Unified Controller

nv Series

TC-net 100 (TN8) Module

Instruction Manual

Notes

(1)

The technical information provided herein describes typical operations and applications of the product and does

not guarantee the intellectual property rights or other rights of Toshiba or third parties nor allows license of its use.

(2)

No part or the whole of this document may be reproduced without prior consent.

(3)

The information herein may be changed in the future without notice.

(4)

All possible measures have been taken to prepare the information herein. If you have any question, comment, or

find any error, please contact us.

PROSEC, TOSLINE, TOSDIC, CIEMAC are trademarks or registered trademarks of Toshiba Corporation.

Microsoft, Windows are registered trademarks of Microsoft Corporation in the U.S. and other countries.

DeviceNet is a registered trademark of Open DeviceNet Vender Association Inc.

© TOSHIBA CORPORATION 2016

All rights reserved

i

Safety Precautions

Sign

Description

Symbol

Meaning

On the product and this operation manual, important information for safe and correct

use to prevent danger to the user and other people as well as property damage is

described.

Understand the following information (signs and symbols) before reading the text, and

follow the described items.

Description of signs

Indicates that failure to avoid it will result in an immediate risk of

DANGER

death or serious injury

(*1)

.

Indicates that failure to avoid it will result in a risk of death or

WARNING

serious injury

(*1)

.

Indicates that failure to avoid it will result in a risk of light or

CAUTION

*1: A serious injury indicates loss of sight, injury, burns (high/low temperature), electri c shock, brok e n bones, or into xatio n that will have aftereffects

and require hospitalization or lo ng-te rm ho spi tal visi ts for heali ng.

*2: An injury indicates an injury, burn, or electric shock that does not need hospitalization or long-term hospital visits for healing.

*3: A property damage indicates consequential damage in terms of breakage of properties or materials.

medium injury

(*2)

or only property damage

(*3)

.

Description of symbols

Prohibited

Mandatory

Warning

(Note) Descriptions of Prohibition, Mandatory Action, and Warning vary depending on the display on the main unit.

Indicates “Prohibition” or “You must not do”.

Specific details are indicated near the symbol

Indicates “Mandatory Action” or “Do as indicated”.

Specific details are indicated near the symbol

Indicates Warning.

Specific details are indicated near the symbol

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

with pictures and text.

with pictures and text.

with pictures and text.

ii

Install the device in a place where

1. Safety Precautions on Installation

Ground

Prohibited

Ground the device.

Otherwise, it may cause an electric

shock or fire.

Do not install, store, or use it in

the following environments.

・ A place with a lot of dust

WARNING

Mandatory

CAUTION

Construct the emergency stop

circuit and interlock circuit

outside

the nv series.

Otherwise, it may cause an injury

accident or damage to the machine if

failure or malfunction occurs in the

nv

series.

Otherwise, it may cause accidents.

・ A place with corrosive gases (SO2,

H2S) ore flammable gases

・ A place with vibrations and shocks

exceeding the allowed values

・ A place with condensations due to

rapid temperature changes

・ A place with low or high

temperature outside of the

installation condition

・ A place with high humidity outside

of the installation condition

・ A place with direct sunlight

・ A place near equipment

generating strong radio waves or

magnetic fields

It may cause accidents.

maintenance and inspection can

Mandatory

6F8C1360

be done easily.

iii

conditions and methods

Prohibited

Mandatory

Do not block the ventilation hole

or air inlet/outlet.

It may cause fire or failure due to

overheat.

For installation and wiring of the

system, observe the installation

described in this document.

Otherwise, it may cause a fall, fire,

failure, or malfunction.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

iv

2. Safety Precautions on Maintenance and Inspection

Mandatory

Prohibited

Mandatory

When installing or removing the

module after wiring, make sure

that the external power supply is

of f.

Otherwise, there will be live electric

poles on the back of the external

terminal block of the module,

causing an electric shock.

Do not drop, crush, or apply

strong shocks to the device or

board.

It may cause failure.

Before touching the device or

board, touch a grounded metal

to discharge the static electricity

of your body.

Otherwise, it may cause malfunction

or failure due to static electricity.

WARNING

CAUTION

Mandatory

Prohibited

Place a board or module

removed from the unit or base

unit on a conductive mat or

conductive bag (used for a

backup board) on a grounded

table.

Otherwise, parts may be

damaged due to static electric ity.

Do not use benzene or thinner to

remove stain on device, module,

or board.

Mandatory

Wipe off stain on the device,

module, or board with a soft

cloth.

For severe stain, use a wet cloth

wrung tightly.

Leaving them stained may cause

wrong decision or malfunction.

It may cause deformation or

discoloration of the device panel,

module, or board.

6F8C1360

v

Do not touch the terminals of the

Do not modify, repair,

disassemble, or adjust the device,

Before using, check that the

Do not touch the terminals of the

3. Safety Precautions on Replacement of Life Limited Parts

WARNING

Mandatory

If the device has power fuses or

alarm fuses, when replacing

them, turn off the switch of the

device.

Otherwise, it may cause an electric

shock or fire.

4. Safety Precautions on Daily Use

Mandatory

No touch

module and unit during

energization.

It may cause an electric shock.

WARNING

When the ambient or internal

temperature of the device rises

abnormally or failure occurs in

the device, stop using the device,

turn off the power, and contact

one of Toshiba's service

representatives.

Prohibited

module, or board.

It may cause an electric shock, fire,

injury, or failure.

Upon faulty operation or failure,

contact Toshiba's branch office or

service offices.

power capacity, frequency,

Mandatory

voltage, and regulation comply

with the device specifications.

If not, it may cause damage of the

device, or fire due to overheat, as

well as not obtaining the original

performance of the device.

Using it as it is may cause fire due to

overheat.

No touch

energization.

module and unit during

It may cause an electric shock.

The power supply module is for the nv

series only. Do not use it alone for

any other purposes.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

vi

Do not touch anything other than

Do not disassemble or modify

Do not forcefully bend, pull, or

Prohibited

Prohibited

the operation part (setting

switches inside the module), such

as the IC parts and terminals,

connectors, and soldered

surfaces inside the module.

Doing so may result in electrostatic

breakdown of the ICs and LSIs,

causing failure. Also, an injury may

occur due to the ends of the part lead

wires, or burns may occur due to hot

parts.

the device or module.

It may cause malfunction or failure as

well as loss of safety of the device.

CAUTION

Prohibited

Prohibited

twist the power cord and cables.

It may cause breaks or heating.

Do not insert any metal into the

gaps of the device main body.

It may cause fire.

5. Safety Precautions on Transportation, Storage, and Disposal

Observe ordinances and rules.

When destroying the product,

Mandatory

observe the ordinances and rules of

the local government.

CAUTION

Prohibited

For transportation and storage of

the product, use a conductive

bag and packaging box.

Otherwise it will cause failure.

6F8C1360

vii

Restrictions on Application

This product is not developed/manufactured for use in systems involving devices that

directly affect human life (Note 1). Do not use them for such applications.

To use this product for systems that involve devices that significantly affect human

safety or maintenance of public functions (Note 2), special considerations (Note 3)

are required in system operation, maintenance, and management. In this case,

contact one of Toshiba's sales representatives.

(Note 1) Devices that directly affect human life include the following.

• Medical devices such as life supporting devices and devices for surgical

units.

(Note 2) Systems that involve devices that significantly affect human safety or

maintenance of public functions include the following.

• Main unit control systems of nuclear power plants, safety protection

systems of nuclear facilities, and other systems that are critical for safety

• Operation control systems of mass transportation systems and air traffic

control systems

(Note 3) Special considerations indicate sufficient discussions with Toshiba's

engineers to construct a safe system (e.g. employing fool-proof design,

fail-safe design, or redundant design).

Disclaimer

Toshiba shall not be responsible for any damage caused by fire or earthquake, acts of

a third party, other accidents, the user's willful acts or negligence, misuse, or use in

abnormal conditions.

Toshiba shall not be responsible for any incidental damage (loss of business profits,

interruption of business, change or loss of stored memory) caused by use of or being

unable to use this product.

Toshiba shall not be responsible for any damage caused by failure to observe the

information described in the operation manual.

Toshiba shall not be responsible for any damage caused by malfunctions due to

combination with any connected device.

Toshiba shall not be responsible for any damage caused by malfunctions due to

combination with any application program created by the customer.

Note

Use your cellular phone or PHS 1 meter or more away from the product main unit in operation,

various transmission cables, and I/O bus cable. Otherwise, the system may malfunction.

6F8C1360

viii

Introduction

This manual describes the functions, methods of installation and setting, and

maintenance and inspection of the TC-net 100 (TN8) module ("TN8 module" hereafter)

for connecting the information/control network TC-net 100 to the Unified Controller nv

series.

To use this device correctly, read "Safety precautions" first.

The manuals related to the TN8 module are as follows.

• Unified Controller nv series Main Unit Operation Manual (6F8C1220)

Describes the main unit hardware of the nv series controller.

• Unified Controller nv series Type 1 Function Manual (6F8C1221)

Describes the functions and basic use of the nv series Type 1.

• Unified Controller nv series Type 2 Function Manual (6F8C1362)

Describes the functions and basic use of the nv series Type 2.

• Unified Controller nv series/Integrated Controller V series Command Manual

(6F8C1226)

Describes the detailed specifications of the instruction words of the program

languages (LD, FBD, and SFC) supported by the nv series and Integrated Controller

V series.

• Unified Controller nv series/Integrated Controller V series nV-Tool (Basic)

Operation Manual (6F8C1290)

Describes how to create, debug, print, and save programs using nV-Tool.

• Unified Controller nv series TC-net 100 Module Manual (6F8C1360)

(This document)

Describes the TC-net 100 (TN8) module, which is common to Type 1 and Type 2

of the nv series.

After reading the manual, place it in a location that can be accessed easily when

necessary.

6F8C1360

ix

●

Describes what the user should be particularly aware of to handle the product correctly.

Describes what the user should observe to handle the product correctly.

Describes a remark.

●

Notational conventions

The following are the notational conventions for better understanding of this

document.

Important:

Note:

Remark:

Reading this document

This document consists of the following chapters.

•Chapter 1 Introducing the TN8 module

Describes the functions, characteristics, and names and functions of the

parts.

•Chapter 2 Installation and wiring

Describes how to install it to the basic unit and how to connect cables.

•Chapter 3 Setting

Describes how to set the switches and parameters to use the module

correctly.

•Chapter 4 Operation

Describes the operations such as checking before operation, startup, and

shutdown.

•Chapter 5 Troubleshooting

Describes troubleshooting such as what to do when failure occurs.

•Chapter 6 Maintenance and inspection

Describes troubleshooting regarding daily inspection and periodical

inspection and how to perform inspections.

•Chapter 7 Application interface

Describes the user application interface and usage constraints.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

x

Chapter 1

Introducing the

TN8

Chapter 2

Installation and

W

Chapter 3

Setting

CONTENTS

1.1 Functions and Characteristics of the TN8 Module ······ 2

1.2 Names and Functions of the Parts ··························· 4

1.2.1 Names of the parts ·············································· 4

Module

1.2.2 Functions of the parts ··········································· 5

iring

6F8C1360

...1

...7

...15

2.1 Installation (Installation to the Basic Unit) ················· 8

2.2 Connecting the TC-net 100 Cable ·························· 10

2.3

Connecting the Serial Communication Port (RS-232C)

································································ 12

Cable

2.4 Replacing the Module ·········································· 13

3.1 Switch Setting ·················································· 16

3.1.1 Station address setting switch

(STN-H, STN-L) ················································ 16

3.1.2 Operation mode setting switch (MODE) ·················· 17

3.2 Network Parameter Setting ··································· 18

3.2.1 Networ k ID and subnet mask ······························· 18

3.2.2 Station address ················································· 19

3.2.3 Overview of multicast address ······························ 19

3.3 Setting with the Engineering Tool ·························· 21

3.3.1 Network parameter setting ··································· 22

3.3.2 Setting the sc an sending bloc ks ····························

3.3.3 Setting the st a te change not i fi cation ·······················

3.4 Network Information ··········································· 38

3.4.1 Referrin g to LAN tran smi ssion map ······················· 38

3.4.2 Accessing the scan data ····································· 39

3.4.3 Clearing the scan unhealthy state ·························· 39

3.4.4 Clearing the overlapping sendi ng SA ····················· 39

3.4.5 LAN control information ······································ 40

3.4.6 Detailed explanation of LAN management information 41

3.4.7 MIB information ················································· 42

3.4.8 Reception system switching ································· 43

3.4.9 Viewing the in-ring map······································· 44

3.5 Option Functions ················································ 45

3.5.1 Setting the self healthy mode parameters ················ 45

3.6 Setting the RAS Information Block in Scan

Transmission ····················································· 47

32

35

xi

Chapter 4

Operation

Chapter 5

Troubleshooting

Chapter 6

Maintenance and

I

Chapter 7

Application

I

Appendix A

Specifications

nspection

...49

...51

...53

6.1 Inspection ························································· 54

6.1.1 Daily inspection ················································· 54

6.1.2 Periodical inspection ·········································· 55

6.2 Life Limited Parts ··············································· 55

nterface

...57

7.1 Information by Socket ········································· 59

7.1.1

7.1.2 Referring to information by socket ························· 60

7.1.3 T iming of generation of information by socket ··········· 61

Configuration of information by socket

······················ 59

7.2 Transmission Path Diagnosis Information ·············· 63

7.2.1 Configu ration o f the s can dat a healthy map ············· 63

7.2.2 Configu ration o f the s can dat a unhealthy map ··········

7.2.3 Configuration of the scan data talker map ················

7.2.4 Configu ration o f RAS in formation ··························

7.2.5

Configuration of in-ring map ···································· 68

64

65

66

7.3 Usage Constraints ·············································· 69

7.4 Restriction on Station Redundant Configuration ······ 70

A.1 General Specifications ········································ 72

A.2 TC-net 100 Transmission Specifications ················· 73

A.3 Function Specifications ······································· 74

...71

A.4 Serial Communication Port (RS-232C) Transmission

Specifications ···················································· 75

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

xii

Appendix B

Outside

D

Appendix C

Related Products

Appendix D

Decimal-hexadecimal

C

imensions

...77

...79

onversion Table

...81

6F8C1360

1

Chapter 1 Introducing the TN8 Module

This chapter describes the functions, characteristics, and names and

functions of the TN8 module

1.1 Functions and Characteristics of the TN8 Module ··· 2

1.2 Names and Functions of the Parts ····················· 4

1.2.1 Names of the parts ·································· 4

1.2.2 Functions of the parts ······························· 5

Chapter 1 Introducing the TN8 Module

2

•

TN821A/TN822A are successor machine for TN821/TN822. Thus, TN821A/TN822A are

Remark

PCMP: Process Control Message Protocol

1.1 Functions and Characteristics of the TN8 Module

The TN8 module is a device to connect the controller main unit of

the Unified Controller nv series to the information and monitoring

control network TC-net 100. For the interface of the TN8 module,

optical fiber cables are provided: One for single bus and one for

dual-redundant bus.

・TN821: Optical fiber cable single bus module

・TN821A: Optical fiber cable single bus module

・TN822: Optical fiber cable dual-redundant bus module

・TN822A: Optical fiber cable dual-redundant bus module

Up to 4 TN8 modules can be installed to the basic unit.

Remark

compatible with TN821/TN822.

Characteristics of the TN8 mo dule

• Openness

The TN8 module is a network for monitoring control that

maintains the openness of the 100 Mbps Ethernet and has the

collision avoidance function and deterministic real time

responsiveness.

• Communication services

The communication services include scan transmission (cyclic

broadcast transmission) that transmits control data periodically,

and normal message transmission.

Scan transmission has 3 modes; high, medium and low, which can

be assigned according to the data update cycle to ensure

deterministic real time responsiveness.

Message transmission supports Toshiba's standard protocol

PCMP as well as TCP, UDP, and IP.

•

• High reliability

Highly reliable system configuration is available with redundancy

of the transmission path.

6F8C1360

1.1 Functions and Characteristics of the TN8 Module

3

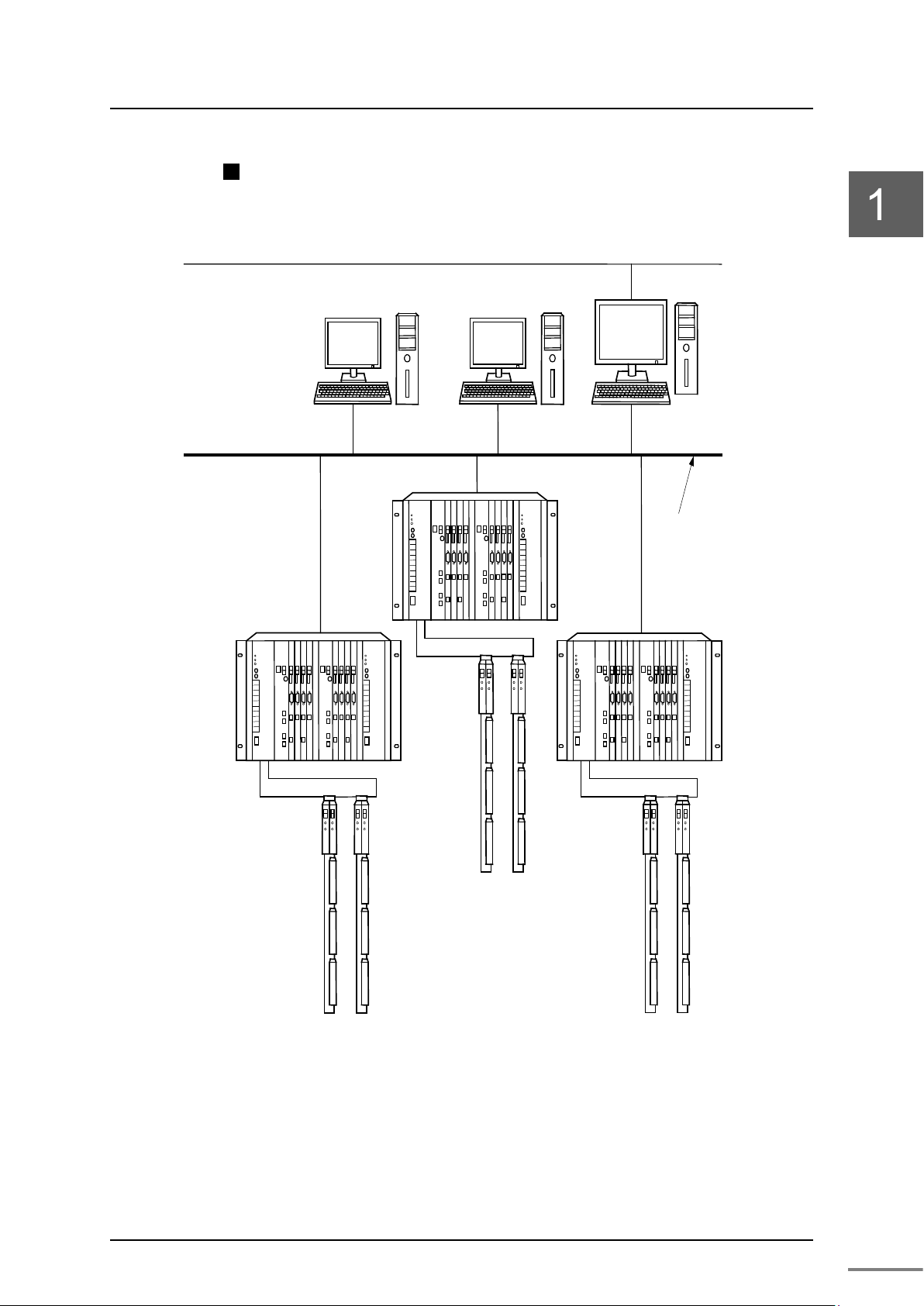

Host system

network

Unified Cont roller nv series

TC-net I/O system

TC-Net 100

Monitoring control newwork

Example of system configuration

Figure 1-1 System configuration example (Optical transmission path)

Unified Controller nv series TC-net100 (TN8) Module Operation Manual

Chapter 1 Introducing the TN8 Module

4

State display LED

・RUN

・ERR

・

A

・SCAN

Station address setting switch

・

・STN L

Operation mode setting switch

・

Serial communication port

・

State display LED(A system)

・

A

・

A

TC

RUN

ERR

L

SCAN

MODE

UN

H

L

STN

TOOL

TN822

L-B

TN-A

LNK-A

ACT-A

TN-B

LNK-B

ACT-B

Optical fiber cable

RUN

ERR

L-A

SCAN

MODE

UN H L

STN

TOOL

TN821

TN-A

LNK-A

ACT-A

Optical fiber cable

For single bus

State display LED

・RUN

・ERR

・

A

・

B

・

CAN

・

A

・

A

TC

State display LED

for B System

TN

For dual-redundant bus

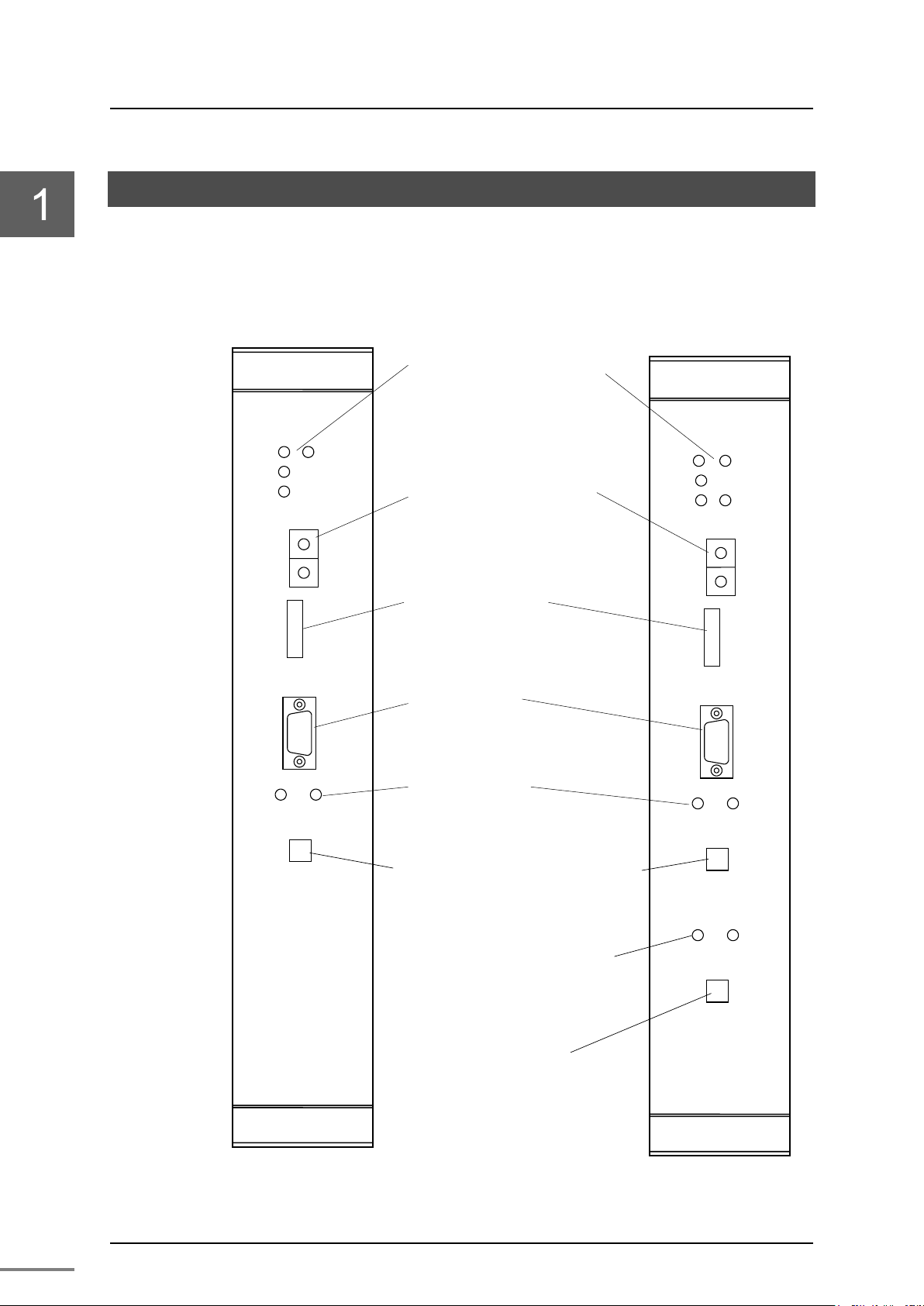

1.2 Names and Functions of the Parts

1.2.1 Names of the parts

821/TN821A

TN822/TN822A

L-

LLS

STN H

MODE

TOOL

LNKACT-

-net 100 modular connector for A system

-A

Figure 1-2 Names of the parts of the TN8 module (TN821/TN821A, TN822/TN822A)

6F8C1360

(B system)

LNKACT-

-net 100 modular connector

(Note) Front panel name is difference between TN821A/TN822A and TN821/TN822.

5

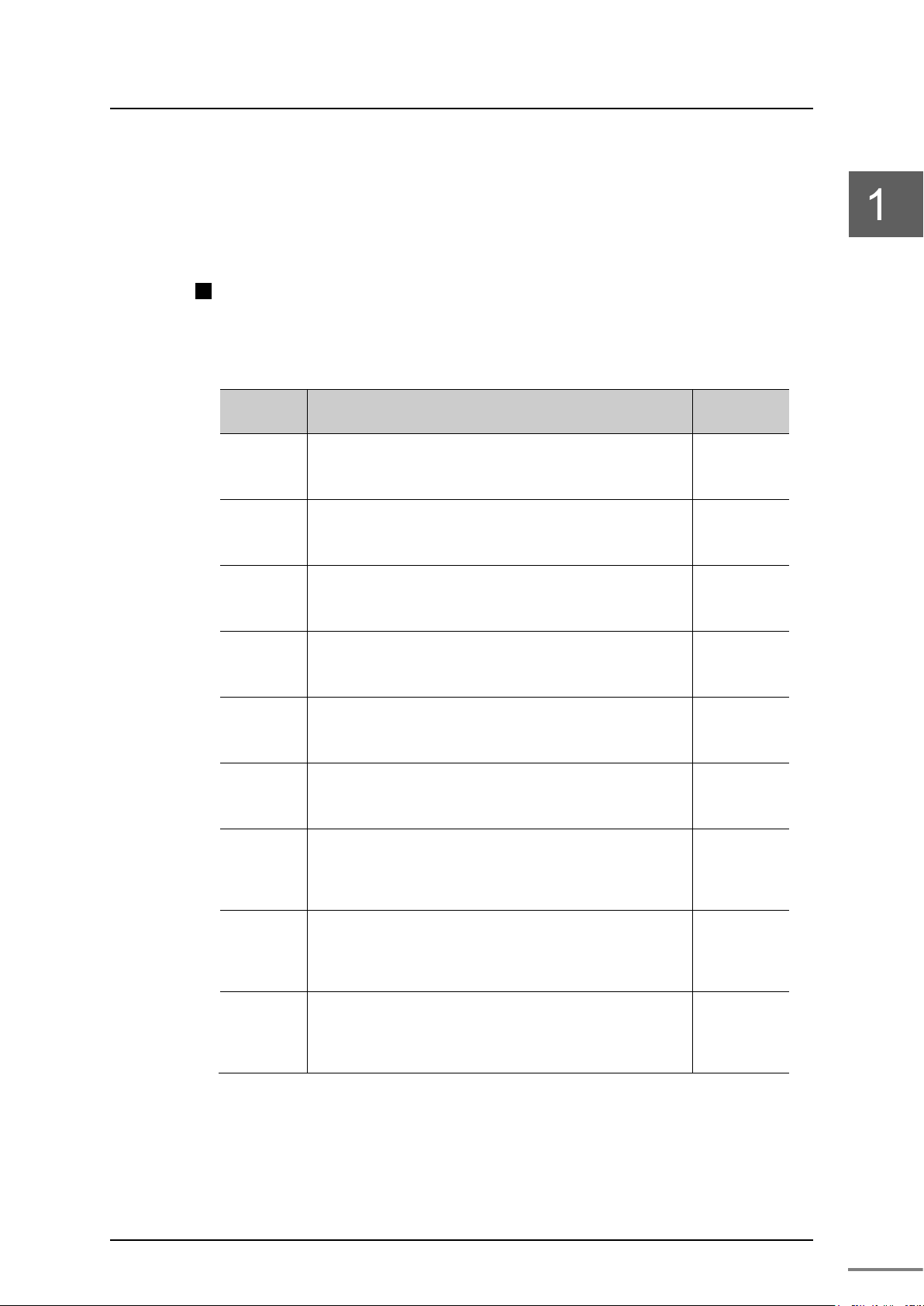

1.2.2 Functions of the parts

Normal

RUN

Displays the hardware operation state.

ON

ERR

Displays the hardware operation state.

OFF

SCAN

Displays the scan transmission state.

SCAN

L-A (green)

Displays the TC-net 100 A system state.

ON

L-B (green)

Displays the TC-net 100 B system state (TN822 only).

ON

LNK-A

Displays the TC-net 100 A system link state.

ON

ACT-A

Displays the TC-net 100 A system frame transmission

Blinking

LNK-B

Displays the TC-net 100 B system link state (TN822

ON

ACT-B

Displays the TC-net 100 B system frame transmission

Blinking

The major functions of the parts are as shown below.

State display LED

Table 1-1 Display details on the state display LED and normal display

1.2 Names and Functions of the Parts

Name Display

(green)

(red)

(green)

(green)

ON: Running

OFF: Down

ON: Down

OFF: Running

ON: SCAN transmission is in execution.

OFF: SCAN transmission is under suspension.

ON: TC-net 100 transmission is in execution.

OFF: TC-net 100 transmission is under suspension.

ON: TC-net 100 transmission is in execution.

OFF: TC-net 100 transmission is under suspension.

ON: Connected to the hub successfully.

OFF: Not connected to the hub.

(green)

state.

Blinking: TC-net 100 frame transmission is in execution.

OFF: TC-net 100 transmission is under suspension.

display

ON during

transmission

(green)

only).

ON: Connected to the hub successfully.

OFF: Not connected to the hub.

(green)

state (TN822 only).

Blinking: TC-net 100 frame transmission is in execution.

OFF: TC-net 100 transmission is under suspension.

(Note) 1.Check the LED states from the front.

2.Refer to “Table 5-1 Diagnosis using the LEDs.

”

Unified Controller nv series TC-net100 (TN8) Module Operation Manual

Chapter 1 Introducing the TN8 Module

6

Station address setting switch (STN-H, STN-L)

Switches to set the station address in hexadecimal. For setting method,

refer to "Chapter 3 Setting."

Operation mode setting switch (MODE)

Switches to set the operation mode. For setting method, refer to

"Chapter 3 Setting."

Serial communication port RS-232C (TOOL)

A RS-232C port for maintenance. The connector is a 9-pin D-sub

connector (socket).

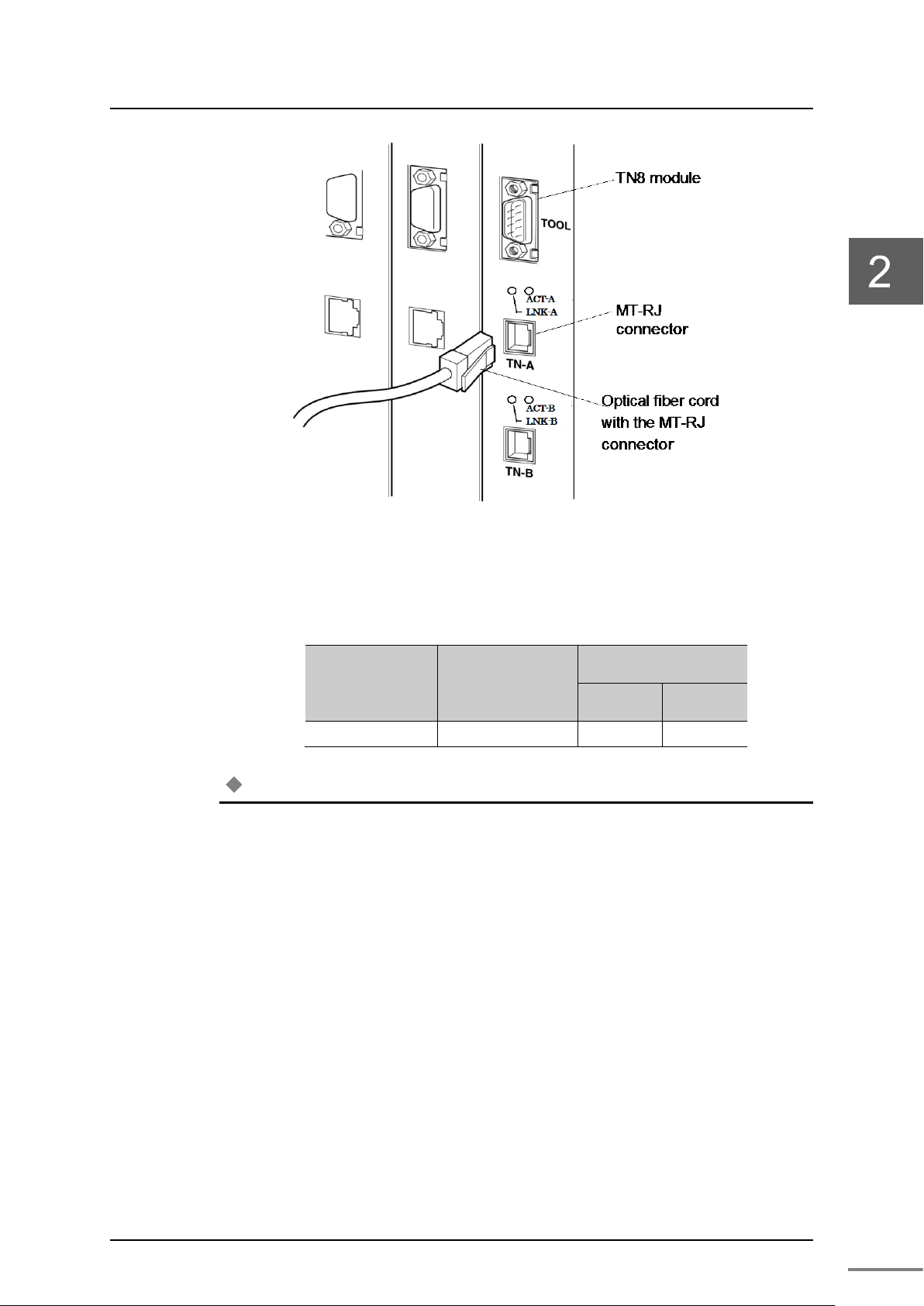

TC-net 100MT-R J connectors (TN-A and TN-B)

A communication port for the TC-net 100. The optical fiber cord with

the MT-RJ connector is connected to it.

6F8C1360

7

Chapter 2 Installation and Wiring

This chapter describes installation and wiring methods of the TN8 module.

Before installation and wiring, read this operation manual thoroughly.

2.1 Installation (Installation to the Basic Unit) ··············· 8

2.2 Connecting the TC-net 100 Cable ························· 10

2.3 Connecting the Serial Communication Port (RS-232C)

Cable ····························································· 12

2.4 Replacing the Module ······································· 13

Chapter 2 Installation and Wiring

8

Before installing or removing the module,

make sure that the basic unit to which th

module is installed is turned off.

Otherwise, it may cause an electric shock.

Do not touch the interior of the product except

the switches.

It may cause an electric shock.

Install it under an environm

the product specifications.

When installing it under an environment that does

not satisfy the product operating temperature range,

apply forced cooling with cooling equipment.

Operating temperature range: 0 to 55

C

Before installation or wiring, remove the static

electricity from your body.

The static electricity accumulated in the human body

may cause failure of the product.

Do not touch the cables carelessly.

Applying stress to the cabl

or accidents.

When installing the product to the basic unit,

do not bend the pins of the station bus

connector.

If it is difficult to insert the module to the basic

unit, remove it

forcing it.

CAUTION

Use a Phillips screwdriver.

To prevent damage to the screws, use a screwdriver

that is suitable for the screws.

CAUTION

Perform a notification check in the application

le

Mandatory

2.1 Installation (Installation to the Basic Unit)

WARNING

e TN8

Mandatory

WARNING

Prohibited

ent that satisfies

CAUTION

°

Prohibited

CAUTION

Prohibited

CAUTION

CAUTION

CAUTION

6F8C1360

es may cause malfunction

once and try again rather than

vel using the transmission protocol.

Prohibited

Prohibited

Prohibited

Prohibited

2.1 Installation (Installation to the Basic Unit)

9

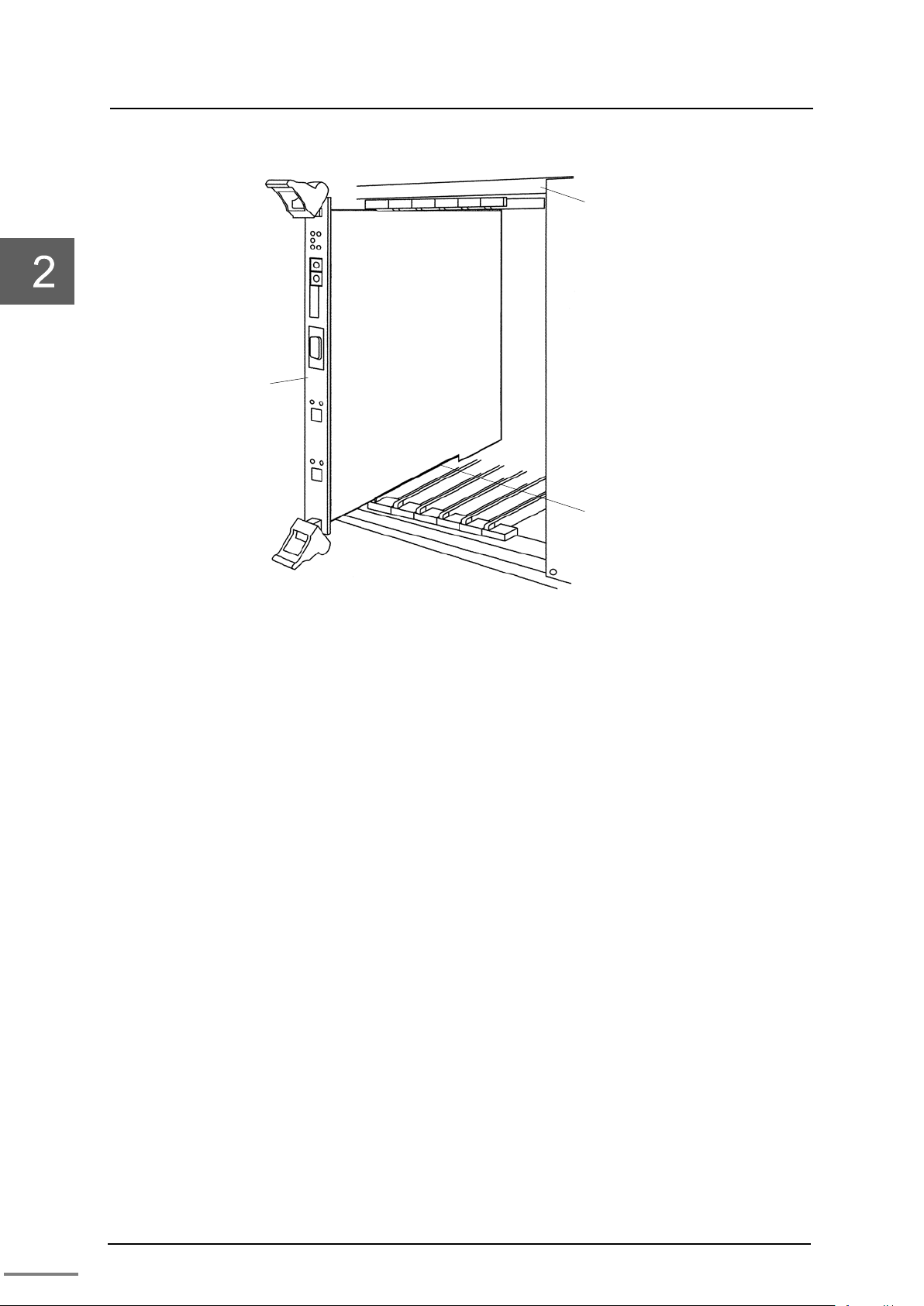

TN8 module

Basic unit

Module guide

of the basic unit

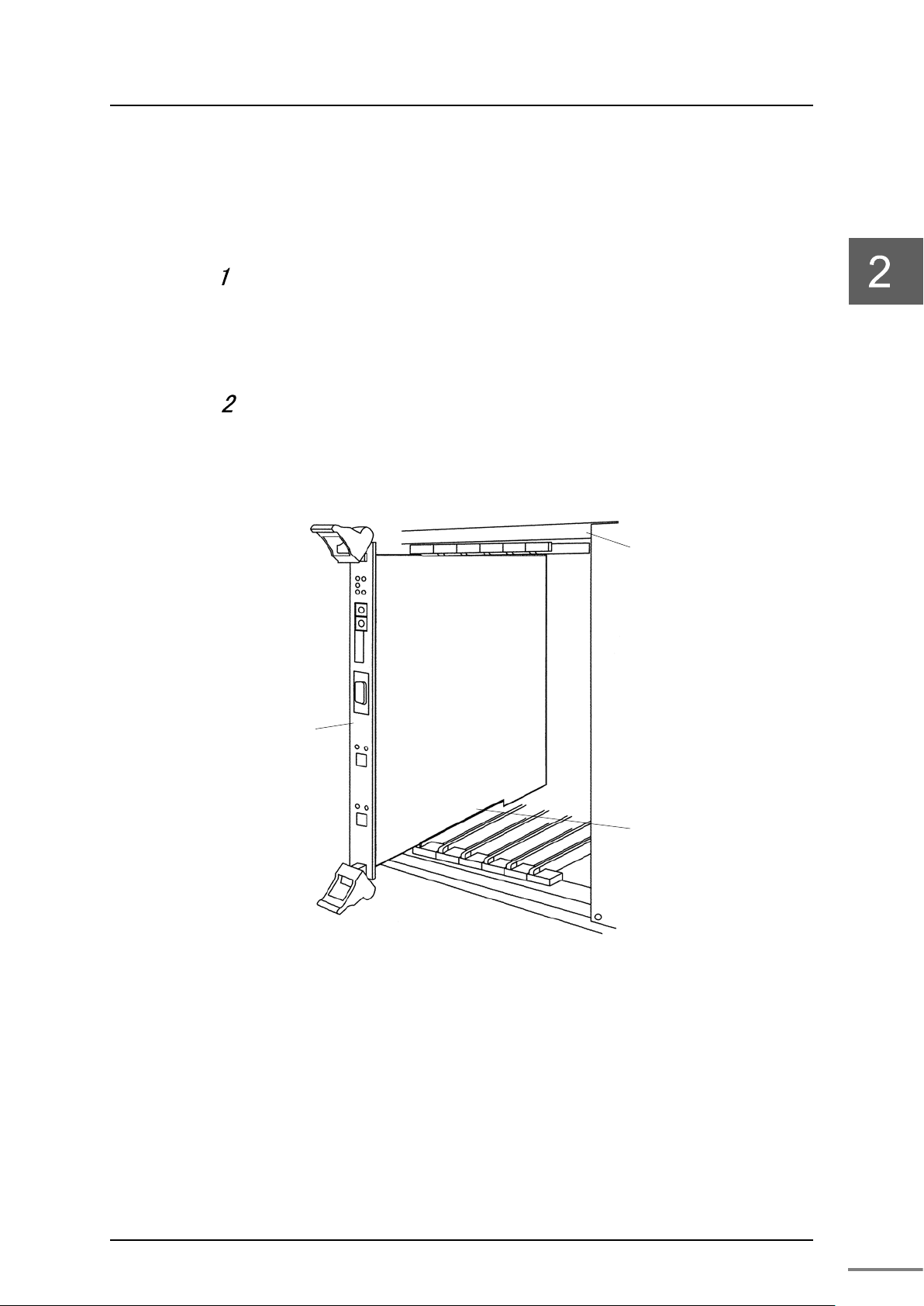

Install the module to the basic unit in the following steps.

As shown in Figure 2-1, insert the module while aligning the

module bottom along the module guide of the basic unit.

The TN8 module can be installed to the following slot numbers.

8-slot basic unit: Slot numbers 2 to 7.

Secure the module.

After installing it to the basic unit, secure it using the screws at the top and

bottom of the module.

Figure 2-1 Installing to the basic unit

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 2 Installation and Wiring

10

Before installation or wiring, remove the static

electricity from your body.

The static electricity accumulated

may cause failure of the product.

Do not touch the cables carelessly.

Applying stress to the cables may cause

malfunction or accidents.

Perform a notification check in the application

level

When an error occurs such as unable to turn on the

power, stop using and contact one of Toshiba's

service representatives.

If you have any question, consult with one of

Toshiba's service representatives.

2.2 Connecting the TC-net 100 Cable

Connect the TC-net 100 cable (optical fiber code) to the TN8 module.

CAUTION

Mandatory

in the human body

CAUTION

Prohibited

CAUTION

Connecting the optical fiber cord (TN821/TN821A, TN822/TN822A)

Connect the optical fiber cord to the MT-RJ type optical connectors

(TN-A and TN-B) as shown below.

using the transmission protocol.

Mandatory

Remove the dust cover of the optical connector.

Remove the dust cover of the optical connector. Pinch the dust cover with

your fingers until it clicks, and then remove it.

Connect the optical fiber cord.

Insert the optical fiber cord into the MT-RJ type connector, and press it in

until it clicks.

Secure the cable.

Secure the cable by clamping it so that no stress is exerted on the cable.

6F8C1360

2.2 Connecting the TC-net100 Cable

11

Allowable bent radius

When

Optical fiber code

5

50

50

Note

The allowable bent radius of the optical fiber cable depends on the product. Follow the

Figure 2-2 Connection of the optical fiber cord

Table 4-1 Allowable bent radius of the cable

fixed

(mm)

When laid

Cable name

Cable outer

diameter (mm)

•

manufacturer's specification of your optical fiber cable.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 2 Installation and Wiring

12

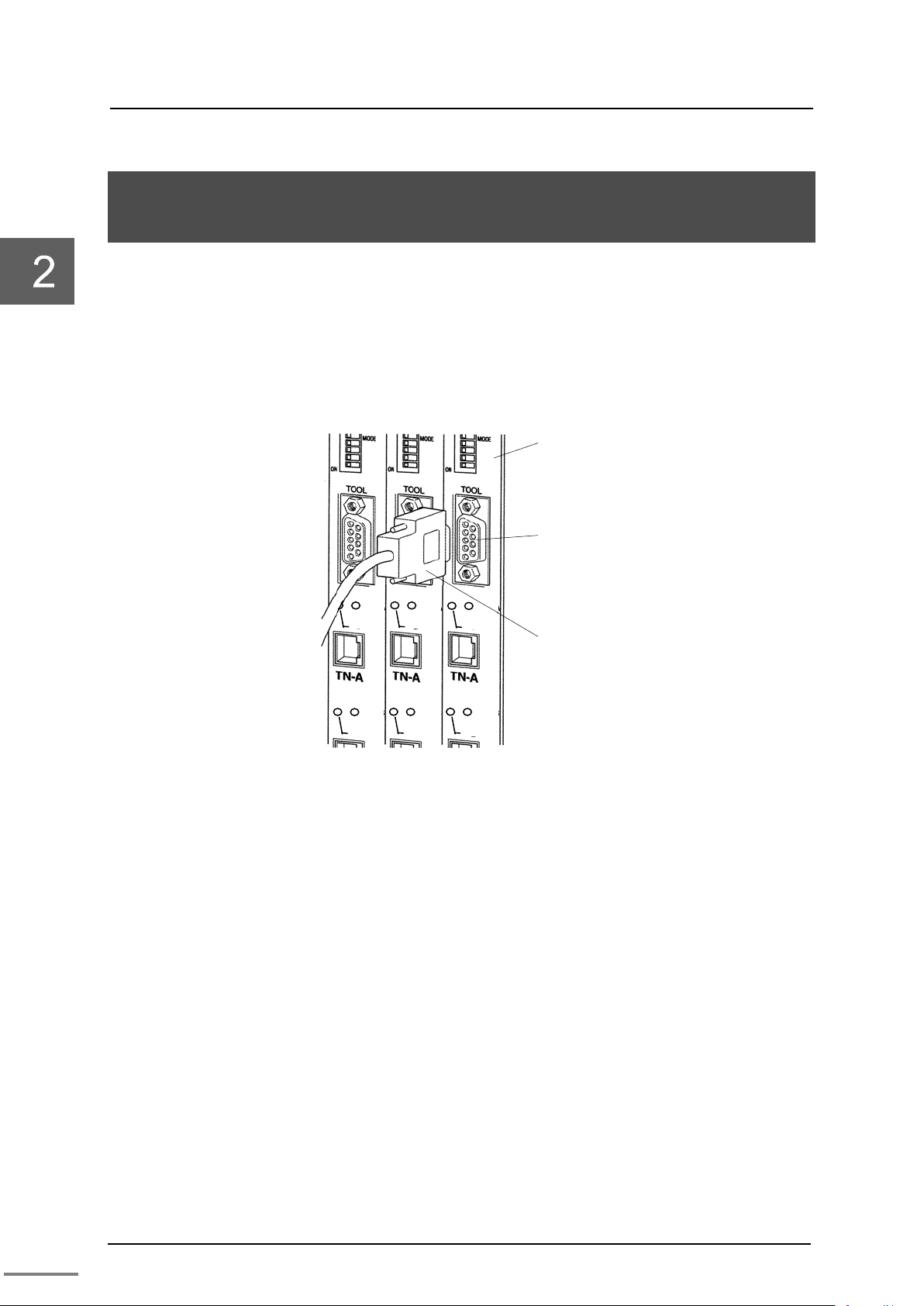

TN8 module

S

(TOOL)

RS-232C cable

ACT-B

LNK-B

ACT-B

LNK-B

ACT-B

LNK-B

ACT-A

LNK-A

ACT-A

LNK-A

ACT-A

LNK-A

2.3 Connecting the Serial Communication Port (RS-232C) Cable

For downloading programs or performing maintenance, the serial

communication port (TOOL) can be used to communicate with the tool.

RS-232C is used for communication.

The RS-232C cable connector is a 9-pin D-sub connector (socket).

erial communication port

Figure 2-3 Connecting the serial communication port

6F8C1360

13

Turn off the basic unit.

When replacing the module, turn off the basic unit

and make sure that the power is off. Otherwise,

failure of the module or electric shock may occur.

2.4 Replacing the Module

CAUTION

When changing the switch settings or in case of failure, replace the

module in the following steps.

Turn off the basic unit.

Make sure that it is off by using LED display.

Unlock the connector lock in the TC-net 100 cable side connected

2.4 Replacing the Module

Mandatory

to the module with your finger, and remove it.

Loosen the screws at the top and bottom of the module with a

Phillips screwdriver, and remove it along the module guide of the

basic unit.

Install the new module to the basic unit, and connect the cables.

Align the switch settings of the new module with that of the

removed unit.

Turn on the power. Use the engineering tool to download the

parameters.

When the download is complete, turn off the basic unit with the

TN8 module implemented again.

Make sure that the basic unit is turned off before wiring the cables.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 2 Installation and Wiring

14

TN8 module

Basic unit

Module guide

of the basic unit

Figure 2-4 Replacing the TN8 module

6F8C1360

15

Chapter 3 Setting

3.1 Switch Setting ············································· 16

3.1.1 Station address setting switch

(STN-H, STN-L) ···································· 16

3.1.2 Operation mode setting switch (MODE) ······ 17

3.2 Network Parameter Setting ····························· 18

3.2.1 Network ID and subnet mask ·················· 18

3.2.2 Station address ··································· 19

3.2.3 Overview of multicast address ·················· 19

3.3 Setting with the Engineering Tool ···················· 21

3.3.1 Network parameter setting ······················· 22

3.3.2 Setting the scan sending blocks ················ 32

3.3.3 Setting the state change notification ··········· 35

3.4 Network Information ····································· 38

3.4.1 Referring to LAN transmission map ··········· 38

3.4.2 Accessing the scan data ························· 39

3.4.3 Clearing the scan unhealthy state ·············· 39

3.4.4 Clearing the overlapping sending SA ·········· 39

3.4.5 LAN control information ·························· 40

3.4.6 Detailed explanation of LAN management

information ·········································· 41

3.4.7 MIB informat ion ···································· 42

3.4.8 Reception system switching ····················· 43

3.4.9 Viewing the in-ring map ·························· 44

3.5 Option Functions ·········································· 45

3.5.1 Setting the self healthy mode parameters ···· 45

3.6 Setting the RAS Information Block in Scan

Transmission ················································ 47

Chapter 3 Setting

16

•

Set the switches that determine the operation mode and station address of the TN8 module

Name

Description

Setting range : 01 to FE(h)

STN-H

STN-H(upper digit address): 0 to F(h)

STN-L

STN-L(lower digit address): 0 to F(h)

Remark

For setting, use a small slotted screwdriver.

Note

Be careful so that the address does not overlap with other nodes.

3.1 Switch Setting

The switches that determine the operation mode and station address are

on the front panel of the TN8 module.

The method to set the switches is shown below.

Important

before turning the power on.

3.1.1 Station address setting switch (STN-H, STN-L)

The station address setting switches are hexadecimal rotary switches that

determines the station address on the TC-net 100 network.

For setting of the IP address, refer to "3.2 Network parameter setting."

Set the station address (1 to 254) that has been assigned upon system

configuration in a HEX code. Assign an address with a different value to

each of the nodes in the system.

Tab l e 3 -1 shows the setting of a station address.

Table 3-1 Station address setting

(Note) (h) indicates hexadecimal.

•

Set the station address in hexadecimal.

For example, if the address value is 28, it is ‘1C’ (h) when converted to

hexadecimal. Therefore, set as follows:

STN-H side: ‘1’

STN-L side: ‘C’

For decimal-hexadecimal conversion, refer to "Appendix D

Decimal-hexadecimal conversion table."

•

6F8C1360

17

Initial setting

1

SM0

Operation

SM0

off

on

off

SM1

off

off

on

SM2

off

off

off

Operation

Normal

For maintenance

SM0: off

2

SM1

SM1: off

3

SM2

SM2: off

4

RV1

Reserved

Not used

off

5

RV2

Reserved

Not used

off

6

IPF

Reserved

Not used

off

7

IP0

IP address

IP0

off

off

on

on

IP1

off

on

off

on

Operatio

nv series 1

Reserve

nv series 2

Too l

IP0: off

8

IP1

Important

•

Never use the maintenance mode.

3.1.2 Operation mode setting switch (MODE)

The operation mode setting switches are 8-bit dip switches that determine

the operation of the TN8 module.

When the switch lever of each bit of the dip switch is turned to left (to the

ON side), it is set to ON; when it is turned to right, it is set to OFF.

Tab l e 3 -2 shows the descriptions of the switches.

Table 3-2 Operation mode setting table

3.1 Switch Setting

Switch

number

Name Function Setting

mode

type

n

172.16.64.x

x

d

Operation mode

172.31.64.xx

(factory

setting)

(normal

setting)

IP1: off

(nv series 1,

standard)

setting

Normally use the normal setting state.

IP address type

"nv series 1" is the standard.

"nv series 2" is used for expansion. Do not use it normally.

Tool setting is used to use network parameters set by the engineering

tool.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

18

3.2 Network Parameter Setting

The network parameters can be set with the operation mode setting

switches and station address setting switches.

For methods to set these switches, refer to "Table 3-1 Station address

setting" and "Table 3-2 Operation mode setting table."

For the TN8 module, the following network parameters must be set.

• IP address type

• Station address

Two IP address types are provided; nv series 1 and nv series 2. Also, it can

be set with the engineering tool.

3.2.1 Network ID and subnet mask

nv series 1 setting (Standard setting)

Use the operation mode setting switches to set the IP address type to "nv

series 1."

This is the standard setting of the unified controller system.

Network ID: 172.16.64.XX

(XX indicates the value of the station address setting switches)

Subnet mask : 255.255.192.0

nv series 2 setting

Use the operation mode setting switches to set the IP address type to "nv

series 2."

This setting is used for expansion of the TC-net 100, and not used

normally.

Network ID: 172.31.64.XX

(XX indicates the value of the station address setting switches)

Subnet mask : 255.255.192.0

Arbitrary setting

Use the operation mode setting switches to set the IP address type to

[Tool setting], and set IPF to [ON].

6F8C1360

19

When this setting is selected, it can be set freely from the engineering tool,

No.

Multicast address

1

225.224.0.1

2

225.224.0.2

3

225.224.0.3

4

225.224.0.4

5

225.224.0.5

6

225.224.0.6

7

225.224.0.7

8

225.224.0.8

9

225.224.0.9

10

225.224.0.10

11

225.224.0.11

12

225.224.0.12

and the value has precedence over the value of the station address setting

switches.

However, the following cannot be used in the IP address.

• Addresses starting with 127(7Fh)

• Addresses with all bits of the network address are "0" or "1"

• Addresses with all bits of the host address are "0" or "1"

The value of the subnet mask consists of a series of "1" from the most

significant bit.

3.2.2 Station address

Use the station address setting switches to set the station address.

Any station address can be set; however, it must be unique within the

system. The available setting range for station addresses is from 01(h) to

FE(h)(1 to 254).

3.2 Network Parameter Setting

When the IP address type is [Tool setting], it has precedence over the

value of the station address setting switches. In this case as well, it is

recommended matching the lowermost value of the specified IP address

(5 in the case of 172.16.64.5) and the value of the station address setting

switches. For [Tool setting], set the station address in the dotted decimal

notation using the engineering tool.

3.2.3 Overview of multicast address

The TN8 module supports 15 multicast addresses.

Support addresses are as follows:

Table3-3 Multicast address

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

20

13

225.224.0.13

14

225.224.0.14

15

225.224.0.15

Group A

Controller 1

Controller 2

Controller 4

Controller 5

Controller 6

Controller

3

PC

Group B

Any of the 15 addresses can be selected and registered by using one TN8

module.

Registration to the TN8 module is performed with the engineering tool.

For the registration method, refer to "3.3 Setting with the engineering

tool."

Figure 3-1 An example of multicast group configuration

In multicast, controllers can be grouped as shown in the example of Figure

3-1.

Controllers 1, 2, 4, and 5 belong to Group A, and Controllers 3, 5, and 6

belong to Group B.

In this example, multicast addresses are set as follows:

• Multicast addresses in Group A ……225.224.0.1

• Multicast addresses in Group B ……225.224.0.2

By doing this, the controllers can be grouped by registering them as

follows:

• Controllers 1, 2, 4……225.224.0.1

• Controllers 3, 6…………225.224.0.2

• Controllers 5……………225.224.0.1 and 225.224.0.2

The setting above allows messages to be passed to the controllers that

belong to the group simultaneously.

6F8C1360

21

•

The switch setting becomes effective from the next startup. Restart the controller after

Ethernet

T

N 8 P

N

8

Engineering

Tool(PC)

IP Address:

Subnet

IP Address:

Subnet

3.3 Setting with the Engineering Tool

Settings to the TN8 module can be done with the engineering tool.

For the operation method of the engineering tool, refer to "Unified

Controller nv series/Integrated Controller V series nV-Too l (Basic)

operation manual "(6F8C1290).

Connect the engineering tool and nv series controller via Ethernet.

The Ethernet connection in the nv controller can be made using the

built-in Ethernet of the CPU module or using the TN8 module. The figure

below illustrates how to engineer the configuration using the built-in

Ethernet of the CPU module (Figure 3-2 System configuration of the

setting example).

172.16.64.1

mask: 255.255.192.0

3.4 Network Information

172.16.64.28

mask: 255.255.192.0

Figure 3-2 System configuration of the example

Set the IP address shown in Figure 3-2 to the CPU module. Using the

rotary switch of the CPU module, set the lowermost digit of the IP address

in hexadecimal (in this case, convert "28" into hexadecimal and set

"1C(h)," i.e. H=1,L=C ).

Set the dip switches DSW-5 and DSW-6 of the CPU module to OFF and

OFF, respectively.

For more information on the dip switches of the CPU module, refer to

"Unified Controller nv series Type 1 Function Manual" (6F8C1221) or

"Unified Controller nv series Type 2 Function Manual" (6F8C1362).

Note

setting.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

22

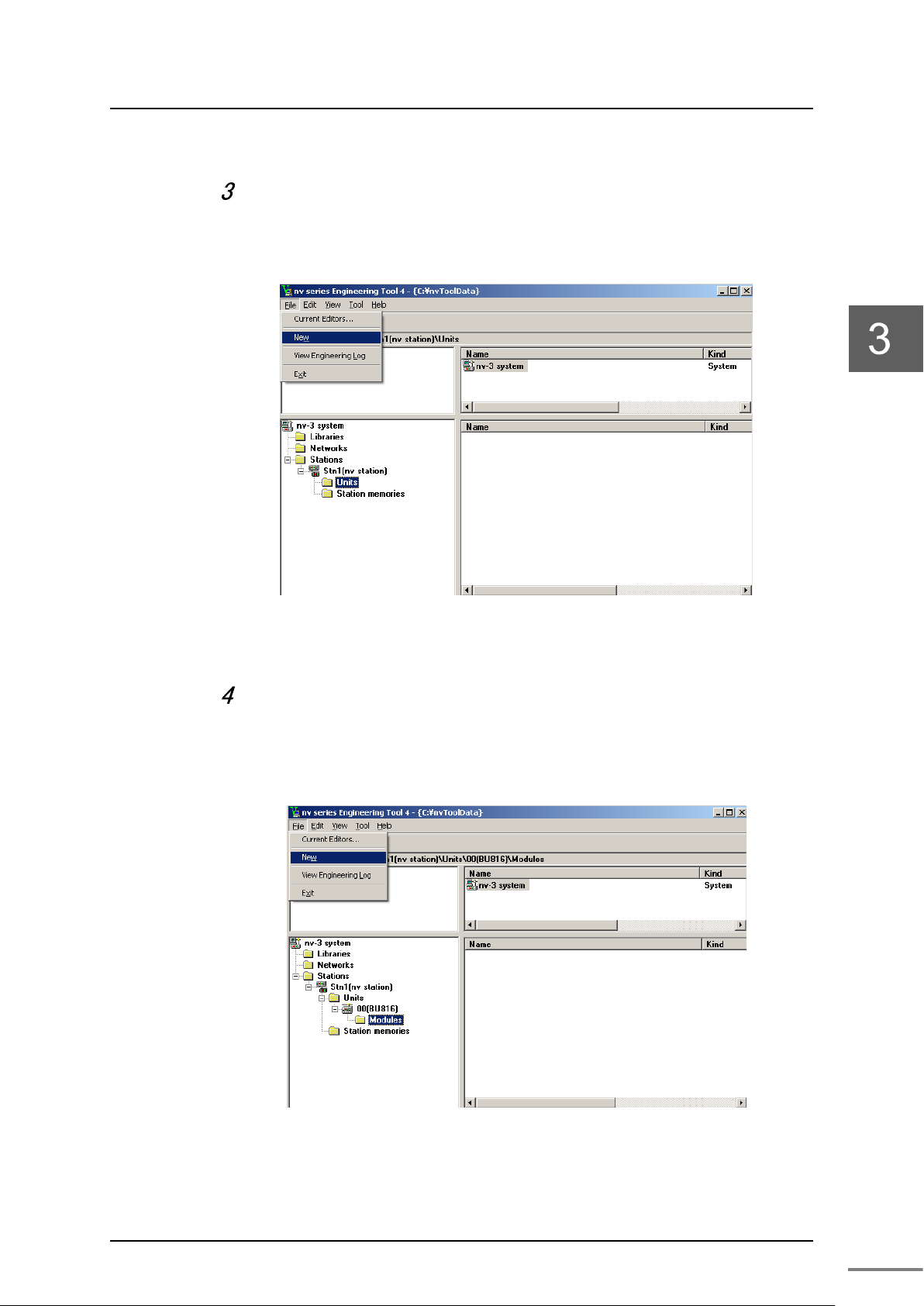

3.3.1 Network parameter setting

Set the network parameters of the TN8 in the following steps.

Select the TN8 module from the product tree.

Select [Station] under the created system, and select [New (W)] from [File

(F)] on the menu bar.

Figure 3-3 Station registration screen

Set the station name.

Select "nv station" from Station model name, and set the station name

("Stn1" is set in this example).

Figure 3-4 Station name setting screen

6F8C1360

3.4 Network Information

23

Add the unit to the station.

Select [Unit] under the created station, and select [New (W)] from [File

(F)] on the menu bar.

Figure 3-5 Unit registration screen

Add the module to the unit.

Select [Module] under the unit, and select [New (W)]. Select "TN8 module"

from the module addition dialog.

Figure 3-6 Module registration screen

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

24

Select the added TN8 module.

When [Module parameter] is selected from [File (F)] on the menu bar, the

module parameter screen is displayed.

Figure 3-7 An example of module registration

6F8C1360

3.4 Network Information

25

•

Be careful so that the address does not overlap with other nodes.

When the registration above is complete, check that the network

information of the corresponding TN8 module can be read from the

serial communication port (TOOL).

From the product tree, open the module parameter screen for the TN8

module previously registered.

Figure 3-8 Module parameter registration screen

Register the IP address type, IP address, and subnet mask.

Note

Individual settings are as follows.

· IP address type: Select from V series Standard 1, V series Standard 2,

and Arbitrary.

V series Standard 1 sets all of the operation mode setting switch Bit 7 to

8 of the TN8 module to OFF .

IP address: 172.16.64.xx ("xx" indicates the value of the station address

setting switch.)

Subnet mask: 255.255.192.0

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

26

V series Standard 2 sets the operation mode setting switch Bit 7 of the

TN8 module to ON and the operation mode setting switch Bit 8 to OFF .

IP address : 172.16.64.xx (xx indicates the value of the station address

setting switches)

Subnet mask : 255.255.192.0

The Arbitrary setting sets the operation mode setting switch Bit 7 of the

TN8 module to ON and the dip switch Bit 8 to ON.

In this case, the values set by the tool have precedence in operation over

the value of the station address setting switch.

• Multi-cast registration count: Set a value in the range of 0 to 4. "0"

indicates none is used.

• Multi-cast IP address: Set an address from the 15 addresses from

225.224.0.1 to 225.224.0.15.

To register multi-cast addresses, align them to

the top.

• Scan transmission: Select "Start" online and write to the TN8

module to start or stop scanning from the

engineering tool.

After selecting "Start," the parameter returns

to "Stop" when the TN8 restarts.

• Scan period High: Set a value in the range of 10 to 1600 (the

unit is 0.1ms). "50" indicates 5ms.

• Scan period Medium: Set a value in the range of 2 to 1000 (the unit

is 1ms). "50" indicates 50ms.

• Scan period Low: Set a value in the range of 2 to 10000 (the

unit is 1ms). "500" indicates 500ms.

• Stop scanning when all controllers are down: The default setting is "No."

By default, when a controller is down, the down controller stops the

transmission of only the scan block with the transmission right. The

remaining scan blocks are continued. If "Yes" is selected, when all the

controllers are down, the transmission of the scan blocks of all the

controllers with the transmission right is stopped.

• Reception system selection: Select from Auto Selection/A system

fixed/B system fixed.

• Maximum node distance: Set an integer value for the distance between

the farthest nodes. The default value is 8km.

Using the default value is recommended.

The value can be changed if system

adjustment is required. For example, if the

distance is 7.3km, set "8km."

6F8C1360

3.4 Network Information

27

•

If the controller is in a redundant configuration, the module parameters of the TN8 can be

• Maximum number of repeater stages:

Set a value for the path with the most

repeater stages. The default value is 3.

• Option switch: For the option switches, refer to "3.5 Option

functions."

For Scan period High, Scan period Medium, Scan period Low, Maximum

node distance, and Maximum number of repeater stages, set the same

values for the entire system.

Download the registered information to the TN8 module.

To download, display the parameter information, and click [Download (D)].

Figure 3-9 An example of module parameter registration

Note

downloaded independently by selecting [Primary (P)] and [Secondary (S)] from [Transmission

target].

Restart it.

The downloaded information becomes effective at the next startup.

After the download is complete, restart it.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

28

From the product tree, set the network.

Select the network under the system, and select [New (W)].

Figure 3-10 Network registration screen

Select [TC-net 1 00LAN] from the network addition dialog.

Select the module under the selected [TC-net 100LAN], and then select

[New (W)].

Figure 3-11 Network addition dialog

6F8C1360

3.4 Network Information

29

Figure 3-12 Network module registration screen

Connect to [TC-net 100LAN].

The TN8 module added previously is displayed on the module addition

dialog. Selecting it connects it to TC-net 100LAN.

Figure 3-13 Network module addition dialog

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

30

Figure 3-14 TC-net 100LAN connection scree n

Connect the engineering tool to the serial communication port

(TOOL) of the TN8 module to obtain the information of the current

TN8 module.

From [Options (O)] in [Hardware Configuration] of the configuration editor,

click [Transmission Parameter (T)] to set the transmission parameter. Use

the serial communication port to confirm it.

Register the following and click [OK].

Transmission method : RS-232C

Port : COM1 (specify the port to use. COM1 in this example)

Timeout time (s): 5

Ethernet timeout time (s): 4

Own station setting: Single

IP Address(172.16.64.1)

6F8C1360

3.4 Network Information

31

Figure 3-15 Transmission parameter setting screen

After the registration is complete, check that the information of the

TN8 module can be read.

Figure 3-16 An example of reading TN8 module information

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

32

3.3.2 Setting the scan sending blocks

Set the scan sending blocks from the product tree.

Select the scan memory of the TC-net 100LAN, and t hen select [Sendin g

Block].

Figure 3-17 Scan sending blocks reading screen

Register each of the blocks.

Register each of the blocks.

Figure 3-18 scan sending blocks setting screen

Block No.: Indicates the scan sending block number.

Word No.: Specify the starting word number used in the block.

Word length: Specify the number of words used in the block.

Transmission speed: Specify the transmission speed of the block in High,

Medium, or Low. The maximum number of items with

each of the transmission speeds are High: 64,

Medium: 128, and Low: 384.

6F8C1360

3.4 Network Information

33

Sending node: Specify the transmission module that sends the block.

Output controller: Specify the controller that uses the block.

Figure 3-19 An example of scan sending blocks registration

Check the setting of the scan sending blocks.

Open the parameter screen of the TN8 module, and select the [Sending

Block] tab.

The transmission speed and information about the slot in which the output

controller using the block are displayed for the registered scan sending

block.

Figure 3-20 Parameter screen of Sending blocks

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

34

Note

If the controller is in a redundant configuration, the module parameters of the TN8 can be

Download the registered data to the TN8.

After checking the data, download it to the TN8 module.

To download, display the parameter information, and select [File

(F)]->[Download (D)].

•

downloaded independently by selecting [Primary (P)] and [Secondary (S)] from [Transmission

target].

Restart it.

The downloaded information becomes effective at the next startup.

After the download is complete, restart it.

Check the registered data.

After the download, display the sending block parameter screen again, and

select [View] -> [Modules] to confirm that the information of TN8 module can

be read.

Figure 3-21 An example of reading TN8 sending blocks information

6F8C1360

35

N8 module

TN8

module.

3.3.3 Setting the state change notification

Set the parameters of state change notification.

Open the parameter screen of the TN8 module, and select the [State

Change Notification] tab.

3.4 Network Information

Figure 3-22 Parameter screen of state change notification

Up to 128 points can be set.

Register "Yes/No" for state change detection. The points with "Yes" are

covered.

In Scan Data Block No., 0 to 2047 blocks are covered.

In Scan Data Word No., 0 to 63 words if the block are covered. The words

are registered in units of 2 words (16 bits x 2), such as 0, 2, 4, …, 58, 60, and

62.

In Scan Data Bit Mask (8 digits in hexadecimal), register which bit in the

word is covered in hexadecimal. Set 0 to the bit to detect it, or 1 not to

detect it.

In Detection Timing, register how the bit changes in order to be detected.

In Notified Controller Slot No., register the slot number (0 to 7) of the

controller that makes a notification when a change occurs in the point.

Note

・Setting register “Yes” for status change detection, “Point No.” is downloaded to T

in the carry. “Point No.” outputted by GET_IFP_INF command becomes “Point No.” from

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

36

Note

If the controller is in a redundant configuration, download the module parameters of the TN8

Download the registered data to the TN8.

After checking the data, download it to the TN8 module.

To downloa d, display the parameter information, and select [File

(F)]->[Download (D)].

•

by selecting [Primary (P)] and [Secondary (S)] from [Transmission Destination].

Restart it.

The downloaded information becomes effective upon the next startup.

After the download is complete, restart it.

Check the registered data.

After the download, display the state change notification parameter screen

again, and select [View] -> [Tools and Modules] to confirm that the

information of TN8 module can be read.

Figure 3-23 An example of reading the state change notification information

According to an example of table 3-23, “point No.2” in [Tool] moves up to “point No.1”

in [Module], because “poi nt No.1” is registe red “No”.

Then, GET_IP_INF command outputs “point No.1”.

6F8C1360

Move up

37

Storage table

GET_IP_INF

information

TC-net

+

+

5

+

8

+9

Storage table in GET_IP_INF command.

Table 3-4 shows storage ta ble det ail .

Table 3-4 Storage table

Status change detection

[W]

Startup factor =1

0

+

State change occurs

1

+

Slot

2

+

Point No.

3

+

Status change

4

Bit history

3.4 Network Information

Remarks

Number of mod ule colum ns of [status chan ge

notification] tab in TN8 module or controller

module.

6

+

Status change

Data

7

+

IP task No.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

38

3.4 Network Information

3.4.1 Referring to LAN transmission m ap

Display LAN transmission map

In the system view, select the TN8 module, and select [LAN

transmission map (S)] from [Tool (T)] on the menu bar.

Figure 3-24 LAN transmission map selection screen

Display talker state and healthy state

Click “St a rt”

Displayed are the talker state and the healthy state of the current scan

blocks

Figure 3-25 Display screen of the scan talker state and healthy state

6F8C1360

39

3.4.2 Accessing the scan data

To access the scan data, double-click the desired block in the LAN

transmission map screen.

Figure3-26 Display screen of scan data

Select Block No. to access the data of the desired block.

Select Display Format to display the data in decimal or hexadecimal. To

write data to the specific word, double-click the data of the word. Enter

the data to write (make sure that the color changes to red), and select

[Write (W)]. The desired data can be written.

3.4 Network Information

To save the displayed data to a file, click [Save (S)] and specify the file

name.

3.4.3 Clearing the scan unhealthy state

The scan unhealthy map retains the state once the unhealthy state is

detected. Therefore, to confirm the state recovery, clear the scan

unhealthy state.

Click [Stop] on the monitor. Select [Clear Scan Unhealthy] to clear the

scan unhealthy state.

3.4.4 Clearing the overlapping sending S A

If the scan block is sent from multiple nodes redundantly, it is an

overlapping sending state. In the LAN transmission map screen, the

background color of the clock changes to red to indicate the occurrence of

the overlapping state. At the same time, two numbers are displayed in

the block, indicating the node number where the overlapping state exists.

To clear the overlapping state, reset the scan sending block, and

download it to the node with the overlapping state.

After clearing the overlapping state, check that the operation is normal.

The overlapping sending map retains the state once the overlapping

sending state is detected. Therefore, to confirm the state recovery, clear

the overlapping sending SA (station address).

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

40

Click [Stop] on the monitor. Select [Clear Overlapping Sending SA] to

clear the overlapping sending SA (station address).

6F8C1360

41

3.4.5 LAN control information

In the system view, select the TN8 module, and select [LAN management

information (N)] from [Tool (T)] on the menu bar.

3.4 Network Information

Figure 3-27 LAN management information selection screen

Displayed is the information on each node connected to TC-net 100LAN .

Figure 3-28 LAN management information screen

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

42

3.4.6 Detailed ex planation of LAN management inf ormation

When [Detailed explanation (D)] in the LAN management information

screen is clicked, each detailed counter is displayed.

Figure 3-29 Detailed explanation of LAN management information

6F8C1360

43

Remark

MIB: Management Information Base

3.4.7 MIB information

When [MIB information (M)] in the LAN management information screen

is clicked, the details of MIB information are displayed.

•

3.4 Network Information

Figure 3-30 MIB information screen

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

44

3.4.8 Reception system switching

Select Reception system of TC-net 100(Normally receive automatically).

When [Reception switching (X)] in the LAN management information

screen is clicked, the configuration dialog is displayed.

Figure 3-31 TC-net 100 reception switching screen

3.4.9 Viewing the in-ring map

The in-ring map displays the nodes that currently belong to the TC-net

100.

To display the in-ring map, click [In-ring Map (I)] in the LAN

management information screen.

The map is updated to the latest information when [Update (R)] is clicked.

Figure3-32 Display scre en of In-ring map

6F8C1360

45

Note

If the controller is in a redundant configuration, download the module parameters of the TN8

Talker area

When the transmission path

When the transmission path is abnormal

Talker area of

Host controller is normal:

Host controller is normal when

Tal ker area of

Other node is normal:

Always unhealthy

3.5 Option Functions

3.5.1 Setting the self healthy mode parameters

In the self healthy mode, the talker block of the node becomes scan

healthy even if an error occurs in the transmission path. In normal

operation of the TN8 module, all scan blocks become unhealthy if an error

occurs in the transmission path due to disconnection. If the TN8 module

is set to the self healthy mode, the scan healthy information of the talker

block of the node stays in the state when an error occurred in the

transmission path.

To set the TN8 module to the self healthy mode, do the following.

In the parameter screen of the TN8 module, set the option switch to

ON and perform a download.

3.5 Option Functions

•

by selecting [Primary (P)] and [Secondary (S)] from [Transmission Destination].

The following table shows the scan healthy information that is provided by

the TN8 module in the self healthy mode to the host controller.

Table 3-4 Scan healthy information in the self healthy mode

the module

other node

is normal

Healthy

Host controller is abnormal

Unhealthy

Healthy

Other node is abnormal:

Unhealthy

transmission path is abnormal:

Continuously healthy

:

Host controller is abnormal when

transmission path is abnormal:

Continuously unhealthy

(e.g. cable disconnection)

Figure 3-33 shows an example of the self healthy mode configuration.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

46

Remark

If an error occurs in the host controller after an error occurs in the transmission path, the

PC

JTNI

Cable

E N T N P U E N T N P

U

configuration

(1)

one

)

two

configuration

-unit

(2

-unit

Figure 3-33 An example of the self healthy mode configuration

•

scan block set for the host controller becomes unhealthy.

If the cable is disconnected in one-unit configuration or two-unit configuration, no RAS

•

information other than scan healthy cannot be provided.

6F8C1360

3.6 Setting the RAS Information Block in Scan Transmission

47

•

Do not write to this block from the application.

3.6 Setting the RAS Information Block in Scan Transmission

The RAS information generated by the TN8 module can be expanded in

scan transmission. To register the RAS information generated by the TN8

module in scan blocks for transmission, use the following registration

conditions. For the registration method, refer to "3.3.2 Setting the scan

sending blocks."

RAS information block setting conditions

• BlockNo: 2048 - Station address (the value of the station address

setting switch)

(Example: Block 2043 if the station address is 5)

• CntSlotNo: Slot number (0 to 7) where the TN8 module is installed

• Speed: Medium (M)

If the conditions above are met, the TN8 module generates RAS

information for the scan block for transmission.

The transmission of the RAS information block starts when a scan sending

start request is received from the host controller. After that, the

transmission of the RAS information block continues even if an error

occurs in the host controller.

The scan talker block must be set in the host controller making the scan

sending start request.

Important

Tab l e 3 -5 shows the information configuration of the RAS information

block.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 3 Setting

48

Word

Update

Install information of the

1

TN8 healthy counter

0.1s 2

Slot 0 healthy counter

0.1s 3

Slot 1 healthy counter

0.1s 4

Slot 2 healthy counter

0.1s 5

Slot 3 healthy counter

0.1s 6

Slot 4 healthy counter

0.1s 7

Slot 5 healthy counter

0.1s 8

Slot 6 healthy counter

0.1s 9

Slot 7 healthy counter

0.1s 10

Reserved - 11

Reserved - 12

Reserved - 13

Reserved - 14

Reserved - 15

Reserved - 16

Controller type

1s

Slot 0 controller

17

Controller subtype

1s 18

Phase/Mode

0.1s 19

Head alarm

0.1s 20

Reserved - 21

Reserved - 22

Controller type

1s

Slot1 controller

23

Controller subtype

1s 24

Phase/Mode

0.1s 25

Head alarm

0.1s 26

Reserved - 27

Reserved - 28

Controller type

1s

Slot2 controller

・

・

・

58

Controller type

1s

Slot7 controller

59

Controller subtype

1s

60

Phase/Mode

0.1s

61

Head alarm

0.1s

62

Reserved -

63

Reserved -

Table 3-5 Inf or m at i on configuration of R AS information block

F 8 7 0

No.

0 Module Type (0x23)

0 0 0 0

cycle

1

0 0

1 1s

target controller(*1)

Remark

・

・

(*1) Install information of the target controller corresponds to 1 - Install, 0 - non-install, 0 bit - 0 slot, 7bits - 7 slots.

6F8C1360

・

・

・

・

For Controller type, controller subtype, phase/mode, head alarm, refer to

the operation manuals of each controller.

49

Chapter 4 Operation

This chapter describes the operations of the TN8 module, such as checking

before operation, startup, and shutdown.

Chapter 4 O perat i on

50

Avoid incorrect setting.

The product does not operate normally if the

switches are set incorrectly. Read this operation

manual thoroughly to avoid incorrect setting.

Stop using immediately when an error occurs.

When an error occurs such as unable to turn on the

power, stop using and contact one of Toshiba's

service representatives.

Note

Checking the switch settings

The switches of the product have been adjusted for the system at the site

adjustment. For normal operation, do not change any switch other than

the ones the customer is required to operate.

CAUTION

CAUTION

Prohibited

Mandatory

Checking before operation

Before turning on the power and operating the product, check again that

the following are as described in this operation manual:

• Switch setting

• Installation

• Wiring

•

Use the engineering tool to check the switch settings (station address setting switch and

operation mode setting switch).

Startup op e r ati on

When the power supply module is turned on, the module starts running

automatically.

When the TN8 module is up and running, check that it is operating

correctly by referring to "Table 1-1 Display details on the state display LED

and normal display" on page 5.

If the module doesn't start up or if the operation is erroneous, stop using

the product immediately and contact one of Toshiba's service

representatives.

Shutdown operation

To s hut down, turn off the power of the power supply module.

6F8C1360

51

Chapter 5 Troubleshooting

This chapter describes troubleshooting for the TN8 module.

Chapter 5 Troubleshooting

52

State name

LED display

LINK-A

ACT-A

Normal

ON -

ON

ON

ON

Blinking

Normal

Switch

Blinking

ON

ON

ON

Blinking

Wrong setting of

Make the setting value

ON -

Blinking

ON

OFF

Wrong setting of

Make the setting value

TC-net 100

Blinking at the

ON

ON

ON

Blinking

TC-net 100

Make them match with

Talker block

Blinking

-

Overlap of talker

Correct the registration

Down

OFF

OFF - - - -

Module error

Contact one of Toshiba's

If the state display LED of the product displays anything different from the

normal display as described in "Table 1-1 Display details on the state

display LED and normal display" on page 5, or if any error is detected in

the human interface station, stop using it immediately and contact one of

Toshiba's service representatives.

To load the RAS data and system log, refer to engineering tool operation

manual.

Fault diagnosis method using the LEDs

Perform diagnosis by referring to the following table.

Table 5-1 Diagnosis using the LEDs

RUN SCAN L-A L-B

operation

setting error

parameter

mismatch

overlap

alternately

same time

-

Loading the RAS data and system log

To load the RAS data and system log, refer to "Unified Controller nv series

/ Integrated Controller V series nV-Tool (Basic) Operation Manual

(6F8C1290)."

alternately

- - -

LINK-B

ACT -B

State Remedy

station address

setting switch

station address

setting switch

parameters do not

match other node

currently in

transmission

blocks is detected

any value other than

(00h) or FF(h).

unique in the system.

the engineering tool.

of the overlapping block.

service representatives

to replace the module.

6F8C1360

When loading fails during serial communication

Load them again. Logs related to serial communication may be traced.

When an error occurs

Load the RAS data and system log before removing the module from the

basic unit.

53

Chapter 6 Maintenance and Inspection

This chapter describes maintenance and inspection such as daily inspection,

periodical inspection, and cleaning of TN 8 module.

6.1 Inspection ···················································· 54

6.1.1 Daily inspection ··································· 54

6.1.2 Periodical inspection ····························· 55

6.2 Life Limited Parts ·········································· 55

Chapter 6 Maint enance and Inspection

54

For safety, avoid touching the interior of the

product.

It may cause an electric shock.

When touching the product for cleaning,

remove the static electricity from your body.

The static electricity accumulat

may cause failure of the product.

When cleaning the product, do not change the

switch setting.

Do not exert any stress on the cables.

Exerting stress on the cables by touching them may

cause malfunction or acc

Stop using immediately when an error occurs.

When an error occurs such as unable to turn on the

power, stop using and contact one of Toshiba's

service representatives.

WARNING

CAUTION

CAUTION

CAUTION

ed in the human body

idents.

Mandatory

Mandatory

Prohibited

Mandatory

6.1 Inspection

6.1.1 Daily inspection

For daily inspection, check the following.

Front p an el

<LED>

Check if each of the LEDs is visible. If not, clean it with a soft cloth. Be

careful not to change the switch settings. Check the LED state from the

front side.

<TC-net 100 connector>

Check the following:

• Cable connection is normal.

• The modular connector is locked.

• Cable connection is not loose or has an abnormal appearance.

If any abnormality is found, contact one of Toshiba's service

representatives.

Ventilation hole

6FE8C1360

6.1 Inspection

55

Check the front panel and upper ventilation hole of the product for dust or

stain. If the ventilation hole is blocked by dust or stain, remove the dust

with a vacuum cleaner, and then wipe it with a soft cloth.

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

Chapter 6 Maint enance and Inspection

56

Part name

Recommended replacement cycle

Organic semiconductor aluminum

15 years

Electrical double layer capacitors

10 years

Optical module (TN821/TN822 only)

It is recommended measuring output power every

Switches, connectors

A sampling test every 10 years is recommended as

Indoor environment

Check if the temperature and humidity of the location where the product

is located are within the product specification range (Table A-1 in

Appendix A).

6.1.2 Periodical inspection

To prevent accidents and use the product safely for long-term operation,

it is recommended performing a periodical inspection every 6 months.

Also, it is recommended replacing life limited parts regularly (refer to "6.2

Life limited parts"). For a periodical inspection, consult with one of

Toshiba's service representatives.

6.2 Life Limited Parts

To u s e t h e product safely for a long time, replace the life limited parts

regularly. When replacing them, consult with one of Toshiba's service

representatives.

The following table shows the life limited parts and their replacement

cycles.

Table 6-1 Life limited parts and their recommended replacement cycles

solid electrolytic capacitors

10 years.

preventive maintenance.

6FE8C1360

6.2 Life Limited Parts

57

Unified Controller nv series TC-net 100 (TN8) Module Operation Manual

57

Chapter 7 Application Interface

This chapter describes information by socket, transmission path diagnosis

information, TN8 module state information, and usage constraints of the

application interface.

7.1 Information by Socket ·································· 59

7.1.1 Configuration of information by socket ········ 59

7.1.2 Referring to information by socket ············ 60

7.1.3 Timing of generation of information by socket ·· 61

7.2 Transmission Path Diagnosis Information ······· 63

7.2.1 Configuration of the scan data healthy map · 63

7.2.2 Configuration of the scan data unhealthy map · 64

7.2.3 Configuration of the scan data talker map ·· 65