www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TOSHIBA Bi-CMOS Integrated Circuit Silicon Monolithic

TB6556F/FG

3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller

Features

• Sine-wave PWM control

• Built-in triangular-wave generator

(carrier cycle = f

• Built-in lead angle control function (0° to 58° in 32 steps)

External setting/automatic internal setting

• Built-in dead time function (setting 2.6 µs or 3.8 µs)

• Supports bootstrap circuit

• Overcurrent protection signal input pin

• Built-in regulator (V

• Operating supply voltage range: V

/252 (Hz))

osc

refout

= 5 V (typ.), 30 mA (max))

= 6 V to 10 V

CC

Weight: 0.33 g (typ.)

TB6556F/FG

TB6556FG:

TB6556FG is a Pb-free product.

The following conditions apply to solderability:

*Solderability

1. Use of Sn-63Pb solder bath

*solder bath temperature = 230˚C

*dipping time = 5 seconds

*number of times = once

*use of R-type flux

2. Use of Sn-3.0Ag-0.5Cu solder bath

*solder bath temperature = 245˚C

*dipping time = 5 seconds

*the number of times = once

*use of R-type flux

1

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

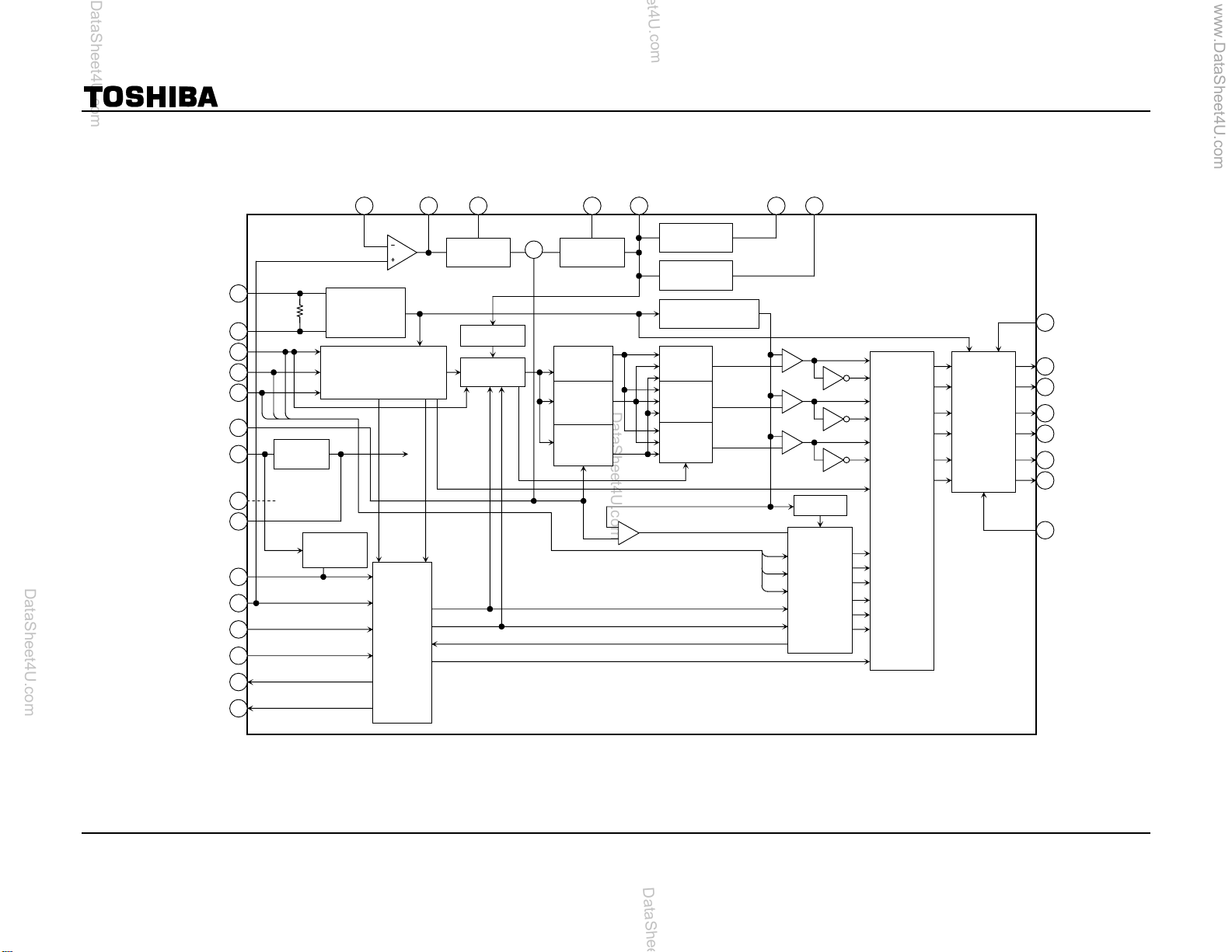

Block Diagram

+

G

G

in

out

PH

2524 26 27

LPF

LA

28

UL

LL

30 29

TB6556F/FG

X

X

out

HU

HV

HW

V

V

CC

GND

V

refout

RES

I

CW/CCW

SS

FG

EV

Peak hold Filter

14

in

15

21

20

19

2

e

Regulator

1

13

23

11

3

dc

18

22

17

16

System clock

generator

Position detector

Power-on

reset

Internal

reference

voltage

FG

Protection

&

reset

Phase

matching

Rotating

direction

ST/SP

CW/CCW

ERR

GB

5-bit AD

Counter

Output

waveform

generator

Upper limit

Lower limit

6-bit triangular

wave generator

Data

select

Comparator

Phase U

Phase V

Phase W

PWM

HU

HV

HW

Comparator

Comparator

Comparator

120/180

Charger

120°-

turn-on

matrix

Switching

120°/180°

and

gate block

protection

on/off

Setting

dead

time

10

12

Td

U

9

X

6

V

8

Y

5

W

7

Z

4

OS

2

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

Pin Description

∼

Pin No. Symbol Description Remarks

TB6556F/FG

21 HU Positional signal input pin U

20 HV Positional signal input pin V

19 HW Positional signal input pin W

18 CW/CCW

11 RES Reset-signal-input pin

2 Ve Volt age command signal With built-in pull-down resistor

24 Gin

25 G

26 PH Peak hold

27 LPF RC low-pass filter Connect the low-pass filter capacitor (built-in 100 kΩ resistor)

28 LA

29 LL Lower limit for LA Set lower limit for LA (LL = 0 V to 5.0 V)

30 UL Upper limit for LA Set upper limit for LA (UL = 0 V to 5.0 V)

12 OS

3 Idc

14 Xin Inputs clock signal

15 X

23 V

17 FG FG signal output pin Outputs 3 PPR of positional signal

16 REV

9 U Outputs turn-on signal

8 V Outputs turn-on signal

7 W Outputs turn-on signal

6 X Outputs turn-on signal

5 Y Outputs turn-on signal

4 Z Outputs turn-on signal

1 VCC Power supply voltage pin VCC = 6 to 10 V

10 Td Inputs setting dead time L: 3.8 µs, H or OPEN : 1.9 µs

22 SS 120°/180° select signal L: 120° tu rn- o n m o de, H o r OPEN: 1 80° turn-on mode

13 GND Ground pin ⎯

refout

Rotation direction signal input

pin

Gain setting I

out

Lead angle setting signal

input pin

Inputs output logic select

signal

Inputs overcurrent protection

signal

Outputs clock signal

out

Outputs reference voltage

signal

Reverse rotation detection

signal

When positional signal is HHH or LLL, gate block protection operates.

With built-in pull-up resistor, built-in digital filter (

L: Forward

H: Reverse

L: Reset (output is non-active)

operation/halt operation, also used for gate protection,

built-in pull-up resistor

signal level at a gain that optimizes the LA

dc

Connect the peak-hold capacitor and discharge resistor to GND, parallel

to each other

Sets 0° to 58° in 32 steps

L: Active LOW

H: Active HIGH

Inputs DC link current.

Reference voltage: 0.5 V

With built-in filter (

With built-in feedback resistor

5 V (typ.), 30 mA (max)

Detects reverse rotation.

Select active HIGH or active LOW using the output logic select pin.

1 µs), built-in digital filter (

∼

−

∼

−

1 µs)

500 ns)

3

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

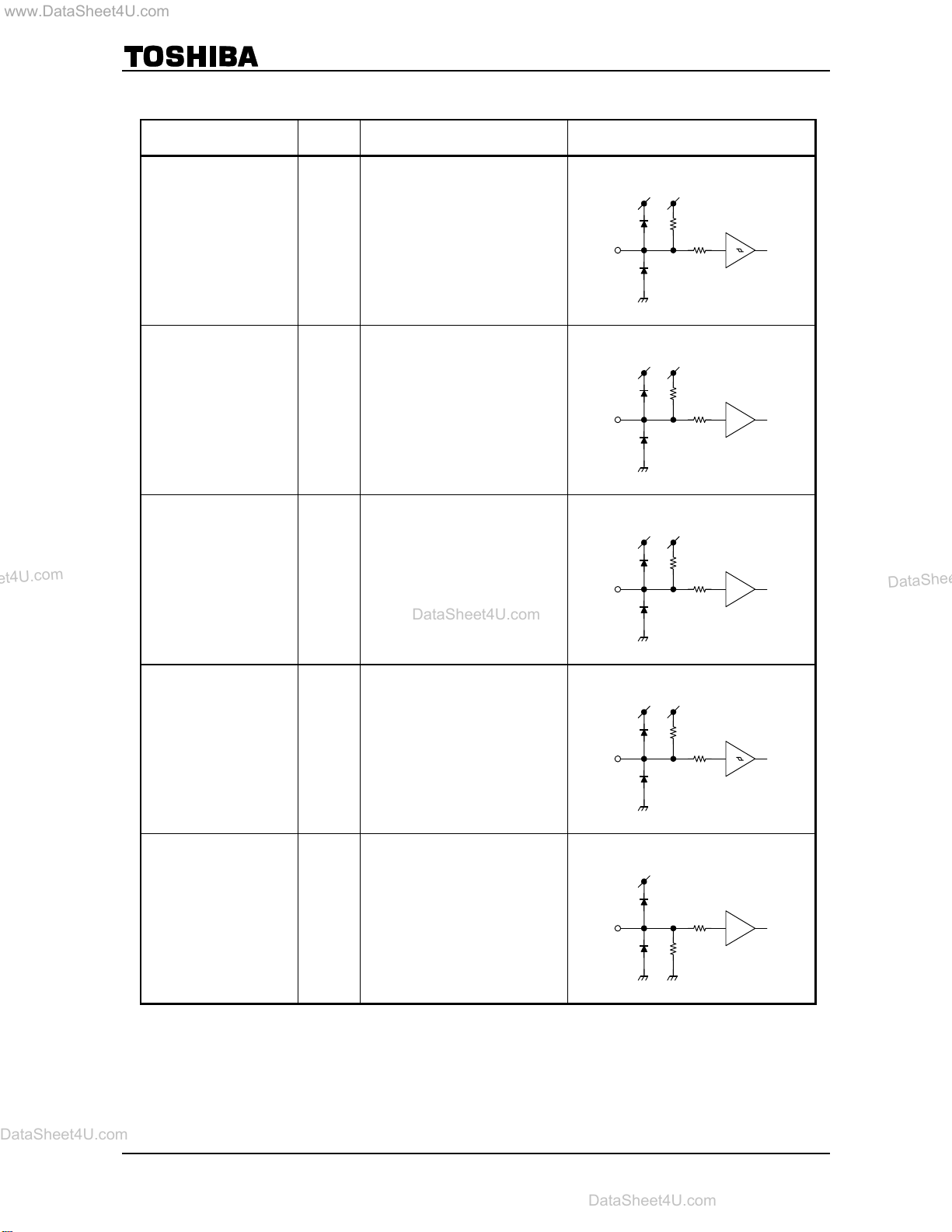

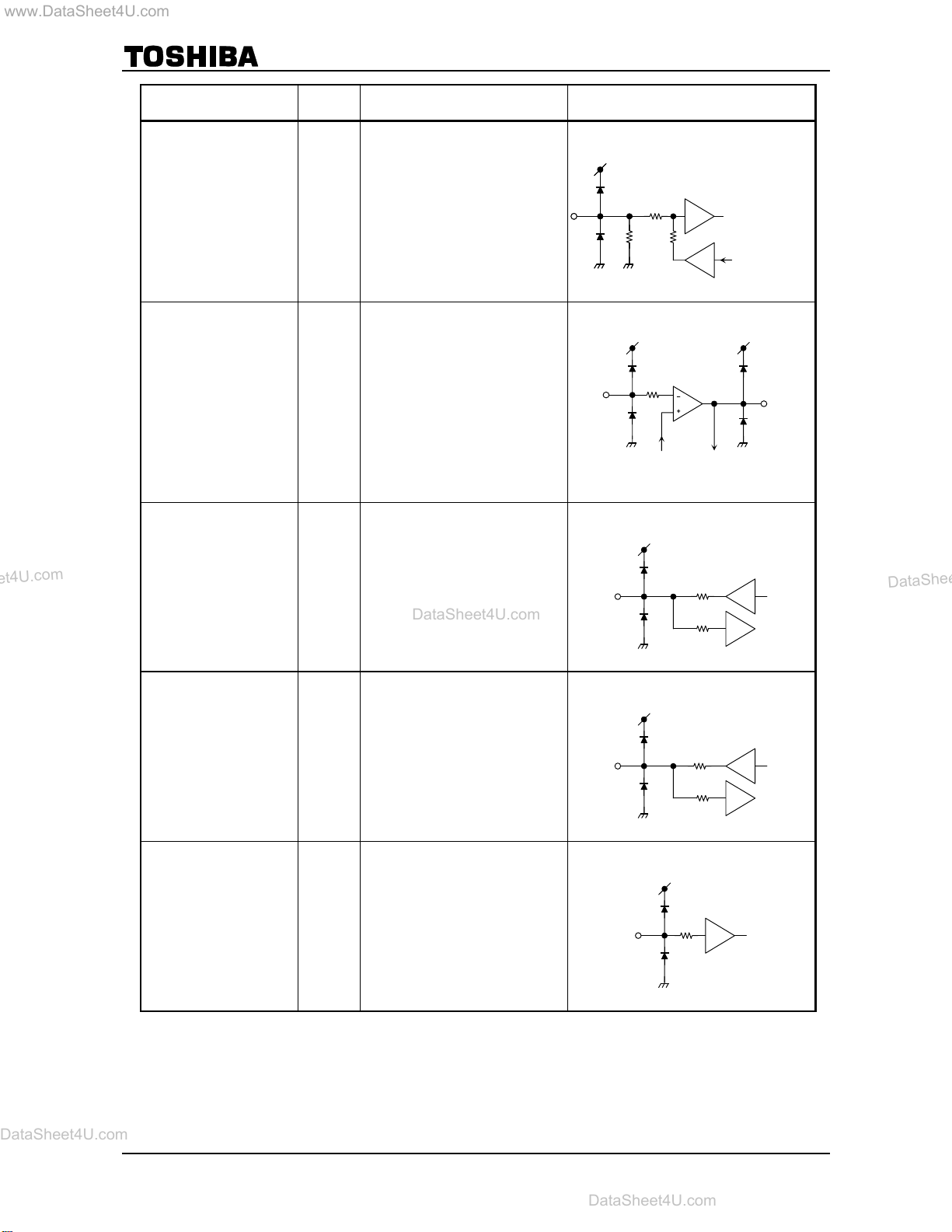

Input/Output Equivalent Ci rcuits

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

Digital

Positional signal input pin U

Positional signal input pin V

Positional signal input pin W

Forward/reverse switching

input pin

L: Forward (CW)

H: Reverse (CCW)

CW/CCW

With Schmitt trigger

HU

Hysteresis 300 mV (typ.)

HV

Digital filter: 500 ns (typ.)

HW

L: 0.8 V (max)

H: V

Digital

L: 0.8 V (max)

H: V

− 1 V (min)

refout

− 1 V (min)

refout

TB6556F/FG

V

V

refout

refout

200 kΩ

2.0 kΩ

V

V

refout

refout

100 kΩ

2.0 kΩ

V

V

refout

refout

Reset input

L: Stops operation (reset)

H: Operates

120°/180° select si g nal

L: 120° turn-on mode

H: 180° turn-on mode

(OPEN)

Voltage command signal

1.0 V < Ve ≤ 2.1 V

Refresh operation

(X, Y, Z pins: ON duty of

8%)

RES

SS

V

e

Digital

L: 0.8 V (max)

H: V

Digital

With Schmitt trigger

Hysteresis: 300 mV (typ.)

L: 0.8 V (max)

H: V

Analog

Input voltage range 0 to 5.4 V

Input voltage of 5.4 V or higher is

clipped to 5.4 V.

refout

refout

− 1 V (min)

− 1 V (min)

100 kΩ

2.0 kΩ

V

V

refout

refout

200 kΩ

2.0 kΩ

V

CC

100 Ω

150 kΩ

4

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

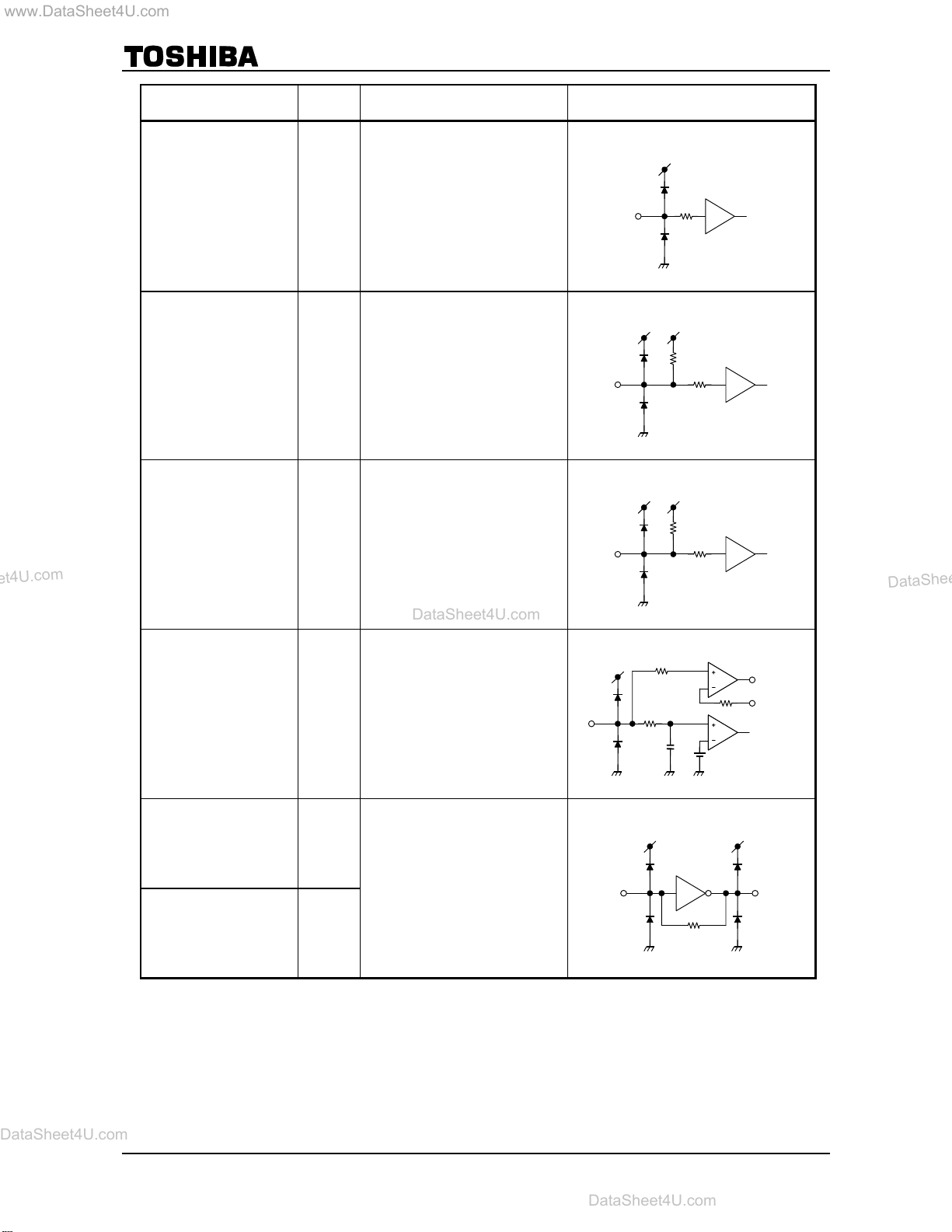

TB6556F/FG

A

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

Lead angle setting signal

input pin

0 V: 0°

5 V: 58°

(5-bit AD)

Gain setting signal input

(LA setting)

Peak hold

(LA setting)

Gin

G

PH

When LA is fixed externally, connect

LL to GND and UL to V

input the setting voltage to the LA pin.

Input voltage range: 0 V to 5.0 V

(V

)

LA

out

refout

Input voltage of V

clipped to V

When LA is fixed automatically, open

the LA pin. In this state, the LA pin is

used only for confirmation of LA width.

Non-inverted amplifier

25 dB (max)

output voltage

G

out

LOW: GND

HIGH: V

CC

Connect the peak-hold capacitor and

discharge resistor to GND, parallel to

each other.

100 kΩ/0.1µF recommended

.

refout

− 1.7 V

refout

, and then

refout

or higher is

V

V

CC

CC

100 Ω

200 kΩ

200 kΩ

utomatic LA

circuit

CC

G

in

100 Ω

Idc

VCC V

To peak

hold circuit

G

out

V

CC

100 Ω

100 Ω

Low-pass filter

(LA setting)

Lower limit for LA LL

LPF

Connect the low-pass filter capacitor

(built-in 100 kΩ resistor)

0.1µF recommended

Clip lower limit for LA

LL = 0 V to 5.0 V

When LL > UL, LA is fixed at LL value.

V

CC

100 kΩ

100 Ω

VCC

100 Ω

5

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

VCC

Upper limit for LA UL

Setting dead time input pin

L: 3.8 µs

H or OPEN: 1.9 µs

Output logic select signal

input pin

L: Active LOW

H: Active HIGH

Overcurrent protection

signal input pin

Clock signal input pin Xin

Td

OS

I

dc

Clip upper limit for LA

UL = 0 V to 5.0 V

When LL > UL, LA is fixed at LL value.

Digital

L: 0.8 V (max)

H: V

Digital

L: 0.8 V (max)

H: V

Analog

Digital filter: 1 µs (typ.)

Gate pr otected at 0.5 V or higher

(released at carrier cycle)

refout

refout

− 1 V (min)

− 1 V (min)

100 Ω

V

V

refout

refout

100 kΩ

2 kΩ

V

V

refout

refout

100 kΩ

2 kΩ

100 Ω

V

CC

200 kΩ

5 pF

0.5 V

V

V

refout

G

out

Gin

Comparator

refout

Clock signal output pin X

Operat ing range

2 MHz to 8 MHz (crystal oscillation)

out

X

in

360 kΩ

6

X

out

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

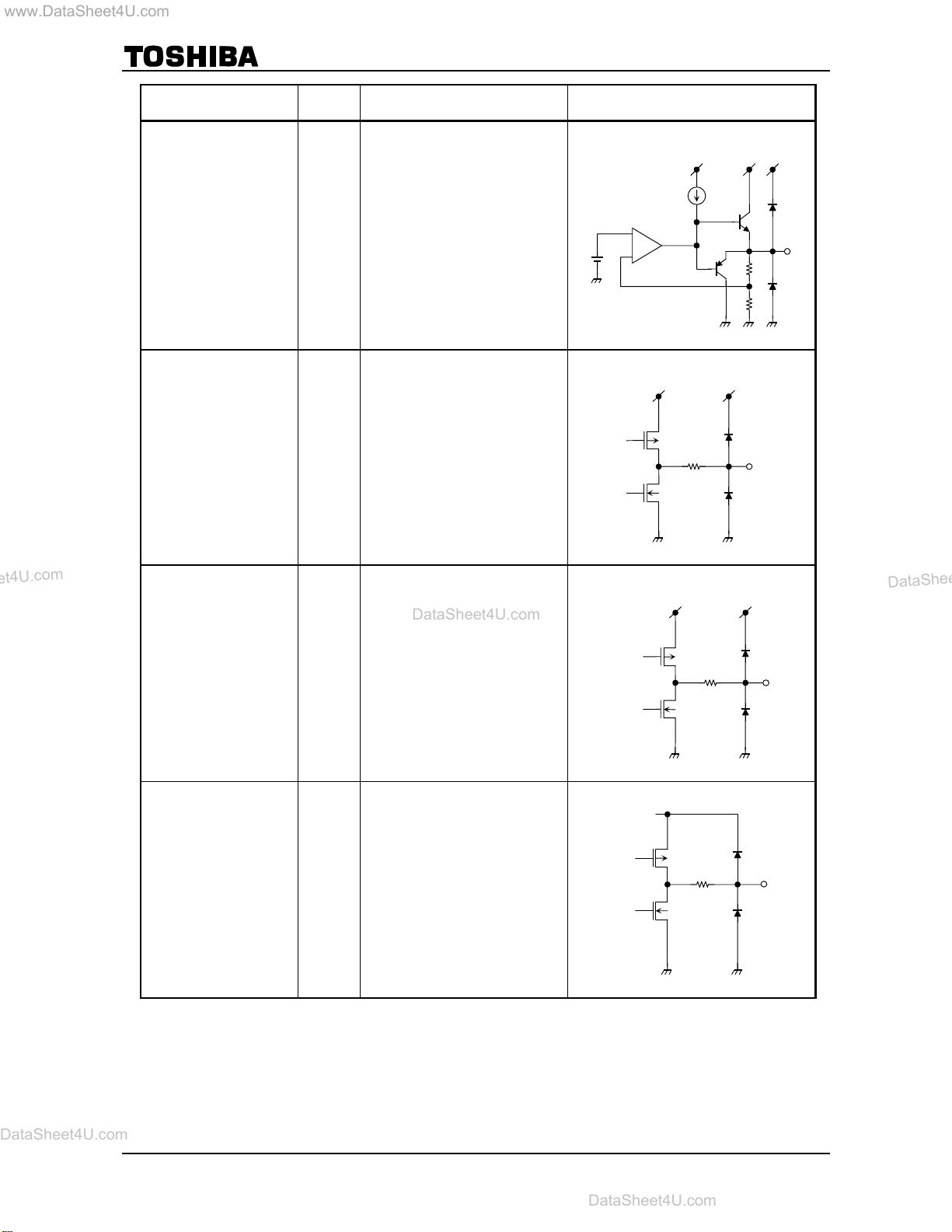

TB6556F/FG

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

VCC VCC

V

CC

Reference voltage signal

output pin

Reverse-rotation-detection

signal output pin

FG signal output pin FG

V

refout

REV

5 ± 0.5 V (max 30 mA)

Digital

Push-pull output: ± 1 mA (max)

Digital

Push-pull output: ± 1 mA (max)

V

refout

V

V

refout

V

refout

100 Ω

refout

100 Ω

Turn-on signal output pin U

Turn-on signal output pin V

Turn-on signal output pin W

Turn-on signal output pin X

Turn-on signal output pin Y

Turn-on signal output pin Z

U

Analog

V

W

Push-pull output: ± 2 mA (max)

X

Y

L: 0.78 V (max)

Z

H: V

− 0.78 V (min)

refout

V

refout

100 Ω

7

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Maximum Ratings

Characteristics Symbol Rating Unit

Supply voltage VCC 12 V

Input voltage

Turn-on signal output current I

Power dissipation PD 1.50 (Note 3) W

Operating temperature T

Storage temperature T

Note 1: V

Note 2: V

in (1)

in (2)

(Ta = 25°C)

pin: Ve, LA, Gin, G

pin: HU, HV, HW, CW/CCW, RES, OS, Idc, Td, SS

V

−0.3~VCC (Note 1)

in (1)

V

−0.3~V

in (2)

2 mA

OUT

−30~115 (Note 4) °C

opr

−50~150 °C

stg

, PH, LPF, LL, UL

out

+ 0.3 (Note 2)

refout

V

Note 3: When mounted on PCB (universal 50 × 50 × 1.6 mm, Cu 30%)

Note 4: Operating temperature r ange is deter m i ned by the PD − Ta characteristic.

Recommended Operati ng Co ndi tions

Characteristics Symbol Min Typ. Max Unit

Supply voltage VCC 6 7 10 V

Crystal oscillation frequency Xin 2 4 8 MHz

(Ta = 25°C)

2.0

1.5

(W)

D

1.0

P

– Ta

D

(1) When mounted on PCB

(2) IC only

(1)

Universal

50 × 50 × 1.6 mm

R

= 110°C/W

th (j-a)

Power dissipation P

0.5

(2)

0

0

50 100 150 200

Ambient temperature Ta (°C)

8

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Electrical Characteristics

Characteristics Symbol

(Ta = 25°C, VCC = 7 V)

Test

Circuit

Supply current ICC ⎯ V

I

-1 Vin = 5 V LA ⎯ 25 50

in (1)

I

-2 Vin = 5 V Ve ⎯ 35 70

Input current

in (1)

I

-1 Vin = 0 V HU, HV, HW, SS −50 −25 ⎯

in (2)

I

-2

in (2)

HIGH

V

in

⎯

⎯ HU, HV, HW, CW/CCW, RES, OS, Td, SS

LOW

Input voltage

H PWM Duty 100% 5.1 5.4 5.7

V

e

⎯

M Refresh → Start motor operation 1.8 2.1 2.4

L

Input hysteresis

voltage

Input delay time

Output voltage

Output leakage

current

Output off-time by

upper/lower transistor

(Note 6)

V

⎯ HU, HV, HW, SS (Note 5) ⎯ 0.3 ⎯ V

H

VDT HU, HV, HW Xin = 4.19 MHz ⎯ 0.5 ⎯

V

DC

V

OUT (H)-1

V

OUT (L)-1

V

REV (H)

V

REV (L)

V

FG (H)

V

FG (L)

V

refout

I

L (H)

I

L (L)

T

OFF (H)

⎯

I

I

I

⎯

I

I

I

V

⎯

⎯

T

OFF (L)

= open ⎯ 5 8 mA

refout

Vin = 0 V CW/CCW, OS, Td, RES −100 −50 ⎯

Turned-off → Refresh 0.7 1.0 1.3

Idc Xin = 4.19 MHz ⎯ 1.0 ⎯

= 2 mA U, V, W, X, Y, Z

OUT

= −2 mA U, V, W, X, Y, Z ⎯ 0.3 0.78

OUT

= 1 mA REV

OUT

= −1 mA REV ⎯ 0.2 1.0

OUT

= 1 mA FG

OUT

= −1 mA FG ⎯ 0.2 1.0

OUT

I

= 30 mA V

OUT

= 0 V U, V, W, X, Y, Z ⎯ 0 10

OUT

V

= 3.5 V U, V, W, X, Y, Z ⎯ 0 10

OUT

Td = HIGH or OPEN, X

I

= ± 2 mA, OS = HIGH/LOW

OUT

Td = LOW, X

I

= ± 2 mA, OS = HIGH/LOW

OUT

Test Condition Min Typ. Max Unit

V

= 4.19 MHz,

in

refout

− 1

V

refout

− 0.78

V

refout

− 1.0

V

refout

− 1.0

4.5 5.0 5.5

refout

= 4.19 MHz,

in

1.5 1.9 ⎯

3.0 3.8 ⎯

⎯ V

refout

⎯ ⎯ 0.8

V

refout

− 0.3

V

refout

− 0.2

V

refout

− 0.2

⎯

⎯

⎯

µA

V

V

µs

V

µA

µs

Overcurrent detection Vdc ⎯ Idc 0.46 0.5 0.54 V

LA gain setting amp

LA limit setting

difference

LA peak hold output

current

Lead angle correction

G

OUT

AMP

OFS

∆L LL = 0.7 V −20 ⎯ 20

∆U

PH

OUT

T

LA (0)

T

LA (2.5)

T

LA (5)

⎯

⎯

⎯ PH output current ⎯ ⎯ 5 mA

⎯ LA = 0 V or OPEN, Hall IN = 100 Hz ⎯ 0 ⎯

⎯ LA = 2.5 V, Hall IN = 100 Hz 27.5 32 34.5

⎯ LA = 5 V, Hall IN = 100 Hz 53.5 59 62.5

output current 5 ⎯ ⎯ mA

OUT

GIN, G

11 kΩ/1 kΩ ⎯ −40 ⎯ mV

OUT

UL = 2.0 V −20 ⎯ 20

mV

°

AMP

VCC (H) ⎯ Output start operation point 4.2 4.5 4.8

VCC monitor

VCC (L) ⎯ No output operation point 3.7 4.0 4.3

V

⎯ Input hysteresis width ⎯ 0.5 ⎯

H

V

Note 5: Toshiba does not implement test i ng befor e shi ppi ng.

9

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Note 6: T

OFF

OS = HIGH

OS = LOW

Turn-on signal (U, V, W)

Turn-on signal (X, Y, Z)

Turn-on signal (U, V, W)

Turn-on signal (X, Y, Z)

0.78 V

0.78 V 0.78 V

T

OFF

V

refout

T

OFF

V

− 0.78 V V

refout

− 0.78 V

refout

T

OFF

V

T

OFF

− 0.78 V

0.78 V

refout

− 0.78 V

10

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

<

<

<

Functional Description

1. Basic operation

The motor is driven by the square-wave turn-on signal based on a positional signal. When the positional

signal reaches number of rotations f = 5 Hz or higher, the rotor position is estimated according to the

positional signal and a modulation wave is generated. The modulation wave and the triangular wave are

compared; then the sine-wave PWM signal is generated and the motor is driven.

From start to 5 Hz: When driven by square wave (120° turn-on) f = f

5 Hz~: When driven by sine-wave PWM (180° turn-on); when f

osc

2. Select drive function

This function can select drive mode.

SS pin

HIGH or OPEN = Sine-wave PWM drive (180° turn-on mode)

LOW = Square-wave drive (120° turn-on mode)

Note: If the position sens ing signal is f = 5 Hz or lower, t he driver is 120° turn-on mode even when SS =

HIGH.

3. Ve voltage command signal function and function to stabilize bootstrap voltage

(1) When the voltage command signal is input at V

Turns off output (gate protection)

(2) When the voltage command signal is input at 1.0 V

Turns on the lower transistor at the regular (carrier) cycle. (ON duty is approx. 8%.)

(3) When the voltage command signal is input at Ve

During sin-wave drive, outputs drive signal as it is. During square-drive, forcibly turns on the lower

transistor at regular (carrier) cycle. (ON duty is approx. 8%)

Note: At startup, turn the l ower tr ansis tor on for a fixed tim e with 1.0 V

transistor gate power supply.

PWM Duty

1.0 V:

e

> 2.1 V:

< Ve

2.1 V:

/(212 × 32 × 6)

osc

= 4 MHz, approx. 5 Hz

< Ve

2.1 V to charge the upper

100%

(1) (2) (3)

2.1 V1.0 V 5.4 V V

e

4. Dead time function: upper/lower transistor output off-time

When the motor is driven by sine-wave PWM, dead time is digitally generated in the IC to prevent a

short circuit caused by the simultaneous turning on of upper and lower external power devices. When a

square wave is generated in full-duty cycle mode, the dead time function is turned on to prevent a short

circuit.

Td Pin Internal Counter T

HIGH or OPEN 8/f

LOW 16/f

1.9 µs

osc

3.8 µs

osc

T

values above are obtained when fosc = 4.19 MHz.

OFF

f

= reference clock (crystal oscillation)

osc

OFF

11

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

5. Correcting the lead angle

The lead angle can be corrected in the turn-on signal range from 0 to 58° in relation to the induced

voltage.

Analog input from LA pin (0 V to 5 V divided by 32):

0 V

= 0°

5 V

= 58° (when more than 5 V is input, 58°)

6. Setting the carrier frequency

This function sets the triangular wave cycle (carrier cycle) necessary for generating the PWM signal.

(The triangular wave is used for forcibly turning on the lower transistor when the motor is driven by

square wave.)

Carrier cycle

= f

/252 (Hz) f

osc

= reference clock (crystal oscillation)

osc

7. Switching the output of the turn-on signal

This function switches the output of the turn-on signal between HIGH and LOW.

Pin OS:

HIGH

= active HIGH

LOW

= active LOW

8. Outputting the reverse rotation detection signal

This function detects the motor rotation direction every electrical angle of 360°. (The output is HIGH

immediately after reset.)

The REV terminal increases with a 180° turn-on mode during LOW.

TB6556F/FG

CW/CCW Pin Actual Motor Rotating Direction REV Pin

LOW (CW)

HIGH (CCW)

9. Protecting input pin

1. Overcurrent protection (Pin I

When the DC-link-current exceeds the internal reference voltage, performs gate block protection.

Overcurrent protection is released for each carrier frequency.

Reference voltage

2. Gate protection (Pin RES)

Output is turned off when the input signal is LOW, restarted when the input signal is HIGH.

The abnormality is detected externally and the signal input to pin RES.

RES Pin OS Pin

LOW

(When RES

CW (fo rward) LOW

CCW (reverse) HIGH

CW (fo rward) HIGH

CCW (reverse) LOW

)

dc

= 0.5 V (typ.)

Output Turn-on Signal

(U, V, W, X, Y, Z)

LOW HIGH

HIGH LOW

= LOW, bootstrap capacitor charging stops.)

12

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

3. Internal protection

• Positional signal abnormality protection

Output is turned off when the positional signal is HHH or LLL; otherwise, it is restarted.

• Low power supply voltage protection (V

For power supply on/off outside the operating voltage range, the turn-on signal output is kept at

high impedance outside the operating voltage range to prevent damage caused by power device

short circuits.

However, if the voltage level is supplied from the V

4.9 V is applied, low power supply voltage protection does not operate.

Power supply

voltage

Turn-on signal

4.5 V (typ.) 4.0 V (typ.)

monitor)

CC

pin, this function is restricted, e.g., when Ve >

e

V

CC

GND

V

M

Output at high impedance

Output at high impedance Output

13

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Operation Flow

Positional signal

(Hall IC)

Voltage

instruction

Oscillator

System clock

generator

Position

detector

Phase matching

(Note)

92%

Phase U

Counter

Phase V

Phase

W

Driven by square wave

Sine-wave pattern

(modulation signal)

Triangular wave

(carrier frequency)

U

X

V

Y

Comparator

W

Z

Output ON duty (U, V, W)

2.1 V (typ.)

Voltage comma nd sign al Ve

5.0 V (typ.)

Note: O utput ON t i m e is decreased by the dead time

(carrier frequency

× 92% − T

× 2)

d

100%

Driven by sine wave

Modulation ratio (modulation signal)

0

Voltage comma nd sign al Ve

2.1 V (typ.)

14

5.4 V (typ.)

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

The modulation waveform is generated using Hall signals. The modulation waveform is then compared

with the triangular wave and a sine-wave PWM signal is generated.

The time (electrical degrees: 60°) from the rising (or falling) edges of the three Hall signals to the next

falling (or rising) edges is counted. The counted time is used as the data for the next 60° phase of the

modulation waveform.

There are 32 items of data for the 60° phase of the modulation waveform. The time width of one data

item is 1/32 of the time width of the 60° phase of the previous modulation waveform. The modulation

waveform moves forward by the width.

HU

HV

HW

S

U

S

V

Sw

⑥ ① ③

⑤ ②

⑥’ ①’ ②’ ③’

*HU, HV, HW: Hall signals

In the above diagram, the modulation waveform (1)’ data moves forward by the 1/32 time width of the

time (1) from HU:

HW:

↓ to HV: ↑.

↑ to HW: ↓. Similarly, data (2)’ moves forward by the 1/32 time width of the time (2) from

If the next edge does not occur after the 32 data items end, the next 32 data items move forward by the

same time width until the next edge occurs.

*t

*t

32

31

30

6

5

4

3

2

1

S

V

* t = t(1) × 1/32

(1)’

32 data items

The modulation wave is brought into phase with every zero-cross point of the Hall signal.

The modulation wave is reset in synchronization with the rising and falling edges of the Hall signal at

every 60° electrical angle. Thus, when the Hall device is not placed at the correct position or during

acceleration and deceleration, the modulation waveform is not continuous at every reset.

15

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

Timing Charts

H

Hall signal

(input)

u

H

v

H

w

TB6556F/FG

FG signal

(output)

Turn-on signal

when driven

by square wave

(output)

Modulation

wave f or m whe n

driven by sine wave

(insi d e of IC)

FG

U

V

W

X

Y

Z

S

S

S

Hall signal

(input)

Hu

H

H

u

v

w

Forward

v

w

FG signal

(output)

Turn-on signal

when driven

by square wave

(output)

Modulation

wave f or m whe n

driven by sine wave

(inside the IC)

FG

U

V

W

X

Y

Z

S

S

S

u

v

w

Reverse

16

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Operating Waveform When Driven by Square Wave

Hall signal

H

U

HV

H

W

Output waveform

U

X

V

Y

W

(CW/CCW = LOW, OS = HIGH)

Z

Enlarged

waveform

W

Z

T

ONU

T

d

T

ONL

T

d

To stabilize the bootstrap voltage, the lower outputs (X, Y, and Z) are always turned on at the carrier cycle

even during off time. At that time, the upper outputs (U, V, and W) are assigned dead time and turned off

at the timing when the lower outputs are turned on. (T

Carrier cycle = f

T

= carrier cycle × 8% (s) (Uniformity)

ONL

/252 (Hz) Dead time: Td = 16/f

osc

varies with input Ve.)

d

(s) (In more than Ve = 5.0 V)

osc

When the motor is driven by a square wave, acceleration or deceleration is determined by voltage V

motor accelerates or decelerates according to the ON duty of T

. (See the diagram of output ON duty on

ONU

page 14.)

Note: At st artup, the motor is driven by a square wave when the Hall signals are 5 Hz or lower (f

the motor is rotating in the reverse direction to that of the TB6556F/FG controlling it (REV

= 4 MHz) and

osc

= HIGH).

. The

e

17

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Operating Waveform When Driven by Sine- Wave PWM

Generation inside of IC

Phase U

Phase V

Phase W

Output waveform

U

X

V

Y

Modulation signal

(CW/CCW = LOW, OS = HIGH)

Triangular wave (carrier frequency)

W

Z

Inter-line voltage

VUV

(U-V)

V

VW

(V-W)

V

WU

(W-U)

When driven by a sine wave, the motor is accelerated or decelerated according to the ON duty of T

the amplitude of the modulation symbol changes according to voltage V

. (See the diagram of the output

e

ON duty on page 14.)

Triangular wave frequency

= carrier frequency = f

/252 (Hz)

osc

Note: At startup, the motor is driven by a sine wave when the Hall signals are 5 Hz or higher (f

motor is rotating in the same direction as the TB6556F/FG controlling it (REV

= LOW).

ONU

= 4 MHz) and the

osc

as

18

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

Example of Application Circuit

g

X

in

14

15

X

out

21

HU

20

HV

19

HW

22

V

e

V

CC

MCU

6 to 10 V

GND

V

refout

RES

CW/CCW

REV

SS

FG

13

23

11

I

dc

18

17

16

TB6556F/FG

V

G = 1 + (R2/R1)

R1

R2

Gin G

System clock

generator

Position detector

reference

Regulator

1

Power-on

reset

3

Protection

2

PH

out

2524 26 27LA28

+

Internal

voltage

FG

&

reset

Peak hold Filter

5-bit AD

Counter

Phase

matching

Rotating

direction

ST/SP

CW/CCW

ERR

GB

LPF

Output

waveform

generator

Upper limit

Lower limit

Triangular wave

enerator6-bit

Selecting

data

Comparator

refoutVrefout

UL LL

Phase U

Phase V

Phase W

PWM

30 29

Comparator

Comparator

Comparator

120/180

Charger

HU

HV

HW

120°-

turn-on

matrix

Switching

120°/180° &

gate block

protection

on/off

Setting

dead time

Power

Driver

supply

M

10

Td

9

U

6

X

8

V

5

Y

7

W

4

Z

12

OS

Pre-driver

(charge

pump)

(Note 1)

Note 2: Connect GND to signal ground on the application circuit.

Note 3: The device may be damaged by short circuits between outputs or between output and supply or ground. Peripheral parts may also be damaged by overvoltage and overcurrent. Design the output lines, V

lines to ensure that no short circuits occur.

Be careful also not to insert the IC in the wrong direction since this may destroy the IC.

Note 1: Connect to ground as necessary to prevent IC malfunction due to noise.

(Note 1)

Hall IC signal

CC

2005-01-19 19

and GND

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

Package Dimensions

TB6556F/FG

Weight: 0.63 g (ty p.)

20

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

Notes on contents

1. Block Diagram s

Some of the functional blocks, circuits, or constants may be omitted or simplified in the block diagram for

explanatory purposes.

2. Equivalent Circuits

The equivale nt circuit diagr ams may b e simplified or some parts of them may be omi tted f or explanatory

purposes.

3. Timing Charts

Timing charts may be simplified for explanatory purposes.

4. Maximum Ratings

The absolute maximum ratings of a semiconductor device are a set of specif ied parameter values t hat must not

be exceeded during operation, even for an instant.

If any of these ratings are exceeded during operation, the electrical characteristics of the device may be

irreparably altered, in which case the reliability and lifetime of the device can no longer be guaranteed.

Moreover, any exceeding of the ratings during operation may cause breakdown, damage and/or degradation in

other equipment. Applications using the device should be designed so that no maximum rating will ever be

exceeded under any operating conditions.

Before using, creating and/or producing designs, refer to and comply with the precautions and conditions set

forth in this document.

5. Application Circuits

The application circuits shown in this document are provided for reference purposes only. Thorough evaluation

is required in the mass production design phase.

In furnishing these examples of application circuits, Toshiba does not grant the use of any industrial property

rights.

6. Test Circuits

Components in test circuits are used only to obtain and confirm device characteri stics. These compo nents and

circuits are not guaranteed to prevent malfunction or failure in application equipment.

Handling of the IC

Ensure that the product is installed correctly to pr event breakdown, damage and/o r degradation i n the product

or equipment.

Over-current protection and heat protection circuits

These protection functions are intended only as a temporary means of preventing out put short circuits or other

abnormal conditions and are not guaranteed to prevent damage to the IC.

If the guaranteed operating ranges of this product are exceeded, these protection features may not operate

and some output short circuits may result in the IC being damaged.

The over-current protection feature is intended to protect the IC from temporary short circuits only.

Short circu its per sisti ng over long periods may cau se excessive stress and damage the IC. Syste ms should

be configured so that any over-current condition will be eliminated as soon as possible.

Counter-electromotiv e force

When the motor reverses or stops, the effect of counter-electromoti ve for ce ma y cause the current to flow to the

power source.

If the power supply is not equipped with sink capability, the power and output pins may exceed the maximum

rating.

The counter-electromotive force of the motor will var y depending on the conditions of use and the features of

the motor. Therefore make sure there will be no damage to or operational problem in the IC, and no damage to

or operational errors in peripheral circuits caused by counter-electromotive force.

21

2005-01-19

www.DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

DataSheet4U.com

TB6556F/FG

RESTRICTIONS ON PRODUCT USE

• The information contained herein is subject to change without notice.

• The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA for any infringements of patents or other rights of the third parties which

may result from its use. No l icense is granted by implication or otherwi se under any patent or patent rights of

TOSHIBA or others.

• TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a s afe design for the entire system, a nd to avoid situations in which a mal function or failure of

such TOSHIBA products could cause loss of human life, bodil y injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, pleas e keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

• The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equi pment , offi ce equipm ent, m easur ing equipm ent, in dust r ial roboti cs, domest ic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

• The products described in this document are subject to the foreign exchange and foreign trade laws.

• TOSHIBA products should not be embedded to the dow nstream products which are prohibited to be pr oduced

and sold, under any law and regulations.

030619EBA

22

2005-01-19

Loading...

Loading...