Toshiba VTV2133 Service Manual

FILE NO. 140-200101

SERVICE MANUAL

COLOR TELEVISION/

VIDEO CASSETTE RECORDER

VTV2133

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

PERFORM A SAFETY CHECK AFTER

7.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

GENERAL SPECIFICATIONS

G-1.Ou tline of the Product

21 inch(508.0

Color CRT 90 degree deflection

2 -Speed 1/2" Video Cassette Recorder

G-2.VCR Format

VHS Standar d

G-3.Video Recording System :Rotary,slant azimuth two head helical scan system

Luminance Compo nent :FM record in g

Chrominance Component :Low frequency converted direct recording

G-4.Broadcasting System

U.K. System I

G-5.Color System NTSC PAL SECAM or Monochrome signal

mmV):Measured diagonally

VHS Recorder/Player

VHS-C Player

NTSC PAL SECAM PAL-M PAL-N

VHS Hi-F i Audio System

G-6.NTSC Playback(PAL 60Hz)

G-7.MESECAM

G-8.Cassette Tape

VHS type video cassette tape Width 12.65mm (1/2 Inch)

VHS-C type video cassette tape Width 12.65mm (1/2 Inch)

G-9.Ta pe Speed

NTSC or P AL-M PAL or SECAM

SP 33.35 mm/sec SP 23.39 mm/sec

LP 16.67 mm/sec LP 11.69 mm/sec

SLP 11.12 mm/sec

G-10.Recording/Playback Time

NTSC or PAL-M(NTSC Playback Only)

at SP Mode Max. 210 min. (with T-210 cassette)

at LP Mode Max. 420 min. (with T-210 cassette)

at SLP Mode Max. 630 min. (with T-210 cassette)

PAL or SECAM

at SP Mode Max. 300 min. (with E-300 cassette)

at LP Mode Max. 600 min. (with E-300 cassette)

G-11.Deck

OVD-5 OVD-6 OVD-6S OVD-6S(Vertical)

G-12.Rewind/Fast Forward Time(Approx.)

FF: 2'15" / Rew 1'48" ( with T-120 cassette with E-180 cassette)

FF: 1'48" / Rew 1'48" ( with T-120 cassette with E-180 cassette)

Yes No

Yes No

G-13.Search Speed

SP 5 and 7 Times(PAL)

LP 7 and 13 Times(PAL)

SP 3 and 5 Times(NTSC)

G-14.Speed

SP 1/5-1/30 Times

LP 1/5-1/30 Times

SLP Times

G-15.Frame Advance

SP 1/10 Times

LP 1/10 Times

SLP Times

GENERAL SPECIFICATIONS

G-16.Antenna Input Impedance

VHF/UHF 75 ohm unbalanced

G-17.Tuner and Receiving channel

Tuner : Contactless Electric tuner

Oscar(W/O HYPER) Oscar(W/ HYPER) France CATV Others

Receiving channel

21 ch~ 69 ch

Tuning System

Frequency syn. Voltage syn. Others

G-18.Preset Channel

80 channels

G-19.I ntermediate Frequency

Picture(FP) 39.5 MHz

Sound (FS) 33.5 MHz MHz MHz

FP-FS 6.0 MHz MHz MHz

G-20. Stereo/Dual TV Sound

Yes( NICAM GERMAN USA JAPAN) No

G-21.V ideo Signal

Input Level 1 Vp-p / 75

Output Level 1 Vp-p / 75 ohm

S/N Ratio 53 dB (Weighted)

Horizontal Resolution at SP Mode 240 Lines

1Tuner Syatem 2Tuner System

MHz MHz

ohm

G-22.A udio Signal

Input Level

Output Level

(0dB=0.775 V rms)

S/N Ratio at SP Mode 42 dB

Harmonic Distortion : 1.5 % (1KHz)

Frequency Response : at SP Mode 100 Hz ~ 10 KHz

Hi-Fi M odel’s Spec NONE

G-23.Heads

Video

FM Audio 2 Rotary Heads

Audio / Control 1 Stationary Head ( Mono Stereo(L,R) )

Erase 1 Full Track Erase

Line -3.8 dB / 50

RCA -3.8 dB / 50 Kohm

Line -3.8 dB / 1

RCA - dB / - Kohm

at LP Mode 100 Hz ~ 5 KHz

at SLP Mode Hz ~ KHz

Depth Multiplex Recording Rotary, Slant Azimuth Two Head

System Helical Scan System

Frequency Response : 20 Hz ~ 20

Dynamic Range : More than 75 dB

Wow And Flutter : Less than 0.01 % Wrms

Channel Separation : More than 60 dB

Harmonic Distortion : Less than 1 %

4 Rotary Heads

Kohm

Kohm

KHz(+-6dB)

G-24.Motor: 3 Motors

Tape/Cassette Loading

Cylinder ( Di re ct Dri ve)

Capstan (Direct Drive)

GENERAL SPECIFICATIONS

G-25.Power Source

230~240 V

EXT DC Jack V

G-26.Power Consumption: 70 W at AC 230 V 50 Hz

Stand by: 6 W at AC 230

Per Year: - kWh / Year

G-27.Dimensions(Approx.)

502 mm(W)

G-28.Weight(Approx.) Net : 26.5 Kg ( - lbs)

Gross: 28.5 Kg ( - lbs)

G-29.Cabinet Material

Cabinet Front:

Cabinet Rear:

Jack Panel:

AC 50Hz AC 60Hz

(at TV and VCR ON)

V 50 Hz

481.5 mm(D) 513 mm(H)

PS 94HB DECABROM

ABS 94V2 NON-DECA

94V0

PS 94HB DECABROM

ABS 94V2 NON-DECA

94V0

PS 94HB DECABROM

ABS 94V2 NON-DECA

94V0

G-30.Cassette Loading System:

G-31.Tape Counter: Linear Time Tape Counter

G-32.Protector:

G-33.Regulation

Safety

UL CSA SAA SI CE BEAB

BS NF NEMKO FEMKO DEMKO IEC65

SEMKO NZ HOMOLO SABS CNS SISIR

NOM AS3159 DENTORI UNE GOST NONE

Radiation

FCC DOC FTZ PTT CE SEV

SABA SI NF NZ HOMOLO UNE

CNS CISPR13 DENTORI AS/NZS NONE

X-Radiation

DHHS HWC PTB DENTORI NONE

G-34.Temperature

Operation 5 ºC~ 40

Storage -20 ºC~ 60 ºC

G-35.Operating Humidity

Less than 80 %RH

G-36.Clockand Timer

Calender : 1990/1/1 ~ 2081/12/31

Built-in 1 Month 8 Events Programmable Timer

One Touc h Recording : Max Time SP Mode 5 LP Mode 10 Hours

Sleep Timer Yes Max 120 Min.( 10 Min. Step) No

On/Off Timer Yes 1 Programs No

Wake Up Timer Yes Programs No

Auto Shut Off 15 Minutes

Power Fuse Dew Sensor

Front Cassette Loading System

Top Loading System

ºC

G-37.Timer back up Time

More than 30 Minutes (at Power Off Mode)

G-38.Terminals

VHF/UHF Antenna Input Din Type F-Type France Type

Front Video Input<AV2,RCA ø8.3>

Front Audio Input<AV2,RCA ø8.3>x2

Rear Video Input<R CA ø8.3>

Rear Audio Input<RCA ø8.3> x2

Rear Video Output<RCA ø8 .3>

Rear Audio Output <RCA ø8 .3> x2

21 Pin (x 1 )<AV1> DC Jack 12V (Center +) AC Inlet

Ear Phone Ext Speaker Diversity

Head Phone(Mono & Stereo, ø3.5)

G-39.Indicator

Indicator

Key Light up Rec/OTR OTPB Play NONE

G-40.O n S creen Display

Menu

G-CODE(o r SHOWVIEW or PLUSCO DE)No. Entry(Opt ion)

Clock CH/AV

Tape Counter Tape Speed

Sleep Time Sound Mute

Control L ev el ( Vol, Bright, Cont, Color, Tint, Sharpness)

Play/Stop/ FF/ Rew /R ec/ OTR /T- Rec/ P ause ( Symbo l Mark)

Auto Tracking/Manual Tracking

Index Repeat Password

VPS PDC

S-Repeat/SR-R/SR-PLAY END Call

NICAM M 1/2, NICAM Off, Audio Output Hi-Fi

G-41.O S D Language

Eng Ger Fre Spa Ita Por Jan

OSD Language Setting

Eng Ger Fre Spa Ita Por Jan Not Applicable

GENERAL SPECIFICATIONS

Standby Rec/OTR T-Rec On Timer CS NONE

(Red) (Red

( ) ( )( )

ATS

Timer Rec Set

Ch Set-up

Auto Tuning Ch Mapping

Ch T uning CH Allocation

Guide Ch Set

TV Set-up

On/Off Timer Set Audio

Picture Tuning Mo de

NICAM Au to/Off

VCR Set-u p

Auto Repeat On/Off System Select

Scena Repeat

User Regist ra tion

System Set-up

Clock Set( Calendar 12H 24H)

Language

)(Red)( )( )

G-42.Speaker

Position

Size 3 inches

Imp. 8 ohm x 2 pcs

Output Max 1.5 + 1.5 W

G-43.EX T Speaker

Yes W Imp ohm NONE

G-44.Carton

Master Carton:

Content: ---- Set

Material: ---- / ---- Corrugated Carton

Dimensions: ---- mm(L) ---- mm(W) ---- mm(D)

Description of Origin Yes No

Gift Box

Material

Dimensions: 586 mm(W) 569

Design: As Per BUYER 's

Description of Origin: Yes No

Drop Test Natural Dropping At 1 Corner / 3 Edges / 6 Surfaces

Container Stuffing: 320 Sets / 40' container

GENERAL SPECIFICATIONS

Front Side Bottom

10% 1.5 + 1.5 W (Typical)

Need No Need

Double/Brown Corruga ted Carton ( with Photo Label)

Double/W hi te Co r ru gat ed Carton ( with Photo Label)

Double Full Color Carton W/Photo

mm(D) 590 mm(H)

Height

25cm 31cm 46cm 62cm 80cm

G-45.Accessories

Channel Film Dew Caution Sheet

Owner's Manual( W/Guarantee Card) [English]

AC Plug Adaptor

Remote Control Unit Quick Set -up Sheet

Rod Ant enn a ( One Pole Two Pole/ F-Type DIN Type France Type)

Loop Antenna( F-Type DIN Type France Type)

U/V Mixer Battery (UM- 4 x 2 )

DC Car Cord (Center+) AC Cord

Guarantee Ca rd AV Cord (Stereo-Mono)

Warning Sheet Regist ra tion Card

Circuit Diagram PTB Sheet

Anti-Theft Sheet 300 ohm t o 75 ohm Antenna P lug

Service Facility List Euro Warranty Information Sh eet

RF Cable

G-46.Other Features

Auto Head Cleaning Index Search

Auto Tracking

CH Auto Set-Up/Auto Clock ATS

VIDEO PLUS+(SHOWVIEW,G-CODE) PDC

HQ (VHS Standard High Quality) VPS

Auto Power On, Auto Play, Auto Rewind, Auto Eject,Auto Rep eat System

Forward / Reverse Picture Search Reverse Slow(for 4Head)

One Touch Playback Anti-Theft

Auto CH Memory T'Text( Fast Top Uni)

TV Auto S hutt off Function TV Monitor

END Call TV/Rec Monitor

AD Skip<CM Sk ip > (30 sec. x 6 times ) Choke Coil

G-47.Switch

Front

Standby Channel Up Volume Up

Play Channel Down Volume Down

Pause/Still F.FWD/Cue Rew/Rev

System Select Eject/Stop Rec/OTR

One Touch Playback Main Power SW

Rear

Color On/Off (SECAM only) Degauss

Main Power SW AC/DC

G-48.Magnetic Fiel d

BV : +0.45G BV : +0.35G BV : +0.25G

BH : 0.18G BH : 0.3 0G BH : 0.30G

BV : -0.15G BV : -0.25G BV : -0.50G

BH : 0.15G BH : 0.15G BH : 0.30G

G-49.Remote Control

Unit: RC-DM

Power Source: D.C 3 V Battery UM - 4 x 2

Glow in Dark Remocon Yes No

Total 42 Key

GENERAL SPECIFICATIONS

0/AV Ch/Tr/Page Up Power

1 Ch/Tr/Page Down Eject

2 Volume Up

3 Volume Down Play/Up(/ Slow)

4 Mute F.FWD/Right

5 Menu Rew/Left

6 Enter/Hold Stop/Down

7 Cancel/Ch Skip/F.T.B. Pause( /Still)

8 ATR/Reveal REC/OTR

9 Text/Mix/TV Speed

Call Index/Time Text Audio Select

TV/Rec Monitor Cyan Timer Rec

Sleep Timer Red Counter Reset

Green Yellow Zero Return

Program( /Video Plus+ or ShowView)

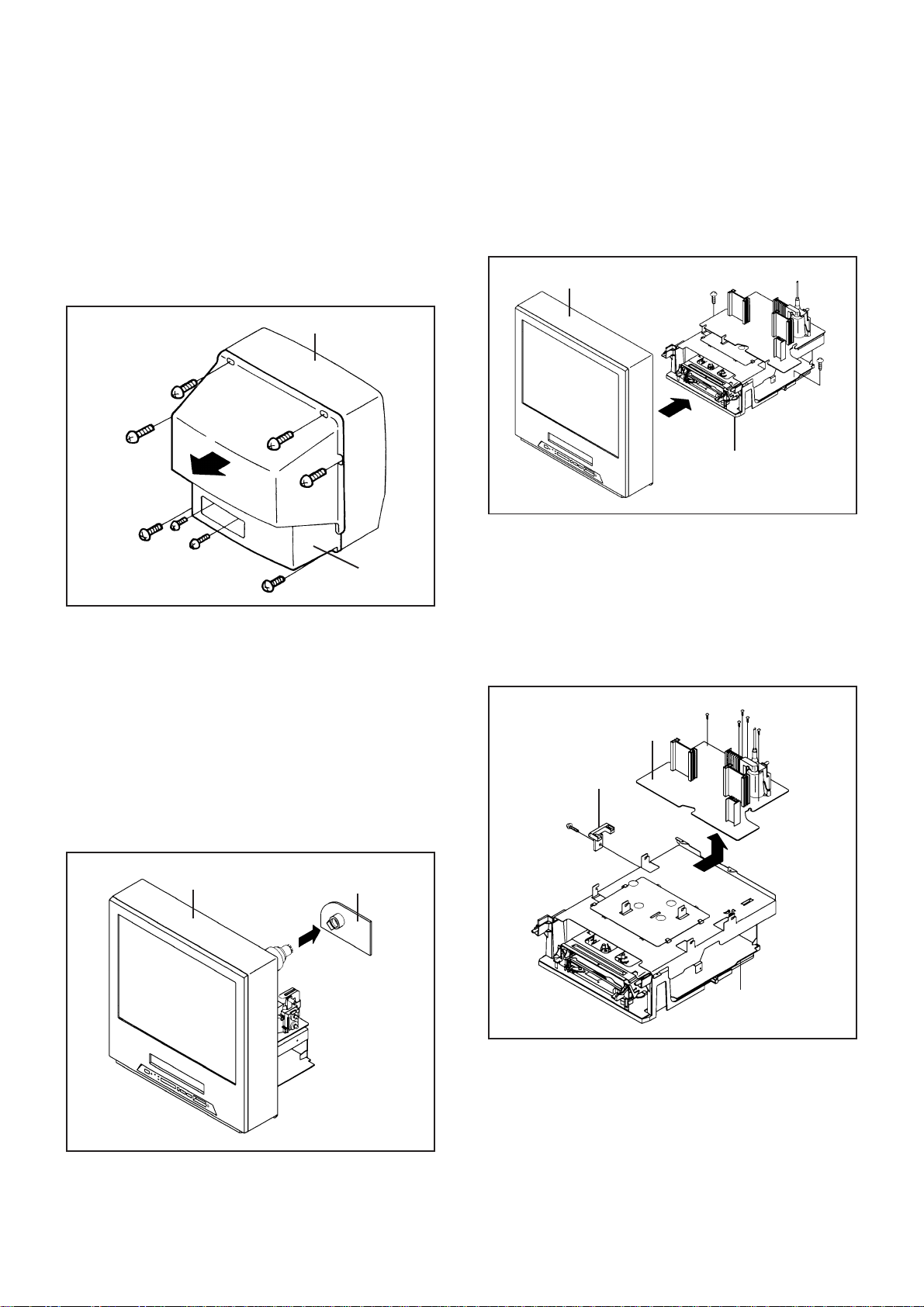

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

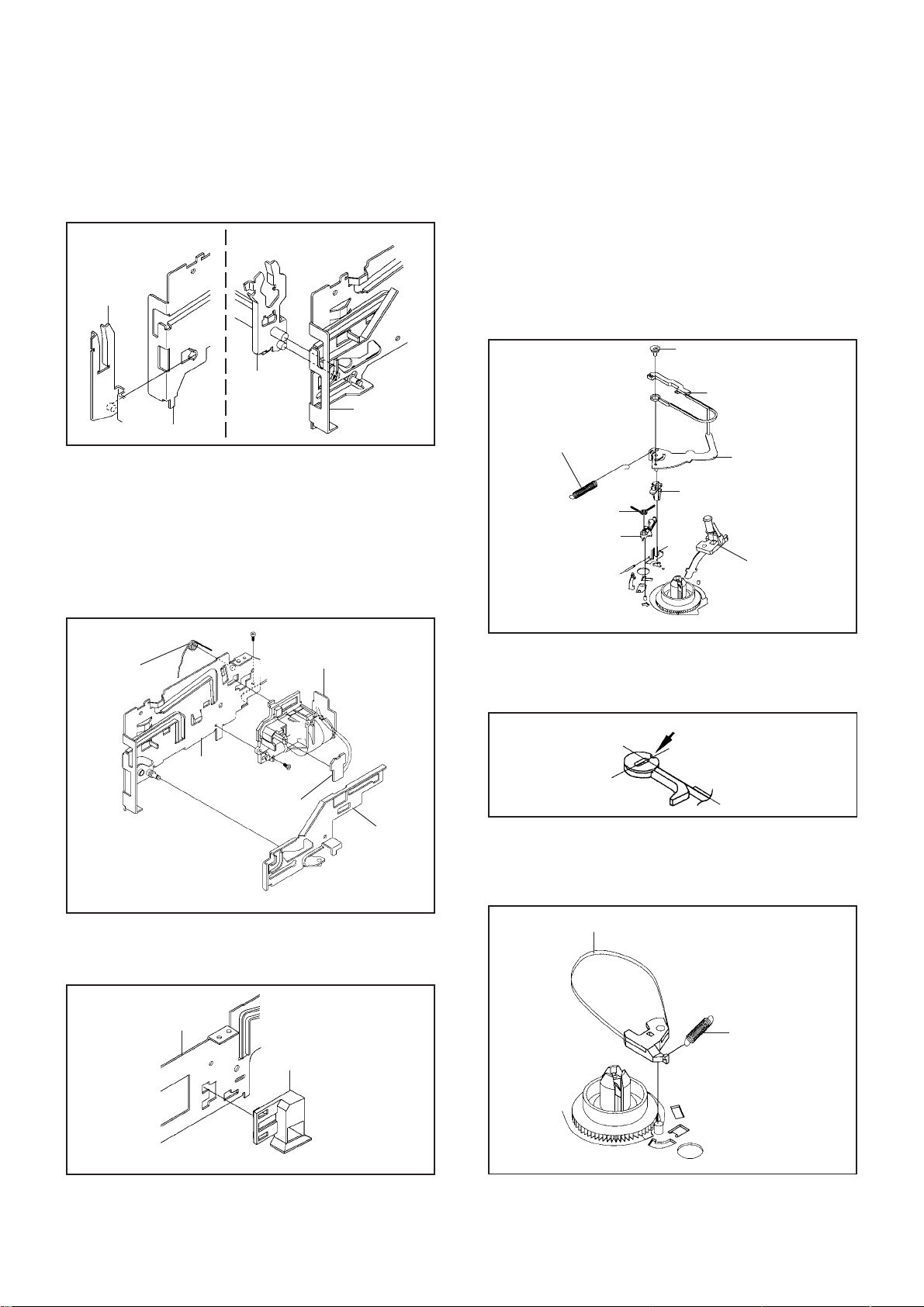

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 6 screws 1.

2.

Remove the 2 screws 2 which are used for holding the

Back Cabinet.

3.

Remove the AC cord from the AC cord hook 3.

4.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

1

1

1

2

2

1

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

2.

Disconnect the following connectors:

(CP802 and CP805).

3.

Remove the CRT PCB in the direction of arrow.

3

Back Cabinet

Fig. 1-1

1-3: TV/VCR BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connectors:

(CP401, CP502, CP503, CP755 and CP4202).

3.

Unlock the support 2.

4.

Remove the TV/VCR Block in the direction of arrow.

Front Cabinet

1

TV/VCR Block

2

UP TO

RELEASE

1-4: MAIN PCB (Refer to Fig. 1-4)

1.

Remove the screw 1.

2.

Remove the Main PCB Holder.

3.

Remove the 2 screws 2.

4.

Remove the 3 screws 3.

5.

Disconnect the following connectors:

(CP810, CP820 and CD001).

6.

Remove the Main PCB in the direction of arrow.

2

2

Main PCB

Main PCB Holder

1

3

3

3

1

Fig. 1-3

Front Cabinet

CRT PCB

VCR Block

Fig. 1-4

Fig. 1-2

DISASSEMBLY INSTRUCTIONS

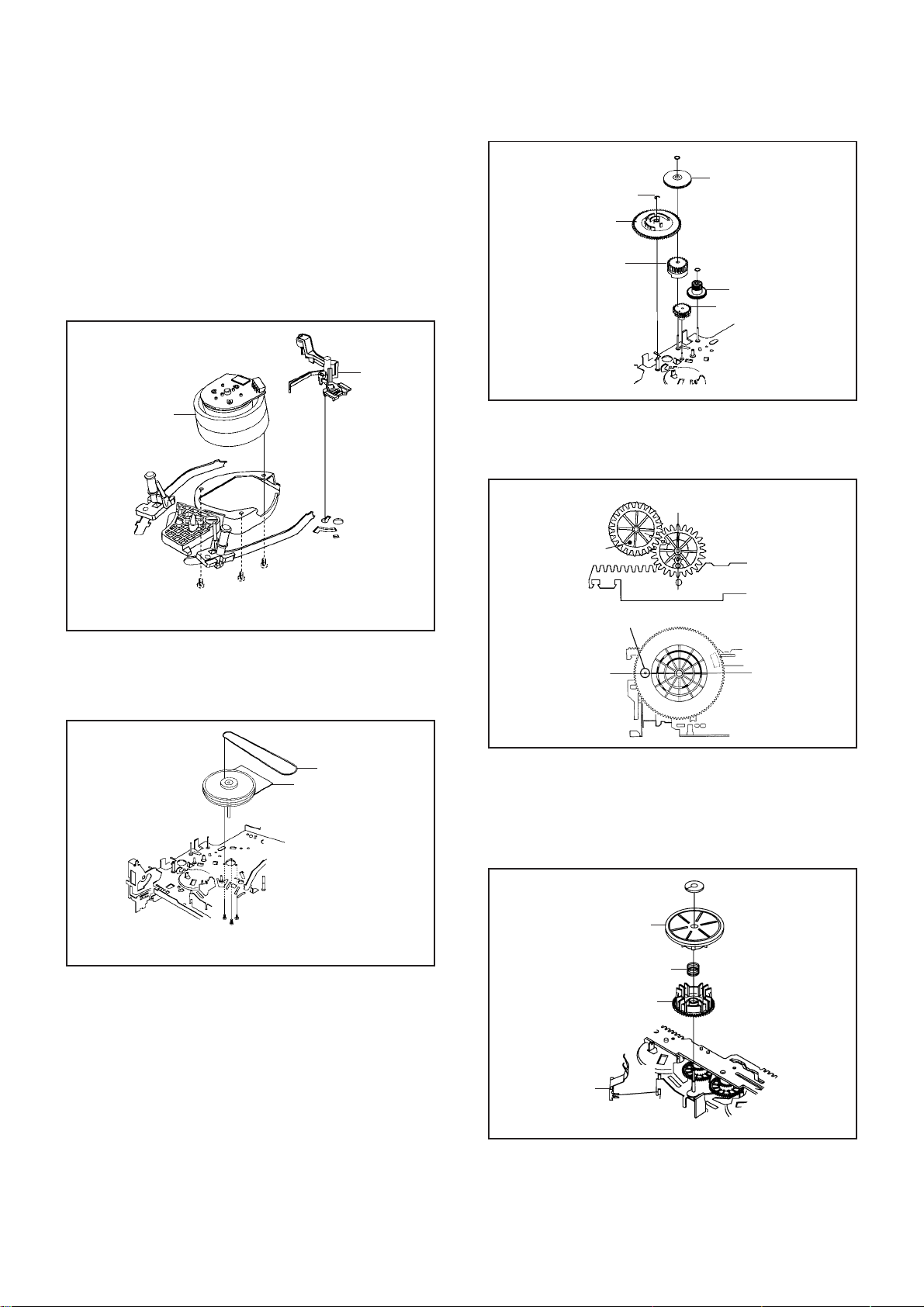

1-5: DECK SHIELD PLATE (Refer to Fig. 1-5)

1.

Remove the 2 screws 1.

2.

Remove the 4 screws 2.

3.

Remove the screw 3.

4.

Remove the Deck Shield Plate in the direction of arrow (A).

5.

Remove the screw 4.

6.

Remove the Shield Plate Bottom in the direction of arrow (B).

Deck Shield Plate

3

1

1

(A)

VCR Block

2

2

(B)

1

1

Syscon PCB

1

Deck Chassis

Fig. 1-6

1-7: JACK PLATE AND SYSCON PCB (Refer to Fig. 1-7)

1.

Remove the screw 1.

2.

Remove the Syscon PCB in the direction of arrow (A).

3.

Remove the 2 screws 2.

4.

Unlock the 2 supports 3.

5.

Remove the Jack Plate in the direction of arrow (B).

Jack Plate

Shield Plate Bottom

4

2

1-6: DECK CHASSIS (Refer to Fig. 1-6)

1.

Remove the 3 screws 1.

2.

Disconnect the following connectors:

(CP1004, CP1005, CP1006, CP4001, CP4004 and

CP4005).

3.

Remove the Deck Chassis in the direction of arrow.

2

Fig. 1-5

Syscon PCB

2

3

(B)

1

(A)

Deck Holder

2

3

Fig. 1-7

DISASSEMBLY INSTRUCTIONS

2. REMOVAL OF DECK PARTS

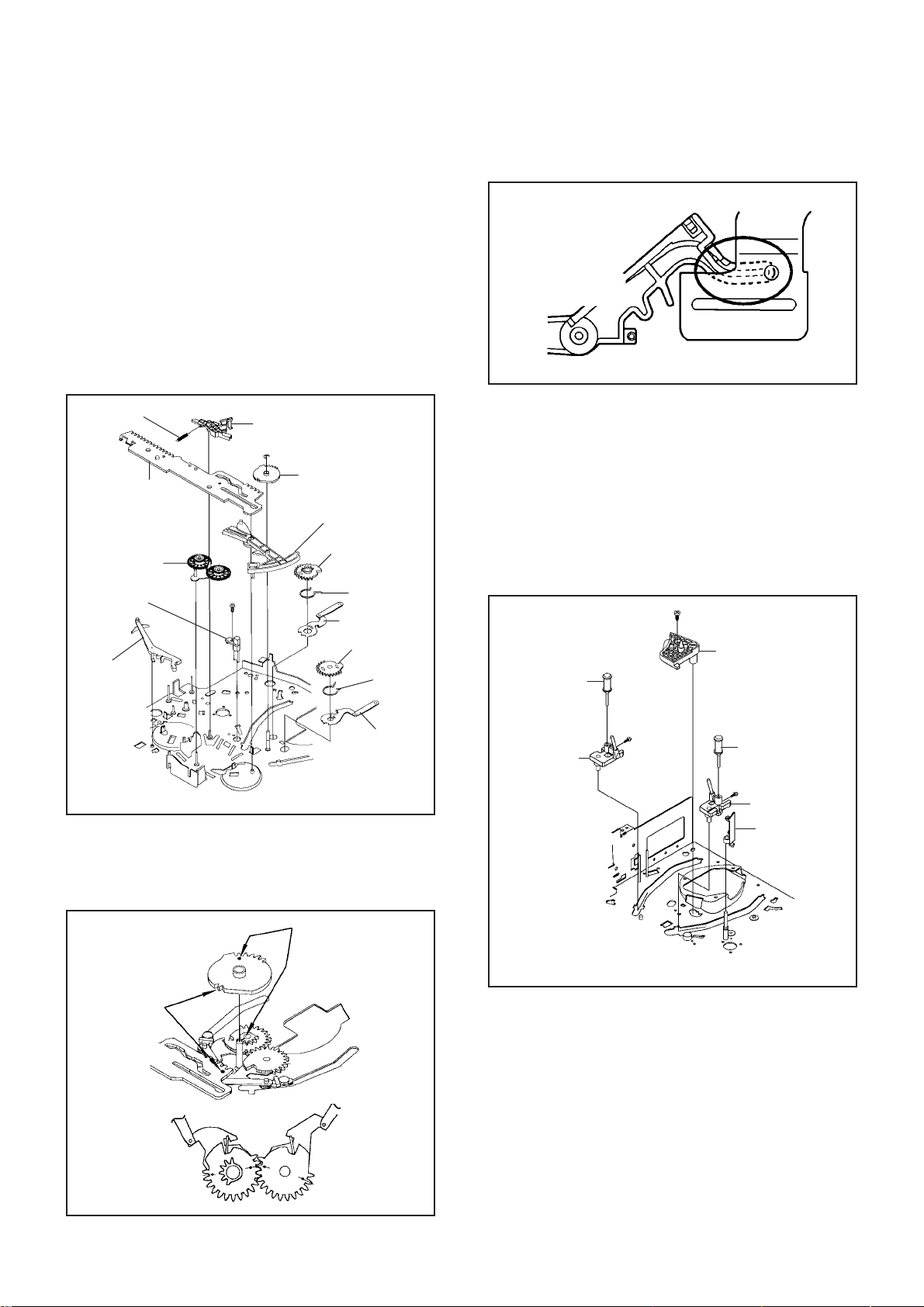

2-1: TOP BRACKET (Refer to Fig. 2-1)

Remove the 2 screws 1.

1.

Slide the 2 supports 2 and remove the Top Bracket.

2.

NOTE

When you install the Top Bracket, install the screw (1)

first, then install the screw (2).

(2)

1

Top Bracket

2

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

Top Bracket

2

Main Chassis

2-2: FLAP LEVER/TAPE GUIDE R (Refer to Fig. 2-2)

Move the Cassette Holder Ass'y to the back side.

1.

Remove the Polyslider Washer 1.

2.

Remove the Flap Lever.

3.

Unlock the 3 supports 2 and remove the Tape Guide R.

4.

(1)

1

Fig. 2-1

NOTE

When you install the Tape Guide L, install as shown in the

circle of Fig. 2-3-B. (Refer to Fig. 2-3-B)

Tape Guide L

REC Lever

• The REC Lever is not installed on the Video Cassette Player.

Fig. 2-3-B

2-4: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-4)

Move the Cassette Holder Ass'y to the front side.

1.

Push the Locker R to remove the Cassette Side R.

2.

Remove the Cassette Side L.

3.

Main Chassis

Cassette Side R

Locker R

Tape Guide R

Flap Lever

2

2

2

Main Chassis

1

Fig. 2-2

2-3: TAPE GUIDE L (Refer to Fig. 2-3-A)

Move the Cassette Holder Ass'y to the back side.

1.

Unlock the 2 supports 1 and remove the Tape Guide L.

2.

Remove the REC Lever. (Recorder only)

3.

REC Lever

Tape Guide L

1

Cassette Side L

Main Chassis

Fig. 2-4

2-5: CASSETTE SIDE L/R (Refer to Fig. 2-5)

Unlock the 4 supports 1 and then remove the Cassette

1.

Side L/R.

NOTE

When you install the Cassette Side R, be sure to move the

Locker R after installing.

1

1

Locker R

Cassette Side R

1

1

Cassette Side L

Fig. 2-5

1

Main Chassis

• The REC Lever is not installed on the Video Cassette Player.

Fig. 2-3-A

DISASSEMBLY INSTRUCTIONS

2-6: LINK ASS'Y (Refer to Fig. 2-6)

Set the Link Ass'y to the Eject position.

1.

Remove the (A) side of the Link Ass'y first, then remove

2.

the (B) side.

Link Ass'y

(A)

Main Chassis

(B)

Link Ass'y

Main Chassis

Fig. 2-6

2-7: LOADING MOTOR ASS'Y (Refer to Fig. 2-7)

Remove the Link Lever.

1.

Remove the Dumper Spring.

2.

Remove the 2 screws 1.

3.

Unlock the support 2 and remove the Loading Motor

4.

Ass'y.

Unlock the 2 supports 3 and remove the Deck PCB

5.

(BOT).

1

Dumper Spring

Loading Motor Ass'y

2

2-9: TENSION ASS'Y (Refer to Fig. 2-9-A)

Move the Inclined S Ass'y to the back side.

1.

Remove the Tension Spring.

2.

Unlock the support 1 and remove the Tension Arm

3.

Ass'y.

Remove the Tension Adjust.

4.

Unlock the 2 supports 2 and remove the Tension Band

5.

Ass'y.

Unlock the support 3 and remove the Tension Holder.

6.

Remove the SS Brake Spring.

7.

Remove the SS Arm Brake.

8.

Tension Adjust

2

Tension Spring

SS Brake Spring

SS Arm Brake

2

1

3

Tension Band Ass'y

Tension Arm Ass'y

Tension Holder

Inclined S Ass'y

Fig. 2-9-A

NOTE

When you install the Tension Adjust, install as shown in

Fig. 2-9-B. (Refer to Fig. 2-9-B)

3

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

1

Deck PCB

(BOT)

2-8: SENSOR COVER L3 (Refer to Fig. 2-8)

Unlock the support 1 and remove the Sensor Cover L3.1.

Main Chassis

Sensor Cover L3

1

Link Lever

Fig. 2-7

Fig. 2-8

Adjust the direction of the Marker to inside.

2-10: T BRAKE ASS'Y (Refer to Fig. 2-10)

Remove the T Brake Spring.

1.

Remove the T Brake Ass'y.

2.

T Brake Ass'y

T Brake Spring

Fig. 2-9-B

Fig. 2-10

DISASSEMBLY INSTRUCTIONS

2-11: S REEL/T REEL (Refer to Fig. 2-11)

Remove the S Reel and T Reel.

1.

Remove the 2 Polyslider Washers 1.

2.

NOTE

Take care not to damage the gears of the S Reel and T

1.

Reel.

The Polyslider Washer may be remained on the back of

2.

the reel.

Take care not to damage the shaft.

3.

Do not touch the section "A" of S Reel and T Reel. (Use

4.

gloves.) (Refer to Fig. 2-11) Do not adhere the stains

on it.

When you install the reel, clean the shaft and oil it. (If

5.

you do not oil, noise may be heard in FF/REW mode.)

After installing the reel, adjust the height of the reel.

6.

(Refer to MECHANICAL ADJUSTMENT)

S Reel

(A)

1

T Reel

(A)

1

NOTE

Do not touch the Pinch Roller. (Use gloves.)

1.

When you install the Pinch Roller Block, install as shown

2.

in the circle of Fig. 2-12-B. (Refer to Fig. 2-12-B)

Fig. 2-12-B

2-13: A/C HEAD (Refer to Fig. 2-13-A)

Remove the screw 1.

1.

Remove the A/C Head Base.

2.

Remove the 3 screws 2.

3.

Remove the A/C Head and A/C Head Spring.

4.

NOTE

Do not touch the A/C Head. (Use gloves.)

1.

When you install the A/C Head Spring, install as shown

2.

in Fig. 2-13-B. (Refer to Fig. 2-13-B)

When you install the A/C Head, tighten the screw (1)

3.

first, then tighten the screw (2), finally tighten the screw

(3).

2-12: PINCH ROLLER BLOCK/P5-3 ARM ASS'Y

(Refer to Fig. 2-12-A)

Remove the P5 Spring.

1.

Remove the screw 1.

2.

Unlock the 2 supports 2 and remove the Cassette

3.

Opener.

Remove the Pinch Roller Block, Pinch Roller Arm

4.

Spring, Pinch Roller Lever Ass'y and P5-3 Arm Ass'y.

P5 Spring

P5-3 Arm Ass'y

1

2

Cassette Opener

2

Pinch Roller Block

Pinch Roller Arm Spring

Pinch Roller Lever Ass'y

Main Chassis

Fig. 2-11

(3)

(1)

2

2

(2)

1

• Screw Torque: 4 ± 0.5kgf•cm (Screw 1)

2

Spring Position

A/C Head

A/C Head Spring

A/C Head Base

Fig. 2-13-A

Fig. 2-13-B

2-14: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-14)

Remove the screw 1.

1.

Remove the FE Head.

2.

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-12-A

FE Head

• The FE Head is not installed on the Video Cassette Player.

• Screw Torque: 4 ± 0.5kgf•cm

1

Fig. 2-14

DISASSEMBLY INSTRUCTIONS

2-15: AHC ASS'Y/CYLINDER UNIT ASS'Y

(Refer to Fig. 2-15)

Unlock the support 1 and remove the AHC Ass'y.

1.

Remove the 3 screws 2.

2.

Remove the Cylinder Unit Ass'y.

3.

NOTE

When you install the Cylinder Unit Ass'y, tighten the

screws from (1) to (3) in order while pulling the Ass'y

toward the left front direction.

AHC Ass'y

Cylinder Unit Ass'y

2

(2)

• Screw Torque: 3 ± 0.5kgf•cm

(1)

2

2

(3)

1

Fig. 2-15

2-16: CAPSTAN DD UNIT (Refer to Fig. 2-16)

Remove the Capstan Belt.

1.

Remove the 3 screws 1.

2.

Remove the Capstan DD Unit.

3.

1

Middle Gear

E-Ring

Main Cam

Pinch Roller Cam

2

Joint Gear

P5 Cam

Fig. 2-17-A

NOTE

When you install the Pinch Roller Cam, P5 Cam and Main

Cam, align each marker. (Refer to Fig. 2-17-B)

Pinch Roller Cam

Check the hole of Main

Chassis can be seen.

Marker

Main Cam

P5 Cam

Capstan Belt

Capstan DD Unit

1

1

1

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-16

2-17: MIDDLE GEAR/MAIN CAM (Refer to Fig. 2-17-A)

Remove the Polyslider Washer 1, then remove the

1.

Middle Gear.

Remove the E-Ring, then remove the Main Cam, P5

2.

Cam and Pinch Roller Cam.

Remove the Polyslider Washer 2, then remove the

3.

Joint Gear.

Fig. 2-17-B

2-18: CLUTCH ASS'Y (Refer to Fig. 2-18)

Remove the Polyslider Washer 1.

1.

Remove the Clutch Ass'y, Ring Spring and Coupling

2.

Gear.

Unlock the 2 supports 2 and remove the Clutch Lever.

3.

1

Clutch Ass'y

Ring Spring

Coupling Gear

Clutch Lever

2

2

Fig. 2-18

DISASSEMBLY INSTRUCTIONS

2-19: LOADING GEAR S/T ASS'Y (Refer to Fig. 2-19-A)

Remove the E-Ring 1 and remove the Main Loading

1.

Gear.

Remove the Capstan Brake Spring.

2.

Slide the Main Rod and remove the Capstan Brake

3.

Ass'y.

Remove the Main Rod, Tension Lever, Clutch Actuator,

4.

Idler Arm Ass'y.

Remove the screw 2.

5.

Remove the LED Reflecter.

6.

Remove the Loading Arm S Ass'y and Loading Arm T

7.

Ass'y.

8.

Remove the Loading Gear S and Loading Gear T.

9.

Remove the Loading Gear Spring.

Capstan Brake Spring

Main Rod

Idler Arm Ass'y

LED Reflecter

Clutch Actuator

Capstan Brake Ass'y

1

2

Main Loading Gear

Tension Lever

Loading Gear T

Loading Gear

Spring

Loading Arm T Ass'y

Loading Gear S

Loading Gear

Spring

2. When you install the Clutch Actuator, install as shown in

the circle of Fig. 2-19-C. (Refer to Fig. 2-19-C)

Clutch Actuator

Fig. 2-19-C

2-20: INCLINED S/T ASS'Y (Refer to Fig. 2-20)

Unlock the support 1 and remove the P4 Cover.

1.

Remove the screw 2.

2.

Unlock the support 3 and remove the Loading Gear

3.

Holder.

Remove the Inclined S.

4.

Remove the Inclined T.

5.

Remove the 2 screws 4, then remove the Guide Roller.

6.

NOTE

Do not touch the roller of Guide Roller.

2

Loading Gear Holder

Guide Roller

3

Loading Arm S Ass'y

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-19-A

NOTES

1. When you install the Loading Arm S Ass'y, Loading Arm

T Ass'y and Main Loading Gear, align each marker.

(Refer to Fig. 2-19-B)

Marker

Main Loading Gear

Marker

Loading Arm T Ass'y

Loading Arm S Ass'y

4

Inclined S

• Screw Torque: 5 ± 0.2kgf•cm (Screw 2)

• Screw Torque: 0.7 ± 0.2kgf•cm (Screw 4)

Guide Roller

4

Inclined T

P4 Cover

1

Fig. 2-20

Fig. 2-19-B

DISASSEMBLY INSTRUCTIONS

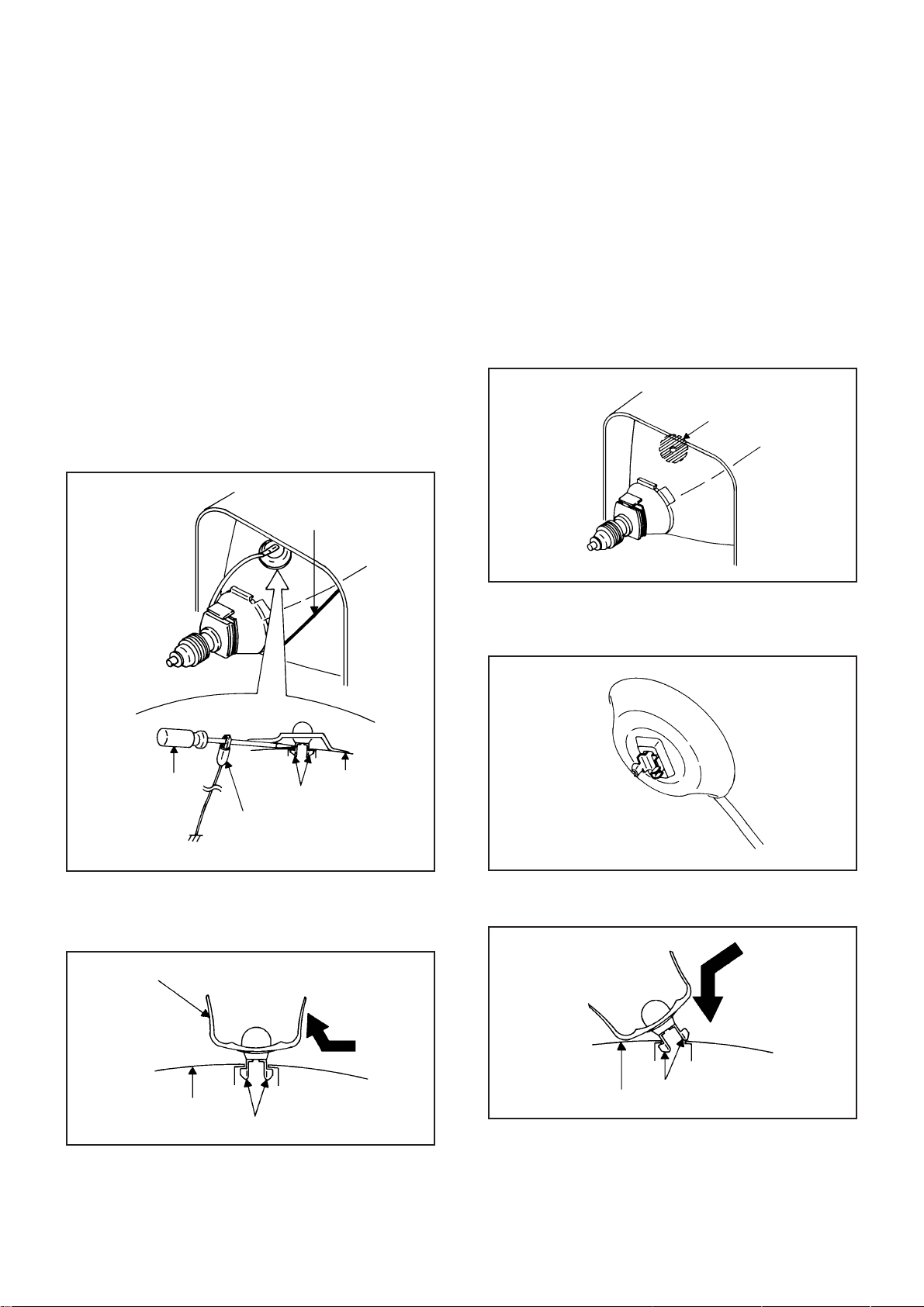

3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

After turning the power off there might still be a potential

*

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

*

Do not use pliers to loosen or tighten the Anode Cap

terminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 3-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction

to remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 3-3.)

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

Location of Anode Cap

Fig. 3-3

Screwdriver

Alligator Clip

GND on the CRT

Flip up the sides of the Rubber Cap in the direction of

2.

the arrow and remove one side of the support.

(Refer to Fig. 3-2.)

Rubber Cap

Support

CRT

Fig. 3-1

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Fig. 3-4

4. Insert one end of the Anode Support into the anode

button, then the other as shown in Fig. 3-5.

CRT

Support

Fig. 3-2

Support

CRT

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

Fig. 3-5

A

A/C

ACC

AE

AFC

AFT

AFT DET

AGC

AMP

ANT

A.PB

APC

ASS'Y

AT

AUTO

A/V

B

BGP

BOT

BPF

BRAKE SOL

BUFF

B/W

C

C

CASE

CAP

CARR

CH

CLK

CLOCK (SY-SE)

COMB

CONV

CPM

CTL

CYL

CYL-M

CYL SENS

D

DATA (SY-CE)

dB

DC

DD Unit

DEMOD

DET

DEV

E

E

EF

EMPH

ENC

ENV

EOT

EQ

EXT

F

F

FBC

FE

FF

FG

FL SW

FM

FSC

FWD

G

GEN

GND

H

H.P.F

KEY TO ABBREVIATIONS

:

Audio/Control

:

Automatic Color Control

:

Audio Erase

:

Automatic Frequency Control

:

Automatic Fine Tuning

:

Automatic Fine Tuning Detect

:

Automatic Gain Control

:

Amplifier

:

Antenna

:

Audio Playback

:

Automatic Phase Control

:

Assembly

:

All Time

:

Automatic

:

Audio/Video

:

Burst Gate Pulse

:

Beginning of Tape

:

Bandpass Filter

:

Brake Solenoid

:

Buffer

:

Black and White

:

Capacitance, Collector

:

Cassette

:

Capstan

:

Carrier

:

Channel

:

Clock

:

Clock (Syscon to Servo)

:

Combination, Comb Filter

:

Converter

:

Capstan Motor

:

Control

:

Cylinder

:

Cylinder-Motor

:

Cylinder-Sensor

:

Data (Syscon to Servo)

:

Decibel

:

Direct Current

:

Direct Drive Motor Unit

:

Demodulator

:

Detector

:

Deviation

:

Emitter

:

Emitter Follower

:

Emphasis

:

Encoder

:

Envelope

:

End of Tape

:

Equalizer

:

External

:

Fuse

:

Feed Back Clamp

:

Full Erase

:

Fast Forward, Flipflop

:

Frequency Generator

:

Front Loading Switch

:

Frequency Modulation

:

Frequency Sub Carrier

:

Forward

:

Generator

:

Ground

:

High Pass Filter

H.SW

Hz

I

IC

IF

IND

INV

K

KIL

L

L

LED

LIMIT AMP

LM, LDM

LP

L.P.F

LUMI.

M

M

MAX

MINI

MIX

MM

MOD

MPX

MS SW

N

NC

NR

O

OSC

OPE

P

PB

PB CTL

PB-C

PB-Y

PCB

P. CON

PD

PG

P-P

R

R

REC

REC-C

REC-Y

REEL BRK

REEL S

REF

REG

REW

REV, RVS

RF

RMC

RY

S

S. CLK

S. COM

S. DATA

SEG

SEL

SENS

SER

SI

SIF

SO

SOL

SP

STB

SW

:

Head Switch

:

Hertz

:

Integrated Circuit

:

Intermediate Frequency

:

Indicator

:

Inverter

:

Killer

:

Left

:

Light Emitting Diode

:

Limiter Amplifier

:

Loading Motor

:

Long Play

:

Low Pass Filter

:

Luminance

:

Motor

:

Maximum

:

Minimum

:

Mixer, mixing

:

Monostable Multivibrator

:

Modulator, Modulation

:

Multiplexer, Multiplex

:

Mecha State Switch

:

Non Connection

:

Noise Reduction

:

Oscillator

:

Operation

:

Playback

:

Playback Control

:

Playback-Chrominance

:

Playback-Luminance

:

Printed Circuit Board

:

Power Control

:

Phase Detector

:

Pulse Generator

:

Peak-to Peak

:

Right

:

Recording

:

Recording-Chrominance

:

Recording-Luminance

:

Reel Brake

:

Reel Sensor

:

Reference

:

Regulated, Regulator

:

Rewind

:

Reverse

:

Radio Frequency

:

Remote Control

:

Relay

:

Serial Clock

:

Sensor Common

:

Serial Data

:

Segment

:

Select, Selector

:

Sensor

:

Search Mode

:

Serial Input

:

Sound Intermediate Frequency

:

Serial Output

:

Solenoid

:

Standard Play

:

Serial Strobe

:

Switch

S

SYNC

SYNC SEP

T

TR

TRAC

TRICK PB

TP

U

UNREG

V

V

VCO

VIF

VP

V.PB

VR

V.REC

VSF

VSR

VSS

V-SYNC

VT

X

X'TAL

Y

Y/C

KEY TO ABBREVIATIONS

:

Synchronization

:

Sync Separator, Separation

:

Transistor

:

Tracking

:

Trick Playback

:

Test Point

:

Unregulated

:

Volt

:

Voltage Controlled Oscillator

:

Video Intermediate Frequency

:

Vertical Pulse, Voltage Display

:

Video Playback

:

Variable Resistor

:

Video Recording

:

Visual Search Fast Forward

:

Visual Search Rewind

:

Voltage Super Source

:

Vertical-Synchronization

:

Voltage Tuning

:

Crystal

:

Luminance/Chrominance

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter SERVICE MODE, Unplug AC cord till lost actual clock time. Then press and hold Vol (-) button of main unit and

remocon key for more than 2 seconds.

The both pressing of set key and remote control key will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 30 minutes before Power On or alternatively, discharge backup capacitor.

Set Key Remocon Key Operations

VOL. (-) MIN 1

VOL. (-) MIN 2

VOL. (-) MIN

VOL. (-) MIN 4

VOL. (-) MIN 5

VOL. (-) MIN 6

VOL. (-) MIN 7

Initialization of the factory.

NOTE: Do not use this for the normal servicing.

Horizontal position adjustment of OSD.

NOTE: Also can be adjusted by using the Adjustment MENU.

Refer to the "ELECTRICAL ADJUSTMENT" (OSD HORIZONTAL).

3

Adjust the PG SHIFTER automatically.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjust the PG SHIFTER manually.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjusting of the Tracking to the center position.

NOTE: Also can be adjusted by pressing the ATR button for more tan 2 seconds

during PLAY.

POWER ON total hours and PLAY/REC total hours are displayed on the screen.

Refer to the "PREVENTIVE CHECKS AND SERVICE INTERVALS" (CONFIRMATION

OF USING HOURS).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "NOTE FOR THE REPLACING OF MEMORY IC".

Releasing of PROTECTION PASSWORD.

VOL. (-) MIN 8

VOL. (-) MIN 9

Method Operations

Press the ATR button on the

remote control for more than

2 seconds during PLAY.

Make the short circuit between

the test point of SERVICE and

the GND.

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

Adjusting of the Tracking to the center position.

Refer to the "MECHANICAL ADJUSTMENT" (GUIDE ROLLER) and "ELECTRICAL

ADJUSTMENT" (PG SHIFTER).

The EOT/BOT/Reel sensor do not work at this moment.

Refer to the "PREPARATION FOR SERVICING"

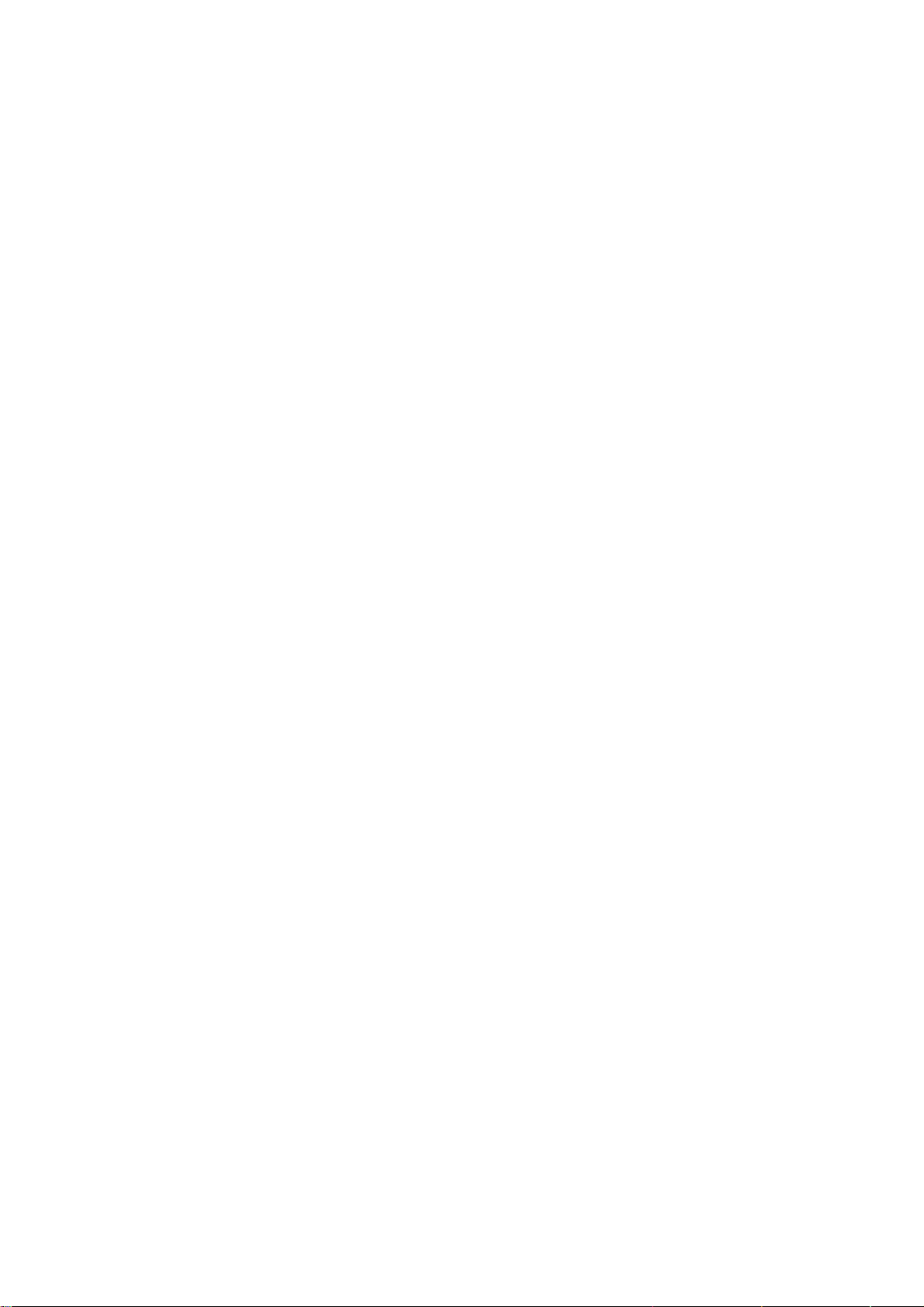

PREVENTIVE CHECKS AND SERVICE INTERVALS

The following standard table depends on environmental conditions and usage. Unless maintenance is properly

carried out, the following service intervals may be quite shortened as harmful effects may be had on other parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

Time

Parts Name

Audio Control Head

Full Erase Head

(Recorder only)

Capstan Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band

Capstan Shaft

Tape Running

Guide Post

Cylinder Unit

: Clean

: Replace

500

hours

1,000

hours

1,500

hours

2,000

hours

3,000

hours

Notes

Clean those parts in

contact with the tape.

Clean the rubber, and parts

which the rubber touches.

Replace when rolling

becomes abnormal.

Clean the Head

CONFIRMATION OF USING HOURS

POWER ON total hours and PLAY/REC total hours can be checked on the screen.

Total hours are displayed in 16 system of notation.

NOTE: The confirmation of using hours will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 30 minutes before Power On.

1.

Set the VOLUME to minimum.

2.

While holding down VOLUME button on front cabinet, press key 6 on remote control for more than 2 seconds

3.

After the confirmation of using hours, turn off the power.

INIT 00 83

POWER ON

PLAY/REC

(16 x 16 x 16 x thousands digit value) + (16 x 16 x hundreds digit value) + (16 x tens digit value) + (ones digit value)

0010

0003

Initial setting content of MEMORY IC.

POWER ON total hours.

PLAY/REC total hours.

PREVENTIVE CHECKS AND SERVICE INTERVALS

CLEANING

NOTE

After cleaning the heads with isopropyl alcohol, do not

run a tape until the heads dry completely. If the heads

are not completely dry and alcohol gets on the tape,

damage may occur.

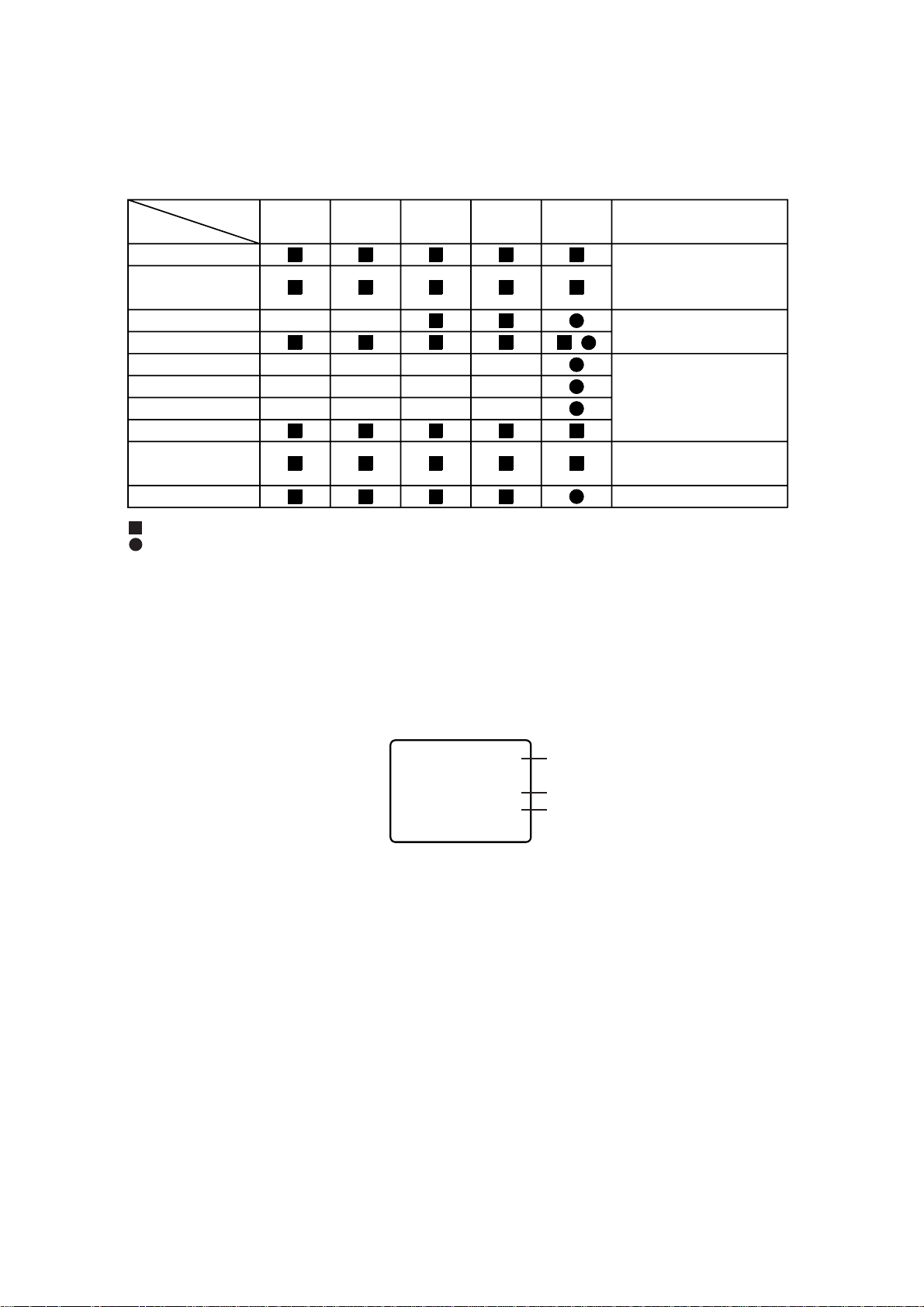

1. AUDIO CONTROL HEAD

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol and clean the audio control head by

wiping it horizontally. Clean the full erase head in the

same manner. (Refer to the figure below.)

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the

gauze moistened with isopropyl alcohol.

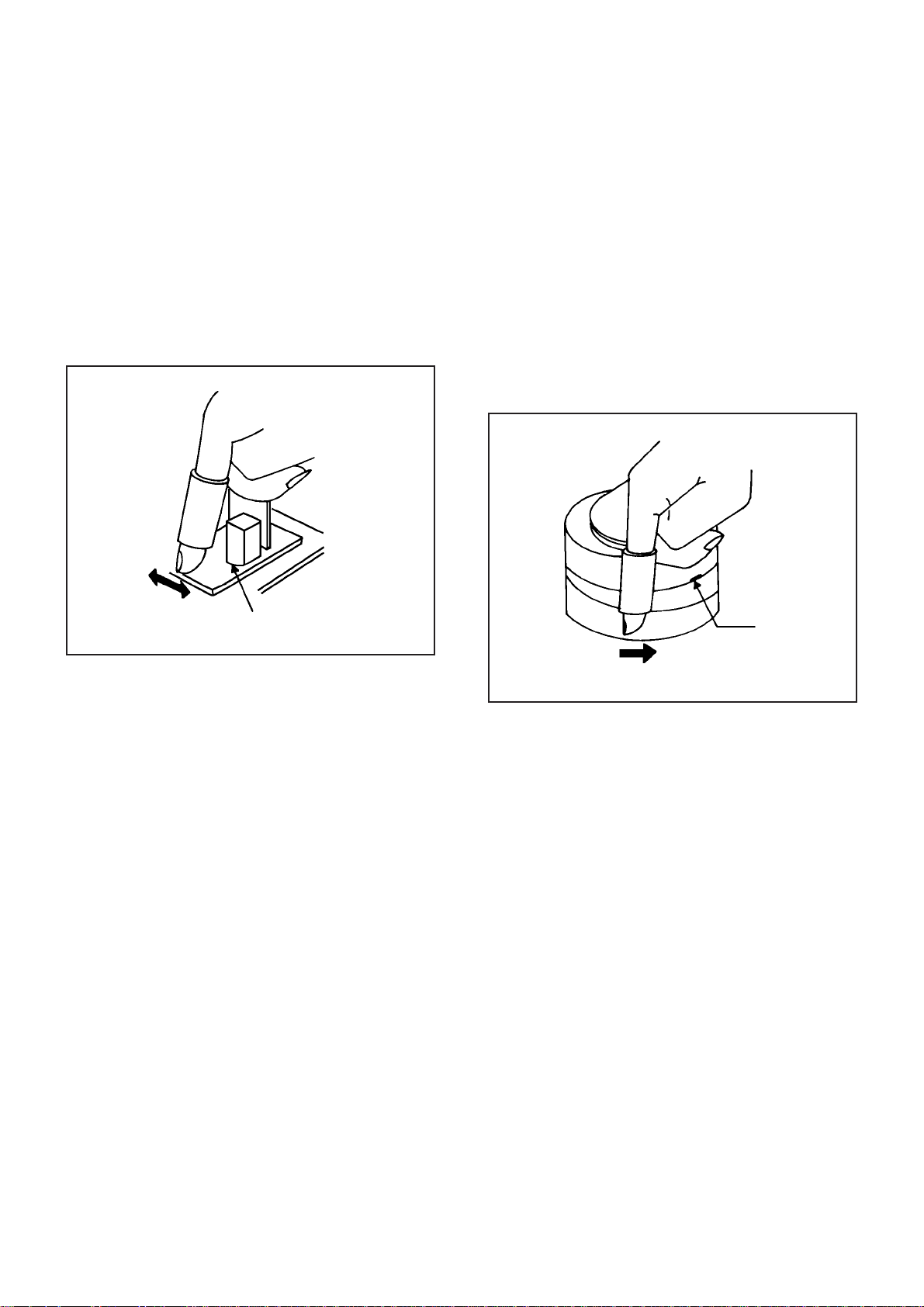

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in

the direction of the arrow). (Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

Audio Control Head

Cylinder Head

NOTE FOR THE REPLACING OF MEMORY IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

NOTE: Initial Data setting will not be possible if clock has been set. To reset clock, either unplug AC cord and allow

at least 30 minutes before Power On or alternatively, discharge backup capacitor.

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9

5C 1E 07 81 EA 80 14 07 C4 81

05

1A 63 65 66 41 1E 3B 2A 17

10

77 63 64 65 64 0A 40 F5 76 A0

20 59 5F 05 F0 00 F0

30 15 28 A0 C4 20 08

5F 05 F0 05 F3 EF 90 6C 38 21

40 10 3A 60 47 03 06 15

BF 1B B5 C3 43 7D 8B 8B 0C

20 24 26 28 2A 2C 2E 30 32

50

60 5B 5E 61 64 67 6A

70 8B 8E 91 94 97 9A

80 A0 CD D2 D9 E1 F0 FF

Enter DATA SET mode by setting VOLUME to minimum.

1.

While holding down VOLUME button on front cabinet, press key 6 on remote control for more than 2 seconds.

2.

ADDRESS and DATA should appear as FIG 1.

22

40 42 44 46 49 4C 4F 52 55 58

6D 70 73 76 79 7C 7F 82 85 88

9D

A5 AA AF B4 B9 BE C3 C8

Table 1

ADDRESS DATA

+A

+B +C +D +E +FINI

1A 31 04 6F 18 2300

1D 1B 3A 0F 4B 20

34 36 38 3A 3C 3E

INIT 00 83

POWER ON

PLAY/REC

3.

ADDRESS is now selected and should "blink". Using the PLAY or STOP button on the remote, step through the

ADDRESS until required ADDRESS to be changed is reached.

4.

Press ENTER to select DATA. When DATA is selected, it will "blink".

5.

Again, step through the DATA using PLAY or STOP button until required DATA value has been selected.

6.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

7.

Repeat steps 3 to 6 until all data has been checked.

8.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

The unit will now have the correct DATA for the new MEMORY IC.

0010

0003

Fig. 1

SERVICING FIXTURES AND TOOLS

Alignment Tape

ST-N5

ST-NF

VTR cleaning kit VTR lubrication kit Grease JG002B

JG022 Master Plane JG024A Reel Disk Height

Back tension cassette gauge

70909103

Adjustment Jig

Torque cassette gauge

(KT-300NR)

70909199

JG153 X Value Adjustment

Screwdriver

Taper nut driver

70909228

JG002E

JG002F

JG154 Cable

Adapter

Dial Torque Gauge

(10~90gf•cm)

(60~600gf•cm)

JG162A Cable (8 Pins)

JG162G Cable (14 Pins)

JG162Y Cable (5 Pins)

Ref. No. Remarks

JG002B

JG002E

JG002F

JG153

JG022/JG024A

JG154

JG162A

JG162G Used to connect the Syscon PCB and Main PCBAPJG162G00

JG162Y Used to connect the Syscon PCB and CRT PCBAPJG162Y00

Tentelometer

Part No.

APJG002B00

APJG002E00

APJG002F00

APJG153000

APJG022000/APJG024A00

APJG154000

APJG162A00

VSR Torque, Brake Torque (S Reel/T Reel Ass'y)

Brake Torque (T Reel Ass'y)

VSR Torque, Brake Torque (S Reel)

X Value Adjustment

Reel Disk Height Adjustment

Used to connect the test point of SERVICE and GROUND

Used to connect the Syscon PCB and Regulator PCB

PREPARA TION FOR SER VICING

How to use the Servicing Fixture

1.

Unplug the connector CP755 and CP4202, then remove the TV/VCR Block from the set.

2.

Unplug the connector CP810, CP820 and CP805, then remove the Main PCB from the VCR Block.

3.

Connect as shown in the below figure using the Service Fixture.

• Connect the Syscon PCB to the Regulator PCB with the cable JG162A.

• Connect the Syscon PCB to the Main PCB with the cable JG162G.

• Connect the Syscon PCB to the CRT PCB with the cable JG162Y.

4.

Remove the Operation PCB from the set, then connect it with the Syscon PCB.

If necessary, connect CD702 (Front A/V Jack Input Terminal)

5.

Short circuit between TP1001 and Ground with the cable JG154.

(Refer to MAJOR COMPONENTS LOCATION GUIDE)

The EOT, BOT and Reel Sensor do not work at this moment.

6.

At that time, the STOP/EJECT button is available to insert and eject the Cassette Tape.

Front Cabinet

Stereo PCB

Syscon PCB

TP1001

CD850

CRT PCB

CP805

Main PCB

JG162Y

CD820

Regulator PCB

CP755

CP820

CP810

JG162G

JG162A

CD9001

To Ground

JG154

Operation PCB

CD702

CD757

Loading...

Loading...