查询TB6551F供应商

TOSHIBA Bi-CM OS Integrated Circ uit Silicon Monolithic

TB6551F

3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller

Features

· Sine-wave PWM control

· Built-in triangular-wave generator

(carrier cycle = f

· Built-in lead angle control function (0° to 58° in 32 steps)

· Built-in dead time function (setting 2.6 µs or 3.8 µs)

· Supports bootstrap circuit

· Overcurrent protection signal input pin

· Built-in regulator (V

· Operating supply voltage range: V

/252 (Hz))

osc

= 5 V (typ.), 30 mA (max))

ref

CC

= 6 V to 10 V

Weight: 0.33 g (typ.)

TB6551F

1

2002-12-24

TB6551F

2002-12-24

V

Y

W

Td

10

Comparator

U

5

8

6

9

time

dead

Setting

Comparator

Comparator

Z

4

7

Switching

120°/180°

120/180

V

U

Phase

Phase

W

Phase

and

gate

Charger

OS

12

block

protection

HUHVHW

PWM

on/off

120°-

matrix

turn-on

LA

23

6-bit triangular

wave generator

Data

select

Comparator

2

Output

4 bits

Counter

5-bit AD

generator

System clock

Position detector

generator

waveform

Phase

matching

voltage

Internal

reference

Regulator

Rotating

direction

FG

Power-on

ST/SP

CW/CCW

ERR

GB

&

reset

Protection

reset

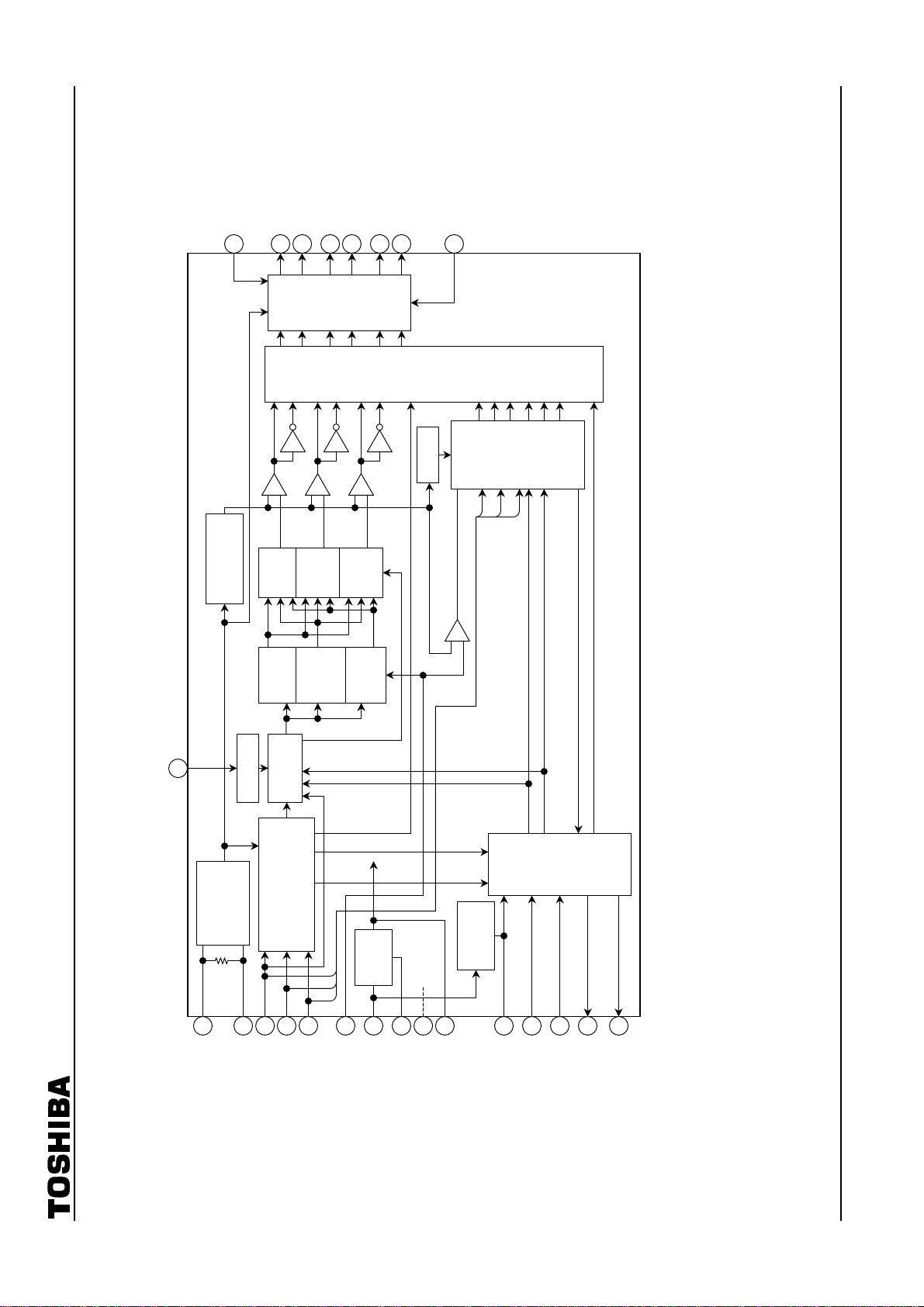

Block Diagram

1

V

CC

3

13

24

refout

V

S-GND

P-GND

14

15

21

20

19

22

in

out

X

HV

HU

X

HW

e

V

11

RES

3

18

17

16

dc

I

FG

REV

CW/CCW

Pin Description

Pin No. Symbol Description Remarks

TB6551F

21 HU

20 HV

19 HW

18 CW/CCW

11 RES Reset-signal-input pin

22 Ve

23 LA

12 OS

3 Idc

14 Xin Inputs clock signal

15 X

24 V

17 FG FG signal output pin Outputs 3PPR of positional signal

16 REV

9 U Outputs turn-on signal

8 V Outputs turn-on signal

7 W Outputs turn-on signal

6 X Outputs turn-on signal

5 Y Outputs turn-on signal

4 Z Outputs turn-on signal

1 VCC Power supply voltage pin VCC = 6 V~10 V

10 Td Inputs setting dead time L: 3.8 ms , H or Open: 2.6 ms

2 P-GND Ground for power supply Ground pin

13 S-GND Ground for signals Ground pin

refout

Positional signal

input pin U

Positional signal

input pin V

Positional signal

input pin W

Rotation direction

signal input pin

Inputs voltage instruction

signal

Lead angle setting signal

input pin

Inputs output logic select

signal

Inputs overcurrentprotection-signal

Outputs clock signal

out

Outputs reference voltage

signal

Reverse rotation detection

signal

When positional signal is HHH or LLL, gate block

protection operates.

With built-in pull-up resistor

L: Forward

H: Reverse

L: Reset (Output is non-active)

Operation/Halt operation

Also used for gate block protection

With built-in pull-down resistor

Sets 0° to 58° in 32 steps

L: Active low

H: Active high

Inputs DC link current.

Reference voltage: 0.5 V

With built-in filter (

With built-in feedback resistor

5 V (typ.), 30 mA (max)

Detects reverse rotation.

Select active high or active low using the output logic select pin.

~

-

1 ms)

3

2002-12-24

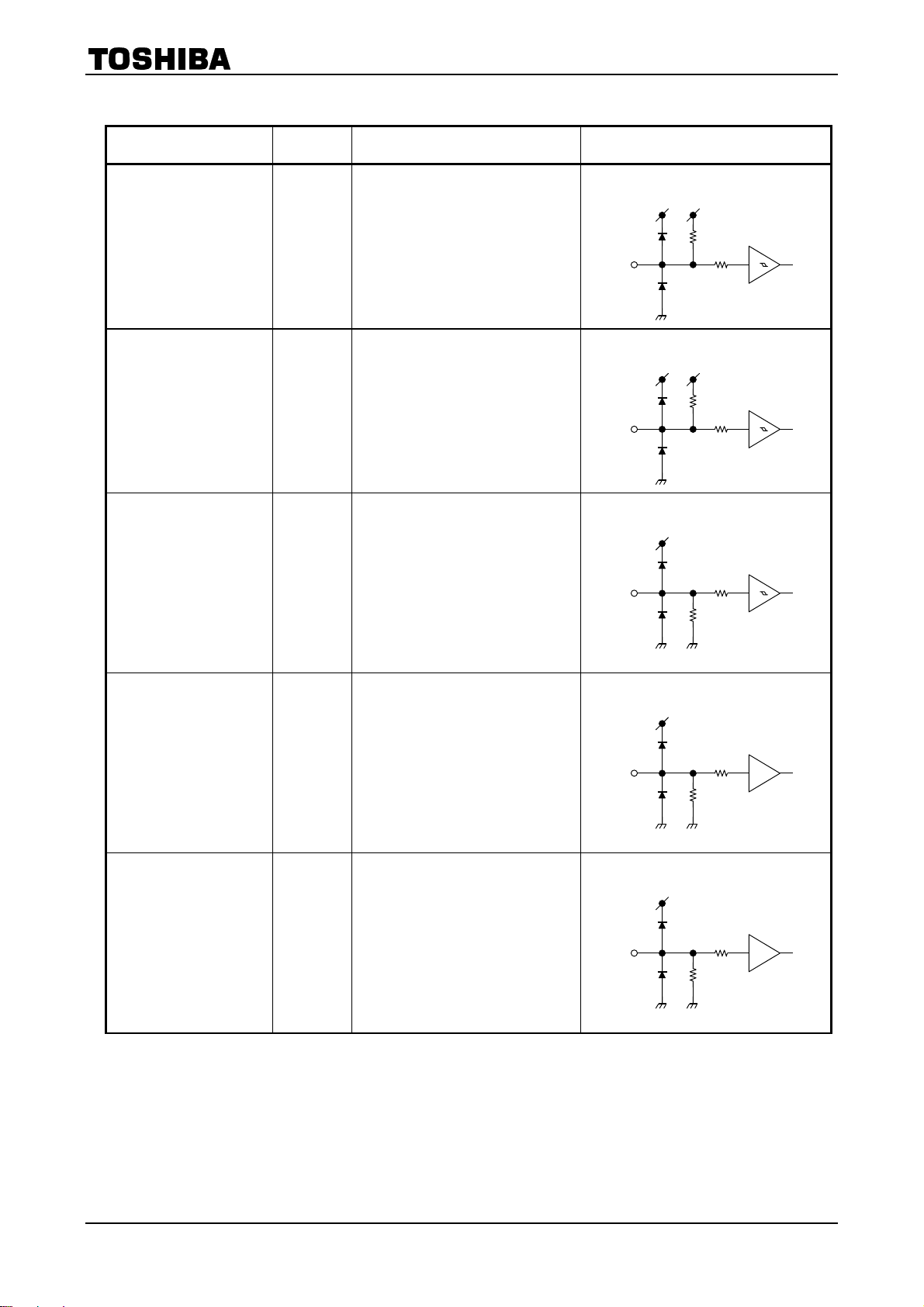

Input/Output Equivalent Circuits

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

TB6551F

Positional signal input pin U

Positional signal input pin V

Positional signal input pin W

Forward/reverse switching

input pin

L: Forward (CW)

H: Reverse (CCW)

Reset input

L: Stops operation (reset).

H: Operates.

Voltage instruction signal

input pin

Turn on the lower transistor

at 0.2 V or less.

(X, Y, Z pins: On duty of 8%)

Lead angle setting signal

input pin

0 V: 0°

5 V: 58°

(5-bit AD)

HU

HV

HW

CW/CCW

RES

V

e

LA

Digital

With Schmitt trigger

Hysteresis 300 mV (typ.)

L : 0.8 V (max)

H: V

Digital

With Schmitt trigger

Hysteresis 300 mV (typ.)

L : 0.8 V (max)

H: V

Digital

With Schmitt trigger

Hysteresis 300 mV (typ.)

L : 0.8 V (max)

H: V

Analog

Input range 0 V to 5.0 V

Input voltage of Vrefout or higher is

clipped to Vrefout.

Analog

Input range 0 V to 5.0 V

Input voltage of V

clipped to V

- 1 V (min)

refout

- 1 V (min)

refout

- 1 V (min)

refout

refout

refout

.

or higher is

V

V

V

refout

refout

refout

VCC

VCC

V

refout

refout

240 k9

2.4 kW

V

120 k9

2.4 kW

2.4 kW

120 k9

120 W

240 k9

120 W

240 k9

4

2002-12-24

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

V

refout

Setting dead time input pin

L : 3.8 ms

H or Open: 2.6 ms

Td

Digital

L : 0.8 V (max)

refout

- 1 V (min)

H: V

V

Output logic select signal

input pin

L: Active low

H: Active high

Overcurrent protection

signal input pin

Clock signal input pin Xin

Clock signal output pin X

OS

I

dc

out

Digital

L : 0.8 V (max)

refout

- 1 V (min)

H: V

Analog

Gate block protected at 0.5 V or higher

(released at carrier cycle)

Operating range

2 MHz to 8 MHz (crystal oscillation)

X

refout

VCC

240 kW

5 pF

V

V

refout

in

360 kW

refout

1.2 kW

refout

2.4 kW

0.5 V

VCC

V

120 k9

V

120 k9

refout

TB6551F

Comparator

X

out

V

V

CC

CC

Reference voltage signal

output pin

Vrefout 5 ± 0.5 V (max 30 mA)

5

2002-12-24

Pin Description Symbol Input/Output Signal Input/Output Internal Circuit

refout

Digital

Reverse-rotation-detection

signal output pin

FG signal output pin FG

REV

Push-pull output: ± 1 mA (max)

Digital

Push-pull output: ± 1 mA (max)

120 W

refout

120 W

TB6551F

V

V

refout

V

V

refout

Turn-on signal output pin U

Turn-on signal output pin V

Turn-on signal output pin W

Turn-on signal output pin X

Turn-on signal output pin Y

Turn-on signal output pin Z

U

V

W

X

Y

Z

Analog

Push-pull output: ± 2 mA (max)

L : 0.78 V (max)

H: V

- 0.78 V (min)

refout

V

refout

120 W

6

2002-12-24

TB6551F

Maximum Ratings

Characteristics Symbol Rating Unit

Supply voltage VCC 12 V

Input voltage

Turn-on signal output current I

Power Dissipation PD 0.9 (Note 3) W

Operating temperature T

Storage temperature T

Note 1: V

Note 2: V

in (1)

in (2)

(Ta ==== 25°C)

pin: Ve, LA

pin: HU, HV, HW, CW/CCW, RES, OS, I

V

-0.3~VCC (Note 1)

in (1)

-0.3~5.5 (Note 2)

V

in (2)

2 mA

OUT

-30~115 (Note 4) °C

opr

-50~150 °C

stg

Td

dc,

V

Note 3: When mounted on PCB (universal 50 ´ 50 ´ 1.6 mm, Cu 30%)

Note 4: Operating temperature range is determined by the PD - Ta characteristic.

Recommended Operating Conditions

Characteristics Symbol Min Typ. Max Unit

(Ta ==== 25°C)

Supply voltage VCC 6 7 10 V

Crystal oscillation frequency Xin 2 4 8 MHz

1.5

(W)

1.0

D

0.5

Power dissipation P

(2)

– Ta

P

D

(1) When mounted on PCB

Universal

50 ´ 50 ´ 1.6 mm

Cu 30%

(2) IC only

R

th (j-a)

(1)

= 200°C/W

0

0

50 100 150 200

Ambient temperature Ta (°C)

7

2002-12-24

TB6551F

Electrical Characteristics

Characteristics Symbol

(Ta ==== 25°C, VCC ==== 15 V)

Test

Circuit

Supply current ICC ¾ V

I

V

in (1)

Iin

-1 Vin = 0 V HU, HV, HW -40 -20 ¾

Input current

Input voltage Vin

(2)

Iin

-2 Vin = 0 V CW/CCW, OS, Td -80 -40 ¾

(2)

-3

I

in (2)

High

¾

¾ HU, HV, HW , CW /CCW, RES , OS, Td

Low

Input hysteresis

voltage

Output voltage

Output leakage

current

Output off-time by

upper/lower transistor

(Note 1)

V

¾ HU, H V, HW, CW/ CCW , RES ¾ 0.3 ¾ V

H

V

OUT (H)-1

V

OUT (L)-1

V

V

V

V

V

T

T

I

I

I

REV (H)

¾

I

REV (L)

I

FG(H)

I

FG(L)

refout

I

V

L (H)

I

L (L)

OFF(H)

OFF(L)

¾

¾

= open ¾ 3 6 mA

refout

= 5 V Ve, LA ¾ 20 40

in

Vin = 5 V RES ¾ 40 80

= 2 mA U, V, W, X, Y, Z

OUT

= -2 mA U, V, W, X, Y, Z ¾ 0.4 0.78

OUT

= 1 mA REV

OUT

= -1 mA REV ¾ 0.5 1.0

OUT

= 1 mA FG

OUT

= -1 mA FG ¾ 0.5 1.0

OUT

I

= 30 mA V

OUT

= 0 V U, V, W, X, Y, Z ¾ 0 10

OUT

V

= 3.5 V U, V, W, X, Y, Z ¾ 0 10

OUT

Td = High or open, X

I

= ± 2 mA, OS = High/Low

OUT

Td = Low, X

I

= ± 2 mA, OS = High/Low

OUT

= 4.19 MHz,

in

Test Condition Min Typ. Max Unit

mA

V

4.5 5.0 5.5

refout

= 4.19 MHz,

in

refout

- 1

¾ ¾ 0.8

V

refout

- 0.78

V

refout

- 1.0

V

refout

- 1.0

2.2 2.6 ¾

3.0 3.8 ¾

¾ V

V

refout

- 0.4

V

refout

- 0.5

V

refout

- 0.5

refout

¾

¾

V

V

¾

mA

ms

Overcurrent detection Vdc ¾ Idc 0.46 0.5 0.54 V

T

Lead angle correction

VCC monitor

L

LA (0)

T

LA = 2.5 V, Hall IN = 100 Hz 27.5 32 34.5

LA (2.5)

L

T

LA (5)

V

Output start operation point 4.2 4.5 4.8

CC (H)

V

No output operation point 3.7 4.0 4.3

CC (L)

= 0 V or Open, Hall IN = 100 Hz ¾ 0 ¾

A

= 5 V, Hall IN = 100 Hz 53.5 59 62.5

A

°

V

VH Input hysteresis width ¾ 0.5 ¾

Note 5: T

OFF

OS = High

Turn-on signal (U, V, W)

Turn-on signal (X, Y, Z)

0.78 V 0.78 V

T

OFF

T

OFF

0.78 V

0.78 V

OS = Low

Turn-on signal (U, V, W)

V

refout

- 0.78 V

V

refout

- 0.78 V

Turn-on signal (X, Y, Z)

T

T

OFF

- 0.78 V V

V

refout

refout

- 0.78 V

8

OFF

2002-12-24

Functional Description

1. Basic operation

The motor is driven by the square-wave turn-on signal based on a positional signal. When the positional

signal reaches number of rotations f = 5 Hz or higher, the rotor position is assumed according to the

positional signal and a modulation wave is generated. The modulation wave and the triangular wave are

compared then the sine-wave PWM signal is generated and the motor is driven.

From start to 5 Hz: When driven by square wave (120° turn-on) f = f

5 Hz~: When driven by sine-wave PWM (180° turn-on) When f

2. Function to stabilize bootstrap voltage

(1) When voltage instruction is input at V

Turns on the lower transistor at regular (carrier) cycle. (On duty is approx. 8%)

(2) When voltage instruction is input at V

During sine-wave drive, outputs drive signal as it is.

During square-wave drive, forcibly turns on the lower transistor at regular (carrier) cycle.

(On duty is approx. 8%)

<

0.2 V:

e

> 0.2 V:

e

/(212 ´ 32 ´ 6)

osc

= 4 MHz, approx. 5 Hz

osc

TB6551F

Note: At startup, to charge the upper transistor gate power supply, turn the lower transistor on for a fixed

time with V

e

<

0.2 V.

3. Dead time function: upper/lower transistor output off-time

When driving the motor by sine-wave PWM, to prevent a short circuit caused by simultaneously turning

on upper and lower external power devices, digitally generates dead time in the IC.

When a square wave is generated in full duty cycle mode, the dead time function is turned on to prevent a

short circuit.

Td Pin Internal Counter T

High or Open 11/f

Low 16/f

T

values above are obtained when fosc = 4.19 MHz.

OFF

f

= reference clock (crystal oscillation)

osc

2.6 ms

osc

3.8 ms

osc

OFF

4. Correcting lead angle

The lead angle can be corrected in the turn-on signal range from 0 to 58° in relation to the induced

voltage.

Analog input from LA pin (0 V to 5 V divided by 32)

0 V = 0°

5 V = 58° (when more than 5 V is input, 58°)

5. Setting carrier frequency

Sets triangular wave cycle (carrier cycle) necessary for generating PWM signal.

(The triangular wave is used for forcibly turning on the lower transistor when driving the motor by

square wave.)

Carrier cycle = f

/252 (Hz) f

osc

= Reference clock (crystal oscillation)

osc

6. Switching the output of turn-on signal

Switches the output of turn-on signal between high and low.

Pin OS:

High = active high

Low = active low

9

2002-12-24

7. Outputting reverse rotation detection signal

Detects motor rotation direction every electrical degrees of 360°. (The output is high immediately after

reset)

REV terminal increases with a 180° turn-on mode at the time of low.

CW/CCW Pin Actual Motor Rotati ng Di rection REV Pin

TB6551F

Low (CW)

High (CCW)

8. Protecting input pin

1. Overcurrent protection (Pin Idc)

When the DC-link-current exceeds the internal reference voltage, performs gate block protection.

Overcurrent protection is released for each carrier frequency.

Reference voltage = 0.5 V (typ.)

2. Gate block protection (Pin RES)

When the input signal level is Low, turns off the output; when High, restarts the output.

Detects abnormality externally and inputs the signal to the pin RES.

RES Pin OS Pin

Low

(When RES = Low, bootstrap capacitor charging stops.)

3. Internal protection

· Positional signal abnormality protection

When the positional signal is HHH or LLL, turns off the output; otherwise, restarts the output.

· Low power supply voltage protection (V

When power supply is on/off, prevents damage caused by short-circuiting power device by

keeping the turn-on signal output at high impedance outside the operating voltage range.

Power supply

voltage

CW (forward) Low

CCW (reverse) High

CW (forward) High

CCW (reverse) Low

Output Turn-on Signal

(U, V, W, X, Y, Z)

Low High

High Low

monitor)

CC

4.5 V (typ.) 4.0 V (typ.)

V

CC

GND

Turn-on signal

Output at high impedance

10

V

M

Output at high impedance Output

2002-12-24

TB6551F

X

Operation Flow

Positional signal

(Hall IC)

Voltage

instruction

Oscillator

System clock

generator

Position

detector

Phase matching

(Note)

92%

Phase U

Counter

Phase V

Phase

W

Driven by square wave

Sine-wave pattern

(modulation signal)

Triangular wave

(carrier frequency)

U

V

Y

Comparator

W

Z

Output ON duty (U, V, W)

0.2 V (typ.)

Voltage instruction Ve

4.6 V

Note: Output ON time is decreased by the dead time.

(carrier frequency ´ 92% - T

´ 2)

d

100%

Driven by sine wave

Modulation ratio (modulation signal)

0.2 V (typ.)

0

Voltage instruction Ve

5 V (V

refout

)

11

2002-12-24

TB6551F

V

The modulation waveform is generated using Hall signals. Then, the modulation waveform is compared

with the triangular wave and a sine-wave PWM signal is generated.

The time (electrical degrees: 60°) from the rising (or falling) edges of the three Hall signals to the next

falling (or rising) edges are counted. The counted time is used as the data for the next 60° phase of the

modulation waveform.

There are 32 items of data for the 60° phase of the modulation waveform. The time width of one data

item is 1/32 of the time width of the 60° phase of the previous modulation waveform. The modulation

waveform moves forward by the width.

HU

HV

HW

S

U

S

V

Sw

(6) (1) (3)

(5) (2)

(6)’ (1)’ (2)’ (3)’

*HU, HV, HW: Hall signals

In the above diagram, the modulation waveform (1)’ data moves forward by the 1/32 time width of the

time (1) from HU: to HW: ¯. Similarly, data (2)’ moves forward by the 1/32 time width of the time (2) from

HW: ¯ to HV: .

If the next edge does not occur after the 32 data items end, the next 32 data items move forward by the

same time width until the next edge occurs.

*t

*t

32

31

30

6

5

4

3

2

1

S

* t = t(1) ´ 1/32

(1)’

32 data items

The modulation wave is brought into phase with every zero-cross point of the Hall signal.

The modulation wave is reset in synchronization with the rising and falling edges of the Hall signal at

every 60° electrical degrees. Thus, when the Hall device is not placed at the correct position or when

accelerating/decelerating, the modulation waveform is not continuous at every reset.

12

2002-12-24

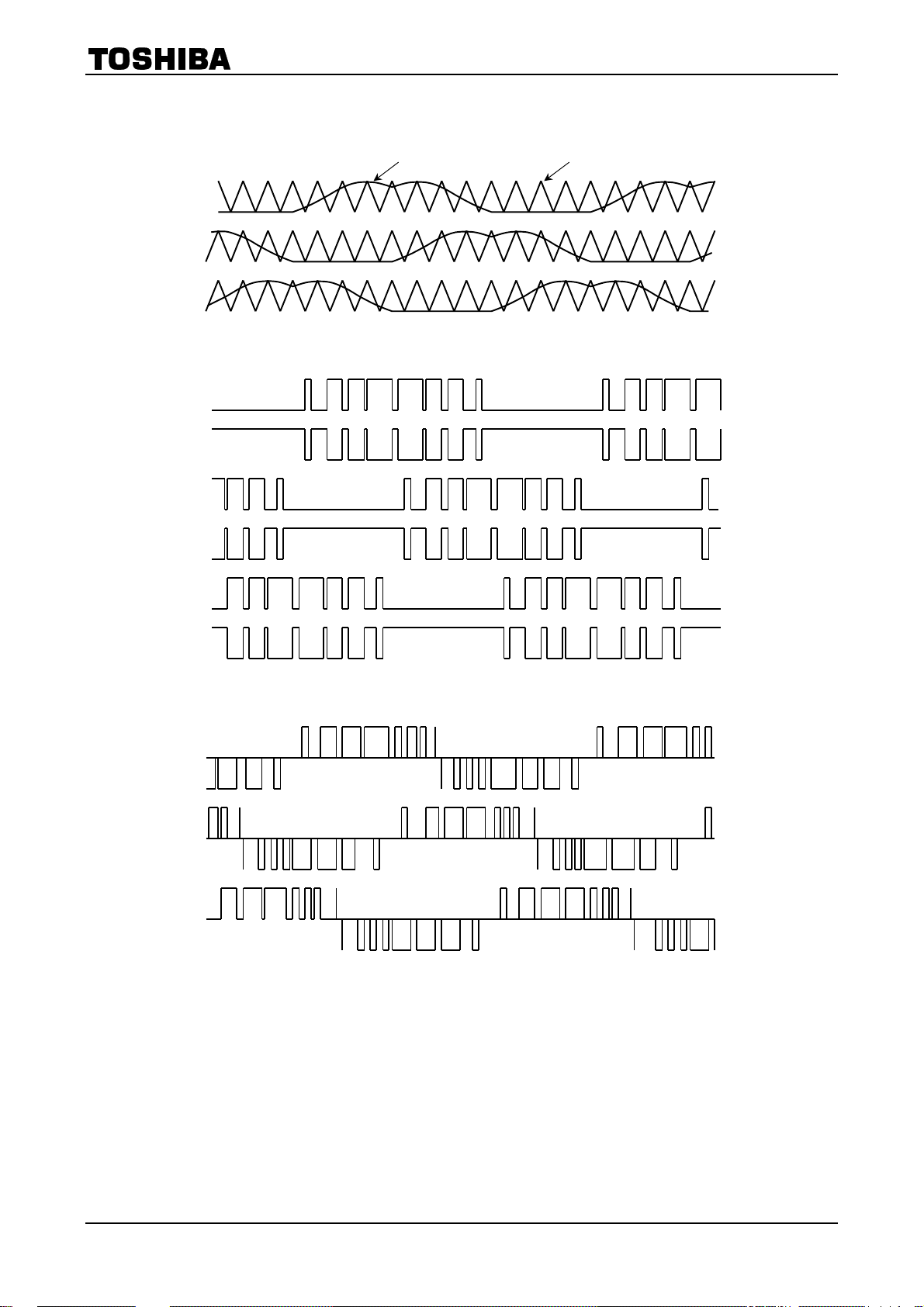

Timing Charts

X

X

H

Hall signal

(input)

u

H

v

H

w

TB6551F

FG signal

(output)

Turn-on signal

when driven

by square wave

(output)

Modulation

waveform when

driven by sine wave

(inside of IC)

FG

U

V

W

Y

Z

S

S

S

Hall signal

(input)

H

H

H

u

v

w

Forward

u

v

w

FG signal

(output)

Turn-on signal

when driven

by square wave

(output)

Modulation

waveform when

driven by sine wave

(inside of IC)

FG

U

V

W

Y

Z

S

S

S

u

v

w

Reverse

13

2002-12-24

TB6551F

Operating Waveform When Driven by Square Wave

Hall signal

H

U

H

V

H

W

Output waveform

U

X

V

Y

W

(CW/CCW ==== Low, OS ==== High)

Z

Enlarged

waveform

W

Z

T

ONU

T

d

T

ONL

T

d

To stabilize the bootstrap voltage, the lower outputs (X, Y, and Z) are always turned on at the carrier cycle

even during off time. At that time, the upper outputs (U, V, and W) are assigned dead time and turned off

at the timing when the lower outputs are turned on. (T

Carrier cycle = f

T

= carrier cycle ´ 8% (s) (Uniformity)

ONL

/252 (Hz) Dead time: Td = 16/f

osc

varies with input Ve)

d

(s) (In more than Ve = 4.6 V)

osc

When the motor is driven by a square wave, acceleration/deceleration is determined by voltage V

motor accelerates/decelerates according to the On duty of T

(see the diagram of output On duty on

ONU

page 11).

Note: At startup, the motor is driven by a square wave when the Hall signals are 5 Hz or lower (f

the motor is rotating in the reverse direction as the TB6551F controls it (REV = High).

e

= 4 MHz) and

osc

. The

14

2002-12-24

TB6551F

Operating Wave form When Driven by Sine-Wave PWM

Generation inside of IC

Phase U

Phase V

Phase W

Output waveform

U

X

V

Y

Modulation signal

(CW/CCW ==== Low, OS ==== High)

Triangular wave (carrier frequency)

Inter-line voltage

When the motor is driven by a sine wave, the motor is accelerated/decelerated according to the On duty of

T

ONU

duty on page 11).

W

Z

V

UV

(U-V)

V

VW

(V-W)

V

WU

(W-U)

when the amplitude of the modulation symbol changes by voltage Ve (see the diagram of output On

Triangular wave frequency = carrier frequency = f

/252 (Hz)

osc

Note: At startup, the motor is driven by a sine wave when the Hall signals are 5 Hz or higher (f

motor is rotating in the same direction as the TB6551F controls it (REV = Low).

15

= 4 MHz) and the

osc

2002-12-24

r

f

g

pump)

(charge

Pre-drive

d

5 V

T

10

Comparator

U

9

V

Y

W

Z

4

7

5

8

6

Setting

dead time

Switching

Comparator

Comparator

120/180

&

120°/180°

Charger

OS

12

gate

block

on/off

protection

120°-

matrix

turn-on

(Note 1)

(Note 1)

HUHVHW

V

U

Phase

Phase

W

Phase

PWM

Triangular wave

generator 6-bit

data

Selecting

Comparator

Output

generator

waveform

4 bit

LA

23

Counter

5-bit AD

refout

V

generator

System clock

Position detector

Phase

Internal

ST/SP

CW/CCW

ERR

GB

Protection

BRK (CHG)

&

reset

matching

e

volta

reference

Rotating

FG

direction

reset

Power-on

Regulator

14

15

21

20

19

out

HV

HU

X

in

X

HW

22

1

e

V

V

CC

13

24

re

V

S-GND

P-GND

2

11

3

18

17

16

dc

I

RES

FG

REV

CW/CCW

(Note 2)

6 V to 10 V

MCU

Note 1: For preventing the IC from misoperation caused by noise for example connect to ground as required.

Note 2: Connect P-GND to signal ground on an application circuit.

Note 3: A short circ uit between the outputs, or between output and supply or ground may damage the device. Periferal parts may also be dameged by overvoltage and overcurrent. Design the output lines, V

Example of Application Circuit

Package Dimensions

TB6551F

Weight: 0.33 g (typ.)

17

2002-12-24

TB6551F

A

RESTRICTIONS ON PRODUCT USE

· TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconducto r

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

· The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

· The products described in this document are subject to the foreign exchange and foreign trade laws.

· The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA CORPORATION for any infringements of intellectual property or other

rights of the third parties which may result from its use. No license is granted by implication or otherwise under

any intellectual property or other rights of TOSHIBA CORPORATION or others.

000707EB

· The information contained herein is subject to change without notice.

18

2002-12-24

Loading...

Loading...