Page 1

INSTALLATION MANUAL

MANUAL DE INSTALACIÓN

MANUEL D’INSTALLATION

MANUALE DI INSTALLAZIONE

EINBAUANLEITUNG

MANUAL DE INSTALAÇÃO

ΕΓΧΕΙΡΊ∆ΙΟ ΕΓΚΑΤΆΣΤΑΣΗΣ

INSTRUKCJA INSTALACJI

INSTALAČNÍ PŘÍRUČKA

PRIRUČNIK ZA UGRADNJU

ÜZEMBE HELYEZÉSI KÉZIKÖNYV

INSTALLATIEHANDLEIDING

AIR CONDITIONER (SPLIT TYPE)

ACONDICIONADOR DE AIRE (TIPO SPLIT)

CLIMATISEUR (SPLIT SYSTEM)

CONDIZIONATORE D’ARIA (TIPO SCOMPONIBILE)

KLIMAGERÄT (GETEILTE AUSFÜHRUNG)

AR CONDICIONADO (TIPO SPLIT)

ΚΛΙΜΑΤΙΣΤΙΚΟ ΜΗΧΑΝΗΜΑ (∆ΙΑΙΡΟΎΜΕΝΟΣ ΤΎΠΟΣ)

KLIMATYZATOR (TYPU DZIELONEGO)

KLIMATIZAČNÍ ZAŘÍZENÍ (DĚLENÝ TYP)

KLIMATSKI UREĐAJ (RASTAVLJIV MODEL)

LÉGKONDICIONÁLÓ (OSZTOTT TÍPUS)

AIR CONDITIONER (TWEEDELIG TYPE)

RAS-13GK Series

Indoor Unit

Unidad Interior

Unité Intérieure

Unità Interna

Innengerät

Unidade Interior

Εσωτερική Μονάδα

Urządzenie Wewnętrzne

Vnitřní Jednotka

Unutarnja Jedinica

Beltéri Egység

Binnenmodule

RAS-13GA Series

Outdoor Unit

Unidad Exterior

Unité Extérieure

Unità Esterna

Außengerät

Unidade Exterior

Εξωτερική Μονάδα

Urządzenie Zewnętrzne

Venkovní Jednotka

Vanjska Jedinica

Kültéri Egység

Buitenmodule

Page 2

CONTENTS

PRECAUTIONS FOR SAFETY ...................................... 1

INSTALLATION DIAGRAM OF INDOOR AND

OUTDOOR UNITS .......................................................... 2

• Optional Installation Parts ................................................ 2

INDOOR UNIT

• Installation Place ............................................................... 3

• Cutting a Hole and Mounting Installation Plate .............. 3

• Electrical Work ................................................................... 4

• Wiring Connection ............................................................. 4

• Piping and Drain Hose Installation .................................. 5

• Indoor Unit Fixing .............................................................. 6

• Drainage ............................................................................. 6

CONTENIDOS

PRECAUCIONES SOBRE SEGURIDAD ....................... 1

DIAGRAMA DE INSTALACIÓN DE LA UNIDAD

INTERIOR Y EXTERIOR ................................................ 2

• Piezas de Instalación Opcional ........................................ 2

UNIDAD INTERIOR

• Lugar de Instalación .......................................................... 3

• Corte de un Orificio y Montaje de la

Placa de Instalación .......................................................... 3

• Trabajo Eléctrico................................................................ 4

• Conexión de Cables .......................................................... 4

• Instalación la Tubería y el Tubo de Desagüe .................. 5

• Instalación de la Unidad Interior ...................................... 6

• Drenaje................................................................................ 6

OUTDOOR UNIT

• Installation Place ............................................................... 7

• Refrigerant Piping Connection ......................................... 7

• Evacuating.......................................................................... 7

• Wiring Connection ............................................................. 8

OTHERS

• Gas Leak Test .................................................................... 8

• Setting of Remote Control Selector Switch .................... 8

• Test Operation ................................................................. 10

• Auto Restart Setting ........................................................ 10

UNIDAD EXTERIOR

• Lugar de Instalación .......................................................... 7

• Conexión de la Tubería Refrigerante ............................... 7

• Evacuación ......................................................................... 7

• Conexión de Cables .......................................................... 8

OTROS

• Comprobación de Fugas................................................... 8

• Configuración del Interruptor de

Selección del Mando a Distancia ..................................... 8

• Prueba de Operación....................................................... 10

• Ajuste de Reinicio Automático ....................................... 10

ENGLISH

ENGLISH

ESPAÑOL

SOMMAIRE

MESURES DE SECURITE ............................................. 1

PLAN D’INSTALLATION DES UNITES

INTERIEURE ET EXTERIEURE ..................................... 2

• Pièces d’Installation en Option ........................................ 2

UNITE INTERIEURE

• Endroit d’Installation ......................................................... 3

• Ouverture du Trou et Montage de

la Plaque d’Installation ...................................................... 3

• Travaux Electriques........................................................... 4

• Connexion des Câbles ...................................................... 4

• Installation de la Conduite et du Tuyau de Purge .......... 5

• Installation de l’Unité Intérieure ....................................... 6

• Drainage ............................................................................. 6

PRECAUZIONI PER LA SICUREZZA............................ 1

SCHEMA DI INSTALLAZIONE DELL’ UNITÀ

INTERNA E DELL’ UNITÀ ESTERNA ........................... 2

• Componenti di Installazione Opzionali ........................... 2

UNITÀ INTERNA

• Luogo per l’Installazione................................................... 3

• Apertura di un Foro e Installazione

della Lastra di Installazione .............................................. 3

• Lavori Elettrici .................................................................... 4

• Collegamento dei Cavi ...................................................... 4

• Installazione dei Tubi e del Tubo di Scarico ................... 5

• Installazione dell’Unità Interna ......................................... 6

• Scarico ................................................................................ 6

UNITE EXTERIEURE

• Endroit d’Installation ......................................................... 7

• Connexion du Tuyau Réfrigérant ..................................... 7

• Evacuation.......................................................................... 7

• Connexion des Câbles ...................................................... 8

AUTRES

• Test de Fuite Gaz ............................................................... 8

• Réglage du Sélecteur de Télécommande ........................ 8

• Opération du Test ............................................................ 10

• Réglage de la Remise en Marche Automatique ............ 10

INDICE

UNITÀ ESTERNA

• Luogo per l’Installazione................................................... 7

• Collegamento dei Tubi del Refrigerante .......................... 7

• Evacuazione ....................................................................... 7

• Collegamento dei Cavi ...................................................... 8

ALTRI

• Test per Perdite di Gas...................................................... 8

• Impostazione del Selettore del Telecomando ................. 8

• Funzionamento di Prova ................................................. 10

• Impostazione per la Rimessa in

Funzione Automatica ...................................................... 10

FRANÇAIS

ITALIANO

Page 3

SICHERHEITSVORKEHRUNGEN ................................. 1

EINBAUZEICHNUNGEN FÜR INNEN- UND

DEUTSCH

AUSSENGERÄT ............................................................ 2

• Zusätzlich erhältliche Installationsteile ...........................2

INNENGERÄT

• Aufstellungsort .................................................................. 3

• Mauerdurchbruch und Befestigung der

Montageplatte ....................................................................3

• Elektrische Anschlüsse .................................................... 4

• Kabelanschlüsse ............................................................... 4

• Installation von Leitungen und Kondensatschlauch ..... 5

• Einbau des Innengeräts .................................................... 6

• Entwässerung .................................................................... 6

PRECAUÇÕES RELATIVAS A SEGURANÇA ............. 1

PORTUGUÊS

ESQUEMA DE INSTALAÇÃO DAS UNIDADES

INTERIOR E EXTERIOR ................................................ 2

• Peças de Instalação Opcionais ........................................ 2

UNIDADE INTERIOR

• Local de Instalação............................................................3

• Cortar um Orifício e Montar a Placa de Instalação ......... 3

• Trabalhos de Electricidade ...............................................4

• Ligações Eléctricas ........................................................... 4

• Instalação da Tubagem e do Tubo Flexível de Dreno .... 5

• Colocação da Unidade Interior ......................................... 6

• Drenagem ........................................................................... 6

INHALT

AUSSENGERÄT

• Aufstellungsort .................................................................. 7

• Anschluß der Kühlmittelleitungen ................................... 7

• Entleeren ............................................................................ 7

• Kabelanschlüsse ............................................................... 8

SONSTIGES

• Überprüfung auf Gas-Undichtigkeit ................................. 8

• Einstellen des Fernbedienungs-Wahlschalters .............. 8

• Probelauf .......................................................................... 10

• Automatische Wiedereinschaltung ................................ 10

ÍNDICE

UNIDADE EXTERIOR

• Local de Instalação............................................................7

• Ligação das Condutas de Refrigeração .......................... 7

• Purga de Ar ........................................................................ 7

• Ligações Eléctricas ........................................................... 8

OUTROS

• Teste de Fugas de Gás......................................................8

• Definição do Interruptor do Telecomando ...................... 8

• Execução do Teste .......................................................... 10

• Definindo de Reiniciação Automática ........................... 10

ΠΡΟΦΥΛΑΞΕΙΣ ΑΣΦΑΛΕΙΑΣ ......................................... 1

∆ΙΆΓΡΑΜΜΑ ΕΓΚΑΤΆΣΤΑΣΗΣ ΤΗΣ

EΛΛΗΝΙΚΑ

ΕΣΩΤΕΡΙΚΉΣ ΚΑΙ ΕΞΩΤΕΡΙΚΉΣ ΜΟΝΆ∆ΑΣ ............. 2

• Προαιρετικά Eξαρτήµατα Eγκατάστασησ ....................... 2

ΕΣΩΤΕΡΙΚΉ ΜΟΝΆ∆Α

• Σηµείο Eγκατάστασησ ....................................................... 3

• Κψιµο Τρύπασ και Τοποθέτηση

Πλάτησ Εγκατάστασησ ...................................................... 3

• Ηλεκτρικέσ Εργασίεσ ........................................................ 4

• Σύνδεση Καλωδίωσησ ....................................................... 4

• Εγκατάσταση Σωλήνωσησ και Εύκαµπτου

Σωλήνα Αποστράγγισησ .................................................... 5

ΠΕΡΙΕΧΟΜΕΝΑ

ZASADY BEZPIECZEŃSTWA ....................................... 1

SCHEMAT INSTALACYJNY URZĄDZENIA

WEWNĘTRZNEGO I ZEWNĘTRZNEGO....................... 2

POLSKI

• Dodatkowe Części Instalacyjne ....................................... 2

URZĄDZENIE WEWNĘTRZNE

• Miejsce Instalacji ............................................................... 3

• Wycinanie Otworu oraz Montaż Płyty Instalacyjnej ....... 3

• Prace Elektryczne .............................................................. 4

• Podłączenie Okablowania.................................................4

• Montaż Instalacji Rurowej i Węża do

Odprowadzania Cieczy ..................................................... 5

• Mocowanie Urządzenia Wewnętrznego ..........................6

• Odprowadzanie Cieczy ..................................................... 6

ΠΕΡΙΕΧΟΜΕΝΑ

• Στερέωση Εσωτερικήσ Μονάδασ ..................................... 6

• Αποστράγγιση .................................................................... 6

ΕΞΩΤΕΡΙΚΉ ΜΟΝΆ∆Α

• Σηµείο Εγκατάστασησ ....................................................... 7

• Σύνδεση Ψυκτικών Σωληνώσεων ..................................... 7

• Εκκένωση ........................................................................... 7

• Σύνδεση Καλωδίωσησ ....................................................... 8

ΛΟΙΠΑ

• Έλεγχοσ ∆ιαρροήσ Αερίου ............................................... 8

• Ρύθµιση του ∆ιακπτη Επιλογήσ Tηλεχειριστηρίου...... 8

• ∆οκιµή Λειτουργίασ......................................................... 10

• Auto Restart Ρύθµιση...................................................... 10

SPIS TREŚCI

URZĄDZENIE ZEWNĘTRZNE

• Miejsce Instalacji ............................................................... 7

• Łączenie Instalacji Rurowej Czynnika Chłodniczego .... 7

• Usuwanie Powietrza .......................................................... 7

• Podłączenie Okablowania................................................. 8

INNE

• Próba Gazoszczelności..................................................... 8

• Ustawianie Przełącznika Wyboru Pilota ..........................8

• Próba Działania ................................................................ 10

• Włączanie Funkcji Automatycznego

Wznawiania Pracy (Auto Restart) ...................................10

Page 4

OBSAH

BEZPEČNOSTNÍ OPATŘENÍ ........................................ 1

SCHÉMA INSTALACE VNITŘNÍ A VENKOVNÍ

JEDNOTKY .................................................................... 2

• Volitelné Doplňky pro Instalaci ......................................... 2

VNITŘNÍ JEDNOTKA

• Místo Instalace................................................................... 3

• Vyvrtání Otvoru a Montáž Instalační Desky .................... 3

• Elektrické Práce................................................................. 4

• Zapojení Vodičů ................................................................. 4

• Montáž Trubek a Vypouštěcí Hadice ............................... 5

• Montáž Vnitřní Jednotky ................................................... 6

• Odvod Vody ........................................................................ 6

SADRŽAJ

MJERE SIGURNOSTI .................................................... 1

SHEMA UGRADNJE UNUTARNJIH I VANJSKIH

JEDINICA ....................................................................... 2

• Dodatni Dijelovi za Ugradnju Prema Izboru .................... 2

UNUTARNJA JEDINICA

• Mjesto Ugradnje ................................................................ 3

• Izrezivanje Rupe i Postavljanje Ploče za Ugradnju ........ 3

• Električni Radovi ................................................................ 4

• Žičana Veza ........................................................................4

• Ugradnja Cijevi i Crijeva za Pražnjenje............................ 5

• Učvršćivanje Unutarnje Jedinice...................................... 6

• Ispust .................................................................................. 6

VENKOVNÍ JEDNOTKA

• Místo Instalace...................................................................7

• Spojování Chladivového Potrubí ...................................... 7

• Vyčerpávání Vzduchu ........................................................ 7

• Zapojení Vodičů ................................................................. 8

OSTATNĺ

• Zkouška Úniku Plynu.........................................................8

• Nastavení Přepínače Dálkového Ovládání ...................... 8

• Zkušební Provoz .............................................................. 10

• Nastavení Automatického Znovuspuštění .................... 10

VANJSKA JEDINICA

• Mjesto Ugradnje ................................................................ 7

• Sklop Cijevi Rashladnog Sredstva ................................... 7

• Pražnjenje........................................................................... 7

• Žičana Veza ........................................................................8

OSTALO

• Proba Isticanja Plina..........................................................8

• Položaji Prekidača za Odabir Daljinskog Upravljača .....8

• Probni Rad........................................................................ 10

• Postava za Automatsko Ponovno Pokretanje .............. 10

ČEŠTINA

ENGLISH

HRVATSKI

TARTALOMJEGYZÉK

BIZTONSÁGI ELŐÍRÁSOK ............................................ 1

BELTÉRI ÉS KÜLTÉRI EGYSÉGEK ÜZEMBE

HELYEZÉSE ................................................................... 2

• Külön Rendelhető Alkatrészek ......................................... 2

BELTÉRI EGYSÉG

• A Felszerelés Helye ........................................................... 3

• Lyuk Kivágása és a Felszerelése ..................................... 3

• Elektromos Munka.............................................................4

• Kábelezés ........................................................................... 4

• A Csövek és a Kondenzvíztömlő Felszerelése ............... 5

• A Beltéri Egység Rögzítése............................................... 6

• Vízelvezetés........................................................................ 6

ΠΕΡΙΕΧΟΜΕΝΑ

INHOUDSOPGAVE

VEILIGHEIDSVOORZORGEN ....................................... 1

INSTALLATIESCHEMA VOOR BINNEN- EN

BUITENMODULES ......................................................... 2

• Optionele Onderdelen ....................................................... 2

BINNENMODULE

• Installatieplaats .................................................................. 3

• Gat Boren en Montageplaat Bevestigen .......................... 3

• Elektriciteit ......................................................................... 4

• Bedrading ........................................................................... 4

• Leidingen en Afvoerslang Installeren .............................. 5

• Binnenmodule Bevestigen................................................ 6

• Afvoer ................................................................................. 6

KÜLTÉRI EGYSÉG

• A Felszerelés Helye ........................................................... 7

• Hűtőközegcső-csatlakozások .......................................... 7

• Légtelenítés ........................................................................ 7

• Kábelezés ...........................................................................8

EGYEBEK

• Tömítettségvizsgálat ......................................................... 8

• A Távirányító Kiválasztó Kapcsolójának Beállítása ....... 8

• Tesztüzem ........................................................................ 10

• Automatikus Újraindítás Beállítás .................................. 10

BUITENMODULE

• Installatieplaats .................................................................. 7

• Koelleidingsaansluiting .................................................... 7

• Afvoeren ............................................................................. 7

• Bedrading ...........................................................................8

OVERIGE

• Gaslektest...........................................................................8

• De Keuzeschakelaar van de

Afstandsbediening Instellen .............................................8

• Testwerking ...................................................................... 10

• Automatische Herstart Instellen.....................................10

MAGYAR

NEDERLANDS

Page 5

PRECAUTIONS FOR SAFETY

For general public use

Power supply cord of parts of appliance for outdoor use shall be at least polychloroprene sheathed flexible cord (design H07RN-F) or cord

designation 245 IEC66. (Shall be installed in accordance with national wiring regulations.)

CAUTION

• THIS AIR CONDITIONER USES THE NEW HFC REFRIGERANT (R410A), WHICH DOES NOT DESTROY THE OZONE LAYER.

R410A refrigerant is apt to be affected by impurities such as water, oxidizing membranes, and oils because the pressure of R410A refrigerant is

approx. 1.6 times of refrigerant R22. As well as the adoption of this new refrigerant, refrigerating machine oil has also been changed. Therefore,

during installation work, be sure that water, dust, former refrigerant, or refrigerating machine oil does not enter the refrigeration cycle of a

new-refrigerant air conditioner.

To avoid mixing refrigerant and refrigerating machine oil, the sizes of charging port connecting sections on the main unit are different from those

for the conventional refrigerant, and different size tools are also required. For connecting pipes, use new and clean piping materials with highpressure withstand capabilities, designed for R410A only, and ensure that water or dust does not enter. Moreover, do not use any existing piping

as its pressure withstand may be insufficient and may contain impurities.

CAUTION

This appliance must be connected to the main power supply by means of a circuit breaker or a switch with a contact separation of at least 3 mm in

all poles. If this is not possible, a power supply plug with earth must be used. This plug must be easily accessible after installation. The plug must

be disconnected from the power supply socket in order to disconnect the appliance completely from the mains.

New refrigerant air conditioner installation

To disconnect the appliance from the main power supply

DANGER

• FOR USE BY QUALIFIED PERSONS ONLY.

• TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SURE ALL POWER SWITCHES ARE OFF.

FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.

• CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTED WRONGLY, ELECTRIC PARTS MAY

BE DAMAGED.

• CHECK THE EARTH WIRE THAT IT IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION.

• DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OR GAS VAPORS.

FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

• TO PREVENT OVERHEATING THE INDOOR UNIT AND CAUSING A FIRE HAZARD, PLACE THE UNIT WELL AWAY (MORE THAN 2 M)

FROM HEAT SOURCES SUCH AS RADIATORS, HEATERS, FURNACE, STOVES, ETC.

• WHEN MOVING THE AIR CONDITIONER FOR INSTALLING IT IN ANOTHER PLACE AGAIN, BE VERY CAREFUL NOT TO GET THE

SPECIFIED REFRIGERANT (R410A) WITH ANY OTHER GASEOUS BODY INTO THE REFRIGERATION CYCLE. IF AIR OR ANY OTHER

GAS IS MIXED IN THE REFRIGERANT, THE GAS PRESSURE IN THE REFRIGERATION CYCLE BECOMES ABNORMALLY HIGH AND IT

RESULTINGLY CAUSES BURST OF THE PIPE AND INJURIES ON PERSONS.

• IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THE INSTALLATION WORK, IMMEDIATELY LET

FRESH AIR INTO THE ROOM. IF THE REFRIGERANT GAS IS HEATED BY FIRE OR SOMETHING ELSE, IT CAUSES GENERATION OF

POISONOUS GAS.

WARNING

• Never modify this unit by removing any of the safety guards or bypassing any of the safety interlock switches.

• Do not install in a place which cannot bear the weight of the unit.

Personal injury and property damage can result if the unit falls.

• Before doing the electrical work, attach an approved plug to the power supply cord.

Also, make sure the equipment is properly earthed.

• Appliance shall be installed in accordance with national wiring regulations.

If you detect any damage, do not install the unit. Contact your TOSHIBA dealer immediately.

CAUTION

• Exposure of unit to water or other moisture before installation could result in electric shock.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully for possible damage.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify the noise level of the unit or where

noise and discharged air might disturb neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Please read this installation manual carefully before installing the unit. It contains further important instructions for proper installation.

REQUIREMENT OF REPORT TO THE LOCAL POWER SUPPLIER

Please make absolutely sure that the installation of this appliance is reported to the local power supplier before installation. If you experience any

problems or if the installation is not accepted by the supplier, the service agency will take adequate countermeasures.

Remark per EMC Directive 89/336/EEC

To prevent flicker impressions during the start of the compressor (technical process), following installation conditions does apply.

1. The power connection for the air conditioner has to be done at the main power distribution. This distribution has to be of an impedance.

Normally, the required impedance is reached at a 32A fusing point. Air conditioner fuse has to be 16A max.!

2. No other equipment should be connected to this power line.

3. For detailed installation acceptance, please contact your power supplier whether its restriction does apply for products like washing machines,

air conditioners or electric ovens.

4. For power details of the air conditioner, refer to the rating plate of the product.

EN 1

Page 6

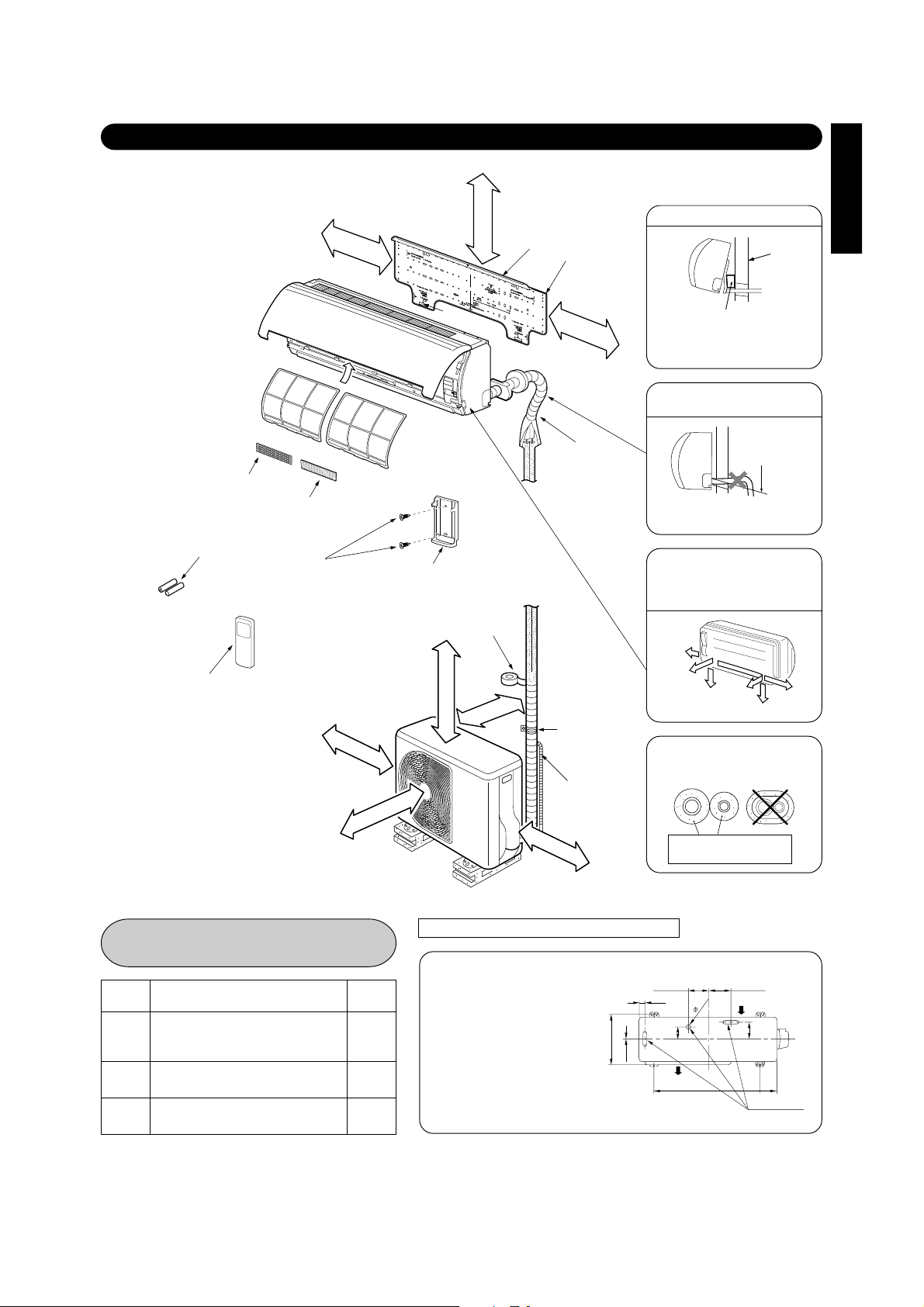

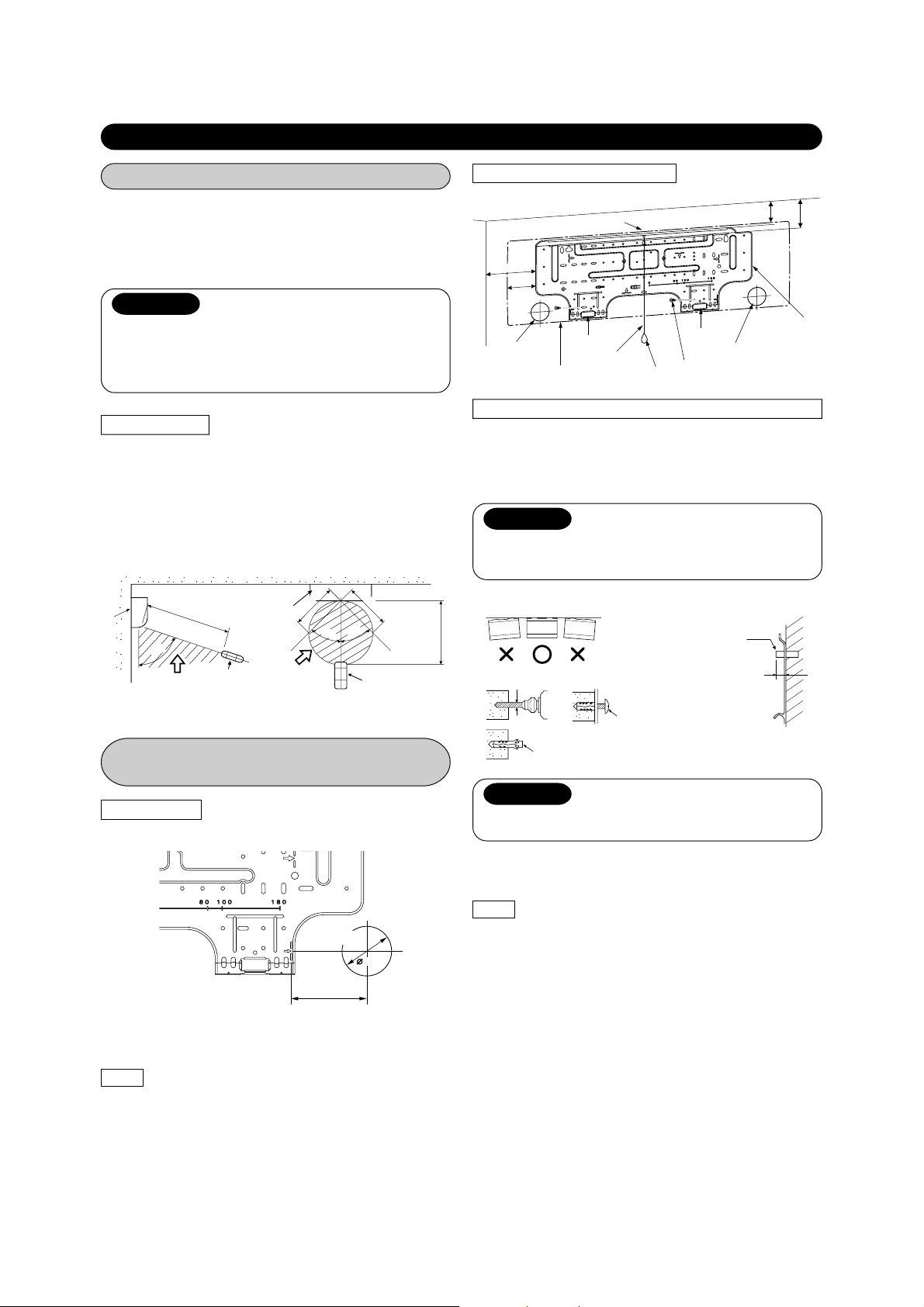

INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR UNITS

5 Filter

3 Batteries

170 m

m or m

ore

Hook

Hook

65 mm or more

1 Installation

plate

170 mm or more

For the rear left and left piping

Wall

Insert the cushion between

the indoor unit and wall, and

ENGLISH

tilt the indoor unit for better

operation.

A

ir

f

ilt

e

r

(A

ttac

h

t

o

t

he

f

r

on

t

p

an

e

l.)

Shield pipe

6 Filter

Do not allow the drain hose to

get slack.

Cut the piping

hole sloped

slightly.

Make sure to run the drain

hose sloped downward.

8 Pan head

wood screw

4 Remote control holder

Vinyl tape

Apply after carrying

out a drainage test.

The auxiliary piping can be

connected to the left, rear left,

rear right, right, bottom right

or bottom left.

Right

2 Wireless remote control

Remark :

• Detail of accessory and installation

parts can see in the accessory sheet.

Optional Installation

Parts

Part

code

Refrigerant piping

Liquid side : ∅6.35 mm

A

Gas side : ∅12.70 mm

Pipe insulating material

B

(polyethylene foam, 6 mm thick)

Putty, PVC tapes

C

Parts name

100 mm or more

o

m

m

00

6

Q’ty

One

each

1

One

each

100 mm or more

r m

re

o

600 mm or more

Saddle

Extension

drain hose

(Not available,

provided by installer)

600 mm or more

Fixing bolt arrangement of outdoor unit

• Secure the outdoor unit with

fixing bolts and nuts if the

unit is likely to be exposed to

a strong wind.

• Use ∅8 mm or ∅10 mm

anchor bolts and nuts.

• If it is necessary to drain the

defrost water, attach drain

nipple 9 and cap water

proof ! to the bottom plate

of the outdoor unit before

installing it.

320 mm

Rear right

Bottom

right

Insulate the refrigerant pipes

separately with insulation, not

together.

6 mm thick heat resisting

polyethylene foam

108 mm

32.5 mm

7 mm

86 mm

Air outlet

600 mm

0

3

Rear

left

125 mm

Air inlet

Drain outlet

Left

Bottom left

102 mm

90 mm

2

EN

Page 7

INDOOR UNIT

Installation Place

• A place which provides the spaces around the indoor unit as

shown in the diagram

• A place where there are no obstacles near the air inlet and outlet

• A place which allows easy installation of the piping to the outdoor

unit

• A place which allows the front panel to be opened

CAUTION

• Direct sunlight to the indoor unit’s wireless receiver should be

avoided.

• The microprocessor in the indoor unit should not be too close

to RF noise sources.

(For details, see the owner’s manual.)

Remote control

• A place where there are no obstacles such as a curtain that may

block the signal from the indoor unit

• Do not install the remote control in a place exposed to direct

sunlight or close to a heating source such as a stove.

• Keep the remote control at least 1 m apart from the nearest TV

set or stereo equipment. (This is necessary to prevent image

disturbances or noise interference.)

• The location of the remote control should be determined as

shown below.

7 m

(Top view)

Indoor unit

Remote

control

* : Axial distance

5 m

Reception range

45

°

5 m

°

5

4

Remote control

Indoor unit

(Side view)

75°

Reception

range

Cutting a Hole and Mounting

Installation Plate

Cutting a hole

When installing the refrigerant pipes from the rear

Mounting the installation plate

Hook

170

85

Pipe hole

Indoor unit

Hook

Thread

Weight

Hook

Pipe hole

7 Mounting screw

When the installation plate is directly mounted on the wall

1.Securely fit the installation plate onto the wall by screwing it in the

upper and lower parts to hook up the indoor unit.

2.To mount the installation plate on a concrete wall with anchor

bolts, use the anchor bolt holes as illustrated in the below figure.

3.Install the installation plate horizontally in the wall.

CAUTION

When installing the installation plate with a mounting screw,

do not use the anchor bolt holes. Otherwise, the unit may fall

down and result in personal injury and property damage.

Installation plate

(Keep horizontal direction.)

ss

s

ss

Anchor bolt

Projection

15 mm or less

* 7 m

5 mm dia. hole

Clip anchor

(local parts)

7 Mounting screw

∅4 x 25

CAUTION

Failure to firmly install the unit may result in personal injury and

property damage if the unit falls.

• In case of block, brick, concrete or similar type walls, make 5 mm

dia. holes in the wall.

• Insert clip anchors for appropriate mounting screws 7.

62

Installation

plate

82.5

1

Pipe hole

65 mm

The center of the pipe hole

is above the arrow.

100 mm

1.After determining the pipe hole position on the mounting plate

(A), drill the pipe hole (∅65 mm) at a slight downward slant to

the outdoor side.

NOTE

• When drilling a wall that contains a metal lath, wire lath or metal

plate, be sure to use a pipe hole brim ring sold separately.

EN

NOTE

• Secure four corners and lower parts of the installation plate with

4 to 6 mounting screws to install it.

3

Page 8

N

L

40 mm

10 mm

30 mm

10 mm

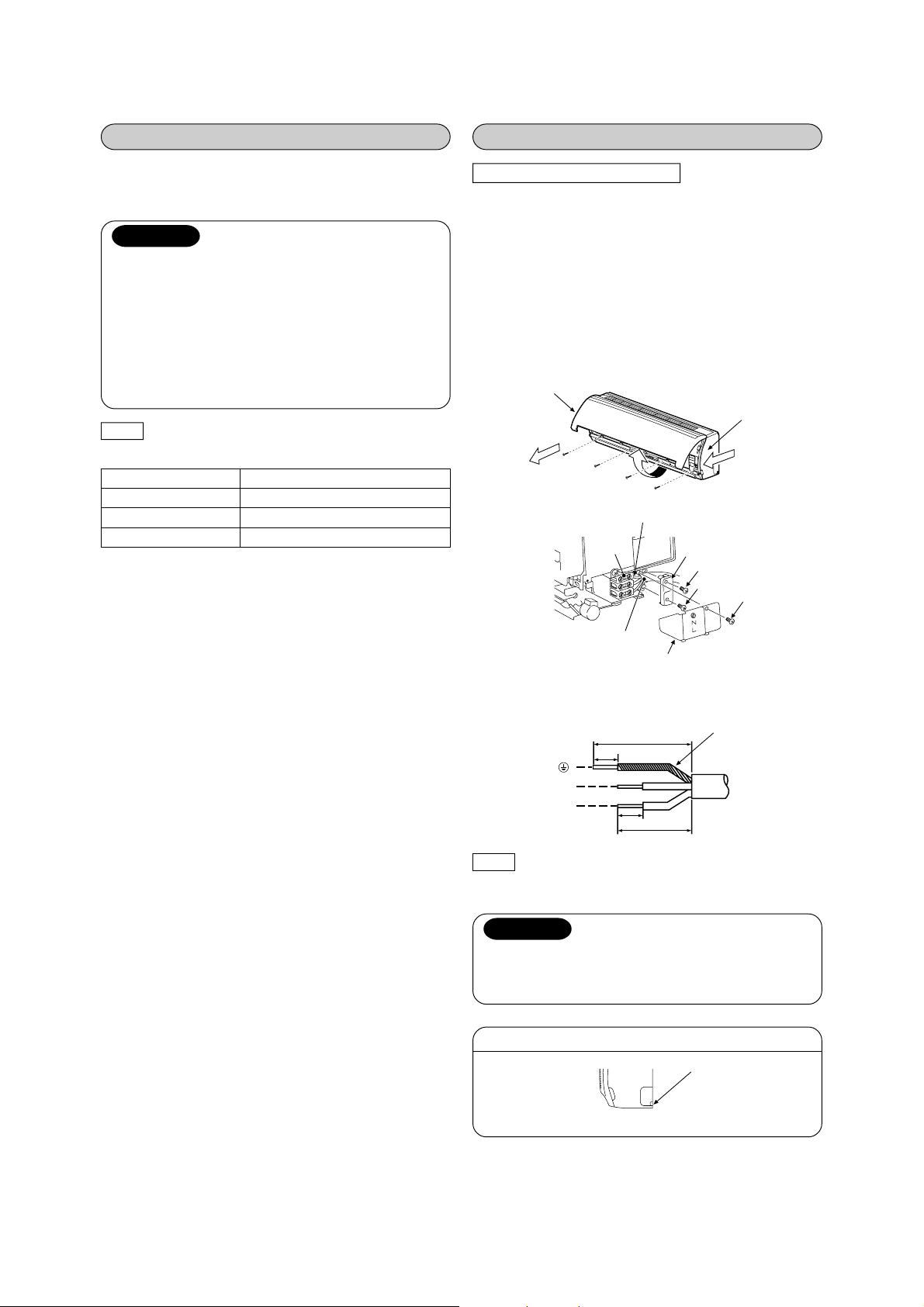

Electrical Work

1.The supply voltage must be the same as the rated voltage of the

air conditioner.

2.Prepare the power source for exclusive use with the air

conditioner.

CAUTION

• This appliance can be connected to the mains in either of the

following two ways.

(1) Connection to fixed wiring:

A switch or circuit breaker which disconnects all poles and

has a contact separation of at least 3 mm must be

incorporated in the fixed wiring. An approved circuit breaker

or switches must be used.

(2) Connection with power supply plug:

Attach power supply plug with power cord and plug it into

wall outlet. An approved power supply cord and plug must

be used.

NOTE

• Ensure all wiring is used within its electrical rating.

Power source 50Hz, 220 – 240 V Single phase

Maximum running current 12A

Plug socket & fuse rating 16A

Power cord 1.3 mm2 or more

Wiring Connection

How to connect the power cord

For the air conditioner that does not have power cord,

connect a power cord to it as mentioned below.

(1) Open the air inlet grille upward.

(2) Remove the four screws securing the front panel.

(3) Slightly open the lower part of the front panel, then pull the

upper part of the front panel toward you to remove it from the

rear plate.

(4) After removing the front panel, remove the power cord connect

cover and the cord clamp.

(5) Connect and secure the power supply cord and secure the cord

clamp and the power cord connect cover.

(6) Put the power supply cord through the notch.

(7) Be sure to smooth the notch with a file, etc.

Air inlet grille

Front panel

2

Terminal

block

1

Earth line

3

Cord clamp

Screw

Screw

Screw

Power supply cord

Power cord

connect cover

Stripping length of the power supply cord

Earth line

NOTE

• Use stranded wire only.

• Wire type : H07RN-F or more

CAUTION

For the air conditioner with the power supply cord

• If the power supply cord is damaged, it must be replaced by

the manufacturer, the service agency, or another similarly

qualified person in order to avoid hazard.

Taking out the power cord

Notch

• Put the power supply cord through the notch.

EN

4

Page 9

How to connect the connecting cable

1

2

1

2

3

4

Wiring of the connecting cable can be carried out without

removing the front panel.

1.Remove the air inlet grille.

Open the air inlet grille upward and pull it toward you.

2.Remove the terminal cover and cord clamp.

3.Insert the connecting cable (according to the local cords) into the

pipe hole on the wall.

4.Take out the connecting cable through the cable slot on the rear

panel so that it protrudes about 15 cm from the front.

5.Insert the connecting cable fully into the terminal block and

secure it tightly with screws.

6.Tightening torque : 1.2 N·m (0.12 kgf·m)

7.Secure the connecting cable with the cord clamp.

8.Fix the terminal cover, rear plate bushing and air inlet grille on the

indoor unit.

CAUTION

• Be sure to refer to the wiring system diagram labeled inside

the front panel.

• Check local electrical cords and also any specific wiring

instructions or limitations.

For Heatpump model

Terminal cover

Connecting cable

about 15 cm

Screw

Screw

Cord clamp

4

1

2

3

Screw

Terminal block

Earth line

Connecting

cable

Stripping length of

the connecting cable

10 mm

10 mm

80 mm

70 mm

10 mm

50 mm

Earth line

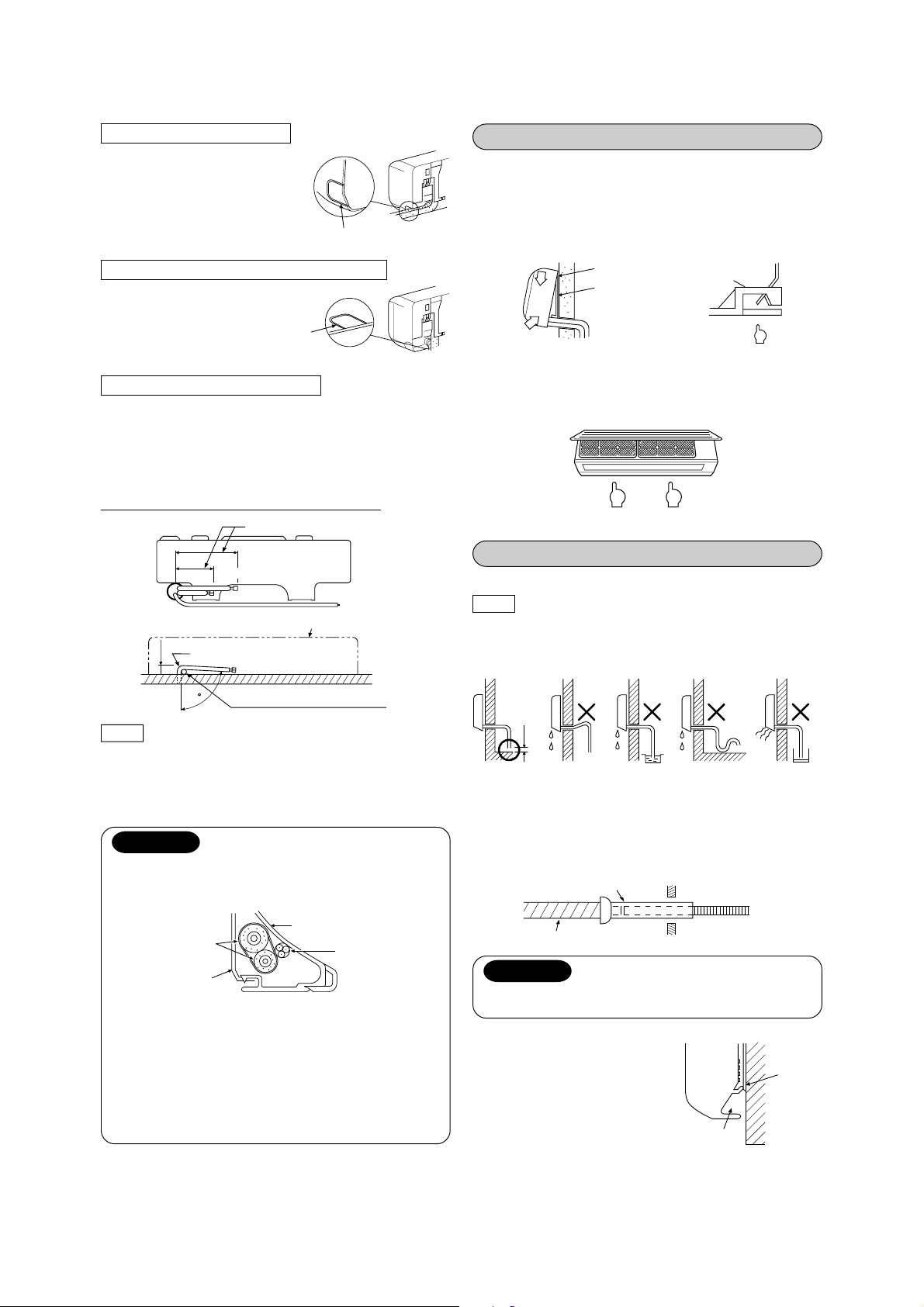

Piping and Drain Hose Installation

Piping and drain hose forming

* Since dewing results in a machine trouble, make sure to insulate

both connecting pipes. (Use polyethylene foam as insulating

material.)

Rear right

Rear left

Bottom left

Changing

Left

Bottom right

Die-cutting

Right

front panel slit

1. Die-cutting front panel slit

For leftward connection, cut out slit on the left side of the front panel.

(A knife will produce splinters, so use nippers.)

2. Changing drain hose

For leftward connection, bottom-leftward connection and rearleftward connection’s piping, it is necessary to change the drain

hose and drain cap.

How to remove the drain cap

Clip the drain cap by needle-nose pliers and pull out.

drain hose

Piping preparation

For Cooling model

Terminal cover

Connecting cable

about 15 cm

Screw

Screw

Cord clamp

1

2

Screw

Terminal block

Earth line

Connecting

cable

Earth line

60 mm

10 mm

10 mm

50 mm

Stripping length of

the connecting cable

NOTE

• Use stranded wire only.

• Wire type : H07RN-F or more

How to install the air inlet grille on the indoor unit

• When attaching the air inlet grille, the contrary of the removed

operation is performed.

How to install the drain hose

Firmly insert drain hose connecting part until hitting on a heat

insulator.

Heat insulator

Drain hose

How to fix the drain cap

1) Insert hexagon wrench (4 mm) in a center head.

4 mm

2) Firmly insert the drain cap.

No gap

Insert a hexagon

wrench (4 mm).

Do not apply lubricating oil

(refrigerant machine oil) when

inserting the drain cap. Application

causes deterioration and drain

leakage of the plug.

CAUTION

Firmly insert the drain hose and drain cap; otherwise, water may

leak.

EN

5

Page 10

In case of right or left piping

• After scribing slits of the

front panel with a knife or

a making-off pin, cut them

with a pair of nippers or

an equivalent tool.

Slit

In case of bottom right or bottom left piping

• After scribing slits of the

front panel with a knife or

a making-off pin, cut them

with a pair of nippers or

Slit

an equivalent tool.

Left-hand connection with piping

Bend the connecting pipe so that it is laid within 43 mm above the

wall surface. If the connecting pipe is laid exceeding 43 mm above

the wall surface, the indoor unit may unstably be set on the wall.

When bending the connecting pipe, make sure to use a spring

bender so as not to crush the pipe.

Bend the connecting pipe within a radius of 30 mm.

To connect the pipe after installation of the unit (figure)

(To the forefront of flare)

270 mm

170 mm

Liquid side

Gas side

Indoor Unit Fixing

1.Pass the pipe through the hole in the wall and hook the indoor

unit on the installation plate at the upper hook.

2.Swing the indoor unit to right and left to confirm that it is firmly

hooked up on the installation plate.

3.While pressing the indoor unit onto the wall, hook it at the lower

part on the installation plate. Pull the indoor unit toward you to

confirm that it is firmly hooked up on the installation plate.

1

2

Hook

Hook here.

1 Installation plate

Press

(unhook)

• For detaching the indoor unit from the installation plate, pull the

indoor unit toward you while pushing its bottom up at the

specified parts.

PushPush

Drainage

1.Run the drain hose sloped downwards.

Outward form of indoor unit

R 30 mm (Use polisin (polyethylene)

43 mm

core or the like for bending pipe.)

0

Use the handle of screwdriver, etc.

8

NOTE

If the pipe is bent incorrectly, the indoor unit may unstably be set on

the wall.

After passing the connecting pipe through the pipe hole, connect

the connecting pipes to the auxiliary pipes and wrap the facing tape

around them.

CAUTION

• Bind the auxiliary pipes (two) and connecting cable with

facing tape tightly. In case of leftward piping and rear-leftward

piping, bind the auxiliary pipes (two) only with facing tape.

Indoor unit

Auxiliary pipes

Installation plate

• Carefully arrange pipes so that any pipe does not stick out of

the rear plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to

one another and cut off the insulating tape wound on the

connecting pipe to avoid double-taping at the joint; moreover,

seal the joint with the vinyl tape, etc.

• Since dewing results in a machine trouble, make sure to

insulate both connecting pipes. (Use polyethylene foam as

insulating material.)

• When bending a pipe, carefully do it, not to crush it.

Connecting cable

NOTE

• The hole should be made at a slight downward slant on the

outdoor side.

50 mm

or more

Do not rise the

drain hose.

Do not put the

drain hose end

into water.

Do not form the

drain hose into

a wavy shape.

Do not put the

drain hose end

in the drainage

ditch.

2.Put water in the drain pan and make sure that the water is

drained out of doors.

3.When connecting extension drain hose, insulate the connecting

part of extension drain hose with shield pipe.

Shield pipe

Inside the roomDrain hose

Extension drain hose

CAUTION

Arrange the drain pipe for proper drainage from the unit.

Improper drainage can result in dew-dropping.

This air conditioner has the

structure designed to drain

water collected from dew, which

forms on the back of the indoor

unit, to the drain pan. Therefore,

do not store the power cord and

other parts at a height above

the drain guide.

Space for pipes

Wall

Drain

guide

6

EN

Page 11

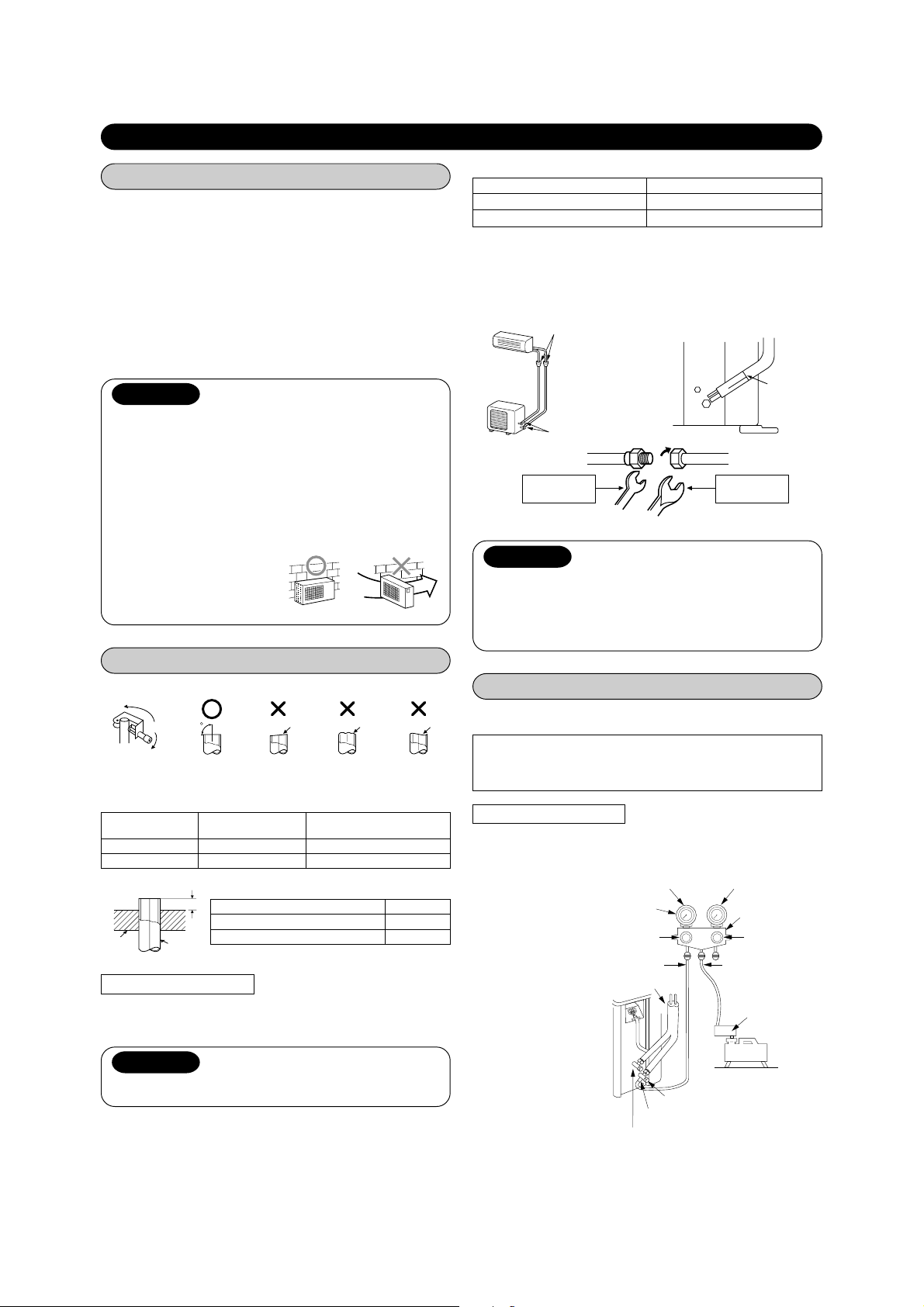

OUTDOOR UNIT

Installation Place

• A place which provides the spaces around the outdoor unit as

shown in the diagram

• A place which can bear the weight of the outdoor unit and does

not allow an increase in noise level and vibration

• A place where the operation noise and discharged air do not

disturb your neighbors

• A place which is not exposed to a strong wind

• A place free of a leakage of combustible gases

• A place which does not block a passage

• When the outdoor unit is to be installed in an elevated position,

be sure to secure its feet.

• An allowable length of the connecting pipe is up to 15 m.

• An allowable height level is up to 6 m.

• A place where the drain water does not raise any problems

CAUTION

1.Install the outdoor unit without anything blocking the air

discharging.

2.When the outdoor unit is installed in a place always exposed

to strong wind like a coast or on a high storey of a building,

secure the normal fan operation using a duct or a windshield.

3.In particularly windy areas, install the unit such as to avoid

admission of wind.

4.Installation in the following places may result in trouble.

Do not install the unit in such places.

• A place full of machine oil

• A saline-place such as the coast

• A place full of sulfide gas

• A place where high-

frequency waves are likely

to be generated as from

audio equipment, welders,

and medical equipment

Strong

wind

Refrigerant Piping Connection

1.Cut the pipe with a pipe cutter.

90

2.Insert a flare nut into the pipe and flare the pipe.

• Projection margin in flaring : A (Unit : mm)

Obliquity

Rigid (clutch type)

Outer dia.

of copper pipe

6.35 0 to 0.5 1.0 to 1.5

12.70 0 to 0.5 1.0 to 1.5

R410A tool used Conventional tool used

Imperial (wing nut type, conventional tool)

Die

A

Pipe

Outer dia. of copper pipe R410A

6.35 1.5 to 2.0

12.70 2.0 to 2.5

Tightening connection

Align the centers of the connecting pipes and tighten the flare nut

as far as possible with your fingers. Then tighten the nut with a

spanner and torque wrench as shown in the figure.

CAUTION

Do not apply excess torque. Otherwise, the nut may crack

depending on the conditions.

Roughness Warp

(Unit : N·m)

Outer dia. of copper pipe Tightening torque

∅6.35 mm 16 to 18 (1.6 to 1.8 kgf·m)

∅12.70 mm 50 to 62 (5.0 to 6.2 kgf·m)

• Tightening torque of flare pipe connections

The operating pressure of R410A is higher than that of R22

(approx. 1.6 times). It is therefore necessary to firmly tighten the

flare pipe connecting sections (which connect the indoor and

outdoor units) up to the specified tightening torque. Incorrect

connections may cause not only a gas leakage, but also damage

to the refrigeration cycle.

Flare at

indoor unit side

Mark line

Flare at

outdoor unit side

Flare nutHalf union

Externally

threaded side

Use a wrench to secure. Use a torque wrench to tighten.

Internally

threaded side

CAUTION

• KEEP IMPORTANT 4 POINTS FOR PIPING WORK.

(1) Take away dust and moisture (inside of the connecting pipes).

(2) Tighten the connections (between pipes and unit).

(3) Evacuate the air in the connecting pipes using a VACUUM

PUMP.

(4) Check gas leak (connected points).

Evacuating

After the piping has been connected to the indoor unit, you can

perform the air purge together at once.

AIR PURGE

Evacuate the air in the connecting pipes and in the indoor unit

using a vacuum pump. Do not use the refrigerant in the outdoor

unit. For details, see the manual of the vacuum pump.

Using a vacuum pump

Be sure to use a vacuum pump with counter-flow prevention

function so that inside oil of the pump does not flow backward into

pipes of the air conditioner when the pump stops.

(If oil inside of the

vacuum pump enters

the air conditioner, which

use R410A, refrigeration

cycle trouble may result.)

1.Connect the

charge hose from

the manifold valve

to the service port

of the packed

valve at gas side.

2.Connect the

charge hose to the

port of the vacuum

pump.

3.Open fully the low

pressure side

handle of the

gauge manifold

valve.

Compound

pressure gauge

–101 kPa

(–76 cmHg)

Handle Lo

Charge hose

(For R410A only)

Connecting pipe

Packed valve at gas side

Service port (Valve core (Setting pin))

Packed valve at liquid side

Pressure gauge

Manifold valve

Handle Hi

(Keep full closed)

Charge hose

(For R410A only)

Vacuum pump adapter for

counter-flow prevention

(For R410A only)

Vacuum

pump

EN

7

Page 12

4.Operate the vacuum pump to start evacuating. Perform

evacuating for about 15 minutes if the piping length is 20 meters.

(15 minutes for 20 meters) (assuming a pump capacity of 27 liters

per minute) Then confirm that the compound pressure gauge

reading is –101 kPa (–76 cmHg).

5.Close the low pressure side valve handle of the gauge manifold

valve.

6.Open fully the valve stem of the packed valves (both gas and

liquid sides).

7.Remove the charging hose from the service port.

8.Securely tighten the caps on the packed valves.

Packed valve handling precautions

• Open the valve stem all the way out, but do not try to open it

beyond the stopper.

• Securely tighten the valve stem cap with torque in the following

table:

Gas side 50 to 62 N·m

(∅12.70 mm) (5.0 to 6.2 kgf·m)

Liquid side 16 to 18 N·m

(∅6.35 mm) (1.6 to 1.8 kgf·m)

Service port

9 to 10 N·m

(0.9 to 1.0 kgf·m)

The hexagon wrench

is required.

4 mm

Stripping length of the connecting cable

For Heatpump model

70 mm

10 mm

Earth line

10 mm

60 mm

Terminal block

Terminal screw

Screw

Connecting cable

For Cooling model

Terminal block

Terminal screw

Screw

Connecting cable

10 mm

60 mm

Earth line

10 mm

50 mm

1(L)

2(N) 3 4

1(L)

2(N)

Earth line

Cord clamp

Earth line

Cord clamp

Wiring Connection

1.Remove the valve cover from the outdoor unit.

2.Connect the connecting cable to the terminals as identified with

their respective matched numbers on the terminal block of indoor

and outdoor unit.

3.When connecting the connecting cable to the outdoor unit

terminals, make a loop as shown in the installation diagram of

indoor and outdoor unit to prevent water coming in the outdoor unit.

4.Insulate the unused cords (conductors) from any water coming in

the outdoor unit. Proceed them so that they do not touch any

electrical or metal parts.

OTHERS

Gas Leak Test

Valve cover

Valve stem

cap connections

Service port

cap connection

• Check the flare nut connections, valve stem cap connections and

service port cap connection for gas leak with a leak detector or

soap water.

CAUTION

• Wrong wiring connection may cause some electrical parts

burn out.

• Be sure to comply with local cords on running the wire from

indoor unit to outdoor unit (size of wire and wiring method,

etc.).

• Every wire must be connected firmly.

NOTE

• Wire type : H07RN-F or 245 IEC66 (2.0 mm2 or more)

Setting of Remote Control

Selector Switch

When two indoor units are installed in the separated rooms, it

is not necessary to change the selector switches.

Remote control selector switch

• When two indoor units are installed in the same room or

adjacent two rooms, if operating a unit, two units may receive

the remote control signal simultaneously and operate. In this

case, the operation can be preserved by setting either one

indoor unit or remote control to B setting. (Both are set to A

setting in factory shipment.)

• The remote control signal is not received when the settings of

indoor unit and remote control are different.

• There is no relation between A setting/B setting and A room/B

room when connecting the piping and cables.

8

EN

Page 13

1. Setting of remote control switch at the

A B

indoor unit side

2. Setting of remote control selector at the

remote control side

How to remove the front panel

(1) Stop the operation of the air conditioner and turn off its main

power supply.

(2) Pull the air inlet grille toward you to open it and remove the air

inlet grille.

(3) First open the horizontal louver, and then remove the front panel

from the back body by pulling it toward you.

Hooks of front panel (4 points)

Screws

Air filter

Push

Screws

Terminal cover

[B] of the remote control is displayed with liquid crystal only

when it is set to [B]. There is no display of [A].

• Enter the battery.

• Push the [CHECK] button by something with thin edge. ([00] is

displayed.)

• If the [MODE] button is pushed while pushing the [CHECK]

button, the small [B] is displayed at the right of the setting

temperature indication section.

* To reset [A] setting, push the [MODE] button again while

pushing the [CHECK] button.

3. Confirm the indoor unit can operate with the

changed setting of the remote control.

[MODE] button

[CHECK] button

Position of remote control selector switch

Remote control selector switch

How to set the remote control selector switch

B settingA setting

A B A B

How to mount the front panel

Push the front panel backwards and make sure all hooks are

locked.

EN

9

Page 14

Test Operation

To switch the TEST RUN (COOL) mode, press RESET button for 10

seconds. (The beeper will make a short beep.)

RESET

RESET button

Auto Restart Setting

This product is designed so that, after a power failure, it can restart

automatically in the same operating mode as before the power

failure.

Information

The product was shipped with Auto Restart function in the off

position. Turn it on as required.

How to set the Auto Restart

• Press and hold the RESET button for about 3 seconds.

After 3 seconds, the electronic beeper makes three short beeps

to tell you the Auto Restart has been selected.

• To cancel the Auto Restart, follow the steps described in the

section Auto Restart Function of the owner’s manual.

10

EN

Page 15

PRECAUCIONES SOBRE SEGURIDAD

Para el uso público general

El cable de alimentación de las piezas del sistema instaladas en el exterior debe ser al menos cable flexible enfundado en policloropreno (modelo

H07RN-F) o del tipo 245 IEC66. (Debe instalarse según las normas de instalación eléctrica de cada país.)

PRECAUCIÓN

• ESTE SISTEMA AIRE ACONDICIONADO UTILIZA EL NUEVO REFRIGERANTE HFC (R410A) QUE NO DAÑA LA CAPA DE OZONO.

El refrigerante R410A puede contaminarse de impurezas, como agua, membrana oxidante y aceites, ya que su presión es aproximadamente 1,6

veces superior a la del refrigerante R22. Gracias al uso del nuevo refrigerante, también se emplea un aceite distinto para el aparato de

refrigeración. Por lo tanto, durante las tareas de instalación, asegúrese de que no se introduzca agua, polvo, otro tipo de refrigerante ni aceite del

aparato de refrigeración en el ciclo de refrigeración del sistema de aire acondicionado que emplea el nuevo refrigerante.

Para impedir que el refrigerante se mezcle con el aceite del aparato de refrigeración, los tamaños de las secciones de conexión de los orificios de

carga de la unidad principal o de las herramientas de instalación son diferentes de las correspondientes al refrigerante convencional. Para la

conexión de tuberías, utilice materiales nuevos, limpios, estancos a alta presión y fabricados exclusivamente para R410A, a fin de que no se

introduzca agua ni polvo. Asimismo, no utilice la tubería existente, ya que presenta problemas de pérdidas y admisión de impurezas.

PRECAUCIÓN

Este aparato debe conectarse al suministro eléctrico mediante un disyuntor o un interruptor que disponga de una separación de contacto de

3 mm como mínimo en todos los polos. Si esto no fuese posible, deberá utilizarse una toma de alimentación provista a tierra. Esta toma deberá

estar fácilmente accesible después de la instalación. La toma deberá desconectarse del enchufe de alimentación provisto para así desconectar

el aparato completamente de la red.

Instalación de sistema de aire acondicionado con un nuevo refrigerante

Para desconectar el aparato de la alimentación principal

PELIGRO

• SOLAMENTE PARA EL USO DE PERSONAS CUALIFICADAS.

• DESACTIVE LA FUENTE DE ALIMENTACIÓN PROVISTA Y EL CORTACIRCUITOS ANTES DE INTENTAR REALIZAR CUALQUIER

TRABAJO ELÉCTRICO. ASEGURESE DE QUE TODOS LOS INTERRUPTORES DE ALIMENTACIÓN Y CORTACIRCUITOS ESTÉN

DESACTIVADOS, SI NO LO HACE PODRÍA CAUSAR DESCARGAS ELÉCTRICAS.

• CONECTE EL CABLE DE CONEXIÓN CORRECTAMENTE. SI ESTE CABLE FUESE CONECTADO ERRONEAMENTE, SE PODRÍAN

DAÑAR LAS PARTES ELÉCTRICAS.

• REVISE EL CABLE A TIERRA QUE NO ESTÉ ROTO NI DESCONECTADO ANTES DE LA INSTALACIÓN.

• NO INSTALE CERCA DE CONCENTRACIONES DE COMBUSTIBLE DE GAS O VAPORES DE GAS.

SI FALLA EN CUMPLIR CON ESTA INSTRUCCION PODRIA RESULTAR EN UN INCENDIO O UNA EXPLOSIÓN.

• PARA EVITAR EL RECALENTAMIENTO DE LA UNIDAD INTERIOR Y LA CAUSA DE POSIBLES INCENCIOS, COLOQUE LA UNIDAD BIEN

LEJOS (A MÁS DE 2 METROS) DE FUENTES DE CALEFACCIÓN TALES COMO RADIADORES, CALEFACTORES, ESTUFAS, HORNOS, ETC.

• CUANDO MUEVA EL ACONDICIONADOR DE AIRE PARA INSTALARLO EN OTRO LUGAR, TENGA CUIDADO DE NO OBTENER EL

REFRIGERANTE ESPECIFICADO (R410A) CON ALGUN OTRO CUERPO GASEOSO EN EL CICLO DE REFRIGERACIÓN. SI EL AIRE O

ALGUN OTRO GAS SE MEZCLARA CON EL REFRIGERANTE, LA PRESIÓN DEL GAS EN EL CICLO DE REFRIGERACIÓN SE VUELVE

ANORMALMENTE ALTA Y ESTO RESULTANDO EN CAUSAR UN ESTALLIDO DE LA TUBERÍA Y DAÑOS EN LAS PERSONAS.

• EN EL CASO DE QUE EL GAS REFRIGERANTE ESCAPARA DE LA TUBERÍA DURANTE EL TRABAJO DE INTALACIÓN,

INMEDIATAMENTE DEJE QUE PASE AIRE FRESCO EN LA HABITACIÓN. SI ESTE GAS REFRIGERANTE ES CALENTADO POR EL

FUEGO O ALGO SIMILAR, CAUSARA LA GENERACIÓN DE UN GAS VENENOSO.

ADVERTENCIA

• Nunca modifique esta unidad quitando uno de las etiquetas de seguridad o puenteando uno de los interruptores de interbloqueo de seguridad.

• No instale esta unidad en un lugar que no sea capaz de resistir el peso de la unidad.

Si la unidad se cayera podría causar daños personales o materiales.

• Antes de hacer un trabajo eléctrico, instale un enchufe aprobado al cable de suministro de alimentación.

Y asegúrese de que el equipo está conectado a tierra.

• El aparato deberá instalarse según las regulaciones de cableado nacional.

Si detectara algún daño, no instale la unidad. Póngase en contacto con su concesionario TOSHIBA inmediatamente.

PRECAUCIÓN

• La exposición de la unidad al agua o a cualquier otro tipo de humedad antes de la instalación puede provocar un cortocircuito.

No almacene la unidad en un sótano mojado, ni la exponga a la lluvia ni al agua.

• Después de desembalajar la unidad, examínela cuidadosamente para ver si hay alguna avería.

• No instale la unidad en un lugar que pueda aumentar la vibración de la misma. Tampoco la instale en un lugar que pueda amplificar el nivel de

ruido de la unidad, o donde el ruido y el aire descargado puedan molestar a los vecinos.

• Para evitar daños personales, tenga cuidado cuando maneje las partes con bordes afilados.

• Lea el manual de instalación a fondo antes de instalar la unidad. El manual contiene instrucciones importantes para la instalación correcta.

INFORMACIÓN NECESARIA PARA EL SUMINISTRADOR DE ALIMENTACIÓN LOCAL

Antes de instalar este sistema de aire acondicionado, no olvide informar de ello al suministrador de alimentación local. Si surge algún problema o

el suministrador de alimentación no acepta la instalación, el sistema de asistencia tomará las medidas correctoras necesarias.

Nota de la directiva EMC 89/336/EEC

Para prevenir fluctuaciones en la corriente durante el arranque del compresor (proceso técnico) se deberán observar estas condiciones de

instalación.

1. La conexión eléctrica del acondicionador de aire deberá llevarse a cabo en la toma principal. Esta alimentación debera ser de baja impedancia.

Normalmente, la impedancia requerida se alcanza a un punto de fusión de 32A. El fusible del acondicionador de aire deberá ser de 16A como

máximo!

2. A esta linea de alimentación no deberá conectarse ningun otro equipo.

3. Consulte con la compañia electrica para obtener información detallada sobre la aceptabilidad de la instalación.

4. Para detalles sobre la alimemtación del acondicionador de aire consulte la placa de especificaciones del producto.

ES

1

Page 16

DIAGRAMA DE INSTALACIÓN DE LA UNIDAD INTERIOR Y EXTERIOR

Posterior izquierda e izquierda

1

7

0

m

m

o

m

á

s

Gancho

65 mm o más

1 Placa de

instalación

Pared

(

In

st

a

5 Filtro

3 Pilas

2 Control remoto

Observación :

• Consulte la hoja de accesorios para ver

en detalle los accesorios y las piezas de

instalación.

le

e

n

e

l p

6 Filtro

8 Tornillo de

a

ne

l f

r

on

cabeza de

madera

1

0

0

m

Gancho

170 mm o m

Inserte la almohadilla entre la

ás

unidad interior y la pared,

y eleve la unidad interior para

facilitar el trabajo.

F

ilt

r

o

d

e a

ir

e

Protección de

ta

l.)

la tubería

No permita que la manguera de

drenaje se afloje.

Corte el orificio

de la tubería

levemente

inclinada.

ESPAÑOL

Haga el orificio para la tubería

levemente inclinado.

4 Soporte del

control remoto

Cinta de vinilo

Aplíquela después

de realizar una

prueba de drenaje.

s

á

m

o

m

0 m

10

600 mm o más

m

o

m

á

s

s

à

m

o

m

m

600

Apoyo

Manguera de

drenaje de

extensión

(No disponible,

suministrado por el

instalador)

60

0 mm

o

màs

La tubería auxiliar se podrá

conectar al lado izquierdo,

posterior izquierdo, posterior

derecho, derecho, inferior

derecho o inferior izquierdo.

Derecho

Posterior

derecho

Inferior

derecho

Posterior

izquierdo

Inferior

izquierdo

Aislamiento de las tuberías

refrigerantes aisle las tuberías

separadamente, no juntas.

Espuma de polietileno de 6 mm

de grosor con resistencia al calor

Izquierdo

Código

de pieza

A

B

C

Piezas de Instalación

Opcional

Nombre de partes

Tubería de refrigerante

Lado líquido : ∅6,35 mm

Lado de gas : ∅12,70 mm

Material aislante de tuberías (espuma

de polietileno de 6 mm de grosor)

Masilla, cintas de PVC

Ctdad.

Cada

uno

1

Cada

uno

Fijación de tornillos de la unidad exterior

• Proteja la unidad exterior con

los tornillos y tuercas de

fijación si va a permanecer

expuesta a la acción de

vientos fuertes.

• Utilice tornillos y tuercas de

anclaje de ∅8 mm o ∅10 mm.

• Si fuera necesario vaciar el

agua descongelada, conecte

el codo de drenaje 9 y la tapa

impermeable ! en la placa

inferior de la unidad exterior

320 mm

32,5 mm

7 mm

Salida de aire

108 mm

antes de instalarla.

2

86 mm

600 mm

30

125 mm

Entrada de aire

102 mm

90 mm

Salida de drenaje

ES

Page 17

UNIDAD INTERIOR

Lugar de Instalación

• Un lugar que brinde espacio alrededor de la unidad interior tal como

se muestra en el diagrama

• Un lugar en el que no haya obstáculos cerca de la entrada y salida de

aire

• Un lugar que permita una instalación fácil de la tubería para la unidad

exterior

• Un lugar que permita que el panel delantero se abra

PRECAUCIÓN

• Se deberá evitar la luz directa del sol sobre el receptor de control

a distancia de la unidad interior.

• El microprocesador de la unidad interior no deberá estar tan cerca

de las fuentes de ruido RF.

(Para los detalles, vea el manual del usuario.)

Control remoto

• Un lugar en el que no haya obstáculos tal como una cortina que

pudiese bloquear las señales del unidad interior

• No instale el control remoto en un lugar expuesto a la luz directa del

sol o ceraca de una fuente de calor, por ejemplo una estufa.

• Mantenga el control remoto por lo menos a 1 m de distancia de su

equipo de TV o estéreo. (Esto es necesario para evitar interrupciones

o ruidos de interferencia.)

• La ubicación del control remoto deberá determinarse tal como se

ilustra abajo.

7 m

(Vista superior)

Unidad interior

Control

remoto

* : Distancia axial

5

Margen de

recepción

45°

5 m

5°

4

Control remoto

m

(Vista lateral)

Unidad interior

75°

Margen de

recepción

Montaje de la placa de instalación

Gancho

170

85

Orificio de

la tubería

Gancho

Hebra

Unidad interior

Gancho

7 Tornillo de montaje

Peso

Orificio de

la tubería

Cuando la placa de instalación es directamente

montada sobre la pared

1. Fije firmemente la placa de instalación sobre la pared atornillando las

partes superior e inferior para enganchar la unidad interior.

2. Para montar la placa de instalación sobre una pared de hormigón con

tacos, utilice los orificios para tacos tal como se muestra en la figura

de abajo.

3. Instale la placa de instalación horizontalmente en la pared.

PRECAUCIÓN

Cuando instale la placa de instalación con un tornillo de montaje no

utilice el orificio del cerrojo de áncora. Si no, la unidad se podría caer

y resultar en daños personales y en daños de propiedad.

Placa de instalación

* 7 m

(Mantenga la posición horizontal.)

Orificio, 5 mm diá

Perno de anclaje

Proyección

15 mm o menos

62

Placa de

instalación

82,5

1

Corte de un Orificio y Montaje

de la Placa de Instalación

Corte de un orificio

Cuando instale las tuberías refrigerantes desde la parte posterior

Orificio de

la tubería

65 mm

El orificio del centro de la

tubería está sobre la flecha.

1. Después de determinar la posición del orificio de la tubería con la

placa de montaje (A), perfore el orificio de la tubería (∅65 mm)

ligeramente inclinado hacia abajo al lado exterior.

NOTA

• Cuando la perforación de una pared que contenga listones, listones

de alambre o placas de metal, asegúrese de utilizar un anillo de borde

como molde del orificio de la tubería vendido por separado.

ES

100 mm

Gancho de anclaje

(partes locales)

7 Tornillo de montaje

∅4 x 25

ss

s

ss

PRECAUCIÓN

Si no instala firmemente la unidad podría causar daños personales

o materiales.

• En caso de paredes de bloques, ladrillos, hormigón o de tipo similar,

haga orificios de 5 mm de diámetro en la pared.

• Inserte tacos para tornillos de montaje 7 apropiados.

NOTA

• Fije las cuatro esquinas y partes inferiores de la placa de instalación

con 4 u 6 tornillos de montaje.

3

Page 18

Trabajo Eléctrico

N

L

40 mm

10 mm

30 mm

10 mm

1. El suministro de voltaje deberá ser igual al del voltaje nominal del

acondicionador de aire.

2. Prepare la fuente de alimentación para el uso exclusivo con el

acondicionador de aire.

PRECAUCIÓN

• Este sistema puede conectarse a la corriente de dos formas

distintas.

(1) Conexión a cable fijo:

Es preciso incorporar al cable fijo un interruptor o disyuntor

que desconecte todos los polos y disponga de una separación

de contacto de 3 mm como mínimo. Es necesario utilizar un

disyuntor o interruptores homologados.

(2) Conexión mediante un enchufe:

Conecte un cable de alimentación con enchufe y enchúfelo en

una toma de corriente de pared. Deben utilizarse un cable de

alimentación y un enchufe homologados.

Conexión de Cables

Cómo conectar el cable de alimentación

En los acondicionadores de aire que carezcan de cable de

alimentación, conecte uno como se indica a continuación.

(1) Tire hacia arriba para abrir la rejilla de entrada de aire.

(2) Retire los cuatro tornillos que aseguran el panel frontal.

(3) Abra ligeramente la parte inferior del panel frontal y tire hacia usted

de la parte superior para extraer el panel de la placa posterior.

(4) Después de quitar el panel frontal, retire la cubierta del terminal y la

abrazadera del cable.

(5) Conecte el cable de alimentación y vuelva a asegurar la abrazadera

y la cubierta del terminal.

(6) Pase el cable de alimentación a través de la ranura.

(7) No olvide igualar los bordes de la ranura con una lima.

Rejilla de entrada de aire

Panel frontal

NOTA

• Asegúrese de que todos los cables se utilizan dentro de su capacidad

eléctrica.

Fuente de alimentación 50Hz, 220 – 240 V Monofásico

Corriente máxima 12A

Enchufe hembra y valor

nominal de fusible

Cable de alimentación 1,3 mm2o más

16A

2

Bloque de

terminales

Cable de alimentación

1

Línea de tierra

Pelado del cable de alimentación

NOTA

• Utilice sólo cable trenzado.

• Tipo de cable : H07RN-F o más

3

Cable con

abrazadera

Tornillo

Tornillo

Tornillo

Cubierta de conexión del

cable de alimentación

Línea de tierra

PRECAUCIÓN

En los acondicionadores de aire con cable de alimentación

• Para evitar cualquier riesgo, si el cable de alimentación está

dañado, debe sustituirlo el fabricante, el servicio técnico o una

persona con una cualificación similar.

Extracción del cable de alimentación

Ranura

• Pase el cable de alimentación a través de la ranura.

4

ES

Page 19

1

2

1

2

3

4

Cómo conectar el cable de conexión

El cableado del cable de conexión puede realizarse sin quitar el

panel frontal.

1. Extraiga la rejilla de entrada de aire.

Tire de la rejilla de entrada de aire hacia fuera para abrirla.

2. Quite la tapa de los terminales y el cable con abrazadera.

3. Inserte el cable de conexión (según los códigos locales) en el orificio

de la tubería de la pared.

4. Saque el cable de conexión a través de la ranura del cable del panel

posterior hasta que sobresalga aproximadamente 15 cm.

5. Inserte el cable de conexión completamente en el bloque de

terminales y asegúrelo fuertemente con un tornillo.

6. Tensamiento de torsión a par : 1,2 N·m (0,12 kgf·m)

7. Asegure el cable de conexión con el cable con abrazadera.

8. Fije la cubierta del terminal, el cojinete de la placa trasera y la rejilla

de entrada de aire de la unidad interior.

Instalación la Tubería

y el Tubo de Desagüe

Formación la tubería y el tubo de desagüe

* Como la condensación produce problemas en el equipo, asegúrese

de aislar las dos tubarías de conexión. (Utilice espuma de polietileno

como material aislante.)

Posterior derecho

Posterior izquierdo

Inferior izquierdo

PRECAUCIÓN

• Asegúrese de consultar con la etiqueta del diagrama del sistema

de cableado en el interior del panel frontal.

• Compruebe los códigos eléctricos locales, así como las

instruciones o limitaciones específicas del cableado.

Para Modelo de Bomba de calor

Cable con

Cubierta del terminal

abrazadera

Tornillo

Cable de conexión

aproximadamente 15 cm

Tornillo

Tornillo

Para Modelo de Refrigeración

Cable con

abrazadera

Cubierta del terminal

Tornillo

Tornillo

Tornillo

Cable de conexión

aproximadamente 15 cm

NOTA

• Utilice sólo cable trenzado.

• Tipo de cable : H07RN-F o más

Bloque de

terminales

4

1

2

3

Línea de

tierra

Cable de

conexión

Bloque de

terminales

1

2

Línea de

tierra

Cable de

conexión

10 mm

10 mm

Pelado del cable de

conexión

Línea de tierra

60 mm

10 mm

10 mm

50 mm

Pelado del cable de

conexión

80 mm

70 mm

10 mm

50 mm

Línea de

tierra

Izquierdo

Inferior derecho

Tapa precortada

Cambio del tubo

de desagüe

Preparación de la tubería

Derecho

1. Tapa precortada

Para la conexión izquierda, haga un corte en la parte izquierda del panel

frontal. (Un cuchillo hace un corte irregular, por lo que debe utilizar tijeras.)

2. Cambio del tubo del desagüe

Para los desagües de las conexiones izquierda, inferior izquierda y

posterior izquierda, es necesario cambiar el tubo y la tapa del desagüe.

Forma de retirar el tapón de desagüe

Sujete la tapa con unos alicates y tire hacia fuera.

Forma de instalar el tapón de desagüe

Introduzca con firmeza la pieza de conexión del tubo de desagüe hasta

que llegue a un aislante térmico.

Aislante térmico

Manguera de drenaje

Forma de fijar el tapón de desagüe

1) Inserte una llave hexagonal (4 mm) en el centro.

Procedimiento para instalar la rejilla de entrada de aire

en la unidad interior

4 mm

• Para instalar la rejilla de entrada de aire ha de realizarse el

procedimiento inverso a su extracción.

2) Inserte firmemente el tapón de desagüe.

Sin

espacio

Inserte una llave

hexagonal (4 mm).

No utilice aceite lubricante (aceite

para maquinaria refrigerante) al

insertar la tapa del desagüe. Su uso

provoca que el enchufe se deteriore

y tenga fugas.

PRECAUCIÓN

Para evitar pérdidas de agua, inserte con firmeza el tubo y la tapa

del desagüe.

ES

5

Page 20

Para las tuberías derecho o izquierdo

• Después de trazar un surco

con un cuchillo o un punzón

alrededor de la pestaña del

panel frontal, córtela con

unas tijeras o una

herramienta similar.

Corte

Para las tuberías inferior derecho o inferior izquierdo

• Después de trazar un surco

con un cuchillo o un punzón

alrededor de la pestaña del

panel frontal, córtela con

unas tijeras o una

Corte

herramienta similar.

Conexión del lado izquierdo de la tubería

Doble la tubería de conexión de tal manera que quede tendida entre

43 mm sobre la superficie de la pared. Si la tubería de conexión fuese

tendida más allá de los 43 mm sobre la superficie de la pared, la unidad

interior podría ser inestable en la pared. Cuando doble la tubería de

conexión, asegúrese de utilizar un torcedor de resortes para no estrujar

la tubería.

Doble la tubería de conexión dentro de un radio de 30 mm.

Conexión de la tubería después de la instalación de la unidad (figura)

(Al lado del frente del destello)

270 mm

170 mm

R 30 mm (Utilice polisin (núcleo de

43 mm

polietileno) o similar para tubería flexible.)

Lado líquido

Lado de gas

Contorno de la unidad interior

Instalación de la Unidad Interior

1. Pase la tubería a través del orificio de la pared, y enganche la unidad

interior sobre la placa de instalación en los ganchos superiores.

2. Mueva la unidad interior hacia la derecha e izquierda para confirmar

que esté firmemente enganchado en la placa de instalación.

3. Mientras presiona la unidad interior sobre la pared por la parte

inferior, engánchelo hacia arriba en la placa de instalación por la parte

inferior. Tire la unidad interior dirigida hacia Ud por la parte inferior

para confirmar que esté firmemente enganchado sobre la placa de

instalación.

1

2

Gancho

Gancho aquí

1 Placa de

instalación

Pulse

(desenganchar)

• Para desmontar la unidad interior de la placa de instalación, tire de la

unidad interior dirigida hacia Ud mientras presiona la parte inferior por

las partes especificadas.

PresionarPresionar

Drenaje