Toyota 5FG, 5FD33~45 Repair Manual

FOREWORD

This manual covers the service procedures of the TOYOTA FORKLIFT

5FGi5FD33 - 45 series. Please use this manual for providing quick, correct

servicing of the corresponding forklift models.

This manual has been edited by combining Repair Manual Pub. No.

as Part I (Sections 0 to 15) and Repair Manual (Supplement)

Pub. No.

Part

August, 1988 while Part

change in September, 1994. For servicing the vehicles after the minor

change, please refer to both Part

Please understand that disagreement can take place between the de

scriptions in the manual and actual vehicles due to change in design

and specifications. Any change or modifications thereafter will be in

formed by Toyota Industrial Equipment Parts & Service News.

For the service procedures of the mounted engine, read the repair man

uals listed below as reference together with this manual.

CE014. as Part 11 (Sections 0 to 4).

I

explains the service procedures for the models produced since

IIcovers those for the models subject to the minor

I

and Part

II.

CEO05

-

-

-

(Reference)

Repair manuals related to this manual are as follows:

TOYOTA INDUSTRIAL EQUIPMENT 3F ENGINE

REPAIR MANUAL (No.

TOYOTA INDUSTRIAL EQUIPMENT 1FZ ENGINE

REPAIR MANUAL (No.

TOYOTA INDUSTRIAL EQUIPMENT 1 IZ, 122 ENGINE

REPAIR MANUAL (N

CE614)

CE627)

O

. CE615-1)

TOYOTA MOTOR CORPORATION

PART

SECTION INDEX (CE005)

GENERAL

I

:

1988.

8-

ENGINE0

CLUTCH

CR

TRANSMISSION

FRONT AXLE

REAR AXLE

&

DIFFERENTIAL

BRAKE

BODY

MATERIAL HANDLING SYSTEM

MAST

CYLINDER

OIL PUMP

OIL CONTROL VALVE

a

a

APPENDIX

GENERAL

Page

EXTERIOR VIEWS

VEHICLE LISTING

ABBREVIATIONS

OPERATIONAL

STANDARD BOLT

TORQUE 0-5

BOLT STRENGTH TYPE IDENTIFICATION

METHOD

TIGHTENING TORQUE TABLE

PRECOAT BOLTS

HIGH PRESSURE HOSE FITTING

TIGHTENING TORQUE

FRAME NUMBER

WIRE ROPE SUSPENSION ANGLE LIST

SAFE LOAD FOR EACH

SUSPENSION ANGLE

COMPONENTS WEIGHT

.........................................

......................................

................................

................................

................................

TIPS

.............................

&

NUT TIGHTENING

..................

..............................

...........................

................................

...........

WlRE ROPE

............................

.........................

0-2

0-3

0-4

0-4

0-5

0-6

0-7

0-7

0-8

0-9

0-10

0-10

RECOMMENDED LUBRICANT QUANTITY

&TYPES

LUBRICATION CHARTS 0-12

PERIODIC MAINTENANCE

INSPECTION METHOD 0-14

PERIODIC REPLACEMENT LUBRICANTS

AND PARTS

.........................................

..........................

.......................

.........................

.....................................

0-11

0-14

0-20

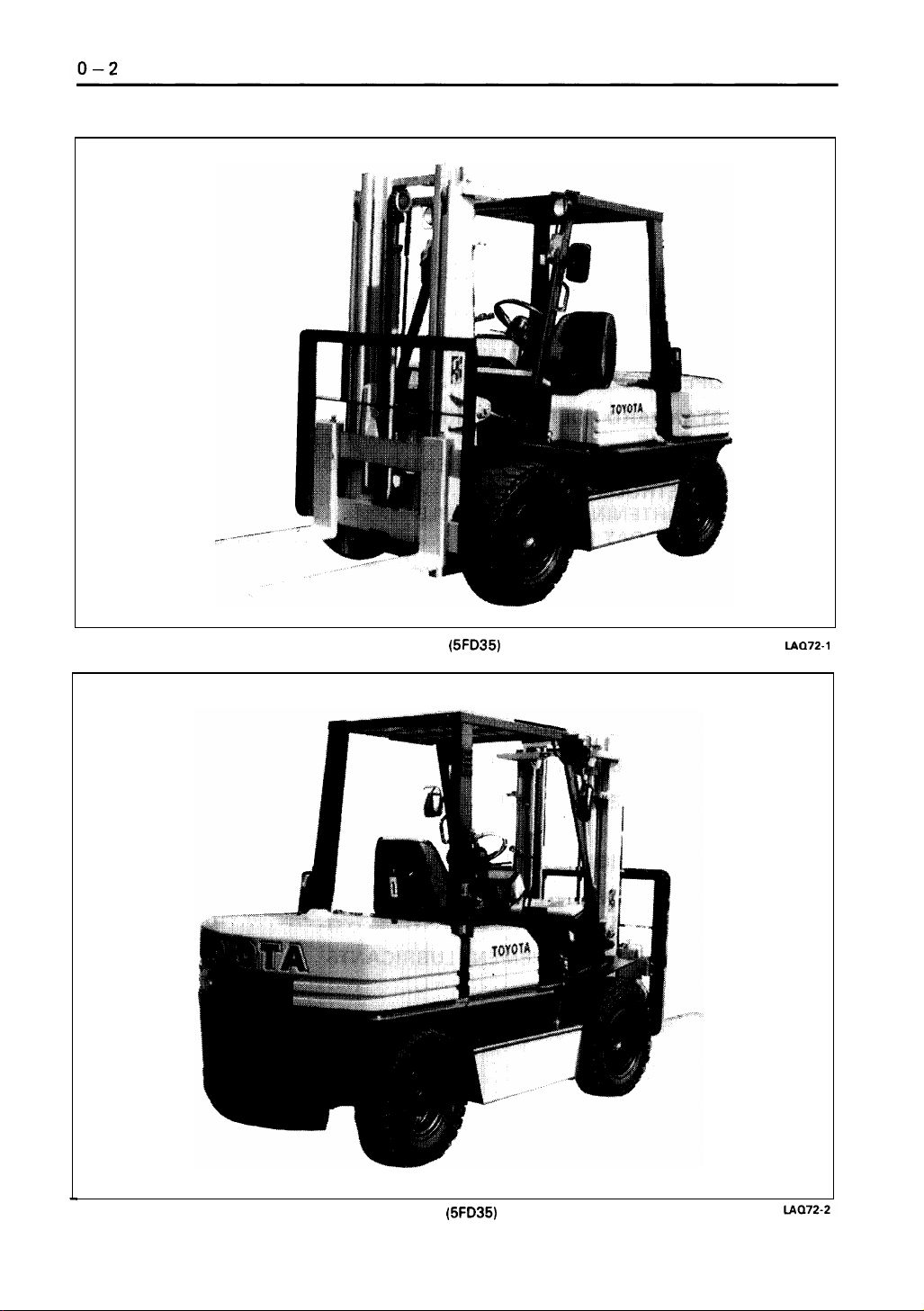

EXTERIOR

VIEWS

Front

View

(5FD35)

~~0.72-1

Rear

View

- 6 -

(5FD35)

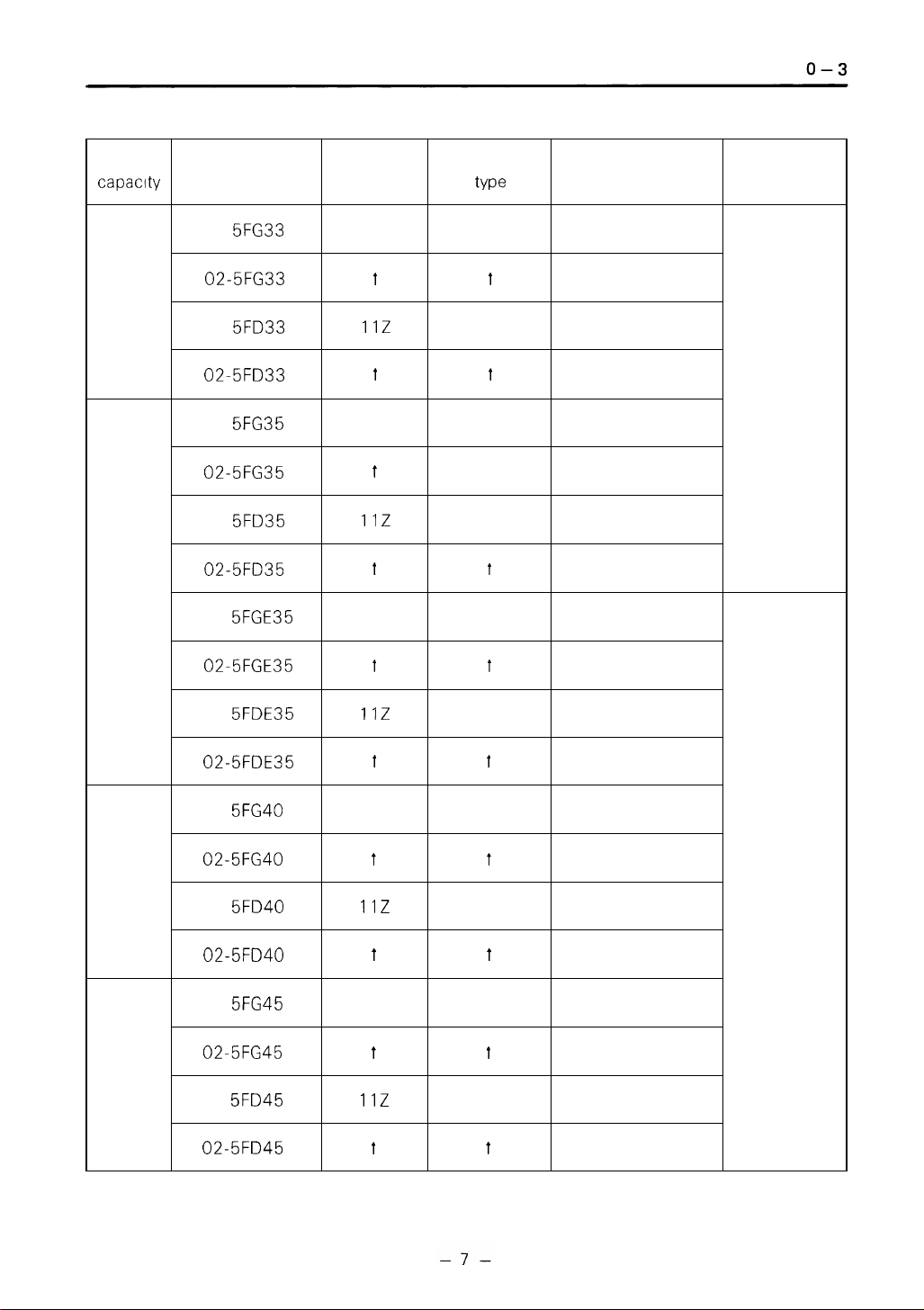

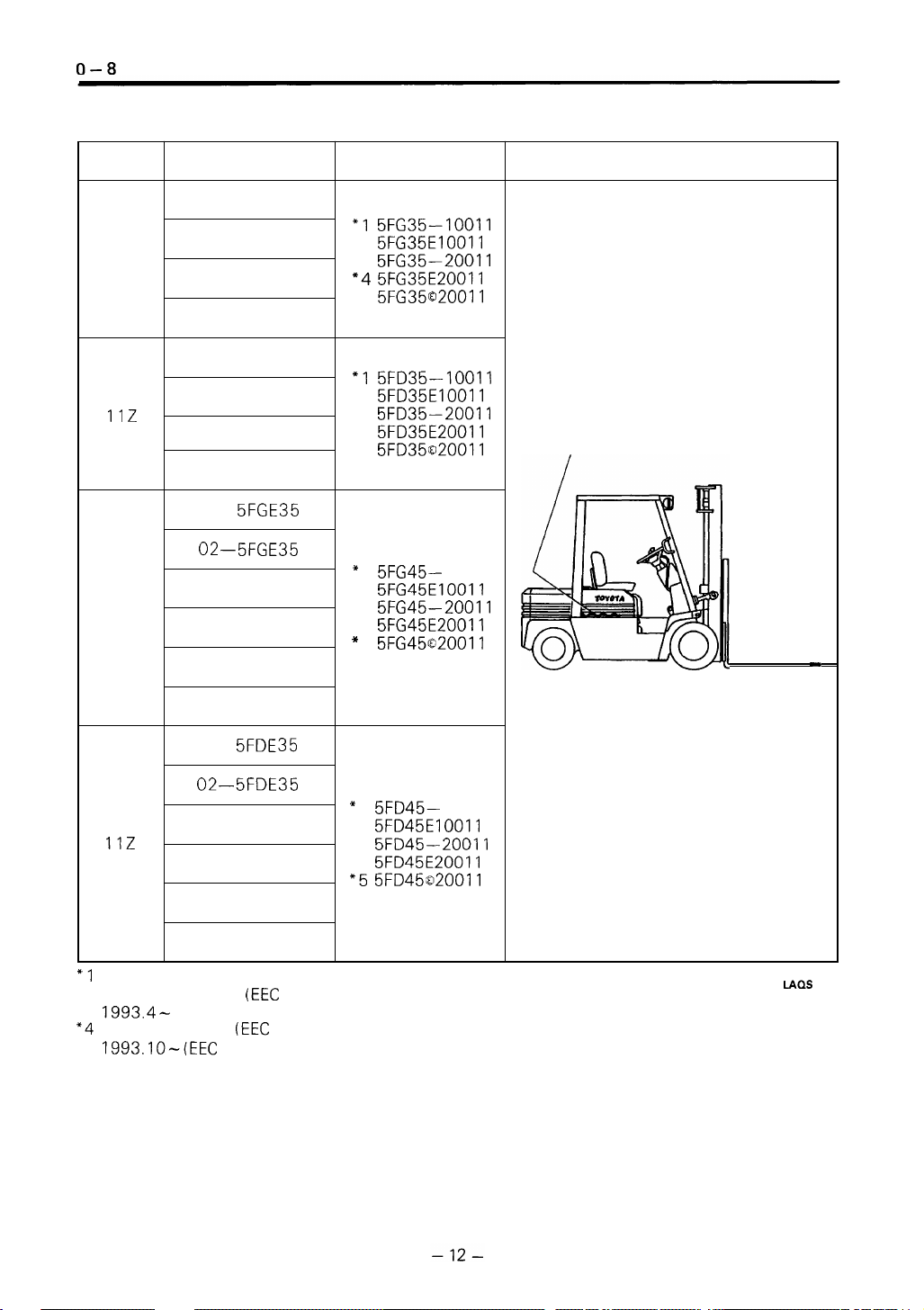

VEHICLE LISTING

Load

capaclty

3.25 ton

3.5 ton

Model

5FG33

02-5FG33

5FD33

02-5FD33

5FG35

02-5FG35

5FD35

02-5FD35

5FGE35

02-5FGE35

Engine

model

3F

t

11Z

t

3F

t

11Z

t

3F

t

Engine

tY Pe

Gasoline

t

Diesel

t

Gasoline

t

Diesel

t

Gasoline

t

Drive system

Clutch

Torgue converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Remarks

Wheel base

1800 mm

(71

in)

4.0 ton

4.5 ton

5FDE35

02-5FDE35

5FG40

02-5FG40

5FD40

02-5FD40

5FG45

02-5FG45

5FD45

02-5FD45

11Z

t

3F

t

11Z

t

3F

t

11Z

t

Diesel

t

Gasoline

t

Diesel

t

Gasoline

t

Diesel

t

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Wheel base

2000

mm

(78.5 in)

ABBREVIATIONS

Abbreviations used in this manual are as follows:

Abbreviation

(Code)

Meaning

Abbreviation

(Code)

4

Meaning

ABDC

ASSY

ATDC

ATM

BTDC

L/

LH

LLC

MTM

OHV

0

PT

0

/s

After button dead center

Assembly

After top dead center

Automatic transmission

Before top dead center

Less

Left hand

Long life coolant

Manual transmission

Overhead valve

Option

Oversize

PS

P/S

RH

SAE

SST

STD

SUB

T

=

OOT

U

/S

W/

-

ASSY

OPERATIONAL TIPS

1. Safe operation

(1) Make sure that correct size wire is used for hoisting a heavy material.

(2)

After jacking up, always support with rigid racks or stands.

2.

Preparation of SSTs and measuring tools

(1)

Prepare SSTs and measuring tools before starting operation.

3.

Clearing and arrangement

(1) Always keep the workshop neat and orderly for easy operation.

(2)

Disassembly of hydraulic equipment shall always be done in a clean place using clean tools.

Horsepower

Power steering

Right hand

Society of automotive engineers

(USA)

Special service tool

Standard

b-assem bl y

Su

Tightening torque

Number of teeth

U

ndersize

With

(00)

4.

Genuine Toyota parts

-

Genuine Toyota parts should be used even in the replacement of packings, gaskets and O

5.

Repairs on electrical system

Before doing any repairs on the electical system, disconnect the cables from the battery terminals.

Be sure to disconnect the negative

6.

Tightening torque for installation

Be sure to observe the tightening torque given in this manual. If not specified, tighten

&

listed in standard bolt

7.

Defect status grasp

Do not start disassembly and replacement as soon as a defect is found, but first grasp whether the

defect requires disassembly and replacement. In the case of torque converter for example, do not

attempt torque converter disassembly

factors as the oil, pressure and rotation status causing the failure.

nut tightening torque.

cable first.

dpon a failure in starting the vehicle, but first check such

rings.

to

the torque

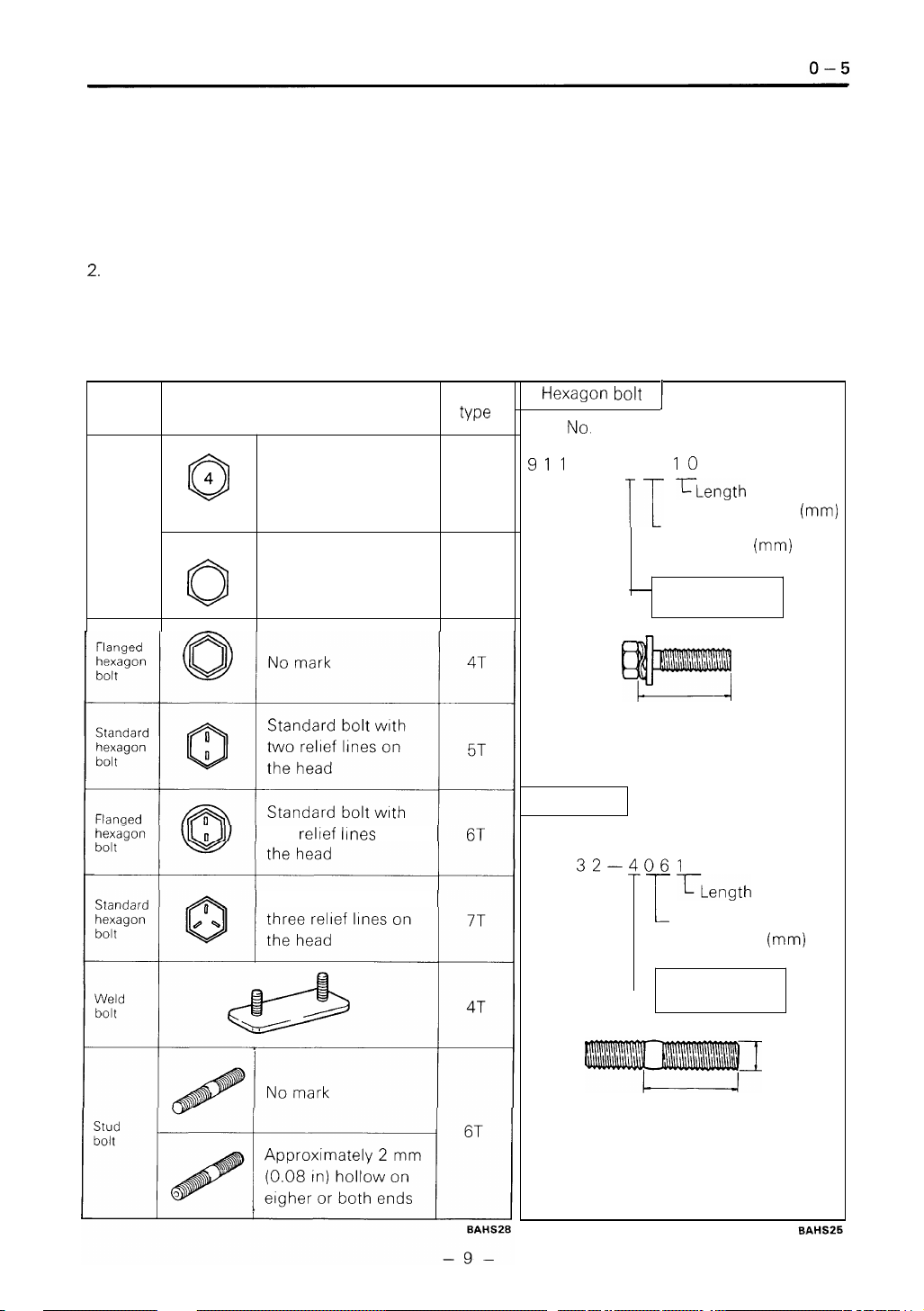

STANDARD BOLT & NUT TIGHTENING TORQUE

Standard bolt and nut tightening torques are not indicated.

Judge the standard tightening torque as shown below.

Find out the straight type of bolt from the list below and then find the bolt tightening torque from

1.

the table.

The nut tightening torque can be judged from the mating bolt type.

2.

BOLT STRENGTH TYPE IDENTIFICATION METHOD

1.

Identification by bolt shape

2.

Identification by part

No.

Standard

hexagon

bolt

Shape and identification method

Number in relief or

0

@

hallmark on the head

No mark

two rel~ef l~nes on

Standard bolt with

Strength

type

4 = 4T

5

=

5T

=

6T

6

7

=

7T

4T

Hexagon bolt

Part

NO.

example

9

I1

11

-

Stud bolt

Part

No.

example

921 32-4-061 4

I

406 10

T~ength under head

-1

Nominal diamter

-

Strength type

Length under head

T~ength (mm)

1

Nominal diameter

(mm)

Nominal

I

diameter

(mm)

-

(mm)

-

Strength type

Length

Nominal

diameter

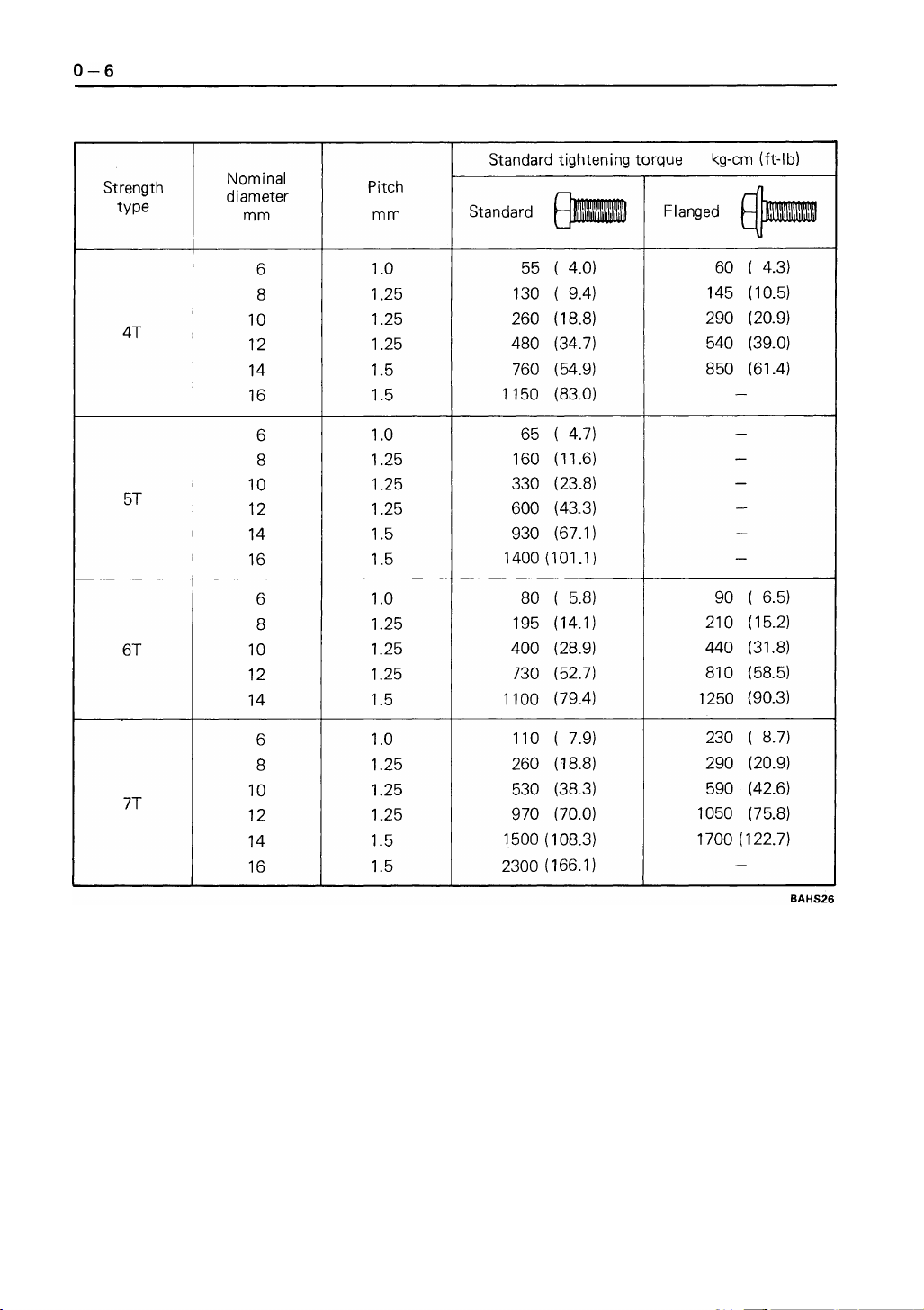

TIGHTENING

TORQUE

TABLE

PR

ECOAT BOLTS

(Bolts with seal lock agent coating on threads)

Do not use the precoat bolt as it is in either

1.

of the following cases:

(a) After it

(b)

When the precoat bolt

ened or tightened) by tightness check,

etc.

Note

:

For torque check, use the lower limit of the

allowable tightening torque range.

bolt moves, retighten

steps below.

Method for reuse of precoat bolts

2.

(1) Wash the bolt and threaded hole. (The (2) Perfectly dry the washed parts by air

threaded hole must be washed even for

replacement of the bolt.)

is

removed.

is

moved (loos

it

according to the

-

Bolts

If the

blowing.

(3) Coat the specified seal lock agent to the

threaded portion of the bolt.

HIGH PRESSURE HOSE FllTlNG TIGHTENING TORQUE

When connecting a high pressure hose, wipe the hose fitting and mating nipple contact sufaces with

1.

clean cloth to remove foreign matters and dirt. Also check no dent or other damage on the contact

surfaces before installation.

a

When connecting

2.

the fitting.

The maximum tightening torque must not exceed twice the standard tightening torque.

3.

Nominal diameter

of screw

5

-

20

UNF

%

-

18

UNF

-

16

UNF

5

-

14

UNF

-

12 UNF

I&

-

12 UNF

PF1/4

PF3/8

PF1/2

PF314

PFI

high pressure hose, hold the hose to align the fitting with the nipple and tighten

-

cm (ft-l b)

Standard tightening torque

Standard

(

18.1)

2.5

5.0

(

36.2)

6.0

(

43.4)

(

43.4)

6.0

(

86.6)

12.0

14.0 (101.2)

(

36.2)

5.0

(

36.2)

5.0

(

43.4)

6.0

(

86.8)

12.0

14.0 (101.2)

2.4

4.8

5.7

5.7- 6.3 (41.2 - 45.5)

11.4- 12.6 (82.4- 91.1)

13.3

4.8

4.8

5.7

11.4-12.6(82.4- 91.1)

13.3

kg

Tightening range

--

2.6

(1

7.4

--

--

5.3 (34.7

-

6.3 (41.2

-

14.7 (96.2

--

5.3 (34.7

-

5.3 (34.7 - 38.3)

-

6.3 (41.2 - 45.5)

--

14.7 (96.2

--

--

--

--

--

Hose inside

diameter

18.8)

38.3)

45.5)

106.3)

38.3)

106.3)

(mm)

6

9

12

12

19

25

9

9

12

19

25

FRAME

NUMBER

Engine

3F

11Z

3F

Model

5FG 33

02

-

5FG 33

5FG 35

-

5FG 35

02

5FD 33

-

5FD 33

02

5FD 35

-

5FD 35

02

5FGE35

02-5FGE35

5FG 40

02

-

5FG 40

5FG 45

Punching

format

"1 5FG35-10011

"

2 5FG35E10011

"

3 5FG35-20011

"4 5FG35E20011

"

5 5FG35O20011

"1 5FD35-10011

"

2 5FD35E10011

"

3 5FD35-20011

"

4 5FD35E20011

*

5 5FD35020011

"

1 5FG45- 1001 1

"

2 5FG45E10011

"

3 5FG45-20011

"

4 5FG45E20011

"

5 5FG45Q20011

Punching ,position

Frame

No. punching position

a

-

5FG 45

02

5FDE35

02-5FDE35

5FD 40

11Z

02

-

5FD 40

5FD 45

-

5FD 45

02

"1 1988.6-1993.3

"

2 1992.11 -1993.3 (EEC

"

3 1993.4-

"4 1993.4- 1993.9 (EEC

"

5

1993.10-(EEC

spec.)

spec.)

spec.)

"

1 5FD45- 1001 1

"

2 5FD45E10011

"

3 5FD45-20011

"

4 5FD45E20011

"5 5FD45~20011

LAQS 1 29

Loading...

Loading...