Page 1

ADJUSTABLE SPEED DRIVES

nC1 Drive

Page 2

Ultra-Compact

Sub-Micro Drive

The nC1 is a sub-micro, or nano-sized drive with a full range of features to meet the

needs of nearly any user. The nC1 is designed to be a simple drop in replacement for a

starter on an existing project or as a new installation. Either way, the nC1’s small size

and full featured design make it a perfect choice for your application.

An Easy Choice

The nC1 drive comes with either single-phase or three-phase input with input voltage

ratings as low as 120 V. This makes it an excellent choice for small OEM applications.

The single-phase input means that the nC1 can be used in applications that were

previously too cost-prohibitive to install a three-phase drive. All nC1’s have a threephase 230 V output.

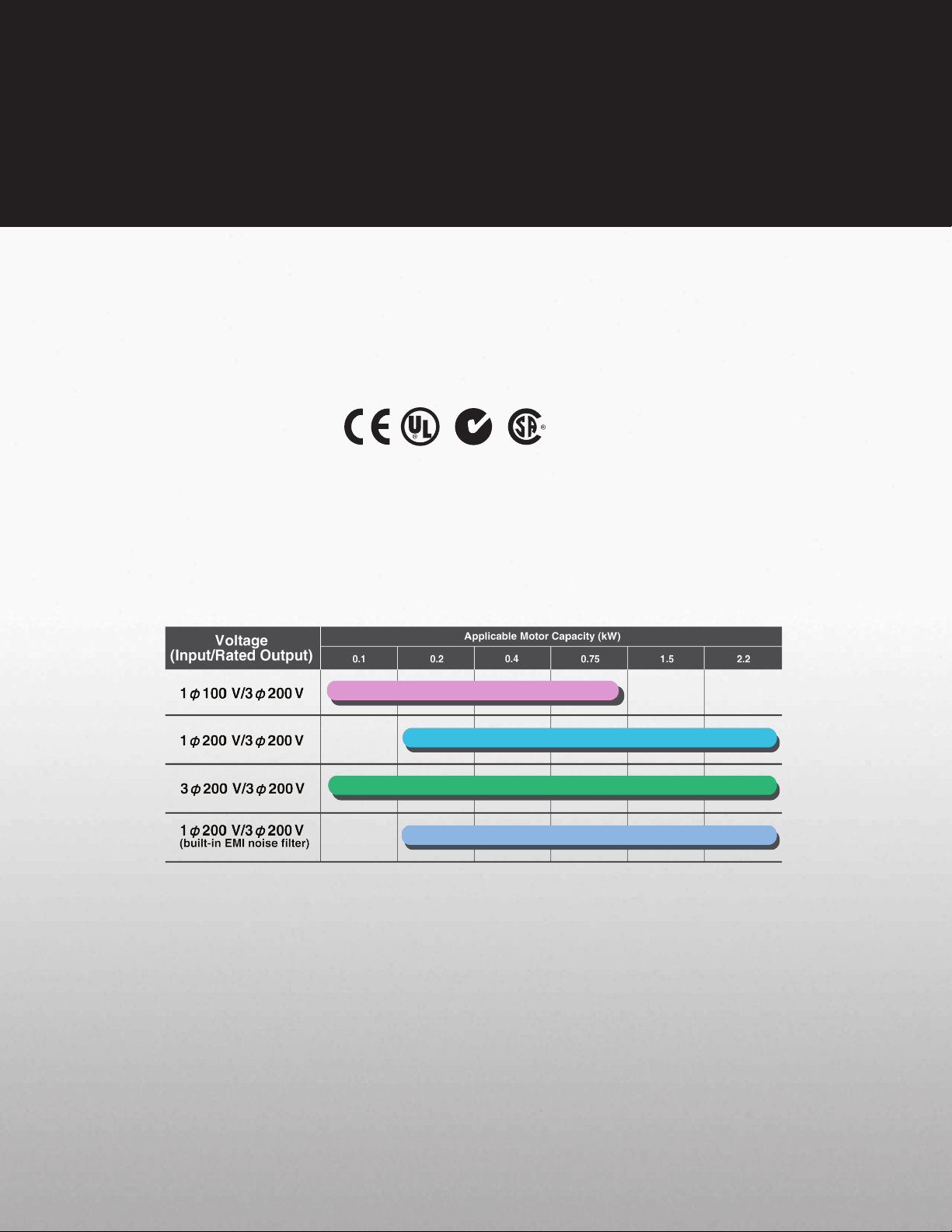

Models and Applicable Motors

Simple to Install

The nC1 is designed to be a drop-in replacement for a starter. The terminal

arrangements for input and output power are even set up like a starter. Side-byside mounting and the unit’s vertical construction allow for a smaller footprint.

The nC1 provides better control of your application, more protection for your motor,

and more room in your cabinet.

Page 3

Easy-to-Use

Easy To Program

The nC1 uses a simple, straightforward programming menu for quick and

easy setup of the drive. There are no complicated sub menus or “hidden”

parameters. By using the built-in programming wizards, the nC1 can be

programmed for simple operations with the push of a button. Available

Windows® programming software makes it a snap to set up the drive.

User-Friendly Operation

The nC1 comes ready to run. Simply mount the drive, run your power

connections and you are ready for operation. Many operations require

no programming whatsoever. The user-friendly interface is designed to

set the speed and start/stop functions of the unit easily. The drive will also

operate from nearly any standard industrial control inputs.

Array of Communications

In today’s fast-paced manufacturing world, coordinated systems require

communications from drive-to-drive and drive-to-system. A built-in port and a

variety of option cards give you versatility in communication selection.

• Built-In RS232/RS485 Port

• Communication Protocol Options

- Ethernet TCP/IP

- Ethernet IP

- DeviceNet

- Modbus RTU

- Modbus Plus

- Johnson Controls Metasys N2

- Probus DP

Page 4

nC1 Drive

Full-Scale

Display

Displays the operating frequency,

parameter information, a monitored

item, the cause of a failure,

and so on.

PROGRAM Lamp

Lights when the inverter is in

parameter setting mode. This lamp

blinks when the parameter “AUH”

or “Gr.U” is selected.

UP Key

Pressing the up key when lamp is

on allows the operating frequency

to be seen.

Input

Terminals

CHARGE Lamp

Indicates that high voltage is still

present within the inverter. Do not

open the cover while this is lit.

MONITOR Key

Displays operating frequencies,

parameter, and error messages.

RUN Lamp

Lights when an ON command

is issued but no frequency signal

is sent out. It blinks when operation

is started.

DOWN Key

Pressing the down key when lamp

is on allows the operating frequency

to be seen.

Built-In

Potentionmenter

Output

Terminals

STOP Key

Pressing of the STOP key while

the RUN key lamp is on will cause

a slowdown-stop.

ENTER Key

Page 5

Standard Specifications

nC1 ASD Standard Specifications

Model Range

1001P-1007P

2002P-2022P

2001PL-2022PL

2002P-2022P

Input Voltage Rating

120 V / Single Phase

230 V / Single Phase

230 V / Three Phase

230 V / Single Phase with

RFI / EMI Filter

KW Range

0.1 - 0.75 KW

0.2 - 2.2 KW

0.1 - 2.2 KW

0.2 - 2.2 KW

HP Range

1/8 - 1 HP

1/4 - 3 HP

1/8 - 3 HP

1/4 - 3 HP

Overload Rating

150% for 60 seconds

Input Voltage Tolerance

+10%, -15%

+10%, -15%

+10%, -15%

+10%, -15%

Input Frequency Rating

50 / 60 Hz

50 / 60 Hz

50 / 60 Hz

50 / 60 Hz

Input Frequency Tolerance

± 5%

±5%

±5%

±5%

Output Voltage Rating

230 V, Three Phase

Color

Munsel 5Y8 / 0.5

Control System

Sinusoidal PWM Control

Output Voltage Range

Adjustable within a range of 100 to 120% of the corrected supply voltage (200 V), nonadjustable to any voltage higher than the input voltage

Output Frequency Range

0.5 - 200 Hz, Default Setting: 0.5 - 80 Hz, Max Frequency: 30 - 200 Hz

Minimum Frequency Step

0.1 Hz: Operation Panel Setting, 0.2 Hz: Analog Input (when the Max Frequency is 100 Hz)

Digital Setting: within ±0.5% of the Max Frequency (-10 to +50°C)

Frequency Accuracy

Analog Setting: within ±1.0% of the Max Frequency (25°C ± 10°C )

V/f Characteristics

V/f, Slip Frequency Compensation, Base Frequency, Base Frequency Voltage and Torque Boost (adjustable amount)

Frequency Setting Signal

Internal Pot on the Front Panel, External Frequency Signal (connectable to a volume with a rated impedance of 3 -10 kΩ), VI Terminal (Input Impedance: 42 kΩ

(Voltage: 0 - 10 Vdc) or 250Ω (Current: 4 - 20 mAdc)). The frequency can be set arbitrarily using a two point setting.

Start-up & Jump Frequency

Adjustable within a range of 0.5 - 10 Hz, up to 1 frequency can be adjusted together with its widths

PWM Carrier Frequency

Selectable from among 2, 4, 8, 12 and 16 kHz (Standard Default Setting: 12 kHz or 4 kHz for models with a Built-In EMI Noise Filter)

Accel / Decel Time

Two selectable Accel / Decel Times adjustable from 0.1 to 3000 seconds

Retry Operation

Selectable number of retries (maximum 10 times); If the protection function is activated, the retry function restarts on completion of a check of the main circuit.

Electric Control

Charging of Capacitor (Deceleration Time can be shortened by activating Forced Shortened Deceleration mode.)

Dynamic Braking

Braking Start Frequency: 0 to Max Frequency, Braking Rate: 0 to 100%, Braking Time: 0 to 20 seconds

Input Terminal Functions

Forward / Reverse Run Input Signal, Jog Run Input Signal, Standby Signal, Preset-Speed Operation Input Signal, Reset Input Signal, etc.

Output Terminal Functions

Frequency Lower Limit Output Signal, Frequency Upper Limit Output Signal, Low-Speed Detection Output Signal, Specified Speed Attainment Output Signal, etc.,

Open Collector, RY Output

Failure Detection Signal

1 Form C contact, Rated: 250 Vac, 2A, cosØ = 0.4

FM / AM Output

PWM Output: (1 mAdc full-scale DC ammeter or 7.5 Vdc full-scale DC ammeter / Rectifier-type AC Voltmeter, 225% Current Max 1 mAdc, 7.5 Vdc full-scale)

Protective Function

Stall Prevention, Current Limitation, Overcurrent, Output Short Circuit, Overvoltage, Overvoltage Limitation, Undervoltage, Ground Fault, Power Supply Phase

Failure, Output Phase Failure Overload Protection by Electronic Thermal Function, Armature Overload at Start-up, Load-Side Overtorque at Start-up, Overheating

Prevention, Detection of Analog Signal Break

Momentary Power Failure Protection

Auto-Restart Control after momentary power failure

Electronic Thermal Characteristics

Switching between Standard Motor / Constant- Torque VF Motor, Overload Trip, Overload Stall Selection

Frequency: Inverter Output Frequency

Alarm: Stall Alarm "C," Overvoltage Alarm "P," Overload Alarm "L," Overheat Alarm "H."

Status: Inverter Status (Frequency, Cause of Activation of Protective Function, Input / Output Voltage, Output Current, etc.) and Parameter Settings

4-Digit, 7-Segment LED

Free-Unit Display: Arbitrary Unit (e.g. Rotating Speed) Corresponding to Output Frequency

Indicator

Lamps indicating the inverter status by lighting, such as RUN lamp and PRG lamp

Use Environments

Indoor- Altitude: 1000 m (maximum), not exposed to direct sunlight, corrosive gas, explosive gas or vibration (less than 5.9m 2) (10 to 55 Hz)

Ambient Temperature

-10 to +50˚C

Storage Temperature

-20 to +65˚C

Relative Humidity

20 to 93% Non-Condensing

nC1 ASD Standard Specifications

Model Range 1001P-1007 P 2002P-2022P 2001PL-2022PL 2002P-2022P

Input Voltage Rating 120 V/Single Phase 230 V/Single Phase 230 V/Three Phase

KW Range 0.1 to 0.75 KW 0.2 to 2.2 KW 0.1 to 2.2 KW 0.2 to 2.2 KW

HP Range 1/8 to 1 HP 1/4 to 3 HP 1/8 to 3 HP 1/4 to 3 HP

Overload Rating 150% for 60 Seconds

Input Voltage Tolerance +10%, -15% +10%, -15% +10%, -15% +10%, -15%

Input Frequency Rating 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Input Frequency Tolerance ± 5% ±5% ±5% ±5%

Output Voltage Rating 230 V, Three Phase

Color Munsel 5Y8 / 0.5

Control System Sinusoidal PWM Control

Output Voltage Range

Output Frequency Range 0.5 to 200 Hz, Default Setting: 0.5 to 80 Hz, Max Frequency: 30 to 200 Hz

Minimum Frequency Step 0.1 Hz: Operation Panel Setting, 0.2 Hz: Analog Input (when the Max Frequency is 100 Hz)

Frequency Accuracy

V/f Characteristics V/f, Slip Frequency Compensation, Base Frequency, Base Frequency Voltage and Torque Boost (Adjustable Amount)

Frequency Setting Signal

Startup & Jump Frequency Adjustable within a Range of 0.5 to 10 Hz; Up to 1 Frequency can be Adjusted Together with its Widths

PWM Carrier Frequency Selectable from among 2, 4, 8, 12, and 16 kHz (Standard Default Setting: 12 kHz or 4 kHz for Models with a Built-In EMI Noise Filter)

Accel/Decel Time Two Selectable Accel/Decel Times Adjustable from 0.1 to 3000 seconds

Retry Operation Selectable Number of Retries (Maximum 10 Times); If Protection Function is activated, Retry Function restarts after a main circuit check.

Electric Control Charging of Capacitor (Deceleration Time can be Shortened by Activating Forced Shortened Deceleration Mode)

Dynamic Braking Braking Start Frequency: 0 to Max Frequency; Braking Rate: 0 to 100%; Braking Time: 0 to 20 seconds

Input Terminal Functions Forward/Reverse Run Input Signal, Jog Run Input Signal, Standby Signal, Preset-Speed Operation Input Signal, Reset Input Signal, etc.

Output Terminal Functions

Failure Detection Signal 1 Form C Contact, Rated: 250 Vac, 2A, cosØ = 0.4

FM/AM Output

Protective Function

Momentary Power Failure Protection Auto-Restart Control after Momentary Power Failure

Electronic Thermal Characteristics Switching between Standard Motor/Constant- Torque VF Motor, Overload Trip, Overload Stall Selection

4-Digit, 7-Segment LED

Indicator Lamps Indicate Inverter Status by Lighting, such as RUN Lamp and PROGRAM Lamp

Use Environments

Ambient Temperature -10 to +50˚C

Storage Temperature -20 to +65˚C

Relative Humidity 20 to 93% Non-Condensing

VOLTAGE HP MODEL NUMBER FLA HEIGHT WIDTH DEPTH WEIGHT

110 V

Single Phase

230 V

Single Phase

230 V

Three Phase

230 V

Single Phase

Built-in RFI / EMI Filter

Adjustable within a Range of 100 to 120% of Corrected Supply Voltage (200 V), Nonadjustable to any Voltage Higher than the Input

Voltage

Digital Setting: within ±0.5% of the Max Frequency (-10 to +50°C)

Analog Setting: within ±1.0% of the Max Frequency (25°C ± 10°C )

Internal Pot on the Front Panel, External Frequency Signal (Connectable to a Volume with a Rated Impedance of 3 to 10 kΩ),

VI Terminal (Input Impedance: 42 kΩ (Voltage: 0 to 10 Vdc) or 250 Ω (Current: 4 to 20 mAdc)). Frequency can be Set Arbitrarily

Using a Two Point Setting

Frequency Lower Limit Output Signal, Frequency Upper Limit Output Signal, Low-Speed Detection Output Signal, Specified Speed

Attainment Output Signal, etc., Open Collector, RY Output

PWM Output: (1 mAdc Full-Scale DC Ammeter or 7.5 Vdc Full-Scale DC Ammeter/Rectifier-Type AC Voltmeter, 225% Current Max

1 mAdc, 7.5 Vdc Full-Scale)

Stall Prevention, Current Limitation, Overcurrent, Output Short Circuit, Overvoltage, Overvoltage Limitation, Undervoltage, Ground Fault,

Power Supply Phase Failure, Output Phase Failure Overload Protection by Electronic Thermal Function, Armature Overload at Startup,

Load-Side Overtorque at Startup, Overheating Prevention, Detection of Analog Signal Break

Frequency: Inverter Output Frequency

Alarm: Stall Alarm “C,” Overvoltage Alarm “P,” Overload Alarm “L,” Overheat Alarm “H.”

Status: Inverter Status (Frequency, Cause of Activation of Protective Function, Input / Output Voltage, Output Current, etc.) and Parameter

Settings

Free-Unit Display: Arbitrary Unit (e.g. Rotating Speed) Corresponding to Output Frequency

Indoor-Altitude: 1000 Meters (Maximum), not Exposed to Direct Sunlight, Corrosive Gas, Explosive Gas or Vibration (Less than 5.9 m2)

(10 to 55 Hz)

Model FLA & Approximate Dimensions (Inches) & Weight (Lbs)

0.12 VFNC1S-1001P 0.7 5.6 2.8 3.9 2.2

0.25 VFNC1S-1002P 1.4 5.6 2.8 3.9 2.2

0.5 VFNC1S-1004P 2.4 5.6 2.8 3.9 2.2

1.0 VFNC1S-1007P 4.0 5.6 4.6 4.9 2.2

0.25 VFNC1S-2002P 1.4 5.6 2.8 3.9 2.2

0.5 VFNC1S-2004P 2.4 5.6 2.8 4.9 2.2

1.0 VFNC1S-2007P 4.0 5.6 2.8 5.4 2.2

2.0 VFNC1S-2015P 7.5 5.6 4.6 6.1 3.3

3.0 VFNC1S-2022P 10 5.6 4.6 6.1 3.3

0.12 VFNC1-2001P 0.7 5.6 2.8 3.9 2.2

0.25 VFNC1-2002P 1.4 5.6 2.8 3.9 2.2

0.5 VFNC1-2004P 2.4 5.6 2.8 4.9 2.2

1.0 VFNC1-2007P 4.0 5.6 2.8 5.4 2.2

2.0 VFNC1-2015P 7.5 5.6 4.6 6.1 3.3

3.0 VFNC1-2022P 10 5.6 4.6 6.1 3.3

0.25 VFNC1S-2002PL 1.2 5.6 2.8 3.9 2.2

0.5 VFNC1S-2004PL 2.3 5.6 2.8 4.9 2.2

1.0 VFNC1S-2007PL 4.0 5.6 2.8 5.4 2.2

2.0 VFNC1S-2015PL 7.5 5.6 4.6 6.1 3.3

3.0 VFNC1S-2022PL 10.7 5.6 4.6 6.1 3.3

230 V/Single Phase with

RFI / EMI Filter

Page 6

North America Headquarters & Manufacturing Facilities (Houston, TX)

TOSHIBA — Quality by Design

Toshiba's culture and history are strongly rooted in quality. Our designs are

technologically innovative, and our products are manufactured from start to

end using only the highest quality domestic and foreign parts.

Product Warranty

Toshiba offers a comprehensive warranty program on its full line of industrial

products. Consult your salesperson or the factory for specific information.

Medium Voltage Motor

G7 Drive

Need to Know More?

Be sure to visit our website located at www.toshiba.com/ind for the latest

information on Toshiba products and services.

Customer Support Services

Toshiba offers 24-hour service nationwide. For assistance of any type

call: 1-800-231-1412.

ADJUSTABLE SPEED DRIVES MOTORS CONTROLS UPS INSTRUMENTATION PLC

Available Through:

INDUSTRIAL DIVISION

13131 West Little York Road, Houston, Texas 77041

Tel 713/466-0277 Fax 713/466-8773

US 800/231-1412 Canada 800/872-2192 Mexico 01/800/527-1204

www.toshiba.com/ind

Copyright 8/2007

*NC1brocct070815*

Loading...

Loading...