Page 1

STE 58792–

INSTRUCTION MANUAL

INDUSTRIAL ROBOT SR–HSP SERIES

CLEAN SPECIFICATIONS

Notice

1. Make sure that this instruction manual is delivered to the final user of

the Toshiba Machine's industrial robot.

2. Be sure to read this manual before installing and operating the

Toshiba Machine's industrial robot.

3. Keep the manual nearby for future reference during use of the robot.

March, 1998

TOSHIBA MACHINE CO., LTD.

TOKYO, JAPAN

Page 2

Copyright 1998 by Toshiba Machine.

All rights reserved.

No part of this document may be reproduced in any form without obtaining prior written

permission from Toshiba Machine.

The information contained in this manual is subject to change without notice.

STE 58792

– 2 –

Page 3

Preface

Toshiba Machine's SR–HSP–CR series system robot is designed and manufactured as

per the clean specifications, taking over the high-speed and high-precision performance

characteristics of the standard SR–HSP series robot.

This manual describes the difference in structure, wiring, piping and maintenance of the

basic robot from the standard specifications. Before actually unpacking, you are

requested to look through this manual.

Also, before using this manual, please understand the name and function of each part,

referring to the Transportation and Installation Manual and Maintenance Manual.

This manual consists of the following four (4) sections.

Section 1 Cautions on Safety

This section deals with the important information on using the robot safely

and properly.

Section 2 Clean Robot Basic specifications

This section describes the basic specifications, outer dimensions and

operating range of the robot.

Section 3 Measures against Dust

This section stipulates the measures against dust when using the robot of

clean specifications.

Section 4 Maintenance and Inspection

This section describes the difference in maintenance and inspection of the

basic robot from the standard specifications.

– 3 –

STE 58792

Page 4

Table of Contents

Page

Section 1 Cautions on Safety ............................................................................ 5

Section 2 Clean Robot Basic specifications ...................................................... 6

2.1 Basic Robot Specifications........................................................... 6

2.2 Outer Dimensions ........................................................................ 7

2.3 Operating Range and Coordinate System ................................... 9

2.4 Tool Wiring and Piping ................................................................. 10

2.4.1 Tool Wiring........................................................................... 10

2.4.2 Tool Air Piping...................................................................... 10

Section 3 Measure against Dust........................................................................ 11

3.1 Specific Measures........................................................................ 11

3.2 Scavenging Piping in the Robot ................................................... 12

3.3 Sealing Robot Cover .................................................................... 13

Section 4 Maintenance and Inspection.............................................................. 14

4.1 Maintenance and Inspection Items............................................... 14

4.2 Lubricating Tool Shaft and Tool Shaft Support Bearing ............... 14

4.3 Replacement Parts List for Maintenance of Robot Mechanism.... 15

– 4 –

STE 58792

Page 5

Section 1 Cautions on Safety

This manual contains the important information to prevent the operators and persons

nearby from injuries, to prevent damage to assets and to ensure correct use.

Make sure that you well understand the following details (indications and symbols)

before reading this manual. Always observe the information that is noted.

[Explanation of indications]

Indication Meaning of indication

Danger

This means that "incorrect handling will lead to fatalities or serious

injuries."

Caution

¿1) Injuries refer to injuries, burns and electric shocks, etc., which do not require

This means that "incorrect handling may lead to personal injuries

¿1) or physical damage ¿2)."

hospitalization or long-term medical treatment.

¿2) Physical damage refers to damages due to destruction of assets or resources.

[Handling the clean robot]

Caution

• Take note that the type of grease used for the ball screw and spline differs from the

standard specifications. Failure to observe this could cause deterioration of robot

performance and malfunction.

• The customer should NEVER change or modify the parts other than those

stipulated in the instruction manual.

• For part replacement, be sure to use the spare parts designated by Toshiba

Machine.

• Carry out the maintenance and inspection regularly.

Unless they are executed, an abnormality or malfunction cannot be found, resulting

in accidents.

STE 58792

– 5 –

Page 6

Section 2 Clean Robot Basic Specifications

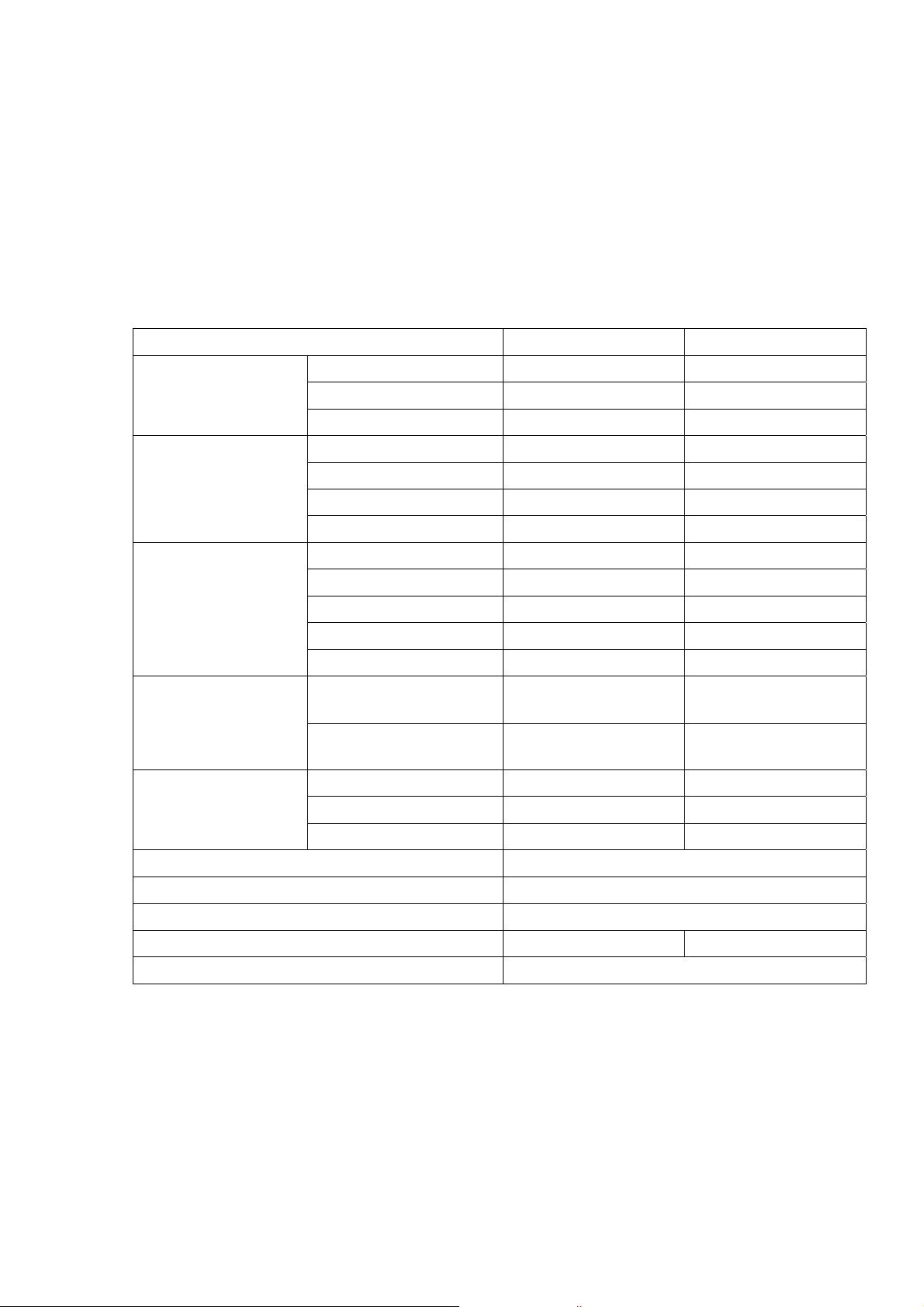

2.1 Basic Robot Specifications

Table 2.1 shows the basic specifications of the clean robot.

Table 2.1 Basic robot specifications

Model SR–654HSP–CR SR–1054HSP–CR

Arm length Full length 650 mm 1,050 mm

Arm 1 350 mm 580 mm

Arm 2 300 mm 470 mm

Operating range Axis 1 ±115° ±115°

Axis 2 ±140° ±145°

Axis 3 (vertical) 185 mm 185 mm

Axis 4 (wrist rotation) ±280° ±360°

Maximum speed Axis 1 255°/s 170°/s

Axis 2 360°/s 270°/s

Axis 3 (vertical) 800 mm/s 800 mm/s

Axis 4 (wrist rotation) 864°/s 576°/s

Composite 4.77 m/s 5.33 m/s

Load Mass of workpiece to

be carried

Permissible inertia

moment at the tip

Repeatability X, Y (plane) ±0.02 mm ±0.03 mm

Axis 3 (vertical) ±0.01 mm ±0.02 mm

Axis 4 (wrist rotation) ±0.03° ±0.03°

Tool wiring and air piping 12 cables and 2 pipelines

Degree of cleanliness Designed for cleanliness 10 (¿ Note 1)

Drive system AC servo motor

Mass of the basic body 65 kgf 95 kgf

Robot controller SR7000

Note 1: Cleanliness 10:

When this robot is operated in the clean bench (cleanliness 1 or less)

installed in the downflow clean room, the number of fine particles of 0.3

µm or over contained in 1 ft3 as measured in the plane of the lower end

position of axis 3 stroke is ten (10) or less.

Air speed of downflow is 0.3 ~ 0.5 m/s.

5 kgf (rated)

(Max. 10 kgf)

0.0663 kgf·m2 0.1 kgf·m2

10 kgf (rated)

(Max. 20 kgf)

– 6 –

STE 58792

Page 7

2.2 Outer Dimensions

Figures 2.1 and 2.2 show the external view of the basic robot.

Figure 2.1 SR–654HSP–CR external view

STE 58792

– 7 –

Page 8

Figure 2.2 SR–1054HSP–CR external view

STE 58792

– 8 –

Page 9

2.3 Operating Range and Coordinate System

For the clean specifications, the operating range of axis 3 (vertical) is smaller than

the standard specifications.

When installing the robot, review the layout after confirming the operating range

shown in Figures 2.3 and 2.4.

The zero point of the base coordinate system and each joint angle is the same as in

the standard specifications.

Figure 2.3 SR–654HSP–CR operating range

Figure 2.4 SR–1054HSP–CR operating range

– 9 –

STE 58792

Page 10

2.4 Tool Wiring and Piping

This paragraph describes the wiring and air piping for the tool.

2.4.1 Tool Wiring

For the tool wiring, see the descriptions on tool wiring (Para. 4.2.2) included in the

Transportation and Installation Manual.

For the wiring, be sure to use the connector at the lower side of arm 2.

2.4.2 Tool Air Piping

In all, two (2) air pipelines (outer dia. 6 mm × inner dia. 4 mm) are available for the

tool. Figures 2.5 and 2.6 show the joint locations of these pipelines.

Lower side of arm 2 Rear side of fixed base

Figure 2.5 Location of SR–654HSP–CR piping joint

Lower side of arm 2 Rear side of fixed base

Figure 2.6 Location of SR–1054HSP–CR piping joint

– 10 –

STE 58792

Page 11

Section 3 Specific Measures

1) Ball screw and spline

The ball screw and spline shafts are hard chrome plated.

Balls of the ball screw nut and spline nut are made of stainless steel.

They are lubricated with clean fluorine base grease.

2) Axis 4 rotating unit

The axis 4 rotating unit has a labyrinth structure.

3) Robot internal scavenging

The arm 2 cover interior and axis 4 rotating unit are scavenged by means of an

air tube.

4) Totally enclosed structure

The arm 2 cover is equipped in such a manner that there is no clearance with

the arm. Additionally, they are completely sealed with sealant to prevent dust

flow into the outside and to increase negative pressure.

5) Painting

Melamin baking finish is used for all paining.

6) Bolt and air fitting

All bolts exposed are made of SUS304.

All air fittings exposed are non-electrolytic nickle plated.

7) User's wiring and piping

The user's wiring and piping run under the arm 2.

The user's wiring can be easily removed and attached by means of a round

connector.

8) Assembly and test

Assembly and test are conducted in the clean booth of class 10000.

9) Packing

After cleaning the robot exterior with alcohol, the entire robot is packed in a

polyethylene bag for delivery.

As no clean measures are taken on controller SR7000, take utmost care of the place

where it is to be installed.

STE 58792

– 11 –

Page 12

3.2 Scavenging Piping in the Robot

An air tube is incorporated in the clean robot for scavenging.

Figures 3.1 and 3.2 show the piping of the air tube.

When operating the robot as the clean robot, scavenge through the air fitting, using

a scavenging vacuum pump (or equivalent to be provided by the user). Yardstick

for the scavenging volume is 75 liters/min.

If the robot is operated without scavenging, the specified degree of cleanliness

cannot be maintained.

Figure 3.1 SR–654HSP–CR scavenging air piping

– 12 –

STE 58792

Page 13

Figure 3.2 SR–1054HSP–CR scavenging air piping

3.3 Sealing Robot Cover

To maintain a better effect, the clean robot cover is filled up with sealant to eliminate

any clearance and to realize a totally closed robot structure. Dust in the robot will

not flow into the outside.

Except for the internal inspection and adjustment, DO NOT remove the cover.

– 13 –

STE 58792

Page 14

Section 4 Maintenance and Inspection

4.1 Maintenance and Inspection Items

The maintenance and inspection schedule and inspection items are the same as in

the standard specifications. For details, see Section 1 of the Maintenance Manual.

Bear in mind that the type of grease for the ball screw and spline differs from the

standard specifications.

4.2 Lubricating Tool Shaft and Tool Shaft Support Bearing

For the tool shaft, use the following grease.

• FONBLINE Grease OT–20 (maker: AUSIMONT)

For the greasing, see Para. 2.3.4 of the Maintenance Manual (STE 58766).

Caution

• Be sure to select the proper grease. If the wrong grease is selected, the robot

performance will deteriorate, resulting in malfunction.

– 14 –

STE 58792

Page 15

4.4 Replacement Parts List for Maintenance of Robot Mechanism

Table 4.1 SR–654HSP–CR replacement parts list for maintenance

Part name Dwg. No./Type Maker Q'ty Remarks

AC servo motor T–Z06030S–OU001 Toshiba 1 For axis 1

T–Y04030S–OU001 Machine 1 For axis 2

T–Z02030S–BOU002 1 For axis 3

T–Y01030S–BOU001 1 For axis 4

Harmonic drive P0712544P1 Harmonic 1 For axis 1

P0713566P1 Drive Systems 1 For axis 2

Planetary

reduction gear

Timing belt

Timing pulley K0713127P1 Toshiba 1 For axis 3

K0713126P1 Machine 1 For axis 3

K0713128P1 1 For axis 4

K0713125P1 1 For axis 4

Ball screw,

spline

Sensor AN9145 Matsushita

GXL–8FB 3 For axis 3

RS–1SH Japan

Harness T0711393G1 Toshiba

Grease SK–1A Harmonic

K0713184P1 Toshiba

Machine

73113×9

75113×20

P0712543P3 Clean spec.

UNITTA 1 For axis 3

1 For axis 4

Controls

Automation

Machine

Drive Systems

1 For axis 4

7 For axes 1, 2

& 4

1 For axis 4

1

500 g,

2.5 kg

OT–20 AUSIMONT 100 g

Caution

• All items other than the sensor and grease listed above are options. When

purchasing them, place an order with us.

• NEVER replace the parts by the customer.

STE 58792

– 15 –

Page 16

Table 4.2 SR–1054HSP–CR replacement parts list for maintenance

Part name Dwg. No./Type Maker Q'ty Remarks

AC servo motor T–Z06030S–OU001 Toshiba 1 For axis 1

T–Y04030S–OU001 Machine 1 For axis 2

T–Y02030S–BOU001 1 For axis 3

T–Z02030S–BOU002 1 For axis 4

Harmonic drive P0712555P1 Harmonic 1 For axis 1

P0712544P1 Drive Systems 1 For axis 2

M0713610P1 1 For axis 4

Timing belt

Timing pulley K0713159P1 Toshiba 1 For axis 3

K0713126P1 Machine 1 For axis 3

K0713158P1 1 For axis 4

K0713160P1 1 For axis 4

Ball screw,

spline

Bearing 6200ZZ 3 For axis 4

6810DDU 1 Contact

Sensor AN9145 Matsushita

GXL–8FB 3 For axis 3

RS–1SH Japan

Harness T0711405G1 Toshiba

73167×9

75172×25

P0712543P3 Clean spec.

UNITTA 1 For axis 3

1 For axis 4

rubber seal

7 For axes 1, 2

Controls

1 For axis 4

Automation

1

Machine

& 4

Grease SK–1A Harmonic

Drive Systems

OT–20 AUSIMONT 100 g

500 g,

2.5 kg

Caution

• All items other than the sensor and grease listed above are options. When

purchasing them, place an order with us.

• NEVER replace the parts by the customer.

STE 58792

– 16 –

Page 17

Edition

No.

–

1

2

3

Revision

Newly prepared. March,

Revised

Date

1998

In Charge

4

APPROVED BY:

CHECKED BY:

PREPARED BY:

– 17 –

STE 58792

Page 18

BARAUCHI

Page 3 (in Japanese version)

(1) 4–ø18 hole, counterbore 26

(2) Controller cable

(3) Cable length

(4) 2–ø22 hole

(5) User's air fitting

(6) Scavenging air fitting

(7) Max. 1000

Page 4

(1) 4–ø18 hole, counterbore 26

(2) Controller cable

(3) Cable length

(4) 2–ø22 hole

(5) User's air fitting

(6) Scavenging air fitting

(7) Max. 950

Page 6

(1) Hand wiring connector

(2) Pipeline B

(3) Pipeline A

(4) Pipeline A

(5) Pipeline B

(6) Scavenging air fitting

(7) Hand wiring connector

(8) Pipeline B

(9) Pipeline A

(10) Pipeline A

(11) Pipeline B

(12) Scavenging air fitting

Page 8

(1) Scavenging in arm 2

(2) Union Y-bend

(3) Scavenging of axis 4 rotating unit

STE 58792

– 18 –

Page 19

(4) Air tube (O.D. 6 mm × I.D. 4 mm)

(5) Elbow

(6) Tool air fitting

(7) Scavenging air fitting

Page 9

(1) Scavenging in arm 2

(2) Union Y-bend

(3) Scavenging of axis 4 rotating unit

(4) Air tube (O.D. 6 mm × I.D. 4 mm)

(5) Elbow

(6) Tool air fitting

(7) Scavenging air fitting

– 19 –

STE 58792

Loading...

Loading...