Page 1

outdoor@unit@installation@manual

instructions@pour@l¹installation@de@l¹unite@d¹exterieur

installationshandbuch@aussengerët

manuale@di@installazione@dell¹unita¹@esterna

manual@de@instalaciún@de@la@unidad@exterior

AIR CONDITIONER (MULTI-SPLIT TYPE)

CLIMATISEUR (TYPE “MULTI-FENTES”)

KLIMAGERÄT (MULTI-SPLIT TYP)

CONDIZIONATORE D’ARIA (TIPO MULTIAMBIENTE)

ACONDICIONADOR DE AIRE (TIPO MULTI-SPLIT)

Heat pump /Cooling only

Pompe à chaleur /Refroidissement uniquement

Wärmepumpe /Nur Kühlung

Pompa di calore /Solo raffreddamento

Bomba de calor /Sólo refrigeración

For general public use

Pour utilisation grand public

Für allgemeine Verwendung

Per l’uso in generale

Para el uso público general

RAS-3M26YAV-E

RAS-4M27YAV-E/RAS-4M27YACV-E

Thank you very much for purchasing TOSHIBA

Air Conditioner. Please read this Installation manual

carefully before using your Air Conditioner.

Avant tout, merci d’avoir porté votre choix sur un

climatiseur TOSHIBA. Avant de le mettre en service,

prière de lire attentivement ce Manuel d’installation.

Wir danken lhnen für den Kauf dieses TOSHIBA-Klimageräts.

Lesen Sie bitte diese. Installations-Handbuch aufmerksam durch,

bevor Sie das Gerät in Betrieb nehmen.

Vi ringraziamo per l’acquisto del condizionatore d’aria TOSHIBA.

Si prega di leggere questo Manuale di installazione prima di usare l’apparecchio.

Muchas gracias por la adquisición de un acondicionador de aire TOSHIBA.

Por favor lea detenidamente este Manual de instalación, antes de usar su

acondicionador de aire.

Page 2

CONTENTS / SOMMAIRE / INHALT / INDICE / CONTENIDOS

Precautions for safety ............................................. 4

Accessory and Installation Parts ........................... 5

Refrigerant Piping ................................................... 6

Installation Place ..................................................... 6

Optional Installation Parts (Local Supply)............. 6

Optional Installation Parts (Separate Sold) ........... 6

Refrigerant Piping Connection............................... 6

MESURES DE SECURITE...................................... 12

Accessoires et pièces d’installation .................... 13

Tuyauterie pour réfrigérant ................................... 14

Lieu d’installation .................................................. 14

Pièce d’installation en option (Fourniture locale) . 14

Pièce d’installation en option

(V endues séparément) .......................................... 14

Raccord de tuyauterie pour réfrigérant ............... 14

Installation ............................................................... 7

Evacuating ............................................................... 8

Electrical W ork ......................................................... 9

Check and Test Operation..................................... 10

MISWIRING (MISPIPING) CHECK ......................... 10

Useful Functions ................................................... 11

Installation/Servicing Tools................................... 11

Installation ............................................................. 15

Evacuation ............................................................. 16

Interventions électriques ...................................... 17

Contrôles et essais................................................ 18

CONTROLES DES MAUVAISES CONNEXIONS

(MAUVAIS RACCORDEMENTS) ............................ 18

Fonctions supplementaires .................................. 19

Outil d’installation /d’entretien ............................. 19

ENGLISH

FRENCH

SICHERHEITSVORKEHRUNGEN .......................... 20

Zubehör und Installationsteile.............................. 21

Kühlmittel-Leitungssystem .................................. 22

Installations-Ort ..................................................... 22

Optionale Installationsteile (örtlich lieferbar)...... 22

Optionale Installationsteile

(getrennt erhältlich)............................................... 22

Kühlmittel-Rohrleitungs-Anschluß ...................... 22

PRECAUZIONI PER LA SICUREZZA..................... 28

Componenti accessori e per l’installazione ........ 29

Tubazioni del refrigerante ..................................... 30

Punto di installazione............................................ 30

Componenti opzionali per l’installazione

(Fornitura locale) ................................................... 30

Componenti opzionali per l’installazione

(Vendute separatamente)...................................... 30

Collegamento delle tubazioni del refrigerante ... 30

Installation ............................................................. 23

Leerpumpen der Rohrleitungen ........................... 24

Arbeiten an der Elektrik ........................................ 25

Prüf- und Testvorgang........................................... 26

ÜBERPRÜFEN AUF FALSCHE VERKABELUNG

ODER ROHRVERLEGUNG .................................... 26

Nützliche Funktionen ............................................ 27

Installation/Wartungswerkzeuge.......................... 27

Installazione........................................................... 31

Svuotamento delle tubature ................................. 32

Collegamenti elettrici ............................................ 33

Operazioni di verifica e di prova ........................... 34

VERIFICA DEGLI EVENTUALI ERR ORI NEI

COLLEGAMENTI ELETTRICI

(NELLE TUBA TURE) ............................................... 34

FunzioniI utili ......................................................... 35

Attrezzi per l’installazione/l’assistenza tecnica .. 35

GERMAN

ITALIAN

PRECAUCIONES SOBRE SEGURIDAD ................ 36

Accesorios y componentes para la instalación .. 37

Tubería de refrigerante .......................................... 38

Sitio de instalación................................................ 38

Componentes opcionales de instalación

(Provisión local)..................................................... 38

Componentes opcionales de instalación

(De venta independiente) ...................................... 38

Conexión de la tubería de refrigerante ................ 38

Instalación.............................................................. 39

Evacuación............................................................. 40

Trabajos eléctricos ................................................ 41

Operación de control y prueba............................. 42

CONTROL DE CABLEADO INCORRECTO

(TUBERÍA INCORRECTA)...................................... 42

Funciones útiles .................................................... 43

Herramientas para la instalación/

el mantenimiento ................................................... 43

3

SPANISH

Page 3

PRECAUTIONS FOR SAFETY

For general public use

Power supply cord of parts of appliance f or outdoor use shall be more than polychloroprene sheathed flexible

cord (Design H07 RN-F), or cord designation 245 IEC 66. (2.5 mm² or more)

UK PLUGS AND SOCKETS ETC (SAFETY) REGULATIONS 1994, SI NUMBER 1768

With regard to Schedule 3, item 7 of the above UK Regulations, this appliance must be permanently connected

to the fixed wiring of the main electrical supply by means other than the use of an approved 13 Amp plug-top as

outlined in the Regulations.

Electrical work must be carried by suitably qualified persons and in accordance with all relevant safety standards and codes of practice.

We recommend that the power supply for this appliance is derived from a suitably protected dedicated circuit.

(for U.K. only)

CAUTION

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY

OZONE LAYER.

R410A refrigerant is apt to be affected by impurity such as water, oxidizing membrane, and oils because pressure of R410A refrigerant is approx. 1.6 times of refrigerant R22. Accompanied with adoption of the new refrigerant, refrigerating machine oil has been also changed. Therefore, during installation work, be sure that water,

dust, former refrigerant, or refrigerating machine oil does not enter into the refrigerating cycle of new-refrigerant

air conditioner.

To prevent mixing of refrigerant or refrigerating machine oil, the sizes of connecting sections of charging port of

the main unit or installation tools are different from those for the conventional refrigerant. Accordingly, the

exclusiv e tools are required for the new refrigerant (R410A) as shown below.

For connecting pipes, use ne w and clean piping materials with high pressure-tight force, which were made for

R410A only, so that water or dust does not enter. Moreover, do not use the existing piping because there are

problems about pressure-tight force and inner impurity in the existing piping.

CAUTION

This appliance must be connected to the mains by means of a switch with a contact separation of at least 3 mm.

The installation fuse (25A D type ) must be used for the power supply line of this air conditioner.

DANGER

• FOR ELECTRICAL WORKS THE WIRING AND CABLES MUST BE PERFORMED IN COMPLIANCE WITH

NATIONAL WIRING STANDARD OR REGULATION.

IF INCORRECT AND INCOMPLETE WIRING IS CARRIED OUT, IT WILL CAUSE AN ELECTRICAL FIRE OR

ELECTRICAL SHOCK.

• USE THE SPECIFIED CABLE (1.0 mm2 or more) AND CONNECT TIGHTLY FOR INDOOR/OUTDOOR

CONNECTION. CONNECT TIGHTLY AND CLAMP THE CABLE SO THAT EXTERNAL FORCE WILL NOT

BE ACTED ON THE TERMINAL.

• WIRE ROUTING MUST BE PROPERLY ARRANGED SO THAT CONTROL BOARD COVER IS FIXED

PROPERLY.

• DO NOT DAMAGE OR SCRATCH THE CONDUCTIVE CORE AND INNER INSULATOR OF THE CABLES.

• DO NOT DEFORM OR SMASH ON THE SURFACE OF THE CABLES. DO NOT PRESS OR FIX THE CORD

AND CABLES FIRMLY WITH STAPLES, etc.

• DO NOT USE THE INTER-CONNECTING CABLE. NEVER EXECUTE THE CONNECTION OF WIRING

WITH OTHER METHOD THAN THE APPROVED ONE. OTHERWISE, OVERHEAT, SMOKE OR FIRE MAY

BE GENERATED BY CONTACT ERROR.

• TURN OFF MAIN POWER SUPPLY AND BREAKER BEFORE ATTEMPTING ANY ELECTRICAL WORK.

MAKE SURE ALL POWER SWITCHES AND BREAKER TURN OFF. FAILURE TO DO SO MAY CAUSE

ELECTRIC SHOCK.

• CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTED BY

WRONG WAY, ELECTRIC PARTS MAY BE DAMA GED.

New Refrigerant Air Conditioner Installation

To Disconnect the Appliance from the Mains Supply.

Engage Dealer or Specialist for Installation.

4

Page 4

• GROUNDING WIRE WORKS MUST BE CONSTRUCTED IN COMPLIANCE WITH INSTALLATION MANUAL.

• BE SURE TO USE THE CORD-CLAMPS AND THE UNIT COVER T O THE SPECIFIED POSITIONS WITH

ATTACHED TO THE PRODUCT. MOUNT THE UNIT COVER FOR CABLES OF CONNECTING SECTION

FIRMLY WITH THE SCREWS.

• DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OF GAS VAPORS.

FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

• IF A REFRIGERATION GAS LEAKS DURING INSTALLATION, BE SURE TO PERFORM VENTILATION.

IF THE REFRIGERANT GAS COMES INTO CONTACT WITH FIRE, A POISONOUS GAS MAY OCCUR.

WHEN INSTALLING AN AIR CONDITIONER, DO NO T ALLOW AIR OR MOISTURE TO REMAIN IN THE

REFRIGERATION CYCLE. OTHERWISE, PRESSURE IN THE REFRIGERATION CYCLE MAY BECOME

ABNORMALLY HIGH SO THAT A RUPTURE OR PERSONAL INJURY MAY BE CAUSED.

WARNING

• Never modify this unit by removing any of the safety guards of b y-passing any of the safety interlock switches.

• Do not install in a place which cannot bear the weight of the unit.

Personal injury and property damage can result if the unit falls.

• Before doing the electrical work, attach an approved cable to the power supply cord.

And make sure the equipment to be earthed.

• For installation, use the tools and piping materials exclusively manufactured for R410A, and install securely in

compliance with this Installation Manual.

Pressure of the used HFC R410A refrigerant becomes higher approx. 1.6 times of that of the conventional

refrigerant. Therefore, if the exclusive piping materials are not used or incomplete installation is carried out, it

may cause a rupture or personal injury, as well water leak, electrical shock, and a fire ma y be caused.

• When installing or moving the air conditioner, do not mix air and so on than the specified refrigerant (R410A)

in the refrigeration cycle. If air and so on is mixed, the pressure in the refrigeration cycle may become abnormally high so that personal injury may be caused by a rupture.

ENGLISH

CAUTION

• Exposure of unit or water or other moisture before installation will result in an electrical short.

Do not store in a wet basement or expose to rain or water.

• After unpacking the unit, e xamine it carefully for possible damage.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify the

noise level of the unit or where noise and discharged air might disturb user’s neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Please read the installation manual carefully before installing the unit. It contains further important instructions

for proper installation.

• Never install a power capacitor for power factor improvement.

Required tools for installation work

1) Philips screw driver

2) Hole core drill (65 mm)

3) Spanner

4) Pipe cutter

5) Knife

6) Reamer

7) Gas leak detector

8) Tape measure

9) Thermometer

10) Mega-tester

11) Electro circuit tester

12) Hexagonal wrench

13) Flare tool

14) Pipe bender

15) Lev el vial

16) Metal saw

R410A (Special requirement)

17) Gauge manifold

(Charge hose : R410A special requirement)

18) Vacuum pump

(Charge hose : R410A special requirement)

19) Torque wrench

1/4 (17 mm) 16N•m (1.6 kgf•m)

3/8 (22 mm) 42N•m (4.2 kgf•m)

1/2 (26 mm) 55N•m (5.5 kgf•m)

20) Copper pipe gauge adjusting projection margin

21) Vacuum pump adapter

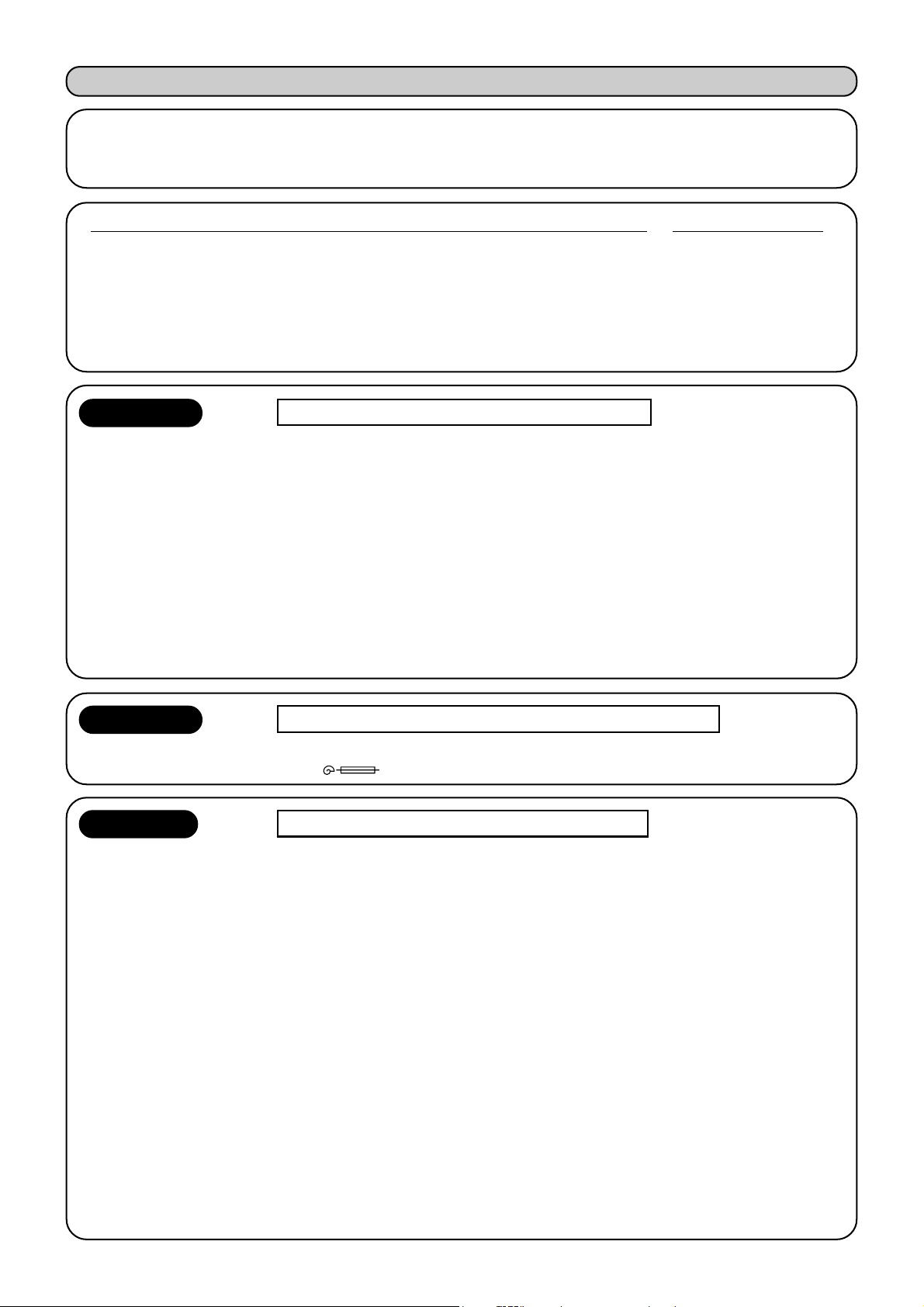

Accessory and Installation Parts

1 2 3

Outdoor unit

installation manual x 1

5

S

P

E

C

IFIC

A

T

IO

N

S

Specifications x 1Owner's manual x 1

Page 5

Refrigerant Piping

• Piping kit used for the conventional refrigerant cannot

be used.

• Use copper pipe with 0.8 mm or more thickness.

•

Flare nut and flare works are also different from those of

the conventional refrigerant. Take out the flare nut attached

to the main unit of the air conditioner, and use it.

Optional Installation Parts

(Separate Sold)

Parts name

RB-M43RE Reducer (Ø12.7 → Ø9.52)

RB-M34EE Expander (Ø9.52 → Ø12.7)

Installation Place

• A place which provides the spaces around the

outdoor unit.

• A place where the operation noise and discharged air

do not disturb your neighbors.

• A place which is not exposed to a strong wind.

• A place which does not block a passage.

• When the outdoor unit is to be installed in an elevated

position, be sure to secure its feet.

• There must be sufficient spaces for carrying the unit

into and out of the site.

• A place where the drain water does not raise any

problem.

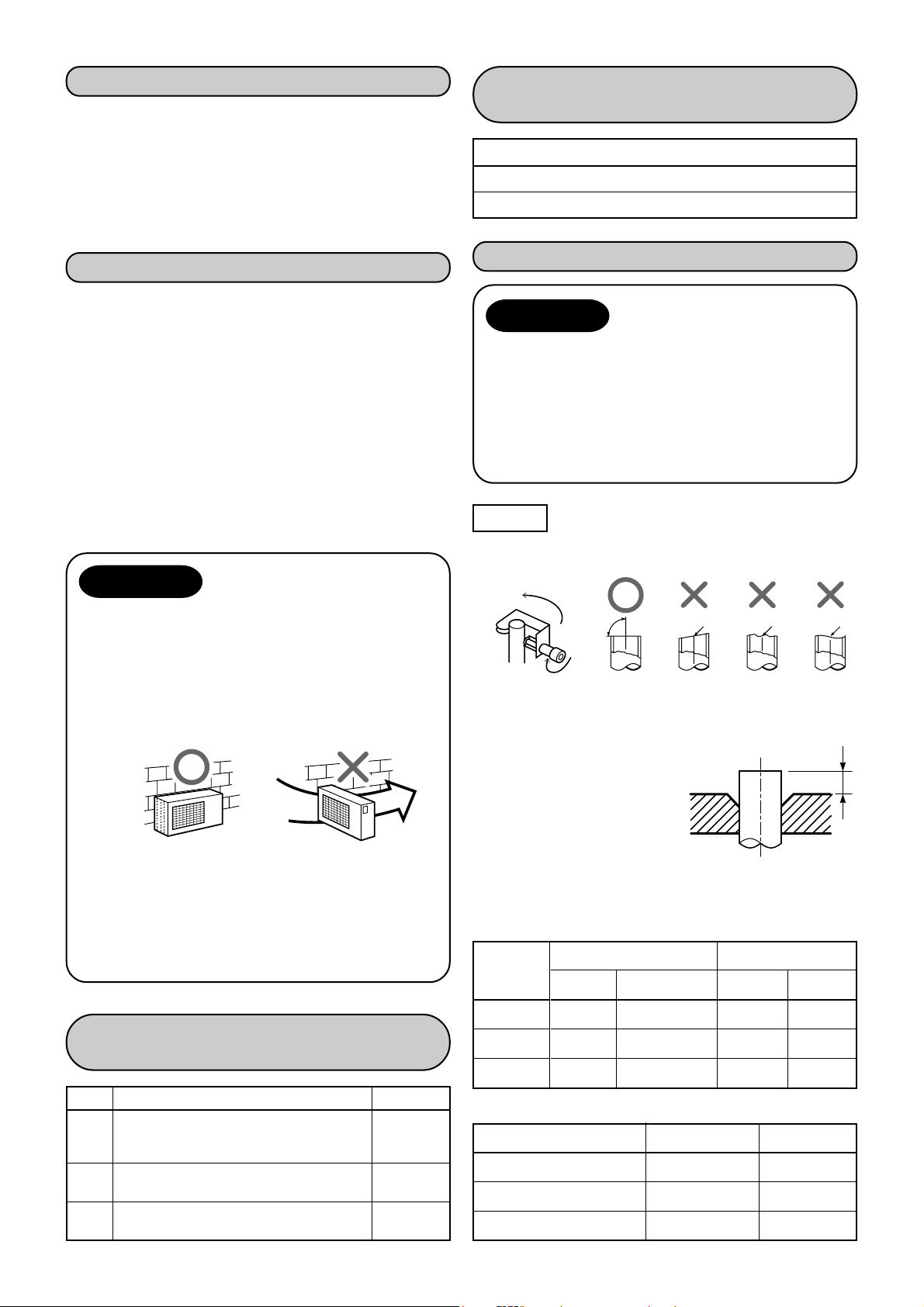

CAUTION

1. Install the outdoor unit without anything blocking

the air discharging.

2. When the outdoor unit is installed in a place

exposed always to a strong wind like a coast or on

a high story of a building, secure the normal fan

operation using a duct or a wind shield.

3. Specially in windy area, install the unit to prev ent

the admission of wind.

Strong

wind

4. Installation in the following places may result in

trouble. Do not install the unit in such places.

• A place full of machine oil.

• A place full of sulfide gas.

• A place where high-frequency waves are likely

to be generated as from audio equipment,

welders, and medical equipment.

Refrigerant Piping Connection

CAUTION

KEEP IMPORTANT 4 POINTS FOR PIPING WORK

1. Take away dust and moisture.

(Inside of the connecting pipes)

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check gas leak. (connected points)

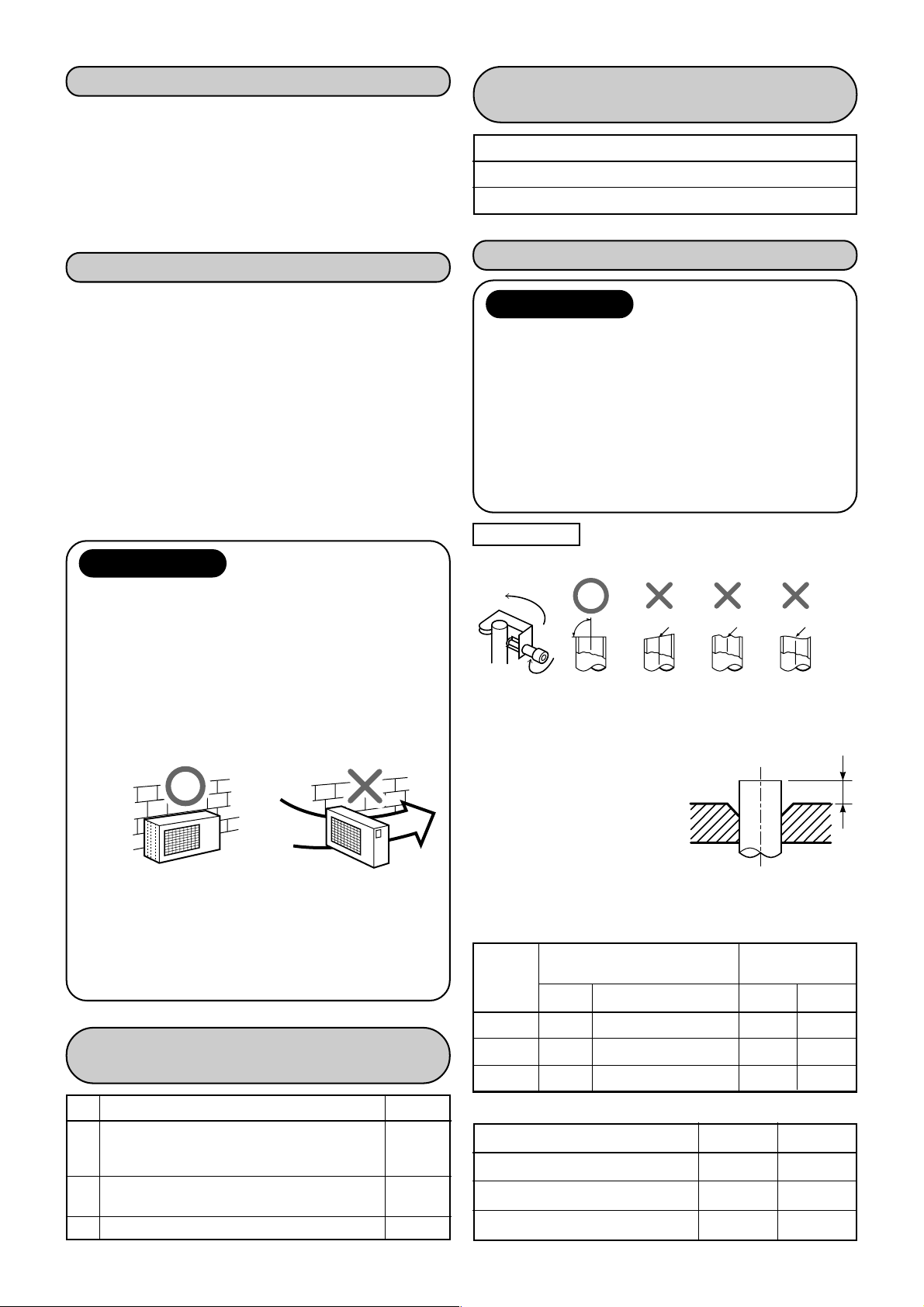

Flaring

1. Cut the pipe with a pipe cutter.

90˚

2. Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional

tools can be used by

adjusting projection

margin of the copper

pipe.

• Projection margin in flaring : B (Unit : mm)

Rigid (Clutch type)

Outer dia.

of copper

pipe

R410A tool used

R410A R22

Obliquity Roughness Warp

Conventional tool used

R410A R22

B

Optional Installation Parts

(Local Supply)

Parts name

Refrigerant piping

A

Liquid side : Ø6.35 mm

Gas side : Ø9.52 mm or Ø12.7 mm

Pipe insulating material

B

(polyethylene foam, 6 mm thick)

C

Putty, PVC tapes

Q’ty

Each

one

1

Each

one

6.35

9.52

12.7

Imperial (Wing nut type)

Outer dia. of copper pipe

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

6.35

9.52

12.7

6

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

Page 6

• Flaring size : A (Unit : mm)

+0

A

Outer dia. of

copper pipe

6.35

9.52

12.7

In the case of flaring for R410A with the

*

R410A R22

9.1 9.0

13.2 13.0

16.6 16.2

- 0.4

A

conventional flare tool, pull out it approx.

0.5 mm more than that for R22 to adjust

to the specified flare size. The copper

pipe gauge is useful for adjusting projection margin size.

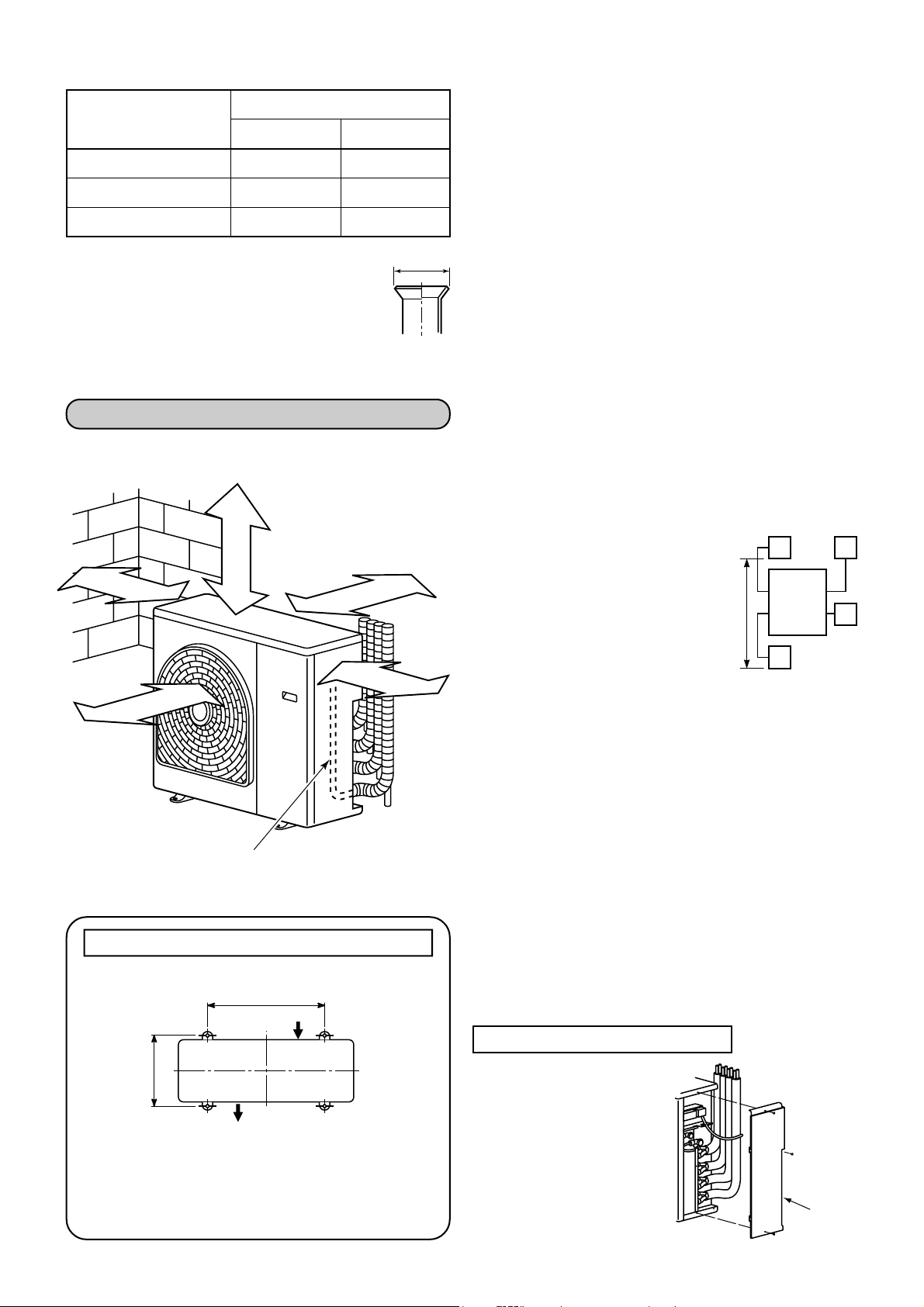

Installation

NOTE : For installation, at least 3 dimensions should be

kept free from obstacles (walls).

100mm or more

from wall

600mm or more

more from wall

100mm or

1. Piping connections to the outdoor unit should be

arranged in the sequence A, B, C , D starting from the

bottom. (For each piping connection, the gas pipe is

on the bottom and the liquid pipe is on the top.)

2. When multiple indoor units are to be connected to

the outdoor unit, make the ends of the pipes and

wires from each indoor unit to ensure that they will

be connected to the outdoor unit correctly.

(Problems caused by indoor units being connected

to the outdoor unit incorrectly are very common in

multiple-unit installations.)

3. The length and height difference of the connecting

pipes between the indoor and outdoor units must be

within the ranges indicated below.

• Total piping length :

4 units (A + B + C + D) Multi,

Non. Additional refrigerant.................. 70 m

3 units (A + B + C) Multi,

Non. Additional refrigerant.................. 50 m

• Minimum piping length :

A or B or C or D = 2 m or more

• Maximum indoor piping length :

A or B or C or D = 25 m or less

• Maximum piping height difference :

A or B or C or D = 15 m or less

A

• Maximum piping/height

difference between 2 units

= 15 m or less

Outdoor

unit

C

D

600mm or more

from wall

600mm or more

As shown in the figure, hang power cord

and connecting cable downward, and

take out it along piping connection port.

Fixing bolt arrangement of outdoor unit

600

Suction side

365

Diffuser

15 m or less

B

4. Connect 2 or more indoor units for heat pump.

5. If the outdoor unit is to be mounted on a wall, make

sure that the platform supporting it is sufficiently

strong. The platform should be designed and

manufactured to maintain its strength o ver a long

period of time, and sufficient consideration should be

given to ensuring that the outdoor unit will not fall.

6. When the outdoor unit is to be mounted high on a

wall, take particular care to ensure that parts do not

fall installer is protected.

7. When doing installation work on level ground, it is usual

to wiring and piping connections to the indoor units.

And/then make to the outdoor unit.

Howe v er if outdoor work is difficult it is possible instead

to make changes to the procedure.

For e xample by making adjustments to the wiring and

piping length on the inside (rather than the outside).

How to remove the side panel

1. Remove screws

of the side panel.

2. Pull the side panel

downward.

• Secure the outdoor unit with the fixing bolts and nuts

if the unit is likely to be exposed to a strong wind.

• Use Ø8 mm or Ø10 mm anchor bolts and nuts.

Side panel

7

Page 7

Tightening connection

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with your fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

CAUTION

• Do not apply excess torque. Otherwise, the nut

may crack depending on the conditions.

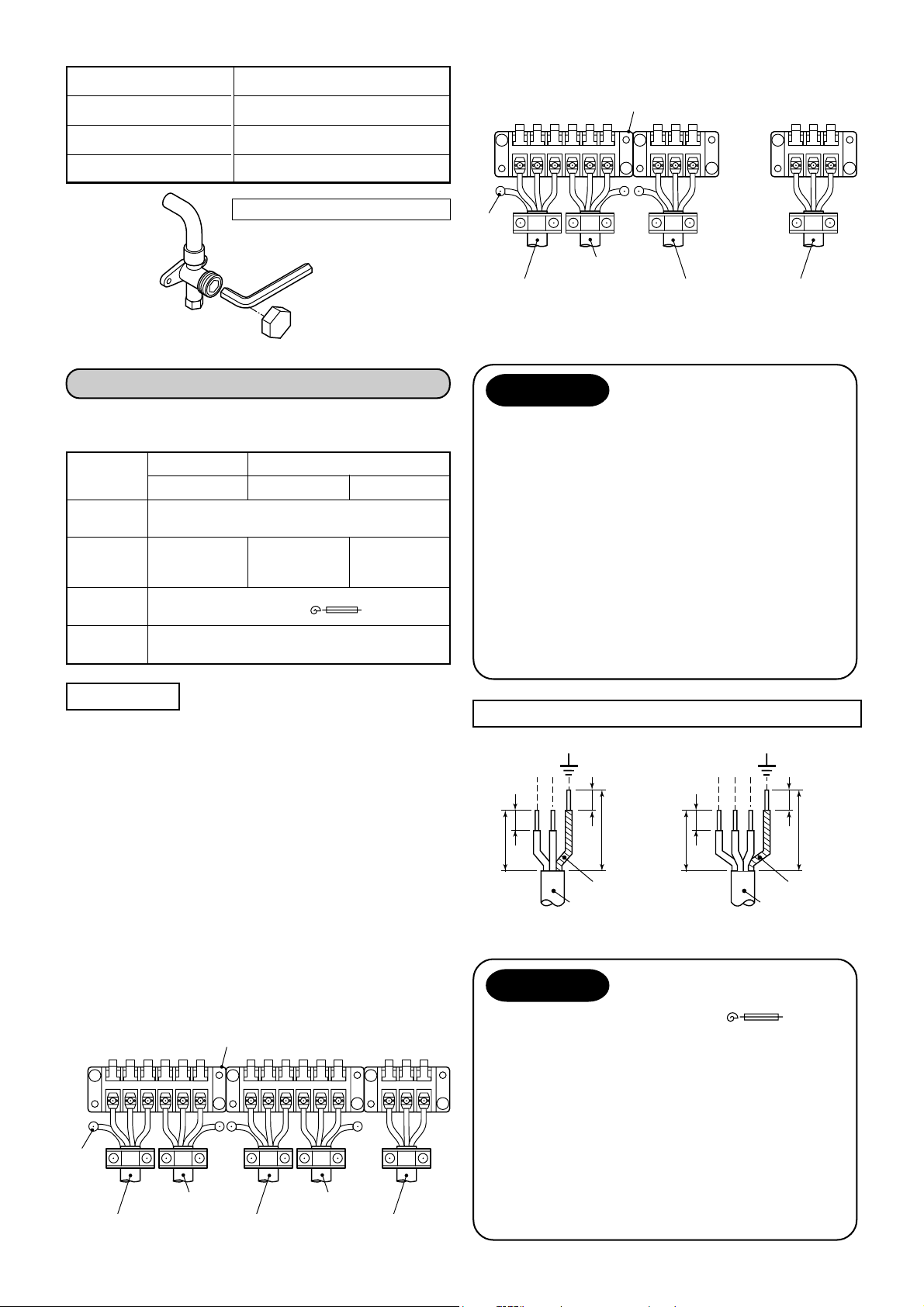

Evacuating

After the piping has been connected to all indoor

unit(s), you can perform the air purge together at once.

AIR PURGE

Evacuate the air in the connecting pipes and in the

indoor unit using vacuum pump.

Do not use the refrigerant in the outdoor unit.

For details, see the manual of vacuum pump.

(Unit : N·m)

Outer dia. of copper pipe Tightening torque

Ø6.35 mm 14 to 18 (1.4 to 1.8 kgf•m)

Ø9.52 mm 33 to 42 (3.3 to 4.2 kgf•m)

Ø12.7 mm 50 to 62 (5.0 to 6.2 kgf•m)

• Tightening torque of flare pipe connections

Pressure of R410A becomes higher than that of R22.

(Approx. 1.6 times) Therefore, using a torque wrench,

tighten firmly the flare pipe connecting sections which

connect the indoor and outdoor

units up to the specified

tightening torque.

Flare at

indoor

unit side

Incorrect connections may

cause not only a gas leakage,

but also a trouble of the

refrigeration cycle.

Flare at

outdoor

unit side

Half union

Externally

threaded side

Use a wrench to secure.

Use a torque wrench to tighten.

Flare nut

Internally

threaded side

4M27 only

Ø6.35

D

C

Ø9.52

Ø6.35

Ø9.52

D UNIT

C UNIT

Outdoor

unit

B

Ø6.35

Ø9.52

B UNIT

Use a vacuum pump

Be sure to use a vacuum pump with counter-flow

prev ention function so that inside oil of the pump does

not flow backward into pipes of the air conditioner when

the pump stops. (If inside oil of the vacuum pump

enters into the air conditioner which adopts R410A, a

trouble of the refrigeration cycle may be caused.)

1. Connect the charge hose from the manifold valve to

the service port of the gas side packed valve.

2. Connect the charge hose to the port of vacuum pump.

3. Open fully the low pressure side handle of the gauge

manifold v alve.

4. Operate the vacuum pump to start for evacuating.

Perform evacuating for about 35 minutes if the piping

length is total 70 meters.

(25 minutes for total 50 meters)

(assuming a pump capacity of 27 liters per minute.)

Then confirm that the compound pressure gauge

reading is –101 kPa ( –76 cmHg).

5. Close the low pressure side valve handle of gauge

manifold.

6. Open fully the valve stem of the packed valves (both

sides of Gas and Liquid).

7. Remove the charging hose from the service port.

8. Securely tighten the caps on the packed valves.

Compound pressure gauge

–101kPa (–76cmHg)

Handle Lo

Charge hose

(For R410A only)

Packed valve

at liquid side

Pressure gauge

Manifold valve

Handle Hi

(Keep full closed)

Charge hose

(For R410A only)

Vacuum pump adapter

for counter-flow prevention

(For R410A only)

3M26

4M27

Ø6.35

A

Connectable capacity class

A B C D T otal

10, 13 16 16

(with reducer)

16 10, 13 10, 13 ——

10, 13 16 16 16

(with reducer)

16 10, 13 10, 13 10, 13

(with expander) (with expander)

(with expander) (with expander) (with expander)

Ø12.7

——

A UNIT

Indoor unit

45

52

Vacuum

pump

Service port

(Valve core (Setting pin))

Packed valve at gas side

Packed valve handling precautions

• Open the valve stem all the way out ; do not try to

open it beyond the stopper.

•

Securely tighten the valve stem cap in torque as follows:

8

Page 8

Gas side (Ø12.7 mm)

Gas side (Ø9.52 mm)

50 to 62 N•m (5.0 to 6.2 kgf•m)

33 to 42 N•m (3.3 to 4.2 kgf•m)

3 units (A + B + C) Multi

Terminal block (Connecting cable)

Liquid side (Ø6.35 mm)

Service por t

14 to 18 N•m (1.4 to 1.8 kgf•m)

14 to 18 N•m (1.4 to 1.8 kgf•m)

Hexagonal wrench is required.

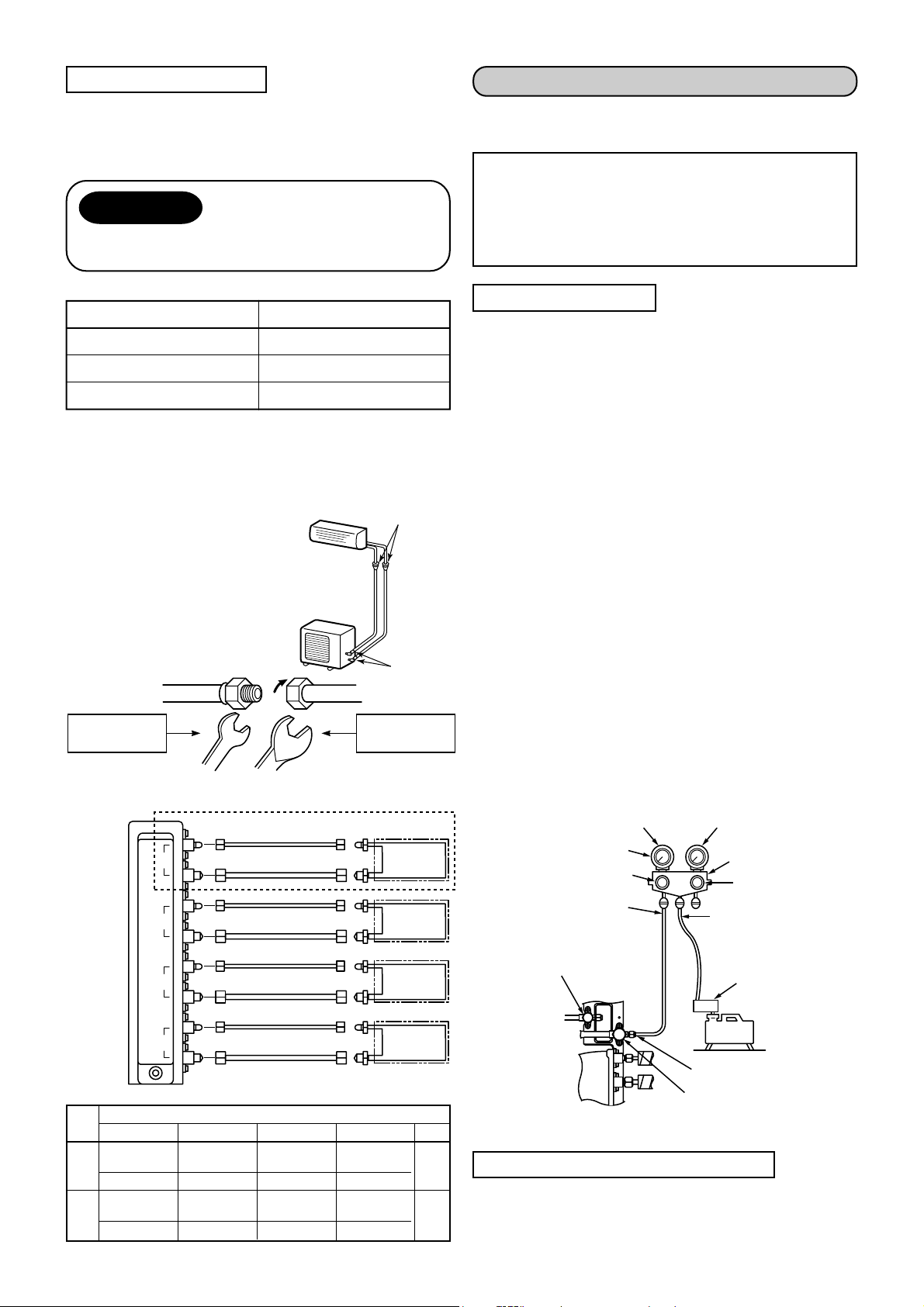

Electrical W ork

For the air conditioner that has no power cord, connect

a power cord to it as mentioned below.

Model

Power

supply

Maximum

running

current

Installation

fuse rating

Power

cord

3 Units Multi 4 Units Multi

3M26YAV-E 4M27YAV-E 4M27YACV-E

220 – 240 V

Single phase 50/60 Hz

15.3 15.3 14.8

25 A (D type )

H07 RN-F or 245 IEC 66

(2.5 mm

2

or more)

Screw

Connecting cable

Connecting cable

(A unit)

(B unit)

Connecting cable

(C unit)

Power cord

CAUTION

• Wrong wiring connection may cause some electrical parts burn out.

• Be sure to use the cord clamps specified positions

with attached to the product.

• Do not damage or scratch the conductive core and

inner insulator of power and inter-connecting

cables when peeling them.

• Be sure to comply with local cords on running the

wire from outdoor unit to indoor unit (size of wire

and wiring method etc.)

• Use the power cord and Inter-connecting cable

with specified thickness, specified type, and

protective devices specified.

How to wire

1. Connect the connecting cable to the terminal as

identified with their respective matched numbers on

the terminal block of indoor and outdoor unit.

H07 RN-F or 245 IEC 66 (1.0 mm2 or more)

2. When connecting the connecting cable to the

outdoor unit terminal, prevent water coming in the

outdoor unit.

3. Insulate the unused cords (conductors) stripped the

sheath of connecting cable with PVC tape.

Process them so that they do not touch any electrical or metal parts.

4. For inter-unit wiring, do not use a cut wire jointed to

another on the way.

Use wires long enough to cover the entire length.

4 units (A + B + C + D) Multi

Terminal block (Connecting cable)

Screw

Connecting cable

Connecting cable

(A unit)

(B unit)

Connecting cable

(C unit)

Connecting cable

(D unit)

Power cord

Stripping length power cord and connecting cable

10

40

Connecting

cable

30

10

LN

10

40

Earth line Earth line

Power cord

123

10

30

CAUTION

• The installation fuse (25A D type ) must be

used for the power supply line of this air conditioner.

• If incorrect/incomplete wiring is carried out, it will

cause an electrical fire or smoke.

• Prepare the power supply for exclusive use with

the air conditioner.

• This product can be connected to the mains.

Connection to fixed wiring :

A switch which disconnects all poles and has a

contact separation of at least 3 mm must be

incorporated in the fixed wiring.

9

Page 9

Red

Yellow

Check mode

Normal operation

Short → Open

Short

Miswiring (mispiping)

check connector

(Color:Red)

D800D801 D802 D803 D804

LED

Check and Test Operation

• Service port cap connection

• Valve stem cap connection

Flare nut

connections

(Outdoor unit)

Flare nut

connections

(Indoor unit)

For R410A, use the leak detector e xclusively manufactured for HFC refrigerant (R410A, R134a, etc.).

The conventional leak detector for HCFC refrigerant (R22, etc.) cannot

*

be used because its sensitivity for HFC refrigerant lowers to approx. 1/40.

• Pressure of R410A becomes approx. 1.6 times of that of R22.

If installation work is incompletely finished, a gas leakage may

occur in the cases such as pressure rise during operation.

Therefore, be sure to test the piping connections for leaking.

• Check the flare nut connections, valve stem cap

connections and service port cap connections

for gas leak with a leak detector or soap water.

MISWIRING (MISPIPING) CHECK

Make sure that the wiring and piping for each room

have the same alphabetical codes (A, B, C, D).

Connect and secure the power cord.

Use the power cord/cables with thickness, type

and protective de vices specified in this manual.

Insulate the unused cords (conductors) with PVC

tape.

1. T u rn on the power breaker.

2. Open side panel of the outdoor unit.

3. Set the indoor unit to COOL mode.

• It is unnecessary to set the temperature.

• Miswiring check can not be executed when

outdoor air temperature is 5°C or less.

4. Start the check

• Disconnect the miswiring check connector

(color : Red) from P.C. board of inverter .

Miswiring (mispiping) check by LED Indication

• For this outdoor unit, the self-miswiring (mispiping) check is possible by using five LEDs (1 Yellow + 4 Red).

LEDs (D800 to D804) are provided on P.C. board of the inv erter.

*

LED

During

check

Result of

judgement

D800 D801 D802 D803 D804

1

*

1

*

1

*

1

*

1

*

ll l l l

lll

l ll

ll l

lll

lll

¤

l

ll

lll

¤¤

¤

¤

l

l

ll

¤¤¤

¤¤

¤

l

¤¤¤¤

ll

¤

l

¤

¤

ll

l

ll

¤¤

¤

l

¤

¤

l

l

¤

¤¤

l

l

¤

l

¤¤

¤¤¤

5. During check (Check time 3 to 20 minutes).

• When an error described in the table below occurred

check operation stops and error code is displayed

on LED .

6. After check, the result of check is displa y ed on LED.

• The Comp. stop when miswiring (mispiping) error

occurred.

• Confirm the contents of table below.

• Turn off the power breaker .

• Correct miswiring/mispiping.

• Connect the miswiring check connector.

• Execute the check operation again.

• Automatically return to the normal operation when it

is normal.

7. Return to normal operation.

• To return to the normal operation during check operation or after miswiring (mispiping) error has been

determined, connect the miswiring check connector.

Description

Normal operation (no error)

Checking A unit

Checking B unit

Checking C unit

Checking D unit

Crush/Clog of Pipe A

Crush/Clog of Pipe B

Crush/Clog of Pipe C

Crush/Clog of Pipe D

Miswiring/Mispiping or Crush/Clog of Pipe A, B

Miswiring/Mispiping or Crush/Clog of Pipe A, C

Miswiring/Mispiping or Crush/Clog of Pipe A, D

Miswiring/Mispiping or Crush/Clog of Pipe B, C

Miswiring/Mispiping or Crush/Clog of Pipe B, D

Miswiring/Mispiping or Crush/Clog of Pipe C, D

A, B, C Miswiring/Mispiping

A, B, D Miswiring/Mispiping

A, C, D Miswiring/Mispiping

B, C, D Miswiring/Mispiping

A, B, C, D Miswiring/Mispiping

Packed valve keeps closed

10

LED : Light Emitting Diode

: LED ON

¤

: LED OFF

l

: LED Flash

1 : 4 units Multi model only

*

Page 10

Red

Yellow

D800D801 D802 D803 D804

LED

Useful Functions

Self-Diagnosis by LED Indication

• For this outdoor unit, the self-diagnosis is possible by using five LEDs (1 Yellow + 4 Red).

LEDs (D800 to D804) are provided on P.C. board of the in verter.

*

LED indication

D800 D801 D802 D803 D804

lllll

l

¤¤

ll¤ll

2

¤

*

2

ll

*

l

¤¤¤

lll¤l

¤

¤¤¤¤

¤

¤¤

1

llll

*

l

¤¤¤l¤

lll

¤¤l¤¤

¤

l

¤¤l¤

lll

¤

lll

l

¤¤

¤¤

¤¤

l

¤

lll

ll

¤¤l¤

ll¤l

l

¤

l

l

ll

ll

ll

l

¤

¤

¤

¤¤

l

¤

l

Indoor

alarm code

None

14

16

17

18

18

19

1A

1B

1C

1C

1C

1C

1C

1C

1C

1C

1C

1D

1E

1F

Contents

Normal running

IGBT short circuit, Compressor motor rare short

Trouble on position detecting circuit

Trouble on current detecting circuit

Outdoor heat exchanger temp. sensor (TE) fault

Suction temp. sensor (TS) fault

Discharge temp. sensor (TD) fault

Trouble on outdoor fan motor

Outdoor temp. sensor (TO) fault

Trouble on compressor system

Temp. sensor (TGa) fault at A room gas side

Temp. sensor (TGb) fault at B room gas side

Temp. sensor (TGc) fault at C room gas side

Temp. sensor (TGd) fault at D room gas side

Gas leakage, TS sensor out of place, PMV, sensor fault

TE sensor out of place, Indoor heat exchanger sensor

(TC) out of place, PMV, sensor fault

Miswiring at indoor or outdoor, Gas leakage , TS,

TC sensor out of place, PMV, sensor fault

Communication trouble between MCU

Compressor lock

Trouble on discharge temp, Gas leakage

Compressor break down

1. If a trouble occurs, LED goes on

according to the contents of

trouble as shown in the left table.

2. When two or more troubles occur,

LEDs go on cyclically (alternately).

3. Usually, LEDs go off.

IGBT :Insulated Gate Bipolar Transistor

PMV : Pulse Modulating Valve

:LED ON

¤

:LED OFF

l

1 :4 units Multi model only

*

2 :Heat pump model only

*

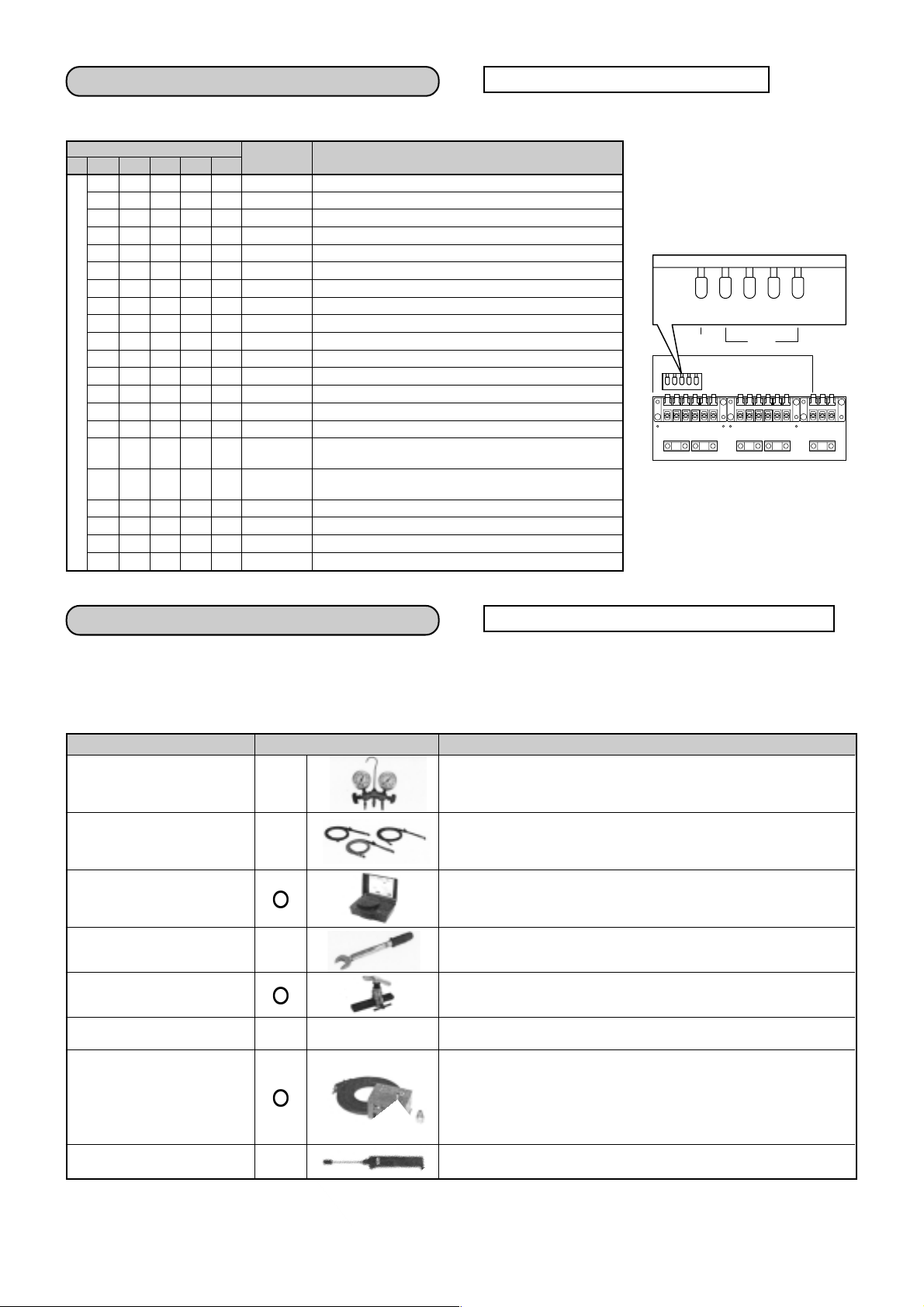

Installation/Servicing T ools

In the case of an air conditioner using R410A, in order to prevent any other refrigerant from being charged accidentally, to

service por t diameter of the outdoor unit control valve (3 way valve) has been changed. (1/2 UNF 20 threads per inch)

• In order to increase the pressure resisting strength of the refrigerant piping flare processing diameter and size of opposite

side of flare nuts has been changed. (for copper pipes with nominal dimensions 1/2 and 5/8)

Changes in the product and components

New tools for R410A

New tools for R410A

Gauge manifold

Charge hose

Electronic balance

for refrigerant charging

Torque wrench

(nominal diam. 1/2, 5/8)

Flare tool

(clutch type)

Gauge for projection adjustment

Vacuum pump adapter

Gas leakage detector

• Incidentally, the “refrigerant cylinder” comes with the refrigerant designation (R410A) and protector coating in the U. S’s ARI

specified rose color (ARI color code: PMS 507).

• Also, the “charge por t and packing for refrigerant cylinder” require 1/2 UNF 20 threads per inch corresponding to the

charge hose’s port size.

Applicable to R22 model

X

X

X

____ ____

X

Changes

As pressure is high, it is impossible to measure by means of conventional gauge. In order to prevent any other refrigerant from being

charged, each port diameter is changed.

In order to increase pressure resisting strength, hose materials and

port size are changed (to 1/2 UNF 20 threads per inch).

When purchasing a charge hose, be sure to confirm the port size.

As pressure is high and gasification speed is fast, it is difficult to read

the indicated value by means of charging cylinder, as air bubbles occur.

The size of opposite sides of flare nuts have been increased. Incidentally, a common wrench is used for nominal diameters 1/4 and 3/8.

By increasing the clamp bar’s receiving hole, strength of spring in the

tool has been improved.

Used when flare is made with using conventional flare tool.

Connected to conventional vacuum pump. It is necessary to use an

adapter to prevent vacuum pump oil from flowing back to the charge

hose. The charge hose connecting part has two ports-one for conventional refrigerant (7/16 UNF 20 threads per inch) and one for R410A.

If the vacuum pump oil (mineral) mixes with R410A a sludge may occur

and damage the equipment.

Exclusive for HFC refrigerant.

11

Page 11

MESURES DE SECURITE

Pour usage public général

Les cordons d’alimentation des éléments de l’appareil pour usage extérieur doivent être meilleurs que les cordons

flexibles gainés en polychloroprène (cordon H07 RN-F), ou les cordons indiqués par la norme 245 IEC 66.

(2.5 mm² ou plus)

ATTENTION

• Ce climatiseur utilise le nouveau réfrigérant HFC (R410A) qui ne nuit pas à la couche d’ozone.

Le réfrigérant R410A peut être contaminé par des impuretés telles que l’eau, les produits oxydants et les huiles

parce que la pression du réfrigérant R410A est 1.6 fois environ celle du réfrigérant R22. L’utilisation du nouveau

réfrigérant a été associée au changement de l’huile de la machine frigorifique. Par conséquent, lors de l’installation

prendre soin d’éviter toute pénétration de l’eau, des poussières, du réfrigérant précédent ou de l’huile de la machine

frigorifique dans le cycle de refroidissement du nouveau climatiseur.

Pour éviter tout mélange des réfrigérants ou des huiles de la machine frigorifique les dimensions des raccords de

l’orifice de remplissage de l’unité principale ou les outils de montage sont différents de ceux du climatiseur à

réfrigérant normal.

En conséquence des outils spéciaux sont requis (R410A) comme énoncé ci-après.

Pour le raccordement des tuyaux, utiliser des outils pour tuyaux neufs, propres et étanches à la pression,

spécialement conçus et fabriqués pour le R410A pour éviter toute pénétration de poussières ou d’eau. En outre, ne

pas utiliser les tuyaux existants car des problèmes concernant l’étanchéité à la pression et la présence d’impuretés

pourraient s’avérer .

ATTENTION

Cet appareil doit être branché sur le secteur à l’aide d’un commutateur avec une séparation de contact de 3 mm au

minimum.

Nouvelle Installation de climatisation à réfrigérant

Débranchement de l’appareil du secteur d’alimentation.

Pour ce climatiseur le fusible (25A type D ) doit être employé dans la line d’alimentation.

DANGER

• LES INTERVENTIONS ELECTRIQUES, LE CABLAGE ET LE BRANCHEMENT DOIVENT ETRE EFFECTUES

CONFORMEMENT AUX NORMES OU AUX REGLEMENTS NATIONAUX.

UN CABLAGE INCORRECT OU INCOMPLET PEUT ENTRAINER UN RISQUE D’INCENDIE OU

D’ELECTROCUTION.

• UTILISEZ LE CABLE SPECIFIE (1,0 mm² ou plus) ET CONNECTEZ-LE BIEN A L’UNITE INTERNE/EXTERNE.

CONNECTEZ BIEN LE CABLE ET SERREZ-LE DE SORTE QUE LA BORNE NE SUBISSE AUCUNE PRESSION

EXTERNE.

• LES CABLES DOIVENT ETRE POSES D’UNE MANIERE ADEQUATE POUR GARANTIR LA BONNE FIXATION

DU VOLET DU TABLEAU DE COMMANDES.

• NE PAS ENDOMMAGER NI RAYER L’AME CONDUCTRICE ET L’ISOLANT INTERIEUR DES CABLES.

• NE PAS DEFORMER NI ECRASER LES CABLES. NE PAS PRESSER NI FIXER LE CORDON ET LES CABLES

A L’AIDE D’AGRAFES, etc.

• NE PAS UTILISER DES CABLES D’INTERCONNEXION. NE JAMAIS EFFECTUER LA CONNEXION DU

CABLAGE AVEC DES METHODES DIFFERENTES DE CELLE APPROUVEE. DANS LE CAS CONTRAIRE UNE

ERREUR DE CONTACT POURRAIT ENTRAINER LA FORMATION DE SURCHAUFFE, FUMEES OU

PROVOQUER UN INCENDIE.

• AVANT D’EFFECTUER TOUTE INTERVENTION ELECTRIQUE DEBRANCHER L’ALIMENTATION ET LE

DISJONCTEUR. S’ASSURER QUE TOUS LES COMMUTATEURS ET LE DISJONCTEUR SONT DESACTIVES.

LE NON-RESPECT DE CETTE CONSIGNE PEUT ENTRAINER UN RISQUE D’ELECTROCUTION.

• BRANCHER CORRECTEMENT LE CABLE DE CONNEXION. UN BRANCHEMENT INCORRECT DE CE CABLE

PEUT ENDOMMAGER LES COMPOSANTS ELECTRIQUES.

• LA MISE A LA TERRE DOIT ETRE EFFECTUEE CONFORMEMENT AUX INSTRUCTIONS DU MANUEL

D’INSTALLATION.

• S’ASSURER D’AVOIR UTILISE LE SERRE-FIL APPROPRIE POUR LE CORDON ET D’AVOIR FIXE LE CAPOT

DE L’UNITE SUR LES POSITIONS INDIQUÉES SUR LE PRODUIT. FIXER FERMEMENT LE CAPOT DES

CABLES DE CONNEXION AU MOYEN DES VIS.

• NE PAS INSTALLER L’APPAREIL A PROXIMITE DE ZONES DE CONCENTRATION DE GAZ COMBUSTIBLES

OU DE VAPEURS DE GAZ.

LE NON- RESPECT DE CETTE INSTRUCTION PEUT PROVOQUER UN RISQUE D’INCENDIE OU

D’EXPLOSION.

Pour l’installation faire appel au distributeur ou à un spécialiste.

12

Page 12

• SI DES FUITES DE GAZ REFRIGERANT S’AVERENT PENDANT L’INSTALLATION, AERER

CONVENABLEMENT LE LIEU D’INSTALLATION.

SI LE GAZ REFRIGERANT ENTRE EN CONTACT AVEC DES FLAMMES, DES GAZ TOXIQUES SE DEGAGENT.

LORS DE L’INSTALLATION D’UN CLIMATISEUR, EVITER TOUTE PERMANENCE D’AIR OU D’HUMIDITE DANS

LE CYCLE DE REFROIDISSEMENT. DANS LE CAS CONTRAIRE LA PRESSION DU CYCLE DE

REFROIDISSEMENT PEUT AUGMENTER EXCESSIVEMENT ET ENTRAINER UN RISQUE DE RUPTURE OU

D’ATTEINTE A LA SANTE.

AVERTISSEMENT

• Ne jamais modifier cette unité en retirant les protecteurs ou en neutralisant les interrupteurs d’interverrouillage de

sécurité.

• Ne pas l’installer dans un endroit ne pouvant pas soutenir le poids de l’unité.

La chute de l’unité peut provoquer des dommages ou des lésions.

• Avant d’effectuer toute intervention électrique brancher un câble homologué sur le cordon de l’alimentation

générale.

S’assurer que l’équipement est mis à la terre.

• Pour l’installation n’utiliser que les outils et les tuyaux spécialement fabriqués pour le R410A et installer en

respectant rigoureusement les instructions fournies dans ce manuel.

La pression du réfrigérant HFC R410A utilisé dans cette unité peut être 1.6 fois supérieure à celle du réfrigérant

traditionnel.

Par conséquent, la non-utilisation des tuyaux prescrits ou une installation incorrecte peuvent entraîner des risques

d’atteinte à la santé, de rupture, des fuites d’eau, d’électrocution et d’incendie.

• Lors de l’installation ou du déplacement du climatiseur éviter tout mélange d’air ou d’autres substances avec le

réfrigérant spécifique (R410A) utilisé pour le cycle de refroidissement.

La pénétration d’air ou d’autres substances dans le cycle pourrait faire augmenter excessivement la pression du

cycle de refroidissement et entraîner le risque de ruptures et d’atteinte à la santé.

FRENCH

ATTENTION

• L’exposition de l’unité à l’eau ou à l’humidité avant l’installation peut provoquer un court-circuit.

Ne pas stocker dans un endroit humide ni exposé à la pluie ou à l’eau.

• Après l’avoir déballé, l’inspecter soigneusement pour vérifier qu’il n’est pas endommagé.

• Ne pas installer dans un endroit pouvant augmenter les vibrations de l’unité. Ne pas installer dans un endroit

pouvant amplifier le bruit de l’unité ou dans un lieu ou le bruit et l’air évacué peuvent déranger les voisins de

l’utilisateur.

• Manipuler avec attention les éléments avec des bords tranchants pour éviter tout risque de lésion.

• Lire avec attention le manuel d’installation avant d’installer l’appareil. Il contient des renseignements importants

pour une bonne installation.

• Ne jamais installer un condensateur pour l’amélioration du facteur de puissance.

Outils requis pour l’installation

1) Tournevis Philips

2) Perceuse (65 mm)

3) Clé

4) Coupe-tubes

5) Couteau

6) Alésoir

7) Détecteur de

fuite de gaz

8) Mètre à ruban

9) Thermomètre

10) Mega-ohmmètre

11) Testeur pour

circuits électriques

12) Clé hexagonale

13) Outil à évaser

14) Cintreuse

15) Niveau à bulle

16) Scie à métaux

R410A (Exigences spéciales)

17) Manomètre de pression

(Tuyau flexible de remplissage: R410A exigence spéciale)

18) Pompe à vide

(Tuyau flexible de remplissage: R410A exigence spéciale)

19) Clé dynamométrique

1/4 (17 mm) 16N•m (1.6 kgf•m)

3/8 (22 mm) 42N•m (4.2 kgf•m)

1/2 (26 mm) 55N•m (5.5 kgf•m)

Excédent de projection de réglage du calibre pour tuyaux en cuivre

20)

21) Adaptateur pour pompe à vide

Accessoires et pièces d’installation

1 2 3

Manuel de l’utilisateur x 1

Unité d’extérieur

manuel d’installation x 1

13

S

P

E

C

IF

IC

A

T

IO

N

S

Caractéristiques techniques x 1

Page 13

Tuyauterie pour réfrigérant

• Il n’est pas possible d’utiliser la tuyauterie conçue pour

le réfrigérant traditionnel.

• Utiliser un tuyau en cuivre de 0.8 mm d’épaisseur.

• L’écrou évase et les évasements sont différents de ceux

du réfrigérant traditionnel.

Retirer l’écrou évasé monté sur l’unité principale du

climatiseur et l’utiliser.

Pièce d’installation en option

(Vendues séparément)

Désignation de la pièce

RB-M43RE Réducteur (Ø12.7 → Ø9.52)

RB-M34EE Expanseur (Ø9.52 → Ø12.7)

Lieu d’installation

• Un endroit permettant d’avoir un espace suffisant

autour de l’unité d’extérieur.

• Un endroit où le br uit de fonctionnement et l’air évacué

ne dérangent pas les voisins.

• Un endroit non exposé à des vents forts.

• Un endroit qui ne bloque pas le passage.

• Lorsque l’unité d’extérieur doit être installée dans une

position élevée, s’assurer que les pieds de l’unité sont

bien fixés.

• S’assurer que l’espace pour entrer et sortir de l’endroit

d’installation est suffisant.

• Un endroit où l’eau de drainage n’entraîne aucun

problème.

ATTENTION

1. Installer l’unité d’extérieur en vérifiant que rien ne

gêne l’évacuation de l’air.

2. Lorsque l’unité d’extérieur est installée dans un

endroit exposé à des vents for ts, comme une côte

ou un étage élevé d’un bâtiment, protéger le

fonctionnement du ventilateur à l’aide d’un conduit

ou d’un écran.

3. Dans les zones exposées aux quatre vents, installer

l’unité d’une manière telle à éviter toute pénétration

du vent dans cette dernière.

Vent fort

4. L’installation dans ces endroits peut entraîner des

problèmes. Ne pas installer l’unité dans ces endroits.

• Un endroit plein d’huile de machine.

• Un endroit plein de sulfure

• Un endroit dans lequel des équipements sonores,

des soudeuses et des appareils médicaux

peuvent générer des ondes à haute fréquence.

Raccord de tuy auterie pour réfrigérant

ATTENTION

LES 4 POINTS ENUMERES CI-APRES SONT

ESSENTIELS POUR LES TRAVAUX CONCERNANT

LA TUY AUTERIE

1. Enlever toute poussière et humidité.

(A l’intérieur des tuyaux de raccordement)

2. Raccordement étanche (entre tuyaux et unité)

3. Purger l’air des tuyaux de raccordement en utilisant

une POMPE A VIDE.

4. Vérifier qu’il n’y a pas des fuites de gaz.

(points de raccordement)

Evasement

1. Couper le tuyau à l’aide d’un coupe-tubes

90˚

2. Introduire un écrou évasé dans le tuyau et évaser ce

dernier.

Les dimensions des évasements du R410A étant

différentes de celles du réfrigérant R22,

il est recommandé d’utiliser les

outils à évaser spécialement

fabriqués pour le R410A.

Toutefois, il est possible

d’utiliser les outils

traditionnels en réglant

l’excédent de projection du

calibre pour tuyau en cuivre.

• Excédent de projection de l’évasement : B (Unité: mm)

Rigide (Type à coulisse)

Diamètre

extérieur

du tuyau

en cuivre

Outils utilisés pour

R410A R22

Obliquité Rugosité Gauchissement

Outils

R410A

traditionnels

R410A R22

B

Pièce d’installation en option

(Fourniture locale)

Désignation de la pièce

Tuyauterie pour réfrigérant

Côté liquide : Ø6.35 mm

A

Côté gaz : Ø9.52 mm ou Ø12.7 mm

Isolant pour tuyaux

B

(Polyéthylène expansé, 6 mm d’épaisseur)

C

Mastic, rubans en PVC

Q.té

Chacun

1

Chacun

6.35

9.52

12.7

Mesures anglaises (Type écrou à oreilles)

Diamètre extérieur tuyau en cuivre

0 à 0.5 (Egal à celui de gauche)

0 à 0.5 (Egal à celui de gauche)

0 à 0.5 (Egal à celui de gauche)

6.35 1.5 à 2.0 1.0 à 1.5

9.52 1.5 à 2.0 1.0 à 1.5

12.7 2.0 à 2.5 1.5 à 2.0

14

1.0 à 1.5 0.5 à 1.0

1.0 à 1.5 0.5 à 1.0

1.0 à 1.5 0.5 à

R410A R22

1.0

Page 14

• Diamètre évasement : A (Unité: mm)

Diamètre extérieur

tuyau en cuivre

6.35 9.1 9.0

9.52 13.2 13.0

12.7 16.6 16.2

En cas d’évasement pour R410A effectué

*

avec un outil traditionnel, retirer l’outil de 0.5

A

R410A R22

+0

- 0.4

A

mm environ plus que pour R22 pour l’ajuster

à la dimension spécifique de l’évasement.

Le calibre pour tuyaux en cuivre permet

d’ajuster la dimension de l’excédent de

projection.

Installation

REMARQUE :Lors de l’installation, maintenir l’appareil

distant de tout obstacle (mur) sur 3 côtés

au moins.

100mm ou

plus du mur

600mm ou plus

Faire passer le cordon d’alimentation et le câble de

branchement vers le bas et le faire sortir par l’orifice

de raccordement du tuyau, comme illustré sur la figure.

Emplacement du boulon de fixation

de l’unité d’extérieur

365

• Fixer l’unité d’extérieur au moyen des boulons et des

écrous correspondants si l’unité risque d’être

exposée à des vents for t s.

• Utiliser des boulons et des écrous de fixation de Ø8

mm ou Ø10 mm.

600mm ou plus

Côté aspiration

Diffuseur

100mm ou

plus du mur

600mm ou

plus du mur

600

1. Le raccordement des tuyaux à l’unité d’extérieur doit

être effectué conformément à la séquence A, B, C, D

en partant du fond. (Pour chaque raccordement, le

tuyau du gaz est situé sur la partie basse et le tuyau

du liquide sur la partie haute).

2. Lorsqu’il est nécessaire de raccorder plusieurs unités

d’intérieur à l’unité d’extérieur, marquer l’extrémité des

tuyaux et des câbles pour garantir le bon

raccordement à l’unité d’extérieur.

(Les problèmes entraînés par le raccordement incorrect des unités d’intérieur aux unités d’extérieur sont

très fréquents sur les installations à unités multiples.)

3. La différence de longueur et de hauteur des tuyaux de

raccordement entre les unités d’intérieur et d’extérieur

doit être comprise dans les plages de valeurs

indiquées ci-après.

• Longueur totale des tuyaux:

4 unités (A + B + C + D) Multi,

Non. Réfrigérant additionnel ................. 70 m

3 unités (A + B + C) Multi,

Non. Réfrigérant additionnel ................. 50 m

• Longueur minimale des tuyaux:

A ou B ou C ou D = 2 m ou plus

• Longueur maximale des

tuyaux à l’intérieur:

A ou B ou C o D = 25 m ou moins

• Différence maximale de

hauteur entre les tuyaux:

A ou B ou C ou D = 15 m ou moins

• Différence maximale de hauteur/

A

C

tuyaux entre 2 unités

= 15 m ou moins.

Unité

d’extérieur

15 m ou moins

B

D

4. Reliez 2 unités internes ou plus pour le modèle à

pompe à chaleur.

5. Si l’unité d’extérieur doit être fixée au mur, s’assurer

que la plate-forme de support est suffisamment solide.

La plate-forme doit être conçue et fabriquée pour durer

longtemps et être en mesure d’éviter toute chute de

l’unité d’extérieur.

6. Lorsque l’unité d’extérieur doit être montée très haut

sur le mur, s’assurer que les différents éléments ne

risquent pas de tomber et que l’installateur est

adéquatement protégé.

7. Lorsque l’installation est effectuée au sol, brancher les

câbles et raccorder les tuyaux des unités d’intérieur en

premier et ceux des unités d’extérieur ensuite.

Si, les interventions à effectuer à l’extér ieur sont

difficiles, il est possible d’effectuer la procédure au

contraire.

Par exemple en modifiant la longueur des câbles et

des tuyaux à l’intérieur (plutôt qu’à l’extérieur).

Mode de démontage du panneau latéral

1. Retirez la vis du panneau

latéral.

2. Tirez le panneau latéral

vers le bas.

Panneau latéral

15

Page 15

Serrage des raccords

Aligner les centres des raccords et serrer l’écrou évasé

avec les doits. Appliquer ensuite une clé dynamométrique

sur l’écrou et serrer comme indiqué sur la figure.

Evacuation

Après avoir terminé de raccorder les tuyaux à (les)

l’unité(s) d’intérieur purger l’air de tous les tuyaux en

même temps.

ATTENTION

• Ne pas serrer trop fort. Un serrage excessif pourrait

provoquer la rupture de l’écrou.

(Unité: N.m)

Diamètre extérieur

du tuyau en cuivre

Ø6.35 mm 14 à 18 (1.4 à 1.8 kgf•m)

Ø9.52 mm 33 à 42 (3.3 à 4.2 kgf•m)

Ø12.7 mm 50 à 62 (5.0 à 6.2 kgf•m)

• Couple de serrage des raccords évasés

La pression du R410A est plus élevée que celle du R22.

(1.6 fois environ).

Par conséquent, serrer au couple

prescrit les raccords évasés de

connexion des unités

d’intérieur aux unités d’

extérieur à l’aide d’une clé

dynamométrique.

Des raccords mal serrés

peuvent provoquer des fuites

de gaz et des défauts au

cycle de refroidissement.

Demi-raccord

Côté extérieur

fileté

Utiliser une clé pour fixer.

D

C

Unité d’

extérieur

B

Couple de serrage

Evasement sur

le côté de l’unité

d’intérieur

Evasement sur

le côté de l’unité

d’extérieur

Ecrou évasé

Côté intérieur

fileté

Utiliser une clé dynamométrique

pour serrer.

4M27 uniquement

Ø6.35

Ø9.52

Ø6.35

Ø9.52

Ø6.35

Ø9.52

UNITE D

UNITE C

UNITE B

PURGE DE L’AIR

Purger l’air des tuyaux et de l’unité d’intérieur à l’aide

d’une pompe à vide.

Ne pas utiliser de réfrigérant dans l’unité d’extérieur.

Pour toute autre information se reporter à la notice

d’instructions de la pompe à vide.

Utiliser une pompe à vide

Utiliser une pompe à vide dotée du dispositif antiretour

pour éviter que l’huile contenue à l’intérieur de la pompe

pénètre dans les tuyaux du climatiseur quand la pompe

s’arrête. (La pénétration de l’huile de la pompe à vide

dans le climatiseur fonctionnant avec le réfrigérant

R410A, peut compromettre le cycle de refroidissement).

1. Raccorder le tuyau de remplissage de la vanne du

collecteur à l’orifice de service de la vanne située sur

le côté du gaz.

2. Raccorder le tuyau de remplissage à l’orifice de la

pompe à vide.

3. Ouvrir totalement la manette de la basse pression sur

le manomètre du collecteur.

4. Mettre en marche la pompe à vide pour déclencher la

purge.

Purger pour 35 minutes environ si la longueur du tuyau

est de 70 mètres.

(25 minutes pour un total de 50 mètres) (en supposant

une capacité de la pompe de 27 litres/minute.)

Vérifier ensuite que la pression indiquée su le

manomètre est de –101 kPa ( –76 cmHg).

5. Fermer la manette de la basse pression sur le

manomètre de pression.

6. Ouvrir totalement la tige des vannes (sur les deux

côtés du Gaz et du Liquide).

7. Retirer le tuyau de remplissage de l’orifice de service.

8. Fixer a fond les chapeaux des vannes.

Manomètre

–101kPa (–76cmHg)

Manette Bas

Tuyau de remplissage

(Pour R410A uniquement)

Vanne compacte sur

le côté du liquide

Manomètre

Manette Bas

Manette Haut

(Maintenir totalement fermée)

Tuyau de remplissage

(Pour R410A uniquement)

Adaptateur antiretour

de pompe à vide

(Pour R410A uniquement)

(avec réducteur)

3M26

(avec réducteur)

4M27

Ø6.35

A

Ø12.7

UNITE A

Unité d’intérieur

Classe de connexion

A B C D T otal

10, 13 16 16

16 10, 13 10, 13 ——

10, 13 16 16 16

16 10, 13 10, 13 10, 13

(avec expanseur) (avec expanseur)

(avec expanseur) (avec expanseur) (avec expanseur)

——

Pompe

à vide

Orifice de service

(Pointeau (Goujon de réglage))

Vanne compacte sur le côté du gaz

Précautions pour la manipulation des vannes

45

52

compactes

• Ouvrir totalement la tige de vanne. Ne pas essayer de

dépasser l’arrêt.

• Serrer adéquatement le chapeau de vanne. Les couples

de serrage sont les suivantes :

16

Page 16

Côté gaz (Ø12.7 mm) 50 à 62 N•m (5.0 à 6.2 kgf•m)

3 Unités (A + B + C) Multi

Côté gaz (Ø9.52 mm) 33 à 42 N•m (3.3 à 4.2 kgf•m)

Côté liquide (Ø6.35 mm) 14 à 18 N•m (1.4 à 1.8 kgf•m)

Orifice de service 14 à 18 N•m (1.4 à 1.8 kgf•m)

Utiliser une clé hexagonale.

Interventions électriques

Si le climatiseur n’est pas doté d’un cordon d’alimentation,

brancher un cordon comme indiqué ci-après.

Modèle

Source

d’alimentation

Courant de

service maximal

Régime nominal

du fusible de

l’équipement

Cordon

d’alimentation

3 Unités Multi 4 Unités Multi

3M26YAV-E 4M27YAV-E 4M27YACV-E

220 – 240 V

Monophasé 50/60 Hz

15.3 15.3 14.8

25 A (type D )

H07 RN-F ou 245 IEC 66

(2.5 mm2 ou plus)

Bornier (Câble de connexion)

Vis

Câble de connexion

Câble de connexion

(Unité A)

(Unité B)

Câble de connexion

(Unité C)

Cordon d’alimentation

ATTENTION

• Une connexion incorrecte des câbles peut

endommager les composants électriques.

• S’assurer d’avoir utilisé le serre-fil approprié pour le

cordon et d’avoir fixé le capot de l’unité sur les

positions indiquées sur le produit.

• Ne pas endommager ni rayer l’âme conductrice et

l’isolant intérieur du cordon et des câbles

d’interconnexion au moment de les dénuder.

• S’assurer que le câble entre l’unité d’extérieur et celle

d’intérieur est posé conformément aux normes locale.

(dimension du câble, m éthode de câblage, etc.)

• Utiliser le cordon d’alimentation et le câble

d’interconnexion d’épaisseur et de type adéquat et

doté de tous les dispositifs de protection prescrit.

Mode de branchement

1. Brancher le câble de connexion sur la borne identifiée

par les nombres correspondants imprimés sur le

bornier des unités d’intérieur et d’extérieur.

H07 RN-F ou 245 IEC 66 (1.0 mm² ou plus)

2. Au moment du branchement du câble de connexion

sur la borne de l’unité d’extérieur prendre soin d’éviter

toute pénétration d’eau dans l’unité d’extérieur.

3. Isoler les fils inutilisés (conducteurs) avec des bandes

de gaine du câble de connexion en les fixant avec du

ruban en PVC.

Prendre soin d’éviter tout contact de ces dernières

avec des éléments électriques ou métalliques.

4. Pour la connexion entre unités, ne pas utiliser un câble

coupé uni à un autre sur le parcours.

Utiliser des câbles suffisamment longs pour couvrir

toute la longueur.

4 Unités (A + B + C + D) Multi

Bornier (Câble de connexion)

Vis

Câble de connexion

Câble de connexion

(Unité A)

(Unité B)

Câble de connexion

Câble de connexion

(Unité C)

(Unité D)

Cordon d’alimentation

Cordon d’alimentation et câb le de conne xion dénudés

10

40

Câble de connexion

30

10

LN

10

Ligne de terre Ligne de terre

Cordon d’alimentation

40

123

10

30

ATTENTION

• Pour ce climatiseur le fusible (25A type D )

doit être employé dans la line d’alimentation.

• Un câblage incorrect/incomplet peut provoquer le

risque d’incendie ou de dégagement de fumée.

• Préparer la source d’alimentation pour usage

exclusif du climatiseur.

• Ce produit peut être branché sur le secteur.

Branchement sur câblage fixe :

Le câblage fixe doit être doté d’un commutateur

qui disjoncte tous les pôles et est doté d’une

séparation de contact de 3 mm au minimum.

17

Page 17

Rouge

Jaune

Mode de vérification

Normale Funktion

Court → Ouvert

Court

Connecteur de verification

d'erreurs de branchement

(raccordement)

(Couleur : Rouge)

D800D801 D802 D803 D804

LED

Contrôles et essais

• Raccord du chapeau de l’orifice

de service

• Raccord du chapeau de vanne

Raccords à

écrou évasé

(Unité d’extérieur)

Raccord à

écrou évasé

(Unité d’intérieur)

Utiliser le détecteur de fuites spécialement fabriqué pour le réfrigérant HFC contenu dans le R410A (R410A, R134a, etc.).

Le détecteur de fuites traditionnel conçu pour le réfrigérant HCFC (R22, etc.) ne peut

*

être utilisé parce que sa sensibilité pour le réfrigérant HFC baisse jusqu’à 1/40 environ.

• La pression de R410A est 1.6 fois celle du R22.

Si l’installation n’a pas été effectuée correctement, une fuite de gaz peut s’avérer

lorsque la pression augmente pendant le fonctionnement, S’assurer que tous les

contrôles pour vérifier la présence de fuites de gaz ont été effectués.

• Vérifier qu’il n’y a pas des fuites de gaz sur les raccords

à écrou évasé, sur ceux du chapeau de vanne et du

chapeau de l’orifice de service à l’aide d’un détecteur

de fuite ou avec de l’eau savonneuse.

CONTROLES DES MAUVAISES CONNEXIONS (MAUVAIS RACCORDEMENTS)

S’assurer que la connexion des câbles et le

raccordement de tuyaux ont le même code alphabétique

pour chaque pièces (A, B, C, D).

Brancher et fixer le cordon d’alimentation.

Utiliser un cordon d’alimentation/des câbles d ’épaisseur,

type et protection spécifié dans ce manuel.

Isoler les fils inutilisés (conducteurs) av ec du ruban en

PVC.

1. Activez l’interrupteur de courant.

2. Ouvrez le panneau latéral de l’unité externe.

3. Réglez l’unité interne sur le mode

REFROIDISSEMENT.

• Il n’est pas nécessaire de régler la température.

• La vér ification d’erreurs de branchement ne peut

être effectuée lorsque la température de l’air

extérieur est de 5°C ou moins.

4. Lancez la vérification

• Débranchez le connecteur de vérification d’erreurs

de branchement (couleur : rouge) de la carte à

circuits imprimés de l’inverseur.

Vérification d’erreurs de branchement (raccordement) par indication de la LED

• Pour cette unité externe, la vérification automatique d’erreurs de branchement (raccordement) est possible à l’aide de

cinq LED (1 jaune + 4 rouges).

Les LED (de D800 à D804) se trouvent sur la carte à circuits imprimés de l’inverseur.

*

LED

Durant la

vérification

Résultat

de

l’évaluation

D800 D801 D802 D803 D804

lllll

1

*

1

*

1 ¤

*

1

*

1

*

lll

l ll

ll l

lll

lll

¤

l

ll

lll

¤¤

¤

l

l

ll

¤¤¤

¤¤

¤

l

¤¤¤¤

ll

¤

l

¤

¤

ll

l

ll

¤¤

¤

l

¤

¤

l

l

¤

¤¤

l

l

l

¤

¤¤

¤¤¤

5. Durant la vérification (temps de vérification de 3 à 20

minutes).

• Lorsqu’une des erreurs décrites dans le tableau ci-

dessous survient, la vérification s’arrête et le code

d’erreur s’affiche sur la LED.

6. Après la vérification, son résultat s’affiche sur la LED.

• Le compresseur s’arrête en cas d’erreur de

branchement (raccordement).

• Vérifiez le contenu du tableau ci-dessous.

• Désactivez l’interrupteur de courant.

• Corr igez les erreurs de branchement/raccordement.

• Branchez le connecteur de vérification d’erreurs de

branchement.

• Exécutez à nouveau la vérification.

• Retour automatique au fonctionnement normal en cas

de normalité.

7. Retour au fonctionnement normal.

• Pour revenir au fonctionnement normal durant la

vérification ou après détection d’une erreur de

branchement (raccordement), branchez le connecteur

de vérification d’erreurs de branchement.

Description

Fonctionnement normal (pas d’erreur)

Vérification de l’unité A

Vérification de l’unité B

Vérification de l’unité C

Vérification de l’unité D

Conduite de A écrasée/bouchée

Conduite de B écrasée/bouchée

Conduite de C écrasée/bouchée

Conduite de D écrasée/bouchée

Erreur de branchement/raccordement ou conduite

de A, B écrasée/bouchée

Erreur de branchement/raccordement ou conduite

de A, C écrasée/bouchée

Erreur de branchement/raccordement ou conduite

de A, D écrasée/bouchée

Erreur de branchement/raccordement ou conduite

de B, C écrasée/bouchée

Erreur de branchement/raccordement ou conduite

de B, D écrasée/bouchée

Erreur de branchement/raccordement ou conduite

de C, D écrasée/bouchée

Erreur de branchement/raccordement de A, B, C

Erreur de branchement/raccordement de A, B, D

Erreur de branchement/raccordement de A, C, D

Erreur de branchement/raccordement de B, C, D

Le tube bondé d’erreurs de branchement/

reccordement de A, B, C, D reste fermé

18

LED : Diode électroluminescente

: LED ON

¤

: LED OFF

l

: LED clignotante

1 : Modèle Multi à 4 unités

*

seulement

Page 18

Fonctions supplementaires

Autodiagnostic à l’aide des indicateurs à LED

• L’autodiagnostic de cette unité d’extérieur peut être effectué à l’aide de cinq indicateurs à LED (1 jaune + 4 rouges).

Les LED (de D800 à D804) se trouvent sur la carte à circuits imprimés de l’inverseur.

*

Identification des LED

D800 D801 D802 D803 D804

lllll

l

¤¤

ll¤ll

2

¤

*

2

ll

*

l

¤¤¤

lll¤l

¤

¤¤¤¤

¤

¤¤

1

llll

*

l

¤¤¤l¤

lll

¤¤l¤¤

¤

l

¤¤l¤

lll

¤

lll

l

¤¤

¤¤

¤¤

l

lll

ll

ll

ll

¤

ll

¤¤l¤

¤¤

ll¤l

l

¤

¤

Code alarme

d’intérieur

l

l

l

¤

¤

¤

l

l

unité

Aucun

14

16

17

18

18

19

1A

1B

1C

1C

1C

1C

1C

1C

1C

1C

1C

1D

1E

1F

Contenus

Fonctionnement normal

Court-circuit IGBT , Court-circuit moteur arrière compresseur

Défaillance dans le circuit de détection de la position

Défaillance dans le circuit de détection du courant

Défaut du détecteur de température (TE) de l’échangeur de chaleur

extér ieur

Défaillance capteur de température d’aspiration (TS)

Capteur température d’évacuation (TD) défectueux

Problème moteur du ventilateur externe

Capteur température extérieure (TO) défectueux

Défaillance dans le système compresseur

Défaillance du capteur de tempér ature (TGa) dans la pièce A sur le côté gaz.

Défaillance du capteur de tempér ature (TGb) dans la pièce B sur le côté gaz.

Défaillance du capteur de tempér ature (TGc) dans la pièce C sur le côté gaz.

Défaillance du capteur de tempér ature (TGd) dans la pièce D sur le côté gaz.

Fuite de gaz, capteur TS en panne, PMV, défaillance du capteur

Capteur TE d’échangeur de chaleur (TC) de l’unité d’intérieur en panne,

PMV, défaillance du capteur

Mauvaise connexion de l’unité d’intérieur ou de celle d’extérieur, Fuites

de gaz, capteurs TS, TC en panne, PMV, défaillance du capteur

Défaut de communication entre MCU

Blocage du compresseur

Problème température d’évacuation, fuite de gaz

Compresseur endommagé

1. En cas de défaillance, le LED

s’allume en fonction du défaut,

comme indiqué dans le tableau

à gauche.

2. En cas de plusieurs défaillances

les LED s’allument en séquence

(alternativement).

3. En principe, les LED s’éteignent.

D800D801D802D803D804

Jaune

IGBT: Transistor bipolaire à tube

isolé

PMV: Lampe modulatrice

d’impulsions

: LED ON

¤

: LED OFF

l

1 : Modèle Multi à 4 unités

*

seulement

2 : Modèle à pompe à chaleur

*

seulement

Rouge

LED

Outil d’installation /d’entretien

En cas d’utilisation d’un climatiseur fonctionnant a vec du R410A, pour éviter le remplissage accidentel avec un autre réfrigérant par l’orifice

de service le diamètre de la vanne de contrôle (vanne à trois voies) de l’unité d’extérieur a été modifié (1/2 UNF 20 filets par pouce).

• Pour augmenter la résistance à la pression de l’évasement des tuyaux du réfrigérant le diamètre et la dimension des côtés

opposées des écrous évasés ont été modifiés. (pour les tuyaux en cuivre avec dimension nominale 1/2 et 5/8)

Changement des produits et des composants

Nouveaux outils pour R410A

Nouveaux outils pour R410A

Manomètre de pression

Tuyaux flexible de

remplissage

Balance électronique pour le

chargement du réfrigérant

Clé dynamométrique

(diamètre nominal. 1/2, 5/8)

Outil à évaser

(de type à coulisse)

Calibre pour le réglage de la

projection

Adaptateur pour pompe

à vide

Détecteur des fuites de gaz

• Le “cylindre du réfrigérant” est identifié par le même code du réfrigérant (R410A) et la couleur de son revêtement de

protection est celle spécifié dans la norme ARI utilisée aux Etats Unis. (Code couleur ARI: PMS 507).

• En outre, “l’orifice de remplissage et le joint du cylindre du réfrigérant” requièrent 1/2 UNF 20 filets par pouce qui correspond à la dimension de l’orifice du tuyau flexible de remplissage.

Applicable au modèle R22

×

×

×

——

×

Modifications

La pression étant élevée, la mesure à l’aide d’un manomètre traditionnel

n’est pas possible. Pour éviter le remplissage avec un réfrigérant différent,

les diamètres de chaque orifice ont été modifiés.

Pour augmenter la résistance à la pression, les matériaux des tuyaux

flexibles et la dimension des orifices ont été modifiés (à 1/2 UNF 20 filets

par pouce). Au moment de l’achat d’un tuyau flexible de remplissage vérifier

la dimension de l’orifice.

La pression étant élevée et la vitesse de gazéification étant rapide, il est

difficile de lire la valeur indiquée par le cylindre de chargement à cause de

la formation de bulles d’air.

Les dimensions des côtés opposées des écrous évasés ont été augmentées.

Pour les diamètres nominaux de 1/4 et 3/8 on utilise un clé normale.

L’augmentation du trou de fixation de la barre de l’agrafe a permis

d’augmenter la résistance du ressort de l’outil.

Utilisé lorsque l’évasement est effectué à l’aide d’un outil à évaser

traditionnel.

Raccordé à une pompe à vide traditionnelle. Il est nécessaire d’utiliser un

adaptateur pour éviter le retour de l’huile de la pompe et sa pénétration

dans le tuyau flexible de remplissage. Le raccord du tuyau flexible de

remplissage est doté de deux orifices, un pour le réfrigérant traditionnel

(7/16 UNF 20 filets par pouce) et un pour le R410A. Si l’huile de la pompe à

vide (minérale) se mélange avec le R410A des boues peuvent se former et

entraîner un risque d’endommagement de l’équipement.

Exclusif pour le réfrigérant HFC.

19

Page 19

SICHERHEITSVORKEHRUNGEN

Zum allgemeinen öffentlichen Gebrauch

Netzkabel der Geräteteile für den Außengebrauch sollten stärker als nur Polychloren beschichtetes flexibles Kabel

(Bezeichnung H07 RN-F), oder Kabel mit der Bezeichnung 245 IEC 66 sein. (2.5 mm² oder stärker)

VORSICHT

• Diese Klimagerät erhält das neue HFC Kühlmittel (R410A), das nicht die Ozonschicht angreift.

Das R410A Kühlmittel ist anfällig gegen Ver unreinigungen wie Wasser, oxydierende Membrane und Öle, da der

Druck des R410A Kühlmittels etwa 1.6 mal so hoch wie der des R22 Kühlmittels ist. Gleichzeitig mit der Anwendung

des neuen Kühlmittels wurde auch das Kühlmaschinenöl gewechselt. Vergewissern Sie sich deshalb während der

Installation, daß kein Wasser, Staub, altes Kühlmittel oder Kühlmaschinenöl in den Kühlkreislauf der Klimagerät mit

dem neuen Kühlmittel eindringen kann.

Um das Mischen des Kühlmittels mit dem Kühlmaschinenöl zu verhindern, sind die Verbindungsgrößen des

Füllanschlusses des Hauptgerätes und die Installationswerkzeuge anders als bei Geräten mit herkömmlichem

Kühlmittel. Folglich sind Spezialwerkzeuge - wie unten beschrieben - für das neue Kühlmittel (R410A) erforderlich.

Benutzen Sie für die Leitungsanschlüsse nur saubere und neue hochdruckfeste Rohrmater ialien, eigens für das

R410A angefertigt, damit kein Wasser oder Staub eindringen können. Benutzen Sie außerdem nicht das bestehende

Rohrleitungs-System, weil darin Probleme mit der Druckfestigkeit und inneren Verunreinigungen auftreten können.

VORSICHT

Dieses Gerät muß mittels einer Sicherung oder einem Schalter mit einem Kontaktabstand von mindestens 3mm an

die Hauptstromzufuhr angeschlossen sein.

Installation der Klimagerät mit neuartigem Kühlmittel

Trennen des Geräts von der Hauptstromzufuhr.

Die Sicherung (25A Typ D ) muß für die Netzleitung dieser Klimaanlage gebraucht werden.

GEFAHR

• BEI ARBEITEN AN DER ELEKTRIK MÜSSEN SCHALTUNG UND VERKABELUNG ENTSPRECHEND

NATIONALER STANDARDS UND VORSCHRIFTEN AUSGEFÜHRT WERDEN.

FALLS DER ANSCHLUSS NICHT RICHTIG ODER UNVOLLSTÄNDIG AUSGEFÜHRT WURDE, KANN EIN

KABELBRAND ODER STROMSCHLAG AUSGELÖST WERDEN.

• BENUTZEN SIE DAS PASSENDE KABEL (1,0 mm² oder stärker) UND SCHLIESSEN SIE ES FEST FÜR DEN