Toshiba SD-H400 Schematic

FILE NO. 810-200329

DOCUMENT CREATED IN JAPAN, Sep., 2003

SERVICE MANUAL

DIGITAL VIDEO

DIGITAL MEDIA SERVER

SD-H400

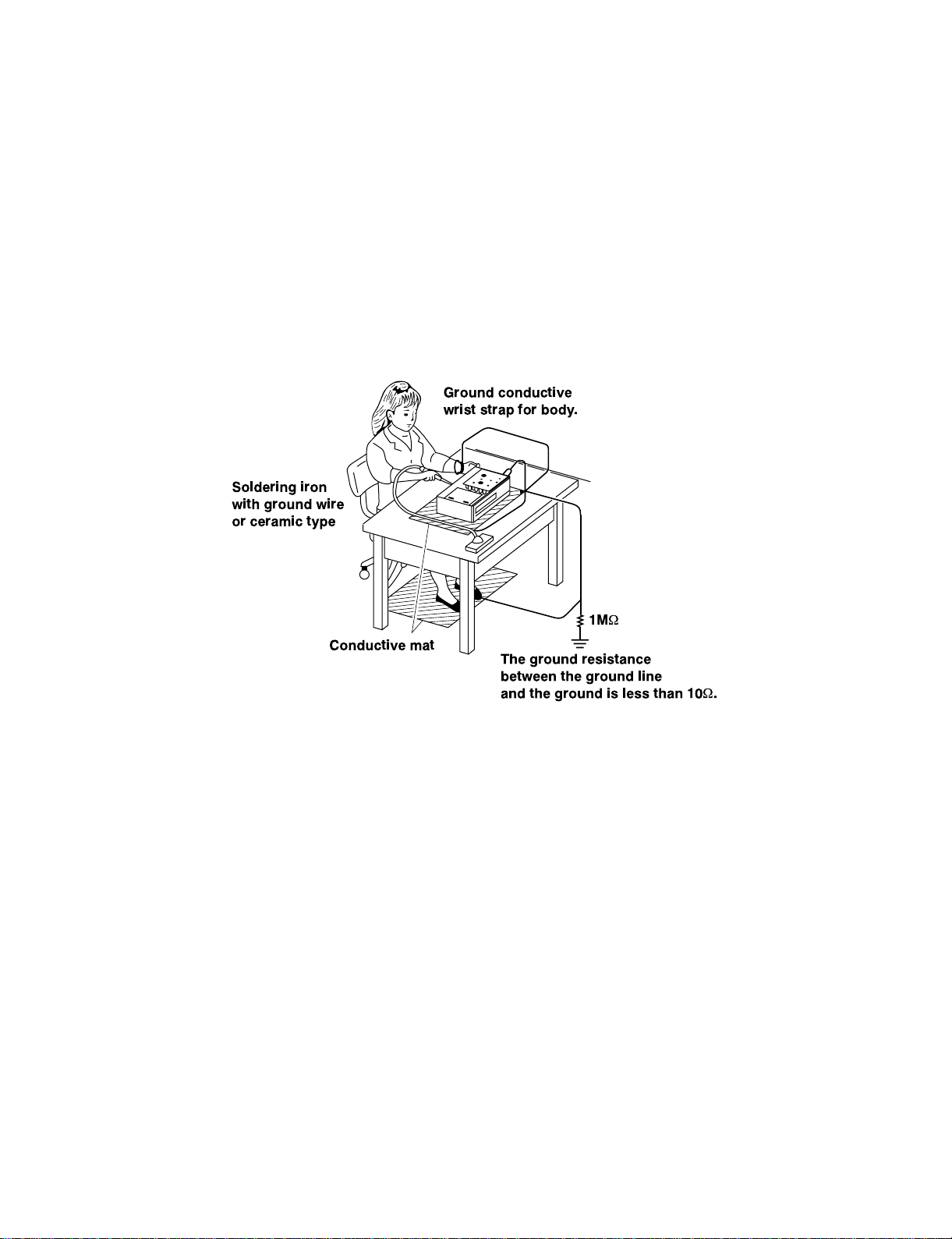

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement,

its life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to

protect the laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

Ground conductive

wrist strap for body.

Soldering iron

with ground wire

or ceramic type

Conductive mat

1M

W

The ground resistance

between the ground line

and the ground is less than 10W.

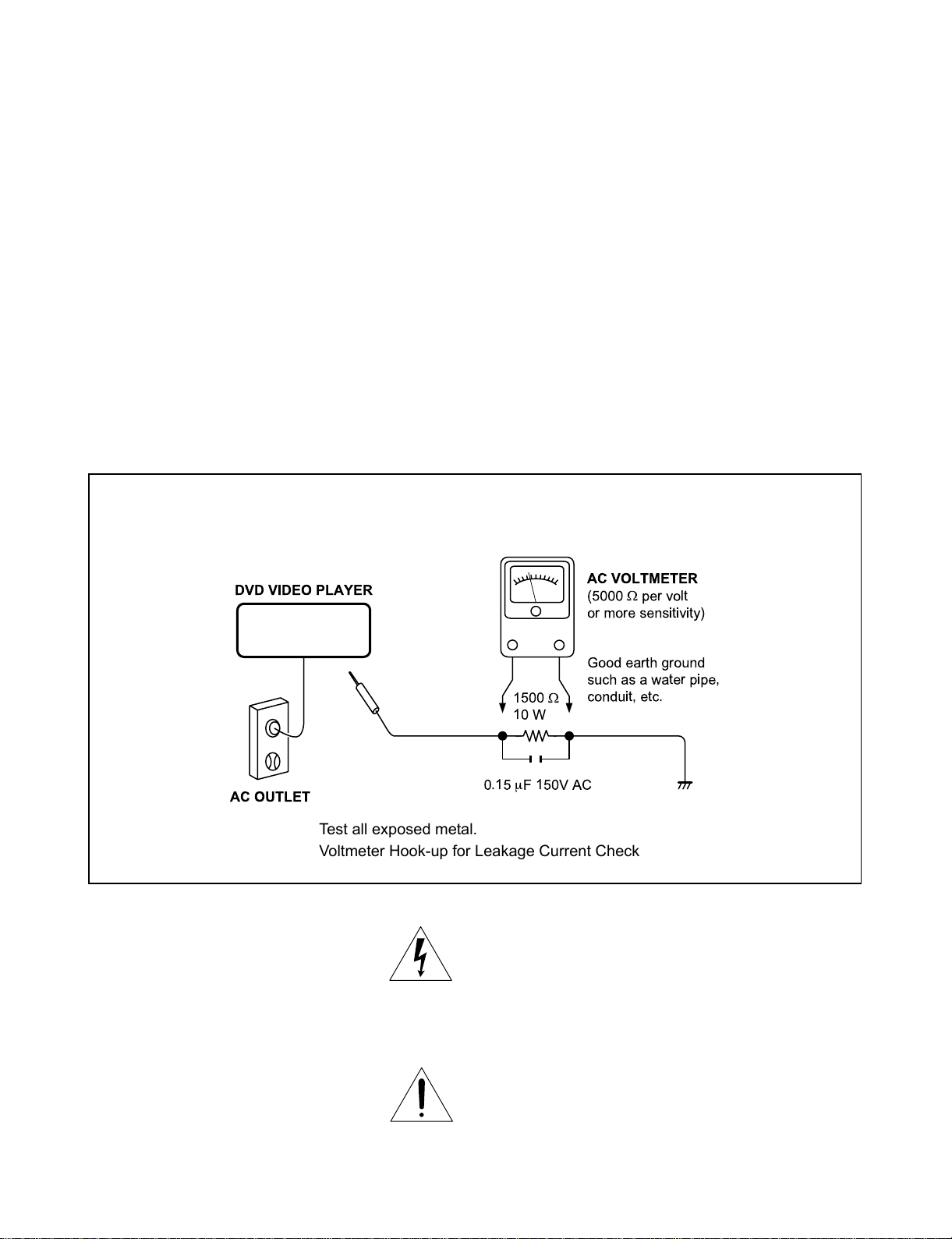

SAFETY NOTICE

SAFETY PRECAUTIONS

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 W per volt or more sensitivity.

Connect a 1500 W 10 W resistor, paralleled by a 0.15 mF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 W resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD VIDEO PLAYER

power plug reversed.

NEVER RETURN A DVD VIDEO PLAYER TO THE

CUSTOMER WITHOUT TAKING NECESSARY

CORRECTIVE ACTION.

DVD VIDEO PLAYER

AC OUTLET

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

AC VOLTMETER

(5000Wper volt

or more sensitivity)

Good earth ground

such as a water pipe,

W

conduit, etc.

1500

10 W

0.15mF 150V AC

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

1. OPERATING INSTRUCTIONS

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

2. LOCATION OF MAIN PARTS AND

MECHANISM PARTS

2-1. Location of Main Parts

2-2. Location of PC Boards

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

1. Replacement of Mechanical Parts

1-1. Cabinet Replacement

1-1-1. Top Cover

1-1-2. HDD

1-1-3. Front Panel

1-1-4. Tray Door

1-1-5. Mechanism Chassis Assembly

1-1-6. Fan

1-1-7. Rear Panel

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

1-2. Solid Resistor Indication

1-3. Capacitance Indication

1-4. Inductor Indication

1-5. Waveform and Voltage Measurement

1-6. Others

2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM

3. BLOCK DIAGRAMS

3-1. DVD Overall Block Diagram

3-2. Power Supply Block Diagram

3-3. KDB Front, Power Switch Block Diagram

3-4. Logical System Block Diagram (DVD)

SECTION 2

1-2. PC Board Replacement

1-2-1. DVD Main PC Board

1-2-2. Tivo PC Board

1-2-3. Power PC board

1-2-4. KDB Front and Power Switch PC Board

SECTION 3

SERVICING DIAGRAMS

3-5. Output Block Diagram (DVD)

3-6. Tivo Block Diagrams

3-6-1. Tivo Block Diagram1

3-6-1. Tivo Block Diagram2

4. CIRCUIT DIAGRAMS

4-1. Power Supply Circuit Diagram

4-2. KDB Front Circuit Diagram

4-3. Power Switch Circuit Diagram

4-4. DVD Main Circuit Diagram

4-5. Tivo Circuit Diagrams

5. PC BOARDS

5-1. Power Switch PC Board

5-2. KDB Front PC Board

5-3. DVD Main PC Board

SAFETY PRECAUTION

NOTICE

ABBREVIATIONS

(1) Integrated Circuit (IC)

(2) Capacitor (Cap)

(3) Resistor (Res)

SECTION 4

PARTS LIST

1. EXPLODED VIEWS

1-1. Packing Assembly

1-2. Chassis Assembly

2. PARTS LIST

GENERAL DESCRIPTIONS

SECTION 1

GENERAL DESCRIPTIONS

1. OPERATING INSTRUCTIONS

Please refer to the owner's manual about the contents.

SECTION 1

2.LOCATION OF MAIN PARTS AND MECHANISM PARTS

2-1. Location of Main Parts

HDD UNIT

MD01

Mechanism chassis

assembly

Fig. 1-2-1

B903 FAN

2-2. Location of PC Boards

UX03 Power Switch

PC board

UT01 Tivo Main board

U801 Power PC board

UD01 DVD Main PC board

UX02 KDB Front PC board

Fig. 1-2-2

SECTION 2

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

CAUTIONS BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to ground as required.

Many screws are used inside the unit. To prevent the screws from missing, dropping, etc.always use a magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care of

the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improperly,

the screw holes will be easily damaged and the parts can not be fixed.

1. REPLACEMENT OF MECHANICAL PARTS

ADJUSTMENT PROCEDURES

PART REPLACEMENT AND

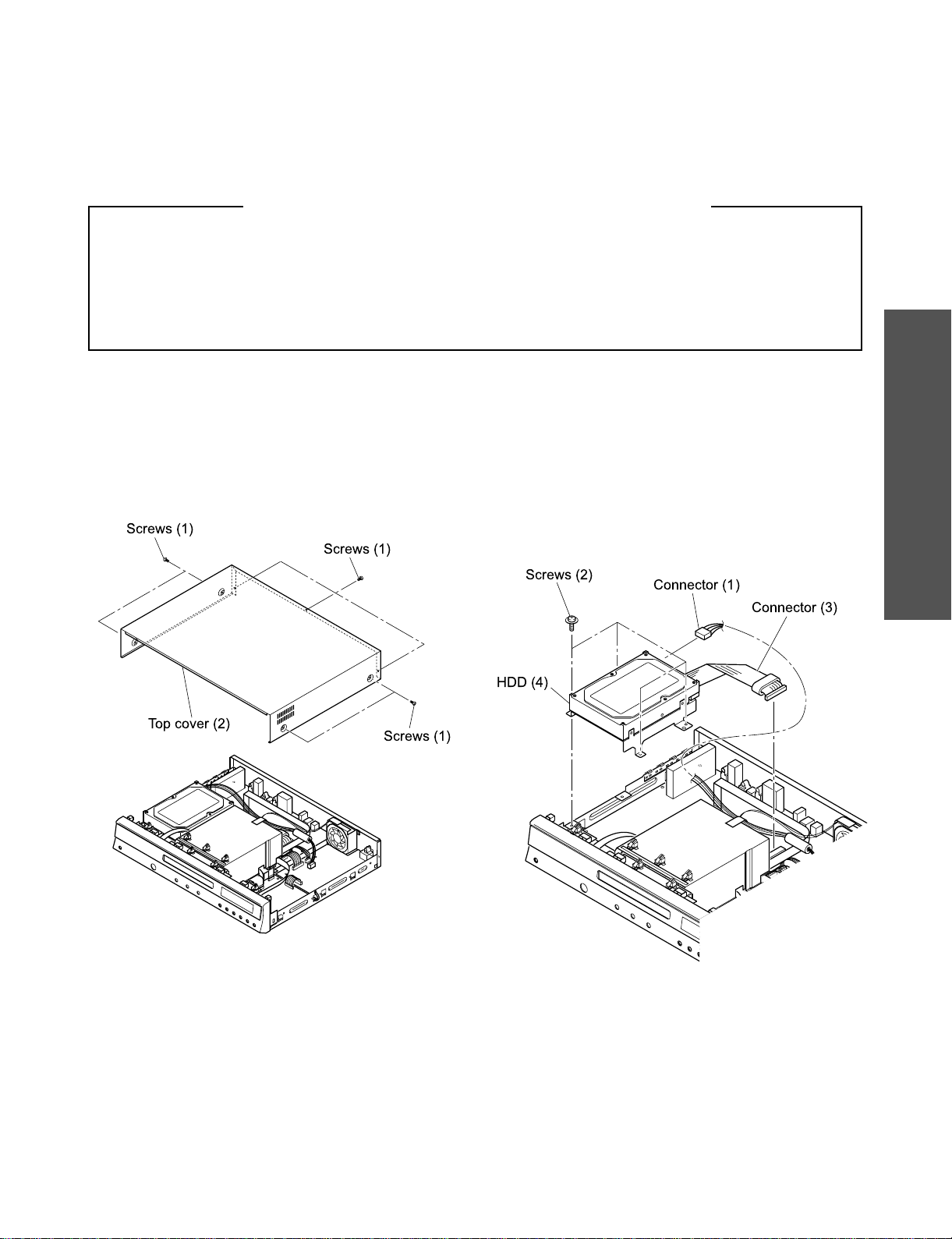

1-1. Cabinet Replacement

1-1-1. Top Cover

1. Remove seven screws (1), then remove the top cover

(2).

Screws (1)

Screws (1)

Top cover (2)

Screws (1)

1-1-2. HDD

1. Disconnect a connector (1).

2. Remove four screws (2) and a connector (3), then

remove the HDD (4).

Screws (2)

HDD (4)

Connector (1)

Connector (3)

SECTION 2

Fig. 2-1-1

Fig. 2-1-2

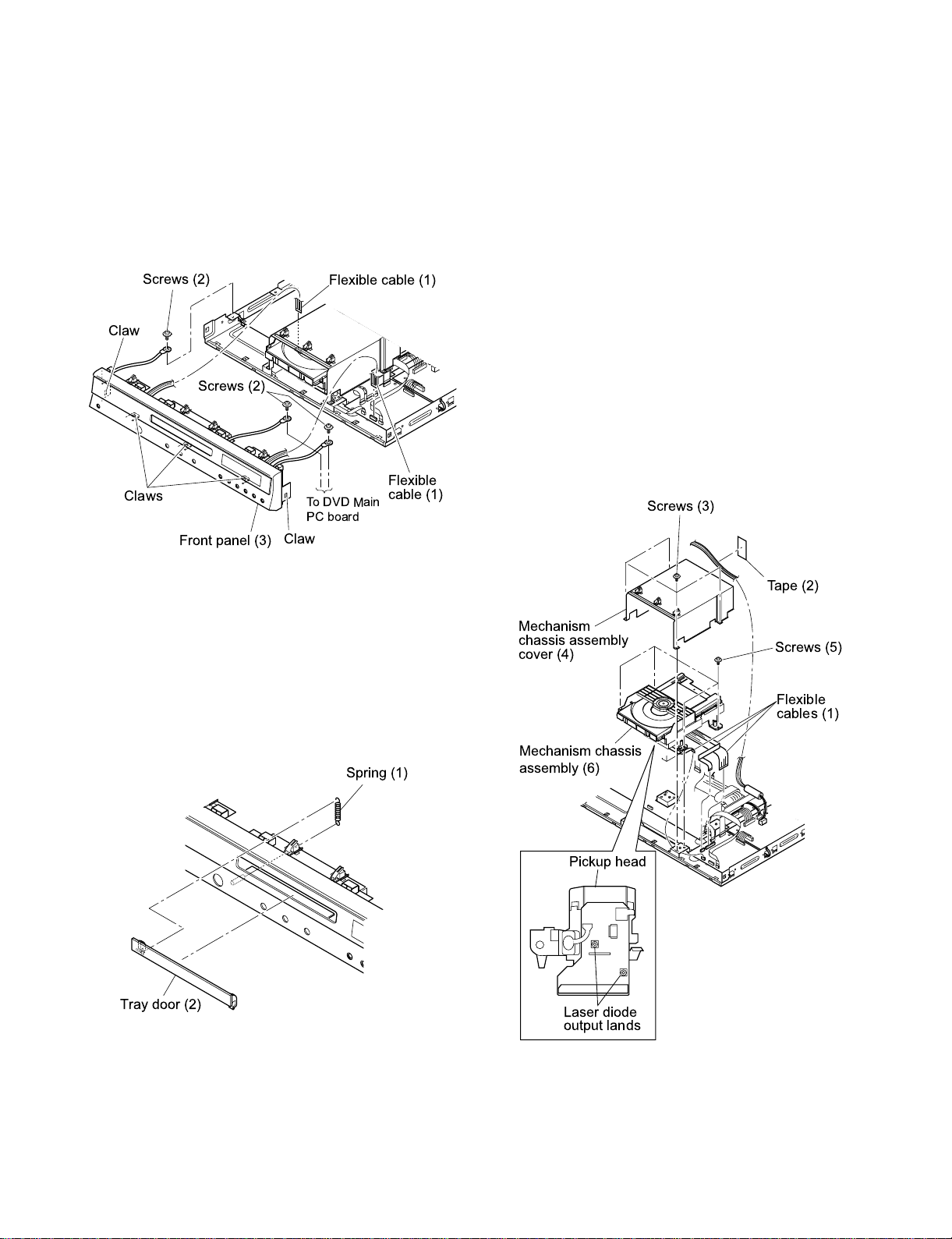

1-1-3. Front Panel

1. Remove the top cover. (Refer to item 1-1-1.)

2. Remove the HDD. (Refer to item 1-1-2.)

3. Disconnect two flexible cadles (1).

4. Remove three screw (2).

5. Release five claws, then remove the front panel (3).

Screws (2)

Claw

Screws (2)

Claws

Front panel (3)

Flexible cable (1)

To DVD Main

PC board

Claw

Flexible

cable (1)

1-1-5. Mechanism Chassis Assembly

Note:

• Before removing the Mechanism chassis assembly (6),

be sure to short-circuit the laser diode output land.

After replacing the Mechanism chassis assembly (6)

and inserting the flexible cables (1), open the land as it

was.

1. Remove the front panel. (Refer to item 1-1-3.)

2. Disconnect three flexible cables (1).

3. Peel off the tape (2) from the mechanism assembly

cover (4).

4. Remove four screws (3), then remove the mechanism

chassis assembly cover (4).

5. Remove four screws (5) , then remove the mechanism

chassis assembly (6).

Screws (3)

Fig. 2-1-3

1-1-4. Tray Door

1. Remove a spring (1).

2. Remove the tray door (2) while slightly bending it.

Spring (1)

Tray door (2)

Fig. 2-1-4

Mechanism

chassis assembly

cover (4)

Mechanism chassis

assembly (6)

Pickup head

Laser diode

output lands

Tape (2)

Screws (5)

Flexible

cables (1)

Fig. 2-1-5

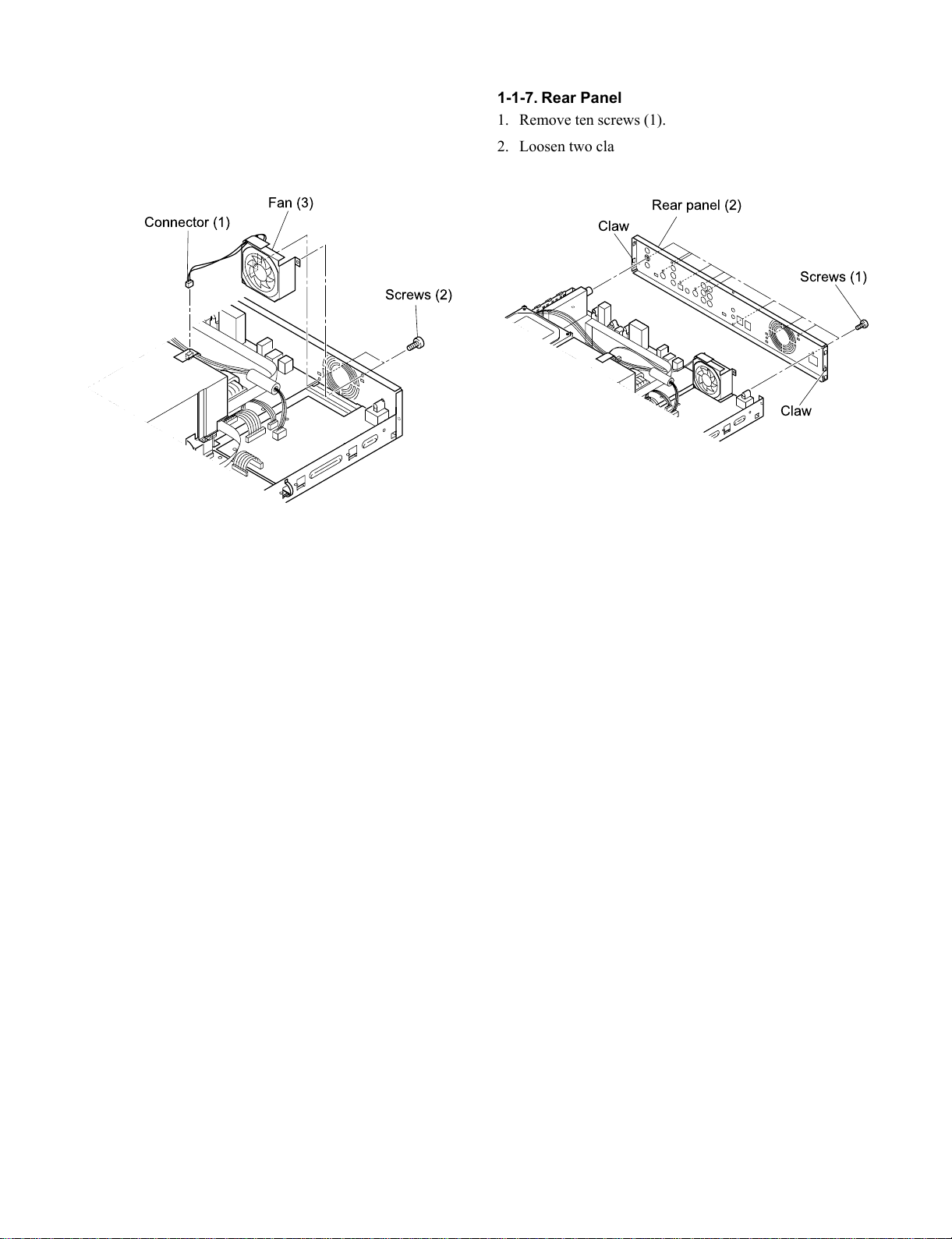

1-1-6. Fan

Screws (1)

Rear panel (2)

Claw

Claw

1. Remove a connector (1) and two screws (2) .

2. Remove the fan (3).

Fan (3)

Connector (1)

Fig. 2-1-6

1-1-7. Rear Panel

1. Remove ten screws (1).

2. Loosen two claws and remove the rear panel (2).

Screws (2)

Fig. 2-1-7

1-2. PC Board Replacement

1-2-1. DVD Main PC Board

Note:

• Before removing the DVD main PC board (4), be sure

to short-circuit the laser diode output land.

After replacing the DVD main PC board (4) and

inserting the flexible cables (2), open the land as it

was.

1. Remove the top cover. (Refer to 1-1-1.)

2. Disconnect a connector (1).

3. Remove seven flexible cables (2).

4. Remove four screws (3), then remove the DVD main

PC board (4).

Flexible cable (2)

Screws (3)

Flexible

cables (2)

Flexible cables (2)

Connector (1)

Note:

• For the detailed information about DVD Main PC

board connection, see Fig. 2-1-9.

TO CNX01

(Tivo PC board)

CN103

Power PC board

Main PC board

IC306

IC401

CN603

CN601

To PX02

To CTN21

(Tivo PC board)

To CTY01

(Tivo PC board)

To Pickuphead

To Loading

motor

To Stepper

CN302

CN901

CN503

CN701

IC502

CN501

IC503

CN502

(KDB Front PC board)

Fig. 2-1-9

IC305

Pickup head

Laser diode

output lands

Fig. 2-1-8

DVD main

PC board (4)

1-2-2. Tivo PC Board

Cautions :

• Danger of explosion if battery is incorrectly

replaced.

• Replace only with the same or equivalent type of

battery.

1. Remove the top cover. (Refer to item 1-1-1.)

2. Remove the HDD. (Refer to item 1-1-2.)

3. Remove the front panel. (Refer to item 1-1-3.)

4. Remove the mechanism chassis assembly. (Refer to 1-

1-5.)

5. Remove the rear panel. (Refer to item 1-1-7.)

6. Disconnect three connectors (1).

7. Remove three flexible cables (2).

8. Remove seven screws (3), then remove the tivo main

PC board (4).

1-2-3. Power PC Board

1. Disconnect four connectors (1)

2. Remove a screw (2) and four screws (3), then remove

the power PC board (4).

Connectors (1)

Connector (1)

Screws (3)

Connector (1)

Screw (3)

Power PC

board (4)

Screw (2)

Tivo main

PC board (4)

Flexible

cables (2)

Screws (3)

Flexible cable (2)

Connectors (1)

Fig. 2-1-11

Fig. 2-1-10

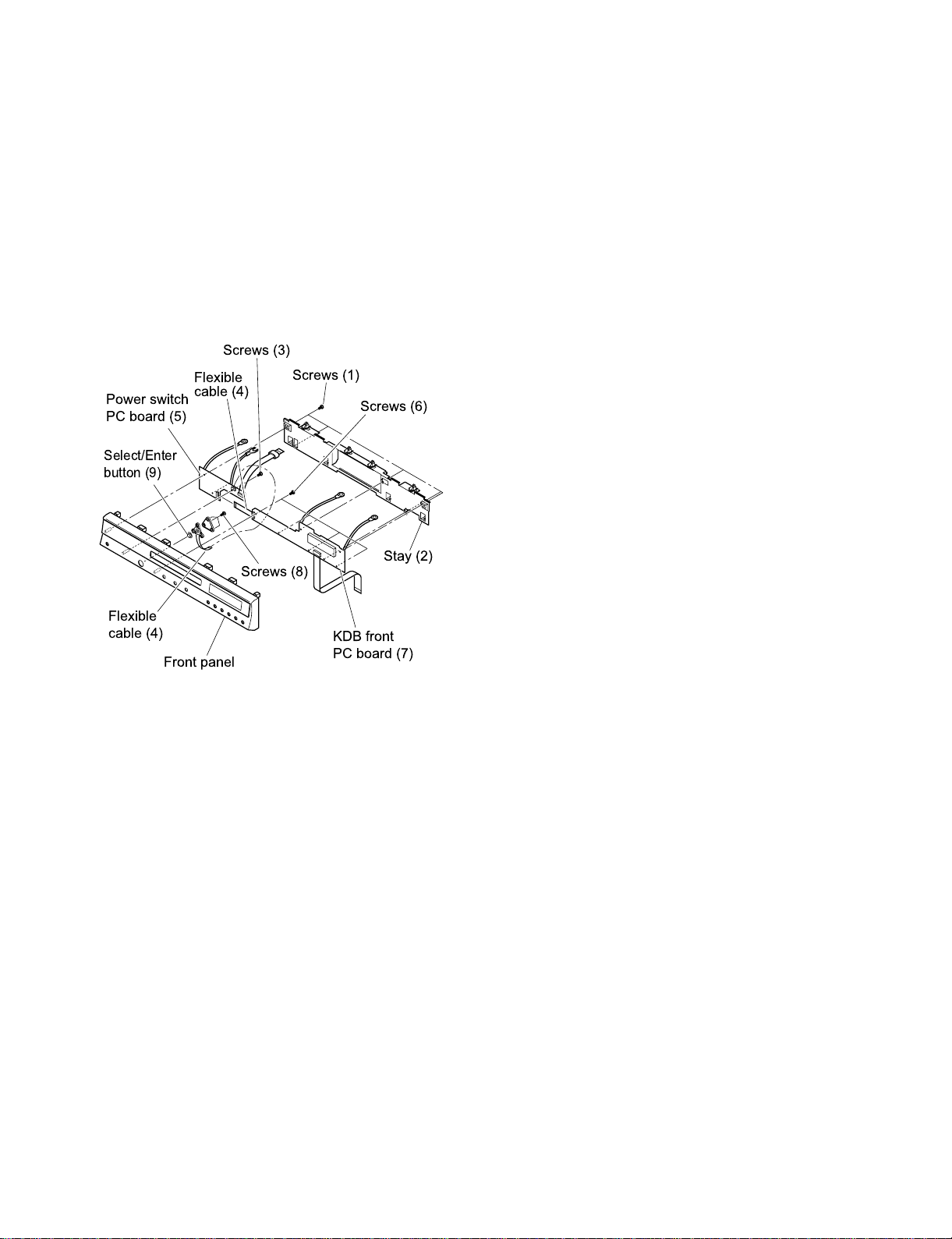

1-2-4. KDB Front and Power Switch PC Board

1. Remove the front panel. (Refer to item 1-1-3.)

2. Remove five screws (1), then remove the stay (2).

3. Remove a screw (3) and two flexible cables (4), then

remove the Power switch PC board (5).

4. Remove four screws (6), then remove the KDB front

PC board (7).

6. Remove the three screws (8), then remove the select/

enter button (9).

Screws (3)

Screws (1)

Screws (6)

Power switch

PC board (5)

Select/Enter

button (9)

Flexible

cable (4)

Flexible

cable (4)

Front panel

Stay (2)

Screws (8)

KDB front

PC board (7)

Fig. 2-1-12

+

NP

100k

Rated Wattage Type Tolerance

104

10x10

4

pF (0.1µF)

Temperature characteristic

(or Temperature characteristic+

Static electricity capacity tolerance)

SECTION 3

SERVICING DIAGRAMS

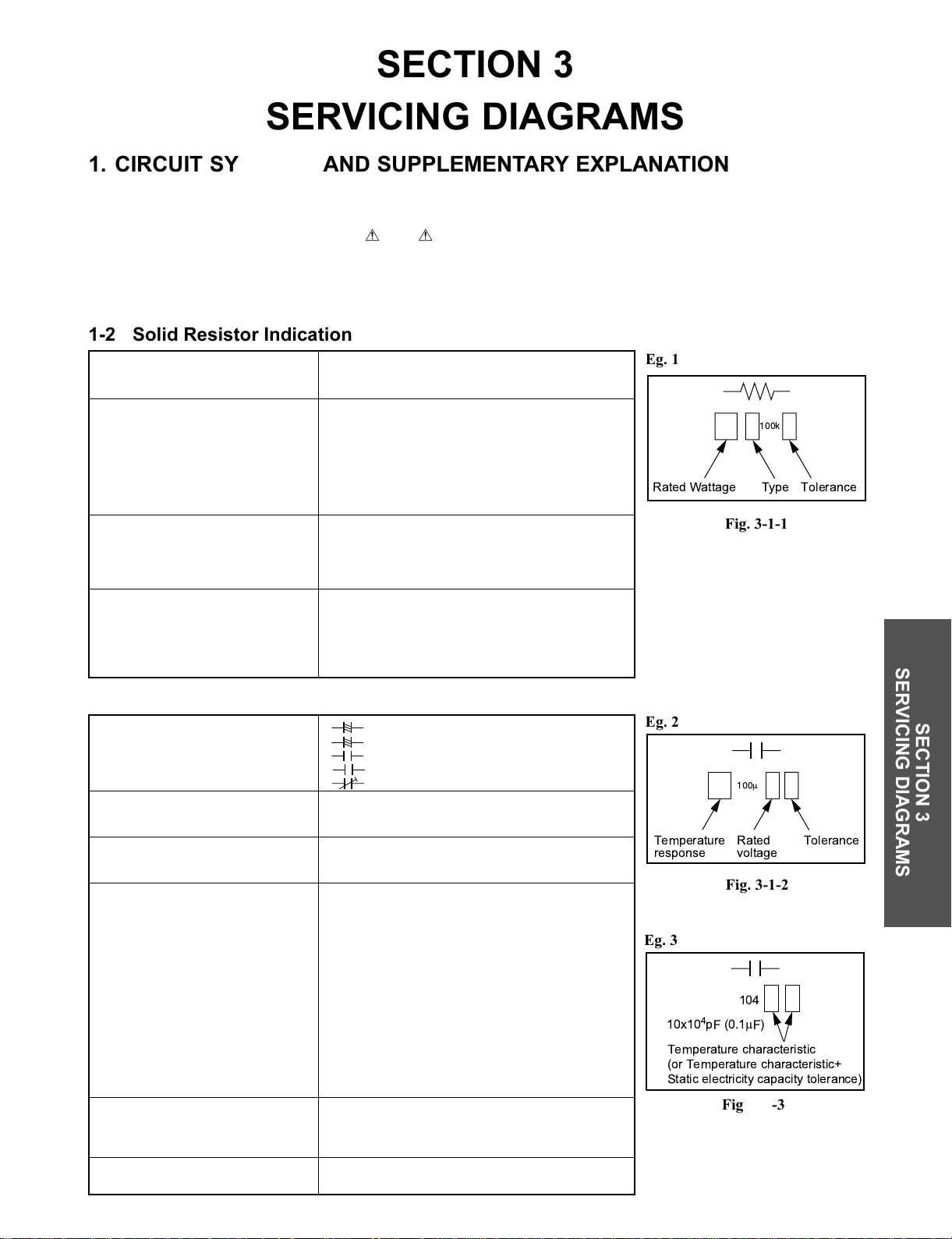

1. CIRCUIT SYMBOLS AND SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

• In the schematic diagram, parts marked (ex.

F801) are critical part to meet the safety regulations,

so always use the parts bearing specified part codes

(SN) when replacing them.

1-2. Solid Resistor Indication

Unit None ........... W

K ........... kW

M ........... MW

Tolerance None ........... ±5%

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

K ........... ±10%

M ........... ±20%

Rated Wattage (1) Chip Parts

None .........1/16W

(2) Other Parts

None ......... 1/6W

Other than above, described in the Circuit Diagram.

Type None ........... Carbon film

S ........... Solid

R ........... Oxide metal film

W ...........Metal film

W ...........Cement

FR ........... Fusible

• Using the parts other than those specified shall violate

the regulations, and may cause troubles such as

operation failures, fire etc.

Eg. 1

Fig. 3-1-1

SERVICING DIAGRAMS

1-3. Capacitance Indication

Symbol

Unit None ........... F

Rated voltage None ........... 50V

Tolerance (1) Ceramic, plastic, and film capacitors of which

Temperature characteristic None ........... SL

(Ceramic capacitor) For others, temperature characteristics are

Static electricity capacity Sometimes described with abbreviated letters as

(Ceramic capacitor) shown in Eg. 3.

........... Electrolytic, Special electrolytic

........... Non polarity electrolytic

........... Ceramic, plastic

M

........... Film

........... Trimmer

m ........... mF

p ........... pF

For other than 50V and electrolytic capacitors,

described in the Circuit Diagram.

capacitance are more than 10 pF.

None ........... ±5% or more

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

(2) Ceramic, plastic, and film capacitors of which

capacitance are 10 pF or less.

None ........... more than ±5% pF

B ........... ±0.1 pF

C ........... ±0.25 pF

(3) Electrolytic, Trimmer

Tolerance is not described.

described. (For capacitors of 0.01 mF and

no indications are described as F.)

Eg. 2

Temperature

response

Eg. 3

100

m

Rated

voltage

Fig. 3-1-2

Fig. 3-1-3

SECTION 3

Tolerance

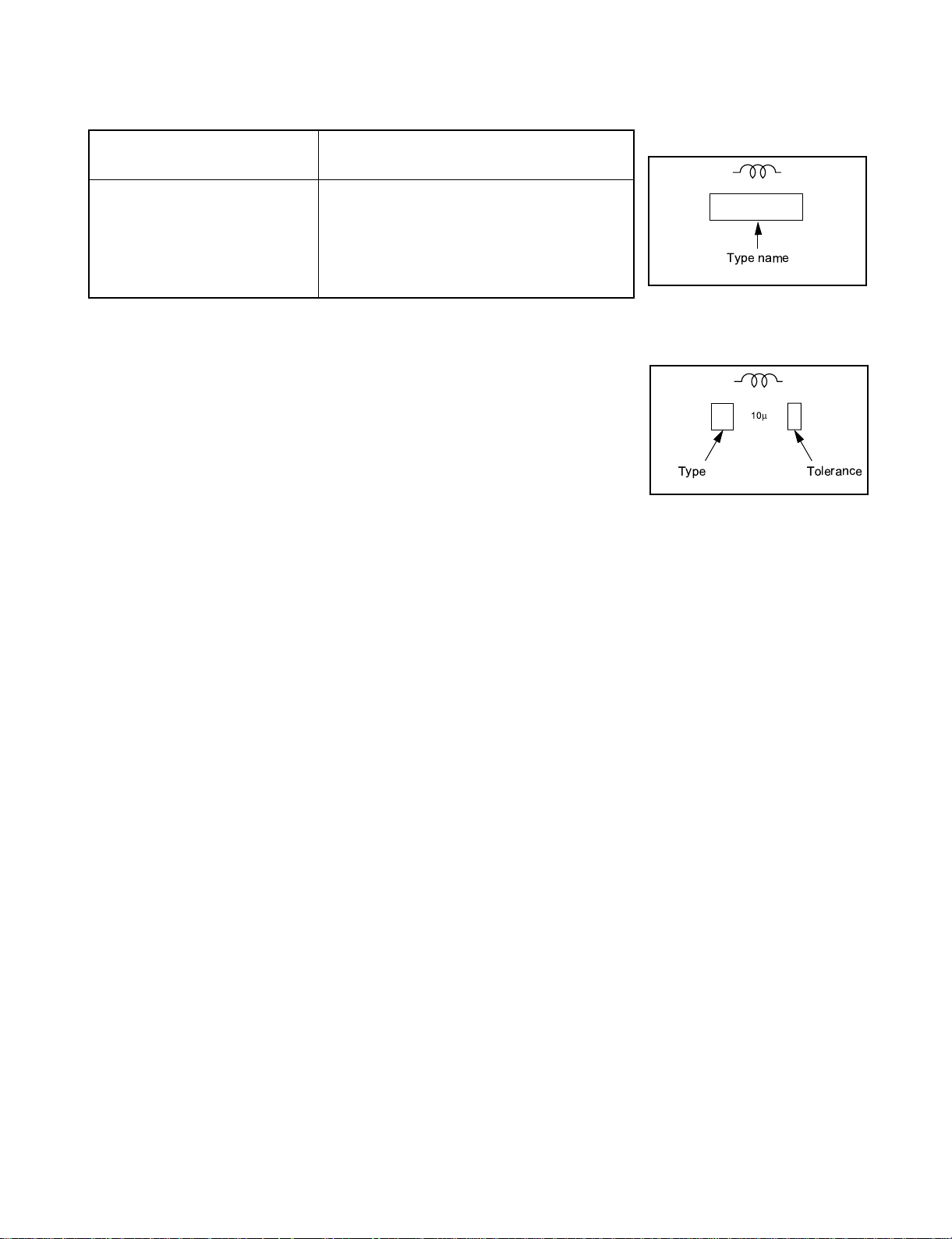

1-4. Inductor Indication

Type name

10

µ

Type Tolerance

Unit None ........... H

m ........... mH

m ........... mH

Tolerance None ........... ±5%

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

K ........... ±10%

M ........... ±20%

1-5. Waveform and Voltage Measurement

• The waveforms for CD/DVD and RF shown in the

circuit diagrams are obtained when a test disc is

played back.

• All voltage values except the waveforms are expressed

in DC and measured by a digital voltmeter.

1-6. Others

• The parts indicated with "NC", "KETSU" or "NO

STUFF" etc. are not used in the circuits of this model.

Eg. 4

Fig. 3-1-4

Eg. 5

Fig. 3-1-5

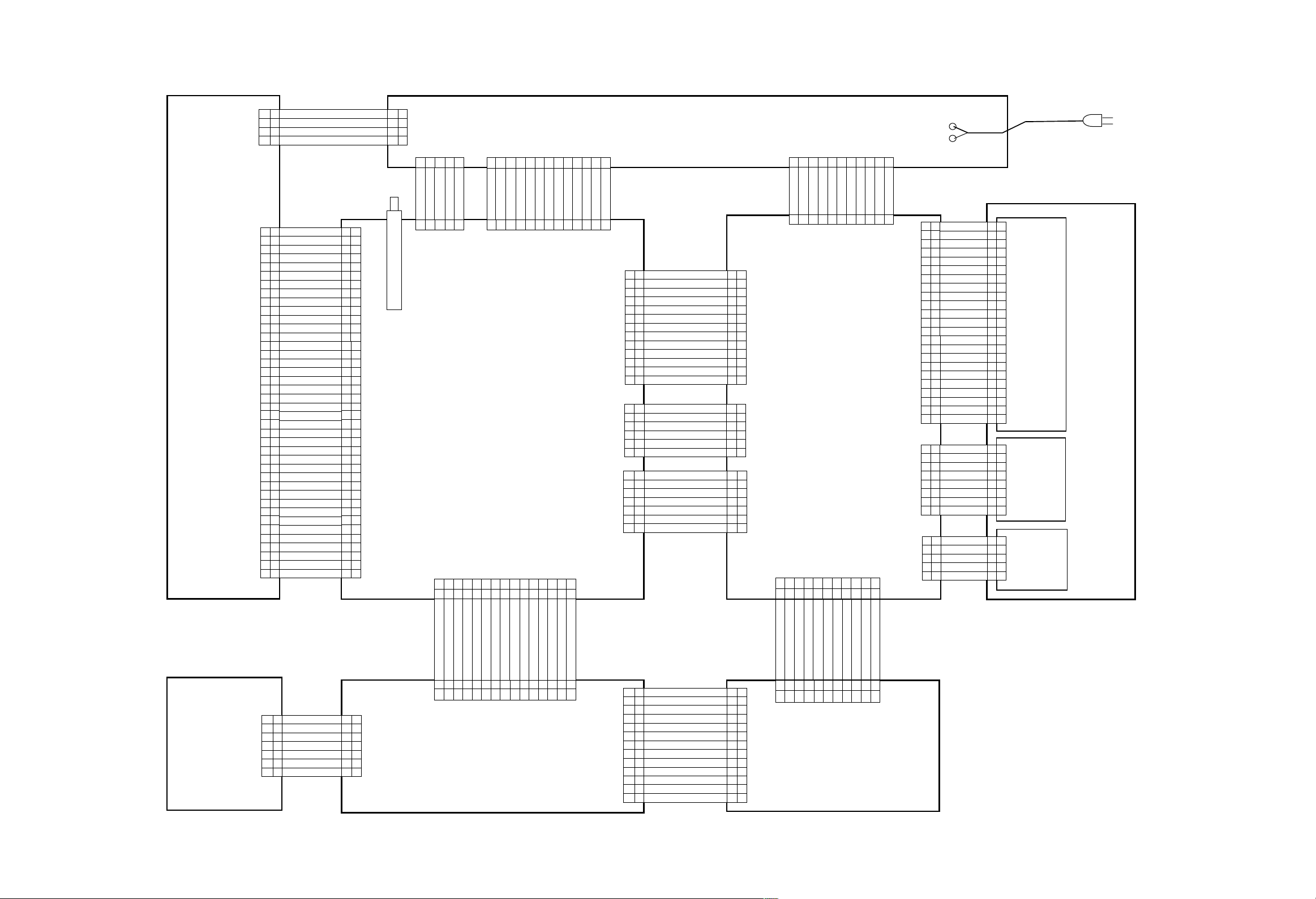

2. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

HARDDISK

1

2

3

4

+12V

GND

GND

+5V

Power Supply Cable

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

2

4

6

8

IDERST

GROUND2

IDEDD7

IDEDD8

IDEDD6

IDEDD9

IDEDD5

IDEDD10

IDEDD4

IDEDD11

IDEDD3

IDEDD12

IDEDD2

IDEDD13

IDEDD1

IDEDD14

IDEDD0

IDEDD15

GROUND1

KEYPIN

IDEDMAR

GROUND3

IDEIOW

GROUND4

IDEIOR

GROUND5

IDEIORDY

CSEL

IDEDMAC

GROUND6

IDEINTRQ

IOCS16

IDEDA1

PDIAG

IDEDA0

IDEDA2

IDECS0

IDECS1

DASP

GROUND7

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

2

4

6

8

10

12

14

16

18

JT22

40P

20

IDE CABLE

22

24

26

28

30

32

34

36

38

40

1

CN104 4P

2

connector

3

4

CN101 5P

connector

12345

NC / E+9V

12345

CNY02

5P

DIP WIRE

Tuner H001

GND

E-9V

GND

NC / +5V

UT01

TiVo MAIN BOARD

CTN25

15P

2

3

4

FFC connector

5

6

1

CN102

13P

connector

123456789

5V

5V

3.3V

3.3V

GND

GND

12V

GND

123456789

CTN5

13P

DIP WIRE

7

9

11

8

13

12

10

13

10

11

13PON13

12V

30V

GND

GND12 12

10

11

CNX01

13P

FFC connector

CTN21

6P

FFC connector

CNY01

7P

FFC connector

15

U801

POWER BOARD

1

2

3

5

7

9

11

13

1

3

5

1

3

5

7

CV-OUTPUT

4

6

8

10

12

2

4

6

2

4

6

VGND

Y-OUTPUT

VGND

C-OUTPUT

VGND

Y-OUTPUT

VGND

Cb-OUTPUT

VGND

Cr-OUTPUT

NC / 5V

TXD / RXD

RTS / WRIGHTX

RXD / TXD

CTS / RTS

DVD SPDIF / IEC958OUT

AUD MUTE / H MUTE F

PW ON

DVD OUTL / FL OUT

DVD OUTR / FR OUT

IPXO

VGND

GND

GND

GND

7

8

9

10

11

12

13

14

15

16

17

18

19

1

2

3

4

5

6

1

2

3

4

5

6

7

CN302

13P

FFC connector

CN601

6P

FFC connector

CN901

7P

FFC connector

CN603 11P

FFC connector

1

CN103 11P

connector

123456789

GND

VDD+3V

VDD+2.5V

GND

M+8V

E+5V

VDD+5V

123456789

CN701

11P

Dip WIRE

UD01

DVD MAIN BOARD

3

5

7

2

6

4

8

10

F-

MGND

VKK -31V

10

CN501

23P

FFC connector

CN503

8P

FFC connector

CN502

5P

FFC connector

9

11

10

Power Cord 120VAC 60HZ

F+11 11

1

VCC

2

3

5

7

9

11

13

15

17

19

21

23

1

3

5

7

1

3

5

RF

LD2

4

MON2

VOR2

6

GND

VREF

8

VCC

FO

10

EO

AO

12

DO

CO

14

BO

F+

16

T-

T+

18

F-

Vcc

20

GND

LD

22

MON

VOR

FMN

FMP

2

GND

LMT

4

DMN

DMP

6

VCC

DMFG

8

GND

LDMP

2

TOPN

LDMN

4

TCLS

2

4

6

8

10

12

14

16

18

20

22

2

4

6

8

2

4

1

3

5

7

9

PICK UP

11

13

15

17

19

21

23

1

3

LOADING

5

7

1

3

STEPPER

5

HEAD

DVD Drive

MOTOR

SELECT ENTER

BUTTON SWITCH

1

3

5

7

F-

F+

GND

STBYLED

KEYSCN1

KEYSCN2

KEYSCN3

POWER LED

14

15

10

12

13

11

PX04

NC

2

L

COM

4

D

C

6

R

U

1

2

3

PX03

4

7P

5

FFC JST connector

6

7

UX03

POWER SWITCH

RCE LED

KEYSCN0

9

DVD LED

KEYSCN4

Live TV_ LED / TV LED

8

7

L_RST / DVDREST

PWR_CTRL / POWERON

REMOTE_OUT/IR RECVON

6

4

2

5

3

1 CACHE LED

PX01

13P

FFC connector

13

11

9

7

5

3

1

12

10

8

6

4

2

PWR_CTRL

L_RST

REMOTE_OUT

DVD_LED

GND

KEYSCAN3

KEYSCAN2

KEYSCAN1

KEYSCAN0

KEYSCAN4

LIVETV_LED

REC_LED

CACHE_LED

1

2

3

4

5

6

7

8

9

10

11

12

13

HMUTE

11

WX01

13P

FFC connector

GND

VKK-34V

8

10

9

7

PX02

11P

FFC connector

UX02

KDB FRONT

E+5V

STB / DSTBX

SCK / DSPCKX

6

5

DVD MAIN / RSTOX

MAIN_TO_KDB / DSPSIOM-D

KDB_TO_MAIN / DSPSIOM-M

4

2

3

1

Fig. 3-2-1

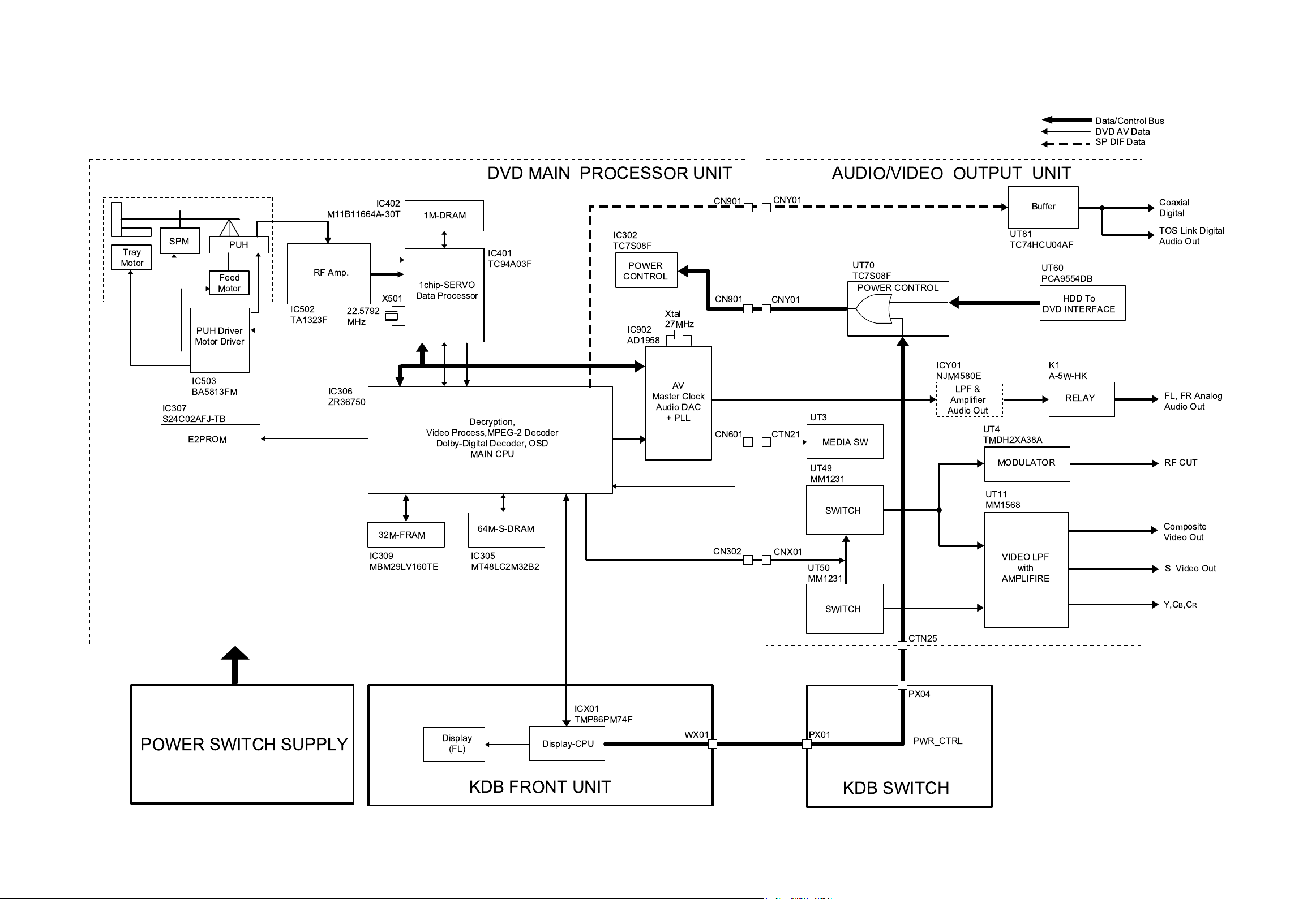

3. BLOCK DIAGRAMS

3-1. DVD Overall Block Diagram

Data/Control Bus

DVD AV Data

SP DIF Data

DVD MAIN PROCESSOR UNIT AUDIO/VIDEO OUTPUT UNIT

Tray

Motor

SPM

PUH Driver

Motor Driver

IC503

BA5813FM

IC307

S24C02AFJ-TB

E2PROM

PUH

Feed

Motor

RF Amp.

IC502

TA1323F

M11B11664A-30T

IC402

X501

22.5792

MHz

IC306

ZR36750

32M-FRAM

IC309

MBM29LV160TE

1M-DRAM

IC401

TC94A03F

1chip-SERVO

Data Processor

Decryption,

Video Process,MPEG-2 Decoder

Dolby-Digital Decoder, OSD

MAIN CPU

64M-S-DRAM

IC305

MT48LC2M32B2

IC302

TC7S08F

POWER

CONTROL

IC902

AD1958

Xtal

27MHz

AV

Master Clock

Audio DAC

+ PLL

CN901

CN901

CN601

CN302

CNY01

CNY01

CTN21

CNX01

UT3

MEDIA SW

UT49

MM1231

SWITCH

UT50

MM1231

UT70

TC7S08F

POWER CONTROL

ICY01

NJM4580E

LPF &

Amplifier

Audio Out

Buffer

UT81

TC74HCU04AF

UT4

TMDH2XA38A

MODULATOR

UT11

MM1568

VIDEO LPF

with

AMPLIFIRE

UT60

PCA9554DB

HDD To

DVD INTERFACE

K1

A-5W-HK

RELAY

Coaxial

Digital

TOS Link Digital

Audio Out

FL, FR Analog

Audio Out

RF CUT

Composite

Video Out

S Video Out

POWER SWITCH SUPPLY

Display

(FL)

Display-CPU

KDB FRONT UNIT

ICX01

TMP86PM74F

WX01

PX01

SWITCH

KDB SWITCH

CTN25

PX04

PWR_CTRL

Y,C

B,CR

Fig.3-3-1

Loading...

Loading...