Toshiba Bi-CMOS Integrated Circuit Silicon Monolithic

y

(

Preliminar

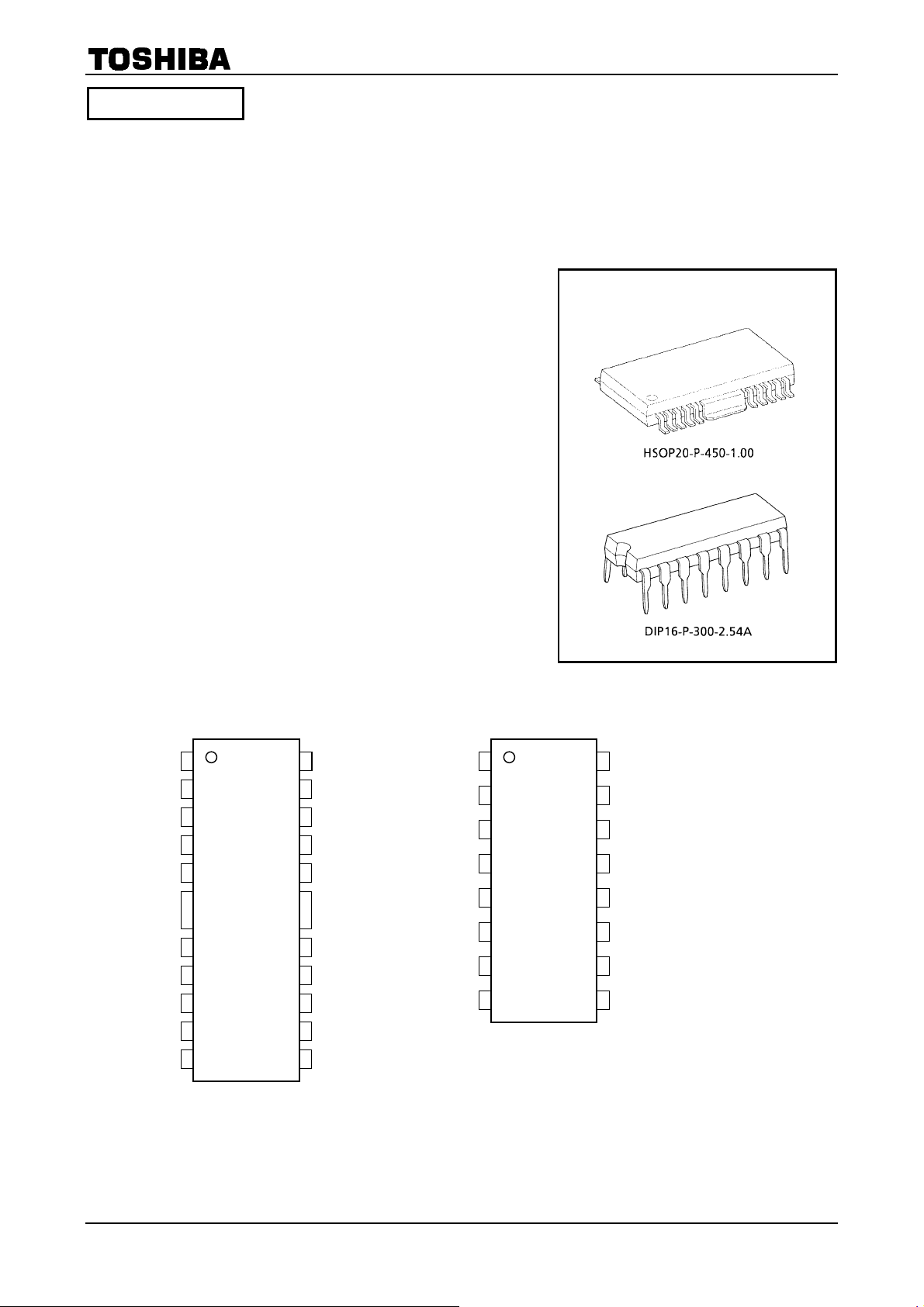

TB6549F,TB6549P

Full-Bridge Driver IC for DC motor

TB6549F/P is a full-bridge driver IC for DC motor which uses

LDMOS for output transistors. High efficient drive is possible by

MOS process with low ON-resistor and PWM drive system. Four

modes such as CW, CCW, short brake, and stop can be chosen by

IN1 and IN2.

Features

• Power supply voltage: 30 V (max)

• Output current: 3.5 A (max)

• Low ON resistor: 0.5 Ω (typ.)

• Capable of PWM controlling

• Standby system

• CW/CCW/short brake/stop function modes.

• Built-in overcurrent protection

• Built-in thermal shutdown circuit

• Package: HSOP-20/DIP-16

Pin Assigument

HSOP20-P-450-1.00

DIP16-P-300-2.54A

TB6549F

TB6549P

Weight

HSOP20-P-450-1.00: 0.79 g (typ.)

DIP16-P-300-2.54A: 1.11 g (typ.)

TB6549F/P

N.C.

CcpA

CcpB

CcpC

N.C.

S-GND

Fin)

N.C.

IN1

IN2

N.C.

OUT1

Note: This product has a MOS structure and is sensitive to electrostatic discharge. When handling this product,

ensure that the environment is protected against electrostatic discharge by using an earth strap, a conductive

mat and an ionizer. Ensure also that the ambient temperature and relative humidity are maintained at

reasonable levels.

V

CC

N.C.

V

reg

SB

N.C.

S-GND

(Fin)

N.C.

PWM

N.C.

OUT2

P-GND

CcpA

CcpB

CcpC

S-GND

S-GND

IN1

IN2

OUT1

V

CC

V

reg

SB

S-GND

S-GND

PWM

OUT2

P-GND

1

2002-08-30

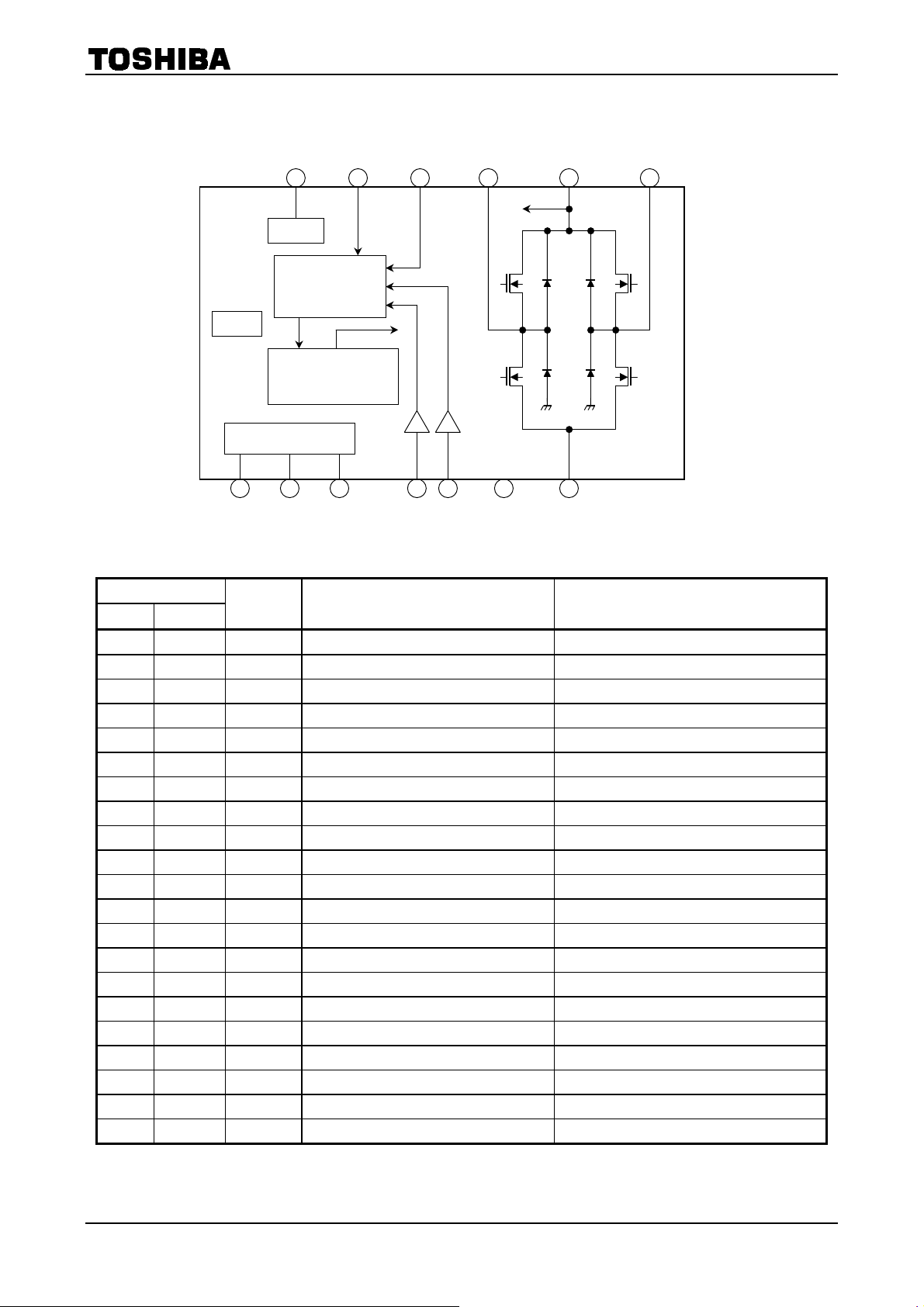

Block Diagram

V

reg

5 V

Control logic

OSC

Overcurrent

detecting circuit

T

SD

Charge pump circuit

PWM

CC

TB6549F/P

OUT1 OUT2 SB V

CcpA CcpB CcpC

IN1 IN2 P-GND

S-GND

Pin Functions

Pin No.

F P

1 (NC) No Connection

2 1 CcpA Capacitor connection pin for charge pump A Connect a capacitor for charge pump

3 2 CcpB Capacitor connection pin for charge pump B Connect a capacitor for charge pump

4 3 CcpC Capacitor connection pin for charge pump C Connect a capacitor for charge pump

5 (NC) No Connection

6 (NC) No Connection

7 6 IN1 Control signal input 1 Input 0/5-V signal

8 7 IN2 Control signal input 2 Input 0/5-V signal

9 (NC) No Connection

10 8 OUT1 Output pin 1 Connect to motor coil pin

11 9 P-GND Power GND

12 10 OUT2 Output pin 2 Connect to motor coil pin

13 (NC) No Connection

14 11 PWM PWM control signal input pin Input 0/5-V PWM signal

15 (NC) No Connection

16 (NC) No Connection

17 14 SB Standby pin H: Start, L: Standby

18 15 V

19 (NC) No Connection

20 16 VCC Power supply input pin V

FIN 4, 5, 12, 13 S-GND GND pin

Pin Name Functional Description Remarks

5 V output pin Connect a capacitor to S-GND

reg

= 10 to 27 V

CC (ope)

2

2002-08-30

TB6549F/P

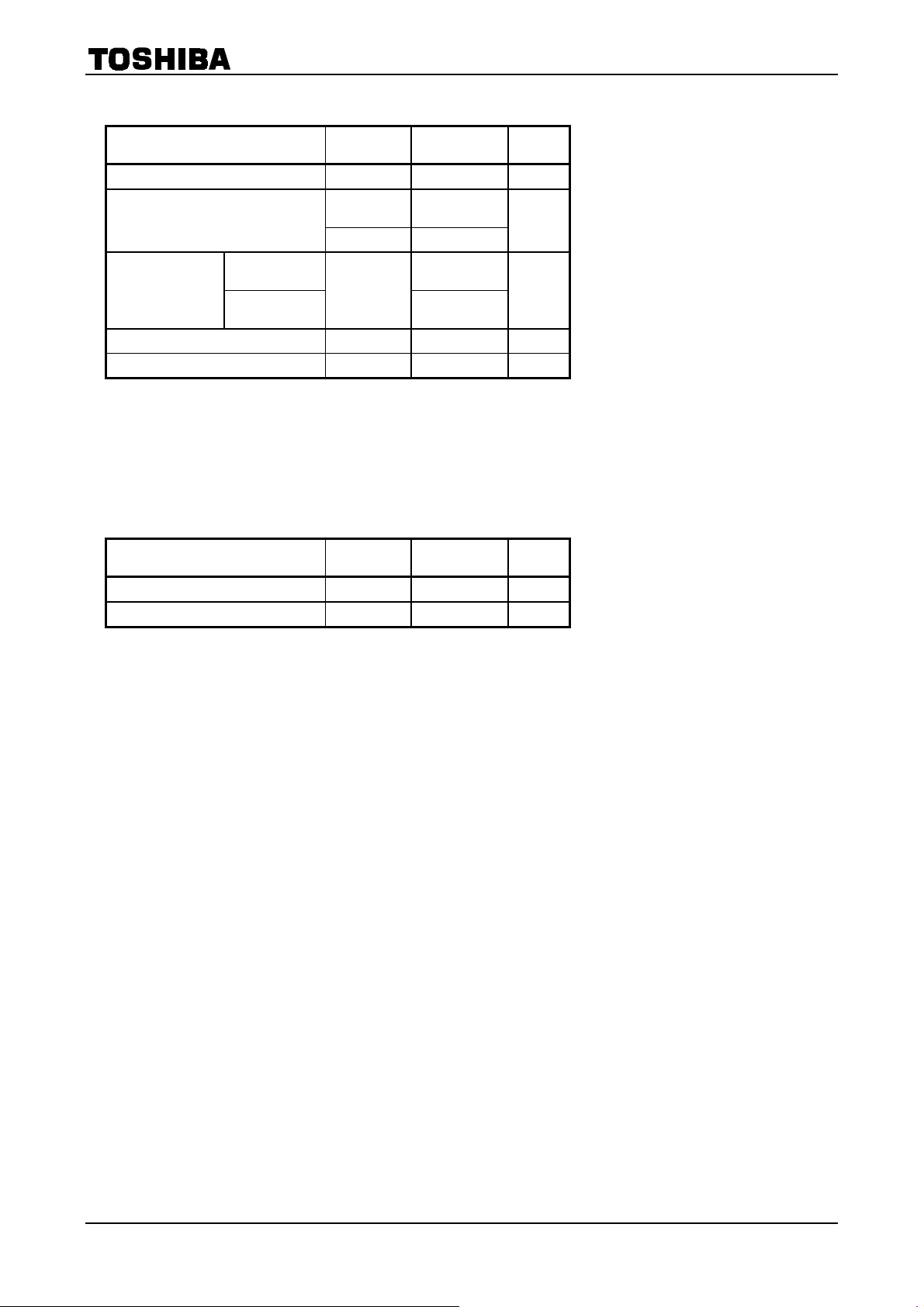

Maximum Ratings

Characteristics Symbol Rating Unit

Supply voltage V

Output current

Power dissipation

Operating temperature T

Storage temperature T

(Ta ==== 25°C)

F

P

CC

IO (Peak)

(Ave) 2.0

I

O

PD

−20 to 85 °C

opr

stg

30 V

3.5

2.5

2.5

−55 to 150 °C

(Note 1)

(Note 2)

(Note 3)

A

W

Note 1: The maximum ratings must be observed strictly. Make sure that all the characteristics listed above never

exceed the maximum ratings.

Note 2: This value is obtained by 115 × 75 × 1.6 mm PCB mounting occupied 30% of copper area.

Note 3: This value is obtained by 50 × 50 × 1.6 mm PCB mounting occupied 50% of copper area.

Operating Range

(Ta ==== 25°C)

Characteristics Symbol Rating Unit

Supply voltage V

PWM frequency f

CC

CLK

10 to 27 V

100 kHz

3

2002-08-30

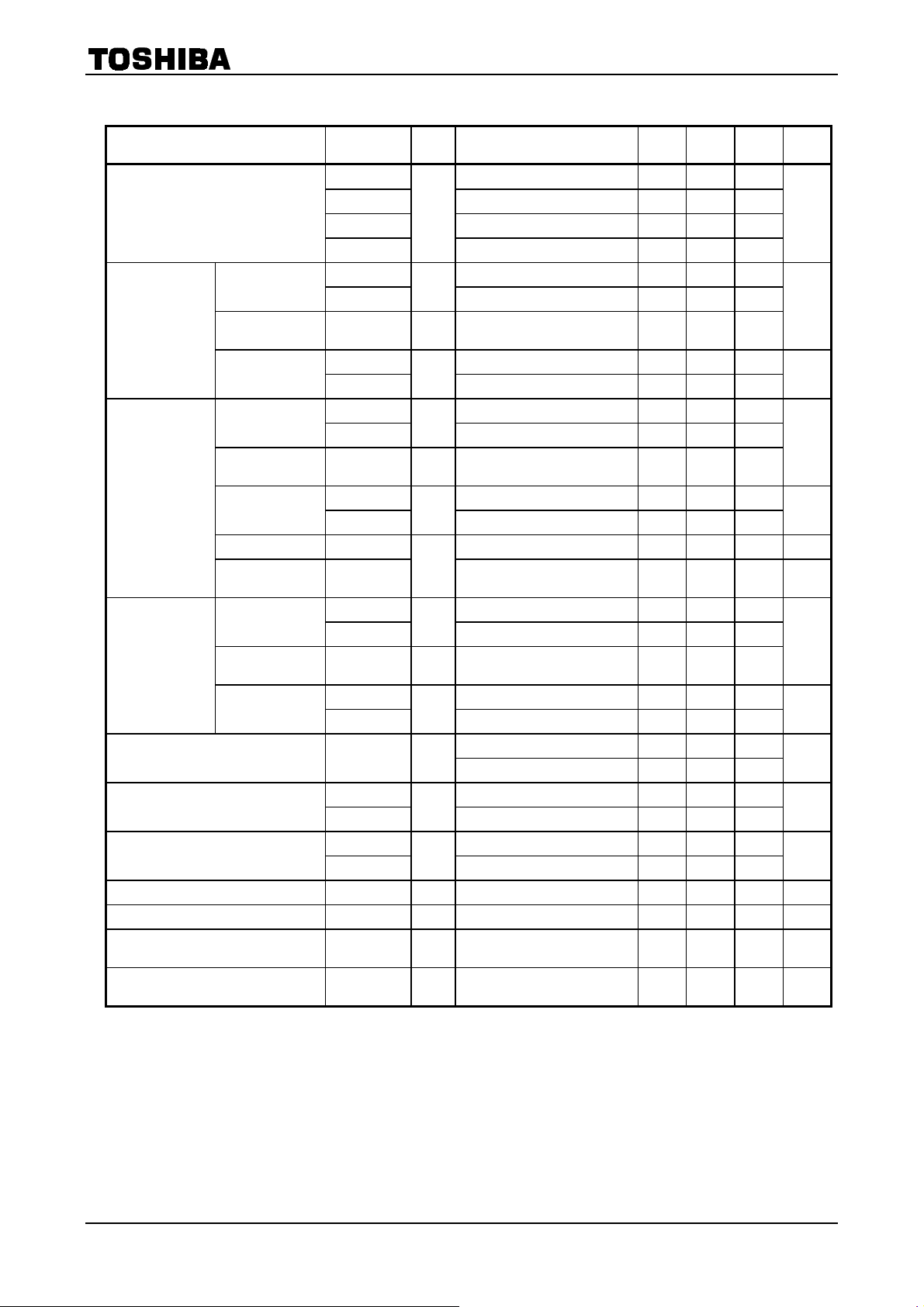

TB6549F/P

Electrical Characteristics

Characteristics Symbol

Supply current

Input voltage

Control circuit

PWM input circuit

Standby circuit

Output ON resistance R

Output leakage current

Diode forward voltage

Internal reference voltage V

Overcurrent detection offset time I

Charge pump rising time t

Thermal shutdown circuit operating

temperature

Hysteresis

voltage

Input current

Input voltage

Hysteresis

voltage

Input current

PWM frequency

Minimum clock

pulse width

Input voltage

Hysteresis

voltage

Input current

(VCC ==== 24 V, Ta ==== 25°C)

Test

Circuit

I

CC1

I

CC2

I

CC3

I

CC4

V

INH

V

INL

V

IN (HYS)

I

INH

I

INL

V

PWMH

V

PWML

V

PWM(HYS)

I

PWMH

I

PWML

f

PWM

tw(

PWM)

V

INSH

V

INSL

V

IN (HYS)

I

INSH

I

INSL

on (U + L)

I

L (U)

I

L (L)

V

F (U)

V

F (L)

reg

SD (OFF)

ONG

T

SD

CW/CCW mode 6 10

Short break mode 4 8

2 5.5

(Not tested) 0.2

V

V

2 5.5

(Not tested) 0.2

V

4

V

I

4 No load 4.5 5 5.5 V

(Not tested) 50 µs

7

(Not tested) 160 °C

Stop mode 4 8

1

(Standby mode) 1 2

2

0.8

= 5 V 50 75

IN

1

VIN = 0 V 5

3

(Not tested) 0.2

PWM

3

V

PWM

Duty = 50% 100 kHz

3

2 µs

2

0.8

= 5 V 50 75

IN

1

VIN = 0 V 5

Io = 0.2 A 1.0 1.75

= 1.5 A 1.0 1.75

I

o

= 30 V (Note 1) 150

CC

5

V

= 30 V 10

CC

= 1.5 A 1.3 1.7

o

6

I

= 1.5 A 1.3 1.7

o

= 0.22 µF, C2 = 0.01 µF

C

1

(Note 2)

Test Condition Min Typ. Max Unit

2 5.5

0.8

= 5 V 50 75

= 0 V 5

1 3 ms

mA

V

µA

V

µA

V

µA

Ω

µA

V

Note 1: Include the current in the circuit.

Note 2: C1 is a capacitor between CcpA and GND. C2 is a capacitor between CcpB and CcpC.

4

2002-08-30

Component Description

1. Control Input/PWM Input Circuit

VDD V

IN1

(IN2, PWM)

100 kΩ

• The input signals are shown below. Input at the CMOS and TTL levels can be provided. Note that the

input signals have a hysteresis of 0.2 V (typ.).

V

V

: 2 to V

INH

: GND to 0.8 V

INL

reg

V

• The PWM input frequency should be 100 kHz or less.

DD

Input/Output Function

Input Output

IN1 IN2 SB PWM OUT1 OUT2 Mode

H H H

L H H

H L H

L L H

H/L H/L L

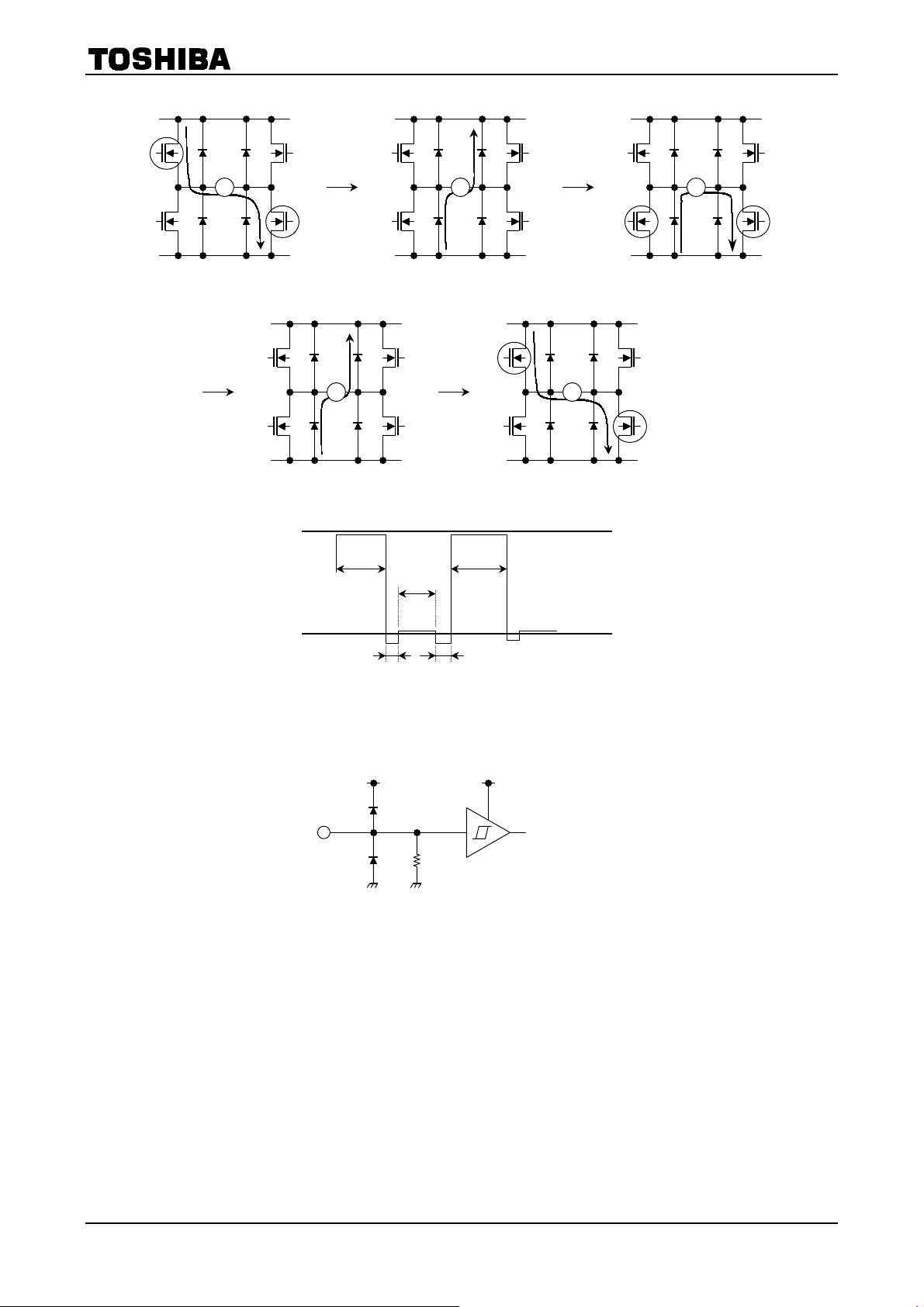

• PWM control function

Motor speed can be controlled by inputting the 0/5-V PWM signal to the PWM pin.

When PWM control is provided, normal operation and short brake operation are repeated.

If the upper and lower power transistors in the output circuit were ON at the same time, a penetrating

current would be produced. To prevent this current from being produced, a dead time of 300 ns (design

target value) is provided in the IC when either of the transistors changes from ON to OFF, or vice versa.

Therefore, PWM control by synchronous rectification is enabled without an OFF time being inserted by

external input. Note that a dead time is also provided in the IC at the time of transition between CW

and CCW or between CW (CCW) and short brake mode, thereby eliminating the need for an OFF time.

H

L

H L H CW/CCW

L L L Short brake

H H L CCW/CW

L L L Short brake

H

L

H

L

L L Short brake

OFF

(high impedance)

OFF

(high impedance)

TB6549F/P

Stop

Standby

5

2002-08-30

TB6549F/P

VCC

VCC

VCC

OUT1 OUT1 OUT1

Output Voltage Waveform

M

GND

PWM ON

t1

VCC

M

PWM OFF → ON

t4 = 300 ns (typ.)

t1

(OUT1)

t2

M

PWM ON → OFF

t2 = 300 ns (typ.)

OUT1 OUT1

GND

t5

t3

t4

GND

PWM ON

t5

M

V

CC

GND

M

GND

PWM OFF

t3

VCC

GND

Note: Please set the pin PWM to High when PWM control function is not used.

2. Standby Circuit

VDD V

SB

100 kΩ

• All circuits are turned off except the standby circuit and the charge pump circuit under the standby

condition.

• Input voltage range is shown below. Input at CMOS and TTL level is possible. Input signal has 0.2-V

(typ.) hysteresis.

V

V

: 2 to V

INSH

: GND to 0.8 V

INSL

reg

V

• Please avoid controlling the output by inputting PWM signal to the standby pin. The output signal

becomes unstable and it may cause the destruction of the IC.

• The charge pump circuit is turned On/Off by the switch of the input signal from the standby pin. If the

switching cycle is shorter than 50 ms, the charge pump circuit will not operate with precise timing.

Therefore, switching cycle of the standby pin should be longer than 50 ms.

• When the Standby condition is changed to the Operation Mode, set IN1 and IN2 to Low level (Stop

Mode) at first. Then switch IN1 and IN2 to High level when the charge pump circuit reaches the stable

condition, VcpA is about V

CC

+ 5 V.

DD

6

2002-08-30

3. Internal Constant-Voltage (5 V) Circuit

VCC

VCC

V

reg

• This IC includes a 5-V power supply for control circuit.

• A capacitor for prevention of oscillation should be connected to S-GND associated with the pin V

No other loads should be connected to pin V

• This IC has a power monitoring function and turns the output OFF when V

reg

.

goes down to 3.0 V

reg

(design target value) or less. With a hysteresis of 0.3 V (design target value), the output are turned ON

when V

reaches 3.3 V (design target value) again .

reg

4. Charge Pump Circuit

VCC

CcpA

TB6549F/P

.

reg

CcpB

CcpC

• This IC has a charge pump circuit for driving the gate for the upper power transistor in the output

circuit. A voltage of V

It takes about 2 ms to boost V

+ 5 V (typ.) is generated by connecting an external capacitor to this IC.

CC

CPA

up V

+ 5 V (typ.) after the switch of the input signal from the

CC

standby pin. (while CcpA = 0.22 µF, and CcpB and CcpC are connected through 0.01 µF).

• The proper capacitance of the external capacitor varies depending on the V

CC value

. Thus, determine

the constant by referring to the following data. The value of the capacitor between CcpB and CcpC

should be such that, while the motor is being driven, the voltage on the CcpA pin will be kept constant,

typically at V

+ 5 V. (If a reduced VCC level causes the voltage on CcpA to start to fall, please adjust

CC

this capacitance value accordingly.)

<External capacitor>

VCC Between CcpB and CcpC Between CcpA and GND

10 V~15 V 0.01 µF~0.047 µF 0.22 µF

15 V~27 V 0.01 µF 0.22 µF

• Reference oscillation is performed by using the internal capacitor.

7

2002-08-30

5. Output Circuit

t

VCC

OUT1

(OUT2)

P-GND

• This IC uses Nch MOS transistors as the upper and lower transistors in the output circuit.

• As output R

• The switching characteristics of the output transistors are shown below.

PWM Input

is 1 Ω (sum for the upper and lower parts/typ.), this IC is a device of the low R

on

t

pLH

t

pHL

TB6549F/P

type.

on

Output Voltage

(OUT1/OUT2)

<Typical Value>

Item Typical Value Unit

t

350

pLH

t

800

pHL

tr 60

tf 100

<Actural Measured Waveform>

t

pLH

(350 ns)

PWM inpu

10%

ns

90%

50%

t

r

90%

50%

10%

t

f

t

pLH

(800 ns)

Output voltage

*: OUT 1, OUT 2; open

t

r

(60 ns)

(100 ns) t

f

8

2002-08-30

6. VCC Power Supply Section

• The V

circuit.

• The operating voltage range is shown below.

V

• This IC has a power monitoring function for preventing an output malfunction on power-up. However,

Toshiba recommends that IN1, IN2, and SB be set to the Low level at power-on.

power supply delivers a voltage to the output circuit, charge pump circuit, and internal 5-V

CC

CC (opr.)

= 10 to 27 V

7. GND Sections

• This IC includes two separate GND sections: S-GND for controlling and P-GND for outputting. Be sure

to short- circuit these two GNDs as close to TB6549 as possible.

8. Power Monitoring Circuit

• This circuit turns the output OFF when V

V

= 4.6 V (typ.)

CC

• With a hysteresis of 0.3 V (design target value), the output turns back ON when V

(design target value) after this circuit starts operating.

9. Thermal Shutdown (TSD) Circuit

This IC includes a thermal shutdown circuit which turns the output OFF when the junction temperature

(Tj) exceeds 160°C (typ.). The output turns back ON automatically. The thermal hysteresis is 20°C.

T

∆T

= 160°C (design target value)

SD

= 20°C (design target value)

SD

10. Overcurrent Detection (ISD) Circuit

This IC includes a circuit which detects a current flowing through the output power transistors. The

current limit is set to 5 A (typ.). The circuit detects a current flowing through each of the four output power

transistors. If the current in any one output power transistor exceeds the set limit, this circuit turns all the

outputs OFF.

This circuit includes a timer which causes the outputs to be OFF for 50 µs (typ.) after detection of an

overcurrent and then turn back ON automatically. If the overcurrent continues to flow, this ON-OFF

operation is repeated. Note that to prevent a malfunction due to a glitch, an insensitive period of 10 µs

(typ.) is provided.

I

LIM

TB6549F/P

becomes 3.0 V (design target value) or less. At this time,

reg

exceeds 3.3 V

reg

Output Current

0

50 µs

(typ.)

10 µs

(typ.)

Insensitive period

50 µs

(typ.)

10 µs

(typ.)

The set limit is 5 A (typ.) as a design target value. The distributions shown below exist because of the

variations in thermal characteristics of different ICs. These distributions should be fully considered in the

motor torque design.

Also, output peak current should be less than 3 A because of the variations below,

Detected current: Approximately from 3.5 to 6.5 A

9

2002-08-30

Test Circuit

V

V

V

V

V

V

V

V

TB6549F/P

1. Icc1, Icc2, Icc3, Icc4, I

INH

, I

INL

, I

INSH

, I

INSL

ICC

V

V

CC

OUT1

OUT2

5V/0

5V/0

5V/0

5

PWM

A IN1

I

IN

A IN2

I

IN

A SB

I

INS

TB6549F/P

P-GND S-GND

reg

CcpC CcpB CcpA

• Icc1: IN1 = 0 V, IN2 = 0 V, SB = 5 V

• Icc2: IN1 = 5 V, IN2 = 5 V, SB = 5 V or IN1 = 0 V, IN2 = 5 V, SB = 5 V

• Icc3: IN1 = 5 V, IN2 = 5 V, SB = 5 V

• Icc4: IN1 = 5 V/0 V, IN2 = 5 V/0 V, SB = 0 V

• I

• I

• I

• I

: IN1 = 5 V, and IN2 = 5 V

INH

: IN2 = 0 V, and IN2 = 0 V

INL

: SB = 5 V

INSH

: SB = 0 V

INSL

2. V

INH

, V

INL

, V

INSH

, V

INSL

A

24V

24V

CcpC CcpB CcpA

reg

5

PWM

IN1 2V/0.8

V

V

CC

OUT1

TB6549F/P

10

OUT2

V

V

2002-08-30

IN2 0.8V/2

SB 2V/0.8

P-GND S-GND

• V

• V

, V

INH

: IN1 = 0.8 V, IN2 = SB = 2 V, Verify that OUT1 = L, OUT2 = H. IN1 = SB = 2 V, IN2 = 0.8 V, Verify

INL

: IN1 = IN2 = SB = 2 V, Verify that OUT1 = OUT2 = L.

INSH

that OUT1 = OUT2 = L.

• V

: IN1 = IN2 = 2 V, SB = 0.8 V, Verify that output function is high impedance.

INSL

TB6549F/P

V

V

V

V

V

V

V

3. V

PWMH

, V

5V/0

2V/0.8V

100kHz

5V

I

PWM

A

• V

PWMH

• V

PWMH

• tw

(PWM)

4. Ron (H + L), Vreg

PWML

, I

PWM

IN1

PWMH

, I

PWML

, f

PWM

, tw

reg

(PWM)

CcpCCcpB CcpA

V

CC

24V

V

OUT1

TB6549F/P

IN2 0

SB 5

P-GND S-GND

, V

, V

, f

PWML

PWML

: PWM = 2 V/0.8 V, 100 kHz, dury: 50 % (rectangle wave), Verify out1

PWM

: PWM = 5 V or PWM = 0 V.

: PWM = 2 V/0.8 V, 100 kHz、dury: 20 % (2 µs) (2 µs/rectangle wave), Verify out1

OUT2

V

V

→

24V

IO

V

5V/0

V

CcpC CcpB CcpA

reg

5

PWM

IN1

V

V

CC

OUT1

TB6549F/P

IN2 0V/5

SB 5

P-GND S-GND

• Ron (H + L): Measure Vds (Sum of upper and lower side) at IO = 0.2 A, and change it to resistor. Same as

at I

= 1.5 A.

O

• Vreg: Vreg pin Voltage.

OUT2

IO

↓

V

11

2002-08-30

TB6549F/P

V

V

V0V

V

V

V0V

5. I

6. V

L (U)

5

F (U)

, I

, V

L (L)

F (L)

30V

A

I

L(L)

V

V

CC

OUT1

PWM

IN1

reg

CcpC CcpB CcpA

TB6549F/P

IN2 0

SB 5

P-GND S-GND

OUT2

A

I

L(H)

V

→

F(H)

24V

IO

V

V

V

CcpC CcpB CcpA

reg

5

PWM

IN1

CC

V

OUT1

TB6549F/P

IN2 0

SB 5

P-GND S-GND

• V

F (U)

, V

F (L)

: I

O

= 1.5 A.

OUT2

IO

↓

V

V

F(L)

12

2002-08-30

TB6549F/P

V

7. t

ONG

24V

V

V

CcpCCcpB CcpA

reg

5

PWM

IN1 0V

CC

V

OUT1

TB6549F/P

IN2 0V

SB 0V → 5V

P-GND S-GND

• t

: SB = 0 V → 5 V. Measure the time to boost CcpA voltage up about 29 V (24 V + 5 V)

ONG

OUT2

13

2002-08-30

TB6549F/P

3.0

(1)

P

2.4

(W)

D

1.8

(2)

1.2

– Ta (TB6549P)

D

(1) When mounted on PCB

(50 × 50 × 1.6mm glass-epoxy

PCB mounting occupied 50% of

copper area.)

(2) IC only

Power dissipation P

0.6

0

0

Ambient temperature Ta (°C)

External Attachments

Symbol Use

C1 Charge pump 0.22 µF

C2 Charge pump

C3 Prevention of V

C4 Absorption of power noise 0.001 µF to 1 µF

C5 Absorption of power noise 50 µF to 100 µF

oscillation 0.1 µF to 1.0 µF

reg

– Ta (TB6549F)

P

D

6

MAX (W)

D

240 40 80 120 160 200

Recommended

Value

4

(Note)

2

No heat sink

Maximum power dissipation P

0

0 50 100 150 200

Ambient temperature Ta (°C)

Remarks

Thermal resistance

R

= 13°C/W

th (j-c)

R

= 130°C/W

th (j-a)

Note: 50 × 50 × 1 mm

Fe heat sink

Infinite heat sink

3

0.01 µF VCC = 24 V (Note)

0.033 µF V

= 12 V (Note)

CC

Note: The recommended values for charge pumps depend on the VCC value. Please refer to the Component

Description 4, Charge Pump Circuit.

14

2002-08-30

Typical Application Diagram

5 V

V

DD

PWM

PORT1

PORT2

PORT3

GND

Microcontroller

20/16

V

OUT1

CC

C

Note 1

4

10/8

14/11

7/6

C

PWM

IN1

1

2/1

CcpA CcpB CcpC

3/2

Note 4

C

2

C

3

4/3

18/15

V

reg

TB6549F/P

8/7

IN2

17/14

SB

TB6549F: Pins 1, 5, 6, 9, 13, 15, 16, and 19 are not connected.

S-GND

FIN/4,5,12,13

P-GND

11/9

Note 5

Note 3

OUT2

12/10

TB6549F/TB6549P

TB6549F/P

C5

24V

M

Note 2

Note 1: Connect VCC and P-GND through the power supply capacitor. This capacitor should be as close as possible

to the IC.

Note 2: When connecting the motor pins through the capacitor for reducing noise, connect a resistor to the capacitor

for limiting the charge current. The switching loss increases for PWM control. Therefore, whenever

practicable, avoid connecting the capacitor if PWM control is required.

Note 3: Short-circuit S-GND and P-GND as close to TB6549 as possible.

Note 4: Connect the capacitor C

to S-GND.

3

Note 5: Connect the capacitors C1 and C2 as close to TB6549 as possible, and the capacitor C1 as close to S-GND.

Note 6: Pins 4, 5, 12, and 13 of the P type are connected to the chip’s bed. Therefore, expanding their round area

produces a better heat radiation effect.

Usage Precautions

• This IC includes an overcurrent detection circuit. However, if a short circuit takes place between output pins or

if an output pin is connected to the voltage source or ground, a heavy current temporarily flows through the IC.

It might destroy the IC. This possibility should be fully considered in the design of the output line, V

and GND line. If the IC is destroyed, a heavy current might continuously flow through it as a secondary effect.

Therefore, Toshiba recommends that a fuse be connected to the power supply line.

• Install this IC properly. If not, (e.g., installing it in the wrong position), the IC might be destroyed.

CC

line,

15

2002-08-30

Package Dimensions

TB6549F/P

Weight: 0.79 g (typ.)

16

2002-08-30

Package Dimensions

TB6549F/P

Weight: 1.11 g (typ.)

17

2002-08-30

TB6549F/P

A

RESTRICTIONS ON PRODUCT USE

• TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

• The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

• The products described in this document are subject to the foreign exchange and foreign trade laws.

• The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA CORPORATION for any infringements of intellectual property or other

rights of the third parties which may result from its use. No license is granted by implication or otherwise under

any intellectual property or other rights of TOSHIBA CORPORATION or others.

000707EB

• The information contained herein is subject to change without notice.

18

2002-08-30

Loading...

Loading...