Toshiba MMU-AP0242H2UL, MMU-AP0092H2UL, MMU-AP0302H2UL, MMU-AP0122H2UL, MMU-AP0362H2UL Engineering Data Book

...

Notice: Toshiba is committed to continuously improving its products to ensure the highest

quality and reliability standards, and to meet local regulations and market requirements. All

features and specifications are subject to change without prior notice.

Engineering

Data Book

E13-303

Heat recovery

Model name:

MMY-MAP_4FT9UL (208/230 V, 60 Hz)

MMY-MAP

_

4FT6UL (460 V, 60 Hz)

Heat pump

Model name:

MMY-MAP_4HT9UL (208/230 V, 60 Hz)

MMY-MAP

_

4HT6UL (460 V, 60 Hz)

Contents

1

Safety caution..............................................................................................2

1 System overview .........................................................................................3

1-1. Allocation standard of model name ....................................................................... 3

1-2. Summary of system equipments ........................................................................... 4

2 Equipment selection procedure ...................................................................8

2-1. Selection flow chart................................................................................................ 8

2-2. Combination conditions for indoor unit and outdoor unit ....................................... 9

2-3. Cooling/heating capacity characteristics.............................................................. 10

2-4. Operational temperature range............................................................................ 22

3 Refrigerant piping design...........................................................................23

3-1. Free branching system ........................................................................................ 23

3-2. Allowable length/height difference of refrigerant piping....................................... 24

3-3. Selection of refrigerant piping.............................................................................. 26

3-4. Charging requirement with additional refrigerant................................................. 28

4 Wiring Design ............................................................................................29

4-1. General ................................................................................................................ 29

4-2. Outdoor unit power supply................................................................................... 29

4-3. Indoor unit power supply...................................................................................... 32

4-4. Design of control wiring ....................................................................................... 33

5 Outdoor unit...............................................................................................35

5-1. Specifications....................................................................................................... 35

5-2. Dimensional drawing ........................................................................................... 55

5-3. Center of gravity .................................................................................................. 63

5-4. Branch header / branch joint................................................................................ 64

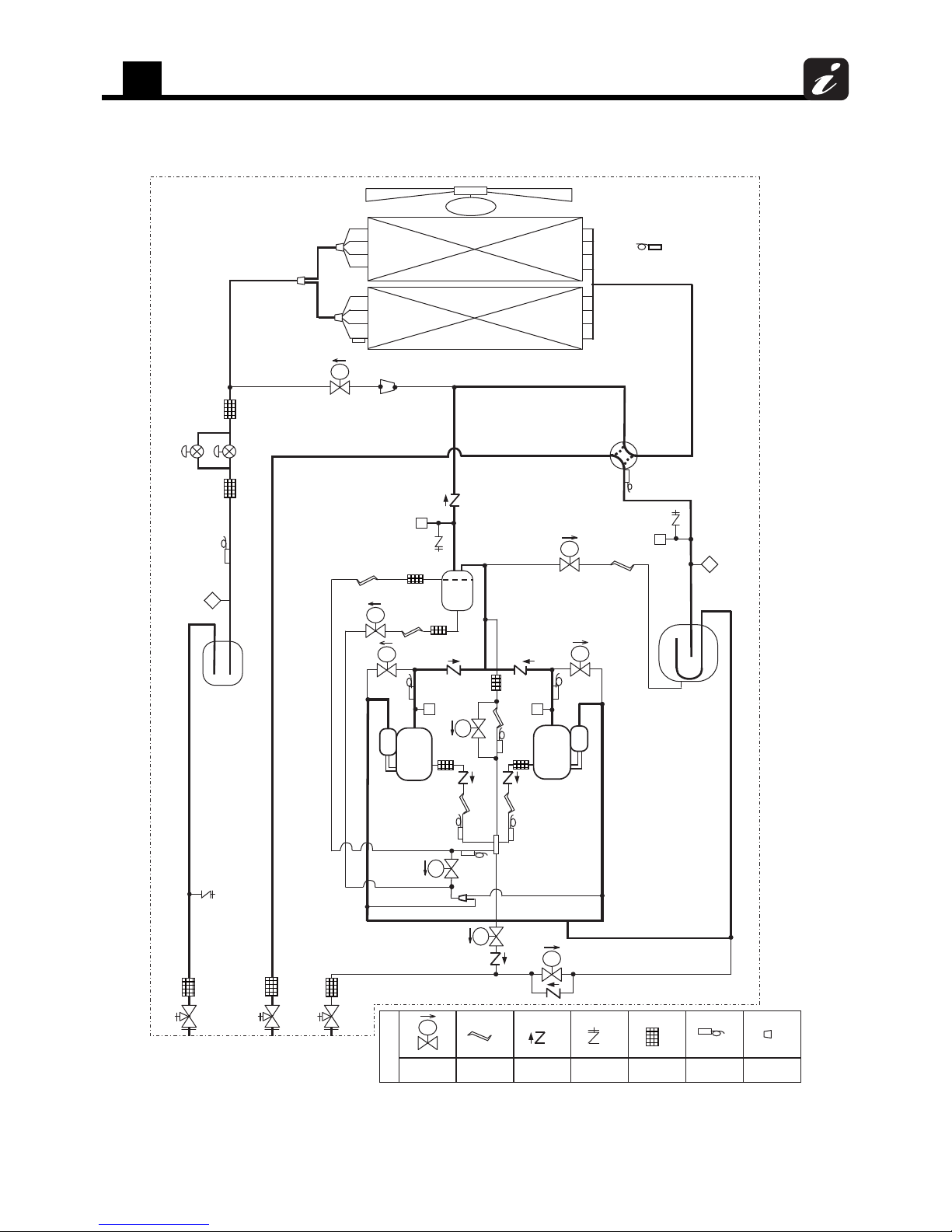

5-5. Refrigerant cycle diagram.................................................................................... 70

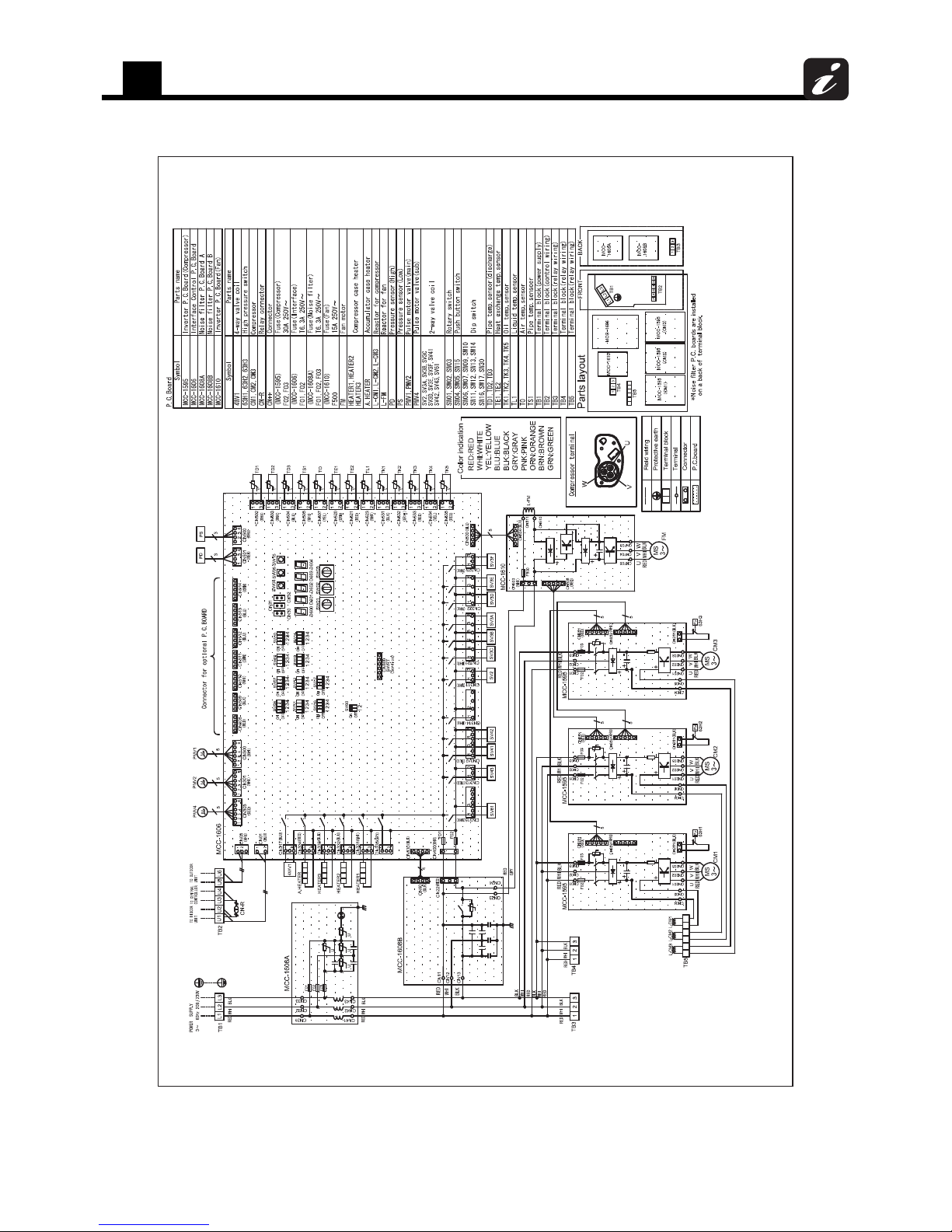

5-6. Wiring diagram..................................................................................................... 74

5-7. Connecting diagram............................................................................................. 82

5-8. Applied control for outdoor unit............................................................................ 83

5-9. Optional PCB of outdoor unit............................................................................... 86

5-10. Sound pressure level data ................................................................................... 94

5-11. FS unit (Flow Selector unit) ................................................................................. 99

6 Indoor unit................................................................................................102

6-1. 4-Way Cassette type ......................................................................................... 102

6-2. Compact 4-Way Cassette type.......................................................................... 126

6-3. Ceiling type........................................................................................................ 137

6-4. High Wall type.................................................................................................... 149

6-5. Medium Static Ducted type ................................................................................ 160

6-6. High Static Ducted type ..................................................................................... 177

6-7. Slim Ducted type................................................................................................ 191

Contents

Safety caution

2

Safety caution

Warnings on refrigerant leakage

Check of Concentration Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its concentration will not

exceed a set limit.

The refrigerant R410A which is used in the air

conditioner is safe, without the toxicity or combustibility

of ammonia, and is not restricted by laws to be imposed

which protect the ozone layer. However, since it

contains more than air, it poses the risk of suffocation if

its concentration should rise excessively. Suffocation

from leakage of R410A is almost non-existent. With the

recent increase in the number of high concentration

buildings, however, the installation of multi air

conditioner systems is on the increase because of the

need for effective use of floor space, individual control,

energy conservation by curtailing heat and carrying

power etc. Most importantly, the multi air conditioner

system is able to replenish a large amount of refrigerant

compared with conventional individual air conditioners.

If a single unit of the multi conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant

accidentally leaks out, its concentration does not reach

the limit (and in the event of an emergency, measures

can be made before injury can occur). In a room where

the concentration may exceed the limit, create an

opening with adjacent rooms, or install mechanical

ventilation combined with a gas leak detection device.

The concentration is as given below.

Concentration limit

Compliance to the local applicable regulations and

standards for the concentration limit is required.

NOTE 1 :

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should

be as charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 22 lbs (10 kg).

The possible amount of leaked refrigerant gas in

rooms D, E and F is 33 lbs (15 kg).

NOTE 2 :

The standards for minimum room volume are as follows.

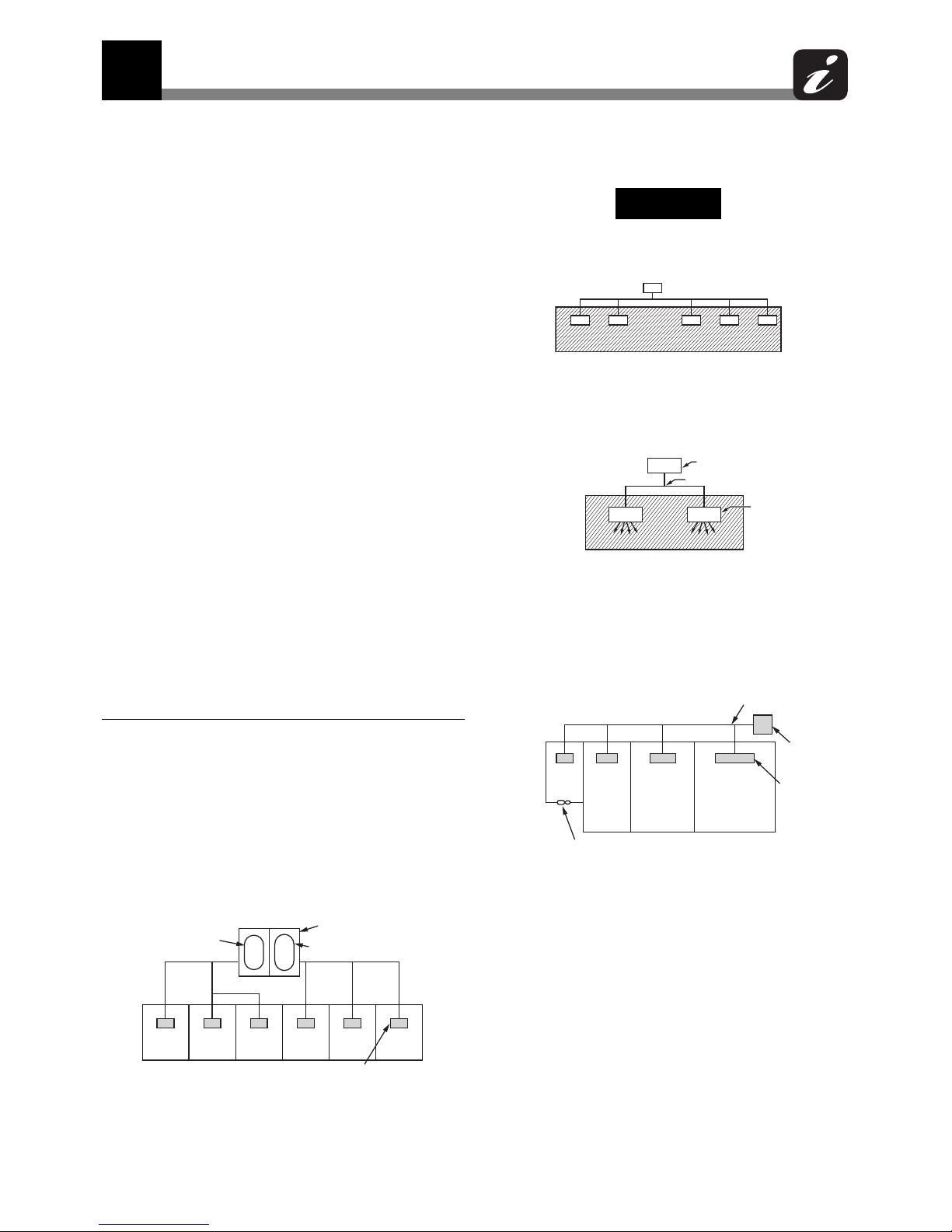

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent

room for ventilation of leaking refrigerant gas

(opening without a door, or an opening 0.15% or

larger than the respective floor spaces at the top or

bottom of the door).

(3) If an indoor unit is installed in each partitioned room

and the refrigerant piping is interconnected, the

smallest room of course becomes the object. But

when a mechanical ventilation is installed interlocked

with a gas leakage detector in the smallest room

where the density limit is exceeded, the volume of

the next smallest room becomes the object.

Total amount of refrigerant (lbs (kg))

Min. volume of the indoor unit installed room (ft

3

(m3))

≤ Concentration limit (lbs/ft

3

(kg/m3))

Outdoor unit

e.g., charged amount

((22 lbs) 10 kg)

e.g.,charged amount

(33 lbs (15 kg))

Room A

Indoor unit

Room B Room C Room D Room E Room F

Important

Outdoor unit

Refrigerant piping

Indoor unit

Outdoor unit

Mechanical ventilation device - Gas leak detector

Indoor unit

Very

small

room

Small

room

Medium

room

Large

room

Refrigerant piping

1

System overview

3

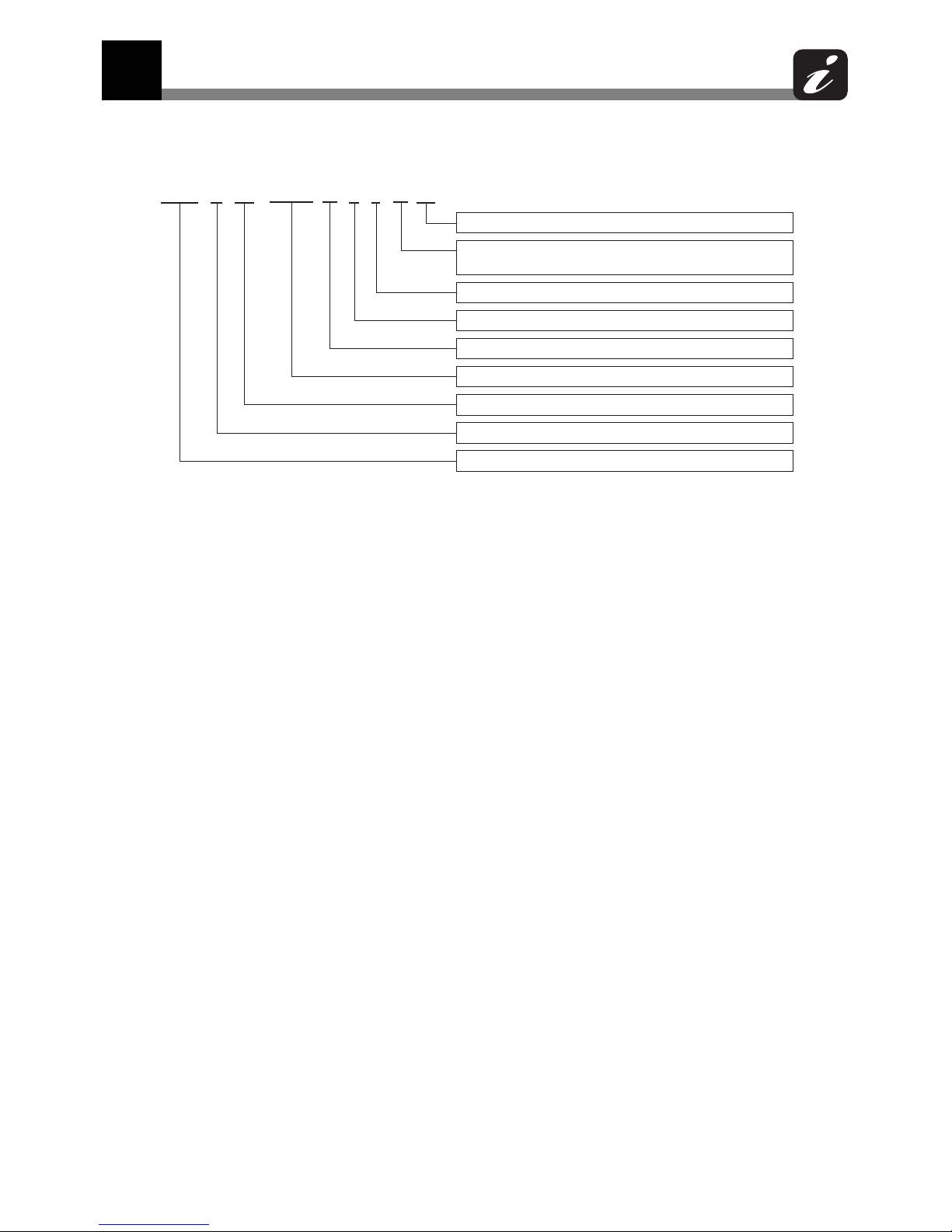

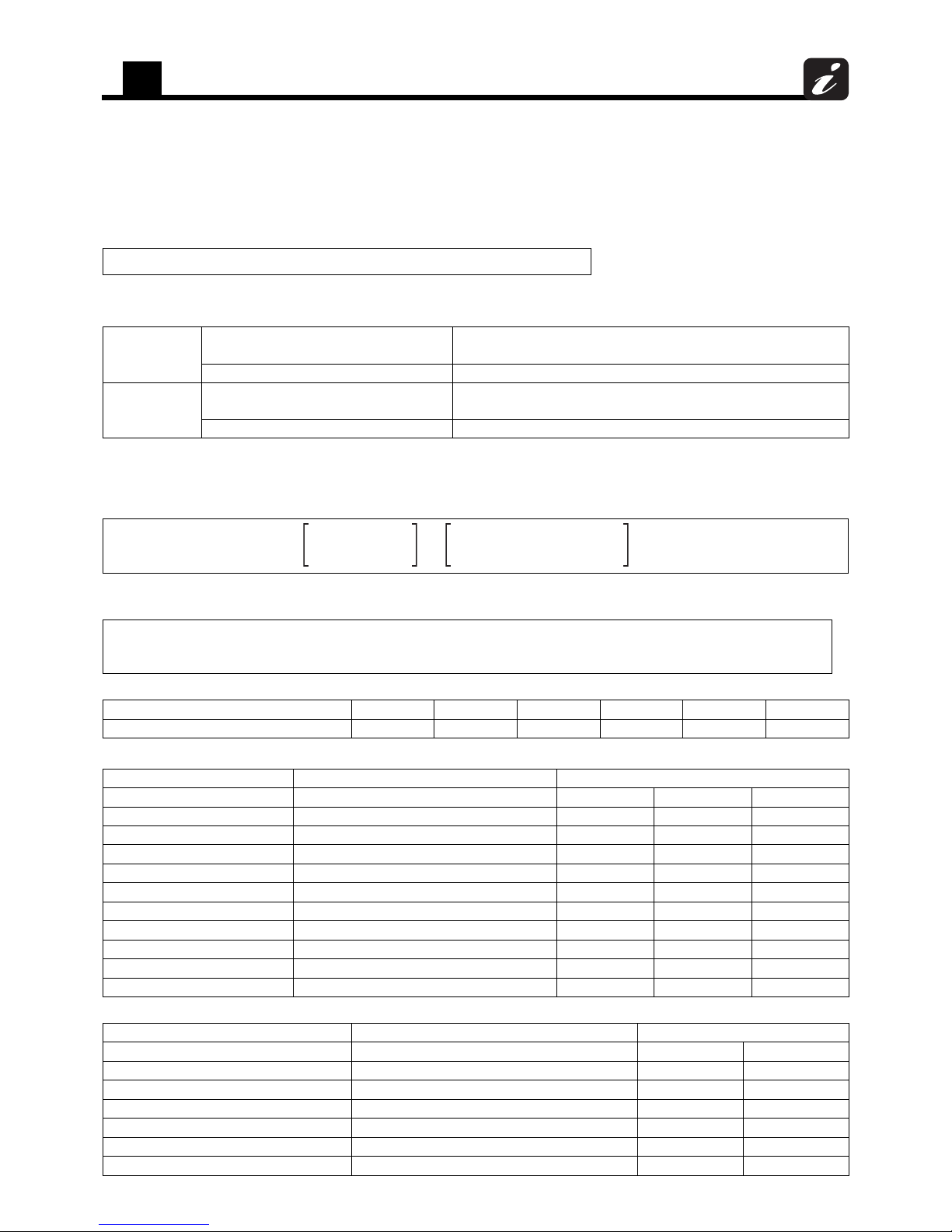

1-1. Allocation standard of model name

MMY- M AP 䕿䕿䕿䚷䕿 䚷䕿 F T UL

UL : USA, Canada

Power supply specifications, 9 : 3phase 208/230 V, 60 Hz

6 : 3phase 460 V, 60 Hz

T : Inverter Unit

F : Heat Recovery, H : Heat Pump

Development series number

Nominal cooling capacity

Refrigerant R410A

M : Single module unit, No mark : Combined Model name

Modular Multi

1 System overview

1

System overview

4

1-2. Summary of system equipments

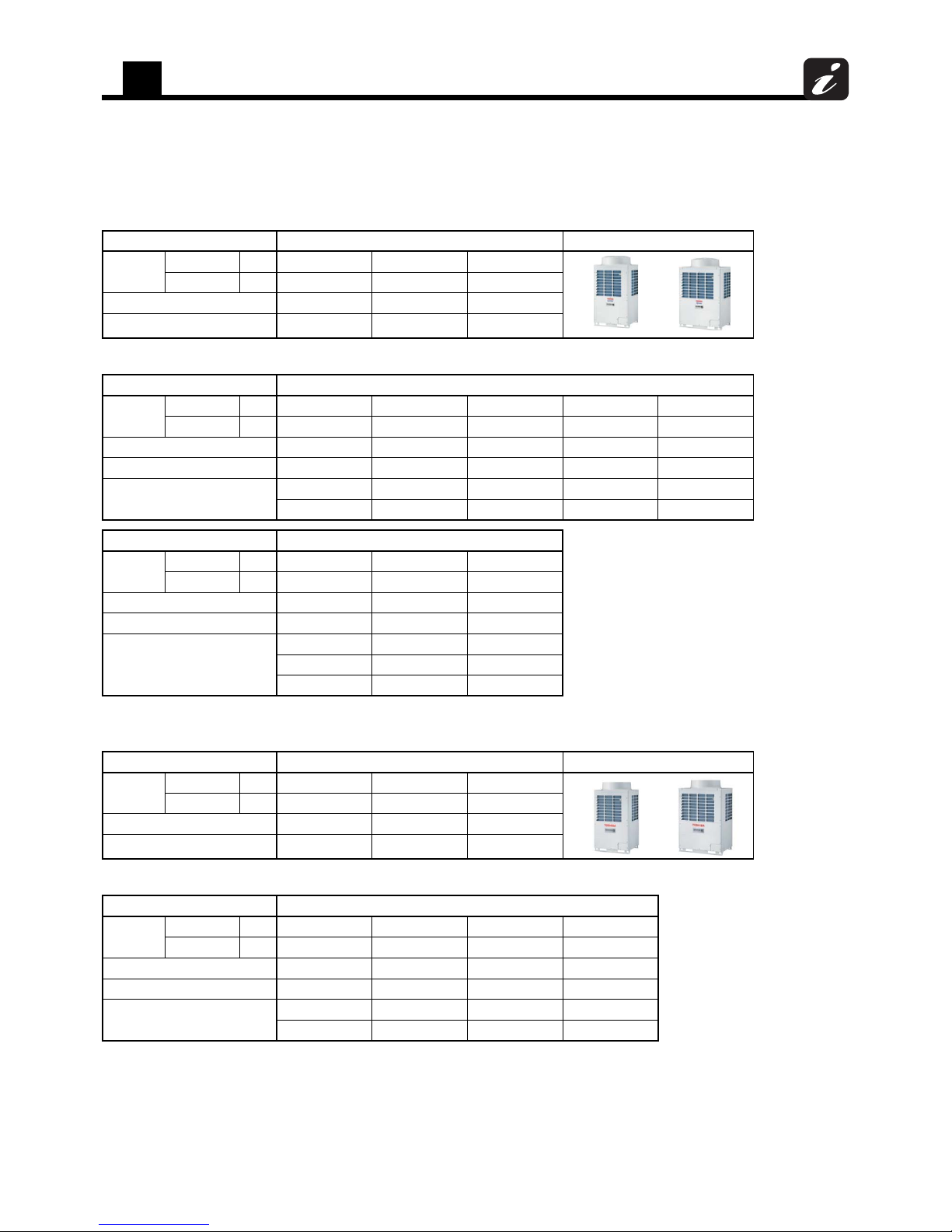

1-2-1. Outdoor units

1-2-1-1. Heat recovery

Combination of outdoor units

1-2-1-2. Heat pump

Combination of outdoor units

Unit type Inverter unit Appearance

Model name

208/230 V, 60 Hz MMY- MAP0724FT9UL MAP0964FT9UL MAP1204FT9UL

460 V, 60 Hz MMY- MAP0724FT6UL MAP0964FT6UL MAP1204FT6UL

Capacity type 072 type 096 type 120 type

Capacity code 72 96 120

Unit type Inverter unit

Model name

208/230 V, 60 Hz MMY- AP1444FT9UL AP1684FT9UL AP1924FT9UL AP2164FT9UL AP2404FT9UL

460 V, 60 Hz MMY- AP1444FT6UL AP1684FT6UL AP1924FT6UL AP2164FT6UL AP2404FT6UL

Capacity type 144 type 168 type 192 type 216 type 240 type

Capacity code 144 168 192 216 240

Combined outdoor units

072 type 096 type 096 type 120 type 120 type

072 type 072 type 096 type 096 type 120 type

Unit type Inverter unit

Model name

208/230 V, 60 Hz MMY- AP2884FT9UL AP3124FT9UL AP3364FT9UL

460 V, 60 Hz MMY- AP2884FT6UL AP3124FT6UL AP3364FT6UL

Capacity type 288 type 312 type 336 type

Capacity code 288 312 336

Combined outdoor units

096 type 120 type 120 type

096 type 096 type 120 type

096 type 096 type 096 type

Unit type Inverter unit Appearance

Model name

208/230 V, 60 Hz MMY- MAP0724HT9UL MAP0964HT9UL MAP1144HT9UL

460 V, 60 Hz MMY- MAP0724HT6UL MAP0964HT6UL MAP1144HT6UL

Capacity type 072 type 096 type 114 type

Capacity code 72 96 114

Unit type Inverter unit

Model name

208/230 V, 60 Hz MMY- AP1444HT9UL AP1684HT9UL AP1924HT9UL AP2284HT9UL

460 V, 60 Hz MMY- AP1444HT6UL AP1684HT6UL AP1924HT6UL AP2284HT6UL

Capacity type 144 type 168 type 192 type 228 type

Capacity code 144 168 192 228

Combined outdoor units

072 type 096 type 096 type 114 type

072 type 072 type 096 type 114 type

1

System overview

5

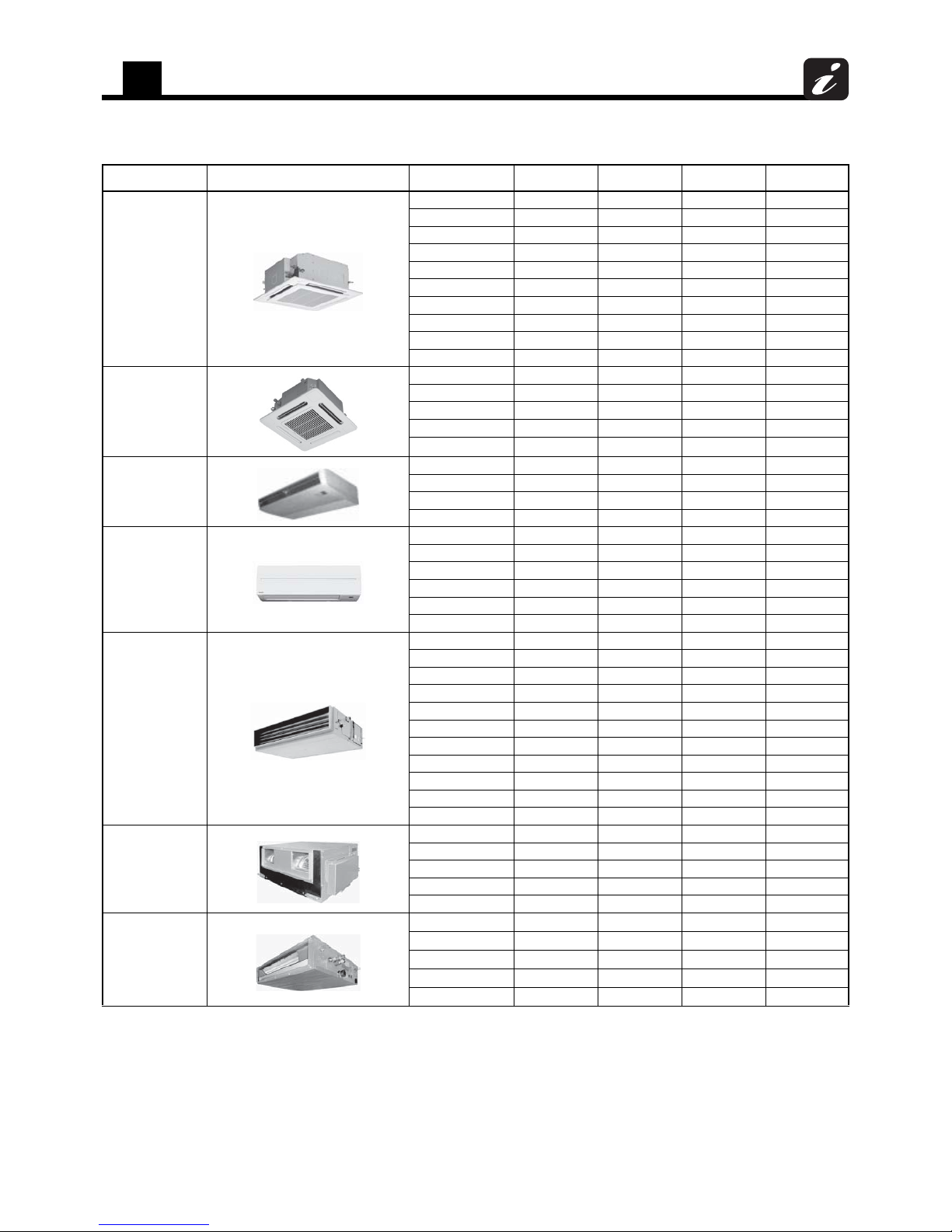

1-2-2. Indoor unit

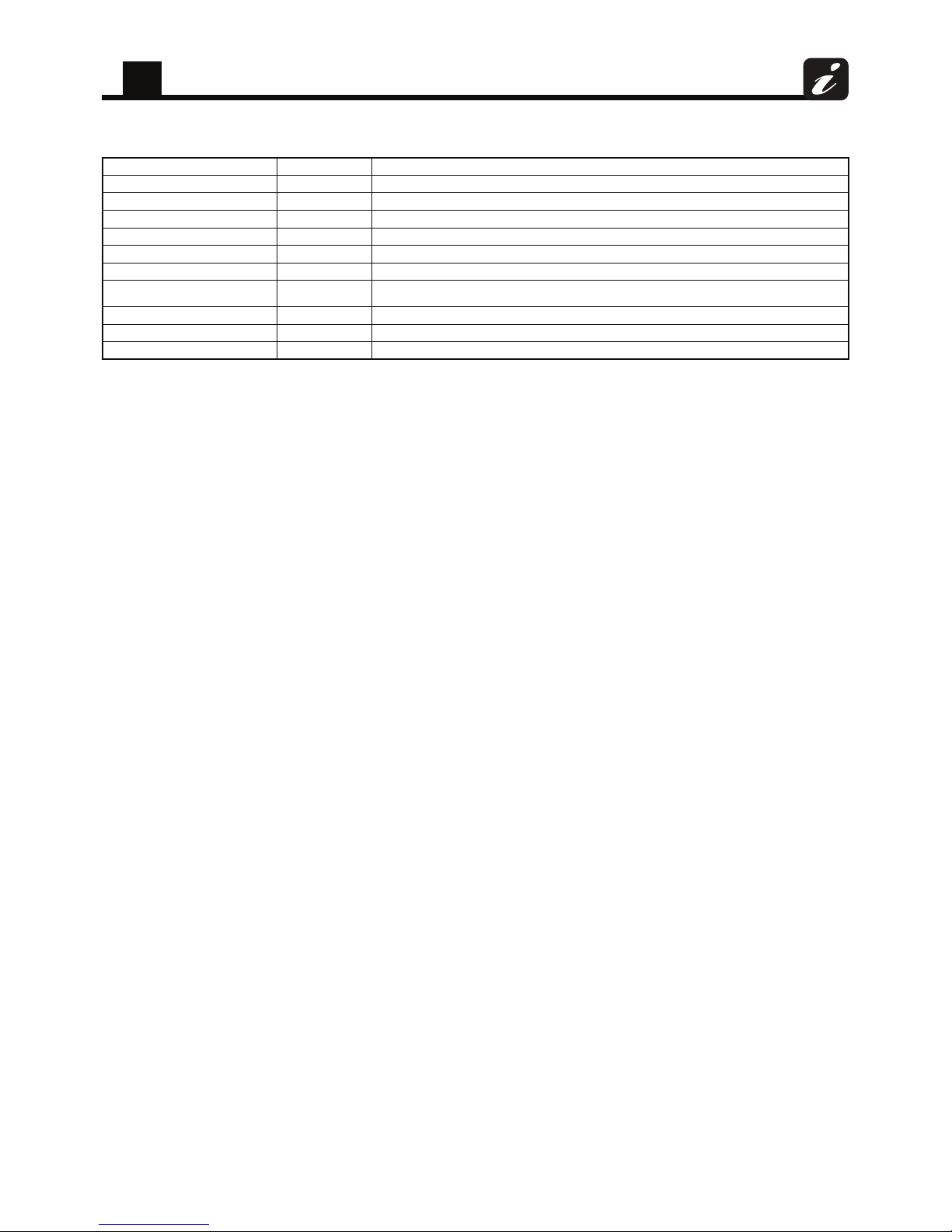

Type Appearance Model name Capacity type Capacity code

Cooling capacity

(kBtu/h)

Heating capacity

(kBtu/h)

4-Way Cassette type

MMU-AP0072H2UL 007 type 7.5 7.5 8.5

MMU-AP0092H2UL 009 type 9.5 9.5 10.5

MMU-AP0122H2UL 012 type 12 12 13.5

MMU-AP0152H2UL 015 type 15.4 15.4 17

MMU-AP0182H2UL 018 type 18 18 20

MMU-AP0212H2UL 021 type 21 21 24

MMU-AP0242H2UL 024 type 24 24 27

MMU-AP0302H2UL 030 type 30 30 34

MMU-AP0362H2UL 036 type 36 36 40

MMU-AP0422H2UL 042 type 42 42 47.5

Compact 4-Way

Cassette type

MMU-AP0071MH2UL 007 type 7.5 7.5 8.5

MMU-AP0091MH2UL 009 type 9.5 9.5 10.5

MMU-AP0121MH2UL 012 type 12 12 13.5

MMU-AP0151MH2UL 015 type 15.4 15.4 17

MMU-AP0181MH2UL 018 type 18 18 20

Ceiling type

MMC-AP0181H2UL 018 type 18 18 20

MMC-AP0241H2UL 024 type 24 24 27

MMC-AP0361H2UL 036 type 36 36 40

MMC-AP0421H2UL 042 type 42 42 47.5

High Wall type

MMK-AP0073H2UL 007 type 7.5 7.5 8.5

MMK-AP0093H2UL 009 type 9.5 9.5 10.5

MMK-AP0123H2UL 012 type 12 12 13.5

MMK-AP0153H2UL 015 type 15.4 15.4 17

MMK-AP0183H2UL 018 type 18 18 20

MMK-AP0243H2UL 024 type 24 24 27

Medium Static Ducted

type

MMD-AP0074BH2UL 007 type 7.5 7.5 8.5

MMD-AP0094BH2UL 009 type 9.5 9.5 10.5

MMD-AP0124BH2UL 012 type 12 12 13.5

MMD-AP0154BH2UL 015 type 15.4 15.4 17

MMD-AP0184BH2UL 018 type 18 18 20

MMD-AP0214BH2UL 021 type 21 21 24

MMD-AP0244BH2UL 024 type 24 24 27

MMD-AP0304BH2UL 030 type 30 30 34

MMD-AP0364BH2UL 036 type 36 36 40

MMD-AP0424BH2UL 042 type 42 42 47.5

MMD-AP0484BH2UL 048 type 48 48 54

High Static Ducted type

MMD-AP0304H2UL 030 type 30 30 34

MMD-AP0364H2UL 036 type 36 36 40

MMD-AP0484H2UL 048 type 48 48 54

MMD-AP0724H2UL 072 type 72 72 81

MMD-AP0964H2UL 096 type 96 96 108

Slim Ducted type

MMD-AP0074SPH2UL 007 type 7.5 7.5 8.5

MMD-AP0094SPH2UL 009 type 9.5 9.5 10.5

MMD-AP0124SPH2UL 012 type 12 12 13.5

MMD-AP0154SPH2UL 015 type 15.4 15.4 17

MMD-AP0184SPH2UL 018 type 18 18 20

1

System overview

6

1-2-3. Branching joints and headers

1-2-4. FS units (Flow selector units)

1-2-5. Remote control

1-2-6. Optional PCB of outdoor unit

Name Model name Appearance

Y-shape branching

joint

Heat recovery

RBM-BY55FUL

RBM-BY105FUL

RBM-BY205FUL

RBM-BY305FUL

Heat pump

RBM-BY55UL

RBM-BY105UL

RBM-BY205UL

RBM-BY305UL

4-branching header

Heat recovery

RBM-HY1043FUL

RBM-HY2043FUL

Heat pump

RBM-HY1043UL

RBM-HY2043UL

8-branching header

Heat recovery

RBM-HY1083FUL

RBM-HY2083FUL

Heat pump

RBM-HY1083UL

RBM-HY2083UL

Branching joint for

connection of outdoor

units

Heat recovery

RBM-BT14FUL

RBM-BT24FUL

Heat pump RBM-BT14UL

Name Model name Appearance

FS unit

RBM-Y0383FUL

RBM-Y0613FUL

RBM-Y0963FUL

Name Model name Remarks

Wired remote control RBC-AMT32UL

Lite-Vision plus remote control RBC-AMS51E-ES

Simple wired remote control RBC-AS41UL

Wireless remote control kit

RBC-AX32U(W)-UL For 4-Way Cassette type

RBC-AX33C-UL For Ceiling type

TCB-AX32UL For Compact 4-Way Cassette type, Medium Static Ducted type, Slim Ducted type

Central remote control BMS-CM1281TLUL

Wired remote control with weekly timer RBC-AMS41UL

Name Model name Remarks

Power peak-cut control board TCB-PCDM4UL Power peak-cut control

External master ON/OFF control boar d TCB-PCMO4UL Extern al master ON/OFF control, Night operation control, Oper ation mode selection control, Snowfall fan control

Output control board TCB-PCIN4UL Error / operation output control, Compressor operation output, Operating rate output

1

System overview

7

1-2-7. Controls

Name Model name Remarks

Remote location ON/OFF Control Box TCB-IFCB-4UL

“1:1 model" Connection Interface TCB-PCNT31TLUL Link adapter for "1:1 model" to enable connection to VRF system network.

LonWorks LN Interface TCB-IFLN642TLUL

Smart BMS manager BMS-SM1280HTLUL

Energy Monitoring Relay Interface BMS-IFWH5UL

Digital I/O Relay Interface BMS-IFDD03UL

BACnet Server

BMS-LSV6UL

BMS-STBN09UL

TCS-NET Relay Interface BMS-IFLSV4UL

Touch Screen Controller BMS-CT5120UL

BMS-IFBN640TLUL

BN Interface

2

Equipment selection procedure

8

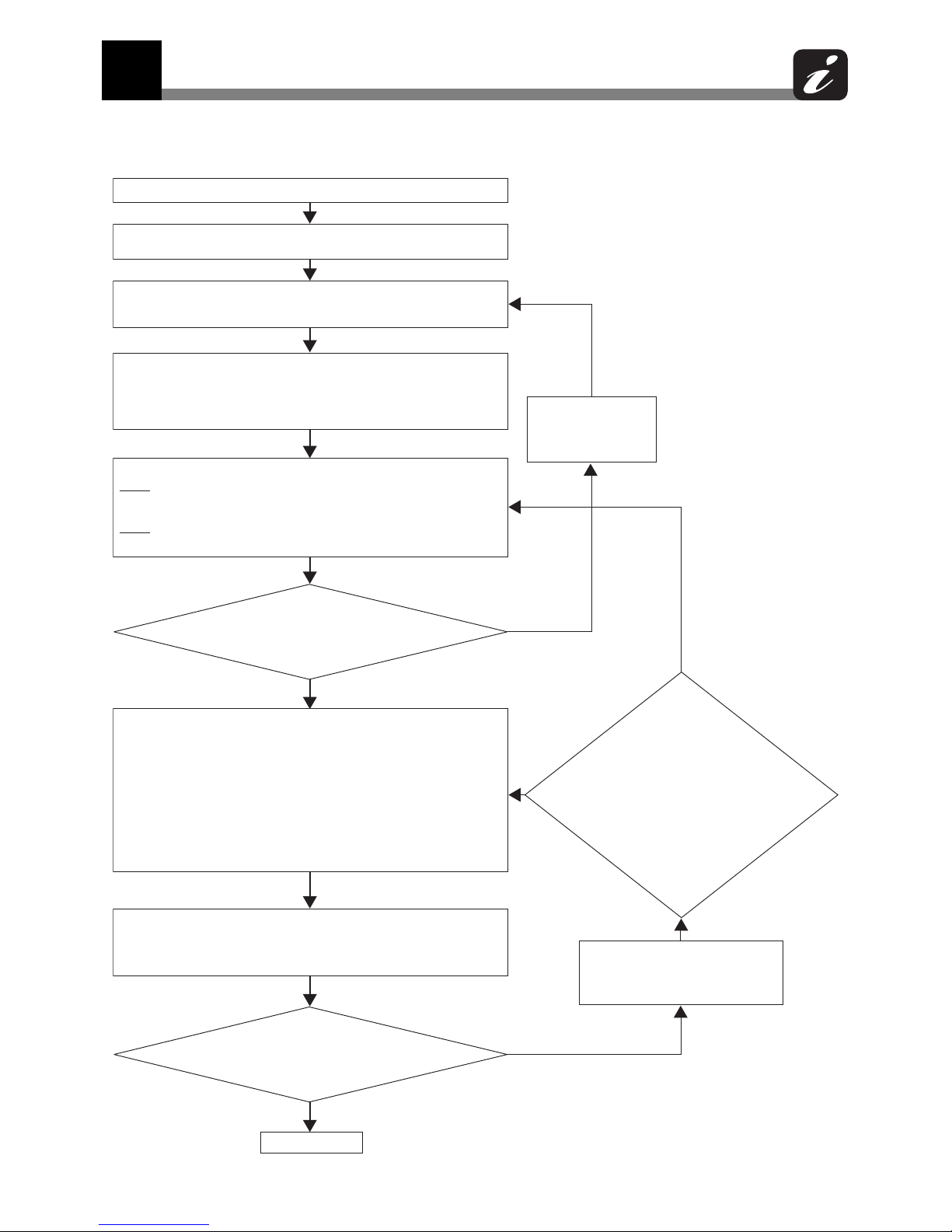

2-1. Selection flow chart

(1) Determination of indoor air-conditioning load at each room.

(2) Preliminary selection of indoor units in the standard capacity no less

than air-conditioning load at each room.

(3) Calculate corrected capacity A of each indoor unit by correcting of

indoor temperature for the standard capacity of each indoor unit.

([Chart 1])

(4) Preliminary selection of outdoor unit in the standard capacity no less

than total values of corrected capacity A in indoor units. At the same time,

check both connectable indoor units number and the outdoor unit

diversity(Connected ratio of indoor units to outdoor units) for the

specifications.

(5) Calculate corrected capacity B of each indoor unit by following 2 steps.

Step1:Find the correction value of "Connecting pipe length and lift" by

both the longest length and the largest height with selected piping

condition at (4) or (4)'. ([Chart 3])

Step2:Calculate capacity B by multiplying the value of step1 by corrected

capacity A.

(6) Corrected capacity B of indoor

unit >= air-conditioning load (for All

rooms)

(9) Corrected capacity C of indoor

unit >= air-conditioning load (for All

rooms)

(7) Find correction values of below items for the standard capacity of

outdoor unit selected at (4) or (4)'.

Then determination of total corrected capacity of the selected outdoor unit

by all multiplying.

-Correction of indoor temperature condition ([Chart 1])

-Correction of outdoor temperature condition ([Chart 2])

-Correction of connecting pipe length and lift between indoor and outdoor

units by both the longest length and the largest height ([Chart 3])

-Correction of outdoor unit diversity in only over 100 % ([Chart 4])

-Correction of frost condition on outdoor heat exchanger when in heating

([Chart 5])

(8) Calculate corrected capacity C of each indoor unit by multiplying the

total corrected capacity of outdoor unit at (7) by proportional division of

each indoor unit standard capacity for total standard capacity of all indoor

units.

end

(4)' Increase of outdoor unit capacity.

At the same time, check both

connectable indoor units number

and the outdoor unit diversity

(5)' <Only cooling>

The correction characteristic

of "connecting pipe length and

lift" ([Chart 3]) between

increased outdoor unit at (4)'

and preliminary selected

outdoor unit at (4) is different.

(The both graphs are

different.)

(2)' Increase of indoor

unit capacity at object

room against airconditioning load

NO

NO

NO

YES

YES

YES

2 Equipment selection procedure

2

Equipment selection procedure

9

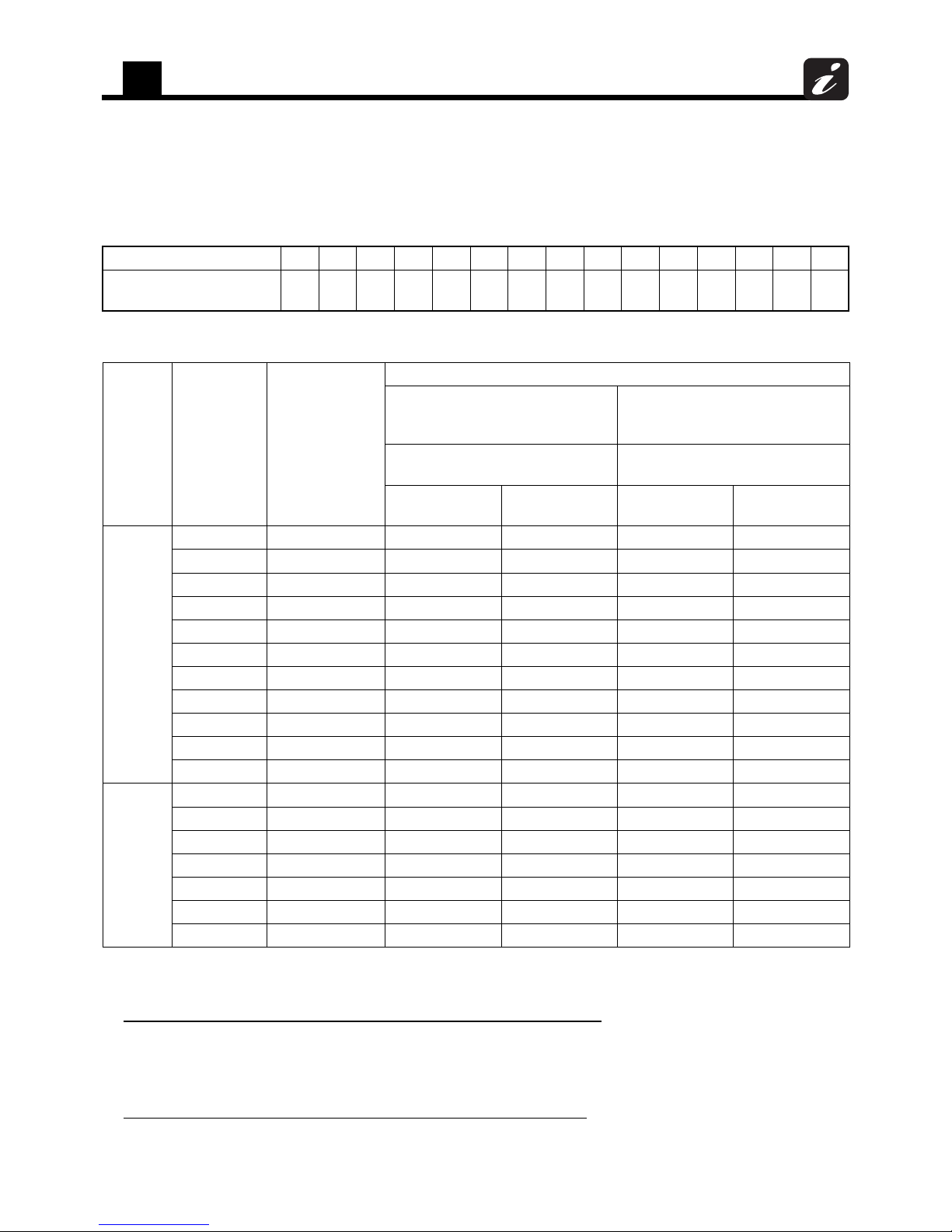

2-2. Combination conditions for indoor unit and

outdoor unit

2-2-1. The capacity code for indoor unit, the capacity code is decided for each capacity rank.

2-2-2. The capacity codes of outdoor units are decided at each capacity type. The maximum number of connectable

indoor units and the total value of capacity codes of the indoor units are also decided.

NOTE

Compared with the capacity code of the outdoor unit, the total value of capacity codes of the connectable indoor

units differs based on the height difference between the indoor units.

When the height difference between the indoor units is 49 ft (15 m) or less

If “Medium Static Ducted Type (MMD-AP***BH)” is excluded in the system: Total indoor capacity code must be

between 80% and 125% of the capacity of the outdoor unit.

Total indoor capacity code must be between 80% and 120% of the capacity of the outdoor unit.

If “one of 007, 009 or 012 of 4-way Air Discharge Cassette type (MMU-AP***H*)” is included in the system:

Total indoor capacity code must be 80% - 105%.

When the height difference between the indoor units is over 49 ft (15 m)

Total indoor unit capacity code (Equivalent to Capacity) must be between 80% and 105% of the capacity of the

outdoor unit.

If “one of 007, 009 or 012 of 4-way Air Discharge Cassette type (MMU-AP***H*)” is included in the system:

Total indoor capacity code must be 80% - 105%.

Capacity rank type 007 009 012 015 018 021 024 027 030 036 042 048 054 072 096

Capacity code

(Equivalent to capacity)

7.5 9.5 12 15.4 18 21 24 27 30 36 42 48 54 72 96

System Outdoor unit

capacity

type

Outdoor

capacity code

(Equivalent to

capacity)

Maximum number of indoor units

If “Medium Static Ducted Type

(MMD-AP***BH)” is excluded in

the system

If “Medium Static Ducted Type

(MMD-AP***BH)” is included in

the system

Height difference between

indoor units

Height difference between

indoor units

49 ft (15 m) or

less

Over 49 ft (15 m) 49 ft (15 m) or

less

Over 49 ft (15 m)

Heat

recovery

072 type 72 12 10 11 10

096 type 96 16 13 15 13

120 type 120 20 16 19 16

144 type 144 24 20 23 20

168 type 168 28 23 26 23

192 type 192 32 26 30 26

216 type 216 36 30 34 30

240 type 240 40 33 38 33

288 type 288 48 40 46 40

312 type 312 48 43 48 43

336 type 336 48 47 48 47

Heat

pump

072 type 72 12 10 11 10

096 type 96 16 13 15 13

114 type11419151815

144 type 144 24 20 23 20

168 type 168 28 23 26 23

192 type 192 32 26 30 26

228 type 228 38 31 36 31

2

Equipment selection procedure

10

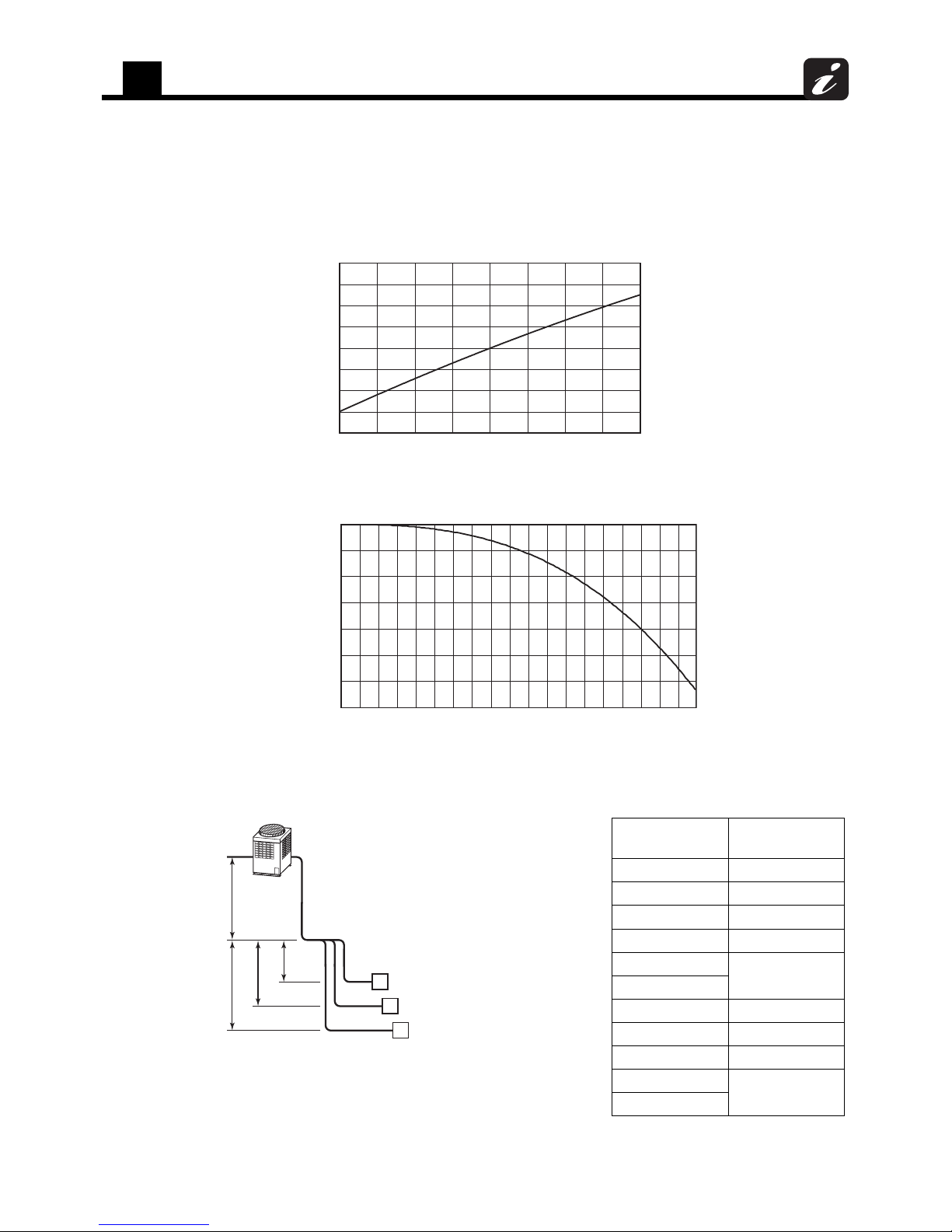

2-3. Cooling/heating capacity characteristics

2-3-1. Heat recovery

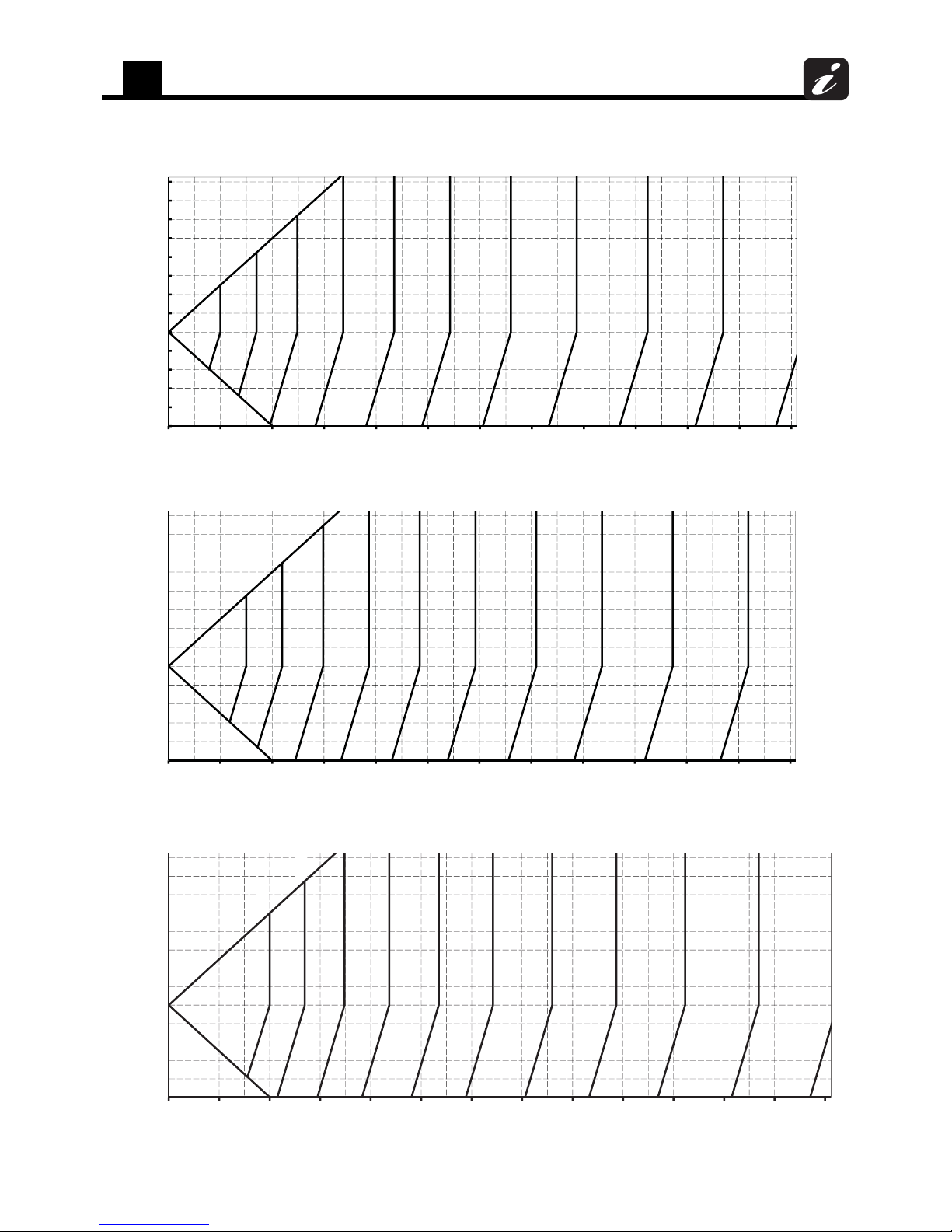

2-3-1-1. Correction charts for cooling capacity calculation

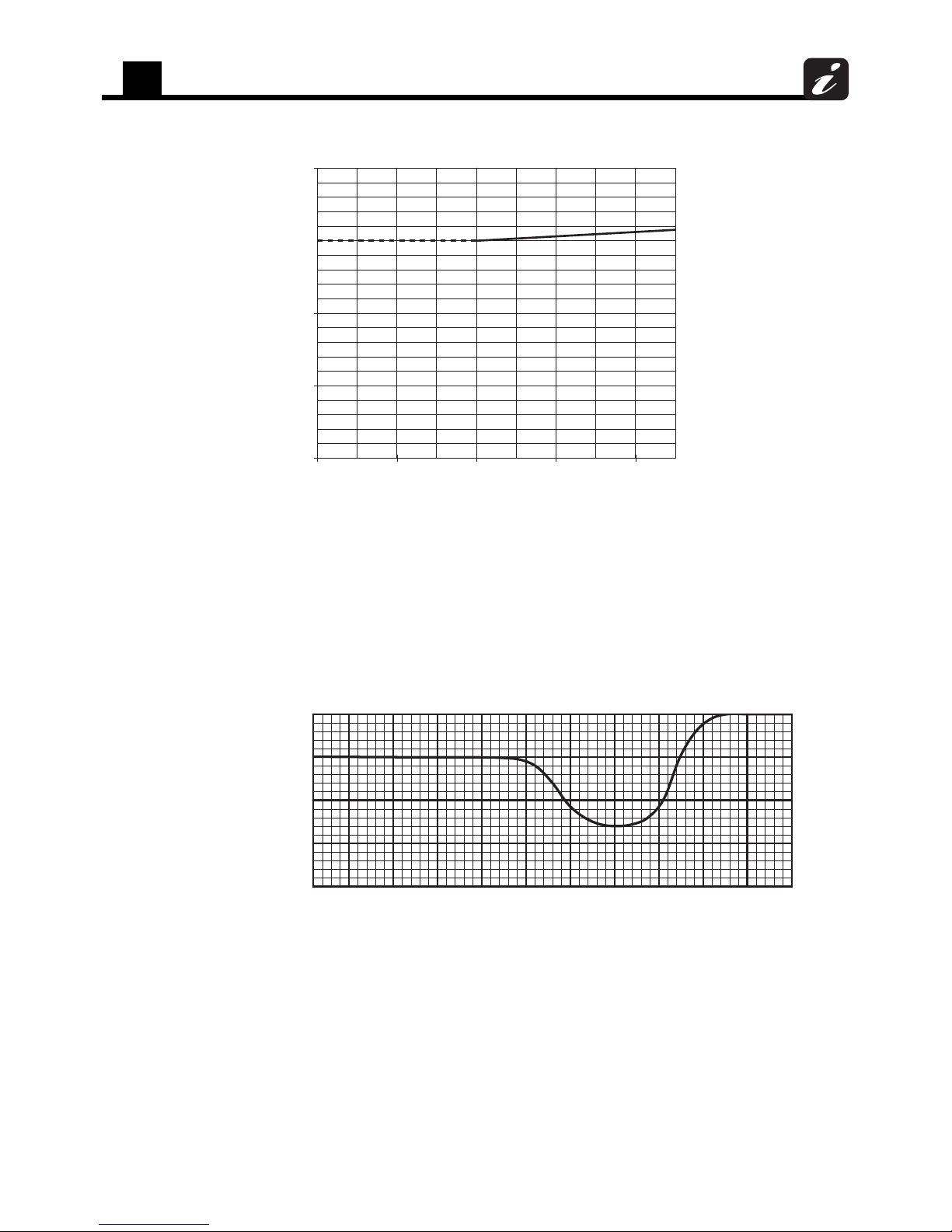

[Chart 1] Indoor air wet bulb temperature vs. capacity correction value

[Chart 2] Outdoor air dry bulb temperature vs. capacity correction value

[Chart 3] Connecting pipe length and lift difference between indoor and outdoor units vs.

capacity correction value

0.8

0.9

1

1.1

1.2

59 61 63 65 67 69 71 73 75

Indoor air wet bulb temp. (°F WB)

Capacity correction value

Outdoor air dry bulb temp. (°F DB)

Capacity correction value

0.85

0.9

0.95

1

1.05

1.1

1.15

1.2

20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 10514

Outdoor unit

Indoor unit

L is the longest one of (lo + la, lo + lb, lo + lc)

H = ho + (Largest one of ha, hb, and hc)

A

ha

hb

hc

ho lo

la

lb

lc

B

C

Outdoor unit

capacity type

Graph

072 A1

096 B1

120 A2

144 A3

168

B2

192

216 A3

240 B2

288 A3

312

B2

336

2

Equipment selection procedure

11

Outdoor unit (A1)

indoor and outdoor units H (ft)

Lift difference height between

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600

Piping equivalent length (ft)

1.0

0.95

0.90

0.875

0.85

0.825

0.80

0.775

0.75

0.925

0.975

indoor and outdoor units H (ft)

Outdoor unit (A2)

Lift difference height between

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600

Piping equivalent length (ft)

1.0

0.975

0.90

0.875

0.85

0.825

0.80

0.775

0.925

- 100

0.95

Outdoor unit (A3)

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Lift difference height between

indoor and outdoor units H (ft)

Piping equivalent length (ft)

0.95

0.90

0.875

0.85

0.825

0.80

0.775

0.75

0.925

0.975

1.0

2

Equipment selection procedure

12

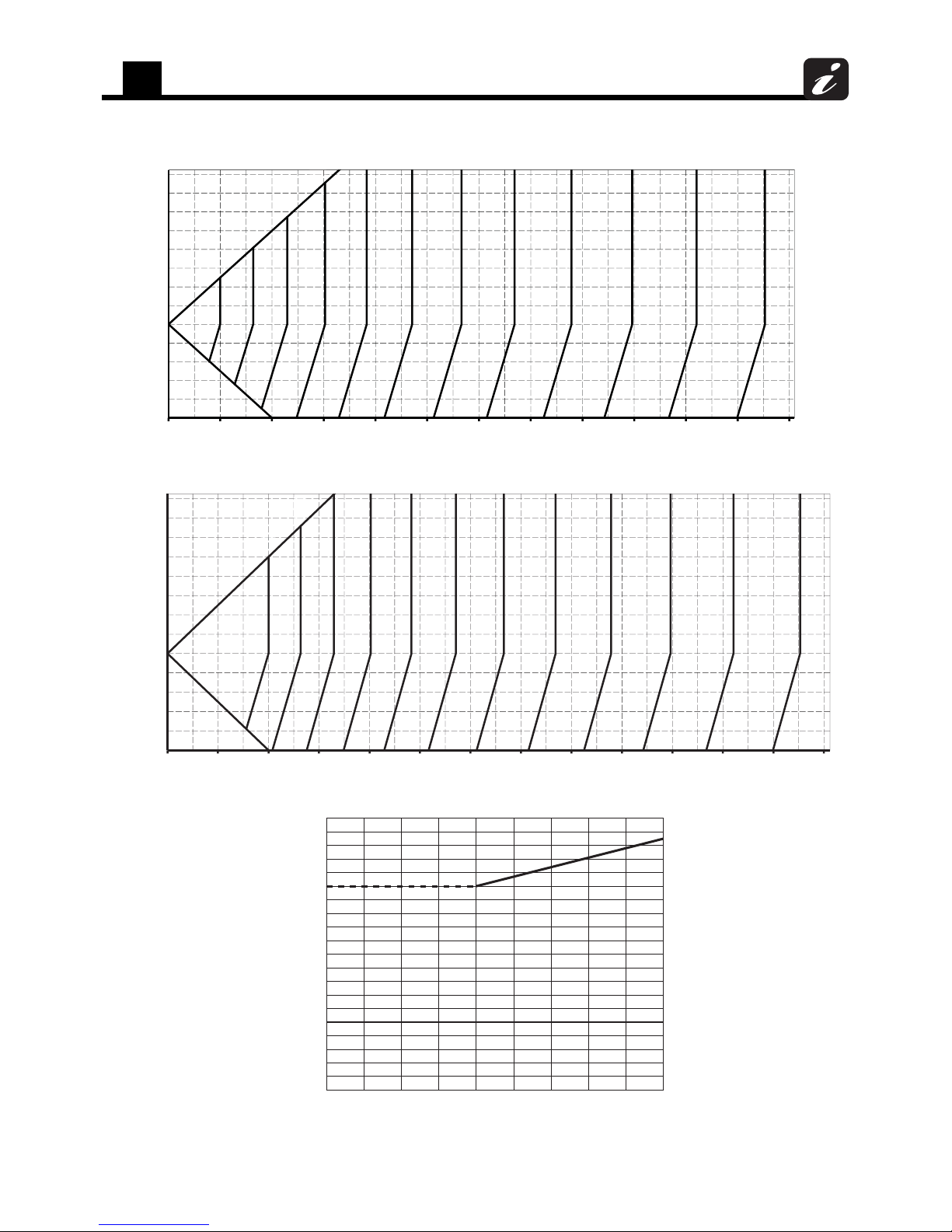

[Chart 4]* Correction of outdoor unit diversity

* Coefficient to use for the correction of the outdoor unit capacity when the total capacity of the indoor units are not

equal to the outdoor unit capacity.

Outdoor unit (B1)

indoor and outdoor units H (ft)

Lift difference height between

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600

Piping equivalent length (ft)

1.0

0.95

0.90

0.875

0.85

0.825

0.80

0.775

0.725

0.75

0.925

0.975

- 100

Outdoor unit (B2)

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Lift difference height between

indoor and outdoor units H (ft)

Piping equivalent length (ft)

1.0

0.95

0.90

0.875

0.85

0.825

0.80

0.775

0.75

0.925

0.975

0.725

0.7

0.8

0.9

1

1.1

80 90 100 110 120

Indoor units total capacity ratio (%)

Capacity correction value

2

Equipment selection procedure

13

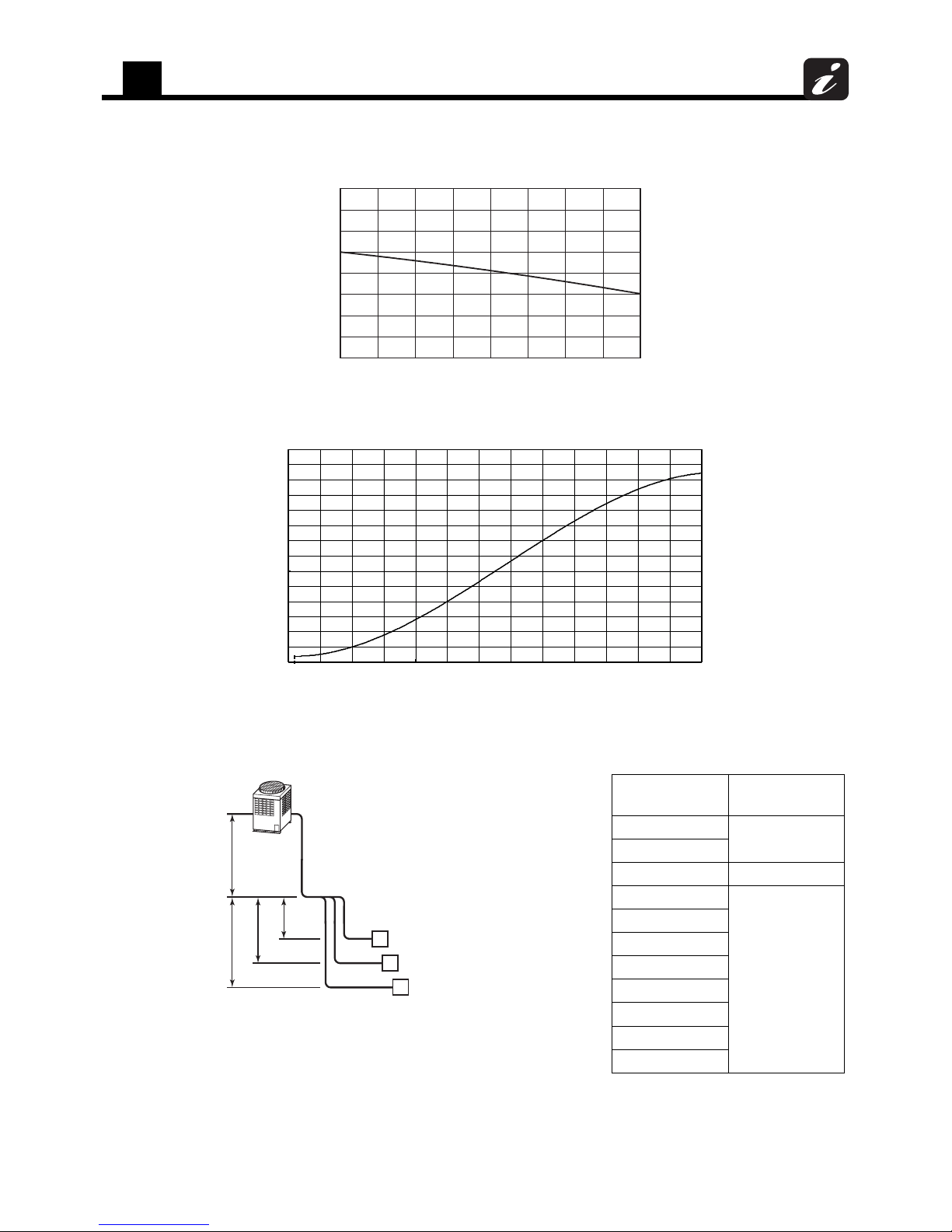

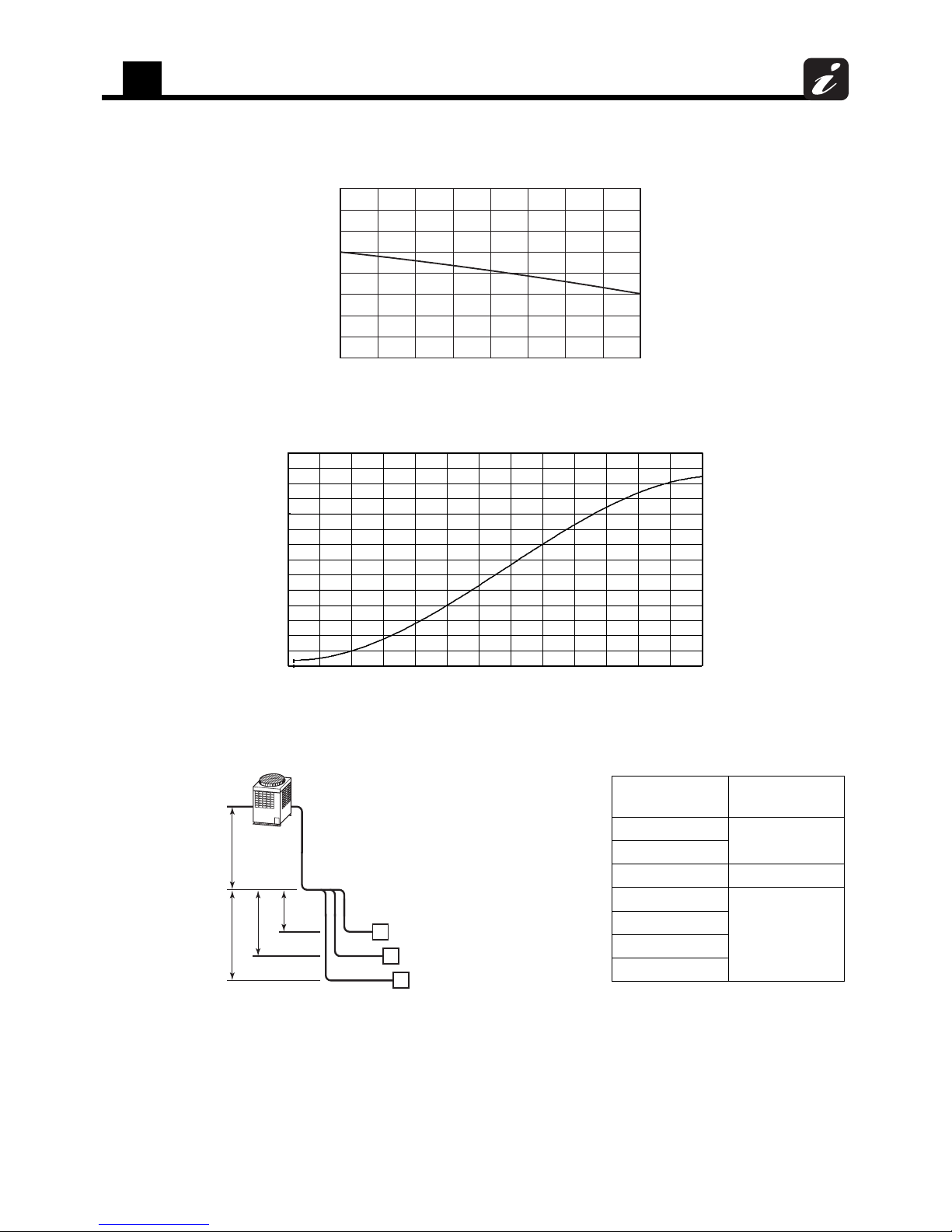

2-3-1-2. Correction charts for heating capacity calculation

[Chart 1] Indoor air dry bulb temperature vs. capacity correction value

[Chart 2] Outdoor air wet bulb temperature vs. capacity correction value

[Chart 3] Connecting pipe length and lift difference between indoor and outdoor units vs.

capacity correction value

0.8

0.9

1

1.1

1.2

61 63 65 67 69 71 73 75 77

Indoor air dry bulb temp. (°F DB)

Capacity correction value

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Capacity correction value

Outdoor ai r wet bulb temp. ( °F WB)

-

4

Outdoor unit

capacity type

Graph

072

X

096

120 Y

144

Z

168

192

216

240

288

312

336

Outdoor unit

Indoor unit

L is the longest one of (lo + la, lo + lb, lo + lc)

H = ho + (Largest one of ha, hb, and hc)

A

ha

hb

hc

ho lo

la

lb

lc

B

C

2

Equipment selection procedure

14

Outdoor unit (X)

indoor and outdoor units H (ft)

Lift difference height between

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600

Piping equivalent length (ft)

1.00

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

0.89

Outdoor unit (Y)

indoor and outdoor units H (ft)

Lift difference height between

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600

Piping equivalent length (ft)

1.00

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

Outdoor unit (Z)

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Lift difference height between

indoor and outdoor units H (ft)

Piping equivalent length (ft)

1.0

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

0.89

2

Equipment selection procedure

15

[Chart 4]* Correction of outdoor unit diversity

* Coefficient to use for the correction of the outdoor unit capacity when the total capacity of the indoor units are not

equal to the outdoor unit capacity.

2-3-1-3. Capacity correction in case of frost on the outdoor heat exchanger when in

heating

Correct the heating capacity when frost can be found on the outdoor heat exchanger.

Heating capacity =Capacity after correction of outdoor unit x Correction value of capacity resulted from

frost (Capacity after correction of outdoor unit: Heating capacity calculated in the

above item 2.)

[Chart 5] Capacity correction in case of frost on the outdoor heat exchanger

2-3-1-4. Rated conditions

Cooling: Indoor air temperature 80 °F DryBulb/67 °F WetBulb, Outdoor air temperature 95 °F DryBulb

Heating: Indoor air temperature 70 °F DryBulb, Outdoor air temperature 47 °F DryBulb/43 °F WetBulb

0.7

0.8

0.9

1

1.1

80 90 100 110 120

Indoor units total capacity ratio (%)

Capacity correction value

Outdoor air wet bulb temp. (°F WB)

Capacity correction value

0.8

0.85

0.9

0.95

1

-4 0 5 10 15 20 25 30 35 40 45 50

2

Equipment selection procedure

16

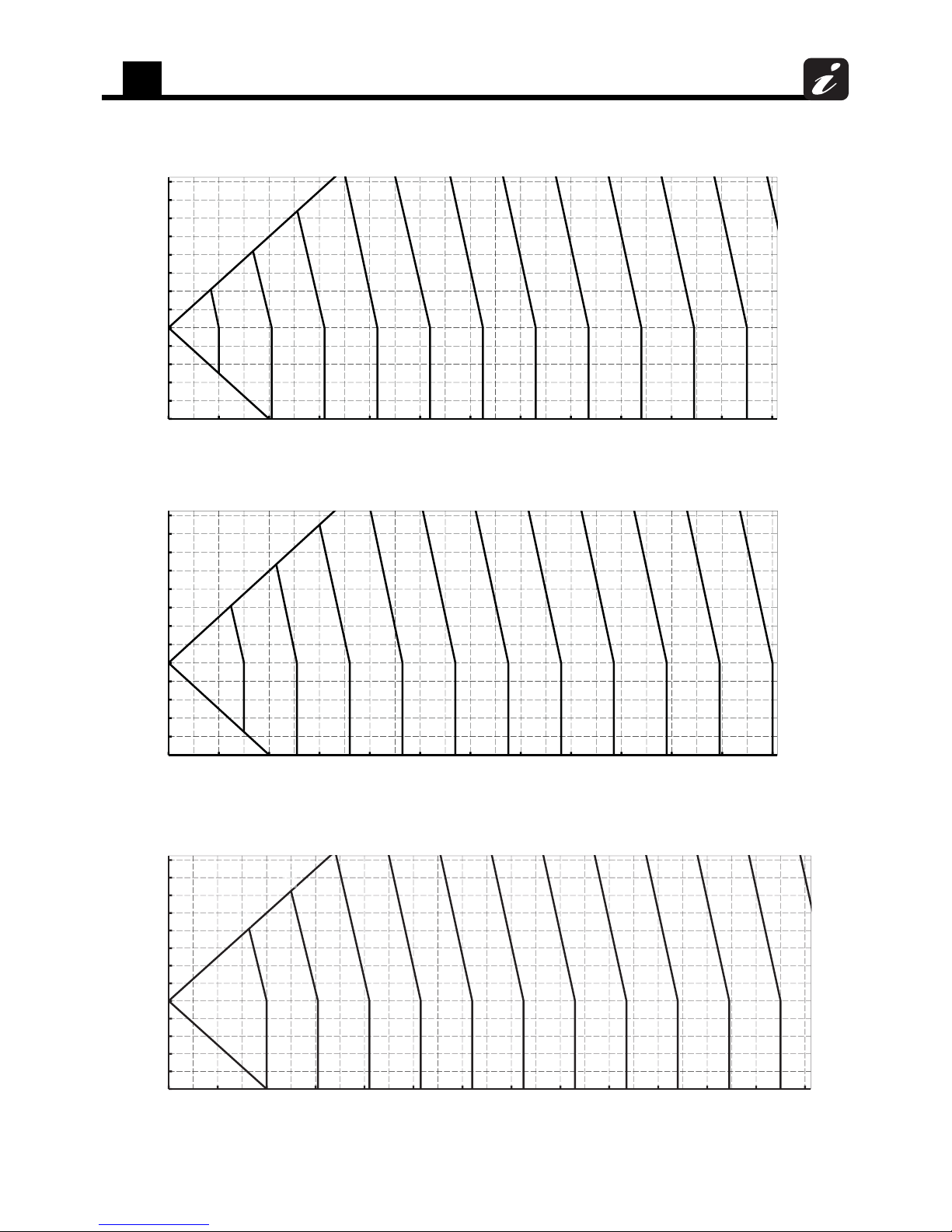

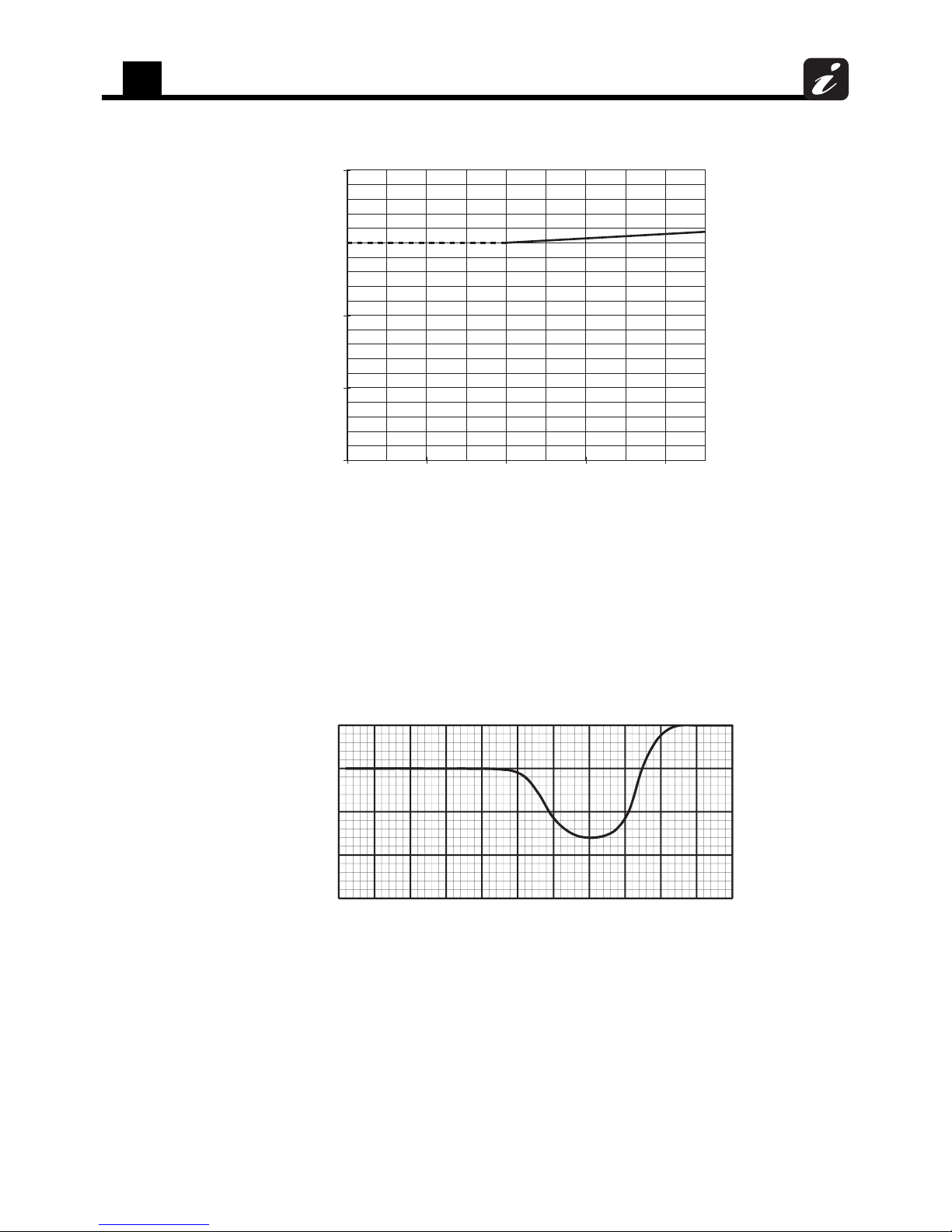

2-3-2. Heat pump

2-3-2-1. Correction charts for cooling capacity calculation

[Chart 1] Indoor air wet bulb temperature vs. capacity correction value

[Chart 2] Outdoor air dry bulb temperature vs. capacity correction value

[Chart 3] Connecting pipe length and lift difference between indoor and outdoor units vs.

capacity correction value

0.8

0.9

1

1.1

1.2

59 61 63 65 67 69 71 73 75

Indoor air wet bulb temp. (°F WB)

Capacity correction value

0.8

0.85

0.9

0.95

1

1.05

1.1

1.15

1.2

25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115

Capacity correction value

Outdoor air dry bulb temp. (°F DB)

Outdoor unit

Indoor unit

L is the longest one of (lo + la, lo + lb, lo + lc)

H = ho + (Largest one of ha, hb, and hc)

A

ha

hb

hc

ho lo

la

lb

lc

B

C

Outdoor unit

capacity type

Graph

072 A1

096 B1

114 A2

144 A3

168

B2

192

228 A3

2

Equipment selection procedure

17

Outdoor unit (A1)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

0.875

0.85

0.825

0.80

0.775

0.725

0.75

1.0

0.95

0.90

0.925

0.975

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

0 50 100 150 200 250 300 350 400 450 500 550 600 650

indoor and outdoor units H (ft)

1.0

0.975

0.90

0.875

0.85

0.825

0.80

0.775

0.725

0.75

0.925

0.95

Piping equivalent length (ft)

Outdoor unit (A2)

Lift difference height between

-120

-100

-80

-60

-40

-20

20

40

60

80

100

120

140

160

180

200

220

0

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700

Outdoor unit (A3)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

0.90

0.875

0.85

0.825

0.80

0.775

0.75

1.0

0.95

0.975

0.925

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

2

Equipment selection procedure

18

[Chart 4]* Correction of outdoor unit diversity

* Coefficient to use for the correction of the outdoor unit capacity when the total capacity of the indoor units are not

equal to the outdoor unit capacity.

Outdoor unit (B1)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

0.875

0.85

0.825

0.80

0.775

0.725

0.75

0.70

0.675

1.0

0.95

0.90

0.925

0.975

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700

Outdoor unit (B2)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

0.90

0.875

0.85

0.825

0.80

0.775

0.70

0.75

0.725

1.0

0.95

0.925

0.975

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

0.7

0.8

0.9

1

1.1

80 90 100 110 120

Indoor units total capacity ratio (%)

Capacity correction value

2

Equipment selection procedure

19

2-3-2-2. Correction charts for heating capacity calculation

[Chart 1] Indoor air dry bulb temperature vs. capacity correction value

[Chart 2] Outdoor air wet bulb temperature vs. capacity correction value

[Chart 3] Connecting pipe length and lift difference between indoor and outdoor units vs.

capacity correction value

0.8

0.9

1

1.1

1.2

61 63 65 67 69 71 73 75 77

Indoor air dry bulb temp. (°F DB)

Capacity correction value

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Capacity correction value

Outdoor ai r wet bulb temp. ( °F WB)

-

4

Outdoor unit

capacity type

Graph

072

X

096

114 Y

144

Z

168

192

228

Outdoor unit

Indoor unit

L is the longest one of (lo + la, lo + lb, lo + lc)

H = ho + (Largest one of ha, hb, and hc)

A

ha

hb

hc

ho lo

la

lb

lc

B

C

2

Equipment selection procedure

20

Outdoor unit (X)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

1.00

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

0.89

0.88

0.87

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700

Outdoor unit (Y)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

1.00

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

0.89

0.88

0.87

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700

Outdoor unit (Z)

Piping equivalent length (ft)

indoor and outdoor units H (ft)

1.00

0.99

0.98

0.97

0.96

0.95

0.94

0.93

0.92

0.91

0.90

0.89

0.88

Lift difference height between

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

2

Equipment selection procedure

21

[Chart 4]* Correction of outdoor unit diversity

* Coefficient to use for the correction of the outdoor unit capacity when the total capacity of the indoor units are not

equal to the outdoor unit capacity.

2-3-2-3. Capacity correction in case of frost on the outdoor heat exchanger when in

heating

Correct the heating capacity when frost can be found on the outdoor heat exchanger.

Heating capacity =Capacity after correction of outdoor unit x Correction value of capacity resulted from

frost (Capacity after correction of outdoor unit: Heating capacity calculated in the

above item 2.)

[Chart 5] Capacity correction in case of frost on the outdoor heat exchanger

2-3-2-4. Rated conditions

Cooling: Indoor air temperature 80 °F DryBulb/67 °F WetBulb, Outdoor air temperature 95 °F DryBulb

Heating: Indoor air temperature 70 °F DryBulb, Outdoor air temperature 47 °F DryBulb/43 °F WetBulb

0.7

0.8

0.9

1

1.1

80 90 100 110 120

Indoor units total capacity ratio (%)

Capacity correction value

0.8

0.85

0.9

0.95

1

-5 0 5 10 15 20 25 30 35 40 45 50

Capacity correction value

Outdoor air wet bulb temp. (°F WB)

2

Equipment selection procedure

22

2-4. Operational temperature range

2-4-1. Heat recovery

2-4-2. Heat pump

6050

Indoor air wet bulb temp. (°F)

70 80 90

40

60

80

100

30

20

10

14

50

70

90

110

82

Continuously

operable

range

Cooling

Range for pull

down operation

Outdoor air dry bulb temp. (°F)

40 50

Indoor air dry bulb temp. (°F)

60 70 80

0

-4

-10

10

60

40

20

50

70

Continuously

operable

range

Heating

Range for warming

up operation

Outdoor air wet bulb temp. (°F)

90

30

Avoid the following place

Places where ambient temperature falls

below 5 °F for more than 72 hours running.

The outdoor heat exchanger may be

damaged by the frost.

The cooling performance may decline

considerably when total operating capacity

of cooling indoor units is less than 38 kBtu/h

while ambient temperature is below 32 °F.

40 50

Indoor air dry bulb temp. (°F)

60 70 80

0

-4

-10

10

60

40

20

50

70

Continuously

operable

range

Heating

Range for warming

up operation

Outdoor air wet bulb temp. (°F)

90

30

50 60

Indoor air wet bulb temp. (°F)

70 80 90

20

40

60

80

100

30

50

70

90

110

23

82

Continuously

operable

range

Cooling

Range for pull

down operation

Outdoor air dry bulb temp. (°F)

115

Avoid the following place

Places where ambient temperature falls

below 5 °F for more than 72 hours running.

The outdoor heat exchanger may be

damaged by the frost.

Refrigerant piping design

3

23

3 Refrigerant piping design

3-1. Free branching system

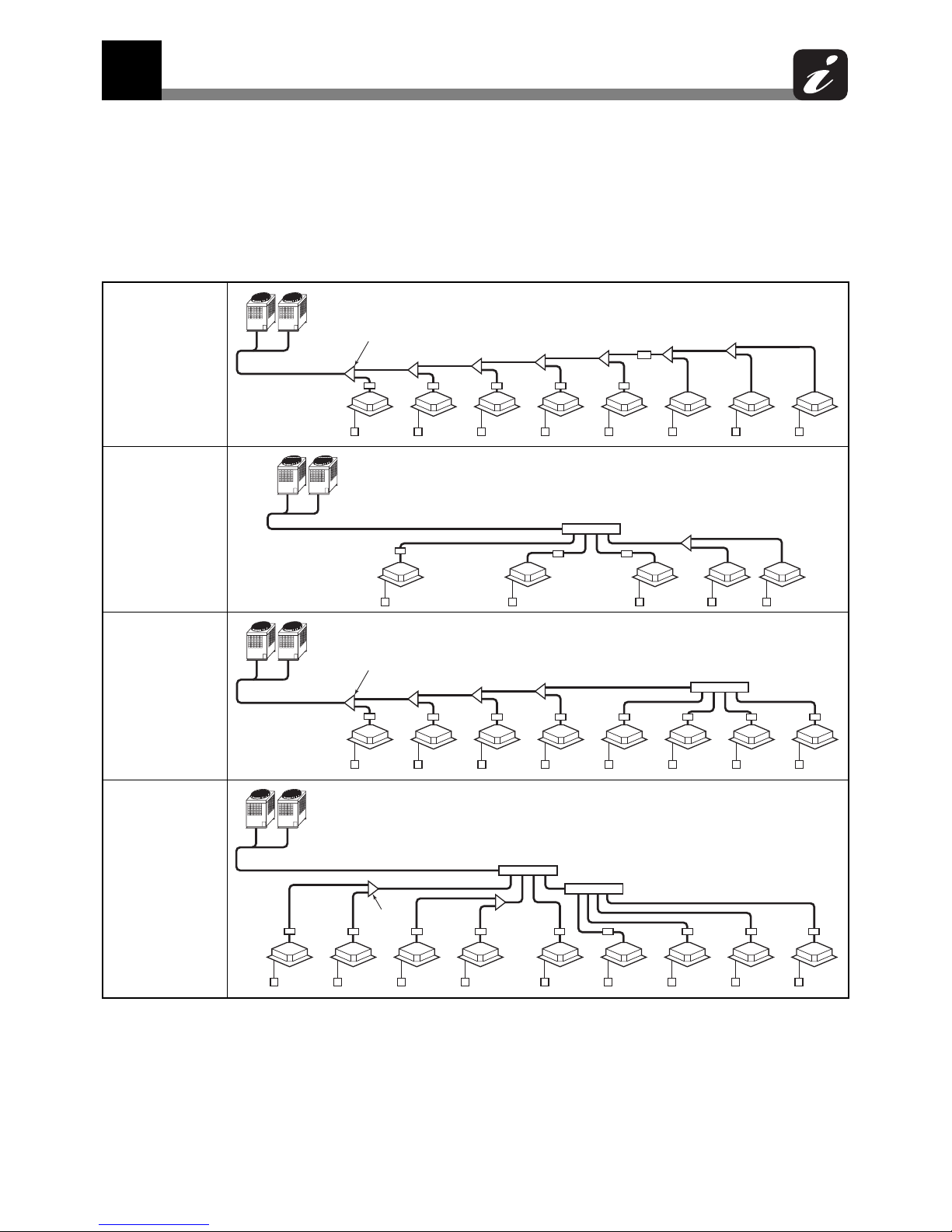

[1] Line branching system

[2] Header branching system

[3] Header branching system after line branching

[4] Line branching system after header branching

[5] Header branching system after header branching

The above five branching systems enable to dramatically increase the flexibility of refrigerant piping design.

Line branching

system

Header

branching

system

Line branching

system after

header

branching

Header

branching

system after

header

branching

Outdoor unit

Branching joint

Indoor unit

Remote

control

FS unit

Outdoor unit

Branching header

Indoor unit

Remote

control

FS unit

Outdoor unit

Branching joint

Indoor unit

Remote

control

Branching header

FS unit

Outdoor unit

Branching header

Indoor

unit

Remote

control

Branching

joint

FS unit

3

Refrigerant piping design

24

3-2. Allowable length/height difference of

refrigerant piping

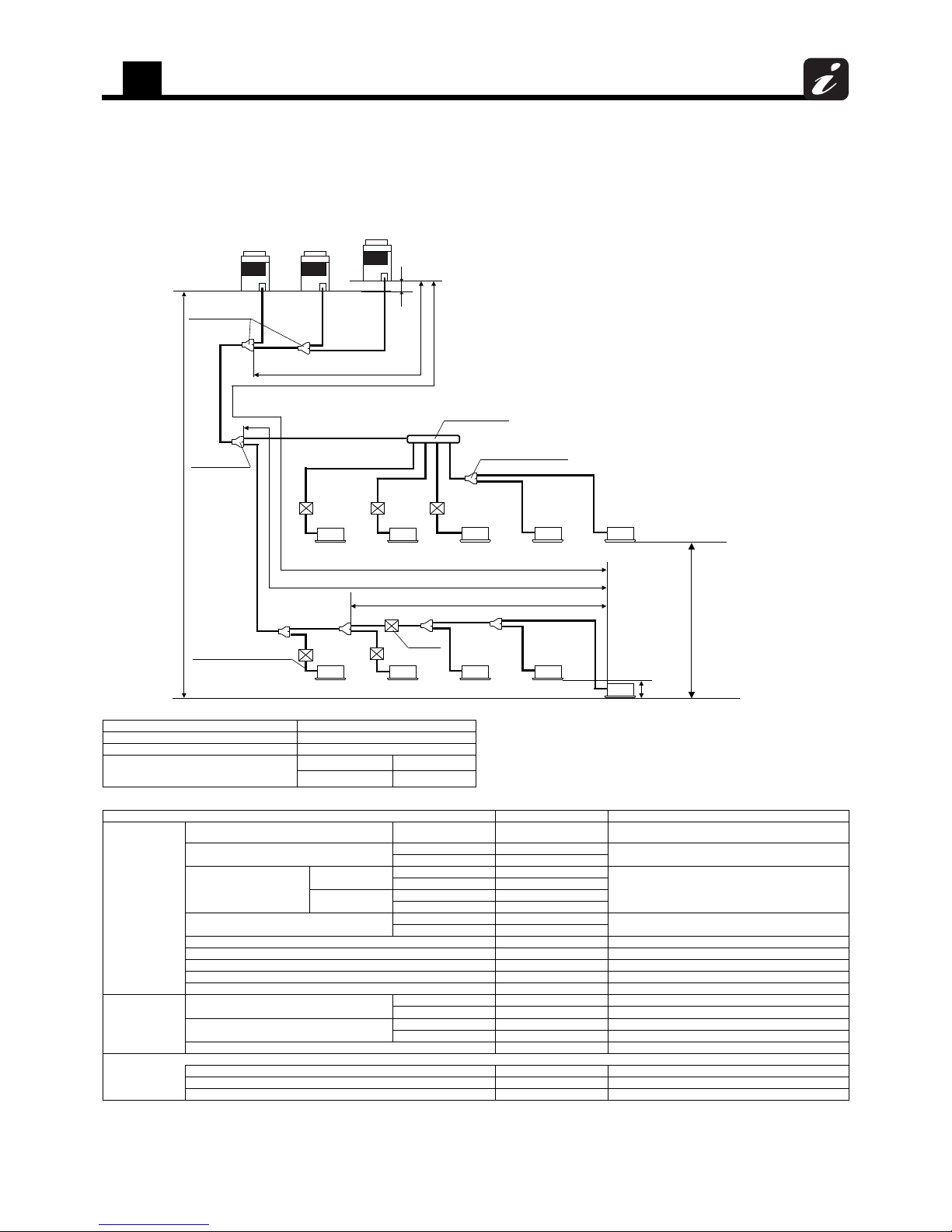

3-2-1. Heat recovery

System restrictions Caution for installation

Allowable length and height difference of refrigerant piping

*1: If “Medium Static Ducted Type (MMD-AP***BH)” is included in the system: Total indoor capacity code must be between 80% and 120% of the capacity of the outdoor unit.

*2: Farthest outdoor unit from the first branching section: Follower unit (C). Farthest indoor unit from the first branching section: indoor unit (o).

*3: If FS unit is connected to multiple indoor units, connect wires of FS unit to one of the indoor unit with main remote control.

*4: Allowable values for length equivalent to furthest pipe are shown below and they vary according to capacity rank of outdoor unit.

072 to 120 type: Equivalent length 605 ft (185 m), Actual length: 540 ft (165 m)

144 to 240 type: Equivalent length 640 ft (195 m), Actual length: 575 ft (175 m)

288 to 336 type: Equivalent length 656 ft (200 m), Actual length: 591 ft (180 m)

Max. No. of combined outdoor units 3 units

Note 1)

Install the outdoor units in order of their capacity codes. A (header unit) ≥ B ≥ C

Note 2)The header unit is connected to the branching joint for outdoor unit which is

directly connected to the main pipe.

Note 3)Y-shaped branching joint must be installed horizontally.

Note 4)Make sure to connect the T-shaped branching joint of liquid pipe as <Fig1>.

Do not connect the T-shaped branching joint as <Fig2>.

Max. capacity of combined outdoor units 28 ton

Max. No. of connected indoor units 48 units

Max. capacity of combined indoor units

H2 ≤ 49 ft (15 m) 125% ( *1)

H2 > 49 ft (15 m) 105%

Allowable value (ft (m)) Pipes

Pipe length

Total extension of pipe (Liquid pipe) Actual length 985 (300)

La + Lb + Lc + LA + L1 + L2 +L3 + L4 + L5 + L6 + L7 + L8 +

a + b + c + d + e + f + g + h + i + j + k + l + m + n + o

Farthest piping length L (*2)(*4)

Equivalent length 656 (200)

Lc + LA + L1 + L3 + L4 + L5 + L6 + L7 + o

Actual length 591 (180)

Main piping length

H2 > 9.8 ft (3 m)

Equivalent length 330 (100)

L1

Actual length 280 (85)

H2 ≤ 9.8 ft (3 m)

Equivalent length 395 (120)

Actual length 330 (100)

Farthest equivalent piping length from the first

branch Li (*2)

H1 > 9.8 ft (3 m) 165 (50)

L3 + L4 + L5 + L6 + L7 + o

H1 ≤ 9.8 ft (3 m) 215 (65)

Farthest equivalent piping length between outdoor units LO (*2) 49 (15) Lc + LA (Lb + LA)

Maximum equivalent piping length of pipes connected to outdoor units 33 (10) La, Lb, Lc

Maximum actual length of pipes connected to indoor units 98 (30) a + f, b + g, c + h, d + i, e + j, k, l

Maximum actual length between FS unit and indoor unit 49 (15) f, g, h, i, j

Maximum equivalent length between branching sections 165 (50) –

Height difference

Height between outdoor and indoor units H1

Upper outdoor units 165 (50) –

Lower outdoor units 98 (30) –

Height between indoor units H2

Upper outdoor units 130 (40) –

Lower outdoor units 9.8 (3) –

Height between outdoor units H3 0.3 (0.1) –

<In case of two or more indoor units are connected with FS unit>

Max. equivalent piping length in group of the FS unit 98 (30) L5 + L6 + m, L5 + L6 + L7 + n, L5 + L6 + L7 + o

Maximum actual length between FS unit and the wired indoor unit (*3) 49 (15) L6 + m, L6 + L7 + n, L6 + L7 + o

Height difference between indoor units in same FS unit H4 1.6 (0.5) –

La

Height difference

between indoor units

in same FS unit:

H4

≤ 1.6 ft (0.5 m)

Height difference between indoor units:

H2

≤ 130 ft (40 m )

(If the outdoor unit is installed in

a higher position than indoor unit)

Height difference

between outdoor units

H3

≤ 0.3ft (0.1 m)

Main

piping

L1

Branching pipe

L2

(a)

Indoor unit c onnecting pipe

FS unit

Farthest equivalent piping length

between outdoor units:

LO

≤ 49 ft (15 m)

Outdoor units

(b)

(c)

Header unit(A)

Follower unit(B)

Follower unit(C)

Lb

Lc

LA

First branc hing

section

a

b

L8

c

Indoor unit

f

gh

FS unit

k

l

Y-shape branching joint

FS unit

H4

H2

on

(o)

(n)

(m)

m

L7

L6L5

L4

e

j

i

Branching header

(Cooling only)

Indoor unit

FS unit

FS unit

FS unit

Max.equivalent piping length in gr oup of the FS unit: Ln≤ 98 ft (30 m )

The longest piping length from the first branchi:

Li

≤ 215 ft (65 m )

The longest piping length:

L

≤ 656 ft (200 m )

L3

H3

FS unit c onnecting pipe

Height difference

between outdoor

and indoor units :

H1

≤ 165 ft (50 m )

(If the outdoor unit is

installed in a higher

position than indoor unit)

H1

d

Branching joint

for outdoor units

(Cooling only)

3

Refrigerant piping design

25

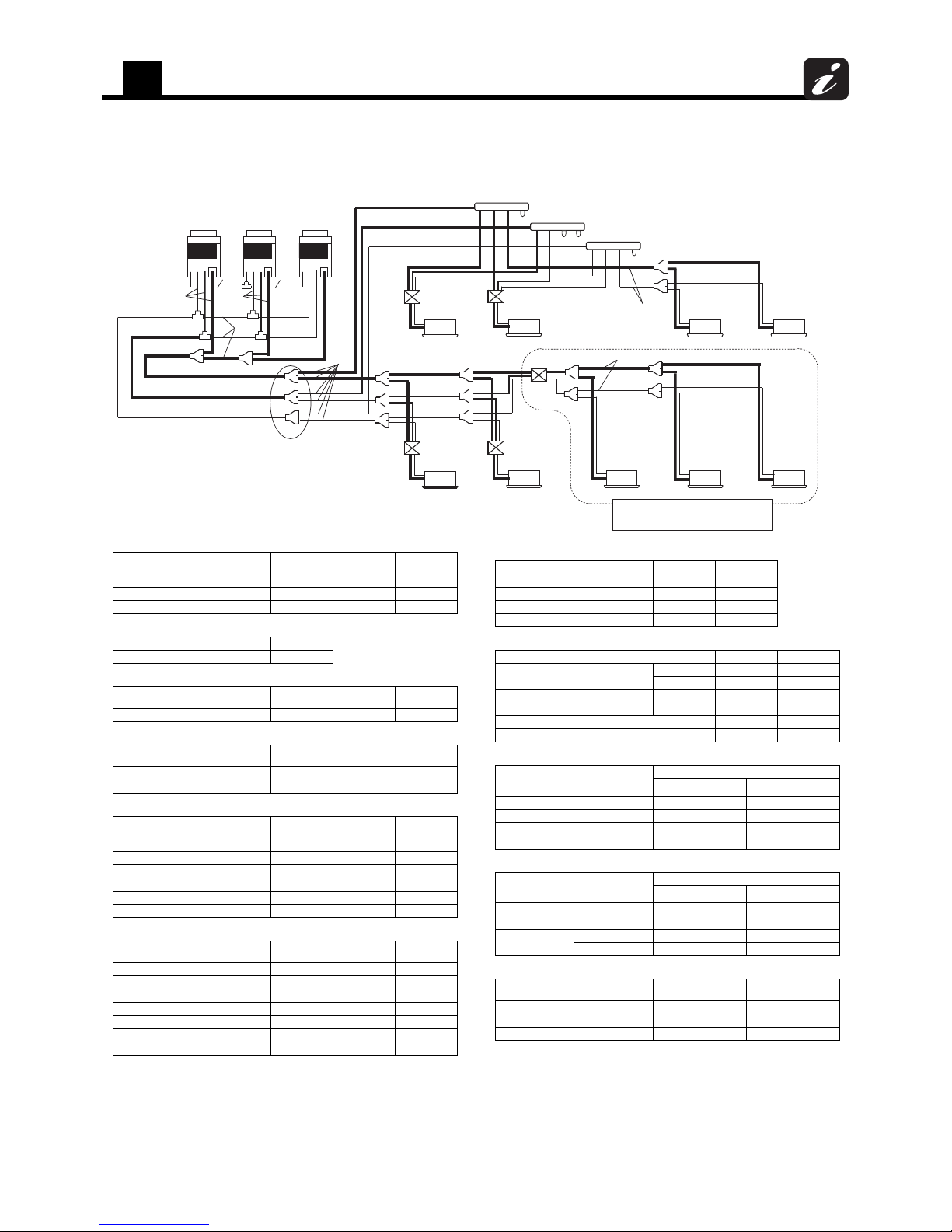

3-2-2. Heat pump

System restrictions

Allowable length and height difference of refrigerant piping

*1: If “Medium Static Ducted Type (MMD-AP***BH)” is included in the system: Total indoor capacity code is between 80% and 120% of the capacity of the outdoor unit.

*2: Farthest outdoor unit from the first branch: (B), farthest indoor unit: (j).

Max. No. of combined outdoor units 2 units

Note 1)The header unit is connected to main piping to indoor units.

Note 2)The header unit is the one with the highest capacity code. A (header unit) ≥ B

Note 3)To connect suction gas pipes to indoor units, use Y-shaped branching joints to

keep pipes level.

Max. capacity of combined outdoor units 19 ton

Max. No. of connected indoor units 38 units

Max. capacity of combined indoor units

H2 ≤ 49 ft (15 m) 125% ( *1)

H2 > 49 ft (15 m) 105%

Item Allowable value (ft (m)) Pipes

Pipe length

Total extension of pipe (liquid pipe) Actual length 985 (300)

La + Lb + L1 + L2 + L3 + L4 + L5 + L 6 + L7 + a + b + c + d +

e + f + g + h + i + j

Farthest piping length L (*1)

Equivalent length 720 (220)

Lb + L1 + L3 + L4 + L5 + L6 + j

Actual length 590 (180)

Main piping length

Equivalent length 395 (120)

L1

Actual length 330 (100)

Farthest equivalent piping length from the first

branch Li (*2)

H1 > 9.8 ft (3 m) 215 (65)

L3 + L4 + L5 + L6 + j

H1 ≤ 9.8 ft (3 m) 295 (90)

Maximum equivalent piping length of pipes connected to outdoor units 33 (10) La, Lb

Maximum actual length of pipes connected to indoor units 98 (30) a, b, c, d, e, f, g, h, i, j

Maximum equivalent length between branching sections 165 (50) L2, L3, L4, L5, L6, L7

Height difference

Height between outdoor and

indoor units H1

Upper outdoor units

H2 > 9.8 ft (3 m) 165 (50)

–

H2 ≤ 9.8 ft (3 m) 230 (70)

Lower outdoor units

H2 > 9.8 ft (3 m) 98 (30)

–

H2 ≤ 9.8 ft (3 m) 130 (40)

Height between indoor units H2 130 (40) –

Height between outdoor units H3 16 (5) –

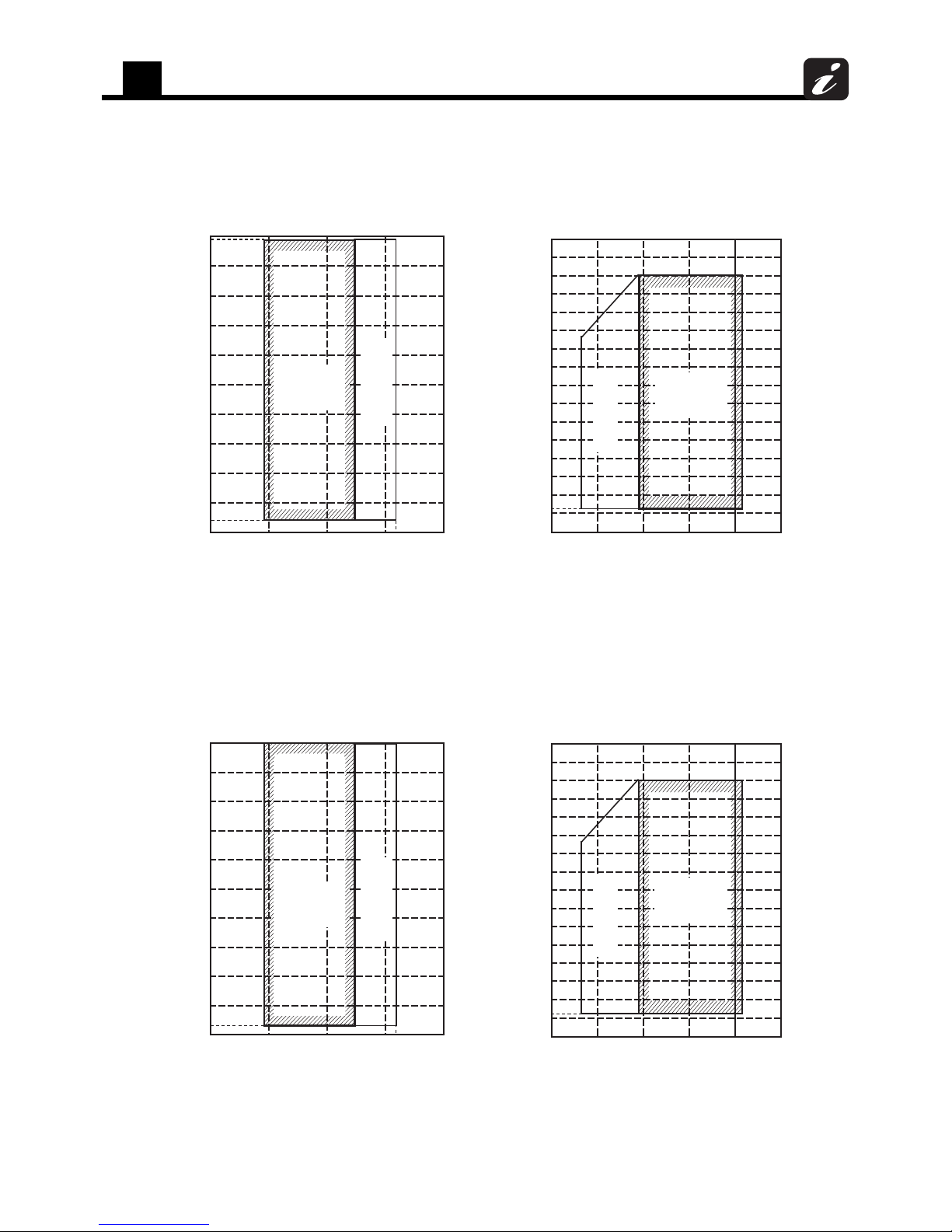

(a)

(b)

Liquid piping

Gas piping

Figure 1 Figure 2

[Inverse connection of a gas-side branch unit]

Figure 3

Figure 4

Correct

Header unit AFollower unit

B

Main pipe

To the indoor unit

Incorrect

Header unit AFollower unit

B

Main pipe

To the indoor unit

Incorrect

Correct

Header unit AFollower unit

B

Main pipe

To the indoor unit

Incorrect

Header unit AFollower unit

B

To gas-side branch unit

Main pipe

To the indoor unit

Follower unit (B)

Height

difference

between

outdoor

units

H3 ≤ 16 ft

(5 m)

Height

difference

between

indoor units:

H2 ≤ 130 ft

(40 m)

Lb

La

Outdoor unit connecting pipes

Main piping L1

Height

difference

between

outdoor

and indoor

units:

H1 ≤ 230 ft

(70 m)

First branching

section

L3

L4

L5

L6

Indoor unit

fgh i

j

The longest piping length from the first branch: Li ≤ 295 ft (90 m)

The longest piping length: L ≤ 720 ft (220 m)

a

b

c

d

e

(j)

Indoor unit

connecting

pipe

Branching pipe L2

L7

Header unit (A)

Branching header

Y-joint

3

Refrigerant piping design

26

3-3. Selection of refrigerant piping

3-3-1. Heat recovery

Outdoor units

Header unit

(A)

Follower unit

(B)

Follower unit

(C)

Indoor unit

Indoor unit

<Cooling only>

<Cooling only>

(1)

(1)

(1)

(2)

(4) Main pipe

Suction gas pipe

Disc hage gas pipe

Liquid pipe

(2)

(3)

Indoor unit

Indoor unit

(9)

(9)

Indoor unit

Indoor unitIndoor unit

(7)

(7)

(7)

(8)

(8)

(8)

(5) (5)

First branc h section

(5)

(5)

(6)

(5)

(6)

(7) (7)

(6)

(6)

(5)

(5)

(5)*3

(5)*3

(5)*3

(8)

*9<Group control>

In case of two or more indoor units are

connected with FS unit

(8)

(9) Branc hing header

(8) Y-Shaped br anching joint

(1) Outdoor unit connecting pipe

(2) Balance pipe

(3) Connecting pipe between outdoor units

(4) Outdoor unit connection piping kit

(5) Main pipe

(6) Branching pipe

(7) FS unit and indoor unit connection pipe

(8) Branching and indoor unit connection pipe

(9) Y-shaped branching joint

(10) Branching header

■ FS unit

*1: The capacity code of outdoor unit and indoor unit, please refer to 2-2.

*2: If the size of the pipe to be selected is larger than the size of the main pipe, please use the same pipe size as the main pipe.

*3: Two pipes in downstream of FS unit and cooling only indoor unit use liquid pipe and suction gas pipe.

*4: The first branching joint, select at capacity code of outdoor unit.

*5: If the total capacity code of indoor units exceed the capacity code of outdoor unit, select the size from the capacity code of the outdoor unit.

*6: For one line pipe line of header branching, total 57 capacity code of indoor units is connectable.

If connecting the branching header to the first branch section with the capacity code of outdoor unit is more than 114 (kBtu/h) and less than 247 (kBtu/h), use the

RBM-2043FUL (4 branch), and RBM-HT2083FUL (8 branch). Also, the branching header can not be used for the first branch section when the capacity code of outdoor

unit is more than 247 (kBtu/h).

*7: The main pipe is the starting point. The follower unit side is the downstream side.

*8: Selection piping is the starting point. The indoor unit side is the downstream side.

*9: Use indoor units with group control if connecting indoor units of two or more to one FS unit.

Outdoor unit capacity type

Suction

gas side

Discharge

gas side

Liquid side

072 type Ø7/8" Ø3/4" Ø1/2"

096 type Ø7/8" Ø3/4" Ø1/2"

120 type Ø1-1/8" Ø3/4" Ø1/2"

Capacity code of outdoor unit (*1) Balance pipe

144 to 336 type Ø3/8"

Total capacity of outdoor

units at downstream side (*1 *7)

Suction gas

side

Discharge

gas side

Liquid side

228 or more Ø1-3/8" Ø1-1/8" Ø3/4"

Total capacity of outdoor units

at downstream side (*1 *7)

Model name

Below 247 RBM-BT14FUL

247 or more RBM-BT24FUL

Capacity code of outdoor unit

Suction

gas side

Discharge

gas side

Liquid side

072, 096 Ø7/8" Ø3/4" Ø1/2"

120 Ø1-1/8" Ø3/4" Ø1/2"

144 Ø1-1/8" Ø7/8" Ø5/8"

168, 192 Ø1-1/8" Ø7/8" Ø3/4"

216, 240 Ø1-3/8" Ø1-1/8" Ø3/4"

288, 312, 336 Ø1-3/8" Ø1-1/8" Ø7/8"

Total cpacity code of indoor units

at downstream side (*1 *2 *3 *8)

Suction

gas side

Discharge

gas side

Liquid side

Below 61 Ø5/8" Ø1/2" Ø3/8"

61 to below 115.5 Ø7/8" Ø3/4" Ø1/2 "

115.5 to below 153.5 Ø1-1/8" Ø7/8" Ø5/8"

153.5 to below 191.5 Ø1-1/8" Ø7/8" Ø3/4"

191.5 to below 239 Ø1-3/8" Ø1-1/8" Ø3/4"

239 to below 334 Ø1-3/8" Ø1-1/8" Ø7/8"

334 or more Ø1-5/8" Ø1-3/8" Ø7/8"

Indoor unit capacity type Gas side Liquid side

007 to 012 type Ø3/8" Ø1/4"

015 to 018 type Ø1/2" Ø1/4"

021 to 054 type Ø5/8" Ø3/8"

072 to 096 type Ø7/8" Ø1/2"

Indoor unit capacity type Gas side Liquid side

007 to 012 type

Pipe length

(Actual length)

49 ft or less Ø3/8" Ø1/4"

Over 49 ft Ø1/2" Ø3/8"

015 to 018 type

Pipe length

(Actual length)

49 ft or less Ø1/2" Ø1/4"

Over 49 ft Ø5/8" Ø3/8"

021 to 054 type Ø5/8" Ø3/8"

072 to 096 type Ø7/8" Ø1/2"

Total capacity code of indoor units

on downstream side from

Y-shaped branching joint (*4 *5)

Model name

For 3 pipe For 2 pipe

Below 61 RBM-BY55FUL RBM-BY55UL

61 to below 134.5 RBM-BY105FUL RBM-BY105UL

134.5 to below 239 RBM-BY20 5FUL RBM-BY205UL

239 or more RBM-BY305FUL RBM-BY305UL

Total capacity code of indoor units

on downstream side from

branching header(*4 *5 *6)

Model name

For 3 pipe For 2 pipe

For 4 branching

Below 134.5 RBM -HY1043FUL RBM-HY1043UL

134.5 or more RBM-HY2043FUL RBM-HY204 3UL

For 8 branching

Below 134.5 RBM -HY1083FUL RBM-HY1083UL

134.5 or more RBM-HY2083FUL RBM-HY208 3UL

Total capacity code of outoor units

on downstream side from FS unit

Max. number of

connectable indoor units

Model name

Below 38 6 RBM-Y0383FUL

38 to below 61 8 RBM-Y0613FUL

61 to 96 or less 8 RBM-Y0963FUL

3

Refrigerant piping design

27

3-3-2. Heat pump

*1: When using a Y-shaped branching joint for the 1st branch, select according to capacity code of the outdoor unit.

*2: Up to a total of 54 (kBtu/h) maximum capacity code is connectable to one line after branching of header.

When using a branching header for the 1st branch and the total capacity codes of all outdoor units are 114 or more, use a RBM-HY2043UL or RBM-HY2083UL regardless of

the total capacity codes of indoor units at downstream side.

*3: Pipe size differs based on the total capacity code value of indoor units at the downstream side.

If the total value exceeds the capacity code of the outdoor unit, apply the capacity code of the outdoor unit.

(7) Branching header

(4) Branching pipe

(5) Indoor unit connecting pipe

First branch section

Indoor unit

Header unit Follower unit

Outdoor unit

(1)(1)

(8) Outdoor unit connection piping kit.

(2)

Ø3/8

(4)

(3) Main piping

(6)

(5) (5) (5) (5)

(4)

(4)

(4)

(4)

(5)

(5)

(5)

(5)

(5)

(6) Y-shaped branching joint

(6)

(6)

(6)

(6)

(1) Outdoor unit connecting pipe

Outdoor unit capacity type

Outdoor unit capacity type

Liquid side

2"/1Ø

2"/1Ø

2"/1Ø

Gas side

8"/7Ø

8"/7Ø

8"/1-1Ø

epyt 270

epyt 690

epyt 411

(2) Balance pipe

Outdoor unit capacity type Balance pipe

8"/3Ø144 to 228 type

(3) Main piping

Liquid side

2"/1Ø

2"/1Ø

8"/5Ø

4"/3Ø

Gas side

8"/7Ø

8"/1-1Ø

8"/1-1Ø

8"/3-1Ø

epyt 690 / 270

epyt 411

epyt2918 /61 / 441

epyt 822

Model nameOutdoor unit

2 RBM-BT14UL

(8) Outdoor unit connection piping kit

(4) Branching pipe

Total capacity codes of indoor

units at downstream side (kBtu/h)(*3)

Gas side

2"/1Ø

8"/5Ø

8"/7Ø

8"/1-1Ø

8"/3-1Ø

32 woleB

16 woleb ot 32

611 woleb ot 16

391 woleb ot 611

erom ro 391

Liquid side

8"/3Ø

8"/3Ø

2"/1Ø

8"/5Ø

4"/3Ø

(6) Y-shaped branching joint (*1)

Total capacity codes of indoor units (kBtu/h)

Total capacity codes of indoor units (kBtu/h)

Model name

LU55YB-MBR

LU501YB-MBR

LU502YB-MBR

16 woleB

631 woleb ot 16

erom ro 631

(7) Branching header (*2)

Below 136

136 to below 241

For 4 branches

For 8 branches

Below 136

136 to below 241

Model name

RBM-HY1043UL

RBM-HY2043UL

RBM-HY1083UL

RBM-HY2083UL

(5) Indoor unit connection pipe

Indoor unit capacity type

007 to 012 type

Pipe length

(actual length)

49 ft or less

Over 49 ft

epyt 810 ot 510

epyt 450 ot 120

epyt 690 ot 270

Liquid side

4"/1Ø

8"/3Ø

2"/1Ø

4"/1Ø

4"/1Ø

Gas side

2"/1

8"/5Ø

8"/7Ø

Ø

2"/1Ø

8"/3Ø

3

Refrigerant piping design

28

3-4. Charging requirement with additional

refrigerant

After the system has been vacuumed, replace the vacuum pump with a refrigerant cylinder and system with

additional refrigerant.

Refrigerant in the system when shipped from the factory

When the system is charged with refrigerant at the factory, the amount of refrigerant needed for the pipes at the site

is not included. Therefore, calculate the additional amount needed and add the required amount to the system.

(Calculation of Heat recovery)

Additional refrigerant charge amount is calculated based on the size of liquid pipe at site and its real length.

(Calculation of Heat pump)

Additional refrigerant charge amount is calculated based on the size of liquid pipe at site and its real length.

Table 1

Table 2

Table 3

Calculating the amount of additional refrigerant required

Heat recovery

Model MMY-MAP

0724FT9UL, 0724FT6UL, 0964FT9UL, 0964FT6UL,

1204FT9UL, 1204FT6UL

Refrigerant amount charged in factory 25.4 lbs

Heat pump

Model MMY-MAP

0724HT9UL, 0724HT6UL, 0964HT9UL, 0964HT9UL,

1144HT9UL, 1144HT6UL

Refrigerant amount charged in factory 25.4 lbs

Additional

refrigerant charge

amount

(lbs) =

Actual length

of liquid pipe

×

Additional refrigerant

charge amount per

liquid pipe 1 ft [Table 1]

× 1.3 +

Adjustment amount of

refrigerant [Table 2]

Additional

refrigerant charge

amount

(lbs) =

Actual length of liquid

pipe

×

Additional refrigerant

charge amount per

liquid pipe 1 ft [Table 1]

+

Adjustment amount of

refrigerant [Table 3]

Liquid pipe outer diameter (in) Ø1/4" Ø3/8" Ø1/2" Ø5/8" Ø3/4" Ø7/8"

Additional refrigerant amount/1 ft (lbs)

0.017 0.037 0.071 0.108 0.168 0.235

Outdoor unit capacity type Adjustment amount of refrigerant (lbs)

Combined outdoor units

072 type 5.5 072 type – –

096 type 20.9 096 type – –

120 type 27.5 120 type – –

144 type 5.5 072 type 072 type –

168 type 23.1 096 type 072 type –

192 type 30.8 096 type 096 type –

216 type 34.1 120 type 096 type –

240 type 37.4 120 type 120 type –

288 type 26.4 096 type 096 type 096 type

312 type 29.7 120 type 096 type 096 type

336 type 33.0 120 type 120 type 096 type

Outdoor unit capacity type Adjustment amount of refrigerant (lbs) Combined outdoor units

072 type 3.31 072 type –

096 type 13.23 096 type –

114 type 15.43 114 type –

144 type 0.00 072 type 072 type

168 type 16.53 096 type 072 type

192 type 27.56 096 type 096 type

228 type 27.56 114 type 114 type

4

Wiring Design

29

4-1. General

• The equipment shall be installed in compliance with NEC and local codes.

• Do not connect high voltage power wires to the control terminal blocks (U1, U2, U3, U4, U5, U6).

• All field wiring insulation rating must comply with NEC and local codes.

• All wiring must be strained relieved as specified by NEC and local codes.

• Do not energize the indoor units until leak check and vacuuming are completed.

• Use copper supply wire.

• Use UL wires rated 600 V for the system interconnection wires.

• Use UL wires rated 300 V for remote control wires.

4-2. Outdoor unit power supply

4-2-1. Heat recovery

Outdoor unit data

208/230 V model

Unit

type

Capacity

type

Model name

MMY-

Power supply

Voltage Range

Compressor

Fan Motor MCA MOCP

Phase and

frequency

Rated

voltage

Min. Max.

Unit No.1 Unit No.2 Unit No.3

(V) (V) (kW) (kW) (kW) (kW) (A) (A)

Single

unit

72

MAP0724FT9U

3 ~ 60 Hz 208/230 V 187 253 2.3 × 2 – – 1.0 34 40

96

MAP0964FT9U

3 ~ 60 Hz 208/230 V 187 253 2.1

× 3 – – 1.0 50 60

120

MAP1204FT9U

3 ~ 60 Hz 208/230 V 187 253 2.7

× 3 – – 1.0 52 60

Combined model

144 AP1444FT9UL 3 ~ 60 Hz 208/230 V 187 253 2.3 × 2 2.3 × 2 – 1.0 × 2 34 + 34 40 + 40

168 AP1684FT9UL 3 ~ 60 Hz 208/230 V 187 253 2.1

× 3 2.3 × 2 – 1.0 × 2 50 + 34 60 + 40

192 AP1924FT9UL 3 ~ 60 Hz 208/230 V 187 253 2.1

× 3 2.1 × 3 – 1.0 × 2 50 + 50 60 + 60

216 AP2164FT9UL 3 ~ 60 Hz 208/230 V 187 253 2.7

× 3 2.1 × 3 – 1.0 × 2 52 + 50 60 + 60

240 AP2404FT9UL 3 ~ 60 Hz 208/230 V 187 253 2.7

× 3 2.7 × 3 – 1.0 × 2 52 + 52 60 + 60

288 AP2884FT9UL 3 ~ 60 Hz 208/230 V 187 253 2.1

× 3 2.1 × 3 2.1 × 3 1.0 × 3

50 + 50 + 50 60 + 60 + 60

312 AP3124FT9UL 3 ~ 60 Hz 208/230 V 187 235 2.7 × 3 2.1 × 3 2.1 × 3 1.0 × 3

52 + 50 + 50 60 + 60 + 60

336 AP3364FT9UL 3 ~ 60 Hz 208/230 V 187 235 2.7 × 3 2.7 × 3 2.1 × 3 1.0 × 3

52 + 52 + 50 60 + 60 + 60

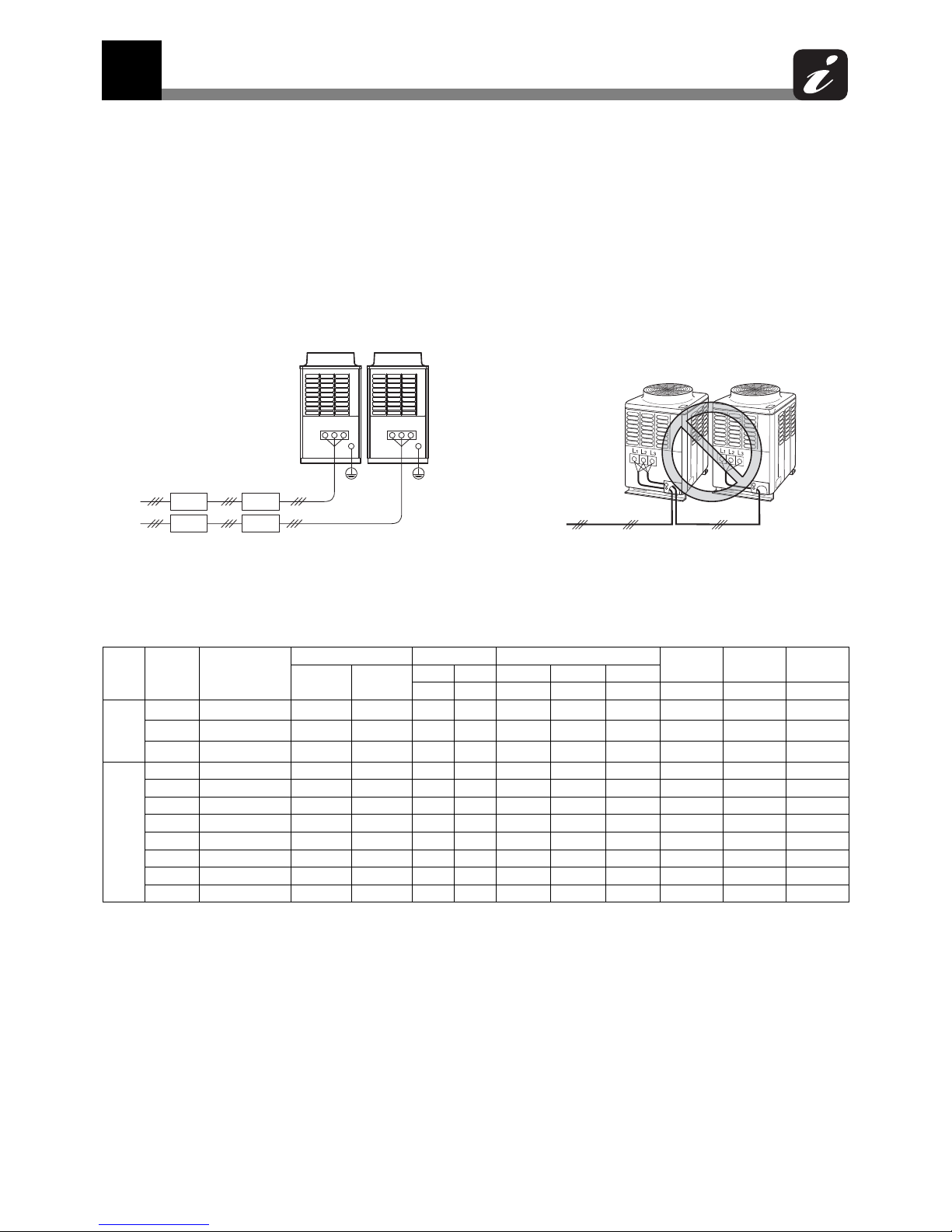

L1L2L3 L1L2L

3

Main power circuit

breaker

Disconnect per NEC

and local codes.

Power supply for

outdoor units

Incorrect

Every outdoor unit must have a dedicated power supply.

4 Wiring Design

4

Wiring Design

30

460 V model

Notes MCA: Minimum Circuit Amps (minimum circuit Amps requires for power supply design.)

MOCP: Maximum Overcurrent Protection (Amps)

Unit

type

Capacity

type

Model name

MMY-

Power supply

Voltage

Compressor

Fan Motor MCA MOCP

Phase

and

frequenc

Rated

voltage

Min. Max.

Unit Unit

Unit No.3

(V) (V) (kW) (kW) (kW) (kW) (A) (A)

Single

unit

72

MAP0724FT6U

3 ~ 60 Hz 460 V 414 506 2.3 × 2 – – 1.0 19 25

96

MAP0964FT6U

3 ~ 60 Hz 460 V 414 506 2.1 × 3 – – 1.0 28 35

120

MAP1204FT6U

3 ~ 60 Hz 460 V 414 506 2.7 × 3 – – 1.0 30 35

Combined model

144 AP1444FT6UL 3 ~ 60 Hz 460 V 414 506 2.3 × 2 2.3 × 2 – 1.0 × 2 19 + 19 25 + 25

168 AP1684FT6UL 3 ~ 60 Hz 460 V 414 506 2.1 × 3 2.3 × 2 – 1.0 × 2 28 + 19 35 + 25

192 AP1924FT6UL 3 ~ 60 Hz 460 V 414 506 2.1 × 3 2.1 × 3 – 1.0 × 2 28 + 28 35 + 35

216 AP2164FT6UL 3 ~ 60 Hz 460 V 414 506 2.7 × 3 2.1 × 3 – 1.0 × 2 30 + 28 35 + 35

240 AP2404FT6UL 3 ~ 60 Hz 460 V 414 506 2.7 × 3 2.7 × 3 – 1.0 × 2 30 + 30 35 + 35

288 AP2884FT6UL 3 ~ 60 Hz 460 V 414 506 2.1 × 3 2.1 × 3 2.1 × 3 1.0 × 3

28 + 28 + 28 35 + 35 + 35

312 AP3124FT6UL 3 ~ 60 Hz 460 V 414 506 2.7 × 3 2.1 × 3 2.1 × 3 1.0 × 3

30 + 28 + 28 35 + 35 + 35

336 AP3364FT6UL 3 ~ 60 Hz 460 V 414 506 2.7 × 3 2.7 × 3 2.1 × 3 1.0 × 3

30 + 30 + 30 35 + 35 + 35

4

Wiring Design

31

4-2-2. Heat pump

Outdoor unit data

208/230 V model

460 V model

Notes MCA: Minimum Circuit Amps (minimum circuit Amps requires for power supply design.)

MOCP: Maximum Overcurrent Protection (Amps)

Unit type

Capacity

type

Model name

MMY-

Power supply Voltage Range Compressor

Fan

Motor

MCA MOCP

Phase and

frequency

Nominal

Vol tag e

Min. Max. Unit No.1 Unit No.2

(V) (V) (kW) (kW) (kW) (A) (A)

Single

unit

072 MAP0724HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.3 × 2 – 1.0 36 40

096 MAP0964HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.1 × 3 – 1.0 50 60

114 MAP1144HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.5 × 3 – 1.0 52 60

Combined

model

144 AP1444HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.3 × 2 2.3 × 2 1.0 × 2 36 + 36 40 + 40

168 AP1684HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.1 × 3 2.3 × 2 1.0 × 2 50 + 36 60 + 40

192 AP1924HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.1 × 3 2.1 × 3 1.0 × 2 50 + 50 60 + 60

228 AP2284HT9UL 3 ~ 60 Hz 208/230 V 187 253 2.5 × 3 2.5 × 3 1.0 × 2 52 + 52 60 + 60

Unit type

Capacity

type

Model name

MMY-

Power supply Voltage Range Compressor

Fan

Motor

MCA MOCP

Phase and

frequency

Nominal

Vol tag e

Min. Max. Unit No.1 Unit No.2

(V) (V) (kW) (kW) (kW) (A) (A)

Single

unit

072 MAP0724HT6UL 3 ~ 60 Hz 460 V 414 506 2.3 × 2 – 1.0 18 20

096 MAP0964HT6UL 3 ~ 60 Hz 460 V 414 506 2.1 × 3 – 1.0 23 25

114 MAP1144HT6UL 3 ~ 60 Hz 460 V 414 506 2.5 × 3 – 1.0 24 25

Combined

model

144 AP1444HT6UL 3 ~ 60 Hz 460 V 414 506 2.3 × 2 2.3 × 2 1.0 × 2 18 + 18 20 + 20

168 AP1684HT6UL 3 ~ 60 Hz 460 V 414 506 2.1 × 3 2.3 × 2 1.0 × 2 23 + 18 25 + 20

192 AP1924HT6UL 3 ~ 60 Hz 460 V 414 506 2.1 × 3 2.1 × 3 1.0 × 2 23 + 23 25 + 25

228 AP2284HT6UL 3 ~ 60 Hz 460 V 414 506 2.5 × 3 2.5 × 3 1.0 × 2 24 + 24 25 + 25

4

Wiring Design

32

4-3. Indoor unit power supply

Electrical characteristics

MCA: Minimum Circuit Amps FLA: Full Load Amps

MOCP: Maximum Overcurrent Protection (Amps)

Power supply wire

Recommended wire diameter and wire length for power supply wire.

Type Model Nominal Voltage (V-Ph-Hz)

Voltage Range (V) FLA MCA MOCP

Min Max AAA

4-Way Cassette

type

MMU-AP0072H2UL 208/230-1-60 187 253 0.6 0.8 15

MMU-AP0092H2UL 208/230-1-60 187 253 0.6 0.8 15

MMU-AP0122H2UL 208/230-1-60 187 253 0.6 0.8 15

MMU-AP0182H2UL 208/230-1-60 187 253 0.6 0.8 15

MMU-AP0212H2UL 208/230-1-60 187 253 0.8 1.0 15

MMU-AP0242H2UL 208/230-1-60 187 253 0.8 1.0 15

MMU-AP0302H2UL 208/230-1-60 187 253 0.8 1.0 15

MMU-AP0362H2UL 208/230-1-60 187 253 1.0 1.3 15

MMU-AP0422H2UL 208/230-1-60 187 253 1.0 1.3 15

Compact 4-Way

Cassette type

MMU-AP0071MH2UL 208/230-1-60 187 253 0.4 0.5 15

MMU-AP0091MH2UL 208/230-1-60 187 253 0.4 0.5 15

MMU-AP0121MH2UL 208/230-1-60 187 253 0.4 0.5 15

MMU-AP0151MH2UL 208/230-1-60 187 253 0.5 0.7 15

MMU-AP0181MH2UL 208/230-1-60 187 253 0.5 0.7 15

Ceiling type

MMC-AP0181H2UL 208/230-1-60 187 253 0.4 0.5 15

MMC-AP0241H2UL 208/230-1-60 187 253 0.5 0.7 15

MMC-AP0361H2UL 208/230-1-60 187 253 0.8 1.0 15

MMC-AP0421H2UL 208/230-1-60 187 253 0.9 1.2 15

High Wall type

MMK-AP0073H2UL 208/230-1-60 187 253 0.2 0.3 15

MMK-AP0093H2UL 208/230-1-60 187 253 0.2 0.3 15

MMK-AP0123H2UL 208/230-1-60 187 253 0.2 0.3 15

MMK-AP0153H2UL 208/230-1-60 187 253 0.4 0.5 15

MMK-AP0183H2UL 208/230-1-60 187 253 0.4 0.5 15

MMK-AP0243H2UL 208/230-1-60 187 253 0.4 0.5 15

Medium Static

Ducted type

MMD-AP0074BH2UL 208/230-1-60 187 253 0.8 1.0 15

MMD-AP0094BH2UL 208/230-1-60 187 253 0.8 1.0 15

MMD-AP0124BH2UL 208/230-1-60 187 253 0.8 1.0 15

MMD-AP0154BH2UL 208/230-1-60 187 253 0.9 1.2 15

MMD-AP0184BH2UL 208/230-1-60 187 253 0.9 1.2 15

MMD-AP0214BH2UL 208/230-1-60 187 253 1.4 1.8 15

MMD-AP0244BH2UL 208/230-1-60 187 253 1.4 1.8 15

MMD-AP0304BH2UL 208/230-1-60 187 253 1.4 1.8 15

MMD-AP0364BH2UL 208/230-1-60 187 253 1.8 2.3 15

MMD-AP0424BH2UL 208/230-1-60 187 253 2.2 2.8 15

MMD-AP0484BH2UL 208/230-1-60 187 253 2.2 2.8 15

High Static Ducted

type

MMD-AP0304H2UL 208/230-1-60 187 253 2.34 2.93 15

MMD-AP0364H2UL 208/230-1-60 187 253 2.34 2.93 15

MMD-AP0484H2UL 208/230-1-60 187 253 2.92 3.65 15

MMD-AP0724H2UL 208/230-1-60 187 253 7.12 8.91 15

MMD-AP0964H2UL 208/230-1-60 187 253 8.34 10.43 15

Slim Ducted type

MMD-AP0074SPH2UL 208/230-1-60 187 253 0.58 0.73 15

MMD-AP0094SPH2UL 208/230-1-60 187 253 0.58 0.73 15

MMD-AP0124SPH2UL 208/230-1-60 187 253 0.60 0.75 15

MMD-AP0154SPH2UL 208/230-1-60 187 253 0.70 0.88 15

MMD-AP0184SPH2UL 208/230-1-60 187 253 0.80 1.00 15

Power supply wiring

Wire side : 2 × AWG12

Ground: 1 × AWG12 or thicker

Up to 164'1'' (50 m)

FS unit

Be sure to use the supplied cable. If the length between the indoor and FS unit exceeds 16 ft (5 m), connect by using

the connection cable kit (RBC-CBK15FUL). (Sold separately)

4

Wiring Design

33

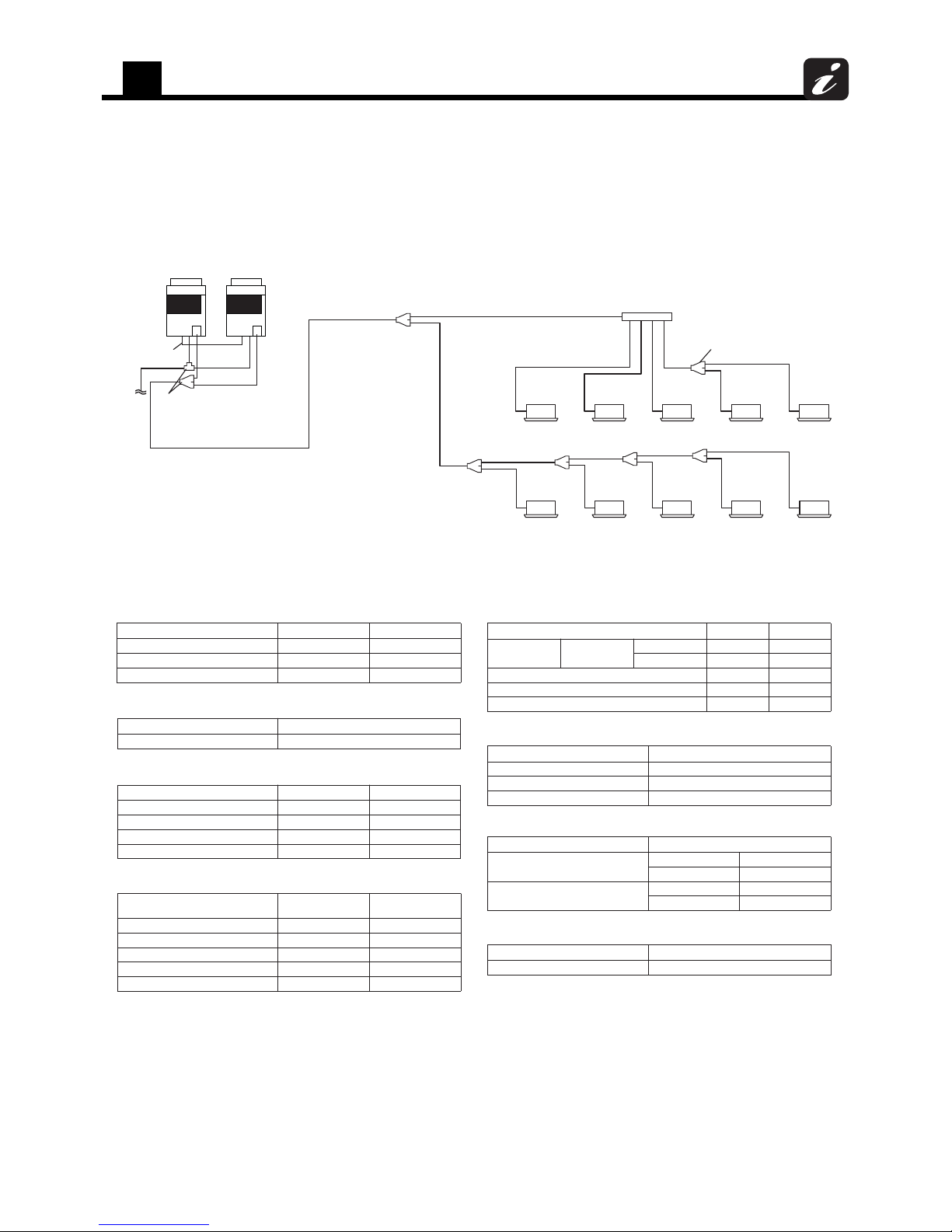

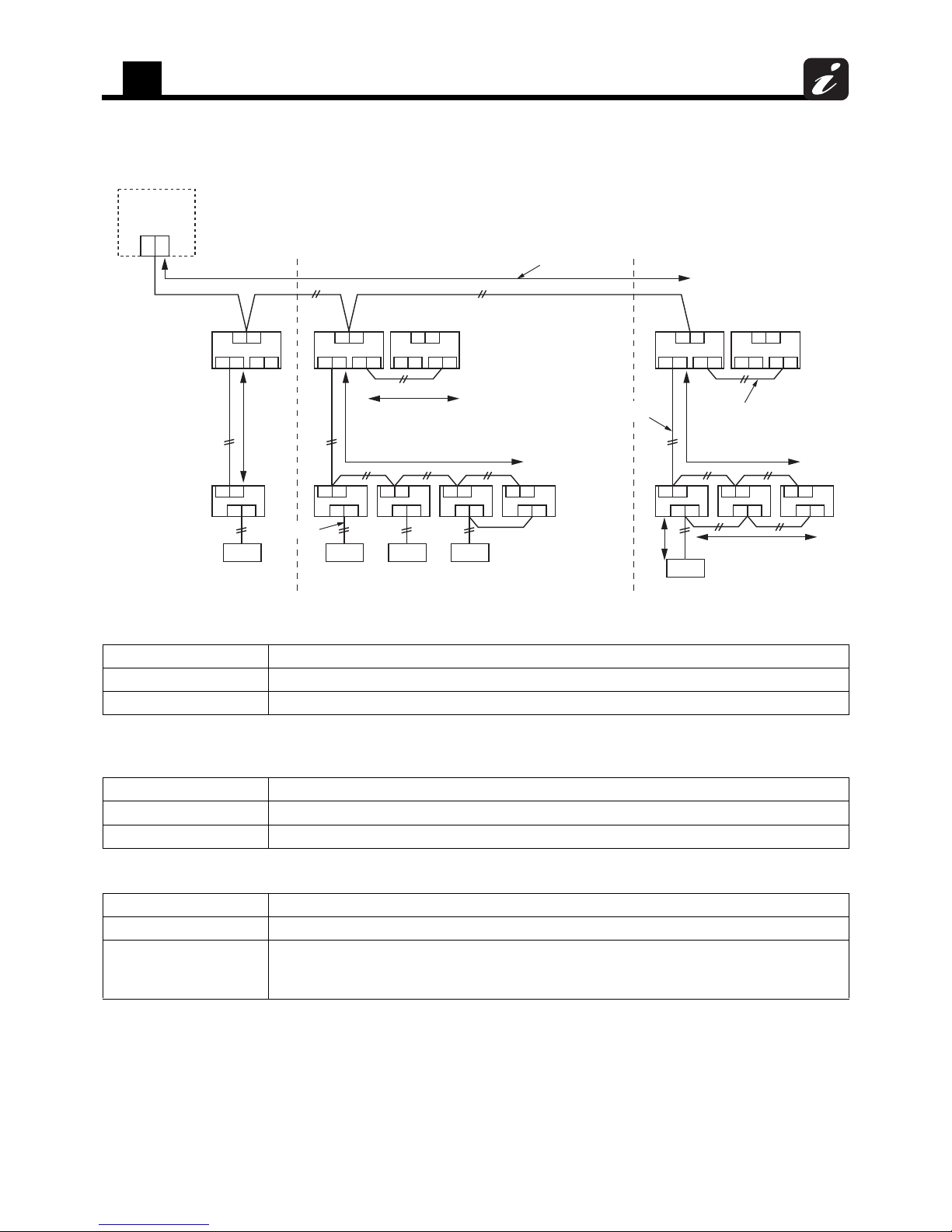

4-4. Design of control wiring

Summary of control wiring

1. All system interconnecting and central control wiring should be 2 conductor shielded cable.

2. On the header unit the control wire shield and the central control wire shield should both be connected to the

same ground screw in the header unit.

3. The remote control wiring can be 2 conductor un-shielded cable.

4. All system interconnecting and control wiring should be sized per table 1, 2 and 3.

5. Control wire and power line wire between FS unit and indoor unit are the accessory parts of FS unit. (Wire length

: 20 ft (6 m))

If the length between indoor unit and FS unit exceeds 16 ft (5 m), connect by using the connection cable kit sold

separately (RBC-CBK15FUL).

roodtuo rewolloFroodtuo redaeH

Central control

U1 U2 U3 U

4

U3U2U1U6U5U

4

U5 U6

U1 U2

U3 U

4

Control wiring between outdoor units (Shielded wire)

Central control wiring (Shielded wire)

Control wiring between indoor and outdoor units (Shielded wire)

Control wiring between indoor units (Shielded wire)

tinu SFtinu SF

2U1UBA2U1U

A

2U1UBA2U1UB

A

B

tinu roodnItinu roodnItinu roodnIIndoor unit

AB

A

BAB

lortnoc etomeRlortnoc etomeRlortnoc etomeR

(Group control)

CN81

CN02

CN81

CN02

CN81

(Cooling only)

4

Wiring Design

34

Restriction of control wiring

Be sure to keep the rule of below tables about size and length of control wiring.

Table-1 Control wiring between indoor and outdoor units (L1, L2, L3), Central control wiring (L4)

(*1): Total length of control wiring length for all refrigerant circuits (L1 + L2 + L3 + L4)

Table-2 Control wiring between outdoor units (L5)

Table-3 Remote control wiring (L6, L7)

Wiring 2-core

Type Shielded cable

Size/Length AWG16: Up to 3280 ft (1000 m) AWG14: Up to 6560 ft (2000 m) (*1)

Wiring 2-core

Type Shielded wire

Size/Length AWG16 to AWG14/Up to 330 ft (100 m) (L5)

Wire 2-core

Size AWG20 to AWG14

Length

• Up to 1640 ft (500 m) (L6 + L7)

• Up 1310 ft (400 m) in case of wireless remote control in group control.

• Up to 660 ft (200 m) total length of control wiring between indoor units (L6)

U3

U4

U1

U2

U1

U3

U2

U4

U5

U6

U1

U2

A B

U3

U4

U1

U2

U5

U6

U1

U2

A B

U1

U2

A

B

U1

U2

A

B

U1

U2

A

B

U3 U4

U1

U2

U5

U6

U3

U4

U1

U2

U5

U6

U1

U2

A

B

U1 U2

A B

U1 U2

A

B

U3

U4

U1

U2

U5

U6

L1

L5

L6

L7

L4

3L2L

Header

unit

Header

unit

Follower

unit

Header

unit

Follower

unit

Central

control

Outdoor unit

Indoor unit

Table-1

Table-2

Table-1

Remote control

Remote control

Remote control

Table-3

5

Outdoor unit

35

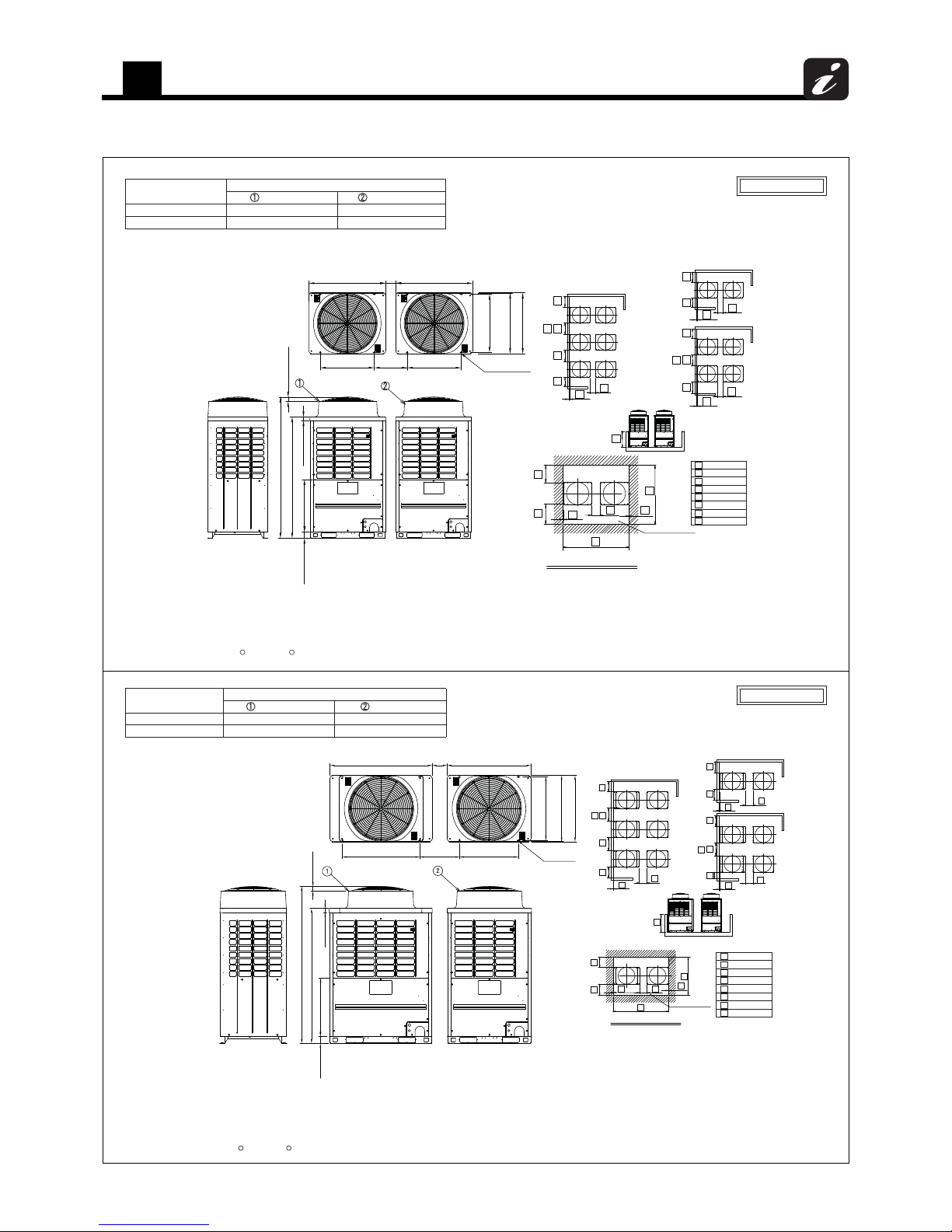

5 Outdoor unit

5-1. Specifications

(*1) Rated conditions

Cooling: Indoor air temperature 80 °F DryBulb/67 °F WetBulb, Outdoor air temperature 95 °F DryBulb

Heating: Indoor air temperature 70 °F DryBulb, Outdoor air temperature 47 °F DryBulb/43 °F WetBulb

072, 096 type: Equivalent piping length: 50 ft, Height difference: 0 ft, 120 type: Equivalent piping length: 75 ft, Height difference: 0 ft

(*2) Value for only outdoor unit

(*3) Setting is necessary

(*4) The amount does not consider extra piping length. Refrigerant must be added on site in accordance with the actual piping length.

(*5) High-pressure switch / High-pressure sensor / Low-pressure sensor / Fusible plug / PC board fuse / Inverter overload protector

(*6) Select wire size based on the larger value of MCA.

MCA: Minimum Circuit Amps (minimum circuit Amps required for power supply design.)

(*7) MOCP: Maximum Overcurrent Protection (Amps)

(*8) This specification is value as of June, 2013, please note that specification is subject to change without notice.

5-1-1. Heat recovery

5-1-1-1. 208/230 V model

Single unit (System with Non-ducted indoor units)

Outdoor unit model name MMY- MAP0724FT9UL MAP0964FT9UL MAP1204FT9UL

Power Supply

Nominal voltage V/Ph/Hz (208 / 230) / 3 / 60

Voltage range V 187 Minimum / 253 Maximum

Cooling

Nominal capacity (*1)

kBtu/h

72 96 120

Rated capacity 69 92 114

Rated power consumption (*2) kW 5.72 7.75 10.10

Rated EER Btu/W 12.1 11.9 11.3

Heating

Nominal capacity (*1)

kBtu/h

81 108 135

Rated capacity 77 103 120

Rated power consumption (*2) kW 6.43 8.74 10.23

Rated COP W/W 3.51 3.45 3.44

Starting Current A Soft Start

Dimension

Packing

Height In 76.3 76.3 76.3

Width In 41.8 50.5 50.5

Depth In 32.6 32.6 32.6

Unit

Height In 72.9 72.9 72.9

Width In 39.0 47.6 47.6

Depth In 30.7 30.7 30.7

Total Weight

Packed lbs 616 788 788

Unit lbs 583 751 751

Color Silky shade (Munsell 1Y8.5/0.5)

Compressor

Type Hermetic twin rotary compressor

Motor output kW 2.3 × 2 2.1 × 3 2.7 × 3

Fan unit

Fan Propeller fan

Motor output kW 1.0 1.0 1.0

Air volume cfm 5,120 7,060 7,620

Maximum external static pressure (*3) In WG 0.20 0.16 0.16

Heat exchanger Finned tube

Refrigerant

Name R410A

Charged refrigerant amount (*4) lbs 25.4 25.4 25.4

High-pressure switch psi OFF: 420 ON: 540

Protective devices (*5)