Page 1

Document Number: 64055-002

Date: June, 2011

TOSHIBA

P9 Adjustable Speed Drive

P9 ASD

Quick Start Guide

Page 2

Document Number: 64055-002

Date: June, 2011

P9 ASD Quick Start Guide

Page 3

Introduction

Congratulations on the purchase of the new P9 Adjustable Speed Drive!

The P9 Adjustable Speed Drive (ASD) is a solid-state AC drive that features Toshiba’s new Virtual

Linear Pump function. Our VLP algorithm was designed to remove a lot of the guess work that is

inherently associated with the setup of pumping systems. And the VLP algorithm allows for precise,

linear, and consistent pump curve responses at any flow or pressure setting!

The Virtual Linear Pump function allows for direct and precise pumping system control. This is

accomplished without the normal concerns of the adverse effects of conventional pumping system control

response curves.

The VLP algorithm coupled with Toshiba International Corporation’s Vector Control Algorithm enables

the motor to develop high starting torque and provide compensation for motor slip, which results in

smooth, quick starts and highly efficient operation.

The P9 ASD uses digitally-controlled pulse width modulation. The programmable functions may be

accessed via the easy-to-use menu or via the Direct Access Numbers (see the P9 ASD Installation and

Operation Manual P/N 64054). This feature, combined with Toshiba International Corporation’s highperformance software, delivers unparalleled motor control, reliability, and ease of use.

The P9 ASD is a very powerful tool, yet surprisingly simple to operate. The user-friendly Electronic

Operator Interface (EOI) of the P9 ASD has an easy-to-read LCD screen. There is also a read-only LED

screen with enhanced visibility that can be read from a greater distance. The EOI provides easy access to

the many monitoring and programming features of the P9 ASD.

The motor control software is menu-driven, which allows for easy access to the motor control parameters

and quick changes when required.

To maximize the abilities of your new P9 ASD, a working familiarity with this guide will be required.

This guide has been prepared for the ASD installer, user, and maintenance personnel. This guide may also

be used as a reference guide or for training. With this in mind, use this guide to develop a system

familiarity before attempting to install or operate the device.

Important Notice

The instructions contained in this guide are not intended to cover all details or variations in equipment

types, nor may it provide contingency concerning the installation, operations, or maintenance of this

equipment. Should additional information be required contact your TIC Sales Representative.

The contents of this guide shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation. The warranty contained in the contract between the parties is the sole warranty of Toshiba

International Corporation and any statements contained herein do not create new warranties or modify the

existing warranty.

Any electrical or mechanical modifications to this equipment without prior written consent of

Toshiba International Corporation may void all warranties and may void the UL/CSA listing or

other safety certifications. Unauthorized modifications may also result in a safety hazard or

equipment damage.

Misuse of this equipment could result in injury and equipment damage. In no event will Toshiba

International Corporation be responsible or liable for direct, indirect, special, or consequential

damage or injury that may result from the misuse of this equipment.

Page 4

About This Guide

This guide was written by the Toshiba International Corporation Technical Publications Group. This

group is tasked with providing technical documentation for the P9 Adjustable Speed Drive. Every

effort has been made to provide accurate and concise information to you, our customer.

At Toshiba International Corporation we are continuously striving for better ways to meet the

constantly changing needs of our customers. E-mail your comments, questions, or concerns about this

publication to Technical-Publications-Dept@tic.toshiba.com.

Guide’s Purpose and Scope

This guide provides information on how to safely install, operate, maintain, and dispose of your

P9 Adjustable Speed Drive. The information provided in this guide is applicable to the

P9 Adjustable Speed Drive only.

This guide provides information on the various features and functions of this powerful cost-saving

device, including

• Installation,

• System operation,

• Configuration and menu options, and

• Mechanical and electrical specifications.

Included is a section on general safety instructions that describe the warning labels and symbols that are

used throughout the guide. Read the guide completely before installing, operating, performing

maintenance, or disposing of this equipment.

This guide and the accompanying drawings should be considered a permanent part of the equipment

and should be readily available for reference and review. Dimensions shown in the guide are in metric

and/or the English equivalent.

Because of our commitment to continuous improvement, Toshiba International Corporation reserves the

right, without prior notice, to update information, make product changes, or to discontinue any product

or service identified in this publication.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this guide.

This guide is copyrighted. No part of this guide may be photocopied or reproduced in any form without

the prior written consent of Toshiba International Corporation.

© Copyright 2011 Toshiba International Corporation.

TOSHIBA® is a registered trademark of Toshiba Corporation. All other product or trade references

appearing in this guide are registered trademarks of their respective owners.

All rights reserved.

Printed in the U.S.A.

Page 5

Contacting TIC’s Customer Support

TOSHIBA INTERNATIONAL CORPORATION

P9 Adjustable Speed Drive

Please complete the Warranty Card supplied with the P9 ASD and return it to Toshiba International Corporation

by prepaid mail. This will activate the 12 month warranty from the date of installation; but, shall not exceed 18

months from the shipping date.

Complete the following information and retain for your records.

Model Number: ______________________________________________________________________

Serial Number: ______________________________________________________________________

Project Number (if applicable): ___________________________________________________________

Date of Installation: __________________________________________________________________

Inspected By: ______________________________________________________________________

Name of Application: ______________________________________________________________

Center

Toshiba International Corporation’s Customer Support Center can be contacted to obtain help in

resolving any Adjustable Speed Drive system problem that you may experience or to provide

application information.

The Support Center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The Center’s toll free

number is US (800) 231-1412/Fax (713) 937-9349 CAN (800) 872-2192 MEX 01 (800) 527-1204.

For after-hours support follow the directions in the outgoing message when calling.

You may also contact Toshiba International Corporation by writing to:

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: ASD Product Manager.

For further information on TIC’s products and services, please visit our website at www.toshiba.com/

ind/.

Page 6

Table of Contents

General Safety Information .................................................................................................... 1

Safety Alert Symbol ...........................................................................................................1

Signal Words ......................................................................................................................1

Special Symbols .................................................................................................................2

Equipment Warning Labels ................................................................................................2

Qualified Personnel ............................................................................................................2

Equipment Inspection .........................................................................................................3

Handling and Storage .........................................................................................................3

Disposal .............................................................................................................................. 3

Installation Precautions ...........................................................................................................4

Location and Ambient Requirements .................................................................................4

Mounting Requirements .....................................................................................................4

Conductor Routing and Grounding ....................................................................................5

Power Connections .............................................................................................................6

Protection ............................................................................................................................6

System Integration Precautions ..............................................................................................7

Personnel Protection ...........................................................................................................7

System Setup Requirements ...............................................................................................8

Operational and Maintenance Precautions ...........................................................................9

Installation and Connections ................................................................................................10

Installation Notes ..............................................................................................................10

Mounting the ASD ............................................................................................................ 11

Connecting the ASD .........................................................................................................12

Lead Length Specifications ..............................................................................................16

I/O and Control ................................................................................................................. 17

Electronic Operator Interface ..............................................................................................24

EOI Operation ...................................................................................................................24

Battery Backup .................................................................................................................24

EOI Remote Mounting .....................................................................................................25

EOI Features .....................................................................................................................26

System Configuration and Menu Options ...........................................................................29

Root Menus ....................................................................................................................... 29

System Operation ................................................................................................................... 59

Operation (Hand) .............................................................................................................. 59

Default Setting Changes ...................................................................................................60

Save User Settings ............................................................................................................61

Virtual Linear Pump ............................................................................................................. 62

P9 ASD Quick Start Guide i

Page 7

Alarms, Trips, and Troubleshooting ....................................................................................66

Alarms and Trips .............................................................................................................. 66

User Notification Codes ...................................................................................................67

Alarms ............................................................................................................................... 68

Trips/Faults .......................................................................................................................70

Enclosure and Conduit Plate Dimensions ........................................................................... 76

Enclosure Dimensions ......................................................................................................76

Conduit Plate Dimensions ................................................................................................ 81

Current/Voltage Specifications .............................................................................................84

Cable/Terminal/Torque Specifications ................................................................................86

Short Circuit Protection Recommendations .......................................................................88

ii P9 ASD Quick Start Guide

Page 8

General Safety Information

DANGER

WARNING

CAUTION

CAUTION

DO NOT attempt to install, operate, maintain, or dispose of this equipment until you have read and

understood all of the product safety information and directions that are contained in this manual.

Safety Alert Symbol

The Safety Alert Symbol is comprised of an equilateral triangle enclosing an exclamation mark. This

indicates that a potential personal injury hazard exists.

Signal Words

Listed below are the signal words that are used throughout this manual followed by their descriptions

and associated symbols. When the words DANGER, WARNING, and CAUTION are used in this

manual, they will be followed by important safety information that must be carefully followed.

The word DANGER preceded by the safety alert symbol indicates that an imminently hazardous

situation exists that, if not avoided or if instructions are not followed precisely, will result in serious

injury to personnel or loss of life.

The word WARNING preceded by the safety alert symbol indicates that a potentially hazardous

situation exists that, if not avoided or if instructions are not followed precisely, could result in serious

injury to personnel or loss of life.

The word CAUTION preceded by the safety alert symbol indicates that a potentially hazardous

situation exists that, if not avoided or if instructions are not followed precisely, may result in minor or

moderate injury.

The word CAUTION without the safety alert symbol indicates a potentially hazardous situation exists

that, if not avoided or if instructions are not followed precisely, may result in equipment and property

damage.

P9 ASD Quick Start Guide 1

Page 9

Special Symbols

To identify special hazards, other symbols may appear in conjunction with the DANGER, WARNING,

and CAUTION signal words. These symbols indicate areas that require special and/or strict adherence

to the procedures to prevent serious injury to personnel or loss of life.

Electrical Hazard Symbol

A symbol that is comprised of an equilateral triangle enclosing

a lightning bolt indicates a hazard of injury from electrical

shock or burn.

Explosion Hazard Symbol

A symbol that is comprised of an equilateral triangle enclosing

an explosion indicates a hazard of injury from exploding parts.

Equipment Warning Labels

DO NOT attempt to install, operate, perform maintenance, or dispose of this equipment until you have

read and understood all of the product labels and user directions that are contained in this manual.

Warning labels that are attached to the equipment will include the exclamation mark within a triangle.

DO NOT remove or cover any of these labels. If the labels are damaged or if additional labels are

required, contact your TIC Sales Representative.

Labels attached to the equipment are there to provide useful information or to indicate an imminently

hazardous situation that may result in serious injury, severe property and equipment damage, or loss of

life if safe procedures or methods are not followed as outlined in this manual.

Qualified Personnel

Installation, operation, and maintenance shall be performed by Qualified Personnel Only. A Qualified

Person is one that has the skills and knowledge relating to the construction, installation, operation, and

maintenance of the electrical equipment and has received safety training on the hazards involved (Refer

to the latest edition of NFPA 70E for additional safety requirements).

Qualified Personnel shall:

• Have carefully read the entire manual.

• Be familiar with the construction and function of the ASD, the equipment being driven, and the

hazards involved.

• Be able to recognize and properly address hazards associated with the application of motor-driven

equipment.

• Be trained and authorized to safely energize, de-energize, ground, lock out/tag out circuits and

equipment, and clear faults in accordance with established safety practices.

• Be trained in the proper care and use of protective equipment such as safety shoes, rubber gloves,

hard hats, safety glasses, face shields, flash clothing, etc., in accordance with established safety

practices.

For further information on workplace safety, visit www.osha.gov.

2 P9 ASD Quick Start Guide

Page 10

Equipment Inspection

• Upon receipt of the equipment, inspect the packaging and equipment for shipping damage.

• Carefully unpack the equipment and check for parts that may have been damaged during shipping,

missing parts, or concealed damage. If any discrepancies are discovered, it should be noted with the

carrier prior to accepting the shipment, if possible. File a claim with the carrier if necessary and

immediately notify your TIC Sales Representative.

• DO NOT install the ASD if it is damaged or if it is missing any component(s).

• Ensure that the rated capacity and the model number specified on the nameplate conform to the

order specifications.

• Modification of this equipment is dangerous and is to be performed by factory trained personnel.

When modifications are required contact your TIC Sales Representative.

• Inspections may be required after moving equipment.

• Contact your TIC Sales Representative to report discrepancies or for assistance if required.

Handling and Storage

• Use proper lifting techniques when moving the ASD; including properly sizing up the load, getting

assistance, and using a forklift if required.

• Store in a well-ventilated location and preferably in the original packaging if the equipment will not

be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with extreme temperatures, rapid

temperature changes, high humidity, moisture, dust, corrosive gases, or metal particles.

• The storage temperature range of the P9 ASD is -13° to 149° F (-25° to 65° C).

• DO NOT store the unit in places that are exposed to outside weather conditions (i.e., wind, rain,

snow, etc.).

• Store in an upright position.

Disposal

Never dispose of electrical components via incineration. Contact your state environmental agency for

details on disposal of electrical components and packaging in your area.

P9 ASD Quick Start Guide 3

Page 11

Installation Precautions

Location and Ambient Requirements

• The TIC ASD is intended for permanent installations only.

• Installation should conform to the National Electrical Code — Article 110 (NEC) (Requirements

For Electrical Installations), all regulations of the Occupational Safety and Health

Administration, and any other applicable national, regional, or industry codes and standards.

Note: For ALL references to the National Electrical Code (NEC), see the latest release of

the National Electrical Code.

• Select a mounting location that is easily accessible, has adequate personnel working space, and

adequate illumination for adjustment, inspection, and maintenance of the equipment (refer to the

NEC Article 110-13).

• DO NOT mount the ASD in a location that would produce catastrophic results if it were to become

dislodged from its mounting location (equipment damage or injury).

• DO NOT mount the ASD in a location that would allow it to be exposed to flammable chemicals or

gases, water, solvents, or other fluids.

• Avoid installation in areas where vibration, heat, humidity, dust, fibers, metal particles, explosive/

corrosive mists or gases, or sources of electrical noise are present.

• The installation location shall not be exposed to direct sunlight.

• Allow proper clearance spaces for installation. Do not obstruct the ventilation openings. Refer to

the section titled Installation and Connections on pg. 10 for further information on ventilation

requirements.

• The ambient operating temperature range of the P9 ASD is 14° to 104° F (-10° to 40° C).

Mounting Requirements

•Only Qualified Personnel should install this equipment.

• Install the unit in a secure and upright position in a well-ventilated area.

• As a minimum, the installation of the equipment should conform to the NEC — Article 110

(NEC), OSHA, as well as any other applicable national, regional, or industry codes and standards.

• Installation practices should conform to the latest revision of NFPA 70E Electrical Safety

Requirements for Employee Workplaces.

• It is the responsibility of the ASD installer/maintenance personnel to ensure that the unit is installed

into an enclosure that will protect personnel against electric shock.

4 P9 ASD Quick Start Guide

Page 12

Conductor Routing and Grounding

WARNING

• Use separate metal conduits for routing the input power, output power, and control circuits.

• A separate ground cable should be run inside the conduit with the input power, output power, and

control circuits.

• DO NOT connect CC to earth ground.

•Use IICC terminal as the return for the V/I input.

• Always ground the unit to prevent electrical shock and to help reduce electrical noise.

• If the ASD is being used in an ungrounded system (floating system) or in an unsymmetrically

grounded system, the EMI filter must be disconnected or removed. The ASD may be damaged if

the EMI filter is used.

• It is the responsibility of the ASD installer/maintenance personnel to provide proper grounding and

branch circuit protection in accordance with the NEC and any applicable local codes.

— The Metal Conduit Is Not An Acceptable Ground —

Grounding Capacitor Switch

The ASD is equipped with noise reduction capacitors which are used to reduce the EMI leakage via the

3-phase power-input circuit and for compliance with the Electromagnetic Compatibility Directive

(EMC).

The effective value of the capacitor may be increased, reduced, or removed entirely via the Selector

Switch, Switching Bar, or the Switching Screw — the type used is typeform-specific.

The Grounding Capacitor Switch allows the user to quickly change the value of the capacitance of the

3-phase input circuit without the use of tools.

See the section titled System Grounding on pg. 14 for more on the Grounding Capacitor.

See figures 4, 5, 6, and 7 on pg. 15 for an electrical depiction of the leakage-reduction functionality of

the Grounding Capacitor and the methods used to set the capacitance value.

P9 ASD Quick Start Guide 5

Page 13

Power Connections

DANGER

CONTACT WITH ENERGIZED WIRING WILL CAUSE

SEVERE INJURY OR LOSS OF LIFE.

• Turn off and lock out/tag out all power sources before proceeding to connect the power wiring to

the equipment.

• After ensuring that all power sources are turned off and isolated in accordance with established

lock out/tag out procedures, connect the 3-phase power source wiring of the correct voltage to the

correct input terminals and connect the output terminals to a motor of the correct voltage and type

for the application (refer to the NEC Article 300 – Wiring Methods and Article 310 – Conductors

For General Wiring). Size the branch circuit conductors in accordance with the NEC Table 310.16.

• Ensure that the 3-phase input power is NOT connected to the output of the ASD. This will damage

the ASD and may cause injury to personnel.

• DO NOT connect resistors across terminals PA – PC or PO – PC. This may cause a fire.

• Ensure the correct phase sequence and the desired direction of motor rotation in the Bypass mode

(if applicable).

Protection

• Ensure that primary protection exists for the input wiring to the equipment. This protection must be

able to interrupt the available fault current from the power line. The equipment may or may not be

equipped with an input disconnect (option).

• All cable entry openings must be sealed to reduce the risk of entry by vermin and to allow for

maximum cooling efficiency.

• External dynamic braking resistors must be thermally protected.

• It is the responsibility of the ASD installer/maintenance personnel to set up the Emergency Off

braking system of the ASD. The function of the Emergency Off braking function is to remove

output power from the drive in the event of an emergency. A supplemental braking system may also

be engaged in the event of an emergency. For further information on braking systems, see

parameters F250 and F304.

Note: A supplemental emergency stopping system should be used with the ASD. Emergency

stopping should not be a task of the ASD alone.

• Follow all warnings and precautions and do not exceed equipment ratings.

6 P9 ASD Quick Start Guide

Page 14

System Integration Precautions

WARNING

The following precautions are provided as general guidelines for the setup of the ASD within the

system.

• The TIC ASD is a general-purpose product. It is a system component only and the system design

should take this into consideration. Please contact your TIC Sales Representative for application-

specific information or for training support.

• The TIC ASD is part of a larger system and the safe operation of the ASD will depend upon

observing certain precautions and performing proper system integration.

• Improperly designed or improperly installed system interlocks may render the motor unable to start

or stop on command.

• The failure of external or ancillary components may cause intermittent system operation (i.e., the

system may start the motor without warning).

• A detailed system analysis and job safety analysis should be performed by the systems designer

and/or systems integrator before the installation of the ASD component. Contact your TIC Sales

Representative for options availability and for application-specific system integration information

if required.

Personnel Protection

• Installation, operation, and maintenance shall be performed by Qualified Personnel Only.

• A thorough understanding of the ASD will be required before the installation, operation, or

maintenance of the ASD.

• Rotating machinery and live conductors can be hazardous and shall not come into contact with

personnel. Personnel should be protected from all rotating machinery and electrical hazards at all

times.

• Insulators, machine guards, and electrical safeguards may fail or be defeated by the purposeful or

inadvertent actions of workers. Insulators, machine guards, and electrical safeguards are to be

inspected (and tested where possible) at installation and periodically after installation for potential

hazardous conditions.

• DO NOT allow personnel near rotating machinery. Warning signs to this effect shall be posted at

or near the machinery.

• DO NOT allow personnel near electrical conductors. Contact with electrical conductors can be

fatal. Warning signs to this effect shall be posted at or near the hazard.

• Personal Protection Equipment (PPE) shall be provided and used to protect employees from any

hazards inherent to system operation.

P9 ASD Quick Start Guide 7

Page 15

System Setup Requirements

CAUTION

• When using the ASD as an integral part of a larger system, it is the responsibility of the ASD

installer/maintenance personnel to ensure that there is a fail-safe in place (i.e., an arrangement

designed to switch the system to a safe condition if there is a fault or failure).

• Power factor improvement capacitors or surge absorbers MUST NOT be installed on the output of

the ASD.

• Use of the built-in system protective features is highly recommended (i.e., E-Off, Overload

Protection, etc.).

• The operating controls and system status indicators should be clearly readable and positioned

where the operator can see them without obstruction.

• Additional warnings and notifications shall be posted at the equipment installation location as

deemed required by Qualified Personnel.

• System safety features should be employed and designed into the integrated system in a manner

such that system operation, even in the event of system failure, will not cause harm or result in

system damage or injury to personnel (i.e., E-Off, Auto-Restart settings, System Interlocks, etc.).

• The programming setup and system configuration of the ASD may allow it to start the motor

unexpectedly. A familiarity with the Auto-Restart (F301), Sleep Timer (F383), and the Start-

Stop (F385) settings are a requirement to use this product.

• There may be thermal or physical properties, or ancillary devices integrated into the overall system

that may allow for the ASD to start the motor without warning. Signs to this effect must be posted

at the equipment installation location.

• If a secondary magnetic contactor (MC) or an ASD output disconnect is used between the ASD and

the load, it should be interlocked to halt the ASD before the secondary contact opens. If the output

contactor is used for bypass operation, it must be interlocked such that commercial power is never

applied to the ASD output terminals (U, V, or W).

• When using an ASD output disconnect, the ASD and the motor must be stopped before the

disconnect is either opened or closed. Closing the output disconnect while the 3-phase output of the

ASD is active may result in equipment damage or injury to personnel.

8 P9 ASD Quick Start Guide

Page 16

Operational and Maintenance

DANGER

Precautions

• Turn off and lock out/tag out the main power, the control power, and instrumentation connections

before inspecting or servicing the drive, opening the door of the enclosure, or connecting/

disconnecting the power wiring to the equipment.

• The capacitors of the ASD maintain a residual charge for a period of time after turning the ASD off.

The required time for each ASD typeform is indicated with a cabinet label and a Charge LED

(shown for smaller ASDs in Figure 2 on pg. 12; LED is located on the front panel of larger ASDs).

Wait at least the minimum time indicated on the enclosure-mounted label and ensure that the

Charge LED has gone out before opening the door of the ASD once the ASD power has been

turned off.

• Turn the power on only after attaching (or closing) the front cover and DO NOT remove or open

the front cover of the ASD when the power is on.

• DO NOT attempt to disassemble, modify, or repair the ASD. Call your TIC Sales Representative

for repair information.

• DO NOT place any objects inside of the ASD.

• If the ASD should emit smoke, or an unusual odor or sound, turn off the power immediately.

• The heat sink and other components may become extremely hot to the touch. Allow the unit to cool

before coming in contact with these items.

•The Auto Start-Stop programmable functions and the Sleep Timer function of the ASD may

allow for the system to start or stop unexpectedly. Signs to this effect are to be clearly posted at the

installation location.

• Remove power from the ASD during extended periods of non-use.

• The system should be inspected periodically for damaged or improperly functioning parts,

cleanliness, and to ensure that the connectors are tightened securely.

P9 ASD Quick Start Guide 9

Page 17

Installation and Connections

CAUTION

The P9 True Torque Control2 Adjustable Speed Drive may be set up initially by performing a few

simple configuration settings. To operate properly, the ASD must be securely mounted and connected to

a power source (3-phase AC input at the R/L1, S/L2, and T/L3 terminals). The control terminals of the

ASD may be used by connecting the terminals of the Terminal Board to the proper sensors or signal

input sources (see the section titled I/O and Control on pg. 17

System performance may be further enhanced by assigning a function to the output terminals of the

Terminal Board and connecting the terminals to the proper indicators or actuators (e.g., LEDs, relays,

contactors, etc.).

Note: The optional ASD interface boards may be used to expand the I/O functionality of the

ASD.

Installation Notes

When a brake-equipped motor is connected to the ASD, it is possible that the brake may not release at

startup because of insufficient voltage. To avoid this, DO NOT connect the brake or the brake contactor

to the output of the ASD.

If an output contactor is used for bypass operation, it must be interlocked such that commercial power is

never applied to the output terminals of the ASD (U/T1, V/T2, and W/T3).

and

Figure 9 on pg 20).

DO NOT apply commercial power to the ASD output terminals U/T1, V/T2, and W/T3.

If a secondary magnetic contactor (MC) is used between the output of the ASD and the motor, it should

be interlocked such that the ST – CC connection is disconnected before the output contactor is opened.

DO NOT open and then close a secondary magnetic contactor between the ASD and the motor unless

the ASD is off and the motor is not rotating.

Note: Re-application of power via a secondary contact while the ASD is on or while the

motor is still turning may cause ASD damage.

The ASD input voltage should remain within 10% of the specified input voltage range. Input voltages

approaching the upper or lower-limit settings may require that the over-voltage and under-voltage stall

protection level parameters be adjusted. Voltages outside of the permissible tolerance should be

avoided.

The frequency of the input power should be ±2 Hz of the specified input frequency.

DO NOT use an ASD with a motor that has a current rating that is greater than the rated current of the

ASD.

The P9 ASD is designed to operate NEMA B motors. Consult with your TIC Sales Representative

before using the ASD for special applications such as with an explosion-proof motor or applications

with a piston load.

Disconnect the ASD from the motor before megging or applying a bypass voltage to the motor.

Interface problems may occur when an ASD is used in conjunction with some types of process

controllers. Signal isolation may be required to prevent controller and/or ASD malfunction (contact

your TIC Sales Representative or the process controller manufacturer for additional information on

compatibility and signal isolation).

Use caution when setting the output frequency. Over speeding a motor decreases its ability to deliver

torque and may result in damage to the motor and/or the driven equipment.

10 P9 ASD Quick Start Guide

Page 18

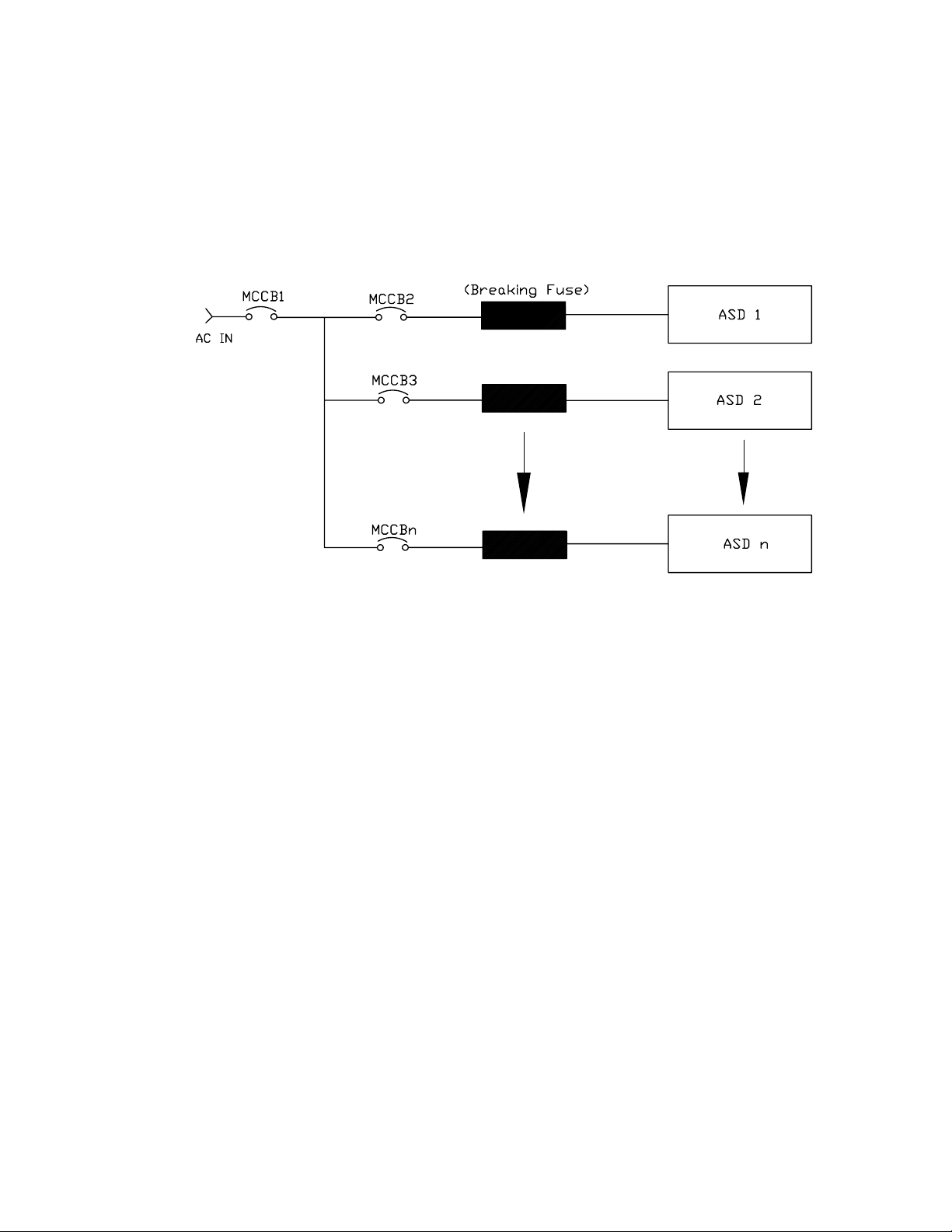

Not all P9 ASDs are equipped with internal primary power input fuses (HP dependent). When

Figure 1. Typical Circuit Breaker Configuration.

CAUTION

connecting two or more drives that have no internal fuse to the same power line as shown in Figure 1,

select a circuit-breaking configuration that will ensure that if a short circuit occurs in ASD 1, only

MCCB2 trips, not MCCB1. If it is not feasible to use this configuration, insert a fuse between MCCB2

and ASD 1.

Mounting the ASD

— The following thermal specifications apply to the 230-volt and 460-volt ASDs ONLY —

Install the unit securely in a well ventilated area that is out of direct sunlight.

The process of converting AC to DC, and then back to AC produces heat. During normal ASD

operation, up to 5% of the input energy to the ASD may be dissipated as heat. If installing the ASD in a

cabinet, ensure that there is adequate ventilation.

DO NOT operate the ASD with the enclosure door open.

The ambient operating temperature rating of the P9 ASD is 14° to 104° F (-10° to 40° C).

When installing adjacent ASDs horizontally, TIC recommends at least 5 cm of space between adjacent

units. However, horizontally mounted ASDs may be installed side-by-side with no space in between the

adjacent units — side-by-side installations require that the top cover be removed from each ASD.

For 150 HP and above ASDs, a minimum of 50 cm of space is required above and below adjacent units

and any obstruction.This space is the recommended minimum space requirement for the ASD and

ensures that adequate ventilation is provided for each unit. More space will provide a better

environment for cooling (see the section titled Enclosure and Conduit Plate Dimensions on pg. 76 for

additional information on mounting space requirements).

Note: Ensure that the ventilation openings are not obstructed.

P9 ASD Quick Start Guide 11

Page 19

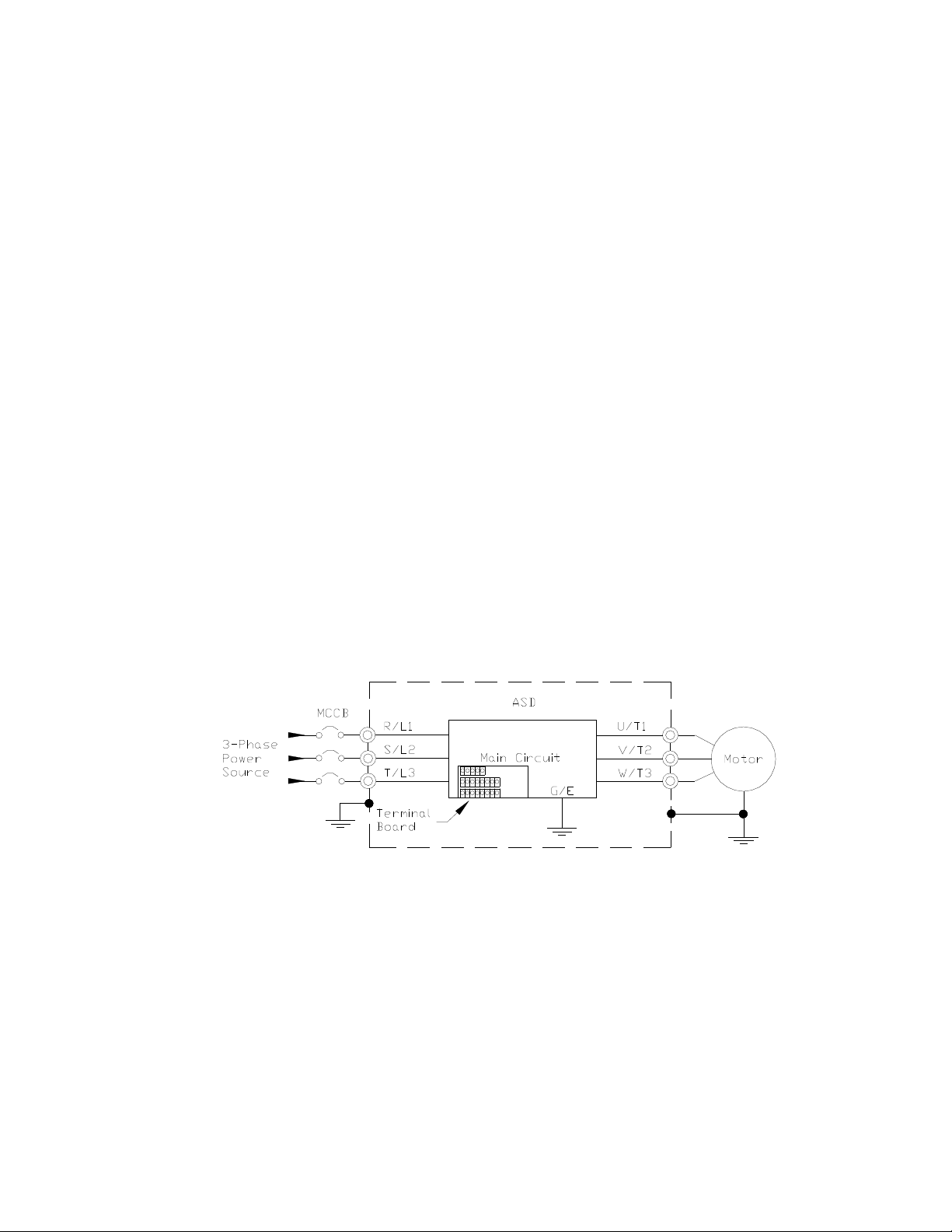

Connecting the ASD

DANGER

DANGER

Charge LED

Grounding Capacitor Switch — Pull for Small capacitance/push for Large capacitance.

Refer to the section titled Installation Precautions on pg. 4 and the section titled Lead Length

Specifications on pg. 16 before attempting to connect the ASD and the motor to electrical power.

Power Connections

Contact With 3-Phase Input/Output Terminals May Cause An

Electrical Shock Resulting In Injury Or Loss Of Life.

See the Typical Connection Diagram on pg. 22 for a system I/O connectivity schematic.

An inductor (DCL) may be connected across the PO and PA/+ terminals to provide additional filtering.

When not used, a jumper must be connected across these terminals.

PA/+ and PB are used for the DBR connection if using a braking resistor.

PC/- is the negative terminal of the DC bus.

R/L1, S/L2, and T/L3 are the 3-phase input supply terminals for the ASD.

U/T1, V/T2, and W/T3 are the output terminals of the ASD that connect to the motor.

The location of the Charge LED for the smaller typeform ASD is provided in Figure 2. The Charge

LED is located on the front door of the enclosure of the larger ASDs.

Figure 2. Typical P9 ASD Input/Output Terminals and the Grounding Capacitor Switch.

12 P9 ASD Quick Start Guide

Page 20

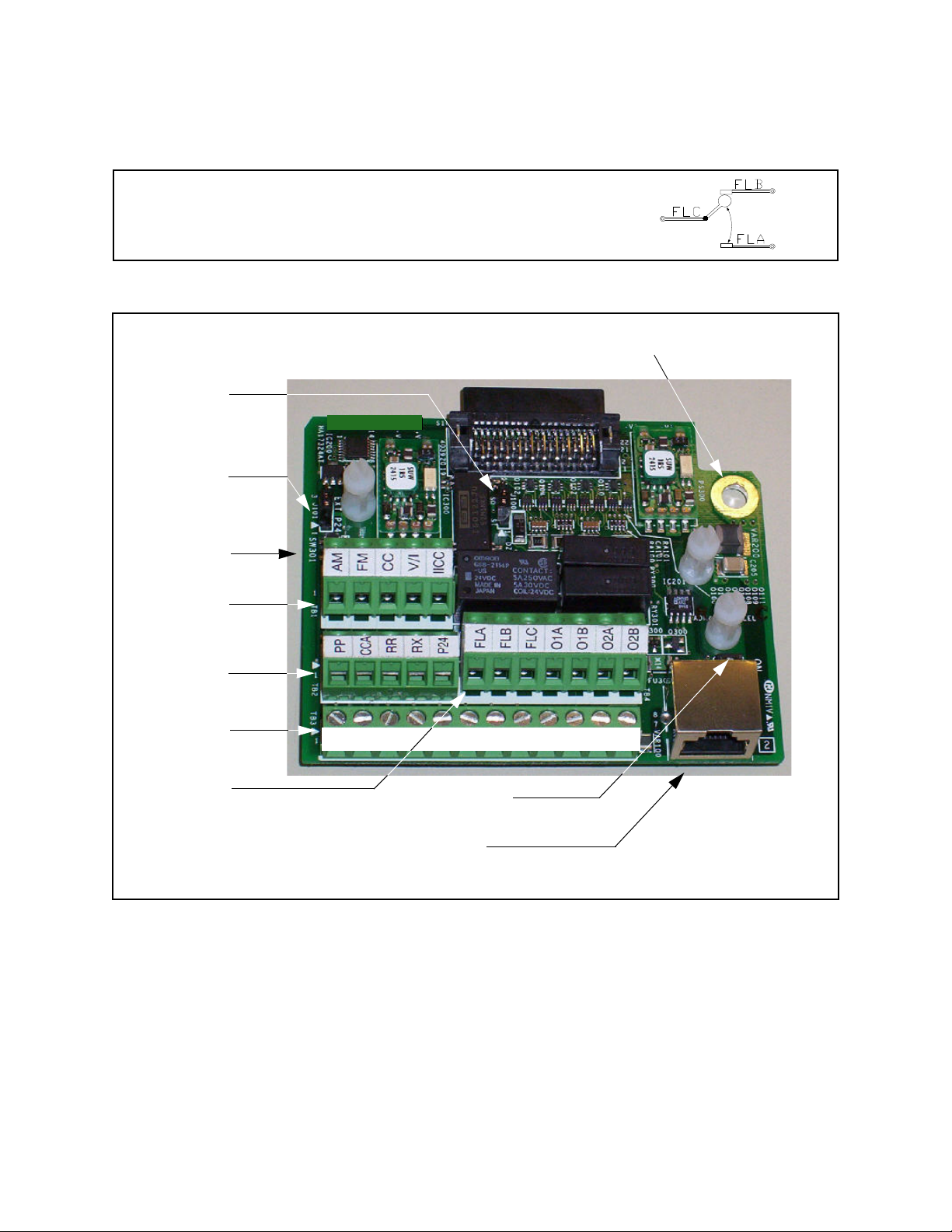

Power Connection Requirements

Connect the 3-phase input power to the input terminals of the ASD at R/L1, S/L2, and T/L3 (see Figure

3 for the typical electrical connection scheme). Connect the output of the ASD to the motor from the

ASD terminals U/T1, V/T2, and W/T3. The input and output conductors and terminal lugs used shall be

in accordance with the requirements listed in the section titled Current/Voltage Specifications on pg. 84.

If multiple conductors are used in parallel for the input or output power and it is necessary to use

separate conduits, each parallel set shall have its own conduit and not share its conduit with other

parallel sets (i.e., place U1, V1, W1, and a ground wire in one conduit and U2, V2, W2 and a ground

wire in another; refer to the NEC Article 300.20 and Article 310.4). National and local electrical codes

should be referenced if three or more power conductors are run in the same conduit (refer to the NEC

Article 310 adjustment factors).

Note: National and local codes should be referenced when running more than three

conductors in the same conduit.

Install a molded case circuit breaker (MCCB) or fuse between the 3-phase power source and the ASD in

accordance with the fault current setting of the ASD and the NEC Article 430.

The ASD is designed and tested to comply with UL Standard 508C. Modifications to the ASD system

or failure to comply with the short circuit protection requirements outlined in this manual may

disqualify the UL rating. See Table 13 on pg. 88 for typeform-specific short circuit protection

recommendations.

As a minimum, the installation of the ASD shall conform to the NEC Article 110, the Occupational

Safety and Health Administration requirements, and to any other local and regional industry codes

and standards.

Note: In the event that the motor rotates in the wrong direction when powered up, reverse

any two of the three ASD output power leads (U, V, or W) connected to the motor.

Figure 3. P9 ASD/Motor Typical Connection Diagram.

P9 ASD Quick Start Guide 13

Page 21

System Grounding

Proper grounding helps to prevent electrical shock and to reduce electrical noise. The ASD is designed

to be grounded in accordance with Article 250 of the NEC or Section 10/Part One of the Canadian

Electrical Code (CEC).

The grounding conductor shall be sized in accordance with Article 250-122 of the NEC or Part One-

Table 6 of the CEC.

— The Metal Conduit Is Not An Acceptable Ground —

The input, output, and control lines of the system shall be run in separate metal conduits and each shall

have its own ground conductor.

ASDs produce high-frequency noise — take steps to avoid the negative effects of noise. Listed below

are some examples of measures that will help to combat noise problems.

• DO NOT install the input power and output power wires in the same duct or in parallel with each

other, and do not bind them together.

• DO NOT install the input/output power wires and the wires of the control circuit in the same duct

or in parallel with each other, and do not bind them together.

• Use shielded wires or twisted wires for the control circuits.

• Ensure that the grounding terminals (G/E) of the ASD are securely connected to ground.

• Connect a surge suppressor to every electromagnetic contactor and every relay installed near the

ASD.

• Install noise filters as required.

Grounding Capacitor

The Grounding Capacitor plays a role in minimizing the effects of leakage current through the ASD

system and through ground paths to other systems. Leakage current may cause the improper operation

of earth-leakage current breakers, leakage-current relays, ground relays, fire alarms, and other sensors

— and it may cause superimposed noise on CRT screens.

The Grounding Capacitor Switch allows the user to quickly change the value of the leakage-reduction

capacitance of the 3-phase input circuit. See figures 4, 5, 6, and 7 on pg. 15 for an electrical depiction of

the leakage-reduction functionality and the methods used to change the capacitance value. The method

used is typeform-specific.

If using a 460-volt 5 HP ASD or a 460-volt ASD that is in the range of 7.5 HP to 25 HP, and the U/T1,

V/T2, and W/T3 connections to the motor are 100 meters or more in length, the ASD Carrier

Frequency must be set to 4 kHz or less when activating or deactivating the Grounding Capacitor

Switch. ASD overheating may occur if the Carrier Frequency is set above 4 kHz when activating or

deactivating the Grounding Capacitor Switch.

See pg. 5 for more information on the Grounding Capacitor Switch and pg. 12 for the location.

14 P9 ASD Quick Start Guide

Page 22

Figure 4. The Grounding Capacitor

Switch is used on typeforms 230-volt

0.75 HP to 10 HP and the 25 and 30

HP/460-volt 1.0 HP to 25 HP.

The value may be set to Maximum

(default setting) or to Zero by pushing or

pulling the switch actuator, respectively.

Figure 5. The Grounding Capacitor

Switch is used on typeforms 230-

volt 15 HP and 20 HP and the 40 HP

to 60 HP/460-volt 30 HP to 100 HP.

The value may be set to Large

(default setting) or Small by pushing

or pulling the switch actuator,

respectively.

Figure 6. The Grounding Capacitor

Bar is used on typeforms 230-volt 75

HP to 125 HP/460-volt 125 HP and

the 150 HP.

The value may be set to Large or

Small (default setting) by connecting

or disconnecting the switching bar,

respectively.

Figure 7. The Grounding Capacitor

Screw is used on typeforms 460-volt

200 HP and above.

The value may be set to Large or

Small (default setting) by placing the

screw in the A position or by placing

the screw in the B position,

respectively.

P9 ASD Quick Start Guide 15

Page 23

Lead Length Specifications

Adhere to the NEC and any local codes during the installation of ASD/motor systems. Excessive lead

lengths may adversely affect the performance of the motor. Special cables are not required.

Lead lengths from the ASD to the motor in excess of those listed in Tab le 1 may require filters to be added

to the output of the ASD.

All Toshiba CT motors use an insulation system that is NEMA MG1 Part 30 compliant.

All Toshiba XT motors use an insulation system that is NEMA MG1 Part 31 compliant.

Tabl e 1 lists the suggested maximum lead lengths for the listed motor voltages..

Table 1. Lead Length Recommendations.

Model

230-Volt All 450 feet 1000 feet

460-Volt

Note: Contact the TIC Customer Support Center for application assistance when using lead

PWM Carrier

Frequency

5 kHz 200 feet 600 feet

5 kHz 100 feet 300 feet

lengths in excess of those listed or for filter selection assistance for a given application.

Exceeding the peak voltage rating or the allowable thermal rise time of the motor

insulation will reduce the life expectancy of the motor.

When operating in the Vector Control mode, the carrier frequency should be set to

2.2 kHz or above.

NEMA MG1 Part 30

Compliant Motors

NEMA MG1 Part 31

Compliant Motors

16 P9 ASD Quick Start Guide

Page 24

I/O and Control

The ASD can be controlled by several input types and combinations thereof, as well as operate within a

wide range of output frequency and voltage levels. This section discusses the ASD control methods and

supported I/O functions.

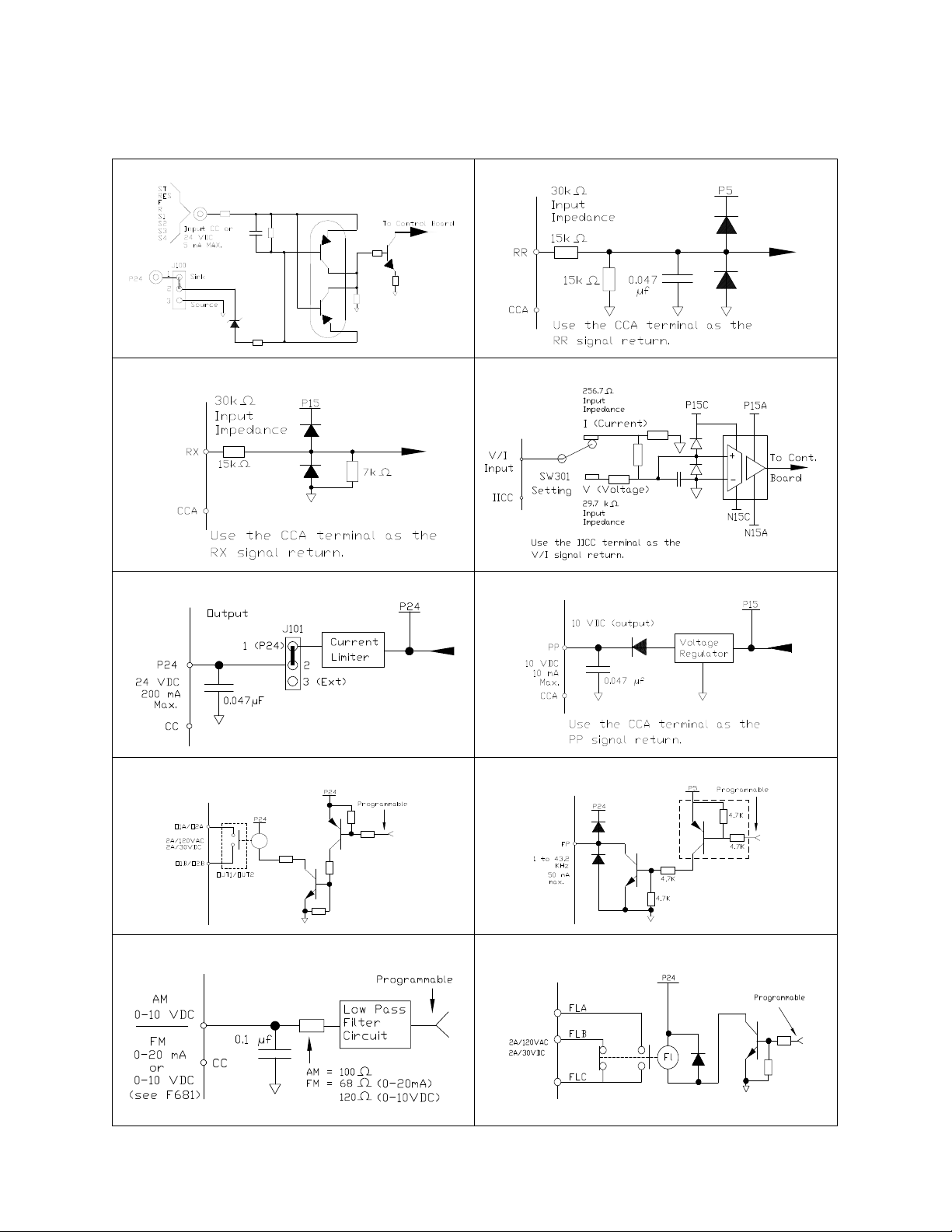

The Terminal Board supports discrete and analog I/O functions and is shown in Figure 9 on pg 20.

Tabl e 2 lists the names, functions, and settings (default settings of programmable terminals) of the input

and output terminals of the Terminal Board.

Note: To use the input lines of the Terminal Board to provide Run commands, the

Command Mode setting must be set to Ter m inal Bloc k.

Typical Connection Diagram on pg. 22 shows the typical connection diagram for the ASD system.

Table 2. Terminal Board Terminal Names and Functions.

Term inal

Name

ST

RES Reset — Multifunctional programmable discrete input. Resets a faulted ASD.

F

R

S1

S2

S3

S4

O1A/B (OUT1)

O2A/B (OUT2)

FLA

FLB

FLC

RR

RX Multifunctional programmable analog input (-10 to +10 VDC input). Figure 12 on pg 21.

V/I

(Select V or I

via SW301)

AM

FM

SU+

P24

PP

FP Pulsed Output

IICC

CCA — Return for the RR, RX, P24, and the PP terminals.

CC

Input/Output

Standby — Multifunctional programmable discrete input. Activation required

for normal ASD operation.

Discrete Input

Connect to CC

to activate

(Sink mode).

Switched

Output

Analog Input

Analog Output

DC Input Externally-supplied 24 VDC backup control power (1.1 A min.).

DC Output

— Return for the V/I input terminal.

— Return for the AM, FM, SU+, and the discrete input terminals.

Forward — Multifunctional programmable discrete input.

Reverse — Multifunctional programmable discrete input.

Preset Speed 1 — Multifunctional programmable discrete input.

Preset Speed 2 — Multifunctional programmable discrete input.

Preset Speed 3 — Multifunctional programmable discrete input.

Preset Speed 4 — Multifunctional programmable discrete input.

External Device 1 — Multifunctional programmable discrete output.

External Device 2 — Multifunctional programmable discrete output.

Fault relay (N.O.).

Fault relay (N.C.).

Fault relay (common).

Frequency Mode 1 — Multifunction programmable analog input. (0.0 to 10

VDC input — 0 Hz to Maximum Frequency).

Unassigned — V — Multifunctional programmable isolated analog voltage

input (0 to 10 VDC input).

Frequency Mode 2 (default SW301 setting) — I — Multifunctional

programmable isolated analog current input (4 [0] to 20 mADC input — 0 Hz

to Maximum Frequency).

Output Current — Current output that is proportional to the output current of

the ASD or to the magnitude of the function assigned to this terminal.

Output Frequency — Current

output frequency of the ASD or to the magnitude of the function assigned to

this terminal. Select Current or Vo lt ag e at F681.

24 VDC output (200 mA max.). Figure 14 on pg 21.

10.0 VDC/10 mA voltage source for an external potentiometer. Figure 15 on pg 21.

Frequency Pulse — Multifunctional programmable output pulse train of a

frequency based on the output frequency of the ASD.

Function (Default Setting If Programmable)

(See Terminal Descriptions on pg. 18)

or Voltage output that is proportional to the

Circuit Config.

Figure 10 on pg 21.

Figure 16 on pg 21.

Figure 19 on pg 21.

Figure 11 on pg 21.

Figure 13 on pg 21.

Figure 18 on pg 21

Figure 17 on pg 21.

DO NOT

to Earth Gnd or to

each other.

connect

P9 ASD Quick Start Guide 17

Page 25

Terminal Descriptions

tandby

orward

reset Speed 1

reset Speed 2

reset Speed 3

reset Speed 4

requency

Note: The programmable terminal assignments may be accessed and changed from the

default settings as mapped on pg. 34 or via the Direct Access method: Program

Direct Access Applicable Parameter Number. See the section titled Program

Mode Menu Navigation on pg. 34 for the applicable Direct Access parameter

numbers. For further information on terminal assignments and default setting

changes, see the sections titled Terminal on pg. 36 and Default Setting Changes on

pg. 60.

Note: See the section titled Cable/Terminal/Torque Specifications on pg. 86 for the ASD

conductor and terminal electrical specifications.

ST — The default setting for this terminal is the Standby mode controller. As the default setting, this

terminal must be activated for normal system operation. The ST terminal is activated by connecting CC

to this terminal (Sink mode). When deactivated, OFF is flashed on the LED screen and the Not-Ready-

to-Run icon is displayed on the LCD screen as shown in Figure 22 on pg 28. This input terminal may be

programmed to any of the functions listed in the P9 ASD Installation and Operation Manual (see

F113).

RES — The default setting for this terminal is Reset. The RES terminal is activated by connecting CC

to this terminal (Sink mode). A momentary connection to CC resets the ASD and any fault indications

from the display. Reset is effective when faulted only. This input terminal may be programmed to any

of the functions listed in the P9 ASD Installation and Operation Manual (see F114).

F — The default setting for this terminal is the Forward run command. The F terminal is activated by

connecting CC to this terminal (Sink mode). This input terminal may be programmed to any of the

functions listed in the P9 ASD Installation and Operation Manual (see F111).

ode 1

R

X

R — The default setting for this terminal is the Reverse run command. The R terminal is activated by

connecting CC to this terminal (Sink mode). This input terminal may be programmed to any of the

functions listed in the P9 ASD Installation and Operation Manual (see F112).

S1 — The default setting for this terminal is the Preset Speed 1. The S1 terminal is activated by

connecting CC

functions listed in the P9 ASD Installation and Operation Manual (see F115).

S2 — The default setting for this terminal is the Preset Speed 2. The S2 terminal is activated by

connecting CC to this terminal (Sink mode). This input terminal may be programmed to any of the

functions listed in the P9 ASD Installation and Operation Manual (see F116).

S3 — The default setting for this terminal is the Preset Speed 3. The S3 terminal is activated by

connecting CC to this terminal (Sink mode). This input terminal may be programmed to any of the

functions listed in the P9 ASD Installation and Operation Manual (see F117).

S4 — The default setting for this terminal is the Preset Speed 4. The S4 terminal is activated by

connecting CC to this terminal (Sink mode). This input terminal may be programmed to any of the

functions listed in the P9 ASD Installation and Operation Manual (see F118).

RR — The default function assigned to this terminal is Frequency Mode 1. The RR terminal accepts a

0 – 10 VDC input signal that is used to control the function assigned to this terminal. This input terminal

may be programmed to control the speed or torque of the motor via an amplitude setting or regulate by

setting a limit. The gain and bias of this terminal may be adjusted for application-specific suitability

(see F210 – F215).

RX — The default function assigned to this terminal is Tor q u e C o m m a n d . The RX terminal accepts a

±10 VDC input signal that is used to control the function assigned to this terminal. This input terminal

may be programmed to raise or lower the speed or torque of the motor via an amplitude setting or this

to this terminal (Sink mode). This input terminal may be programmed to any of the

18 P9 ASD Quick Start Guide

Page 26

4

ternal Device

ternal Device

terminal may be used to regulate the speed or torque of a motor by setting a limit. The gain and bias of

this terminal may be adjusted for application-specific suitability (see F216 – F221).

V/I — The V/I terminal has the dual function of being able to receive an input voltage or current. The

function as a voltage input is to receive a 0 – 10 VDC input signal. The function as a current input is to

receive a 0 – 20 mA input signal. Using either input type, the function is to control the 0.0 – Maximum

Frequency output or the 0.0 to 250% torque output of the ASD. This is an isolated input terminal. This

terminal may be programmed to control the speed or torque of the motor and cannot process both input

types simultaneously. SW301 must be set to V or I to receive a voltage or current, respectively (see

Figure 9 on pg 20). Terminal scaling is accomplished via F201 – F206. The gain and bias of this

terminal may be adjusted for application-specific suitability (see F470 – F471).

SU+ — Control Power Supply Backup input terminal. This terminal accepts the user-supplied

24 VDC backup power to the control circuits (only). Backup power is used in the event of an open

MCCB or during a momentary loss of the 3-phase input power. Parameter settings, real-time clock

information, and trip history information are retained with the use of the SU+ backup power. See the

section titled Battery Backup on pg. 24 for more information on system backup features.

P24 — +24 VDC at 200 mA power supply for customer use.

PP — The function of output PP is to provide a 10 VDC/10 mADC (max.) output that may be divided

using a potentiometer. The tapped voltage is applied to the RR input to provide manual control of the

RR programmed function.

O1A/B (OUT1A/B) — The default function assigned to this terminal is External Device 1. The

function as External Device 1 is to activate/deactivate an auxiliary motor once the VLP level has

remained within the VLP Maximum Zone or the VLP Minimum Zone for the time setting of F480.

The OUT1 terminal is rated at 2 A/120 VAC and 2 A/30 VDC. This terminal may be set to any of the

functions listed in the P9 ASD Installation and Operation Manual (see F130).

O2A/B (OUT2A/B) — The default function assigned to this terminal is External Device 2. The

function as External Device 2, in conjunction with External Device 1, is to activate/deactivate an

auxiliary motor once the VLP level has remained within the VLP Maximum Zone or the VLP

Minimum Zone for the time setting of F480. The OUT2 terminal is rated at 2 A/120 VAC and 2 A/30

VDC. This terminal may be set to any of the functions listed in the P9 ASD Installation and Operation

Manual (see F131).

FP — The default function of this output terminal is to output a series of pulses at a rate that is a

function of the ASD output frequency (50 mA max. at 1.0 kHz to 43.3 kHz). As the output frequency of

the ASD goes up so does the FP output pulse rate. This terminal may be programmed to provide an

output pulse rate that is proportional to the magnitude of the user-selected item from the P9 ASD

Installation and Operation Manual. For further information on this terminal, see parameter F676

.

AM — This output terminal produces an output current that is proportional to the output frequency of

the ASD or of the magnitude of the function assigned to this terminal. The available assignments for

this output terminal are listed in the P9 ASD Installation and Operation Manual. For further

information on this terminal, see F670.

FM — This output terminal produces an output current or voltage that is proportional to the output

frequency of the ASD or of the magnitude of the function assigned to this terminal. The available

assignments for this output terminal are listed in the P9 ASD Installation and Operation Manual. For

further information on this terminal, see F005. The Voltage/Current output selection is performed at

F681.

FLA — One of two normally open contacts that, under user-defined conditions, connect to FLC.

FLB — One of two normally closed contacts that, under user-defined conditions, connect to FLC.

C

FLC — FLC is the common leg of a single-pole double-throw form C relay. The FL relay is the Fault

Relay by default, but may be programmed to any of the selections listed in the P9 ASD Installation and

Operation Manual. For further information on this terminal, see F132 and Figure 8 on pg 20.

P9 ASD Quick Start Guide 19

Page 27

Note: The relay is shown in the normal operating condition. During

a faulted condition, the relay connection is FLC-to-FLA.

J101

TB1

TB2

TB3

J100

SW200

TB4

SW301

RES

CC

F

R

S1

S2

S3

S4

CC

ST

FP

+SU

Ensure that the ground screw is securely in

place to prevent arcing, intermittent

operation, or system failure.

1 to 2 = Sink (*)

2 to 3 = Source

1 to 2 = Sys. Supplied (

*

)

2 to 3 = Ext. Supplied

(24V)

V/I Switch (I*)

See Typical Connection Diagram on pg. 22 for more information on the Terminal Board.

Half / Full Duplex (*) Switch

CAUTION

S4

RS485 4-Wire Communication

*

= Default Setting

W301

Note: The FLA, FLB, and FLC contacts are rated at 2A/120 VAC and 2A/30 VDC.

Figure 8. FLA, FLB, and FLC Switching Contacts Shown in the Normal Operating Condition.

Figure 9. Terminal Board. Sink Source

See the section titled Terminal Descriptions on pg. 18 for terminal descriptions.

See the section titled Cable/Terminal/Torque Specifications on pg. 86 for information on the proper

cable/terminal sizes and torque specifications when making Terminal Board connections.

20 P9 ASD Quick Start Guide

Page 28

I/O Circuit Configurations

Figure 10. Discrete Input. Figure 11. RR Input.

Figure 12. RX Input. Figure 13. V/I Isolated Input.

Figure 14. P24 Output. Figure 15. PP Output.

Figure 16. OUT1/OUT2 Output. Figure 17. FP Output.

Figure 18. AM/FM Output. Figure 19. Fault Relay (shown not faulted).

P9 ASD Quick Start Guide 21

Page 29

Typical Connection Diagram

Note: When connecting multiple wires to the PA, PB, PC, or

PO terminals, do not connect a solid wire and a

stranded wire to the same terminal.

Figure 20. The P9 ASD Typical Connection Diagram.

Note: The AM, FM, and the +SU analog terminals are referenced to CC.

The RR, RX, P24, and the PP analog terminals are referenced to CCA.

The isolated V/I analog terminal references IICC.

22 P9 ASD Quick Start Guide

Page 30

Startup and Test

DANGER

Before turning on the ASD ensure that:

• R/L1, S/L2, and T/L3 are connected to the 3-phase input power.

• U/T1, V/T2, and W/T3 are connected to the motor.

• The 3-phase input voltage is within the specified tolerance.

• There are no shorts and all grounds are secured.

• All personnel are at a safe distance from the motor and the motor-driven equipment.

P9 ASD Quick Start Guide 23

Page 31

Electronic Operator Interface

The P9 ASD Electronic Operator Interface (EOI) is comprised of an LED screen, an LCD screen, two

LEDs, a rotary encoder, and five keys. These items are shown and described on pg. 26.

EOI Operation

The EOI is the primary input/output device for the user. The EOI may be used to monitor system

functions, input data into the system, perform diagnostics, and view performance data (e.g., motor

frequency, bus voltage, torque, etc.).

The software used with the P9 ASD is menu driven; thus, making it a select and click environment. The

operating parameters of a motor may be selected and viewed or changed using the EOI (or via

communications).

Battery Backup

The EOI is equipped with a battery backup system. The function of the backup system is to retain the EOI

SRAM programming in the event of a power outage, or if an EOI removal and installation from one

system to another is required without the loss of programming.

Listed below are the items retained by the battery backup system:

Trip History,

EOI Contrast,

Real-Time Clock Information,

Monitored Items,

Password and Lockout Information,

Alarm Information,

Main Monitor Items,

Prohibited Items, and

Save User Settings Information (Parameter settings may be saved by the user).

The battery backup system must be activated by the installer or maintenance personnel to use the backup

function.

To activate the battery backup system, remove the Phillips screw from the front of the LED/LCD display

unit. Remove the LED/LCD display unit from the ASD. From the circuit side of the display unit, remove

the jumper at J1, pins 2 and 3. Place the jumper at J1, pins 1 and 2.

The expected battery life cycle is four and a half years.

Note: The Battery backup system does not supply power to the LED/LCD display.

LED/LCD Screen Installation Note

When installing the LED/LCD display unit of the EOI, ensure that the left side of the display is inserted

first with the top and bottom catches (see Phillips screws at underside of display) securely in place. This

ensures the proper alignment and electrical connection of the CNX connector of the LED/LCD display

unit PCB. Gently hold the display in place while securing the Phillips mounting screw.

If improperly seated, the periphery of the LED/LCD display unit will not be flush with the EOI surface

and the unit will not function properly.

24 P9 ASD Quick Start Guide

Page 32

EOI Remote Mounting

The EOI may be mounted remotely using the optional ASD-MTG-KIT9. The kit contains all of the

hardware required to mount the EOI of the 9-Series ASD remotely.

System operation and EOI operation while using the remotely-mounted EOI are the same as with the

ASD-mounted configuration.

See the P9 ASD Installation and Operation Manual for more information on mounting the EOI remotely.

P9 ASD Quick Start Guide 25

Page 33

EOI Features

LCD Screen

Rotary Encoder

Hand/Auto

Mode

Key

Escape Key

Stop-Reset Key

Key (LED)

Run Key

(LED)

LED Screen

HAND

/AUTO

Figure 21. The P9 ASD Electronic Operator Interface Features.

LED Screen

Rotary Encoder

— Displays the running frequency, active Fault, or active Alarm information.

— Used to access the P9 ASD menu selections, change the value of a displayed

parameter, and performs the Enter key function. Turn the Rotary Encoder either clockwise or

counterclockwise to perform the Up or Down functions of the displayed menu selection. Press the Rotary

Encoder to perform the Enter (select) function. Press while turning for times-ten increment/decrement.

LCD Screen

— Displays configuration information, performance data (e.g., output frequency, bus

voltage, torque, etc.), diagnostic information, and LED screen information in expanded normal text.

Hand/Auto Key

— Toggles the system to and from the Hand and Auto modes. The Hand/Auto key is

disabled while the Fault screen is active. The Hand/Auto key LED is on when the system is in the Hand

mode. The Hand mode allows the Command and Frequency control functions to be carried out via the

EOI.

The Auto mode enables the Command and Frequency control functions to be carried out via the

Terminal Board, RS485, Communication Board, Pulse Input, or the settings of F003/F004. The (F003/

F004) selection may be made via

Program

Fundamental Standard Mode Selection Command

Mode and Frequency Mode 1, respectively.

The availability of Hand mode control (Command and Frequency control) may be disabled via Program

Utilities

Prohibition Hand/Auto Key Command Override and Hand/Auto Key Frequency

Override. The availability of the Hand mode of operation may be reinstated by changing this setting or

performing a Reset (see F007).

ESC Key

— Returns the system to the previous level of the menu tree, toggles between the EOI

Command screen and the Frequency Command screen, or cancels changes made to a field if pressed

while still in the reverse video mode (dark background/light text). The three functions are menu-specific.

Run Key

while stopped or red while running to alert personnel.

Mode Key

the system through the three root menus (see Figure 25 on pg. 29). While looping through the root menus,

the Program menu will display the root menu screen or the Program sub-menu item being accessed prior

to pressing the Mode key.

26 P9 ASD Quick Start Guide

— Issues the Run command while in the Hand mode. The Run key LED illuminates green

— Provides a means to access the three root menus. Pressing the Mode key repeatedly loops

Page 34

Stop-Reset Key

LED/LCD Screen Information

LED

LCD

LED

LCD

A A 1 1

b b 2 2

C C 3 3

d d 4 4

E E 5 5

F F 6 6

G G 7 7

H H 8 8

I I 9 9

J J 0 0

L L

M M

n n

O O

P P

b

q

r r

S S

t t

U U

v v

y y

- -

1. Issues the Off command (decelerates to Stop at the programmed rate) if pressed once while in the

Hand mode in accordance with the setting of F721.

2. Initiates an Emergency Off Fault if pressed twice quickly from the Hand or Auto modes. The

Emergency Off function terminates the P9 ASD output and stops the motor in accordance with the

setting of F603.

3. Resets active Faults and/or active Alarms if pressed twice quickly. The source of the Faults or

Alarms must be determined and corrected before normal ASD operation can resume.

— This key has three functions.

LED/LCD Screen

The LED screen is used to display the output frequency, active alarms and/or active faults.

If there are no active alarms or faults, the output frequency is displayed.

During an active alarm, the display toggles to and from the running frequency and the active alarm.

During an active fault, the fault is displayed.

Loss of the ST-to-CC connection flashes Off.

LED Character/Font

Information

Characters displayed on the LED screen will be

of the seven-segment format. Not all alphanumeric characters are used with the LED

P9 ASD Quick Start Guide 27

screen.

Listed are the seven-segment characters used

with the LED screen along with the same

characters as they are displayed on the LCD

screen.

LCD Character/Font

Information

All alpha-numeric characters are available.

Page 35

LCD Screen

Speed Reference %

Speed Reference Hz

User-Selected

Monitored Parameters (see

Not-Ready-to-Run

Indicator (ST-to-CC required)

Ready-to-Run Indicator

Appears When ST is Connected

to CC

Main Monitor Selections on pg. 33)

Figure 22. Frequency Command Screen.

Forward Run Active

Reverse Run Active

Discrete I/O Terminal Status Or

Alarm Condition

Item Number 1 of 43

Speed at Trip (If Applicable)

Active DC Bus Voltage

Monitored items

Command

Active Output Current

ASD Output Voltage

Screen Name

(Only 5 Items Listed)

Active Frequency

Primary Menu Items

Screen Name

Item Number 1 of 15

Program Menu items

{

(Only 5 Items Listed)

The LCD screen is the primary user input/output information center. Parameter settings may be viewed or

changed using the LCD display unit of the EOI. To view or change a parameter setting using the LCD

screen, press the Mode key until the Program menu is displayed. Turn the Rotary Encoder until the

desired Primary Menu item (see pg. 34) is within the cursor block. Press the Rotary Encoder to select

the item from the Primary Menu (repeat the press-to-select for submenu items).

See the section titled Default Setting Changes on pg. 60 for more information on changing parameter

settings.

Upon reaching the desired parameter selection, the current setting may be viewed, or selected and changed

by pressing the Rotary Encoder and the setting will take on the reverse video format (dark background/

light text). Turn the Rotary Encoder to change the parameter setting. Press the ESC key while the new

parameter setting is in the reverse video mode to exit the selection without saving the change or press the

Rotary Encoder while the parameter setting is in the reverse video mode to accept the change.

Repeated ESC key entries at any time takes the menu back one level each time the ESC key is pressed

until the Frequency Command screen is reached. Further ESC entries will toggle the system to and from

the Frequency Command screen and the EOI Command menu.

Note: Changes carried out from the EOI Command screen will be effective for EOI-

controlled ASD operation only. See the section titled EOI Command Mode on pg. 30 for

further information on EOI Command Mode operations.

Primary Menus of the LCD Screen

The three primary screens of the LCD screen are displayed while accessing the associated operating

mode: the Frequency Command, Monitor, and the Program Menu screens.

Figure 23. Monitor Screen (see pg. 31 for more on the Monitor screen items).

Figure 24. Program Menu Screen (see pg. 34 for more on the Program Menu Screen).

28 P9 ASD Quick Start Guide

Page 36

System Configuration and Menu Options

Frequency

Command

Mode

Monitor

Mode

Program

Mode

EOI Command

Mode

Root Menus

The Mode key accesses the three primary modes of the P9 ASD: the Frequency Command mode, the

Monitor mode, and the Program mode. From either mode, press the Mode key to loop through to the

other two modes (see Figure 25). While in the Frequency Command mode, pressing the ESC key

toggles the menu to and from the EOI Command mode and the Frequency Command mode.

The Alarm or Fault information will be displayed in the event of an active Alarm or Fault. Alarm text

will be displayed on the Frequency Command screen and on the LED screen when active. Fault

information will be displayed via the Fault screen. See Alarms and Trips on pg. 66 for more information

on Alarms and Tr ip s.

Figure 25. P9 ASD Root Menu Navigation.

Frequency Command Mode

Frequency Setting

While operating in the Hand mode (Hand LED is illuminated on the EOI), the running frequency of the

motor may be set from the Frequency Command screen. Using the Rotary Encoder, enter the

Frequency Command value, connect ST to CC, and provide a Run command (F and/or R) and then

press the Run key. The motor will run at the Frequency Command speed and may be changed while

running. See Figure 22 on pg. 28 and Operation (Hand) on pg. 59 for more information on the Frequency

Command mode.

P9 ASD Quick Start Guide 29

Page 37

EOI Command Mode

The EOI Command mode is accessed by pressing the ESC key from the Frequency Command screen.

With the exception of the VLP Control Enable/Disable, the control settings of the EOI Command menu

are effective for EOI control only.

The EOI Command mode provides quick access to the following menu parameters:

Direction — Forward or Reverse.

Stop Pattern — The Decel Stop or Coast Stop setting determines the method used to stop the

motor when using the Stop-Reset key of the EOI. The Decel Stop setting enables the Dynamic

Braking system setup at F304 or the DC Injection Braking system setup at F250, F251, and F252.

The Coast Stop setting allows the motor to stop at the rate allowed by the inertia of the load.

Note: The Stop Pattern setting has no effect on the Emergency Off settings of F603.

V/f Group — One of 4 V/f profiles may be selected and run. Each V/f profile is comprised of 4 user

settings: Base Frequency, Base Frequency Voltage, Manual Torque Boost, and Electronic

Thermal Protection. Expanded descriptions of these parameters may be found in the P9 ASD

Installation and Operation Manual.

Accel/Decel Group — One of 4 Accel/Decel profiles may be selected and run. Each of the Accel/

Decel profiles is comprised of three user settings: Acceleration, Deceleration, and Pattern.

Expanded descriptions of these parameters may be found in the P9 ASD Installation and Operation