Toshiba nv Series, SA9A1 Instruction Manual

Unified Controller

6F8C1511

nv

Series

type2 SOE Function

Instruction Manual

Notes

(1)The technical information provided herein describes typical operations and applications of the product and does not

guarantee the intellectual property rights or other rights of Toshiba or third parties nor allows license of its use.

(2)No part or the whole of this document may be reproduced without prior consent.

(3)The information herein may be changed in the future without notice.

(4)All possible measures have been taken to prepare the information herein. If you have any question, comment, or find

any error, please contact us.

PROSEC, TOSLINE, TOSDIC, CIEMAC are trademarks or registered trademarks of Toshiba Corporation.

Microsoft, Windows are registered trademarks of Microsoft Corporation in the U.S. and other countries.

IBM is a registered trademark of International Business Machines Corporation.

Device Net is a registered trademark of Open DeviceNet Vendor Association Inc.

Safety Precautions

On the product and this instruction manual, important information for safe and correct use to

prevent danger to the user and other people as well as property damage is described.

Understand the following information (signs and symbols) before reading the text, and follow

the described items

Description of signs

Sign Description

DANGER

WARNING

CAUTION

*1: A serious injury indicates loss of sight, injury, burns (high/low temperature), electric shock,

broken bones, or intoxication that will have aftereffects and require hospitalization or long-term

hospital visits for healing.

*2: An injury indicates an injury, burn, or electric shock that does not need hospitalization or

long-term hospital visits for healing.

*3: A property damage indicates consequential damage in terms of breakage of properties or

materials.

Indicates that failure to avoid it will result in an immediate risk of death or

serious injury(*1).

Indicates that failure to avoid it will result in a risk of death or serious

injury(*1).

Indicates that failure to avoid it will result in a risk of light or medium

injury(*2) or only property damage(*3).

Description of symbols

Symbol Meaning

Prohibited

Mandatory

Warning

(Note) Descriptions of Prohibition, Mandatory Action, and Warning vary depending on the display on the

main unit.

Indicates “Prohibition” or “You must not do”.

Specific details are indicated near the symbol

Indicates “Mandatory Action” or “Do as indicated”.

Specific details are indicated near the symbol

Indicates Warning.

Specific details Specific details are indicated near the symbol

pictures and text.

with pictures and text.

with pictures and text.

with

Unified Controller nv series type2 SOE Function Instruction Manual

i

1. Safety Precautions on Installation

WARNING

Ground

Prohibited

Mandatory

Prohibited

Mandatory

Ground the device.

Otherwise, it may cause an electric shock

or fire.

Do not install, store, or use it in

the following environments.

・ A place with a lot of dust

・ A place with corrosive gases (SO

or flammable gases

・ A place with vibrations and shocks

exceeding the allowed values

・ A place with condensations due to rapid

temperature changes

・ A place with low or high temperature

outside of the installation condition

・ A place with high humidity outside of the

installation condition

・ A place with direct sunlight

・ A place near equipment generating

strong radio waves or magnetic fields

It may cause accidents.

Install the device in a place

where maintenance and

inspection can be done easily.

Otherwise, it may cause accidents.

Do not block the ventilation hole

or air inlet/outlet.

It may cause fire or failure due to overheat.

For installation and wiring of the

system, observe the installation

conditions and methods

described in this document.

CAUTION

, H2S)

2

Prohibited

Mandatory

Mandatory

Mandatory

Do not insert any foreign object

such as wasted lines into the

module or unit.

It may cause fire, failure, or malfunction.

Install the power module,

controller module, and I/O

module to the dedicated base

unit.

Otherwise, it may cause an electric shock,

injury, or failure.

Do not use it alone or for other purposes.

Install or remove the module,

base unit, and terminal block

while the power is off.

Otherwise, it may cause an electric shock,

malfunction, or failure.

When connecting the

connectors and cables or

installing the module to the base

unit, press them fully until they

clicks, and secure them with

screws tightly.

Insufficient tightening may cause failure or

malfunction due to vibrations.

ii

Otherwise, it may cause a fall, fire, failure,

or malfunction.

6F8C1511

2. Safety Precautions on Wiring

WARNING

Mandatory

Mandatory

Mandatory

Mandatory

Mandatory

Mandatory

Connect the cables while the

power is off.

Otherwise, it may cause an electric shock

or failure.

When wiring the module, use

crimp contacts with sheath, or

cover it with tape.

Otherwise, exposed conductors may

cause an electric shock.

Connect an external power

supply that matches the rating.

Otherwise, it may cause an explosion or

fire.

Wiring work must be done by

qualified experts.

Wrong wiring may cause a fire, electric

shock, or failure.

Install a fuse that matches the

current capacity to the external

circuit for overload protection of

the relay output module.

Otherwise, a load short-circuit may cause

an accident or damage to the machine.

When using the contact relay

used for relay output, check the

contact life.

If the contact life of the relay is expired, an

output error may occur due to a defective

contact, resulting in an accident or damage

to the machine.

Contact relays have a life due to wearing

of the contact. If the life is expired,

replace it with a new one.

Mandatory

CAUTION

Mandatory

Mandatory

Mandatory

Install the terminal block cover

securely to the terminal block.

Exposed conducting parts may cause an

electric shock.

Observe the tightening torque.

If it is too loose, it may come off.

If the tightening torque is out of specified

range, it may be broken off.

M3.5 screw: 0.8 to 1.2 N・m

M3 screw: 0.5 to 0.75 N・m

Install the battery before use.

If the RAM is operated without any battery,

memory data or programs may be lost,

causing an accident or damage to the

machine due to malfunction.

Replace the battery according to the

battery replacement cycle guideline.

Turn on the power in the

following order:

Turn on the power of the nv series, and

then turn on the I/O module supply

external power and external load

power.

If this order is not followed, it may cause

an accident or damage to the machine due

to malfunction.

Unified Controller nv series type2 SOE Function Instruction Manual

iii

Mandatory

For system safety, turn off the

load power before the power of

the nv series.

If this order is not followed, it may cause

an accident or damage to the machine.

Share the external power supply for the I/O

module with the load power supply

whenever possible. If this is not possible,

construct the system so that the external

power supply and load power supply are

turned off simultaneously.

Mandatory

Construct the emergency stop

circuit and interlock circuit

outside the nv series.

Otherwise, it may cause an injury accident

or damage to the machine if failure or

malfunction occurs in the nv series.

iv

6F8C1511

3. Safety Precautions on Daily Use

WARNING

No touch

Prohibited

Mandatory

Do not touch the terminals of

the module and unit during

energization.

It may cause an electric shock.

Do not modify, repair,

disassemble, or adjust the

device, module, or board.

It may cause an electric shock, fire, injury,

or failure.

Upon faulty operation or failure, contact

one of Toshiba's branch offices or service

agencies.

Before using, check that the

power capacity, frequency,

voltage, and regulation comply

with the device specifications.

If not, it may cause damage of the device,

or fire due to overheat, as well as not

obtaining the original performance of the

device.

Mandatory

Prohibited

When there is any smoke or

strange odor, turn off the power.

Otherwise, it may cause a fire or electric

shock.

Contact one of Toshiba's branch offices or

service agencies.

When the ambient or internal

temperature of the device rises

abnormally or failure occurs in

the device, do not use the

device.

Using it as it is may cause fire due to

overheat.

Turn off the power, and contact one of

Toshiba's service representatives.

Mandatory

Prohibited

When performing program

changes during operation,

forced output, run, or halt

operations, ensure safety.

Wrong operations or failure to ensure

safety may cause an accident or damage

to the machine.

Do not forcefully bend, pull, or

twist the power cord and cables.

It may cause breaks or heating.

CAUTION

No touch

Prohibited

Do not touch the card parts,

contacts, connectors, or

soldered surface in the module.

Ends of the lead wire of the parts may

cause an injury, or electrostatic breakdown

of the ICs or LSIs may occur, resulting in

failure.

Do not insert any metal into the

gaps of the device main body.

It may cause fire.

Unified Controller nv series type2 SOE Function Instruction Manual

v

4. Safety Precautions on Maintenance and Inspection

When replacing the power fuse

or alarm fuse of the device, turn

off the device.

Otherwise, it may cause an electric shock

or fire.

Replace fuses or batteries with

specified items.

Using anything other than specified may

cause a fire or failure.

Be extremely careful when

measuring the power supply

voltage at the power terminal

part of the module during an

inspection.

Mandatory

Prohibited

When installing or removing the

module, unit, terminal block, or

wiring cable, make sure that the

external power supply is off.

Otherwise, there will be live electric poles

on the back of the external terminal block

of the module, causing an electric shock.

Do not connect the battery in

reverse, charge, disassemble,

overheat it, throw it into fire, or

short-circuit it.

It may cause an explosion or fire.

WARNING

Mandatory

Mandatory

Mandatory

Mandatory

Mandatory

Prohibited

Replace the battery every 5

years.

If the battery is worn, the data or programs

saved in the controller module may be lost,

causing an accident or damage to the

machine due to malfunction.

Replace the shutdown capacitor

every 8 years.

If the shutdown capacitor is worn, the data

or programs saved in the controller module

may be lost, causing an accident or

damage to the machine due to

malfunction.

Do not drop, crush, or apply

strong shocks to the device,

module, or board.

Otherwise it will cause failure.

CAUTION

Mandatory

Prohibited

Otherwise, it may cause an electric shock.

Replace the battery for the

controller module every 4 years

(confirmation required) if the

annual average temperature is

30C or less, or every 2 years

(confirmation required) if it is

above 30C.

If the battery is worn, the data or programs

saved in the controller module may be lost

depending on the application, causing an

accident or damage to the machine due to

malfunction.

When replacing the module, do

not install the different type.

Otherwise, it may cause an accident or

damage to the machine due to

malfunction.

vi

6F8C1511

Mandatory

Mandatory

Before touching the device,

module, or board, touch a

grounded metal to discharge the

static electricity of your body.

Otherwise, it may cause malfunction or

failure due to static electricity.

Wipe off stain on the device,

module, or board with a soft

cloth.

For severe stain, use a wet cloth wrung

tightly.

Leaving them stained may cause wrong

decision or malfunction.

Mandatory

Prohibited

Place a board or module

removed from the unit or base

unit on a conductive mat or

conductive bag (used for a

backup board) on a grounded

table.

Otherwise, parts may be damaged due to

static electricity.

Do not use benzene or thinner

to remove stain on device,

module, or board.

It may cause deformation or discoloration

of the device panel, module, or board.

Unified Controller nv series type2 SOE Function Instruction Manual

vii

5. Safety Precautions on Transportation, Storage, and Disposal

Prohibited

Do not throw the lithium battery

into a fire.

The battery may explode.

WARNING

Mandatory

When dispose the product, it

treats as industrial waste and

follows the ordinances and

rules.

Otherwise, it may cause environmental

damage.

CAUTION

Mandatory

For transportation and storage

of the product, use a conductive

bag and packaging box.

Otherwise it will cause failure.

viii

6F8C1511

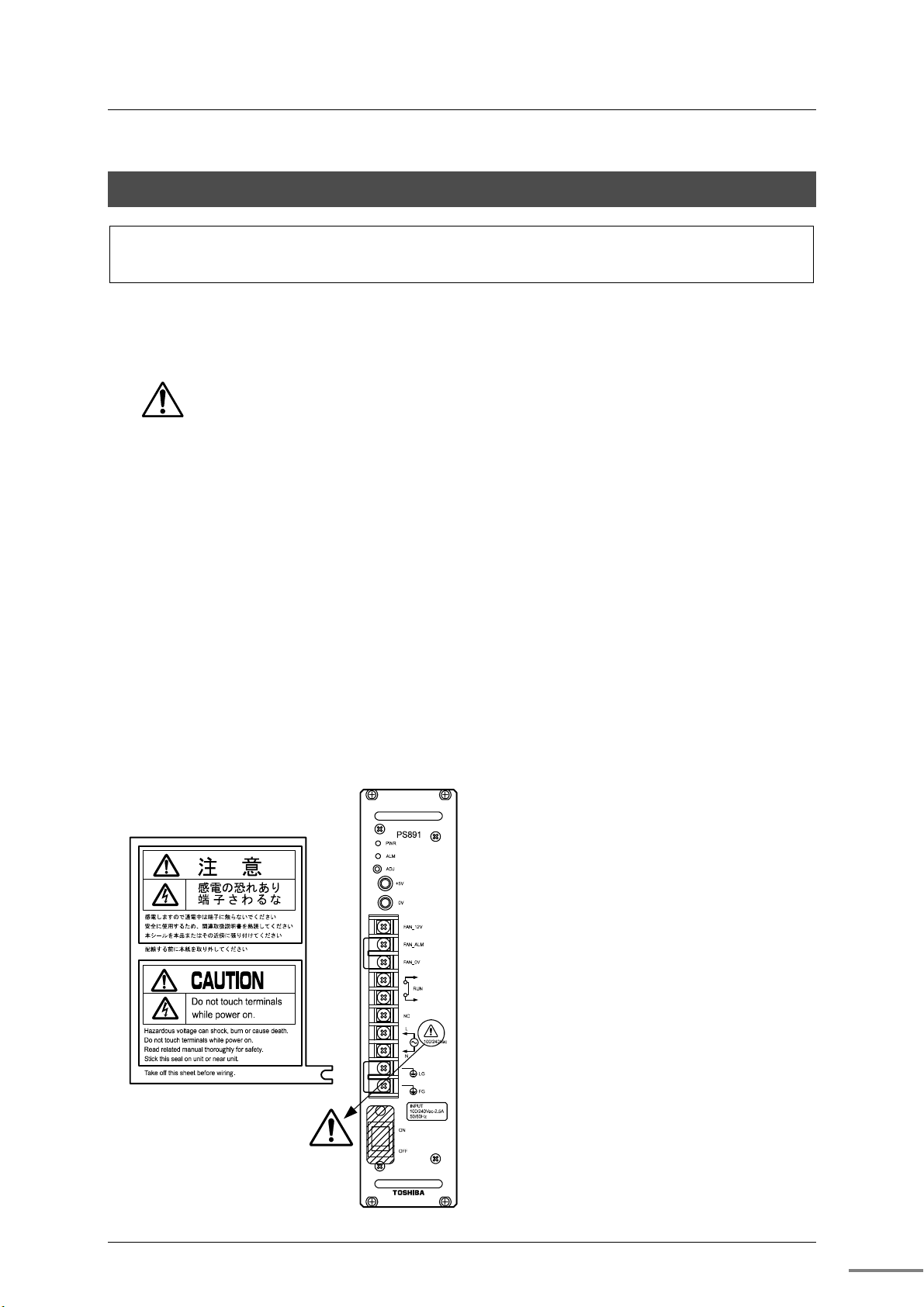

6. Checking the Warning Label on the Main Body

Check that warning label is attached on the main body.

If the label is missing or hard to read due to stain, contact our service department.

[Warning symbols on the nv series main body]

This symbol is a warning symbol for dangerous parts. It is attached on places

where there is a risk of an electric shock or a risk of damage to the main body due

to wrong wiring.

Note the following where this symbol is present.

● Touching the power input terminal of the power supply module while the power is on

causes an electric shock and is very dangerous.

Do not touch the power input terminal.

● For safety, turn off the power before wiring or performing maintenance and inspection.

● Wire the power input terminal correctly, and avoid applying any voltage exceeding the

specified voltage range. It may cause failure or damage.

● Perform connector connection of the nV-Tool port after turning off the power of the

nV-Tool (such as the PC).

Turn on the power of the nV-Tool after connection.

Be careful not to short-circuit the connector pins with the connector cover.

[Warning stickers]

The warning sticker as shown in the left

figure is attached to the power terminal of

the nv series (except for power supplies

below 24V).

Remove the sticker from the mount, and

attach it on the main body of the nv series,

or on a location near the nv series where it

can be seen easily.

There are stickers in both Japanese and

English. Use the one that suits your need.

When wiring, remove the sticker mount.

If the sticker is damaged, contact your

distributor.

Unified Controller nv series type2 SOE Function Instruction Manual

ix

Restrictions on Application

■

This product is not developed/manufactured for use in systems involving devices that

directly affect human life (Note 1). Do not use them for such applications.

■ To use this product for systems that involve devices that significantly affect human safety or

maintenance of public functions (Note 2), special considerations (Note 3) are required in

system operation, maintenance, and management. In this case, contact one of Toshiba's

sales representatives.

(Note 1) Devices that directly affect human life include the following.

Medical devices such as life supporting devices and devices for surgical units.

(Note 2) Systems that involve devices that significantly affect human safety or

maintenance of public functions include the following.

Main unit control systems of nuclear power plants, safety protection systems of

nuclear facilities, and other systems that are critical for safety

Operation control systems of mass transportation systems and air traffic control

systems

(Note 3) Special considerations indicate sufficient discussions with Toshiba's engineers to

construct a safe system (e.g. employing fool-proof design, fail-safe design, or

redundant design).

Disclaimer

Toshiba shall not be responsible for any damage caused by an earthquake, lightning and

■

wind, fire for which Toshiba is not responsible for, acts of a third party, other accidents, the

user's willful acts or negligence, misuse, or use in abnormal conditions.

■ Toshiba shall not be responsible for any incidental damage (loss of business profits,

interruption of business, change or loss of stored memory) caused by use of or unable to

use of this product.

■ Toshiba shall not be responsible for any damage caused by failure to observe the

information described in the operation manual.

■ Toshiba shall not be responsible for any damage caused by malfunctions due to combination

with any connected device.

■ Toshiba shall not be responsible for any damage caused by malfunctions due to combination

with any application program created by the customer.

6F8C1511

x

Precautions on Usage

Installation

●

Use your cellular phone or PHS one meter or more away from the product main unit in

operation, various transmission cables, and I/O cable. Otherwise, the system may cause

malfunction.

When connecting the connectors and cables or installing the module to the base unit,

secure them with screws tightly.

Insufficient tightening may cause failure or malfunction due to vibrations.

Power wiring

●

Keep the cables from other lines as much as possible. Especially, keep them away by

200mm or more from power lines.

The terminal screw size is M3.5. As applicable crimp contacts, use the one for 3.5M

screws whose width is 7mm or less.

Do not connect anything to the NC part.

Use of sample programs

●

Use the sample programs described in the operation manual after performing an operation

check.

Make sure to perform an operation check before actual operation to avoid an accident due

to malfunction.

Do not drop, bump, or apply strong shocks to the device or module. It may cause failure.

Battery replacement

●

Battery replacement can be done while the unit is energized or not energized. When

replacing the battery while the unit is not energized, complete the replacement within 3

minutes. If the unit is left without a battery for a long time, the content of the RAM

memory may be lost.

The Battery Normal LED (BAT) may illuminate during battery replacement. This is not an

error.

If the voltage decreases with the battery installed, the state will be detected normally and

the LED goes off.

The battery voltage is not compatible with manganese batteries or alkaline batteries. Do

not mix them.

Do not use a battery when 3 years or more have passed since the production date.

Maintenance

●

Place a module removed from the unit on a conductive mat or conductive bag (used for a

backup board) on a grounded table.

Otherwise, parts may be damaged due to static electricity.

Before touching the device or module, touch a grounded metal to discharge the static

electricity of your body. Otherwise, it may cause malfunction or failure due to static

electricity.

Wipe off stain on the device or module with a soft cloth.

For severe stain, use a wet cloth wrung tightly.

Leaving them stained may cause wrong decision or malfunction.

Do not use benzene or thinner to remove stain on device or module.

It may cause deformation or discoloration of the device panel or module.

To keep the system normal and avoid unnecessary troubles, perform daily inspections,

regular inspections, and cleaning.

Unified Controller nv series type2 SOE Function Instruction Manual

xi

Observe the following

●

To assure safety of the operator and normal operation of the device when the device is used,

observe the following.

1. Before installation, operation, maintenance, or inspection, read this operation manual

and all the related manuals thoroughly to obtain device information, safety information,

and other considerations. Use the device after reading the operation manual

thoroughly.

2. Do not install or store it in the following environments.

(1) A place with a lot of dust

(2) A place with corrosive gases (SO

(3) A place with vibrations and shocks

(4) A place with low or high temperature outside of the installation condition described in

this manual

(5) A place with high humidity

3. When the ambient or internal temperature of the device rises abnormally or failure occurs

in the device, stop using the device, turn off the power, and contact one of Toshiba's

service representatives.

4. Do not open the case of the device during operation for any purpose other than switch

setting.

5. Do not modify the device.

6. Be careful not to drop the product during transportation.

7. The device is intended for people with general knowledge on handling of control devices

in terms of installation, wiring, usage, and maintenance. Wrong handling may cause an

electric shock, fire, failure, or malfunction. Those who have insufficient knowledge on

handling of control devices or electric devices should avoid performing installation, wiring,

usage, and maintenance, and delegate the task to someone with expertise.

, H2S)

2

xii

8. This document and related materials are intended for people with general knowledge on

handling of control devices.

If you have any question, please do not hesitate to ask us.

6F8C1511

Introduction

This manual describes the functions, methods of installation and setting, and maintenance and

inspection of the sequence of event function ("SOE function" hereafter) and the high-speed

serial I/O adapter module ("SA9A1 module" hereafter) in the Unified Controller nv series type2.

To use the devices correctly and safely, read "Safety Precautions" before use. After reading

this manual, keep it in a safe place so that you can read it whenever necessary.

Repairs and replacements due to depletion or wear are offered at cost even within the warranty

period of this product.

The manuals related to the SOE function and the SA9A1 module are as follows.

Unified Controller nv series Controller Unit Instruction Manual (6F8C1220)

Describes the overview, installation and operation methods, and maintenance/inspection

of Unified Controller nv series type1 and type2 Controller Units.

Unified Controller nv series type2 Functional Manual (6F8C1362)

Describes the functions and use of type2 and information necessary to create user

programs.

Unified Controller nv series / Integrated Controller V series Programing Instructions

(LD/FBD/SFC/ST) (6F8C1226)

Describes the detailed specifications of the instruction words of the program languages

(LD, FBD, SFC and ST) supported by the nv series and V series.

Unified Controller nv series / Integrated Controller V series Engineering Tool 4 Operation

Manual -Basic- (6F8C1290)

Describes how to create, debug, print, and save programs using nV-Tool.

Unified Controller nv series / Integrated Controller V series Engineering Tool 4 Operation

Manual -Setup- (6F8C1291)

Describes how to set up nV-Tool.

Unified Controller nv series time service module TS811 Instruction Manual (6F8C1514)

Describes the functions, methods of installation and setting, and maintenance and

inspection of time service module TS811.

The figures and diagrams in the description are provided to help the reader to understand

better. They may not be same as the actual products. Note that modifications of the product

may be made without any prior notice for the improvement of the performance and functionality.

Unified Controller nv series type2 SOE Function Instruction Manual

xiii

Notational conventions

●

The following are the notational conventions for better understanding of this document.

Important

Note

Remark

Reading this document

●

This document consists of the following chapters.

Chapter 1 Introducing the SA9A1 module

Describes functions and characteristics of the SA9A1 module, and names

Describes what the user should be particularly aware of to handle the product

correctly.

Describes what the user should observe to handle the product correctly.

Describes a remark.

and functions of the parts.

Chapter 2 Installation and wiring

Describes how to install and wire the TC-net I/O base unit and the SA9A1

module.

Chapter 3 Setting

Describes how to set the switches and parameters to use the module

correctly.

Chapter 4 Startup/Shutdown and Operation

Describes the startup and shutdown method of a SOE functional system and

the operations of the SOE Information Screen.

Chapter 5 Troubleshooting

Describes troubleshooting such as what to do when failure occurs.

Chapter 6 Maintenance and inspection

Describes details and methods of daily inspection and periodical inspection,

and maintenance parts and life limited parts.

Chapter 7 Application interface

xiv

Describes usage constraints of the user application, and the examples of the

diagnostic functions.

6F8C1511

CONTENTS

Chapter 1

Introducing the

SA9A1 Module

…1

Chapter 2

Installation and

Wiring

…9

Chapter 3

Setting

…21

Chapter 4

Startup/Shutdown

and Operation

…43

1.1 Functions and Characteristics of the SA9A1 Module ··· 2

1.2 Names and Functions of the Parts

2.1 Types of I/O Base Units ············································· 12

2.2 Installing the Module

2.3 Connecting the TC-net I/O Loop Transmission Cable 18

2.4 Replacing the Module

2.5 Removing the Base Unit

3.1 Switch Setting of the SA9A1 ······································ 22

3.2 Setting with the Engineering Tool ······························ 24

3.3 SOE Guidance tag registration ·································· 33

3.4 Time service module TS811

3.5 OIS-DS Engineering Tool ··········································· 39

4.1 Checking the Switch before Startup ·························· 44

4.2 Startup of the System

4.3 Shutdown of the System

4.4 Start SOE Information

4.5 Show SOE Information ·············································· 48

4.6 Switch Node

4.7 Update event run mode

4.8 SOE Restart

4.9 Save CSV file

4.10 Close SOE Information

······························· 5

1.2.1 Names of the parts ··············································· 5

1.2.2 Functions of the parts ············································ 6

················································· 13

2.2.1 Vertical Installing of the module ····························· 13

2.2.2 Horizontal Installing of the module ·························· 17

················································ 19

············································ 20

3.1.1 Loop address setting switch (STN-H, STN-L) ············ 22

3.1.2 Operation mode setting switch (MODE) ··················· 23

3.1.3 Maintenance switch (MAINT) ································ 23

3.2.1 Module parameter setting ····································· 25

······································· 36

3.4.1 TS811 function ··················································· 36

3.4.2 About leap second correction ································ 37

3.5.1 Event Condition ·················································· 39

3.5.2 Program Menu ··················································· 40

3.5.3 Guidance ·························································· 41

················································ 44

··········································· 45

················································ 46

4.4.1 Start from Guidance ············································ 46

4.4.2 Start from TOSDIC-CIE DS OIS-DS Program ··········· 47

······························································ 50

············································· 51

······························································· 51

····························································· 52

·············································· 54

Unified Controller nv series type2 SOE Function Instruction Manual

xv

Chapter 5

Troubleshooting

…55

Chapter 6

Maintenance and

Inspection

…59

Chapter 7

Application

Interface

…65

6.1 Inspection ································································· 60

6.1.1 Daily inspection ·················································· 60

6.1.2 Periodical inspection ··········································· 62

6.2 Maintenance Parts ····················································· 63

6.3 Life Limited Parts

······················································ 63

7.1 Usage Constraints ····················································· 66

7.1.1 Combination with the other modules and

engineering tool ················································· 66

7.1.2 Implementation Constraints ·································· 66

7.2 About TS811 diagnostic ············································ 67

7.2.1 TS811 diagnostic function····································· 67

7.2.3 Sample program 1 ·············································· 67

7.2.4 Sample program 2 ·············································· 68

xvi

6F8C1511

Appendix A

Specifications

…69

Appendix B

Outside

Dimensions

…73

Appendix C

Related Products

…75

Appendix D

DecimalHexadecimal

Conversion Table

…77

Appendix E

Component

Module

…81

A.1 Common Specifications ············································ 70

A.2 SA9A1 Specifications

A.3 BU901 Specifications

A.4 24VDC System Power Supply Specifications

················································ 71

················································ 72

············· 72

Unified Controller nv series type2 SOE Function Instruction Manual

xvii

xviii

6F8C1511

Chapter 1 Introducing the SA9A1 Module

This chapter describes functions and characteristics of the SA9A1

module, and names and functions of the parts.

1.1 Functions and Characteristics of the SA9A1 Module

1.2 Names and Functions of the Parts

1.2.1 Names of the parts ·················································· 5

1.2.2 Functions of the parts ·············································· 6

································· 5

····· 2

1

Chapter 1 Introducing the SA9A1 Module

1.1 Functions and Characteristics of the SA9A1 Module

The SA9A1 module collects TC-net I/O event data in the Unified Controller nv

series type2.

The SA9A1 module connects to the Unified Controller nv Series type2 controller

module via high-speed serial TC-net I/O loop transmission, and to the I/O

module via high-speed serial TC-net I/O bus transmission.

Characteristics of the SA9A1 module

・ Relays the TC-net I/O loop and TC-net I/O bus transmission.

・ Allows high-speed data transfer because I/O data between TC-net I/O buses

is directly transferred between the dedicated transmission gate arrays.

・ Realizes highly reliable data transfer because a data check and error

correction of I/O data are performed with ECC.

・ Up to two units of SA9A1 can be installed to one base unit, allowing single or

redundant configuration.

・ Collection of event data

The engineering tool supervises change of the registered digital input data in

a cycle of 1ms. If change of the digital input data is detected, a time stamp is

attached and saved to data.

・ Collection of analog data

The analog input data can be obtained, if the analog input module is

registered into the engineering tool and change of the digital input data will be

detected.

・ Collection and Analysis of event data by OIS

The OIS collects and analyzes the event data which the SA9A1 saved.

Note

SA9A1 and other module cannot be installed on the same base unit each.

Since there are constraints in assignment, refer to 7.1 Usage Constraints.

2

6F8C1511

1.1 Functions and Characteristics of the SA9A1 Module

Specification outline of the SA9A1 module

Table 1-1 Specification outline of the SA9A1 module

Item SA9A1

Event object numbers Max. 240 objects

I/O module numbers Max. 16 modules

AI object points*1 Max. 8 points

Support modules DI936, DI934, DI944, AI919

Detection cycle 1ms

Time stamp Year/Month/Day/Hour/Minute/Second/ms

Connection numbers per a

controller*2

Event data numbers Max. 2048

*1 : The AI object point store information when change information of DI object point.

*2 : If one node of SA9A1 module is used, the connection number of other SA9**

modules will decrease by one node.

*3 : A node is one element which constitutes the network.

One unit per a node*3

Two units per a node*3 in case of duplex system

Unified Controller nv series type2 SOE Function Instruction Manual

3

Chapter 1 Introducing the SA9A1 Module

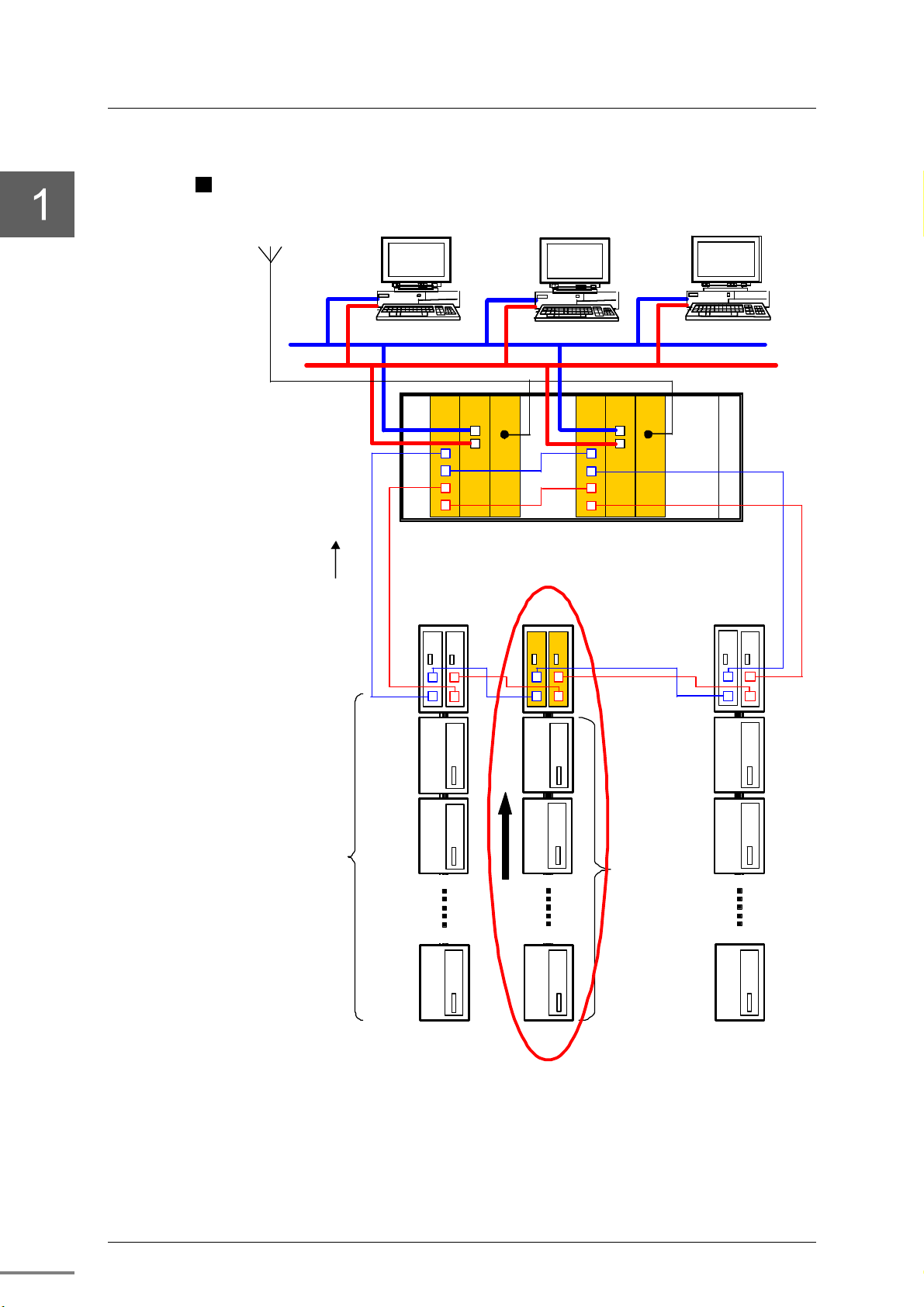

A

Example of system configuration

GPS antenna

Input data

Engineering tool

PU

821

SA

SA

911

911

OIS #1

Primary Secondary

FN

812

TS

811

SA

9A1

SA

9A1

PU

821

FN

812

OIS #2

Ethernet

TS

811

TC-net I/O loop

SA

911

SA

911

TC-net I/O

DO

934

DO

934

bus

DO

934

DO

934

936

936

DI

DI

DI module

or

I module

AO

928

AI

F

919

AO

928

Figure 1-1 Example of SOE function system configuration

F

4

6F8C1511

1.2 Names and Functions of the Parts

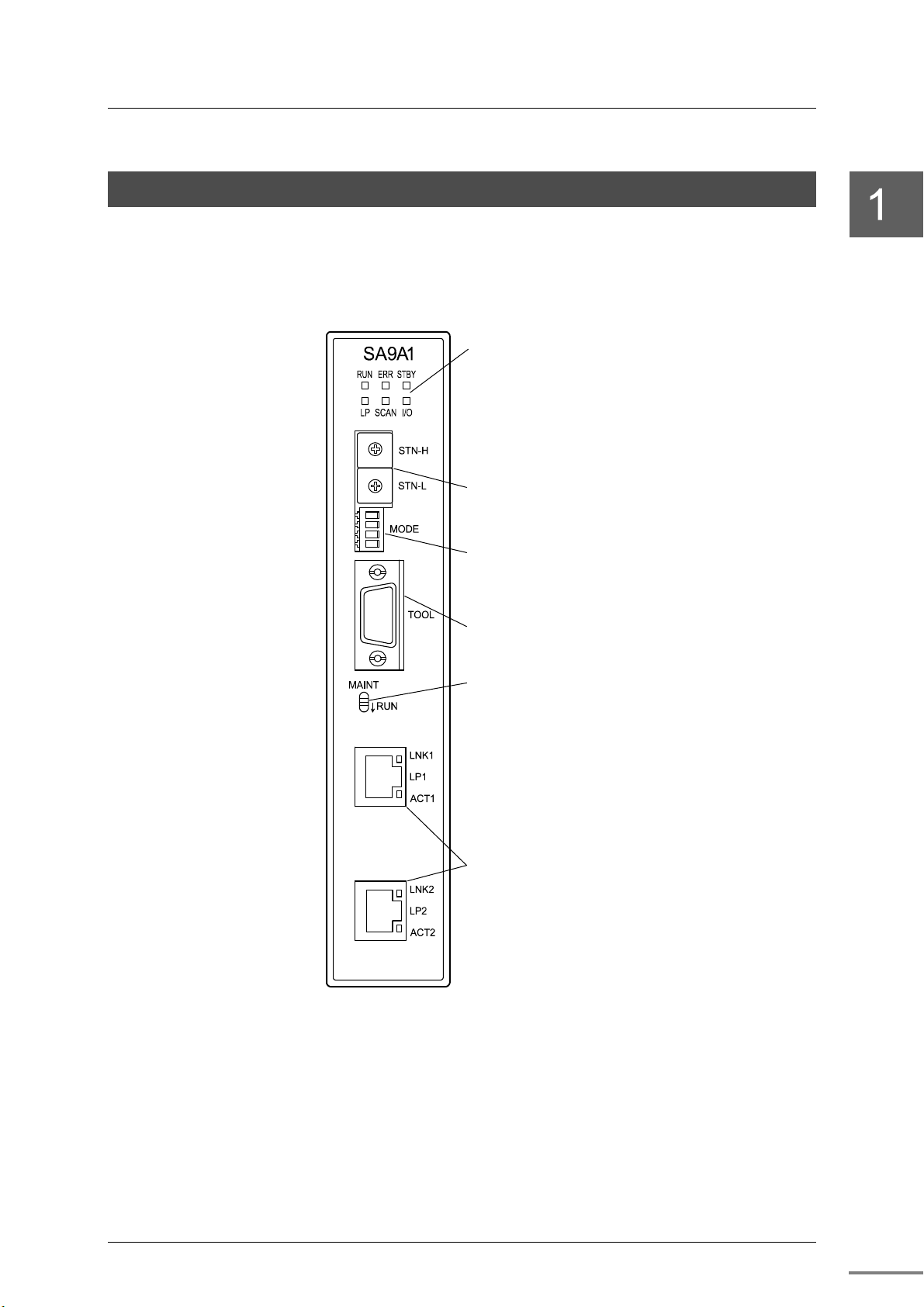

1.2.1 Names of the parts

Figure 1-2 shows the names of the parts of the SA9A1 module respectively.

State display LED

・RUN

・ERR

・I/O

・LP

・SCAN

・STS

1.2 Names and Functions of the Parts

Loop address setting switch

・STN-H

・STN-L

Operation mode setting switch

・MODE

Serial communication port

・TOOL

Maintenance switch

・MAINT

TC-net I/O loop connectors

・LP1

・LP2

Figure 1-2 Names of the parts of the SA9A1 module

Unified Controller nv series type2 SOE Function Instruction Manual

5

Chapter 1 Introducing the SA9A1 Module

1.2.2 Functions of the parts

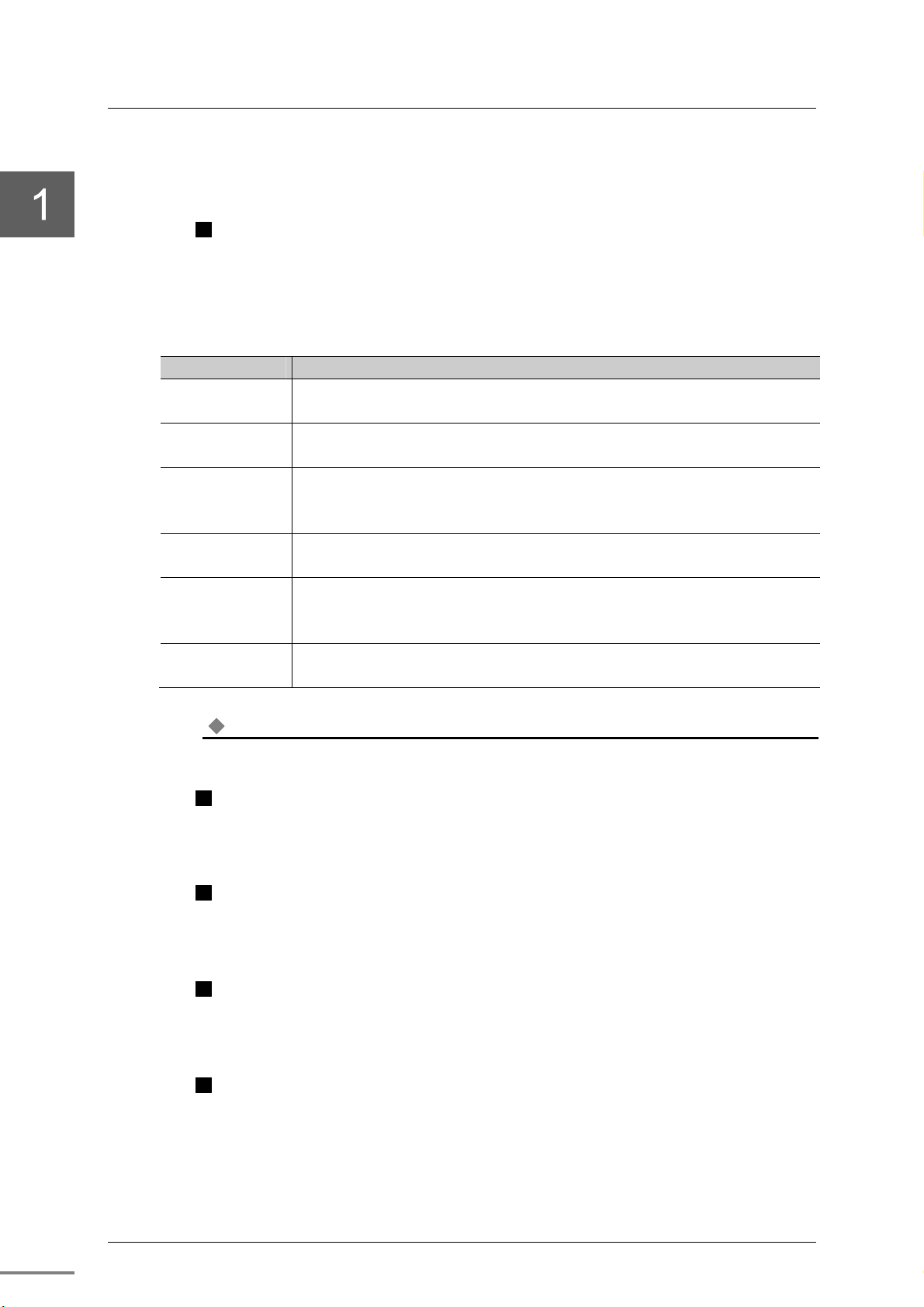

State display LED

The SA9A1 has state display LEDs in the front that displays the state of the

module.

Table 1-2 SA9A1 state display LED

LED name Description

RUN(green)

ERR(red)

STBY(green)

LP(green)

SCAN(green)

I/O(green)

Note

When the maintenance switch is set to the maintenance state (MAINT), all LEDs go off.

ON : Module is normal or waiting for parameter download

OFF : Module is abnormal

ON : Module is abnormal

OFF : Module is normal

ON : SA9A1 is in redundancy, standby system

OFF : SA9A1 is in redundancy, online system

or SA9A1 is in single configuration

ON : TC-net I/O loop is normal

OFF : Disconnection of TC-net I/O loop exists

ON : TC-net I/O loop side scan transmission is running normally

OFF : TC-net I/O loop side scan transmission is in suspension

Blinking : TC-net I/O loop side scan block is overlapping

ON : TC-net I/O bus side scan reception is running normally

OFF : TC-net I/O bus side scan reception is in suspension

Loop address setting switch (STN-H, STN-L)

The switch sets the address of the SA9A1 on the TC-net I/O loop in

hexadecimal. For the setting method, refer to "Chapter 3 Setting."

Operation mode setting switch (MODE)

The switch sets the operation mode of the SA9A1. For the setting method,

refer to "Chapter 3 Setting."

Serial communication port (TOOL)

This is an RS-232C port for maintenance. The connector is a 9-pin D-sub

connector (socket).

Maintenance switch (MAINT)

This switch is used to insert or remove the SA9A1 module online.

For module replacement, refer to "Chapter 2 Installation and wiring."

6

6F8C1511

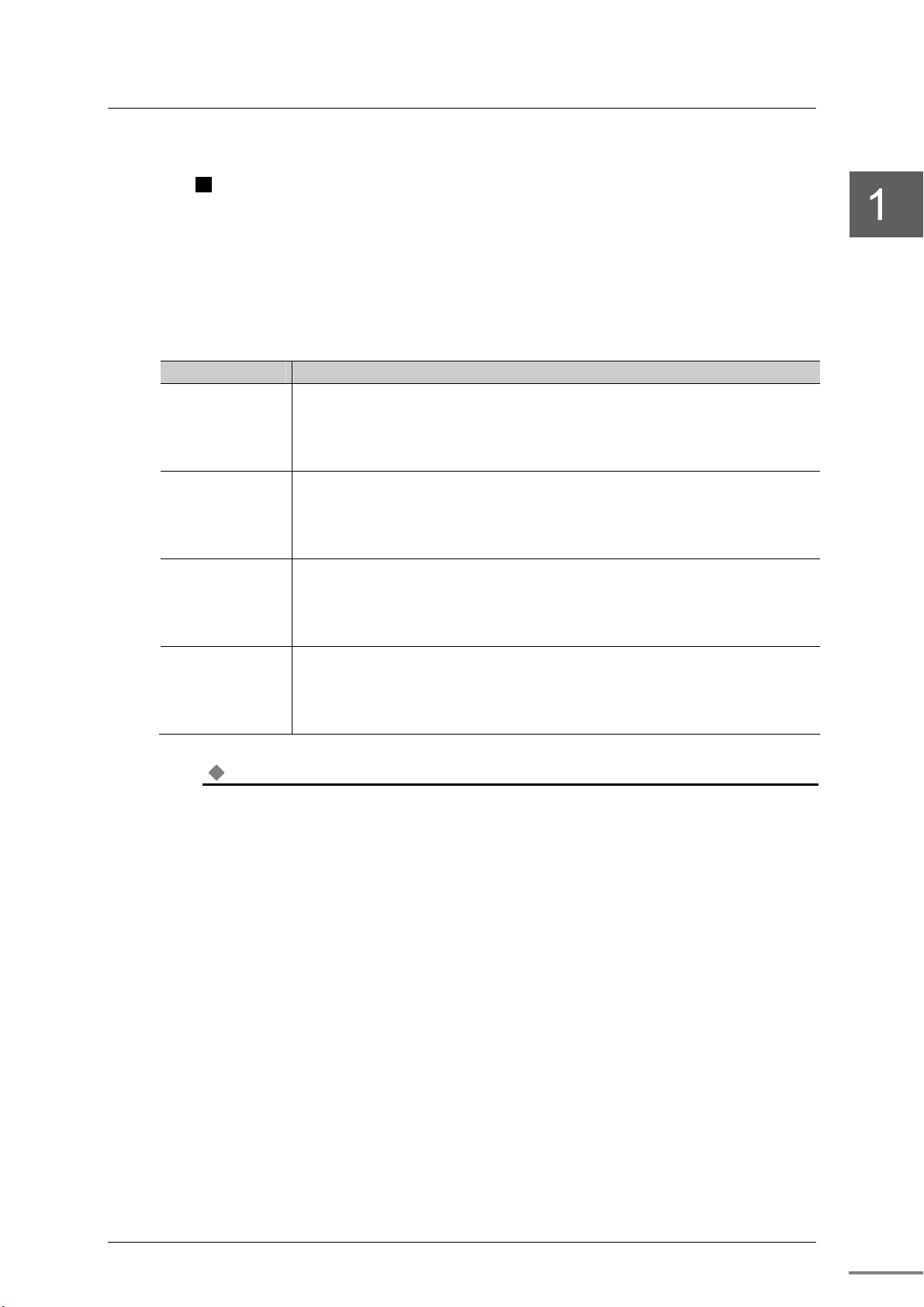

1.2 Names and Functions of the Parts

TC-net I/O loop transmission connector (LP1、LP2)

The TC-net I/O transmission cable is connected. For TC-net I/O loop

connection, refer to "Chapter 2 Installation and wiring."

The connector has LEDs that indicate the transmission state of the TC-net I/O

loop. The display details are as shown in the table below.

Table 1-3 TC-net I/O loop transmission connector LED display

LED name Description

LNK1(green) Indicates that the link state of the LP1 connection side has been

established.

ON : Established (normal)

OFF : Not established (abnormal)

ACT1(yellow) Indicates that transmission or reception in the LP1 connection side is

performed.

Blinking : Transmission/reception is done (normal)

Other than above : Transmission/reception is not done (abnormal)

LNK2(green) Indicates that the link state of the LP2 connection side has been

established.

ON : Established (normal)

OFF : Not established (abnormal)

ACT2(yellow) Indicates that transmission or reception in the LP2 connection side is

performed.

Blinking : Transmission/reception is done (normal)

Other than above : Transmission/reception is not done (abnormal)

Note

When the maintenance switch is set to the maintenance state (MAINT), all LEDs go off.

Unified Controller nv series type2 SOE Function Instruction Manual

7

Chapter 1 Introducing the SA9A1 Module

8

6F8C1511

Chapter 2 Installation and Wiring

This chapter describes how to install and wire the TC-net I/O base unit

and the SA9A1 module.

2.1 Types of I/O Base Units ···········································

2.2 Installing the Module ···············································

2.2.1 Vertical Installing of the module ································ 13

2.2.2 Horizontal Installing of the module ···························· 17

2.3 Connecting the TC-net I/O Loop Transmission Cable ·· 18

2.4 Replacing the Module ··············································

2.5 Removing the Base Unit ··········································

12

13

19

20

9

Chapter 2 Installation and Wiring

y

A

WARNING

WARNING

CAUTION

Before installing or removing the module,

make sure that the basic unit to which the

SA9A1 module is installed is turned off.

Otherwise, it may cause an electric shock.

Do not touch the interior of the product

except the switches.

It may cause an electric shock.

Install it under an environment that satisfies

the product specifications.

When installing it under an environment that does

not satisfy the product operating temperature range,

apply forced cooling with cooling equipment.

Operating temperature range: 0 to 55C

Mandatory

Prohibited

Prohibited

CAUTION

CAUTION

CAUTION

CAUTION

Before installation or wiring, remove the

static electricity from your body.

The static electricity accumulated in the human body ma

cause failure of the product.

Do not touch the cables carelessly.

pplying stress to the cables may cause malfunction or

accidents.

Do not perform wiring, insertion of the

TC-net I/O bus cable connector, or

installation, removal, or replacement of the

base unit while the power is on.

It may cause an electric shock or malfunction.

When installing the product to the base unit, be careful not

to snap or bend the TC-net I/O bus connector pins.

When installing the product to the basic

unit, do not break or bend the pins of the

TC-net I/O bus connector.

Prohibited

Prohibited

Prohibited

Prohibited

If it is difficult to insert the module to the

CAUTION

10

6F8C1511

basic unit, remove it once and try again

rather than forcing it.

Mandatory

Loading...

Loading...