFF, disconnect A35 and C1

Standard:

A35-20 ~ C1-3 Continuity

A35-21 ~ C1-4 Continuity

A35-20 ~ Frame No continuity

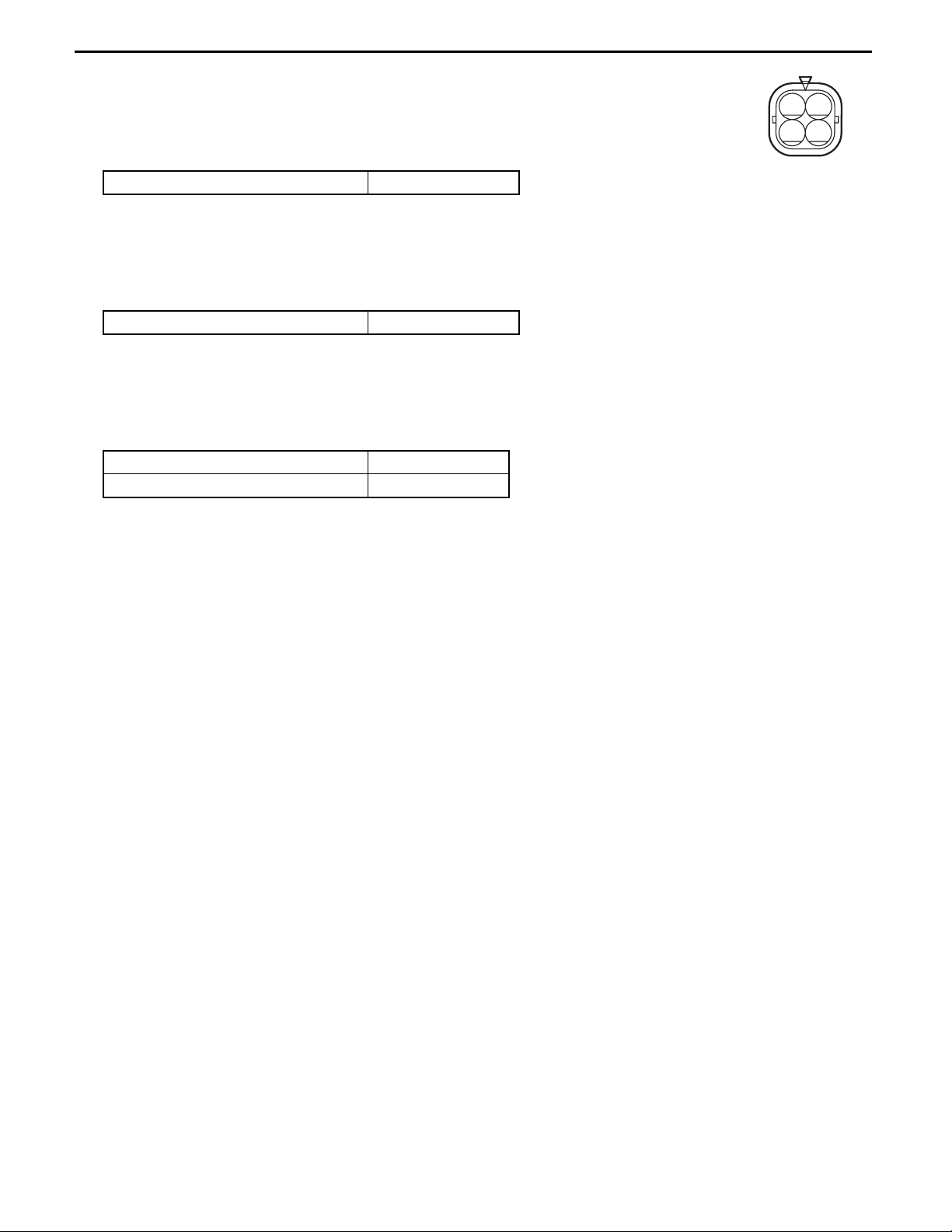

z Error code 01-6 (O2 sensor heater open abnormality)

Electrical System Troubleshooting

Section 19

Related portion

19-25

A35

Engine

controller

6 (HT)

Probable cause

c O2 Sensor defect

d Harness defect

e Engine controller defect

Error code 01-6

Disconnect the battery negative terminal (for

more than 10 seconds), after inspecting and

correcting disconnection and water entry of C1,

AC2, reconnect all connectors and battery

negative terminal, turn the ignition key switch

ON (start the engine), and check whether or not

there is an error.

c Turn the ignition key switch ON.

(Start and run the engine for more than 10

seconds.)

d Turn the ignition key switch OFF for more

than10 seconds.

e Turn the ignition key switch ON.

(Start and run the engine for more than 10

seconds.)

f Check for errors.

No error

AC2

9

1

TAB

REC

Connector contact defect

R/B EFI Main relay

main relay

C1

2

1

EFI

2

O

sensor

Error

2 sensor individual inspection

O

OK

Inspection 2:

O

2 sensor heater power voltage inspection

OK

Inspection 3:

Harness continuity and short circuit inspection

OK

Engine controller defect

NGInspection 1:

O2 sensor defect

NG

Harness defect

NG

Harness defect

19-2619-26

Electrical System Troubleshooting

Section 19

Inspection 1:

Carry out O

2 sensor individual inspection.

Ignition key switch OFF, disconnect C1, connect A35

Standard: (Sensor side)

C1-2 ~ C1-1 13 ~ 16 Ω (20°C)

Inspection 2:

Carry out O

2 sensor heater power voltage inspection.

Ignition key switch OFF, diconnect C1, connect A35, start engine

Standard:

C1-2 ~ Frame 8 ~ 16 V

Inspection 3:

Inspect for continuity and short circuiting of the harness.

Ignition key switch OFF, disconnect A35 and C1

Standard:

A35-6 ~ C1-1 Continuity

A35-6 ~ Frame No continuity

12

34

C1

Loading...

Loading...