Page 1

INSTALLATION MANUAL

MANUEL DINSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

AIR CONDITIONER

CLIMATISEUR

KLIMASYSTEM

CONDIZIONATORE D’ARIA

VOLUME-1

AIRE ACONDICIONADO

Indoor Unit

Unité intérieure

Raumeinheit

Assolutamente solo per uso commerciale

Unità interna

Unidad interior

[4-way Air Discharge Cassette Type]

[Type cassette à 4 voies de soufflage]

[4-Wege-Kassetten-Modell]

[Tipo a cassetta per mandata d'aria a 4 vie]

[Modelo de cassette con descarga de aire de 4 vías]

Strictly for commercial use only

Uniquement à usage commercial

Nur für den gewerblichen Bebrauch

Únicamente para uso comercial

MMU-AP0071MH

MMU-AP0091MH

MMU-AP0121MH

MMU-AP0151MH

MMU-AP0181MH

Page 2

ADOPTION OF NEW REFRIGERANT

This Air Conditioner adopts a new HFC refrigerant

(R410A) which does not destruct the ozone layer.

We would lik e to express our deepest thanks to your purchase this Air

Conditioner.

This manual describes the details of installation method of the indoor

unit.

Prior to installation, please read this manual thoroughly to understand the

contents.

If you are an installer or a dealer , please pass this manual to the

customer and clearly explain the contents.

For piping connections such as Y-shape branch, branching joints, header

branch of the indoor and outdoor units must be selected in accordance to

the total system capacity.

These items are supplied separately as accessories.

UTILISATION DU NOUVEAU REFRIGERANT

Ce climatiseur utilise le nouveau réfrigérant HFC

(R410A), qui ne détruit pas la couche d’ozone.

VERWENDUNG EINES NEUEN KÜHLMITTELS

Dieses Klimagerät arbeitet mit dem neuen HFC

Kältemittel R410A. Dieses Kältemittel g reift die

Ozonschicht nicht an.

Nous vous remercions d’av oir choisi ce climatiseur.

Ce manuel décrit la procédure d’installation de l’unité intérieure.

Av ant de procéder à l’installation, veuillez lire attentivement ce manuel et

vous assurer d’en avoir compris le contenu.

Si vous êtes un monteur ou un revendeur, veuillez remettre ce manuel au

client en lui expliquant clairement son contenu.

Choisissez les raccords des tuyauteries, tels que les embranchements

en Y, les raccords d’embranchement, l’embranchement du collecteur des

unités intérieures et extérieures, en fonction de la puissance totale du

système.

Ces éléments sont des accessoires fournis séparément.

Wir danken Ihnen, dass Sie sich für dieses Klimagerät entschieden

haben.

In diesem Handbuch wird die Installation der Inneneinheit beschrieben.

Bevor Sie mit der Installation beginnen, lesen Sie dieses Handbuch

sorgfältig.

Wenn Sie zu einem Installationsbetrieb oder zu einem Händler gehören,

geben Sie das Handbuch an Ihren Kunden weiter und erklären ihm den

Inhalt.

Rohrleitungsverbindungen wie Y-Abzweige, Abzweiganschlüsse und

Verteiler für Innen- und Außeneinheiten müssen entsprechend der

Systemleistung ausgewählt werden.

Diese Teile werden separat als Zubehör geliefert.

IMPIEGO DI NUOVO REFRIGERANTE

Questo condizionatore d’aria impiega il nuovo

refrigerante HFC (R410A) che non distrugge lo

strato d’ozono .

ADOPCIÓN DE NUEVO REFRIGERANTE

Este acondicionador de aire utiliza el nuev o

refrigerante HFC (R410A) que no daña la capa de

ozono.

Porgiamo i nostri sinceri ringraziamenti per aver acquistato questo

condizionatore d’aria.

Questo manaule presenta informazioni dettagliate riguardo come

installare l’unità esterna.

Prima d’iniziare l’installazione, leggere attentamente questo manuale per

comprendere le istruzioni contenute.

È importante che l’installatore o il rivenditore forniscano questo manuale

al cliente e lo informino bene delle istruzioni in esso fornite.

Per il collegamento dei tubi relativi a derivazione Y, giunti di derivazione,

collettore di derivazione di unità interne ed esterne, i tubi devono essere

scelti in funzione della capacità totale del sistema.

Queste parti sono da acquistare a parte, come parti accessorie.

Gracias por haber adquirido este acondicionador de aire.

Este manual describe en detalle el método de instalación de la unidad

interior.

Antes de realizar la instalación, lea detenidamente el manual para

entenderlo por completo.

Si es un instalador o un distribuidor, hágale llegar el man ual al cliente y

explique claramente.

Para las conexiones de la tubería, como la derivación en Y, las juntas de

derivación, se deben elegir las derivaciones con colector de las unidades

interior y exterior según la capacidad total del sistema.

Estos elementos vienen por separado, en calidad de accesorios.

Page 3

CONTENTS

VOLUME-1

Accessory parts and Parts to be procured locally.... 1

1

PRECAUTIONS FOR SAFETY ........................... 2

2

SELECTION OF INSTALLATION PLACE ........... 3

3

INSTALLATION OF INDOOR UNIT..................... 5

4

DRAIN PIPING WORK ........................................ 9

5

REFRIGERANT PIPING.................................... 12

SOMMAIRE

Pièces accessoires et pièces non fournies ............. 29

1

MESURES DE SECURITE................................30

2

SELECTION DU LIEU D’INSTALLATION......... 31

3

INSTALLATION DE L’UNITE INTERIEURE ...... 33

4

INSTALLATION DES TUYAUX

D’EVACUATION ................................................ 37

5

TUYAUX DE RÉFRIGÉRANT............................ 40

INHALT

6

ELECTRIC WORK.............................................14

7

APPLICABLE CONTROLS............................... 18

8

TEST RUN......................................................... 21

9

TROUBLESHOOTING....................................... 23

10

MAINTENANCE ................................................ 28

6

TRAVAUX D’ÉLECTRICITÉ .............................. 42

7

COMMANDES UTILISABLES .......................... 46

8

ESSAI DE FONCTIONNEMENT ....................... 49

9

DÉPANNAGE .................................................... 51

10

ENTRETIEN ...................................................... 56

ENGLISHITALIANO FRANCAISDEUTSCHESPAÑOL

Zubehör und bauseits bereitzustellende Teile ......... 57

1

SICHERHEITSVORKEHRUNGEN .................... 58

2

AUSWAHL DES AUFSTELLUNGSORTES ...... 59

3

INSTALLATION DER RAUMEINHEIT ............... 61

4

INSTALLATION DES

KONDENSWASSER-ABLAUFS ....................... 65

5

KÜHLMITTELLEITUNGEN ............................... 68

INDICE

Accessori e parti da acquistare sul posto ............... 85

1

PRECAUZIONI PER LA SICUREZZA .............. 86

2

SCELTA DEL POSTO D’INSTALLAZIONE....... 87

3

INSTALLAZIONE DELL’UNITÀ INTERNA ........ 89

4

LAVORO PER TUBAZIONE DI SCARICO ........ 93

5

TUBAZIONI DEL REFRIGERANTE.................. 96

CONTENIDO

6

ELEKTROARBEITEN ....................................... 70

7

STEUERUNGSMÖGLICHKEITEN.................... 74

8

TESTLAUF ........................................................ 77

9

FEHLERSUCHE................................................79

10

WARTUNG ........................................................ 84

6

COLLEGAMENTI ELETTRICI........................... 98

7

COMANDI APPLICABILI ................................ 102

8

FUNZIONAMENTO DI PR OVA........................ 105

9

RISOLUZIONE DEI PROBLEMI ..................... 107

10

MANUTENZIONE............................................ 112

Componentes accesorios y componentes de

suministro local........................................................ 113

1

PRECAUCIONES PARA SU SEGURIDAD ..... 114

2

SELECCIÓN DEL LUGAR

DE INSTALACIÓN........................................... 115

3

INSTALACIÓN DE LA UNIDAD INTERIOR .... 117

4

CANALIZACIÓN DE DRENAJE ..................... 121

5

TUBERÍA DE REGRIGERANTE ..................... 124

6

INSTALACIÓN ELÉCTRICA ........................... 126

7

CONTROLES APLICABLES .......................... 130

8

PRUEBA DE FUNCIONAMIENTO .................. 133

9

RESOLUCIÓN DE PROBLEMAS ................... 135

10

MANTENIMIENTO........................................... 140

Page 4

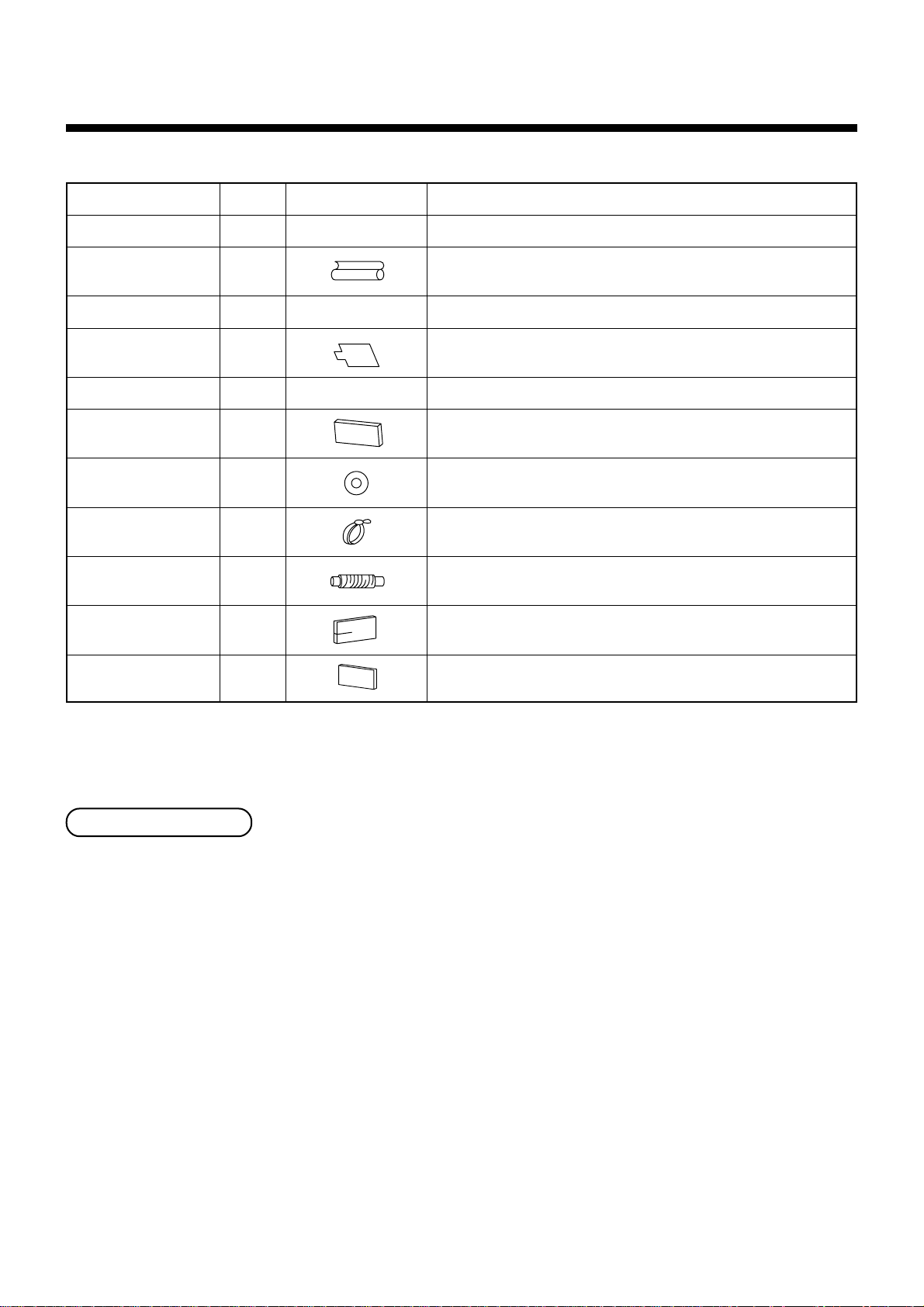

Accessory parts and Parts to be procured locally

H Accessory parts

Part name

Installation Manual

Heat insulating pipe

Installation pattern

Installation gauge

Pattern fixing screw

Heat insulator

Washer

Hose band

Flexible hose

Heat insulator A

Q’ty

1

2

1

2

4

1

8

1

1

1

Shape

This manual

——

M5 × 16L

Usage

(Ensure handover to customer)

For heat insulation of the pipe connecting section

For checking of ceiling opening and the main unit position

For positioning of the ceiling position

(To be used with the installation pattern)

For attach the installation pattern

For heat insulation of drain connecting section

For hanging unit

For connecting drain pipe

For adjusting core-out of drain pipe

For sealing of wire connecting port

Heat insulator B

1

For sealing of wire connecting port

Refrigerant piping

• Piping material used for the conventional refrigerant cannot be used.

• Use copper pipe only with a wall thickness of 0.8 mm or more for Ø6.4, Ø9.5, Ø12.7.

• Flare nut and flare operations are also different from those of the conventional refrigerant.

Use the flare nut fitted to the indoor unit of the air conditioner.

1

Page 5

1

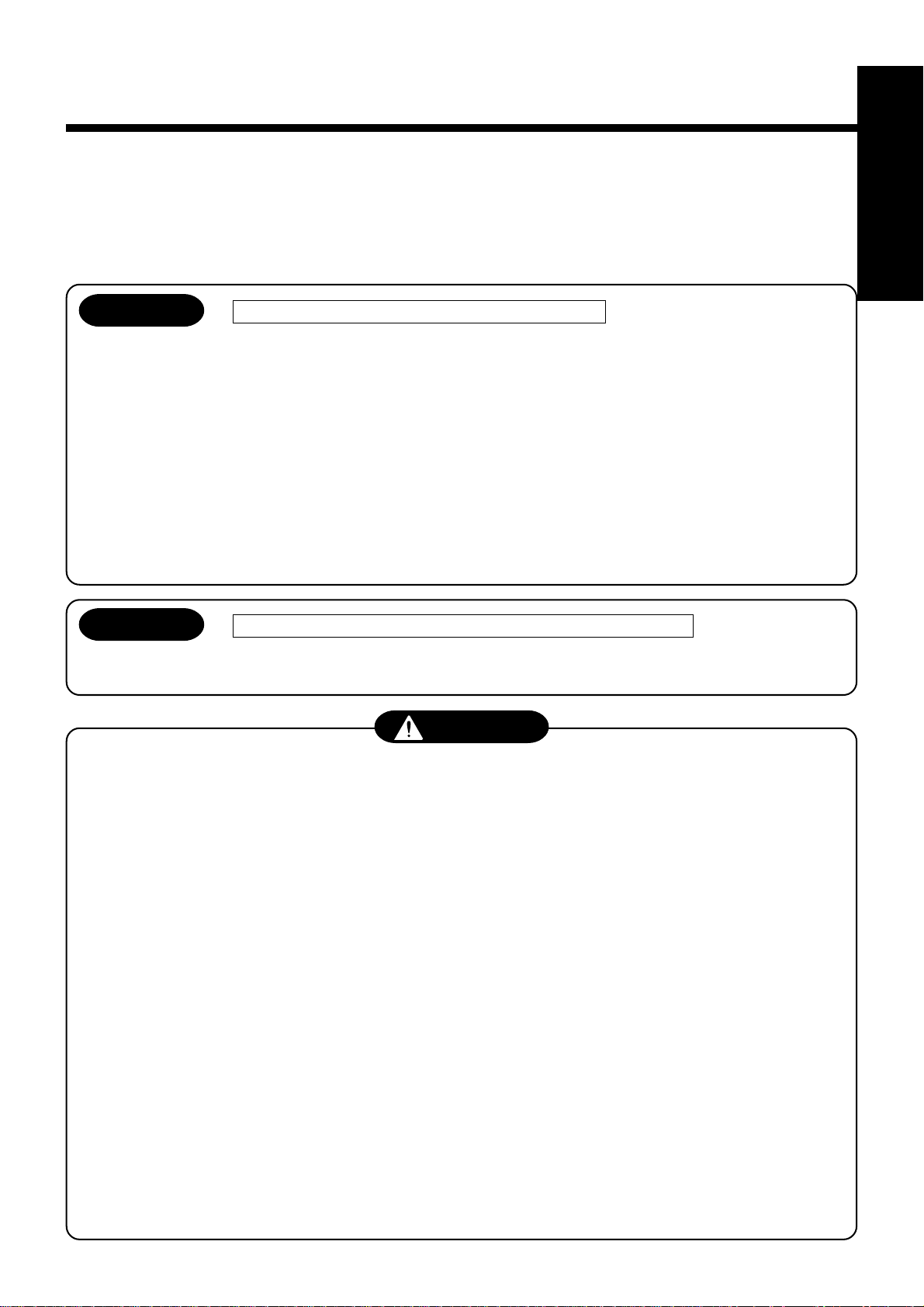

• Ensure that all Local, National and International regulations are satisfied.

• Important safety information are describes in this installation manual.

Please ensure this manual is read thoroughly and kept for future reference.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before any unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

PRECAUTIONS FOR SAFETY

CAUTION New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER FEATURES A NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DEPLETE OZONE LAYER.

The pressure of R410A is 1.6 times higher than that of former refrigerant R22. The refrigerating oil has also been

changed. Therefore be sure that any former refrigerant, refrigerant oil or any other contaminants do not enter the

refrigerating cycle of the air conditioner, during either installation or service work. If incorrect tools or operating

procedures are used, there is a possibility of a serious accident. Use only tools and materials that have been

designed to operate with R410A.

To prevent the risk of charging with an incorrect refrigerant, the dimensions of the charging port connections are different

to those used for conventional refrigerant. Therefore only tools designed to operate with R410A can be used.

For connecting pipes, use piping specifically designed for R410A.

During installation, ensure pipes are clean and ensure contaminants do not enter the pipes as the system is affected

by impurities such as water, oxide scales, dirt, oil, etc. Do not use existing pipe work from previous installation as this

will cause problems due to pressure resistances and impurities within the pipe.

ENGLISH

CAUTION To Disconnect the Appliance from Main Power Supply.

This appliance must be connected to the main power supply by means of a switch with a contact separation of at

least 3 mm.

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause an electric shock.

• Connect all of the installation wiring correctly.

If the installation wiring is incorrect electrical parts may be damaged.

• During the transportation and installation of the air conditioning unit, ensure that gaseous matter

other than the specified refrigerant does not enter into the refrigeration cycle.

If a refrigerant becomes contaminated with foreign gases, the gas pressure within the refrigerant cycle will become

abnormally high and may result in the fracture of pipework and possible human injury.

• Do not modify this unit by removing any of the safety guards or by overriding any of the safety

interlock switches.

• Exposure of the unit to water or other forms of moisture before installation may cause a short-circuit

of the electrical parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine for possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that in

the event of a refrigerant leak the rooms does not exceed the critical level.

2

Page 6

1

PRECAUTIONS FOR SAFETY

• Install the air conditioner securely in a location where the base can sustain the weight of the unit

adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the unit falling.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gases may be generated.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gases maybe

generated.

• Electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Ensure the power supply to the air conditioner is exclusive to that unit only.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use only the specified wiring during the unit installation. Ensure that all terminals are securely fixed,

so preventing any external forces having a negative effect on the terminals.

• Conform to the regulations of the local electric authority when wiring the power supply.

Inappropriate grounding may cause an electric shock.

• Do not install the air conditioner in a location that maybe subjected to a risk of exposure to a

combustible gas.

If a combustible gas leaks and becomes concentrated around the unit, a fire may occur.

2

SELECTION OF INSTALLATION PLACE

WARNING

• The air conditioner must be installed in a location that can support the weight of the unit effectively.

If the unit is not installed on a foundation that can support its weight effectively, the unit may fall down, resulting in

possible human injury.

• Where required ensure that the units installation is sufficient enough to withstand against an earthquake.

An insufficient installation could result in the unit falling, causing possible human injury.

• Install the air conditioner at a minimum height of 2.5 m from the floor.

Do not insert your hands or others into the unit while the air conditioner is operating.

CAUTION

Upon approval from the customer, install the air conditioner in a place that satisfies the following

conditions.

• A place where the unit can be installed horizontally.

• A place where a sufficient servicing space can be maintained for safety maintenance and unit check.

• A place where the drain water can be exited from the unit, without causing a problem.

Avoid installing in the following places.

• Places exposed to air with a high salt content (seaside area), or places exposed to large quantities of sulfide gas

(hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Places exposed to oil, vapor, oil smoke or corrosive gas.

• Places where organic solvent is used nearby.

• Places close to a machine generating high frequency.

• Places where the discharged air blows directly into the window of the neighbouring house. (For outdoor unit)

• Places where the noise from the outdoor unit can be easily transmitted to the neighboring property.

(When installing the air conditioner on the boundary with a neighbour, pay due attention to the level of noise.)

• Places with poor ventilation.

3

Page 7

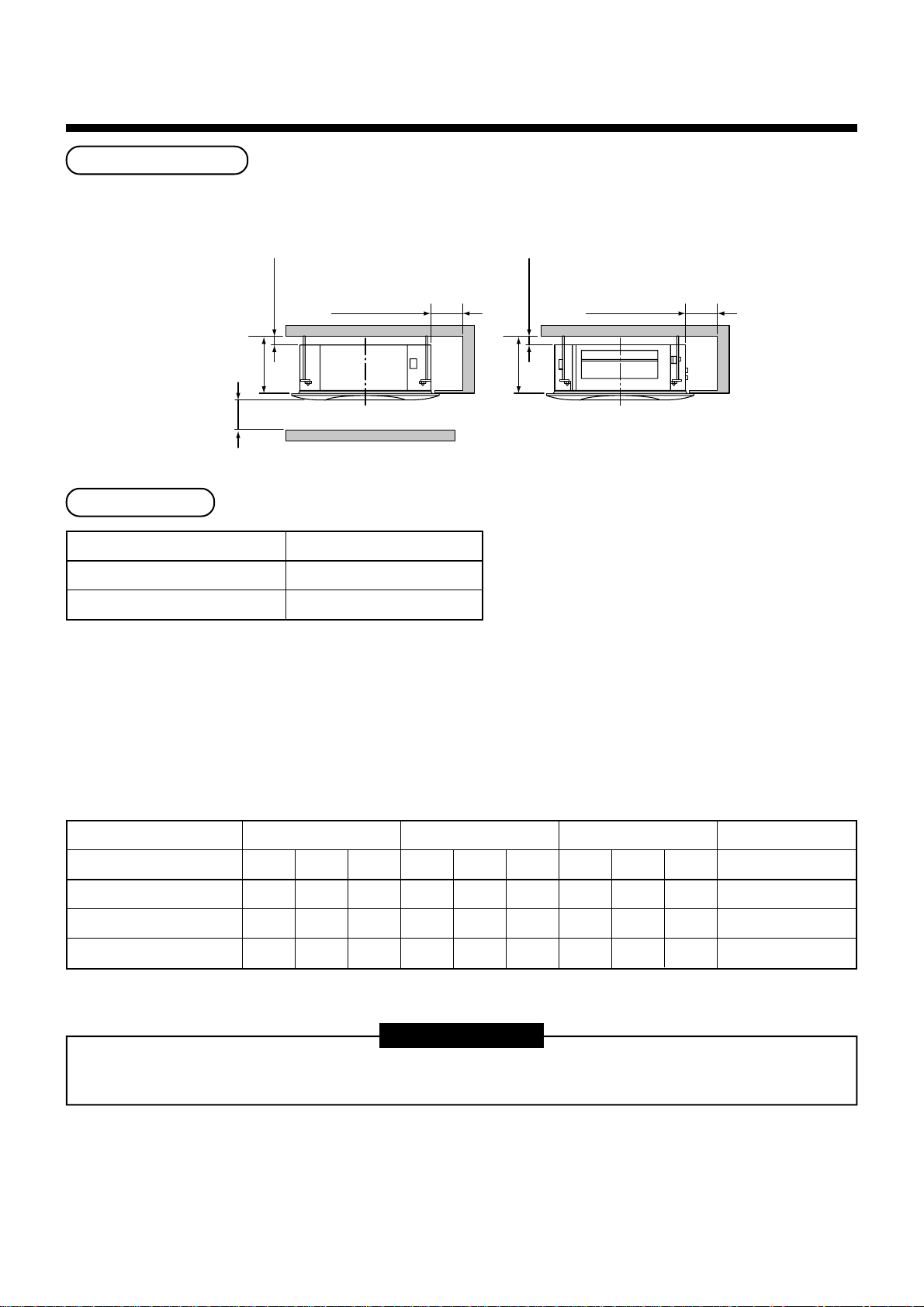

Installation space

Ensure there is sufficient space to install the unit and to perform maintenance work as and when required.

Keep 15mm or more for clearance between top plate of the indoor unit and the ceiling surface.

Installation space

1000

or more

283

or more

15 or more

1000 or more

Obstacle

283

or more

15 or more

1000 or more

Ceiling height

Model MMU-

0071 to 0121 type

0151 to 0181 type

When the ceiling height exceeds the standard distance of a 4-way discharge cassette as detailed in the following

table. The air-flow may not be sufficient to heat the room. It is therefore necessary to set the unit to high ceiling

mode or adjust the direction of the ceiling discharge.

If fitting a separately supplied filter, it will also be necessary to set to high ceiling mode.

For setup of the high ceiling mode, refer to the details of Applicable controls “To incorporate a filter sold separately”

and “In case of installation to high ceiling” within this Manual.

Installable ceiling height

Up to 2.7 m

Up to 3.5 m

Installable ceiling height list

Indoor unit Capacity type

Discharge direction

Standard (At shipment)

High ceiling (2)

High ceiling (3)

0071 to 0121 type 0151 type 0181 type

4-way 3-way 2-way 4-way 3-way 2-way 4-way 3-way 2-way

2.7 ——2.9 ——3.2 ——

———3.2 ——3.4 ——

———3.5 ——3.5 ——

Setup of high ceiling

Setup data

0000

0002

0003

(Unit: m)

REQUIREMENT

• When high ceiling (1) or (3) is used with 4-way blowing, a draft is easily recognized due to drop of discharge

temperature.

The air filter cleaning signal duration (Notification of filter cleaning) on the remote controller can be changed

according to the condition of installation.

If the room is not heated due to the installation place or construction of the room, the detection temperature of

heating can be raised.

For setup method, refer to “Change of lighting term of filter sign” and “To secure better effect of heating” in the

Applicable controls of this Manual.

4

Page 8

2

SELECTION OF INSTALLATION PLACE

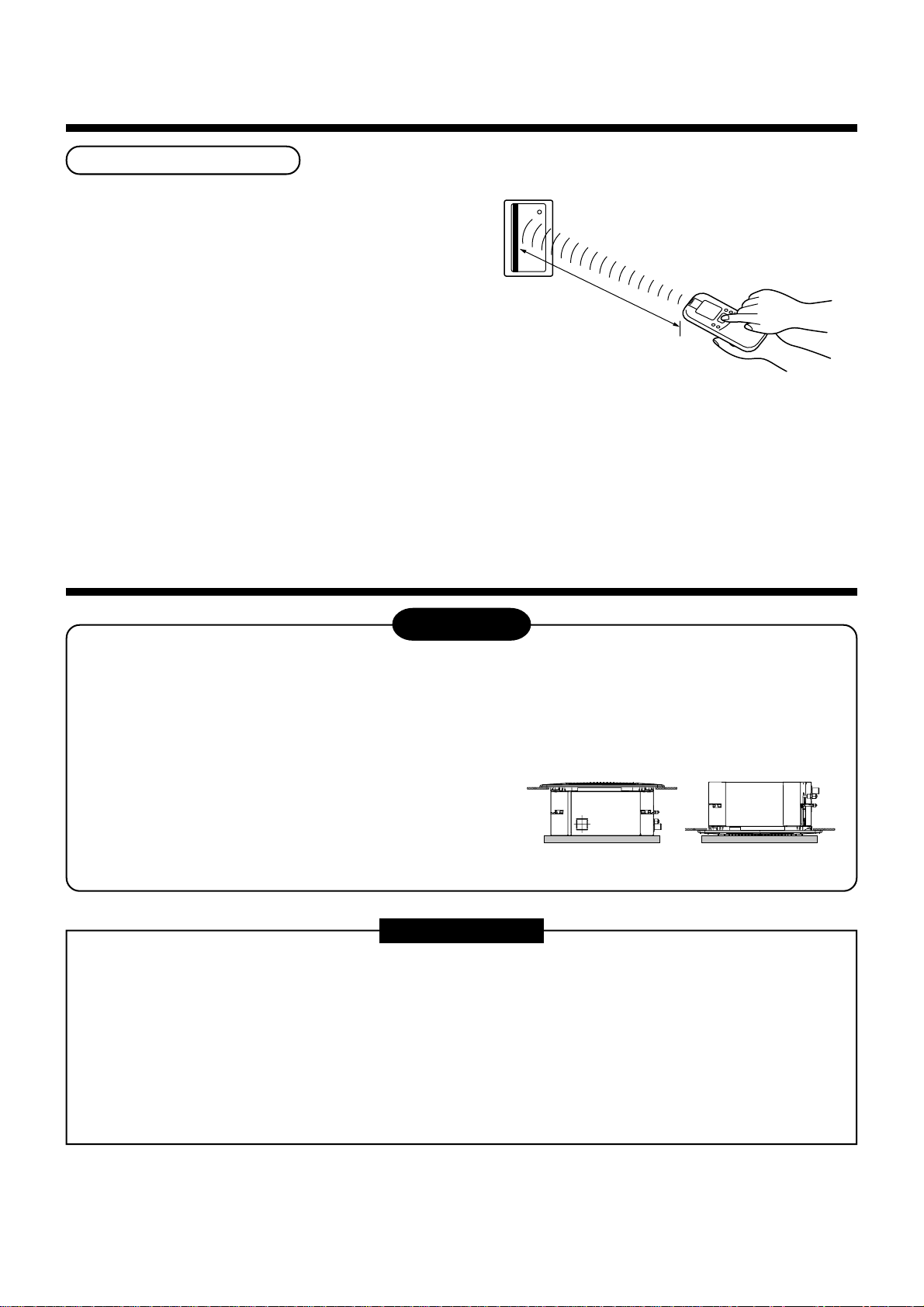

In case of wireless type

The wireless remote controller can be operated up to a

maximum of 8 m from the infra-red receiver.

Therefore ensure that the remote controller will be

mounted and used within this stated parameter.

• To prevent malfunction do not mount or operate in a

location that is subjected to either a fluorescent lamp

or direct sunlight.

• A maximum of 6 indoor units with wireless remote

control can be installed within the same room.

8 m or less

3

INSTALLATION OF INDOOR UNIT

WARNING

The installation of the air conditioning unit must be positioned in a location that can sufficiently support its weight

and give protection against adverse environmental conditions.

Failure to do so may result in unit damage and possible human injury.

Any incomplete installation may also cause possible risk of human injury.

• Unpack the package, take out the product and then place it

on the floor so that the same surface directs underneath as

it is placed in the package.

If the both sides are turned over, a deformation of mounting

metal of the ceiling panel which is sold separately, etc may

be caused. Accordingly the product may be damaged and

the installation becomes impossible in some cases.

REQUIREMENT

Strictly comply to the following rules to prevent damage of the indoor units and human injury.

• Do not place heavy objects on the indoor unit. (Even when units are still packaged)

• Always carry the unit as packaged from the factory wherever possible.

If carrying in the indoor unit unpacked by necessity, be sure to use buffering cloth, etc. to prevent damaging

the unit.

• To move the indoor unit, hold the hanging brackets (4 positions) only.

Do not apply force to other parts (refrigerant pipe, drain pan, foamed parts, or resin parts etc.).

• To be carried by two or more persons. Do not strap the unit in positions other than that stated.

OK NO GOOD

5

Page 9

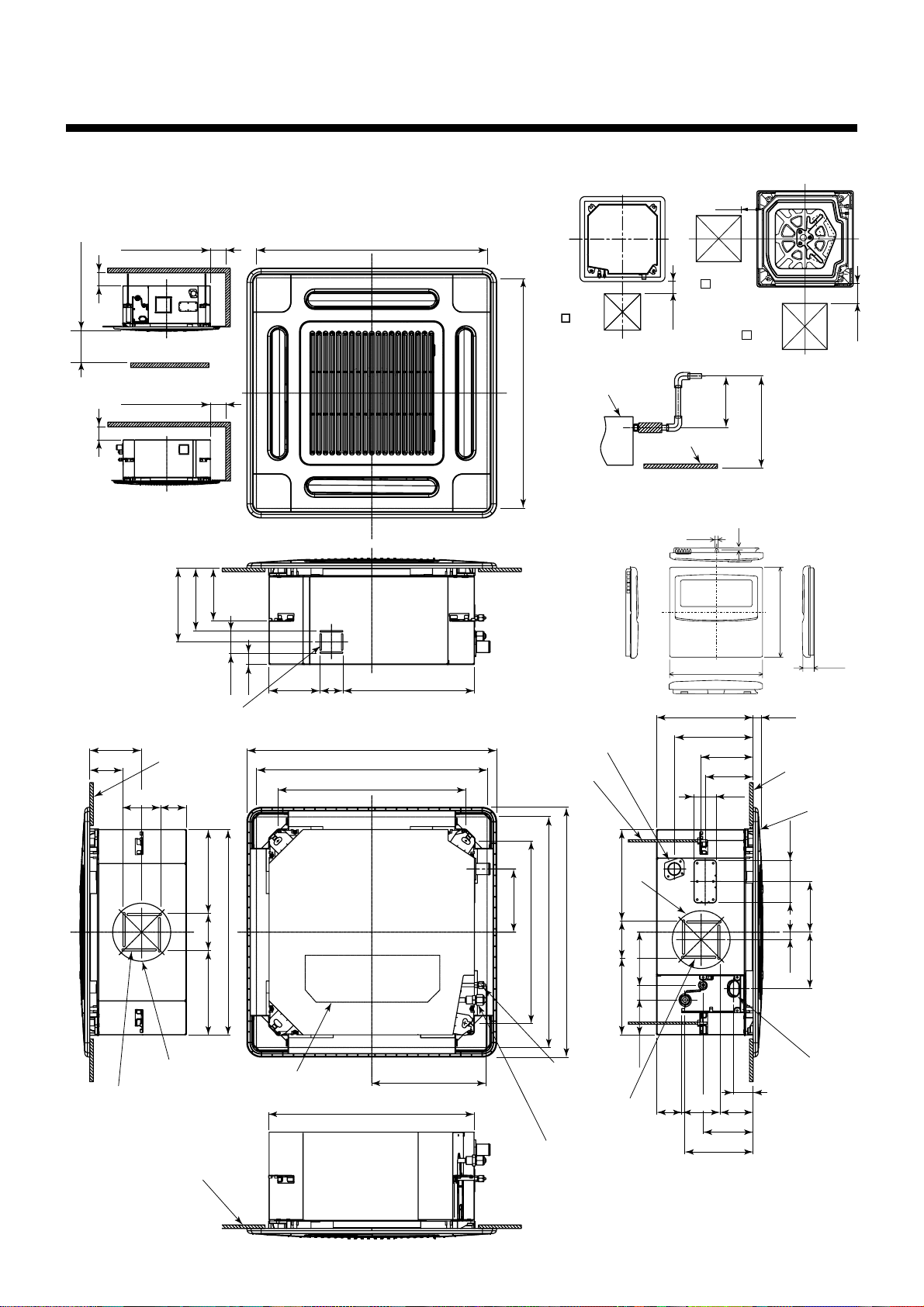

Dimensional view

200

1000 or more

15 or more

1000 or more

Obustacle

1000 or more

15 or more

Space required for

installation and servicing

149

175

207

64

Knockout for flesh

145.5

93

105

air intake Ø100

Bottom face

of ceiling

70

595 to 660 Ceiling open dimension

142 64 368.5

29

700 Panel external dimension

595 to 660 Ceiling open dimension

525 Hanging bolt pitch

Check port

( 450)

Check port

(o 450)

200

Check port

( 450)

Drain-up standing-up size

Indoor unit

627.5

or less

Stand-up

Bottom face

of ceiling

Stand-up

850 or less

Note)

595 to 660 Ceiling open dimension

As ABS is used for the drain discharge port of the main unit,

the vinyl chlor paste cannot be used.

Use the flexible hose (Band fix) included in the package.

4

2.7

• Wired remote

controller

120

(RBC-AMT31E)

120

268 27

220.5

Drain discharge port

Hanging bolt

M10 or W3/8

local arrange

145.5

134

63

Bottom face

of ceiling

Ceiling panel

200

16

105235 235

Ø162

For branch duct knockout

square hole Ø150

Bottom face of ceiling

575 Unit external dimension

Electric parts box

320.5

575 Unit external dimension

120

Ø162

256

177

525 Hanging bolt pitch

700 Panel external dimension

595 to 660 Ceiling open dimension

Refrigerant pipe

(Liquid) Ø6.4

For branch ductt

knockout square

hole Ø150

Refrigerant pipe (Gas)

0151, 0181MH : Ø12.7

0071 to 0121MH : Ø9.5

214 105

97.5 42 148

55

9310570

139.5

190.5

142

21

158

Wiring connection

port

6

Page 10

M5 × 16L screws (Attached)

These screws are exclusive to the

installation pattern. When installing

the ceiling panel, the other exclusive

screws attached to the ceiling panel

(sold separately) are used.)

Indoor unit

Installation pattern

(Attached)

Cut off the installation

pattern along slit of

the main unit.

3

INSTALLATION OF INDOOR UNIT

Ceiling opening and installation of hanging bolts

• Evaluate and determine the piping and wiring requirements inside the ceiling prior to the hanging of the unit.

• After installation place of the indoor unit has been determined, create opening in ceiling and install the hanging

bolts.

• For the ceiling opening size and pitch for hanging bolts refer to the dimensional drawing and the supplied

installation pattern.

• Once the ceiling void has been created, ensure that the drain pipe, refrigerant pipes, inter-connecting wires and all

control wires are in place prior to installing the actual indoor unit.

Please procure the hanging bolts and nuts for

Hanging bolt

M10 or W3/8

installation of the indoor unit at local site.

Nut

M10 or W3/8

How to use the supplied installation pattern

The installation pattern is enclosed within the packaging of the air conditioner.

Existing ceiling void

Use the pattern to determine the position and size of the opening and location of the hanging bolts.

New ceiling void

Use the pattern to determine the position of the new ceiling opening.

Cut off slit section of the main unit of the installation pattern.

Cut off the outside of the pattern according to size of the ceiling

opening. (There is a slit on the standard opening size section.)

• Install the indoor unit after installation of the hanging bolts.

• Using the supplied pattern attach it to the indoor unit using the

supplied fixing screws (M5 × 16L 4off). (Screw pattern to the ceiling

panel hanging brackets of the indoor unit)

• When creating the opening ensure it is as per the outer dimensions

of the supplied pattern.

4 pieces

12 pieces

Opening a ceiling and installation of hanging bolts

Treatment of ceiling

The ceiling differs according to the structure of the building. For details, consult your architect.

In the process after the ceiling panels have been removed, it is important to reinforce the ceiling construction and

ensure the ceiling remains in a horizontal position. This is to prevent possible vibration of the ceiling panels.

1. Cut and remove the ceiling material.

2. Reinforce the cut surface of the ceiling construction and add support for fixing the end of ceiling panel.

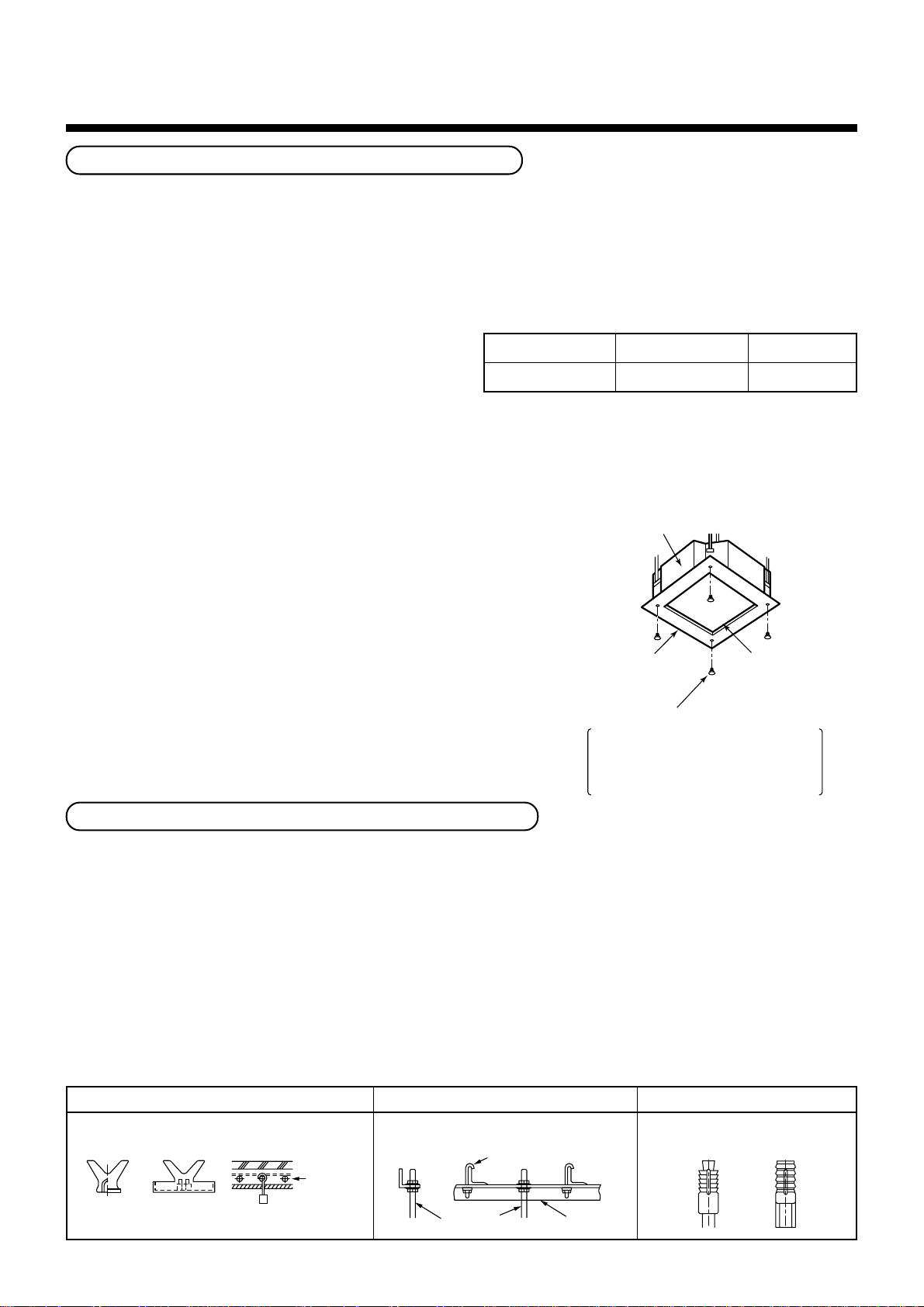

Installation of hanging bolt

Use M10 hanging bolts (4 off, locally procured).

When mounting the unit, set the pitch of the hanging bolts according to the size of the unit as detailed on the

dimensional drawing.

New concrete slab

Install the bolts with insert brackets or anchor

bolts.

(Blade type

bracket)

(Slide type

bracket)

Anchor bolt

(Pipe hanging

anchor bolt)

Reinforcing

steel

Steel flame structure

Use existing angles or install new

support angles.

Hanging bolt

Hanging bolt Support angle

7

Existing concrete slab

Use a hole-in anchors, hole-in

plugs, or a hole-in bolts.

Page 11

Installation of indoor unit

• Attach the nut (M10 or W3/8: Procured locally) and washer (Ø34 mm)

to the hanging bolt.

• Put washers at either side of the T-groove on the hanging bracket of

the indoor unit in order to hang the unit.

• Using a spirit level, check that all four sides are horizontal.

(Horizontal positioned within 5 mm)

• Cut off the installation gauge from the installation pattern.

• Using the installation gauge check and adjust clearance between the

indoor unit and the ceiling opening (1) (10 to 42 mm on each side).

Ensure that the unit is level to the ceiling and within a distance of (2)

23 mm to 28 mm below.

The installation gauge has details of how to use printed on it.

Note) Install the indoor unit so that the end part of opening does not

come into contact with the drain socket piping.

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Nut

(W3/8 or M10)

(1) M10 washer supplied, all other material

must be procured locally.

(2) To ensure that the unit is mounted safely, the

hanging bolt must be positioned just below

the hanging bracket as shown in the diagram.

(1)

M10 flat washer

(Accessory)

(2)

M10 flat washer

(Accessory)

Level vial (Horizontal: within 5 mm)

Indoor unit

Hanging

metal

10 to 42

Installation gauge

mm (2)

Hanging bolt

23 to 28

Ceiling board

Indoor unit

mm (1)

Ceiling board

REQUIREMENT

Before installation of the indoor unit be sure to

remove the transportation cushion found between

the fan and the bell mouth.

Running the unit without removing the cushion

may damage the fan motor.

Be sure to remove the cushion for transportation

between the fan and the bell mouth.

1) 23 to 28 mm

Installation gauge 2) 10 to 42 mm

Installation of ceiling panel

(Sold separately)

Install the ceiling panel after completion of the

installation of the indoor unit, including all piping and

wiring.

Install the ceiling panel as per the supplied Installation

Manual.

Check the installation dimensions of the indoor unit

and the ceiling opening are correct and then install.

REQUIREMENT

Ensure the ceiling panel is mated to the ceiling

surface or the indoor unit.

If the panel and unit are not mated together this

may result in the formation of dew condensation

causing a possible water leak.

First remove the 4 corner caps from the ceiling

panel and fit to the indoor unit.

Installation of remote controller (Sold separately)

For installation of the wired remote controller, follow the Installation Manual supplied with the remote controller.

• Do not expose remote controller to direct sunlight or excessive heat.

• When using a wireless type remote controller check receiver on the indoor unit receives a signal.

• For a wireless type controller ensure that it is used and mounted a minimum distance of 1m apart from any other

electrical devices (TV, Stereo, etc). As this may cause interference with the devices.

8

Page 12

4

As long as possible (10cm)

VP30 or more

Downward slope

1/100 or more

VP25

VP25

VP25

(Collective pipes)

Riser (Trap)

90˚ Bend

max

45˚

max

45˚

OK

NO GOOD

Socket for VP25 vinyl chloride pipe

(To be local procure)

Align the attached hose band to the

end of hose, set the tightening

position upward, and then tighten it.

Indoor unit body

Drain pipe

connecting port

(Transparent)

Flexible hose

(Accessory)

VP25 vinyl chloride pipe

(To be local procure)

DRAIN PIPING WORK

CAUTION

• Install the drain piping so that the water

drains effectively.

• Apply heat insulation to prevent dew

condensation from forming.

• Incorrectly installed pipework may result

in a water leak.

Pipe material/Insulator and size

The following materials for piping work and insulation

are to be procured locally.

Hard vinyl chloride pipe socket for VP25

Pipe material

Insulator

Hard vinyl chloride pipe VP25

(Outer diameter Ø32 mm)

Foamed polyethylene foam, thickness:

10 mm or more

REQUIREMENT

• Ensure insulating of the drain pipes and connecting parts on the indoor units.

• The drain pipe should have a downward slope of at least 1/100 and ensure

there are no swells or blockages as this will cause abnormal sounds.

• The maximum traverse length of drain pipe is 20 m. Provide support

brackets at intervals of 1.5 to 2 m where necessary to prevent movement.

• Install the combined piping as shown in the illustration.

• Do not create an air purge in the pipework,

as the water would leak from this point.

Heat

insulator

1.5m to 2m

1/100 or more

downward

Arched

shape

Trap

Support

bracket

NO

GOOD

• The hard vinyl-chloride pipe cannot be connected

• Adhesive agent cannot be used for the pipe

Connection of flexible hose

• Insert the soft socket of the supplied flexible hose

into the connecting port of the drain pipe.

• Align the supplied hose band to the pipe connecting

port end, and tighten.

• Fix the soft socket with the supplied hose

• The supplied flexible hose can bend up to

directly to the drain pipe connecting port of the indoor unit.

For connection with the drain pipe connecting port,

ensure that the supplied flexible hose is fitted.

connecting port (hard socket) on the indoor unit.

Be sure to use the supplied hose band for fixing,

otherwise there is a risk of damage or water

leakage from the drain pipe connecting port.

REQUIREMENT

band, tighten at the upper position of the

unit.

a maximum of 45°

Drain pipe connecting port

(Hard socket)

Attached hose band

Soft socket Hard socket

Adhesive agent prohibited

VP25 vinyl chloride pipe

(Procured locally)

Attached flexible hose

Socket for VP25

(Procured locally)

9

Page 13

Connection of drain pipe

Check the draining

• Connect the hard socket (Procured locally) to the

hard socket side of the supplied flexible hose which

has been installed.

• Connect the drain pipes (Procured locally) in turn to

the connected hard sockets.

REQUIREMENT

• Using a adhesive agent for vinyl chloride,

connect the hard vinyl chloride pipes so that

water does not leak.

• Allow sufficient time for the adhesive to set and

harden. (Refer to the instructions of the

adhesive.)

Drain up

When it is not possible to achieve a natural downward

slope on the drain pipe, you can create a vertical lift

(Drain up) on the pipe.

• Set the height of the drain pipe within 850 mm from

the bottom surface of the ceiling.

• The drain pipe should be piped from the drain pipe

connecting port horizontally for a maximum of

300 mm and then piped vertically.

• After piping the vertical lift, ensure the pipework is

set to a downward gradient.

After completion of drain piping,

Check water drains away and that no water leaks from

any of the connecting parts. At the same time check

for any abnormal sounds from the drain pump.

Ensure drainage is checked during cooling mode.

When the electric work has finished:

• Before installing the ceiling panel, pour water as

shown in the following figure, check water drains

from the drain pipe connecting port (Transparent) in

COOL mode and then check there are no water

leaks from the drain pipes.

When the electric work has not finished:

• Pull out the float switch connector (3P: Red) from

P.C. board connector (CN34: Red) of the electric

parts box. (Ensure the power is turned off.)

• Connect the single-phase 220-240V, 1N, 50Hz (or

220V, 1N, 60Hz) power to the terminal blocks R (L)

and S (N). (Never apply 220-240V to (A), (B), (U1)

and (U2).)

• Pour water referring to the figure.

(Amount: 1500 cc to 2000 cc)

• When the power is turned on, the drain pump motor

drives automatically. Check water is drained from

the drain pipe connecting port (Transparent), and

then check there is no water leak from the drain

pipes.

• After checking for water leaks on the drain, turn off

the power supply, and re-attach the float switch

connector to the original position (CN34) on the P.C.

board and refit the electric parts box.

Indoor unit

300mm

or less

Rising up

627.5mm or less

Rising up 850mm or less

Underneath of ceiling

10

CN34

(RED)

220–240V, 1N ~, 50Hz

220V 1N ~, 60Hz

R(L) S(N)

Red

Black

Pull out connector CN34 (Red) from P.C. board.

Black

White

Page 14

4

DRAIN PIPING WORK

Thermal insulating process

• After checking of the draining, using the supplied thermal insulation fit to the flexible hose leaving no clearance at

the connecting port of the indoor unit.

• Fit locally procured thermal insulation to the drain pipe leaving no clearance between the supplied insulation.

Flexible hose

Attached heat insulator

Hose band

Heat insulator to be

procured locally

Hard vinyl chloride pipe

CAUTION

Ensure water is poured slowly.

To reduce risk of water spreading throughout the

unit, resulting in a possible fault.

Air

discharge area

Drain pan

Check panel

Insert the leading part of the

hose between the heat

exchanger and the drain pan,

and then bend it downward.

Polyethylene hand pump for

pouring water in drain pan

Vessel

Water (1500cc to 2000cc)

11

Page 15

5

REFRIGERANT PIPING

WARNING

• If refrigerant gas leaks during the installation work, ventilate the room immediately.

• If the leaked refrigerant comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant does not leak.

• If refrigerant gas leaks into the room and flows near to a source of fire, noxious gas maybe generated.

REQUIREMENT

When using long lengths of refrigerant piping. Provide support brackets at intervals of 2.5 m to 3 m.

If the pipes are not fixed abnormal sounds maybe generated.

Ensure the supplied R410A flare nuts are used.

Permissible pipe length and permissible height difference

This differs depending on the outdoor units. For details, refer to the Installation Manual supplied with the outdoor

unit.

Piping material and dimensions

Piping material

Indoor unit capacity type MMU-

Pipe size (mm)

• Use new and clean pipe, ensuring that the pipes are not contaminated with dust, oil, moisture, etc.

Gas side

Liquid side

Phosphor deoxidization seamless pipe for air conditioner

0071 to 0121 type 0151 to 0181 type

Ø9.5 Ø12.7

Ø6.4 Ø6.4

Pipe flaring

Flaring

1. Cut the pipe with a pipe cutter.

• Flaring diam. meter size :

A (Unit : mm)

NO GOODOK

90˚

2. Place flare nut onto the pipe, and flare the pipe.

(Use the flare nut fitted to the unit or one that is

R410A compatible)

As the flaring sizes of R410A differ from that used

on R22. It is recommended to use a dedicated

R410A flaring tool. However a conventional flare

tool can be used, by adjustment of the projection of

the copper pipe.

Obliquity Roughness Warp

Outer diam. of copper pipe

6.4

9.5

12.7

15.9

In case of flaring for R410A with the conventional

*

flare tool, make a margin of 0.5 mm longer than that

of R22 pipe so that the flare size matches with the

specified size.

The copper pipe gauge is useful for adjusting the

projection margin size.

A

+0

A

- 0.4

R410A

9.1

13.2

16.6

19.7

12

Page 16

5

REFRIGERANT PIPING

• Projection margin in flaring :

B (Unit : mm)

Rigid (Clutch type)

Outer diam. of

copper pipe

6.4

9.5

12.7

15.9

R410A tool used

R410A R22

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

Imperial (Wing nut type)

Outer diam. of copper pipe

6.4

9.5

12.7

15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

2.0 to 2.5 1.5 to 2.0

Connection of refrigerant pipe

Connect all the refrigerant pipes with the flare

connection method

• As the unit is sealed to atmospheric pressure.

It is not abnormal that no “Push....” sound will be

heard upon the removal of the flare nut.

• Ensure use of two spanners for the connecting of the

pipework to the indoor unit.

B

Airtight test/Air purge, etc.

For carrying out airtight test, air purge, gas leak check

and addition of refrigerant refer to the Installation

Manual supplied with the outdoor unit.

Open fully valves of the outdoor unit

Gas leak check

Using a leak detector or soapy water, check for gas

leaks at the connecting pipework and the caps on the

service valves.

REQUIREMENT

Use a leak detector designed specifically for HFC

refrigerant (R410A, R134a, etc.).

Heat insulating process

Fit heat insulation to the gas and liquid pipes

separately.

During cooling mode, the temperature of the liquid and

the gas pipes are reduced. Therefore ensure sufficient

insulation is fitted to prevent dew condensation.

• On the gas side ensure that the heat insulation used

is heat resistant to a minimum temperature of 120°C

• Using the supplied heat insulation. Insulate the

interconnecting parts of the indoor unit, ensuring that

there is no exposure of any refrigerant pipework.

As detailed in the below illustration.

Work using double spanner

• Refer to the following table for tightening torque.

Connecting pipe

outer dia. (mm)

Ø6.4

Ø9.5

Ø12.7

Ø15.9

Tightening torque

(N•m)

14 to 18

(1.4 to 1.8 kgf•m)

33 to 42

(3.3 to 4.2 kgf•m)

50 to 62

(5.0 to 6.2 kgf•m)

68 to 82

(6.8 to 8.2 kgf•m)

Re-tightening

torque (N•m)

18

(1.8 kgf•m)

42

(4.2 kgf•m)

50

(5.0 kgf•m)

68

(6.8 kgf•m)

REQUIREMENT

Apply the thermal insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to

the outside causes water leak.)

Set notching upward.

Pipe side

Main unit

Attached heat insulating pipe

13

(Required at the site)

Page 17

6

ELECTRIC WORK

WARNING

1. Using the specified wires, ensure the wires are connected and securely fixed so that no

external force can transmit to the connecting part of the terminals.

Poor connection may cause risk of fire, etc.

2. Ensure connection of earth wire. (Grounding work)

Do not connect the earth wire to a gas pipe, mains water pipe, lightning rod, or the earth wire of a telephone.

Incorrect earthing will cause risk of an electric shock.

3. For electrical installation work, strictly follow the Local and national Regulations of each

country and the Installation Manual. A designated power supply must be used.

Capacity shortage of the power supply or incomplete installation may cause an electric shock or a fire.

CAUTION

Ensure an earth leakage breaker is installed.

Failure to install, may result in a electric shock.

REQUIREMENT

• For power supply wiring, strictly conform to the Local authorities in each country.

• For wiring of the power supply of the outdoor units, follow to the outdoor unit Installation Manual.

• Never connect 220–240V control wiring to the terminal blocks (U1, U2, U3, U4, U5, U6) fault will be. (Caused.)

• Arrange the electrical wiring so that they do not come into contact with high-temperature parts of the pipework;

this is to prevent the risk of insulation melting and causing a possible accident.

• After connecting wires to the terminal block. Secure wiring with cable clamp.

• Store wiring Install control wiring and refrigerant piping within the same line.

• Do not turn on power of the indoor unit until vacuuming of the refrigerant pipe has finished.

14

Page 18

6

ELECTRIC WORK

Power supply specifications

Power supply wiring and communication wiring are to be procured locally.

For the power supply specification, follow the table below. Ensure power supply is adequate. An insufficient power

supply could result in unit failure.

For specification of the power capacity of the outdoor unit and the power supply wires, refer to the Installation

Manual supplied with the outdoor unit.

220–240V, 1N ~ 50Hz

220V, 1N ~ 60Hz

(Up to 1000 m) Twist wire : 1.25 mm²

(Up to 2000 m) Twist wire : 2.00 mm²

(Up to 1000 m) Twist wire : 1.25 mm²

(Up to 2000 m) Twist wire : 2.00 mm²

Indoor unit power supply (*1)

Communication line

Power supply

Power supply switch/Earth leakage breaker or power supply wiring/fuse rating for indoor

units should be selected by the accommodated total current values of the indoor units.

Power supply wiring

Indoor/Outdoor inter-unit wiring (*2)

Central control line wiring (*3)

Remote controller wiring (*4)

20 m or less Twist wire : 2.0 mm²

50 m or less Twist wire : 3.5 mm²

Q’ty 2

Wire size

Q’ty 2

Wire size

Q’ty 2

Wire size Twist wire : 0.5 to 2.0 mm²

Indoor unit power supply (*1)

• Indoor unit power supply, must have a dedicated supply and be separate to that of the outdoor unit.

• Arrange the power supplies to the indoor and outdoor units, so that a common earth leakage breaker and main

switch can be used.

• Power supply cable specification : Cable 3-core 2.5 mm², in conformity with Design 60245 IEC 57.

Indoor/Outdoor inter-unit wiring, Central controller wiring (*2) (*3)

• Use a 2 core non polarity cable.

• To prevent any possible noise issues, use a shielded 2 core wire.

• The total stated length of communication wiring is determined by the interconnecting length of indoor to outdoor

cable plus the length of the central control communication cable.

Remote controller wiring (*4)

• For wiring remote controllers a 2 core polarity cable must be used.

CAUTION

Remote controller wiring, remote

controller inter-unit wiring

Total wire length of remote controller

wiring and remote controller inter-unit

wiring = L + L1 + L2 + … Ln

Total wire length of remote controller inter-unit wiring = L1 + L2 + … Ln

Indoor unit

Remote

controller

wiring

Remote

controller

Twist wire: 0.5mm

In case of wired type only

In case of wireless type included

Indoor unit

L1 L2 Ln

Remote controller inter-unit wiring

2

to 2.0 mm2 × 2

Indoor unit Indoor unit

Up to 500 m

Up to 400 m

Up to 200 m

(Max. 8 units)

The remote controller wire

(Communication line) and AC220–

240V (Power supply) wires cannot

be parallel to contact each other

and cannot be stored in the same

conduits. If doing so, a trouble

may be caused on the control

system due to noise, etc.

15

Page 19

Cable connection

REQUIREMENT

• Be sure to locate the cable through the cable connection port of the indoor unit.

• Ensure additional wire length of approximately 100 mm at the indoor unit electric parts box.

This is to enable ease of any service work in the future.

• The low-voltage circuit is provided for the remote controller.

• Remove the cover of the electric parts box by removing the mounting screws (3 off) and push the hooking section.

(The cover of the electric parts box remains hanged to the hinge.)

• Tighten the screws on the terminal block and secure the cables with cord clamp fitted to the electric parts box.

(Do not apply tension to the connecting section of the terminal block.)

• Using the supplied thermal insulation for the sealing of the cable connecting port, seal the cable connecting port.

(Otherwise dew condensation may be caused.)

• Mount the cover of the electric parts box ensuring the cables are not pinched.

(Mount the cover after the ceiling panel has been wired to the electric box.)

Screws

P.C. board

Indoor/Outdoor

inter-unit cable/

Remote controller

terminal block

Cord clamp Heat insulator B

Hooking section

U1U2A B

Power supply

terminal block

R(L) S(N)

Screw

10

70

Earth line

Connecting

cord

Electric parts box

Cover of electric parts box

Thermal insulation to cabling connecting port

S

R

(N)

(L)

10

50

Adhered surface

Heat insulator A

Notched section

16

Page 20

6

Cord Clamp

5P connector (White)

Wire from ceiling panel

ELECTRIC WORK

Remote controller wiring

• Strip approximately 14 mm of insulation off of the connecting wires.

• As the remote controller wire has no polarity, there is no problem if connections to indoor unit terminal blocks A

and B are reversed.

Wiring diagram

Terminal block for remote controller

wiring of indoor unit

Terminal block

A

B

Remote controller wire (Field supply)

Wiring between indoor and outdoor units

Outdoor power supply

Earth

Indoor unit

Earth

LN

Header outdoor unit

U1U1U3 U4 U5U6

Control wiring between indoor and outdoor units

Control wiring between indoor units

U2U1 A B

Outdoor power supply

Earth

Control wiring between outdoor units

Indoor unit

Earth

LN U2U1 A B

Follower outdoor unit

U1U1U3 U4 U5U6

Indoor unit

U2U1 A B

A

Remote

B

controller unit

NOTE

A outdoor unit that is

inter-connected to the

indoor units automatically

becomes the header unit.

Connection of shield wire closed terminal

Indoor unit

Earth

LN U2U1 A B

Earth

LN

BA

Indoor power supply

220-240V, 1N ~5Hz

220V, 1N ~60Hz

Earth leakage

breaker

Power switch

Pull box

Remote

controller

Pull box

Address setup

Set up the addresses as per the Installation Manual

supplied with the outdoor unit.

Wiring on the ceiling panel

As per the Installation Manual of the ceiling panel,

connect the connector (2P: Red) of the ceiling panel to

the connector (5P: White) onto the P.C. board within

the electric parts box.

Remote

controller

17

BA

Remote controller

Pull box

BA

[Group control]

Page 21

7

T

T

T

T

T

T

APPLICABLE CONTROLS

NOTIFICATION

When using the equipment for the first time, the remote controller will not accept any commands for a short

period of time.

• Automatic address

• While automatic addressing no operations can be performed on the remote control.

• Automatic addressing will take a maximum duration of 10 minutes (generally 5 minutes).

• Upon turning on the unit after completion of automatic addressing, a maximum period of

10 minutes (generally 3 minutes) are required prior to the start up operation of the outdoor unit.

All indoor units are shipped from factory as standard. Change if necessary.

To change the setup use the main remote controller (wired remote controller).

* The setup change for wireless remote controller, sub remote controller or a unit without a controller (Centrally

controlled.) is not possible. In such cases, temporarily install a separate main remote controller.

Applicable control setup

Basic operation procedure for setup change

Change the setup while operation of the equipment is stopped.

(Be sure to stop the operation of a set.)

Procedure

1

2

Push the

as shown in the figure.

Check that the displayed item code is [10].

• If the item code indicates any characters other than [10], push the

button to erase the display and retry the operation from the first step.

(For some time after the

of the remote controller cannot be accepted.)

(In a group control, the firstly displayed

indoor unit No. becomes the center unit.)

Each time the

Select the indoor unit that requires a change to the setup.

During this time the indoor unit that is selected can be

confirmed as the louver and fan will be operated.

Using

SET

, CL and

TEMP.

the buttons, select the item code [**].

TES

buttons simultaneously for 4 seconds or more, after a while, the display part flashes

TES

button has been pushed, the operation

UNIT

button is pressed, the indoor unit No. in the group control is displayed consecutively.

Description

3

TIME

buttons, select set data [

SET

button. During this time, if the display changes from flashing to permanently on, the setup is

CL

button clears the set up contents which has been set. In this case, restart from Procedure 2.

TES

TES

button deletes the display and returns the status to the

TES

button. (The setup is configured.)

button has been pushed, the remote

****

].

4

5

6

Using the

Push the

complete.

• To change the setup of an indoor unit that is not selected, restart operation from Procedure 2.

• To change to a different setup within the selected indoor unit, restart operation from Procedure

Pushing the

When the setup is finished, push the

Pushing the

normal stopped status.

(For a period of time after the

controller will not accept any commands.)

6

1

6

CODE No.

UNIT No.

R.C. No.

TEMP.

TIMER SET

FILTER

TEST

RESET

TES

(* The display changes according

to the indoor unit model.)

∗

∗∗

SWING/FIXTIME

SETTING

ON / OFF

FAN

MODE

VENT

UNITSET CL

UNIT No.

R.C. No.

UNIT No.

∗∗∗∗∗

∗

R.C. No.

3

3

2

5

CODE No.

CODE No.

∗∗

.

18

Page 22

7

APPLICABLE CONTROLS

In case of installation to high ceiling

When the unit is to be installed at a height that exceeds the standard value, adjustment to the air volume is

necessary.

• For the operation procedure, refer to the item “To incorporate a filter sold separately”.

• For the “Setup data” in Procedure 4 , select from the “Installable ceiling height list”.

In case of remote controller-less (Group control)

To set the unit to high ceiling operation, there is a method that requires the changing of the short plugs on the indoor

P.C. board. The details are shown in the below table.

This method is only to be used where a standard wired remote controller (Group control) is not used.

∗ Upon changing the high ceiling setting

• Select setting by the changing of the short plugs

on the indoor P.C. board.

Short plug position

Short

CN112 CN111 CN110

CN112 CN111 CN110

CN112 CN111 CN110

Open

Set

data

0000

0002

0003

Filter sold separately

Standard filter (At shipment)

High ceiling (2)

High ceiling (3)

• Short plug position

(CN112, CN111, CN110 from the left)

19

Page 23

Change of lighting time of filter sign

Group control

Depending on the conditions of the installation, the

time period of the filter clean sign can be changed.

Follow to the basic operation procedure

(1 → 2 → 3 → 4 → 5 → 6 ).

• For the item code in Procedure 3 , specify [01].

• For the [Set data] in Procedure 4 , select the setup

data of filter sign lighting time from the following

table.

Setup data

0000

0001

0002

0003

0004

Filter sign lighting time

None

150H

2500H (At shipment from factory)

5000H

10000H

Increased heating effect

In a group control, a remote controller can control up

to a maximum of 8 units.

• For cabling procedure and cables of the individual

line (Identical refrigerant line) system, refer to

“Electric work” in this Manual.

• Wiring between indoor units in a group is performed

in the following method.

Connect the indoor units by connecting the remote

ontroller inter-unit cables from the remote controller

terminal blocks (A, B) of the indoor unit connected

with a remote controller to the remote controller

terminal blocks (A, B) of the other indoor unit.

(No polarity)

• For address setup, refer to the Installation Manual

supplied with the outdoor unit.

If it is not possible to achieve satisfactory heating due

to the installation environment or the structure of the

room. The detected temperature can be increased.

Also use a circulator, etc to circulate hot air near the

ceiling.

Follow to the basic operation procedure

(1 → 2 → 3 → 4 → 5 → 6 ).

• For the item code in Procedure 3 , specify [06].

• For the set data in Procedure 4 , select the setup

data of the required temperature shift value from the

below table.

Setup data

0000

0001

0002

0003

0004

0005

0006

Detection temp shift value

No shift

+1°C

+2°C (At shipment from factory)

+3°C

+4°C

+5°C

+6°C

20

Page 24

8

T

T

TEST RUN

Before test operation

• Before turning on the power supply, carry out the following

procedures.

1) Using 500V-megger, check there is 1MΩ or more between the

terminal block of the power supply and the earth.

If 1MΩ or less is detected, do not run the unit.

2) Check that all the valves of the outdoor unit are fully opened.

• Never push the electromagnetic contactor to carry out a forced test operation.

(It is very dangerous because a protective device does not work.)

To protect the compressor at

startup. Ensure the power supply

is left on for 12 or more hours

before operation.

WARNING

How to execute test operation

• To carry out a fan operation in a single indoor unit, firstly turn off the power supply to the unit. Then short CN72

found on the P.C. board. Once completed turn the power to the unit back on and start the unit in FAN only mode.

Upon completion of the test do not forget to remove the short circuit on CN72.

• Using the remote controller, check the unit is in normal operation. For the operation procedure, refer to the

supplied Owner’s Manual. A forced test operation can be executed in the following procedure under the condition

of thermo.-OFF of room temperature.

In order to prevent the test operation from running continuously, the operation will cease after a period of

60 minutes. The unit will then return back to its original operation.

NOTE

Do not use a forced operation in cases other

than test operation because it applies an

excessive load onto the air conditioner.

In case of wired remote controller

Procedure

TES

button pushed down for 4 seconds or more.

ON / OFF

MODE

button.

button, select the operation mode, [COOL] or [HEAT].

1

2

3

Keep the

[TEST] is displayed on the display part and the selection of the test mode is

permitted.

Push

Using

• Do not run the air conditioner in a mode other than [COOL] or [HEAT].

• The temperature controlling function will not work during the test operation.

• Fault detection will perform as usual.

1, 5

Description

FILTER

RESET

TEMP.

TEST

TIMER SET

ON / OFF

2, 4

FAN

SWING/FIXTIME

UNITSET CL

TEST

MODE

VENT

3

ON / OFF

button to stop the operation.

4

5

After the test operation, push the

(Display part is the same as procedure 1 )

Push the

([TEST] disappears on the display part and the status returns to a normal.)

TES

button to cancel (release from) the test operation mode.

21

Page 25

In case of wireless remote controller

Procedure

1

2

3

4

Description

Remove a small screw which fixes the nameplate of the receiver unit.

Remove the nameplate of the sensor section by inserting a minus screwdriver, etc into the notch at the bottom

of the plate, and set the Dip switch to [TEST RUN ON].

Execute a test operation with button on the wireless remote controller.

• , , and LED flash during test operation.

• Under status of [TEST RUN ON], the temperature adjustment from the wireless remote controller is invalid.

Do not use this method in the operation other than test operation because the equipment is damaged.

Use either COOL or HEAT operation mode for a test operation.

* The outdoor unit does not operate approx. 3 minutes after power-ON and operation stop.

After the test operation finished, stop the air conditioner from the wireless remote controller, and return Dip

switch of the receiver section as before.

(A 60-minutes timer clearing function is attached to the receiver section in order to prevent a continuous test

operation.)

Small screw

Receiver unit

M4 × 25 screw

(2 pieces)

Notch

Nameplate

Spacer

N

22

E

Page 26

9

3

2

1

ON / OFF

FAN

TEMP.

SWING/FIXTIME

MODE

VENT

UNITSET CL

FILTER

RESET

TEST

TIMER SET

T

T

CODE No.

UNIT No.

R.C. No.

TROUBLESHOOTING

Confirmation and check

When a fault occurs in the air conditioner, the check

code and the indoor unit No. will appear on the display

part of the remote controller.

The check code will only be displayed while the unit is

in operation.

If the display disappears, operate the air conditioner

according to the following “Confirmation of error

history” for confirmation.

Confirmation of error history

When a fault occurs in the air conditioner, the error

history can be confirmed with the following procedure.

(The error history is stored in memory and can contain

up to 4 errors).

This history can be confirmed from either the operating

status the or the stop status.

CODE No.

UNIT No.

R.C. No.

Check code Indoor unit No. in which

an error occurred

Procedure

1

2

3

Description

When pushing the

or more, the display similar to the one shown in the figure to the right

will appear.

If [Service Check] is displayed, the fault code will be stored in the

error history mode.

• 01 (Order of error history) is displayed in CODE No. window.

• Check Code is displayed in the CHECK window.

• The indoor unit address, where the fault has occurred will be

displayed in the UNIT No. window.

When pushing the

chronological order.

The numbers displayed within the CODE No. window can vary between 1 and 4. 1 being the most recent fault

and 4 being the oldest.

CAUTION

Do not push the CL button as this will erase all of the error history for that indoor unit.

After confirmation, push the

SET

TES

and

TEMP.

buttons simultaneously for 4 seconds

buttons, the error history stored within the memory will be displayed in

TES

button. This will return the display back to its original mode.

23

Page 27

Check method

On the remote controller (Main remote controller, Central control remote controller) and the interface P.C. board of

the outdoor unit, a check display LCD (Remote controller) or 7-segment display (on the outdoor interface P.C.

board) operation is provided. Therefore the operation status can be known. Using this self-diagnosis function, a fault

and the location of this fault within the air conditioning system can be located, as shown in the table below.

Check code list

The following list shows each check code. Find the check contents from the list according to part to be checked.

• In case of a fault from the indoor remote controller: See “Main remote controller display” in the list.

• In case of a fault from the outdoor unit: See “Outdoor 7-segment display” in the list.

• In case of a fault from the indoor unit with a wireless remote controller:

See “Sensor block display of receiving unit” in the list.

Terminology

Check code Wireless remote cont rolle r

Main

remote

controller

display

E01 —— —

E02 —— —

E03 —— 97

E04 —— 04

E06 E06

— E07 ——

E08 E08 Duplicated indoor addresse s 96

E09 —— 99

E10 —— CF

E12 E12

E15 E15 — 42

E16 E16

E18 —— 97, 99

E19 E19

E20 E20

E23 E23 — 15

E25 E25 — 15

E26 E26

E28 E28 Detected outdoor un it nu mber d2

E31 E31

Outdoor 7-segment display

Auxiliary code

No. of indoor uni ts i n wh ich

sensor has been nor mally

received

01: Indoor/Outdoor

communication

02: Communication between

outdoor units

00: Capacity over

01 ~: No. of connected units

00: Header is nothing

02: Two or more header units

01: Outdoor of other line

connected

02: Indoor of other line

connected

No. of outdoor uni ts whi ch

received signal normal ly

01: IPDU1 error

02: IPDU2 error

03: IPDU1, 2 error

04: Fan IPDU error

05: IPDU + Fan IPDU error

06: IPDU2 + Fan IPDU error

07: All IPDU error

AI-NET central

control display

04

42

89

96

42

15

CF

Operation

AI-NET : Artificial Intelligence.

IPDU : Intelligent Power Drive Unit

¡ : Lighting,

ALT. : Flashing is alternately when there are two flashing LED.

SIM : Simultaneous flashing when there are two flashing LED.

Sensor block display

of receiving unit

Timer Ready Flash

ll

¤

ll

¤

ll

¤

ll

ll

ll

¤

¤

¤

¤

ll

ll

¤

ll

ll

ll

ll

ll

ll

ll

¤

¤

¤

ll

ll

ll

ll

¤

¤

ll

¤

¤

¤

¤

¤

¤

¤

: Flashing, l : Goes off

¤

Check code name Judging device

Communication error between indo or and remote

controller (Detected at re mote co ntr ol ler s i de)

Remote controller transmission error Remote controller

Communication error between indo or and remote

controller (Detected at indoor si de)

Communication circu it err or b etw een indo or/o utdo or

(Detected at indoo r sid e)

Decrease of No. of indoor units I/F

Communication circu it err or b etw een indo or/o utdo or

(Detected at outdoor s id e)

Duplicated indoor addresse s Indoor / I/F

Duplicated main remote contro llers Remote controller

Communication error between indo or MCU Indoor

Automatic address s tar t er ror I/F

Indoor is noth ing dur ing au to matic a ddre s sin g I/F

Capacity over / No. of connec ted indoor unit s I/F

Communication error between indo or units Indoor

Outdoor header units qua nt ity error I/F

Other line connected during automati c addre ss I/F

Sending error in co mmuni cation be tween ou tdoor un it s I/F

Duplicated fol lower o utd oor addr esses I/F

Decrease of No. of connected outd oor uni ts I/F

Follower outdoor un it err or I/F

IPDU communication erro r I/F

Remote controller

Indoor

Indoor

I/F

24

Page 28

9

y

TROUBLESHOOTING

Check code Wireless remote cont rolle r

Main

remote

controller

display

F01 —— 0F

F02 —— 0d

F03 —— 93

F04 F04 — 19

F05 F05 — A1

F06 F06 — 18

F07 F07 — 18

F08 F08 — 1b

F10 —— OC

F12 F12 — A2

F13 F13

F15 F15 — 18

F16 F16 — 43

F23 F23 — 43

F24 F24 — 43

F29 —— 12

F31 F31 — 1C

H01 H01

H02 H02

H03 H03

H04 H04 — 44

H06 H06 — 20

H07 H07 — d7

H08 H08

H14 H14

H16 H16

L03 —— 96

L04 L04 — 96

L05 —— 96

L06 L06 No. of indoor units with priority 96

L07 —— 99

L08 L08 — 99

L09 —— 46

L10 L10 — 88

L20 L20 — 98

L28 L28 — 46

L29 L29

L30 L30 Detected indoor address b6

— L31 ———Extended I/C error I/F

Outdoor 7-segment display

Auxiliary code

01: Comp. 1 side

02: Comp. 2 side

01: Comp. 1 side

02: Comp. 2 side

01: Comp. 1 side

02: Comp. 2 side

01: Comp. 1 side

02: Comp. 2 side

01: TK1 sensor error

02: TK2 sensor error

03: TK3 sensor error

04: TK4 sensor error

—

01: TK1 oil circuit system error

02: TK2 oil circuit system error

03: TK3 oil circuit system error

04: TK4 oil circuit system error

01: IPDU1 error

02: IPDU2 error

03: IPDU3 error

04: Fan IPDU error

05: IPDU1 + Fan IPDU error

06: IPDU2 + Fan IPDU error

07: All IPDU error

AI-NET central

control display

43

IF

1d

17

d4

44

d7

CF

Sensor block display

of receiving unit

Timer Ready Flash

Operation

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

¡

¤

l

¤

l

¤

l

¤

l

¤

l

¤

¡

¤

¡

¤

¡

¤

¡

¤

¡

¤

Check code name Judging device

ALT Indoor TCJ sensor error Indoor

l

ALT Indoor TC2 sensor error Indoor

l

ALT Indoor TC1 sensor error Indoor

l

AL T TD1 sensor error I/F

¡

AL T TD2 sensor error I/F

¡

ALT TE1 sensor error I/F

¡

ALT TL sensor error I/F

¡

ALT TO sensor error I/F

¡

ALT Indoor TA se nso r er ror Indoor

l

ALT TS1 sensor error I/F

¡

ALT TH sensor error I PDU

¡

AL T Outdoor temp. sensor miscabling (TE, TL) I/F

¡

AL T Outdoor pressure sensor miscabling (Pd, Ps) I/F

¡

ALT Ps sensor error I/F

¡

ALT Pd sensor error I/F

¡

SIM Indoor other error Indoor

l

SIM Indoor EEPROM error I/F

¡

l

l

l

l

l

l

l

l

l

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

Compressor break down IPDU

Magnet switch error

Overcurrent relay opera tion

Compressor trouble (loc k)

Current detect circu it sy ste m err or IPDU

Comp 1 case ther mo op era tion I/F

Low pressure protective oper ation I/F

Oil level down de tec tive pro tec t ion I/F

Oil leve l de te ct ive t e mp sen sor error I/F

Comp 2 case ther mo op era tion I/F

Oil leve l de te ct ive c ir cuit error

Magnet switch error

Overcurrent relay opera tion

SIM Indoor center unit duplicated Indoor

SIM Outdoor line address duplicated I/F

Duplicated indoor un its with priority

SIM

(Displayed in indo or u ni t w ith pr iority)

Duplicated indoor un its with priority

SIM

(Displayed in uni t o ther th an in door un it w i th p ri ority )

SIM Group line in individual indoor unit I ndoor

SIM Indoor group/Address unset Indoor , I /F

SIM Indoor capacity unset Indoor

SIM Outdoor capacity unset I/F

SIM Duplicated central control addresses AI-NET , Indo or

SIM Over No. of connected outdoor uni ts I/F

SIM No. of IPDU error I/F

SIM Indoor outside interlock Indoor

MG-SW

Overcurrent rela

IPDU

I/F

MG-SW

Overcurrent relay

I/F

I/F

25

Page 29

Check code Wireless remote cont rolle r

g

Main

remote

controller

display

P01 —— 11

P03 P03 — 1E

P04 P04

P05 P05

P07 P07

P10 P10 Detected indoor addres s Ob

P12 —— 11

P13 P13 — 47

P15 P15

P17 P17 — bb

P19 P19 Detected outdoor un it nu mber O8

P20 P20 — 22

P22 P22

P26 P26

P29 P29

P31 P31 — 47

—— — b7 By alarm devi ce ALT Error in indoor group AI-NET

—— — 97 — AI-NET communication system error AI-NET

—— — 99 — Duplicated network adapters AI-NET

Outdoor 7-segment display

Auxiliary code

01: Comp. 1 side

02: Comp. 2 side

01: Phase-missing detection

02: Phase error

01: Comp. 1 side

02: Comp. 2 side

01: TS condition

02: TD condition

0[: IGBT short

: Fan motor position

1

[

detective circu it err or

3[: Fan motor trouble

: TH sensor temp. error

C

[

(Heat sink overheat)

D[: TH sensor error

E

: Vdc output error

[

01: Comp. 1 side

02: Comp. 2 side

01: Comp. 1 side

02: Comp. 2 side

AI-NET central

control display

21

AF

IC

AE

1A

14

16

Sensor block display

of receiving unit

Timer Ready Flash

Operation

l

¤¤

l

¤

l

¤

l

¤

l

¤

l

¤¤

l

¤¤

l

¤¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

l

¤

Check code name Judging device

ALT Indoor fan motor error Indoor

AL T Discharge temp. TD1 error I/F

¤

ALT High-pressure SW syste m opera t ion IPDU

¤

ALT Phase-missing detection /Phas e e rror I/F

¤

ALT Heat sink overheat error IPDU, I/F

¤

ALT Indoor overflow error Indoor

ALT Indoor fan motor error Indoor

ALT Outdoor liquid back detection error I/F

ALT Gas leak detection I/F

¤

AL T Discharge temp. TD2 error I/F

¤

ALT 4-way valve inverse error I/F

¤

ALT High-pressure protective opera tio n I/F

¤

ALT Outdoor fan IPDU error IP DU

¤

ALT G-TR short protection error IPDU

¤

ALT Comp position detective circuit system error IPDU

¤

ALT Other indoor unit error (G roup te r minal u nit error) Indoor

¤

Error detected by TCC-LINK central control device

Check code Wireless remote cont rolle r

Central

control

device

indication

C05 —— — —

C06 —— — —

C12 —— — —

P30

Outdoor 7-segment display

Auxiliary code

Differs accor din g to error c ont ent s o f unit w ith oc cur ren ce o f al ar m Group control bra nch ing un i t er ror

—— (L20 is displayed.) Duplicated central con trol addres ses

AI-NET central

control display

Sensor block display

of receiving unit

Timer Ready Flash

Operation

Terminology

TCC-LINK : TOSHIBA Carriea Cominication Link.

26