Page 1

SERVICE MANUAL

DIGITAL VIDEO

DVD VIDEO PLAYER

FILE NO. 813-9906

SUPPLEMENT

SD-9100

– SUMMARY –

This service manual covers only the different points from the service manual, file no. 810-9807,

for model SD-9000 since SD-9100 are basically the same designing as SD-9000.

Please refer to the file no. 810-9807 for other information.

Feb., 2000 s

Page 2

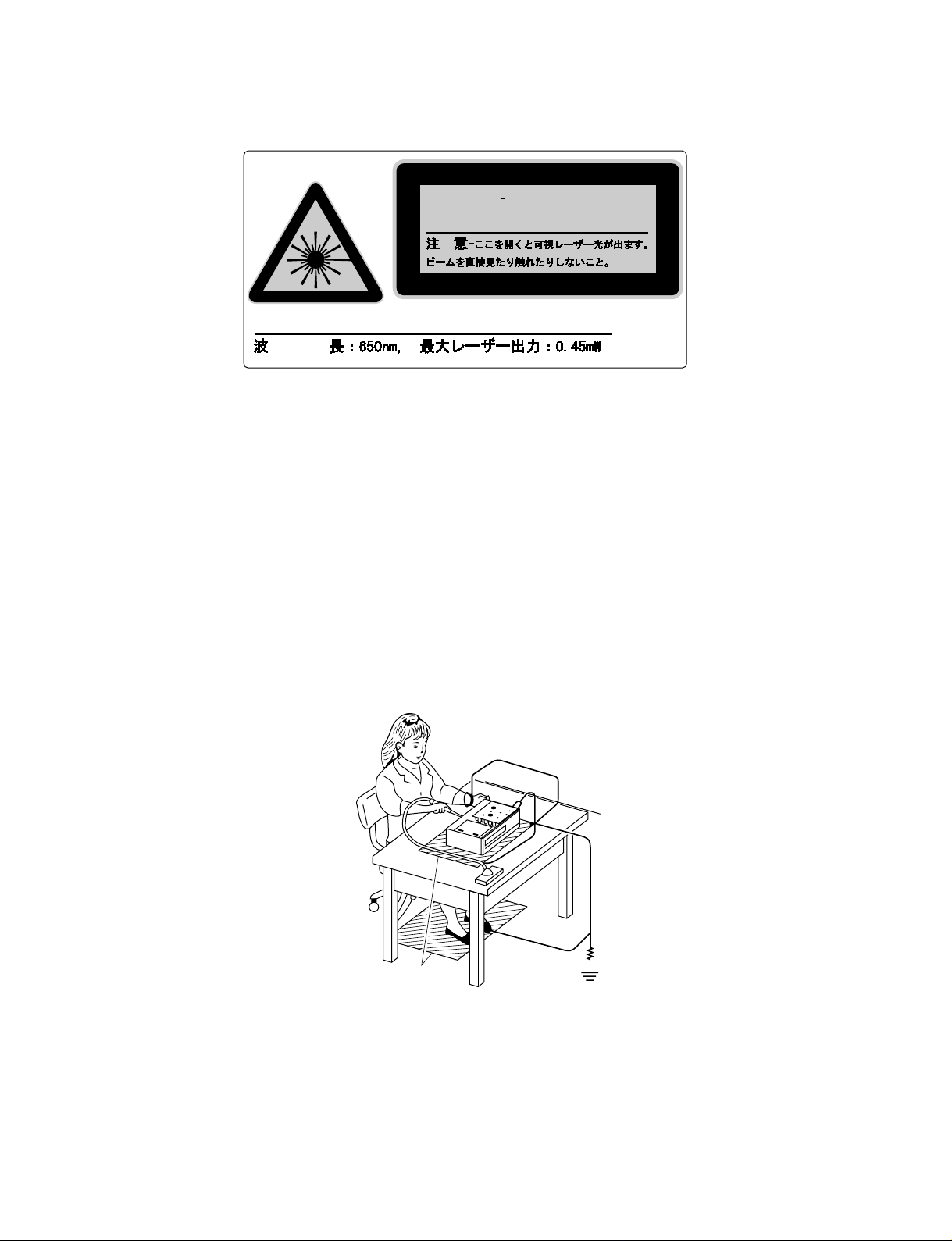

LASER BEAM CAUTION LABEL

VISIBLE LASER RADIATION

CAUTION

WHEN OPEN AND INTERLOCK DEFEATED

DO NOT STARE INTO BEAM.

WAVE LENGTH:650nm, MAX.LASER POWER:0.45mW

98763036

When the power supply is being turned on, you may not remove this laser cautions label. If it removes, radiation of a laser

may be recceived.

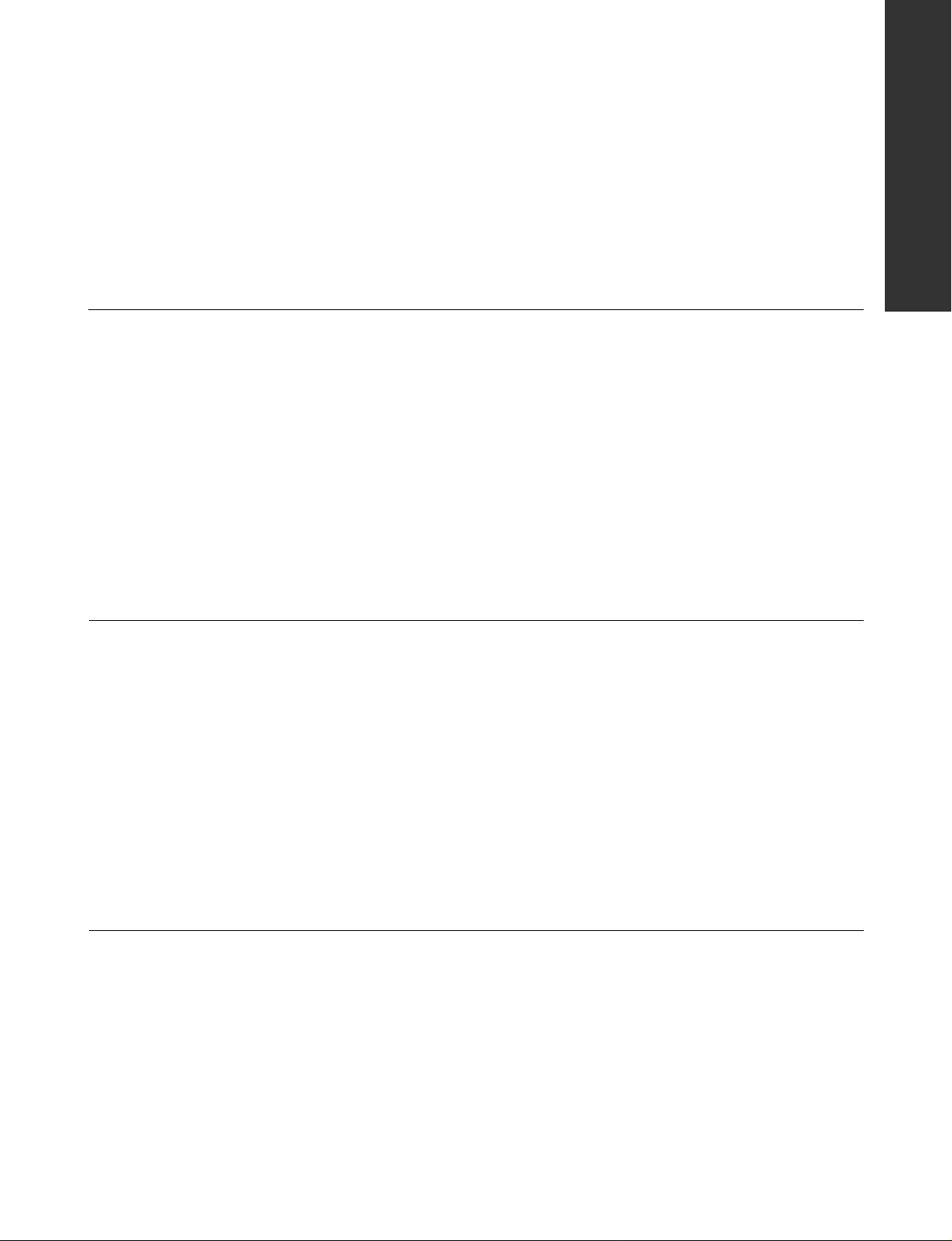

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement, its

life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to protect the

laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

Ground conductive

wrist strap for body.

Soldering iron

with ground wire

or ceramic type

1MΩ

Conductive mat

The ground resistance

between the ground line

and the ground is less than 10Ω.

Page 3

GENERAL DESCRIPTIONS

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

1. OPERATING INSTRUCTIONS................................................ 1 - 1

General descriptions such as location of mechanical parts and troubleshooting are the same as SD-9000.

Please refer to the service manual for SD-9000 (File No. 810-9807).

SECTION 2

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

Part replacement and adjustment procedures are the same as SD-9000.

Please refer to the service manual for SD-9000 (File No. 810-9807).

SECTION1

SERVICING DIAGRAMS

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION..................................... 3- 1

1-1. Precautions for Part Replacement ..................................... 3-1

1-2. Solid Resistor Indication..................................................... 3-1

1-3. Capacitance Indication ....................................................... 3-1

1-4. Inductor Indication ............................................................. 3-2

1-5. Waveform and Voltage Measurement .............................. 3 - 2

1-6. Others ................................................................................... 3-2

1-7. When Replaced ROM ICs or Upgraded Firmware ......... 3 -2

2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM.......................................................... 3-3

SAFETY PRECAUTION ................................................................. 4-1

NOTICE ............................................................................................. 4-1

ABBREVIATIONS ........................................................................... 4-1

1. Integrated Circuit (IC) ............................................................ 4-1

2. Capacitor (Cap) ....................................................................... 4-1

3. Resistor (Res) ........................................................................... 4-1

SECTION 3

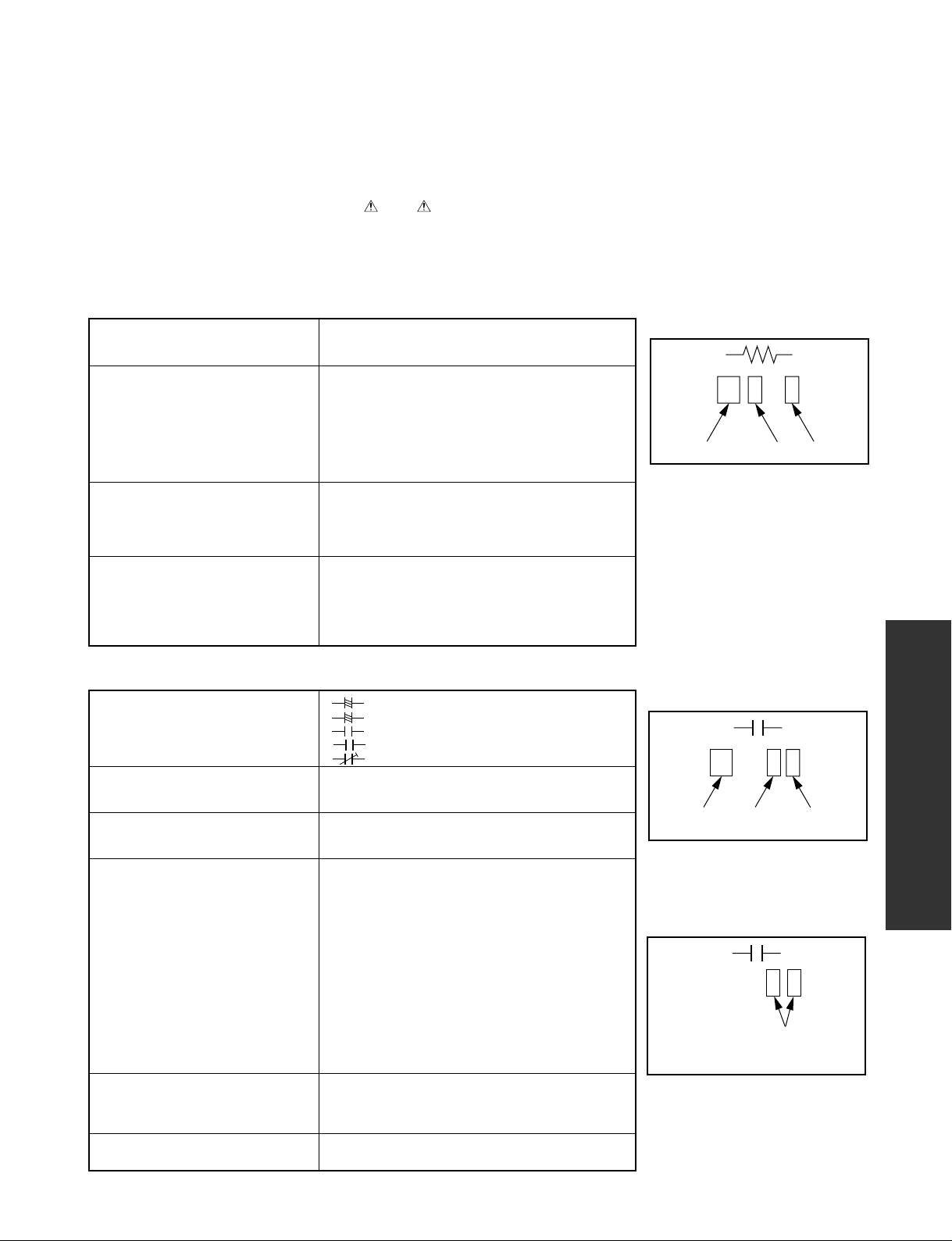

3. BLOCK DIAGRAMS.................................................................. 3-5

3-1. Overall Block Diagram .......................................................3-5

3-2. Main Block Diagram ........................................................... 3-7

3-2-1. Logical System Block Diagram...................................... 3-7

3-3. Output Block Diagram........................................................ 3-9

4. CIRCUIT DIAGRAMS........................................................... 3-11

4-1. Output Circuit Diagram................................................3-11

4-2. Sub Video Circuit Diagram .......................................... 3-16

SECTION 4

PARTS LIST

4. EXPLODED VIEWS ................................................................. 4 -2

4-1. Packing Assembly ............................................................. 4-2

4-2. Remote Control Unit........................................................ 4-2

4-3. Chassis Assembly ............................................................... 4-3

4-4. Mechanism Assembly........................................................ 4-4

5 . PARTS LIST ............................................................................... 4 -5

Page 4

SECTION 3

100k

Rated Wattage Type Tolerance

100µ

Temperature

response

Rated

voltage

Tolerance

SERVICING DIAGRAMS

1. CIRCUIT SYMBOLS AND SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

• In the schematic diagram, parts marked (ex.

F801) are critical part to meet the safety regulations,

so always use the parts bearing specified part codes

(SN) when replacing them.

1-2. Solid Resistor Indication

Unit None ...........Ω

K ...........kΩ

M ...........MΩ

Tolerance None ...........±5%

B ...........±0.1%

C ...........±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

K ...........±10%

M ...........±20%

Rated Wattage (1) Chip Parts

None.........1/16W

(2) Other Parts

None.........1/6W

Other than above, described in the Circuit Diagram.

Type None ...........Carbon film

S ...........Solid

R ...........Oxide metal film

W ...........Metal film

W ...........Cement

FR ...........Fusible

• Using the parts other than those specified shall violate

the regulations, and may cause troubles such as

operation failures, fire etc.

Eg. 1

Fig. 3-1-1

1-3. Capacitance Indication

Symbol

Unit None ...........F

Rated voltage None ...........50V

Tolerance (1) Ceramic, plastic, and film capacitors of which

Temperature characteristic None ........... SL

(Ceramic capacitor) For others, temperature characteristics are

Static electricity capacity Sometimes described with abbreviated letters as

(Ceramic capacitor) shown in Eg. 3.

+

........... Electrolytic, Special electrolytic

NP

...........Non polarity electrolytic

...........Ceramic, plastic

M

...........Film

...........Trimmer

µ ...........µF

p ...........pF

For other than 50V and electrolytic capacitors,

described in the Circuit Diagram.

capacitance are more than 10 pF.

None ...........±5% or more

B ...........±0.1%

C ...........±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

(2) Ceramic, plastic, and film capacitors of which

capacitance are 10 pF or less.

None ...........more than ±5% pF

B ...........±0.1 pF

C ...........±0.25 pF

(3) Electrolytic, T rimmer

Tolerance is not described.

described. (For capacitors of 0.01 µF and

no indications are described as F.)

Eg. 2

Fig. 3-1-2

Eg. 3

104

4

pF (0.1µF)

10x10

Temperature characteristic

(or Temperature characteristic+

Static electricity capacity tolerance)

Fig. 3-1-3

SERVICING DIAGRAMS

SECTION 3

3-1

Page 5

1-4. Inductor Indication

Type name

10µ

Type Tolerance

Unit None ...........Η

µ ...........µH

m ...........mH

Tolerance None ...........±5%

B ...........±0.1%

C ...........±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

K ...........±10%

M ...........±20%

1-5. Waveform and Voltag e Measurement

• The waveforms for CD/DVD and RF shown in the

circuit diagrams are obtained when a test disc is

played back.

• All voltage values except the waveforms are expressed

in DC and measured by a digital voltmeter.

1-6. Others

• The parts marked with “NC” or “KETU” in the circuit

diagrams are not used for this model.

1-7. When Replaced ROM ICs or Upgraded Firmware

Eg. 4

Fig. 3-1-4

Eg. 5

Fig. 3-1-5

1. When replaced the following ROM ICs, it is necessary

to write the data into the new ICs.

1) IC615 (firmware)

2) IC613 (Setup default data and other information)

2. When the firmware is upgraded, rewriting the new

firmware into IC615 may be requested for servicing.

DATA UPDATE KIT

(RS-232C Interface/cable)

RS-232C

cable

Computer

(MS-DOS/PC-DOS)

3. Connect a computer to the main PC board of the DVD

video player with using DATA UPDATE KIT (P/No.

79080074). (Fig. 3-2-6)

4. Writing operation

Refer to the instruction attached to the data floppy

disc.

MAIN PC Board

DVD video player

Note:

• The firmware and setup data floppy discs are not available as service parts.

For more information, consult TOSHIBA service office in your area.

Fig. 3-1-6

3-2

Page 6

2. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

3-3

Fig. 3-2-1

3-4

Page 7

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram

3-5

Fig.3-3-1

3-6

Page 8

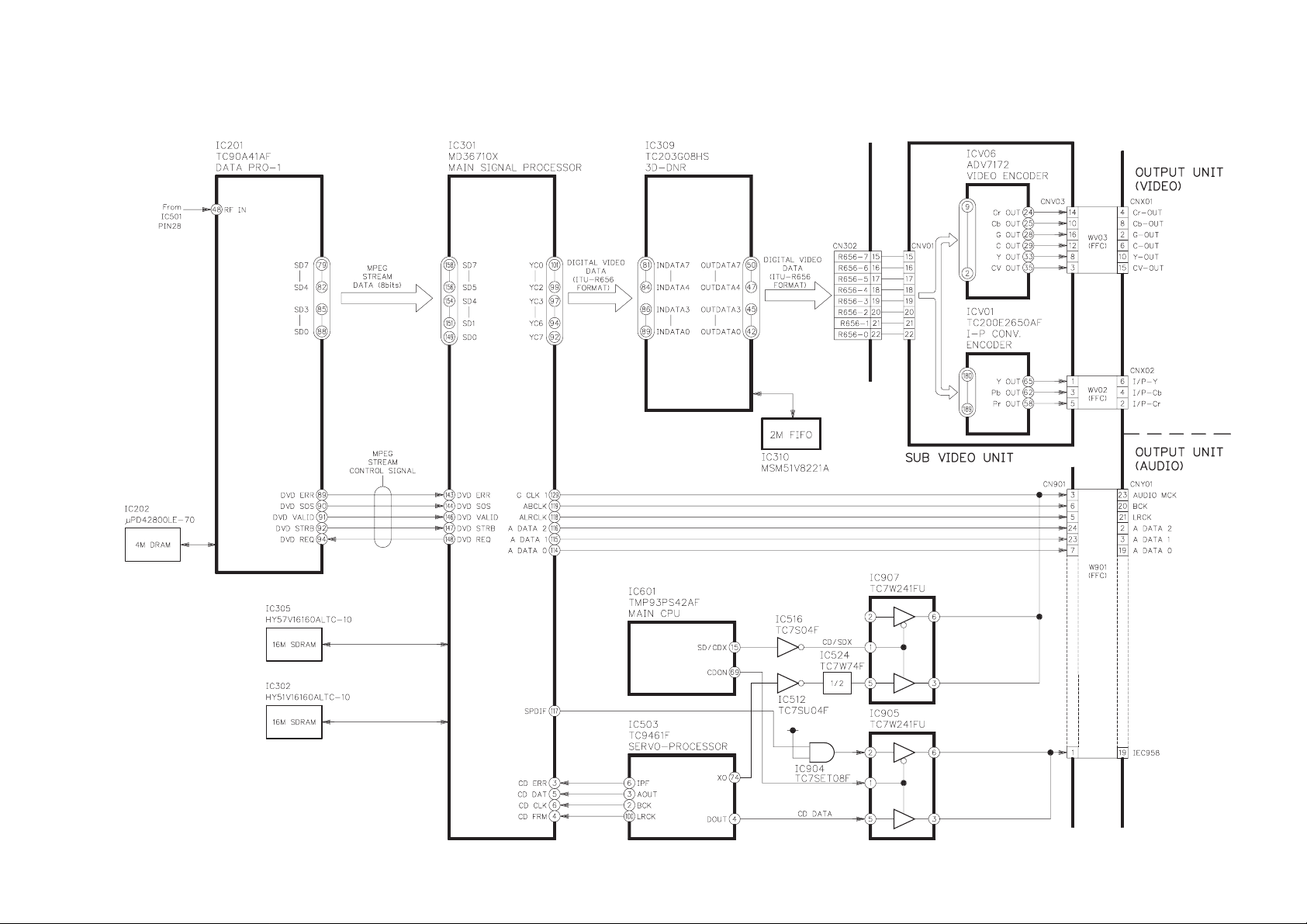

3-2. Main Block Diagram

3-2-1. Logical System Block Diagram

3-7

Fig. 3-3-2

3-8

Page 9

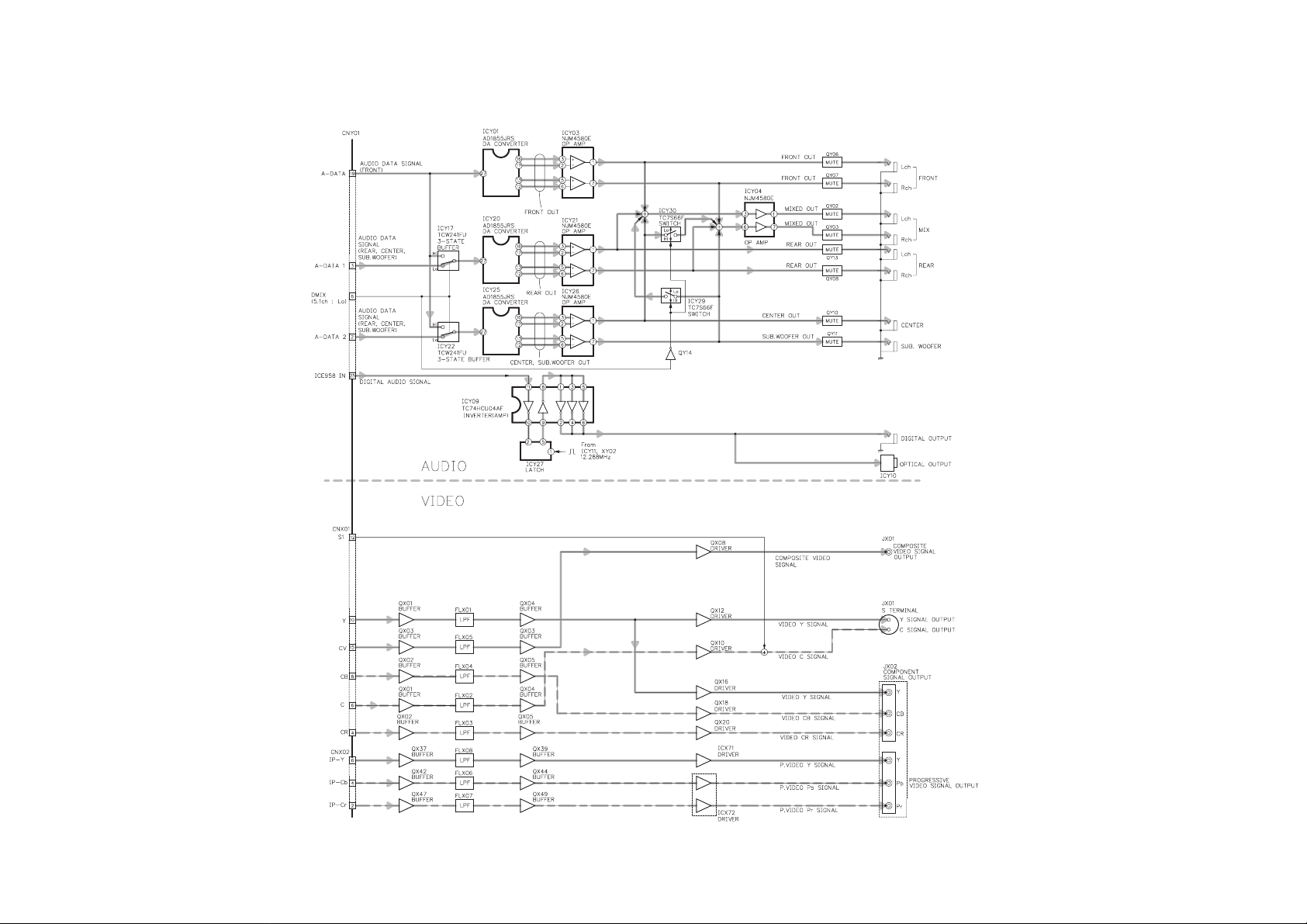

3-3. Output Block Diagram

3-9

Fig. 3-3-3

3-10

Page 10

4. CIRCUIT DIAGRAMS

4-1. Output Circuit Diagram

Waveform points

(CNY01)

Pin

Wave

No

No

21

8

20

8

2, 3, 19

8

17

6

16

6

15

6

DAC control

signal

Audio data signal

(Surround)

Digital audio signal

(a)

(b)

(c)

(a)

(b)

(c)

Audio

data

control

signal

Audio data signal

(Front)

Front out

Surround out

MIXED

out

4

(a)

5

(a)

4

(b)

5

(b)

Y signal

Cb signal

Cr signal

C signal

Composit video signal

1

2

3

3

Audio data signal

(Center sub woofer)

Center sub

woofer out

3-11

7

Fig. 3-4-1

3-12

Page 11

4. CIRCUIT DIAGRAMS

4-1. Output Circuit Diagram

Waveform points

(CNY01)

Pin

Wave

No

No

21

8

(a)

20

8

(b)

2, 3, 19

17

16

15

8

(c)

6

(a)

6

(b)

6

(c)

Audio

data

control

signal

Digital audio signal

Audio data signal

(Front)

DAC control

signal

Front out

MIXED

out

Page 12

4

(a)

5

(a)

4

(b)

5

(b)

Page 13

Y signal

Composit video signal

C signal

1

2

Cb signal

3

3

Page 14

Audio data signal

(Surround)

Surround out

Audio data signal

(Center sub woofer)

Center sub

woofer out

Page 15

7

Page 16

Cr signal

Fig. 3-4-2

Page 17

Part Loca No. tion

CNX01 A9

CNX02 J10

CNY01 C1

CNY02 G8

CNY03 B8

CW01 L5

CW02 G2

CW03 A4

CW04 A4

CW05 C2

CW06 C2

CW07 C2

CW08 A6

CW09 B7

CW10 F2

CW11 E4

CW12 J2

CW13 L2

CW14 B6

CW15 B2

CW16 C2

CW17 C2

CX01 A10

CX02 B11

CX03 B11

CX04 A12

CX05 B11

Part Loca No. tion

CX06 A12

CX07 B12

CX08 B13

CX09 B13

CX10 B13

CX11 B15

CX12 B15

CX13 C14

CX14 D12

CX15 C13

CX16 B13

CX17 C15

CX18 D15

CX19 D15

CX20 D15

CX21 E15

CX22 E15

CX23 E15

CX24 E11

CX25 E11

CX26 F15

CX27 G15

CX28 F15

CX29 H10

CX30 H11

CX31 H13

CX32 H14

Part Loca No. tion

CX33 J9

CX34 J10

CX35 J13

CX36 J15

CX37 J13

CX38 J15

CX39 J14

CX40 H15

CX41 K13

CX42 J14

CX43 K13

CX45 K14

CX46 J15

CX47 K15

CX49 L13

CX52 K15

CX53 K14

CX54 G15

CX55 G15

CX56 H15

CX57 H15

CX58 H15

CX59 E15

CX60 B12

CX61 J10

CY01 C3

CY02 C3

Part Loca No. tion

CY03 C3

CY04 C4

CY05 D4

CY06 D4

CY07 E4

CY08 E4

CY09 E2

CY10 D4

CY11 D4

CY12 E4

CY13 E4

CY14 C5

CY15 C5

CY16 C5

CY17 C5

CY18 E5

CY19 E5

CY20 E5

CY21 E5

CY22 D5

CY23 D5

CY24 D5

CY25 D7

CY26 E7

CY27 D7

CY28 D7

CY29 B4

Part Loca No. tion

CY30 B4

CY31 A4

CY32 A5

CY36 B2

CY37 B2

CY38 B2

CY39 B3

CY41 B4

CY42 E5

CY43 D6

CY44 D7

CY45 E7

CY46 G3

CY47 J2

CY48 H4

CY49 H4

CY50 G4

CY51 G4

CY52 G4

CY53 G4

CY54 H4

CY55 H4

CY56 G5

CY57 G5

CY58 G5

CY59 H5

CY60 H5

Part Loca No. tion

CY61 H5

CY62 G5

CY63 H5

CY64 G6

CY65 H15

CY66 G5

CY67 J5

CY68 H15

CY69 K2

CY70 K3

CY71 M2

CY72 K4

CY73 K4

CY74 L4

CY75 L4

CY76 K4

CY77 K4

CY78 L4

CY79 L4

CY80 K5

CY81 K5

CY82 K5

CY83 L5

CY84 L5

CY85 L5

CY86 K5

CY87 M5

Part Loca No. tion

CY88 K5

CY89 L5

CY90 K6

CY91 L5

CY92 G8

CY93 G7

CY94 H8

CY95 H7

CY96 H8

CY97 H7

CY98 J8

CY99 J7

DX01 G10

DX02 G11

DX03 H13

DX04 H14

DX05 F10

DX06 G10

DX07 G10

DX08 C16

DX09 D16

DY01 D6

DY02 G2

DY03 F4

DY04 J2

DY05 L1

EX01 A9

Part Loca No. tion

EX02 A9

EX03 A9

EX04 A9

EX05 B9

EX06 B9

EX07 B9

EX08 B9

EX09 B9

EX10 B9

EX11 B9

EX12 B9

EX13 B9

EX14 B13

EX15 A13

EX16 B12

EX17 C11

EX18 C12

EX19 C11

EX20 D11

EX21 C16

EX22 D15

EX23 D15

EX24 E15

EX25 E15

EX26 E15

EX27 F15

EX28 F15

Part Loca No. tion

EX29 F15

EX30 F15

EX31 F15

EX32 H15

EX33 G16

EX34 H15

EX35 G15

EX36 G15

EX37 H15

EX38 J11

EX39 J11

EX40 K11

EX41 K11

EX42 J13

EX43 K13

EX44 L13

EY01 C1

EY02 D1

EY03 D1

EY04 D1

EY05 D1

EY06 D1

EY07 D1

EY08 D1

EY09 D1

EY10 D1

EY11 D1

Part Loca No. tion

EY12 D1

EY13 E1

EY14 E1

EY15 E1

EY16 E1

EY17 E1

EY18 E4

EY19 E4

EY20 D6

EY21 E5

EY22 A5

EY23 B8

EY24 B8

EY25 A6

EY26 A6

EY27 F8

EY28 F7

EY29 F7

EY30 F7

EY31 F7

EY32 E1

EY33 F7

EY34 G8

EY35 G7

EY36 G7

EY37 H7

EY38 H7

Part Loca No. tion

EY39 H7

EY40 H7

EY41 J7

EY42 J7

EY43 G5

EY44 H5

EY45 K5

EY46 L5

EY47 J4

EY48 M4

EY49 E1

EY50 E1

EY51 E1

EY52 E1

EY53 E1

EY54 A6

EY55 A6

EY56 J3

EY57 L3

EY58 F1

EY59 F4

EY60 J4

EY61 M4

EY62 F3

EY63 F3

EY64 G4

FLX01 B11

Part Loca No. tion

FLX02 C11

FLX03 C11

FLX04 C11

FLX05 D11

FLX06 K12

FLX07 L12

FLX08 J12

FLY01 B7

FLY02 B7

FLY03 B5

ICX71 H14

ICX72 J14

ICX91 C13

ICX92 F11

ICX93 H10

ICY01 D3

ICY02 C3

ICY03 D5

ICY04 D7

ICY05 C7

ICY06 E7

ICY07 E2

ICY08 E3

ICY09 C4

ICY10 A6

ICY11 A2

ICY15 A3

Part Loca No. tion

ICY17 H2

ICY18 J3

ICY19 J3

ICY20 H3

ICY21 H5

ICY22 K2

ICY23 M3

ICY24 M3

ICY25 L3

ICY26 L5

ICY27 A5

ICY28 C2

ICY29 C6

ICY30 E6

ICY31 F2

ICY32 F3

ICY33 B3

JPY02 B5

JX01 C16

JX02 E16

JX03 F16

JY01 G8

JY02 B6

LY01 E1

LY02 E2

LY03 C3

LY04 D4

Part Loca No. tion

LY06 B4

LY07 A6

LY08 G2

LY09 J2

LY10 K4

LY11 G4

LY12 B3

QX01 B10

QX02 C10

QX03 D10

QX04 B12

QX05 C12

QX06 B12

QX07 B13

QX08 B14

QX10 C14

QX12 C14

QX14 D13

QX15 D13

QX16 E14

QX18 F14

QX20 F14

QX22 F13

QX23 E13

QX24 E10

QX25 F10

QX26 F10

Part Loca No. tion

QX27 F10

QX28 F12

QX29 H9

QX31 H11

QX33 H12

QX35 H13

QX37 J11

QX39 J13

QX42 K11

QX44 K13

QX47 L11

QX49 L13

QX52 A11

QX53 B11

QY01 E4

QY02 C8

QY03 E7

QY04 E7

QY05 C6

QY06 F5

QY07 F6

QY08 H6

QY09 M4

QY10 K6

QY11 L6

QY12 J4

QY13 G6

Part Loca No. tion

QY14 E6

QY15 F4

QY16 J4

QY17 M4

QY18 F3

QY19 G3

QY20 G3

QY21 G3

QY22 F4

QY23 F4

QY24 J3

QY25 K2

QY26 L2

QY27 M1

QY28 G7

QY29 C4

QY30 C3

RV01 K15

RV02 K15

RV03 K15

RV05 F10

RV06 A14

RV07 A12

RV10 B10

RV11 C9

RV12 C9

RV13 D9

Part Loca No. tion

RV14 D9

RV15 B10

RV16 C10

RV17 C10

RV18 D10

RV19 D9

RV20 A14

RV21 A14

RV22 A14

RV23 A14

RV24 A14

RV25 B14

RV26 B14

RV27 B14

RV28 B14

RV29 C14

RV30 C14

RV31 D14

RV32 D14

RV33 E14

RV34 E14

RV35 F14

RV36 F14

RV37 J11

RV38 J11

RV39 J11

RV40 K11

Part Loca No. tion

RV41 J11

RV42 K11

RV43 L11

RV44 K11

RV45 L11

RV46 G9

RV47 G10

RV48 G10

RV49 G11

RV50 G12

RV51 G12

RV52 G13

RV53 G14

RV54 J13

RV55 H14

RV57 J15

RV58 J15

RV59 K15

RV60 K15

RV96 C9

RV97 A10

RV98 A10

RV99 D10

RW01 K6

RW02 K6

RW03 L6

RW04 L6

Part Loca No. tion

RW05 K6

RW06 L6

RW07 E5

RW08 G3

RW09 B4

RW10 A5

RW11 C 3

RW12 E6

RW13 C6

RW14 E6

RW15 E3

RW16 F3

RW17 J2

RW18 L1

RW20 F2

RW21 F7

RW22 F7

RW23 E3

RW24 F3

RW25 J3

RW26 M3

RW27 B6

RW28 B6

RW29 F5

RW30 E4

RW31 F4

RW32 F5

Part Loca No. tion

RW33 H6

RW34 J6

RW35 L6

RW36 M6

RW37 G7

RW38 F7

RW39 C4

RW40 C4

RW41 C3

RW42 C3

RW44 A5

RW45 F7

RW46 F7

RX01 A10

RX02 A10

RX03 B10

RX04 B10

RX05 B10

RX06 B10

RX07 C10

RX08 C10

RX09 C10

RX10 C10

RX11 D10

RX12 D10

RX13 D10

RX14 D11

Part Loca No. tion

RX15 C11

RX16 C11

RX17 B11

RX18 B11

RX19 B12

RX20 C12

RX21 C12

RX22 C12

RX23 A11

RX24 A11

RX25 A11

RX26 B12

RX27 A12

RX28 A12

RX29 A12

RX30 B12

RX31 B12

RX32 B12

RX33 B13

RX34 B13

RX35 A12

RX36 A13

RX37 A13

RX38 A13

RX39 A13

RX40 B13

RX41 B12

Part Loca No. tion

RX42 B12

RX43 B12

RX44 B13

RX45 C13

RX46 C13

RX47 C13

RX48 C14

RX49 D13

RX50 D12

RX51 D12

RX52 E13

RX53 A14

RX54 B14

RX55 B14

RX56 B14

RX57 B14

RX58 B14

RX59 C14

RX60 C14

RX61 C14

RX62 D14

RX63 D14

RX64 C15

RX65 C15

RX66 D15

RX67 D15

RX68 D15

Part Loca No. tion

RX69 D15

RX70 D15

RX71 E10

RX72 E10

RX73 E10

RX74 E10

RX75 E10

RX76 F10

RX77 F9

RX78 F9

RX79 F10

RX80 F10

RX81 F10

RX82 F11

RX83 E12

RX84 E12

RX85 E13

RX86 E13

RX87 F13

RX88 F13

RX89 F13

RX90 F13

RX91 F13

RX92 E13

RX93 E13

RX94 F13

RX95 E13

Part Loca No. tion

RX96 D14

RX97 D14

RX98 D14

RX99 E14

RY01 A2

RY02 D1

RY03 D1

RY04 D1

RY05 D3

RY06 C4

RY07 E4

RY08 D5

RY09 E5

RY10 D5

RY11 E5

RY12 D5

RY13 E5

RY14 C5

RY15 E5

RY16 D5

RY17 E5

RY18 C5

RY19 E5

RY20 D6

RY21 E6

RY22 D7

RY23 E7

Part Loca No. tion

RY24 C7

RY25 E7

RY26 E7

RY27 D8

RY28 E7

RY29 D8

RY30 E7

RY31 D8

RY32 E8

RY33 B5

RY34 B5

RY35 A5

RY36 A5

RY37 A6

RY38 B6

RY39 D6

RY40 D7

RY41 F7

RY45 B2

RY46 E7

RY47 E6

RY48 D7

RY49 D7

RY50 F5

RY51 F5

RY52 F6

RY53 F6

Part Loca No. tion

RY54 F6

RY55 G3

RY56 G4

RY57 J4

RY58 G4

RY59 G5

RY60 H4

RY61 H4

RY62 G5

RY63 H5

RY64 G5

RY65 H5

RY66 G5

RY67 H5

RY68 G5

RY69 H5

RY70 G6

RY71 H6

RY72 G6

RY73 H6

RY74 G6

RY75 J6

RY76 G8

RY77 G7

RY78 H8

RY79 H7

RY80 H8

RY81 H7

Part Loca No. tion

RY82 J8

RY83 J7

RY84 K3

RY85 K3

RY86 K4

RY87 M4

RY88 K4

RY89 K4

RY90 L4

RY91 L4

RY92 K5

RY93 L5

RY94 K5

RY95 L5

RY96 K5

RY97 L5

RY98 K5

RY99 L4

RZ01 E14

RZ02 E14

RZ03 F14

RZ04 F14

RZ05 F15

RZ06 E15

RZ07 E15

RZ08 E15

RZ09 E15

RZ10 E15

Part Loca No. tion

RZ11 F15

RZ12 G14

RZ13 G14

RZ14 F15

RZ15 G15

RZ16 G15

RZ17 G15

RZ18 G15

RZ19 G15

RZ20 G15

RZ21 G15

RZ22 G15

RZ23 H15

RZ24 H15

RZ25 H15

RZ26 H15

RZ27 H15

RZ28 G14

RZ29 G14

RZ30 G14

RZ31 G13

RZ32 G13

RZ33 H12

RZ34 G12

RZ35 G12

RZ36 G11

RZ37 G11

RZ38 G11

Part Loca No. tion

RZ39 G10

RZ40 G10

RZ41 G10

RZ42 G9

RZ43 G9

RZ44 J9

RZ45 J9

RZ46 J9

RZ47 A10

RZ48 J11

RZ49 J10

RZ50 J11

RZ51 J11

RZ52 J12

RZ53 J14

RZ54 J15

RZ55 J15

RZ56 J15

RZ57 J12

RZ58 J15

RZ59 J12

RZ60 J12

RZ61 J13

RZ62 J14

RZ63 J13

RZ64 J13

RZ65 J13

RZ66 H15

Part Loca No. tion

RZ67 J15

RZ68 J16

RZ69 J16

RZ70 J15

RZ71 K16

RZ74 J14

RZ75 K13

RZ76 K12

RZ77 K12

RZ78 K13

RZ79 K12

RZ80 K12

RZ81 K13

RZ82 K13

RZ83 K13

RZ84 K13

RZ85 K11

RZ86 K11

RZ87 K11

RZ91 L12

RZ92 L13

RZ93 K11

RZ94 K12

RZ96 L12

RZ97 L12

RZ98 L13

SY01 D6

XY02 B2

3-13

Page 18

1

JX01 Composite video output

C-16

5

CNX01

(a) Pin (Cb)

(b) Pin (C

8

4

B-9

r

)

C-9

2

JX01 S-video output

3

JX02 Y/Cb/Cr output

CVBS output

75Ω terminated

100% color bar

V: 500 mV/div

H: 20 s/div

S-Y/C

75Ω terminated

Y

100% color bar

C

V: 500 mV/div

H: 20 µs/div

Component output

75Ω terminated

Y

100% color bar (Play)

Cb

Cr

V: 500 mV/div

H: 20 µs/div

D-16

E-16

100% color bar (Play)

(a)

(b)

V: 1 V/div

H: 20 µs/div

6

CNY01

(a) Pin (S DATA)

(b) Pin (S CLOCK)

(c) Pin (DA2CSX)

7

17

16

15

(a)

(b)

(c)

V: 5 V/div

H: 20 µs/div

JY01 L ch output / R ch output

L ch output

R ch output

V: 2 V/div

H: 200 µs/div

D-1

D-1

D-1

H-8

4

CNX01

(a) Pin (Y)

(b) Pin (C)

10

6

100% color bar (Play)

(a)

(b)

V: 1 V/div

H: 20 µs/div

CNY01

8

(a) Pin (LRCK)

B-9

(b) Pin (BCK)

C-9

(c) Pin (ADATA)

3-14

21

20

19

(ADATA2)

2

(ADATA1)

3

5.1ch

D-1

D-1

D-1

E-1

E-1

(a)

(b)

(c)

Fig. 3-4-2

Page 19

IC

ICY01

DA CONVERTER

1

2.5

2

4.9

3

3.2

4

3.5

5

6

7

8

9

10

11

2.3

12

2.4

13

2.4

14

15

2.4

16

2.3

17

4.9

18

3.3

19

20

21

22

23

4.9

24

2.4

25

2.4

26

1.3

27

4.9

28

ICY02

REGURATOR

1

6.5

2

3

1.2

4

4.9

5

6.5

ICY03

OP AMP

1

4.9

2

4.9

3

4.9

4

4.9

5

4.9

6

4.9

7

4.9

8

9.2

ICY04

OP AMP

1

4.9

2

4.9

3

4.9

4

5

4.9

6

4.9

7

4.9

8

9.2

ICY17

0

3-STATE

BUFFER

4.7

1

0

2

1.3

3

0

4

1.3

5

1.3

6

4.7

7

4.9

8

ICY18

AND GATE

0

1

0

2

0

3

0

4

4.9

5

ICY19

OR GATE

1

0

2

0

3

0

4

0

5

4.9

ICY20

DA CONVERTER

1

0

2

2.5

3

4.9

4

3.2

5

3.5

6

0

7

0

8

0

9

0

10

0

11

0

12

2.3

13

2.4

14

2.4

15

0

16

2.4

17

2.3

18

4.9

19

3.3

20

0

21

0

22

0

23

0

24

4.9

25

2.4

26

2.4

27

1.3

28

4.9

ICY21

OP AMP

4.9

1

4.9

2

4.9

3

0

4

4.9

5

4.9

6

4.9

7

9.2

8

ICY22

3-STATE

BUFFER

1

4.7

2

0

3

1.3

4

0

5

1.3

6

1.3

7

4.7

8

4.9

ICY23

AND GATE

1

0

2

0

3

0

4

0

5

4.9

ICY24

OR GATE

1

0

2

0

3

0

4

0

5

4.9

ICY07

0

0

0

0

0

0

0

0

0

0

0

0

0

0

AND GATE

0

1

0

2

0

3

0

4

4.9

5

ICY08

OR GATE

1

0

2

0

3

0

4

0

5

4.9

ICY09

INVERTER

2.5

1

2.5

2

2.5

3

2.5

4

2.5

5

2.5

6

0

7

2.5

8

2.5

9

2.5

10

2.0

11

2.6

12

2.0

13

4.9

14

ICY10

D-IN

2.5

VCC

4.9

GND

ICY11

OSCILLATOR

1

4.9

2

0

3

0

4

0

5

0

6

4.9

7

2.5

8

4.9

ICY15

3-STATE

BUFFER

1

0

2

0

3

0

4

0

5

0

6

2.5

7

4.9

8

4.9

ICY25

DA CONVERTER

0

1

2.5

2

4.9

3

3.2

4

3.5

5

0

6

0

7

0

8

0

9

0

10

0

11

2.3

12

2.4

13

2.4

14

0

15

2.4

16

2.3

17

4.9

18

3.3

19

0

20

0

21

0

22

0

23

4.9

24

2.4

25

2.4

26

1.3

27

4.9

28

ICY26

OP AMP

1

4.9

2

4.9

3

4.9

4

0

5

4.9

6

4.9

7

4.9

8

9.2

ICY27

D-FLIP-FLOP

1

2.6

2

2.5

3

2.5

4

0

5

2.5

6

4.9

7

4.9

8

4.9

ICY28

REGURATOR

1

6.5

2

0

3

1.2

4

4.9

5

6.5

ICY29

SWITCH

1

4.9

2

4.9

3

0

4

0

5

9.2

ICY30

SWITCH

4.9

1

4.9

2

0

3

0

4

4.9

5

ICY31

AND GATE

1

0

2

0

3

0

4

0

5

4.9

ICY32

OR GATE

1

0

2

0

3

0

4

0

5

4.9

ICY33

3-STATE

BUFFER

0

1

0

2

0

3

0

4

0

5

2.5

6

4.9

7

4.9

8

ICX71

OP AMP

6.4

1

3.8

2

3.8

3

4

1.9

5

3.8

6

3.8

7

9.3

8

ICX72

OP AMP

6.4

1

3.8

2

3.8

3

4

3.8

5

3.8

6

6.4

7

9.3

8

0

0

Transistor

QY01

SWITCH

4.9

1

4.9

2

4.9

3

0

4

0

5

0

6

QY02

SWITCH

1

0

2

0

3

0

4

0

5

0

6

0

QY03

SWITCH

1

0

2

0

3

0

4

0

5

0

6

0

QY06

SWITCH

1

0

2

0

3

0

4

0

5

0

6

0

QY07

SWITCH

1

0

2

0

3

0

4

0

5

0

6

0

QY08

SWITCH

1

0

2

0

3

0

4

0

5

0

6

0

QY09

SWITCH

1

4.9

2

4.9

3

4.9

4

5

6

QY10

SWITCH

1

2

3

4

5

6

QY11

SWITCH

1

2

3

4

5

6

QY12

SWITCH

4.9

1

4.9

2

4.9

3

4

5

6

QY13

SWITCH

1

2

3

4

5

6

QY18

SWITCH

4.9

1

4.9

2

4.9

3

4

5

6

QY29

REGURATOR

9.2

1

7.4

2

6.5

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

3

8.2

4

9.2

5

8.2

6

QY30

REGURATOR

9.2

1

7.4

2

6.5

3

8.2

4

9.2

5

8.2

6

QX01

BUFFER

1

1.8

2

1.1

3

0

4

2.1

5

1.4

6

0

QX02

BUFFER

1

2.1

2

1.4

3

0

4

2.1

5

1.4

6

0

QX04

BUFFER

1

2.7

2

2.0

3

0

4

2.4

5

1.7

6

0

QX05

BUFFER

1

2.7

2

2.0

3

0

4

2.7

5

2.0

6

0

QX06

BUFFER

1

9.2

2

2.7

3

2.1

4

9.2

5

2.4

6

1.8

QX07

MIX AMP

BUFFER

1

9.2

2

1.6

3

1.0

4

6.0

5

6.0

6

5.5

QX08

DRIVER

1

—

2

5.4

3

9.2

4

4.7

5

5.4

6

0

QX10

DRIVER

1

3.4

2

2.7

3

0

4

0

5

0

6

0

QX12

DRIVER

1

3.1

2

2.4

3

0

4

0

5

0

6

0

QX16

SWITCH

1

3.1

2

2.4

3

0

4

0

5

0

6

0

QX18

DRIVER

1

2.6

2

2.6

3

4

5

6

QX20

DRIVER

1

2.6

2

2.0

3

4

5

6

QX22

SWITCH

1

2

0.7

3

4

5

0.7

6

QY05

SWITCH

E

C

B

4.7

QY14

SWITCH

E

C

4.7

B

QY15

SWITCH

4.9

E

C

4.9

B

QY16

SWITCH

4.9

E

C

4.9

B

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

QY17

SWITCH

E

4.9

C

0

B

4.9

QY19

SWITCH

E

4.9

C

0

B

4.9

QY20

SWITCH

E

4.9

C

0

B

4.9

QY21

SWITCH

E

4.9

C

0

B

4.9

QY22

SWITCH

4.9

E

0

C

4.9

B

QY23

SWITCH

E

4.9

C

0

B

4.9

QY24

SWITCH

E

4.9

C

0

B

4.9

QY25

SWITCH

4.9

E

0

C

4.9

B

QY26

SWITCH

4.9

E

0

C

4.9

B

QY27

SWITCH

E

4.9

C

0

B

4.9

QX15

SWITCH

E

C

0/3.3

B

QX23

SWITCH

3.6

E

9.2

C

4.9

B

QX37

BUFFER

E

2.4

C

0

B

1.7

QX39

BUFFER

E

2.1

C

9.3

B

2.7

QX42

BUFFER

E

2.6

C

0

B

1.9

QX44

BUFFER

E

2.2

C

9.3

B

2.9

QX47

BUFFER

2.6

E

0

C

1.9

B

QX49

BUFFER

2.2

E

9.3

C

2.9

B

0

—

3-15

Page 20

2 5 6 7 89

10134

A

B

C

D

E

F

4-2. Sub Video Circuit Diagram

Part Loca No. tion

CNV01 E1

CNV02 E9

CNV03 D1

CV01 F4

CV02 F5

CV03 F6

CV04 E7

CV05 E7

CV06 E7

CV07 E7

CV08 E7

CV09 E7

CV10 E7

CV11 E8

CV12 E8

CV13 D7

CV14 C7

CV15 C9

CV16 B6

CV17 A4

CV18 C4

CV19 C2

CV20 F4

CV21 E3

CV22 F3

CV23 E3

CV24 D3

CV25 D2

CV26 E2

CV27 E2

CV28 E2

CV29 E2

CV30 F1

CV31 E8

EV01 D1

EV02 D1

EV03 D1

EV04 D1

EV05 D1

EV06 D1

EV07 D1

EV08 D1

EV09 D1

EV10 D1

EV11 E1

EV12 E1

EV13 E1

EV14 E1

EV15 E1

EV16 E1

EV17 E1

EV18 E1

EV19 E1

EV20 F1

EV21 F1

EV22 F1

EV23 F1

EV24 F1

EV25 F1

EV26 F1

EV27 F1

EV28 F1

EV29 F1

EV30 F1

EV31 F1

EV32 F1

EV33 G1

EV34 G1

EV35 G1

EV36 G1

EV37 G1

EV38 G1

EV39 G1

EV40 G1

Part Loca No. tion

EV41 G1

EV42 G1

EV43 G1

EV44 F5

EV45 F5

EV46 F9

EV47 F9

EV48 F9

EV49 F9

EV50 F9

EV51 F9

EV52 F3

EV53 E2

EV54 D2

EV55 F4

EV56 F7

EV57 D8

EV58 D8

EV59 E7

EV60 E8

EV61 E8

EV62 E7

FLV01 F4

FLV02 F3

ICV01 D6

ICV02 C3

ICV03 A5

ICV04 D8

ICV05 D8

ICV06 E3

JPV01 F3

JPV02 D1

LV01 F6

LV02 E9

QV01 E8

QV02 E8

QV03 E8

RMV01 F1

RMV02 G2

RMV03 F1

RMV04 F1

RV01 G3

RV02 E8

RV03 E8

RV04 E8

RV05 E8

RV06 E8

RV07 E8

RV08 E7

RV09 E8

RV11 F1

RV12 G2

RV13 G2

RV14 D2

RV15 D2

RV16 D2

RV17 E2

RV18 E2

RV19 E2

RV20 E2

RV21 F1

RV22 E3

RV23 F3

RV24 F3

RV25 F3

RV26 D3

RV27 F1

RV28 D3

RV29 D3

RV30 E4

RV31 E4

TPV01 F3

TPV02 F3

TPV03 E3

G

3-16

NC: Not used.

Fig. 3-4-3

3-17

Page 21

SECTION 4

PARTS LIST

SAFETY PRECAUTION

The parts identified by !( ) mark are critical for safety. Replace only with part number specified.

The mounting position of replacement is to be identical with originals.

The substitute replacement parts which do not have the same safety characteristics as specified in the parts list may create

shock, fire or other hazards.

NOTICE

The part number must be used when ordering parts in order to assist in processing, be sure to include the model number and

description.

ABBREVIATIONS

1. Integrated Circuit (IC)

2. Capacitor (Cap)

• Capacitance Tolerance (for Nominal Capacitance more than 10pF)

Table 4-2-1

Symbol

T olerance %B± 0.1C± 0.25D± 0.5

Symbol

T olerance %

• Capacitance Tolerance (for Nominal Capacitance 10pF or less)

Symbol

Tolerance pFB± 0.1C± 0.25D± 0.5

3. Resistor (Res)

• Resistance tolerance

P

+ 100

0

Q

+ 30

– 10

T

+ 50

– 10

Ex. 10pF G = 10pF ± 2pF

F

± 1

U

+ 75

– 10

Table 4-2-2

F

± 1

Table 4-3-1

G

± 2

V

+ 20

– 10

G

± 2

J

± 5

W

+ 100

– 10

K

± 10

X

+ 40

– 20

Ex. 10MF J = 10µF ± 5%

M

± 20

Y

+ 150

– 10

N

± 30

Z

+ 80

– 20

PARTS LIST

SECTION 4

Symbol

T olerance %B± 0.1C± 0.25D± 0.5

F

± 1

4-1

G

± 2

J

± 5

Ex. 470 ohm J = 470 ohm ± 5%

K

± 10

M

± 20

Page 22

4. EXPLODED VIEWS

4-1. Packing Assembly

4-2. Remote Control Unit

Fig. 4-4-1

Fig. 4-4-2

4-2

Page 23

4-3. Chassis Assembly

Fig. 4-4-3

4-3

Page 24

4-4. Mechanism Assembly

Fig. 4-4-4

4-4

Page 25

LOCATION

4-5

NUMBER

- MECHANICAL PARTS -

M491 79070015 Motor,Feed RF-300PA

MC01 79070158 Chassis Assy,Mechanism

MC03 79070022 Tray

MC04 79070139 Clamper Assy

MC14 79070024 Belt,Loading

MC63 79070028 Screw 2.6x3.5mm

MC65 79070064 Screw 2.6x8W12mm

MP01 79070339 Mechanism Assy Pick Up

MP02 79070023 Chassis,Sub

MP13 79070011 Gear Assy Feed Motor

MP36 79070016 Dumper,Rubber Front

MP37 79070082 Dumper,Rubber Rear

MP61 79070019 Screw 1.7x0.5W9mm

MP64 79070020 Screw 1.7x4.0mm

MP66 79070018 Screw 1.7x4.5mm

MP67 79070017 Washer W-5-1.65

MP90 79070012 Gear A Kit

MP91 79070013 Gear B Kit

MP92 79070014 Gear,Rack

MT491 79040001 Hole Element HW-101A-E

MT492 79040001 Hole Element HW-101A-E

RM01 79070025 Motor Assy,Loading

S491 79070026 Switch SW-SSCF

W102 79080145 Cable,Flexible FFC,4P,L120

W501 79080020 Cable,Flexible FFC,21P,L292

W502 79080021 Cable,Flexible FFC,19P,L185

W503 79080059 Cable,Flexible FFC,5P,L288

W602 79080142 Cable,Flexible FFC-10P-L150

W901 79080178 Cable,Flexible FFC-25P-L180

WV02 79080182 Cable,Flexible FFC,6P,L120

WV03 79080177 Cable,Flexible FFC-17P-L120

WY02 79080183 Cable,Flexible FFC,10P,L440

ZF01 79078001 Remote Control Unit,SE-R0002

ZF02 79078002 Cover,Battery

ZF03 79078003 Cover,Remote Control Unit

! ZF10 79077028 Owners Manual English/SPANISH

ZF17 79070272 Warranty Card USA

ZF20 79070037 Cable,AV

ZF21 79070049 Cable,S

ZF30 79070042 Bag,Polyethylene

ZF31 79080026 Bag,Polyethylene (Power Cord)

ZG01 79071060 Front Panel

ZG03 79071033 Panel,Tray

ZG07 79071034 Knob,HP VR

ZG08 79071035 Button,Power

ZG20 79073014 Cover,Top

! ZG21 79070371 Label,Rating USA

ZG26 79073033 Foot Assy,Front

! ZG27 79070162 Label,PU Caution

ZG33 79079011 Base Main PCB

ZG60 79070165 Screw 3.0x6.0mm

ZK01 79075034 Case

ZK02 79075024 Packing,R

ZK03 79075023 Packing,L

ZK04 79070033 Bag,Polyethylene

ZK06 79075025 Separator

ZZ01 79070274 Test Disc DVDZ-9044

79080074 Kit,Data Update

PART

NUMBER DESCRIPTION

Page 26

LOCATION

C841 79020064 Cap,Electrolytic 39MF M 50V

C842 79020007 Cap,Electrolytic 22MF M 50V

- RESISTORS -

R803 79030045 Res,Oxide Metal 56kohm J 2W

R804 79030025 Res,Oxide Metal 82kohm J 2W

R805 79030039 Res,Carbon 4.7kohm J 1/6W

R806 79030026 Res,Oxide Metal 330kohm J 1W

R807 79030032 Res,Carbon 680ohm J 1/6W

R808 79030011 Res,Oxide Metal 0.47ohm J 1W

R809 79030033 Res,Carbon 3.3kohm J 1/6W

R810 79030028 Res,Oxide Metal 22ohm J 1/2W

R811 79030034 Res,Carbon 2.4kohm J 1/6W

R812 79030035 Res,Carbon 2.7kohm J 1/6W

R824 79030046 Res,Oxide Metal 62ohm J 1/2W

R825 79030036 Res,Carbon 330ohm J 1/6W

R826 79030037 Res,Carbon 7.5kohm G 1/4W

R827 79030038 Res,Carbon 1kohm G 1/4W

R828 79030039 Res,Carbon 4.7kohm J 1/6W

R829 79030004 Res,Carbon 1kohm J 1/6W

R830 79030029 Res,Carbon 100kohm G 1/4W

R832 79030004 Res,Carbon 1kohm J 1/6W

R833 79030047 Res,Oxide Metal 910ohm J 1/2W

R834 79030041 Res,Carbon 2kohm G 1/4W

R835 79030041 Res,Carbon 2kohm G 1/4W

R836 79030041 Res,Carbon 2kohm G 1/4W

R837 79030041 Res,Carbon 2kohm G 1/4W

R838 79030042 Res,Carbon 680ohm G 1/4W

R839 79030041 Res,Carbon 2kohm G 1/4W

R840 79030002 Res,Carbon 10kohm J 1/6W

R841 79030043 Res,Carbon 180ohm J 1/6W

R842 79030042 Res,Carbon 680ohm G 1/4W

R843 79030030 Positive ThermisterPTH8L510-T

R845 79030044 Res,Carbon 2.7kohm G 1/4W

R846 79030039 Res,Carbon 4.7kohm J 1/6W

R847 79030035 Res,Carbon 2.7kohm J 1/6W

R848 79030004 Res,Carbon 1kohm J 1/6W

R849 79030043 Res,Carbon 180ohm J 1/6W

R850 79030009 Res,Oxide Metal 220ohm J 1/2W

- MISCELLANEOUS -

F801 79087001 Fuse 1.6A,250V

F822 79070061 Protector 125V,3.0A

F823 79070061 Protector 125V,3.0A

P801 79088005 Power Cord

RF823 79030017 Res,Fusible 560ohm J 1/2W

T801 79080006 Line Filter 253YOR7

T802 79010013 Power Transformer SRW3020ED-204

EU04 79081011 PC Board Assy Power Switch

EU03 79081010 PC Board Assy Front

- INTEGRATED CIRCUITS -

IC101 79040132 IC TMP47C416F-RE12

- MISCELLANEOUS -

A101 79080148 Display,FL 7-ST-33GK

MT101 79080140 Module,RMT GP1U261X

S101 79080141 Switch Push

S102 79080141 Switch Push

S103 79080141 Switch Push

S104 79080141 Switch Push

S105 79080141 Switch Push

X101 79070006 Oscillator,Ceramic 8MHz

EU07 79081012 PC Board Assy HP AMP

- INTEGRATED CIRCUITS -

ICU01 79040044 IC NJM4580E

- TRANSISTORS -

QU01 79050029 Transistor,Chip IMD3A

QU03 79050038 Transistor,Chip 2SD2114K

QU31 79050001 Transistor,Chip RN2402

QU32 79050001 Transistor,Chip RN2402

QU33 79050001 Transistor,Chip RN2402

QU34 79050038 Transistor,Chip 2SD2114K

QU35 79050038 Transistor,Chip 2SD2114K

- CAPACITORS -

CU01 79020093 Cap,Electrolytic 220MF M 10V

CU02 79020094 Cap,Electrolytic 0.0001MF M 6.3V

CU03 79020094 Cap,Electrolytic 0.0001MF M 6.3V

CU04 79020093 Cap,Electrolytic 220MF M 10V

CU07 79020092 Cap,Electrolytic 10MF M 16V

CU08 79020092 Cap,Electrolytic 10MF M 16V

CU11 79020092 Cap,Electrolytic 10MF M 16V

CU32 79020093 Cap,Electrolytic 220MF M 10V

4-6

NUMBER

- ELECTRICAL PARTS -

EU02 79085011 PC Board Assy Power

- INTEGRATED CIRCUITS -

! Q803 79040100 IC STR-F6535

Q821 79040104 IC UPC1093J

Q830 79040105 IC BA10324A

- TRANSISTORS -

! Q802 79050026 Photo Coupler PC123FY2

! Q804 79050026 Photo Coupler PC123FY2

Q822 79050007 Transistor 2SC3852

Q823 79050007 Transistor 2SC3852

Q824 79050034 Transistor 2SA1757F

Q825 79050005 Transistor 2SC2236-Y

Q827 79050004 Transistor 2SC2458-Y

Q828 79050004 Transistor 2SC2458-Y

Q829 79050008 Transistor RN1201

- DIODES -

! D802 79060016 Diode ERA15-06

! D803 79060016 Diode ERA15-06

! D804 79060016 Diode ERA15-06

! D805 79060016 Diode ERA15-06

! D806 79060009 Diode RU-1P

D807 79060013 Diode AG01

D808 79060015 Diode 1SS133

D809 79060029 Diode,Zener 6.8V

D810 79060013 Diode AG01

D811 79060013 Diode AG01

D812 79060015 Diode 1SS133

D821 79060008 Diode RU2YX

D822 79060017 Diode RU4Z

D823 79060032 Diode RK49LF-L1

D824 79060013 Diode AG01

D825 79060013 Diode AG01

D829 79060015 Diode 1SS133

D831 79060015 Diode 1SS133

D832 79060015 Diode 1SS133

D833 79060015 Diode 1SS133

D835 79060012 Diode ERA15-02

D836 79060007 Diode,Zener UZ3.0BSB

D837 79060004 Diode,Zener UZ5.1BSB

D838 79060004 Diode,Zener UZ5.1BSB

D839 79060004 Diode,Zener UZ5.1BSB

D840 79060006 Diode,Zener UZ5.6BSB

D841 79060013 Diode AG01

D842 79060013 Diode AG01

D843 79060027 Diode,Zener UZ12BSB

- COILS -

! L801 79070051 Coil,Choke ZBF253D-02

! L802 79070051 Coil,Choke ZBF253D-02

! L821 79010001 Coil 20ƒÊH

- CAPACITORS -

! C801 79020027 Cap,Ceramic 0.22MF Z 275V

! C802 79020028 Cap,Ceramic 470pF Z 250V

! C803 79020028 Cap,Ceramic 470pF Z 250V

! C804 79020013 Cap,Ceramic 0.01MF Z 250V

! C805 79020042 Cap,Electrolytic 100MF D 450V

! C806 79020016 Cap,Film 0.033MF J 630V

! C808 79020015 Cap,Ceramic 150pF J 1kV

C809 79020067 Cap,Electrolytic 27MF M 35V

C810 79020078 Cap,Ceramic 470pF K 50V

! C811 79020029 Cap,Ceramic 220pF Z 250V

C812 79020068 Cap,Ceramic 390pF K 2kV

C813 79020079 Cap,Ceramic 2200pF K 50V

C814 79020069 Cap,Film 0.1MF J 50V

C821 79020020 Cap,Electrolytic 820MF M 16V

C823 79020019 Cap,Electrolytic 1200MF M 10V

C825 79020082 Cap,Electrolytic 1500MF M 10V

C826 79020002 Cap,Electrolytic 22MF M 100V

C828 79020077 Cap,Electrolytic 220MF M 25V

C829 79020022 Cap,Electrolytic 220MF M 10V

C830 79020001 Cap,Electrolytic 22MF M 16V

C831 79020043 Cap,Electrolytic 470MF M 16V

C832 79020035 Cap,Electrolytic 100MF M 10V

C833 79020043 Cap,Electrolytic 470MF M 16V

C834 79020043 Cap,Electrolytic 470MF M 16V

C835 79020007 Cap,Electrolytic 22MF M 50V

C836 79020007 Cap,Electrolytic 22MF M 50V

C837 79020021 Cap,Film 0.22MF J 50V

C840 79020064 Cap,Electrolytic 39MF M 50V

PART

NUMBER DESCRIPTION

LOCATION

NUMBER

!

!

!

!

!

!

!

!

!

!

PART

NUMBER DESCRIPTION

Page 27

LOCATION

X301 79089003 Oscillator SMD49,27MHz

X501 79080014 Oscillator SMD49,33.86MHz

X601 79080015 Oscillator CSACV20.00MX040

EU16 79086001 PC Board Assy Progressive

- INTEGRATED CIRCUITS -

ICV01 79040142 IC TC200E2650AF

ICV02 79040128 IC MSM51V8221A

ICV03 79040128 IC MSM51V8221A

ICV04 79040128 IC MSM51V8221A

ICV05 79040066 IC UPC29L33T

ICV06 79040139 IC ADV7172

- TRANSISTORS -

QV01 79050016 Transistor,Chip 2SC2712

QV02 79050016 Transistor,Chip 2SC2712

QV03 79050016 Transistor,Chip 2SC2712

- CAPACITORS -

CV01 79020062 Cap,Electrolytic 47MF M 16V

CV10 79020049 Cap,Electrolytic 10MF M 16V

CV12 79020062 Cap,Electrolytic 47MF M 16V

CV22 79020061 Cap,Electrolytic 100MF M 6.3V

CV31 79020049 Cap,Electrolytic 10MF M 16V

EU05 79085019 PC Board Assy Output

- INTEGRATED CIRCUITS -

ICX71 79040138 IC MC14577CFL1

ICX72 79040138 IC MC14577CFL1

ICY01 79040101 IC AD1855JRS

ICY02 79040102 IC NJM2370U05

ICY03 79040044 IC NJM4580E

ICY04 79040044 IC NJM4580E

ICY07 79040007 IC TC7S08F

ICY08 79040008 IC TC7S32F

ICY09 79040074 IC TC74HCU04AF

ICY10 79080019 Terminal,Optical GP1F32T

ICY11 79040130 IC NJU6321PE-TE1

ICY15 79040087 IC TC7W241FU

ICY17 79040087 IC TC7W241FU

ICY18 79040007 IC TC7S08F

ICY19 79040008 IC TC7S32F

ICY20 79040101 IC AD1855JRS

ICY21 79040044 IC NJM4580E

ICY22 79040087 IC TC7W241FU

ICY23 79040007 IC TC7S08F

ICY24 79040008 IC TC7S32F

ICY25 79040101 IC AD1855JRS

ICY26 79040044 IC NJM4580E

ICY27 79040013 IC TC7W74F

ICY28 79040102 IC NJM2370U05

ICY29 79040072 IC TC7S66F

ICY30 79040072 IC TC7S66F

ICY31 79040007 IC TC7S08F

ICY32 79040007 IC TC7S08F

ICY33 79040087 IC TC7W241FU

- TRANSISTORS -

QX01 79050022 Transistor,Chip HN1A01F-Y

QX02 79050022 Transistor,Chip HN1A01F-Y

QX03 79050022 Transistor,Chip HN1A01F-Y

QX04 79050022 Transistor,Chip HN1A01F-Y

QX05 79050022 Transistor,Chip HN1A01F-Y

QX08 79050015 Transistor,Chip HN1B01F

QX10 79050015 Transistor,Chip HN1B01F

QX12 79050015 Transistor,Chip HN1B01F

QX16 79050015 Transistor,Chip HN1B01F

QX18 79050015 Transistor,Chip HN1B01F

QX20 79050015 Transistor,Chip HN1B01F

QX22 79050032 Transistor,Chip IMX1

QX23 79050030 Transistor,Chip DTC143EKA

QX37 79050018 Transistor,Chip 2SA1162

QX39 79050016 Transistor,Chip 2SC2712

QX42 79050018 Transistor,Chip 2SA1162

QX44 79050016 Transistor,Chip 2SC2712

QX47 79050018 Transistor,Chip 2SA1162

QX49 79050016 Transistor,Chip 2SC2712

QY01 79050012 Transistor,Chip RN4601

QY02 79050014 Transistor,Chip HN1C03F

QY03 79050014 Transistor,Chip HN1C03F

QY05 79050030 Transistor,Chip DTC143EKA

QY06 79050014 Transistor,Chip HN1C03F

QY07 79050014 Transistor,Chip HN1C03F

QY08 79050014 Transistor,Chip HN1C03F

QY09 79050012 Transistor,Chip RN4601

4-7

NUMBER

- MISCELLANEOUS -

JU01 79089009 Jack,HP

VRU01 79030049 Res,Variable

EU01 79083006 PC Board Assy Main

- INTEGRATED CIRCUITS -

IC201 79040110 IC TC90A41AF

IC202 79040061 IC UPD424800LE70

IC202 79040145 IC NN514800AJ-60T

IC203 79040066 IC UPC29L33T

IC204 79040008 IC TC7S32F

IC205 79040008 IC TC7S32F

IC301 79040122 IC MD36710X

IC302 79040063 IC HY57V16160ATC-10

IC305 79040063 IC HY57V16160ATC-10

IC307 79040130 IC NJU6321PE-TE1

IC308 79040011 IC TC7W04F

IC309 79040123 IC TC203G8AF-0101(Z)

IC310 79040128 IC MSM51V8221A

IC311 79040013 IC TC7W74F

IC312 79040119 IC TC7SH86F

IC313 79040119 IC TC7SH86F

IC314 79040119 IC TC7SH86F

IC501 79040114 IC TA1254AF

IC503 79040109 IC TC9461F

IC504 79040006 IC TC7S04F

IC505 79040136 IC BA5917FP-E2

IC506 79040029 IC TC74HC4053AF

IC507 79040039 IC NJM3403AMC

IC508 79040072 IC TC7S66F

IC509 79040129 IC RT2124AFS-T

IC510 79040040 IC BA6844FP

IC512 79040006 IC TC7S04F

IC516 79040006 IC TC7S04F

IC517 79040014 IC TA75S01F

IC518 79040050 IC NJM2107F

IC519 79040009 IC TC7S86F

IC520 79040008 IC TC7S32F

IC521 79040009 IC TC7S86F

IC522 79040011 IC TC7W04F

IC523 79040013 IC TC7W74F

IC524 79040013 IC TC7W74F

IC525 79040121 IC AD8561AR

IC526 79040050 IC NJM2107F

IC527 79040131 IC TC74HC4066AFT

IC528 79040126 IC BU6481KV

IC529 79040125 IC TC7W66FU

IC530 79040072 IC TC7S66F

IC601 79040143 IC TMP93CS42AF-9417

IC602 79040041 IC PST591-IDT

IC603 79040027 IC TC74HC32AF

IC604 79040030 IC TC74AC573F

IC605 79040124 IC TC74HC08AF

IC607 79040007 IC TC7S08F

IC608 79040006 IC TC7S04F

IC609 79040030 IC TC74AC573F

IC613 79040135 IC 24C04AFJA

IC614 79040144 IC W26010AT-15

IC615 79040127 IC LH28F800SGE-70

IC616 79040007 IC TC7S08F

IC617 79040087 IC TC7W241FU

IC902 79040066 IC UPC29L33T

IC904 79040108 IC TC7SET08F

IC906 79040087 IC TC7W241FU

IC907 79040087 IC TC7W241FU

- TRANSISTORS -

Q501 79050019 Transistor,Chip 2SA1182

Q502 79050010 Transistor,Chip RN1411

Q503 79050015 Transistor,Chip HN1B01F

Q504 79050032 Transistor,Chip IMX1

Q505 79050030 Transistor,Chip DTC143EKA

Q506 79050015 Transistor,Chip HN1B01F

Q507 79050037 Transistor,Chip 2SC4944-GR

Q508 79050036 Transistor,Chip 2SA1832-GR

Q511 79050010 Transistor,Chip RN1411

Q512 79050010 Transistor,Chip RN1411

Q601 79050031 Transistor,Chip DTA114EKA

- DIODES -

D501 79060018 Diode,Chip 1SS193

D502 79060018 Diode,Chip 1SS193

D503 79060018 Diode,Chip 1SS193

- MISCELLANEOUS -

PART

NUMBER DESCRIPTION

LOCATION

NUMBER

PART

NUMBER DESCRIPTION

Page 28

LOCATION

CY63 79020089 Cap,Film 220pF J 100V

CY64 79020085 Cap,Electrolytic 100MF M 10V

CY65 79020085 Cap,Electrolytic 100MF M 10V

CY66 79020086 Cap,Electrolytic 220MF M 16V

CY67 79020086 Cap,Electrolytic 220MF M 16V

CY72 79020083 Cap,Electrolytic 10MF M 50V

CY75 79020085 Cap,Electrolytic 100MF M 10V

CY76 79020086 Cap,Electrolytic 220MF M 16V

CY77 79020086 Cap,Electrolytic 220MF M 16V

CY78 79020086 Cap,Electrolytic 220MF M 16V

CY79 79020086 Cap,Electrolytic 220MF M 16V

CY80 79020090 Cap,Film 1000pF J 100V

CY81 79020090 Cap,Film 1000pF J 100V

CY82 79020089 Cap,Film 220pF J 100V

CY83 79020090 Cap,Film 1000pF J 100V

CY84 79020090 Cap,Film 1000pF J 100V

CY85 79020089 Cap,Film 220pF J 100V

CY86 79020086 Cap,Electrolytic 220MF M 16V

CY87 79020086 Cap,Electrolytic 220MF M 16V

CY88 79020089 Cap,Film 220pF J 100V

CY89 79020089 Cap,Film 220pF J 100V

CY90 79020085 Cap,Electrolytic 100MF M 10V

CY91 79020085 Cap,Electrolytic 100MF M 10V

CY92 79020091 Cap,Film 4700pF J 63V

CY93 79020091 Cap,Film 4700pF J 63V

CY94 79020091 Cap,Film 4700pF J 63V

CY95 79020091 Cap,Film 4700pF J 63V

CY96 79020091 Cap,Film 4700pF J 63V

CY97 79020091 Cap,Film 4700pF J 63V

CY98 79020091 Cap,Film 4700pF J 63V

CY99 79020091 Cap,Film 4700pF J 63V

- MISCELLANEOUS -

FLX01 79010008 Coil TH286LAIS15674

FLX02 79010008 Coil TH286LAIS15674

FLX03 79010008 Coil TH286LAIS15674

FLX04 79010008 Coil TH286LAIS15674

FLX05 79010008 Coil TH286LAIS15674

FLX06 79010016 Filter H287LDKS-15818

FLX07 79010016 Filter H287LDKS-15818

FLX08 79010016 Filter H287LDKS-15818

JX01 79089004 Plate,Jack Video

JX02 79089013 Plate,Jack Component

JY01 79089006 Plate,Jack Audio

JY02 79089007 Plate,Jack Digital Audio

SY01 79080018 Relay EG2-9

XY02 79089008 Crystal HC49/U24.576MHz

4-8

NUMBER

QY10 79050014 Transistor,Chip HN1C03F

QY11 79050014 Transistor,Chip HN1C03F

QY12 79050012 Transistor,Chip RN4601

QY13 79050014 Transistor,Chip HN1C03F

QY14 79050030 Transistor,Chip DTC143EKA

QY15 79050001 Transistor,Chip RN2402

QY16 79050001 Transistor,Chip RN2402

QY17 79050001 Transistor,Chip RN2402

QY18 79050012 Transistor,Chip RN4601

QY19 79050001 Transistor,Chip RN2402

QY20 79050001 Transistor,Chip RN2402

QY21 79050001 Transistor,Chip RN2402

QY22 79050001 Transistor,Chip RN2402

QY23 79050001 Transistor,Chip RN2402

QY24 79050001 Transistor,Chip RN2402

QY25 79050001 Transistor,Chip RN2402

QY26 79050001 Transistor,Chip RN2402

QY27 79050001 Transistor,Chip RN2402

QY28 79050014 Transistor,Chip HN1C03F

QY29 79050014 Transistor,Chip HN1C03F

QY30 79050014 Transistor,Chip HN1C03F

- DIODES -

DY01 79060022 Diode,Chip 1SS368

DY02 79060022 Diode,Chip 1SS368

DY03 79060026 Diode UDZS10B

DY04 79060022 Diode,Chip 1SS368

DY05 79060022 Diode,Chip 1SS368

- CAPACITORS -

CW05 79020083 Cap,Electrolytic 10MF M 50V

CW06 79020083 Cap,Electrolytic 10MF M 50V

CW09 79020095 Cap,Electrolytic 1000MF M 25V

CW10 79020086 Cap,Electrolytic 220MF M 16V

CW11 79020086 Cap,Electrolytic 220MF M 16V

CW12 79020086 Cap,Electrolytic 220MF M 16V

CW13 79020086 Cap,Electrolytic 220MF M 16V

CX01 79020039 Cap,Electrolytic 47MF M 10V

CX17 79020088 Cap,Electrolytic 1000MF M 10V

CX20 79020088 Cap,Electrolytic 1000MF M 10V

CX21 79020088 Cap,Electrolytic 1000MF M 10V

CX22 79020033 Cap,Electrolytic 470MF M 6.3V

CX23 79020033 Cap,Electrolytic 470MF M 6.3V

CX37 79020039 Cap,Electrolytic 47MF M 10V

CX38 79020035 Cap,Electrolytic 100MF M 10V

CX40 79020033 Cap,Electrolytic 470MF M 6.3V

CX42 79020039 Cap,Electrolytic 47MF M 10V

CX43 79020039 Cap,Electrolytic 47MF M 10V

CX46 79020033 Cap,Electrolytic 470MF M 6.3V

CX49 79020039 Cap,Electrolytic 47MF M 10V

CX52 79020033 Cap,Electrolytic 470MF M 6.3V

CX53 79020039 Cap,Electrolytic 47MF M 10V

CY10 79020086 Cap,Electrolytic 220MF M 16V

CY11 79020086 Cap,Electrolytic 220MF M 16V

CY12 79020086 Cap,Electrolytic 220MF M 16V

CY13 79020086 Cap,Electrolytic 220MF M 16V

CY14 79020090 Cap,Film 1000pF J 100V

CY15 79020090 Cap,Film 1000pF J 100V

CY16 79020089 Cap,Film 220pF J 100V

CY17 79020086 Cap,Electrolytic 220MF M 16V

CY18 79020090 Cap,Film 1000pF J 100V

CY19 79020090 Cap,Film 1000pF J 100V

CY20 79020089 Cap,Film 220pF J 100V

CY21 79020086 Cap,Electrolytic 220MF M 16V

CY22 79020089 Cap,Film 220pF J 100V

CY23 79020089 Cap,Film 220pF J 100V

CY25 79020085 Cap,Electrolytic 100MF M 10V

CY26 79020085 Cap,Electrolytic 100MF M 10V

CY29 79020084 Cap,Electrolytic 47MF M 25V

CY42 79020085 Cap,Electrolytic 100MF M 10V

CY43 79020085 Cap,Electrolytic 100MF M 10V

CY49 79020085 Cap,Electrolytic 100MF M 10V

CY50 79020083 Cap,Electrolytic 10MF M 50V

CY52 79020086 Cap,Electrolytic 220MF M 16V

CY53 79020086 Cap,Electrolytic 220MF M 16V

CY54 79020086 Cap,Electrolytic 220MF M 16V

CY55 79020086 Cap,Electrolytic 220MF M 16V

CY56 79020090 Cap,Film 1000pF J 100V

CY57 79020090 Cap,Film 1000pF J 100V

CY58 79020089 Cap,Film 220pF J 100V

CY59 79020090 Cap,Film 1000pF J 100V

CY60 79020090 Cap,Film 1000pF J 100V

CY61 79020089 Cap,Film 220pF J 100V

CY62 79020089 Cap,Film 220pF J 100V

PART

NUMBER DESCRIPTION

LOCATION

NUMBER

PART

NUMBER DESCRIPTION

Page 29

SPECIFICATIONS

DVD Video Player/Outputs/Supplied Accessories

[DVD Video Player]

Power supply 120V AC, 60 Hz

Power consumption 25W

Mass 7.0 kg

External dimensions 430 x 96 x 300 mm (W/H/D)

Signal system Standard NTSC

Laser Semiconductor laser, wavelength 650 nm

Frequency range DVD linear sound : 48kHz sampling 4 Hz to 22 kHz

96kHz sampling 4 Hz to 44 kHz

Audio CD : 4Hz to 20 kHz

Signal-to-noise ratio More than 112 dB

Audio dynamic range More than 112 dB

Harmonic distortion Less than 0.001%

Wow and flutter Below measurable level (less than ± 0.001% (W. PEAK))

Operating conditions Temperature: 5 °C to 35 °C, Operation status: Horizontal

[Outputs]

Video output 1.0 V (p-p), 75 Ω, negative sync., pin jack x 1

S video output (Y) 1.0 V (p-p), 75 Ω, negative sync., Mini DIN 4-pin x 1

(C) 0.286 V (p-p), 75 Ω

Color difference output (interlaced)

Color difference output (progressive)

Audio output (optical) Optical connector x 1

Audio output (coaxial) 0.5 V (p-p), 75 Ω, pin jack x 1

Audio output (mixed out) 2.0 V (rms), 220 Ω, pin jacks (L, R) x 1

Audio output (5.1ch surround) 2.0 V (rms), 220 Ω, pin jacks x 6

Headphone terminal 32 Ω (10 mW), impedance; more than 8 Ω

(Y) 1.0 V (p-p), 75Ω, negative sync., pin jack x 1

(Cb)/(Cr) 0.7 V (p-p), 75 Ω, pin jack x 2

(Y) 1.0 V (p-p), 75Ω, negative sync., pin jack x 1

(Cb,Pb)/(Cr,Pr) 0.7 V (p-p), 75 Ω, pin jack x 2

[Supplied Accessories]

S video cable.................................................................. 1

Audio /video cable .......................................................... 1

Remote control (SE-R0002) ........................................... 1

Batteries (AA)................................................................. 2

* Designs and specifications are subject to change without notice.

Page 30

Loading...

Loading...