Toshiba MMK-AP0072H, MMK-AP0122H, MMK-AP0092H INSTALLATION MANUAL

INSTALLATION MANUAL

MANUEL DINSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

MANUAL DE INSTALAÇÃO

INSTALLATIE HANDLEIDING

ЕГЧЕЙСЙДЙП ЕГКБФБУФБУЗУ

SUPER MODULAR MULTI SYSTEM

SMMS

SMMS

SMMS

SMMS

SMMS

SMMS

CLIMATISEUR

KLIMAGERÄT

CONDIZIONATORE D'ARIA

APARATO DE AIRE ACONDICIONADO

AR CONDICIONADO

AIRCONDITIONER

SMMS КЛЙМБФЙУФЙКП

SMMS

Indoor Unit

Unité intérieure

Raumeinheit

Unità interna

Unidad interior

Unidade interior

Voor commercieel gebruik (niet geschikt voor huishoudelijk gebruik)

Binnenunit

ЕущфесйкЮ mпнЬдб

AIR CONDITIONER

For commercial use (Not accessible to the general public)

Pour usage commercial (Vente interdite au grand public)

Nur für gewerbliche Nutzung (kein öffentlicher Zugang)

Per uso commerciale (Non accessibile a clienti generici)

Para uso comercial (no destinado al público en general)

Para uso comercial (não acessível ao público em geral)

Гйб емрпсйкЮ чсЮуз (Мз дйбиЭуймп уфп ехсэ кпйнь)

<High-Wall Type>

<Type mural haut>

<Wand modell>

<Tipo per mura alte>

<Tipo parte alta de la pared>

<Tipo para Parede Alta>

<Hogewandmodel>

<Фэрпт фпрпиефзмЭнпх шзлЬ уфпн фпЯчп>

MMK-AP0072H,

MMK-AP0092H,

MMK-AP0122H

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new

refrigerant HFC (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the

ozone layer.

Thank you very much for purchasing TOSHIBA Air Conditioner.

Please read this Installation manual carefully before using your Air

Conditioner.

• Be sure to obtain the “Owner’s manual” and “Installation manual” from

constructor (or dealer).

Request to constructor or dealer

Please clearly explain the contents of the Owner’s manual and hand over it.

UTILISATION DU NOUVEAU REFRIGERANT

Ce climatiseur est d’un type inédit qui utilise le nouveau

réfrigérant HFC (R410A) au lieu du réfrigérant

traditionnel R22, afin d’éviter la destruction de la couche

d’ozone.

EINFÜHRUNG EINES NEUEN KÜHLMITTELS

Dies ist ein neuartiges Klimagerät. Anstatt des

herkömmlichen Kühlmittels R22 verwendet es das neue

ozonschicht-schonende HFC Kühlmittel R410A.

ADOZIONE DI UN NUOVO REFRIGERANTE

Questo condizionatore d'aria è di un tipo nuovo che

adotta un nuovo refrigerate HFC (R410A) al posto del

refrigerante convenzionale R22, per prevenire la

distruzione dello strato di ozono dell'atmosfera terrestre.

ADOPCIÓN DE NUEVO REFRIGERANTE

Este aparato de aire acondicionado es un modelo

reciente que incorpora el nuevo refrigerante HFC

(R410A) en lugar del refrigerante convencional R22

para así evitar daños en la capa de ozono.

Nous vous remercions pour avoir choisi un climatiseur TOSHIBA.

Veuillez lire attentivement ce Manuel d’installation avant d’utiliser votre

climatiseur.

• Assurez-vous que le constructeur (ou le revendeur) vous remette le

“Manuel du propriétaire” et le “Manuel d’installation”.

Demande au constructeur ou au revendeur

Veuillez expliquer clairement le contenu du Manuel du propriétaire et le

remettre au client.

Wir danken Ihnen, dass Sie sich für ein TOSHIBA Klimagerät entschieden haben.

Bitte lesen Sie diese Installations-Handbuch, bevor Sie Ihr Klimagerät

benutzen, sorgfältig.

• Lassen Sie sich die “Betriebsanleitung” und das “Installations-Handbuch”

unbedingt vom Installateur oder vom Lieferanten aushändigen.

Eine Bitte an den Installateur oder Lieferanten:

Bitte erklären Sie dem Käufer den Inhalt der Betriebsanleitung und händigen

sie ihm aus.

Grazie di aver acquistato un condizionatore d'aria TOSHIBA.

Prima di usare il condizionatore d'aria, leggere con attenzione questo

Manuale di installazione.

• Si raccomanda di tenere a portata di mano il “Manuale del proprietario”

e il “Manuale di installazione” ricevuti dal produttore (o dal rivenditore).

Richiesta al produttore o al rivenditore

Spiegare chiaramente il contenuto del Manuale del proprietario e

consegnarne una copia all'utente.

Muchas gracias por haber adquirido el aparato de aire acondicionado TOSHIBA.

Lea atentamente este Manual de instalación antes de utilizar el aparato de aire

acondicionado.

• Asegúrese de que el fabricante (o distribuidor) le proporcione el “Manual del

propietario” y el “Manual de instalación”.

Solicitud al fabricante o distribuidor

Explique con claridad el contenido del Manual del propietario y entréguelo al

cliente.

ADOPÇÃO DO NOVO REFRIGERANTE

Este ar condicionado é um modelo novo que adopta um

novo refrigerante HFC (R410A) em vez do refrigerante

convencional R22 para evitar a destruição da cama de

ozono.

TOEPASSING VAN EEN NIEUW K OELMIDDEL

Deze airconditioner is een nieuwe type dat werkt met

een nieuw koelmiddel HFC (R410A) in plaats van met

het conventionele koelmiddel R22, als bijdrage om de

aantasting van de ozonlaag te reduceren.

ХЙПИЕФЗУЗ НЕПХ ШХКФЙКПХ

Фп рбсьн Клймбфйуфйкь еЯнбй нЭпт фэрпт рпх хйпиефеЯ нЭп

шхкфйкь HFC (R410A) уфз иЭуз фпх ухмвбфйкпэ

шхкфйкпэ R22 рспкеймЭнпх нб впзиЮуей уфзн рспуфбуЯб

фпх ьжпнфпт.

HFC

R410A R22

Muito obrigada por adquirir o Ar Condicionado TOSHIBA.

Leia atentamente este Manual de inslatação antes de utilizar o seu ar

condicionado.

• Não se esqueça de receber o “Manual do utilizador” e o “Manual de

inslatação” do fabricante (ou agente).

Pedido ao fabricante ou agente

Explique por favor o conteúdo do Manual do utilizador e entregue-o.

Hartelijk dank voor uw keuze voor een airconditioner van TOSHIBA.

Lees deze installatiehandleiding zorgvuldig door voordat u de

airconditioner gaat gebruiken.

• Zorg ervoor dat u zowel de “gebruiksaanwijzing” als de

“installatiehandleiding” van de installateur (of leverancier) krijgt.

Verzoek aan de installateur of de leverancier

Leg de inhoud van de gebruiksaanwijzing duidelijk uit en overhandig de

gebruiksaanwijzing nadien aan de klant.

Убт ехчбсйуфпэме рплэ рпх рспфймЮубфе гйб фзн бгпсЬ убт Энб

Клймбфйуфйкь TOSHIBA.

Рбсбкблпэме дйбвЬуфе рспуечфйкЬ фйт ЕгчейсЯдйп ЕгкбфЬуфбузт рсйн брь фз

чсЮуз фпх Клймбфйуфйкпэ.

ВевбйщиеЯфе ьфй п кбфбукехбуфЮт (Ю п рщлзфЮт) убт рбсЭдщуе кбй фйт

ПдзгЯет ЧсЮузт кбй фп ЕгчейсЯдйп ЕгкбфЬуфбузт.

РбсЬклзуз гйб фпн кбфбукехбуфЮ Ю фпн рщлзфЮ

Рбсбкблю еозгЮуфе ме убцЮнейб фб ресйечьменб фщн Пдзгйюн ЧсЮузт кбй

CONTENTS

Accessory parts and parts to be procured locally....................................... 1

1

PRECAUTIONS FOR SAFETY............................................................... 2

2

SELECTION OF INSTALLA TION PLACE............................................... 3

3

INST ALLATION OF INDOOR UNIT ........................................................ 5

4

CUTTING A HOLE AND MOUNTING INSTALLATION PLATE .............. 6

5

PIPING AND DRAIN HOSE INSTALLATION.......................................... 7

6

INDOOR UNIT FIXING ............................................................................ 9

7

DRAINAGE ............................................................................................. 9

8

REFRIGERANT PIPING ....................................................................... 10

9

ELECTRIC WORK ................................................................................ 12

10

APPLICABLE CONTROLS .................................................................. 16

11

TEST RUN ............................................................................................ 18

12

TROUBLESHOOTING .......................................................................... 20

ENGLISH

Pièces accessoires et pièces non fournies ................................................ 25

1

MESURES DE SECURITE ................................................................... 26

2

SELECTION DU LIEU D’INST ALLATION ............................................. 27

3

INST ALLATION DE L’UNITE INTERIEURE .......................................... 29

4

DÉCOUPAGE D’UN TROU ET MONTA GE DE LA PLAQUE

D’INSTALLATION ................................................................................. 30

5

INST ALLATION DE LA TUYAUTERIE ET DU TUYAU FLEXIBLE

D’ÉVACUATION .................................................................................... 31

INHALT

SOMMAIRE

Zubehör und bauseits bereitzustellende Teile............................................ 49

1

SICHERHEITSVORKEHRUNGEN........................................................ 50

2

AUSWAHL DES AUFSTELLUNGSOR TES .......................................... 51

3

INST ALLATION DER RAUMEINHEIT................................................... 53

4

HERAUSTRENNEN EINER ÖFFNUNG UND MONTAGE DER

INSTALLATIONSPLATTE..................................................................... 54

5

INST ALLATION DER ROHRLEITUNGEN UND DES

KONDENSATSCHLAUCHS.................................................................. 55

INDICE

Accessori e parti da acquistare sul posto .................................................. 73

1

PRECAUZIONI PER LA SICUREZZA .................................................. 74

2

SCELTA DEL POSTO D’INSTALLAZIONE........................................... 75

3

INST ALLAZIONE DELL’UNITÀ INTERNA ............................................ 77

4

T A GLIARE UN FORO E MONTARE LA PIASTRA D’INSTALLAZIONE ...

5

INST ALLAZIONE DEI TUBI E DEL TUBO FLESSIBILE DI SCARICO ......

6

FISSAGGIO UNITÀ INTERNA .............................................................. 81

CONTENIDO

Componentes accesorios y componentes de suministro local................ 97

1

PRECAUCIONES PARA SU SEGURIDAD........................................... 98

2

SELECCIÓN DEL LUGAR DE INSTALACIÓN ..................................... 99

3

INST ALACIÓN DE LA UNIDAD INTERIOR ........................................ 101

4

Hacer un agujero y montar la placa de instalaciÓN ........................ 102

5

INST ALACIÓN DE LA TUBERÍA Y LA MANGUERA DE DESAGÜE... 103

6

FIJACIÓN DE LA UNIDAD INTERIOR ............................................... 105

6

FIXA TION DE L’UNITÉ INTÉRIEURE ................................................... 33

7

ÉVACUATION........................................................................................ 33

8

TUYAUX DE RÉFRIGÉRANT ............................................................... 34

9

TRA VA UX D’ÉLECTRICIT É.................................................................. 36

10

COMMANDES UTILISABLES .............................................................. 40

11

ESSAI DE FONCTIONNEMENT ........................................................... 42

12

DÉPANNAGE ........................................................................................ 44

6

BEFESTIGUNG DER INNENEINHEIT.................................................. 57

7

KONDENSATABLAUF .......................................................................... 57

8

KÜHLMITTELLEITUNGEN ................................................................... 58

9

ELEKTROARBEITEN ........................................................................... 60

10

STEUERUNGSMÖGLICHKEITEN ....................................................... 64

11

TESTLAUF............................................................................................ 66

12

FEHLERSUCHE ................................................................................... 68

7

SCARICO .............................................................................................. 81

8

TUBAZIONI DEL REFRIGERANTE...................................................... 82

9

COLLEGAMENTI ELETTRICI .............................................................. 84

10

78

79

COMANDI APPLICABILI ...................................................................... 88

11

FUNZIONAMENTO DI PROVA ............................................................. 90

12

RISOLUZIONE DEI PROBLEMI ........................................................... 92

7

DESAGÜE........................................................................................... 105

8

TUBERÍA DE REGRIGERANTE......................................................... 106

9

INSTALACIÓN ELÉCTRICA ............................................................... 108

10

CONTROLES APLICABLES .............................................................. 112

11

PRUEBA DE FUNCIONAMIENTO ...................................................... 114

12

RESOLUCIÓN DE PROBLEMAS....................................................... 116

FRANCAIS

DEUTSCH

ITALIANO

ESPAÑOL

Acessórios e peças adquiridas localmente ............................................. 121

1

PRECAUÇÕES DE SEGURANÇA ..................................................... 122

2

SELECÇÃO DO LOCAL DE INSTALAÇÃO ....................................... 123

3

INST ALAÇÃO DA UNIDADE INTERIOR ............................................ 125

4

ABRIR UM ORIFÍCIO E MONT AR A CHAPA DE INSTALAÇÃO ....... 126

5

INST ALAÇÃO DA TUBAGEM E MANGUEIRA DE DRENAGEM ....... 127

6

FIXAÇÃO DA UNIDADE INTERIOR ................................................... 129

INHOUD

ÍNDICE

Accessoires en niet meegeleverde onderdelen ....................................... 145

1

VOORZORGSMAA TREGELEN V OOR UW VEILIGHEID ................... 146

2

KEUZE VAN DE LOCATIE VOOR DE INSTALLATIE.......................... 147

3

INST ALLATIE V AN DE BINNENUNIT................................................. 149

4

EEN DOORVOEROPENING MAKEN EN DE INSTALLATIEPLAAT

MONTEREN ........................................................................................ 150

5

INST ALLATIE VAN DE LEIDINGEN EN DE AFVOERSLANG .......... 151

РЕСЙЕЧПМЕНБ

Рбселкьменб бнфбллбкфйкЬ кбй ЕобсфЮмбфб брь фзн фпрйкЮ бгпсЬ .... 169

1 РСПЦХЛБОЕЙУ БУЦБЛЕЙБУ ............................................................. 170

2 ЕРЙЛПГЗ ФПХ ЧЩСПХ ЕГКБФБУФБУЗУ ......................................... 171

3 ЕГКБФБУФБУЗ ФЗУ ЕУЩФЕСЙКЗУ МПНБДБУ ................................ 173

4

КПШЙМП ФСХРБУ КБЙ ФПРПИЕФЗУЗ ФЗУ РЛБКБУ ЕГКБФБУФБУЗУ .....

5 ЕГКБФБУФБУЗ УЩЛЗНЩУЗУ КБЙ ЕХКБМРФПХ УЩЛЗНБ

БРПУФСБГГЙУЗУ ............................................................................... 175

174

7

DRENAGEM........................................................................................ 129

8

TUBA GEM DE REFRIGERANTE ....................................................... 130

9

TRABALHOS DE ELECTRICID ADE .................................................. 132

10

CONTROLOS APLICÁVEIS ............................................................... 136

11

TESTE DE FUNCIONAMENTO .......................................................... 138

12

RESOLUÇÃO DE PROBLEMAS........................................................ 140

6

MONTEREN V AN DE BINNENUNIT................................................... 153

7

AFVOER.............................................................................................. 153

8

KOELMIDDELLEIDINGEN ................................................................. 154

9

ELEKTRISCHE BEDRADING ............................................................ 156

10

BEDIENINGSELEMENTEN ................................................................ 160

11

WERKINGSTEST ............................................................................... 162

12

STORINGEN VERHELPEN................................................................. 164

6 УФЕСЕЩУЗ ФЗУ ЕУЩФЕСЙКЗУ МПНБДБУ....................................... 177

7 БРПУФСБГГЙУЗ ................................................................................. 177

8 УЩЛЗНЩУЗ ШХКФЙКПХ МЕУПХ ....................................................... 178

9 ЗЛЕКФСЙКЗ ЕСГБУЙБ ....................................................................... 180

10 ЕЦБСМПУЙМПЙ ЕЛЕГЧПЙ .................................................................. 184

11 ДПКЙМЗ ЛЕЙФПХСГЙБУ ...................................................................... 186

12 БНФЙМЕФЩРЙУЗ РСПВЛЗМБФЩН .................................................... 188

PORTUGUÊS

NEDERLANDS

ЕЛЛЗНЙКБ

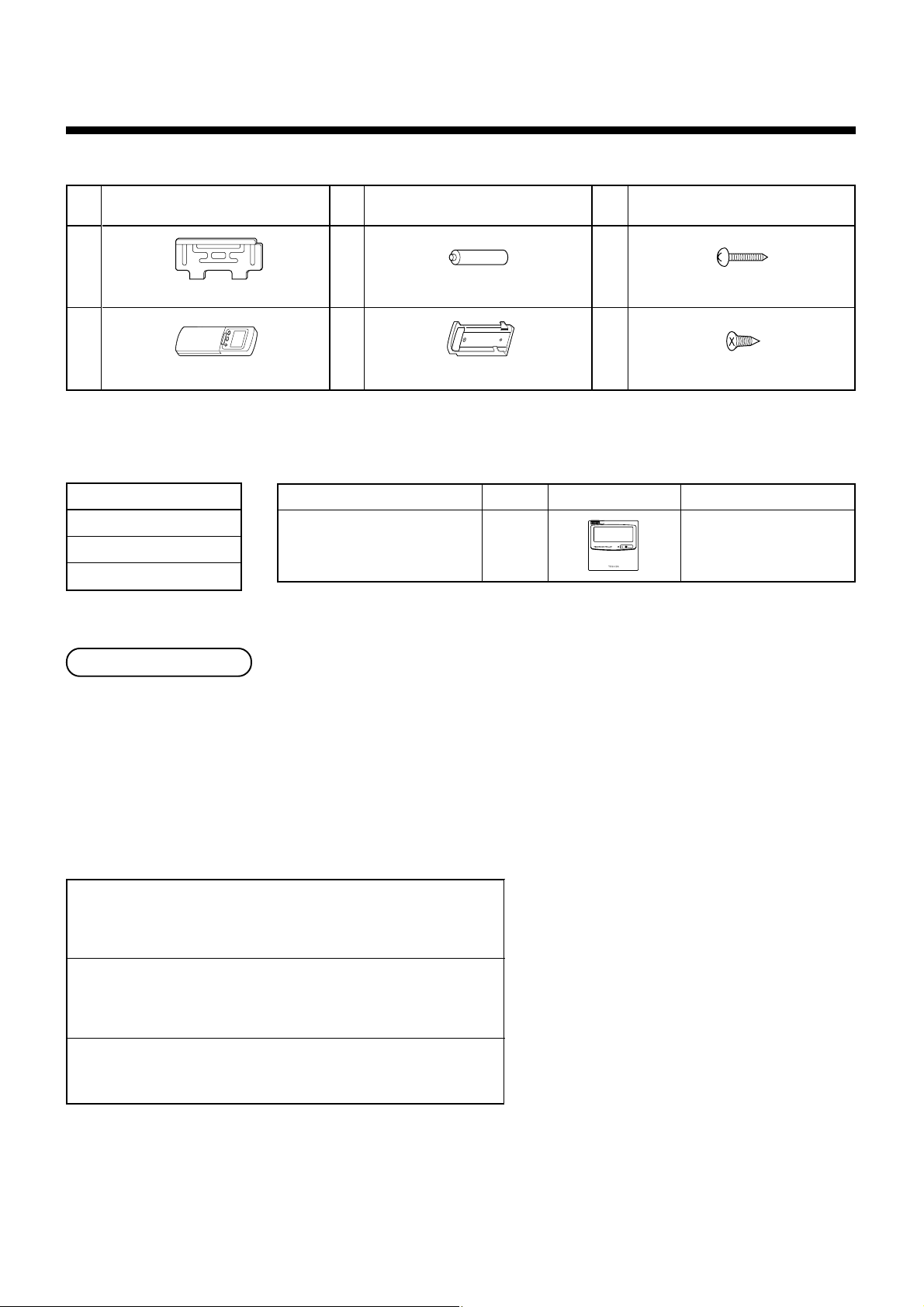

Accessory parts and parts to be procured locally

H Accessory parts

Part

No.

1

Installation plate × 1

2

Wireless remote controller × 1

<Others>

Name

Owner’ s manual

Installation manual

Paper pattern

Part name (Q'ty)

Part

No.

3

Battery × 2

4

Remote controller holder × 1

Part name (Q'ty)

<Separate sold parts>

Part name

Standard wired remote controller

Q’ty

1

Part

No.

5

Mounting screw Ø4 × 25 l x 6

6

Pan head wood screw Ø3.1 × 16 l × 2

Shape

Part name (Q'ty)

Usage

Model : RBC-AMT21E

Refrigerant piping

• Piping material used for the conventional refrigerant cannot be used.

• Use copper pipe with 0.8 mm or more thickness for Ø6.4, Ø9.5.

• Flare nut and flare works are also different from those of the conventional refrigerant. Take out the flare nut

attached to the indoor unit of the air conditioner, and use it.

H Parts to be procured locally

Connecting pipe (Liquid side)

(6.4mm (diam.), Nominal (diam.) 1/4” thick 0.8mm)

MMK-AP0072H to MMK-AP0122H

Connecting pipe (Gas side)

(9.5mm (diam.), Nominal (diam.) 3/8” thick 0.8mm)

MMK-AP0072H to MMK-AP0122H

Power supply cord

Cable 3-core 2.5mm

2

, in conformity with Design 60245 IEC57

1

1

PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

CAUTION New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil

does not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are charged from those for the conventional refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does

not enter. Moreover, do not use the existing piping because there are problems with pressure-resistance force and

impurity in it.

ENGLISH

CAUTION To Disconnect the Appliance from Main Power Supply

This appliance must be connected to the main power supply by means of a switch with a contact separation of at

least 3 mm.

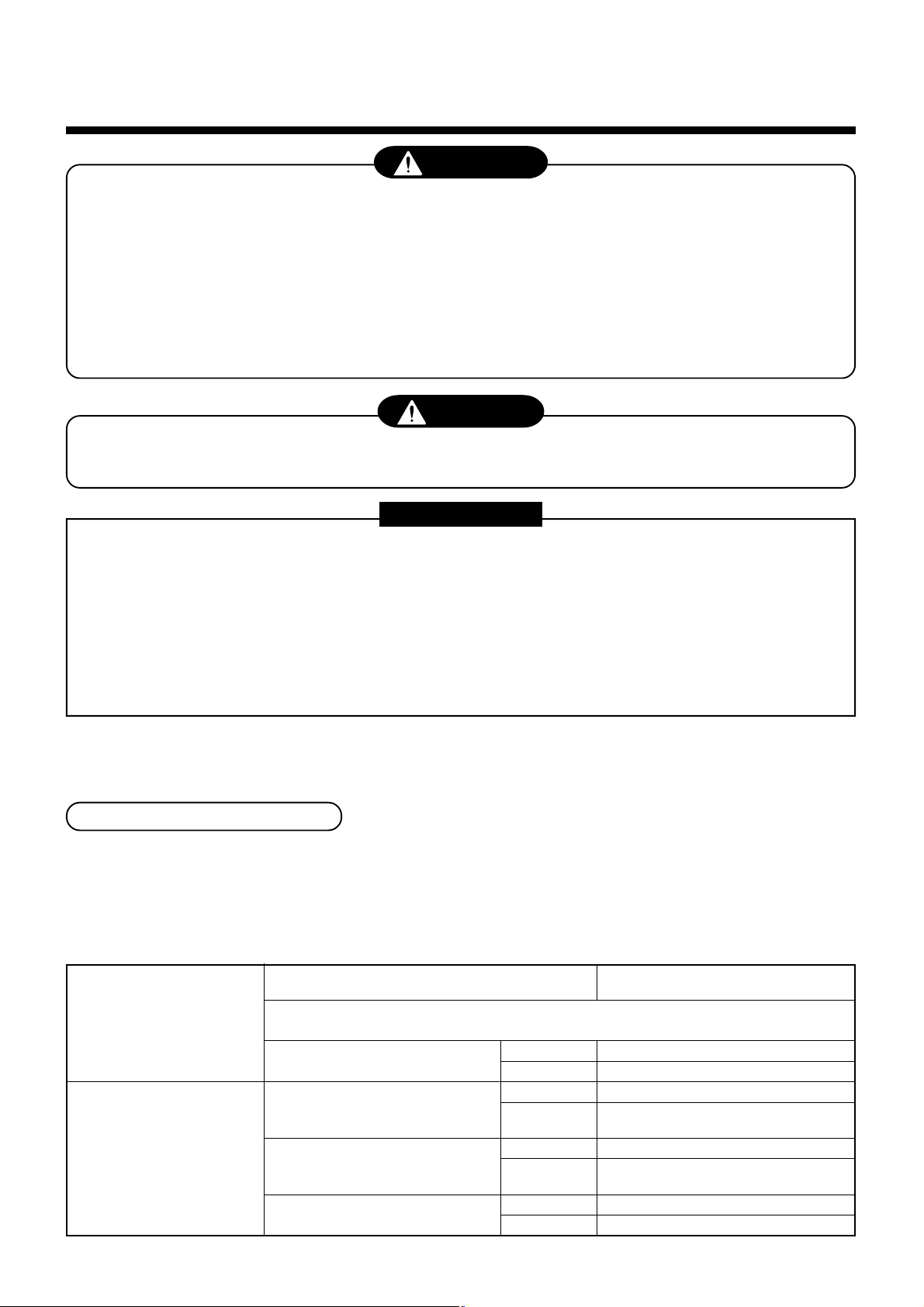

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• When moving the air conditioner for the installation into another place, be very careful not to

enter any gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally

high and it as a result causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the safety

interlock switches.

• Exposure of unit to water or other moisture before installation may cause a short-circuit of

electrical parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully if there are possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that

the concentration of refrigerant leakage occur in the room does not exceed the critical level.

2

1

PRECAUTIONS FOR SAFETY

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix. To prevent external forces

applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

2

SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner where there is sufficient strength to weight of the unit.

If strength is insufficient, the unit may fall down resulting in human injury.

• Perform a specified installation work to guard against an earthquake.

An incomplete installation can cause accidents by the units failing and dropping.

CAUTION

• Do not install the air conditioner in a location subject to a risk of exposure to combustible gas.

Should the combustible gas leak and collect near the unit, fire may occur.

Upon approval of the customer, install the air conditioner in a place that satisfies the following

conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be ensured for safe maintenance and check.

• Place where drained water will not cause any problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide gas

(hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place near door or window where may come to contact with the outside air of high humidity. (Dewing may be caused.)

• Place where special spray is frequently used.

• Place with poor ventilation.

3

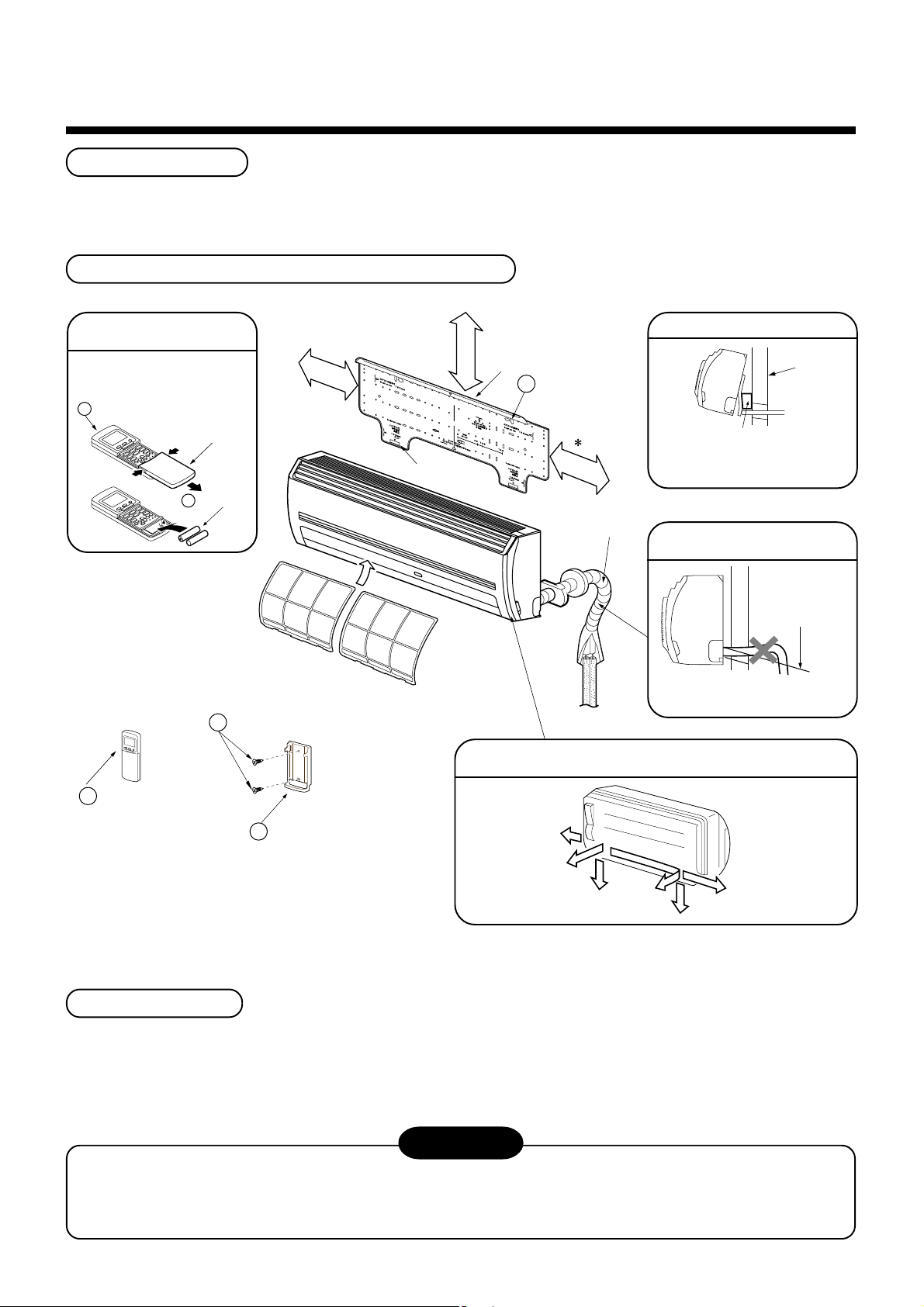

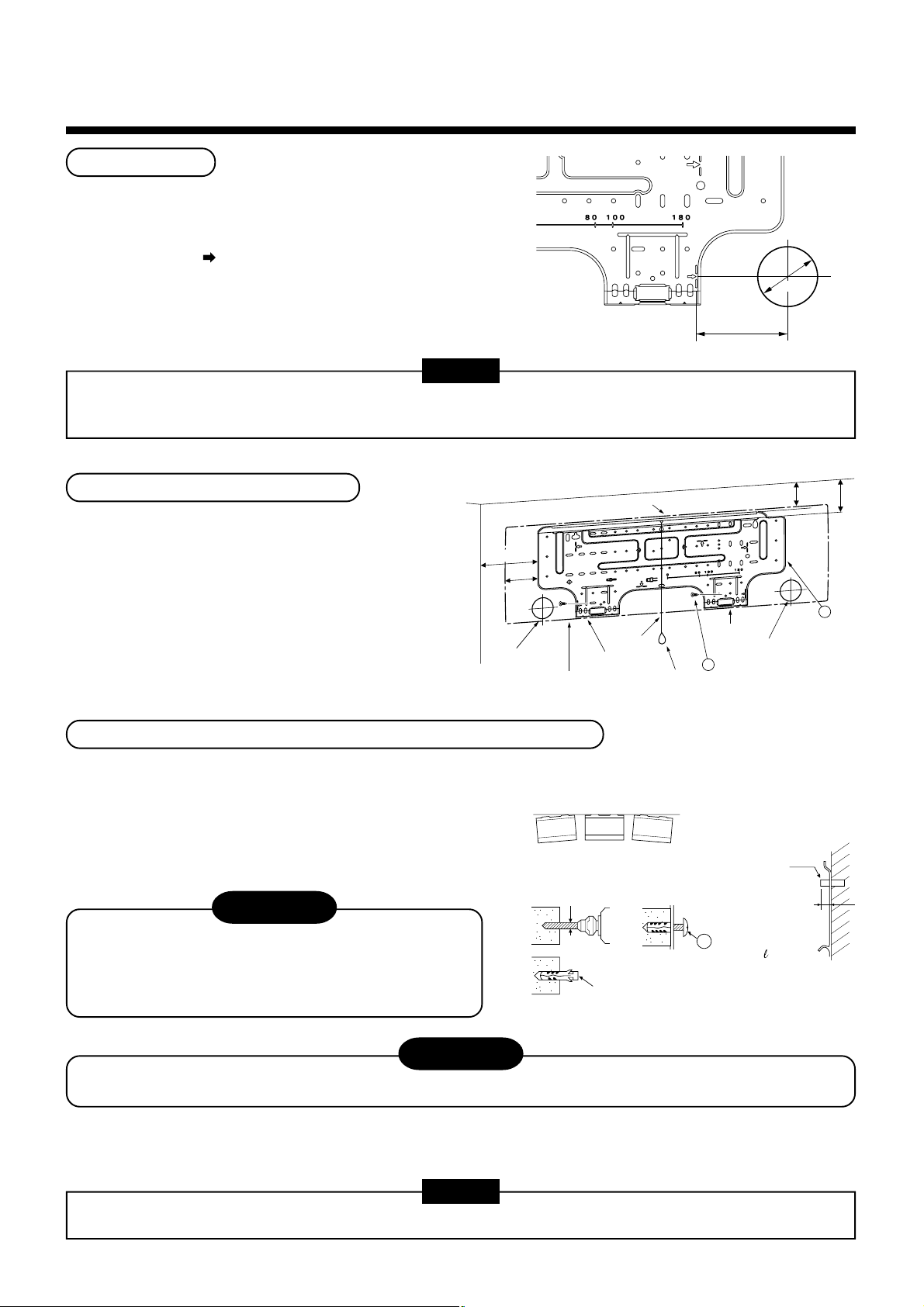

Installation space

Reserve space required to install the indoor unit and for service work.

Keep 100mm or more for clearance between top plate of the indoor unit and the ceiling surface.

Installation diagram of Indoor and outdoor units

Before installing the

wireless remote controller

• With the remote controller cover

open, load the batteries supplied

correctly, observeing their polarity.

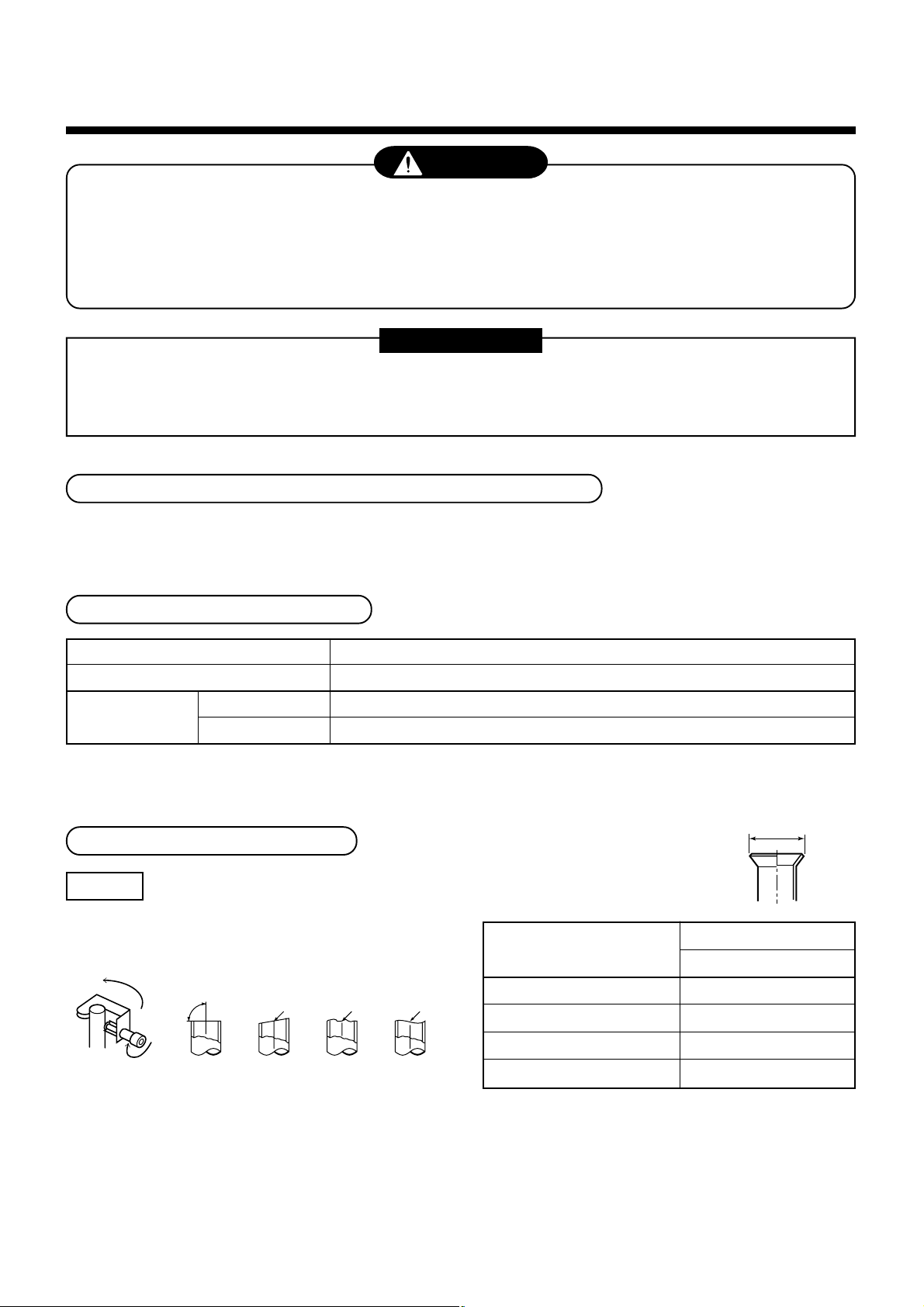

2 W ireless remote controller

Cover

3 Batteries

6

Pan head wood screw

170mm

or more

Air filter

(Attach to the front panel)

Hook

For the rear left and left piping

Hook

100 mm or more

1

Installation

plate

Wall

Insert the cushion between the

170mm

or more

Shield pipe

indoor unit and wall, and tilt the

indoor unit for better operation.

Do not allow the drain hose to

get slack

Cut the piping hole

sloped slightly

Make sure to run the drain hose

sloped downward.

The auxiliary piping can be connected the left, rear left, rear right,

right, bottom right or bottom left.

2

Wireless

remote controller

4

Remote control holder

Right

Rear right

Bottom right

Rear left

∗ When installing the Flow Selector Unit (FS Unit),

keep a space more than 300mm for wiring work.

Installation place

• A place which provides the spaces around the indoor unit as shown in the above diagram.

• A place where there is no obstacle near the air inlet and outlet.

• A place that allows easy installation of the piping to the outdoor unit.

• A place which allows the front panel to be opened.

CAUTION

• Direct sunlight to the indoor unit’ s wireless receiver should be avoided.

• The microprocessor in the indoor unit should not be too close to RF noise sources.

(For details, see the owner’ s manual.)

Left

Bottom left

4

2

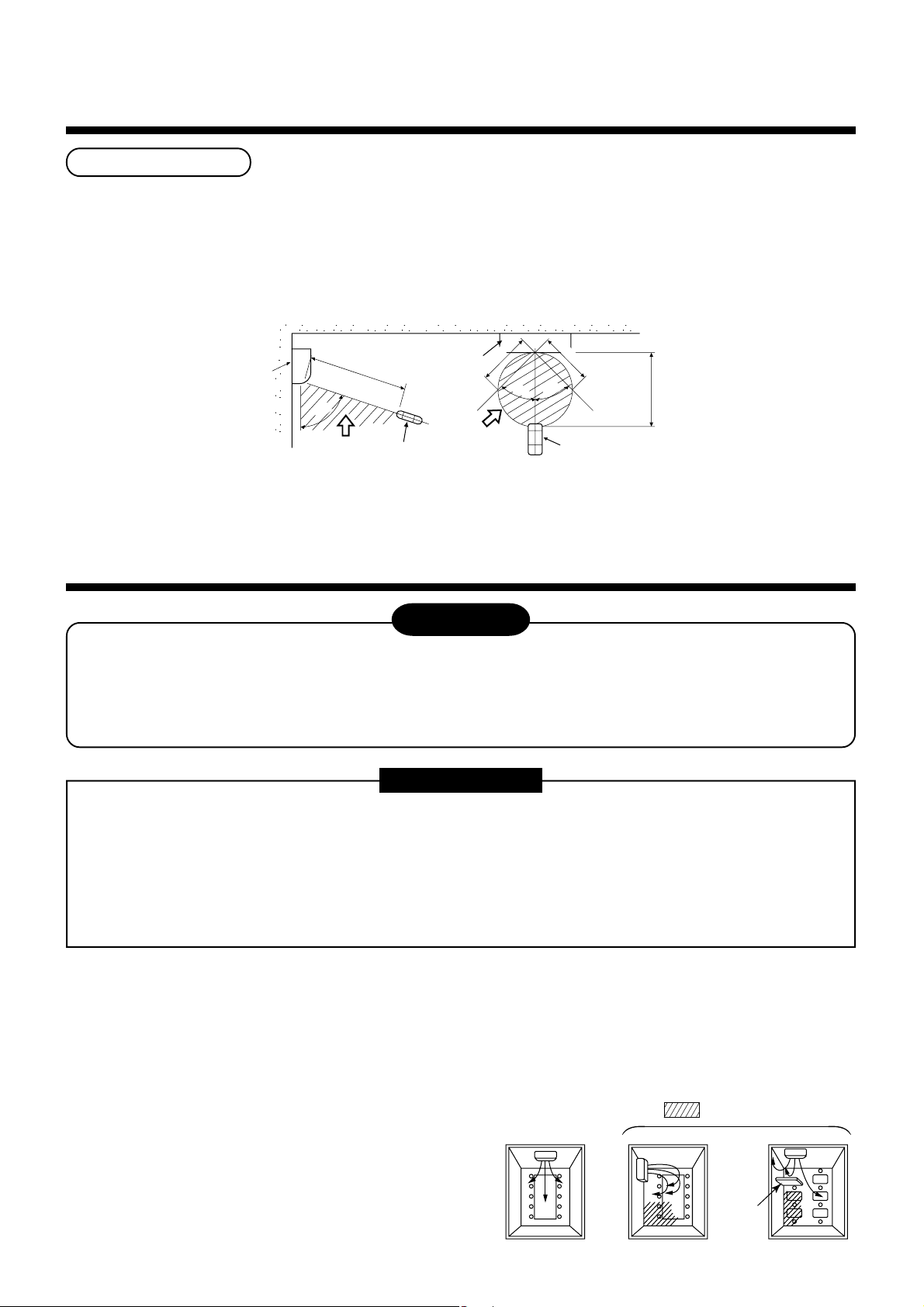

SELECTION OF INSTALLATION PLACE

Remote controller

• A place where there are no obstacles such as a curtain that may block the signal from the indoor unit.

• Do not install the remote controller in a place exposed to direct sunlight or close to a heating source, such as a

stove.

• Keep the remote controller at least 1m apart from the nearest TV set or stereo equipment.

(This is necessary to prevent image distur-bances or noise interference.)

• The location of the remote controller should be determined as shown below.

(Top view)

Indoor unit

Reception range

Remote controller

* : Axial distance

5 m

45

˚

45˚

5

m

Remote controller

3

(Side view)

7 m

Indoor unit

75˚

Reception

range

INSTALLATION OF INDOOR UNIT

WARNING

Install the air conditioner certainly to sufficiently withstand the weight.

If the strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work to guard against strong wind or earthquake.

An incomplete installation can cause accidents by the units falling and dropping.

REQUIREMENT

* 7 m

Strictly comply with the following rules to prevent damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit. (Even units are packaged)

• Carry in the indoor unit as it is packaged if possible. If carrying in the indoor unit unpacked by necessity, be

sure to use buffering cloth, etc. to not damage the unit.

• To move the indoor unit, do not apply force to the refrigerant pipe, drain pan, foamed parts, or resin parts, etc.

• Carry the package by two or more persons, and do not bundle it with PP band at positions other than specified.

Be careful to the following items when installing the unit.

• Considering air discharge direction, select an

installation place where discharge air can circulate

evenly in a room. Avoid to install the unit at place with

“NO GOOD” mark in the right figure.

OK NO GOOD

Bad installation place

Good installation place

Cooled well all over.

: Not cooled well.

Screen

5

4

Projection

15mm or less

7

Mounting screw

Ø4 × 25

Clip anchor

(local parts)

5mm dia. hole

Anchor bolt

NO

GOOD

NO

GOOD

OK

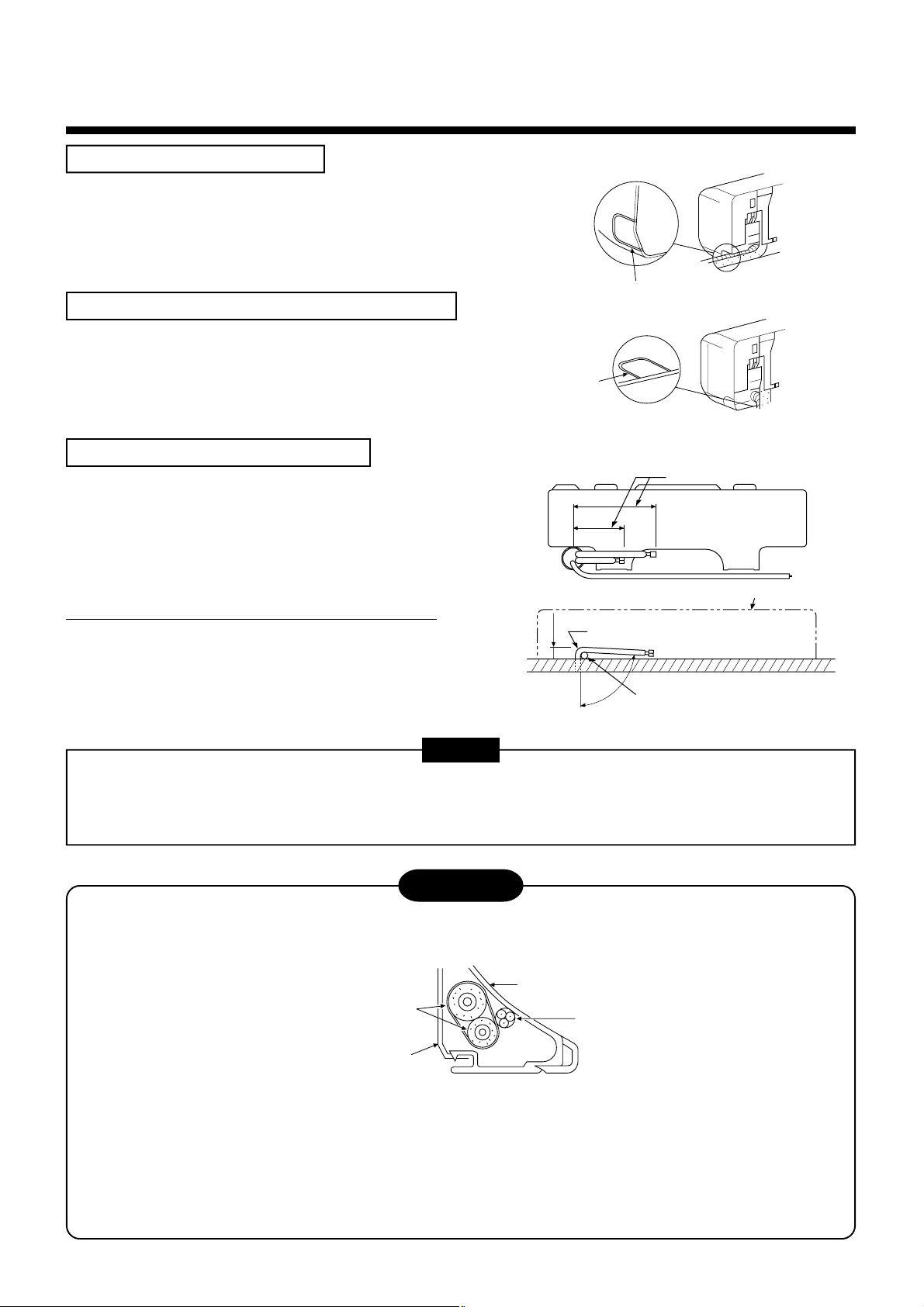

CUTTING A HOLE AND MOUNTING INSTALLATION PLATE

Cutting a hole

In case of installing the refrigerant pipes from the rear:

1. Decide the hole position for piping at 100mm from

the arrow mark (

drill a hole with Ø65mm at a slight downward slant

toward outdoor side.

) on the installation plate and

The center of the pipe

hole is above the arrow.

100 mm

Pipe

hole

65 mm

NOTE

• When drilling a wall that contains a metal lath, wire lath or metal plate, be sure to use a pipe hole brim ring sold

separately.

Mounting the installation plate

For installation of the indoor unit,

use the paper pattern in the accessory parts.

170

85

Pipe hole

Indoor unit

When the installation plate is directly mounted on the wall

1. Securely fit the installation plate onto the wall by screwing

it in the upper and lower parts to hook up the indoor unit.

2. To mount the installation plate on a concrete wall with

anchor bolts, utilize the anchor bolt holes as illustrated in

the above figure.

3. Install the installation plate horizontally in the wall.

CAUTION

Hook

Hook

Thread

Weight

Hook

Pipe hole

Mounting screw

5

107

Installation

plate

127.5

1

When installing the installation plate with a mounting

screw, do not use the anchor bolt hole.

Otherwise the unit may fall down and result in personal

injury and property damage.

CAUTION

Failure to firmly install the unit may result in personal injury and property damage if the unit falls.

• In case of block, brick, concrete or similar type walls, make 5mm dia. holes in the wall.

• Insert clip anchors for appropriate

• Secure four corners and lower parts of the installation plate with 4 to 6 mounting screws to install it.

mounting screws.

NOTE

6

5

H

n

PIPING AND DRAIN HOSE INSTALLATION

Piping and drain hose forming

* Apply thermal-insulation for both refrigerant pipe and drain hose surely so that no dewing generates inside of the

equipment. (Use polyethylene foam for insulating material.)

Rear right

Rear left

Bottom left

Left

Bottom right

Right

Die-cutting

front panel slit

Changing

drain hose

Piping

preparation

1. Die- cutting front panel slit

For piping work at the left side, cut off the left slit for notching of the front panel.

(A knife will produce flaws on the panel, so use nippers.)

2. Changing drain hose

For piping work at the left side, lower left side, and left back side, it is necessary to change the drain hose and

drain cap.

How to remove the drains cap

Clip drain cap by needle- nose pliers, and pull out.

How to install the drain hose

Firmly insert drain hose connecting part until hitting on

a heat insulator.

eat insulator

Drain hose

How to fix the drains cap

1) Insert hexagonal wrench (Ø4mm) in a center

head.

4 mm

2) Firmly insert drains cap.

No gap

Insert a hexagon

wrench (4 mm)

Do not apply lubricating oil

(refrigerant machine oil) when

inserting the drain cap.

Application causes deterioratio

and drain leakage of the plug.

CAUTION

Firmly insert the drain hose and drain cap; otherwise, water may leak.

7

In case of right or left piping

270mm

170mm

43 mm

(To the fore front of flare)

Liquid side

Gas side

Outward form of indoor unit

R 30 mm (Use polish polyethylene

core or the like for bending pipe.)

Use the handle of screwdriver, etc.

80˚

• After scribing slits of the front panel with a knife or a

marking-off pin, cut them with a pair of nippers or an

equivalent tool.

In case of bottom right or bottom left piping

• After scribing slits of the front panel with a knife or a

marking- off pin, cut them with a pair of nippers or an

equivalent tool.

Left- hand connection with piping

Bend the connecting pipe so that it is laid within 43mm above

the wall surface. If the connecting pipe is laid exceeding

43mm above the wall surface, the indoor unit may unstably

be set on the wall. When bending the connecting pipe, make

sure to use a spring bender so as not to crush the pipe.

Bend the connection pipe within a radius of 30 mm.

To connect the pipe after installation of the unit (figure)

Slit

Slit

If the pipe is bent incorrectly, the indoor unit may unstably be set on the wall.

After passing the connecting pipe through the pipe hole, connect the connecting pipe to the auxiliary pipes and

wrap the facing tape around them.

• Bind the auxiliary pipes (two) and connecting cable with facing tape tightly. In case of leftward piping and rear-

leftward piping, bind the auxiliary pipes ( two) only with facing tape.

• Carefully arrange pipes so that any pipe does not stick out of the rear plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to each other and cut off the insulating tape wound

on the connecting pipe to avoid double- taping at the joint, moreover, seal the joint with the vinyl tape, etc.

• Since dewing results in a machine trouble, make sure to insulate both the connecting pipes.

• When bending a pipe, carefully do it, not to crush it.

(Use polyethylene foam as insulating material.)

Auxiliary pipes

Installation plate

NOTE

CAUTION

Indoor unit

Connecting cable

8

6

INDOOR UNIT FIXING

1. Pass the pipe through the hole in the wall, and hook the

indoor unit on the installation plate at the upper hooks.

2. Swing the indoor unit to right and left to confirm that it is firmly

hooked up on the installation plate.

3. While pressing the indoor unit onto the wall, hook it at the

lower part on the installation plate. Pull the indoor unit toward

you to confirm that it is firmly hooked up on the installation

plate.

• For detaching the indoor unit from the installation plate, pull the

indoor unit toward you while pushing its bottom up at the

specified parts.

Hook

1

2

Hook here

1

Installation plate

Press

(unhook)

PushPush

7

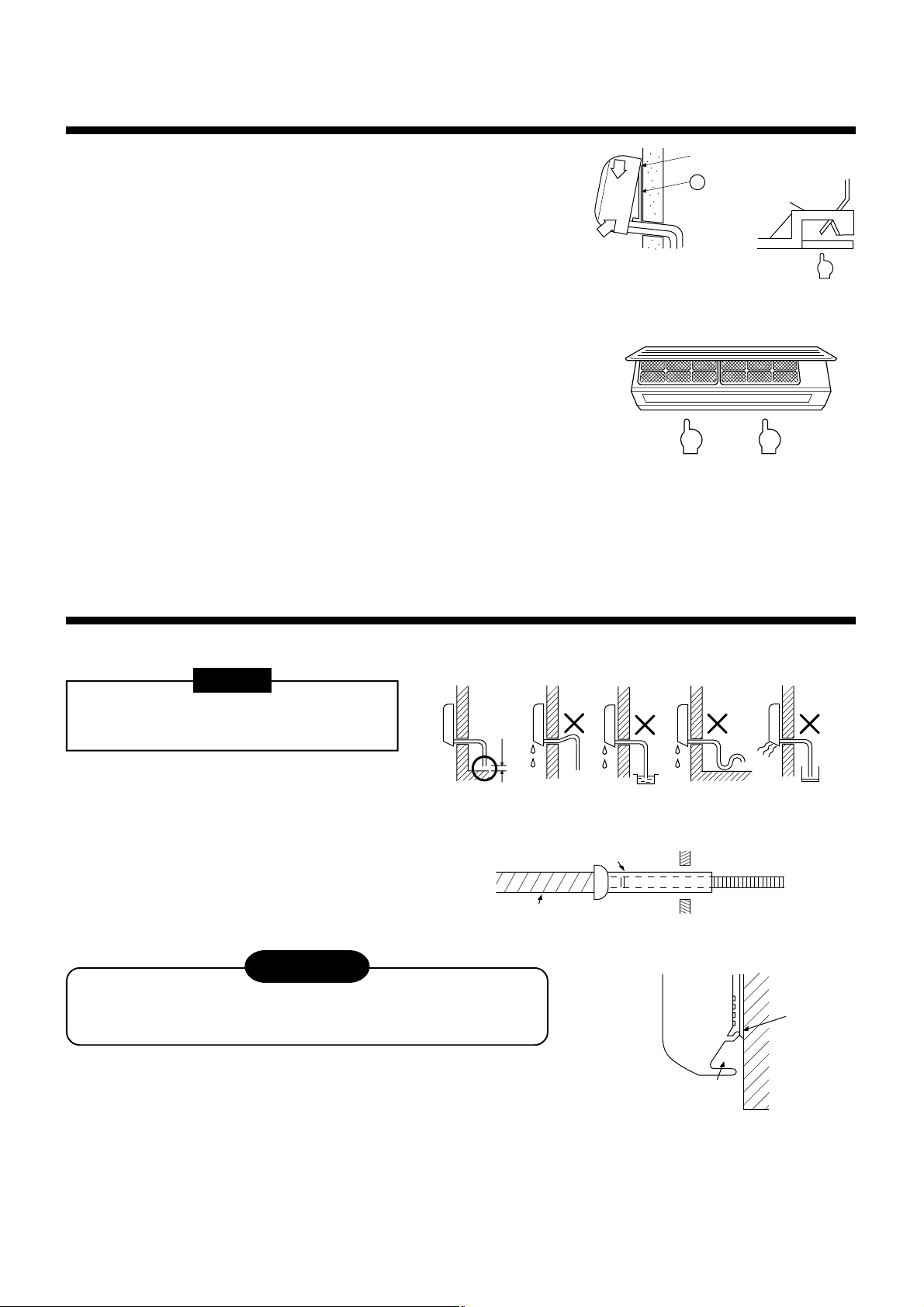

1. Run the drain hose sloped downwards.

DRAINAGE

NOTE

• Hole should be made at a slight downward

slant on the outdoor side.

2. Put water in the drain pan and make sure that

the water is drained out of doors.

3. When connecting extension drain hose,

insulate the connecting part of extension

drain hose with shield pipe.

CAUTION

Arrange the drain pipe for proper drainage from the unit.

Improper drainage can result in dew- dropping.

Do not rise the drain hose.

50 mm

or more

Do not put the

drain hose end

into water.

Shield pipe

Drain hose

Inside the

room

Do not form the drain hose

into a wavy shape.

Do not put the

drain hose end in

the drainage ditch.

Extension drain hose

Wall

Drain

guide

This air conditioner has the structure designed to drain water collected

from dew, which forms on the back of the indoor unit, to the drain pan.

Therefore, do not store the power cord and other parts at a height

above the drain guide.

9

Space for pipes

8

REFRIGERANT PIPING

WARNING

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

• If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

• If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas may

generate.

REQUIREMENT

When the refrigerant pipe is long, set the support brackets to fix the pipe with 2.5 to 3m intervals. If the pipe is

not fixed, abnormal sound may generate.

Be sure to use the flare nuts attached to the indoor unit or those for R410A.

Permissible pipe length and permissible height difference

They are different according to the used outdoor unit. For details, refer to the Installation Manual attached to the

outdoor unit.

Piping material and dimensions

Piping material

Model

Pipe size (mm)

• Use a clean and new pipe, and check that impurity such as dust, oil, moisture, etc. does not adhere in the pipe.

Gas side

Liquid side

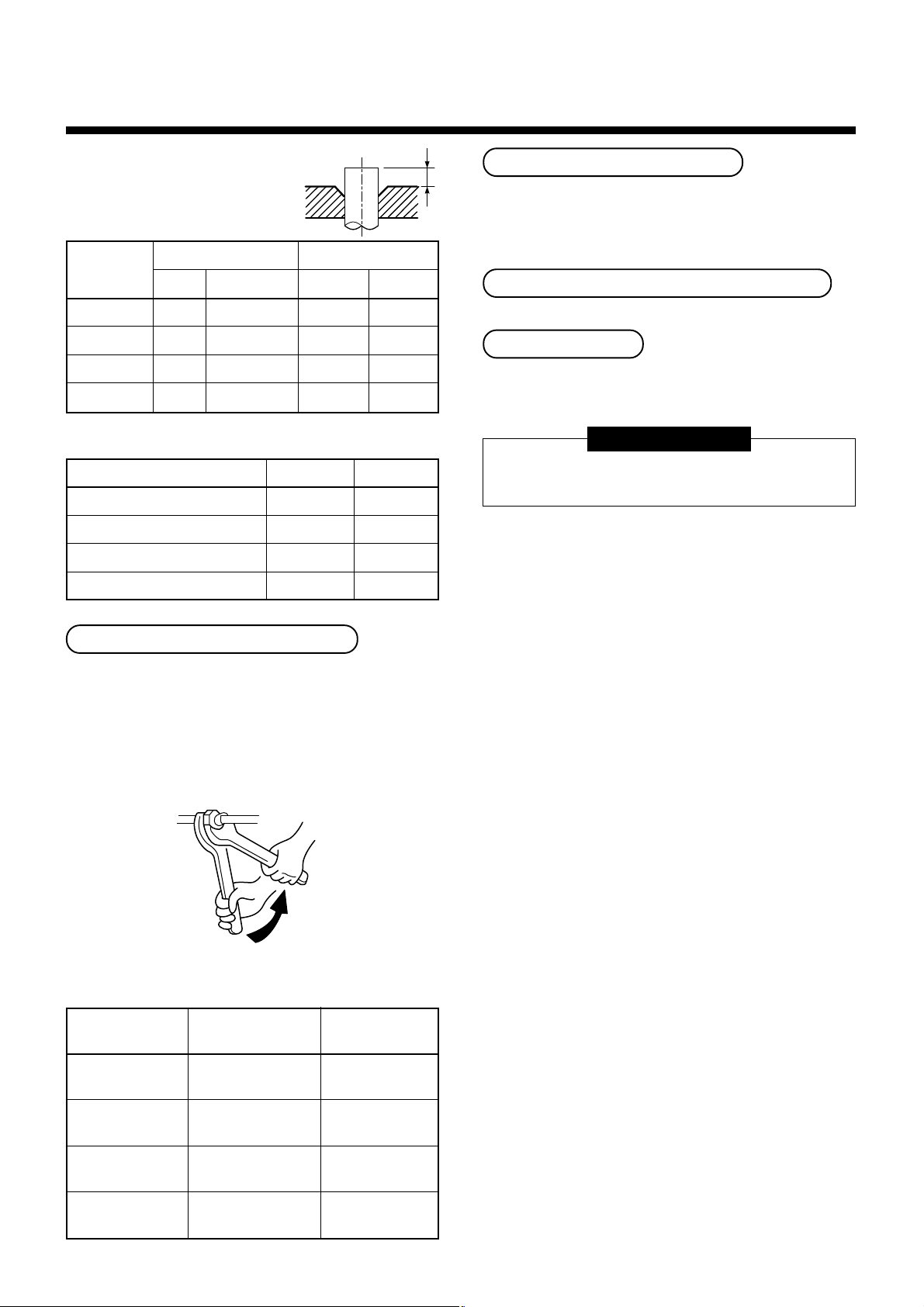

Pipe Forming/End Positioning

Phosphor deoxidization joint-less pipe for air conditioner

MMK-AP0072H to MMK-AP0122H

Ø9.5

Ø6.4

• Flaring diam. meter size :

A

A (Unit : mm)

Flaring

1. Cut the pipe with a pipe cutter.

OK NO GOOD

90˚

Obliquity Roughness Warp

Outer diam. of copper pipe

6.4

9.5

12.7

+0

A

-

0.4

R410A

9.1

13.2

16.6

2. Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional tools can be used by

adjusting projection margin of the copper pipe.

15.9

In case of flaring for R410A with the conventional

*

flare tool, pull it out approx. 0.5 mm more than that

for R22 to adjust to the specified flare size.

The copper pipe gauge is useful for adjusting

projection margin size.

10

19.7

8

REFRIGERANT PIPING

• Projection margin in flaring :

B (Unit : mm)

Rigid (Clutch type)

Outer diam. of

copper pipe

6.4

9.5

12.7

15.9

Imperial (Wing nut type)

Outer diam. of copper pipe

R410A tool used

R410A R22

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

6.4

9.5

12.7

15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

2.0 to 2.5 1.5 to 2.0

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

B

Airtight test/Air purge, etc.

For airtight test, air purge, addition of refrigerant, and

gas leak check, follow the Installation Manual attached

to the outdoor unit.

Open fully valves of the outdoor unit

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap

of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for

HFC refrigerant (R410A, R134a, etc.).

Connection of refrigerant pipe

Connect all the refrigerant pipes with flare connecting

work.

• Since the atmospheric pressure only is sealed as the

sealing gas, it is not abnormal that “Pushu…” sound

is not heard when the flare nut is removed.

• Be sure to use a double spanner for pipe connecting

work of the indoor unit.

Work using double spanner

• Refer to the following table for tightening torque.

Connecting pipe

outer dia. (mm)

Ø6.4

Tightening torque

(N•m)

14 to 18

(1.4 to 1.8 kgf•m)

Re-tightening

torque (N•m)

18

(1.8 kgf•m)

Ø9.5

Ø12.7

Ø15.9

33 to 42

(3.3 to 4.2 kgf•m)

50 to 62

(5.0 to 6.2 kgf•m)

68 to 82

(6.8 to 8.2 kgf•m)

42

(4.2 kgf•m)

50

(5.0 kgf•m)

68

(6.8 kgf•m)

11

9

ELECTRIC WORK

WARNING

1. Using the specified wires, ensure to connect the wires, and fix wires securely so that the

external strength of the wires do not transmit to the connecting part of the terminals.

Incomplete connection or fixation may cause a fire, etc.

2. Be sure to connect earth wire. (Grounding work)

Do not connect the earth wire to gas pipe, city water pipe, lightning rod, or the earth wire of telephone.

Incomplete grounding causes an electric shock.

3. For electric work, strictly follow to the Local Regulation in each country and the Installation

Manual, and use an exclusive circuit.

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a fire.

CAUTION

Be sure to install an earth leakage breaker.

If an earth leakage breaker is not installed, an electric shock may be caused.

REQUIREMENT

• For power supply wiring, strictly conform to the Local Regulation in each country.

• For wiring of power supply of the outdoor units, follow to the Installation Manual of each outdoor unit.

• Never connect 220–240V power to the terminal blocks (A, B, U1, U2, X, Y, etc.) for control wiring.

(Otherwise, the system will be failed.)

• Perform the electric wiring so that it does not come to contact with the high-temperature part of the pipe.

The coating may melt resulted in an accident.

• After connecting wires to the terminal blocks, provide a trap and fix wires with the wire clamp.

• Store the refrigerant piping line and control wiring line in the same line.

• Do not turn on the power of the indoor unit until vacuuming of the refrigerant pipes completes.

Power supply specifications

Cables and remote controller wires are procured locally.

For the power supply specifications, follow to the table below. If capacity is little, it is dangerous because overheat or

seizure may be caused.

For specifications of the power capacity of the outdoor unit and the power supply cables, refer to the Installation

Manual attached to the outdoor unit.

220–240V ~ 50Hz

220V

Twist wire : 2.0 mm²

Twist wire : 2.5 mm²

Twist wire : 0.5 to 2.0 mm²

~ 60Hz

2

2

2

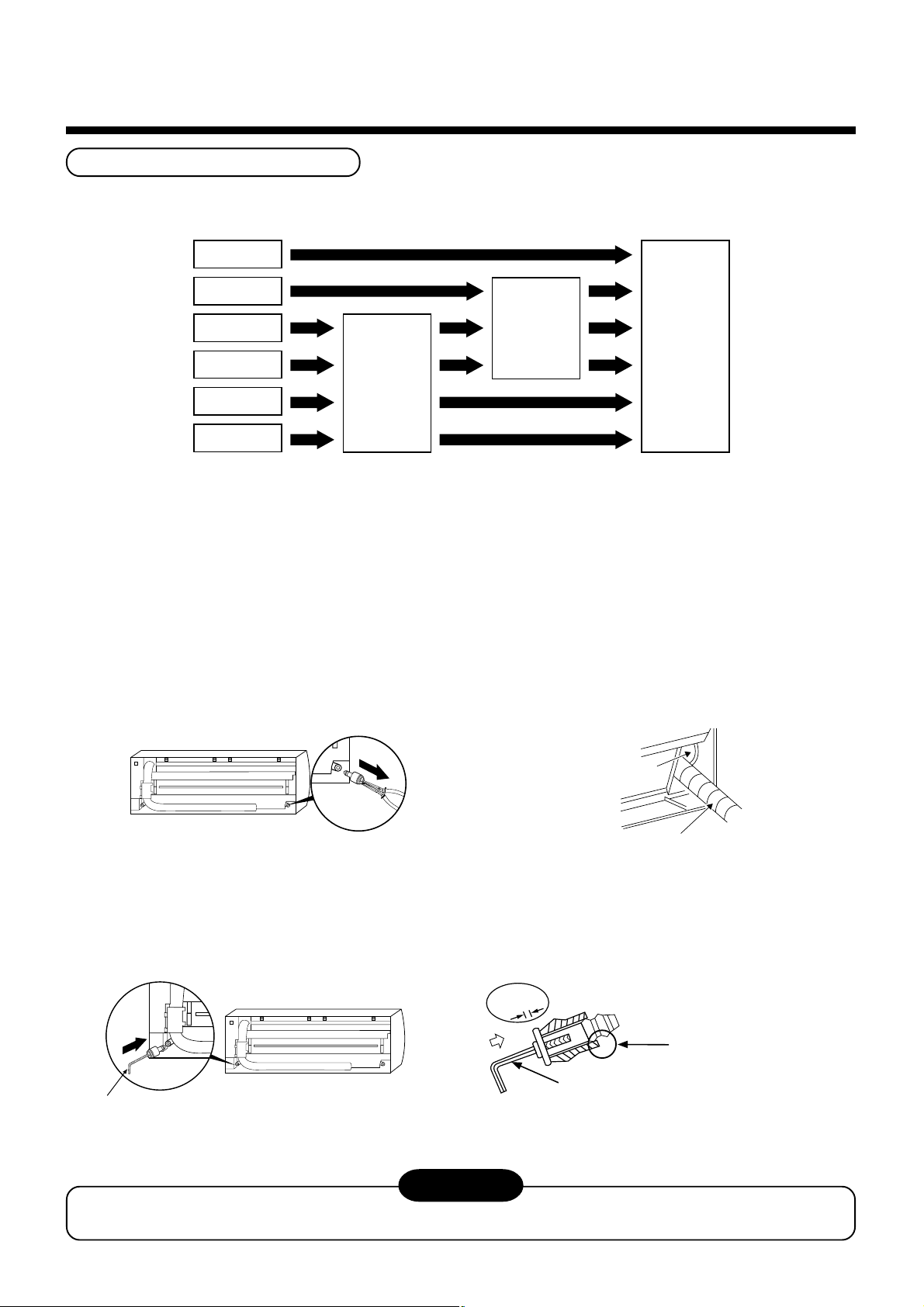

Indoor unit power supply (*1)

Communication line

Power supply

Power supply switch/Earth leakage breaker or power supply wiring/fuse rating for

indoor units should be selected by the accummulated total current values of the indoor units.

Power supply wiring

Indoor/Outdoor inter-unit wiring (*2)

Central control line wiring (*3)

Remote controller wiring (*4)

20m or less

50m or less

Q’ty

Wire size

Q’ty

Wire size

Q’ty

Wire size

(Up to 1000m) Twist wire : 1.25 mm²

(Up to 2000m) Twist wire : 2.00 mm²

(Up to 1000m) Twist wire : 1.25 mm²

(Up to 2000m) Twist wire : 2.00 mm²

12

9

el

ELECTRIC WORK

Indoor unit power supply (*1)

• For the power supply of the indoor unit, prepare the exclusive power supply separated from that of the outdoor unit.

• Arrange the power supply, earth leakage breaker, and main switch of the indoor unit connected to the same

outdoor unit so that they are commonly used.

• Power supply cord specification : Cable 3-core 2.5mm², in conformity with Design 60245 IEC 57.

Indoor/Outdoor inter-unit wiring, Central controller wiring (*2) (*3)

• 2-core with polarity wires are used for the Indoor/Outdoor inter-unit wiring and Central controller wiring.

• To prevent noise trouble, use 2-core shield wire.

• The length of the communication line means the total length of the inter-unit wire length between indoor and

outdoor units added with the central control system wire length.

Remote controller wiring (*4)

• 2-core with non-polarity wire is used for wiring of the remote controller wiring and group remote controllers wiring.

Remote controller wiring, remote

controller inter-unit wiring

Total wire length of remote controller

wiring and remote controller inter-unit

wiring = L + L1 + L2 + … Ln

Total wire length of remote controller inter-unit wiring = L1 + L2 + … Ln

Indoor unit

Remote

controller

wiring

Remote

controller

Twist wire: 0.5mm2 to 2.0mm2× 2

In case of wired type only

In case of wireless type included

Indoor unit

L1 L2 Ln

Remote controller inter-unit wiring

Up to 500m

Up to 400m

Up to 200m

Indoor unit Indoor unit

(Max. 8 units)

The remote controller wire

(Communication line) and

AC220–240V wires cannot be

parallel to contact each other and

cannot be stored in the same

conduits. If doing so, a trouble

may be caused on the control

system due to noise, etc.

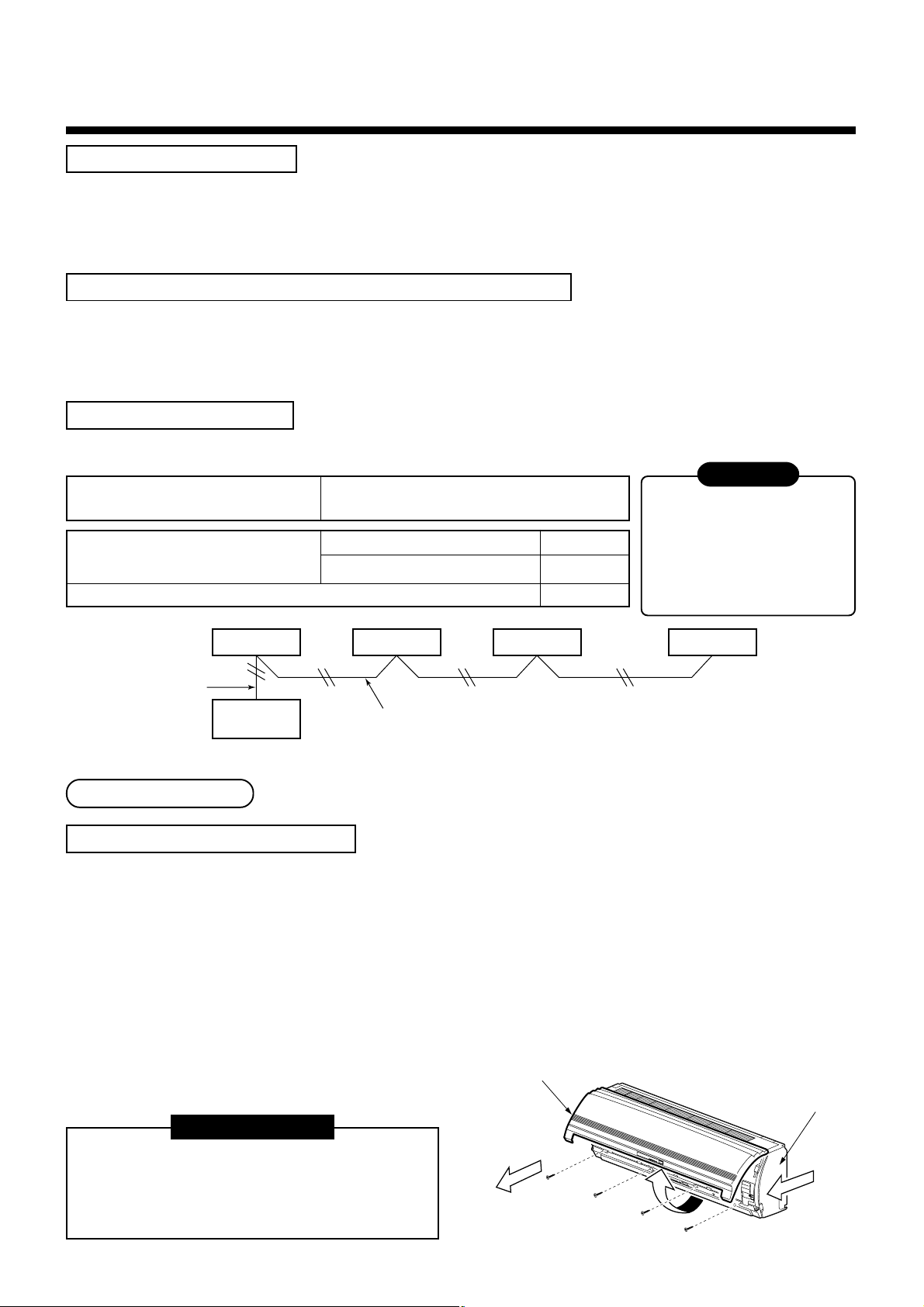

Wiring connection

How to connect the power cable

For the air conditioner that does not have power cable, connect a power cable to it as mentioned below.

1. Open the air inlet grille upward.

2. Remove the four screws securing the front panel.

3. Slightly open the lower part of the front panel then pull the upper part of the front panel toward you to remove it

from the rear plate.

4. After removing the front panel, remove the power cable connect cover and the cord clamp.

5. Connect and secure the power supply cable and secure the cord clamp and the power connect cover.

6. Cut the slit and front panel, and put the power supply cable through the notch.

7. Be sure to smooth the notch with a file, etc.

Air inlet grille

CAUTION

REQUIREMENT

• Be sure to pass the cable through the cable

connection port of the indoor unit.

• The low-voltage circuit is provided for the remote

controller.

13

Front pan

2

1

3

Loading...

Loading...