1

TOSHIBA BiCD Integrated Circuit Silicon Monolithic

Weight:

HZIP25-P-1.00F: 7.7g (typ.)

HZIP25-P-1.00F

TB6600HG

PWM Chopper-Type bipolar

Stepping Motor Driver IC

The TB6600HG is a PWM chopper-type single-chip bipolar sinusoidal

micro-step stepping motor driver.

Forward and reverse rotation control is available with 2-phase,

1-2-phase, W1-2-phase, 2W1-2-phase, and 4W1-2-phase excitation

modes.

2-phase bipolar-type stepping motor can be driven by only clock signal

with low vibration and high efficiency.

Features

• Single-chip bipolar sinusoidal micro-step stepping motor driver

• Ron (upper + lower) = 0.4 Ω (typ.)

• Forward and reverse rotation control available

• Selectable phase drive (1/1, 1/2, 1/4, 1/8, and 1/16 step)

• Output withstand voltage: Vcc = 50 V

• Output current: I

I

• Packages: HZIP25-P-1.00F

• Built-in input pull-down resistance: 100 kΩ (typ.), (only TQ terminal: 70kΩ(typ.))

• Output monitor pins (ALERT): Maximum of I

• Output monitor pins (MO): Maximum of I

• Equipped with reset and enable pins

• Stand by function

• Single power supply

• Built-in thermal shutdown (TSD) circuit

• Built-in under voltage lock out (UVLO) circuit

• Built-in over-current detection (ISD) circuit

OUT

= 5.0 A (absolute maximum ratings, peak)

OUT

= 4.5 A (operating range, maximal value)

= 1 mA

ALERT

= 1 mA

MO

TB6600HG

TB6600HG

2014-01-30

2

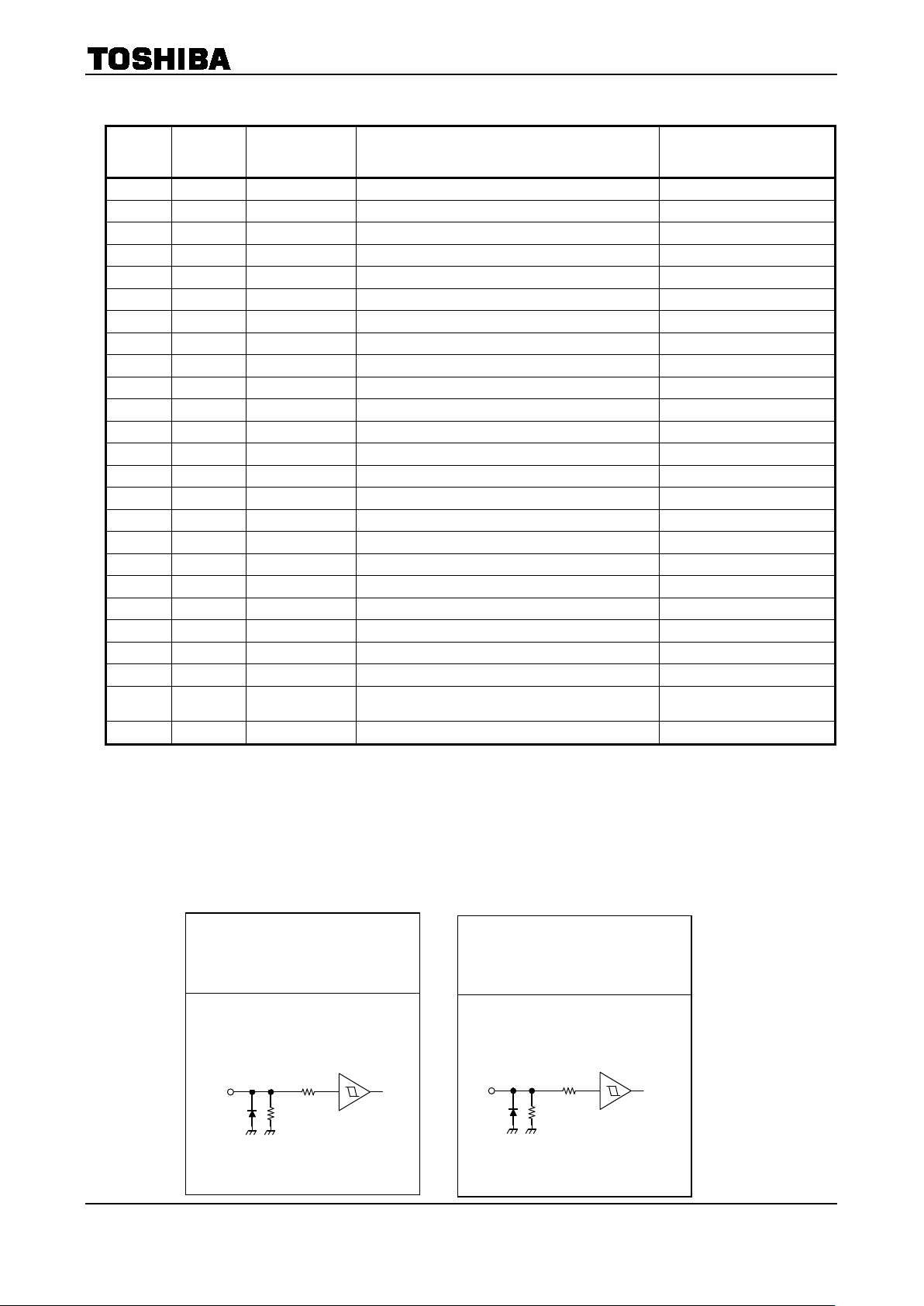

Pin Functions

Input pins

100k

VDD 10kΩ

7

TB6600HG

Pin No.

1 Output ALERT TSD / ISD monitor pin Pull-up by external resistance

2 ― SGND Signal ground

3 Input TQ Torque (output current) setting input pin

4 Input Latch/Auto Select a return type for TSD. L: Latch, H: Automatic return

5 Input Vref

6 Input Vcc Power supply

7 Input M1 Excitation mode setting input pin

8 Input M2 Excitation mode setting input pin

9 Input M3 Excitation mode setting input pin

10 Output OUT2B B channel output 2

11 ― NFB B channel output current detection pin

12 Output OUT1B

13 ― PGNDB

14 Output OUT2A

15 ― NFA A channel output current detection pin

16 Output OUT1A

17 ― PGNDA

18 Input ENABLE Enable signal input pin H: Enable, L: All outputs off

19 Input RESET Reset signal input pin L: Initial mode

20 Input Vcc Power supply

21 Input CLK CLK pulse input pin

22 Input CW/CCW Forward/reverse control pin L: CW, H:CCW

23 ― OSC Resistor connection pin for internal oscillation setting

24 Output Vreg Control side connection pin for power capacitor

25 Output MO Electrical angle monitor pin Pull-up by external resistance

I/O Symbol Functional Description Remark

Voltage input for 100% current level

B channel output 1

Power ground

A channel output 2

A channel output 1

Power ground

Connecting capacitor to

SGND

<Terminal circuits>

Input pins

(M1, M2, M3,CLK, CW/CCW,

ENABLE, RESET, Latch/Auto)

(TQ)

10kΩ

Ω

0kΩ

2014-01-30

3

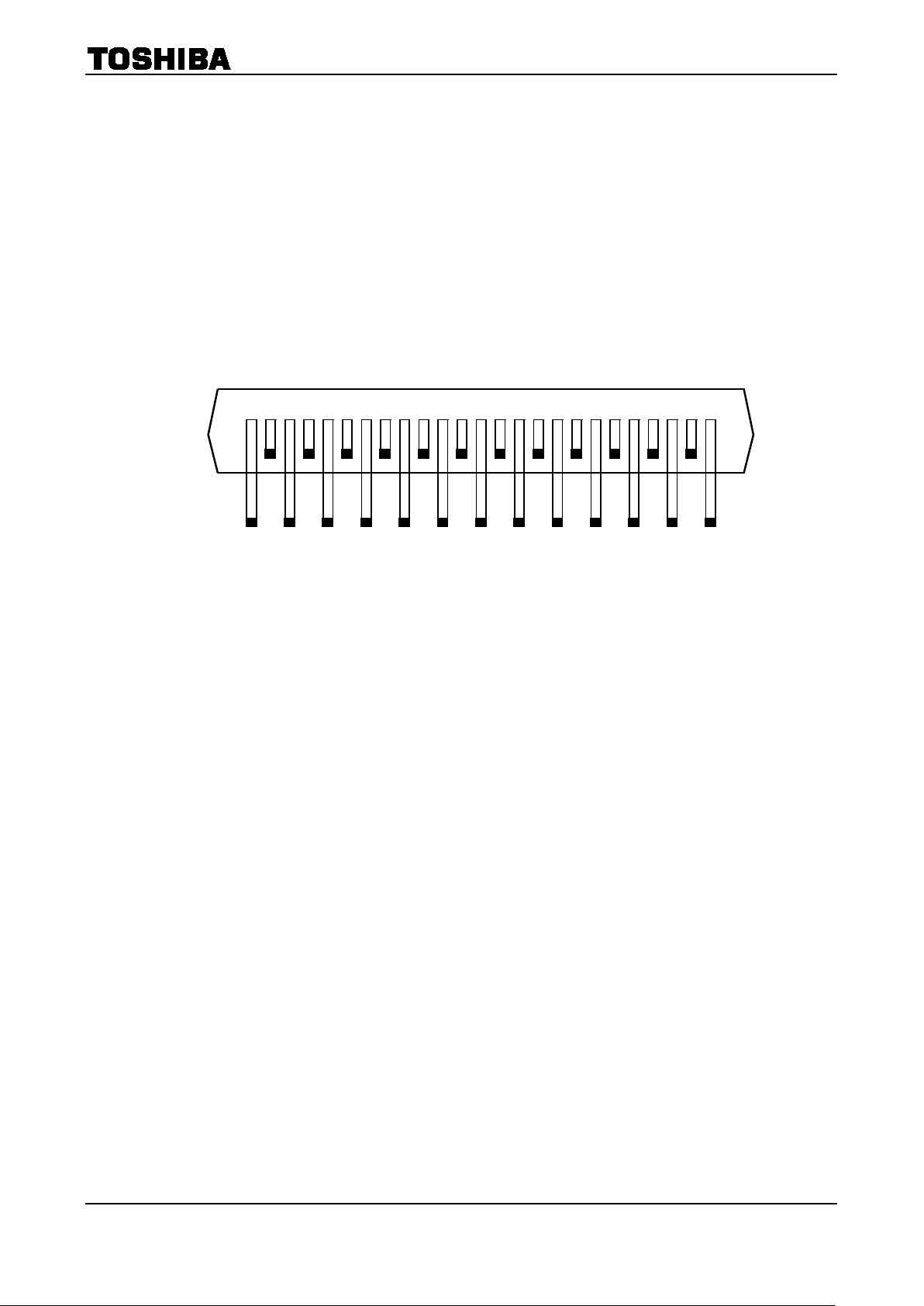

(

MO

M1

RESETTQALERT

Vref

PGNDA

CLK

OSC

N

FA

PGNDB

N

FB

M3

23251113151719

21

1618202224

13579

Vcc

CW/CCW

Vreg

2468101214

SGND

Latch/Auto

VccM2OUT2B

OUT1B

OUT2A

OUT1A

ENA BLE

Pin Assignment

Top View)

TB6600HG

2014-01-30

4

Block Diagram

M1

M2

CLK

M3

OSC

1/3

TSD / ISD / UVLO

MO

ALERT

OUT1A

OUT2A

NFA

OUT1B

OUT2B

NFB

Vref

SGND

PGNDB

Current selector

circuit A

3 4 12

15

14

16

6, 20

1

25

24 7 8 9 22

21

19

18

17

2

Current selector

circuit B

11

10

RESET

13

PGNDA

23

5

Latch/Auto TQ

Vcc

Vreg

100%/30%

ENABLE

CW/CCW

Sett ing of Vref

Reg(5V)

Input

circuit

OSC

Input

TQ

L 30%

H 100%

Voltage ratio

Pre

-drive

Pre

-drive

TB6600HG

H-Bridge

driver A

H-Bridge

driver B

2014-01-30

5

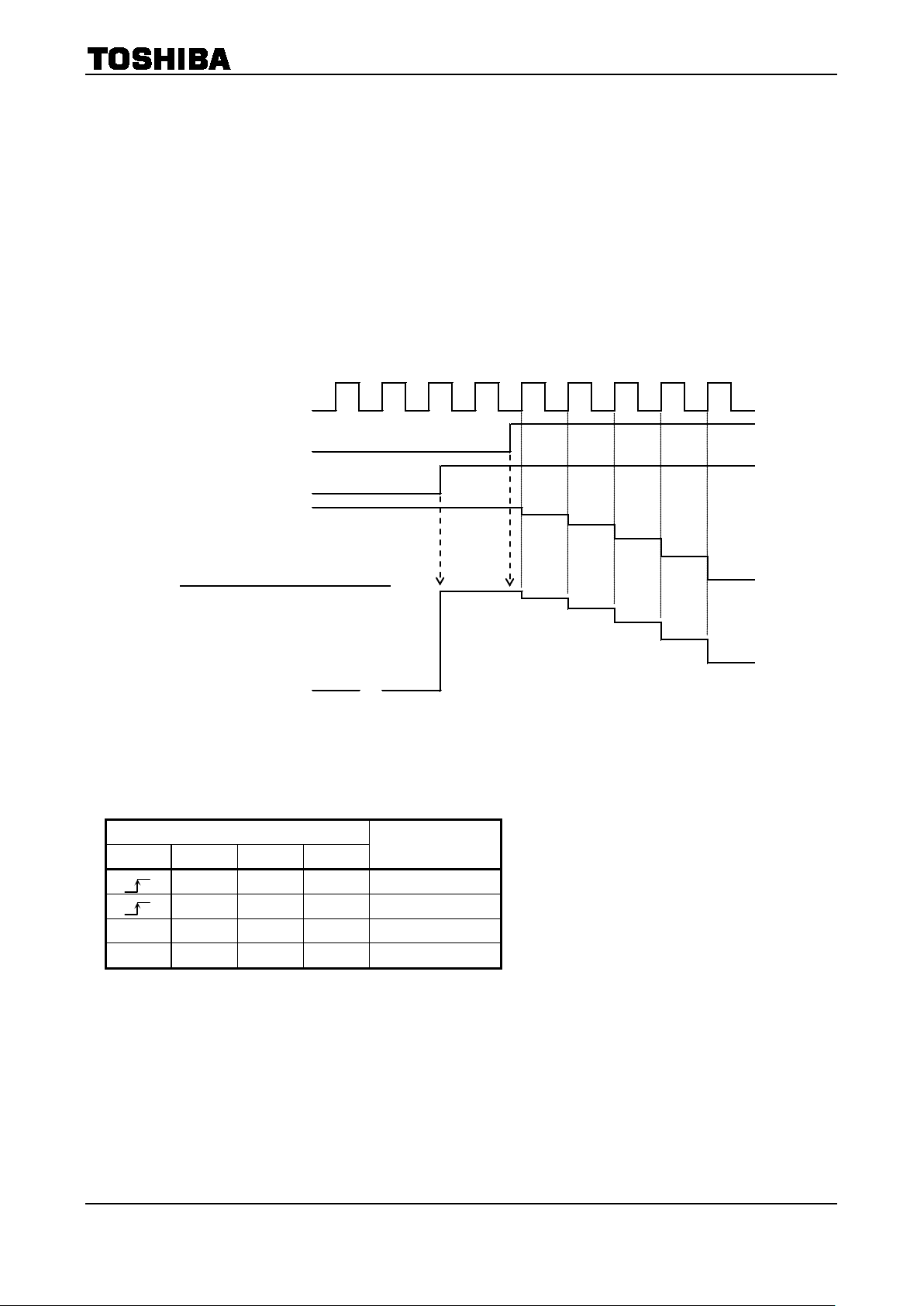

Description of Functions

1. Excitation Settings

The excitation mode can be selected from the following eight modes using the M1, M2 and M3 inputs. New

excitation mode starts from the initial mode when M1, M2, or M3 inputs are shifted during motor operation.

In this case, output current waveform may not continue.

TB6600HG

Input

M1 M2 M3

L L L

L L H 1/1 (2-phase excitation, full-step)

L H L

L H H

H L L 1/4 (W1-2 phase excitation)

H L H 1/8 (2W1-2 phase excitation)

H H L 1/16 (4W1-2 phase excitation)

H H H

Note: To change the exciting mode by changing M1, M2, and M3, make sure not to set M1 = M2 = M3 = L or M1 = M2 =

M3 = H.

(Operation of the internal circuit is almost turned off.)

1/2A type (1-2 phase excitation A type)

1/2B type (1-2 phase excitation B type)

(Operation of the internal circuit is almost turned off.)

Mode

(Excitation)

Standby mode

( 0%, 71%, 100% )

( 0%, 100% )

Standby mode

Standby mode

The operation mode moves to the standby mode under the condition M1 = M2 = M3 = L or M1 = M2 = M3

= H.

The power consumption is minimized by turning off all the operations except protecting operation.

In standby mode, output terminal MO is HZ.

Standby mode is released by changing the state of M1=M2=M3=L and M1=M2=M3=H to other state.

Input signal is not accepted for about 200 μs after releasing the standby mode.

2014-01-30

6

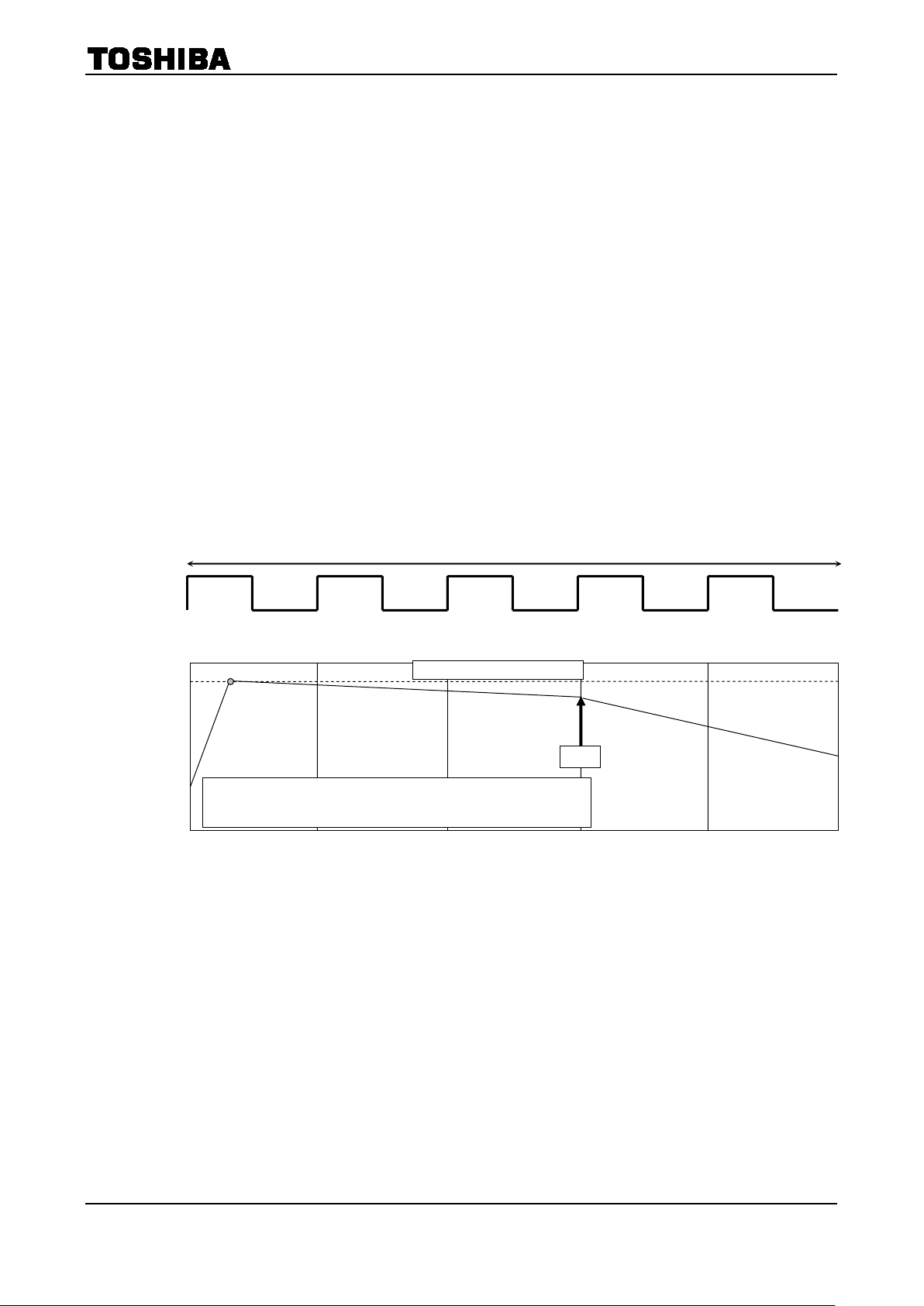

2. Function

(例1)

内部電流設定

Z

出力電流(A相)

CLK

RESET

ENABLE

(Example 1)

Internal current set

Output

(*)

(1)To turn on the output, configure the ENABLE pin high. To turn off the output, configure the ENABLE

pin low.

(2) The output changes to the Initial mode shown in the table below when the ENABLE signal goes High

level and the RESET signal goes Low level. (In this mode, the status of the CLK and CW/CCW pins are

irrelevant.)

(3) As shown in the below figure of Example 1, when the ENABLE signal goes Low level, it sets an OFF on

the output. In this mode, the output changes to the initial mode when the RESET signal goes Low level.

Under this condition, the initial mode is output by setting the ENABLE signal High level. And the motor

operates from the initial mode by setting the RESET signal High level.

CLK CW/CCW RESET ENABLE

L H H CW

H H H CCW

X X L H Initial mode

X X X L Z

(phase A )

(*: Output current starts rising at the timing of PWM frequency just after ENABLE pin outputs high.)

current

Input

TB6600HG

Command of the standby has a higher priority

Output mode

than ENABLE. Standby mode can be turned on

and off regardless of the state of ENABLE.

X: Don’t Care

2014-01-30

7

fchop(kHz)

Min

Typ.

Max

30 - 60 - 51 - 40 - 120 - 20

-

3. Initial Mode

When RESET is used, the phase currents are as follows.

Excitation Mode Phase A Current Phase B Current

1/1 (2-phase excitation, full-step) 100% -100%

1/2A type (1-2 phase excitation A type) (0%, 71%, 100%) 100% 0%

1/2B type (1-2 phase excitation B type) (0%, 100%) 100% 0%

1/4 (W1-2 phase excitation) 100% 0%

1/8 (2W1-2 phase excitation)

1/16 (4W1-2 phase excitation)

current direction is defined as follows.

OUT1A → OUT2A: For ward dir ec tion

OUT1B → OUT2B: Forward direction

100% 0%

100% 0%

4. 100% current settings (Current value)

100% current value is determined by Vref inputted from external part and the external resistance for

detecting output current. Vref is doubled 1/3 inside IC.

Io (100%) = (1/3 × Vref) ÷ R

The average current is lower than the calculated value because this IC has the method of peak current

detection.

Pleas use the IC under the conditions as follows;

NF

TB6600HG

0.11Ω ≤ R

≤ 0.5Ω, 0.3V ≤ Vref ≤ 1.95V

NF

5. OSC

Triangle wave is generated internally by CR oscillation by connecting external resistor to OSC terminal.

Rosc should be from 30kΩ to 120kΩ. The relation of Rosc and fchop is shown in below table and figure. The

values of fchop of the below table are design guarantee values. They are not tested for pre-shipment.

Rosc(kΩ)

2014-01-30

TB6600HG

8

OSC

Interna

Waveform

f

chop

NF

40

fast

Decay

Mode

Charge mode → NF: Predefined current level → Slow mode →

Predefined Current Level

6. Decay Mode

It takes approximately five OSCM cycles for charging-discharging a current in PWM mode. The 40% fast

decay mode is created by inducing decay during the last two cycles in Fast Decay mode.

The ratio 40% of the fast decay mode is always fixed.

The relation between the master clock frequency (fMCLK), the OSCM frequency (fOSCM) and the PWM

frequency (fchop) is shown as follows:

fOSCM = 1/20 ×fMCLK

fchop = 1/100 ×fMCLK

When Rosc=51kΩ, the master clock=4MHz, OSCM=200kHz, the frequency of PWM(fchop)=40kHz.

6-1. Current Waveform and Mixed Decay Mode settings

The period of PWM operation is equal to five periods of OSCM.

The ratio 40% of the fast decay mode is always fixed.

The “NF” refers to the point at which the output current reaches its predefined current level.

MDT means the point of MDT (MIXED DECAY TIMMING) in the below diagram.

M

l

%

MDT(Mixed decay timing) → Fast mode → Current monitoring →

(When predefined current level > Output current) Charge mode

MDT

2014-01-30

9

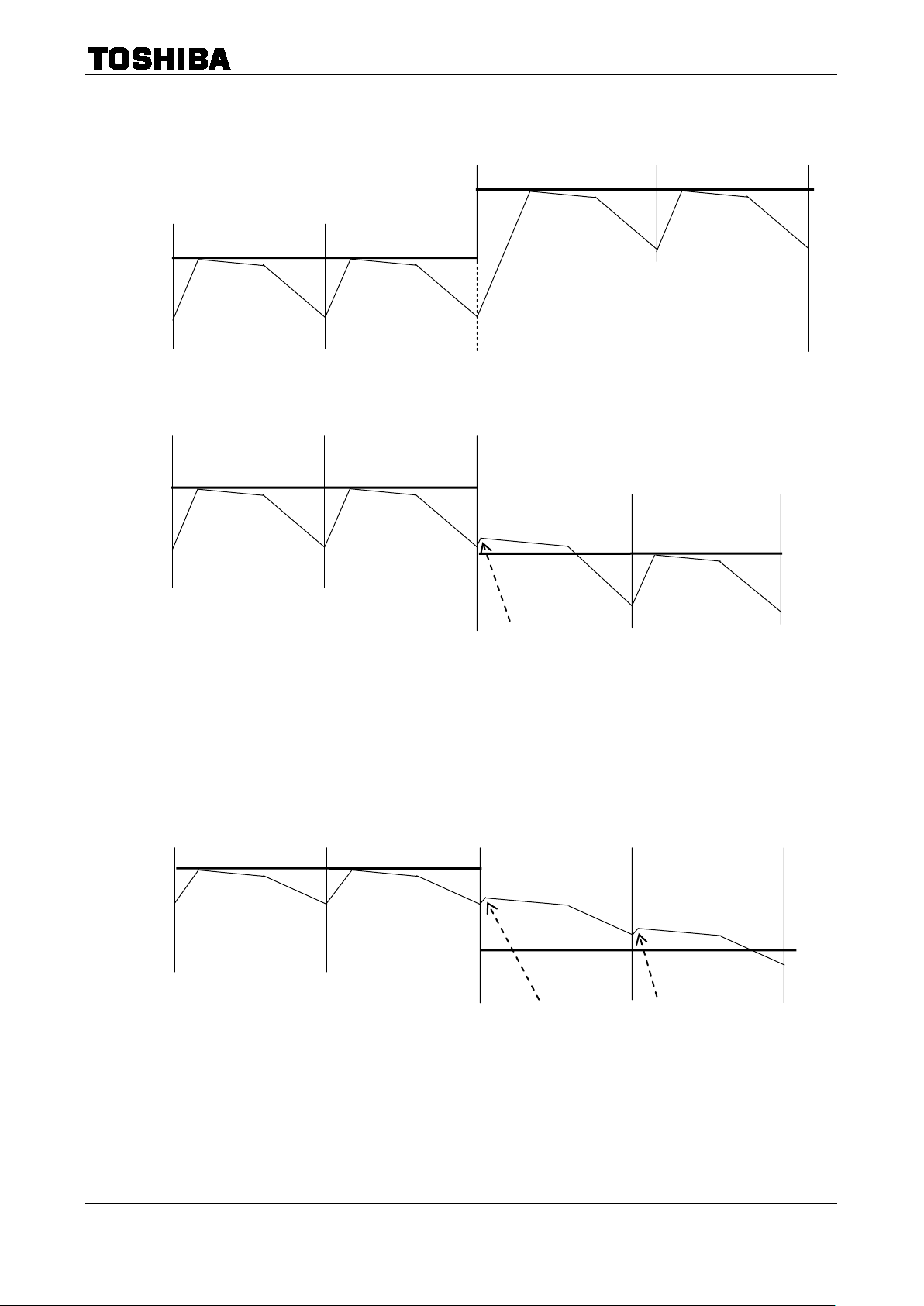

6-2. Effect of Decay Mode

Predefined

Curre

Slow

Slow

Fast

Predefined

Curre

Slow

Charge

Fast

Fast

Fast

Slow

Even if the output current rises above the predefined current at the RNF point, the

Slow

Slow

Charge

Slow

Fast

Slow

Fast

Charge

Predefined

Curre

Predefined

Curre

Fast

Charge

Fast

ned current at the RNF point, the

Slow

Slow

Slow

Slow

Fast

Fast

Charge

Charge

Fast

Charge

Fast

Charge

Predefined

Curre

Predefined

Curre

• Increasing the current (sine wave)

nt Level

TB6600HG

nt Level

• Decreasing the current (In case the current is decreased to the predefined value in a short time because

it decays quickly.)

nt Level

nt Level

Charge

Even if the output current rises abov e the predefi

current control mode is briefly switched to Charge mode for current sensing.

• Decreasing the current (In case it takes a long time to decrease the current to the predefined value

because the current decays slowly.)

nt Level

nt Level

Charge Charge

current control mode is briefly switched to Charge mode for current sensing.

During Mixed Decay and Fast Decay modes, if the predefined current level is less than the output current at

the RNF (current monitoring point), the Charge mode in the next chopping cycle will disappear (though the

current control mode is briefly switched to Charge mode in actual operations for current sensing) and the

current is controlled in Slow and Fast Decay modes (mode switching from Slow Decay mode to Fast Decay

mode at the MDT point).

Note: The above figures are rough illustration of the output current. In actual current waveforms, transient response

curves can be observed.

2014-01-30

10

NF

NF

OS

Internal

waveform

I

OUT

f

chop

f

chop

Predefined

Predefined Current Level

40

Fast

DECAY

MODE

MDT (MIXED DECAY TIMMING) points

NF

40

Fast

DECAY

MODE

I

OUT

f

chop

f

chop

Predefined

Current Level

CLK signal input

Switches to Fast mode after Charge mode

NF

MDT (MIXED DECAY TIMMING) points

NF

NF

I

OUT

f

chop

f

chop

Predefined

CLK signal input

f

chop

MDT (MIXED DECAY TIMMING) points

Predefined Current

Level

40

Fast

DECAY

MODE

t at the

switched to Charge

Predefined

Current Level

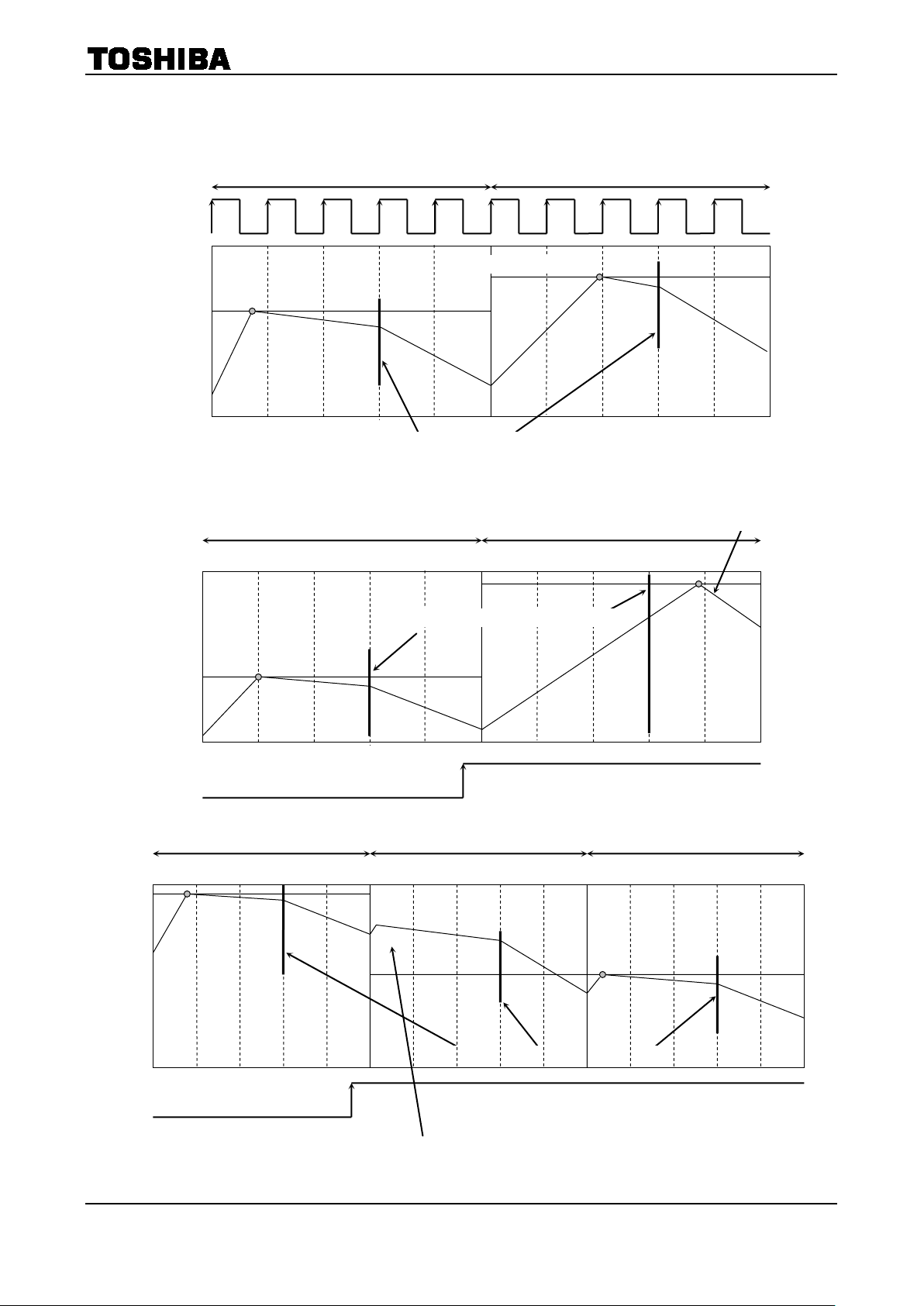

6-3. Current Waveforms in Mixed Decay Mode

CM

Current Level

%

• When the NF points come after Mixed Decay Timing points

%

• When the output current value > predefined current level in Mixed Decay mode

Current

Level

%

Even if the output current rises above the predefined curren

RNF point, the current control mode is briefly

mode for current sensing.

TB6600HG

2014-01-30

11

Output Stage Transistor Operation Mode

U1

L1

U2

L2

PGND

OFF

OFF

U1

L1

U2

L2

OFF

ON

Note

PGND

U1

L1

U2

L2

Note

PGND

Note

RNF

Vcc

ON

ON

Charge Mode

Slow Mode

Fast Mode

ON

RNF

Vcc

RNF

Vcc

OFF

OFF

OFF

ON

ON

TB6600HG

OUT1 OUT2

Load

Load

OUT1 OUT2

OUT1 OUT2

Load

Output Stage Transistor Operation Functions

CLK U1 U2 L1 L2

CHARGE ON OFF OFF ON

SLOW OFF OFF ON ON

FAST OFF ON ON OFF

Note: The above chart shows an example of when the current flows as i ndicated b y the arrows in t he above figures .

If the current flows in the opposite direction, refer to the follo wing char t:

CLK U1 U2 L1 L2

CHARGE OFF ON ON OFF

SLOW OFF OFF ON ON

FAST ON OFF OFF ON

Upon transitions of above-mentioned functions, a dead time of about 300 ns (Design guarantee value) is inserted

respectively.

2014-01-30

TB6600HG

12

・

1

90°C (typ.) (Note)

160°C (typ.) (Note)

Junction temperature (Chip temperature)

H

0.3ms or more when Rosc=51k

(*)Output current starts rising at the

timing of PWM frequency just after

ENABLE pin outputs high.

(*)

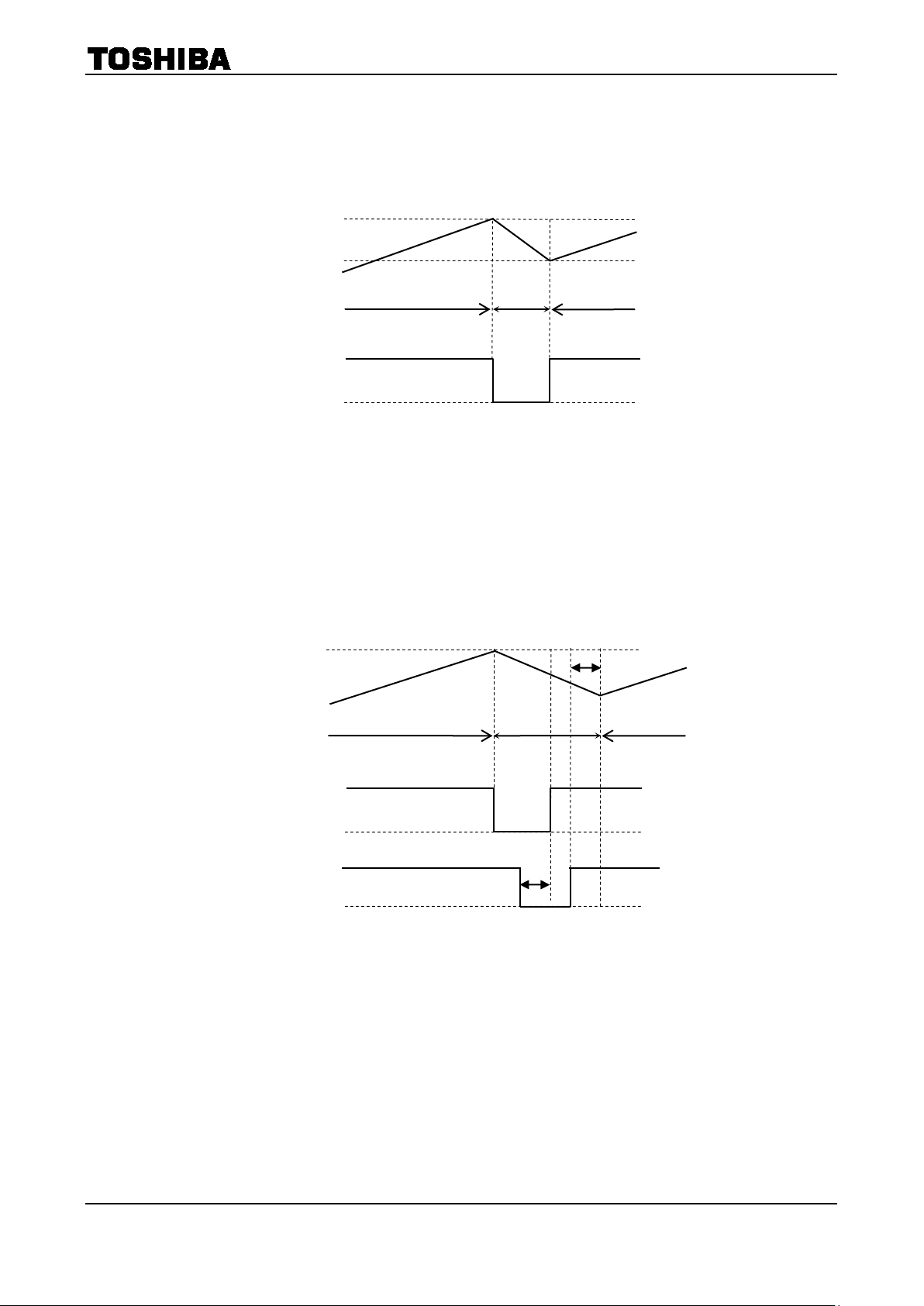

Thermal Shut-Down circuit (TSD)

(1) Automatic return

TSD = 160°C (typ.) (Note)

TSDhys = 70°C (typ.) (Note)

Junction temperature (Chip temperature)

Automatic return has a temperature hysteresis shown in the above figure.

In case of automatic return, the return timing is adjusted at charge start of fchop after the temperature falls to the

return temperature (90°C (typ.) in the above figure).

The return period after the temperature falls corresponds to one cycle to two cycles of fchop.

(2) Latch type

TSD = 160°C (typ.) (Note)

60°C (typ.) (Note)

Output state

ALERT output

Output state

ALERT output

Output on Output off Output on

H

L

Output on Output off Output on

L

ENABLE input

The operation returns by programming the ENABLE as H → L → H shown in above figure or turning on power

supply and turning on UVLO function. In this time, term of L level of ENABLE should be 0.3ms or more.

To recover the operation, the junction temperature (the chip temperature) should be 90°C or less when ENABLE

input is switched from L to H level. Otherwise, the operation does not recover.

State of internal IC when TSD circuit operates.

The states of the internal IC and outputs, while the shutdown circuit is operating, correspond to the state when

ENABLE is L.

The state after automatic return corresponds to the state when ENABLE is H. Please configure the Reset L to

rotate the motor from the initial state.

H

L

Ω

Note: Pre-shipment testing is not perf or med.

2014-01-30

TB6600HG

13

Latch/Auto is an input pin for determining the return method of TSD.

If Latch/Auto pin outputs low, TSD function returns by either of turning on power supply again or programming

the ENABLE as H → L → H.

If Latch/Auto pin outputs high, it returns automatically.

In standby mode, TSD function returns automatically regardless of the state of the Latch/Auto pin.

When power supply voltage Vcc is less than 8V, TSD function cannot operate regardless of the state of the

Latch/Auto pin.

2014-01-30

14

ISD (Over current detection)

・

DMOS

Power transistor current

6.5A (typ.)

Dead band

1

Output on Output off Output on

(*)Output current starts rising at the

timing of PWM frequency just after

EN

H

0.3ms or more when Rosc=51k

(*)

Current that flows through output power MOSFETs are monitored individually. If over-current is detected

in at least one of the eight output power MOSFETs, all output power MOSFETs are turned off then this

status is kept until ENABLE signal is input. In this time, term of L level of ENABLE should be 0.3ms or

more.

Masking term of 1μs or more (typ. when Rosc=51kΩ) (Note) should be provided in order to protect detection

error by noise. ISD does not work during the masking term.

Over c urrent detection value ISD=6.5 A (Note)

TB6600HG

ABLE pin outputs high.

Output state

ALERT output

μs or more(typ.)

L

ENABLE input

The operation returns by programming the ENABLE as H → L → H shown in above figure or turning

on power supply and turning on UVLO function.

State of internal IC when ISD circuit operates.

The states of the internal IC and outputs, while the over current detection circuit is operating, correspond to the

state when ENABLE is L.

The state after automatic return corresponds to the state when ENABLE is H. Please configure the Reset L to

rotate the motor from the initial state.

H

L

Note: Pre-shipment testing is not performed.

Ω

Return method of ISD

ISD function returns by either of turning on power supply again or programming the ENABLE as H → L → H

regardless of the state of the Latch/Auto pin.

In standby mode, ISD function cannot operate.

When power supply voltage Vcc is less than 8V, ISD function cannot operate.

2014-01-30

TB6600HG

15

・

Under Voltage Lock Out (UVLO) circuit

Outputs are shutoff by operating at 5.5 V (Typ.) of Vcc or less.

It has a hysteresis of 0.5 V (Typ.) and returns to output when Vcc reaches 6.0 V (Typ.). The following values are

design guarantee values.

State of internal IC when UVLO circuit operates.

The states of the internal IC and outputs correspond to the state in the ENABLE mode and the initial mode at

the same time.

After a return, it can start from the initial mode.

When Vcc falls to around 5.5 V and UVLO operates, output turns off.

It recovers automatically from the initial mode when both Vcc rise to around 6.0 V or more. The following

values are design guarantee values.

2014-01-30

TB6600HG

16

up resistance)

ALERT output

ALERT terminal outputs low in detecting either TSD or ISD.

ALERT terminal is connected to power supply externally via pull-up resistance.

V

Applied voltage to pull-up resistance is up to 5.5 V. And conducted current is up to 1 mA.

It is recommended to gain 5 V by connecting the external pull-up resistance to Vreg pin.

MO output

MO turns on at the predetermined state and output low.

MO terminal is connected to power supply externally via pull-up resistance.

V

Applied voltage to pull-up resistance is up to 5.5 V. And conducted current is up to 1 mA.

It is rec ommended to gain 5 V by connecting the external pull-up resistance to Vreg pin.

Voltage pull-up of MO and ALERT pins

・It is recommended to pull-up voltage to Vreg pin.

・In case of pull-up to except 5 V (for instance, 3.3 V etc.), it is recommended to use other power supply (ex. 3.3 V)

while Vcc output between the operation range. When Vcc decreases lower than the operation range and Vreg

decreases from 5 V to 0 V under the condition that other power supply is used to pull-up voltage, the current

continues to conduct from other power supply to the IC inside through the diode shown in the figure. Though this

phenomenon does not cause destruction and malfunction of the IC, please consider the set design not to continue

such a state for a long time.

・As for the pull-up resistance for MO and ALERT pins, please select large resistance enough for the conducting

current so as not to exceed the standard value of 1 mA.

Please use the resistance of 30 kΩ or more in case of applying 5 V, and 20 kΩ or more in case of applying 3.3 V.

= 0.5 V (max.) at 1 mA

ALERT

TSD ISD ALERT

Under TSD detection Under ISD detection

Normal Under ISD detection

Under TSD detection

Normal Normal Z

= 0.5 V (max.) at 1 mA

MO

State MO

Initial Low

Not initial Z

Normal

Low

(To pull-

(To Vreg in the IC)

2014-01-30

17

Sequence and current level in each excitation mode

CLK

100

(%)

0 −100

t0

t1

t2

t7

t8

t4

t5

t6

IA

100

(%)

0

−100

IB

MO

CLK

100

(%)

0

−100

t0

t1

t2

t3

t7

t8

t4

t5

t6

IA

100

(%)

0

−100

IB

MO

It operates from the initial state after the excitation mode is switched.

1/1-step Excitation Mo de (M1: L, M2: L, M3: H, CW Mo d e )

TB6600HG

t3

1/1-step Excitation Mo de (M1: L, M2: L, M3: H, CCW Mo d e)

2014-01-30

18

1/2-step Excitation Mode (A type) (M1: L, M2: H, M3: L, CW Mode)

CLK

100

(%)

0 −100

t0

t1

t2

t3

t7

t8

t4

t5

t6

71 −71

IA

100

(%)

0

−100

71

−71

IB

MO

CLK

100

(%)

0

−100

t0

t1

t2

t3

t7

t8

t4

t5

t6

71

−71

IA

100

(%)

0

−100

71

−71

IB

MO

It operates from the initial state after the excitation mode is switched.

TB6600HG

1/2-step Excitation Mode (A type) (M1: L, M2: H, M3: L, CCW Mode)

2014-01-30

19

1/2-step Excitation Mo de (B type) (M1: L, M2: H, M3: H, CW Mode)

CLK

100

(%)

0 −100

t0

t1

t2

t3

t7

t8

t4

t5

t6

IA

100

(%)

0

−100

IB

MO

CLK

100

(%)

0

−100

t0

t1

t2

t3

t7

t8

t4

t5

t6

IA

100

(%)

0

−100

71

−71

IB

MO

It operates from the initial state after the excitation mode is switched.

TB6600HG

1/2-step Excitation Mo de (B type) (M1: L, M2: H, M3: H, CCW Mode)

2014-01-30

20

1/4-step Excitation Mode (M1: H, M2: L, M3: L, CW Mode)

CLK

100

(%)

0

−100

t0

t1

t2

t3

t7

t8

t4

t5

t6

71

−71

IA

IB

t9

t10

t11

t15

t16

t12

t13

t

14

38 −38

92

92

100

(%)

0

100

71

71

38

−38

92

−92

MO

It operates from the initial state after the excitation mode is switched.

CLK

100

(%)

0

100

t0

t1

t2

t3

t7

t8

t4

t5

t6

71

71

IA

IB

t9

t10

t11

t15

t16

t12

t13

t

14

38

−38

92

−92

100

(%)

0

−100

71

−71

38

−38

92

−92

MO

−

TB6600HG

−

−

1/4-step Excitation Mode (M1: H, M 2: L, M3: L, CCW Mode)

−

−

2014-01-30

21

1/8-Step Excitation Mode (M1: H, M 2: L, M3: H, CW Mode)

IA

IB

It operates from the initial state after the excitation mode is switched.

MO

38

CLK

t0

t1

t2

t3

t7

t8

t4

t5

t12

t13

t6

100

(%)

98

92

83

71

56

38

20

0 −20

38

56 −71

−92 −98

−100

100

(%)

98

92

83

71

56

20

0

20 −38

56

71 −98 −100

t9

t10

t11

t14

t17

t18

t15

t16

t19

t20

t21

t22

t27

t28

t24

t25

t29

t30

t31

t32

t23

t26

−83

−83

−92

−

−

TB6600HG

−

−

−

2014-01-30

22

1/8-Step Excitation Mode (M1: H, M2: L, M3: H, CCW Mode)

It operates from the initial state after the excitation mode is switched.

MO

38

83

−92

−83

71

CLK

100

(%)

98

92

83

71

56

38

20

0

−20

38

−56 −92

−98

100

100

(%)

98

92

83

71

56

20 0 −20

−38

56

−71 −98

100

t0

t1

t2

t3

t7

t8

t4

t5

t12

t13

t6

t9

t10

t11

t14

t17

t18

t15

t16

t19

t20

t21

t22

t27

t28

t24

t25

t29

t30

t31

t32

t23

t26

IA

IB

−

−

TB6600HG

−

−

−

−

2014-01-30

TB6600HG

23

−100

−98 0 −96

−88

−92

−77

−71

−56

−63

−47

−38

−29

−20

−10

−83

10

20

29

38

47

56

63

71

77

83

88

92

96

98

100

[%]

CLK

IA

IB

It operates from the initial state after the excitation mode is switched.

MO

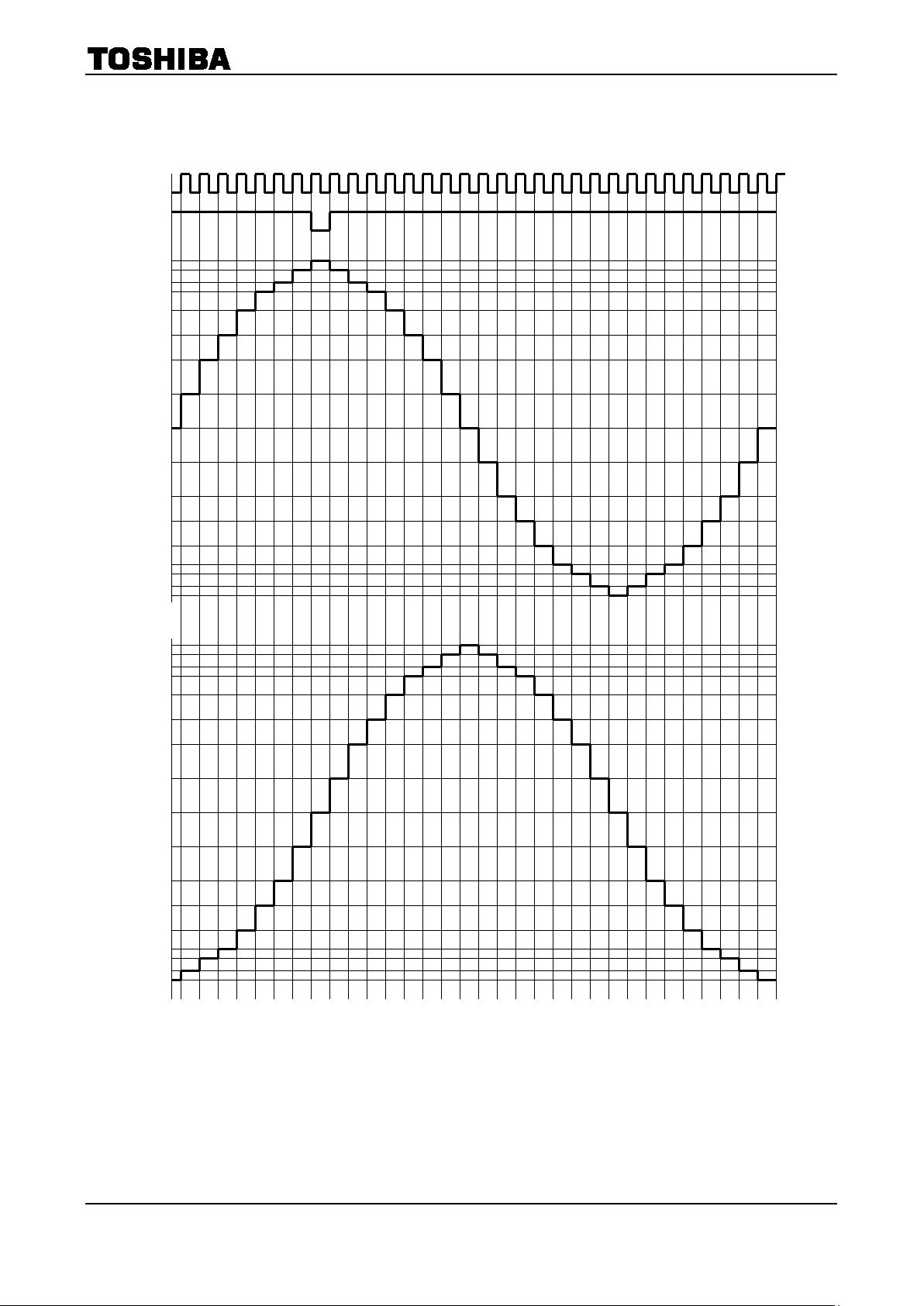

1/16-step Excitatio n M o de (M1: H, M2: H, M3: L, CW Mo d e)

t0・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・t64

2014-01-30

TB6600HG

24

−100

−98 0 −96

−88

−92

−77

−71

−56

−63

−47

−38

−29

−20

−10

−83

10

20

29

38

47

56

63

71

77

83

88

92

96

98

100

[%]

CLK

IA

IB

MO

It operates from the initial state after the excitation mode is switched.

1/16-step Excitatio n M o de (M1: H, M2: H, M3: L, CCW Mode)

t0・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・t64

2014-01-30

25

Current level

Current level (1/16, 1/8, 1/4, 1/2, 1/1 )

θ16 --- 100.0 ---

θ15 95.5 99.5 100.0

θ14 94.1 98.1 100.0

θ13 91.7 95.7 99.7

θ12 88.4 92.4 96.4

θ11 84.2 88.2 92.2

θ10 79.1 83.1 87.1

θ9 73.3 77.3 81.3

θ8 66.7 70.7 74.7

θ7 59.4 63.4 67.4

θ6 51.6 55.6 59.6

θ5 43.1 47.1 51.1

θ4 34.3 38.3 42.3

θ3 25.0 29.0 33.0

θ2 15.5 19.5 23.5

θ1 5.8 9.8 13.8

θ0 --- 0.0 ---

%

Max.

Unit

1/16,

1/8, 1/4,

1/2, 1/1

Min.

Typ.

2-phase, 1-2-phase, W1-2-phase, 2W1-2-phase, 4W1-2-phase excitation (unit: %)

TB6600HG

2014-01-30

26

Absolute Maximum Ratings (Ta = 25° C)

Characteristic Symbol Rating Unit

TB6600HG

Power supply voltage Vcc

I

Output current (per one phase)

Drain current (ALERT, MO)

O

(PEAK)

I

(ALERT)

I

(MO)

Input voltage V

IN

50 V

5.0 A

1 mA

6

V

3.2 (Note 1)

Power dissipation P

Operating temperature T

Storage temperature T

opr

stg

D

40 (Note 2)

-30 to 85 °C

-55 to 150 °C

W

Note 1: Ta = 25°C, No heatsink

Note 2: Ta = 25°C, with infinite heatsink.

The absolute maximum ratings of a semiconduct or device are a set of ratings that must not be exceeded, even for a

moment. Do not exceed any of these ratings.

Exceeding the rating (s) may cause the device breakd own, damage or deterioration, and ma y result injury by explosion

or combustion.

Please use the IC within the specifie d operating ranges.

Operating Range (Ta = −30~85°C)

Characteristic Symbol Test Condition Min Typ. Max Unit

Power supply voltage Vcc

Output current I

Input voltage

Clock frequency in logical part f

Chopping frequency f

OUT

V

V

ref

CLK

chop

IN

― 0.3 ― 1.95 V

See page 7.

― 8.0 ―

42

V

― ― ― 4.5 A

― 0 ― 5.5

V

― ― ― 200 kHz

20 40 60 kHz

Note: Two Vcc terminals should be programmed the same voltage.

The maximum current of the operating range can not be necessarily conducted depending on various

conditions because output current is limited by the power dissipation P

.

D

Make sure to avoid using the IC in the condition that would cause the temperature to exceed Tj (avg.)

=107°C.

The power supply voltage of 42 V and t he out put c urrent of 4. 5 A are the maximum values of operating range.

Please design the circuit with enough derat ing within t his r ange b y cons ide r ing the power supply variation, the

external resistance, and the electrical charact eristic s of the IC. I n case of exceeding the p ower suppl y voltage

of 42 V and the output current of 4.5 A, the IC will not operate normally.

2014-01-30

TB6600HG

27

step mode)

Electrical Characteristics (Ta = 25°C

, Vcc = 24 V)

Characteristic Symbol Test Condition Min Typ. Max Unit

Input voltage

High V

Low V

IN (H)

IN (L)

M1, M2, M3, CW/CCW, CLK,

RESET, ENABLE, Latch/Auto, TQ

2.0 ― 5.5

-0.2 ― 0.8

V

Input hysteresis voltage VH ― 400 ― mV

M1, M2, M3, CW/CCW, CLK,

― 50 75

μA

Input current

I

IN (H)

RESET, ENABLE, Latch/Auto

VIN = 5.0 V

TQ, VIN = 5.0 V ― 70 105

M1, M2, M3, CW/CCW, CLK,

I

IN (L)

RESET, ENABLE, Latch/Auto, TQ

V

= 0 V

IN

― ― 1

Output open,

Icc

RESET: H, ENABLE: H、

1

M1:L, M2:L, M3:H (1/1-

― 4.2 7

CLK:L

Vcc supply current

Icc

Output open,

RESET: L, ENABLE: L

2

M1:L, M2:L, M3:H (1/1-step mode)

mA

― 3.6 7

CLK:L

Icc

Current limit

Vref input

circuit

voltage

Input current I

Divider ratio V

Minimum CLK pulse width

Output residual voltage

V

NF

IN(Vref)

/V

ref

tw

CLKH

tw

CLKL

V

OL

VOL ALERT

Internal constant voltage Vreg

Chopping frequency f

chop

Standby mode (M1:L, M2:L, M3:L) ― 1.8 4

3

Vref = 3.0 V(Note 1), TQ=H 0.9 1.0 1.1 V

Vref = 3.0 V(Note 1)

Maximum current: 100%, TQ=H ― 3

NF

CLK 2.2 ― ― μs

MO

= 1 mA ― ― 0.5 V

I

OL

External capacitor = 0.1 μF

(in standby mode)

― ―

1 μA

― ―

4.5 5.0 5.5 V

Rosc=51kΩ 28 40 52 kHz

Note 1: Though Vref of the test condition for pre-shipment is 3.0V, make sure to configure Vref within the operating

range which is written in page 26 in driving the motor.

Electrical Characteristics (Ta = 25°C, Vcc = 24 V)

Characteristic Symbol Test Condition Min Typ. Max Unit

Output ON resistor Ron U + Ron

Output transistor switching characteristics

Output leakage

current

Upper side

Lower side I

t

t

ILH

LL

L

r

f

I

= 4 A ― 0.4 0.6 Ω

OUT

VNF = 0 V, Output: Open

Vcc = 50 V

― 50 ―

― 500 ―

― ― 5

― ― 5

2014-01-30

ns

μA

28

Timing Waveforms and Names

CLK

Vcc

GND

tr

tf

10%

90%

90%

10%

CLKH

tw

CLKH

tw

CLKL

OUT1B, OUT2B

tw

Figure 1 Timing Waveforms and Nam es

OUT1A, OUT2A,

TB6600HG

Figure 2 Timing Waveforms and Names

2014-01-30

29

Power Dissipation

②

TB6600HG

TB6600HG

PD – Ta

80

60

(W)

D

①

40

20

Power dissipation P

③

0

25 0

① Infinite heatsink

Rθj-c = 1°C/W

② HEATSINK (RθHS = 3.5°C/W)

Rθj-c + RθHS = 4.5°C/W

③ IC only

Rθj-a = 39°C/W

75

50

Ambient temperature Ta ( °C)

100

125

150

2014-01-30

TB6600HG

30

(例2)

Z

出力電流(A相)

CLK

RESET

ENABLE

内部電流設定

(例1)

内部電流設定

Z

出力電流(A相)

CLK

RESET

ENABLE

(Example 1)

Internal current set

Output current

(Example

Internal current set

Output current

(*:Output current starts rising at the timing of PWM frequency just after ENABLE pin outputs high.)

(*)

(*)

1. How to Turn on the Power

In applying Vcc or shutdown, ENABLE should be Low.

See Example 1(ENABLE = High → RESET = High) and Example 2(RESET = High → ENABLE = High)

as follows. In example 1, a motor can start driving from the initial mode.

(1) CLK: Current step proceeds to the ne xt m ode with respect to every rising edge of CLK.

(2) ENABLE: It is in Hi-Z state in low level. It is output in high level.

RESET: It is in the initial mode (Phase A=100% and Phase B=0%) in l ow level.

①ENABLE=Low and RESET=Low: Hi-Z. Internal current setting is in initial mode.

②ENABLE=Low and RESET=High: Hi-Z. Internal current setting proceeds by internal counter.

③ENABLE=High and RESET=Low: O utput in the initial mode (Phase A=100% and Phase B=0%).

④ENABLE=High and RESET=High: O utput at the value which is determined by the internal counter.

<Recommended control input sequence>

(Phase A)

2)

(Phase A)

2014-01-30

31

Application Circuit

24V

M1

M2

CW/CCW

CLK

ENABLE

M3

OSC

TSD/ISD/UVLO

MO

ALERT

Vcc

OUT1A

OUT2A

NFA

OUT1B

OUT2B

NFB

Vref

Current selector

circuit A

Current selector

circuit B

MCU

0.2

0.2

24V

RESET

PGNDA

PGNDB

Latch/Auto

Vreg

51kΩ

TQ

100%/

30%

0.1μF 47μF

fuse

0.1μF

Control

logic

1/3

OSC

Reg (5V)

SGND

Pre

-drive

Pre

-drive

TB6600HG

H-Bridge

driver A

Ω

H-Bridge

driver B

Ω

Note 1: Capacitors for the power supply lines should be connected as close to the IC as possible.

Note 2: C ur rent detecting resistances (R

NFA and RNFB) should be connected as close to the IC as possible.

Note 3: Pa y at tention for wire layout of PCB not t o all ow GND line to have large common impeda nce.

Note 4: External capacitor connecting to Vreg should be 0.1μF. Pay attention for the wire between this

capacitor and Vreg terminal and the wire between this capacitor and SGN D not to be influenc ed b y

noise.

Note 5: The IC may not operate normally whe n large common impedance is exist ed in GND line or the IC is

easily influenced by noise. For exampl e, if the IC operates continuously for a long t ime under the

circumstance of large current and high voltage, the number of clock signals inputted to CLK

terminal and that of steps of output curr ent wavef orm may n ot proportion al. And so, the IC ma y not

operate normally. To avoid this malfunction, make sure t o conduct Note.1 to Note.4 and evaluate

the IC enough before using the IC.

2014-01-30

32

Package Dimensions

Unit:

.

Note

TB6600HG

Weight: 7.7 g (typ.)

mm

Note:These dimensions are measured from the surface of the heat sink

2014-01-30

TB6600HG

33

Notes on Contents

1. Block Diagrams

Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for

explanatory purposes.

2. Equivalent Circuits

The equivalent circuit diagrams may be simplified or some parts of them may be omitted for explanatory

purposes.

3. Timing Charts

Timing charts may be simplified for explanatory purposes.

4. Application Circuits

The application circuits shown in this document are provided for reference purposes only. Thorough evaluation

is required, especially at the mass production design stage.

Toshiba does not grant any license to any industrial property rights by providing these examples of application

circuits.

5. Test Circuits

Components in the test circuits are used only to obtain and confirm the device characteristics. These components

and circuits are not guaranteed to prevent malfunction or failure from occurring in the application equipment.

IC Usage Considerations

Notes on handling of ICs

[1] The absolute maximum ratings of a semiconductor device are a set of ratings that must not be exceeded, even

for a moment. Do not exceed any of these ratings.

Exceeding the rating(s) may cause the device breakdown, damage or deterioration, and may result injury by

explosion or combustion.

[2] Use an appropriate power supply fuse to ensure that a large current does not continuously flow in case of over

current and/or IC failure. The IC will fully break down when used under conditions that exceed its absolute

maximum ratings, when the wiring is routed improperly or when an abnormal pulse noise occurs from the

wiring or load, causing a large current to continuously flow and the breakdown can lead smoke or ignition. To

minimize the effects of the flow of a large current in case of breakdown, appropriate settings, such as fuse

capacity, fusing time and insertion circuit location, are required.

[3] If your design includes an inductive load such as a motor coil, incorporate a protection circuit into the design to

prevent device malfunction or breakdown caused by the current resulting from the inrush current at power ON

or the negative current resulting from the back electromotive force at power OFF. IC breakdown may cause

injury, smoke or ignition.

Use a stable power supply with ICs with built-in protection functions. If the power supply is unstable, the

protection function may not operate, causing IC breakdown. IC breakdown may cause injury, smoke or ignition.

[4] Do not insert devices in the wrong orientation or incorrectly.

Make sure that the positive and negative terminals of power supplies are connected properly.

Otherwise, the current or power consumption may exceed the absolute maximum rating, and exceeding the

rating(s) may cause the device breakdown, damage or deterioration, and may result injury by explosion or

combustion.

In addition, do not use any device that is applied the current with inserting in the wrong orientation or

incorrectly even just one time.

2014-01-30

TB6600HG

34

Points to remember on handling of ICs

(1) Over current Detection Circuit

Over current detection circuits (referred to as current limiter circuits) do not necessarily protect ICs under all

circumstances. If the over current detection circuits operate against the over current, clear the over current

status immediately.

Depending on the method of use and usage conditions, such as exceeding absolute maximum ratings can cause

the over current detection circuit to not operate properly or IC breakdown before operation. In addition,

depending on the method of use and usage conditions, if over current continues to flow for a long time after

operation, the IC may generate heat resulting in breakdown.

(2) Thermal Shutdown Circuit

Thermal shutdown circuits do not necessarily protect ICs under all circumstances. If the thermal shutdown

circuits operate against the over temperature, clear the heat generation status immediately.

Depending on the method of use and usage conditions, such as exceeding absolute maximum ratings can cause

the thermal shutdown circuit to not operate properly or IC breakdown before operation.

(3) Heat Radiation Design

In using an IC with large current flow such as power amp, regulator or driver, please design the device so that

heat is appropriately radiated, not to exceed the specified junction temperature (T

These ICs generate heat even during normal use. An inadequate IC heat radiation design can lead to decrease

in IC life, deterioration of IC characteristics or IC breakdown. In addition, please design the device taking into

considerate the effect of IC heat radiation with peripheral components.

(4) Back-EMF

When a motor rotates in the reverse direction, stops or slows down abruptly, a current flow back to the motor’s

power supply due to the effect of back-EMF. If the current sink capability of the power supply is small, the

device’s motor power supply and output pins might be exposed to conditions beyond absolute maximum ratings.

To avoid this problem, take the effect of back-EMF into consideration in system design.

(5) Short-circuiting between outputs, air contamination faults, faults due to improper grounding, short-circuiting

between contiguous pins

Utmost care is necessary in the design of the power supply lines, GND lines, and output lines since the IC may

be destroyed by short-circuiting between outputs, air contamination faults, or faults due to improper grounding,

or by short-circuiting between contiguous pins. They may destroy not only the IC but also peripheral parts and

may contribute to injuries for users. Over current may continue to flow in the IC because of this destruction

and cause smoke or ignition of the IC. Expect the volume of this over current and add an appropriate power

supply fuse in order to minimize the effects of the over current. Capacity of the fuse, fusing time, and the

inserting position in the circuit should be configured suitably.

) at any time and condition.

j

2014-01-30

TB6600HG

35

RESTRICTIONS ON PRODUCT USE

• Toshiba Corporation, and its subsidiaries and affiliates (collectively "TOSHIBA"), reserve the right to make changes to the information

in this document, and related hardware, software and systems (collectively "Product") without notice.

• This document and any information herein may not be reproduced without prior written permission from TOSHIBA. Even with

TOSHIBA's written permission, reproduction is permissible only if reproduction is without alteration/omission.

• Though TOSHIBA works continually to improve Product's quality and reliability, Product can malfunction or fail. Customers are

responsible for complying with safety standards and for providing adequate designs and safeguards for their hardware, software and

systems which minimize risk and avoid situations in which a malfunction or failure of Product could cause loss of human life, bodily

injury or damage to property, including data loss or corruption. Before customers use the Product, create designs including the

Product, or incorporate the Product into their own applications, customers must also refer to and comply with (a) the latest versions of

all relevant TOSHIBA information, including without limitation, this document, the specifications, the data sheets and application notes

for Product and the precautions and conditions set forth in the "TOSHIBA Semiconductor Reliability Handbook" and (b) the

instructions for the application with which the Product will be used with or for. Customers are solely responsible for all aspects of their

own product design or applications, including but not limited to (a) determining the appropriateness of the use of this Product in such

design or applications; (b) evaluating and determining the applicability of any information contained in this document, or in charts,

diagrams, programs, algorithms, sample application circuits, or any other referenced documents; and (c) validating all operating

parameters for such designs and applications. TOSHIBA ASSUMES NO LIABILITY FOR CUSTOMERS' PRODUCT DESIGN OR

APPLICATIONS.

• PRODUCT IS NEITHER INTENDED NOR WARRANTED FOR USE IN EQUIPMENTS OR SYSTEMS THAT REQUIRE

EXTRAORDINARILY HIGH LEVELS OF QUALITY AND/OR RELIABILITY, AND/OR A MALFUNCTION OR FAILURE OF WHICH

MAY CAUSE LOSS OF HUMAN LIFE, BODILY INJURY, SERIOUS PROPERTY DAMAGE AND/OR SERIOUS PUBLIC IMPACT

("UNINTENDED USE"). Except for specific applications as expressly stated in this document, Unintended Use includes, without

limitation, equipment used in nuclear facilities, equipment used in the aerospace industry, medical equipment, equipment used for

automobiles, trains, ships and other transportation, traffic signaling equipment, equipment used to control combustions or explosions,

safety devices, elevators and escalators, devices related to electric power, and equipment used in finance-related fields. IF YOU USE

PRODUCT FOR UNINTENDED USE, TOSHIBA ASSUMES NO LIABILITY FOR PRODUCT. For details, please contact your

TOSHIBA sales representative.

• Do not disassemble, analyze, reverse-engineer, alter, modify, translate or copy Product, whether in whole or in part.

• Product shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any

applicable laws or regulations.

• The information contained herein is presented only as guidance for Product use. No responsibility is assumed by TOSHIBA for any

infringement of patents or any other intellectual property rights of third parties that may result from the use of Product. No license to

any intellectual property right is granted by this document, whether express or implied, by estoppel or otherwise.

• ABSENT A WRITTEN SIGNED AGREEMENT, EXCEPT AS PROVIDED IN THE RELEVANT TERMS AND CONDITIONS OF SALE

FOR PRODUCT, AND TO THE MAXIMUM EXTENT ALLOWABLE BY LAW, TOSHIBA (1) ASSUMES NO LIABILITY

WHATSOEVER, INCLUDING WITHOUT LIMITATION, INDIRECT, CONSEQUENTIAL, SPECIAL, OR INCIDENTAL DAMAGES OR

LOSS, INCLUDING WITHOUT LIMITATION, LOSS OF PROFITS, LOSS OF OPPORTUNITIES, BUSINESS INTERRUPTION AND

LOSS OF DATA , A ND (2) DISCLAIMS ANY AND ALL EXPRESS OR IMPLIED WARRANTIES AND CONDITIONS RELATED TO

SALE, USE OF PRODUCT, OR INFORMATION, INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, ACCURACY OF INFORMATION, OR NONINFRINGEMENT.

• Do not use or otherwise make available Product or related software or technology for any military purposes, including without

limitation, for the design, development, use, stockpiling or manufacturing of nuclear, chemical, or biological weapons or missile

technology products (mass destruction weapons). Product and related software and technology may be controlled under the

applicable export laws and regulations including, without limitation, the Japanese Foreign Exchange and Foreign Trade Law and the

U.S. Export Administration Regulations. Export and re-export of Product or related software or technology are strictly prohibited

except in compliance with all applicable export laws and regulations.

• Please contact your TOSHIBA sales representative for details as to environmental matters such as the RoHS compatibility of Product.

Please use Product in compliance with all applicable laws and regulations that regulate the inclusion or use of controlled substances,

including without limitation, the EU RoHS Directive. TOSHIBA ASSUMES NO LIABILITY FOR DAMAGES OR LOSSES

OCCURRING AS A RESUL T OF NONCOMPLIANCE WITH APPLICABLE LAWS AND REGULATIONS.

2014-01-30

Loading...

Loading...