Page 1

.ILE NO. A02-001

SPLIT TYPE

RAS-13UKV-E

RAS-13U AV-E

PRINTED IN JAPAN, Mar.,2002 ToMo

Page 2

CONTENTS

1. SPECIFICATIONS ..................................................................................... 3

2. REFRIGERANT R410A ............................................................................. 5

3. CONSTRUCTION VIEWS ........................................................................ 13

4. WIRING DIAGRAM.................................................................................. 15

5. SPECIFICATIONS OF ELECTRICAL PARTS ......................................... 17

6. REFRIGERANT CYCLE DIAGRAM ........................................................ 18

7. CONTROL BLOCK DIAGRAM ................................................................ 20

8. OPERATION DESCRIPTION................................................................... 22

9. INSTALLATION PROCEDURE................................................................ 35

10. HO W TO DIA GNOSE THE TROUBLE...................................................... 44

11. HO W TO REPLACE THE MAIN P AR TS................................................... 63

12. EXPLODED VIEWS AND PARTS LIST ................................................... 74

– 2 –

Page 3

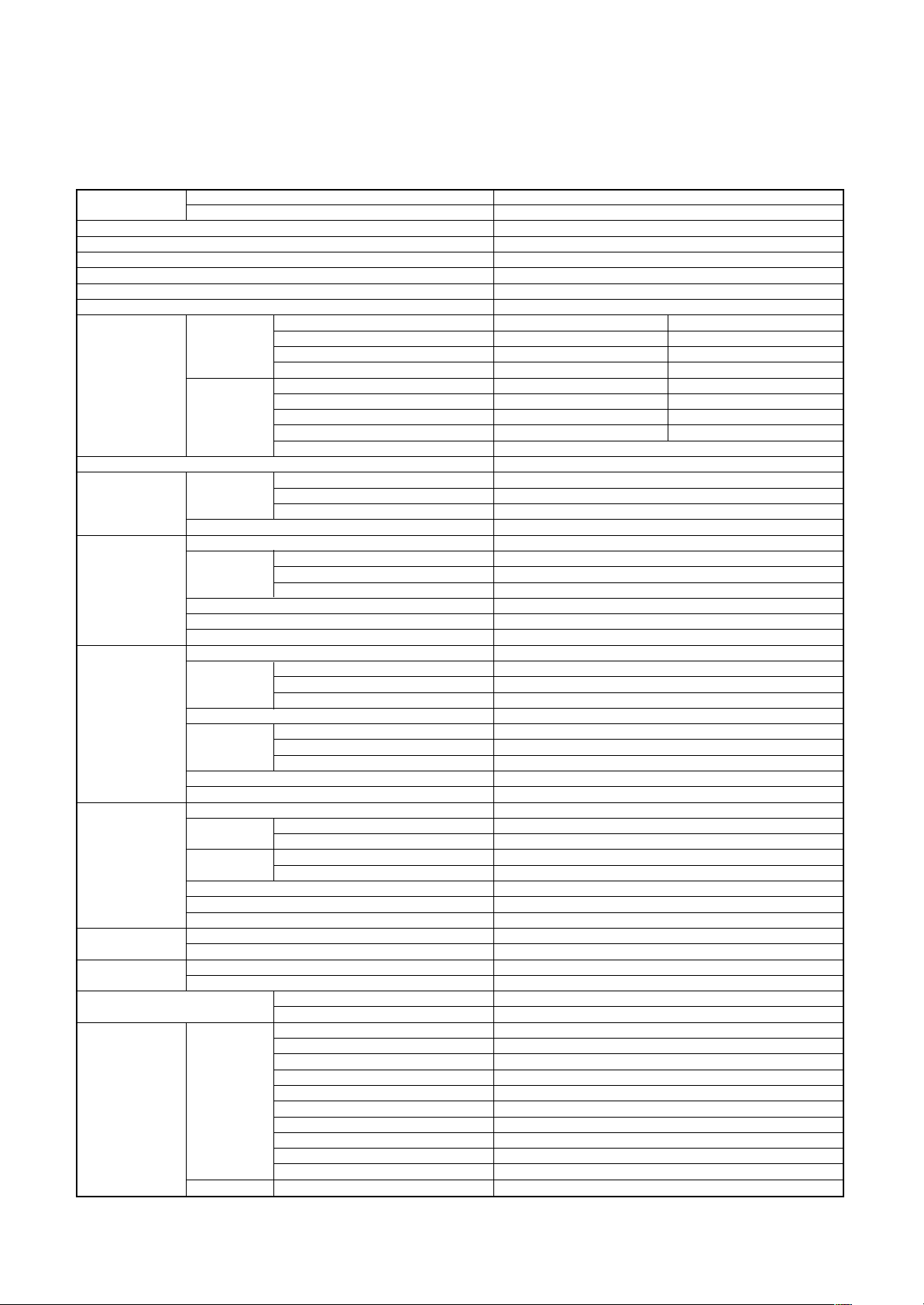

1. SPECIFICATIONS

1-1. Specifications

RAS-13UKV-E/RAS-13UAV-E

Unit model Indoor

Outdoor

Current limited

Cooling capacity (kW)

Cooling capacity range (kW)

Heating capacity (kW)

Heating capacity range (kW)

Power supply

Electric Indoor Operation mode

characteristics

Outdoor Operation mode

COP (Cooling/Heating)

Operating noise Indoor High (Cooling / Heating) (dB•A)

Outdoor (Cooling / Heating) (dB•A)

Indoor unit Unit model

Dimension Height (mm)

Net weight (kg)

Fan motor output (W)

Air flow rate (Cooling / Heating) (m³/h)

Outdoor unit Unit model

Dimension Height (mm)

Net weight (kg)

Compressor Motor output (W)

Fan motor output (W)

Air flow rate (Cooling / Heating) (m³/h)

Piping Type

connection

Refrigerant Name of refrigerant

Wiring connection Power supply

Usable temperature range Indoor (Cooling / Heating) (°C)

Accessory Indoor unit Installation plate

Indoor unit Liquid side

Outdoor unit Liquid side

Maximum length (Per unit) (m)

Maximum chargeless length (m)

Maximum height difference (m)

Weight (kg)

Interconnection

Outdoor unit Drain nipple

Running current (A)

Power consumption (W)

Power factor (%)

Running current (A)

Power consumption (W)

Power factor (%)

Starting current (A)

Medium (Cooling / Heating) (dB•A)

Low (Cooling / Heating) (dB•A)

Width (mm)

Depth (mm)

Width (mm)

Depth (mm)

Type

Model

Gas side

Gas side

Outdoor (Cooling / Heating) (°C)

Wireless remote controller

Remote controller holder

Flat head wood screw

Purifying filter

Zeolite filter

Batteries

Mounting screw

Installation manual

Owner’s manual

Twin rotary type with DC-inverter variable speed control

220 – 230 –240V – 1Ph – 50/60Hz

Cooling Heating

0.15 0.15

30 30

87 87

Cooling Heating

5.07 / 4.84 / 4.63 5.40 / 5.16 / 4.94

1060 1130

95 95

3 Wires : includes earth (Outdoor)

• The specifications may be subject to change without notice for purpose of improvement.

RAS-13UKV-E

RAS-13UAV-E

—

3.5

0.9 – 4.0

4.2

0.9 – 6.0

5.55 / 5.31 / 5.09

3.21 / 3.62

39 / 39

33 / 34

26 / 28

48 / 50

RAS-13UKV-E

275

790

208

10

30

530 / 620

RAS-13UAV-E

550

780

270

38

750

DA91A1F-44F

43

2410 / 2410

Flare connection

Ø6.35

Ø9.52

Ø6.35

Ø9.52

15

15

10

R410A

0.8

4 Wires : includes ear th

21 – 32 / 0 – 28

10 – 43 / –10 – 24

1

1

1

2 (Ø3.1 x 16L)

1

1

2

6 (Ø4 x 25L)

1

1

1

– 3 –

Page 4

1-2. Operation Characteristic Curve

<Cooling> <Heating>

7

6

RAS-13UKV-E

5

4

3

Current (A)

2

• Conditions

Indoor : DB 27˚C/WB 19˚C

Outdoor : DB 35˚C

1

Air flow : High

Pipe length : 5m

230V

0

0 20 40 60 80 100

Compressor speed (rps)

7

6

RAS-13UKV-E

5

4

3

Current (A)

2

• Conditions

Indoor : DB 20˚C

Outdoor : DB 7˚C/WB 6˚C

1

Air flow : High

Pipe length : 5m

230V

0

0 20 40 60 80 100

Compressor speed (rps)

1-3. Capacity Variation Ratio According to Temperature

<Cooling> <Heating>

105

100

95

90

85

80

75

70

Capacity ratio (%)

65

60

55

50

32 34

Current Limited Start

RAS-13UKV-E

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length 5m

36 38 40 4233 35 37 39 41 43

Outdoor temp. (˚C)

120

110

100

90

80

70

60

50

Capacity ratio (%)

40

30

20

10

0

–10–9–8–7–6–5–4–3–2–1012345678910

RAS-13UKV-E

• Conditions

Indoor : DB 20˚C

Indoor air flow : High

Pipe length : 5m

Outdoor temp. (˚C)

Capacity ratio : 100% = 3.5 kW (RAS-13UKV-E)

*

– 4 –

Page 5

2. REFRIGERANT R410A

This air conditioner adopts the new refrigerant HFC

(R410A) which does not damage the ozone layer.

The working pressure of the new refrigerant R410A

is 1.6 times higher than conventional refrigerant

(R22). The refrigerating oil is also changed in

accordance with change of refrigerant, so be careful

that water, dust, and existing refrigerant or refrigerating oil are not entered in the refrigerant cycle of the

air conditioner using the new refrigerant during

installation work or servicing time.

The next section describes the precautions for air

conditioner using the new refrigerant. Conforming to

contents of the next section together with the

general cautions included in this manual, perform

the correct and safe work.

2-1. Safety During Installation/Servicing

As R410A’s pressure is about 1.6 times higher than

that of R22, improper installation/servicing may

cause a serious trouble. By using tools and materials exclusive for R410A, it is necessary to carry out

installation/servicing safely while taking the following

precautions into consideration.

(1) Never use refrigerant other than R410A in an air

conditioner which is designed to operate with

R410A.

If other refrigerant than R410A is mixed, pressure in the refrigeration cycle becomes abnormally high, and it may cause personal injury, etc.

by a rupture.

(2) Confirm the used refrigerant name, and use

tools and materials exclusive for the refrigerant

R410A.

The refrigerant name R410A is indicated on the

visible place of the outdoor unit of the air conditioner using R410A as refrigerant. To prevent

mischarging, the diameter of the service port

differs from that of R22.

(3) If a refrigeration gas leakage occurs during

installation/servicing, be sure to ventilate fully.

If the refrigerant gas comes into contact with fire,

a poisonous gas may occur.

(4) When installing or removing an air conditioner,

do not allow air or moisture to remain in the

refrigeration cycle. Otherwise, pressure in the

refrigeration cycle may become abnormally high

so that a rupture or personal injury may be

caused.

(5) After completion of installation work, check to

make sure that there is no refrigeration gas

leakage.

If the refrigerant gas leaks into the room, coming

into contact with fire in the fan-driven heater,

space heater, etc., a poisonous gas may occur.

(6) When an air conditioning system charged with a

large volume of refrigerant is installed in a small

room, it is necessary to exercise care so that,

even when refrigerant leaks, its concentration

does not exceed the marginal lev el.

If the refrigerant gas leakage occurs and its

concentration exceeds the marginal level, an

oxygen starvation accident may result.

(7) Be sure to carry out installation or removal

according to the installation manual.

Improper installation may cause refrigeration

trouble, water leakage, electric shock, fire, etc.

(8) Unauthorized modifications to the air conditioner

may be dangerous. If a breakdown occurs

please call a qualified air conditioner technician

or electrician.

Improper repair’s may result in water leakage,

electric shock and fire, etc.

2-2. Refrigerant Piping Installation

2-2-1. Piping Materials and Joints Used

For the refrigerant piping installation, copper pipes

and joints are mainly used. Copper pipes and joints

suitable for the refrigerant must be chosen and

installed. Furthermore, it is necessary to use clean

copper pipes and joints whose interior surfaces are

less affected by contaminants .

(1) Copper Pipes

It is necessary to use seamless copper pipes

which are made of either copper or copper alloy

and it is desirable that the amount of residual oil

is less than 40 mg/10 m. Do not use copper

pipes having a collapsed, deformed or discolored portion (especially on the interior surface).

Otherwise, the expansion v alve or capillary tube

may become bloc ked with contaminants.

As an air conditioner using R410A incurs

pressure higher than when using R22, it is

necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A

are as shown in Table 2-2-1. Never use copper

pipes thinner than 0.8 mm even when it is

available on the market.

– 5 –

Page 6

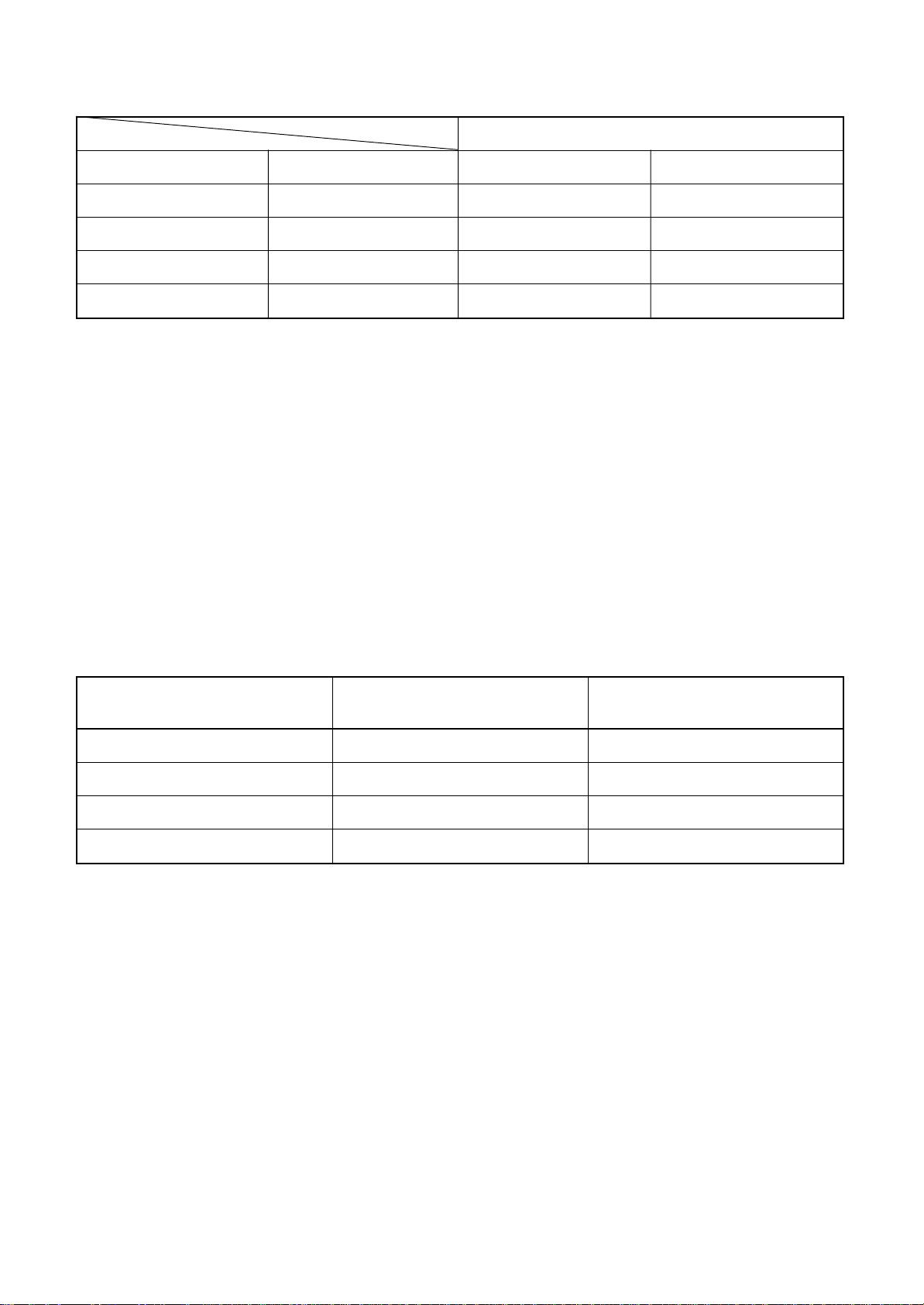

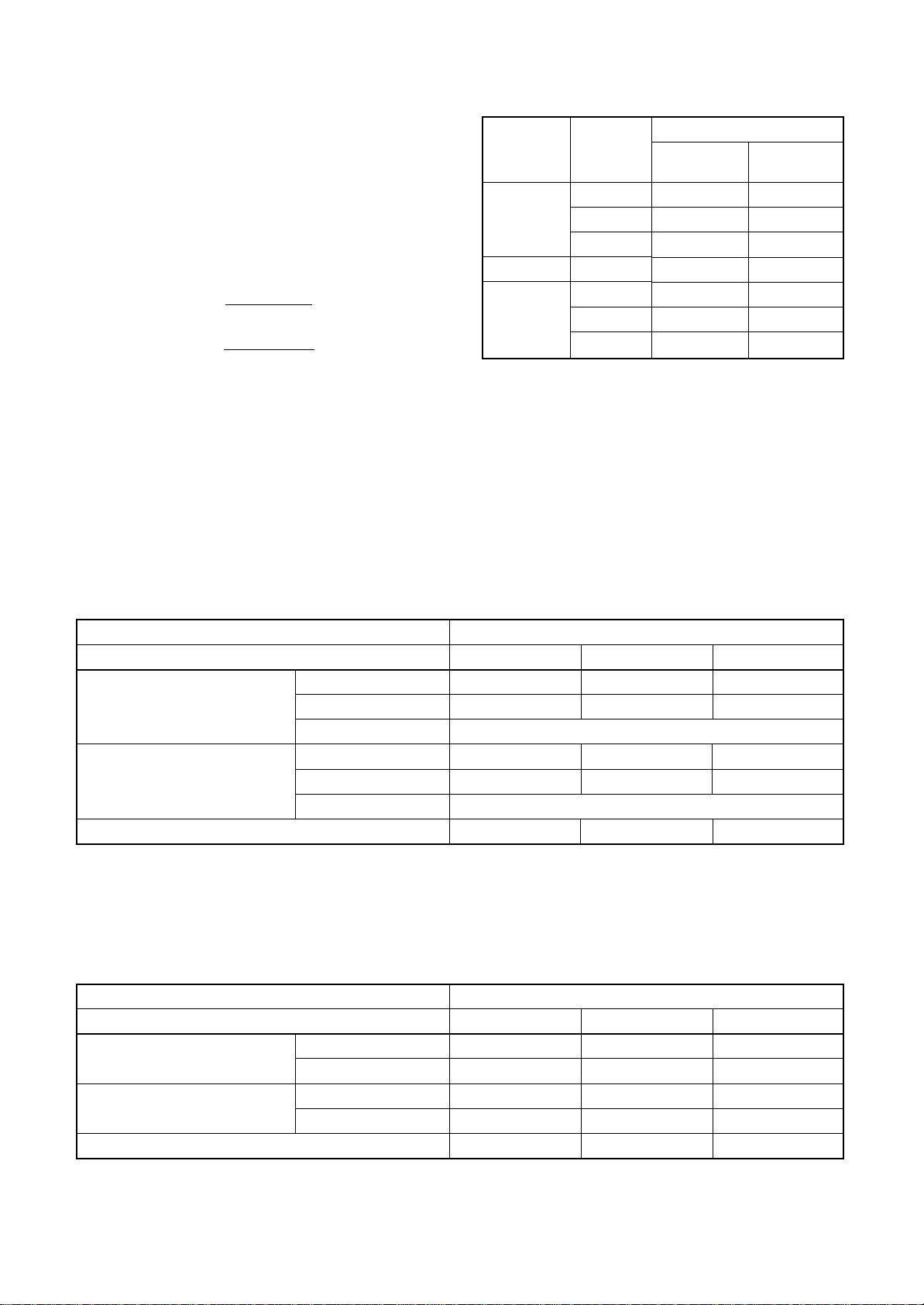

Table 2-2-1 Thicknesses of annealed copper pipes

Thickness (mm)

Nominal diameter

1/4

3/8

1/2

5/8

(2) Joints

For copper pipes, flare joints or soc ket joints are

used. Prior to use , be sure to remove all contaminants.

a) Flare Joints

Flare joints used to connect the copper pipes

cannot be used for pipings whose outer

diameter exceeds 20 mm. In such a case,

socket joints can be used.

Sizes of flare pipe ends, flare joint ends and

flare nuts are as shown in Tables 2-2-3 to 22-6 below .

Outer diameter (mm)

6.35

9.52

12.70

15.88

R410A R22

0.80 0.80

0.80 0.80

0.80 0.80

1.00 1.00

b) Socket Joints

Socket joints are such that they are brazed

for connections, and used mainly for thick

pipings whose diameter is larger than 20 mm.

Thicknesses of socket joints are as shown in

Table 2-2-2.

Table 2-2-2 Minimum thicknesses of socket joints

Nominal diameter

1/4

3/8

1/2

5/8

Reference outer diameter of

copper pipe jointed (mm)

2-2-2. Processing of Piping Materials

When performing the refrigerant piping installation,

care should be taken to ensure that water or dust

does not enter the pipe interior, that no other oil

other than lubricating oils used in the installed air

conditioner is used, and that refrigerant does not

leak. When using lubricating oils in the piping

processing, use such lubricating oils whose water

content has been removed. When stored, be sure to

seal the container with an airtight cap or any other

cover.

Minimum joint thickness

(mm)

6.35

9.52

12.70

15.88

(1) Flare Processing Procedures and Precautions

a) Cutting the Pipe

By means of a pipe cutter, slowly cut the pipe

so that it is not deformed.

b) Removing Burrs and Chips

If the flared section has chips or burrs,

refrigerant leakage may occur. Carefully

remove all b urrs and clean the cut surface

before installation.

c) Insertion of Flare Nut

0.50

0.60

0.70

0.80

– 6 –

Page 7

d) Flare Processing

Make certain that a clamp bar and copper

pipe have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conventional flare tool.

Flare processing dimensions differ according

to the type of flare tool. When using a

conventional flare tool, be sure to secure

“dimension A” by using a gauge for size

adjustment.

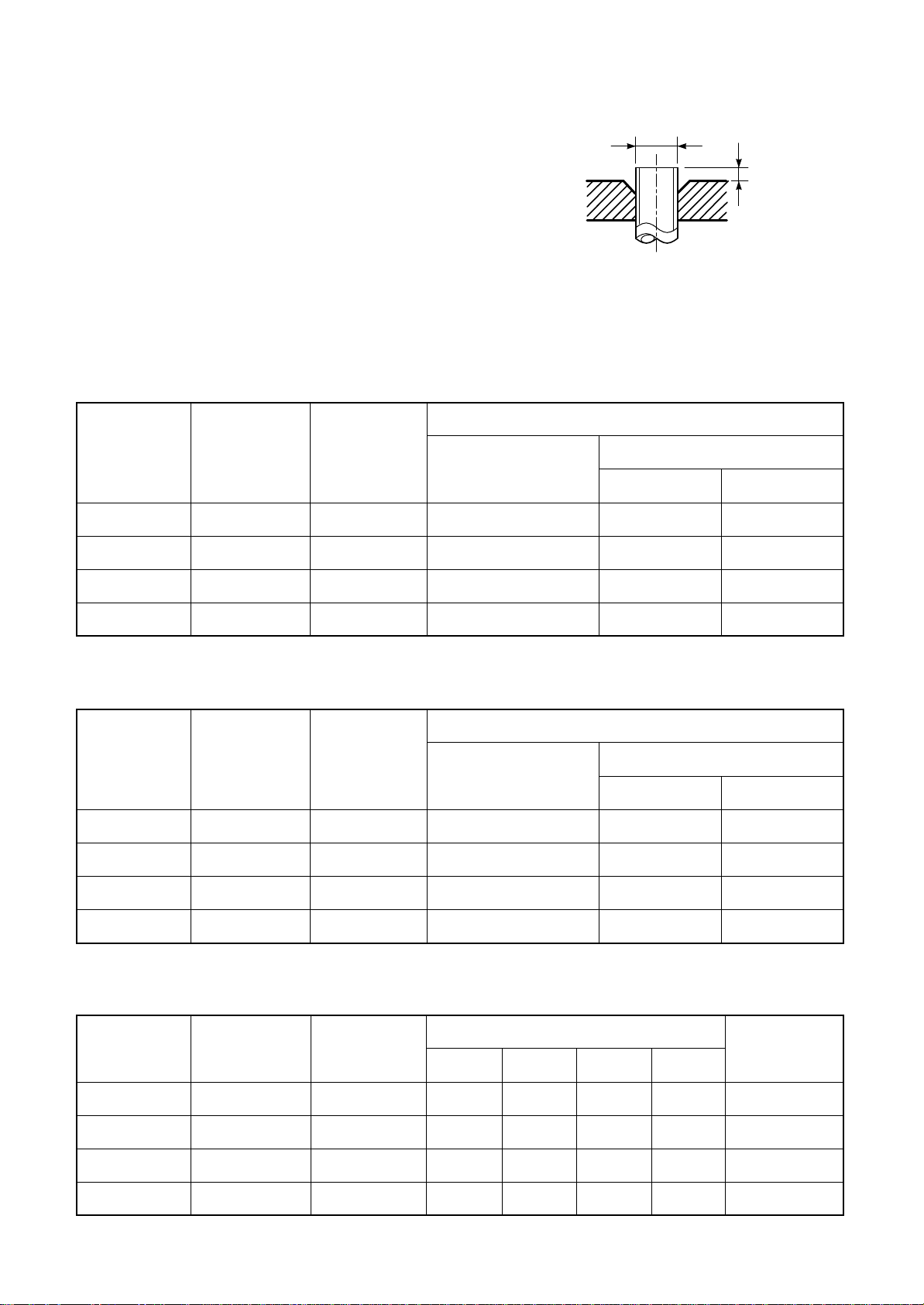

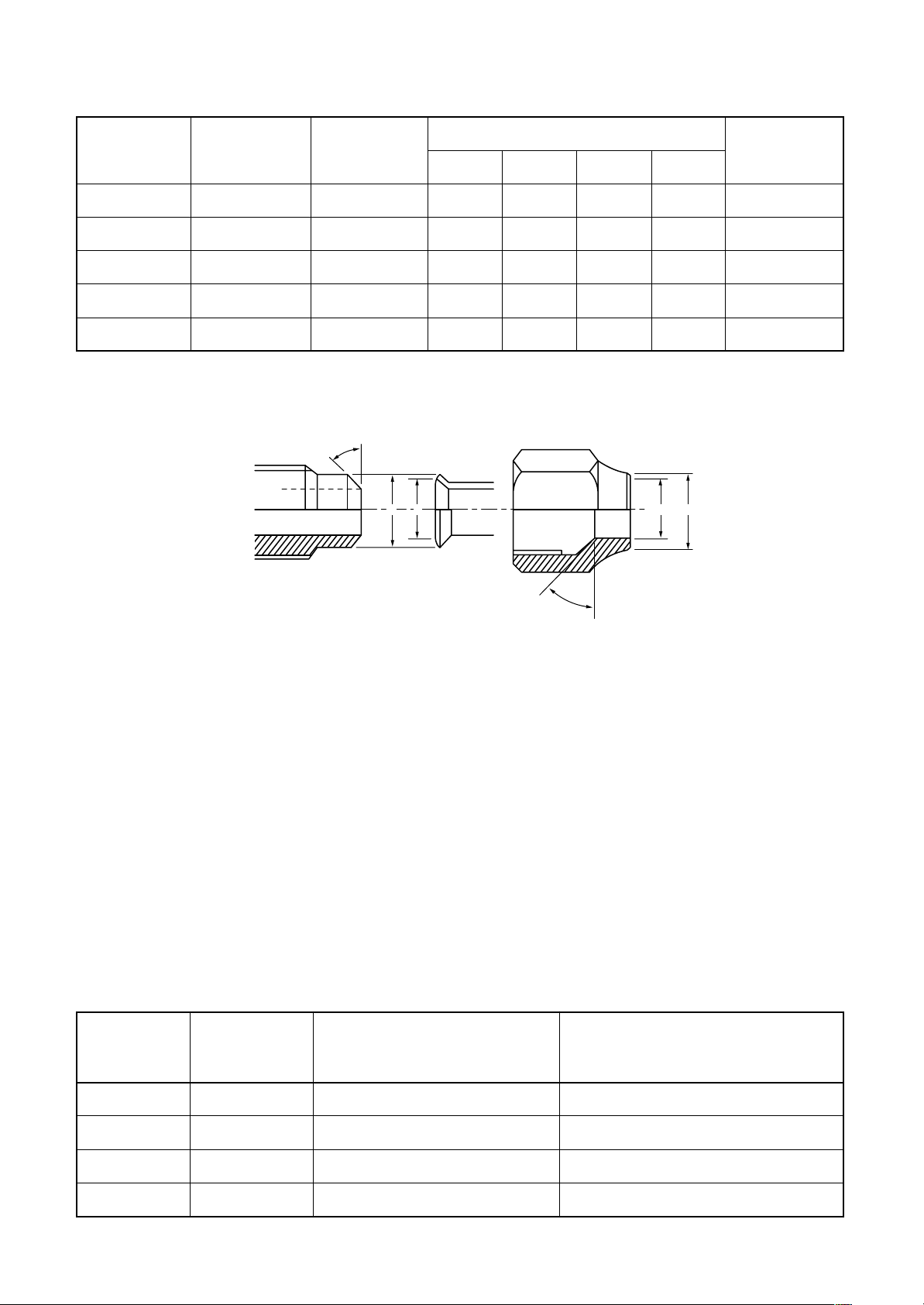

Table 2-2-3 Dimensions related to flare processing for R410A

ØD

A

Fig. 2-2-1 Flare processing dimensions

Nominal

diameter

1/4

3/8

1/2

5/8

Nominal

diameter

1/4

3/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

Flare tool for R410A

clutch type

0 to 0.5 1.0 to 1.5 1.5 to 2.0

0 to 0.5 1.0 to 1.5 1.5 to 2.0

0 to 0.5 1.0 to 1.5 2.0 to 2.5

0 to 0.5 1.0 to 1.5 2.0 to 2.5

Table 2-2-4 Dimensions related to flare processing for R22

A (mm)

A (mm)

Outer

diameter

(mm)

6.35

9.52

Thickness

(mm)

0.8

0.8

Flare tool for R410A

clutch type

0 to 0.5 0.5 to 1.0 1.0 to 1.5

0 to 0.5 0.5 to 1.0 1.0 to 1.5

Conventional flare tool

Clutch type Wing nut type

Conventional flare tool

Clutch type Wing nut type

1/2

5/8

Nominal

diameter

1/4

3/8

1/2

5/8

12.70

15.88

0.8

1.0

0 to 0.5 0.5 to 1.0 1.0 to 2.0

0 to 0.5 0.5 to 1.0 1.0 to 2.0

Table 2-2-5 Flare and flare nut dimensions for R410A

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

ABCD

9.1 9.2 6.5 13

13.2 13.5 9.7 20

16.6 16.0 12.9 23

19.7 19.0 16.0 25

Dimension (mm)

– 7 –

Flare nut

width

(mm)

17

22

26

29

Page 8

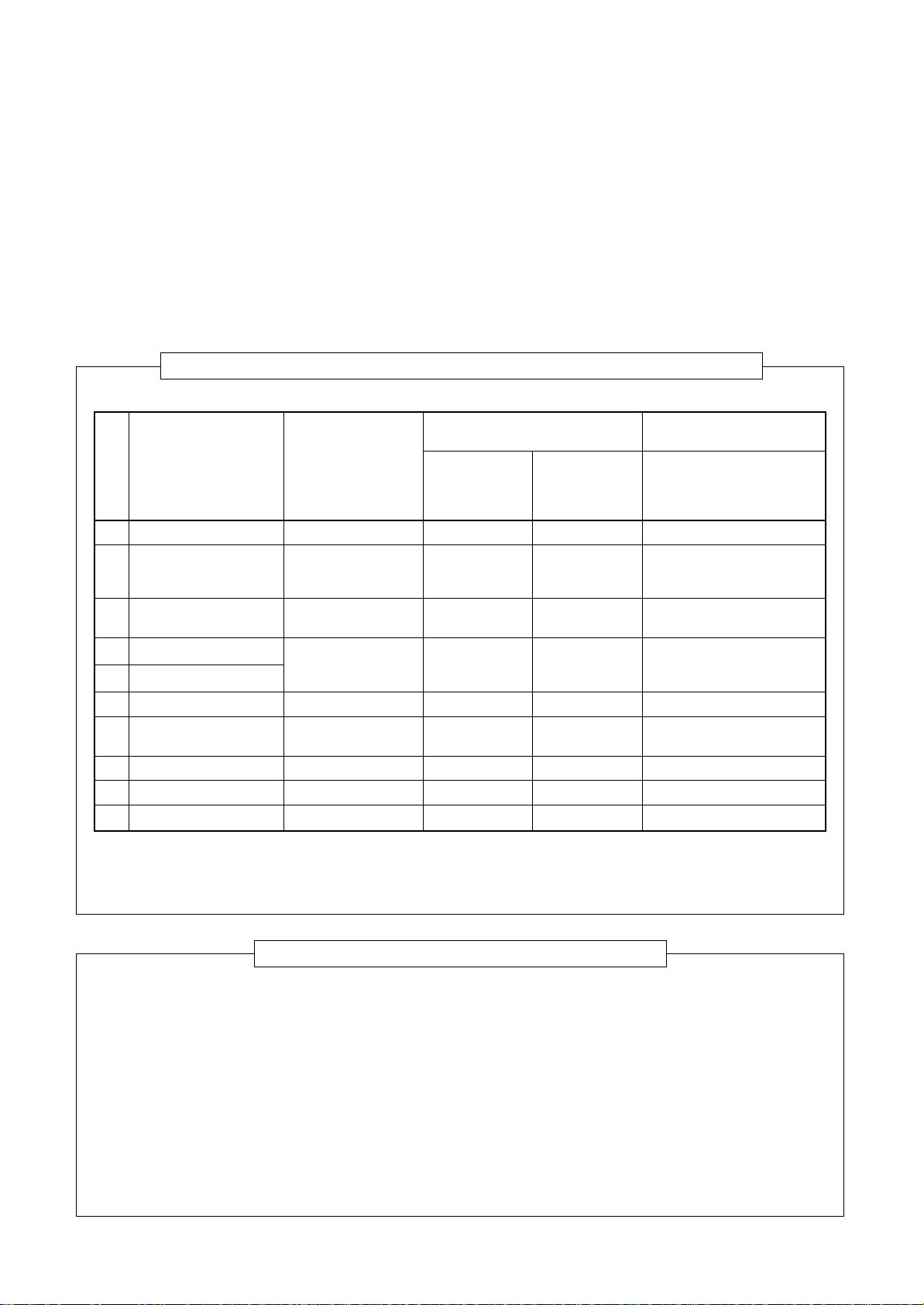

Table 2-2-6 Flare and flare nut dimensions for R22

Nominal

diameter

1/4

3/8

1/2

5/8

3/4

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

19.05

Thickness

(mm)

0.8

0.8

0.8

1.0

1.0

˚ to 46

45

Dimension (mm)

Flare nut

width

ABCD

9.0 9.2 6.5 13

13.0 13.5 9.7 20

16.2 16.0 12.9 20

19.7 19.0 16.0 23

23.3 24.0 19.2 34

˚

B A

D

C

(mm)

17

22

24

27

36

Fig. 2-2-2 Relations between flare nut and flare seal surface

(2) Flare Connecting Procedures and Precautions

a) Make sure that the flare and union portions

do not have any scar or dust, etc.

b) Correctly align the processed flare surface

with the union axis.

c) Tighten the flare with designated torque by

means of a torque wrench. The tightening

torque for R410A is the same as that for

conventional R22. Incidentally, when the

torque is weak, the gas leakage may occur.

Table 2-2-7 Tightening torque of flare for R410A [Reference values]

Nominal

diameter

Outer

diameter

(mm)

Tightening torque

N•m (kgf•cm)

43˚ to 45

˚

When it is strong, the flare nut may crack and

may be made non-removable. When choosing the tightening torque, comply with values

designated by manufacturers . Table 2-2-7

shows reference v alues.

NOTE :

When applying oil to the flare surface, be sure to use

oil designated by the manufacturer. If an y other oil is

used, the lubricating oils may deteriorate and cause

the compressor to burn out.

Tightening torque of torque

wrenches available on the market

N•m (kgf•cm)

1/4

3/8

1/2

5/8

6.35

9.52

12.70

15.88

14 to 18 (140 to 180)

33 to 42 (330 to 420)

50 to 62 (500 to 620)

63 to 77 (630 to 770)

– 8 –

16 (160), 18 (180)

42 (420)

55 (550)

65 (650)

Page 9

2-3. Tools

2-3-1. Required Tools

The service port diameter of pac ked valve of the outdoor unit in the air conditioner using R410A is changed to

prevent mixing of other refrigerant. To reinforce the pressure-resisting strength, flare processing dimensions

and opposite side dimension of flare nut (For Ø12.7 copper pipe) of the refrigerant piping are lengthened.

The used refrigerating oil is changed, and mixing of oil may cause a trouble such as generation of sludge,

clogging of capillary, etc. Accordingly, the tools to be used are classified into the following three types.

(1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

(2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

(3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

Conventional air

conditioner installation

Whether new equipment

can be used with

conventional refrigerant

¡

(Note 1)

*

X

X

¡

¡

X

¡

X

No.

1

2

3

4

5

6

7

8

9

10

Used tool

Flare tool

Copper pipe gauge for

adjusting projection

margin

Torque wrench

(For Ø12.7)

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Charging cylinder

Usage

Pipe flaring

Flaring by

conventional flare

tool

Connection of flare

nut

Evacuating,

refrigerant charge,

run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

Refrigerant charge

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

R410A

Whether

conventional

equipment

can be used

(Note 1)

*

(Note 1)

*

air conditioner installation

Existence of

new equipment

for R410A

(Note 2)

X

X

X

X

X

X

X

(Note 1) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

(Note 2) Charging cylinder for R410A is being currently developed.

General tools (Conventional tools can be used.)

In addition to the above e xclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

(1) Vacuum pump

Use vacuum pump by

attaching vacuum pump adapter.

(2) Torque wrench (For Ø6.35, Ø9.52)

(3) Pipe cutter

(4) Reamer

(5) Pipe bender

(6) Level vial

(7) Screwdriver (+, –)

(8) Spanner or Monkey wrench

(9) Hole core drill (Ø65)

(10) Hexagon wrench

(Opposite side 5mm)

(11) Tape measure

(12) Metal saw

Also prepare the following equipments for other installation method and run chec k.

(1) Clamp meter

(2) Thermometer

(3) Insulation resistance tester

(4) Electroscope

– 9 –

Page 10

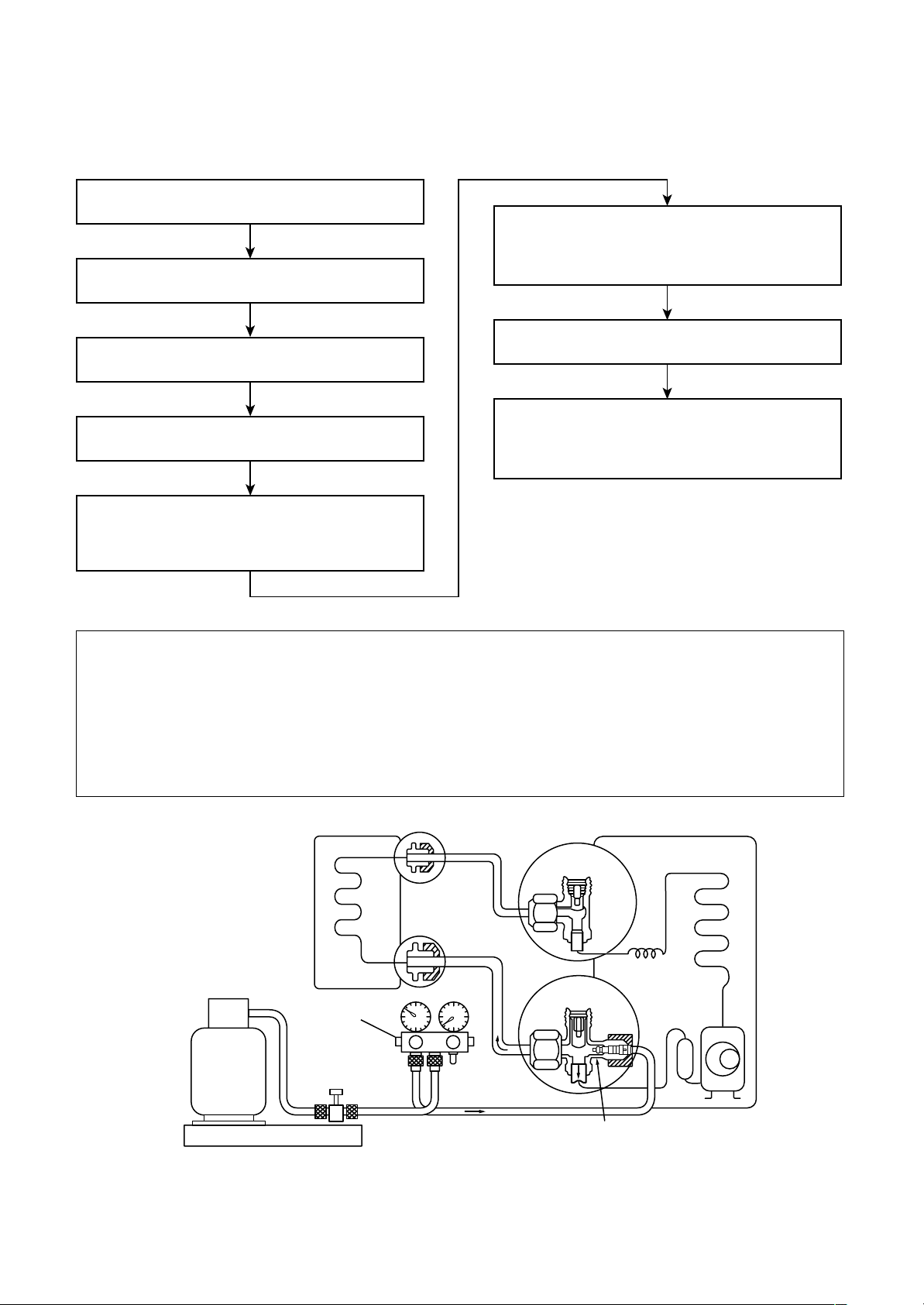

2-4. Recharging of Refrigerant

When it is necessary to recharge refrigerant, charge the specified amount of new refrigerant according to the

following steps .

Recover the refrigerant, and check no refrigerant

remains in the equipment.

Connect the charge hose to packed valve service

port at the outdoor unit’s gas side.

Connect the charge hose to the vacuum pump

adapter.

Open fully both packed valves at liquid and gas

sides.

When the compound gauge’s pointer has indicated

–0.1 Mpa (–76 cmHg), place the handle Low in the

fully closed position, and turn off the vacuum pump’s

power switch.

Keep the status as it is for 1 to 2 minutes, and ensure

that the compound gauge’s pointer does not return.

Set the refrigerant cylinder to the electronic balance,

connect the connecting hose to the cylinder and the

connecting port of the electronic balance, and charge

liquid refrigerant.

Place the handle of the gauge manifold Low in the

fully opened position, and turn on the vacuum pump’s

power switch. Then, evacuating the refrigerant in the

cycle.

(For refrigerant charging, see the figure below.)

(1) Never charge refrigerant exceeding the specified amount.

(2) If the specified amount of refrigerant cannot be charged, charge refrigerant bit by bit in COOL mode.

(3) Do not carry out additional charging.

When additional charging is carried out if refrigerant leaks, the refrigerant composition changes in the

refrigeration cycle, that is characteristics of the air conditioner changes, refrigerant exceeding the

specified amount is charged, and working pressure in the refrigeration cycle becomes abnormally high

pressure, and may cause a rupture or personal injury.

(INDOOR unit)

(Liquid side)

(OUTDOOR unit)

Opened

Refrigerant cylinder

(With siphon pipe)

Check valve

Open/Close valve

for charging

Electronic balance for refrigerant charging

Fig. 2-4-1 Configuration of refrigerant charging

(Gas side)

Closed

Service port

– 10 –

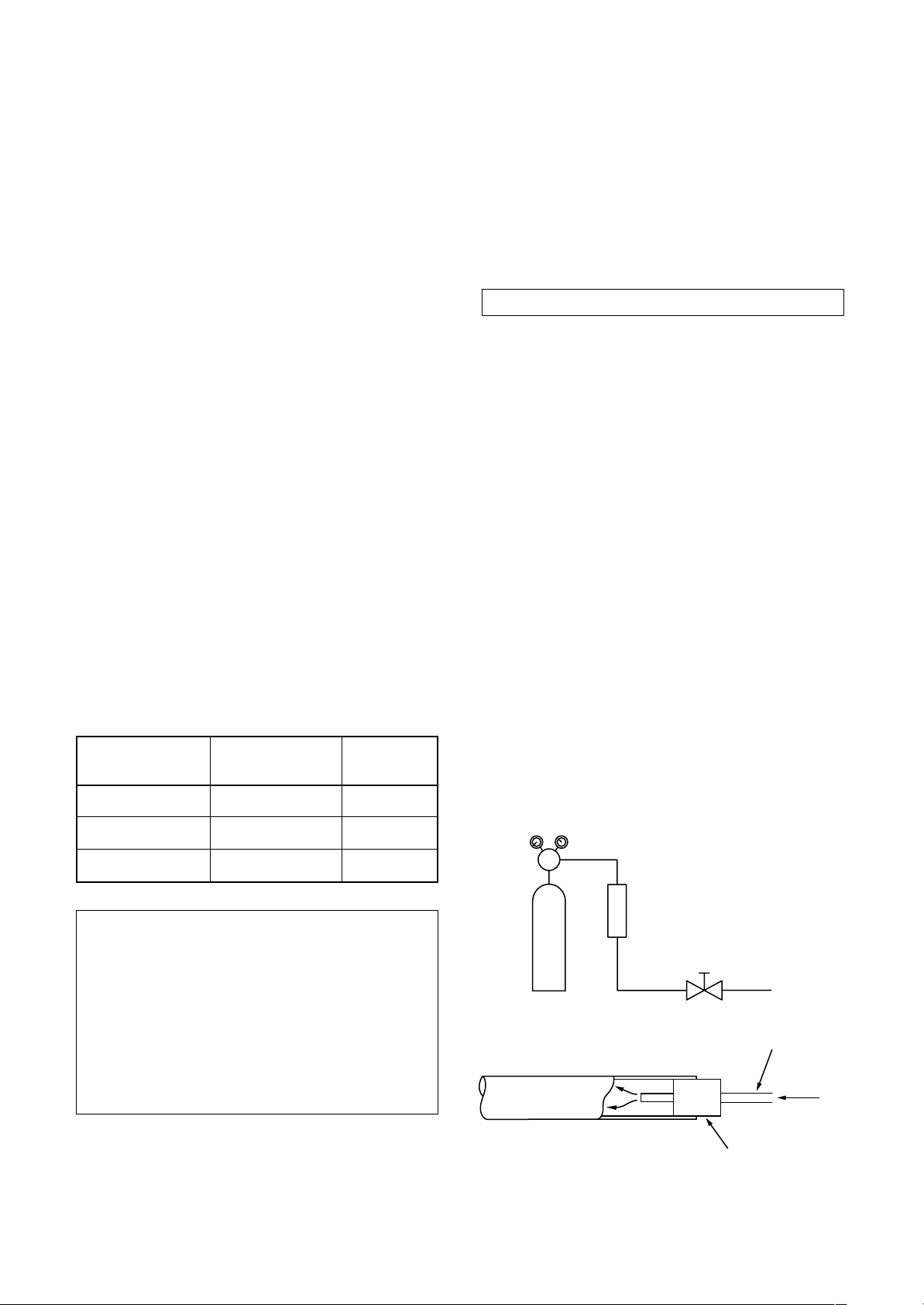

Page 11

(1) Be sure to make setting so that liquid can be charged.

(2) When using a cylinder equipped with a siphon, liquid can be charged without turning it upside down.

It is necessary for charging refrigerant under condition of liquid because R410A is mixed type of refrigerant.

Accordingly, when charging refrigerant from the refrigerant cylinder to the equipment, charge it turning the

cylinder upside down if cylinder is not equipped with siphon.

[ Cylinder with siphon ] [ Cylinder without siphon ]

Gauge manifold

OUTDOOR unit

Refrigerant

cylinder

Gauge manifold

OUTDOOR unit

cylinder

Refrigerant

Electronic

balance

R410A refrigerant is HFC mixed refrigerant.

Therefore, if it is charged with gas, the composition of the charged refrigerant changes and the

characteristics of the equipment varies.

2-5. Brazing of Pipes

2-5-1. Materials for Brazing

(1) Silver brazing filler

Silver brazing filler is an alloy mainly composed

of silver and copper. It is used to join iron,

copper or copper alloy, and is relatively expensive though it excels in solderability.

Electronic

balance

Siphon

Fig. 2-4-2

(1) Phosphor bronze brazing filler tends to react

with sulfur and produce a fragile compound

water solution, which may cause a gas

leakage. Therefore, use any other type of

brazing filler at a hot spring resort, etc., and

coat the surface with a paint.

(2) When performing brazing again at time of

servicing, use the same type of brazing filler.

(2) Phosphor bronze brazing filler

Phosphor bronze brazing filler is generally used

to join copper or copper alloy.

(3) Low temperature brazing filler

Low temperature brazing filler is generally called

solder, and is an alloy of tin and lead. Since it is

weak in adhesive strength, do not use it for

refrigerant pipes.

2-5-2. Flux

(1) Reason why flux is necessary

• By removing the oxide film and any foreign

matter on the metal surface, it assists the flo w

of brazing filler.

• In the brazing process, it prevents the metal

surface from being oxidiz ed.

• By reducing the brazing filler’s surface tension,

the brazing filler adheres better to the treated

metal.

– 11 –

Page 12

(2) Characteristics required for flux

Nitrogen gas

cylinder

Pipe

Flow meter

M

Stop valve

From Nitrogen cylinder

Nitrogen

gas

Rubber plug

• Activated temperature of flux coincides with

the brazing temperature.

• Due to a wide effective temperature range, flux

is hard to carbonize.

• It is easy to remove slag after brazing.

• The corrosive action to the treated metal and

brazing filler is minimum.

• It excels in coating performance and is harmless to the human body.

As the flux works in a complicated manner as

described above, it is necessary to select an

adequate type of flux according to the type and

shape of treated metal, type of brazing filler and

brazing method, etc.

(3) Types of flux

• Noncorrosive flux

Generally, it is a compound of borax and boric

acid.

It is effective in case where the br azing temperature is higher than 800°C.

• Activated flux

Most of fluxes generally used for silver brazing

are this type.

It features an increased o xide film remo ving

capability due to the addition of compounds

such as potassium fluoride, potassium chloride

and sodium fluoride to the borax-boric acid

compound.

(4) Piping materials for brazing and used braz-

ing filler/flux

2-5-3. Brazing

As brazing work requires sophisticated techniques,

experiences based upon a theoretical knowledge, it

must be performed by a person qualified.

In order to prevent the oxide film from occurring in

the pipe interior during brazing, it is effective to

proceed with brazing while letting dry Nitrogen gas

(N2) flow .

Never use gas other than Nitrogen gas.

(1) Brazing method to prevent oxidation

1) Attach a reducing valve and a flow-meter to

the Nitrogen gas cylinder.

2) Use a copper pipe to direct the piping material, and attach a flow-meter to the cylinder.

3) Apply a seal onto the clearance between the

piping material and inserted copper pipe for

Nitrogen in order to prevent backflow of the

Nitrogen gas.

4) When the Nitrogen gas is flowing, be sure to

keep the piping end open.

5) Adjust the flow rate of Nitrogen gas so that it

is lower than 0.05 m3/Hr or 0.02 MPa (0.2kgf/

cm2) by means of the reducing valv e.

6) After performing the steps above, keep the

Nitrogen gas flowing until the pipe cools

down to a certain extent (temperature at

which pipes are touchable with hands).

7) Remove the flux completely after brazing.

Copper - Copper

Copper - Iron

(1) Do not enter flux into the refrigeration cycle.

(2) When chlorine contained in the flux remains

(3) When adding water to the flux, use water

(4) Remove the flux after brazing.

Piping

material

Used brazing Used

filler flux

Phosphor copper Do not use

Silver Paste flux

Iron - Iron

Silver Vapor flux

within the pipe, the lubricating oil deteriorates. Therefore, use a flux which does not

contain chlorine.

which does not contain chlorine (e.g. distilled

water or ion-exchange water).

Fig. 2-5-1 Prevention of oxidation during brazing

– 12 –

Page 13

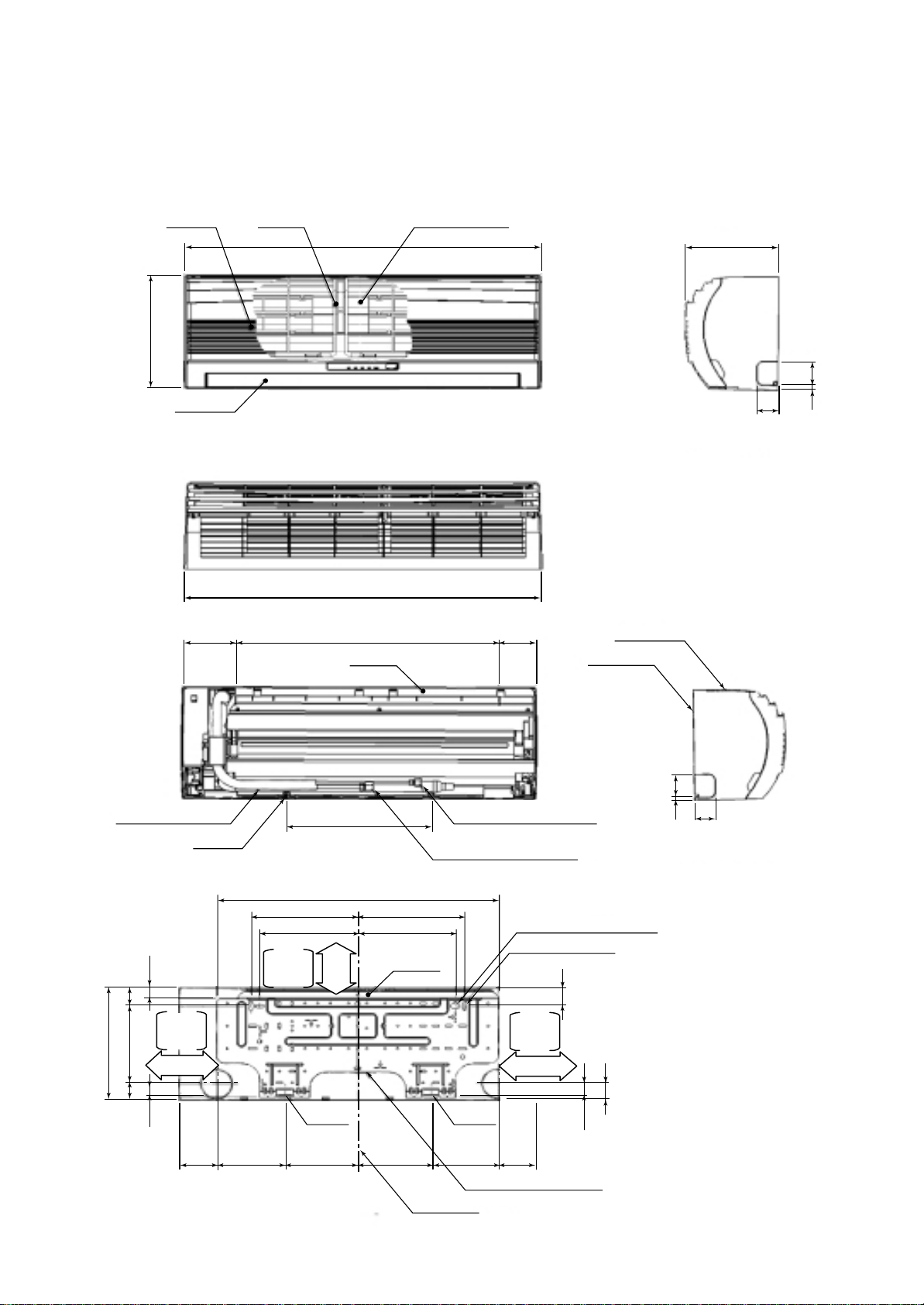

3-1. Indoor Unit

RAS-13UKV-E

Air inlet Air filter Heat exchanger

275

3. CONSTRUCTION VIEWS

790

208

606

Air outlet

790

120 590 80

Hanger

Drain hose (0.54m) Connecting pipe (0.43m)

Hanger

321

(Flare Ø6.35)

Connecting pipe (0.33m)

(Flare Ø9.52)

620

235 235

For stud bolt (Ø8 to Ø10)

For stud bolt (Ø6)

Minimum

distance

to wall

120 or more

275

26

190 4540

Minimum

distance

to wall

120 or more

Minimum

distance

to ceiling

66 or

more

215215

Hanger

45

Front panel

Back body

48

Knock out system

60

48

6

Knock out system

32

HangerHanger

90 150 160 160 150

Center line

– 13 –

40

32

90

Installation plate outline

Page 14

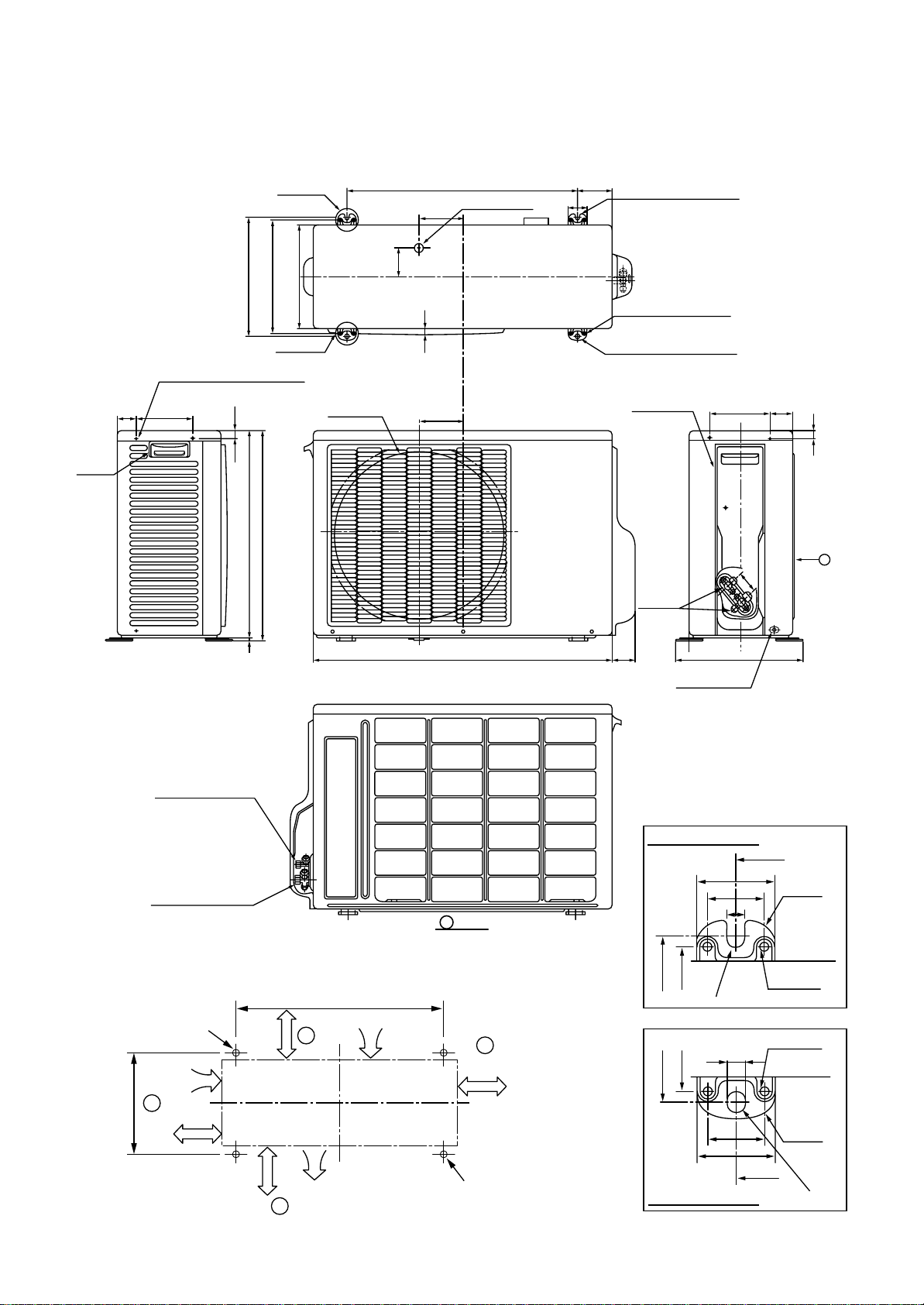

3-2. Outdoor Unit

RAS-13UAV-E

Hanger

A leg part

310

296

(ø6 hole pitch)

(Anchor bolt long hole pitch)

B leg part

Ø4.5 embossing (Ø4STS used)

(For sunshade roof attaching)

14749,5

21

540

548

270

Fan guard

600

Ø25 drain hole

115

76

90

Ø11 x 17U-shape hole

50

(For Ø8-Ø10 anchor bolt)

8-Ø6 hole

(For fixing outdoor unit)

16

Ø11 x 17 long hole

(For Ø8-Ø10 anchor bolt)

115.5

Valve cover

Charging

port

157

59

21

54

Z

Connecting pipe port

(Pipe dia.Ø6.35)

Connecting pipe port

(Pipe dia.Ø9.52)

4 x Ø11 x 17U-shape hole

(For Ø8-Ø10 anchor bolt)

Intake

100 or

C

310

more

200 or more

8

Mounting dimensions of anchor bolt

600

50 or

more

D

Intake

Outside line

of product

Outlet

B

780 61

Z

view

A

250 or more

(Minimum distance

from wall)

4 x Ø11 × 17 long hole

(For Ø8-Ø10 anchor bolt)

322

Earth terminal

Detailed A leg part

50

36

11

310

296

R5.5

11

310

296

36

50

Detailed B leg part

600

2-Ø6 hole

2-Ø6 hole

600

R15

Outside line

of product

Outside line

of product

R15

R5.5

– 14 –

Page 15

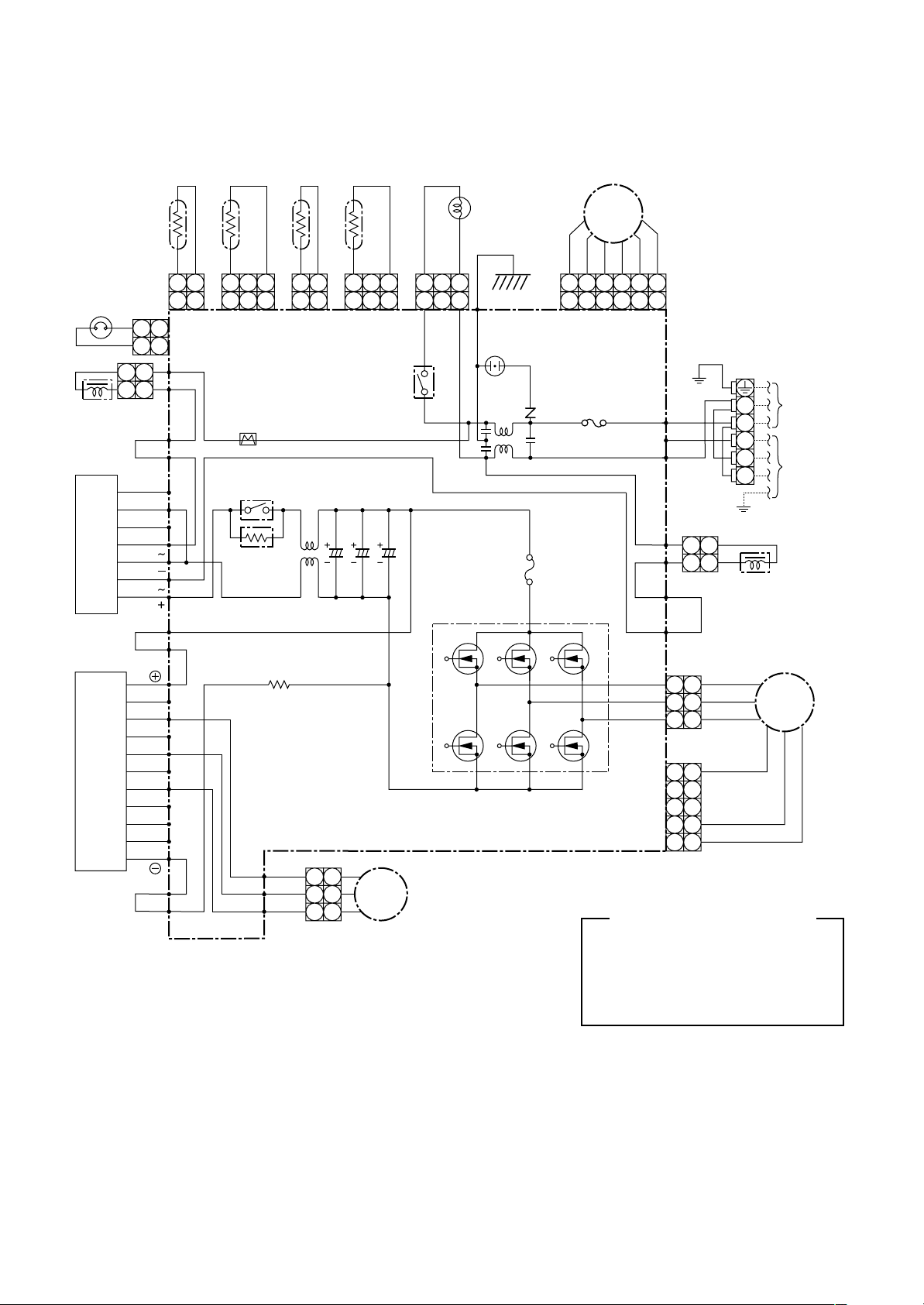

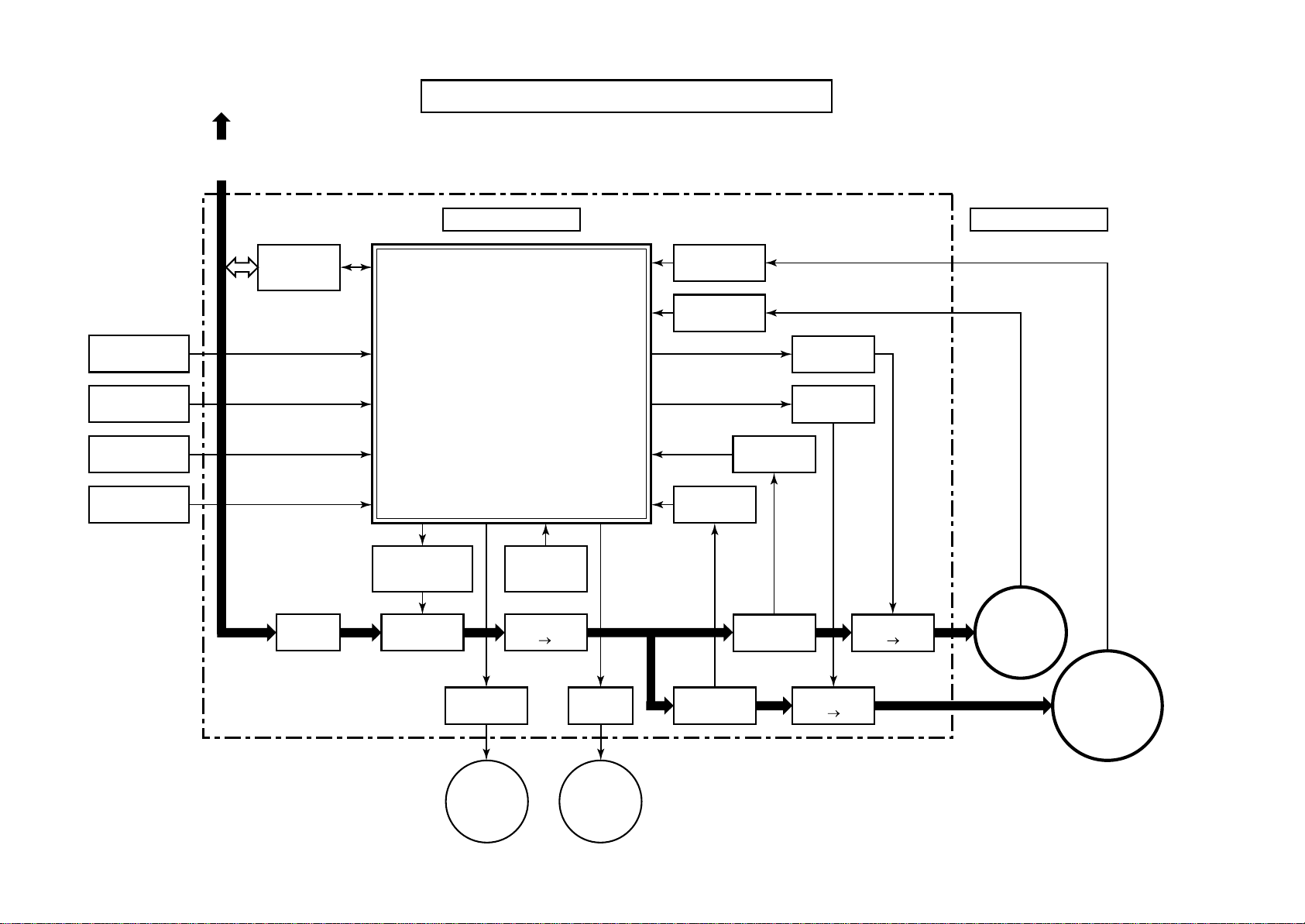

4-1. Indoor Unit

RAS-13UKV-E

COLOR IDENTIFICATIONBLU

BLK : BLACK

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

GRN & YEL: GREEN & YELLOW

CN01

(BLU)

BLK

121

BLK

HEAT EXCHANGER

SENSOR (TC)

BLK

BLK

THERMO SENSOR

(TA)

CN25

(WHI)

1

2

3

4

5

6

7

8

9

AND INDICATING PARTS

10

INFRARED RAYS RECEIVING

MCC-861

11

10

11

BLU

1

BLU

2

BLU

3

BLU

4

BLU

5

BLU

6

BLU

7

BLU

8

BLU

9

BLU

WHI

CN03

(WHI)

121

CN13

(WHI)

1

2

3

4

5

6

7

8

9

10

10

11

11

2

2

1

2

3

4

5

6

7

8

9

MAIN P.C. BOARD

1 4

FUSE

F01

T3.15A

AC 250V

MCC-867

4. WIRING DIAGRAM

21 3

WHIBLK

CN23 CN21CN24

3

RED

R04

2

LINE

FILTER

CN08

21 43

HA JEM-A

TERMINAL

BLOCK

GRN & YEL

DB01R05

C03

INDOOR

UNIT

DC5V

DC12V

OUTDOOR

UNIT

CN10

6

(WHI)

1

1

3

3

4

4

5

5

66

5

CN07

(WHI)

1

1

2

2

CIRCUIT

3

3

4

4

POWER SUPPLY

5

5

FAN MOTOR

RED

BLK

WHI

DC MOTOR

YEL

BLU

WHI

1

YEL

YEL

YEL

YEL

1

2

2

3

3

4

4

5

5

LOUVER MOTOR

T a ble 4-1-1 Simple check for failure diagnosis

Check items

OPERATION indicator

1

Terminal block

2

Fuse 3.15A

3

DC 5V

4

DC 12V

5

DC 325V

6

(DC310 to 340V)

Check to see if the OPERATION indicator goes on and off when the main switch or

breaker is turned on.

(Check the primary and secondary voltage of the transformer.)

Check the power supply voltage between and . (Refer to the name plate.)

(Check the primary and secondary voltage of the transformer.)

Check the fluctuating voltage between

Check to see if the fuse blows out.

(Check the R04 of the varistor.)

Check the voltage at the No.4 pin on CN13 connector of the infrared receiver.

(Check the transformer and the power supply circuit of the rated voltage.)

Check for voltage at the white lead of the louver motor.

(Check the transformer and the power supply circuit of the rated voltage.)

Check for voltage at the No.1 pin on CN10 connector.

(Check the DB01, R05 and C03.)

Refer to the service data for the detailed failure diagnosis.

– 15 –

Diagnosis result

and . (DC 15 to 60V)

Page 16

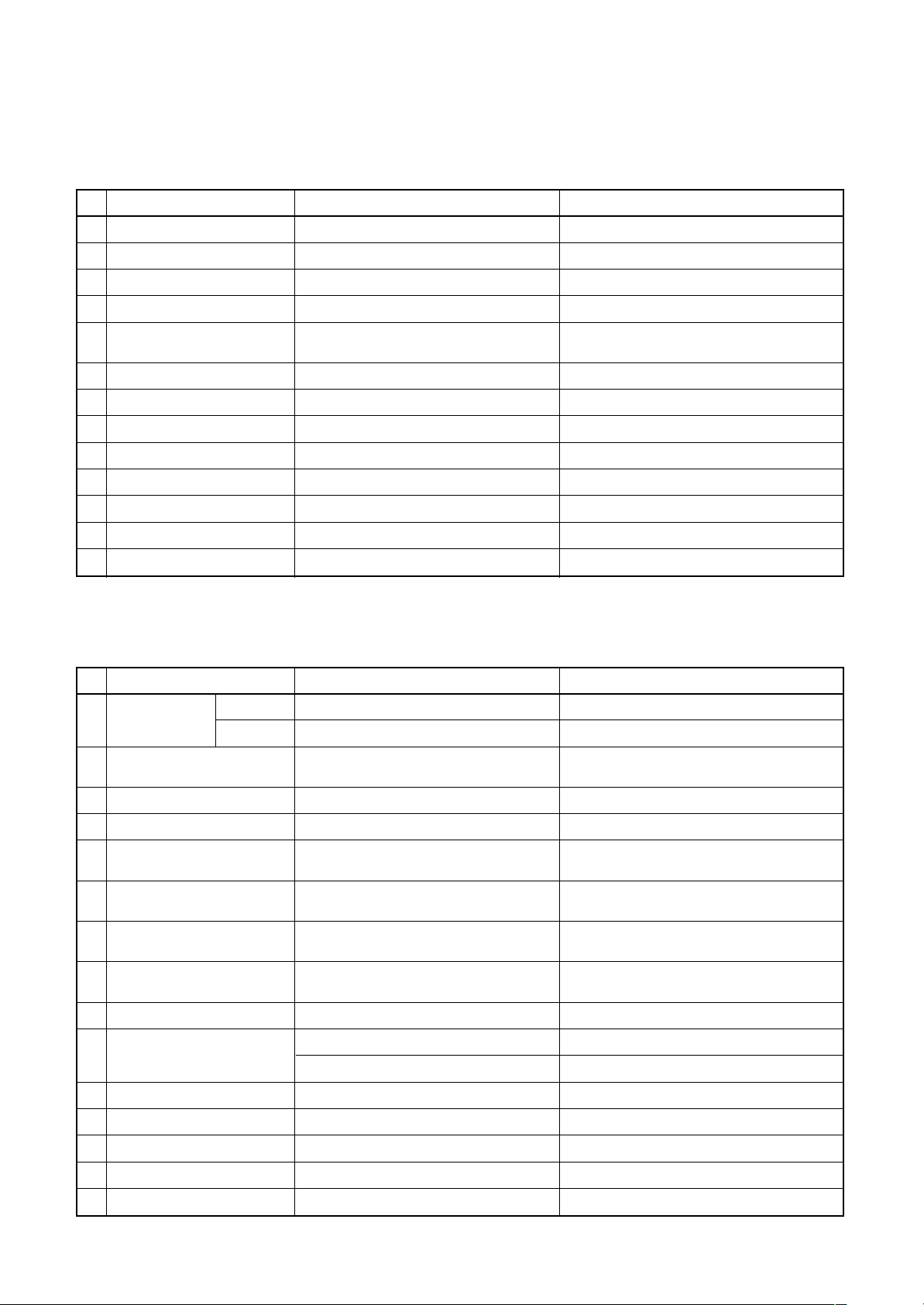

4-2. Outdoor Unit

RAS-13UAV-E

PULSE

MODULATING

VAL VE

TE

THERMOSTAT

FOR

COMPRESSOR

121

2

121

2

REACTOR

ORN

P10

G

E

A

CONVERTER

MODULE

DB01

BRW

BU

EU

BV

EV

BW

EW

BX

IGBT MODULE

BY

BZ

Q200

BLU P18

112

2

CN600

CN500

P07

P08

P09

P19

P20

P17

TD

11223

CT

POEWR RELA Y

ELECTRONIC

STARTER

P.C. BOARD

(MCC-813)

P21

P22

P23

3

TO

RED

WHI

BLK

TS

112

2

C12 C13 C14

1

1

2

2

3

3

COMPRESSOR

11223311223

CN701

RELAY

CM

COIL for

4-WAY VALVE

3

BLK

P06 CN703CN603CN602CN601

V ARIST OR

Q300

WHI

112

SURGE

ABSORBER

F04

FUSE

T3.15A

PMV

YEL

ORN

BLU

RED

GRY

3

44556

2

3

F01

FUSE

T25A

RED : RED ORN : ORANGE

WHI : WHITE PUR : PURPUL

BLK : BLACK YEL : YELLOW

BLU : BLUE GRY : GRY

BRW: BROWN PNK : PINK

6

P01

BLK

ORN

P03

WHI

P02

P11

P12

P13

P14

CN300

CN301

IGBT : Insulated Gate Bipolar Transistor

COLOR IDENTIFICATIONBLU

121

1

1

2

2

3

3

1

1

2

2

3

3

4

4

5

5

N

L

3

2

1

2

REACTOR

PUR

RED

WHI

BLK

YEL

PNK

GRY

F AN MOTER

FM

POWER

SUPPLY

220-240V~

50/60Hz

TO

INDOOR

UNIT

– 16 –

Page 17

5-1. Indoor Unit

RAS-13UKV-E

5. SPECIFICATIONS OF ELECTRICAL PARTS

No.

1

Fan motor (for indoor)

2

Thermo. sensor (TA-sensor)

3

DC-DC transformer (T01)

4

Microcomputer

Heat exchanger temp. sensor

5

(TC-sensor)

6

Line filter (L01)

7

Diode (DB01)

8

Capacitor (C03)

9

Fuse (F01)

10

Power supply IC (IC01)

11

Varistor (R21, R109)

12

Resistor (R01)

13

Louver motor

Parts name

5-2. Outdoor Unit

RAS-13UAV-E

Type

ICF-340-30-2

( – )

SWT-70

µPD780024AGK

( – )

SS11V-06270

D3SBA60

KMH450VNSN120M25C

FCU 250V, 3.15A

STR-L472

15G561K

RF-5TK4R7

MP24GA

Specifications

DC340V, 30W

10kΩ at 25°C

DC390V, Secondary DC15V, 12V, 7V

10kΩ at 25°C

27mH, AC0.6A

4A, 600V

120µF, 450V

T3.15A, 250V

560V

4.7Ω, 5W

Output (Rated) 1W, 16poles, 1phase DC12V

No.

SC coil

1

(Noise filter)

2

DC-DC transformer

3

Reactor

4

Outside fan motor

Suction temp. sensor

5

(TS sensor)

Discharge temp. sensor

6

(TD sensor)

Outside air temp. sensor

7

(TO sensor)

Heat exchanger temp. sensor

8

(TE sensor)

9

Terminal block (6P)

10

Fuse

11

Electrolytic capacitor

12

Transistor module

Parts name

L03

L01

Model name

ADR2520-R15TB

ADR2516-0R6TB

SWT-43

CH-38

ICF-140-43-1

(Inverter attached)

(Inverter attached)

(Inverter attached)

(Inverter attached)

——

For protection of switching power source

For protection of inverter input overcurrent

LLQ2G501KHUATF , 400LISN500K35F

6MBI25GS-060-01 or 6MBI25GS-060-01A

Rating

15A, 0.6mH

20A, 150µH

Primary side DC280V, Secondary side

7.5V x 1, 13V x 1, 26.5V x 3, 16V x 1, 15V x 1

L=10mH, 16A x 2

DC140V, 43W

10kΩ (25°C)

62kΩ (20°C)

10kΩ (25°C)

10kΩ (25°C)

20A, AC250V

3.15A, AC250V

25A, AC250V

500µF, DC400V X 3 pieces

25A, 600V

13

Compressor

14

Compressor thermo.

15

Converter module

DA91A1F-44F

US-622KXTMQO-SS

MP7003

– 17 –

3-phases 4-poles 750W

OFF: 125 ± 4°C, ON: 90 ± 5° C

Diode: 25A, 600V, IGBT: 40A, 600V

Page 18

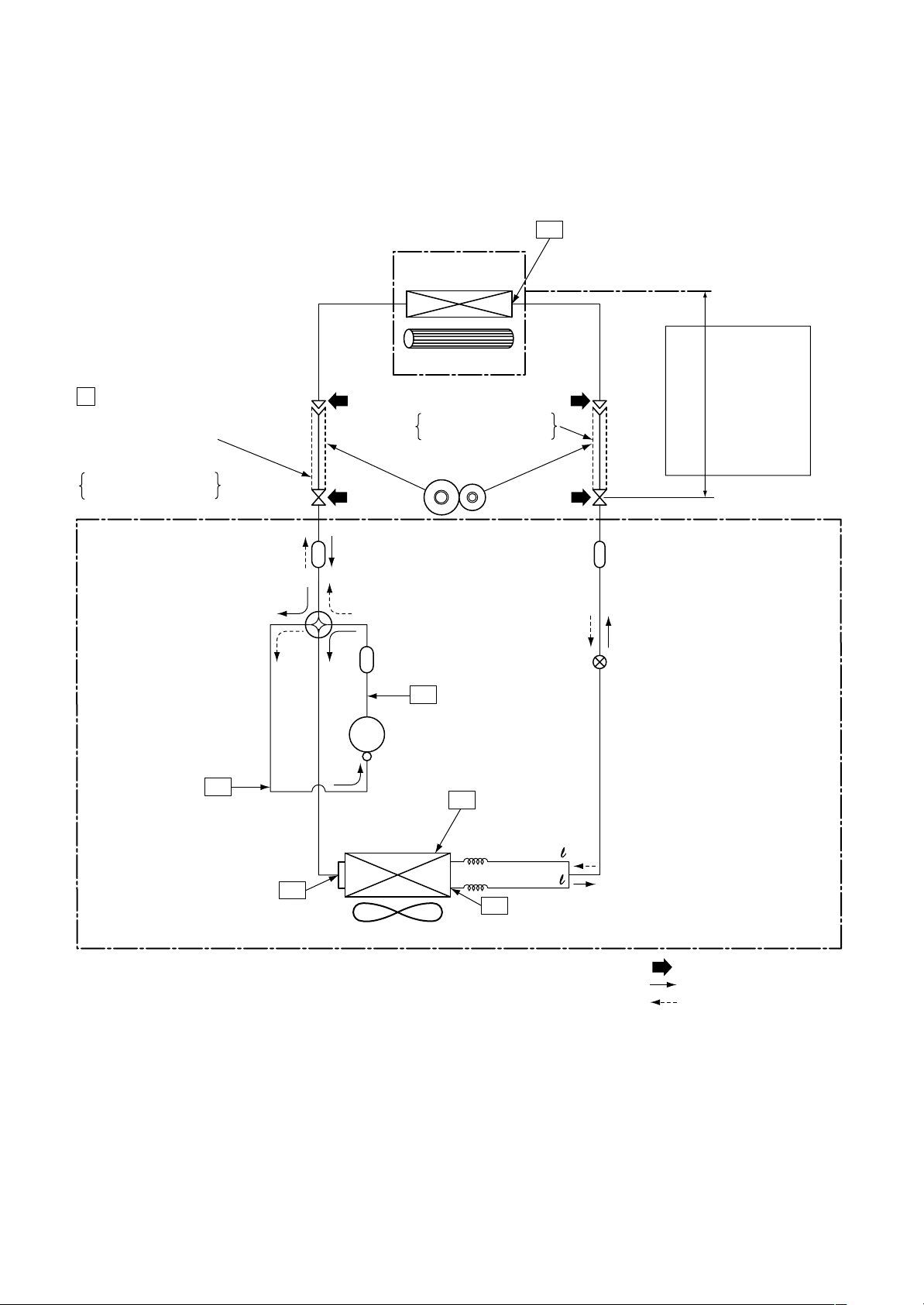

6. REFRIGERANT CYCLE DIAGRAM

6-1. Refrigerant Cycle Diagram

RAS-13UKV-E/RAS-13UAV-E

P

Pressure measurement

Gauge attaching port

Vacuum pump connecting port

Deoxidized copper pipe

Outer dia. : 9.52mm

Thickness : 0.8mm

INDOOR UNIT

Indoor heat

exchanger

Cross flow fan

Deoxidized copper pipe

Outer dia. : 6.35mm

Thickness : 0.8mm

Sectional shape

of heat insulator

T1

Temp. measurement

Allowable height

difference : 10m

Allowable pipe length

Max. : 15m

4-way valve

(CHV-0213)

TS

Temp. measurement

T2

Muffler

Muffler

TD

Compressor

DA91A1F-44F

Outdoor heat

exchanger

Propeller fan

OUTDOOR UNIT

TO

Split capillary

Ø1.5 x 200

Ø1.5 x 200

TE

Strainer

Pulse modulating

valve at liquid side

(SEV15RC2)

Refrigerant amount : 0.8kg

NOTE :

Gas leak check position

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

NOTE :

• The maximum pipe length of this air conditioner is 15 m. The additional charging of refrigerant is unnecessary

because this air conditioner is designed with charge-less specification.

– 18 –

Page 19

6-2. Operation Data

<Cooling>

Temperature

condition (°C)

Indoor Outdoor

27/19 35/–

Model

name

13UKV-E

Standard

pressure

P (MPa)

0.8 to 1.0

Heat exchanger

pipe temp.

T1 (°C) T2 (°C)

9 to 11 49 to 50

Indoor fan

mode

High

Outdoor fan

mode

High

Compressor

revolution

<Heating>

Temperature

condition (°C)

Indoor Outdoor

20/– 7/6

Model

name

13UKV-E

Standard

pressure

P (MPa)

2.5 to 2.7

Heat exchanger

pipe temp.

T1 (°C) T2 (°C)

42 to 44 0 to 3

Indoor fan

mode

High

Outdoor fan

mode

High

Compressor

revolution

NOTES :

(1) Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent.

(Thermistor themometer)

(2) Connecting piping condition : 5 m

(rps)

77

(rps)

83

– 19 –

Page 20

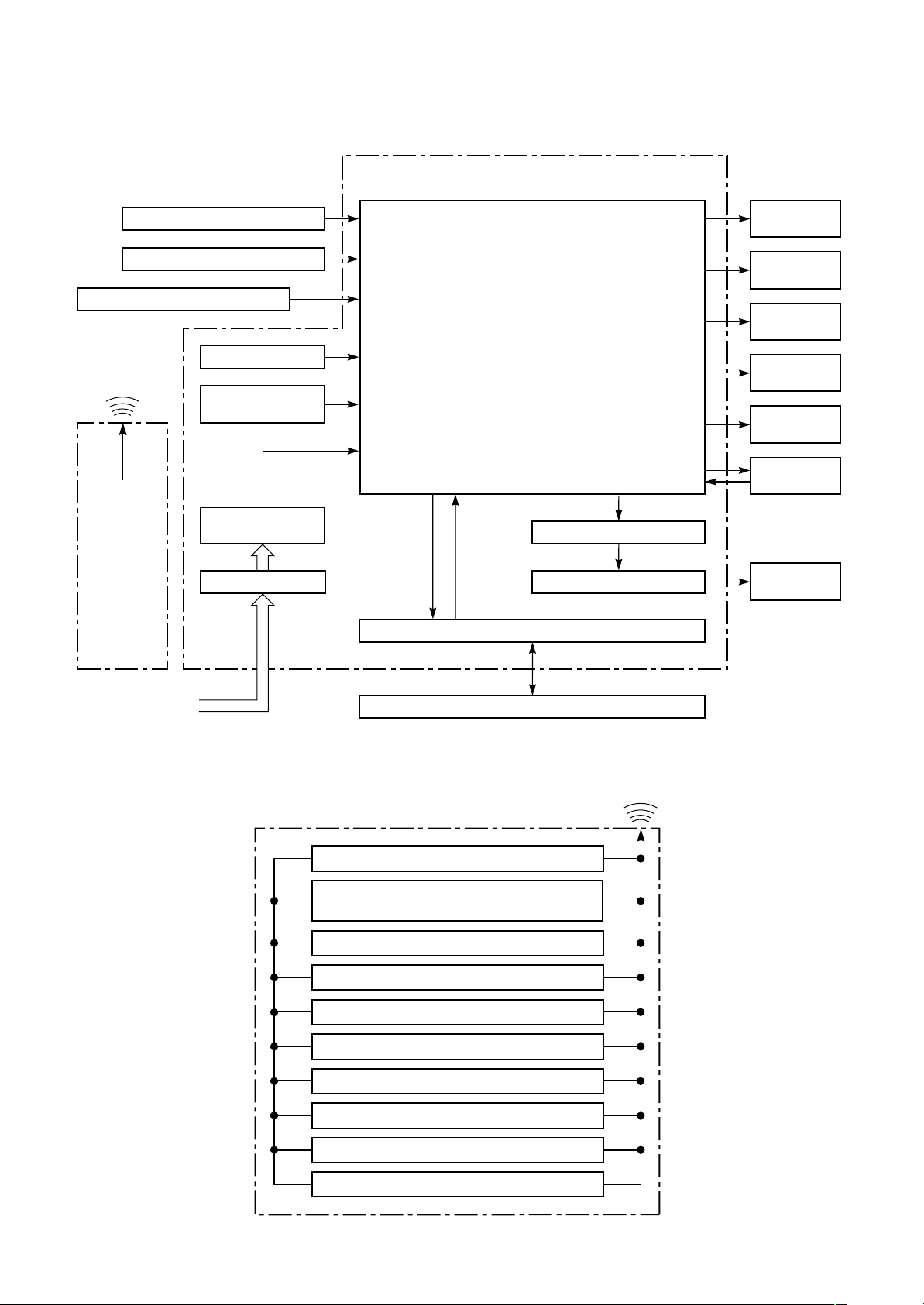

7-1. Indoor Unit

RAS-13UKV-E

Heat Exchanger Sensor

7. CONTROL BLOCK DIAGRAM

Indoor Unit Control Panel

M.C.U

Functions

Powerful

Display

Temperature Sensor

Infrared Rays Signal Receiver

Infrared

Rays

Initializing Circuit

36.7kHz

Clock Frequency

Oscillator Circuit

Power Supply

Remote

Controller

Noise Filter

From Outdoor Unit

Circuit

• Louver Control

• 3-minute Delay at Restart for Compressor

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

• Serial Signal Communication

Louver ON/OFF Signal

Louver Driver

Serial Signal Transmitter/Receiver

Serial Signal Communication

Operation

Display

Timer

Display

Filter

Sign Display

PRE DEF.

Sign Display

Indoor

Fan Motor

Louver

Motor

REMOTE CONTROLLER

Infrared

Rays

Remote Controller

Operation (START/STOP)

Operation Mode Selection

AUTO, COOL, DRY, HEAT, FAN ONLY

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

ECO

Hi-POWER

– 20 –

Page 21

RAS-13UAV-E

7-2. Outdoor Unit (Inverter Assembly)

For INDOOR UNIT

220–230–240 V

to 50/60 Hz

MICRO-COMPUTER BLOCK DIAGRAM

MCC813 (P.C.B) OUTDOOR UNIT

Inddor unit

send/receive

circuit

M.C.U

• PWM synthesis function

• Input current release control

Discharge

temp. sensor

• IGBT over-current detect control

• Outdoor fan control

• High power factor correction control

Outdoor air

temp. sensor

– 21 –

Suction temp.

sensor

• Inverter output frequency control

• A/D converter function

• P.M.V. control

• Discharge temp. control

• 4-way valve control

Heat exchanger

temp.sensor

• Signal communication to indoor unit

Rotor position

detect circuit

Rotor position

detect circuit

Gate drive

circuit

Gate drive

circuit

Over current

detect circuit

Over current

sensor

Noise

Filter

High Power

factor Correction

circuit

Input current

sensor

Driver circuit

of P.M.V.

P.M.V.

Clock

frequency

16MHz

Converter

(AC DC)

Relay

circuit

4-way

valve

Over current

sensor

Over current

sensor

Inverter

(DC AC)

Inverter

(DC

AC)

P.M.V : Pulse Modulating Valve

M.C.U : Micro Control Unit

Outdoor

Fan motor

Compressor

Page 22

8. OPERATION DESCRIPTION

8-1. Outline of Air Conditioner Control

This air conditioner is a capacity-variable type air

conditioner, which uses DC motor for the indoor fan

motor and the outdoor fan motor. And the capacityproportional control compressor which can change

the motor speed in the range from 13 to 110 rps is

mounted. The DC motor drive circuit is mounted to

the indoor unit. The compressor and the inverter to

control fan motor are mounted to the outdoor unit.

The entire air conditioner is mainly controlled by the

indoor unit controller.

The indoor unit controller drives the indoor fan motor

based upon command sent from the remote controller, and transfers the operation command to the

outdoor unit controller.

The outdoor unit controller receives operation

command from the indoor unit side, and controls the

outdoor fan and the pulse modulating valve. (P.M.V)

Besides, detecting rev olution position of the compressor motor, the outdoor unit controller controls

speed of the compressor motor by controlling output

voltage of the inv erter and switching timing of the

supply power (current transfer timing) so that motors

drive according to the operation command. And

then, the outdoor unit controller transfers re versely

the operating status information of the outdoor unit

to control the indoor unit controller.

As the compressor adopts four-pole

brushless DC motor, the frequency of the

supply power from inverter to compressor is

two-times cycles of the actual number of

revolution.

(1) Role of indoor unit controller

The indoor unit controller judges the operation

commands from the remote controller and

assumes the following functions.

• Judgment of suction air temperature of the

indoor heat exchanger by using the indoor

temp. sensor. (TA sensor)

• Temperature setting of the indoor heat exchanger by using heat exchanger sensor

(TC sensor) (Prevent-freezing control)

• Louver motor control

• Indoor fan motor operation control

• LED (Light Emitting Diode) display control

• Transferring of operation command signal

(Serial signal) to the outdoor unit

• Reception of information of operation status

(Serial signal including outside temp. data) to

the outdoor unit and judgment/display of error

(2) Role of outdoor unit controller

Receiving the operation command signal (Serial

signal) from the indoor controller, the outdoor

unit performs its role.

• Compressor operation

control

• Operation control of

outdoor fan motor

• P.M.V . control

• Detection of inverter input current and current

release operation

• Over-current detection and prevention oper ation to IGBT module (Compressor stop function)

• Compressor and outdoor fan stop function

when serial signal is off (when the serial signal

does not reach the board assembly of outdoor

control by trouble of the signal system)

• Transferring of operation information (Serial

signal) from outdoor unit to indoor unit

• Detection of outdoor temperature and operation revolution control

• Defrost control in heating operation (Temp.

measurement by outdoor heat exchanger and

control for four-way valve and outdoor fan)

(3) Contents of operation command signal (Serial

signal) from indoor unit controller to outdoor unit

controller

The following three types of signals are sent

from the indoor unit controller.

• Operation mode set on the remote control

• Compressor revolution command signal

defined by indoor temperature and set temperature

(Correction along with variation of room

temperature and correction of indoor heat

exchanger temperature are added.)

• For these two types of signals ( [Operation

mode] and [Compressor revolution] ), the

outdoor unit controller monitors the input

current to the inverter, and perfo rms the

followed operation within the range that current

does not exceed the allowable value.

• Temperature of indoor heat exchanger by

indoor heat exchanger sensor

(Minimum revolution control)

Operations follow ed

to judgment of serial

signal from indoor

side.

– 22 –

Page 23

(4) Contents of operation command signal (Serial

signal) from outdoor unit controller to indoor unit

controller

The following signals are sent from the outdoor

unit controller.

• The current operation mode

• The current compressor revolution

• Outdoor temperature

• Existence of protective circuit operation

For transf erring of these signals, the indoor

unit controller monitors the contents of signals,

and judges existence of trouble occurrence.

Contents of judgment are described below.

• Whether distinction of the current operation

status meets to the operation command

signal

• Whether protective circuit operates

When no signal is received from the outdoor

unit controller, it is assumed as a trouble.

8-1-2. Current Release Control

The outdoor main circuit control section (Inverter

assembly) detects the input current to the outdoor

unit. If the current value with compressor motor

speed instructed from indoor side exceeds the

specified value, the outdoor main circuit control

section controls compressor motor speed by reducing motor speed so that value becomes closest to

the command within the limited value.

8-1-3. Power Factor Improvement Control

Po w er factor improvement control is performed

mainly aiming to reduce the current on much power

consumption of cooling/heating operation. Controlling starts from the time when input power has

reached at a certain point. To be concrete, IGBT of

the power factor impro vement circuit is used, and

the power factor is improved by keeping IGBT on f or

an arbitrary period to widen electro-angle of the

input current.

8-1-1. Capacity Control

The cooling and heating capacity is varied by

changing compressor motor speed. The inverter

changes compressor motor speed by changing AC

220–230–240V power to DC once, and controls

capacity by changing supply power status to the

compressor with transistor module (includes 6

transistors). The outline of the control is as follows:

The revolution position and re volution speed of the

motor are detected by detecting winding electromotive force of the compressor motor under operation,

and the revolution speed is changed so that the

motor drives based upon revolution speed of the

operation command by changing timing (current

transfer timing) to exchange in verter output voltage

and supply power winding.

Detection of the revolution position f or controlling is

performed 12 times per 1 revolution of compressor.

The range of supply power frequency to the compressor differs according to the operation status

(COOL, HEAT, DRY).

Table 8-1-1 Compressor revolution range

Operation

mode

COOL

HEAT

Model

name

13UKV-E

Compressor

revolution (rps)

13 to 88

16 to 110

8-1-4. Prevent-Freezing Control

The indoor heat exchanger sensor detects refrigerant vapor temperature in COOL/DR Y operation.

If the temperature is below the specified value ,

compressor motor speed is reduced so that operation is performed in temperature below the specified

value to prev ent-freezing of indoor heat exchanger.

8-1-5. P. M. V. (Pulse Modulating Valve)

Using P.M.V., refrigerant flow of refrigeration cycle is

varied for the optimum temperature.

After the power has been turned on, when a serial

operation signal is received from indoor at the first

time, or when PMV alarm is detected and the

equipment is reactivated, move the valve once until

it hits on the stopper for positioning of the valve.

In this case, ticktack sound may be heard.

8-1-6. Louver Control

(1) V e rtical air flow louvers

Positions of v ertical air flow louvers are automatically controlled according to the operation

status (AUTO : A , COOL : , DRY : ,

HEAT : , FAN ONLY : ). Besides, positions

of vertical air flow louvers can be arbitrarily set

by pushing the [FIX] button.

(2) Swing

If the [SWING] button is pushed during running

operation, vertical air flow louvers start swinging.

When the [FIX] button is pushed, swinging stops.

– 23 –

Page 24

8-1-7. Indoor Fan Control (DC Fan Motor)

(1) The indoor fan is operated by the stepless speed

change DC motor.

(2) For air flow level, speed of the indoor fan motor

is controlled in five steps (LOW, LOW+, MED ,

MED+ and HIGH). If AUTO mode is selected,

the fan motor speed is automatically controlled

by the difference between the preset temperature and the room temperature.

LOW+= LOW + MED

2

MED+= MED + HIGH

Operation

mode

COOL

DRY

HEAT

T ab le 8-1-2

Fan

mode

H

M

L

—

H

M

L

RAS-13UKV-E

Motor speed Air flow rate

(rpm) (m³/h)

1210 530

1010 420

810 330

780 320

1290 620

1110 470

930 380

2

8-1-8. Outdoor Fan Control (DC Fan Motor)

Although the outdoor fan motor drives the outdoor fan by non-step variable system of the re volution speed, the

revolution speed is restricted to three steps on the convenience of controlling. If a strong wind is lashing outside

of the room, the operation may be continued as the outdoor f an stops in order to protect the outdoor fan motor.

If a fan lock occurred due to entering of foreign matter, the air conditioner stops and an alarm is displayed.

<COOL, DRY>

Model name

Compressor revolution (rps)

TO ≥ 38°C

Outdoor temp. sensor TO TO < 38°C

TO < 15°C

TO ≥ 38°C

ECONO. operation TO < 38°C

TO < 15°C

TO is abnormal

<HEAT>

Model name

Compressor revolution (rps)

Outdoor temp. sensor TO

ECONO. operation

TO is abnormal

TO ≥ 5°C

TO < 5°C

TO ≥ 5°C

TO < 5°C

T a ble 8-1-3

RAS-13UAV-E

To 13.8 To 34.7 From 35.3

390 840 840

390 700 840

390

390 700 840

390 390 700

390

700 700 840

T a ble 8-1-4

RAS-13UAV-E

To 16.8 To 57.4 From 58.0

390 650 840

650 650 840

390 390 650

390 650 650

390 650 840

– 24 –

Page 25

8-2. Description of Operation Circuit

• Turning [ON] the breaker flashes the operation

lamp. (1Hz)

This is the display of power-ON (or notification of

power failure).

• When pushing [START/STOP] b utton of the remote

controller, receive sound is issued from the main

unit, and the next operations are perf ormed

together with opening the vertical air flow louvers.

8-2-1. Cooling Operation

(The Remote Controller MODE Button

is Set to the COOL

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing [START/STOP] button.

• A cooling operation signal is transmitted to outdoor

unit.

• The outdoor unit controls the outdoor fan relay

R01, R02 and R03, and the compressor motor

speed according to the operation command signal

sent from the indoor unit.

• When [FAN] button is set to AUTO, the indoor fan

motor operates as shown in Fig. 8-2-1. When

[FAN] button is set to LOW , LOW+ ,

MED , MED+

operates with a constant air flow.

or HIGH , the motor

Position)

(1) Cooling capacity control

• The cooling capacity and room temperature

are controlled by changing the compressor

motor speed according to both the difference

between the temperature detected by the room

temperature sensor and the temperature set

by TEMP

button and also any change in

room temperature.

• When compressor has been activated or

reactivated, it operates with Max. 41 rps for 2

minutes, with Max. 91 rps from 2 minute to 3

minutes, and with Max. 88 rps after 3 minutes

passed.

• When room temperature is lower than set

temperature, indoor fan motor is oper ated at

fan speed L as shown in Fig. 8-2-1 while the

outdoor unit stops.

(2) Prevent-freezing control

If temperature of indoor heat exchanger detected by the indoor heat exchanger sensor is

5°C or lower, compressor motor speed is

gradually lowered to prevent freezing of the

indoor heat exchanger. If temperature is 7°C or

higher, return the operation to the above item

(1).

(3) Current release control

The input current of compressor and outdoor fan

motor (Precisely inverter main circuit control

section) which occupy most of air conditioner

input is detected by the outdoor current sensor,

and compressor motor speed is gradually

lowered so that current value does not exceed

9.0A if current value exceeds 9.0A. When the

current value lowers to 8.5A, return the operation to the above item (1).

˚C

+3

M+

*1

*1

*1

L

In normal

operation

Set

temp.

+2.5

+2

+1.5

+1

(Room temp.) – (Set temp.)

+0.5

0

–0.5

NOTE :

1: Calculated from difference in motor speed of

*

M+ and L, and controlled.

Fig. 8-2-1 Setting of air flow [F an AUTO]

– 25 –

9.0

8.5

Current value (A)

Comp. motor

speed down

Comp. motor

speed keep

Normal control

Fig. 8-2-2

Page 26

Zone

Operation stop zone

Normal down zone

of motor speed

Slow down of

motor speed

Keep zone :

Motor speed is not changed.

Slow-up zone of motor speed

Normal operation zone

F

117

TD

(˚C)

112

108

105

98

E

D

C

B

A

Release of

motor speed

(4) Limit for maximum compressor motor speed

by indoor fan speed

When outdoor temperature sensor detected

32°C or lower , and indoor heat exchanger

sensor detected 17°C or lower , the maximum

compressor motor speed is limited by the indoor

fan speed.

For e xample, the compressor motor speed is

limited as described in the table below.

T a ble 8-2-1

6) Control 6 (F zone) : Operation stop zone

If TD detect value exceeds 117°C during

operation, stop the operation immediately.

Then, restart the operation when TD detect

value becomes 105°C or lower.

Air flow rate

HIGH

M+

MED.

L–, L

UL, SUL

(5) Louver control

The vertical air flow louvers are automatically set

to horizontal or cool memory position.

When temperature of indoor heat exchanger

becomes 5°C or lower by the pre vent-freezing

control and the compressor is turned off, the

vertical air flow louvers close once and then

return to the position of previous time.

(6) Discharge temperature control

(Common control to cooling and heating)

The discharge temperature of refrigerant gas

from the compressor is detected by the discharge temperature sensor , and controls operating compressor motor speed.

1) Control 1 (A zone) : Normal operation zone

When TD detect value is 98°C or lower, the

operation is performed with operating motor

speed instructed by the serial signal.

2) Control 2 (B zone) : Slow-up zone of motor

speed

When TD detect value is 98°C or higher,

operating motor speed is slowly up.

3) Control 3 (C zone) : Keep zone

When TD detect value is 105°C or higher,

operating motor speed is not changed if

raising operation speed.

4) Control 4 (D zone) : Slow down zone of motor

speed

When TD detect value is 108°C or higher,

operating motor speed is slowly down.

5) Control 5 (E zone) : Normal down of motor

speed

When TD detect value is 112°C or higher,

operating motor speed is down.

RAS-13UKV-E

(rps)

77

65

53

30

30

rps : round per second

Fig. 8-2-3 Compressor motor speed control

(7) ECO operation control

When the ECO button of the remote controller is

pushed, quiet and mild operation is performed by

restraining air flow and operating motor speed.

1) Indoor air flow is controlled between SUL

and L.

2) The set temperature increases 0.5°C per 1

hour up to +2°C starting from the set temperature when ECO mode has been received.

TA [˚C]

+4.0

+3.5

+3.0

+2.5

+2.0

+1.5

+1.0

+0.5

Tsc

–0.5

–1.0

–2.0

– 26 –

Fig. 8-2-4

rps FAN

40

35

31

27

22

18

13

OFF

L–

UL

SUL

L

Page 27

8-2-2. DRY Operation

(The Remote Controller MODE Button

is Set to the DRY

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing [START/STOP] button.

• Dry operation signal is transmitted to outdoor unit.

• The Cooling operation giving priority to dehumidi-

fying, which restrains the indoor fan speed and

compressor motor speed, is performed.

• The indoor fan motor operates as shown in Fig. 82-5. (Fan speed is AUTO only.)

• The outdoor fan motor operates as described in

Table 8-1-3, and the compressor motor speed

according to the operation command signal sent

from the indoor unit.

+2.5

+2.0

+1.5

Position)

L–

*1

[Basic control]

Set

temp.

(Room temp.) –

0

–0.5

–1

–1.5

–2

(Set temp.)

–5.0

–5.5

[FAN AUTO]

LOW

1

*

2

*

M+

HIGH

*1, *2 : Approximate revolution speed of M+ and L to

linear according to temperature.

Fig. 8-2-6 Setting of air flow

[Cold draft preventing control]

The upper limit of fan revolution speed is shown

below.

+1.0

SUL

+0.5

(Room temp.) – (Set temp.)

Set

temp.

0

–0.5

NOTE :

*1 : Middle motor speed between L – and SUL

Fig. 8-2-5 Setting of air flow

8-2-3. Heating Operation

Transferring of heating operation signal from indoor

unit to outdoor unit starts.

The indoor fan motor operates by the room temper ature when selecting “AUTO” of “FAN” as shown in

Fig. 8-2-6, and operates with a set air flow when

selecting “Low ” to “High ”.

However, to prev ent cold draft, revolution speed of

the fan is restricted by indoor heat exchanger when

air flow is A UTO (Fig. 8-2-7) and starting of FAN

Manual.

44

43

31

30

A + 4

A – 8

FAN

AUTO

33

32

20

19

2

*

A

A – 8

Starting

of FAN

Manual

HIGH

Approximate

revolution speed

of HIGH and SUL

linear by Tc.

*

SUL

( NOTE : *1)

SUL

Stop

Fig. 8-2-7 Cold draft preventing control

NOTES :

(1) Stops for 2 minutes after thermostat-OFF.

(2) 24°C when the set temp. is 24°C or more

Set temp. when the set temp. is belo w 24 °C

(3) SUL : Super ultra lo w

3

[In starting and in stability]

• Until 12 minutes passed after operation start

FAN AUTO

FAN Manual

• When 12 to 25 minutes passed after

operation start and room temp. is 3°C or

lower than set temp.

• Room temp. < Set temp. –4°C

In starting

In stability

• When 12 to 25 minutes passed after operation start

and room temp. is higher than (set temp. –3°C)

• When 25 minutes or more passed after operation

start

• Room temp. ≥ Set temp. –3.5°C

– 27 –

Page 28

The outdoor unit controls the outdoor fan based

upon the operation signal sent from the indoor unit,

and also controls revolution speed of the compressor motor.

The power coupler (IC20) for four-way v alve is

turned on, and turned off in defrost operation.

(1) Heating capacity control

Calculate the difference between temperature

detected by room temp. sensor every minute and

the set temp. set on “Temp. indicator” and

variation amount of room temp.

Then, obtain the correction amount of the

command signal, and correct the current frequency command signal.

(2) High-temp. release contr ol

If temperature of the indoor heat exchanger

detected by the indoor heat exchanger sensor is

55°C or higher, compressor motor speed is

gradually lowered to prevent over-temp. rising of

compressed pressure.

If temperature becomes below 48°C, return to

above item (1).

(3) Current release control

The input current of compressor and outdoor fan

motor (Precisely inverter main circuit control

section) which occupy most of air conditioner

input is detected by the outdoor current sensor.

The compressor motor speed is lowered gradually according to the range of TO (outside air

temp.) if the input current e xceeds the current

value determined in each zone as shown in Fig.

8-2-8 so that the input current does not exceed

the set value.

In case that the current lowered by approx. 0.5A

than each set value, return to above item (1).

TO

9.8A

10.3A

10.8A

Outside air temp. (˚C)

16.0

15.5

11.0

10.5

Fig. 8-2-8

(4) Defrost control

1) Detection of frost

In heating operation, time duration while the

compressor operates is counted, and defrost

operation starts by any condition described

below.

a. The counted time is 28 minutes or more,

and status that temperature of the outdoor

heat exchanger detected by the outdoor

heat exchanger is –20°C or lower continued for 2 minutes or more.

b. The counted time is 28 minutes or more,

and status that temperature of the outdoor

heat exchanger detected by the outdoor

heat exchanger is –7°C or lower and

temperature lowered by 2.5 °C than the

minimum value of the outdoor heat exchanger during 10 to 15 minutes count

time continued for 2 minutes or more.

c. The counted time is 34 minutes or more,

and status that temperature of the outdoor

heat exchanger detected by the outdoor

heat exchanger is –5°C or lower and

temperature lowered by 3.0 °C than the

minimum value of the outdoor heat exchanger during 10 to 15 minutes count

time continued for 2 minutes or more.

d. If the following three conditions are satis-

fied, defrost operation (Timer defrost)

starts after heating operation for 37

minutes.

1) Setting on remote controller, H EAT

(mode), HIGH (Fan), 30°C (temp.) .

2) Room temp. is 19°C to 24°C, and

outside air temp. is 5°C or lower.

3) Defrost operation has been already

performed once.

2) Defrost operation

Operation of the compressor is stopped

once, turn off power coupler for four-way

valve after 10 seconds, and then exchange

the four-wa y v alv e .

After 20 seconds, restart operation of the

compressor. Turn off the outdoor fan just

when the compressor stopped.

If temperature of the indoor heat exchanger

lowered than 38°C , stop the indoor fan.

3) Defrost reset

Resetting operation from defrost to heating is

performed when any one of the fo llo wing

conditions is satisfied.

a. Temperature of the outdoor heat ex-

changer rose to +8°C or higher.

b. A status that temperature of the outdoor

heat exchanger is +5°C or higher continued for 80 seconds.

c. Defrost operation continued for 15 min-

utes.

In resetting defrost operation, the compressor

stops for 50 seconds if defrost has started

under condition a. to c. in item 1), but the

compressor is reset to heating operation

keeping operated if defrost has started under

condition d. in item 1).

(5) Louver control

When the compressor is turned off by high-temp.

release control, the vertical air flow louvers close

once and then return to the position of previous

time.

– 28 –

Page 29

8-2-4. Automatic Operation

(1) As shown in Fig. 8-2-9, the operation mode

(COOL, DRY, HEAT) is selected according to the

outside temperature and room temperature

when the operation has started.

The operation in Fan mode continues until an

operation mode is selected.

If the room temperature is 20°C or higher when

“AUTO” operation started within 2 hours after

“HEAT” operation had stopped, select an opera-

tion mode after Fan operation of ultra low fan.

In AUTO operation, the set temperature of each

operation can be corrected by the remote

controller in the range of 17 to 30°C.

(2) After selecting the operation mode (COOL, DR Y,

HEAT), select an operation mode again when a

status that the compressor was turned off by the

room temperature or outside air temperature

continues for 15 minutes.

(3) Po werful Cool mode control

When the outside temperature is above 32°C

and indoor temperature is above 28°C , select

Cool mode control. In Cool mode, the air flow

louver directs downward. When the room temperature gains access to the set temperature, it

becomes cool memory position.

TA

28

26

24

23

Heating with setting

on remote controller

Ts = 25˚C

20

Ts correction by outside

temperature ( To)

5

–2 –10+1

15 18 24 32 To

8-3. Temporary Operation

• Temporary Auto operation, existence of Auto

Restart, and Temporary Cooling operation can be

set by the TEMPORARY button of the indoor

controller.

Powerful Cooling/Drying with

setting on remote controller

Ts = 25˚C

Cooling/Drying with setting on remote controller

Ts = 25˚C

Monitoring

(Follow to the Fan control in previous

mode when being selected again.)

Fig. 8-2-9

8-3-1. Temporary Auto Operation

• When the TEMPORARY button is pushed, the

Auto operation with set temperature fix ed at 25 °C

starts. Controlling is same as that of Auto operation by the remote controller .

• When the TEMPORAR Y button is pushed again,

the operation stops.

• During T emporary Auto operation, operation by the

remote controller is accepted.

• Using the Auto Restart function, the Temporary

Auto operation starts when power failure is reset.

TEMPORARY button

Fig. 8-3-1

T a ble 8-3-1

TEMPORARY button Control

OFF → ON Temporary Auto operation start

After pushing button

for 3 seconds

After pushing button Temporary Cooling

for 10 seconds operation start

Auto Restart control select

8-3-2. Temporary Cooling Operation

• When the TEMPORARY operation button keeps

pushed for 10 seconds, Cooling operation of which

compressor motor speed and the indoor fan speed

are fixed starts.

Compressor motor speed :

13 : 30 rps

Indoor fan speed : Low

• When the TEMPORARY operation button is

pushed again, the operation stops.

• Auto Restart function is unavailable.

– 29 –

Page 30

8-4. Auto Restart Function

This indoor unit is equipped with an automatic

restarting function which allows the unit to restart

operating with the set operating conditions in the

event of a power supply being accidentally shut

down. The operation will resume without warning

three minutes after power is restored.

This function is not set to work when shipped from

the factory. Therefore it is necessary to set it to

work.

• When the unit is standby (Not operating)

8-4-1. How to Set the Auto Restart Function

To set the auto restart function, proceed as follows:

The power supply to the unit must be on ; the

function will not set if the power is off.

Push the [TEMPORARY] button located in the

center of the front panel continuously for three

seconds.

The unit receives the signal and beeps three times.

The unit then restarts operating automatically in the

event of power supply being accidentally shut down.

Operation

Push [TEMPORARY] b utton for more

than three seconds.

0

3S

TEMPORARY button

• When the unit is in operation

Operation

Push [TEMPORARY] b utton for more

than three seconds.

Motions

The unit is on standby.

↓

The unit starts to operate. The green lamp is on.

↓ After approx. three seconds,

The unit beeps three times The lamp changes from

and continues to operate. green to orange.

If the unit is not required to operate at this time, push [TEMPORARY]

button once more or use the remote controller to turn it off.

Motions

The unit is in operation. The green lamp is on.

↓

The unit stops operating. The green lamp is turned off.

The unit beeps three times.

If the unit is required to operate at this time, push [TEMPORARY]

button once more or use the remote controller to turn it on.

TEMPORARY button

0

3S

• While this function is being set, if the unit is in

operation, the orange lamp is on.

• This function can not be set if the timer operation

has been selected.

↓ After approx. three seconds,

• When the unit is turned on by this function, the

louver will not swing even though it was swinging

automatically before shutting down.

• While the filter check lamp is on, the TEMPORARY

button has the function of filter reset button.

– 30 –

Page 31

8-4-2. How to Cancel the Auto Restart

Function

To cancel auto restart function, proceed as follows :

Repeat the setting procedure : the unit receives the

signal and beeps three times.

• When the system is on stand-by (not operating)

The unit will be required to be turned on with the

remote controller after the main power supply is

turned off.

Operation

Push [TEMPORARY] button for more

than three seconds.

0

3S

TEMPORARY button

• When the system is operating

Operation

Push [TEMPORARY] button for more

than three seconds.

Motions

The unit is on standby.

↓

The unit starts to operate. The orange lamp is on.

↓ After approx. three seconds,

The unit beeps three times The lamp changes from

and continues to operate. orange to green.

If the unit is not required to operate at this time, push [TEMPORARY]

button once more or use the remote controller to turn it off.

Motions

The unit is in operation. The orange lamp is on.

↓

The unit stops operating. The orange lamp is turned off.

↓ After approx. three seconds,

The unit beeps three times.

If the unit is required to operate at this time, push [TEMPORARY]

button once more or use the remote controller to turn it on.

TEMPORARY button

0

3S

• While this function is being set, if the unit is in operation, the orange lamp is on.

8-4-3. Power Failure During Timer Operation

When the unit is in timer operation, if it is turned off

because of power failure , the timer operation is

cancelled. Therefore, set the timer operation again.

NOTE :

The Everyday Timer is reset while a command

signal can be received from the remote controller

even if it stopped due to a power failure.

8-5-1. How to Turn Off Filter Check Lamp

Push [FILTER] button on the remote controller .

Or push [TEMPORARY] b utton on the indoor unit.

Then we have to clarify it.

NOTE :

If [TEMPORARY] b utton is pushed while the filter

check lamp is not indicating, the indoor unit will start

the automatic operation.

When you want a temporary operation while the filter