Page 1

FILE NO. 110-200001

General Descriptions

Adjustment Procedures

Servicing diagrams

Part List

SERVICE MANUAL

NC MECHANICAL DECK

VIDEO CASSETTE RECORDER

W-708

General Descriptions

Adjustment Procedures

Servicing Diagrams

Parts List

Mar., 2000 Y

Page 2

SAFETY NOTICE

SAFETY PRECAUTIONS

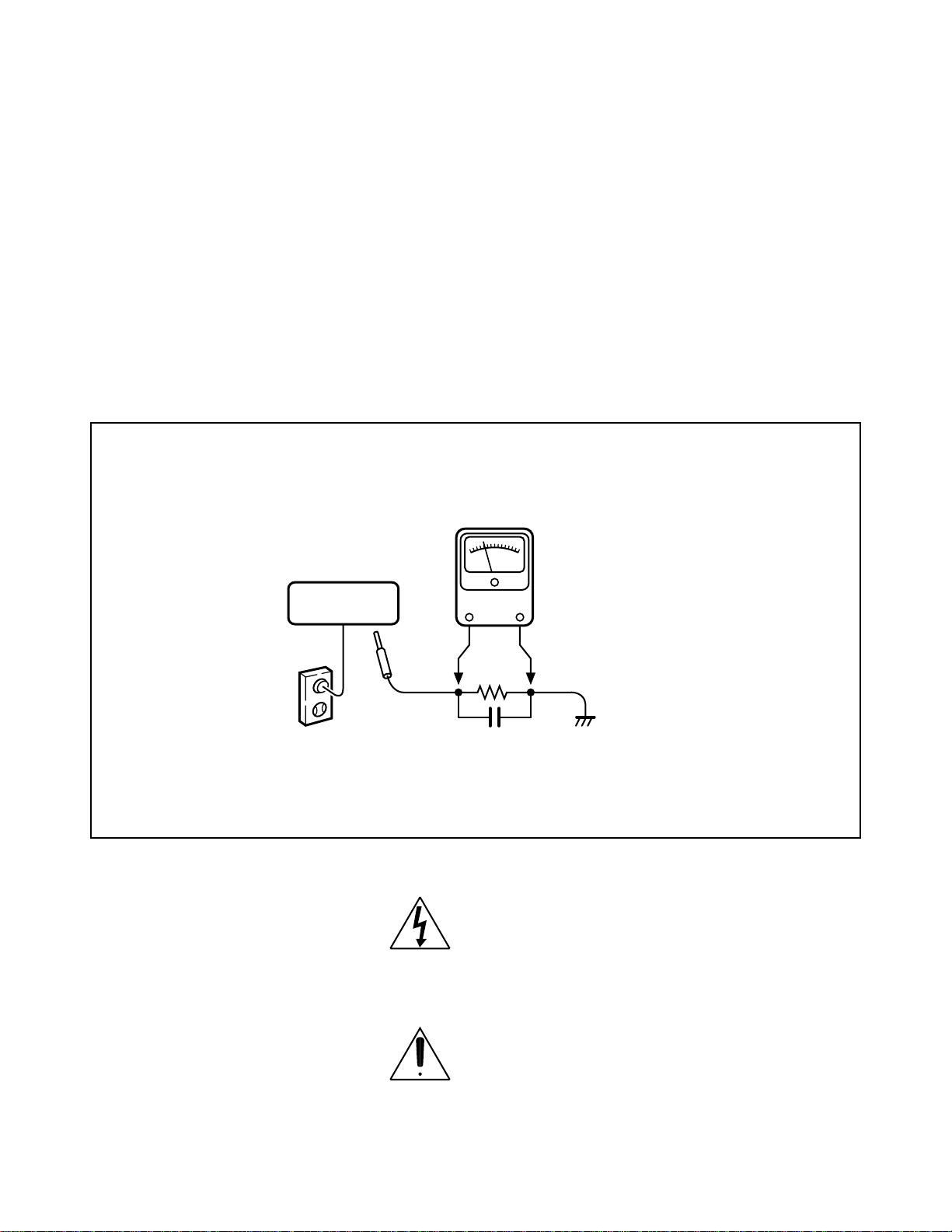

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC Voltmeter, having 5000 W per volt or more sensitivity. Connect a 1500 W 10 W resistor, paralleled by a

0.15 µF 150V AC capacitor between a known good

earth ground (water pipe, conduit, etc.) and all exposed metal parts of cabinet (antennas, handle

bracket, metal cabinet, screwheads, metal overlays,

control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 W resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading exceeding 0.3 V indicates that a dangerous potential exists, the fault must be located and corrected.

Repeat the above test with the VCR power plug

reversed.

NEVER RETURN A VCR TO THE CUSTOMER

WITHOUT TAKING NECESSARY CORRECTIVE

ACTION.

VIDEO CASSETTE

RECORDER

AC OUTLET

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

1500 W

10 W

0.15µF 150V AC

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within

the product's enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to

persons.

AC VOL TMETER

(5000 W per volt or

more sensitivity)

Good earth ground

such as a water pipe,

conduit, etc.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions

in the literature accompanying the appliance.

Page 3

Top

Parts List

Servicing Diagrams

Adjustment Procedures

Top

Adjustment Procedures

Servicing Diagrams

SECTION 1

GENERAL DESCRIPTIONS

1. OWNER'S MANUAL

Parts List

Page 4

Video Cassette Recorder

W-708

W-701

OWNER’S MANUAL

POWER

EJECT

PROG.TV

REC

PAUSE/STILL

REV FF

PLAY

STOP

This publication is printed

on recycled paper

70971842

Page 5

SAFETY PRECAUTIONS

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric

shock to persons.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO RAIN

OR MOISTURE. DANGEROUS HIGH VOLTAGES ARE PRESENT INSIDE

THE ENCLOSURE. DO NOT OPEN THE CABINET. REFER SERVICING TO

QUALIFIED PERSONNEL ONLY.

CAUTION: TO PREVENT ELECTRIC SHOCK, MATCH WIDE BLADE OF PLUG TO

WIDE SLOT, FULLY INSERT.

Product Name: Video Cassette Recorder

Model Number: W-708/W-701

FCC Notice: “Declaration of Conformity”

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Contact: Toshiba America Consumer Products, Inc.

Address: 1420 Toshiba Drive, Lebanon, TN37087

Telephone: 615-449-2360

User Installer Caution: Changes or modification made to this equipment not expressly

approved by Toshiba Corporation or parties authorized by Toshiba Corporation could

void the user’s authority to operate the equipment.

Note to CATV system installer:

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the

NEC that provides guidelines for proper grounding and, in particular, specifies that the cable

ground shall be connected to the grounding system of the building, as close to the point of cable

entry as practical.

2

Page 6

IMPORT ANT PRECAUTIONS

Save Original Packing Materials

The original shipping carton and packing materials will come in handy if you ever have to ship

your VCR. For maximum protection, repack the set as it was originally packed at the factory.

Avoid Volatile Liquid

Do not use volatile liquids, such as an insect spray, near the unit.

Do not leave rubber or plastic products touching the unit for a long time. They will mar the

finish.

Moisture Condensation

Never operate this unit immediately after moving it from a cold location to a warm location.

When the VCR is exposed to such a change in temperature, moisture may condense on the

cylinder inside, one of its most crucial internal parts. To prevent the VCR from possible

damage, do not use the unit for at least 2 hours when there is an extreme or sudden change

in temperature.

Compatibility

This video cassette recorder (VCR) is compatible with any other VCR bearing the

mark. HQ VHS equipment is also compatible with existing, non-HQ VHS equipment.

Copyright

It is permissible to record television programs, film, video tapes and other material only in the

event that third party copyrights and other rights are not violated.

INTRODUCTION

As an E

NERGY STAR

product model meets the E

®

Partner, TOSHIBA has determined that this product or

NERGY STAR

®

guidelines for energy efficiency.

In the spaces provided below, record the Model and Serial No. located at the rear of your video

cassette recorder.

Model No. Serial No.

Retain this information for future reference.

3

Page 7

IMPORTANT SAFETY

INSTRUCTIONS

CAUTION: PLEASE READ AND OBSERVE ALL WARNINGS AND INSTRUCTIONS

GIVEN IN THIS OWNER’S MANUAL AND THOSE MARKED ON THE UNIT.

RETAIN THIS BOOKLET FOR FUTURE REFERENCE.

This set has been designed and manufactured to assure personal safety. Improper use can

result in electric shock or fire hazard. The safeguards incorporated in this unit will protect

you if you observe the following procedures for installation, use and servicing. This unit is

fully transistorized and does not contain any parts that can be repaired by the user.

DO NOT REMOVE THE CABINET COVER, OR YOU MAY BE EXPOSED TO

DANGEROUS VOLTAGE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL

ONLY.

1. Read owner’s manual

After unpacking this product, read the owner’s manual carefully, and follow all

the operating and other instructions.

2. Power Sources

This product should be operated only from the type of power source indicated

on the marking label. If you are not sure of the type of power supply to your

home, consult your product dealer or local power company. For products

intended to operate from battery power, or other sources, refer to the operating

instructions.

3. Grounding or Polarization

This product may be equipped with a polarized alternating current line plug (a

plug having one blade wider than the other). This plug will fit into the power

outlet only one way. This is a safety feature. If you are unable to insert the plug

fully into the outlet, try reversing the plug. If the plug should still fail to fit, contact

your electrician to replace your obsolete outlet. Do not defeat the safety

purpose of the polarized plug.

4. Ventilation

Slots and openings in the cabinet are provided for ventilation and to ensure

reliable operation of the product and to protect it from overheating, and these

openings must not be blocked or covered. The openings should never be

blocked by placing the product on a bed, sofa, rug or other similar surface. This

product should not be placed in a built-in installation such as a bookcase or rack

unless proper ventilation is provided or the manufacturer’s instructions have

been adhered to.

5. Heat

The product should be situated away from heat sources such as radiators, heat

registers, stoves, or other products (including amplifiers) that produce heat.

4

Page 8

6. Water and Moisture

Do not use this product near water - for example, near a bath tub, wash bowl,

kitchen sink, or laundry tub; in a wet basement; or near a swimming pool and

the like.

7. Cleaning

Unplug this product from the wall outlet before cleaning. Do not use liquid

cleaners or aerosol cleaners. Use a damp cloth for cleaning.

8. Power-Cord Protection

Power-supply cords should be routed so that they are not likely to be walked

on or pinched by items placed upon or against them, paying particular attention

to cords at plugs, convenience receptacles, and the point where they exit from

the product.

9. Overloading

Do not overload wall outlets; extension cords, or integral convenience receptacles

as this can result in a risk of fire or electric shock.

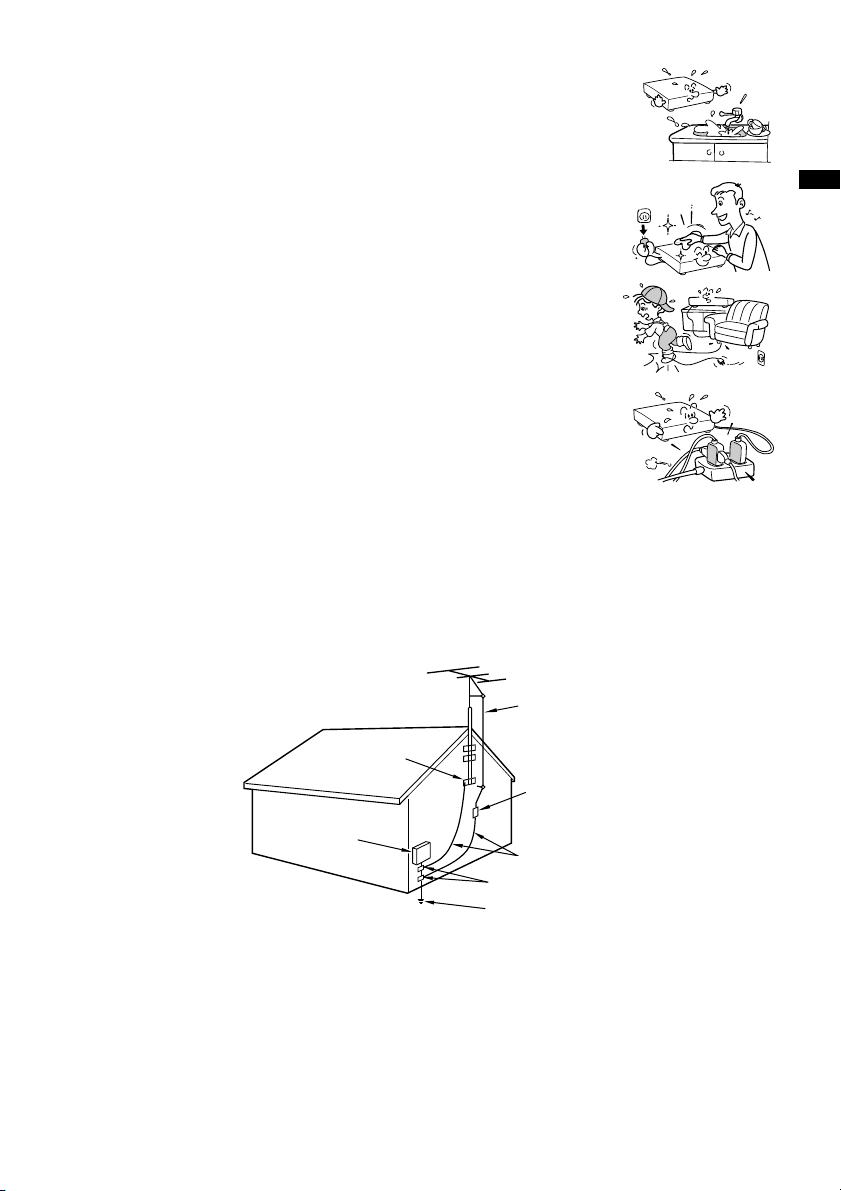

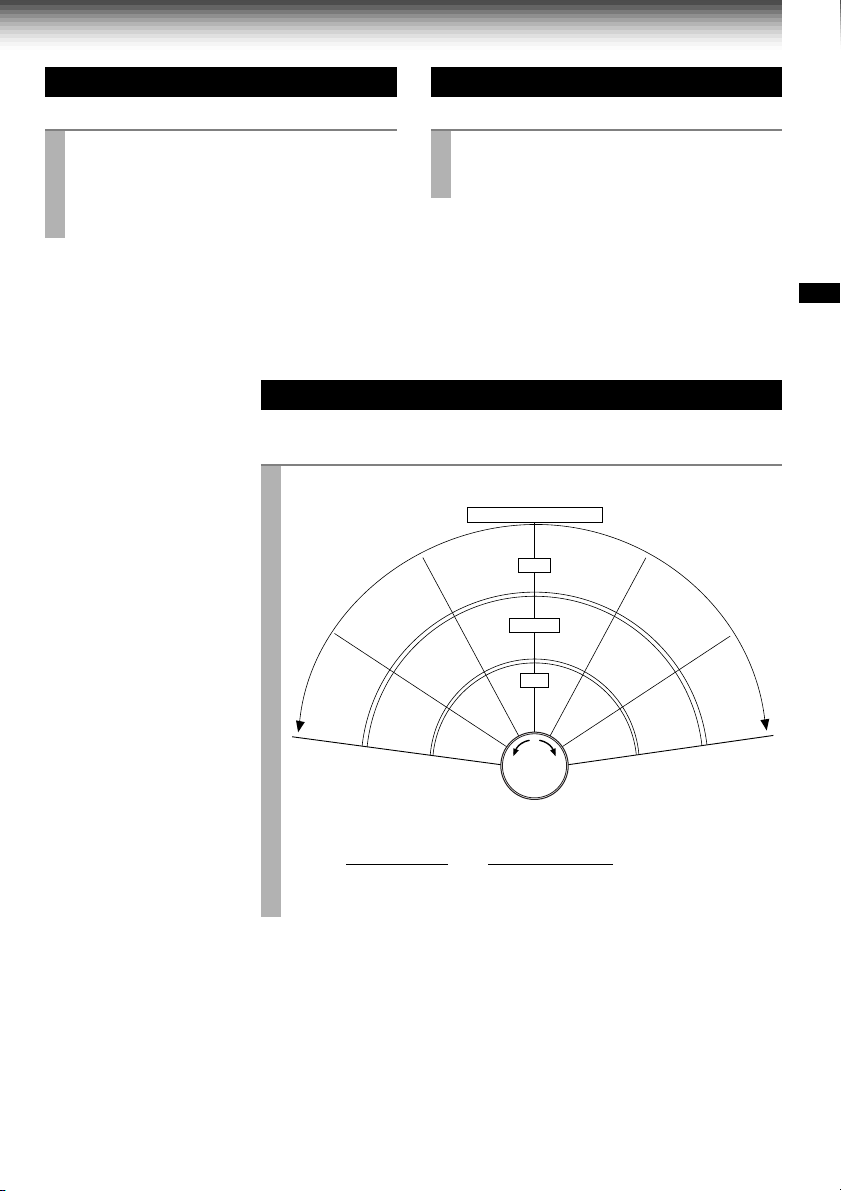

10. Outdoor Antenna Grounding

If an outside antenna or cable system is connected to the product, be sure the antenna or cable system

is grounded so as to provide some protection against voltage surges and built-up static charges. Article

810 of the National Electrical Code, ANSI/NFPA 70, provides information with regard to proper

grounding of the mast and supporting structure, grounding of the lead-in wire to an antenna discharge

unit, size of grounding conductors, location of antenna-discharge unit, connection to grounding

electrodes, and requirements for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE

ANTENNA

LEAD IN

WIRE

GROUND

CLAMP

ANTENNA

DISCHARGE UNIT

(NEC SECTION 810-20)

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250, PART H)

S2898A

ELECTRIC

SERVICE

EQUIPMENT

NEC – NATIONAL ELECTRICAL CODE

INTRODUCTION

11. Power Lines

An outside antenna system should not be located in the vicinity of overhead power lines or other electric

light or power circuits, or where it can fall into such power lines or circuits. When installing an outside

antenna system, extreme care should be taken to keep from touching such power lines or circuits as

contact with them might be fatal.

5

Page 9

IMPORTANT SAFETY

INSTRUCTIONS

12. Lightning

For added protection for this product during storm, or when it is left unattended

and unused for long periods of time, unplug it from the wall outlet and

disconnect the antenna or cable system. This will prevent damage to the

product due to lightning and power-line surges.

13. Object and Liquid Entry

Never push objects of any kind into this product through openings as they may

touch dangerous voltage points or short-out parts that could result in a fire or

electric shock. Never spill liquid of any kind on the product.

14. Attachments

Do not use attachments not recommended by the product manufacturer as they may cause hazards.

15. Accessories

Do not place this product on an unstable cart, stand, tripod, bracket, or table.

The product may fall, causing serious injury to a child or adult, and serious

damage to the product. Use only with a cart, stand, tripod, bracket, or table

recommended by the manufacturer, or sold with the product. Any mounting of

the product should follow the manufacturer’s instructions, and should use a

mounting accessory recommended by the manufacturer.

A product and cart combination should be moved with care. Quick stops,

excessive force, and uneven surfaces may cause the product and cart

combination to overturn.

16. Damage Requiring Service

Unplug this product from the wall outlet and refer servicing to qualified service personnel under the

following conditions:

a) When the power-supply cord or plug is damaged.

b) If liquid has been spilled, or objects have fallen into the product.

c) If the product has been exposed to rain or water.

d) If the product does not operate normally by following the operating instructions. Adjust only those

controls that are covered by the operating instructions as an improper adjustment of other controls

may result in damage and will often require extensive work by a qualified technician to restore the

product to its normal operation.

e) If the product has been dropped or damaged in any way.

f) When the product exhibits a distinct change in performance - this indicates a need for service.

S3125A

17. Servicing

Do not attempt to service this product yourself as opening or removing covers

may expose you to dangerous voltage or other hazards. Refer all servicing to

qualified service personnel.

18. Replacement Parts

When replacement parts are required, be sure the service technician has used replacement parts

specified by the manufacturer or have the same characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or other hazards.

19. Safety Check

Upon completion of any service or repairs to this product, ask the service

technician to perform safety checks to determine that the product is in proper

operating condition.

6

Page 10

Contents

INTRODUCTION

Provides important notes and general

explanation of the VCR, including names of the

buttons, jacks, etc.

SAFETY PRECAUTIONS .................... 2

IMPORTANT PRECAUTIONS.............. 3

IMPORT ANT SAFETY

INSTRUCTIONS................................... 4

Contents .............................................. 7

Identification of Controls ................... 8

• Front Panel

• Remote Control

• VCR Display

• Rear Panel

PREPARATION

Explains what you need to do before operating

the VCR.

How to Use the Remote Control ...... 10

Connections ...................................... 11

Auto Set Up ....................................... 14

Initial Settings Using On-screen

Display ............................................... 15

• Setting the Language

• Optional settings on the SET UP

screen

• Setting the Clock

Storing Channels on the VCR .......... 17

Video Cassette Use .......................... 20

PLAYBACK

Explains variable functions concerning

playback.

Playback ............................................ 21

•19µ HEAD

• DNR

Variable Speed Playback.................. 22

• Picture Search

• Still Picture

• Slow-motion Picture

• Frame Advance

• Double Speed Playback

• Shuttle Dial Operation

Useful Functions in Tape

Operation........................................... 24

• Counter Function

• Tape Remaining Time

• Index Search Function

RECORDING

Explains recording functions.

Recording a TV Program .................. 26

• Watching a TV program while

recording another

• Recording off time setting

Timer Program Recording ............... 27

VCR Plus+® system Set-up .............. 30

VCR Plus+

®

system Recording........ 32

MTS Broadcast Compatibility.......... 34

Simulcast Recording ........................ 35

ADDITIONAL INFORMATION

Multi Brand Remote Control ............ 36

Before Calling Service Personnel ... 38

Specifications ................................... 40

Accessories....................................... 40

LIMITED WARRANTY........................ 41

INTRODUCTION

7

Page 11

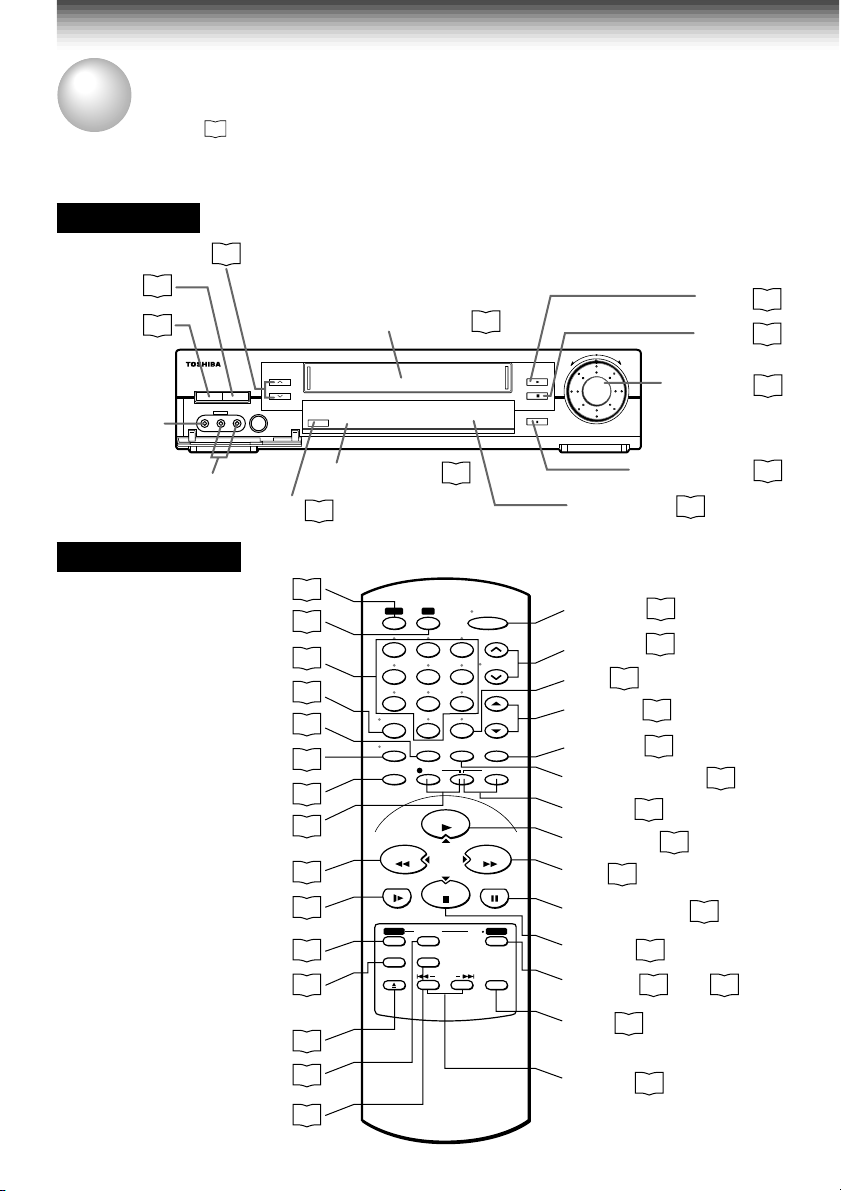

INTRODUCTION

Identification of Controls

See the page in for details.

This manual shows the names of buttons in italics.

Front Panel

CHANNEL

EJECT

POWER

LINE IN 2

VIDEO jack

LINE IN 2 AUDIO

(L/MONO, R) jacks

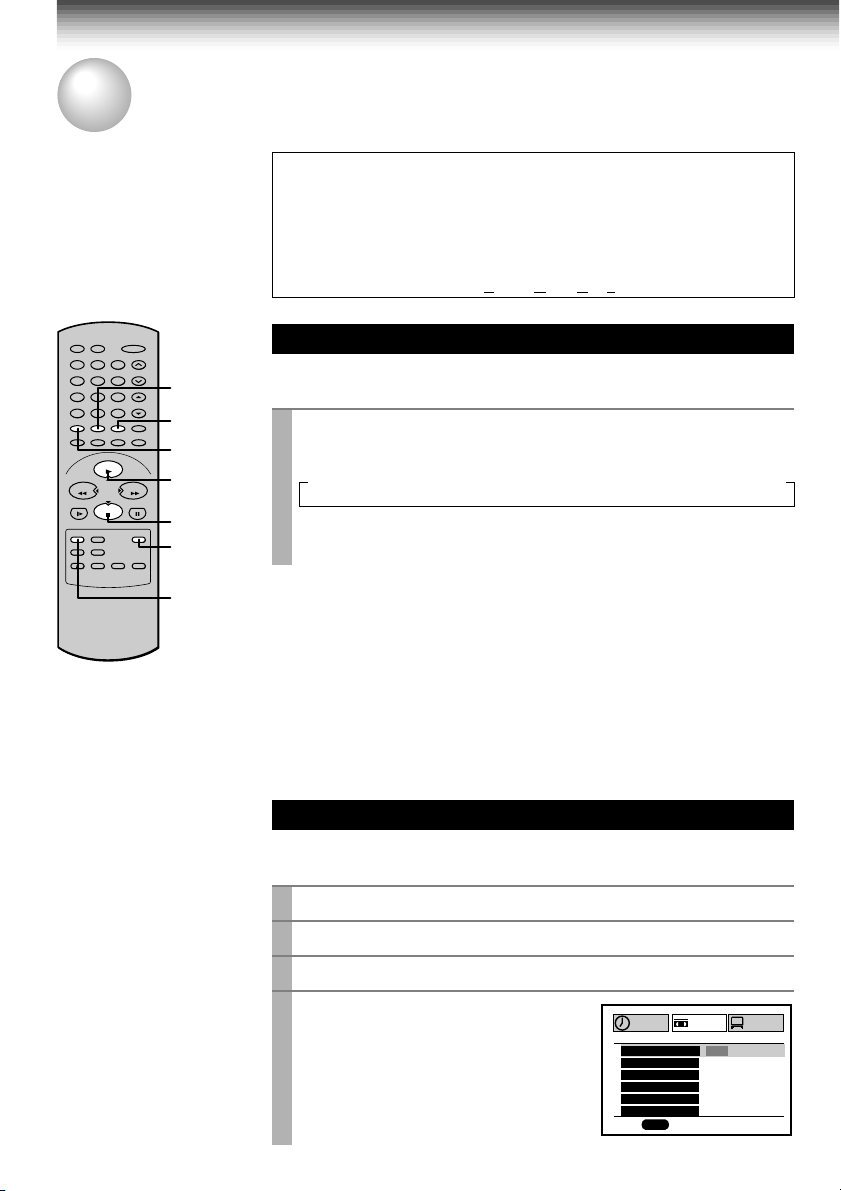

Remote Control

To operate this VCR.

To operate your TV.

REMAIN/COUNTER

8

20

15

Number buttons

(For W-708 only)

26

POWER

c EJECT

LINE IN 2

VIDEO L-MONO-AUDIO-R

REC

VCR

TV

I.SELECT

DISPLAY

SP/SLP

REC

REW

SLOW

PROG.

VCR Plus+

EJECT

CANCEL

A.SELECT

Cassette compartment

CHANNEL

REC

Remote sensor

26

14

36

26

26

24

24

26

26

*

21

22

15

32

20

29

34

20

10

23

100

0

REMAIN/

COUNT RESET

COUNTER

REC

PLAY/x2

CURSOR

STOP

CANCEL

A.SELECTVCR Plus

65

9

19

POWER

CH/TRK

TV VOL

TV/VCR

TIMER

FFREW

PAUSE/STILL

µ

/

VCR TV

1

4

78

I.SELECT

DISPLAY

SP/SLP

SLOW

PROG. ENTER

+

EJECT INDEX

REV

FWD

(

)

PAUSE/STILL

PLAY

STOP

PAUSE/STILL

VCR display

POWER

CH/TRK

100

TV VOL

TV/VCR

15

26

18

36

26

COUNT RESET

TIMER

PLAY/x2

FF

28

*

*

21

PAUSE/STILL

*

STOP

DNR

ENTER

DNR

21

16

21

(For W-708 only)

INDEX

* These buttons are used to control the

cursor on the screen.

25

PLAY

STOP

SHUTTLE

9

24

21

22

19

µ

21

21

21

23

22

Page 12

VCR Display

INTRODUCTION

VCR indicator

Cassette indicator

POWER indicator

POWER

SLP

REC

REC (Recording)

indicator

Tape speed indicator

(SP/SLP)

Rear Panel

To wall outlet

VCR

TIMER

Timer recording indicator

REMAIN indicator

REMAIN

OFF indicator

PM

AM

OFF

DT

CH

Channel indicator

Tape running direction/speed indicator

LINE OUT VIDEO jack

LINE IN 1 VIDEO jack

HM

Multifunctional indicator

DT (Digital Auto Tracking) indicator

RF IN (FROM ANT.) terminal

L

Hi-Fi (L/R) indicators

R

L: Left channel

R:Right channel

S

off: Normal track

LINE IN 1 AUDIO jacks (L, R)

CH selector (3/4)

LINE OUT AUDIO jacks (L, R)

LINE IN 1 AUDIO (Rear), 2 (Front) jacks

If the connected equipment is monaural (has one audio output jack), connect the L (MONO) side, the same

sound is recorded on both L and R on the Hi-Fi track.

RF OUT (TO TV) terminal

9

Page 13

PREPARATION

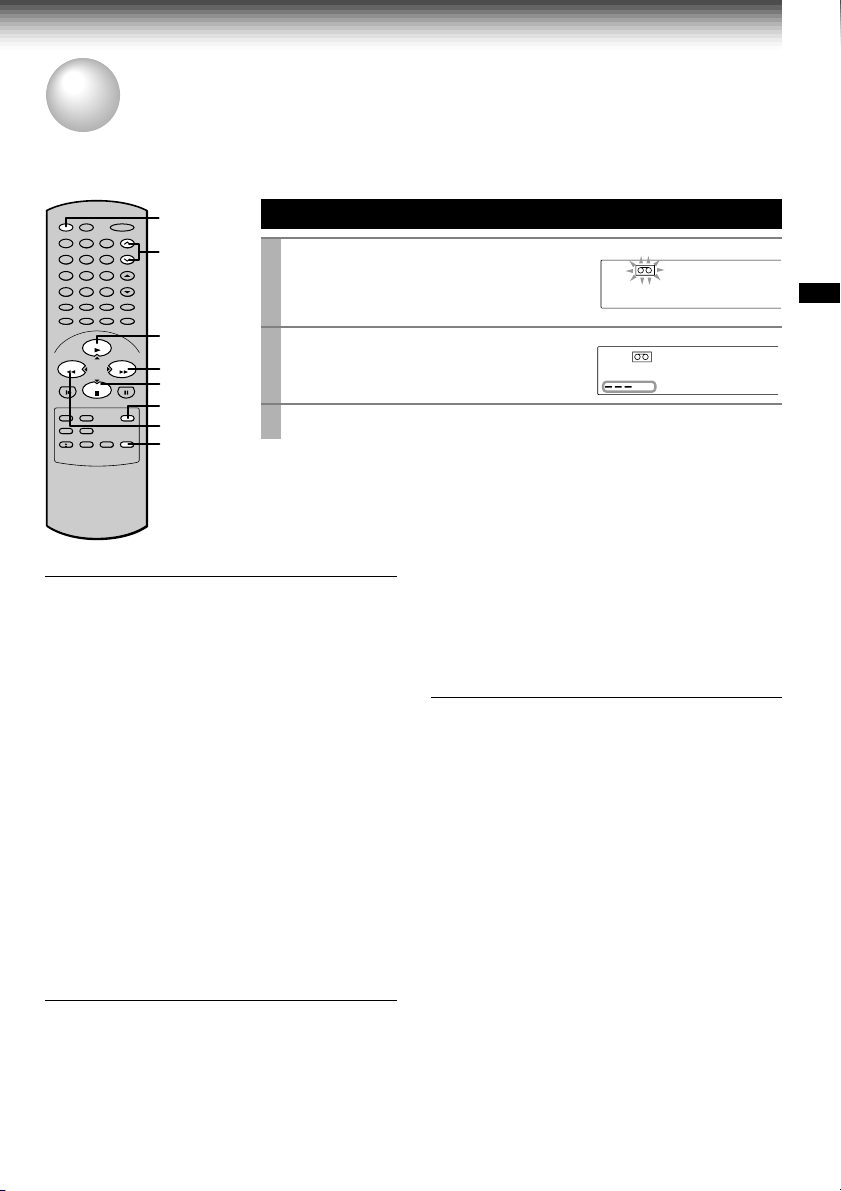

How to Use the Remote Control

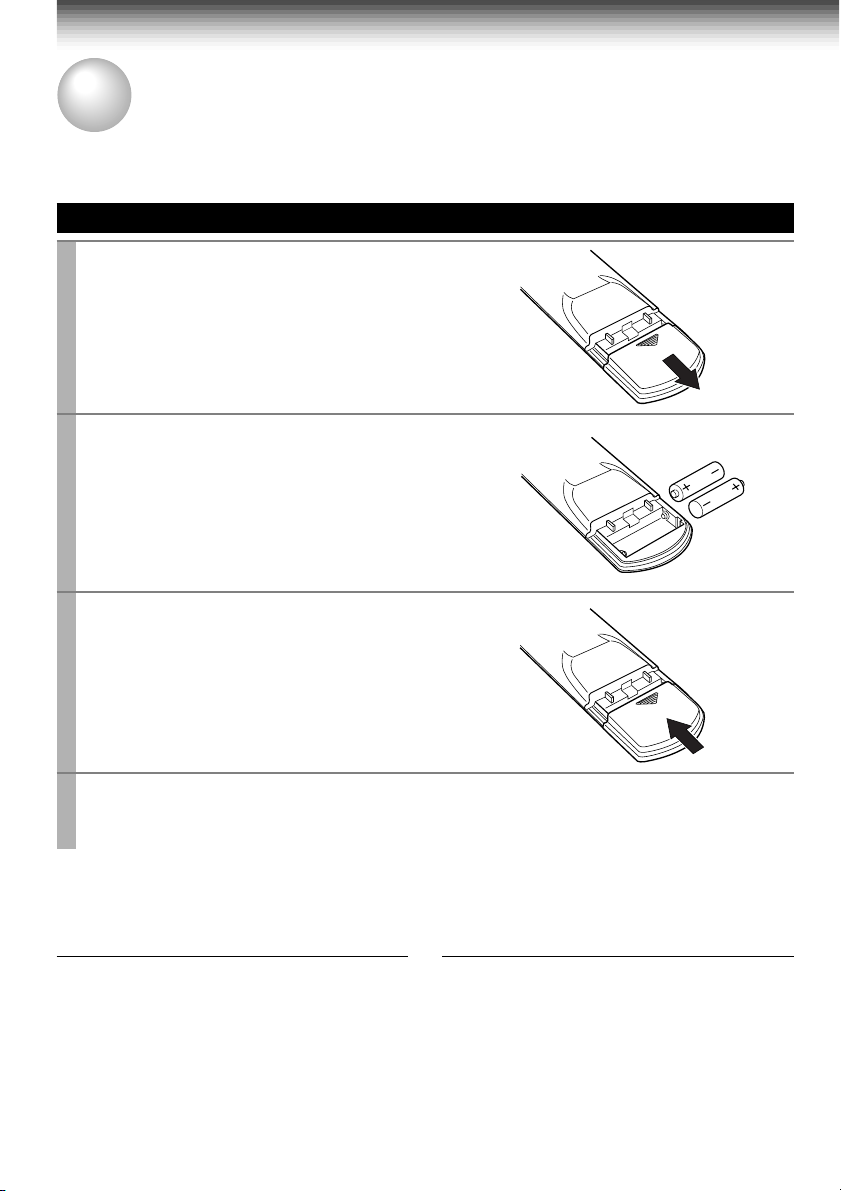

This section explains how to get ready for remote control operation.

Setting up the Remote Control

Open the battery compartment lid on the

1

rear panel.

Install 2 batteries (“AAA” size) following

2

the polarity diagrams.

Close the battery compartment lid.

3

Point the remote control at the VCR and press the buttons within the operating range.

4

Distance: within about 7 m from the front of the remote sensor

Angles: within about 30˚ in every direction

Notes on batteries

• The life of the batteries is about 1 year

depending on the conditions of use.

• If the remote control does not operate correctly,

replace all batteries with new ones.

• If the remote control is not to be used for a

long period of time, remove the batteries to

avoid possible damage from battery corrosion.

10

Caring for the remote control

• Do not expose the remote sensor of the VCR

to a strong light source such as direct sunlight

or illumination (especially high-frequency

lighting) when using the remote control.

• Be careful not to spill water on the remote

control or to place it on anything wet, and avoid

sharp impacts.

Page 14

PREPARATION

Connections

Before you use this VCR, it is necessary to connect it to your TV. Several ways of connecting are

available depending on your use of TV or cable box. Select one which is applicable to your equipment.

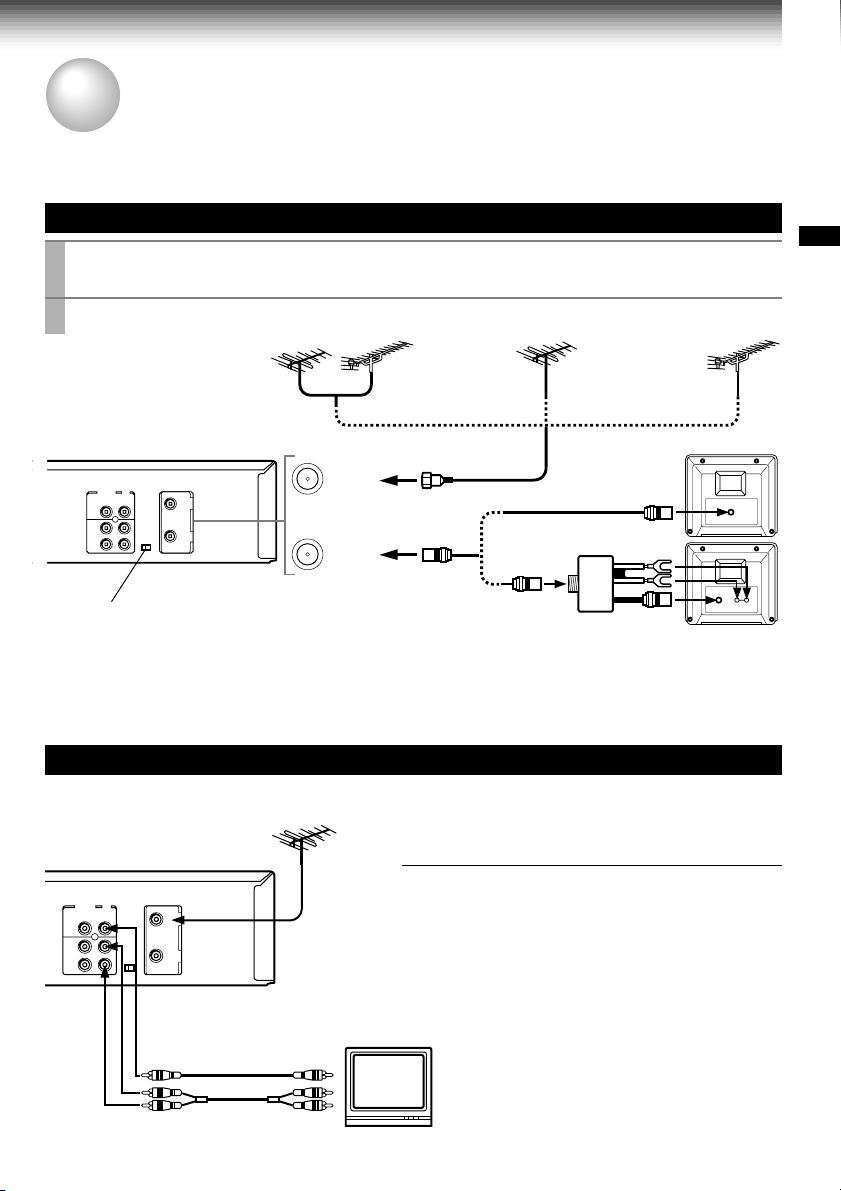

Antenna/VCR/TV Connection

Disconnect the antenna cable from your TV and connect it to the RF IN terminal on the

1

VCR.

Connect the RF OUT terminal to the TV.

2

PREPARATION

VHF/UHF combinaion

antenna

IN

(FROM ANT.)

OUT

(TO TV)

Setting the VCR Output Channel

When the VCR is connected in this way, the VCR sends the output

signals to channel 3 or 4 on your TV. Set the output channel

selector (CH selector) of the VCR to “3” or “4”, whichever is vacant

in your area.

VHF antenna

only

1

2

AUDIO/VIDEO Connections

The AUDIO/VIDEO jacks are also available to connect your TV.

When connected your TV using the

AUDIO/VIDEO OUT jacks

To watch video pictures, set the video input mode on

your TV. For the video input mode, refer to the

manual of your TV.

UHF antenna

only

Antenna splitter

(not supplied)

VHF/UHF

VHF UHF

LINE OUT VIDEO

VIDEO IN

AUDIO INLINE OUT AUDIO

11

Page 15

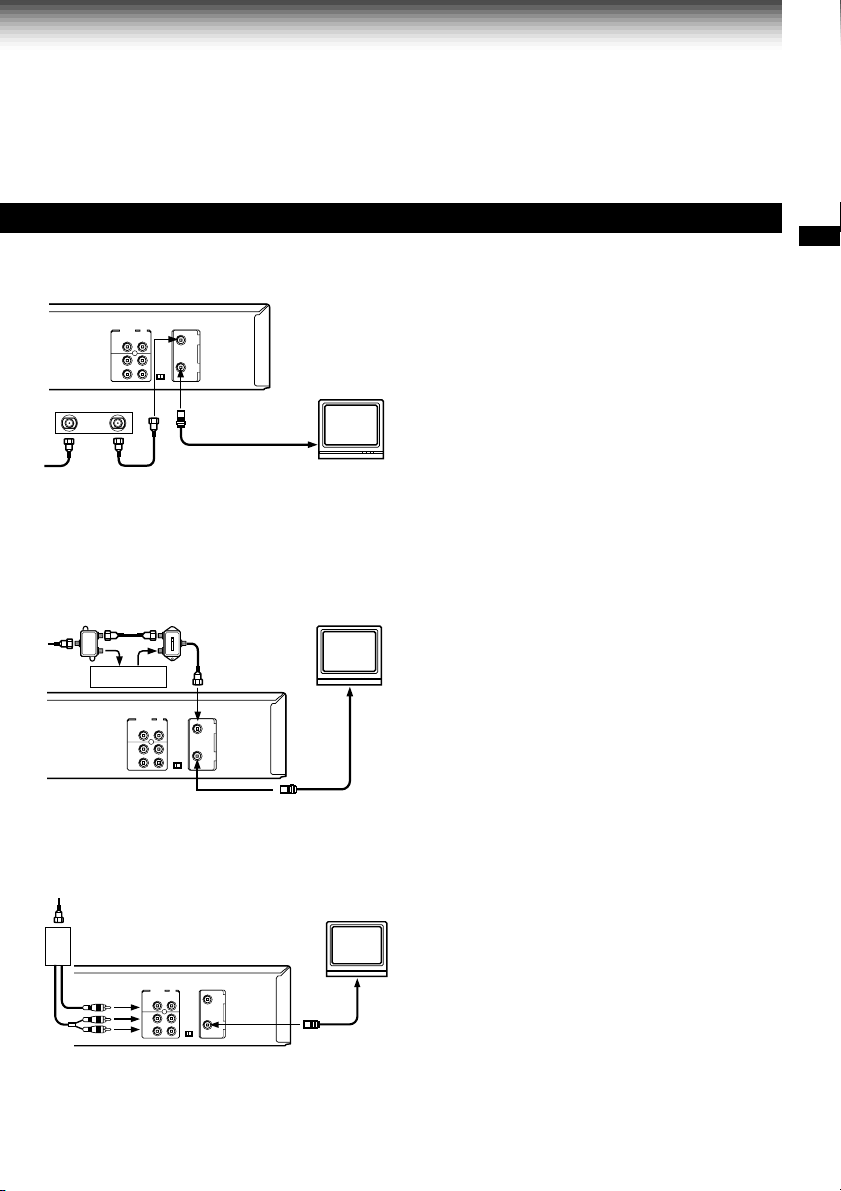

Connections (continued)

Cable Connection

Choose one of the below according to your usage of the cable box.

This set-up will enable you to:

– record an unscrambled channel.

– watch an unscrambled channel while recording

it.

– record an unscrambled channel while watching

another (only when you connect a cable-

Incoming cable

compatible TV).

You will need to:

• select TV channel 3 or 4 to receive video

signals. (See page 11.)

• to record a channel while watching another,

press

TV/VCR

the “VCR” indicator in the VCR display and

select a desired channel on the TV (only when

you connect a cable-compatible TV).

on the remote control to turn off

Incoming cable

12

Cable Box

IN OUT

This set-up will enable you to:

– record an unscrambled channel.

– watch an unscrambled channel while recording

it.

– record an unscrambled channel while watching

another (scrambled or unscrambled).

You will need to:

• set TV channel to the output channel of the

cable box.

• turn on the cable box and select cable channel

3 or 4 according to the output channel of the

VCR.

• to record a channel while watching another,

press

TV/VCR

the “VCR” indicator in the VCR display and

select a desired cable channel on the cable

box.

on the remote control to turn off

Page 16

Cable Box

Cable Box

PREPARATION

This set-up will enable you to:

– watch an unscrambled or scrambled channel

while recording it.

– record any channels through the cable box.

You will need to:

OUTIN

A/B switch

A

A

A

B

B

B

• set TV channel 3 or 4 to receive video signals.

(See page 11.)

• set VCR channel to the output channel of the

cable box, and select a desired cable channel

on the cable box.

• while the VCR is turned off or the “VCR”

indicator is not lit in the VCR display, set TV

channel to the output channel of the cable box.

This set-up will enable you to:

– watch an unscrambled or scrambled channel

while recording it.

– record an unscrambled channel while watching

another unscrambled channel (only when you

connect a cable-compatible TV).

• A/B switch “A”: record and watch an

unscrambled channel which

comes bypassing the cable box.

• A/B switch “B”: record and watch a scrambled

or unscrambled channel coming

through the cable box.

This set-up will enable you to:

Box

Cable

– watch or record a channel through the cable

box via the LINE IN 1 (AUDIO/VIDEO) jacks.

You will need to:

• press

I.SELECT

shows “L1”.

so that the VCR display

13

Page 17

PREPARATION

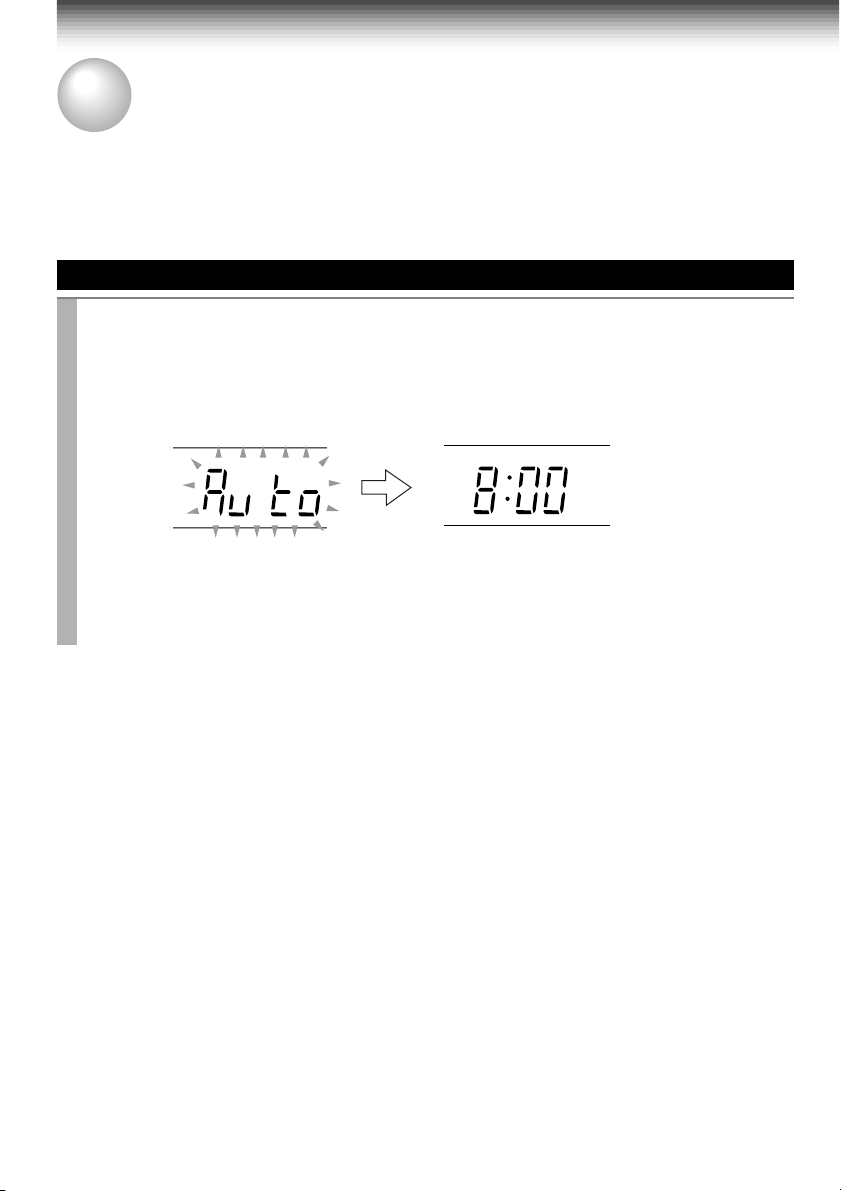

Auto Set Up

The Auto Set Up function automatically sets the tuner channels and clock when power is first connected

to the VCR.

Preparation

• Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video

connection (page 11).

• Press

I.SELECT

• Press

Auto Set Up

Connect the antenna cable to the VCR (see page 11). Then connect the VCR’s power

1

plug to an AC outlet.

“Auto” flashes in the VCR display as the VCR automatically tunes in all active stations.

When Auto Set Up is completed successfully, the current time will be displayed.

so that the channel number will appear if “L1” or “L2” is displayed in the VCR display.

VCR

to set the remote control operating the VCR.

VCR display

Tuning in progress.

VCR display

PM

Auto Set Up completed.

• If the VCR fails to set the clock, “– : – –” will be displayed. Set the clock manually. (Refer

to “Setting the clock” on page 16.)

Notes

• If you press the

• If Auto Set Up is not perform successfully, perform the clock and Tuner Channel procedures manually

(page 16 to 18).

• If, however, you want to add or delete channels, refer to “Adding or erasing channels” on page 18.

CANCEL

button, the Auto Set Up is cancelled.

14

Page 18

PREPARATION

Initial Settings Using On-screen Display

Language selection must be set first when the VCR is first plugged in, or after it encounters a power

failure. You can also easily make necessary settings using the on-screen displays.

Preparation

• Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video

connection (page 11).

• Press

23

1

4

78

0

PLAY/x2

VCR

to set the remote control operating the VCR.

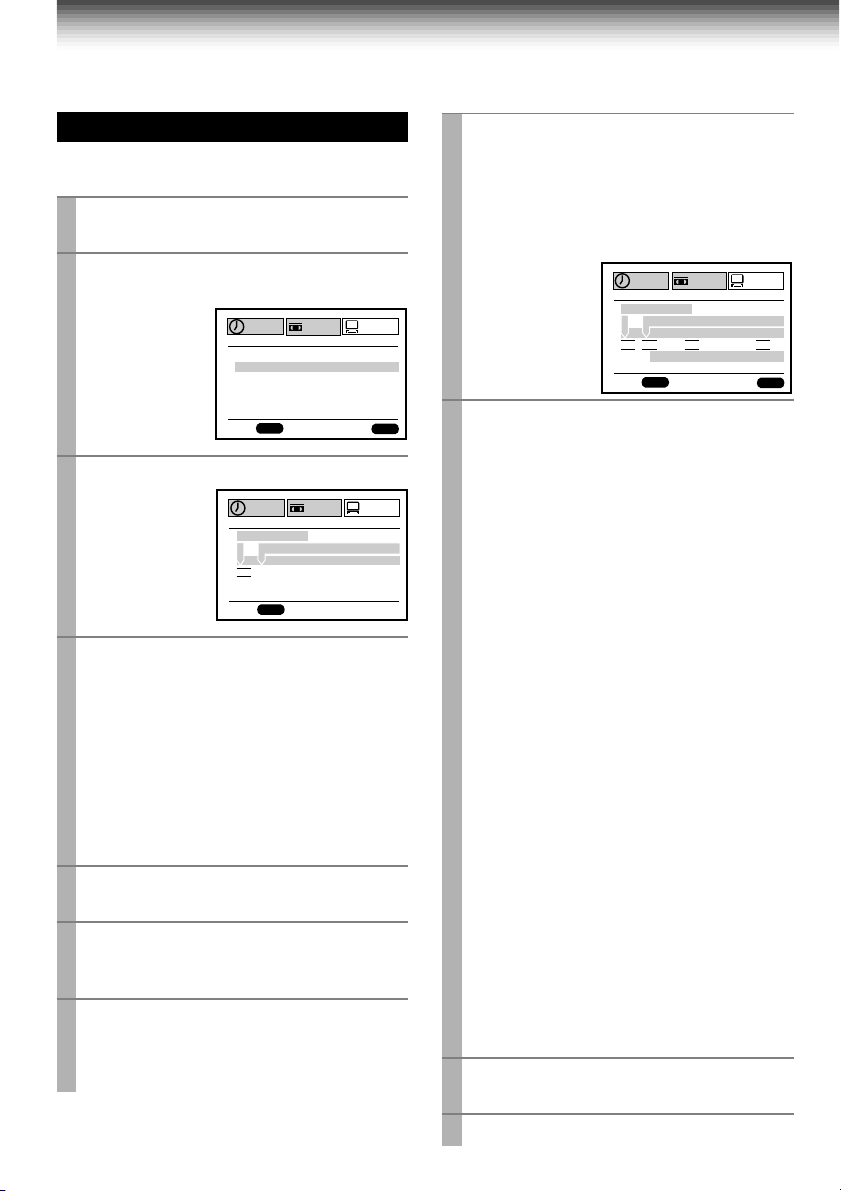

Setting the Language

VCR

POWER

65

9

100

REW

FF

FFREW

STOP

PLAY/x2,

STOP

ENTER

PROG.

Press

Press

POWER

PROG.

.

1

2

The following screen appears on the TV.

Select the language using

3

(

CURSOR

) or

) , and press

The screen turns to the MENU screen.

to turn on the VCR.

PLAY/x2

STOP (CURSOR

PROG.

.

n

ED:

PROGRAM

PROG

PROGRAM

SET UP

E

n

GLSIH

n

FRA

E

SPA

MEnU

SET UP

ÇA I

ñ

PRESET

S

OL

PRESET

PREPARATION

Press

PROG.

4

to return to the normal TV screen.

Optional settings on the SET UP screen

Other optional settings can be made. Press

ENTER

while “SET UP” is selected on the

MENU screen. The screen turns to the SET UP screen.

SET UP

PROGRAM

n

GUAG

nn

PROG

H

GT

n

E

TAPE LE

SAP SET

SIMULCAST

ANTE A

LA

X

DS InOF

n

ED:

To exit, press

PRESET

120 016 801

n

OFFO

n

OFFO

UATOUA

M

n

EG RFA SPE

n

OFFO

PROG.

Page 24

Page 34

Page 35

n

With “AUTO” set, a TV broadcast will appear via the TV tuner after

playback.

Move down here, and set to “AUTO” or “MANU”.

If you made the Audio/Video connection (page 11), set to “MANU”.

To change the language, move down here and set to the desired one.

With “ON” set, you can see the station ID and program title displayed on

TV.

n

ED:

PROG

ENTER

(Continued)

15

Page 19

Initial Settings Using On-Screen Display (continued)

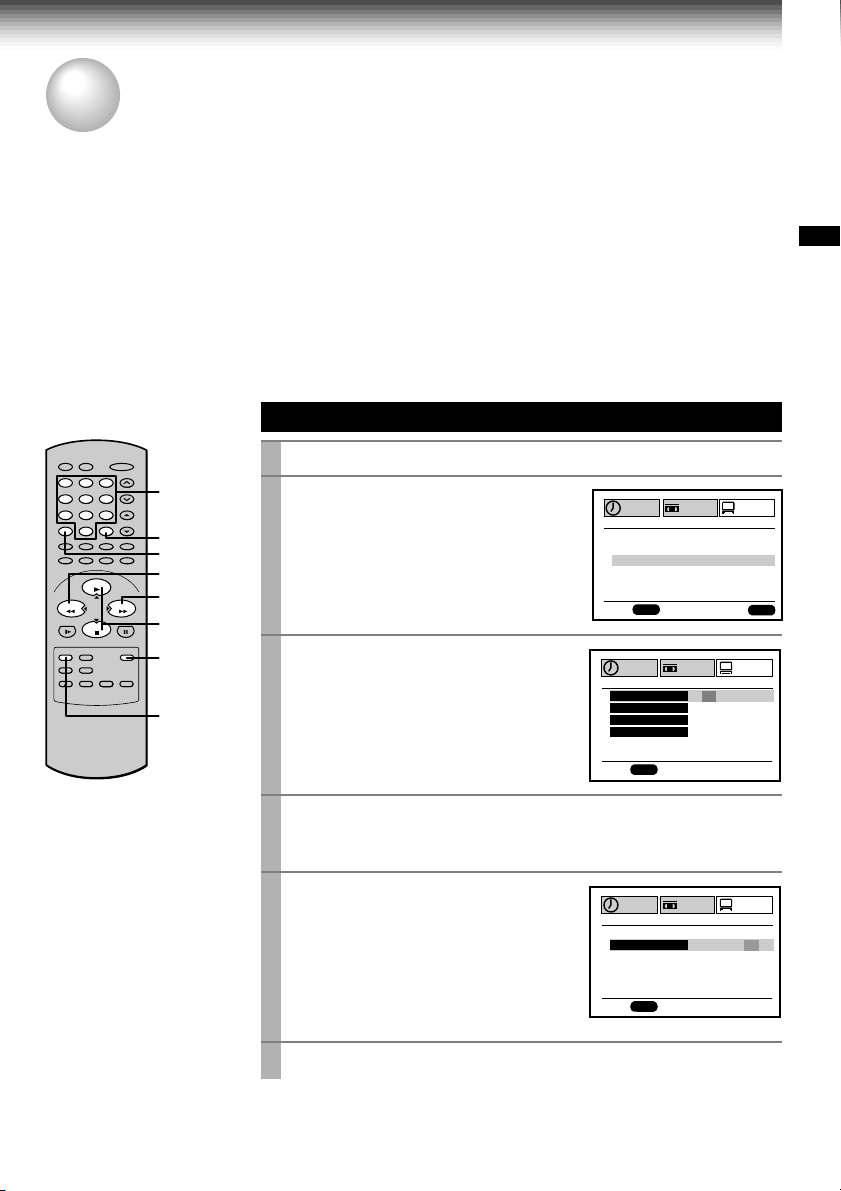

Setting the Clock

Example: To set the clock to 2:30 p.m. on

August 25 (summer time) 2000.

Press

PROG.

1

The MENU screen appears on the TV.

Select “PRESET” using FF or

2

press

ENTER

Note

“GUIDE CH” is for

W-708 only.

Press

3

Select “A UTO” or “MANU” using

4

x2

or

STOP

AUTO: The VCR automatically sets or

adjusts the clock.

If you select “AUTO” mode, proceed to step 8.

MANU: You can set the clock manually.

If you select “MANU” mode, select “SUMMER

TIME” using FF. Set to “IN” or “OUT” for the

summer (daylight saving) time using

or

STOP

the description in step 9.)

Move to the next using FF.

5

(To move back, press

Vary the digits to set the hour.

6

PLAY/x2

STOP

: To decrease.

Repeat steps 5 and 6 to set the minutes,

7

month, day, and the year (by the last two

digits).

Proceed to step 10 to start the clock.

.

REW

.

SET UP

PRESET

ET

RY

OX / D S S

SET UP

PRESET

AA

TED

E

A

M

ENTER

PROGRAM

CLOCK S

MEMO

CH

CABLE B

GU I DE HC

PROG

n

ED:

to select “CLOCK SET”.

PROGRAM

CL

O

CK S E T

SUMMEMERTI

TOU1000SA1’/

12 :

PROG

M

00

MANU

n

ED:

PLAY/

.

. (F or “IN” and “OUT” selections, see

REW

.)

: To increase.

PLAY/x2

, and

ENTER

RYETI

Press

8

ENTER

to start the “AUTO” clock

set feature.

After a while, the VCR automatically updates

the clock using the data broadcast by the

local TV stations.

The following screen will appear on TV

depending on the broadcast at your location.

O

CK S E T

SUMMEMERTI

n

I

M

57

:

9

PROG

PLAY/x2

SET UP

M

E

EAS

AR

E

A

10 00SA1’/

M

REW

PROGRAM

CL

AUTO AUTO AUTO AUTO

n

ED:

Select the options using FF or

9

Change the data using

STOP

.

1) Set “SUMMER TIME (DaylightSaving Time)”.

IN, daylight-saving time begins on the first

Sunday in April. Because the clock

automatically changes from 2:00 AM to

3:00 AM (forward one hour), remember

that any part of a scheduled Timer

Recording that falls between these two

times will not be recorded.

OUT, daylight-saving time ends on the last

Sunday in October. The VCR clock

automatically changes from 2:00 AM to

1:00 AM (back one hour). Therefore, it can

affect your recording length if one is set

for this time.

2) Set “Time Zone”.

If you select “AUTO” for your time zone,

the VCR sets the clock using the first

Coordinated Universal Time information it

finds. If the time is not correct, select

another time zone or use the “MANU”

option.

3) Set “CH”.

If you don't know the clock data channel,

select “AUTO”. The VCR will scan

automatically to tune the channel carrying

the clock data.

If AUTO CLOCK SET is unsuccessful, set the

time and date through the “MANU” clock set

menu selection.

Press

PROG.

10

Now the clock starts.

.

PRESET

OH

n

EZ

CTI

TER

n

TED

AEYTI

ENTER

.

or

2

16

11

Press

PROG.

to exit.

Page 20

PREPARATION

Storing Channels on the VCR

This section is required if you receive only normal TV or unscrambled cable channels, or use a cable box

between your TV and the VCR.

Incoming Antenna/Cable (CATV) Signals

The VCR scans through all receivable TV and CATV channels and stores only the active

ones in your area into the memory. Once the storing is finished, you can select a desired

channel using

Preparation

• Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video

connection (page 11).

• Press

I.SELECT

23

1

4

78

0

PLAY/x2

STOP

CH/TRK

.

so that the channel number will appear if “L1” or “L2” is displayed in the VCR display.

Incoming Antenna/Cable (CATV) Signals

Press

PROG.

1

Number

65

buttons

9

100

FFREW

100

I.SELECT

REW

FF

PLAY/x2,

STOP

ENTER

Select “PRESET” using FF or

2

and press

Note

“GUIDE CH” is for W-708 only.

Select “CH MEMORY” using

3

x2

or

STOP

1, 6

to display the MENU screen.

REW

ENTER

.

PLA Y/

, and press

ENTER

.

,

PROGRAM

CLOCK S

CH

CABLE B

GU I DE HC

PROG

n

ED:

PROGRAM

TV / C TAV

AUTO SCA

ADD CH

ERAS CEH

n

SET UP

MEMO

SET UP

ET

RY

OX / D S S

PRESET

TV TVAC

––

––

PRESET

OFFO

CH

CH

PREPARATION

ENTER

n

n

ED:

Set “TV/CATV“ to “TV” or “CATV” using FF or

4

TV: To store channels received via the antenna.

CATV: To store channels received via the incoming cable.

Select “AUTO SCAN” using

5

or

STOP

, and press FF to set to

“ON”.

The VCR starts scanning and the

PLA Y/x2

PROGRAM

AUTO SCA

channels are stored in the VCR in

ascending order. When the scanning is

finished, the screen automatically

n

ED:

returns.

Press

PROG.

6

to exit.

PROG

PROG

REW

TV

n

.

SET UP

PRESET

OCH2

n

17

Page 21

Storing Channels on the VCR (continued)

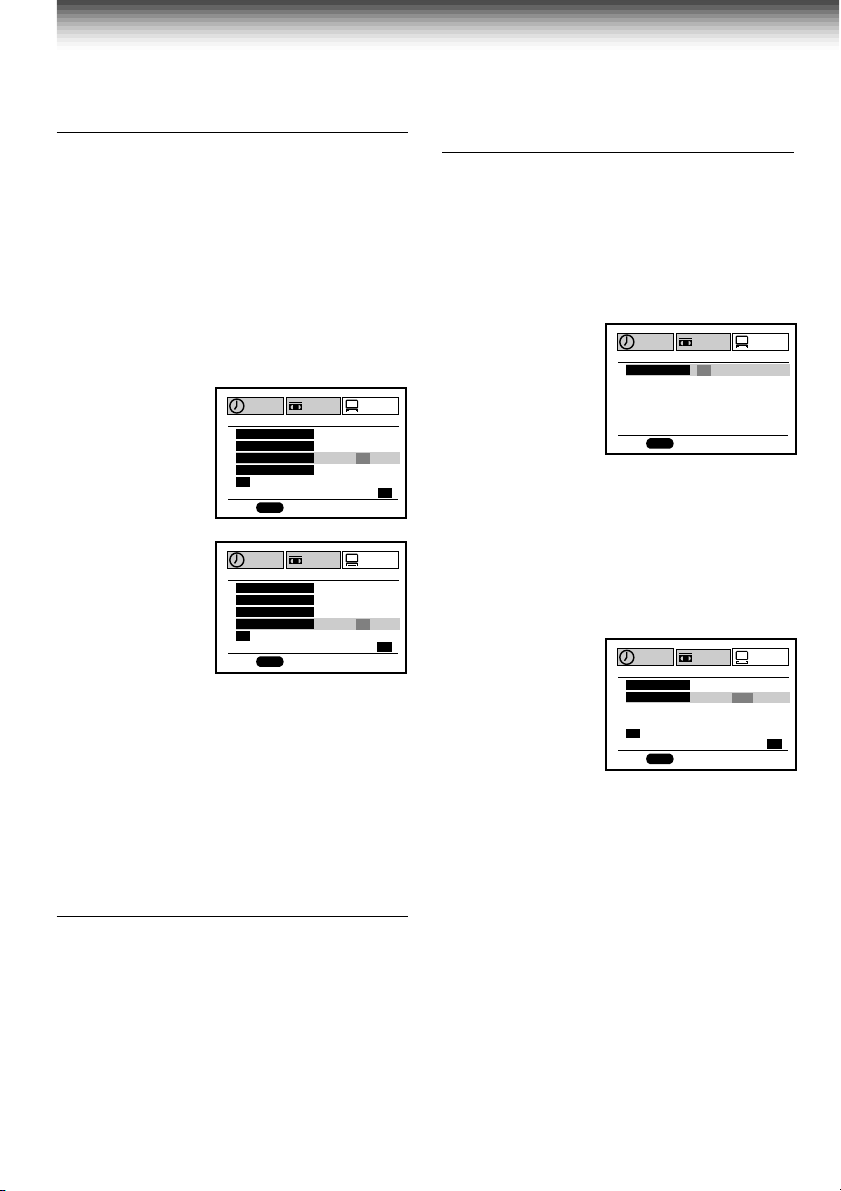

Adding or erasing channels

Adding channels

If a desired channel cannot be scanned

automatically because of a weak signal, it can be

added to the memory.

Erasing channels

You can erase a stored channel from the memory

if it is unnecessary.

1)Follow steps 1 to 3 of “Incoming Antenna/CATV

Signals”.

2)Select “ADD CH” or “ERASE CH” using

or

STOP

.

To add channels

To erase channels

PROGRAM

TV / C TAV

AUTO SCA

ADD CH

ERAS CEH

OSETCH

T

PROG

n

ED:

PROGRAM

TV / C TAV

AUTO SCA

ADD CH

ERAS CEH

OSETCH

T

PROG

n

ED:

PUSH ~90EYSK

PUSH ~90EYSK

3)Enter a channel number of 1 to 125 using

number buttons

.

For more than 100 number, first press

For CATV channels, refer to the chart below.

(For other orders, check with your cable

company.)

4)Repeat steps 2) and 3) to add or erase

channels as necessary.

5)Press

PROG.

to exit.

n

n

SET UP

SET UP

PLAY/X2

PRESET

TV

FFO

––

––

PRESET

TV

FFO

––

––

100

TVAC

n

O

n

O

n

O

TVAC

n

O

n

O

n

O

.

Cable Box/DSS Output Channel

Setting

To set the Cable Box/DSS output Channel on the

VCR.

1)Press

2)Select “PRESET” using FF or

3)Select “CABLE BOX/DSS” using

4)Select “NO”, “C.BO X” or “DSS” using FF or

5)If set to “C.BOX” or “DSS”, select “OUTPUT CH”

6)Press

PROG.

to display the MENU screen.

REW

ENTER

STOP

.

, and press

ENTER

ED:

USE

n

.

PROGRAM

PROG

, and press

PLAY/X2

SET UP

C.BOXO

n

or

PRESET

SSD

REW

according to your connection type.

using

PLAY/X2

or

STOP

. Then enter the output

channel number of your cable box (Usually 3 or

4, check the rear of the cable box.) or line input

mode “L1” using the

I.SELECT

button according

to your connection.

SET UP

n

O

C.BOX

PRESET

3

SSD

HC

PROG.

to exit.

USE

OUT UT CHP

n

ED:

PROGRAM

OSETCH

T

PUSH ~90EYSK

PROG

Selecting stored channels

Once the active channels have been stored, you

can select the channels in two ways below.

Number buttons

To enter digits of the channel number.

• For one-digit number, enter 0 before.

• For more than 100 number, first press

• Each

number button

needs to be pressed

within 2 seconds.

CH/TRK

To shift up or down the stored channel numbers.

18

100

.

Page 22

Channel reference chart

Number on the VCR

Corresponding channel number

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

10 11 12 13 A B C D E F G H I J K L M N O P Q

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

R S T U V W AA BB CC DD EE FF GG HH II JJ KK LL MM NN OO

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 – –

PP QQ RR SS TT UU VV WW XX YY ZZ AAA BBB 65 66 67 68 69 70 71

93 94 95 96 97 98 99 100 101 102 103

–––––––––––…–––––

93 94 A-5 A-4 A-3 A-2 A-1 100 101 102 103

TV

CATV STD (HRC/IRC)

123456789

–23456789

1(A-8)

234

…

121 122 123 124 125

…

121 122 123 124 125

5(A-7) 6(A-6)

7

CATV signals

• STD (standard) cable TV signals

• HRC (Harmonic Related Carriers) cable TV signals

• IRC (Incremental Related Carriers) cable TV signals

IRC is also called ICC (Incremental Coherent Carriers)

89

…

…

…

PREPARATION

19

Page 23

PREPARATION

Video Cassette Use

Video Cassette Use

Loading a cassette

Push the cassette into the cassette compartment with the window side facing up and the

label side towards the front. The VCR is automatically turned on. The indicator will

appear in the VCR display.

Ejecting a cassette

Press

EJECT

. The cassette is ejected from the cassette compartment.

Warning

Do not insert your hands or any foreign objects into the compartment. This may result

in injury or damage. Take special care with children to avoid accidents.

Precautions when using video cassettes

Video cassettes have a safety tab to prevent accidental erasure. If the tab has already been removed,

recording cannot be performed.

To prevent accidental erasure

Remove this safety tab with a screwdriver.

• Avoid exposing cassettes to direct sunlight. Keep them away from heaters.

Avoid extreme humidity, vibrations or shock, strong magnetic fields (near a motor, transformer or

magnet) and dusty place.

20

To record again

Cover the tab hole with adhesive tape.

Page 24

PLAYBACK

K

Playback

This section explains the basic playback operation.

Preparation

• Select the video channel (3 or 4) or video input mode on the TV.

• Press

VCR

to set the remote control operating the VCR.

Basic Playback

Load a recorded cassette.

1

Pow er is turned on.

If the cassette has no safety tab,

playback starts automatically.

Press

2

3

PLAY/x2

T o stop pla yback, press

Rewinding / Fast-forwarding

Press

REW

to start playback.

or FF in the stop mode.

23

1

4

78

0

PLAY/x2

STOP

VCR

CH/TR

65

9

100

2

FFREW

FF

3

µ

19

REW

DNR

STOP

POWER

PLAYBACK

POWER

SP

VCR

DT

.

Adjusting the tracking

When playback starts, the VCR automatically

adjusts the tracking for clear pictures and sound

(Digital Auto Tracking).

The “DT” indicator blinks during the adjusting.

If the VCR cannot locate the best possible

tracking point, hold down one of

CH/TRK

to

adjust the tracking manually.

• To resume the digital auto tracking, hold down

both

CHANNEL

on the VCR simultaneously for

about 2 seconds.

Notes

• During the adjusting, the playback picture and

sound may be distorted.

• The digital auto tracking is activated only in the

playback mode.

• To reset the manual tracking point to the center,

press both

simultaneously for not longer than 1 second.

• The noise on the screen may not be completely

CHANNEL

on the VCR

eliminated depending on the tape used,

especially when the tape was recorded on

another VCR.

19µ HEAD

You can view high quality pictures while playing

back a tape recorded in the SLP tape speed.

By pressing 19µ repeatedly, the 19µ HEAD mode

is displayed on the TV screen as follows:

19U HEAD AUTO: Usually set to “AUTO”. As the

playback starts, the VCR automatically activates

the 19µ head and reproduces high quality pictures .

19U HEAD OFF: Set to “OFF” if the pictures are

marred by dots.

Note

During playback with the 19µ head, momentary

noises or shakes may be produced when you

change the mode to the picture search or

variable speed playback.

DNR (Digital Noise Reduction)

(For W-708 only)

The noise reduction function of this VCR is based

on a digital signal system utilizing memory, and is

effective in the playback of noisy tapes.

Furthermore the CSE (Color Signal

Enhancement) circuit, which is included in the

system, compensates for color signal weakness

and gives the best possible color. Thanks to this

circuit color distortion is reduced and a sharp

picture is played back.

Press

DNR

DnR On: Usually set to “On”.

DnR OFF: This function will not work.

Notes

• The DNR playback is available only in the

playback mode.

• Depending on the recorded picture, for example

too vivid or too noisy, you may not notice a

reduction in the noise.

• The noise reduction may not work on pictures

recorded from special equipment such as TV

game machines or computers.

repeatedly to select the following:

The “DnR On” will appear on the TV

screen and you can view the picture

with less noise.

21

Page 25

PLAYBACK

Variable Speed Playback

You can play back a tape at various tape speeds.

Picture Search

23

1

4

78

0

PLAY/x2

STOP

65

9

100

PLAY/x2

REW

FFREW

FF

PAUSE/STILL

SLOW

A tape runs at 5 times or 7 times the normal playback speed so

that you can quickly locate a particular scene.

Press FF or

1

The tape runs at 5 times the normal playback speed.

To change the tape speed to 7 times the normal playback

2

REW

speed, press and hold

If you release it, the tape speed returns to 5 times.

Note

If you press FF or

forwarding or rewinding.

REW

during picture search, the mode changes to fast-

To resume normal playback

Press

PLAY/x2

.

during playback.

FF

or

REW

.

Still Picture

A picture freezes so that you can watch

closer.

Press

1

PAUSE/STILL

The picture freezes.

To resume normal playback

PAUSE/STILL

Press

Notes

• The still mode is automatically cancelled after

about 5 minutes and returns to normal playback.

• The still picture may shake if a picture of a fastmoving object or scene is frozen. This is not a

defect in the unit.

Adjusting Still Picture Stability

If the still picture is distorted or flickers, hold

down one of

stable.

Note

The distortion of the still picture may not be

eliminated completely.

Note

When playing back a tape which is recorded in S-VHS format, distortion may occur during the variable speed

playback.

CH/TRK

during playback.

.

until the picture becomes

Slow-motion Picture

The tape runs at 1/7th or 1/15th the normal

playback speed.

Press

SLOW

1

The tape runs at about 1/7th the normal

playback speed.

Each time you press

alternates between 1/7th and 1/15th.

To resume normal playback

PLAY/x2

Press

Notes

• The slow-motion picture mode is automatically

cancelled after about 5 minutes and returns to

normal playback.

• The slow-motion picture may flicker up and down.

This is not a defect in the unit.

Adjusting the Tracking Manually

If the slow-motion picture is noisy, hold down one

of

CH/TRK

Note

The noise in the slow-motion picture may not be

eliminated completely.

during playback.

SLOW

, the speed

.

until the best picture is obtained.

22

Page 26

Frame Advance

A picture advances frame by frame.

Press

1

PLAY/x2

Each time you press

during still playback.

PLAY/x2

, the picture

advances one frame.

If you press and hold

PLAY/x2

, the tape runs

at 1/30th the normal playback speed.

To resume normal playback

Press

PAUSE/STILL

.

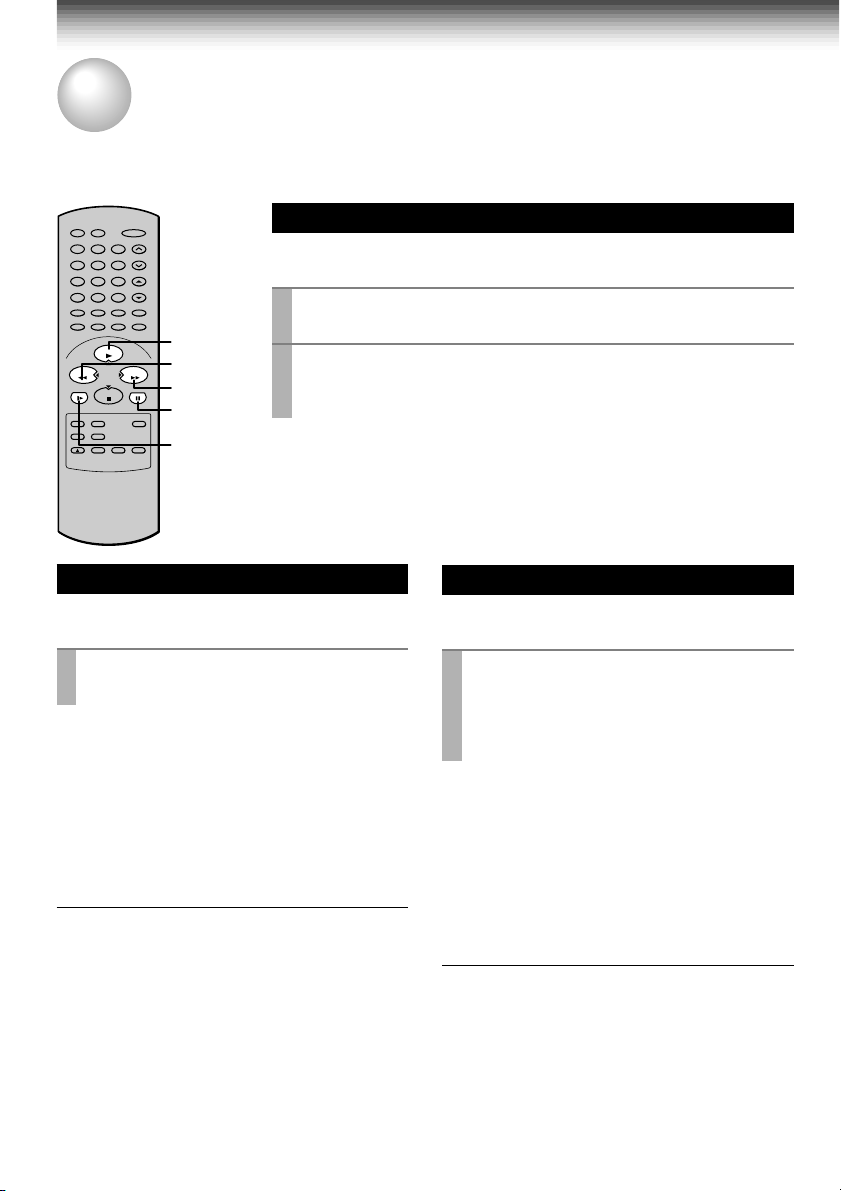

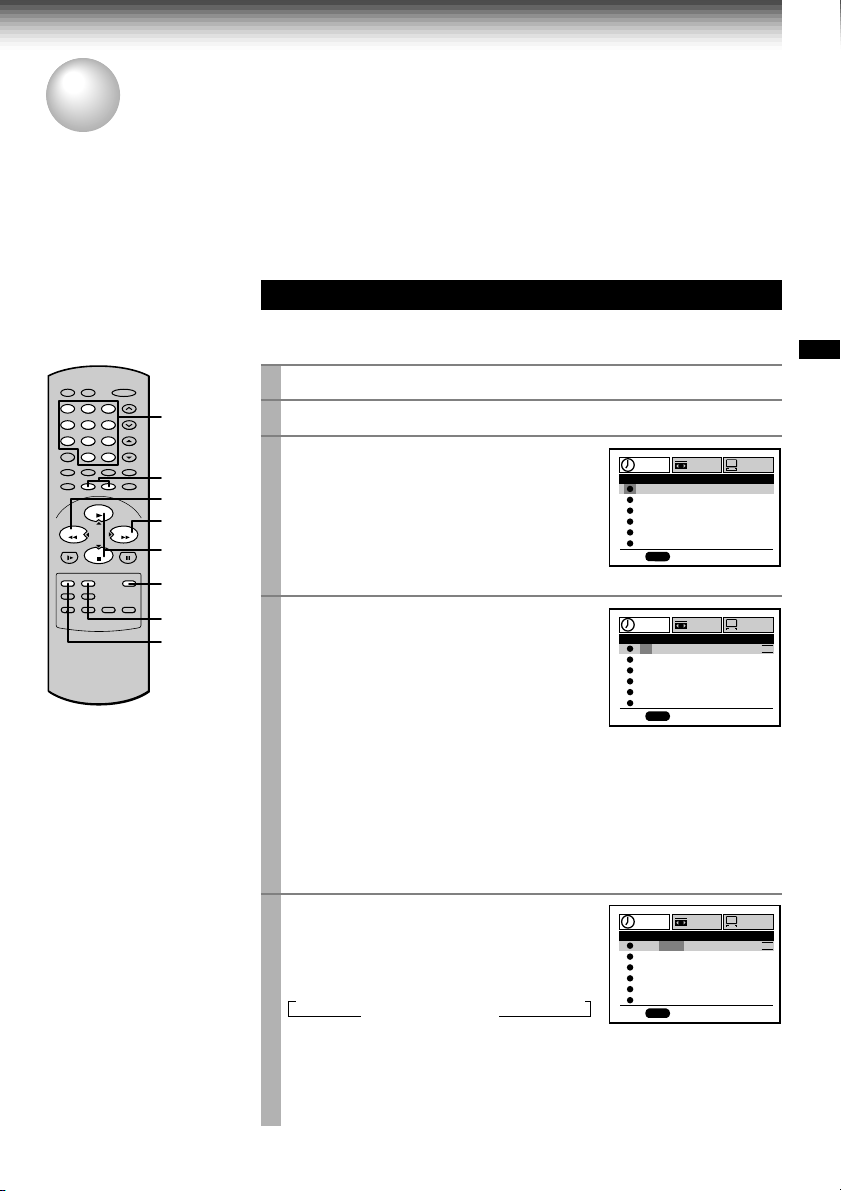

Shuttle Dial Operation

You can also activate the picture search and slow playback at

various speeds by turning the shuttle dial on the VCR.

Double Speed Playback

A tape runs at twice the normal speed.

Press

1

PLAY/x2

The picture runs at twice the normal playback

speed.

To resume normal playback

PLAY/x2

Press

during playback.

.

PLAYBACK

1

Turn the

shuttle dial

i

t

c

e

r

i

d

k

c

a

b

y

a

l

P

Rewinding

R

:

n

o

Rewinding

e

v

e

Picture

search

on the VCR.

Initial mode of tape operation

Picture

search

–x7

–x5

Reverse

playback

Rewinding

Reverse

playback

Reverse

playback

–x1

–x1

playback

–x1

Stop

Playback

Reverse

–x1

P

l

a

y

b

a

c

k

Fast-

Picture

Search

forwarding

d

i

r

e

c

t

Fast-

forwarding

i

o

n

:

F

o

r

w

a

r

d

Fast-

forwarding

Double

speed

playback

x2

Picture

Still

Slow

1/15

x

1/7

x

search

x5

Slow

x7

Normal

playback

x1

e

s

r

The playback speeds differ depending on the recording tape speed of

the tape as follows.

Picture search Reverse playback

SP: x5 x7 -x1

SLP: x15 x21 -x3

Notes

• The still picture mode will be released automatically after about 5 minutes

and forward playback will start.

• Fast-forwarding or rewinding started from the stop mode continues even if

the

shuttle dial

is released. To stop, press

STOP

.

• The reverse playback mode will be released automatically after about 25

seconds and forward playback will start.

• Noise bar may appear in reverse playback.

Note

If you playback a tape recorded in the SLP tape speed or a tape recorded on another VCR in various speed

mode, the picture may be noisy or monochrome.

23

Page 27

PLAYBACK

Useful Functions in Tape Operation

These functions will help your playback.

S-VHS Quasi Playback (SQPB)

• This VCR can also play back a tape which is recorded in S-VHS format.

But the playback picture does not have the same quality and resolution as

the original S-VHS playback picture.

• This VCR cannot record in S-VHS format.

* SQPB is an abbreviation for S-VHS Quasi Playback.

Counter Function

23

1

4

78

0

PLAY/x2

65

REMAIN/

9

FFREW

COUNTER

COUNT RESET

DISPLAY

PLAY/x2

STOP

ENTER

100

STOP

You can view the clock, linear time counter or tape remaining

time in the VCR display or on the TV screen.

Each time you press

1

REMAIN/COUNTER

changes in sequence as follows:

→ Linear time counter (HMS) → Tape remaining time (REMAIN/RT) → Clock

The indication above will also appear on the TV screen by pressing

DISPLAY

. The y are s witchable with

REMAIN/COUNTER

, the VCR display

.

24

PROG.

To reset the linear time counter to “0H00M00S”

The counter is automatically reset to “0H00M00S” when a cassette is

ejected. If you want to reset at another point, such as the beginning of a

new recording, just press

COUNT RESET

.

Notes

• The linear time counter does not work on non-recorded portions on the tape.

• When the tape is ejected or the VCR is turned off, the display changes to

clock.

• If the tape rewinds back over “0H00M00S”, “–” appears in the VCR display.

• The displayed time of the linear time counter is only an approximation.

Tape Remaining Time

To view the tape remaining time in the VCR display, select the

tape length beforehand.

Turn on the VCR and load a cassette.

1

Press

PROG.

2

Select “SET UP” using FF or

3

Select the length of the tape.

4

T120: for a T-120 tape or shorter

T160: for a T-140 or T-160 tape

T180: for a T-180 tape

to display the MENU screen.

REW

, and press

TAPE LE

SAP SET

SIMULCAST

ANTE A

LA

X

n

ED:

PROGRAM

nn

n

GUAG

DS InOF

PROG

ENTER

SET UP

H

GT

n

120 016 801

OFFO

OFFO

UAT

E

n

EG RFA SPE

OFFO

.

PRESET

n

n

O

M

n

n

UA

Page 28

Press

PROG.

5

6

Press

to exit.

REMAIN/COUNTER

.

The remaining time (“RT - : - -”) appears in the VCR display.

Notes

• The displayed remaining time is an approximation.

• The remaining time is calculated according to the tape speed (SP or SLP)

and the cassette type.

23

1

4

78

0

PLAY/x2

Index Search Function

65

9

100

3

FFREW

STOP

2

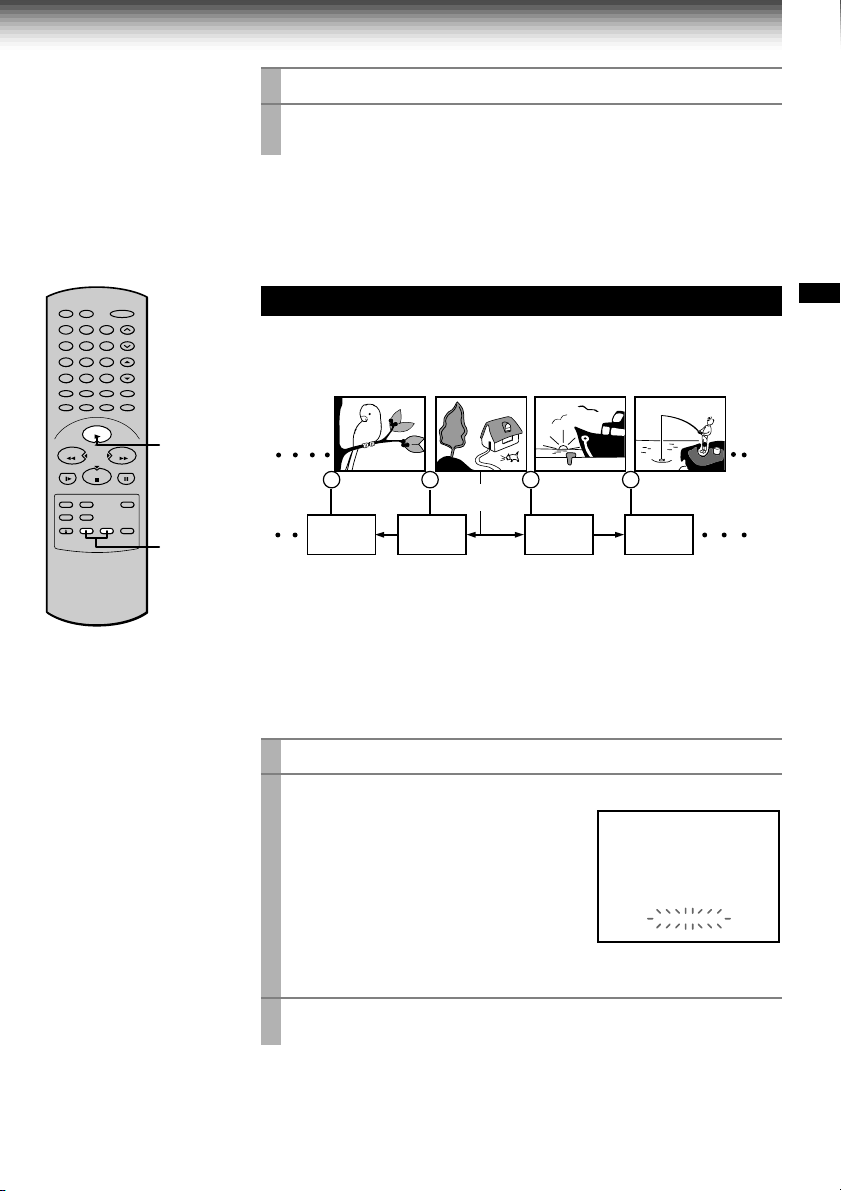

The VCR can find a point where a registered index signal is on a

tape and play back for about 5 seconds. You can easily locate

the desired program by inputting the index signal.

2 1 1 2

Playback

for 5 sec.

Index search

Playback

for 5 sec.

Playback

for 5 sec.

Playback

for 5 sec.

PLAYBACK

Registering index signals

Each time a recording starts, an index signal is automatically registered.

To register it somewhere else, press

Note

A certain interval is required between the index signals: more than 1 minute in

the SP tape speed and more than 3 minutes in the SLP tape speed.

INDEX

f during recording.

Index search

Load a cassette with the index signals registered.

1

Press

INDEX

2

g INDEX:To search in the reverse

INDEX f:To search in the forward

The VCR fast-forwards or rewinds the

tape. When an index signal is found, the

VCR plays back the tape for about 5

seconds, and then resumes fastforwarding or rewinding. This is repeated

each time at an index signal.

in the stop or playback mode.

direction.

direction.

00000

HMS

INDEX MARK

Press

3

PLAY/x2

when the desired program is found.

Normal playback starts.

Notes

• At the very beginning of the tape, the index search may not work properly.

• If you registered the index signals on a tape recorded on another VCR, the

recording may be blurred at the index point and the index search may not

work properly.

25

Page 29

RECORDING

T

Recording a TV Program

This section explains the basic recording operation.

Preparation

Select the video channel (3 or 4) or video input mode on the TV.

Basic Recording

Load a cassette with the safety tab attached.

to

1

Press

2

TV/VCR

indicator appears in the VCR displa y.

Select a channel to record with

3

CHANNEL

or

number buttons

control.

If you see “L1” or “L2” in the VCR display, press

channel number appears.

• If you record cable channels via the cable box, make the output

channel number of the cable box or “L1” appear, depending on your

connection. (See pages 11 – 13.)

Press

4

SP/SLP

recording tape speed.

SP: Suitable for general recording with

better picture and sound quality.

SLP: Suitable for tripling recording time, but with less picture and

sound quality than using the SP tape speed.

Press

5

REC

simultaneously press both

the remote control.

Recording starts.

so that the “VCR”

on the VCR, or

on the remote

to select the

on the VCR, or

23

1

4

65

78

0

100

3

9

2

PLAY/x2

STOP

5

4

FFREW

6

I.SELEC

To record from other

connected equipment

In step 3, press

switch the display as follows:

LI: To record via the LINE IN

1 jacks on the rear panel.

L2: To record via the LINE IN

2 jacks on the front panel.

I.SELECT

CH/TRK

REC

on

POWER

SLP

VCR

POWER

SLP

VCR

I.SELECT

POWER

SLP

VCR

POWER

SLP

VCR

REC

CH

so that the

CH

TIMERREC

CH

Press

6

Watching a TV program while

recording another

1) While recording, press

“VCR” indicator.

2) Choose another channel using the channel

selector on the TV.

TV/VCR

to turn off

Skipping unnecessary scenes while

recording

Press

PAUSE/STILL

to stop recording

momentarily. To resume recording, press

PAUSE/STILL

Note

The VCR automatically shifts to the stop mode if the

recording pause mode continues for 10 minutes.

again.

26

STOP

to stop recording.

Recording off time setting

By setting the recording off time, the recording

stops and the VCR is turned off automatically.

While recording, press

repeatedly to set the desired off time.

Each time you press

about 4 hours later and “- : - -” appear cyclically.

POWER

SLP

VCR

REC

Notes

• To cancel the recording in progress, press

• If the VCR clock is not set, this function will not

activate.

REC

on the VCR

REC

, each half-hour up to

PM

CH

OFF

STOP

.

Page 30

RECORDING

Timer Program Recording

The programmable timer allows you to record up to 6 different programs over one month.

Preparation

• Select the video channel (3 or 4) or video input mode on the TV.

• Make sure that the clock is set correctly (page 16).

• Store the channels on the VCR (pages 18 and 19).

• If you record cable channels via the cable box, keep the cable box turned on and select a channel to record

on the cable box.

Timer Programming Procedure

Example: To record cable channel 25 in the SP tape speed from

9:30 p.m. until 10:00 p.m. on August 30. Today is August 25.

Load a cassette with the safety tab attached.

23

1

4

78

0

PLAY/x2

65

4

9

100

10

REW

FF

FFREW

STOP

PLAY/x2,

STOP

ENTER

CANCEL

2, 9

1

Press

PROG.

2

Select “PROGRAM” using FF or

3

REW

, and press

Move to the next using FF, and enter

4

the channel number 25 by using

PLAY/x2, STOP

buttons

to display the MENU screen.

ENTER

or

.

number

.

SET UP

PROGRAM

O

CH DATE O DFF SP

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

n

ED:

PROGRAM

CH DATE O D

25

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: –

n

ED:

n

PROG

SET UP

O

n

– / –– –: –– – : –

PROG

PRESET

PRESET

FF SP

–

–

–

–

–

–

–

–

SLP

–

–

–

–

–

RECORDING

If you use the cable box, enter the output channel number of the

cable box with

I.SELECT

number buttons

or make “L1” appear by pressing

, depending on your connection. (See page 13.)

To make corrections:

Press

REW

to move back to the item, or FF to forward.

Move to the next using FF, and set

5

the recording date using

STOP

.

The date changes as follows:

→ 8/25 → 8/26 → … → 9/24 →

MO~FR ←

WKLY

PLAY/x2

WKLY

SA ←

SU →

or

…

n

ED:

SET UP

PROGRAM

O

CH DATE OFF DPS

25 8/30

–:–– –:––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

PROG

[WKLYSU]…[WKLYSA]: You can record TV programs on the same

channel on the day and time every week.

[MO~FR]: You can record TV programs on the same channel on the

day and time Monday through Friday.

PRESET

n

(Continued)

SLP

–

–

–

–

–

27

Page 31

Timer Program Recording (continued)

Move to the next using FF, and set

6

the hour and minutes of the

recording start time.

Move to the next, and set the

7

recording off time.

Move to the next, and select the tape

8

speed (SP) using

For the tape speed “AUTO (Auto Speed

Select)”, see below.

To set another program, press FF, and

select the next line pressing

Repeat steps 4 to 8.

Press

PROG.

9

Now programming is completed.

Press both

10

The power turns off and the VCR enters

the timer standby mode.

.

TIMER

PLAY/x2

or

STOP

STOP

.

simultaneously.

SET UP

PROGRAM

CH DATE OFF DPS

25 8/30:30

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– – : ––

PROG

n

ED:

PROGRAM

CH DATE OFF DPS

25 8/30 9:30

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

PROG

n

ED:

.

PROGRAM

CH DATE OFF DPS

25 8/30 9:3010:00

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

PROG

n

ED:

POWER

TIMER

O

9

SET UP

O

SET UP

O

PRESET

n

P

SLP

–:––

M

–

–

–

–

–

PRESET

n

P

P

SLP

:00

10

M

M

–

–

–

–

–

PRESET

n

P

P

SP

M

M

–

–

–

–

–

TIMERREC

Auto Speed Select

If you are not sure the tape is long enough for

timer program recording in the SP tape speed,

set the recording tape speed to “AUTO”.

Recording starts in the SP tape speed and the

VCR automatically selects the tape speed to

record the program to the end. If the tape length

is not long enough, the tape speed automatically

changes from SP to SLP.

28

Notes

• Make sure that the tape length is selected correctly

according to the tape used on the SET UP screen

(page 24).

• When the SLP tape speed is selected and the tape

length is not sufficient to record the program to the

end, the program cannot be recorded to the end.

• The picture will be distorted when playing the part

where the recording tape speed is switched from

SP to SLP with the Auto Speed Select feature.

Page 32

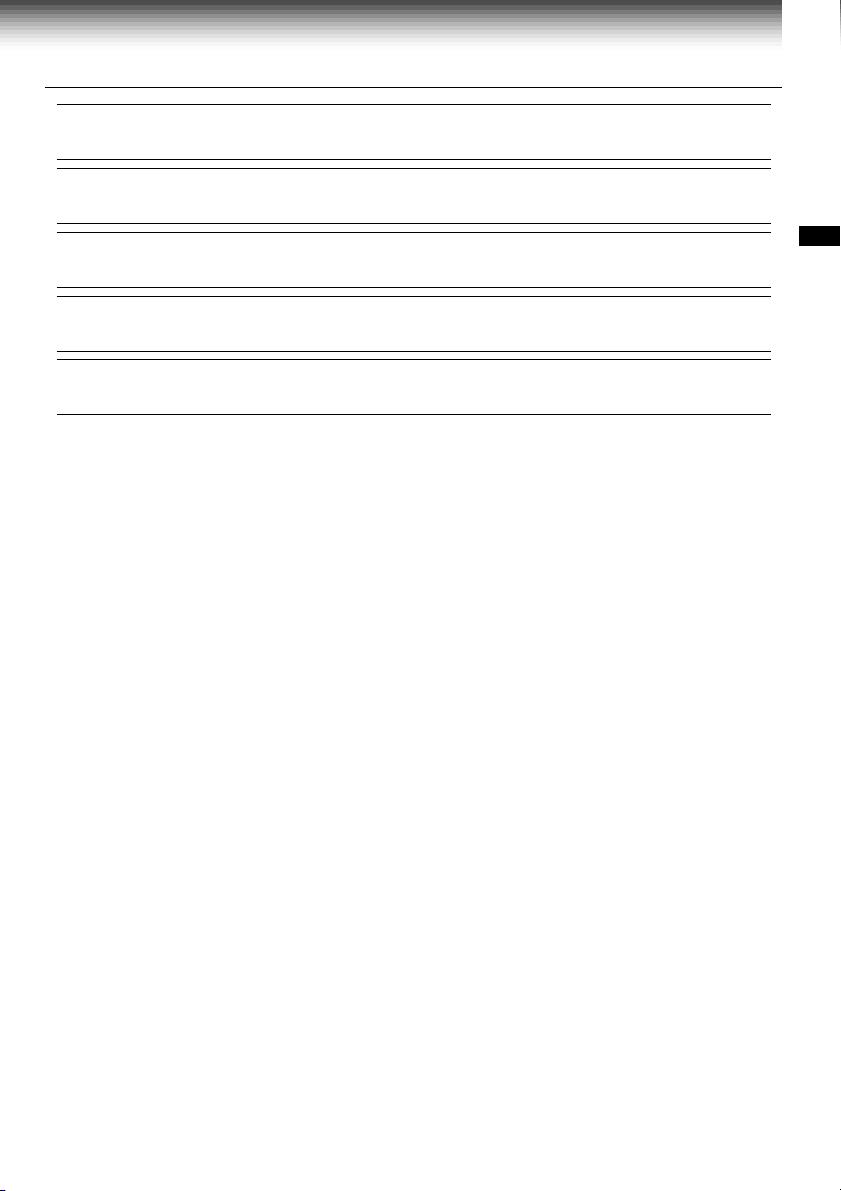

Confirming the timer programs

(in the timer standby mode)

Press

PROG.

.

The screen for confirming will appear.

SET UP

PROGRAM

CH DATE OFF DPS

25 8/30 9:3010:00

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

PROG

n

ED:

After about 30 seconds, the screen disappears.

PRESET

O

n

P

M

If a power failure occurs during the

timer program recording (including

VCR Plus+

®

system recording (page

32))

• When a power failure has occurred, “- -:- -”

appears in the VCR display. Since the

P

SP

M

–

–

–

–

–

programmed contents have been cleared,

reset the clock and timer programming.

• When power has failed for a short time, the

colon of the current time display blinks. The

programmed contents are not affected. Reset

the clock.

Changing/cancelling the timer

programs

1) If the TIMER indicator is lit, press both

to turn it off, and then turn the VCR on by

pressing

POWER

.

2)With steps 2 to 9, change the items.

To cancel a program, select the program you

want to cancel in step 4, and press

The line is then cleared.

3)Press both

TIMER

to return to the timer

standby mode.

TIMER

CANCEL

Recording or playback in the timer

standby mode

First press both

standby mode, and then press

on the VCR. The VCR will be available for use.

• Be sure to press both

the VCR to the timer standby mode after you

are finished.

TIMER

to release the timer

TIMER

POWER

to turn

again to return

Error indication

The “E” (Error) indicator appears in the VCR

display if you press both

–– a cassette is not loaded.

–– the loaded cassette has no safety tab.

–– no timer program is set.

In these cases, a recording can not be made.

TIMER

when:

Overlaps of the programs

If two timer programs overlap, the recording start

time of program 2 has priority over the recording

off time of program 1.

Overlapped portion (not recorded)

Program 1

(Start time)

.

Program 2

(Start time)

RECORDING

29

Page 33

RECORDING

VCR Plus+® system

Set-up (For W -708 only)

VCR Plus+® system is a timer recording system for an easier programming that requires you only to enter

a PlusCode® programming number assigned to a desired program. This section explains the necessary

set-up to make VCR Plus+® system recordings.

The flow chart below will give you an idea

as to what must be done to use the VCR

®

system feature.

Plus+

Setting the Clock (page 16)

↓

Storing Channels on the VCR

(page 18)

↓

VCR Plus+® system Set-up

↓

VCR Plus+

®

system Recording

Sample of a Guide channel chart from a local TV listing

VCR Plus+® SYSTEM CHANNEL NUMBERS

Broadcast

channels

3 KCRA (NBC).................3

6 KVIE (PBS)...................6

10 KXTV (CBS)................10

13 KOVR (ABC)...............13

19 KCSO (SPAN).............19

31 KRBK (IND).................31

40 KTXL

58 KSCH

44 KBHK

24 KCPM

4 KRNV

42 KFCB

7 KGO

(FOX)

(IND)

(IND)

(NBC)

(NBC)

(IND)

(ABC)

Assigned

channels

................40

................25

.................15

...............24

...............28

.................27

.................28

Cable

channels

A & E........................39

AMC.........................35

BET..........................57

BRAV.......................54

CMTV.......................14

CNBC.......................23

CNN......................... 42

C-SPAN....................28

CUNY.......................29

DIS...........................53

ESPN.......................34

FAM.........................47

HBO......................... 33

Assigned

channels

(page 32)

Sample of a Channel line-up chart from a cable-TV

* VCR Plus+ and PlusCode are registered

company

trademarks of Gemstar Development

Corporation. The VCR Plus+ system is

manufactured under license from Gemstar

Development Corporation.

CHANNEL LINE-UP CHART

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

Channel 8

Channel 9

ME/U

8 WISH

4 WTTV

6 WRTV

VCA/Local origination

HOME BOX OFFICE

A.P News Plus

9 WGN.

You must give the VCR the special

numbers for guide channels (also called

®

VCR Plus+

system channel numbers)

assigned to each channel that you receive

in your home. The VCR identifies the

channel to be recorded by the guide

channel number you enter.

The guide channel numbers are published

in TV guide magazine, selected local TV

publications, or the channel guide from

cable company. If you cannot find the

numbers, call Gemstar’s customer service

department at 1-800-4321-VCR.

30

Page 34

Preparation

• Select the video channel (3 or 4) or video input mode on the TV.

• Prepare the list like below.

Example

Station

HBO 33 7

ESPN 34

AMC 35

Guide channel number

(on the TV Guide, local TV listings etc.)

Your home channel number (on the channel line-up

chart supplied by cable companies)

23

1

4

78

0

PLAY/x2

Guide Channel Setting

Press

PROG.

1

65

9

100

7

2,4

FFREW

STOP

3,6,7

ENTER

Select “PRESET” using FF or

2

Select “CH MEMOR Y” using

3

Set “TV/CATV” to “TV” or “CATV” using FF or

4

Press

5

Select “GUIDE CH” using

6

or

STOP

1,5,8

Enter channel numbers on the right of the guide channel

7

.

PLAY/x2

PROG.

to return to the PRESET screen.

PLA Y/x2

, and press

ENTER

(the case of CATV mode)

.

REW

or

, and press

STOP

, and press

REW

PROGRAM

TOSET

PROG

n

ED:

ENTER

.

ENTER

.

SET UP

HGU DEIHCEOMCH

125 125

11

22

33

HGU DEIHCE

OM

HC

PUSH 0~9 KEYS

PRESET

CH

RECORDING

.

numbers.

Find a guide number you marked on the list using

and enter the corresponding home channel number if necessary by

using

number buttons

.

Example: To enter home channel number

7 (HBO) with guide channel number 33

assigned.

In some areas, one channel may be

assigned more than one guide channel

number. In this case, enter the home

channel number to each of the guide

channel numbers.

PLAY/x2

PROGRAM

30 30

131

23

337

TOSET

PROG

n

ED:

or

SET UP

HGU DEIHCEOMCH

3

32

HGU DEIHCE

OM

HC

PUSH 0~9 KEYS

STOP

PRESET

CH

,

Press

PROG.

8

to exit.

The set-up is all over and your VCR Plus+® system recording is now

available .

31

Page 35

RECORDING

VCR Plus+® system

Recording (For W-708 only)

After performing the VCR Plus+® system set-up, you can easily program a recording simply by entering

the PlusCode® programming number. The numbers are published in the TV listings of newspapers, TV

guide magazine, etc.

Preparation

• Make sure that the clock is set correctly (page 16).

• Load a cassette with a safety tab.

Sample of TV program listing in a TV guide magazine

5PM

FAM

POPEYE

HBO

MAKING OF A CHAMPION

A look at gymnast and Olympic hopeful Kim

Zmeskal from novice to seasoned competitor.

NIK

HEY DUDE

One of Ted’s teachers stays at the ranch.

USA

5:35

MY TWO DADS

TBS

GOOD TIMES

Cartoon

Children

Comedy

Comedy

725692

793571

237945

586858

2261858

VCR Plus+® system Programming

Press

23

1

4

78

0

PLAY/x2

1

65

2

9

100

2

7

REW

FF

FFREW

STOP

PLAY/x2,

STOP

PROG.

5

CANCEL

1

3

VCR Plus+

The VCR Plus+ screen appears.

Enter a PlusCode® programming

number.

Example: To record a program with the

PlusCode® programming number 36295

(fictitious code).

Press

number button 3, 6, 2, 9 and 5

Confirm that the number is entered

correctly.

To correct a mistake, press

enter the correct number.

Select “MODE” using

STOP

, and set the recording

frequency .

OnCE: To record once.

DAILY(MO~FR): To record programs on

the same channel at the same time

Monday through Friday.

WEEKLY: To record programs on the

same channel at the same time on the

same day every week.

.

CANCEL

PLA Y/x2

or

.

and

PROGRAM

VCR P US+L

PLUSC DEO

MODE

SPEED

OSETPLUSCODE

T

PUS SH~90EYK

PROG

n

ED:

PROGRAM

VCR P US+L

PLUSC DEO

MODE

SPEED

PROG

n

ED:

®

PlusCode

programming

number

SET UP

PRESET

–

92

5

36

R

F

n

CEMO~

O

AUPS

SL

P

O

T

ENTER

SET UP

PRESET

592

36

R

F

n

CEMO~

O

AUPS

SL

P

O

T

ENTER

WKLY

WKLY

32

Select “SPEED” using

4

STOP

, and set the recording tape

speed.

For AUTO speed, see page 28.

PLA Y/x2

or

PROGRAM

VCR P US+L

PLUSC DEO

MODE

SPEED

n

ED:

PROG

SET UP

n

O

SL

36

CEMO~

AUPS

P

T

PRESET

592

R

F

O

WKLY

ENTER

Page 36

Press

5

ENTER

.

The program setting is now memorized.

To set another program, repeat steps 1 to 5.

6

To finish press the two

7

TIMER

buttons simultaneously .

The VCR enters the timer standby mode.

SET UP

PROGRAM

CH DATE OFF DPS

25 8/30 9:3010:00

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– –: ––

–– – / –– –: –– – : ––

PROG

n

ED:

POWER

TIMER

PRESET

O

n

P

P

SLP

M

M

–

–

–

–

–

TIMERREC

RECORDING

Confirming the VCR Plus+® system

timer programs

Before the VCR enters the timer standby

mode (TIMER indicator not lit)

1)Press

2)Press

PROG.

to display the MENU screen.

ENTER

to select “PROGRAM”.

Check the programmed data.

3)Press

PROG.

to exit.

During the timer standby mode (TIMER

indicator lit)

Press

PROG.

.

The screen for confirming appears.

After about 30 seconds, the screen disappears.

Canceling the VCR Plus+® system

timer programs

1) If the TIMER indicator is lit, press both

to turn it off, and turn on the VCR by pressing

POWER

2)Press

3)Press

.

PROG.

to display the MENU screen.

ENTER

to select “PROGRAM”.

4)Select a program which you want to cancel.

5)Press

CANCEL

.

The line is cleared out.

6)Press

PROG.

to exit.

TIMER

Recording or playback in the timer

standby mode

First press both

standby mode, and then press

on the VCR. The VCR will be available for use.

• Be sure to press both

the VCR to the timer standby mode after you

have finished.

TIMER

to release the timer

TIMER

POWER

to turn

again to return

Error indications

If “FULL / CANCEL PROG?” message appears

on the TV during programming, no more

programs can be entered. If you want to add

another, delete one existing program on the

screen by using

If an incorrect PlusCode® programming number is