Page 1

TOSHIBA CMOS Integrated Circuit Silicon Monolithic

T B 6 5 4 8 F

3-Phase Full-Wave PWM Sensorless Controller for Brushless DC Motors

TB6548F is a 3-phase full-wave sensorless controller for

brushless DC motors. It is capable of controlling voltage by PWM

signal input. It is capable of PWM type sensorless driving when

used conjunction with TA84005F

Features

• 3-phase full-wave sensorless drive

• PWM control (PWM signal is supplied from external sources.)

• Turn-on signal output current: 20 mA

• Built-in protection against overcurrent

• Forward/reverse modes

• Built-in lead angle control function (0, 7.5, 15 and 30 degrees)

• Built-in lap turn-on function

Weight: 0.32 g (typ.)

TB6548F

1

2001-08-28

Page 2

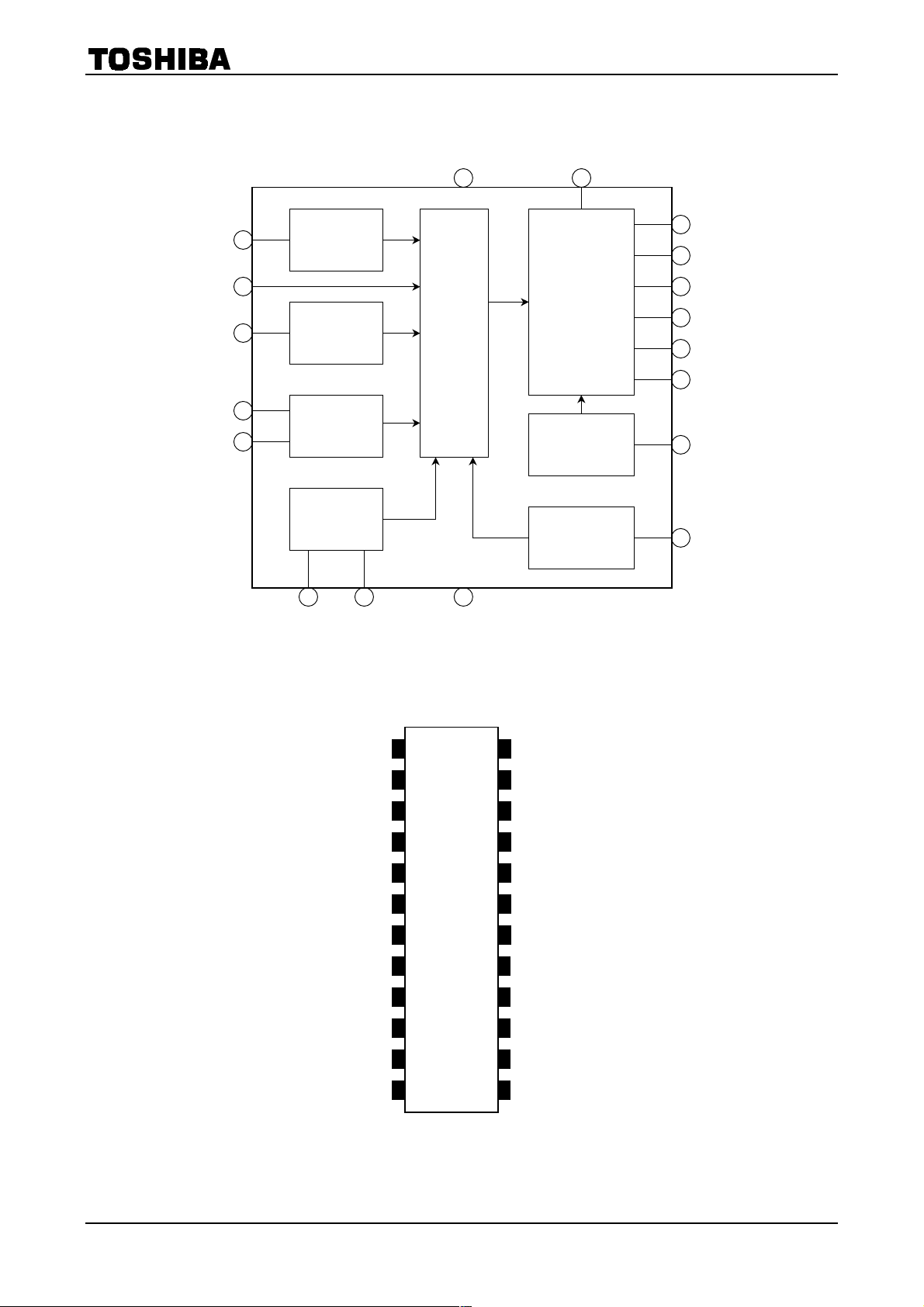

Block Diagram

TB6548F

V

13

DD

FG_OUT

6

PWM

SEL_LAP

CW_CCW

LA0

LA1

Pin Assignment

3

8

4

1

2

PWM Control

Rotation

Instruction

Circuit

Lead Angle

Setting Circuit

Clock

Generator

Circuit

10

11

Tin

XT

Timing

Control

12

GND X

Turn-on Signal

Forming Circuit

Overcurrent

Protection

Circuit

Position

Detection

Circuit

14

17

21

15

19

22

23

24

OUT_UP

OUT_VP

OUT_WP

OUT_UN

OUT_VN

OUT_WN

OC

WAVE

NC

NC

NC

X

Tin

1

2

3

4

5

6

7

8

9

10

T

11

12

24

23

22

21

20

19

18

17

16

15

14

13

WAVE

OC

OUT_WN

OUT_WP

NC

OUT_VN

NC

OUT_VP

NC

OUT_UN

OUT_UP

V

DD

LA0

LA1

PWM

CW_CCW

FG_OUT

SEL_LAP

X

GND

2

2001-08-28

Page 3

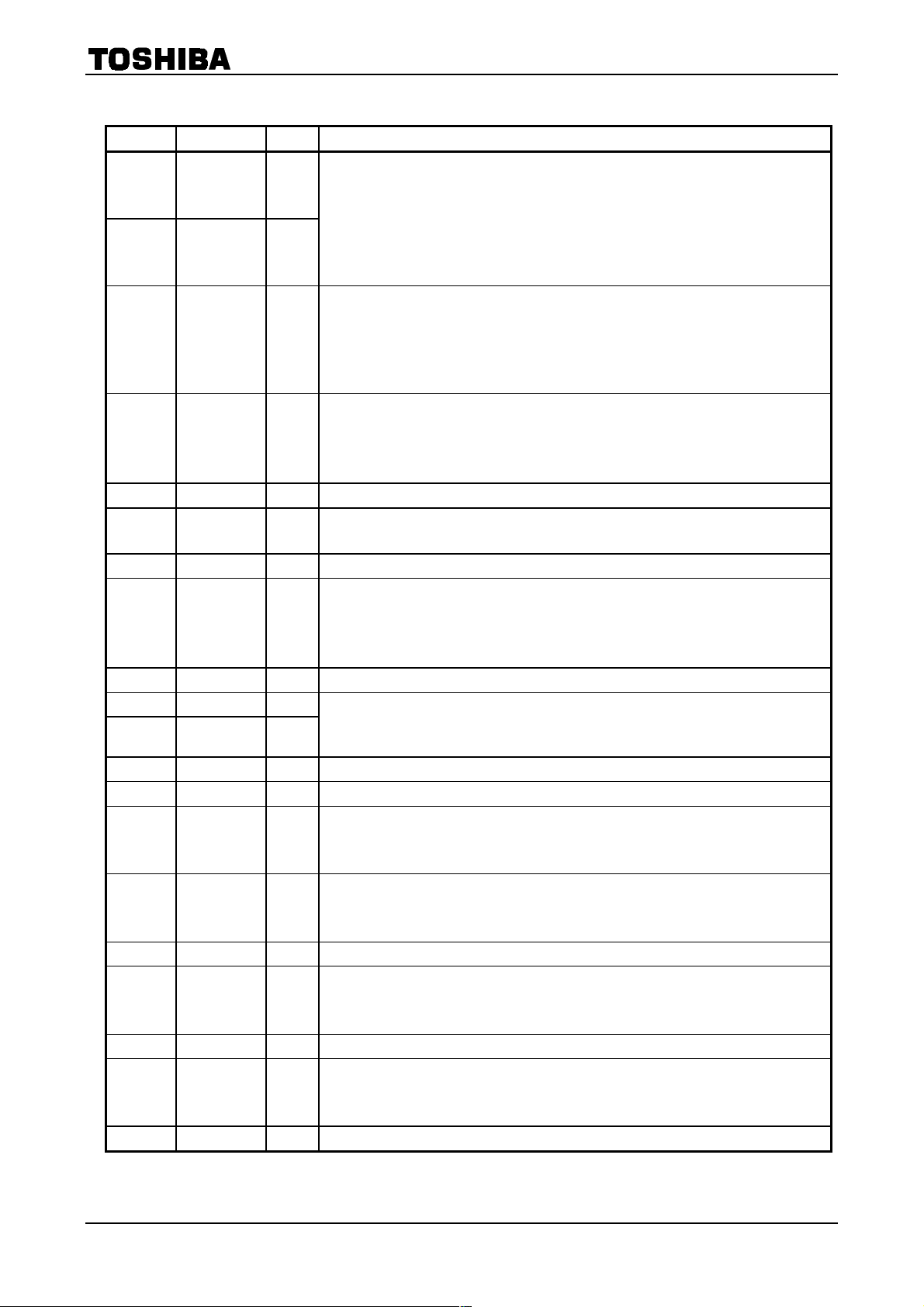

Pin Description

Pin No. Symbol I/O Description

Lead angle setting signal input pin

1 LA0 I

2 LA1 I

3 PWM I

4 CW_CCW I

5 NC Not connected

6 FG_OUT O

7 NC Not connected

8 SEL_LAP I

9 NC Not connected

10 X

11 X

12 GND Connected to GND.

13 V

14 OUT_UP O

15 OUT_UN O

16 NC Not connected

17 OUT_VP O

18 NC Not connected

19 OUT_VN O

20 NC Not connected

Tin

DD

T

• LA0 = Low, LA1 = Low: Lead angle 0 degree

• LA0 = High, LA1 = Low: Lead angle 7.5 degree

• LA0 = Low, LA1 = High: Lead angle 15 degree

• LA0 = High, LA1 = High: Lead angle 30 degree

• Built-in pull-down resistor

PWM signal input pin

• Inputs Low-active PWM signal

• Built-in pull-up resistor

• Disables input of duty-100% (Low) signal

High for 250 ns or longer is required.

Rotation direction signal input pin

• High: Reverse (U → W → V)

• Low, Open: Forward (U → V → W)

• Built-in pull-down resistor

Number of ratation detection signal output pin

• Equiralent to U-phase signal (except PWM)

Lap turn-on select pin

• Low: Lap turn-on

• High: 120 degrees turn-on

• Built-in pull-up resistor

Resonator connecting pin

• Selects starting commutation frequency.

Connected to 5-V power supply.

Starting commutation frequency f

U-phase upper turn-on signal output pin

• U-phase winding wire positive ON/OFF switching pin

• ON: Low, OFF: High

U-phase lower turn-on signal output pin

• U-phase winding wire negative ON/OFF switching pin

• ON: High, OFF: Low

V-phase upper turn-on signal output pin

• V-phase winding wire positive ON/OFF switching pin

• ON: Low, OFF: High

V-phase lower turn-on signal output pin

• V-phase winding wire negative ON/OFF switching pin

• ON: High, OFF: Low

st

TB6548F

= Resonator frequency fxt/(6 × 217)

3

2001-08-28

Page 4

Pin No. Symbol I/O Description

W-phase upper turn-on signal output pin

21 OUT_WP O

22 OUT_WN O

23 OC I

24 WAVE I

• W-phase winding wire positive ON/OFF switching

• ON: Low, OFF: High

W-phase lower turn-on signal output pin

• W-phase winding wire negative ON/OFF switching pin

• ON: High, OFF: Low

Overcurrent signal input pin

• High on this pin can put constraints on the turn-on signal which is performing PWM

control.

• Built-in pull-up resistor

Positional signal input pin

• Inputs majority logic synthesis signal of three-phase pin voltage.

• Built-in pull-up resistor

Functional Description

1. Sensorless Drive

On receipt of PWM signal start instruction turn-in signal for forcible commutation (commutation

irrespective of the motor’s rotor position) is output and the motor starts to rotate. The motor’s rotation

causes induced voltage on winding wire pin for each phase.

When signals indicating positive or negative for pin voltage (including induced voltage) for each phase

are input on respective positional signal input pin, the turn-on signal for forcible commutation is

automatically switched to turn-on signal for positional signal (induced voltage).

Thereafter turn-on signal is formed according to the induced voltage contained in the pin voltage so as to

drive the brushless DC motor.

2. Starting commutation frequency

The forcible commutation frequency at the time of start is determined by the resonator’s frequency and

the number of counter bit (within the IC).

Starting commutation frequency f

The forcible commutation frequency at the time of start can be adjusted using inertia of the motor and

load.

• The forcible commutation frequency should be set higher as the number of magnetic poles increases.

• The forcible commutation frequency should be set lower as the inertia of the load increases.

3. PWM Control

PWM signal can be reflected in turn-on signal by supplying PWM signal from external sources.

The frequency of the PWM signal shoud be set adequately high with regard to the electrical frequency of

the motor and in accordance to the switching characteristics of the drive circuit.

Because positional detection is performed in synchronization with the falling edges of PWM signal,

positional detection cannot be performed with 0% duty or 100% duty.

(resonator pin and counter bit select pin)

= Resonator frequency fxt/(6 × 2

st

pin

(bit + 3)

TB6548F

) bit = 14

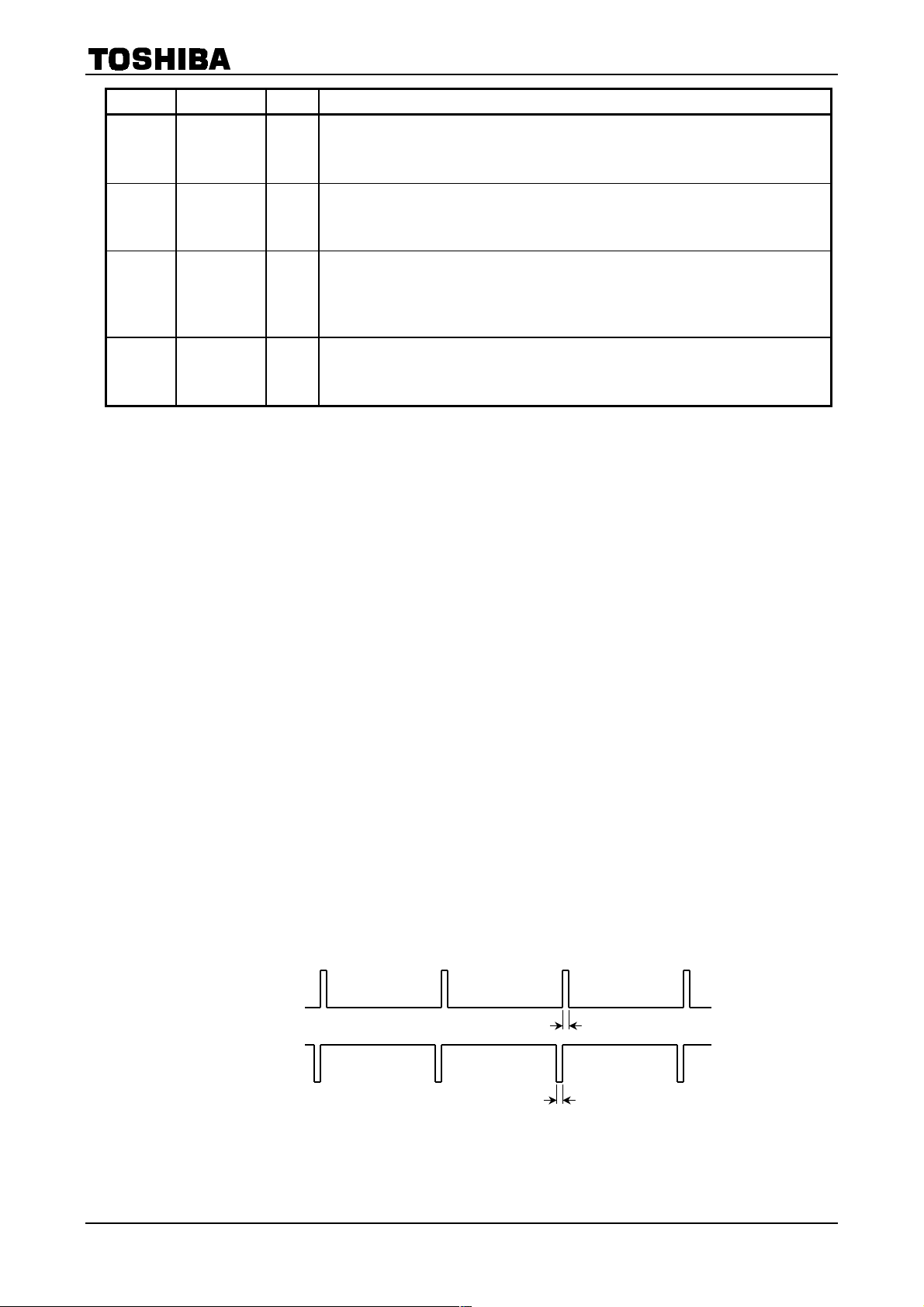

Duty (max)

250 ns

Duty (min)

250 ns

The voltage applied to the motor is duty 100% because of the storage time of the drive circuit even if the

duty is 99%.

4

2001-08-28

Page 5

4. PWM Control

Upper turn-on

signal (OUT-P)

Lower turn-on

signal (OUT-N)

Output

voltage

of TA84005F

TB6548F

5

2001-08-28

Page 6

5. Positional Variation

Since positional detection is performed in synchronization with PWM signal, positional variation occurs

in connection with the frequency of PWM signal. Be especially careful when the IC is used for high-speed

motors.

PWM signal

Output voltage

of TA84005F

TB6548F

Reference voltage

Pin voltage

Positional signal

Ideal detection timing Actual detection timing

Variation is calculated by detecting at two consecutive rising edges of PWM signal.

1/f

< Detection time variation < 2/f

p

p

fp: PWM frequency

6

2001-08-28

Page 7

6. Lead Angle Control

The lead angle is 0 degree during the starting forcible commutation and when normal commutation is

started, automatically changes to the lead angle which has been set using LA0 and LA1. However, if both

LA0 and LA1 are set for High, the lead angle is 30 degrees in the starting forcible commutation as well as

in normal commutation.

TB6548F

Induced voltage

Turn-on signal

(1) Lead angle: 0 degree

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

(2) Lead angle: 7.5 degrees

(3) Lead angle: 15 degree

(4) Lead angle: 30 degree

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

7. Lap Turn-on Control

When SEL_LAP = High, the turn-on degree is 120 degrees. When SEL_LAP = Low, Lap Turn-on Mode

starts.

In Lap Turn-on Mode, the time between zero-cross point and the 120 degrees turn-on timing becomes

longer (shaded area in the below chart) so as to create some overlap when switching turn on signals. The

lap time differs depending ong the lead angle setting.

30 degrees

22.5 degrees

15 degrees

PWM control

PWM control

U V

PWM control

PWM control

PWM control

PWM control

PWM control

PWM control

PWM control

W

PWM control

PWM control

Induced voltage

Turn-on signal

(1) Lead angle: 0 degree

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

(2) Lead angle: 7.5 degrees

(3) Lead angle: 15 degree

(4) Lead angle: 30 degree

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

OUT_UP

OUT_UN

OUT_VP

OUT_VN

OUT_WP

OUT_WN

PWM control

PWM control

U V

PWM control

PWM control

PWM control

PWM control

PWM control

PWM control

PWM control

7

W

PWM control

PWM control

2001-08-28

Page 8

8. Start/Stop Control

Start/Stop is controlled using PWM signal input pin.

A stop is acknowledged when PWM signal duty is 0, and a start is acknowledged when ON-signal of a

frequency 4 times higher than the resonator frequency or even higher is input continuously.

Timing chart

PWM signal

Detection

timing

Start

TB6548F

512 periods at the resonator frequency

PWM signal

Detection

timing

Stop

512 periods at the resonator frequency

Note: Take sufficient care for noise on PWM signal input pin.

First detection

First detection

Second detection Start

Second detection

and stop

8

2001-08-28

Page 9

TB6548F

Maximum Ratings

Characteristics Symbol Rating Unit

Power supply voltage V

Input voltage V

Turn-on signal output current I

Power dissipation PD 590 mW

Operating temperature T

Storage temperature T

(Ta ==== 25°C)

DD

in

OUT

opr

stg

5.5 V

−0.3 to V

+ 0.3 V

DD

20 mA

−30 to 85 °C

−55 to 150 °C

Recommended Operating Conditions

Characteristics

Power supply voltage V

Input voltage V

PWM frequency f

Oscillation frequency f

Symbol Test Condition Min Typ. Max Unit

DD

in

PWM

osc

(Ta ==== −−−−30 to 85°C)

4.5 5.0 5.5 V

−0.3

16 kHz

1.0 10 MHz

V

DD

+ 0.3

V

9

2001-08-28

Page 10

TB6548F

Electrical Characteristics

Characteristics

Static power supply current I

Dynamic power supply current I

Input current

Input voltage

Input hysteresis voltage V

Output voltage

Output leak current

Output delay time

(Ta ==== 25°C, VDD ==== 5 V)

Symbol

DD

DD (opr)

I

(H)

IN-1

I

(L)

IN-1

I

(H) VIN = 5 V, CW_CCW, LA0, LA1 50 75

IN-2

(L) VIN = 0 V, CW_CCW, LA0, LA1 −1 0

I

IN-2

VIN (H)

(L)

V

IN

H

V

(H)

O-1

V

(L)

O-1

V

(H)

O-2

V

(L)

O-2

V

(H)

O-3

V

(L)

O-3

IL (H)

Test

Circuit

PWM = H, X

PWM = 50% Duty, X

= 5 V, PWM, OC, WAVE_U,

V

IN

SEL_LAP

= 0 V, PWM, OC, WAVE_U,

V

IN

SEL_LAP

PWM, OC, SEL_LAP, CW_CCW

WAVE_U, LA0, LA1

PWM, OC, SEL_LAP, CW_CCW

WAVE_U, LA0, LA1

PWM, OC, SEL_LAP, CW_CCW

WAVE_U, LA0, LA1

I

= −1 mA

OH

OUT_UP, OUT_VP, OUT_WP

I

= 20 mA

OL

OUT_UP, OUT_VP, OUT_WP

I

= −20 mA

OH

OUT_UN, OUT_VN, OUT_WN

I

= 1 mA

OL

OUT_UN, OUT_VN, OUT_WN

I

= −0.5 mA

OH

FG_OUT

I

= 0.5 mA

OL

FG_OUT

= 5.5 V, V

V

DD

OUT_UP, OUT_VP, OUT_WP

OUT_UN, OUT_VN, OUT_WN

Test Condition Min Typ. Max Unit

= H 0.1 0.3 mA

Tin

= 4 MHz 1 3 mA

Tin

0 1

−75 −50

3.5 5

GND 1.5

0.6 V

4.3 V

GND 0.5

4.0 V

GND 0.5

4.0 V

GND 0.5

= 0 V

OUT

0 10

FG_OUT

(L)

I

L

= 5.5 V, V

V

DD

OUT_UP, OUT_VP, OUT_WP

OUT_UN, OUT_VN, OUT_WN

OUT

= 5.5 V

0 10

FG_OUT

t

pLH

t

pHL

PWM-Output

0.5 1

0.5 1

DD

DD

DD

µA

V

V

µA

µs

10

2001-08-28

Page 11

Application Circuit Example

VDD = 5 V

V

DD

PWM signal

PWM

WAVE

TB6548F

VM = 20 V

Positional detection signal

COMP

FG signal

OUT_UP

OUT_UN

OUT_VP

GND

OUT_VN

OUT_WP

OUT_WN

OC

Over current detection

signal

FG_OUT

<TB6548F> <TA84005F>

IN_UP

IN_UN

IN_VP

IN_VN

IN_WP

IN_WN

ISD

GND

OUT_U

OUT_V

OUT_W

RF

VISD1

VISD2

M

1 Ω

0.01 µF

Note 1: Take enough care in designing output V

line and GND line to avoid short circuit between outputs, VDD

DD

fault or GND fault which may cause the IC to break down.

Note 2: The above application circuit and values mentioned are just an example for reference. Since the values may

vary depending on the motor to be used, appropriate values must be determined through experiments before

using the device.

11

2001-08-28

Page 12

Package Dimensions

TB6548F

Weight: 0.32 g (typ.)

12

2001-08-28

Page 13

TB6548F

RESTRICTIONS ON PRODUCT USE

• TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

• The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

• The products described in this document are subject to the foreign exchange and foreign trade laws.

• The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA CORPORATION for any infringements of intellectual property or other

rights of the third parties which may result from its use. No license is granted by implication or otherwise under

any intellectual property or other rights of TOSHIBA CORPORATION or others.

000707EBA

• The information contained herein is subject to change without notice.

13

2001-08-28

Loading...

Loading...