Page 1

Owners Manual

TEC LOAD CELL SCALE

(WITH LABEL PRINTER)

MODEL SL57 SERIES

(US. Version)

TEC

TOKYO ELECTRIC CO., LTD.

Page 2

WARNING

This equipment generates, uses, and can radiate radio frequency energy and if not installed

and used in accordance with the instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference

in which case the user at his own expense will be required to take whatever measures may

be required to correct the interference.

Page 3

TABLE OF CONTENTS

Page

INTRODUCTION.................................................................................................................................. 1

PRECAUTIONS.................................................................................................................................... 1

1. SPECIFICATIONS........................................................................................................................ 2

2. OVERVIEW................................................................................................................................... 3

3. REMOTE DISPLAY....................................................................................................................... 3

4. KEY ARRANGEMENT.................................................................................................................. 4

5. KEY AND LAMP FUNCTIONS..................................................................................................... 4

6. LEVEL ADJUSTMENT.................................................................................................................. 7

7. CLEANING THE PRINT HEAD..................................................................................................... 7

8. REMOVAL AND REPLACEMENT OF LABEL ROLL................................................................... 8

9. NOTES BEFORE STARTING OPERATION................................................................................ 9

10. OPERATION PROCEDURES

10-1. Weighed Article Registration............................................................................................. 10

10-2. Fix Price Registration....................................................................................................... 1 1

10-3. By Count Registration....................................................................................................... 12

10-4. Tare Function Procedures................................................................................................. 14

10-5. Save Function Procedures................................................................................................ 16

10-6. Unit Price per 1/2, 1/4 lbs................................................................................................. 18

10-7. Date Change..................................................................................................................... 19

10-8. Shelf Life Date Setting..................................................................................................... 20

10- 9. Print Test Label............................................................................................................ 20

1 1. TOTAL OPERATION PROCEDURES

11- 1. Individual Department Read......................................................................................... 21

1 1-2. Grand Total Read............................................................................................................ 21

11- 3. Individual Department Reset......................................................................................... 22

1 1-4. Grand Total Reset............................................................................................................ 22

12. PROGRAMMING PROCEDURES

12- 1. Date and Time Setting................................................................................................... 23

1 2-2. Unit Price Presetting or Changing................................................................................... 23

12-3. Name or Message Programming...................................................................................... 23

12-4. Address or Message Programming (Bottom of label)...................................................... 24

12-5. Print Item ON/OFF Setting or Changing.......................................................................... 24

13. ERROR MESSAGE TABLE........................................................................................................ 26

14. BEFORE YOU CALL FOR SERVICE......................................................................................... 26

Copyright ^ 1995

by T€C Corporation

All Rights Rasarvad

1-14-10 Uchikanda, Chiyoda-ku, Tokyo, JAPAN

Page 4

INTRODUCTION

We thank you very much for purchasing our TEC Electronic SL57 Series Scale.

This series has been designed with TEC reliability and offer a cost efficient system for a modest

investment.

And the SL57 (with thermal printer) takes advantage of the latest technology in microprocessors.

Because of this, the decreased cabinet size permits the system to be placed virtually anywhere in your

store.

Your deli, and specialty departments can enjoy these high quality reliable TEC products. Improve your

operating effectiveness and watch the increased utilization of your front end scanning investment. This

electronic Load Cell scale eliminates all moving parts and furnishes an accurate digital display of all

information.

We believe that your needs will now be fully satisfied, and you will have total reliability in price

calculation. This manual will help to acquaint you with the proper operation and care of the SL57 series

scale. Please keep it handy for future reference.

PRECAUTIONS

1. DON'T SUBJECT the weighing

platter to SUDDEN SHOCKS.

4. NEVERUSETHINNEROROTHER

VOLATILE SOLVENT for clean

ing.

DON'T PRESS THE KEYS TOO

HARD.

Keys will operate correctly if

they are merely touched lightly.

5. DON'T POUR WATER directly on

scale.

3. Clean the cover and platter by

wiping with a dry cloth or a cloth

soaked with detergent and

wring out thoroughly.

6. To insure scale is operating cor

rectly, place a known weight on

platter and check for correct

computing.

7. When in use, avoid locations subject to vibration and direct sunlight.

1 -

8. After the end of daily work, turn

the power OFF, clean and in

spect the exterion of the scale to

allow you to use the scale at its

Page 5

1. SPECIFICATIONS

Items SL57-30L-US

Maximum Capacity

Minimum Scale Division 0.01 lbs

Using Weight Range 0.20 ~ 30 lbs

Display Range 0 ~ 30.05 lbs

Tare

Unit Price Presettable

Minimum Price Display $ 0.01

Power Requirement

Current Consumption

Temperature Limits 23° ~ 104°F

Relative Humidity

Weight

Remote Display;

Weight

Unit Price 4 digits

Total Price

Display Designations

Remote Display Mode

Print Head

Label

30 lbs

0.01 ~ 30 lbs

$ 0.01 ~ 99.99

AC 120V ±10%, 60 Hz

120V • 1A. 60 Hz

35% ~ 85% RH (No condensation)

26.5 lbs

4 digits

5 digits

NET, PREPACK, ERROR

Dual sides

Thermal Print Head

RICOH 120LA or equivalent

Dimensions (approximate)

6.

- 2 -

Page 6

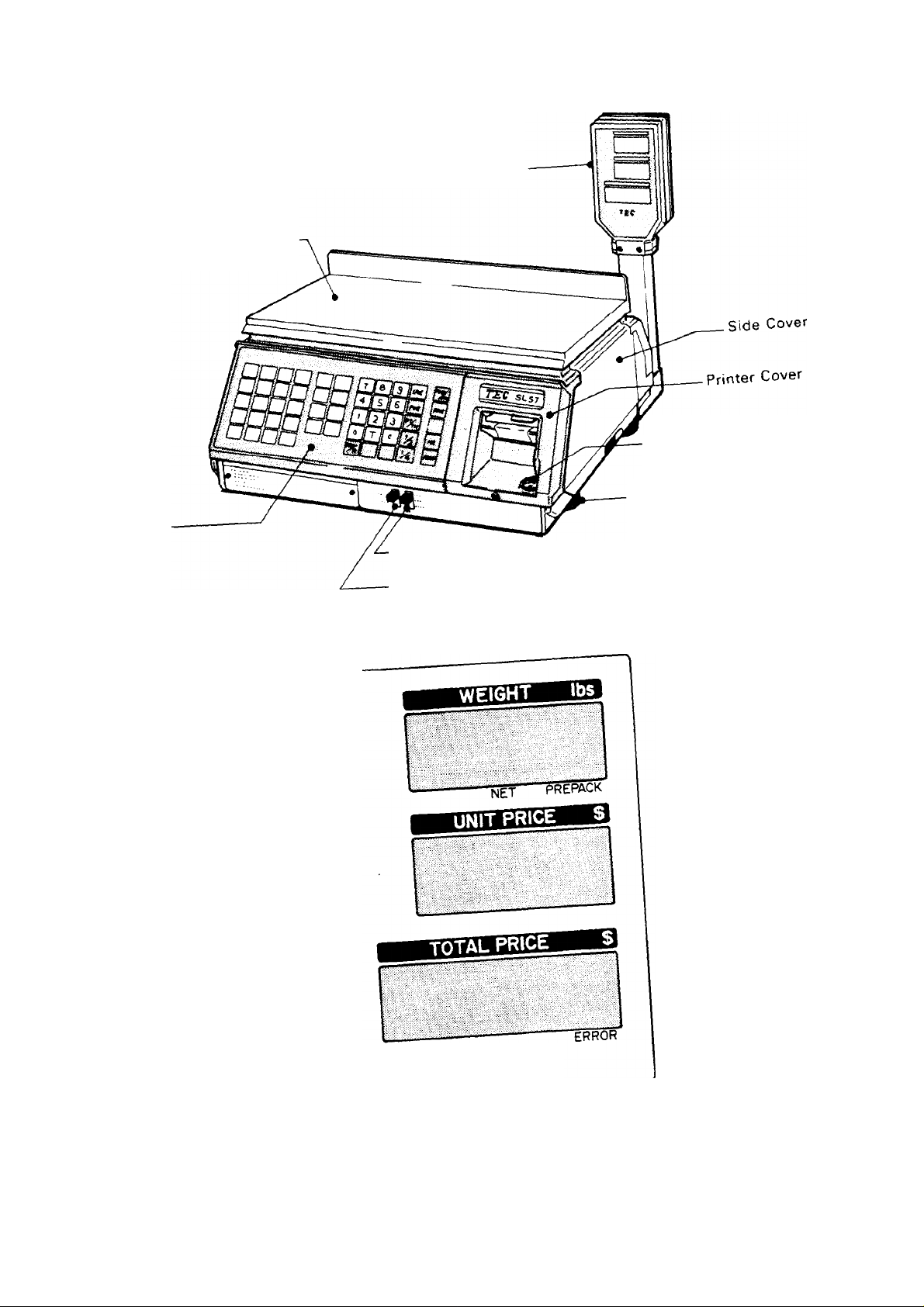

2. OVERVIEW

Keyboard

Remote Display

Platter

Level Gauge

Adjusting Leg

•Mode Switch (1)

3. REMOTE DISPLAY

• Mode Switch (2)

TEC

CAPACITY 30X0.01 lbs

- 3 -

Page 7

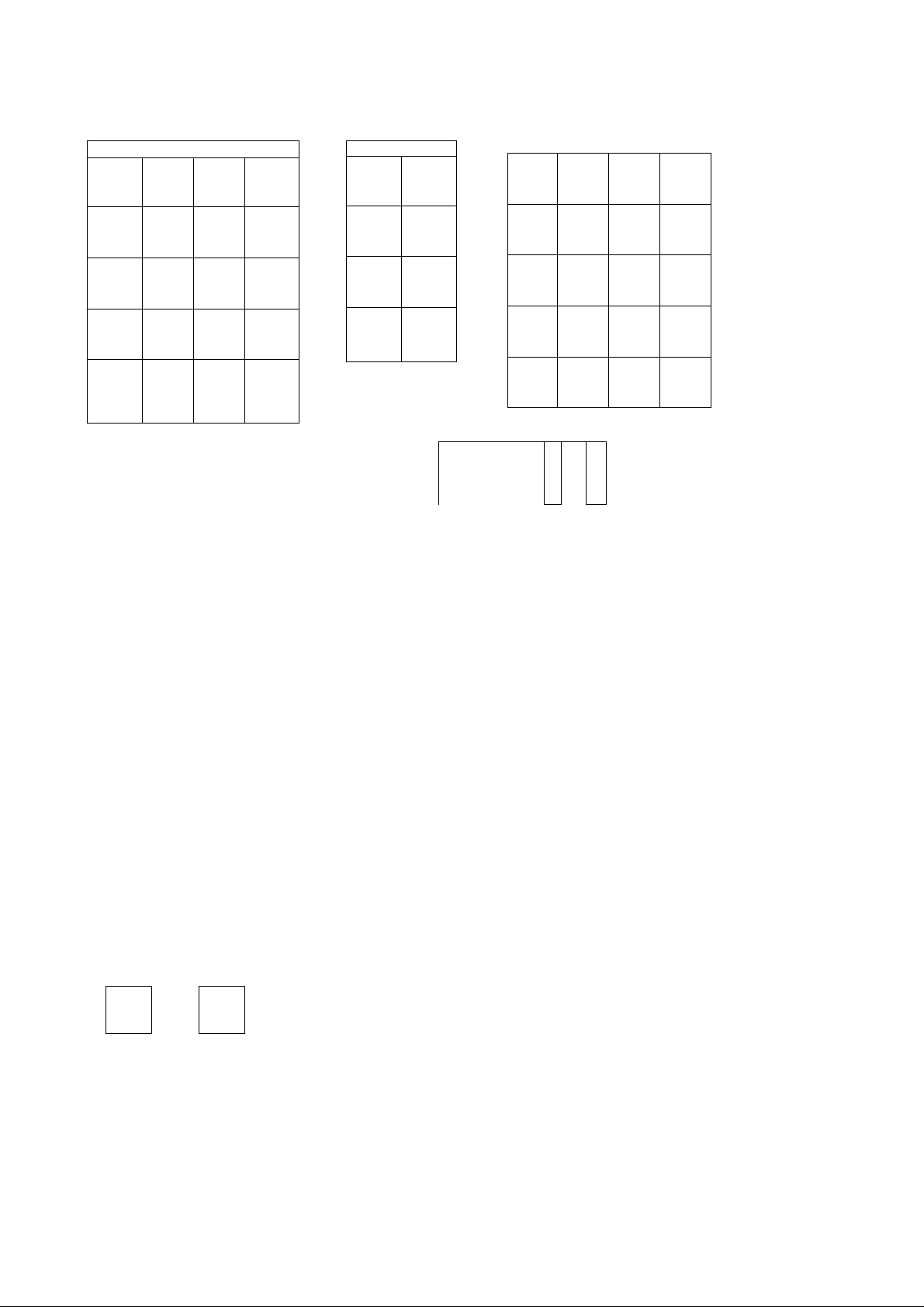

4. KEY ARRANGEMENT

POWER

ZERO

PROG

MR

FEED

1

5

9

13

17

Unit Price Preset Keys

NOTE: The characters indicated on the Unit Price Preset keys and the Department keys are shown for

the convenience of explanation in this manual. The indications on the actual unit are not as

shown in this illustration.

2

6

10

14

18

3

7 8

1 1 12

15 16

19 20

4

Department Keys -

I I

I

V

u

ly

in

11

MANUAL

X/Z PROG.

7

4 5

1

0

PRT

AUTO

L-1

8

2

T

3

WEIGH (X)

FIX(Z)

>-•

BY COUNKPROGJ

9

6

3

c

SAVE

FOR

7m

7

7

5. KEY AND LAMP FUNCTIONS

Name of Key or Lamp

CLEAR Key

DATE & TIME Key

TM

DEPARTMENT Keys

8 keys

1 VIII

FEED Key

FEED

1. This key is used for enter-clear of numeric key.

2. Thist^ey is used to release the scale from the save or error mode.

1. This key is used to indicate the date on remote display.

2. This key is used for temporary date change.

1. These keys are used to program the department name.

2. These keys are used to register the sale items. At this time, the

Department keys are also used as the Label Issue keys.

3. In "X/Z" mode switch (2) position,these keys are used to generate

the Department Total Reports.

This key is used to feed labels.

Function

Page 8

Name of Key or Lamp

Function

FOR Key

FOR

Mode Switch (1)

WEIGH (X)

FIX(Z)

BY COUNT(PROGJ

Mode Switch (2)

AUTO

MANUAL

X/Z PROG.

1. This key is used to issue the "BY COUNT" label with split price.

2. In "X/Z" mode switch (2) position, this key is used to issue the TEST

label.

"WEIGH (X)" position:

1. This position is used in weighing function of SL57.

2. This position is used to read (X) all the accumlated sales totals stored

in the unit when mode switch (2) is set to "X/Z PROG." position.

"FIX (Zr position:

1. The unit price enters directly to total price, and that total price

cannot be changed by any weighing after that.

2. This position is used to reset (Z) all the accumlated sales totals

stored in the unit when mode switch (2) is set to "X/Z PROG."

position.

"BY COUNT (PROG.)" position:

1. It is possible to produce labels which contain information of quantity

pricing, instead of weight.

2. This position is used to set the various programs when mode switch

(2) is set to "X/Z PROG." position.

"AUTO" position:

1. This position is used to issue weighing label when mode switch (1)

is set to "WEIGH" or "FIX" position.

2. This position is used to issue By Count label when mode switch (1)

is set to "BY COUNT" position.

The label is issued in succession after peeling it.

"MANUAL" position:

This position is used to issue a label by depressing the PRINT key or

DEPARTMENT key.

"X/Z PROG." position:

1. This position is used to read (X) or reset (Z) all the accumulated sales

totals in the unit when mode switch (1) is set to "WEIGH (X)" or "FIX

(Z)" position.

2. This position is used to set the various programs when mode switch

(1) is set to "BY COUNT (PROG.)" position.

MR Key

MR

Numeric Keys

Per 1/2, 1/4 lbs Keys

V,

Va

1. In "X/Z" mode switch (2) position, this key is used to generate the

Grand Total Read Report.

2. This key is used to select the items in programming.

These keys are used to enter the numeric data (Unit Price, Tare

weight,etc.).

These keys are used to calculate the unit price by 1/2 lbs or 1/4 lbs.

NOTE:

When the 1/2(1/4) key is depressed, the unit price is multipled by 2(4).

- 5 -

Page 9

Name of Key or Lamp

Function

POWER/ZERO Key

POWER

/ZERO

PRINT/VERIFY Key

PRT/*

PROGRAM Key

PROG.

SAVE Key

SAVE

TARE Key

This key is used to supply power to the main circuit and to adjust

"ZERO" point.

1. This key has the function of label issue.

2. During programming, data is input to the SL57 by using this key.

This key is not used in SL57 system.

This key is used to save tare and unit price after taking off the

commodity from the platter.

1. This key is used to subtract or clear the tare weight.

2. This key is used to preset tare weight beforehand through the

numeric keys.

UNIT PRICE PRESET Keys

1

20

NET Lamp

PREPACK Lamp

ERROR Lamp

These keys are used to set and call the unit price of frequently used

commodities.

Lights when tare is subtracted.

■T

Lights when SAVE key is pressed.

\ I /

Lights when this scale is improperly operated or has caused a function

error.

\ I /

6 -

Page 10

6. LEVEL ADJUSTMENT

Set the scale on a stable and level surface.

Level the scale by turning the adjusting legs so that the air bubble comes to

the center circle. For example, in the case of the condition shown in the left

figure, turn the adjusting legs (1) and (2) in the direction shown so that the

Correct Incorrect

bubble comes to the center of the circle.

7. CLEANING THE PRINT HEAD

•(2)

)

If the print head is dirty, clear printing is not performed. It is recommended to clean the head with thermal

head cleaner everyday, before starting operation by following procedure:

1. Remove the printer cover and side cover. Then

pull the head-up lever to arrow direction.

2. Wipe off the dirt on the [■ portion] with the

thermal head cleaner.

Then set the label, and push down the print

head.

NOTE: Do not damage the print head when

cleaning.

- 7 -

Page 11

8. REMOVAL AND REPLACEMENT OF LABEL ROLL

1. Remove the printer cover and side cover.

Then pull the head-up lever to arrow direction.

2. Remove the core of the label roll and the label

backing paper.

NOTE: To remove the label backing paper,

loosen the paper by turning the paper

clockwise and remove the paper

stopper.

Be careful to never turn the paper

winding shaft clockwise.

Head-up Lever

Label End Sensors

Referring to the figure on the right, set the label

roll on the unit.

3. Push down the printer head, and close the

covers.

NOTE: When the label roll is replaced, press

the feed key to confirm that the label

is issued correctly.

- 8 -

Page 12

9. NOTES BEFORE STARTING OPERATION

(1) Be sure to insert the power plug into AC outlet.

(2) When the power key is turned on, the scale goes through the test scanning sequence, such as

0000,0000,00000, then 1111,1111,11111

key is turned on over about 1 6 seconds after the power plug is connected to the AC outlet, all "8"s

appear on all displays for a moment, then zeros are displayed and the scale is ready for use.

(3) While scale is in the test sequence, do not put anything on the platter.

(4) Do not move the unit while it is in operation. Should it become necessary to move it at any time,

turn the power switch to OFF position and be sure to readjust the level indicator after relocating

the scale.

(5) Should a power failure occur during operation, remove the commodity from the platter and insert

the power plug into AC outlet again when power is restored.

(6) If scale is used with an unrated power source, inaccurate scaling or other errors may occur,

(7) If Zero Point has shifted during scaling, and no tare is displayed, adjust Zero Point by depressing

Zero key twice.

....................

and zeros appear on the displays. When the power

- 9

Page 13

10. OPERATION PROCEDURES

10-1. Weighed Article Registration [Mode SW. (1): WEIGH position]

★ Auto Mode [Mode SW. (2); AUTO position]

(1) Press unit price preset key or enter

the unit price.

ex.) Unit price of $ 2.50/lb,

WEIGHT U. PRICE

n nn

U.kMJ

3 c n

w ,3u

T. PRICE

n nn

u.uu

(2) Place an article on the platter.

(3) The label is issued automatically.

pitmiN

«T WT, iIPIS PRICE/li S3 1 TOTAL PRICE 631

149 Mi lto n S t.

★ Manual Mode [Mode SW. (2); MANUAL position]

(1) Press unit price preset key or enter

the unit price.

ex.) Unit price of $ 2.50/lb is set

in preset key [3.

JUL 25

2,00 2.50

SOI

itAUG 04

$5 . 0 0

3$ nn

4. .UU

(Sample label)

n nn

u.uu

C n

C,DU

3r cn nr

C nn

b.UU

(2) Place an article on the platter.

(3) Press I PRT/* I or department key

for the article.

PRT !

or 1 I~H

(4) The label is issued.

imoionJIIL 25 saL№rAUG04

2.00 2.50

NETWtiga PHtCE/li £jj

$5 . 0 D

TOTAL PRICE 69

149 Mi I ton St.

I^Q-pg. (Sample labels)

nn

C.UU C,3u

Po r k

11

^«JUL25 »i»ftüG04

2.00

NET WT.ilSn

2.50

PXICE/li

149 Mi I ton St.

sen

TOTAL PRICE 63

r nn

J.UU

When the Mode SW. (2) is set to AUTO position, the character(s) registered in the department key is

(are) printed in the department name area of the label.

When thefPRT/* | key is pressed with the Mode SW, (2) set to MANUAL position, the character(s) printed

in the department name area of the label is (are) also that (those) registered in advance in the department

key. The data (Weight data. Item data, and Total Price data) of the issued label is added to the department

No. 8 memory,

- 10 -

Page 14

10-2. Fix Price Registration [Mode SW. (1): FIX position]

★ Auto Mode [Mode SW. (2): AUTO position]

(1) Press unit price preset key or enter

the unit price.

ex.) Unit price of $ 3.00/lb is set

in preset key [7].

(2) Place an article on the platter.

(3) The label is issued automatically.

.«i.JUL 25

Knurrig piMCt/tia

ld9 Hilton St.

* Manual Mode [Mode SW. (2): MANUAL position]

(1) Press unit price preset key or enter

the unit price.

1.50

1.S lbs

sii nAU6 04

$3 . 0 0

TOTAL PRICE

WEIGHT U. PRICE T. PRICE

n nn D n n

u.u u

*.

(Sample label)

3.U U

nit

3

.uu

ex.) Unit price of $ 3.00/lb.

(2) Place an article on the platter.

(3) Press [ PRT/* I or department key

for the article.

(4) The label is issued.

0 0

1.S lbs

TT

PRT

or

I-i

MBuJUL 25 sai nAU6 04

1.50

«T *T. 'IS Piac£/»

M9 Milton St.

TOTAL PRICE

(Sample labels)

n

nn

u.u u

1

cri

Ch i c ke n # 1

».JUL25 sun AUG 04

1.50

KTHIT.'JS ««/»iä

1d9 Hilton St

j nn

J.U U

3

J.U U

TOTAL PRICE 63

nn

- 1 1 -

Page 15

10-3. By Count Registration [Mode SW. (1): BY COUNT position]

★ General Operation

(1) Enter the quantity of sale.

(Max. 2 digits)

(2) Press I FOR|.

(3) Enter the total price or press the

preset key.

(4) Press I PRT/ * I or department key

for the article.

(5) When Mode SW.(2) is set to

MANUAL position, single la

bel is issued.

(6) When Mode SW.(2) is set to

AUTO position, the label is

issued in succession after

peeling it.

5

FOR

1

PRT

5

2

or

I'1I

PMBB JUL 25 su.itA116 04

5Pitcis $1.25

iofT.-E3 tm/nii

1(19 Milton St.

lOIAl PRICE gg

IBWT.'JS P1WCt/t;3

149 Milton St.

(Sample labels)

WEIGHT

.

U. PRICE

n

ne

.OS

|.гs

.05

Fr u i ts

MB.JUL25 ai.TAUG04

BPifcfs $1.25

TOTAL PRICE

T .PRICE

n nn

u.uw

n nn

u.uo

n nn

★ Single Item Registration

(1) Enter the total price or press the

preset key.

(2) Press I PRT/* I or department key

for the article.

(3) The label is issued.

PRT

iMaaJUL 25

SOI IT

mm $1.25

KTwt.Ea nact/iij}

149 Milton St.

I-tl

AUG 04

TOTAL PRICE gg

.'.?S

!.?5

Ve g e ta bl e s

«..JUL25 sun AUG 04

iplfcis $1.25

icTWTus mcuti'A ^jiWjm-iriBki

149 Milton St.

(Sample labels)

- 12 -

Page 16

★ Split Price Operation

(1) Enter the quantity of sale.

(Max. 2 digits)

WEIGHT U. PRICE T. PRICE

n in

0

U, r -

n nn

u.wu

(2) Press I FOR |.

(3) Enter the quantity for that total

price. (Max. 2 digits)

(4) Press ! FOR |.

(5) Enter the total price or press the

preset key.

(6) Press [PRT/* ! or department key

for the article.

(7) The label is issued.

3 0 0

PRT

JUL 25 «uitAUG 04

MBK

10TOS

HTWT.gg fm/tii

U9 Milton St.

FOR

5

F(3R

or

1-1

TOTAL PRICE R

o

r

o *c

^ J

o «n

r . lU

in

. tu

n IC

u. O

nn

i

.uw

Ve g e ta bl e s

■ •JUL 25 •uitAU6 04

KTWT.G? (HI(I/llEa

M9 Milton St.

10TOS

TOTAL PRICE ga

n nn

u.u u

n nn

u.uu

n nn

u.uu

n nn

u.uu

5 nn

C.uu

{Sample labels)

- 13 -

Page 17

10-4. Tare Function Procedures

There are two kinds of tare subtraction procedures, one is "Direct tare", another is "Preset tare

Mode SW. (1): WEIGH or FIX 1

Mode SW. (2): MANUAL J

[

(1) Place tare weight on the platter.

(2) Press [T].

(3) Start the weighing or fix price

operation.

(4) The label is issued.

(5) Remove the article together with

tare.

NOTE; Tare weight subtraction is available with up to 30 lbs. When tare weight subtraction is in

operation, however, the scalable range for net weight becomes less by the amount of the tare.

(Net weight = Gross weight - Tare weight)

NOTE: When the tare weight exceeds 0.20 lbs with the Mode SW.(2) set to AUTO position, one tare

label will be issued automatically. To prevent this, set the Mode SW. (2) to MANUAL position.

- 14

Page 18

★ Preset Tare Subtraction #1

Mode SW. (1): WEIGH I

Mode SW. (2): MANUAL

J

(1) Enter the tare weight.

ex.)Tare weight of 0.50 lbs.

(2) Press .

(3) Place the tare of 0.50 lbs on the

platter.

(4) Start the weighing operation.

★ Preset Tare Subtraction #2 «iiamiiai

„ r Mode SW. (1); FIX I

L Mode SW. (2): MANUAL J

WEIGHT □ .PRICE

n nn

u.uu

n c n

U.JU

i<- NET

n nn

u.uu

NET

n

u.uu

n nn

u.uu

n nn

u.uu

T. PRICE

n nn

u.uu

n nn

u.uu

(1) Enter the tare weight.

ex.)Tare weight of 0.50 lbs.

(2) Press [T] ■

(3) Place the tare of 0.50 lbs on the

platter.

(4) Start the fix price operation.

-)tC- net

->K- NET

ft nn

u.uu

n

U.JU

n nn

u.uu

-I

cn

J,JU

n nn

u.uu

15 -

Page 19

10-5. Save Function Procedures

Save key is used to save tare weight and unit price (or total price) after taking off the article from the

platter.

★ Weighed Article Mode Saving [Mode SW. (1): WEIGH]

(1) Place tare weight on the platter. •

(2) Press key.

(3) Enter the unit price.

(4) Press I SAVE j key. Tare and Unit

Price are saved.

(5) Place an article on.

ex.) Weight of 2 lbs.

(6) When Mode SW. (2) is set to

MANUAL position, pressf^T/* |

or department key.

2

PRT

The label

is issued.

0.50 Ibl

X—7.^

I I

5

SAVE

ZI

I'TI

WEIGHT U. PRICE T. PRICE

n

n

Ci

U.JK

n nn

u.uu

NET

0

n nn

u.uu

1 y . . —

NET

n nn

u.uu

NET

n nn

C.uu

NET PREPACK

nn

u.uu

n nn

U.u u

5 cn

C.3u

^ C H

C.3u

PREPACK

г.so

n nn

u.uu

n nn

u.uu

n

nn

u.uu

n nn

u.uu

r nn

^.uu

(7) Remove the article together with

tare.

(8) Press [§ key.

Clear the save mode and unit

price.

(9) Press key.

(10) Press [T] key.

The scale is ready for use.

- n C n

»(- NET

. n

U. JU

TC- net

U.JU

n

nn

u.uu

PREPACK

/l\

?. s c

n nn

u.uu

n nn

u.uu

n nn

u.uu

16 -

Page 20

★ Fix Price Mode Saving [Mode SW. (1): FIX]

(1) Enter the tare weight.

(2) Press ¡2 key.

(3) Enter the total price.

(4) Press I SAVE | key. Tare weight and

Total Price are saved.

ex.) Aticle of 5 lbs and tare of

0.50 lbs.

(6) When Mode SW. (2) is set to MAN

UAL position, Press IPRT/* | or

department key.

0

SAVE

PRT

The label

is issued.

w

0

I~1

WEIGHT

n nn

u.uu

. n

i(- NET

0

• oc«

TC- net

. n C«

tC- net

C nn

J.uu

u.^u

U. PRICE

PREPACK

T. PRICE

O C O

u.^u

n no

u.uu

3 nn

3m

3 nn

3m u

3 nn

5.UU

-)|f NET PREPACK

(7) Press key.

Clear the save mode and total

price.

(8) Remove the article together with

tare.

TT

Tare weight

is cleared

automatically.

c nn

3mu

NET

n nn n no

u.uu

n nn

u«uu

u.uu

- 17

Page 21

10-6. Unit Price per 172,1/4 lbs [Mode SW. (1); WEIGH]

★ Per 1/2 lbs

(1) Enter the unit price.

WEIGHT U. PRICE T. PRICE

n nn

0

u.uu

?. s c

n nn

u.uu

(2) Press key.

(3) Place an article on the platter.

(4) When Mode SW. (2) is set to AUTO

position, the label is issued

automatically.

★ Per 1/4 lbs

(1) Press unit price preset key.

ex.) Unit price of $ 0.75/lb is set

in preset key Q].

(2) Press 1^ key.

Z lbs

XT

iMBaJUL 25 sBiirAUG 04

2.00 5.00

KTwt.igg Fwct/iiga

149 Hilton St.

$1 0 . 00

TOTAL PRICE g?

n nn

u.uu

^ nn c nn

u.uu u.uu

(Sample label)

WEIGHT

n nn

u.uu u.uu

C nn

u.uu

U. PRICE T. PRICE

J. o

D nn n nn

n nn

u.uu

in nn

lU.UU

n no

u.uu

u.uu

(3) Place an article on the platter.

(4) When Mode SW. (2) is set to AUTO

position, the label is issued

automatically.

NOTE: The SL57 will check details of unit price, if unit price after calculation (1/2 lbs; 2 times, 1/4

lbs: 4 times) is exceeded 4 digits then unit price will be cleared.

NOTE: i3] or key should be depressed after key-in unit price.

maJUL 25 aunAUG 04

2.00 3.00

m m. 'is rm/t

149 Hi I ton St.

$6 . 0 0

TO T AL PR i C F

^

5 nn

C.uu u.uu o.uu

(Sample label)

5 nn c nn

18 -

Page 22

10-7. Date Change [Mode SW.(2): AUTO or MANUAL]

The date can be changed temporarily.

(1) Press I DT/TM I key.

(2) Enter the new date,

ex.) Aug. 10th. '87

T. PRICE

Current setting

date

nnnnno

uuuu.uO

nnno tn

UUUO. fw

no #n on

uO lu.O «

(3) Press

I

PHI/* I key.

★ When original date is desired.

(1) Press I DT/TM I key.

(2) Press key.

(3) Press I PRT/* I key.

aM

PRT

(Finish)

no <o o n

uO lU.O I

- 19

Page 23

10-8. Shelf Life Date Setting [Mode SW.(2): AUTO or MANUAL]

With the SL57 system, the shelf life date can be set for the article(s).

^^ U. PRICE T. PRICE

¡1) Press IDT/TM I key.

(2) Press I SAVE | key.

(3) Enter new shelf life date.

(Max. 3 digits)

(4) Press I PRT/* I key.

10-9. Print Test Label [Mode SW. (2): X/Z PROG.]

At the "X/Z PROG." position, depression of \ FOR | key will issue a label indicating the area which is

within the print matrix.

Please, check the condition of thermal head with this label everyday before starting operation.

20 -

Page 24

11. TOTAL OPERATION PROCEDURES [Mode SW.{2): X/Z PROG.]

The READ (X) reports allow to read the totals but not clear memories, while the RESET (Z) reports allow

to read the totals and at the same time all the resettable memories will be cleared when the reports

have been issued.

11-1. Individual Department Read [Mode SW. (1): WEIGH (X)]

(1) Press the required department

key.

(2) The report is issued.

11-2. Grand Total Read [Mode SW. (1): WEIGH (X)]

(1) Press I MR I key.

(2) The report is issued.

NOTES;

1. Read or Reset mark

DPT-n O

DPT-n *

GRAND O

GRAND *

Department Read mark (n = 1 ~ 8)

Department Reset mark (n = 1 ~ 8)

Grand Total Read mark

Grand Total Reset mark

2. Tatal Memory clear

CO

Total operation

Individual Department

“O

0)

QC

Grand Total

■ 4-»

Individual Department

O

0)

tr

Grand Total

Dept. Total Memory

Grand Total Memory

Not cleared Not cleared

Not cleared

Cleared

Cleared

21 -

Not cleared

Not cleared

Cleared

Page 25

11-3. Individual Department Reset [Mode SW. (1): FIX (Z)]

(1) Press the required department

key.

(2) The reset report is issued.

11-4. Grand Total Reset [Mode SW. (1): FIX (Z)]

(1) Press I MR I key.

(2) The reset report is issued. Then all

the resettable memories will be

cleared.

- 22 -

Page 26

12. PROGRAMMING PROCEDURES

[Mode SW.(1): BY COUNT (PROG.)]

[Mode SW.(2): X/Z PROG.]

In this chapter are described operations to add to or change the data already programmed in the

"PROG"mode. To enable the programming operations in the "BY COUNT (PROG.)" position of the Mode

SW.(1) and the "X/Z PROG." position of the Mode SW. (2).

12-1. Date and Time Setting

ex.) To set the date "July 25th. '87" and time "21:09":

Mode SW. (1): BY COUNT (PROG.).

Mode SW. (2): X/Z PROG.

(01'12) (01-31)

1 0 9

2

Hour '-Minute

(00-23) (00-59)

PRT/*

—

NOTE: The SL57 will check details of date (time) input, any wrong date (time) will result in error mode,

and correct date (time) should be entered again.

12-2. Unit Price Presetting or Changing

ex.) To set $ 2.50 to Preset key Q, and $ 3.00 to Preset key Q:

Mode SW. (1): BY COUNT (PROG.)

Mode SW. (2): X/Z PROG.

(Max. 4 dig.)

PRT/-X-

PRT/*

(Max. 4 dig.)

12-3. Name or Message Programming

(Department Name, Clerk Name, Article Name, or Commercial Message etc.)

ex.) To program "Beef #1"for Department key Q .

Mode SW. (1): BY COUNT (PROG.)

Mode SW. (2): X/Z PROG.

0

0

2

(Space) (#) (1)

2 0 3

—

0

1

3

—

PRT/*

PRT/* —► The label is issued.

(B) (e) (e)

Character code: 3 digits

(See Table 1)

(f)

NOTE: Up to 20 regular-sized characters (including spaces) can be programmed on one line.

- 23

Page 27

12-4. Address or Message Programming (Bottom of label)

(Store Address, Telephone No., Special Message etc.)

ex.) To program the address "149 Milton St.".

Mode SW. (1): BY COUNT (PROG.).

Mode SW (2): X/Z PROG,

2

0

0

(Space) (M)

5 0

(S)

4 1

—

3

704

—

(t)

3

6

0 9

—

2

4

1

*□

6

—

—

1

PRT/*

—

2

MR 3 0

7

0

4

1

—

(1) (4)

Character code. 3 digits

(See Table 1)

—

1

5 —

6

(t) (0) (n)

3 0

4

—

614

309

(9)

—

2

0

(Space)

0

NOTE: Up to 26 small-sized characters (including spaces) can be programmed on one line.

12-5 Print Item ON/OFF Setting or Changing

This operation specifies whether each print item on the issued in registration labels is to be printed

or not.

ex.) To non-print the "PACKED ON date", "SELL BY date", and "Total Price".

Mode SW. (1): BY COUNT (PROG.)

Mode SW. (2): X/Z PROG.

[1]

PRT/*

-0-

MR

-a-

PRT/*

NOTE: [?]-

0-

MR

MR

T. PRICE

nnnn

uuuu

T. PRICE

nonnn

Packed on date (Switching by |_1J key)

(0: Print, 1: Non-print)

Sell by date (Switching by 2^ key)

(0: Print, 1. Non-print)

Name or Message (Switching by [Ti key)

(0: Print, 1: Non-print)

Address or Message (Switching by key)

(0: Print, 1: Non-print)

Unit Price (Switching by Qj key)

(0: Print. V. Non-print)

Weight (Switching by [|] key)

(0: Print, 1: Non-print)

Total Price (Switching by '¿i key)

(0: Print, 1; Non-print)

S symbol (Switching by key)

(0: Pirnt, 1: Non-print)

Quantity (Switching by key)

(0: Print, 1: Non-print)

- 24 -

Page 28

Table 1: Character Code Table

Column Code

Row

Code

\Col

00 SP

01

02

0 3

04

05

06

07

08

09

3 4 5 6

2

0

!

1

“

2 B

3

4

$

5 E u e

%

6

&

'

7

8

(

9 I

)

1 0 J

+

1 1

1 2

1 3

1 4

<

— =

>

@ P

A Q a

R b

C S c

T

D

F V f

w

G

H X h

Y i

z

K

c

\

L

M

]

/s

N

▼

d

9

j z

k

1

m

n

7

P

q

r/sA

s

t

u

/€

V

w

X

• •

y

CE

1

1

1

1

/3

8 9

E

E

/s

E

0

0

A

• •

A

U

N

f

—¥

4—

a

A

r

A

n

I

n

£

O

i

1 5

ex.)

COL

A 0

4 0 1

First enter the Column code and then the Row code for the required character. For example, to access

"A", enter 401.

ROW

7

/

0

0

_

4>

0

t

- 25

Page 29

13. ERROR MESSAGE TABLE

Take the following action if an error message has appeared on the total price display with the buzzer

sounding.

Message

H

L

P

Cause

Print head is not properly set.

The label has run out.

The label is not placed over the label

end sensors.

The label interrupts the label issued

sensors.

Press key, and set the print head.

Press key, and set a new label roll.

Press[^key, and setthe label correctly.

(Refer to Section 8.)

Press key and FEED| key. Then

remove the label.

Solution

14. BEFORE YOU CALL FOR SERVICE

It is our primary concern to give you full satisfaction and better service. If, however, any problem arises

in connection with the operation of this scale, please check the following points once more before

calling for service:

A) Is the power plug fully inserted into AC outlet?

B) Is the power switch turned ON?

C) Is AC power being properly supplied to outlet? (Check it using other electric appliance.)

D) Check circuit breaker.

E) Has there been a power failure of any sort?

F) Has the operation been carried out in the correct order?

This scale has been manufactured under strict quality control. If you have trouble, however, DO NOT

TRY TO FIX IT BY YOURSELF. Pull the power plug out of the AC outlet, and contact your TEC

representative.

CAUTION:

The specifications are subject to change without notice.

- 26

Page 30

printed in japan

E1-04316A 9509100(D)

Loading...

Loading...