Page 1

Strats

ELECTRONIC KEY TELEPHONE SYSTEM

INSTALLATION AND MAINTENANCE MANUAL

S

Page 2

-

TOSHIBA SYSTEM PRACTICES

ELECTRONIC KEY TELEPHONE SYSTEM

e..

TOSHIBA PUBLICATIONS

SECTION 100-003-000 .

JULY

1984

Strata” S

(AKA: HARRIS LANIER SERIES III)

ELECTRONIC KEY TELEPHONE SYSTEM

INSTALLATION AND MAINTENANCE MANUAL

TABLE OF CONTENTS

FCC REGULATIONS

GENERAL DESCRIPTION

INSTALLATION INSTRUCTIONS

POWER SUPPLY INSTALLATION INSTRUCTIONS

PROGRAMMING PROCEDURES

OPERATING PROCEDURES

FAULT FINDING PROCEDURES

.

SECTION 100-003-000

SECTION 100-003-l 00

SECTION 100-003-200

SECTION 100-003-250

SECTION 100-003-300

SECTION 100-003-400

SECTION 100-003-500

Page 3

TOSHIBA SYSTEM PRACTICES

ELECTRONIC KEY TELEPHONE SYSTEM

GENERAL DESCRIPTION

SECTION 100-003-l 00

Strata

S@

GENERAL DESCRIPTION

,.--

Page 4

P

...

TOSHIBA SYSTEM PRACTICES

ELECTRONIC KEY TELEPHONE SYSTEM

_..

PARAGRAPH

TABLE of CONTENTS

ILLUSTRATION LIST

01

02

02.00

02.10

03

04

05

06

06.00

06.10

06.20

06.30

06.40

07

07.00

07.10

07.20

GENERAL

PHYSICALDESCRIPTI’ONS’:::::::::::::::::::::::::

Key Service Unit

Electronic Key Telephone

TABLE A-SUMMARY OF

ELECTRICAL CHARACTERISTICS

FEATURES and SERVICES

TABLEB-STANDARDFEATURES’:::::::::::::::::::::: 5

TABLE C-OPTIONAL FEATURES

SYSTEM OPERATION

SYSTEM CONFIGURATION ’ : : : : : : : : : : : : : : : : : : : : : : : : :

Key Service Unit

Power Supply Assembly

Station Equipment

Installation

Maintenance

FEATURESandOPERATlON

General

Standard Features

OptionalFeatures

................................

......................

................................

GENERAL

SECTION 100-003-l 00

Strata S

GENERAL DESCRIPTION

TABLE

............................

............................

............................

............................

of CONTENTS

SUBJECT

ELEC;R;C~;CHARACTERlST;CS -

......................

...................... 5

........................

...........................

................

...................

...................

: : : : : : : : : :

::::::::

::::::::

OESCRlPTlON

JULY 1994

PAGE

i

i

1

1

1

2

4 .

5

5

6

8

8

8

9

10

10

10

10

10

12

NUMBER

1

2

3

4

5

6

7

8

3

10

11

12

13

14

15

TITLE

MKSU (Dimensions)

MKSU Cabinet

MKSU (Internal)

1 O-key “S” Electronic Key Telephone (EKT)

1 O-key Speakerphone EKT

Busy Lamp Field (BLF) EKT

20-key

Executive EKT

SystemDiagram

Functional Block Diagram

MKSU (Internal)

1 O-key

Key Layout

lo-key

BLF EKT

PO-keyEKT”::.

“S”

EKT

EKT

...............................

...............................

..........................

.............................

............................

................

.......................

.......................

......................................

........................

............................

............................

.....................................

. .

-

::::::::

:::::::::

PAGE

1

1

1

2

3

3

3

6

7

8

3

3

9

10

10

Page 5

P

GENERAL

DESCRIPTION

SECTION 100-003-100

JULY 1984

w..

Ot GENERAL-

01 .OO Summary Description

01.01

Strata

S is an electronic key telephone system with many standard features utilizing stored program control, custom LSI circuitry,

solid-state space division switching, and reduced

station cabling. Served by a key service unit

(MKSU) housed in a single cabinet, the system has

a capacity of three central office/PBX lines, one

intercom line, and eight station lines.

01.02 Strata S utilizes specially designed

electronic key telephones (EKTs). Each EKT is connected to the system via industry-standard 2-pair

cabling, and is equipped with a push-button dial

pad. Solid-state electronics within the MKSU

translate signals from the station dial pad into

either DTMF or rotary dial signals, as required by

the central off ice.

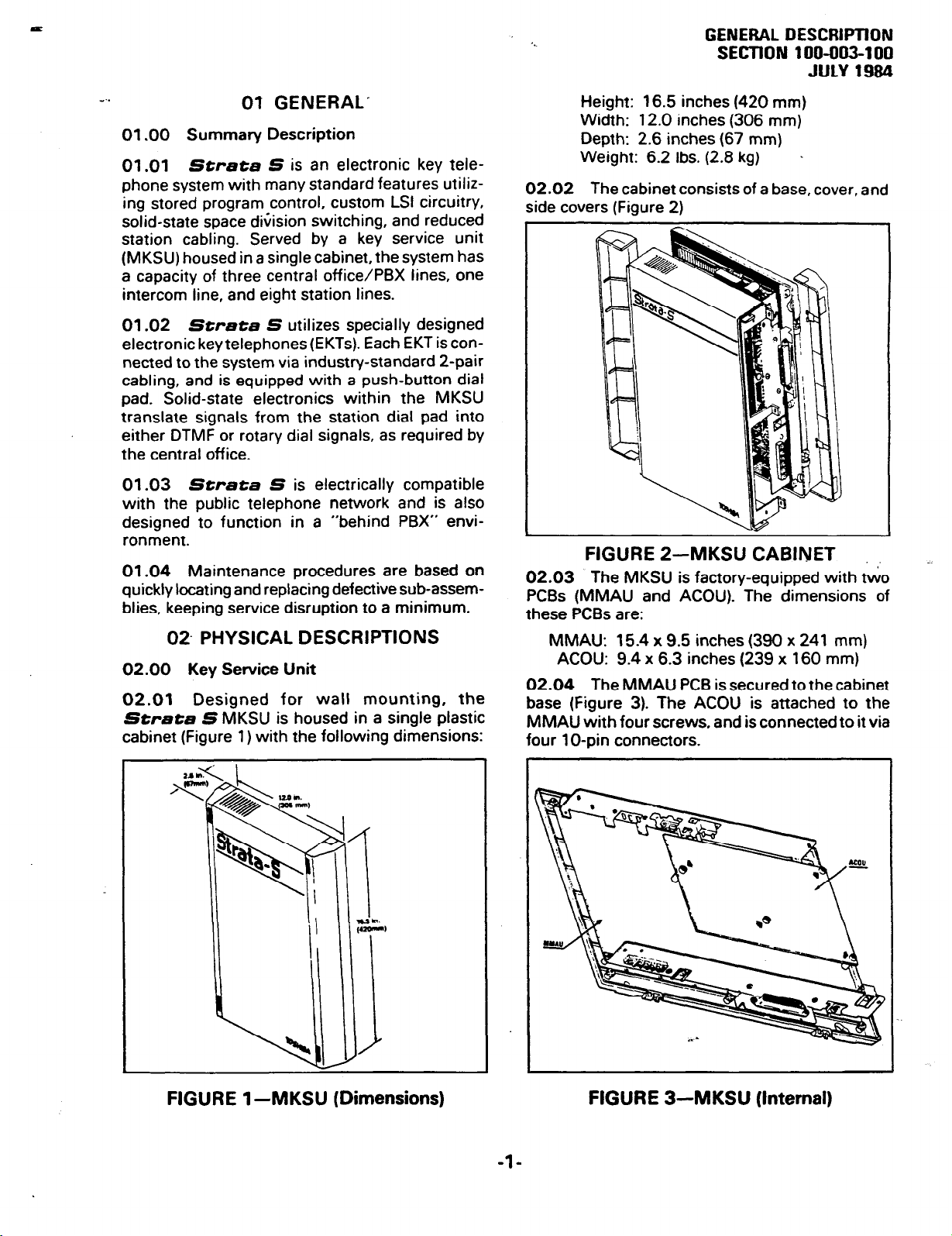

02.02 The cabinet consists of a base, cover. and

side covers (Figure 2)

Height: 16.5 inches (420 mm)

Width: 12.0 inches (306 mm)

Depth: 2.6 inches (67 mm)

Weight: 6.2 Ibs.

(2.8

kg) .

01.03 Strata S is electrically compatible

with the public telephone network and is also

designed to function in a “behind PBX” environment.

01.04 Maintenance procedures are based on

quickly locating and replacing defective sub-assemblies, keeping service disruption to a minimum.

02 PHYSICAL DESCRIPTIONS

02.00 Key Service Unit

02.01 Designed for wall mounting, the

Strata S MKSU is housed in a single plastic

cabinet (Figure 1) with the following dimensions:

I

FIGURE 2-MKSU CABINET

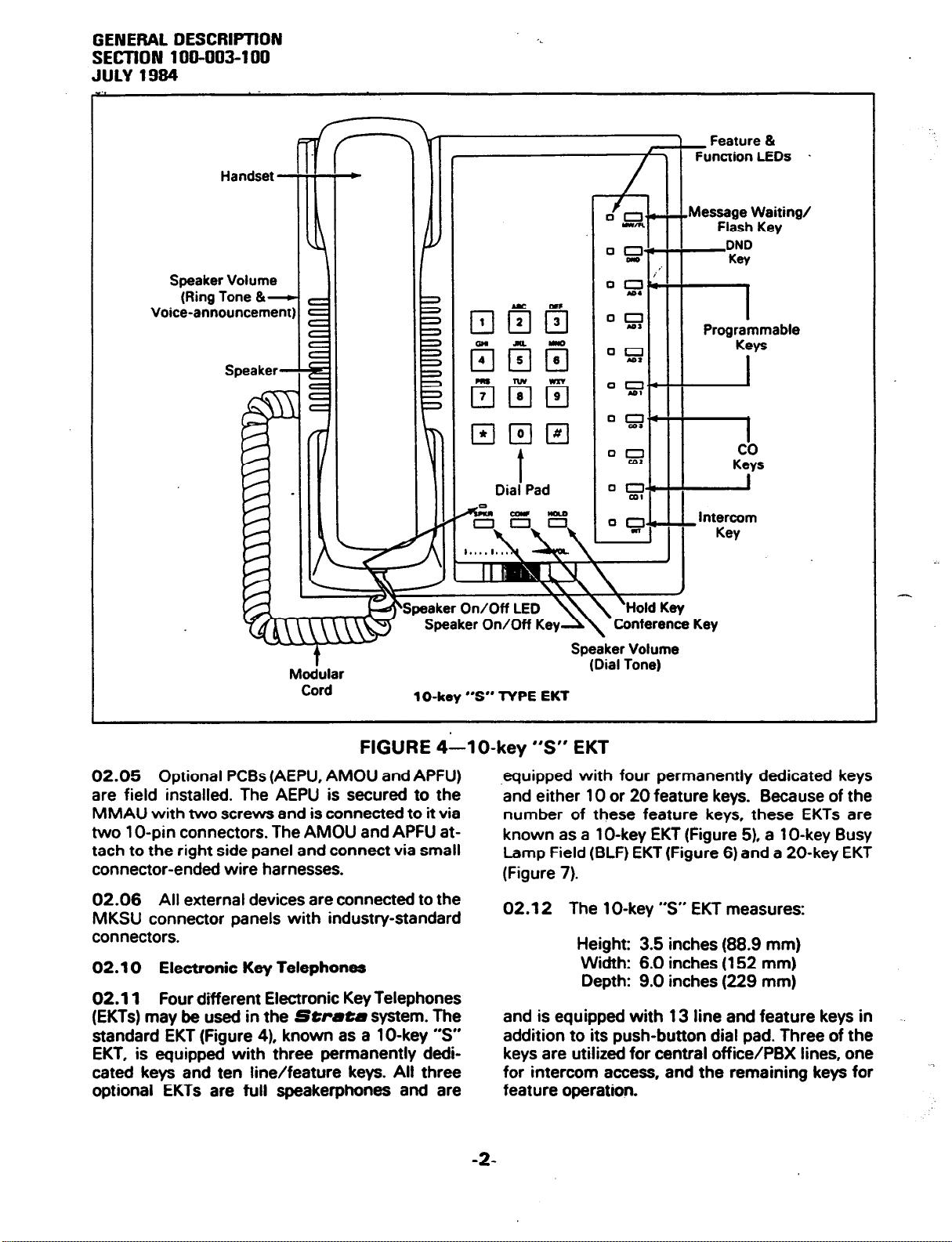

02.03 The MKSU is factory-equipped with two

PCBs (MMAU and ACOU). The dimensions of

these PCBs are:

MMAU: 15.4 x 9.5 inches (390 x 241 mm)

ACOU: 9.4 x 6.3 inches (239 x 160 mm)

02.04

base (Figure 3). The ACOU is attached to the

MMAU with four screws. and is connected to it via

four 1 O-pin connectors.

The MMAU PCB is secured to the cabinet

FIGURE 1 -MKSU (Dimensions)

FIGURE 3-MKSU (Internal)

-l-

Page 6

GENERAL DESCRIPTION

SEGTION 106-003-100

JULY 1984

Speaker

-I

‘.

/

o O.+,,Messege Waiting/

YIR

I

“52

CQ

3

cl

Yo

I

OSb

OS

“- Kers

,.

Flash Key

DND

Kay

I

Programmable

Modluler

Cord

1 O-key l *S’* TVPE EKT

L

FIGURE 4-l O-key “S” EKT

02.05 Optional PCBs (AEPU, AMOU and APFU)

are field installed. The AEPU is secured to the

MMAU with two screws and is connected to it via

two 1 O-pin connectors. The AMOU and APFU attach to the right side panel and connect via small

connector-ended wire harnesses.

02.06 All external devices are connected to the

MKSU connector panels with industry-standard

connectors.

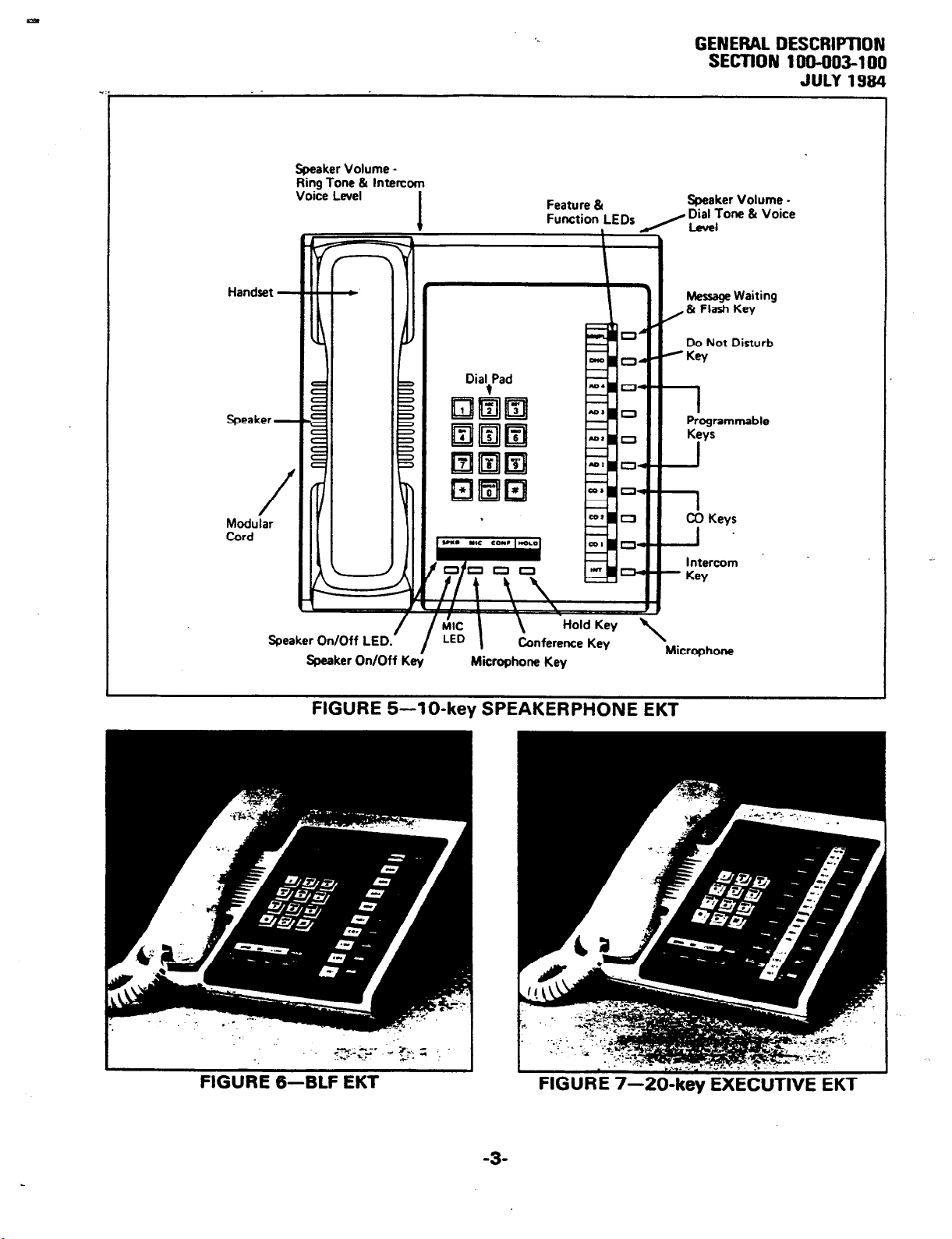

02.10 Electronic Key Telephones

02.11 Four diierent Electronic Key Telephones

(EKTs) may be used in the

standard EKT (Figure 4), known as a lo-key “S”

EKT, is equipped with three permanently dedi-

cated keys and ten line/feature keys. All three

optional EKTs are full speakerphones and are

Strata

system. The

Speaker Volume

(Dial Tone)

.equipped with four permanently dedicated keys

and either 10 or 20 feature keys. Because of the

number of these feature keys, these EKTs are

known as a lo-key EKT (Figure 5). a lo-key Busy

Lamp Field (BLF) EKT (Figure 6) and a 20-key EKT

(Figure 7).

02.12 The 1 O-key “S” EKT measures:

Height: 3.5 inches (88.9 mm)

Width: 6.0 inches (152 mm)

Depth: 9.0 inches (229 mm)

and is equipped with 13 line and feature keys in

addition to its push-button dial pad. Three of the

keys are utilized for central office/PBX lines, one

for intercom access, and the remaining keys for

feature operation.

-2-

Page 7

Speaker Volume -

Rina Tone 81 Intercom

Voice Level

‘.

Feature &

Function LEDs

GENERAL DESCRlPTlDN

SECTION 100-003-l 00

JULY 1984

!Speaker Volume -

Dial Tone & Voice

/Level

Handset -

Speaker -

/

Modular

Cord

Speaker On/Off LED.

!+eaker On/Off Key

FIGURE

5-lo-key SPEAKERPHONE EKT

/

’ rk

LED

Dial,Pad

Hold Key

\

Conference Key

,& Flash Key

/

I

/KW

.--

.-.--

1

-I .

.--

- Key

\

Microphone

Message Waiting

Do Not Disturb

I

Programmable

Keys

CO Keys

Intercom

.?yJii~$’ - ;rF. ; ‘,

I

:

4’

FIG&E 6-BLF EKT

-3-

Page 8

GENERAL DESCRIPTION

SECTION 100-003-100

JULY 1994

-..

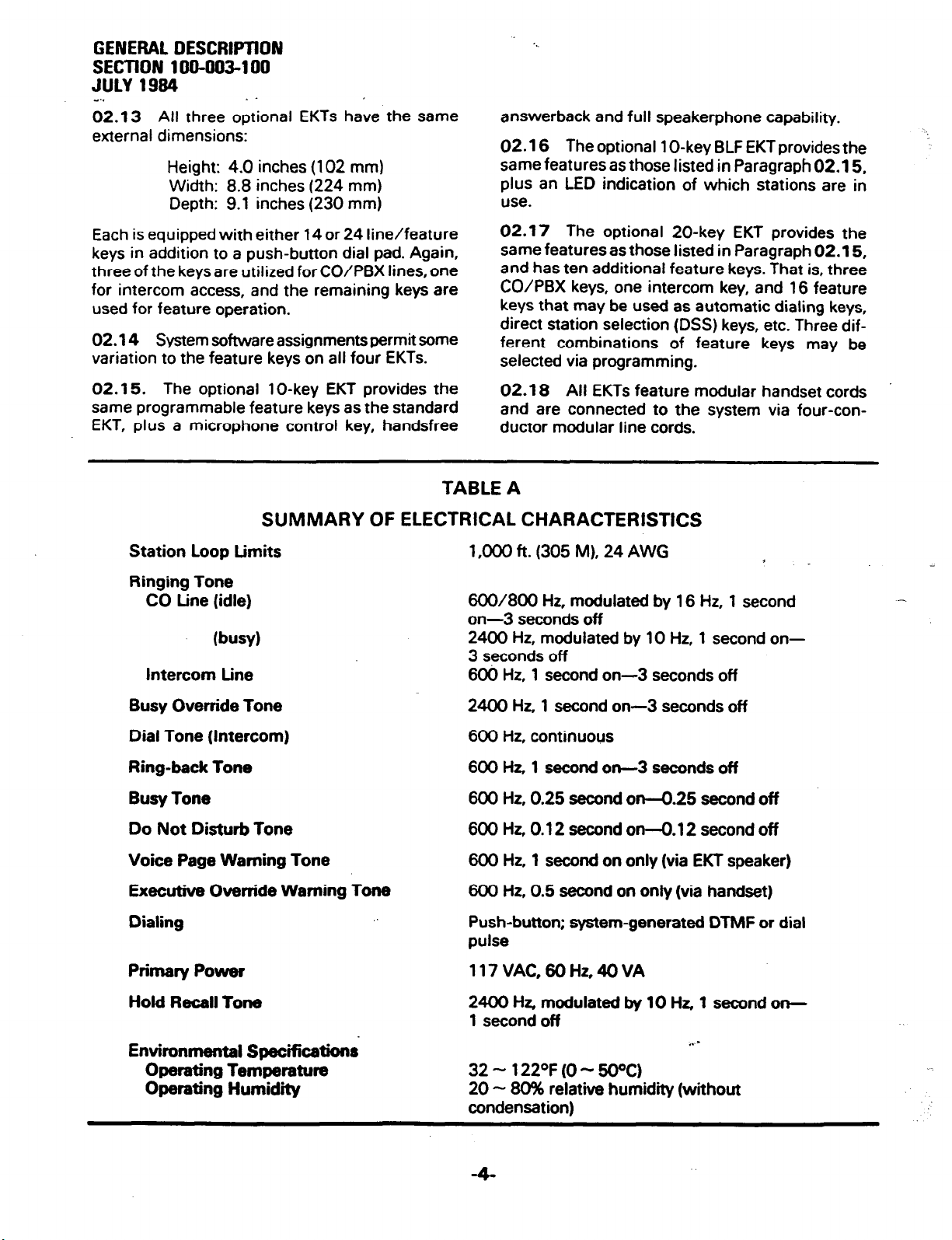

02.13 All three optional EKTs have the same

external dimensions:

Height: 4.0 inches (102 mm)

Width: 8.8 inches (224 mm)

Depth: 9.1 inches (230 mm)

. -

answerback and full speakerphone capability.

02.16 The optional 1 O-key BLF EKT provides the

same features as those listed in Paragraph 02.15,

plus an LED indication of which stations are in

use.

Each is equipped with either 14 or 24 line/feature

keys in addition to a push-button dial pad. Again,

three of the keysare utilized for CO/PBX lines, one

for intercom access, and the remaining keys are

used for feature operation.

02.14 System software assignments permit some

variation to the feature keys on all four EKTs.

02.15. The optional 1 O-key EKT provides the

same programmable feature keys as the standard

EKT, plus a microphone control key, handsfree

TABLE A

SUMMARY OF ELECTRICAL CHARACTERISTICS

Station Loop Limits

Ringing Tone

CO tine (idle)

(busy)

Intercom Line

02.17 The optional 20-key EKT provides the

same features as those listed in Paragraph 02.15,

and has ten additional feature keys. That is, three

CO/PBX keys, one intercom key, and 16 feature

keys that may be used as automatic dialing keys,

direct station selection (DSS) keys, etc. Three different combinations of feature keys may be

selected via programming.

02.18 All EKTs feature modular handset cords

and are connected to the system via four-conductor modular line cords.

1 ,DOD ft. (305 M), 24 AWG

600/800 Hz, modulated by 16 Hz, 1 second

on--3secondsoff

2400 Hz, modulated by 10 Hz, 1 second on3 seconds off

606 Hz, 1 second on-3 seconds off

4

Busy Override Tone

Dial Tone (Intercom)

Ring-back Tone

Busy Tone

Do Not Disturb Tone

Voice Page Warning Tone

Executive Override Warning Tone

Dialing

Primary Power

Hold Recall Tone

Environmental Specifications

Operating Temperature

Operating Humidity

.

2400 Hz, 1 second on-3 seconds off

600 Hz, continuous

600 Hz, 1 second on-3 seconds off

600 Hz, 0.25 second on-O.25 second off

600 Hz, 0.12 second on-O. 12 second off

600 Hz, 1 second on only (via EKT speaker)

600 Hz, 0.5 second on only (via handset)

Push-button; system-generated DTMF or dial

pulse

117VAC,6OHz,4OVA

2400 Hz, modulated by 10 Hz, 1 second on-

1 second off

. . =

32 - 122OF (0 - 50%)

20 - 6096 relative humidity (without

condensation)

Page 9

GENERAL DESCRIPTION

SECTION 100-003-l 00

JULY 1994

-.’ 03 ELECTRIC/ii CHARACTERISTICS

03.01 The electrical characteristics of the systern are detailed in Table A.

03.02 The MKSU operates from an external 24

VDC power supply.

03.03 Loss of AC power will cause operational

failure of the system. System memory, however, is

STANDARD FEATURES

l

All Call Voice Page

l

Alternate Point Answer

l

Automatic Dialing-System

l

Automatic Hold Recall

l

Automatic Privacy -

l

Automatic Release from Hold

l

Busy Override

l

Conference-Multi-station (non-amplified)

l

Conference-Multi-trunk (non-amplified)

l

Distinctive Ringing

l

DTMF and Dial Pulse Compatible

l

External Page Interface

l

Flash Key (PBX Transfer or CO Dial Tone

Recall)

protected from loss due to power failure with a

memory back-up battery. Full system reserve

power is available as an option.

04.01 The features and services of the

Strata S electronic key telephone system are

summarized in Tables B and C, which list the

standard and optional features, respectively.

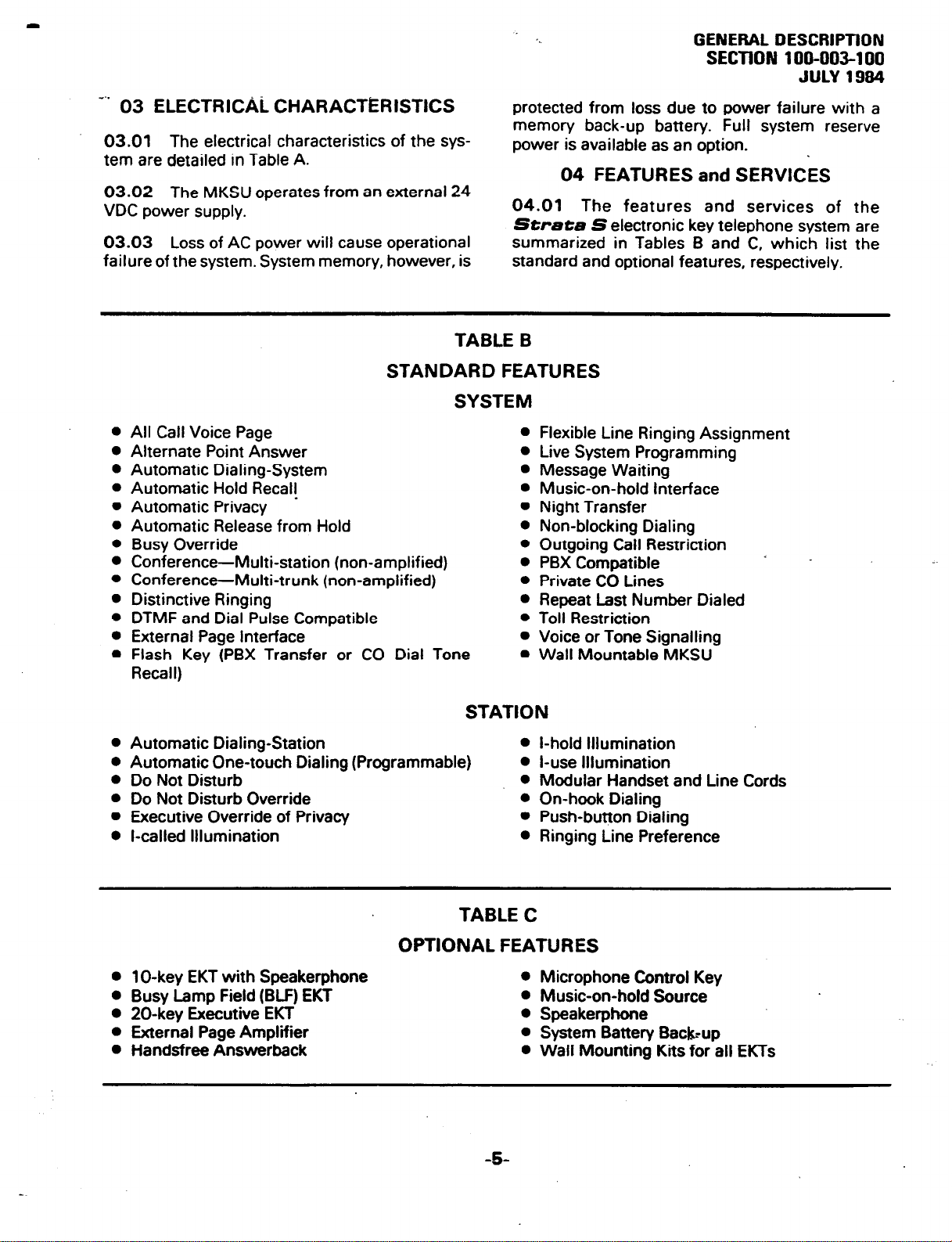

TABLE B

SYSTEM

l

l

l

l

l

l

l

l

l

l

l

l

l

04 FEATURES and SERVICES

Flexible Line Ringing Assignment

Live System Programming

Message Waiting

Music-on-hold Interface

Night Transfer

Non-blocking Dialing

Outgoing Call Restriction

PBX Compatible

Private CO Lines

Repeat Last Number Dialed

Toll Restriction

Voice or Tone Signalling

Wall Mountable MKSU

l

Automatic Dialing-Station

l

Automatic One-touch Dialing (Programmable)

l

Do Not Disturb

l

Do Not Disturb Override

l

Executive Override of Privacy

l

l-called Illumination

OPTIONAL FEATURES

0 1 O-key EKT with

l

Busy Lamp Field

l

20-key

l

External Page Amplifier

l

Handsfree Answerback

Executive EKT

Speakerphone

(BLF) EKT

STATION

l

l

l

l

l

l

TABLE C

l

l

l

l

l

-5

i-hold Illumination

l-use Illumination

Modular Handset and Line Cords

On-hook Dialing

Push-button Dialing

Ringing Line Preference

Microphone

Music-on-hold

Control Key

Source

Speakerphone

System Battery Baaup

Wall

Mounting Kits for all EKTs

Page 10

GENERAL DESCRIPTION

SECTION 100-003-l 00

AJLY 1984

M..

05 SYSTEii OPERATIO’N

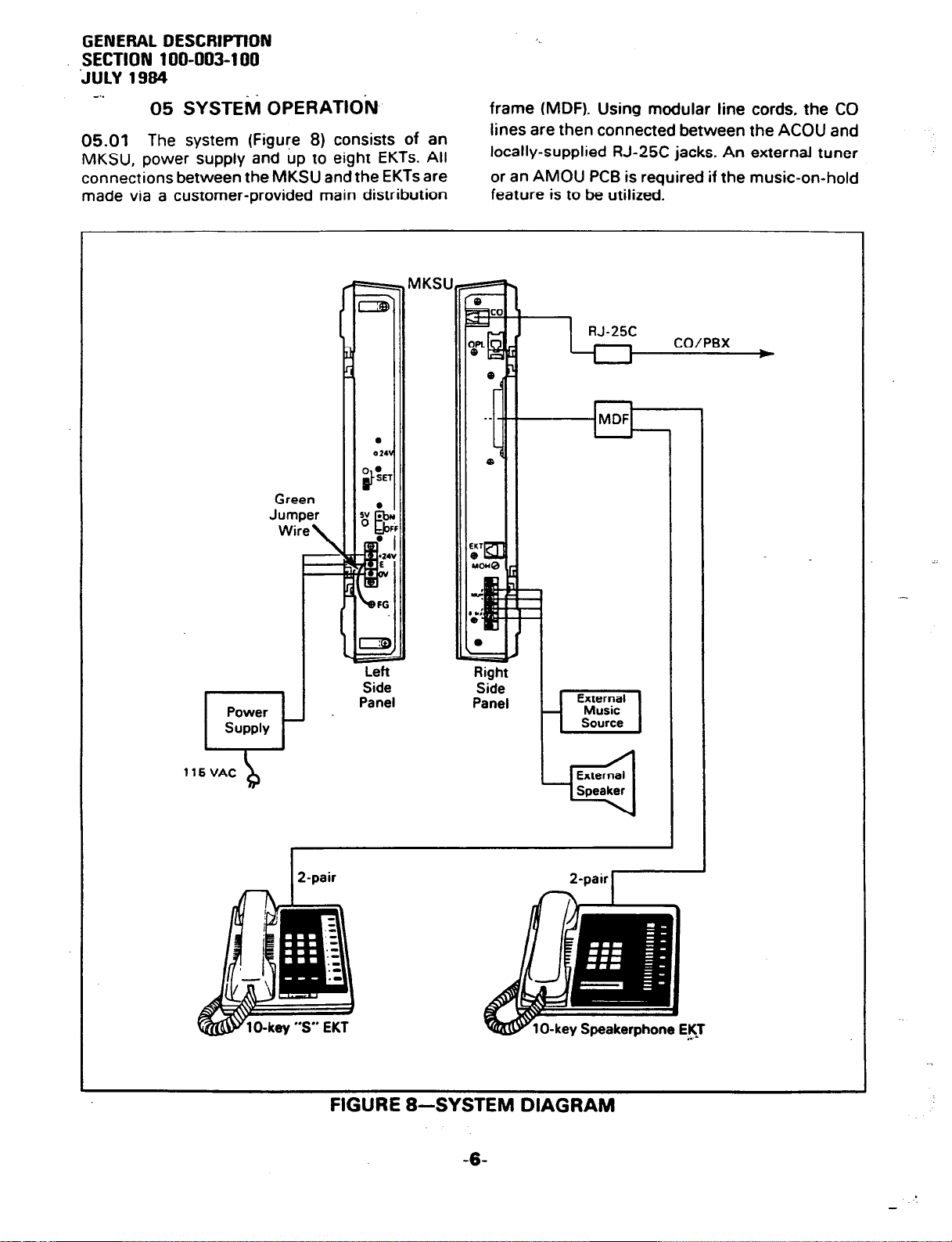

05.01 The system (Figure 8) consists of an

MKSU, power supply and up to eight EKTs. All

connections between the MKSU and the EKTs are

made via a customer-provided main distribution

MKSU MKSU

frame (MDF). Using modular line cords, the CO

lines are then connected between the ACOU and

locally-supplied RJ-25C jacks. An external tuner

or an AMOU PCB is required if the music-on-hold

feature is to be utilized.

5 VAC

Side

Panel

b

f External 1

2-pair

n +

FIGURE 8-SYSTEM DIAGRAM

-6-

Page 11

E

‘.

GENERAL DESCRIPTION

SECTION 100-003-l 00

JULY 1994

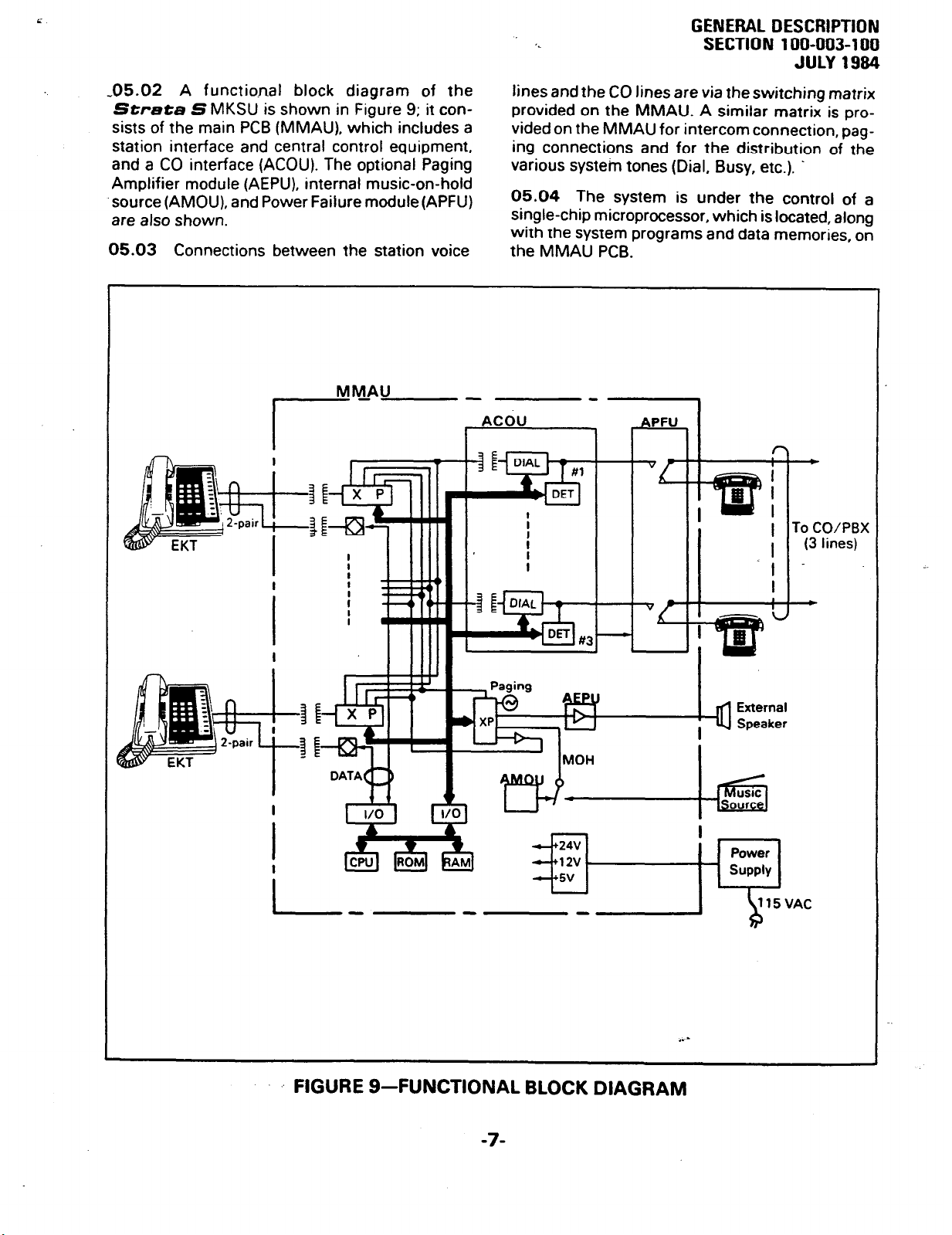

-05.02 A functio.nal block diagram of the

Strata S MKSU is shown in Figure 9; it con-

sists of the main PCB (MMAU), which includes a

station interface and central control equipment,

and a CO interface (ACOU). The optional Paging

Amplifier module (AEPU), internal music-on-hold

.source (AMOU), and Power Failure module(APFU)

are also shown.

05.03 Connections between the station voice

MM-AU

I---- -ncou - --z-I

lines and the CO lines are via theswitching matrix

provided on the MMAU. A similar matrix is provided on the MMAU for intercom connection, pag-

ing connections and for the distribution of the

various system tones (Dial, Busy, etc.). .

05.04 The system is under the control of a

single-chip microprocessor, which is located, along

with the system programs and data memories, on

the MMAU PCB.

-

To

CO/PBX

1 (3 lines)

I

DATA

-

115VAC

b

. . -

FIGURE 9-FUNCTIONAL BLOCK DIAGRAM

-7-

Page 12

GENERAL DESCRIPTION

SECTION 100-003-l 00

JULY 1984

e..

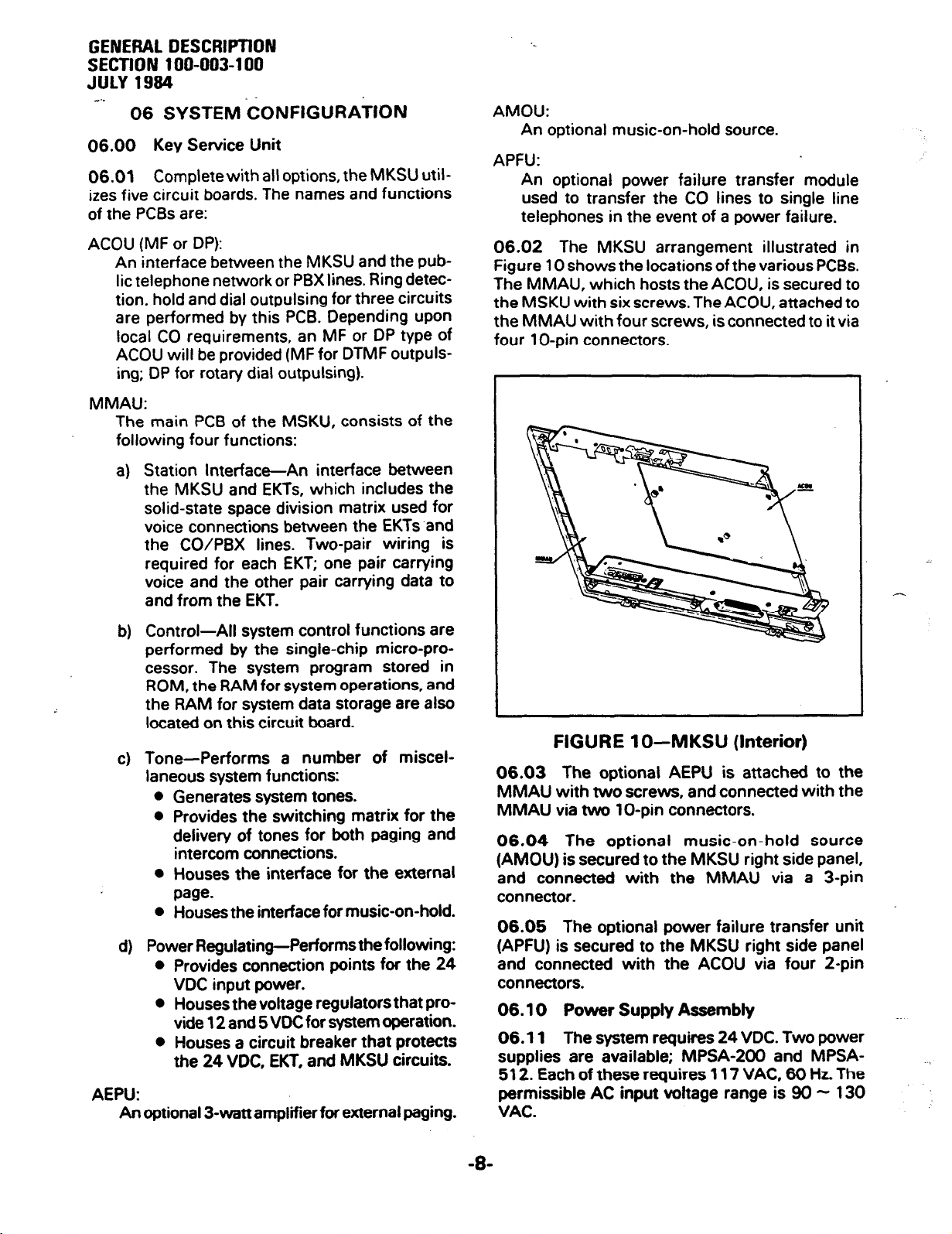

06 SYSTEM CONFIGURATION

06.00 Key Service Unit

06.01 Completewith all options, the MKSU util-

izes five circuit boards. The names and functions

of the PCBs are:

AMOU:

An optional music-on-hold source.

APFU:

An optional power failure transfer module

used to transfer the CO lines to single line

telephones in the event of a power failure.

ACOU (MF or DP):

An interface between the MKSU and the pub-

lic telephone network or PBX lines. Ring detection, hold and dial outpulsing for three circuits

are performed by this PCB. Depending upon

local CO requirements, an MF or DP type of

ACOU will be provided (MF for DTMF outpuls-

ing; DP for rotary dial outpulsing).

MMAU:

The main PCB of the MSKU, consists of the

following four functions:

a) Station Interface-An interface between

the MKSU and EKTs, which includes the

solid-state space division matrix used for

voice connections between the EKTs .and

the CO/PBX lines. Two-pair wiring is

required for each EKT; one pair carrying

voice and the other pair carrying data to

and from the EKT.

b) Control-All system control functions are

performed by the single-chip micro-processor. The system program stored in

ROM, the RAM for system operations, and

the RAM for system data storage are also

located on this circuit board.

c) Tone-Performs a number of miscel-

laneous system functions:

l

Generates system tones.

0 Provides the switching matrix for the

delivery of tones for both paging and

intercom connections.

l

Houses the interface for the external

paw.

l

Houses the interface for music-on-hold.

d) Power Regulating-Performs the following:

l

Provides connection points for the 24

VDC input power.

l

Houses the voltage regulators that pro-

vide 12 and 5 VDC for system operation.

l

Houses a circuit breaker that protects

the 24 VDC, EKT, and MKSU circuits.

AEPU:

An optional 3-watt amplifier for external paging.

06.02 The MKSU arrangement illustrated in

Figure 10 shows the locations of the various PCBs.

The MMAU, which hosts the ACOU, is secured to

the MSKU with six screws. The ACOU, attached to

the MMAU with four screws, is connected to it via

four 1 O-pin connectors.

FIGURE lo-MKSU (Interior)

06.03 The optional AEPU is attached to the

MMAU with two screws, and connected with the

MMAU via two lo-pin connectors.

06.04 The optional music-on-hold source

(AMOU) is secured to the MKSU right side panel,

and connected with the MMAU via a 3-pin

connector.

06.05 The optional power failure transfer unit

(APFU) is secured to the MKSU right side panel

and connected with the ACOU via four 2-pin

connectors.

06.10 Power Supply Assembly

06.11 The system requires 24 VDC. Two power

supplies are available; MPSA-200 and MPSA-

512. Each of these requires 117 VAC, 60 Hz. The

permissible AC input voltage range is 90 - 130

VAC.

Page 13

GENERAL DESCRIPTION

SECTlON 100-003-l 00

JULY 1994

-..06.12 An optional battery back-up unit (PBBU)

is available for the MPSA-200. With the optional

battery back-up assembly installed, all functions of

the Strata S system. will continue to operate

for several hours (the actual time period is in direct

ratio to the type and size of batteries selected) after

a loss of normal electrical power. No calls will be

disconnected during switch-over to battery power.

1 O-key 1 O-key

#l

#2

20-key 20-key 20-key

#I #2 #3

FIGURE 1 l-l O-key “S” EKT

06.20 Station Equipment

06.21

“S” electronic key telephone (Figure 11) are:

handset, dial pad, speaker, sliding ringing/speaker

volume control, 3-position volume control, one

intercom key, three CO/PBX line keys and nine

feature keys. LED indicators are provided for all

keys except FOLD] and [m%] keys. With the

exception of the three permanently dedicated

keys, the feature keys can be assigned to one of

two modes by programming (see Figure 12).

06.22 Standard features of the 1 O-key “S” EKT

include, among other standard features, paging,

one-touch automatic dialing keys,

In initialized mode, three of the keys are utilized for

CO/PBX lines, one for intercom

for

Do Not Disturb and Message Waiting/Flash.

The principal components of the lo-key

_- -.

and auto-redial.

access, four keys

one-touch automatic dialing and one each for

FIGURE 12-KEY LAYOUT

06.23 The optional lo-key EKT (Figure 13) provides the same programmable feature keys as the

standard EKT. plus a microphone control keym,

handsfree answerback and full speakerphone

capability.

I

FIGURE 13-l O-key EKT

I

-S-

Page 14

GENEML DESCRlPTlDN

SECTION 100-003-l 00

aJ~lY 1994 _ _

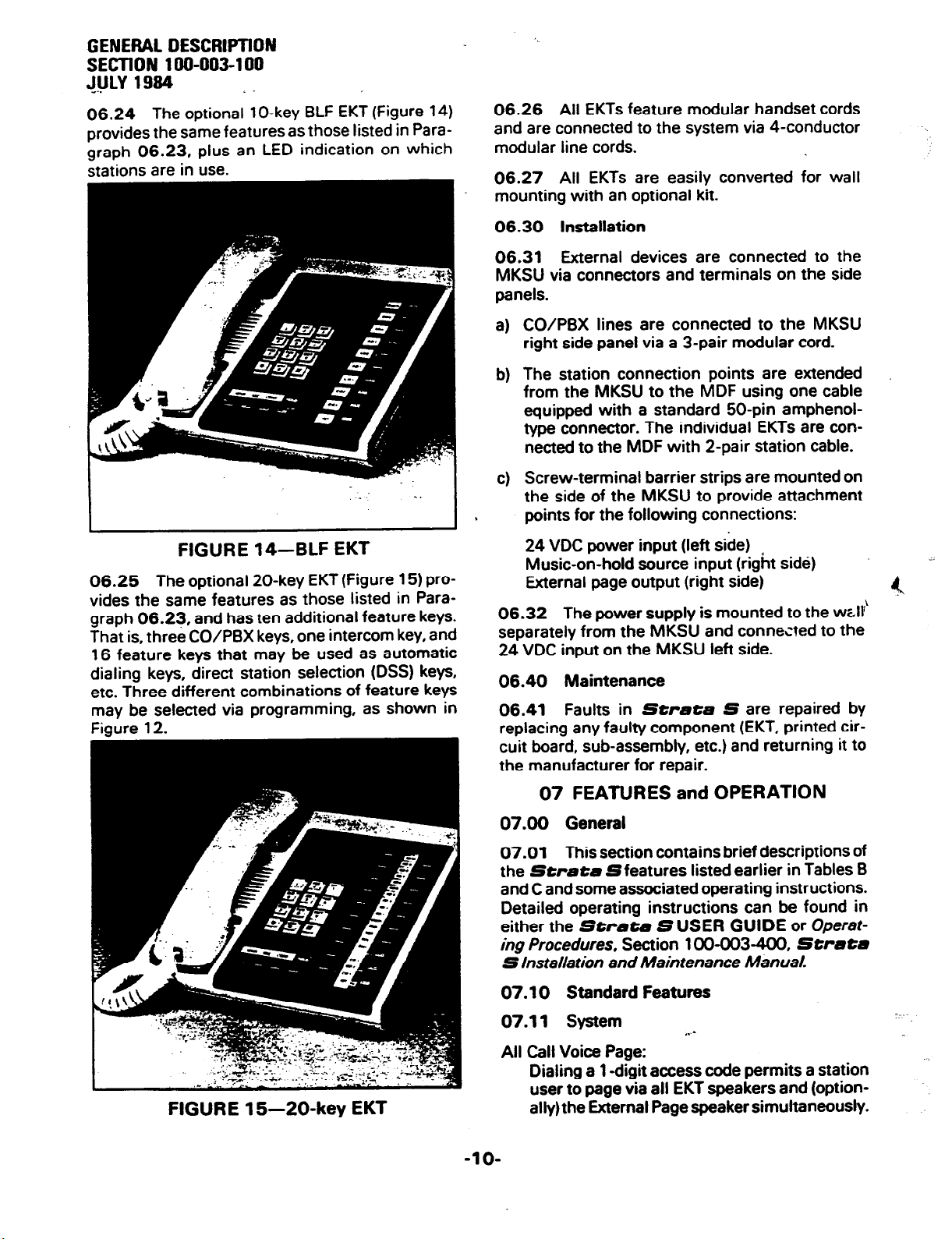

06.24 The optional lo-key BLF EKT (Figure 14)

provides the same features as those listed in Paragraph 06.23, plus an LED indication on which

stations are in use.

- :

. .

I

FIGURE 14--BLF EKT

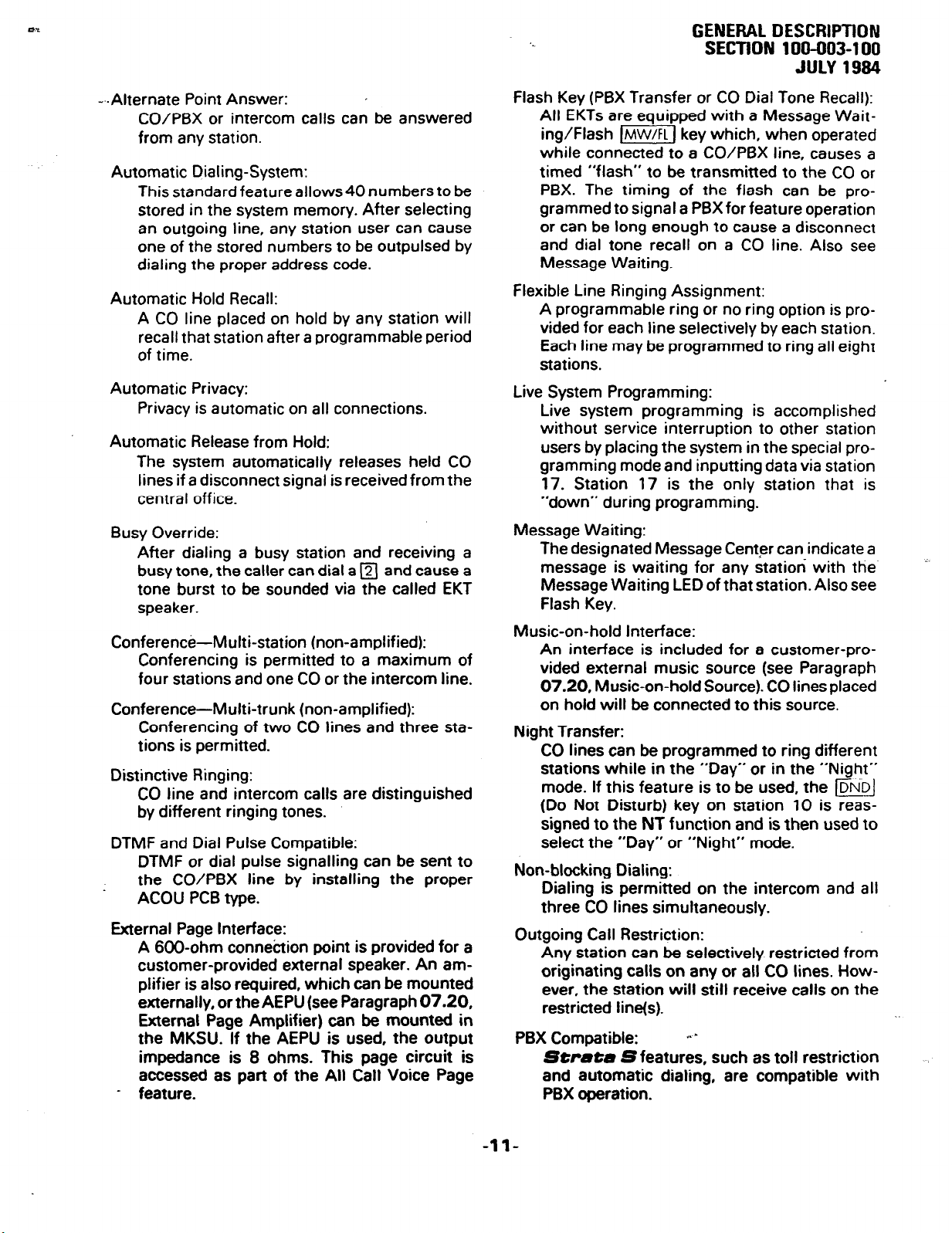

06.25 The optional 20-key EKT (Figure 15) provides the same features as those listed in Para-

graph 06.23, and has ten additional feature keys.

That is, three CO/PBX keys, one intercom key, and

16 feature keys that may be used as automatic

dialing keys, direct station selection (DSS) keys,

etc. Three different combinations of feature keys

may be selected via programming, as shown in

Fiaure 12.

06.26 All EKTs feature modular handset cords

and are connected to the system via 4-conductor

modular line cords.

06.27 All EKTs are easily converted for wall

mounting with an optional kit.

06.30 Installation

06.31 External devices are connected to the

MKSU via connectors and terminals on the side

panels.

CO/PBX lines are connected to the MKSU

a)

right side panel via a 3-pair modular cord.

The station connection points are extended

b)

from the MKSU to the MDF using one cable

equipped with a standard 50-pin amphenoltype connector. The individual EKTs are connected to the MDF with 2-pair station cable.

Screw-terminal barrier strips are mounted on

cl

the side of the MKSU to provide attachment

points for the following connections:

24 VDC power input (left side)

Music-on-hold source input (right side)

External page output (right side)

06.32

separately from the MKSU and connected to the

24 VDC input on the MKSU left side.

06.40 Maintenance

06.41 Faults in Strata S are repaired by

replacing any faulty component (EKT, printed circuit board, sub-assembly, etc.) and returning it to

the manufacturer for repair.

The power supply is mounted to the well’

. .

-.

?4

FIGURE 15-20-key EKT

07 FEATURES and OPERATION

07.00

07.01 This section contains brief descriptions of

the

and C and some associated operating instructions.

Detailed operating instructions can be found in

either the Strata S USER GUIDE or Operating Procedures. Section 100-003-4C0,

S Jnstallation and Maintenance Manual.

General

Strata

Sfeatures listed earlier in Tables B

07.10 Standard Features

07.11 System

All Call Voice Page:

Dialing a 1 -digit access code permits a station

user to page via all EKT speakers and (optionally)the External Page speaker simultaneously.

-1 o-

Strata

Page 15

GENERAL DESCRIPTION

SECTION 100-003-100

JULY 1984

--.Alternate Point Answer:

CO/PBX or intercom calls can be answered

from any station.

Automatic Dialing-System:

This standard feature allows 40 numbers to be

stored in the system memory. After selecting

an outgoing line, any station user can cause

one of the stored numbers to be outpulsed by

dialing the proper address code.

Automatic Hold Recall:

A CO line placed on hold by any station will

recall that station after a programmable period

of time.

Automatic Privacy:

Privacy is automatic on all connections.

Automatic Release from Hold:

The system automatically releases held CO

lines if a disconnect signal is received from the

central off ice.

Busy Override:

After dialing a busy station and receiving a

busy tone, the caller can dial a q and cause a

tone burst to be sounded via the called EKT

speaker.

Conference-Multi-station (non-amplified):

Conferencing is permitted to a maximum of

four stations and one CO or the intercom line.

Conference-Multi-trunk (non-amplified):

Conferencing of two CO lines and three sta-

tions is permitted.

Distinctive Ringing:

CO line and intercom calls are distinguished

by different ringing tones.

DTMF and Dial Pulse Compatible:

DTMF or dial pulse signalling can be sent to

the CO/PBX line by installing the proper

ACOU PCB type.

External Page Interface:

A 6OD-ohm connection point is provided for a

customer-provided external speaker. An amplifier is also required, which can be mounted

externally, or the AEPU (see Paragraph 07.20,

External Page Amplifier) can be mounted in

the MKSU. If the AEPU is used, the output

impedance is 8 ohms. This page circuit is

accessed as part of the All Call Voice Page

- feature.

Flash Key (PSX Transfer or CO Dial Tone Recall):

All EKTs are equipped with a Message Wait-

ing/Flash m) key which, when operated

while connected to a CO/PBX line, causes a

timed “flash” to be transmitted to the CO or

PBX. The timing of the flash can be programmed to signal a PBX for feature operation

or can be long enough to cause a disconnect

and dial tone recall on a CO line. Also see

Message Waiting.

Flexible Line Ringing Assignment:

A programmable ring or no ring option is pro-

vided for each line selectively by each station.

Each line may be programmed to ring all eight

stations.

Live System Programming:

Live system programming is accomplished

without service interruption to other station

users by placing the system in the special pro-

gramming mode and inputting data via station

17. Station 17 is the only station that is

“down” during programming.

Message Waiting:

The designated Message Cent‘er can indicate a

message is waiting for any station with the

Message Waiting LED of that station. Also see

Flash Key.

Music-on-hold Interface:

An interface is included for a customer-provided external music source (see Paragraph

07.20, Music-on-hold Source). CO lines placed

on hold will be connected to this source.

Night Transfer:

CO lines can be programmed to ring different

stations while in the “Day” or in the “Night”

mode. If this feature is to be used, the w

(Do Not Disturb) key on station 10 is reas-

signed to the NT function and is then used to

select the “Day” or “Night” mode.

Non-blocking Dialing:

Dialing is permitted on the intercom and all

three CO lines simultaneously.

Outgoing Call Restriction:

Any station can be selectively restricted from

originating calls on any or all CO lines. How-

ever, the station will still receive calls on the

restricted line(s).

PBX Compatible: +a-

Strutu

and automatic dialing, are compatible with

PBX operation.

Sfeatures, such as toll restriction

-ll-

Page 16

GENERAL OESCRlWlON

SECTION 100-003-l 00

JULY 1984

e..

- Private CO Lines:

Restrictions may be programmed into the sys-

tem so that selected CO line(s) may appear

only on selected station(s).

Do Not Disturb Override (Programmable Option):

After reaching a DND station, that station may

be advised that a call is waiting by dialing q . A

tone signal will be heard at the DND station.

Repeat Last Number Dialed:

The last number dialed by each station is

always stored by the system and will be dialed

automatically whenever the station user selects

an outgoing line and depresses the q key.

Toll Restriction:

Selectively programmed on a per-station, per-

line basis.

tion by rejecting the numbersa andm as the

first or second digit and limiting the total

number of digits dialed to seven or eight.

Voice or Tone Signalling:

A programmable system feature that option-

ally selects either tone ringing or voice page as

the primary method of intercom call signalling.

The calling station, however, may choose the

alternate method by dialing a following the

station number.

Wall Mountable MKSU:

The MKSU is designed for wall mounting only.

07.12 Station

Automatic Dialing-Station:

Each EKT can store a private list of ten fre-

quently used telephone numbers.

Automatic One-touch Dialing (Programmable):

This feature can be used with an EKT that

includes m keys in its programmed as-

signments.

a) A station number can be stored at each

m key.

b) A number stored in the memory can be

sent over a CO line by depressing the

appropriate a key after accessing the

CO line.

NOTE:

Each a key is counted as one of the 10

possible stored numbers available to each

station.

Do Not Disturb:

This feature is activated and deactiited by

alternate depressions of the m key. A sta-

tion calling a station that is in the DND mode

will receive a fast busy tone.

Strata S

performs toll restric-

Executive Override of Privacy:

A station that is programmed for this feature

will override the automatic privacy feature and

enter any existing conversation within the system. A warning tone, however, is inserted

before the overriding station is actually con-

nected. A maximum of two stations can be

programmed for executive override.

l-called Illumination:

A distinctive flash appears on the intercom

LED at the EKT that is actually being called.

l-hold Illumination:

The EKT user is shown a distinctive LED flash

to indicate a line actually placed on hold at that

EKT. All other stations see the usual on-hold

flash.

l-use Illumination:

A distinctive flash rate shows the line presently in use at a given EKT. Other stations see

a steadily illuminated LED for that line.

Modular Handset and Line Cords:

All EKTs are equipped with modular handset

and line cords.

On-hook Dialing:

Strata S

handset still on-hook. Call progress can be

heard via the telephone speaker; no need to

pick up the handset until your party answers.

Push-button Dialing:

All

Streta

button dial pads.

Ringing Line Preference:

A line ringing at a station can be answered by

merely lifting the handset or depressing the

m key (optional speakerphone EKTs only).

The ringing line will be automatically selected.

07.20 Optional Features

1 D-key EKT with Speakerphone:

An optional EKT provides handsfree answerback and full speakerphone capability.

Busy Lamp Field (BLF) El&

An optional lD-key EKT provides handsfree

answerback, full speakerphone capability, and

an LED panel showing the busy/idle

lets you dial your calls with the

SEKTs are equipped with push-

status

of

-12-

Page 17

f

a-

GENERAL DESCRIPTION

SECTION 100-003-l 00

JULY 1994

each station. A station in the DND mode will

show as busy.

ZO-key Executive EKT:

An optional executive unit provides handsfree

answerback, full speakerphone capability and,

via 10 additional feature keys, automatic dial-

ing access, four one-touch automatic dialing

telephone numbers, redial last number dialed,

a pause key, or may be used as a DSS station.

External Page Amplifier:

This optional external page 3-watt amplifier

(AEPU PCB) allows a customer-provided external speaker to be accessed in an all-call

operation by dialing non the intercom (see

Paragraph 07.11, External Page Interface).

Handsfree Answerback:

All optional EKTs are equipped for handsfree

answerback on voice-announced intercom

calls.

Microphone Control Key:

All optional EKTs have a 1-1 key that ’

may be used to cut off the microphone when

the speakerphone is in use, thereby permitting

a private local conversation. _

Music-on-hold Source:

This optional electronic music source (AMOU

PCB), when installed. illiminates the need for a

custome.r-provided external music source and

provides electronic-generated music to CO

lines placed on hold.

Speakerphone:

All optional EKTs are fully functional speaker-

phones.

System Battery Back-up:

An optional PCB can be plugged into the

MPSA-200 power supply to provide automatic

switching to standby battery power. During

normal power conditions the batteries are kept

fully charged by the power supply.

Wall Mounting Kits for EKTs:

All Strata S EKTs are easily converted for

wall mounting with optional kits.

-13-

,. -

Page 18

-

TOSHIBA SYSTEM PRACTICES

ELECTRONIC KEY TELEPHONE SYSTEM

SECTION 100-003-200

INSTALLATION

JULY 1984

,

StrataS --.

INSTALLATION INSTRUCTIONS

Page 19

TOSHIBA SYSTEM PRACTICES

ELECTRONIC KEY TELEPHONE SYSTEM

_..

INSTALLATION

SECTION 100-003-200

JULY 1984

Strata S

INSTALLATION INSTRUCTIONS

TABLE of CONTENTS

PARAGRAPH

01

02

02.00

03

03.00

03.10

03.20

03.30

04

04.00

05

o:.:o

06.10

07

07.00

07.10

07.20

07.30

07.40

08

08.00

08.10

09

09.00

09.10

09.20

09.30

10

10.00

10.10

10.20

10.30

10.40

11

11.10

12

12.00

12.10

12.20

13

13.00

13.10

13.20

13.30

13.40

13.50

SUBJECT

TABLE of CONTENTS ............................

ILLUSTRATION LIST

GENERAL . .... . ..I :: : : : ::: : :: ::: : ::: ::: : ::

PACKING

Inspection

MKSU LOCATlON’REdlJiREMENTS’ : : : : : : : : : : : : : : : : : : : : : :

Power Requirements ..........................

Ventilation Requirements ........................

Environment Factors ..........................

Cabling Considerations .........................

MKSU MOUNTING

Wall Mounting theMKSU ’ : : : : : : : : : : : : : 1 : : : : : : : : : :

PRINTED CIRCUIT BOARD DESCRIPTIONS

OPTION SELECTION .......... : : : : : : : : : : : : : : : : : :

External Page Option Selection ......................

Music-on-hold Option Selection

PCBINSTALLATION

General Information ...........................

AMOU (MOH Source) Installation ................ ) ...

APFU (Power Failure Transfer Unit) Installation ............ : :

AEPU (External Page Unit) Installation ...................

MKSU Cover Installation .........................

POWER CONNECTION ...........................

Cable Connection ............................

Test Procedure

CABLECONNECTIONS - : : : : : : : : : : : : : : : : : : : : : : : : : : :

MDF Configuration ............................

Station Cable Connection ........................

Intercom Code Assignment ........................

CO Line Connection ...........................

EKT INFORMATION .............................

General

lo-key S EKT Wall Mounting .......................

Optional EKT Wall Mounting .......................

Installing the Handset Hanger Kit .....................

EKT Connections

SYSTEM POWER-UP INITIAL& . : : : : : : : : : : : : : : : : : : : : : : :

Clearing Automatic Dialing ........................

SYSTEM TEST PROCEDURES

lo-keys EKTFunctional Check’ : : : : : : : : : : : : : : : : : : : : : :

Optional EKT Functional Check ......................

Feature Check

MISCELLANEOUS EQljlPMENT%NhiECTiONS ’ : : : : : : : : : : : :- : : : :

Wiring Connections ...........................

Music-on-hold Source ..........................

External Paging Connections .......................

Direct External Speaker Connection ....................

External Amplifier Connection

PowerFailureTransfer

.................................

....... . . . . . . . . . . . . . . . . . . . . .

................................

se-

. ..::::::::::::::::::::::

PAGE

i

ii

1

1

1

1

1

1

1 ’

1

1

1

2

2

2

3

3

3

3

.

4’

4

5

5

5

5

6

6

7

7

7

7

7

10

10

11

12

12

12

13

13

14

15

15

15

15

15

15 -.

17

17

Page 20

TOSHIBA SYSTEM PRACTICES

ELECTRONIC KEY TELEPHONE SYSTEM

w..

INSTALLATION

SECTION 100-003-200

JULY 1984

Strata S

INSTALLATION INSTRUCTIONS

ILLUSTRATION LIST

NUMBER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

::

33

34

TITLE PAGE

SideCovers .................................................................

WallMountedMKSU ........................................................

MKSUwith PCBs ............................................................

External Pagelerminals ......................................................

MMAUSwitches ............................................................

MKSUCoverScrews .........................................................

MountedAMOUPCB

AMOU/MMAU Cable Connection

MountedAPFUPCB .........................................................

APFU Connection

Mounted AEPU PCB

System Diagram

MKSU Cable Clamping

MDF/EKT Wiring

RJ25C Wiring

1 D-key “S” EKT

1 O-key Speakerphone EKT

BLFEKT

20-key EKT

KeyLayout

Wall Mount Bracket

BracketSlots ................................................................

“S” EKT Wire Routing

Removing Optional EKT Base .................................................

EKT Wire Access

EKT Wire Routing

Handset Hanger Kit

SET Switch .

MKSU Connection

MMAU SW3 Switch

MMAU SW2 Switch

AEPU Volume Switch

Power Failure Transfer Diagram

PFf Telephone Connections

...............................................................

....................................................................

.........................................................

..................................................................

...............................................................

_

........................................................

............................................. 4

............................................................

......................................................... 5

.............................................................

.......................................................

............................................................ 8

............................................................. 9

....................................................

..........................................................

........................................................

............................................................

............................................................

..........................................................

...........................................................

.........................................................

.........................................................

........................................................

............................................... 16

...................................................

2

2

2

3

3

3

4

4

4

6

7

7

9

9

. ....... 9

10

10

10

11

11

11

11

12

12

15

15

16

16

17

-ii-

Page 21

--.

01. GENERAL I

01.01

procedures necessary to ensure proper operation

of the

This section describes the installation

Strata S

system.

02 PACKING

02.00 Inspection

02.01

examine all packages and carefully note any vis-

ible damage. If any damage is found, bring it to the

attention of the delivery carrier and make the

proper claims.

02.02 Check the number of cartons and the

contents of the Strata S shipment against the

purchase order and packing slip. If it is determined

that any cartons are missing, contact your delivery

carrier immediately. If it is determined that any

equipment within a carton is missing, contact your

Toshiba supplier immediately.

02.03 After unpacking (prior to beginning the

installation), inspect all equipment for damage. If

any damage isdetected, contact your delivery card

rier immediately. If possible, retain all original the

packing material.

When a Strata S system is received,

CAUTION:

When handling (installing, removing, examining, etc.) a printed circuit board. do not

touch the back (soldered) side or the edge

connector. Always hold a PCB by its edge.

03

MKSU LOCATION REQUIREMENTS

03.00 Power Requirements

03.01

VDC. This is provided by the power supply (MPSA),

which in turn requires power from a grounded

115 VAC outlet. The outlet should be protected

1 separately and rated at 15 amps.

03.02 The 54-inch cord provided to connect the

MPSA to the MKSU dictates the relative location

of the power supply. The power supply is also

equipped

03.03 Two power supplies are available;

MPSA-200 and MPSA-512. The MESA-200 is

used when battery backup power is required.

The Strata S MKSU requires 24

with a 10-h. AC power cord.

INSTAUATION

SECTION 100-003-200

JULY 1994

ing. The recommended battery pack, which is

customer-supplied, consists of two maintenancefree automobile 12 VDC batteries (maximum: 80amp/hour rating). With the optional PBBU assembly installed, all functions of the Strata S

system will continue to operate for several hours

after a loss of normal electrical power (the actual

time period is in direct ratio to the type and size of

batteries selected). No calls will be disconnected

during switch-over to battery power.

03.10 Ventilation Requirements

03.11 Sufficient ventilation should exist to allow

dissipation of the -heat generated by the power

supply and MKSU.

03.20 Environmental Factors

03.21

within 20 - 80% (without condensation), and the

temperature should be relatively constant within a

range of 32 - 122OF(O- 5OOC). In addition, expos-

ing the MKSU to an excessive amount of dust and

airborne chemicals may cause a failure-take this

into consideration during site selection.

Humidity at the MKSU location should be

03.30 Cabling Considerations

03.31

stations are within loo0 cable feet (305 m) of it.

Acceptable cable

phone station

having two or more twisted wire pairs.

The MKSU must be located so that all

is

22 or 24 AWG inside tele-

cable, jacketed but

not shielded,

04 MKSU MOUNTING

04.00 Wall Mounting the MKSU

04.01

the following steps:

1)

2)

3)

To mount the MKSU on the wall perform

Remove both side covers from the MKSU (Figure 1).

Hold the MKSU against the wall in its planned

location and mark the screw locations through

the centers of the two keyholes on the upper

sides of the MKSU.

Lay the MKSU aside for the moment and start

two screws into the wall at the marked

loca-

tions. Use l-W-inch panhead wood screws

and stop when they have penetrated to half -.

their depth. c*

03.04 An optional battery backup unit (PBBU) is

available for the MPSA-200. It is a printed circuit

board that mounts inside the power supply hous-

-l-

Hang the MKSU on the two screws and start

4)

two additional screws in the lower two holes.

Tghten all four screws.

Page 22

INSTALLATION

SECTION

100-003-200

JULY 1994

‘.

5) Knockouts are provided on the top and bottom

of the side covers to permit cables to enter the

MKSU. Remove the appropriate knockouts.

FIGURE 1 -SIDE COVERS

6) Reinstall the side covers.

7) Refer to Section 100-003-250,

Installation

200 installation),

(or Section 100-003-255,

and follow the appropriate

instructions for installing the selected MPSA.

A completed installation with an MPSA-512

should aooear as shown in Fiaure 2.

MPSA-512

MPSA-

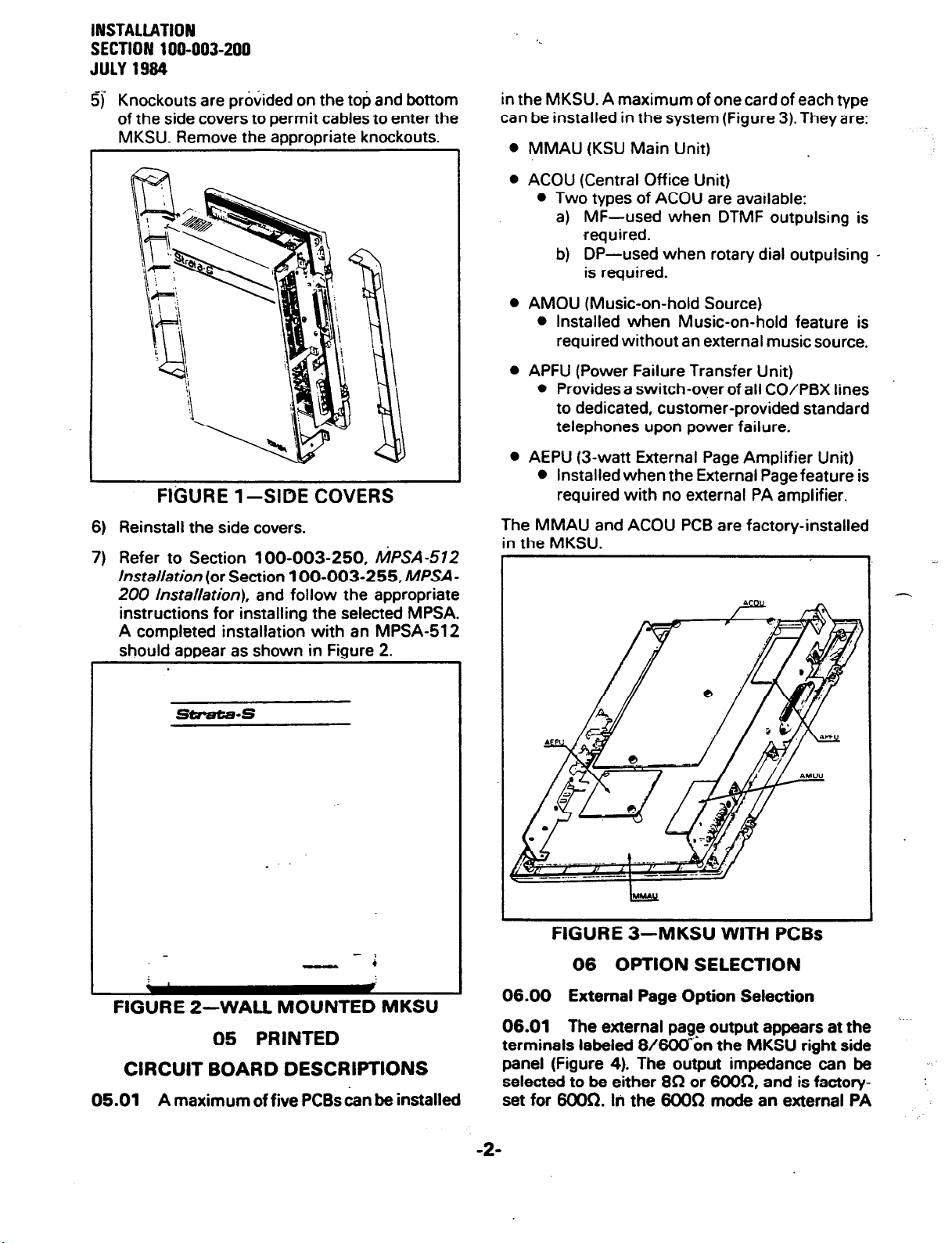

in the MKSU. A maximum of one card of each type

can be installed in the system (Figure 3). They are:

l

MMAU (KSU Main Unit)

l

ACOU (Central Office Unit)

l

Two types of ACOU are available:

a) MF-used when DTMF outpulsing is

required.

b) DP-used when rotary dial outpulsing -

is required.

l

AMOU (Music-on-hold Source)

l

Installed when Music-on-hold feature is

required without an external music source.

0 APFU (Power Failure Transfer Unit)

l

Provides a switch-over of all CO/PBX lines

to dedicated, customer-provided standard

telephones upon power failure.

l

AEPU (3-watt External Page Amplifier Unit)

l

Installed when the External Page feature is

required with no external PA amplifier.

The MMAU and ACOU PCB are factory-installed

in the MKSU.

s--s

- 2

-

.

FIGURE 2-WALL MOUNTED MKSU

05 PRINTED

CIRCUIT BOARD DESCRIPTIONS

05.01

A maximum of five PCBs can be installed

FIGURE 3-MKSU WITH PCBs

06 OPTION SELECTION

06.01 The external pag? output appears at the

terminals labeled 8/6OOkn the MKSU right side

panel (Figure 4). The output impedance can be

selected to be either 8R or 6OOR. and is facton/set for 6OOR. In the 6OOR mode an external PA

-2-

--

-.

:

Page 23

_..

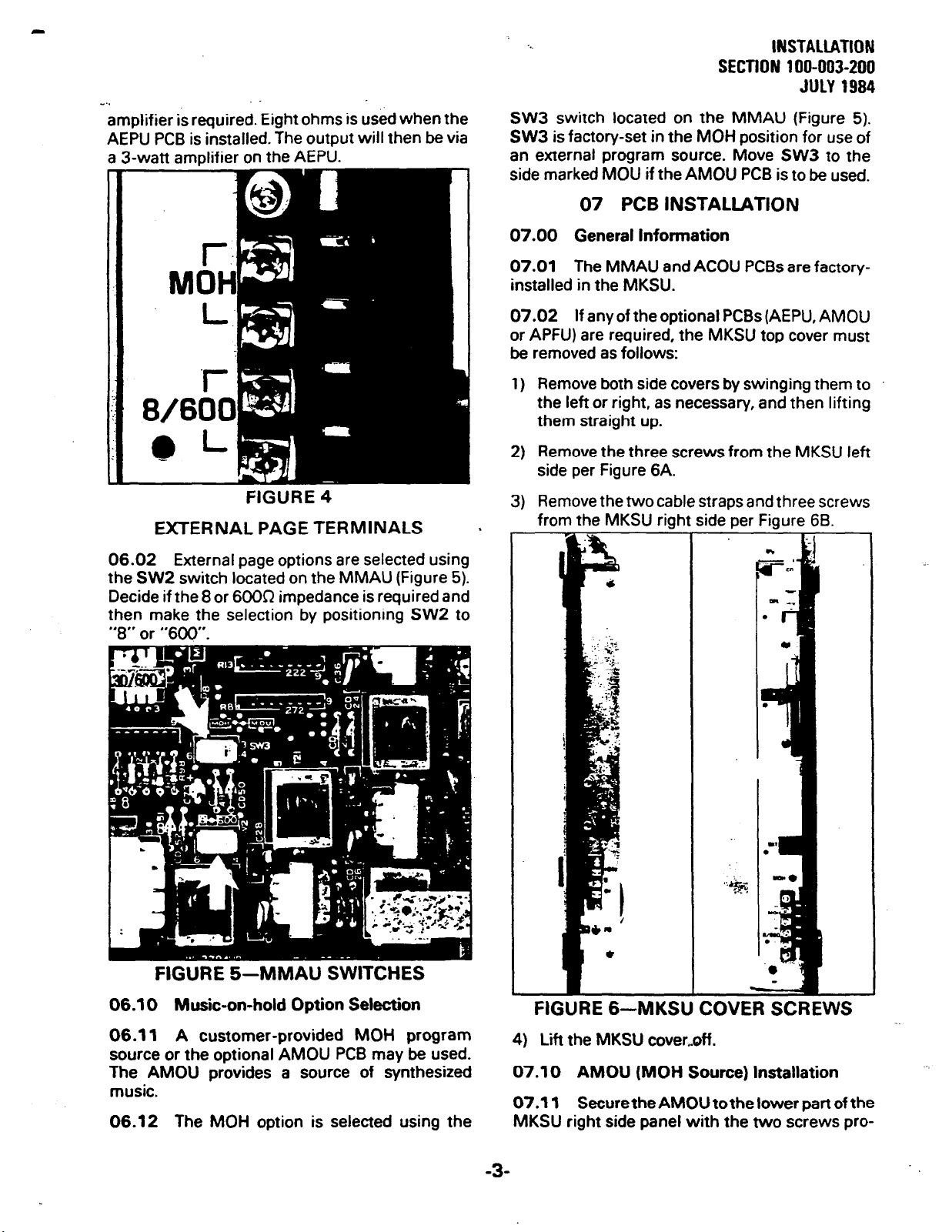

amplifier is required. Eight ohms is used when the

AEPU PCB is installed. The output will then be via

a 3-watt amplifier on the AEPU.

‘..

INSTALlATlON

SECTION 100-003-200

JULY 1984

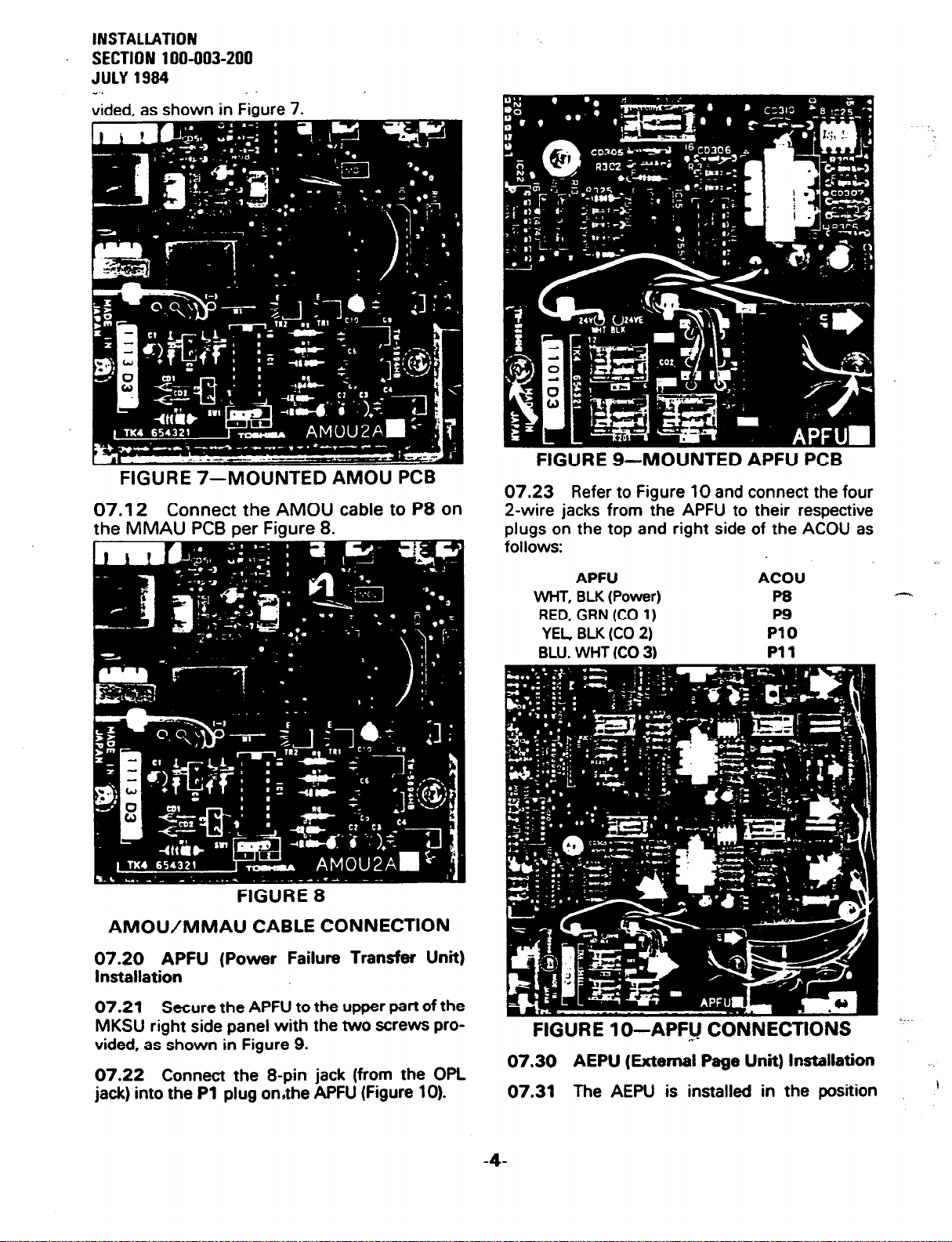

SW3 switch located on the MMAU (Figure 5).

SW3 is factory-set in the MOH position for use of

an external program source. Move SW3 to the

side marked MOU if the AMOU PCB is to be used.

07 PCB INSTALLATION

07.00 General Information

07.01 The MMAU and ACOU PCBs are factory-

installed in the MKSU.

07.02 If any of the optional PCBs (AEPU, AMOU

or APFU) are required, the MKSU top cover must

be removed as follows:

1) Remove both side covers by swinging them to

the left or right, as necessary, and then lifting

them straight up.

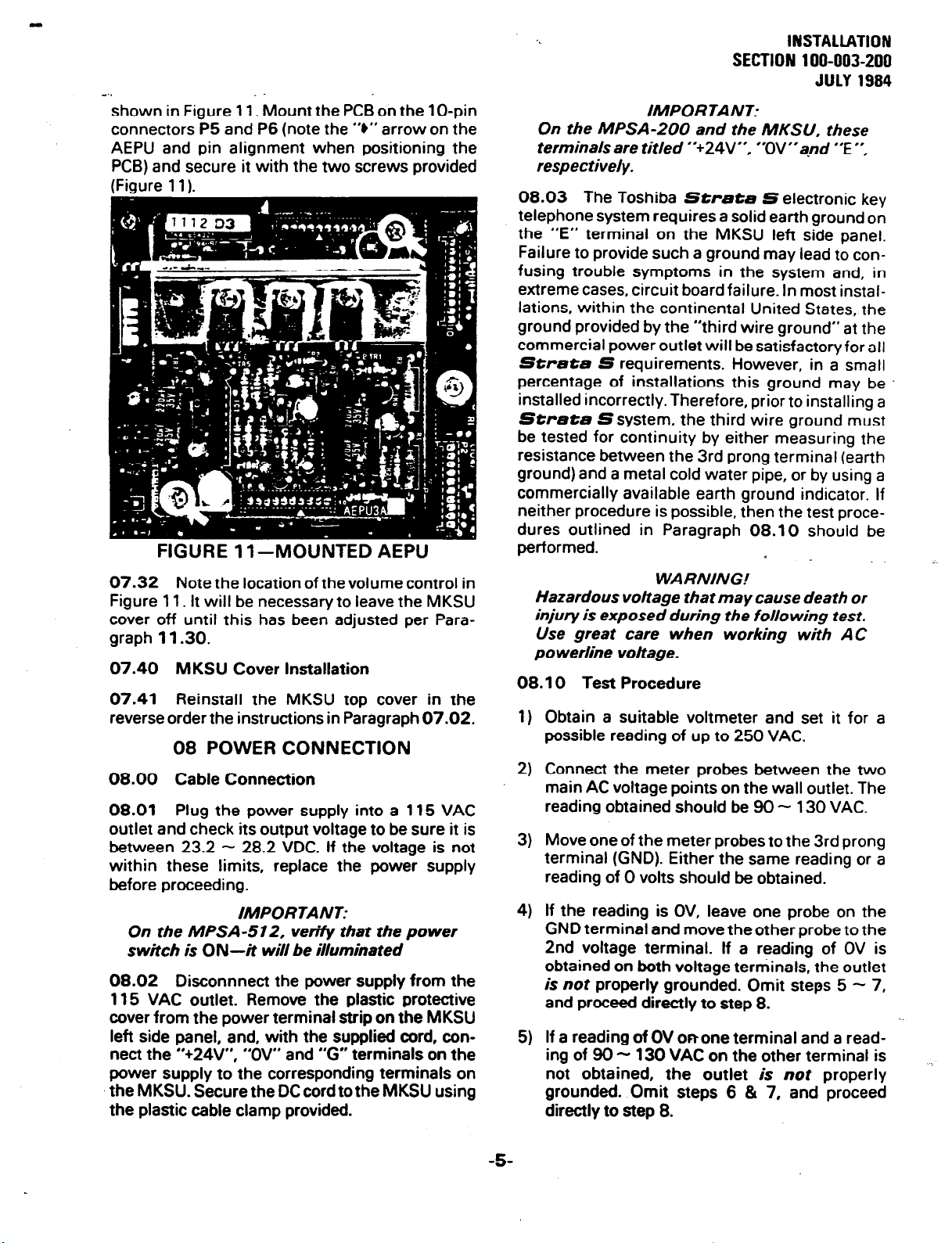

2) Remove the three screws from the MKSU left

side per Figure 6A.

FIGURE 4

EXTERNAL PAGE TERMINALS

06.02 External page options are selected using

the SW2 switch located on the MMAU (Figure 5).

Decide if the 8 or 6DOQ impedance is required and

then make the selection by positioning SW2 to

“8” or

3) Remove the two cable straps and three screws

from the MKSU right side per Figure 6B.

FIGURE 5-MMAU SWITCHES

06.10 Music-on-hold Option Selection

06.11 A customer-provided MOH program

source or the optional AMOU PCB may be used.

The AMOU provides a source of synthesized

music.

06.12 The MOH option is selected using the

FIGURE 6-MKSU COVER SCREWS

4) Lift the MKSU cover,&.

07.10 AMOU (MOH Source) Installation

07.11 Secure the AMOU to the lower part of the

MKSU right side panel with the two screws pro-

-3-

Page 24

INSTALLATION

SECTION 100-003-200

JULY

1994

v..

vided, as shown in Figure 7.

FIGURE 7-MOUNTED AMOU PCB

07.12

the MMAU PCB Der Figure 8.

Connect the AMOU cable to

PB

on

FIGURE g--MOUNTED APFU PCB

07.23 Refer to Figure 10 and connect the four

2-wire jacks from the APFU to their respective

plugs on the top and right side of the ACOU as

follows:

FIGURE 8

AMOWMMAU CABLE CONNECTION

07.20 APFU (Power Failure Transfer Unit)

Installation

07.21

MKSU right side panel with the two screws pro-

vided, as shown in Figure 9.

07.22 Connect the 8-pin jack (from the OPL

jack) into the

Secure the APFU to the upper part of the

Pl

plug on,the APFU (Figure 10).

APFU ACOU

WHT, Bu( (Power)

RED, GRN (CO 1)

YEL BU( (CO 2)

BLU, WHT (CO 3)

P8

PS

PlO

Pll

FIGURE lo-APF&j CONNECTIONS --.-

07.30 AEPU (External Page Unit) Installation

07.31

The AEPU is installed in the position

4

Page 25

e..

shown in Figure 11. Mount the PCB on the lo-pin

connectors P5 and P6 (note the “6” arrow on the

AEPU and pin alignment when positioning the

PCB) and secure it with the two screws provided

(Figure 11).

FIGURE 1 l-MOUNTED AEPU

07.32 Note the location of the volume control in

Figure 11. It will be necessary to leave the MKSU

cover off until this has been adjusted per Paragraph

07.40 MKSU Cover

07.41

11.30.

Installation

Reinstall the MKSU top cover in the

reverse order the instructions in Paragraph 07.02.

08 POWER CONNECTION

08.00 Cable Connection

08.01

Plug the power supply into a 115 VAC

outlet and check its output voltage to be sure it is

between 23.2 - 28.2 VDC. If the voltage is not

within these limits, replace the power supply

before proceeding.

IMPORTANT:

On the MPSA-512, verify that the power

switch is ON-it will be illuminated

08.02 Disconnnect the power supply from the

115 VAC outlet. Remove the plastic protective

cover from the power terminal strip on the MKSU

left side panel, and, with the supplied cord, connect the “+24V”, “OV” and “G” terminals on the

power supply to the corresponding terminals on

the MKSU. Secure the DC cord to the MKSU using

the plastic cable clamp provided.

INSTALLATION

SECTION 100-003-200

JULY 1984

IMPORTANT:

On the MPSA-200 and the MKSU. these

terminals are titled

respectively.

**+24V’-,

‘OV”qd “E “.

08.03 The Toshiba Strata S electronic key

telephone system requires a solid earth ground on

the “E” terminal on the MKSU left side panel.

Failure to provide such a ground may lead to confusing trouble symptoms in the system and, in

extreme cases, circuit board failure. In most instal-

lations, within the continental United States, the

ground provided by the “third wire ground” at the

commercial power outlet will be satisfactory for all

Strata S requirements. However, in a small

percentage of installations this ground may be

installed incorrectly. Therefore, prior to installing a

Strata S system, the third wire ground must

be tested for continuity by either measuring the

resistance between the 3rd prong terminal (earth

ground) and a metal cold water pipe, or by using a

commercially available earth ground indicator. If

neither procedure is possible, then the test procedures outlined in Paragraph 08.10 should be

performed.

WARNING!

Hazardous vottage that may cause death or

injury is exposed during the following test.

Use great care when working with AC

po werline voltage.

08.10 Test Procedure

Obtain a suitable voltmeter and set it for a

1)

.

possible reading of up to 250 VAC.

Connect the meter probes between the two

2)

main AC voltage points on the wall outlet. The

reading obtained should be 90 - 130 VAC.

Move one of the meter probes to the 3rd prong

3)

terminal (GND). Either the same reading or a

reading of 0 volts should be obtained.

If the reading is OV, leave one probe on the

4)

GND terminal and move the other probe to the

2nd voltage terminal. If a reading of OV is

obtained on both voltage terminals, the outlet

is not

properly grounded. Omit steps 5 - 7,

and proceed directly to step 8.

If a reading of OV onone terminal and a read-

5)

ing of 80 - 130 VAC on the other terminal is

not obtained, the outlet is not properly

grounded. Omit steps 6 & 7, and proceed

directly to step 8.

.

-5

Page 26

INSTALLATION

SECTION 100-003-200

JULY 1994

-..

6) If a reading of OV on one terminal and a reading of 90 - 130 VAC on the other terminal is

obtained, remove both probes from the outlet.

7) Set the meter on the “OHMS/Rxl” scale,

place one probe on the GND terminal and the

other probe on the terminal which produced a

reading of OV. A reading of less than IS2

should be obtained. If a reading of more than

1 R is obtained, the outlet is not adequately

grounded.

8) If the above tests show that the outlet is

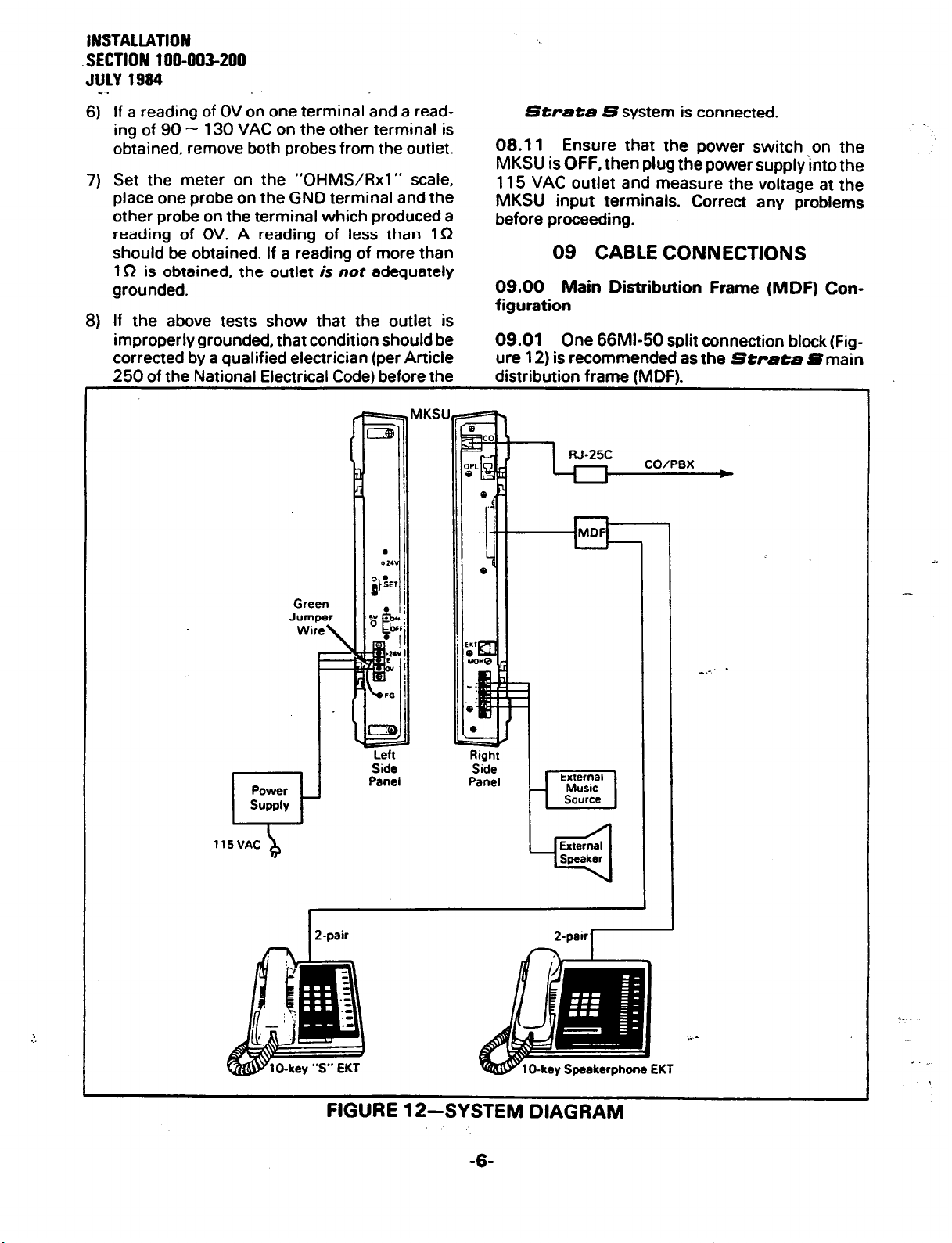

improperly grounded, that condition should be 09.01 One 66ML50 split connection block (Fig-

corrected by a qualified electrician (per Article

250 of the National Electrical Code) before the distribution frame (MDFL

-

Strata S system is connected.

08.11 Ensure that the power switch on the

MKSU is

115 VAC outlet and measure the voltage at the

MKSU input terminals. Correct any problems

before proceeding.

OFF,

then plug the power supply-into the

09 CABLE CONNECTIONS

09.00 Main Distribution Frame (MDF) Con-

figuration

ure 12) is recommended as the Strata Smain

MKSU

115VAC

-L-

P-pair 2-0ai.I

FIGURE 12-SYSTEM DIAGRAM

-6-

Page 27

‘k

INSTAUATION

SECTlON 100-003-200

JULY 1994

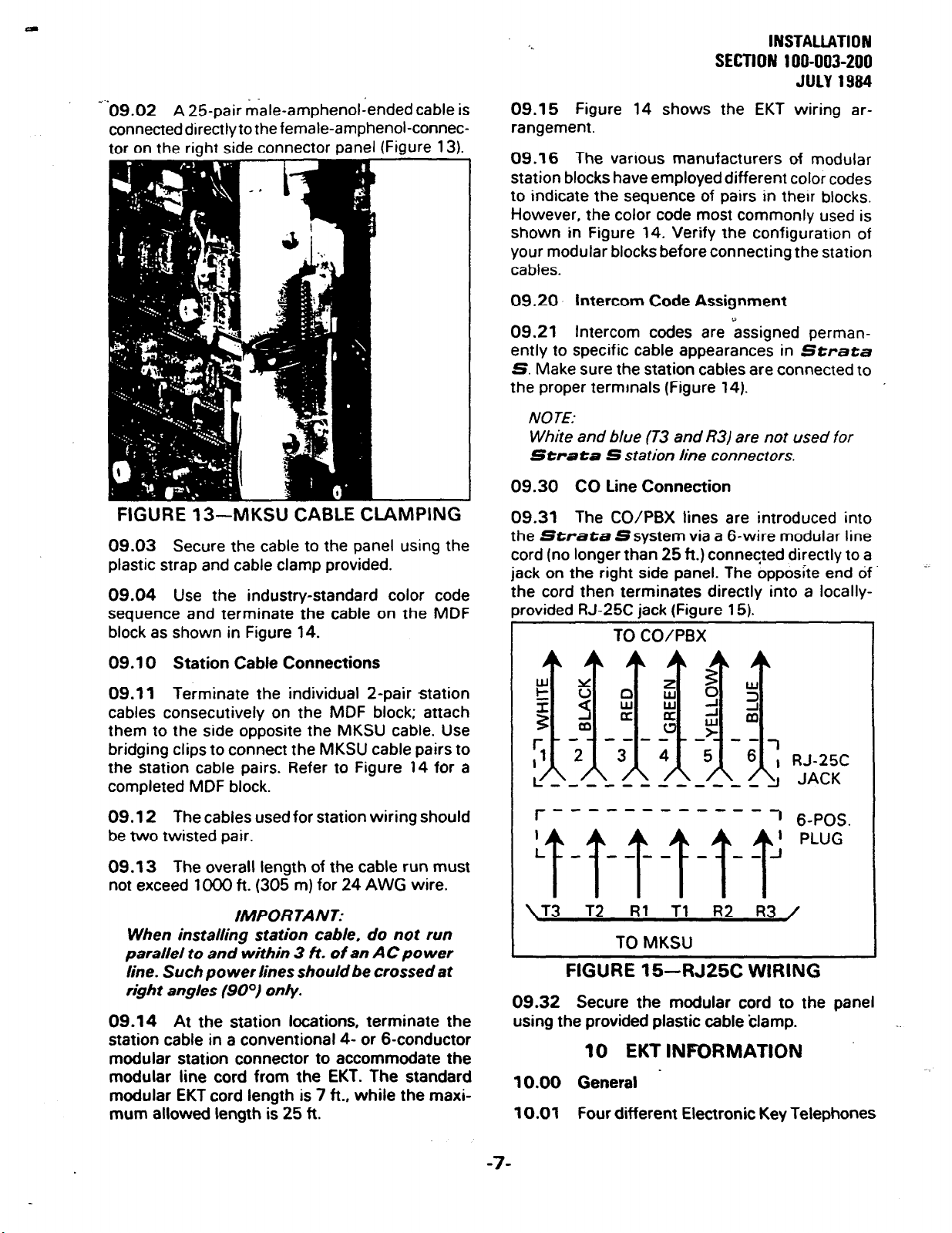

-‘09.02 A 25-pair &ale-amphenoliended cable is

connecteddirectlytothefemale-amphenol-connector on the riqht side connector panel

(Figure 13).

FIGURE 13-MKSU CABLE CLAMPING

09.03 Secure the cable to the panel using the

plastic strap and cable clamp provided.

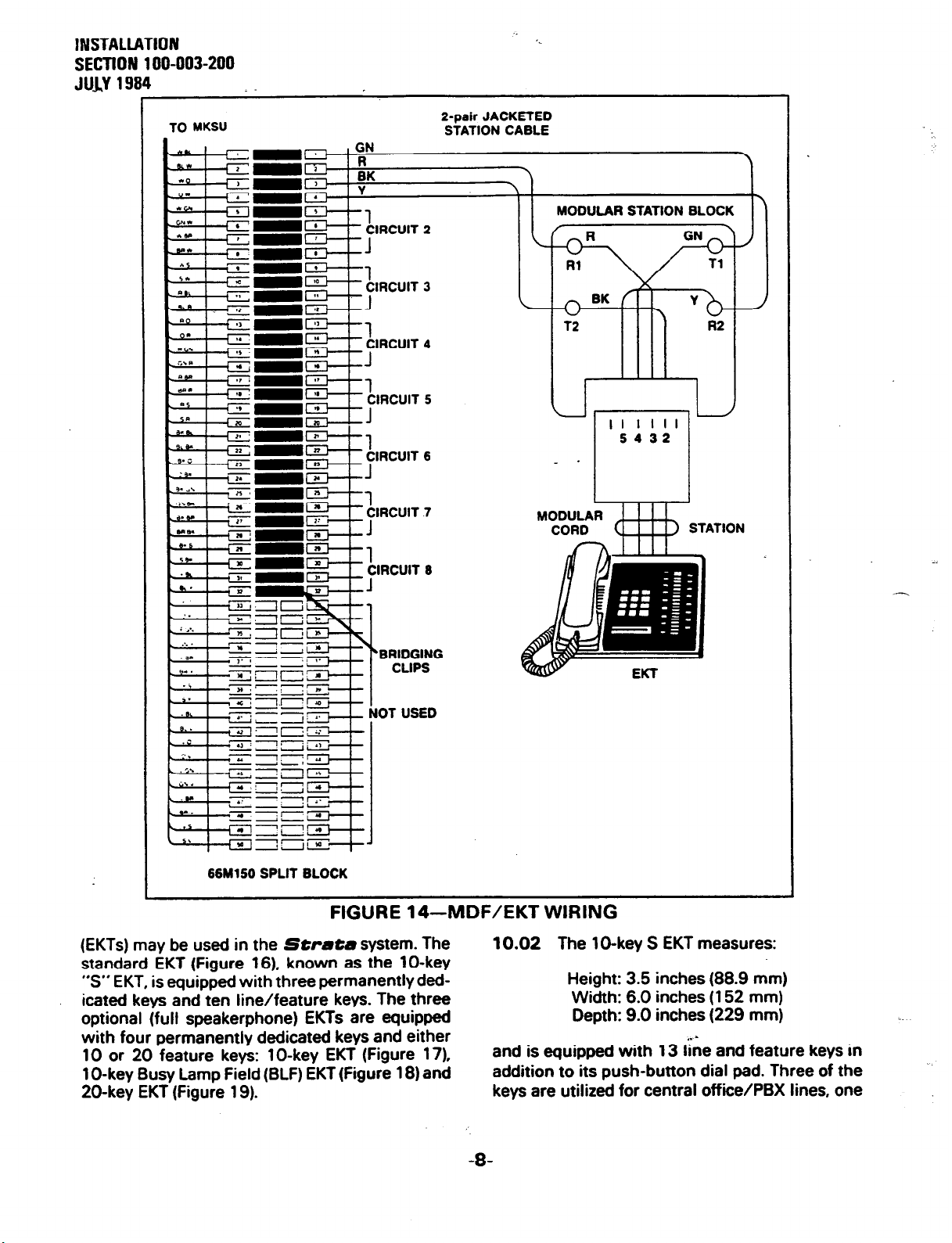

09.04 Use the industry-standard color code

sequence and terminate the cable on the MDF

block as shown

in Figure 14.

09.15 Figure 14 shows the EKT wiring arrangement.

09.16

station blocks have employed different color codes

to indicate the sequence of pairs in their blocks.

However, the color code most commonly used is

shown in Figure 14. Verify the configuration of

your modular blocks before connecting the station

cables.

The various manufacturers of modular

09.20 intercom Code Assignment

7

09.21 Intercom codes are assigned perman-

ently to specific cable appearances in Strata

S. Make sure the station

the proper terminals (Figure 14).

NOTE:

White and blue (T3 and R3/ are not used for

Strata S station line connectors.

cables are connected to

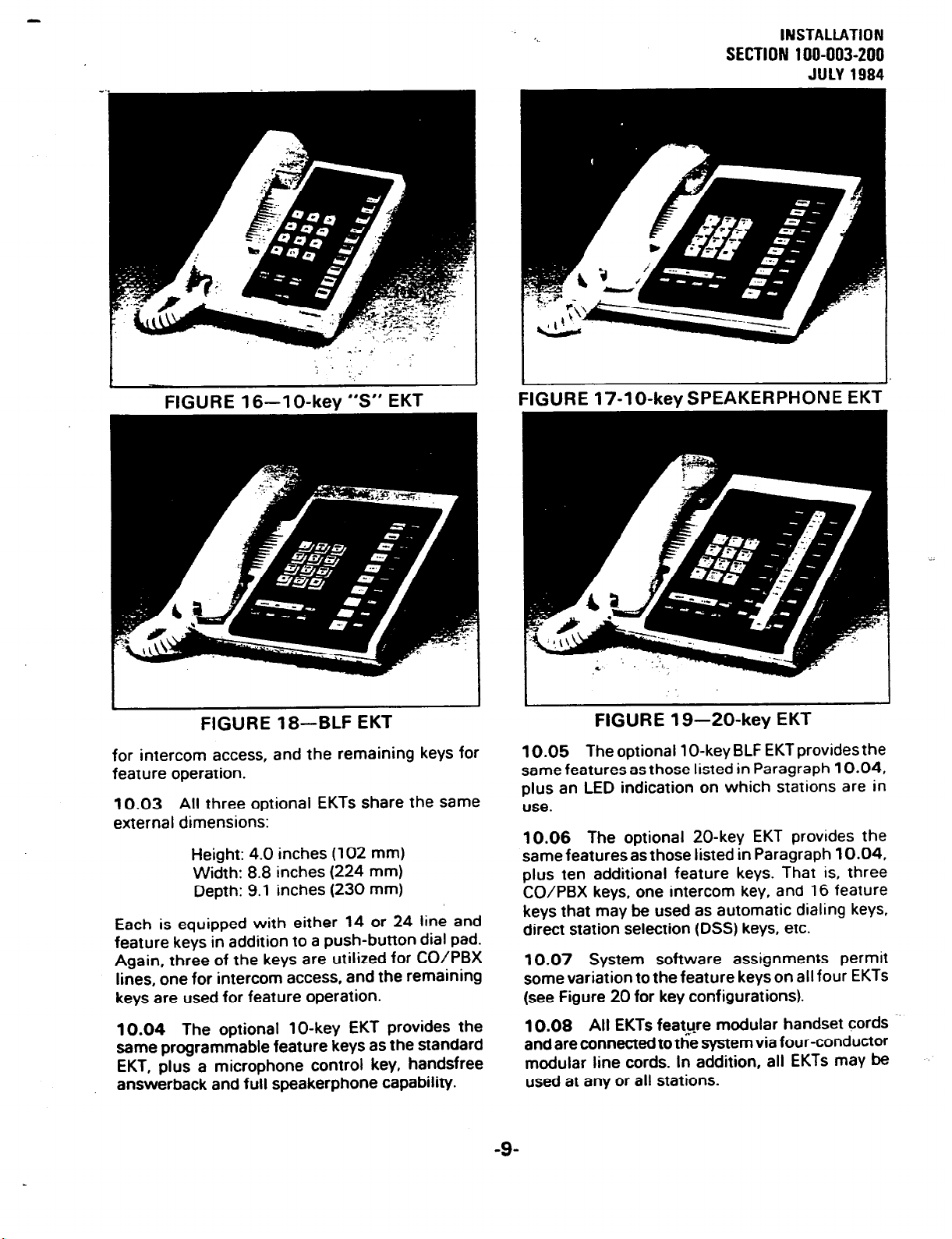

09.30 CO Line Connection

09.31

the Strata Ssystem via a 6-wire modular line

cord (no longer than 25 ft.) conneqted directly to a

jack on the right side panel. The opposite end df

The CO/PBX tines are introduced into

the cord then terminates directly into a locally-

rovided RJ-25C jack (Figure 15).

TO CO/PBX

09.10 Station Cable Connections

09.11

cables consecutively on the MDF block; attach

them to the side opposite the MKSU cable. Use

bridging clips to connect the MKSU cable pairs to

the station cable pairs. Refer to Figure 14 for a

completed MDF block.

09.12 The cables used for station wiring should

be two twisted pair.

09.13

not exceed 1 DO0 ft. (305 m) for 24 AWG wire.

parallel to and within 3 ft. of an AC po wer

Terminate the individual 2-pair station

The overall length of the cable run must

/MPORTANT:

When installing station cable, do not run

line. Such power lines should be crossed at

right angles (9OO) only.

09.14 At the station locations, terminate the

station cable in a conventional 4- or 6-conductor

modular station connector to accommodate the

modular line cord from the EKT. The standard

modular EKT cord length is 7 ft., while the maximum allowed length is 25 ft.

z

n

W

ki

a

a

-a

4

-w--v-------

r

3

I

-a

--

-?

RJ-25C

JACK

1 6-POS.

\T3 T2 Rl Tl R2 R3 /

TO MKSU

FIGURE 15-RJ25C WIRING

09.32 Secure the modular cord to the panel

using the provided plastic cable ‘clamp.

10 EKT INFORMATION

10.00 General .

10.01 Four different Electronic Key Telephones

-7-

Page 28

lNSTALl.ATlON

SECTION 100-003-200

JlJlv1994

TO MKSU

:

I-pair

JACKETED

STATION CABLE

'.

MODULAR STATION BLOCK

II

5432

- .

L

-El-l- Ynbu”

“7r:

%R

-c

--i

-7

66M160 SPLIT BLOCK

l-IcjUHt 14-MUi- tK I WlHlNIj

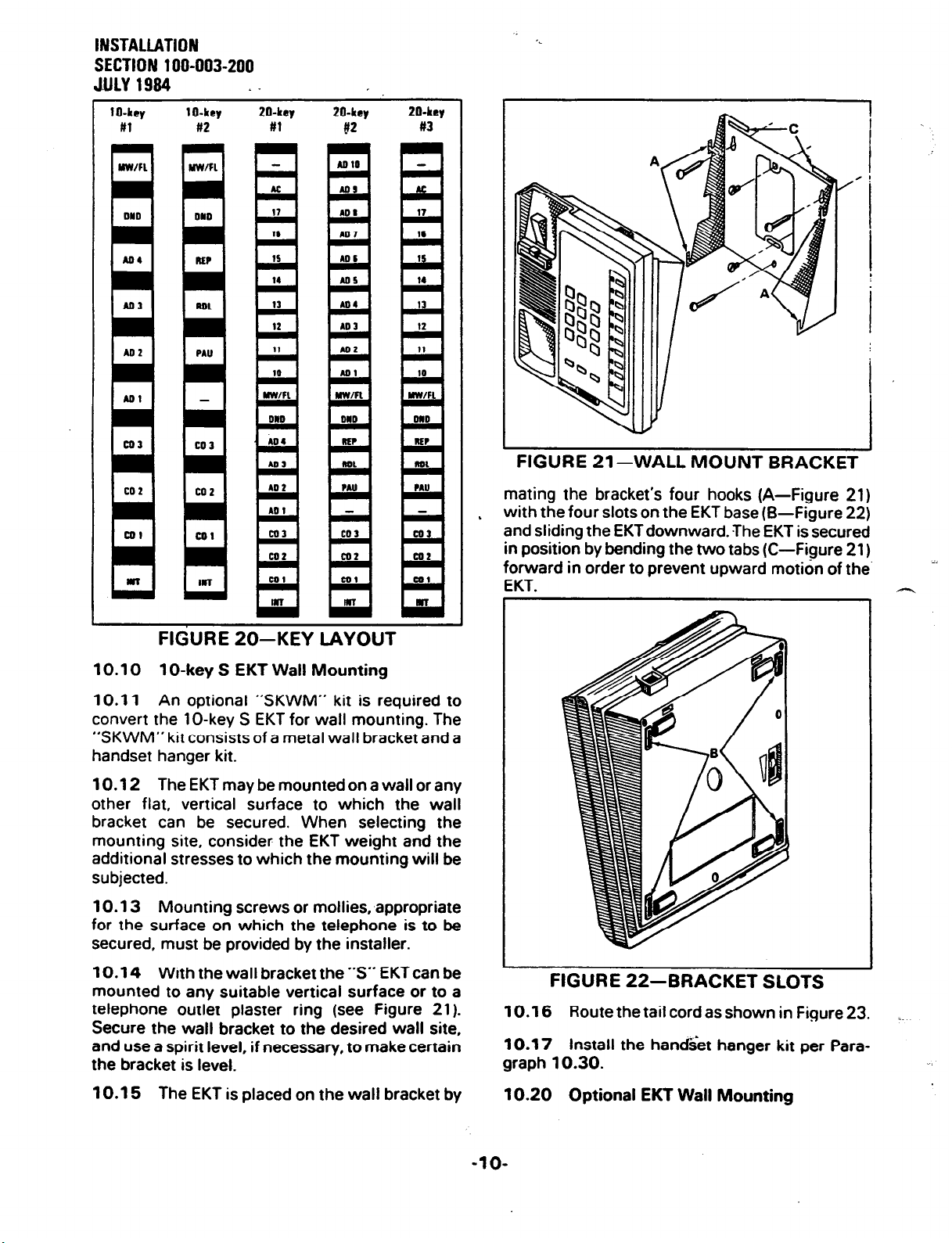

(EKTs) may be used in the

standard EKT (Figure 16). known as the 1 O-key

“S” EKT, is equipped with three permanentlyded-

icated keys and ten line/feature keys. The three

optional (full speakerphone) EKTs are equipped

with four permanently dedicated keys and either

10 or 20 feature keys: lo-key EKT (Figure 17).

1 O-key Busy Lamp Field (BLF) EKT (Figure 18) and

20-key EKT (Figure 19).

Strata

BRIDGING

CLIPS

idOT USED

I

system. The

I .... J

MODULAR

CORD

10.02

and is equipped with 13 line end feature keys in

addition to its push-button dial pad. Three of the

keys are utilized for central offiie/PBX lines, one

The lO-key S EKT measures:

Height: 3.5 inches (88.9 mm)

Width: 6.0 inches (152 mm)

Depth: 9.0 inches (229 mm)

STATION

I. -

-8-

Page 29

‘..

SECTION 100-003-200

INSTALLATION

JULY 1984

; ‘. _.

I

FIGURE 16-l

O-key

-.

“S” EKT

I

I

FIGURE 17-lo-key SPEAKERPHONE EKT

FIGURE 18-BLF EKT

for intercom access, and the remaining keys for

feature operation.

10.03 All three optional EKTs share the same

external dimensions:

Height: 4.0 inches (102 mm)

Width: 8.8 inches (224 mm)

Depth: 9.1 inches (230 mm)

Each is equipped with either 14 or 24 line and

feature keys in addition to a push-button dial pad.

Again, three of the keys are utilized for CO/PBX

lines, one for intercom access, and the remaining

keys are used for feature operation.

10.04 The optional lo-key EKT provides the

same programmable feature keys as the standard

EKT, plus a microphone control key, handsfree

answerback and full speakerphone capability.

FIGURE 19-20-key EKT

10.05 The optional 1 O-key BLF EKT provides the

same features as those listed in Paragraph 10.04,

plus an LED indication on which stations are in

use.

10.06

same featuresas those listed in Paragraph 10.04,

plus ten additional feature keys. That is, three

CO/PBX keys, one intercom key, and 16 feature

keys that may be used as automatic dialing keys,

direct station selection (DSS) keys, etc.

10.07 System software assignments permit

some variation to the feature keys on all four EKTs

(see Figure 20 for key configurations).

10.08 All EKTs feat_u_re modular handset cords -.

and are connected to the system via four-conductor

modular line cords. In addition, all EKTs may be

used at any or all stations.

The optional 20-key EKT provides the

-9-

Page 30

INSTALLATION

SECTION 100-003-200

JULY 1994 . -

PAU

-

H

FIGURE 21 -WALL MOUNT BRACKET

mating the bracket’s four hooks (A-Figure 21)

with the four slots on the EKT base (B-Figure 22)

L

and sliding the EKTdownward. The EKT is secured

in position by bending the two tabs (C-Figure 21)

forward in order to orevent ubward motion of the.

EKT.

1

I.

FIGURE 20-KEY LAYOUT

10.10 1 O-key S EKT Wall Mounting

10.11 An optional ‘SKWM” kit is required to

convert the

“SKWM”

handset hanger kit.

10.12 TheEKTmaybemountedonawallorany

other flat, vertical surface to which the wall

bracket can be secured. When selecting the

mounting site, consider the EKT weight and the

additional stresses to which the mounting will be

subjected.

10.13 Mounting screws or mollies, appropriate

for the surface on which the telephone is to be

secured, must be provided by the installer.

10.14 With the wall bracket the “S” EKT can be

mounted to any suitable vertical surface or to a

telephone outlet plaster ring (see Figure 21).

Secure the wall bracket to the desired wall site,

and use a spirit level, if necessary, to make certain

the bracket is level.

10.15 The EKT is placed on the wall bracket by

IO-key S EKT for wall mounting. The

kit

consists of a metal wall bracket and a

I

FIGURE 22-BRACKET SLOTS

10.16

10.17 Install the handset hanger kit per Para-

graph 10.30.

10.20 Optional EKT Wall Mounting

Route the tail cord as shown in Figure 23. _.

-lO-

Page 31

*-

SECTlON 100-003-200

INSTALIATION

JULY 1994

knockouts are appropriate for the tail cord route,

and then cut them.

FIGURE 23-

10.21 An optional handset hanger kit (HWMA)

is also required to convert the optional EKTs for

wall mounting.

10.22 All optional EKTs are mounted in the

same manner, and they may be mounted on a wall

or any other flat, vertical surface to which the base

can be secured. When selecting the mounting

site, consider the EKT weight and the additional

stresses to which the mounting will be subjected.

10.23 Mounting screws or mollies, appropriate

for the surface on which the telephone is to be

secured, must be provided by the installer.

10.24 Locking tabs secure the EKT’s base. The

direction in which the base is attached to the EKT

determines whether it will be used as a desk unit

or wall unit (it is factory-configured as a desk unit).

Disengage the locking tabs by pushing downward

on the base (Figure 24).

“S” EKT WIRE ROUTING

FIGURE 25-EKT WIRE ACCESS

10.26 Secure the base to the desired wall site.

Use a spirit level and make certain the top of the

base is level and that the deeper portion is down.

10.27 Route the tail cord through the holes in

the base and secure the EKT (Figure 26).

-I

FIGURE 26-EKT WIRE ROUTING

10.28 Install the handset hanger kit per Para-

graph 10.30.

FIGURE 24

REMOVING OPTIONAL EKT BASE

10.25 Refer to Figure 25, choose which of the

10.30 Installing the Handset Hanger Kit

10.31

hanger kit (available from your Toshiba supplier)

must be used whenever an EKT is wall-mounted.

(When ordering specify if “S” EKT or optional

EKT-the HWMA is included in the SKWM kit.)

The remainder of the installation is the same for all

EKT types.

10.32 Remove the -card cover by inserting a

paper clip in the hole at one end. Bend the cover up

and remove it and the number card.

Refer to Figure 27, the optional handset

-ll-

Page 32

INSTALLATION

SECTION 100-003-200

JULY 1994

10.34 install the handset hanger into place and

tighten the screws. Reinstall the number card and

card cover.

. -

FIGURE 28-SET SWITCH

c) Depress the m key on station 17.

l

SPKR LED goes on.

d) Dial lqRm[ on the dial pad.

e) Depress the a and m keys.

l

The corresponding LEDs go on.

FIGURE 27-HANDSET HANGER KIT

10.35 An optional 13-ft. handset cord is available from your Toshiba supplier, and it is suggested that this cord be used when wall-mounting

an EKT.

10.40 EKT Connections

10.41 Connect the appropriate length line cord

to the modular connector, route the cord to the

EKT and connect to the EKT modular jack. Test the

EKT per Paragraph 12.

11 SYSTEM POWER-UP INITIALIZE

11 .Ol The

system data assignments stored in ROM that can

be entered at any time by performing the initialize

sequence outlined below. The system must be

initialized when it is first installed. This will allow

the system to be tested and any faults to be corrected before time is spent on programming.

11.02

refer to Figure 28 and perform the following steps:

a) Place the power switch on the MKSU in the

ON position.

b) Depress the SET switch and allow it to lock

. SETLEDgoeson.

l

Strcsta

S has a list of standard

To initialize the system data memory,

MW/FL LED on station 17 goes on.

f) Depress the IHoLD1 key.

l

The LEDs on station 17 for intercom through

I.

AD 4 begin flickering. ,

g) Depress and release the SET switch again.

. SET LED goes off.

l

Station 17 LEDs go off.

h) Cycle the MKSU power switch OFF and ON.

11 .l 0 Clearing Automatic Dialing

11 .l 1 The Automatic Dialing memon/ will con-

tain random numbers when the system is powered

up initially. To clear the memory; therefore pre-

venting meaningless numbers from being dialed,

proceed as follows:

a) Lock in the SET switch on the MKSU.

l

The SET LED and MW/FL LED on station

17willgoon.

b) Depress the m key on station 17.

l

SPKR LED will light steadily.

c) Dial mmrj on the dial pad.

l

SPKR LED will flash continuously.

d) Depress the a and m keys.

0 The corresponding LEDs will light

e) Depress the m] key.

l

All station 17 LEDs &xcept MW/FL) will go

Off.

f) Release the SET switch on the MKSU.

1.

-

-12-

Page 33

l

The SET LED and MW/FL LED on station

17 will go off.

,.

‘-

j) Depress the wj key.

. DND LED: off.

INSTALLATION

SECTION 100-003-200

JULY 1994

12 SYSTEM TEST PROCEDURES

12.00 1 O-key S EKT Functional Check

12.01 In order to verify the basic system func-

tions and confirm the proper functioning of the

EKT itself, perform the following test procedure at

each station equipped with a IO-key S EKT, begin-

ning with station 10.

12.02 With handset on-hook:

Depress the m!] key.

4

l

INT LED: l-use flash.

l

SPKR LED: on steady.

l

Listen for intercom dial tone via EKT

speaker.

Adjust speaker volume with the sliding volume

b)

control on the face of the EKT.

Depress the r6i] key.

c)

l

CO 1 LED: l-use flash.

l

SPKR LED: on steady.

l

Listen for CO/PBX dial tone via EKT

speaker.

Dial any digit (2 - 9) on the dial pad and dial

d)

tone will stop.

Depress the m] key.

e)

l

Listen for circuit break followed by dial

tone after approximately 2 seconds.

Depress the m key.

f)

l

CO 2 LED: l-use flash.

l

SPKR LED: on steady.

l

Listen for CO/PBX dial tone via EKT

speaker.

NOTE.

if no CO/PBX facility is connected to a CO

key, dial tone will not be heard but the LED is

still functional.

g) Depress the [ml key.

l

CO 3 LED: l-use flash.

l

SPKR LED: on steady.

l

Listen for CO/PBX dial tone via EKT

speaker.

h) Depress the IsPKRl key.

l

SPKR LED: off.

l

EKT speaker: off.

i) Depress the 1x1 key.

l

DND LED: on.

k) Depress the m key.

l

CO 1 LED: l-use flash.

l

SPKR LED: on steady.

l

Listen for CO/PBX dial tone via EKT

speaker.

I) Depress the WlDl key.

l

CO 1 LED: l-hold flash.

l

Speaker off (no dial tone).

. SPKR LED: off.

m) Depress the m key.

0 CO 1 LED: l-use flash.

l

SPKR LED: on steady.

l

Listen for CO/PBX dial tone via EKT ’

speaker.

n) Depress the ml key.

l

CO 1 LED: Conference call flash rate.

l

Dial tone continues.

o) Depress the m and m keys.

@ CO 1 LED: off.

. SPKR LED: off.

l

Dial tone: off.

.

p) Call EKT from another station.

l

Listen for caller’s voice via speaker after

the single tone signal.

l

Called station’s INT LED: l-called flash.

q) Dial q at calling station.

l

Tone signalling heard via the called station’s speaker.

r) Adjust the tone signalling volume with the

volume control on the bottom of the EKT.

s) Depress the m key.

l

INT LED: l-use flash.

l

SPKR LED: on.

l

Listen for intercom dial tone via the EKT

speaker.

t) Lift handset.

. SPKR LED: off.

l

Speaker: off.

l

Listen for dial tone via handset receiver.

.

u) Call another station and talk into the handset

transmitter.

l

Verify that your voice can be heard via -.

called EKT speaker.

v) Hang up.

12.03 This completes the station functional

-13-

Page 34

lNSTAU.ATlON

SECTION 100-003-200

JULY 1984

check for the standard EKT; repeat the procedure

for all standard EKTs in the system. See Paragraph

12.10 for optional EKT functional checks.

12.10 Optional EKT Functional Check

12.11 In order to verify the optional EKT’s func-

tions and confirm the proper functioning of the

EKT itself, perform the following test procedure on

each optional EKT.

12.12 With handset on-hook:

Depress the m key.

a)

0 INT LED: l-use flash.

l

SPKR LED: on steady.

l

MIC LED: on steady (if equipped).

l

Listen for intercom dial tone via the EKT

speaker.

Adjust speaker volume with the volume con-

b)

trol on the rear right-hand side of the EKT.

Depress the mj key.

d

l

CO 1 LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

l

Listen for CO/PBX dial tone via the EKT

speaker.

Dial any digit (2

d)

- 9) on the dial pad and dial

tone will stop.

Depress the -1 key.

d

l

Listen for circuit break followed by dial

tone after approximately 2 seconds.

Depress the (co4 key.

f)

l

CO 2 LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

l

Listen for CO/PBX dial tone via the EKT

speaker.

NOTE:

If no CO/PBX facility is connected to a CO

key. dial tone will not be heard but the LEO is

still functional.

g) Depress the m key.

l

CO 3 LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

l

Listen for CO/PBX dial tone via the EKT

speaker.

h) Depress the m key.

. SPKR 81 MIC LEDs: off.

l

EKT speaker: off.

i) Depress the m key. .

l

DND LED: on.

Depress the m key.

j)

. DND LED: off.

Depress the m key.

W

l

CO 1 LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

l

Listen for CO/PBX dial tone via the EKT

speaker.

Depress the [ml key.

l

CO 1 LED: l-hold flash.

l

Speaker: off (no dial tone).

. SPKR & MIC LEDs: off.

Depress the ml key.

m)

l

CO 1 LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

l

Listen for CO/PBX dial tone via the EKT

speaker.

Depress the -1 key.

n)

0 CO 1 LED: Conference call flash rate.

l

Dial tone continues.

Depress the m and mj keys.

0)

. CO 1 LED: off.

.

. SPKR & MIC LEDs: off.

l

Dial tone: off.

Call EKT from another station.

P)

l

Listen for caller’s voice via the called EKT’s

speaker after the single tone signal.

l

Called station’s INT LED: l-called flash.

Dial q at calling station.

4)

l

Tone signalling heard via called EKT’s

speaker.

Adjust tone signalling volume with volume

r)

control on the rear left-hand side of the EKT

being tested.

Depress the m key.

9

l

INT LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

l

Listen for intercom dial tone via the EKT

speaker.

Lift handset.

t)

. SPKR & MIC LEDs: off.

0 Speaker: off.

l

Listen for dial tone via the handset

receiver.

Call another station and talk into the handset

4

,. -

transmitter.

l

Verify that your voice can be heard via the

called EKT’s speaker.

-

_..~

-.

-14-

Page 35

-.‘v) Hold down the [ml key, and set the handset

back on-hook.

0 INT LED: l-use flash.

l

SPKR & MIC LEDs: on steady.

w) Tap the EKT microphone and verify that the

sound can be heard via the called EKT speaker.

x) Depress the (MUIE/MICI key while tapping the

microphone and verify that the sound cannot

be heard via the called EKT speaker (MIC LED

off momentarily-if equipped).

y) Depress the m key.

. INT LED: off.

. SPKR & MIC LEDs: off.

12.13 This completes the station functional

check for the optional EKTs; repeat the procedure

for all optional EKTs in the system.

12.20 Feature Check

'..

13.10 Music-on-Hold Source

13.11 A customer-provided MOH program

source (tape deck, tuner, or commercial source) or

the optional AMOU PCB may be used as the

music-on-hold source.

a) When the AMOU PCB is used, refer to Para-

graph 07.1 Ofor installation instructions. Verify

that the SW3 switch on the MMAU is set to

MOU (Figure 30). Adjust the volume with the

volume control labeled MOH on the MKSU

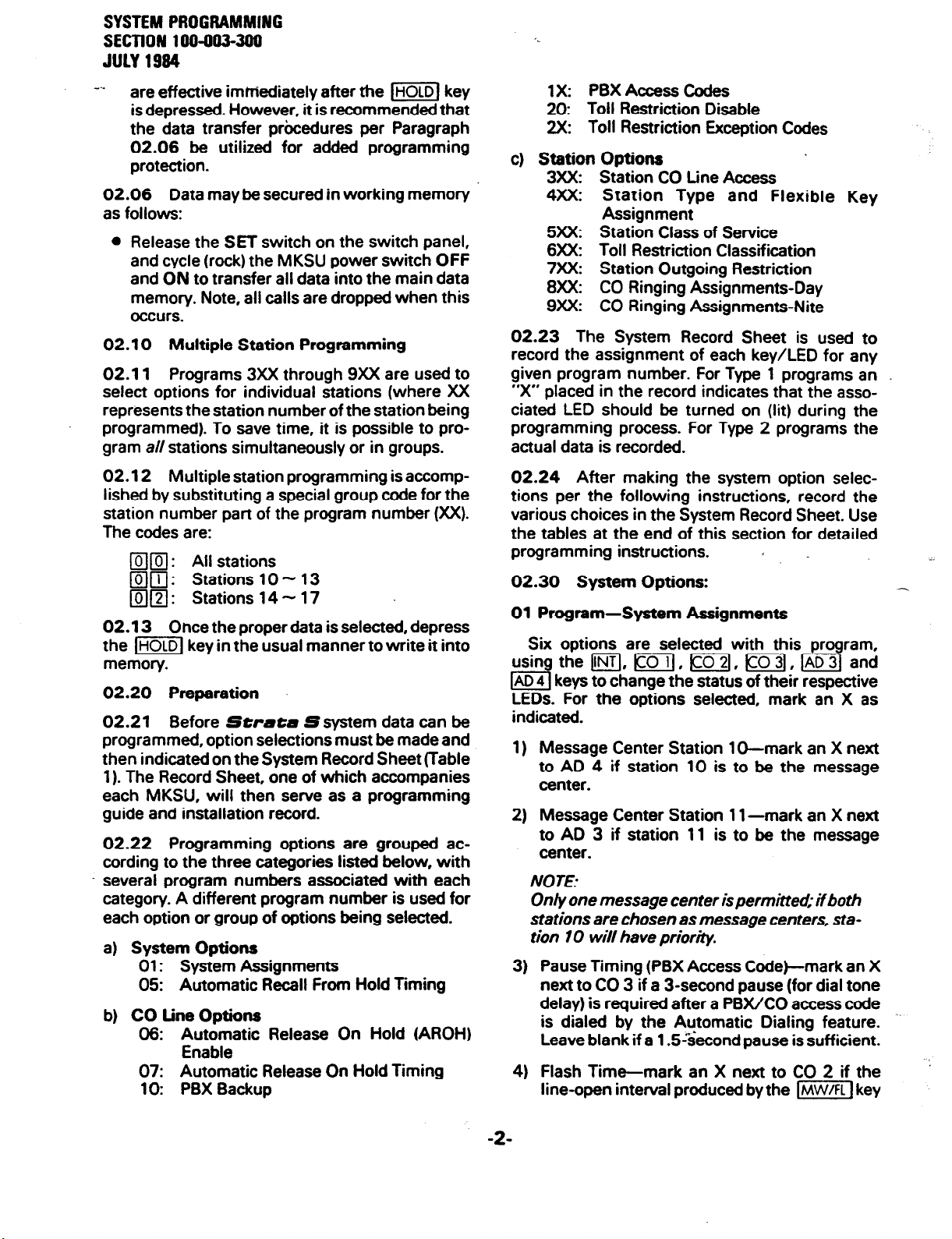

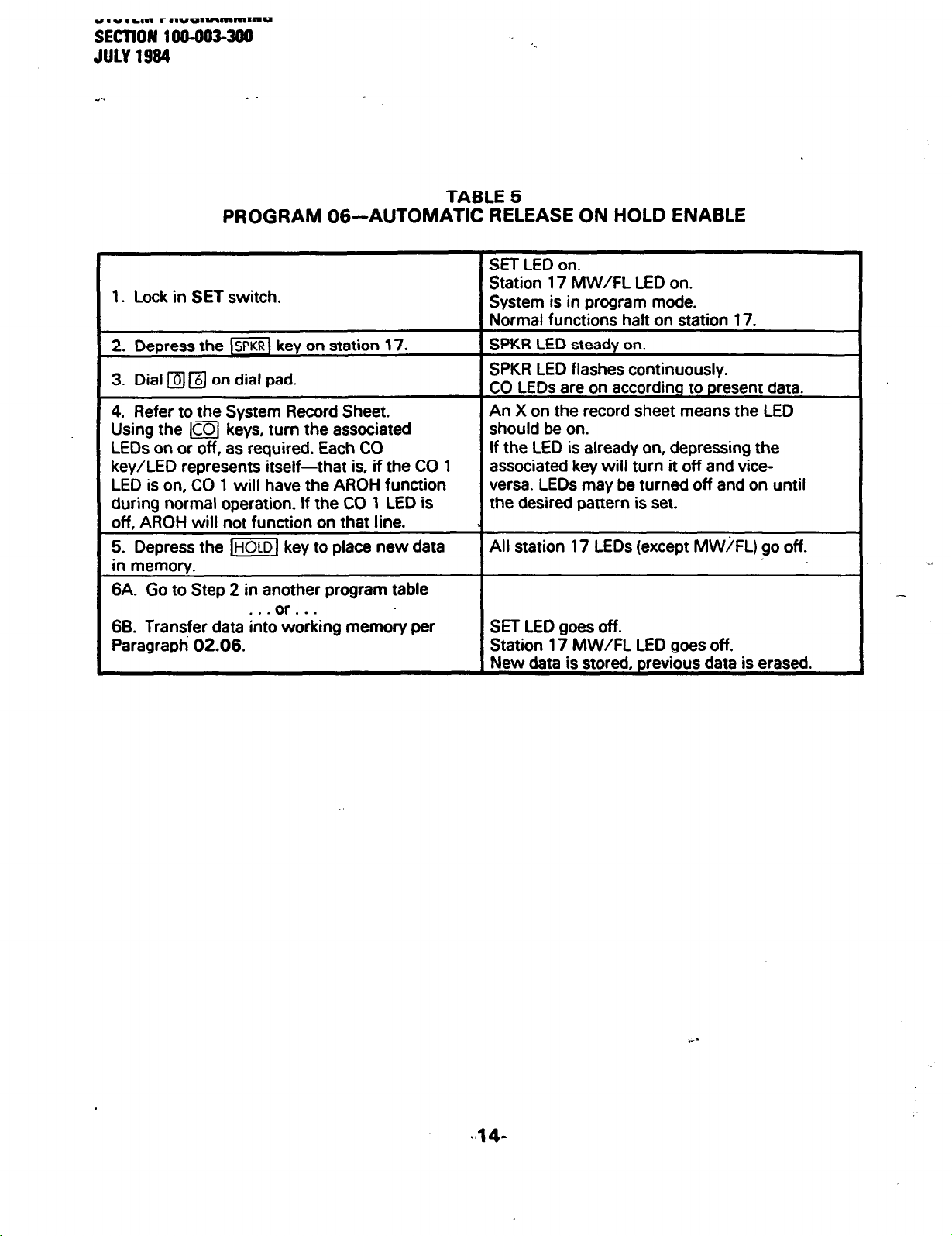

riaht side oanel.