Toshiba MMK-AP0073H, MMK-AP0073H-C, MMK-AP0093H, MMK-AP0093H-C, MMK-AP0123H INSTALLATION MANUAL

...

SUPER MODULAR MULTI SYSTEM AIR CONDITIONER

Installation Manual

Indoor Unit

Model name:

Для коммерческого использования

For commercial use

Pour usage commercial

Nur für gewerbliche Nutzung

Per uso commerciale

Para uso comercial

Para uso comercial

Voor commercieel gebruik

Για εμπορική χρήδη

Ticari amaçlý kullaným için

High-Wall Type

MMK-AP0073H, MMK-AP0073H-C

MMK-AP0093H, MMK-AP0093H-C

MMK-AP0123H, MMK-AP0123H-C

MMK-AP0153H, MMK-AP0153H-C

MMK-AP0183H, MMK-AP0183H-C

MMK-AP0243H, MMK-AP0243H-C

Installation Manual 1

Manuel d’installation 31

Installations-handbuch 61

Manuale di installazione 91

Manual de instalación 121

Manual de Instalação 151

Installatiehandleiding 181

Εγχειρίδιο εγκατάστασης 211

Руководство по установке 241

English

Français

Deutsch

Italiano

Español

Português

Nederlands

Ελληνικά

Русский

Montaj Kılavuzu 271

301

Türkçe

SMMS High-Wall Type

Please read this Installation Manual carefully before installing the Air Conditioner.

• This Manual describes the installation method of the indoor unit.

• For installation of the outdoor unit, follow the Installation Manual attached to the outdoor unit.

Installation Manual

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the

conventional refrigerant R22 in order to prevent destruction of the ozone layer.

Contents

1 ACCESSORY PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 PRECAUTIONS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 SELECTION OF INSTALLATION PLACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 INSTALLATION OF INDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 CUTTING A HOLE AND MOUNTING INSTALLATION PLATE . . . . . . . . . . . . . . 8

6 PIPING AND DRAIN HOSE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 INDOOR UNIT FIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 DRAINAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 REFRIGERANT PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

10 ELECTRIC WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11 APPLICABLE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

12 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

13 TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-EN

–1–

SMMS High-Wall Type

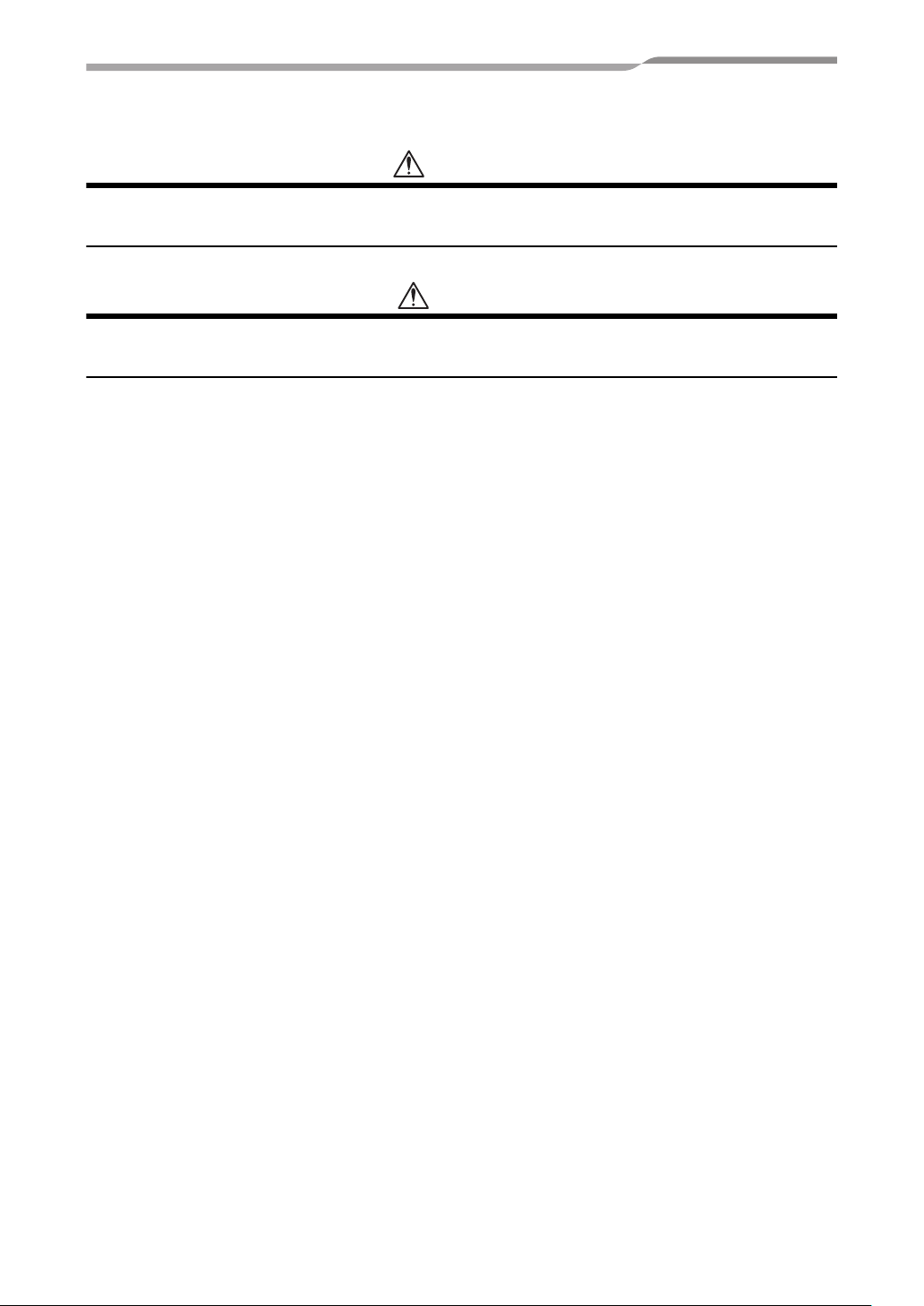

1 ACCESSORY PARTS

Accessory parts

Part name Q’ty Shape

Installation plate 1

Wireless remote controller 1

Battery 2

Remote control holder 1

Mounting screw Ø4 × 25 6

Installation Manual

Pan head wood screw Ø3.1 × 16 2

Screw Ø4 × 10 2

Heat insulator 1

<Others>

Name

Owner’s manual

Installation manual

EN

–2–

2-EN

SMMS High-Wall Type

Installation Manual

2 PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety.

Observe them without fail.

• After the installation work, perform a trial operation (test run) to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install (including moving)/

maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone

wires.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Install the refrigerant pipe securely during the installation work before operating the air

conditioner.

If the air conditioner is operated with the valve open and without the refrigerant pipe, the compressor

sucks air and the refrigeration cycle is over pressurized, which may cause a burst or injury.

• When moving the air conditioner for the installation into another place, be very careful not to

enter any gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes

abnormally high and it resultingly causes pipe burst and injuries on persons.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure

that the concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight

adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas

might generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix.

To prevent external forces applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

3-EN

–3–

SMMS High-Wall Type

• For the refrigerant recovery work (collection of refrigerant from the pipe to the compressor),

stop the compressor before disconnecting the refrigerant pipe.

If the refrigerant pipe is disconnected while the compressor is working with the valve open, the

compressor sucks air and the refrigeration cycle is over pressurized, which may cause a burst or injury.

Installation Manual

CAUTION

New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

• The characteristics of R410A refrigerant are; easy to absorb water, oxidizing membrane or oil, and its

pressure is approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant,

refrigerating oil has also been changed. Therefore, during installation work, be sure that water, dust,

former refrigerant, or refrigerating oil does not enter the refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of

charging port of the main unit and installation tools are changed from those for the conventional

refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or

dust does not enter.

To Disconnect the Appliance from Main Power Supply.

• This appliance must be connected to the main power supply by means of a switch with a contact

separation of at least 3 mm.

• The installation fuse must be used for the power supply line of this conditioner.

• Tighten the flare nut with a torque wrench in the specified manner.

Excessive tightening of the flare nut may cause a crack in the flare nut after a long period, which may

result in refrigerant leakage.

• Wear heavy gloves and a long sleeve shirt during the installation work to avoid injury.

EN

–4–

4-EN

SMMS High-Wall Type

Installation Manual

3 SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner at enough strong place to withstand the weight of the unit.

If the strength is not enough, the unit may fall down resulting in injury.

CAUTION

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks and stays around the unit, a fire may occur.

Upon approval of the customer, install the air conditioner in a place that satisfies the

following conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be ensured for safety maintenance and check.

• Place where drained water will not cause any problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide

gas (hot spring).

(Should the unit be used in these places, special protective measures are needed.)

• A restaurant kitchen where a lot of oil is used or place near machines in a factory (Oil adhering to the

heat exchanger and resin part (cross flow fan) in the indoor unit may reduce the performance, generate

mist or dew drop, or deform or damage resin parts.)

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into the window of the neighbour house. (Outdoor unit)

• Place where noise of the outdoor unit is easily transmitted.

(When install the outdoor unit on the boundary with the neighbour, pay due attention to the level of noise.)

• Place with poor ventilation.

• Do not use the air conditioner for special purposes such as preserving food, precision instruments, or art

objects, or where breeding animals or growing plants are kept. (This may degrade the quality of

preserved materials.)

• Place where any of high-frequency appliances (including inverter devices, private power generators,

medical equipment, and communication equipment) and inverter-type fluorescent light is installed.

(A malfunction of the air conditioner, abnormal control, or problems due to noise to such appliances/

equipment may occur.)

• When the wireless remote controller is used in a room equipped with an inverter-type fluorescent light or

at a place exposed to direct sunlight, signals from the remote controller may not be received correctly.

• Place where organic solvent is used.

• Place near a door or window exposed to humid outside air (Dew dropping may form.).

• Place where special spray is used frequently.

5-EN

–5–

SMMS High-Wall Type

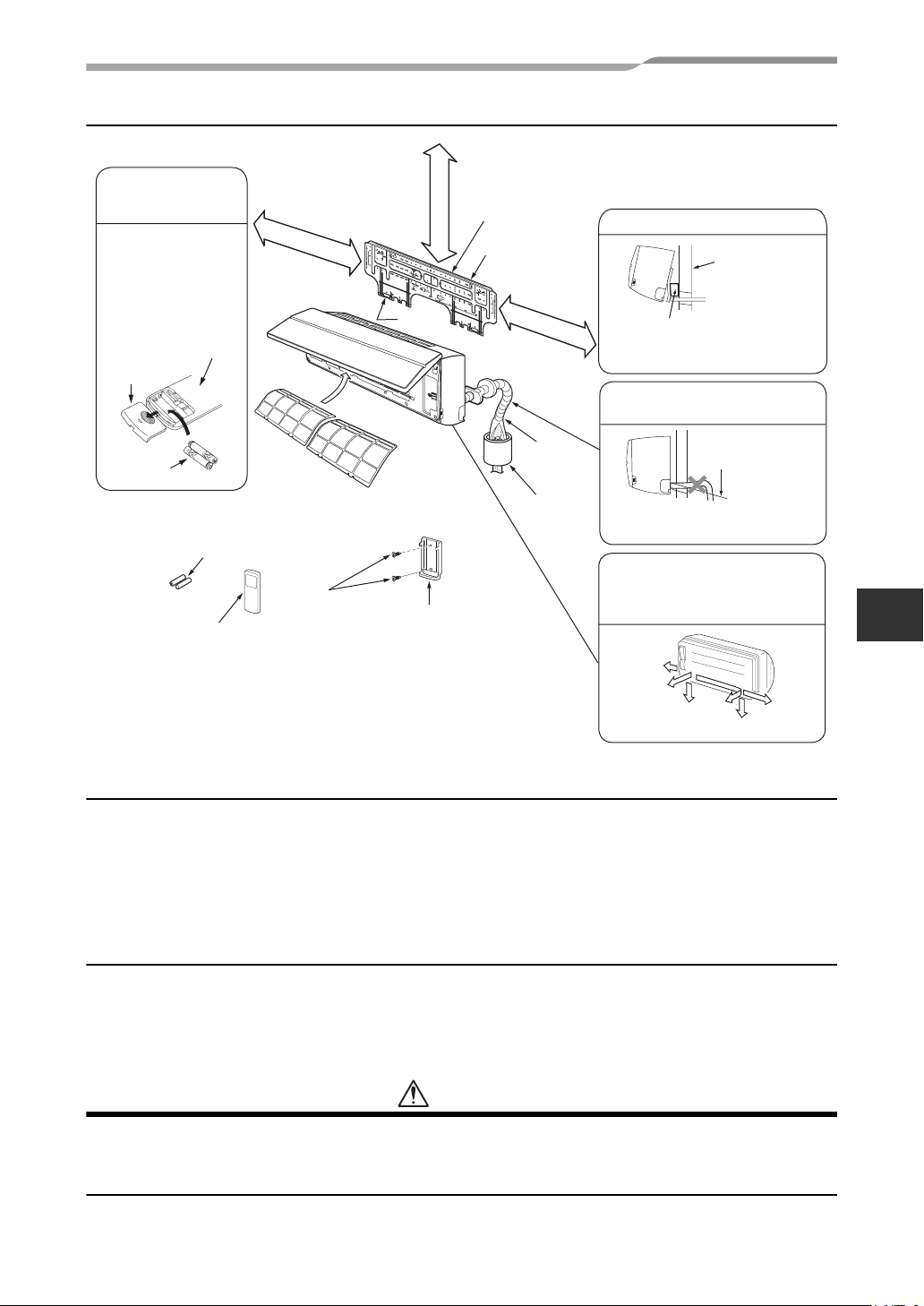

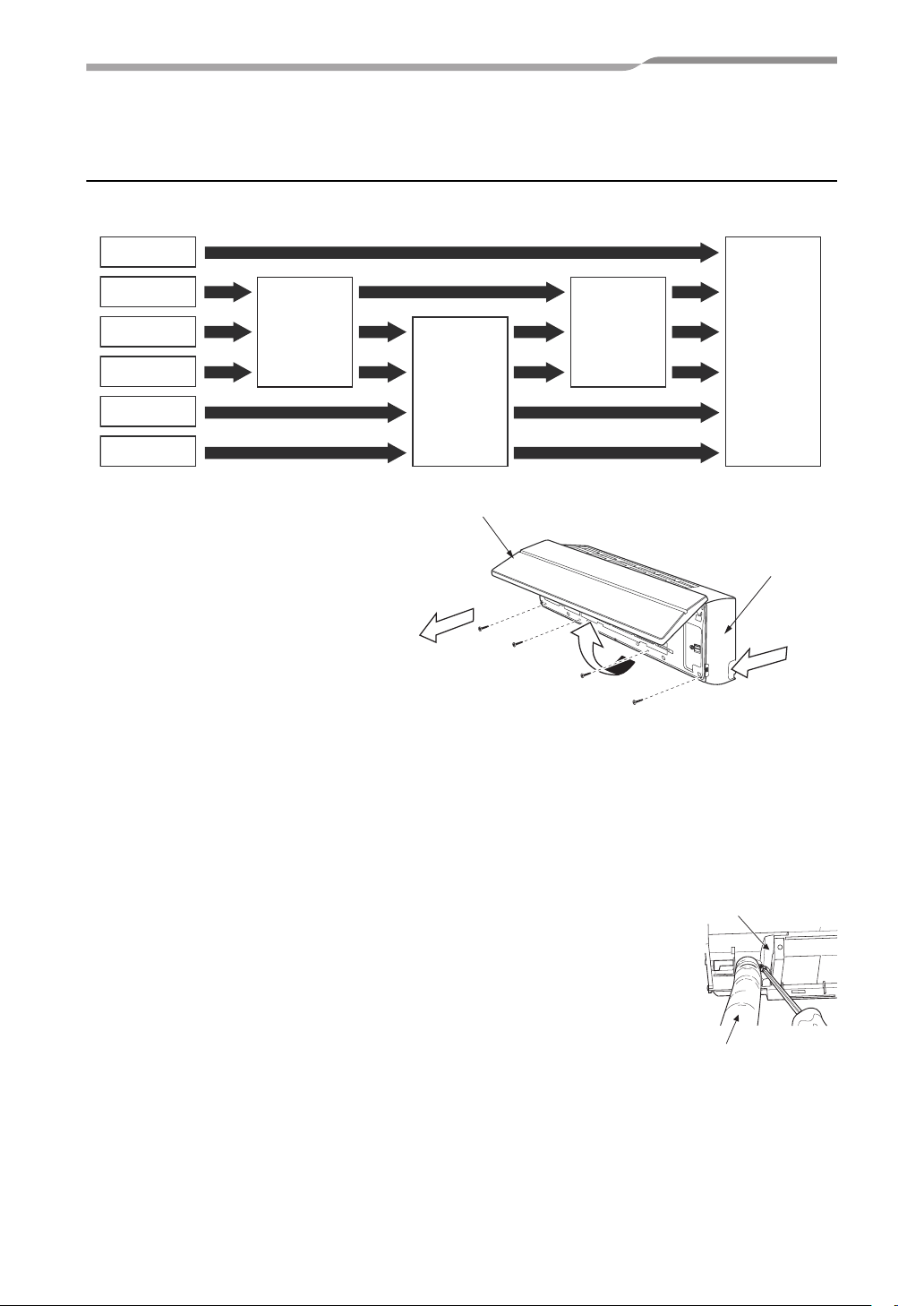

Installation diagram of Indoor and outdoor units

Before installing the

wireless remote

controller

1.Remove the battery

cover.

2.Insert 2 new

batteries (R03 [AAA]

type) following the

(+) and (–) positions.

Wireless

remote controller

Cover

A

C

L

Batteries

Batteries

Wireless remote

control

8

5

0

m

m

(

A

tta

c

h

to

th

Pan head wood

screw

*

2

o

r

m

o

r

e

*1

Hook

A

i

r

f

i

l

t

e

r

e

fr

o

nt

pa

n

e

l

.)

Remote control

holder

Hook

Installation plate

110mm or more

1

7

0

m

m

o

r

m

Shield pipe

Heat

insulator

o

r

e

Installation Manual

For the rear left and left piping

Wall

Insert the cushion between the

indoor unit and wall, and tilt the

indoor unit for better operation.

Do not allow the drain hose to get

slack.

Cut the piping hole

sloped slightly.

Make sure to run the drain hose

sloped downward.

The auxiliary piping can be

connected to the left, rear left, rear

right, right, bottom right or bottom

left.

Right

Rear right

Bottom right

Rear left

Bottom left

Left

EN

Installation space

The indoor unit shall be installed so that its top surface comes at a height of 2m or more.

Also it must be avoided to put anything on top of the indoor unit.

*1 Reserve space required to install the indoor unit and for service work.

Keep 110mm or more for clearance between top plate of the indoor unit and the ceiling surface.

*2 Provide a space as shown for service clearance for the cross flow fan.

Installation place

• A place which provides the spaces around the indoor unit as shown in the above diagram.

• A place where there is no obstacle near the air inlet and outlet.

• A place that allows easy installation of the piping to the outdoor unit.

• A place which allows the front panel to be opened.

CAUTION

• Direct sunlight to the indoor unit’ s wireless receiver should be avoided.

• The microprocessor in the indoor unit should not be too close to RF noise sources.

(For details, see the owner’ s manual.)

–6–

6-EN

SMMS High-Wall Type

Installation Manual

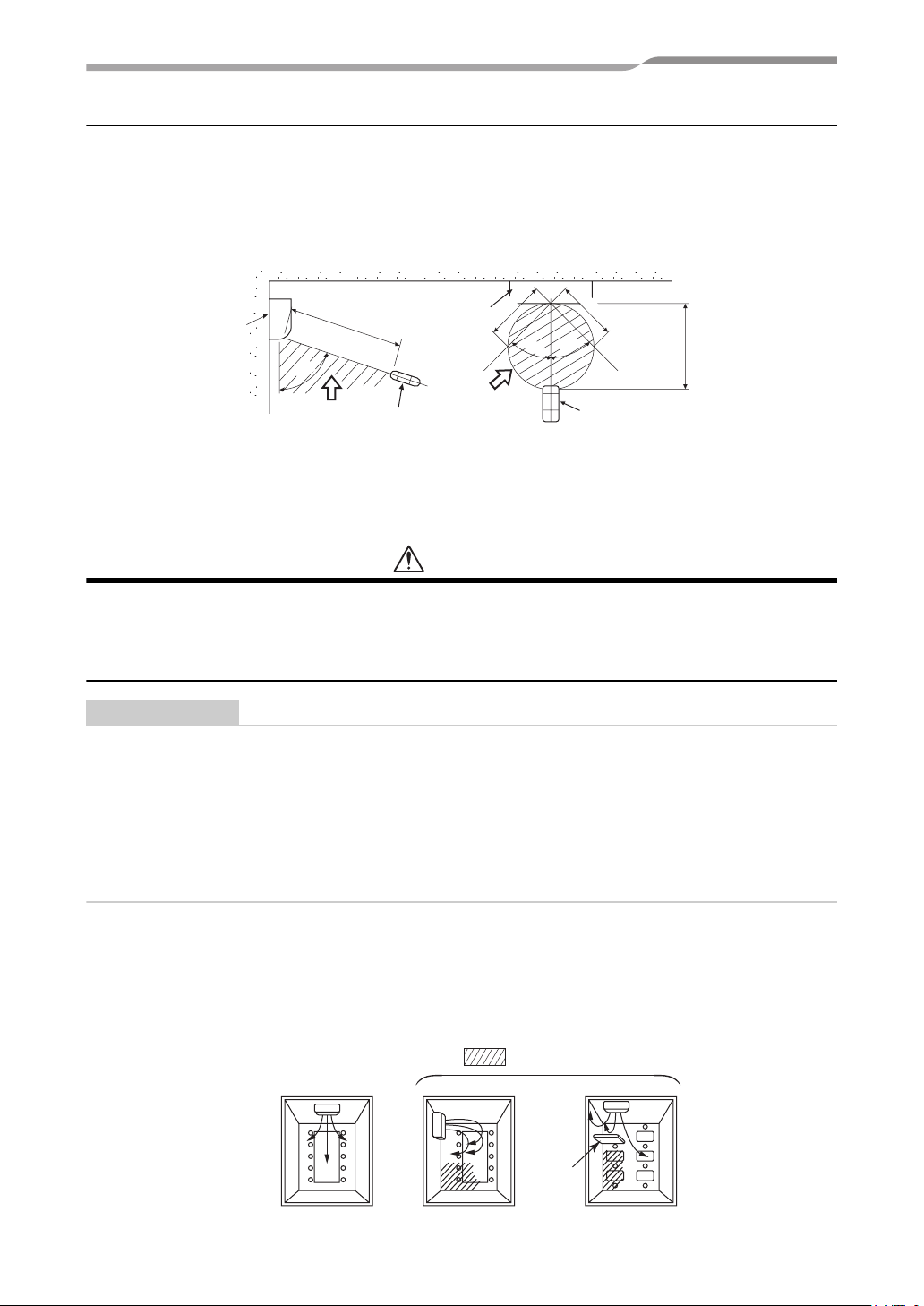

Wireless remote controller

• A place where there are no obstacles such as a curtain that may block the signal from the indoor unit.

• Do not install the remote controller in a place exposed to direct sunlight or close to a heating source, such

as a stove.

• Keep the remote controller at least 1m apart from the nearest TV set or stereo equipment.

(This is necessary to prevent image disturb-bounces or noise interference.)

• The location of the remote controller should be determined as shown below.

Indoor unit

(Side view) (Top view)

7

m

°

5

7

Reception

range

Indoor unit

Reception range

Remote controller

* : Axial distance

5 m

4

5

m

°

5

5

4

°

Remote controller

* 7 m

4 INSTALLATION OF INDOOR UNIT

WARNING

Install the air conditioner certainly to sufficiently withstand the weight.

If the strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work to guard against strong wind or earthquake.

An incomplete installation can cause accidents by the units falling and dropping.

REQUIREMENT

Strictly comply with the following rules to prevent damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit. (Even units are packaged)

• Carry in the indoor unit as it is packaged if possible. If carrying in the indoor unit unpacked by necessity,

be sure to use buffering cloth, etc. to not damage the unit.

• To move the indoor unit, do not apply force to the refrigerant pipe, drain pan, foamed parts, or resin

parts, etc.

• Carry the package by two or more persons, and do not bundle it with plastic band at positions other than

specified.

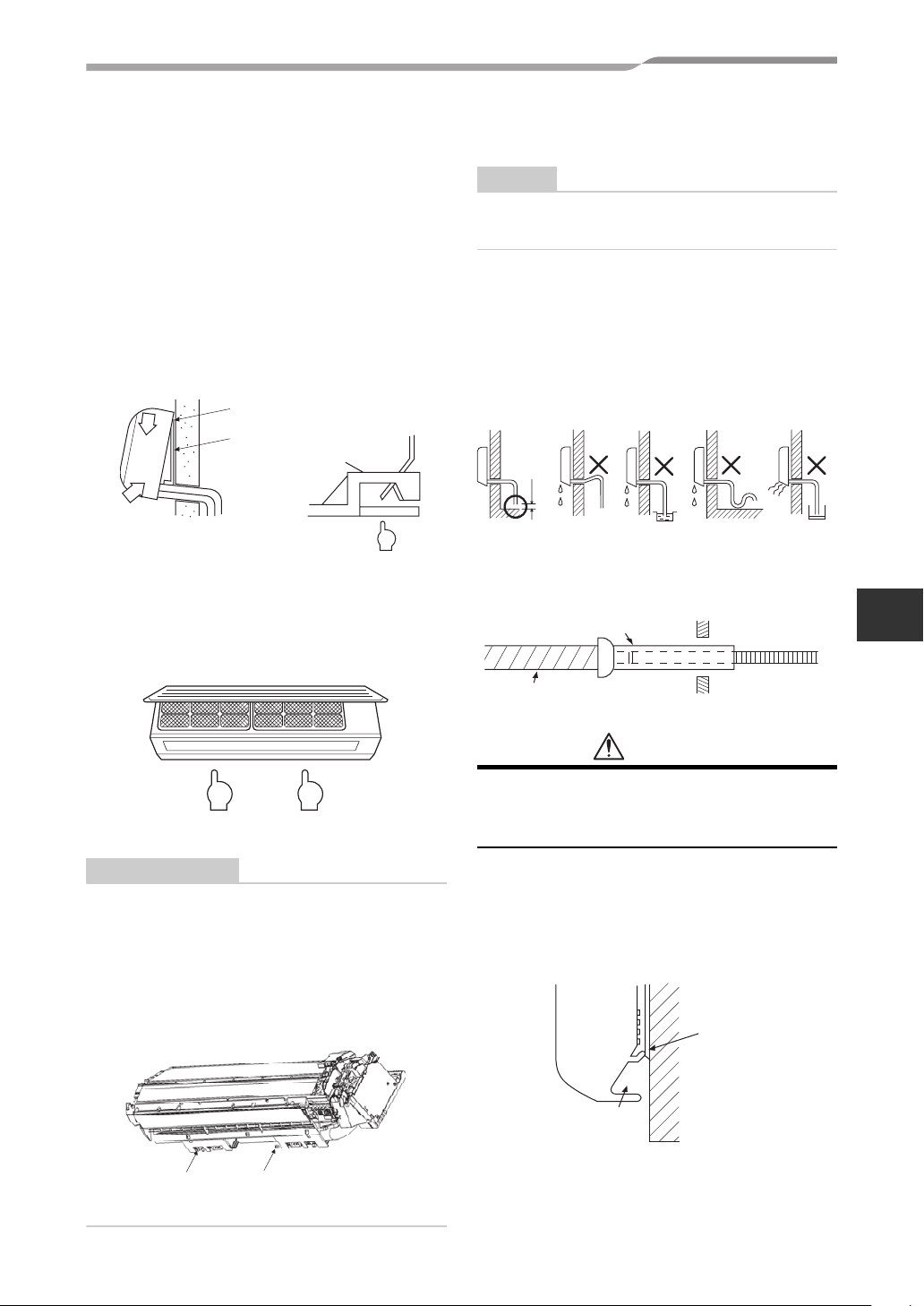

Be careful to the following items when installing the unit.

• Considering air discharge direction, select an installation place where discharge air can circulate evenly

in a room. Avoid to install the unit at place with “NO GOOD” mark in the right figure.

OK NO GOOD

Bad installation place

: Not cooled well.

Screen

7-EN

Good installation place

Cooled well all over.

–7–

SMMS High-Wall Type

Installation Manual

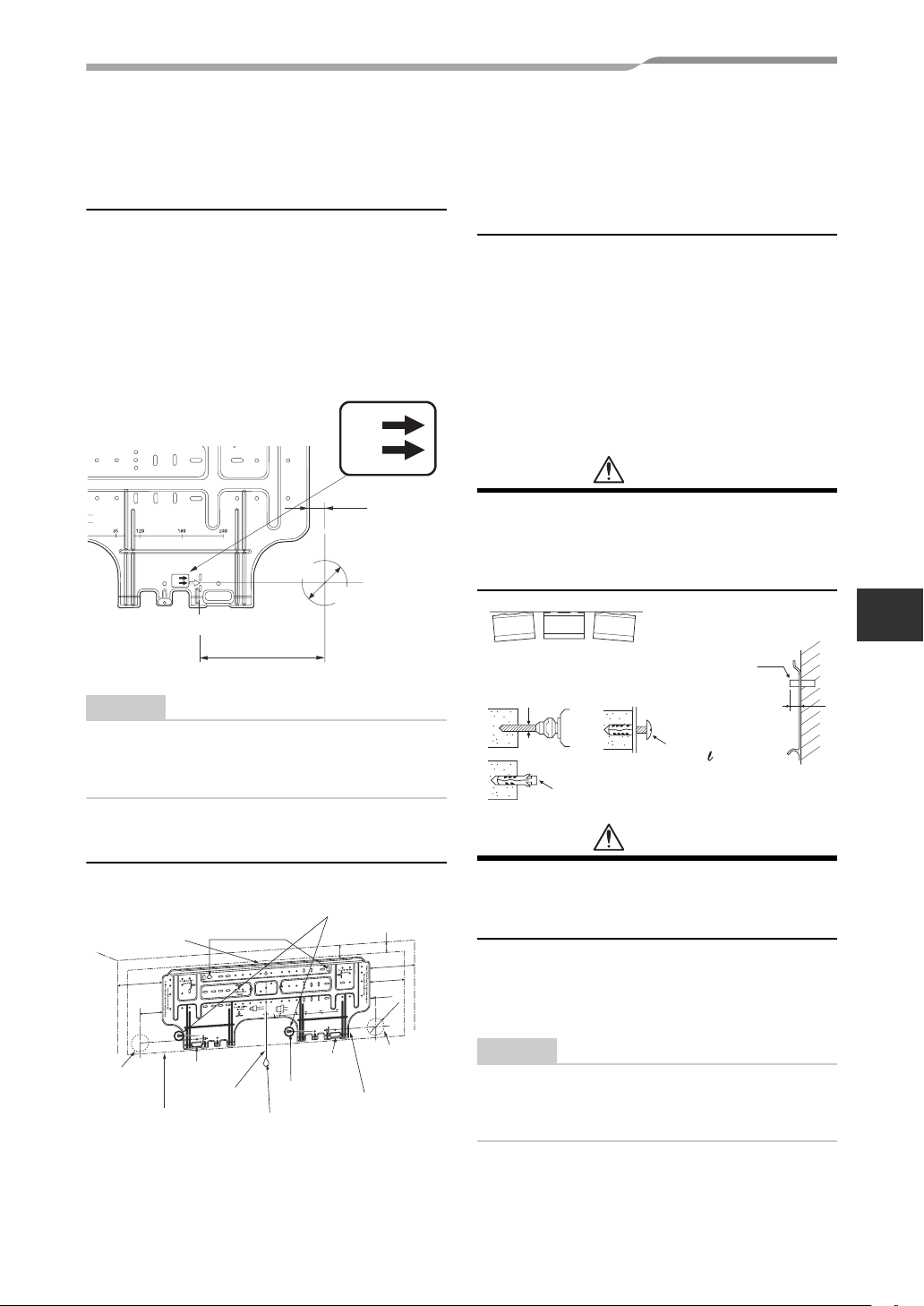

5 CUTTING A HOLE AND MOUNTING INSTALLATION

PLATE

Cutting a hole

In case of installing the refrigerant pipes from the

rear:

1. Decide the hole position for piping at

180mm from the arrow mark (Ö) on the

installation plate and drill a hole at a slight

downward slant toward outdoor side.

Pipe hole; dia.65mm: AP007-AP018 type

Pipe hole; dia.80mm: AP024 type

80

65

1111012101

23mm

180mm

Pipe hole

dia. 65mm:

AP007-AP018 type

dia. 80mm:

AP024 type

80

65

1111012101

The centre of the pipe hole is above the arrow

NOTE

• When drilling a wall that contains a metal lath,

wire lath or metal plate, be sure to use a pipe

hole brim ring sold separately.

When the installation plate is

directly mounted on the wall

1. Securely fit the installation plate onto the

wall by screwing it in the upper and lower

parts to hook up the indoor unit.

2. To mount the installation plate on a

concrete wall with anchor bolts, utilize the

anchor bolt holes as illustrated in the above

figure.

3. Install the installation plate horizontally in

the wall.

CAUTION

When installing the installation plate with a

mounting screw, do not use the anchor bolt hole.

Otherwise the unit may fall down and result in

personal injury and property damage.

NO

GOOD

5mm dia. hole

OK NO

GOOD

Clip anchor

(local parts)

Anchor bolt

Projection

15mm or less

Mounting screw

4 × 25

EN

Mounting the installation plate

Be sure that the installation plate is fix to the wall

with screws to make the indoor unit fit to the wall.

Pipe hole

Hook

170

85

Indoor unit

Anchor bolt holes

Hook

Thread

Hook

Mounting

Screw

Weight

50

132

23

dia.65mm

Pipe hole

(dia. 65mm

dia. 80mm)

Installation

plate

40

170

CAUTION

Failure to firmly install the unit may result in

personal injury and property damage if the unit

falls.

• In case of block, brick, concrete or similar type

walls, make 5mm dia. holes in the wall.

• Insert clip anchors for appropriate mounting

screws.

2m or more from floor

NOTE

• Secure four corners and lower parts of the

installation plate with 6 mounting screws to

install it.

–8–

8-EN

SMMS High-Wall Type

Installation Manual

6 PIPING AND DRAIN HOSE INSTALLATION

Piping and drain hose forming

* Apply heat-insulation for both refrigerant pipe and drain hose surely so that no dew generates inside of

the equipment. (Use polyethylene foam for insulating material.)

Rear right

Rear left

Bottom left

Left

Bottom right

Right

Removing

front panel

Die-cutting

front panel

slit

Changing

drain hose

Piping

preparation

1. Remove the front panel

The front panel must be removed for piping

Air inlet grille

connections in the left, bottom left, and rear

left directions.

Front panel

• Open the air inlet grille upward.

• Remove the four screws securing the

front panel.

• Slightly open the lower part of the front

panel, and then pull the upper part of the

front panel toward you to remove it from

2

1

3

the rear plate.

2. Die-cutting front panel slit

Cut out the slit on the leftward or right side of the front panel for the left or right connection and the slit on

the bottom left or right side of the front panel for the bottom left or right connection with a pair of nippers.

3. Changing drain hose

For leftward connection, bottom-leftward connection and rear leftward connection's piping, it is necessary

to change the drain hose and drain cap.

Without changing the drain hose position, the indoor unit will not fit to the wall.

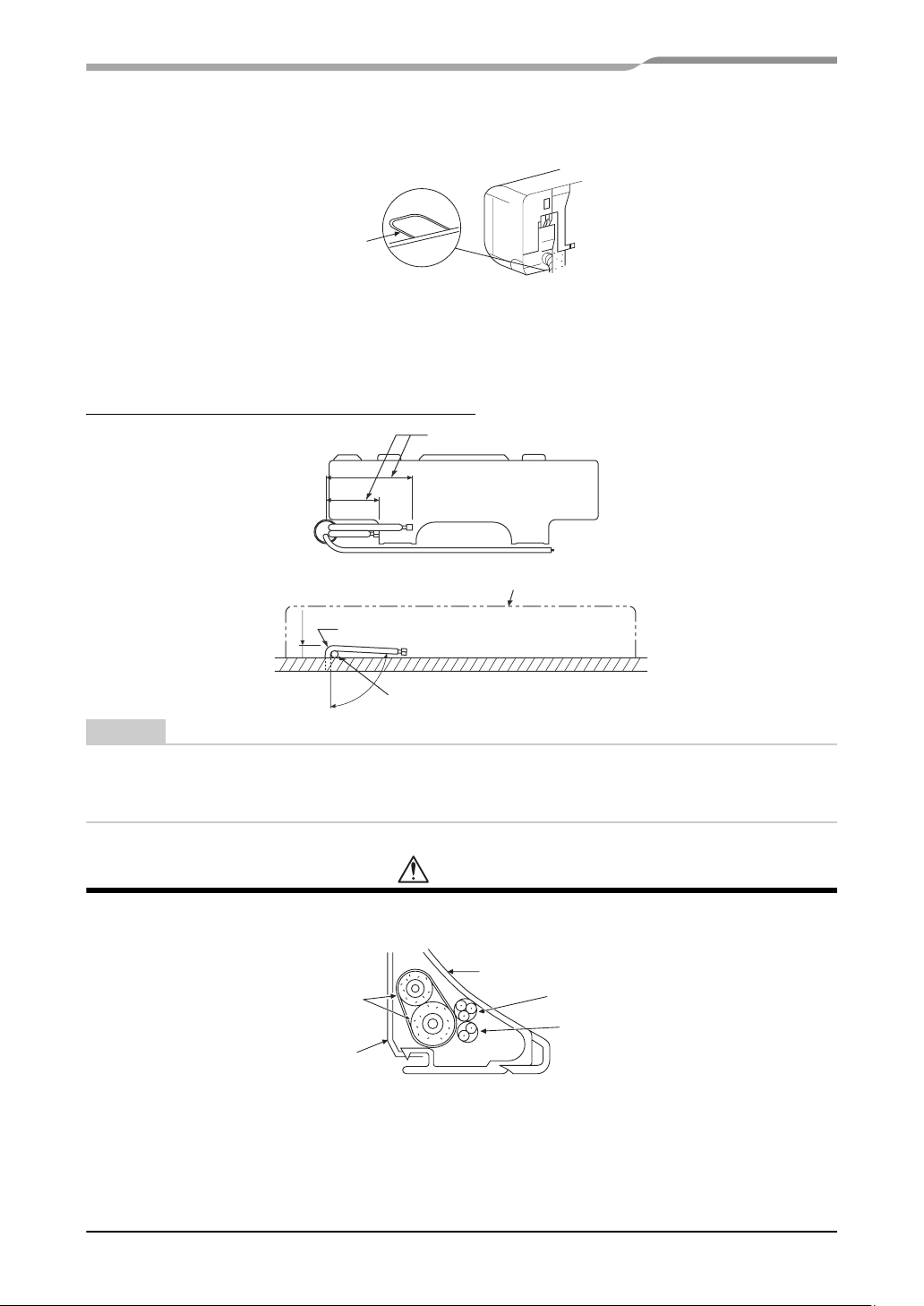

How to remove the drain hose

• The drain hose can be removed by removing the screw securing the drain hose

and then pulling out the drain hose.

• When removing the drain hose, be careful of any sharp edges of steel plate. The

edges can injuries.

• To install the drain hose, insert the drain hose firmly until the connection part

contacts with heat insulator, and the secure it with original screw.

Heat insulator

Drain hose

9-EN

–9–

SMMS High-Wall Type

How to remove the drains cap

Clip the drain cap by needle-nose pliers and pull out.

How to fix the drains cap

1) Insert hexagonal wrench (dia. 4mm) in a centre head.

4mm

2) Firmly insert drains cap.

No gap

Installation Manual

Do not apply lubricating oil (refrigerant

machine oil) when inserting the drain cap.

Insert a hexagon

wrench (4 mm)

Application causes deterioration and drain

leakage from the plug.

CAUTION

Firmly insert the drain hose and drain cap; otherwise, water may leak.

How to remove the drain hose

1) Remove the front panel.

2) Remove the screws of drain hose.

3) Pull out the drain hose.

▼ In case of right or left piping

• After scribing slits of the front panel with a knife or a marking-off pin, cut them with a pair of nippers or an

equivalent tool.

How to fix the drain hose

1) Put the drain hose.

2) Screw the drain hose to the indoor unit.

3) Install the front panel.

EN

Slit

–10–

10-EN

SMMS High-Wall Type

Installation Manual

▼ In case of bottom right or bottom left piping

• After scribing slits of the front panel with a knife or a marking-off pin, cut them with a pair of nippers or an

equivalent tool.

Slit

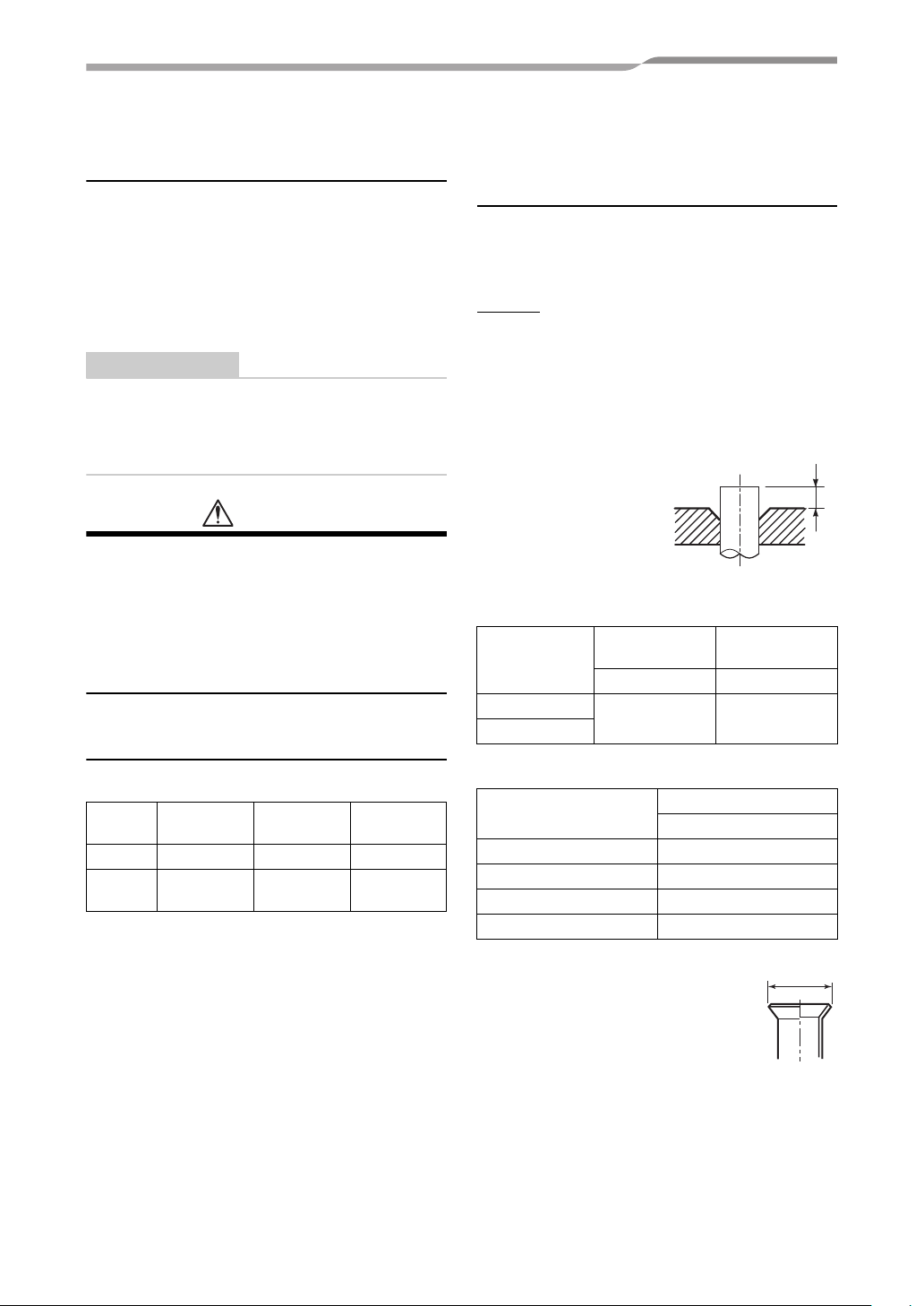

▼ Left-hand connection with piping

Bend the connecting pipe so that it is laid within 43mm above the wall surface. If the connecting pipe is laid

exceeding 43mm above the wall surface, the indoor unit may unstably be set on the wall. When bending

the connecting pipe, make sure to use a spring bender so as not to crush the pipe.

Bend the connection pipe within a radius of 30 mm.

To connect the pipe after installation of the unit (figure)

(To the fore front of flare)

570mm

420mm

43mm

R 30 mm (Use polish polyethylene core

or the like for bending pipe.)

°

0

8

Gas side

Liquid side

Outward form of indoor unit

Use the handle of screwdriver, etc.

NOTE

If the pipe is bent incorrectly, the indoor unit may unstably be set on the wall.

After passing the connecting pipe through the pipe hole, connect the connecting pipe to the auxiliary pipes

and wrap the facing tape around them.

CAUTION

• Bind the auxiliary pipes (two) and power supply wiring and control wiring with facing tape tightly. In case

of leftward piping and rear leftward piping, bind the auxiliary pipes (two) only with facing tape.

Indoor unit

Auxiliary pipes

Installation plate

Power supply wiring

Control wiring

11-EN

• Carefully arrange pipes so that any pipe does not stick out of the rear plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to one another and cut off the insulating tape

wound on the connecting pipe to avoid double-taping at the joint, moreover, seal the joint with the vinyl

tape, etc.

• Since dew results in a machine trouble, make sure to insulate both the connecting pipes.

(Use polyethylene foam as insulating material.)

• When bending a pipe, carefully do it, not to crush it.

–11–

SMMS High-Wall Type

Installation Manual

7 INDOOR UNIT FIXING

1. Pass the pipe through the hole in the wall,

and hook the indoor unit on the installation

plate at the upper hooks.

2. Swing the indoor unit to right and left to

confirm that it is firmly hooked up on the

installation plate.

3. While pressing the indoor unit onto the wall,

hook it at the lower part on the installation

plate. Pull the indoor unit toward you to

confirm that it is firmly hooked up on the

installation plate.

Hook here

1

Installation plate

2

Hook

Press

(unhook)

• For detaching the indoor unit from the installation

plate, pull the indoor unit toward you while

pushing its bottom up at the specified parts.

8 DRAINAGE

1. Run the drain hose sloped downwards.

NOTE

• Hole should be made at a slight downward slant

on the outdoor side.

2. Put water in the drain pan and make sure

that the water is drained out of doors.

3. When connecting extension drain hose,

insulate the connecting part of extension

drain hose with shield pipe.

Do not rise the drain hose.

50 mm

or more

Do not put the

drain hose end

into water.

Shield pipe

Do not form the drain hose

into a wavy shape.

Do not put the

drain hose end

in the drainage

ditch.

EN

PushPush

REQUIREMENT

The lower part of indoor unit may float, due to the

condition of piping and you cannot fix it to the

installation plate. In that case, use the screws

provided to fix the unit and the installation plate.

Especially when the pipes are pulled out from

the left side, the unit must be screwed to the

installation plate.

screw screw

Drain hose

Inside the

room

Extension drain hose

CAUTION

Arrange the drain pipe for proper drainage from

the unit.

Improper drainage can result in dew-dropping.

This air conditioner has the structure designed to

drain water collected from dew, which forms on the

back of the indoor unit, to the drain pan.

Therefore, do not store the power cord and other

parts at a height above the drain guide.

Wall

Drain guide

Space for pipes

–12–

12-EN

SMMS High-Wall Type

9 REFRIGERANT PIPING

Installation Manual

Refrigerant Piping

1. Use copper pipe with 0.8 mm or more

thickness. (In case pipe size is dia. 15.9,

with 1.0mm or more.)

2. Flare nut and flare works are also different

from those of the conventional refrigerant.

Take out the flare nut attached to the main

unit of the air conditioner, and use it.

REQUIREMENT

When the refrigerant pipe is long, provide support

brackets at intervals of 2.5 to 3m to clamp the

refrigerant pipe. Otherwise, abnormal sound may

be generated.

CAUTION

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of

the connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

Pipe size

(dia.: mm)

MMK-

Gas side 9.5 12.7 15.9

Liquid

side

AP007 to

AP012 type

6.4 6.4 9.5

AP015 to

AP018 type

AP024 type

Permissible Piping Length and

Height Difference

They vary according to the outdoor unit.

For details, refer to the Installation Manual attached

to the outdoor unit.

Flaring

• Cut the pipe with a pipe cutter.

Remove burrs completely.

Remaining burrs may cause gas leakage.

• Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly

manufactured for R410A are recommended.

However, the

conventional tools can

be used by adjusting

projection margin of the

copper pipe.

▼ Projection margin in flaring: B (Unit: mm)

Rigid (Clutch type)

Outer dia. of

copper pipe

6.4 , 9.5

12.7 , 15.9

R410A tool used

R410A R410A

0 to 0.5 1.0 to 1.5

Conventional

tool used

▼ Flaring dia. meter size: A (Unit: mm)

0

+

A

Outer dia. of copper pipe

6.4 9.1

9.5 13.2

12.7 16.6

15.9 19.7

-0.4

R410A

B

13-EN

* In case of flaring for R410A with the

conventional flare tool, pull it out

approx.

0.5 mm more than that for R22 to

adjust to the specified flare size.

The copper pipe gauge is useful for

adjusting projection margin size.

–13–

A

SMMS High-Wall Type

Installation Manual

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

(Unit: N•m)

Outer dia. of copper pipe Tightening torque

6.4 mm (dia.) 14 to 18 (1.4 to 1.8 kgf•m)

9.5 mm (dia.) 33 to 42 (3.3 to 4.2 kgf•m)

12.7 mm (dia.) 50 to 62 (5.0 to 6.2 kgf•m)

15.9 mm (dia.) 68 to 82 (6.8 to 8.2 kgf•m)

▼ Tightening torque of flare pipe connections

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times) Therefore, using a torque

wrench, tighten the flare pipe connecting sections

which connect the indoor and outdoor units of the

specified tightening torque.

Incorrect connections may cause not only a gas

leak, but also a trouble of the refrigeration cycle.

Align the centres of the connecting pipes and

tighten the flare nut as far as possible with your

fingers. Then tighten the nut with a spanner and

torque wrench as shown in the figure.

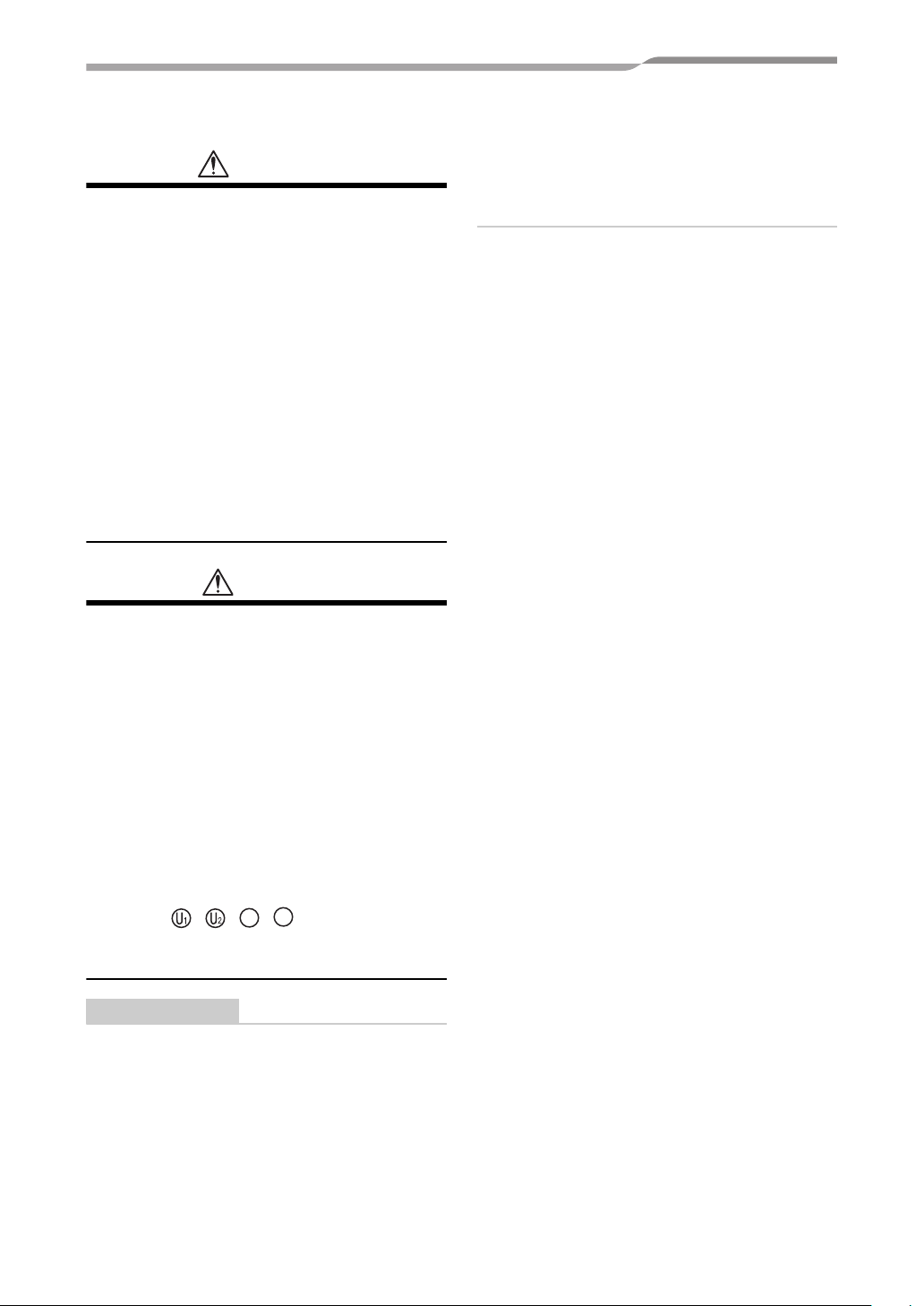

Heat insulation

Heat insulation for the pipes should be done

separately for the liquid side and gas side. Because

both of the liquid and gas side pipes become a low

temperature during cooling operation, sufficient

heat insulation should be done to prevent

condensation.

• Heat insulator with a heat resistance of 120°C or

more must be used for the gas side pipe.

• The pipe connection section of the indoor unit

must be heat insulated securely and compactly

with the attached heat insulator.

Fix with vinyl tape

Heat insulator

(attached)

Local side pipe

Airtight test/Air purge, etc.

For airtight test, air purge, addition of refrigerant,

and gas leak check, follow the Installation Manual

attached to the outdoor unit.

EN

Work using double spanner

REQUIREMENT

Tightening with an excessive torque may crack the

nut depending on installation conditions.

Tighten the nut within the specified tightening

torque.

Piping with outdoor unit

• Shape of valve differs according to the outdoor

unit.

For details of installation, refer to the Installation

Manual of the outdoor unit.

Open fully valves of the outdoor

unit

Gas leak check

Check with a leak detector or soap water whether

gas leaks or not, from the pipe connecting section

or cap of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively HFC

refrigerant (R410A, R134a, etc.).

–14–

14-EN

SMMS High-Wall Type

10 ELECTRIC WORK

WARNING

1. Using the specified wires, ensure to

connect the wires, and fix wires securely so

that the external tension to the wires do not

affect the connecting part of the terminals.

Incomplete connection or fixation may cause a

fire, etc.

2. Be sure to connect earth wire. (grounding

work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes,

water pipes, lightning rods or ground wires for

telephone wires.

3. Appliance shall be installed in accordance

with national wiring regulations.

Capacity shortage of power circuit or

incomplete installation may cause an electric

shock or a fire.

Installation Manual

• Run the refrigerant piping line and control wiring

line in the same line.

• Do not turn on the power of the indoor unit until

vacuuming of the refrigerant pipes completes.

CAUTION

• If incorrect/incomplete wiring is carried out, it

will cause an electrical fire or smoke.

• Be sure to install an earth leakage breaker that

is not tripped by shock waves.

If an earth leakage breaker is not installed, an

electric shock may be caused.

• Be sure to use the cord clamps attached to the

product.

• Do not damage or scratch the conductive core

and inner insulator of power and interconnecting wires when peeling them.

• Use the power cord and Inter-connecting wire

of specified thickness, type, and protective

devices required.

• Never connect 220–240V power to the terminal

blocks ( , , , , etc.) for control

wiring.

(Otherwise, the system will fail.)

REQUIREMENT

• For power supply wiring, strictly conform to the

Local Regulation in each country.

• For wiring of power supply of the outdoor units,

follow the Installation Manual of each outdoor

unit.

• Perform the electric wiring so that it does not

come to contact with the high-temperature part

of the pipe.

The coating may melt resulting in an accident.

• After connecting wires to the terminal blocks,

provide a trap and fix wires with the cord clamp.

A B

15-EN

–15–

SMMS High-Wall Type

Installation Manual

Power supply wire and communication wires specifications

Power supply wire and communication wires are procured locally.

For the power supply specifications, follow the table below. Power supply wiring and communication wiring

are to be procured locally.

For specifications of the power capacity of the outdoor unit and the power supply wires, refer to the

Installation Manual supplied with the outdoor unit.

Indoor unit power supply

• Prepare an exclusive power supply for the indoor unit independently of the outdoor unit.

• Arrange the power supplies to the indoor and outdoor units, so that a common earth leakage breaker and

main switch can be used.

• Power supply wire specification: Cable 3-core 2.5mm², in conformity with Design H07 RN-F or 60245

IEC 57.

▼ Power supply

Power supply

Power supply switch/Earth leakage breaker or power supply wiring/fuse rating for indoor units should be selected by

the accumulated total current values of the indoor units.

Power supply wiring Below 50m 2.5 mm²

Control wiring, Central controller wiring

• Use a 2 core non polarity wire.

• To prevent any possible noise issues, use a shielded 2 core wire.

• The total stated length of communication wiring is determined by the interconnecting length of indoor to

outdoor wire plus the length of the central control communication wire.

220–240V ~ 50Hz

220V ~ 60Hz

EN

▼ Communication line

Control wiring between indoor units, and outdoor

unit (2-core shield wire)

Central control line wiring (2-core shield wire) Wire size

Wire size

(Up to 1000m) 1.25 mm²

(Up to 2000m) 2.0 mm²

(Up to 1000m) 1.25 mm²

(Up to 2000m) 2.0 mm²

Wired remote controller wiring

This wiring is not required when using the supplied wireless remote controller.

• For wiring remote controllers a 2 core non polarity wire must be used.

Wired remote controller wiring, remote controller inter-unit wiring Wire size: 0.5mm² to 2.0mm²

Total wire length of wired remote controller wiring and remote

controller inter-unit wiring = L + L1 + L2 + … Ln

Total wire length of wired remote controller inter-unit wiring = L1 + L2 + … Ln Up to 200m

In case of wired type only Up to 500m

In case of wireless type included Up to 400m

CAUTION

The remote controller wire (Communication line) and AC220–240V wires cannot be parallel to contact

each other and cannot be stored in the same conduits. If doing so, a trouble may be caused on the control

system due to noise, etc.

–16–

16-EN

SMMS High-Wall Type

Installation Manual

Wired remote

controller

wiring

Indoor unit

Wired remote

controller

L1 L2 Ln

Remote controller inter-unit wiring

Indoor unit Indoor unit Indoor unit

(Max. 8 units)

Control wiring between indoor and outdoor units

NOTE

An outdoor unit that is interconnected to the indoor units automatically becomes the header unit.

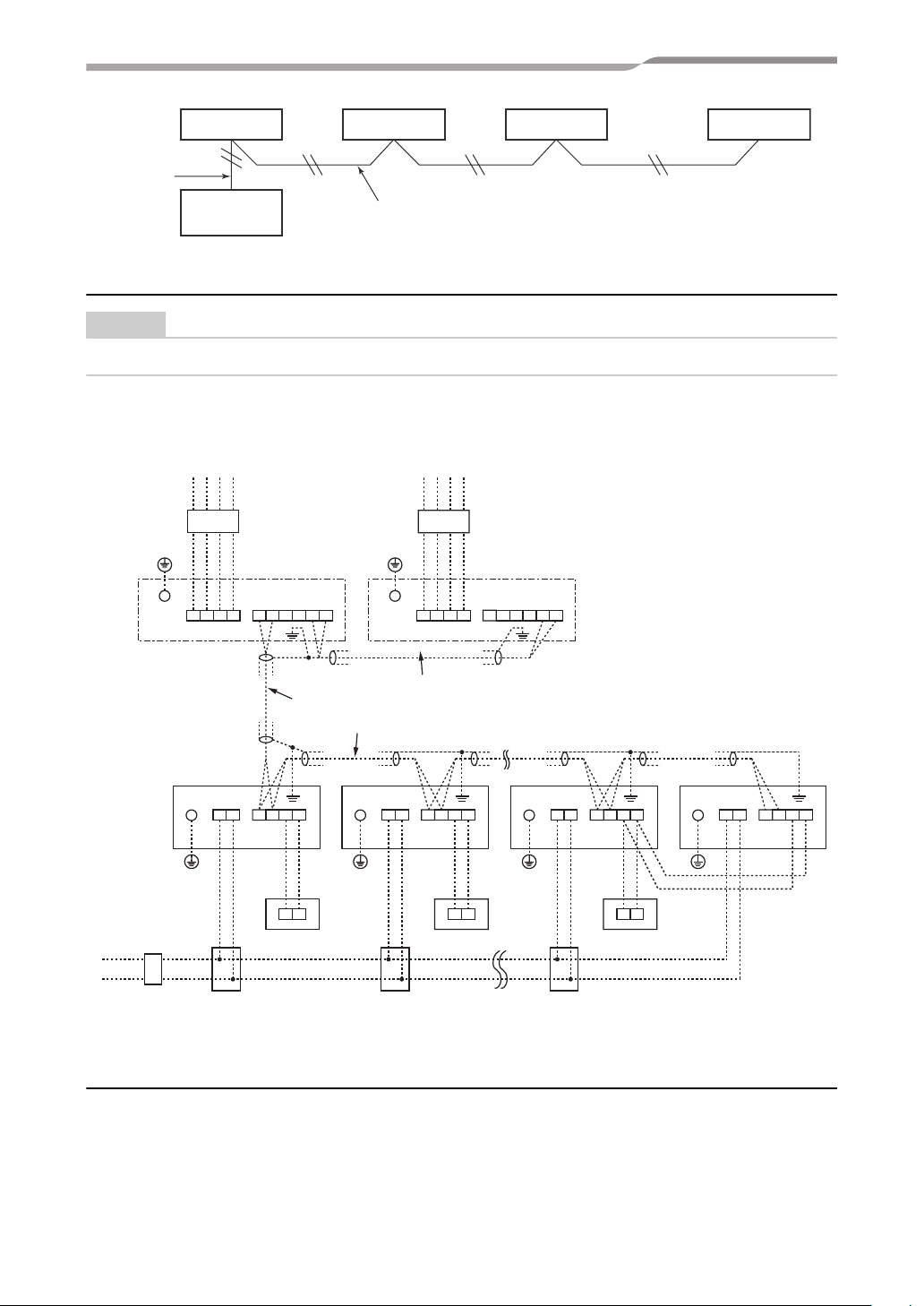

▼ Wiring example

Outdoor Power supply

380V-415V ~, 50Hz

380V ~, 60Hz

Earth

terminal

Earth leakage

breaker

Header outdoor unit Follower outdoor unit

U1 U2 U3 U4L1 L2 L3 N U5 U6

Outdoor Power supply

380V-415V ~, 50Hz

380V ~, 60Hz

Earth

terminal

Earth leakage

breaker

U1 U2 U3 U4L1 L2 L3 N U5 U6

Control wiring between outdoor units

Earth Earth

U1 U2L N A B

A B

Remote controller Remote controller

U1 U2L N A B

A B

Indoor unit Indoor unit Indoor unit Indoor unit

Earth Earth

Indoor power supply

220-240V, ~, 50Hz

220V ~, 60Hz

Earth leakage

breaker power

switch

Control wiring between indoor and outdoor units

Control wiring between indoor units

U1 U2

L N A B

A B

Remote controller

Pull box Pull box Pull box

Address setup

Set up the addresses as per the Installation Manual supplied with the outdoor unit.

U1 U2L N A B

17-EN

–17–

SMMS High-Wall Type

Installation Manual

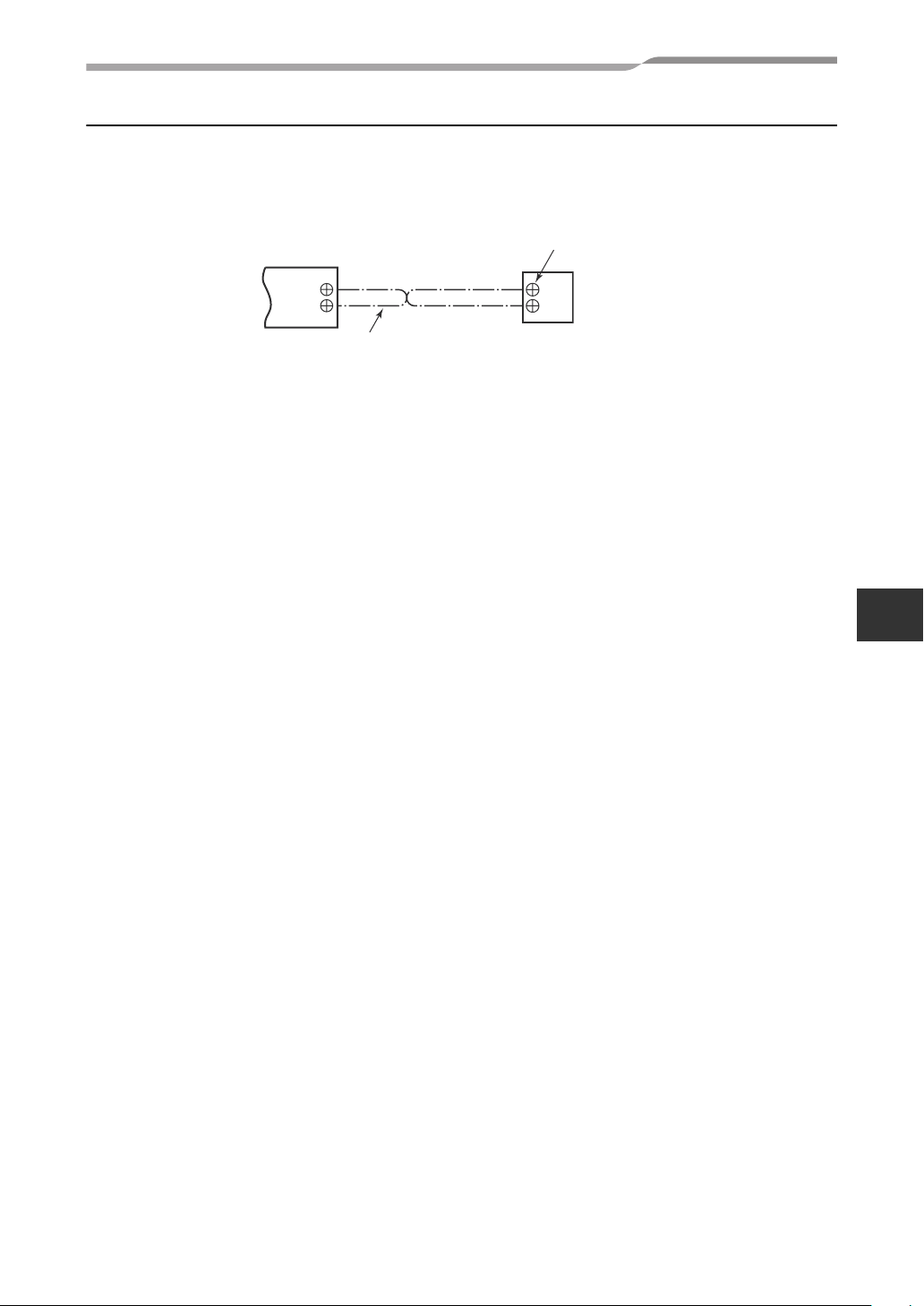

Wired remote controller wiring

• As the wired remote controller wire has non-polarity, there is no problem if connections to indoor unit

terminal blocks A and B are reversed.

▼ Wiring diagram

Terminal block for

remote controller

wiring of indoor unit

Terminal block

A

B

Wired remote controller wire

(Procured locally)

A

B

Wired remote

controller unit

EN

–18–

18-EN

SMMS High-Wall Type

Installation Manual

Wiring Connection

How to connect the power supply wiring

and control wiring

The power supply wire and the control wire can be

connected without removing the front panel.

REQUIREMENT

Connect the power supply wire after connecting the

control wire for this model.

1. Remove the air inlet grille.

Open the air inlet grille upward and pull it

toward you.

2. Remove the terminal cover and the clamp

base.

3. Insert the power supply wire and control

wire (according to the local rule) into the

pipe hole on the wall.

4. Take the power supply wire out of the cable

slot on the rear panel so that it protrudes

about 150mm from the front.

5. Insert the control wire fully into the control/

wired remote controller terminal block ,

, , and secure it tightly with screws.

A B

6. Clamp the control wire with the cord clamp.

7. Install the clamp base with a screw.

8. Insert the power supply wire fully into the

terminal block and secure it tightly with

screws. Tightening torque: 1.2 N·m (0.12

kgf·m) Secure the earth line with the earth

screw.

9. Clamp the power supply wire with the cord

clamp.

10.Attach the terminal cover and the air inlet

grille to the indoor unit.

CAUTION

• Be sure to refer to the wiring diagram attached

inside the front panel.

• Check local electrical cords and also any

specific wiring instructions and limitations.

• Do not catch the control wire when installing the

clamp base.

Power supply terminal block

Terminal block for

communication/remote

controller wiring

Terminal

Cover

Screw

Power

supply wire

about

150mm

<Stripping length of the power supply wire>

Terminal block

for control/

wired remote

controller wiring

Control wire

Cord clamp

Power

supply

terminal

block

Cord

clamp

Screw

N

L

U1U2A

Clamp base

95mm

20mm

10mm

R(L)

B

R(L)

S(N)

Screw

Earth screw for

power supply wire

<Connecting control wire>

R(L) S(N)

R(L)

S(N)

Earth screw

Earth line

75mm

S(N)

Earth

wire for

shield

wire

Earth screw for

shield wire

19-EN

Terminal

block

for control/

wired remote

controller

wiring

Cord

clamp

<Connecting wired remote controller wire>

U1 U2 A

B

Wired

remote

controller

wire

–19–

Cord clamp

2

Power supply wire

<Connecting power supply wire>

ABU1U

Earth screw

Earth

wire for

power

supply

wire

Clamp

base

SMMS High-Wall Type

Installation Manual

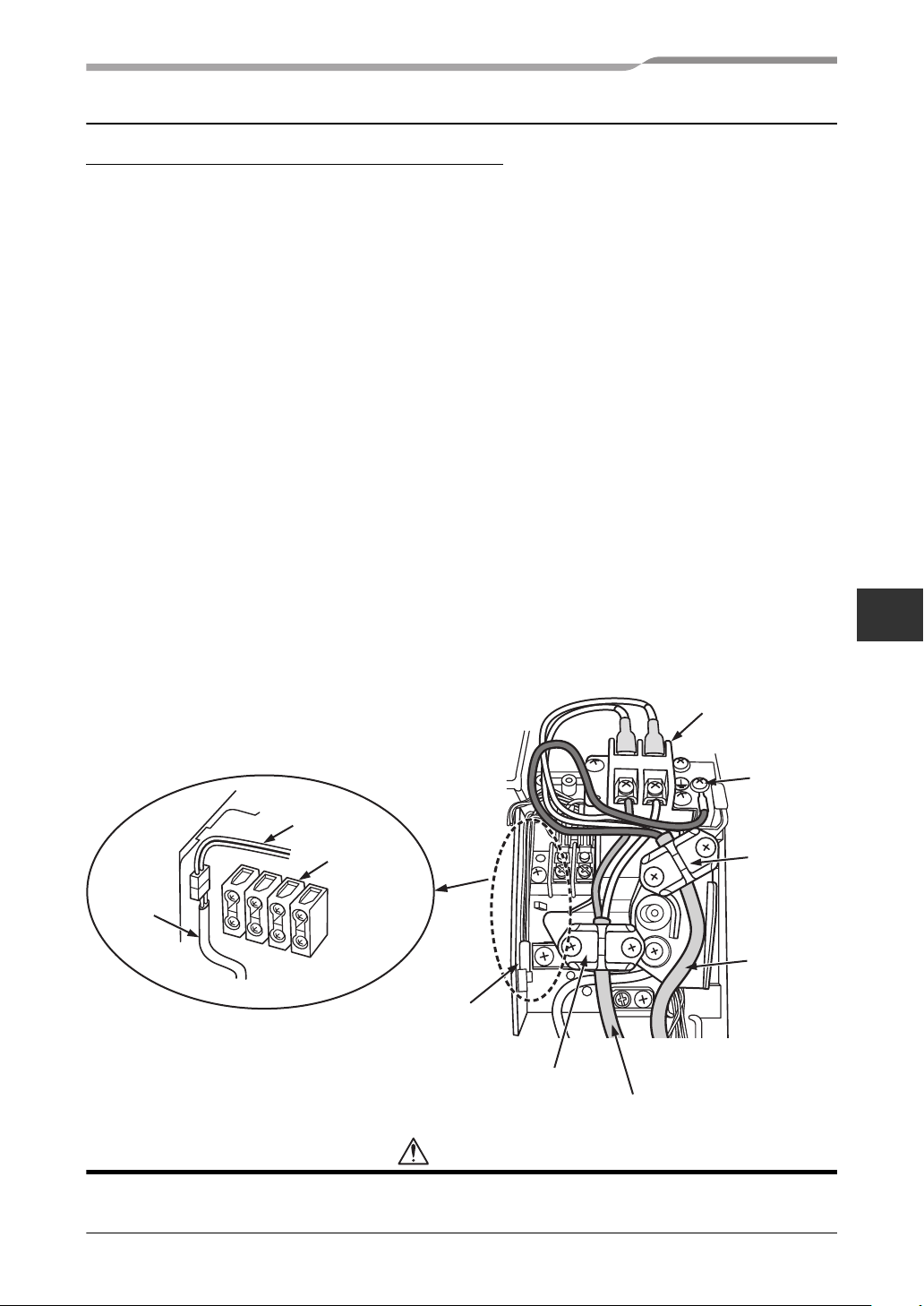

Wiring connection for flow selector unit

How to connect the wiring of flow selector unit

Connect the power supply wire and the communication wire supplied with the flow selector unit to the indoor

unit.

1. Remove the air inlet grille.

Open the air inlet grille upward and pull it toward you.

2. Remove the four screws securing the front panel.

3. Slightly open the lower part of the front panel, and then pull the upper part of the front panel

toward you to remove it from the rear plate.

4. Remove the terminal cover and the clamp base.

5. Insert the control wire fully into the control/wired remote controller terminal block and secure

it tightly with screws.

6. Connect the control wire connector of the flow selector unit to the lead with a connector to the

left of the control/wired remote controller terminal block.

7. Clamp the control wire and the control wire of the flow selector unit with the cord clamp.

8. Install the clamp base with a screw.

9. Insert the power supply wire fully into the terminal block and secure it tightly with screws.

Tightening torque: 1.2 N·m (0.12 kgf·m)

Secure the earth line with the earth screw.

10.Clamp the power supply wire with the cord clamp.

11.Insert the power supply wire fasten terminal of the flow selector unit into the power supply

terminal.

Secure the earth line with the earth screw.

12.Clamp the power supply wire of the flow selector unit tight with the cord clamp.

13.Attach the terminal cover, the front panel and the air inlet grille to the indoor unit.

Power supply

terminal block

EN

R(L)

Control wire

from the

flow selector

Control wire

Terminal

block for

control/wired

remote

controller

wiring

Connector

Cord clamp

S(N)

2

ABU1U

Power supply wire

Earth screw

for flow

selector unit

Cord clamp

Power

supply wire

of flow

selector unit

CAUTION

Confirm that every wires are stored in the electric parts box without getting caught before attaching the

terminal cover.

–20–

20-EN

Loading...

Loading...