Page 1

SERVICE MANUAL

FINISHER

MJ-1103/1104

Model: MJ-1103/1104

Publish Date: August 2008

File No. SME070020C0

R070921E5300-TTEC

Ver03_2009-06

Page 2

Trademarks

• Molykote is a registered trademark of Dow Corning Corporation.

• Other company names and product names in this manual are the trademarks of their respective

companies.

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with respect to the use of the

information contained herein.

Page 3

General Precautions for Installation/Servicing/Maintenance

for MJ-1103/1104

The installation and service should be done by a qualified service

technician.

1. When installing the MJ-1103/1104, be sure to follow the instructions described in the “Unpacking/

Set-Up Procedure for the MJ-1103/1104”.

2. The MJ-1103/1104 should be installed by an authorized/qualified person.

3. The Finisher is quite heavy; MJ-1103 weighs approximately 40 kg (88.19 lb.) and MJ-1104 weighs

approximately 70 kg (154.32 lb.), therefore pay full attention when handling it.

4. Before starting installation, servicing or maintenance work, be sure to turn OFF and unplug the

equipment first.

5. The equipment shall be installed near the socket outlet and shall be accessible.

6. Be sure to fix and plug in the power cable securely after the installation so that no one trips over it.

7. When selecting the installation site, avoid placing the finisher / hole punch unit and equipment on

different levels or inclined floors.

8. The equipment shall be installed near the socket outlet and shall be easily accessible.

9. When the MJ-1103/1104 is removed from the equipment due to malfunction or other reasons but no

substitute machine is to be installed, be sure to remove all the installation hardware from the equipment as well.

10.When servicing or maintaining the MJ-1103/1104, be careful about the rotating or operation sections

such as gears, pulleys, sprockets, cams, belts, etc.

11.When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related materials.

Be careful not to reassemble small parts such as screws, washers, pins, E-rings, toothed washers,

harnesses to the wrong places.

12.Basically, the machine should not be operated with any parts removed or disassembled.

13.Delicate parts for preventing safety hazard problems (such as switches, sensors, etc. if any) should

be handled/installed/adjusted correctly.

14.Use suitable measuring instruments and tools.

15.During servicing or maintenance work, be sure to check the serial No.plate and other cautionary

labels (if any) to see if they are clean and firmly fixed.

If not, take appropriate actions.

16.The PC board must be stored in antistatic envelope and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

Before using the wrist band, pull out the power cable plug of the equipment and make sure that

there is no uninsulated charged objects in the vicinity.

Page 4

17.For the recovery and disposal of used MJ-1103/1104, consumable parts and packing materials, follow the relevant local regulations/rules.

18.After completing installation, servicing and maintenance of the MJ-1103/1104, return the MJ-1103/

1104 to its original state, and check operation.

19.When the equipment is used after the option is removed, be sure to install the parts or the covers

which have been taken off so that the inside of the equipment is not exposed.

20.When you move the finisher, do not move it in the direction of the arrow as shown in the figure below

otherwise it might topple over.

21.Unplug the power cable and clean the area around the prongs of the plug and socket outlet once a

year or more. A fire may occur when dust lies on this area.

Page 5

CONTENTS

MJ-1103/1104

1. SPECIFICATIONS, ACCESSORY AND CONSUMABLES.......................................... 1-1

1.1 Specifications....................................................................................................................... 1-1

1.1.1 Finisher section (Common for MJ-1103/1104) ....................................................... 1-2

1.1.2 Saddle stitch section (MJ-1104) ............................................................................. 1-5

1.2 Accessory ............................................................................................................................ 1-6

1.3 Consumables....................................................................................................................... 1-6

2. GENERAL DESCRIPTION............................................................................................ 2-1

2.1 Main Components................................................................................................................ 2-1

2.2 Sectional View ..................................................................................................................... 2-2

2.3 Electric Parts Layout............................................................................................................ 2-7

2.4 Symbols and Functions of Various Components................................................................. 2-9

2.5 Diagram of Signal Blocks................................................................................................... 2-13

2.6 Description of Interface Signals ......................................................................................... 2-15

3. DESCRIPTION OF OPERATIONS ............................................................................... 3-1

3.1 Basic Operations ................................................................................................................. 3-1

3.1.1 GENERAL DESCRIPTION..................................................................................... 3-1

3.1.2 Junction Box........................................................................................................... 3-3

3.1.3 Simple Stack Mode ................................................................................................ 3-4

3.1.4 Job offset stack mode / Staple stack mode............................................................ 3-9

3.1.5 Operation in the saddle stitch section .................................................................. 3-14

3.2 Flow Chart ......................................................................................................................... 3-20

3.3 Description Of Circuit......................................................................................................... 3-23

3.3.1 Finishier section ................................................................................................... 3-23

3.3.2 Saddle section...................................................................................................... 3-35

4. DISASSEMBLY AND INSTALLATION ........................................................................ 4-1

4.1 Covers ................................................................................................................................ 4-1

4.2 Units (Finisher section) ...................................................................................................... 4-13

4.3 Units (Saddle section: MJ-1104) ....................................................................................... 4-26

4.4 Rollers (Finisher section)...................................................................................................4-38

4.5 Rollers (Saddle section: MJ-1104).................................................................................... 4-58

4.6 Motor (Finisher section).....................................................................................................4-64

4.7 Motor (Saddle section: MJ-1104)...................................................................................... 4-74

4.8 Solenoid............................................................................................................................. 4-79

4.9 Sensors / Switches (Finisher section)................................................................................ 4-91

4.10 Sensors / Switches (Saddle section: MJ-1104) ............................................................... 4-110

4.11 PC Boards / Discharge Brush.......................................................................................... 4-120

4.12 Procedure for lowering the movable tray ......................................................................... 4-124

5. ADJUSTMENTS............................................................................................................ 5-1

5.1 Adjusting the Alignment Position ......................................................................................... 5-1

5.2 Adjusting the Stapling Position ............................................................................................ 5-4

5.3 Stapling/folding position adjustment in saddle unit .............................................................. 5-6

5.3.1 Folding position adjustment.................................................................................... 5-8

5.3.2 Stapling position adjustment ................................................................................ 5-10

5.4 Saddle Stitch Skew Adjustment......................................................................................... 5-12

6. TROUBLESHOOTING .................................................................................................. 6-1

6.1 Paper Transport Jam........................................................................................................... 6-1

6.1.1 Paper jam in entrance section................................................................................ 6-1

6.1.2 Paper jam in buffer unit-1 ....................................................................................... 6-3

6.1.3 Paper jam in buffer unit-2 ....................................................................................... 6-5

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

1

CONTENTS

Page 6

6.1.4 Paper jam in finishing tray section.......................................................................... 6-7

6.1.5 Paper jam in movable tray section ....................................................................... 6-12

6.1.6 Cover open jam .................................................................................................... 6-13

6.2 Paper Transport Jam in Saddle Stitch Section (MJ-1104)................................................. 6-15

6.2.1 Paper jam in Saddle Stitch Finisher transport section.......................................... 6-15

6.2.2 Paper jam in side alignment section..................................................................... 6-19

6.2.3 Paper jam in stack transport section .................................................................... 6-19

6.2.4 Paper jam in folding section ................................................................................. 6-21

6.2.5 Paper jam in additional folding section................................................................. 6-22

6.3 Other Errors....................................................................................................................... 6-23

6.3.1 Stapler related error ............................................................................................. 6-23

6.3.2 Saddle Stitch Finisher stapler related error (MJ-1104)......................................... 6-25

6.3.3 Communication Related Error .............................................................................. 6-26

6.3.4 Memory error........................................................................................................ 6-27

7. PREVENTIVE MAINTENANCE (PM) / FIRMWARE UPDATE ..................................... 7-1

7.1 Maintenance and Inspection Points..................................................................................... 7-1

7.2 Firmware Update ................................................................................................................. 7-6

7.2.1 Update of CNV board ............................................................................................. 7-6

7.2.2 Update of FIN board............................................................................................... 7-8

7.2.3 Update of SDL board............................................................................................ 7-10

8. ELECTRIC CIRCUIT ..................................................................................................... 8-1

8.1 Harness Diagram................................................................................................................. 8-1

8.2 Circuit Diagram .................................................................................................................... 8-5

8.3 PC board ........................................................................................................................... 8-32

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

2

Page 7

1. SPECIFICATIONS, ACCESSORY AND CONSUMABLES

1.1 Specifications

• Product Type

MJ-1103: Console Finisher (2 trays)

MJ-1104: Console Saddle Stitch Finisher (3 trays)

• Paper Stacking Device Stationary Tray or Movable Tray, Saddle Tray (MJ-1104)

• Paper Size A3, A4, A4-R, A5, A5-R, A6-R, B4, B5, B5-R, FOLIO, A3 wide,

LD, LG, LT, LT-R, ST, ST-R, COMPUTER, 13”LG, 8.5”SQ,

8K, 16K, 16K-R

1

• Paper Basis Weight 64 - 300g/m

• Stacking Mode Simple, Job Offset, Staple and composite, Center-binding (MJ-1104)

• Dimensions with Sub-tray put in: W 617 x D 603 x H 1,085 (mm)

with Sub-tray drawn out: W 750 x D 603 x H 1,085 (mm)

• Gross Weight

MJ-1103: Approximately 40kg (88.19 lb)

MJ-1104: Approximately 70kg (154.32 lb)

• Power Supply DC24V±10% and DC5V±5% supplied from the main equipment.

• Power Consumption DC24V Average 3.7A or less

5V 1.0A or less

2

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

1 - 1

SPECIFICATIONS, ACCESSORY AND CONSUMABLES

Page 8

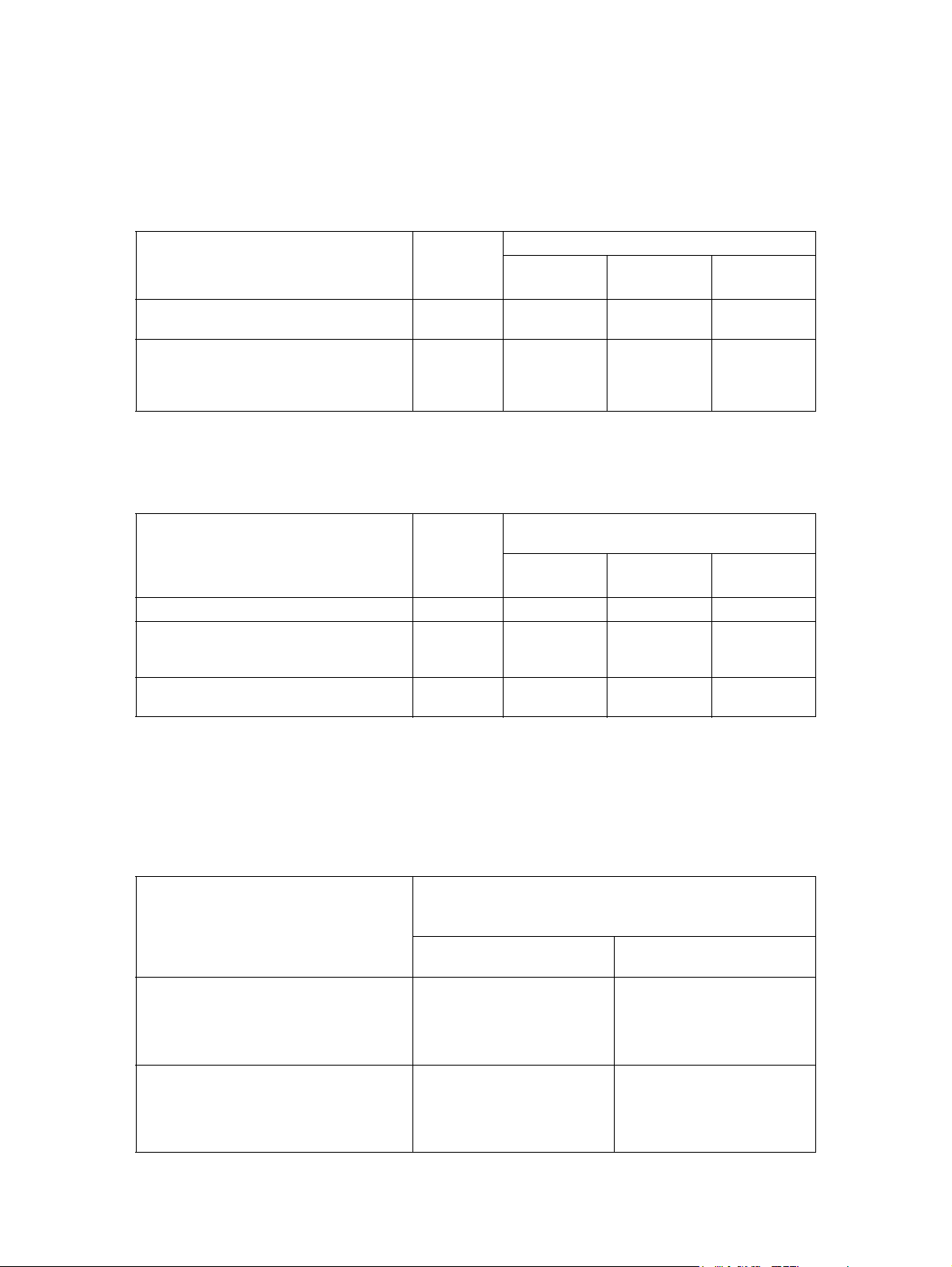

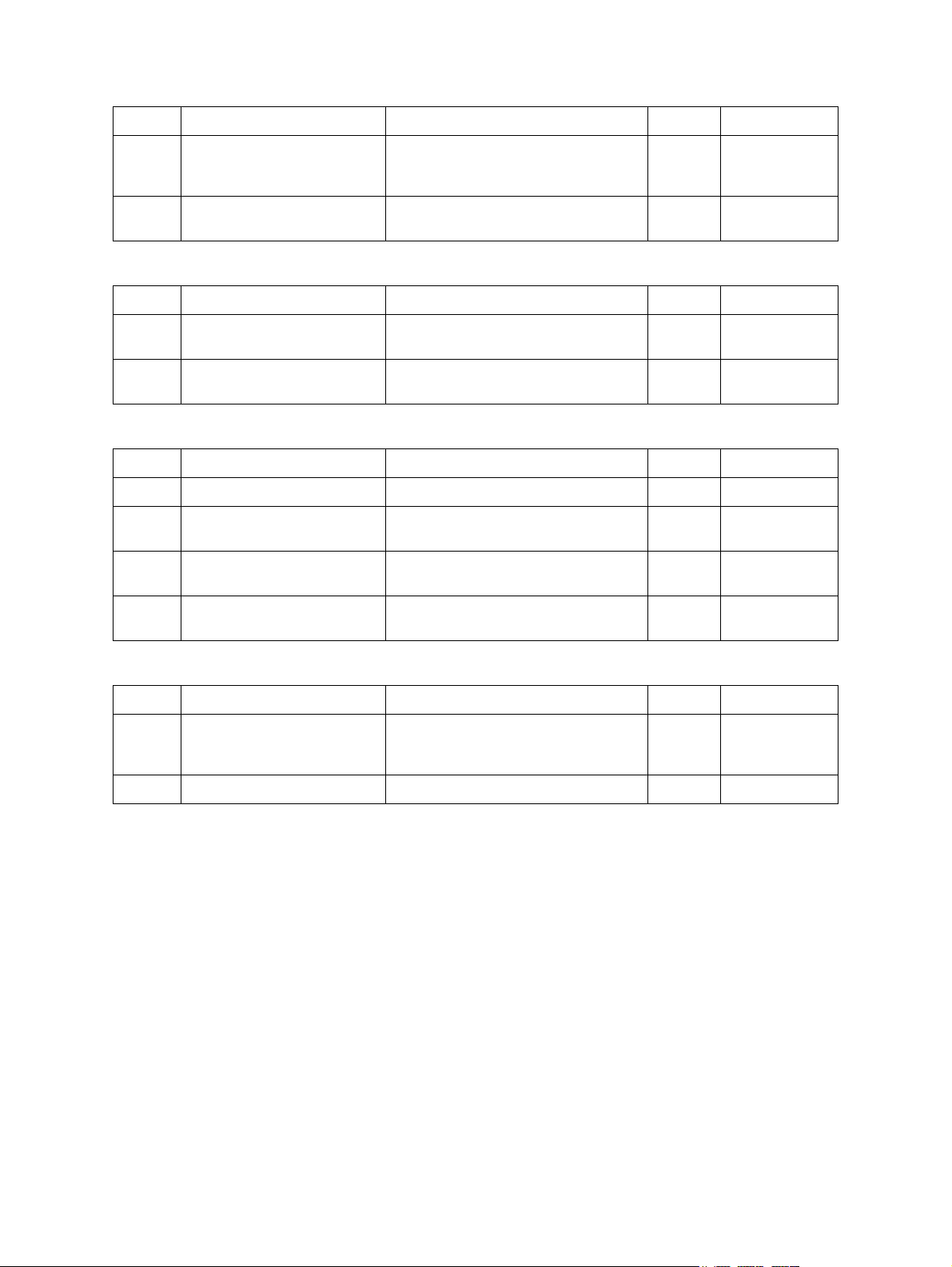

1.1.1 Finisher section (Common for MJ-1103/1104)

• Stacking Type Facedown

• Stacking Height with

Stationary Tray

Paper Size Stacking

A4, B5, LT, A5-R, ST-R, 8.5”SQ, 16K,

Postcard, A4-TAB, LT-TAB, A6-R

A3, A4-R, B4, FOLIO, LD, LG, LT-R,

COMPUTER, B5-R, 13”LG, 8K, 16K-R,

A3 wide, 12” x 18”, 13” x 19”,

320 x 450mm, 320 x460mm, Universal

Height

36.75mm 250 225 190

18.4mm 125 112 95

The maximum stacking height is 18.4 mm for mixed size paper.

ÅgFullÅh status is defined as when the stationary tray paper-full sensor (S18) detected the full status of paper in the size available for feeding.

Movable tray (in the job offset stack mode)

Paper Size Stacking

A4, B5, LT, 8.5”SQ, 16K, A4-TAB, LT-TAB 350mm 3,000 2,700 2,300

A3, A4-R, B4, FOLIO, LD, LG, LT-R,

COMPUTER, 13”LG, 8K, 16K-R,

A3 wide,12" x 18"

ST-R, A5-R, B5-R, A6-R, Postcard,

Universal

Height

80g/m

175mm 1,500 1,350 1,150

- 500 500 500

Number of sheets (reference)

64 - 80g/m

Paper

2

81 - 90g/m2

Paper

Number of sheets (reference)

2

Paper 90g/m2 Paper 105g/m2

91 - 105g/m2

Paper

Paper

The maximum stacking height is 175 mm for mixed size paper. However, ST-R, A5-R, B5-R, A6-R

and non-standard sizes are not acceptable for mixed size paper.

ÅgFullÅh status is defined as when the number of paper whose maximum stacking height is 350

mm has reached 3,000 or when the number of paper in other sizes has reached 1,500.

The maximum number of sheets acceptable is 1,500 for mixed size paper. However, ST-R, A5-R,

B5-R, A6-R and non-standard sizes are not acceptable for mixed size paper.

Movable tray (in the staple stack mode)

Paper Size

Front/Rear Single Position

Stapling

A4, B5, LT, A4-TAB, LT-TAB A paper-full status is detected

either when the number of

stacks reaches 100 or when

the number of sheets reaches

2,000.

A3, A4-R, B4, FOLIO, LD, LG, LT-R,

COMPUTER, 13”LG, 8K, 16K, 8.5”SQ

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS, ACCESSORY AND CONSUMABLES

A paper-full status is detected

either when the number of

stacks reaches 50 or when

the number of sheets reaches

1,000.

1 - 2

Stacking Height

64 - 105 g/m

2

(reference)

Two-Position Stapling

A paper-full status is detected

either when the number of

stacks reaches 150 or when

the number of sheets reaches

2,000.

A paper-full status is detected

either when the number of

stacks reaches 75 or when

the number of sheets reaches

1,000.

Page 9

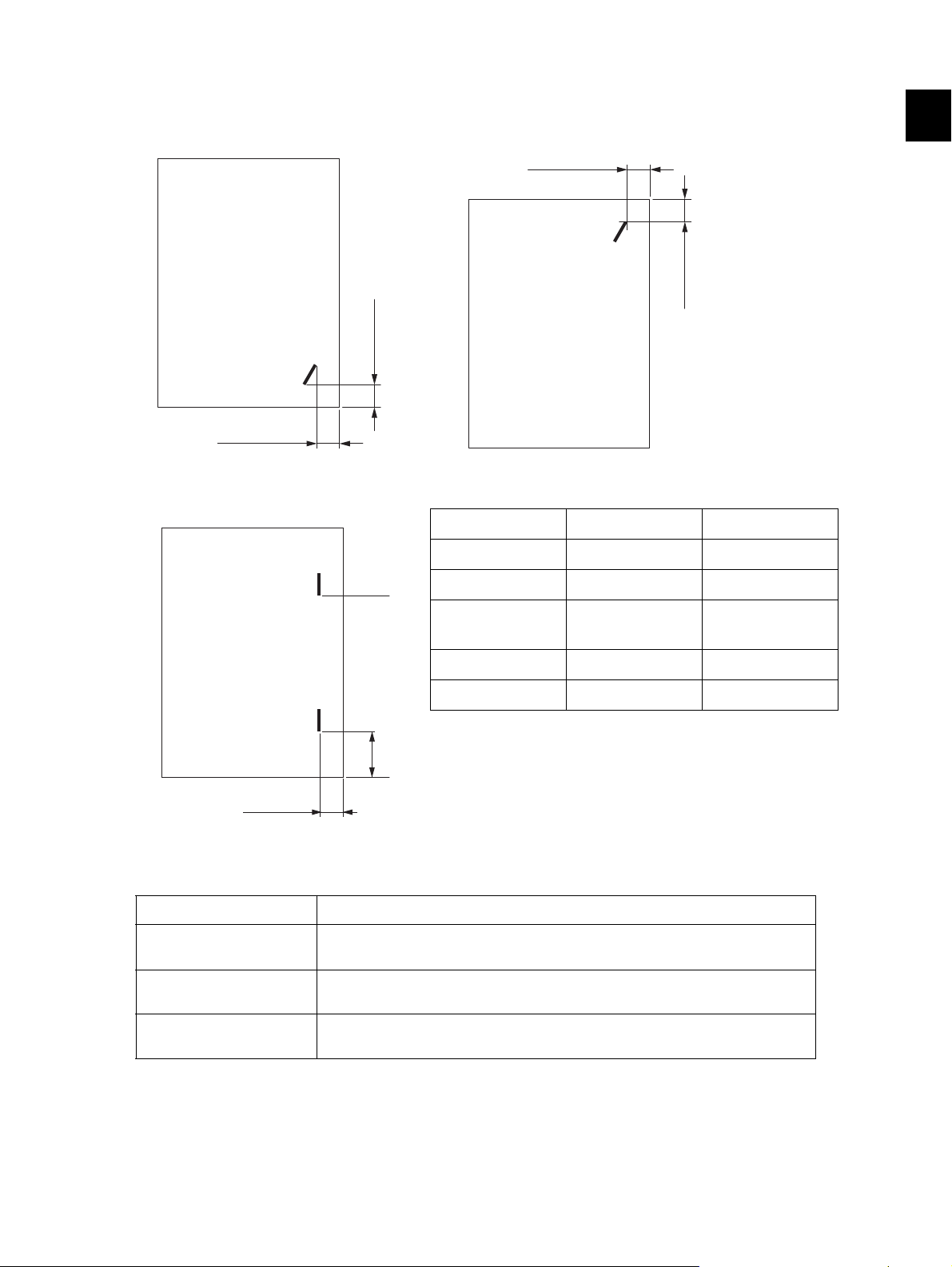

• Stapling Position

4.5 ±3.0 mm

6 ±3.5 mm

4.5 ±3.0 mm

6 ±3.5 mm

A

B

5 ±3.0 mm

Front single position Rear single position

Fig. 1-1 Fig. 1-2

Two-Position Stapling

Paper Size A B

A3, A4, A4-TAB 81.0 ±3.5mm 205.0 ±3.5mm

1

• Paper Size for stapling

Stapling Position Paper Size

Front Single A3, A4, A4-R, B4, B5, FOLIO, LD, LG, LT, LT-R, COMPUTER, 13”LG,

Rear Single A3, A4, A4-R, B4, B5, FOLIO, LD, LG, LT, LT-R, COMPUTER, 13”LG,

Two-Positions A3, A4, A4-R, B4, B5, FOLIO, LD, LG, LT, LT-R, COMPUTER, A4-TAB,

Fig. 1-3

A4-R, FOLIO 37.5 ±3.5mm 161.5 ±3.5mm

B4, B5, COMPUTER

LD, LT, LT-TAB 72.0 ±3.5mm 196.0 ±3.5mm

LT-R, LG 40.5 ±3.5mm 164.5 ±3.5mm

8.5”SQ, 8K, 16K, A4-TAB, LT-TAB

8.5”SQ, 8K, 16K, A4-TAB, LT-TAB

LT-TAB

61.0 ±3.5mm 185.0 ±3.5mm

Stapling is not available for paper in sizes other than the above.

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

SPECIFICATIONS, ACCESSORY AND CONSUMABLES

1 - 3

Page 10

• Paper Basis Weight for stapling 64 - 105g/m

2

• The number of Stapleable Sheet

Paper Size

64 - 80g/m

Paper

2

81 - 90g/m

Paper

A4, B5, LT, 8.5”SQ, 16K 50 50 30

2

91 - 105g/m

Paper

2

A3, A4-R, B4, FOLIO, LD, LG, LT-R,

30 30 15

COMPUTER, 13”LG, 8K

Maximum number of sheets acceptable for stapling:

A4, B5, LT, 8.5”SQ, 16K, A4-TAB, LT-TAB - 50 sheets

A3, A4-R, B4, FOLIO, LD, LG, LT-R, COMP, 13”LG, 8K - 30 sheets

* Two sheets of cover sheet (200-256 g/m2) can be included.

• Staple Loading exclusive cartridge (5,000 staples)

• Manual Stapling available

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS, ACCESSORY AND CONSUMABLES

1 - 4

Page 11

1.1.2 Saddle stitch section (MJ-1104)

• Binding method Center-binding only

• Paper Size A3, B4, A4-R, LD, LG, LT-R

• Number of sheets available for stapling

64 - 80g/m2 Paper 81 - 90g/m2 Paper 91 - 105g/m2 Paper

15 15 10

* One sheet of cover sheet (200-256 g/m2) can be included.

1

• Paper Basis Weight for stapling 64 - 105g/m

2

• Staple Loading exclusive cartridge (2,000 staples)

• Exiting paper not folded Not available

• Exiting paper not stapled Exited when only one sheet in the stack is unstapled

• Stapling interval 120 mm

• Number of stacks available

No thick paper cover included

Paper Size

Under 5 sheets/books 50 40

Under 10 sheets/books 30 25

Under 155 sheets/books 25 -

64 - 90g/m

2

Paper 91 - 105g/m2 Paper

Thick paper cover included

Paper Size

Under 5 sheets/books 50 30

64 - 90g/m2 Paper 91 - 105g/m2 Paper

Under 10 sheets/books 15 15

Under 155 sheets/books 10 -

A paper-full status is detected when the number of stacks reaches the values shown below.

Paper Size No thick paper cover included Thick paper cover included

Under 5 sheets/books 50 50

Under 10 sheets/books 30 15

Under 155 sheets/books 25 10

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

1 - 5

SPECIFICATIONS, ACCESSORY AND CONSUMABLES

Page 12

1.2 Accessory

Unpacking Instruction 1set 1set

Movable tray 1pc 1pc

Connect rail plate 1pc 1pc

Connect rail 1pc 1pc

Connect plate 1pc 1pc

Joint plate 1pc 1pc

Position plate 1pc 1pc

Connector cover 1pc 1pc

Saddle tray - 1pc

Slide tray - 1pc

Leveling arm - 1pc

Screw: TBID M4x8 6pcs 6pcs

Screw: TBID M4x12 4pcs 4pcs

Screw: M3x8 5pcs 5pcs

MJ-1103 MJ-1104

Screw: M3x12 - 2pcs

Screw: M3x6 - 2pcs

Harness clamp 1pc 1pc

1.3 Consumables

• Staple cartridge for the Finisher section

exclusive cartridge (STAPLE-2400: 5,000staples X 3 cartridges /box)

• Staple cartridge for the saddle stitch section (MJ-1104)

exclusive cartridge (STAPLE-3100: 2,000staples X 4 cartridges /box)

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS, ACCESSORY AND CONSUMABLES

1 - 6

Page 13

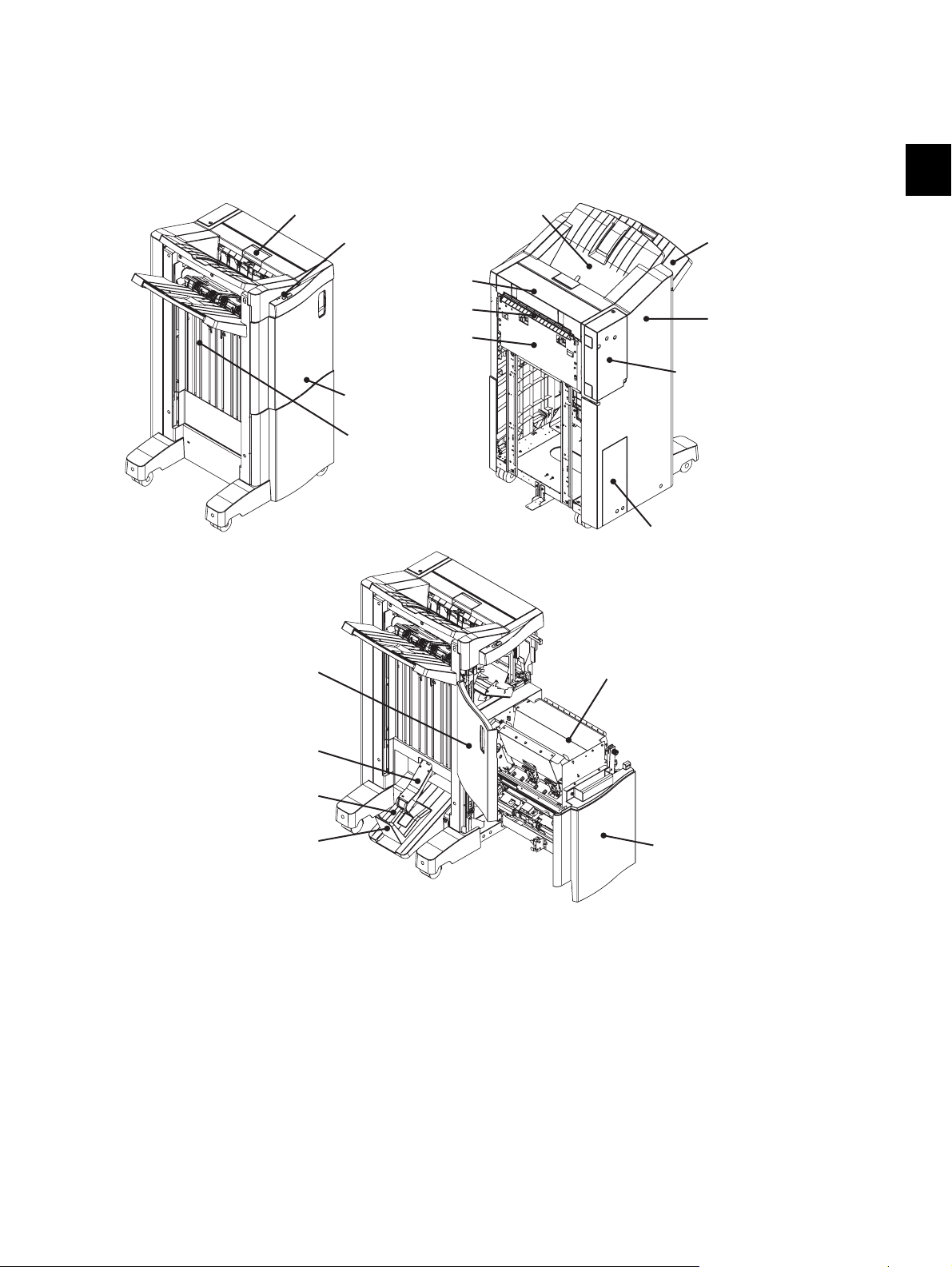

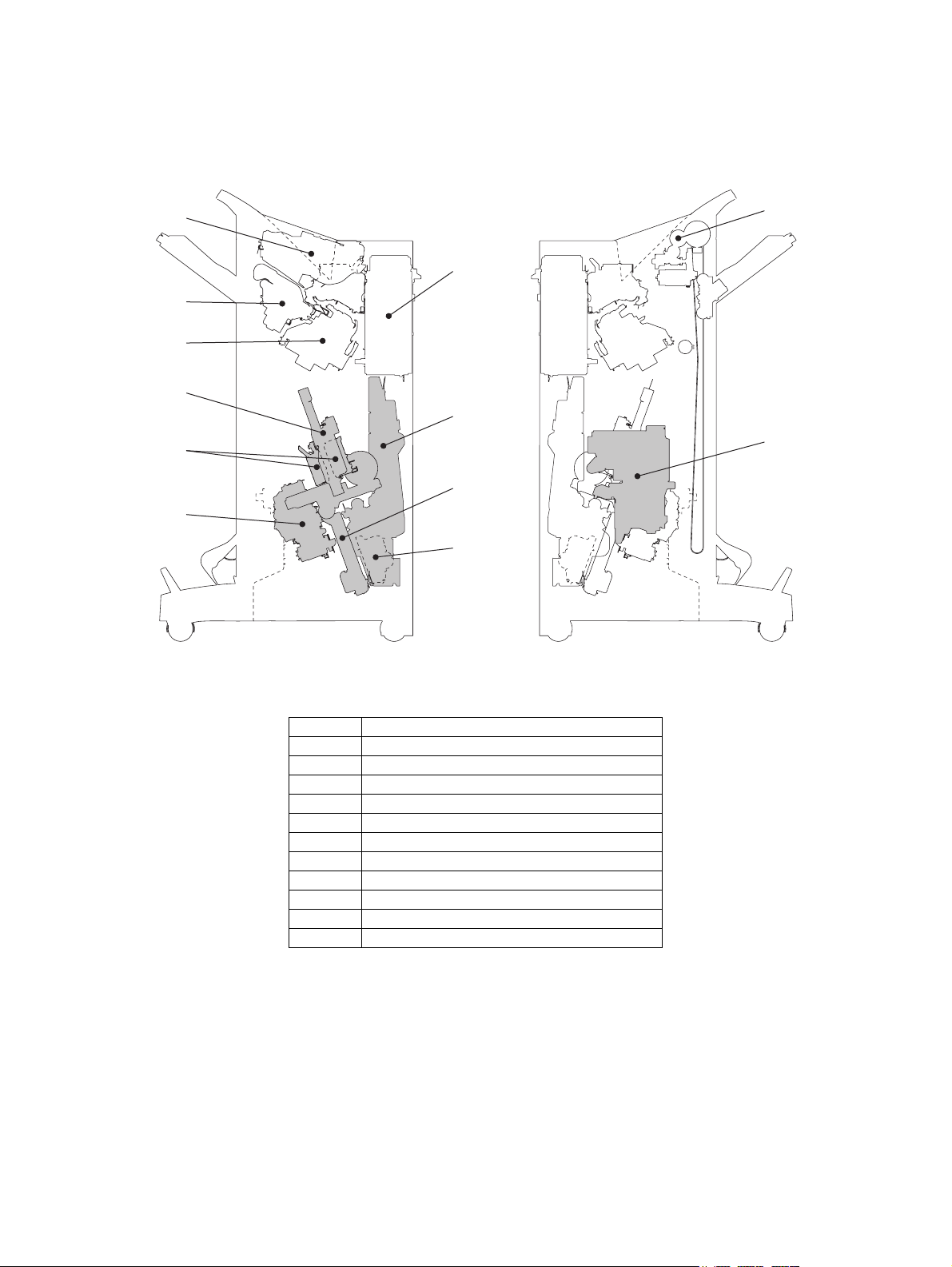

2. GENERAL DESCRIPTION

Front upper cover

Stationary Tray

Movable Tray

Jam access lever

MJ-1103

MJ-1104

Staple bottoms

Rght upper cover

Relay Guide

Rear cover

Saddle Tray

Slide Tray

Leveling arm

Grate-shaped guide

Rght cover

PC board access cover

Saddle access cover

Saddle unit

Front cover

Front lower cover

2.1 Main Components

2

Fig. 2-1

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

2 - 1

GENERAL DESCRIPTION

Page 14

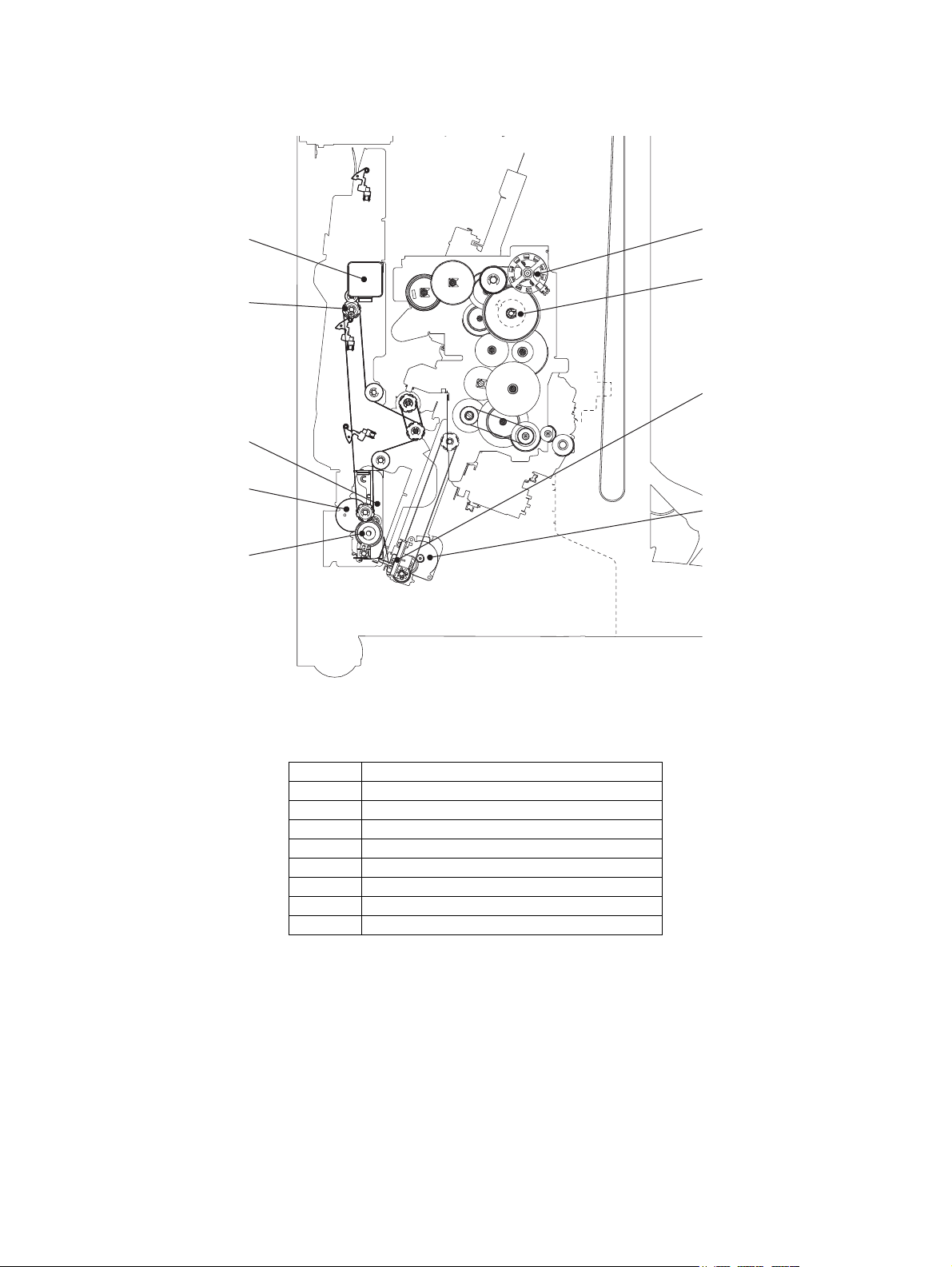

2.2 Sectional View

6

7

8

1

5

12

2

3

4

9

10

11

[A] Units

Fig. 2-2

1 Junction box unit

2 Buffer unit

3 Finishing tray unit

4Stapler

5 Movable tray shift motor unit

6 Switchback unit

7 Stacker unit (MJ-1104)

8 Paper holding unit (MJ-1104)

9 Side alignment unit (MJ-1104)

10 Saddle stapler unit (MJ-1104)

11 Folding drive unit (MJ-1104)

12 EFS unit (MJ-1104)

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

2 - 2

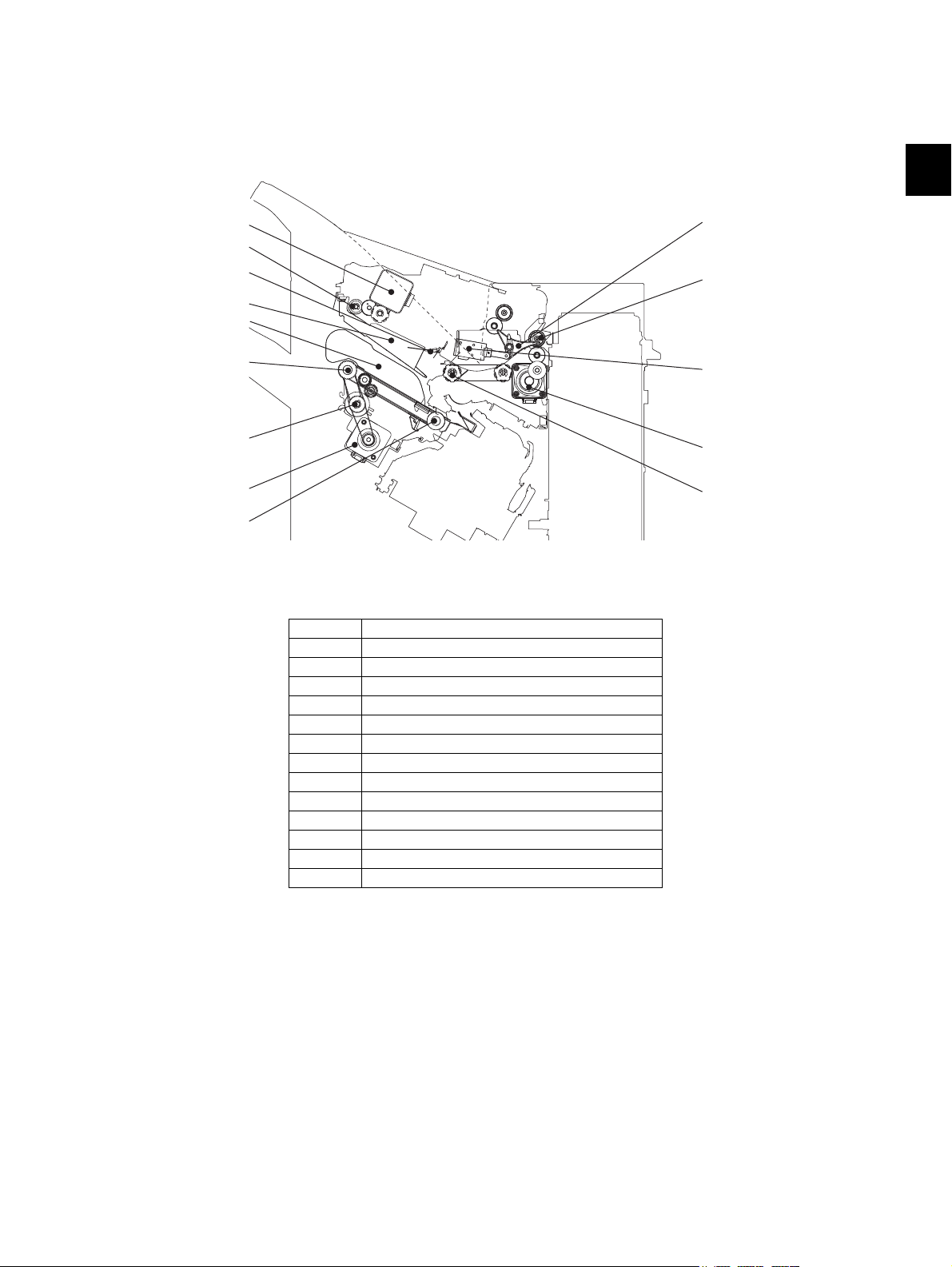

Page 15

[B] Finisher section

M4

3

4

5

6

CLT2

9

M1

8

7

SOL2

M8

2

1

[B-1] Front side view

2

Fig. 2-3

1 Buffer roller

2 Paper pusher plate

3 Buffer tray

4 Finishing tray

5 Stack transport roller-2

6 Stack transport roller-1

7 Gate flap

8 Entrance roller

9Exit roller

M1 Entrance motor

M4 Buffer roller drive motor

M8 Stack transport motor

CLT2 Paper exit guide clutch

SOL2 Gate solenoid

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

2 - 3

GENERAL DESCRIPTION

Page 16

[B-2] Rear side view

M2

M12

6

M7

CLT1

2

3

SOL5

4

5

1

7

M11

M3

Fig. 2-4

1 Stationary tray roller

2 Entrance roller

3 Flapper

4 Feeding roller

5 Junction roller

6 Shutter

7 Paddle

M2 Buffer tray guide motor

M3 Paddle motor

M7 Transport motor

M11 Exit motor

M12 Movable tray shift motor

CLT1 Shutter clutch

SOL5 Transport path switching solenoid

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

2 - 4

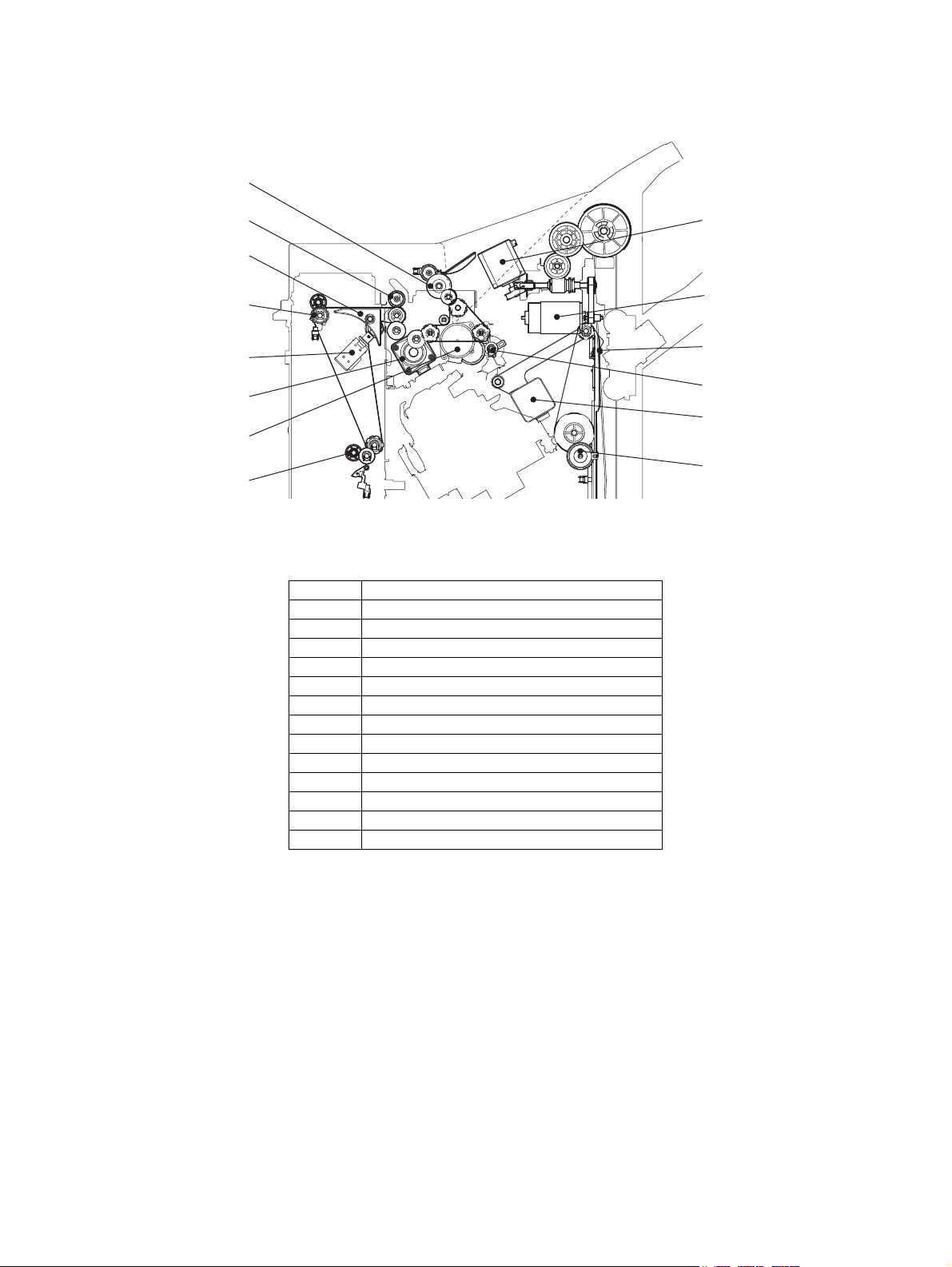

Page 17

[C] Saddle section

1

M15

5

6

7

8

SOL6

3

2

4

M20

[C-1] Front side view

2

Fig. 2-5

1Jog

2 Additional folding carrier

3 Folding roller

4 Saddle exit roller

5 Folding blade cam

6 Folding blade

7 Assisting roller

8 Ejecting roller

M15 Side alignment motor

M20 Additional folding motor

SOL6 Assisting roller solenoid

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

2 - 5

GENERAL DESCRIPTION

Page 18

[C-2] Rear side view

M16

M14

4

CLT3

M17

1

3

2

CLT4

Fig. 2-6

1 Transport roller

2 Paper holding damper

3 Paper holding cam

4 Stacker carrier

M14 Stacker motor

M16 saddle transport motor

M17 Folding motor

CLT3 Folding blade clutch

CLT4 Paper holding clutch

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

2 - 6

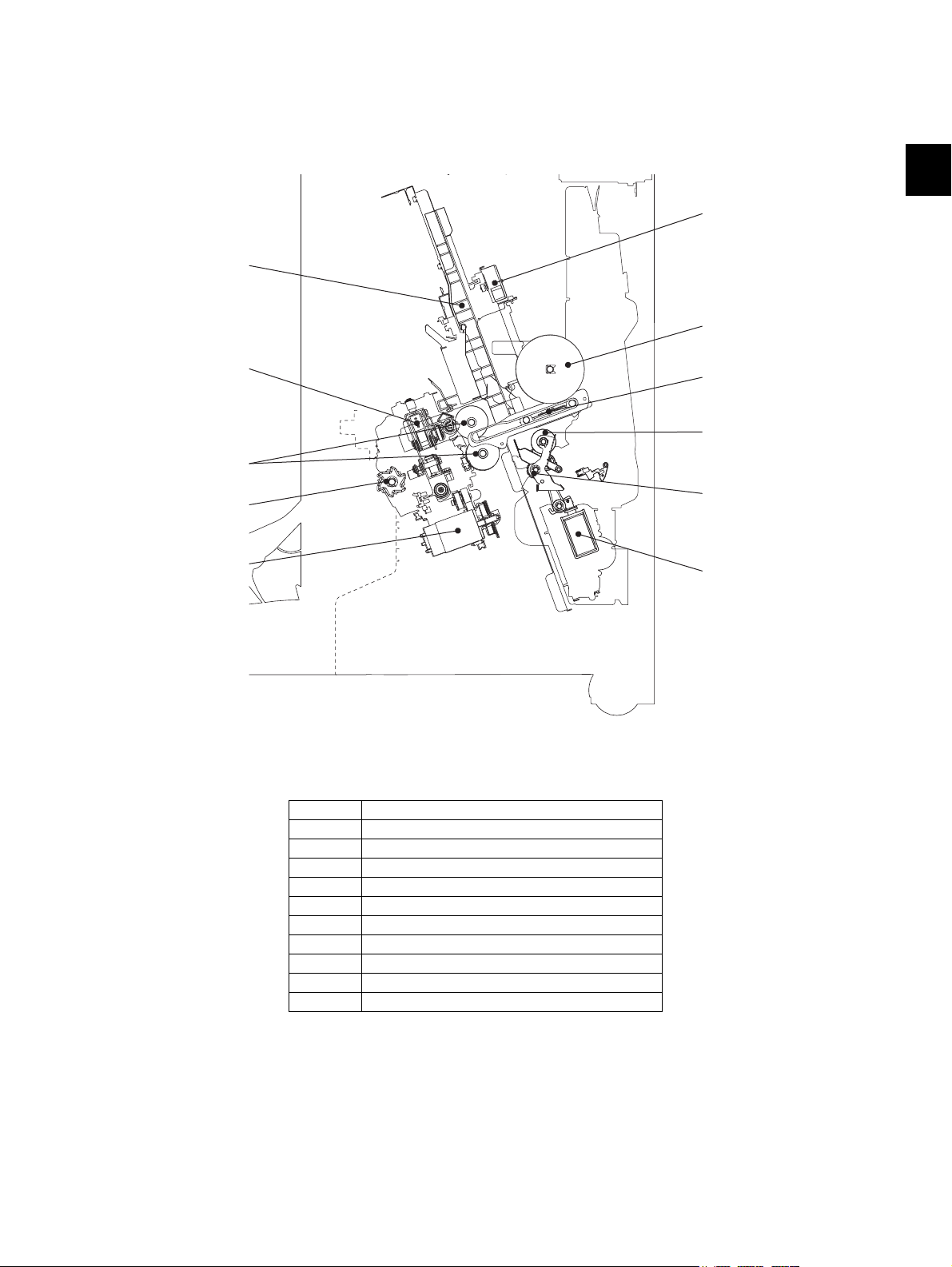

Page 19

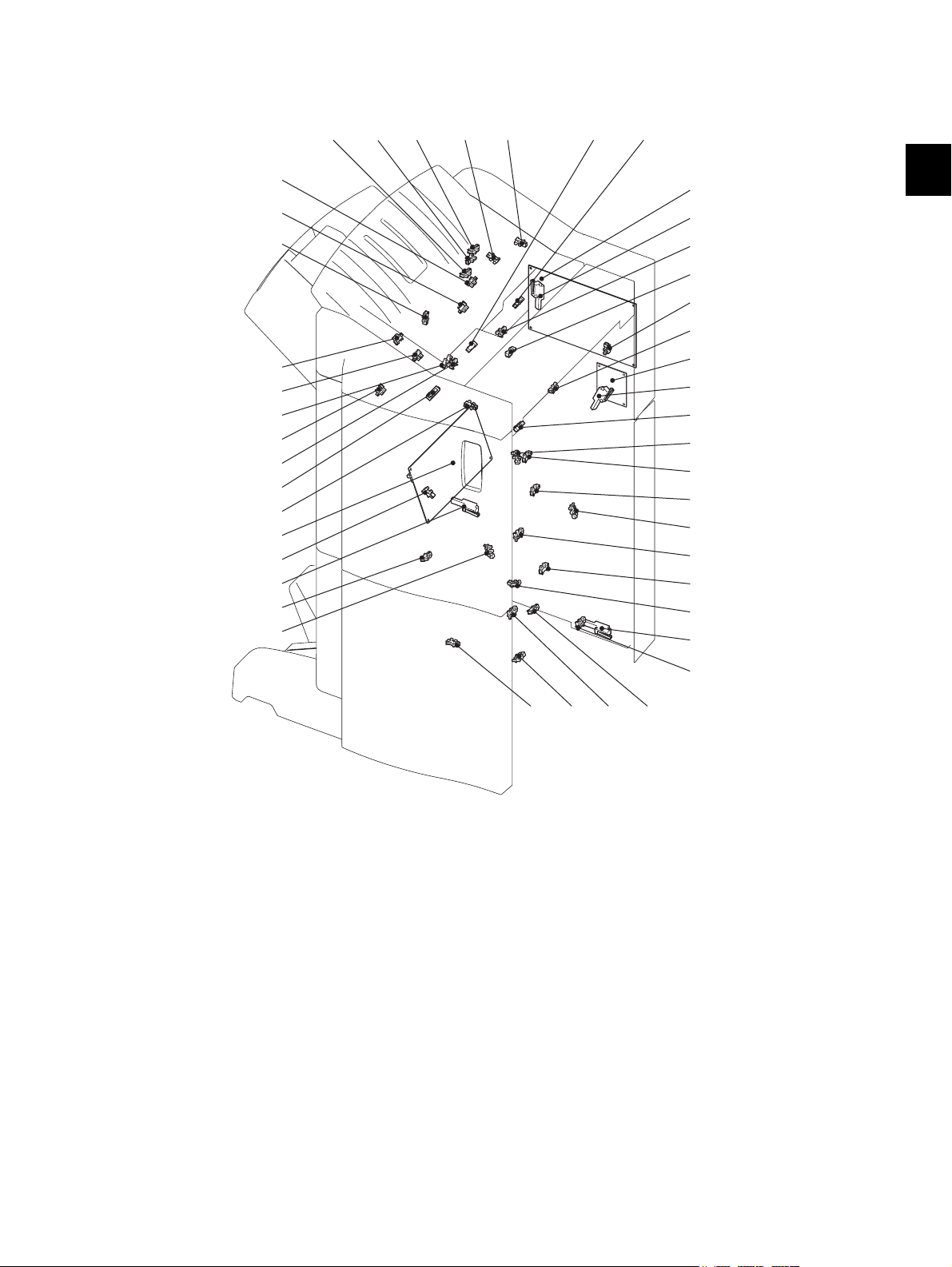

2.3 Electric Parts Layout

S27

S35

S34

S36

SW5

S38

S41

S28

S42

SDL

S31

S39

S32

S29S33 S30

S15 S23S5S13S14 S3

SW2

S18

S1

S25

S26

I/F

SW4

S16

S8

S6

S17

S12

S7

S4

S9

S11

S10

SW3

SW1

S2

S22

FIN

2

Fig. 2-7

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

GENERAL DESCRIPTION

2 - 7

Page 20

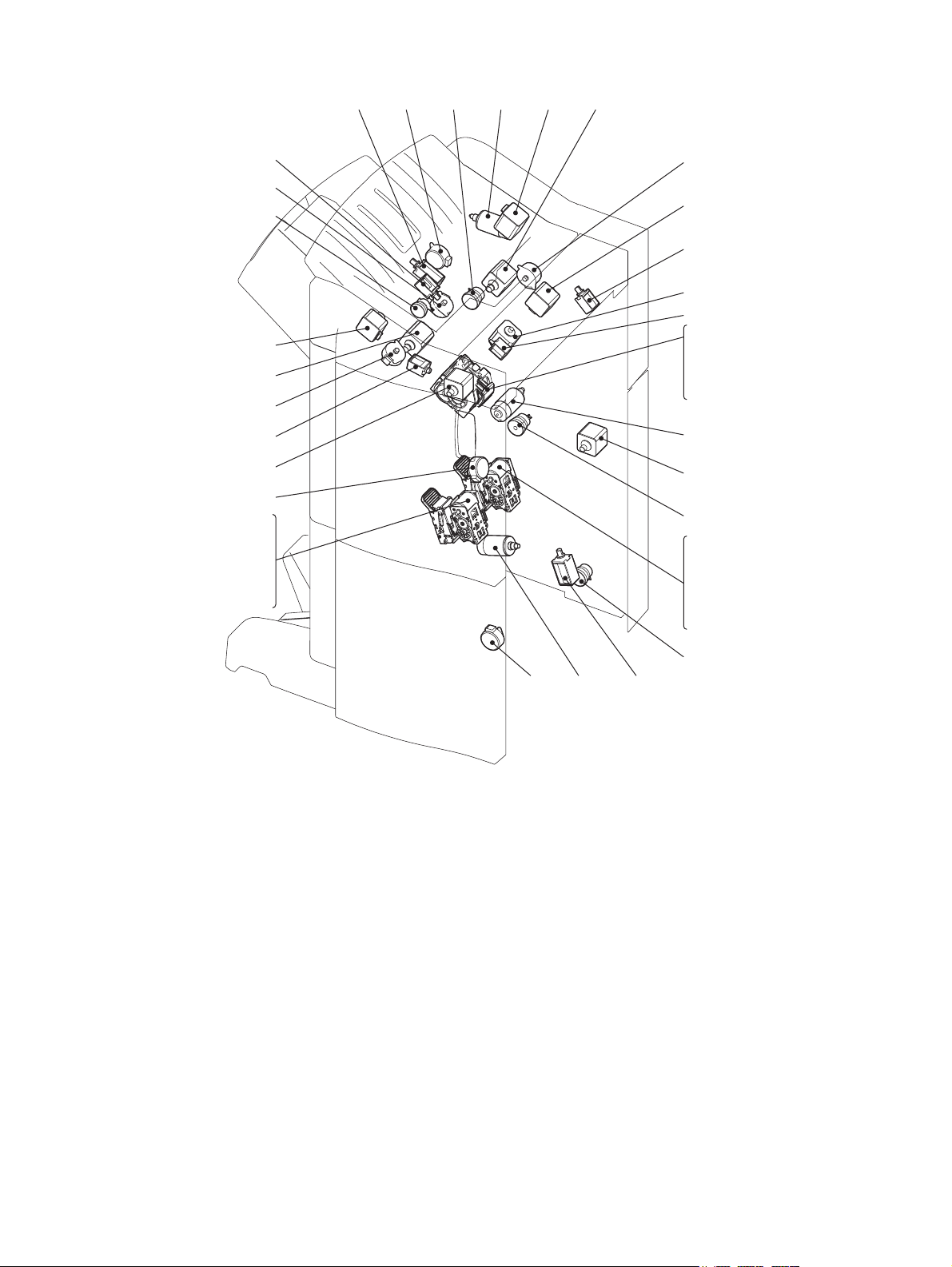

SOL2 M10 M2M12

M3

M7

M1

CLT2

M9

SOL1

SOL5

M16

M14 M20 SOL6

CLT4

CLT3

M13

S19

S20

S21

M17

M19

S44

S46

S48

S50

SOL3

CLT1

M4

M5

SOL4

M8

M11

M15

M6

M18

S43

S45

S47

S49

Fig. 2-8

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

2 - 8

Page 21

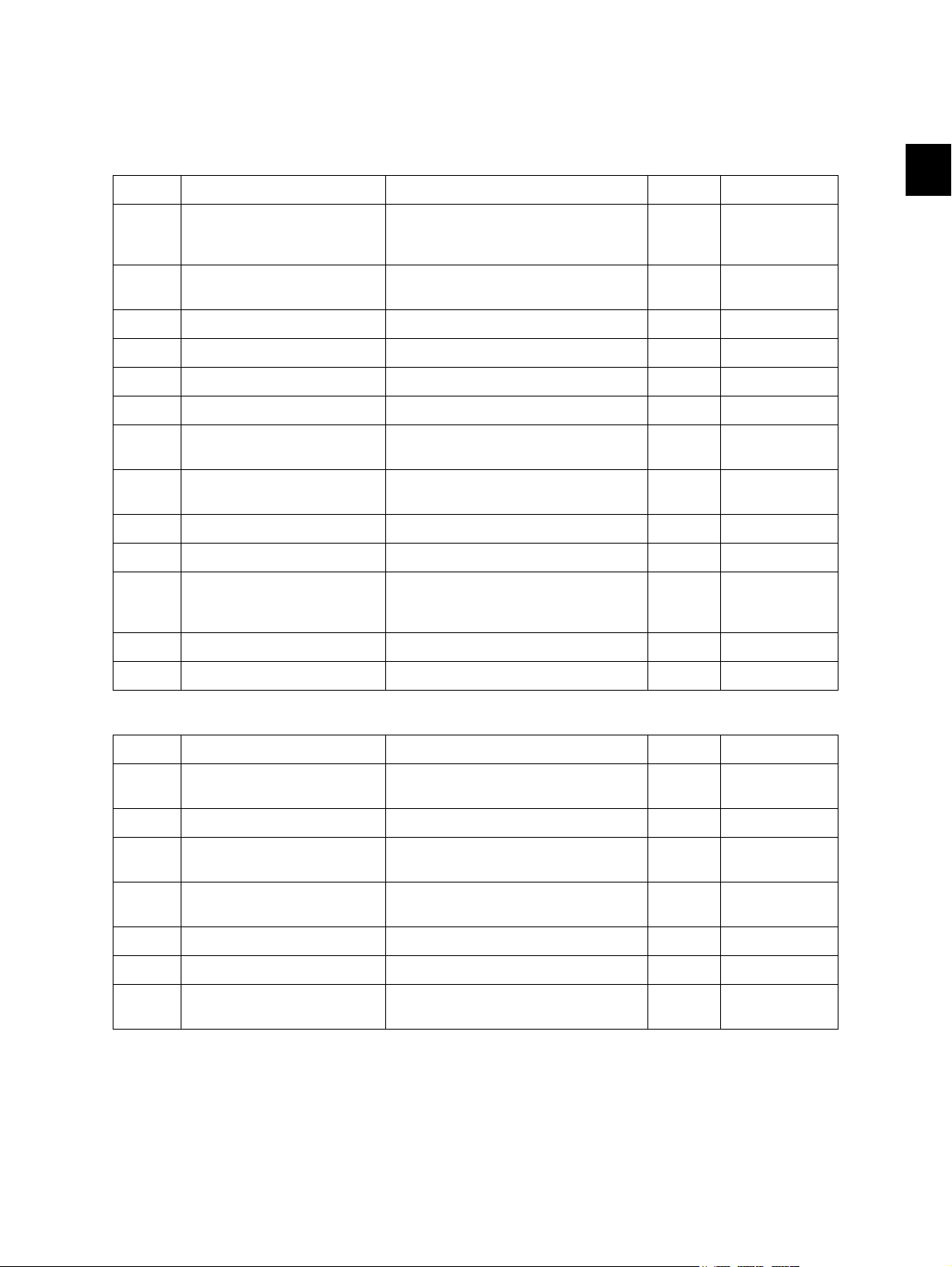

2.4 Symbols and Functions of Various Components

The column <P-I> shows the page and item number in the parts list.

1. Motors (Finisher section : Common for MJ-1103/1104)

Symbol Name Function P-I Remarks

2

M1 Entrance motor Transports paper from the junction box

to the stationary tray or the exit roller by

driving the entrance roller.

M2 Buffer tray guide motor Adjusts the width of the buffer tray

guide.

M3 Paddle motor Drives the paddle. P5-I7 P.2-8 "Fig. 2-8"

M4 Buffer roller drive motor Drives the buffer roller. P8-I24 P.2-8 "Fig. 2-8"

M5 Front alignment motor Drives the front alignment plate. P8-I6 P.2-8 "Fig. 2-8"

M6 Rear alignment motor Drives the rear alignment plate. P8-I6 P.2-8 "Fig. 2-8"

M7 Transport motor Drives the roller of the finishing tray

and drives the shutter.

M8 Stack transport motor Drives the eject arm and the belt exiting

stacks of paper to the movable tray.

M9 Stapler unit shift motor Shifts the stapler unit right and left. P11-I1 P.2-8 "Fig. 2-8"

M10 Assist arm motor Drives the assist arm. P8-I14 P.2-8 "Fig. 2-8"

M11 Exit motor Transports paper from the entrance

roller to the buffer tray by driving the

exit roller.

M12 Movable tray shift motor Lifts up/down the movable tray. P12-I25 P.2-8 "Fig. 2-8"

M13 Stapler motor Operates the stapler. P11-I20 P.2-8 "Fig. 2-8"

P5-I22 P.2-8 "Fig. 2-8"

P8-I30 P.2-8 "Fig. 2-8"

P3-I13 P.2-8 "Fig. 2-8"

P8-I33 P.2-8 "Fig. 2-8"

P5-I22 P.2-8 "Fig. 2-8"

2. Motors (Saddle section: MJ-1104)

Symbol Name Function P-I Remarks

M14 Stacker motor Lifts the stacker up or down to the

paper stapling/folding position.

M15 Side alignment motor Opens or closes the alignment plate. P23-I20 P.2-8 "Fig. 2-8"

M16 Saddle transport motor Transports paper from the paper feed-

ing gate to the stacker.

M17 Folding motor Folds paper by driving a folding blade

and exits the folded paper.

M18 Front stapler motor Operates the front stapler. P22-I5 P.2-8 "Fig. 2-8"

M19 Rear stapler motor Operates the rear stapler. P22-I5 P.2-8 "Fig. 2-8"

M20 Additional folding motor Adds another fold on paper already

folded.

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

2 - 9

P20-I6 P.2-8 "Fig. 2-8"

P26-I29 P.2-8 "Fig. 2-8"

P19-I24 P.2-8 "Fig. 2-8"

P24-I4 P.2-8 "Fig. 2-8"

GENERAL DESCRIPTION

Page 22

3. Electromagnetic spring clutches (Finisher section : Common for MJ-1103/1104)

Symbol Name Function P-I Remarks

CLT1 Shutter clutch Transmits the drive of the transport

P3-I27 P.2-8 "Fig. 2-8"

motor to the shutter opening/closing

section.

CLT2 Paper exit guide clutch Transmits the stack transport motor

P10-I26 P.2-8 "Fig. 2-8"

drive to the paper exit guide.

4. Electromagnetic spring clutches (Saddle section: MJ-1104)

Symbol Name Function P-I Remarks

CLT3 Folding blade clutch Transmits the drive of the folding motor

P19-I19 P.2-8 "Fig. 2-8"

to the folding blade.

CLT4 Paper holding clutch Transmits the drive of the saddle trans-

P21-I22 P.2-8 "Fig. 2-8"

port motor to the paper holding cam.

5. Solenoids (Finisher section : Common for MJ-1103/1104)

Symbol Name Function P-I Remarks

SOL1 Catching solenoid Catches paper on the buffer tray. P5-I4 P.2-8 "Fig. 2-8"

SOL2 Buffer roller lift solenoid Moves up/down the buffer roller

(Turned ON to lift up the roller).

SOL3 Patting solenoid Drops paper on the buffer tray to the

finisher tray.

SOL4 Gate solenoid Switches paper transport destination

(stationary tray / movable tray).

P8-I6 P.2-8 "Fig. 2-8"

P8-I5 P.2-8 "Fig. 2-8"

P7-I29 P.2-8 "Fig. 2-8"

6. Solenoids (Saddle section: MJ-1104)

Symbol Name Function P-I Remarks

SOL5 Transport path switching sole-

noid

Switches destinations where paper is

to be transported (Finisher section or

saddle stitch section).

SOL6 Assisting roller solenoid Operates the assisting roller. P27-I14 P.2-8 "Fig. 2-8"

P16-I23 P.2-8 "Fig. 2-8"

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

2 - 10

Page 23

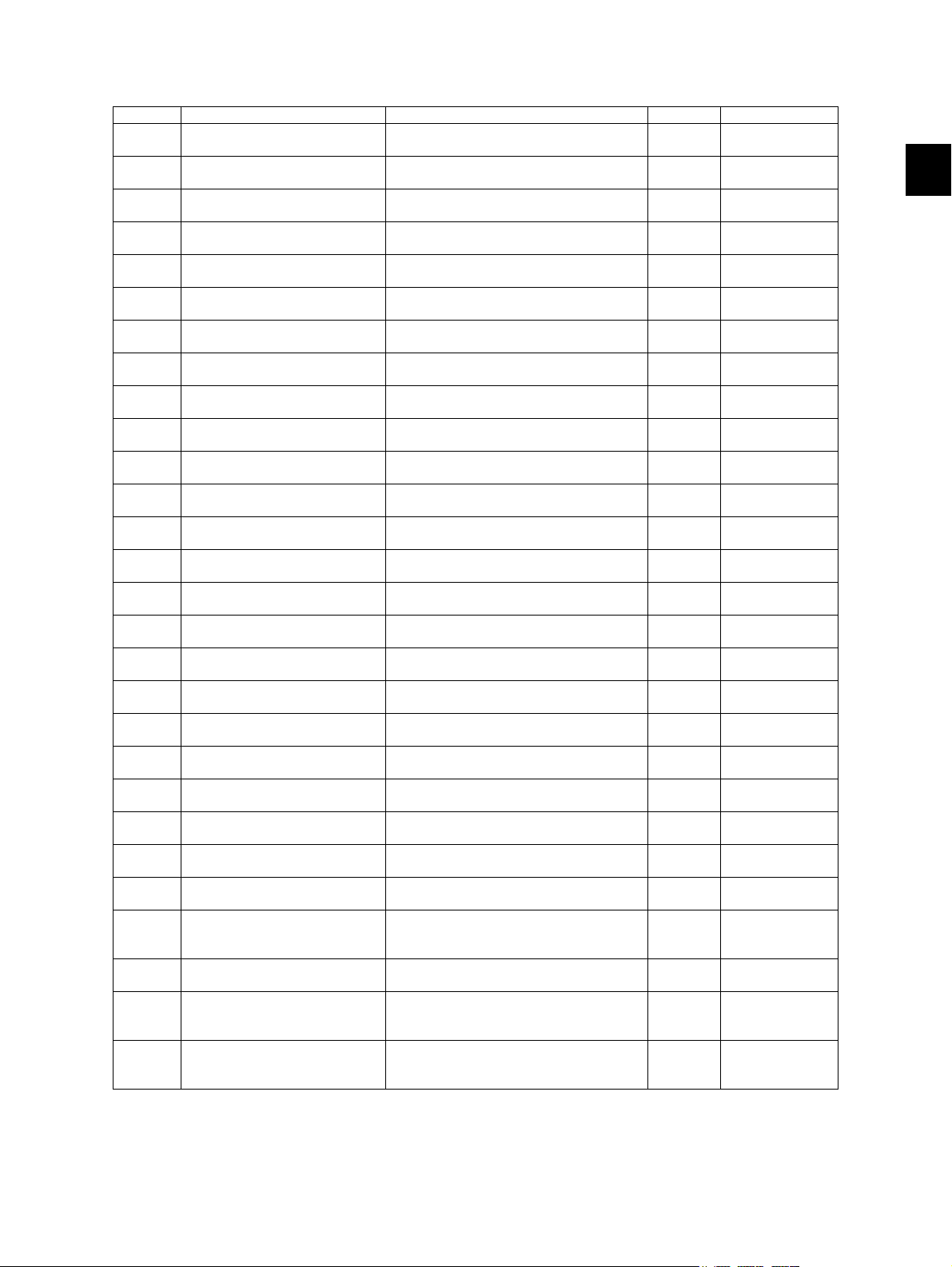

7. Sensors and switches (Finisher section : Common for MJ-1103/1104)

Symbol Name Function P-I Remarks

S1 Entrance sensor Detects paper transported from the

junction box.

S2 Transport sensor Detects the paper transported to the

entrance of the buffer tray.

S3 Paddle home position sensor Detects the home position of the pad-

dle.

S4 Shutter opening/closing sen-

sor

S5 Buffer tray home position sen-

sor

S6 Paper holder home position

sensor

S7 Front alignment plate home

position sensor

S8 Rear alignment plate home

position sensor

S9 Stack exit belt home position

sensor

S10 Stapler unit home position

sensor

Detects the home position of the shutter.

Detects that the buffer tray is at the outermost position.

Detects the home position of the paper

holder cam.

Detects the home position of the front

alignment plate.

Detects the home position of the rear

alignment plate.

Detects the home position of the stack

exit belt.

Detects if the stapler unit is at the front

side (home position).

S11 Stapler interference sensor Detects when the stapler unit interferes

with other mechanical section.

S12 Finishing tray paper detection

sensor

S13 Movable tray position-A sen-

Detects the presence/absence of the

paper on the finishing tray.

Detects the movable tray position. P4-I15 P.2-7 "Fig. 2-7"

sor

S14 Movable tray position-B sen-

Detects the movable tray position. P4-I15 P.2-7 "Fig. 2-7"

sor

S15 Movable tray position-C sen-

Detects the movable tray position. P4-I15 P.2-7 "Fig. 2-7"

sor

S16 Movable tray paper-full sen-

sor

S17 Movable tray paper exist sen-

sor

S18 Stationary tray paper-full sen-

sor

Detects the upper surface of paper set

on the movable tray.

Detects the presence/absence of the

paper on the movable tray.

Detects the paper-full state of the stationary tray.

S19 Stapler home position sensor Detects the home position in the stapler

for the stapling operation.

S20 Staple top position sensor Detects the staple top position in the

stapler.

S21 Staple empty sensor Detects the empty status of staples in

the stapler cartridge.

S22 Feeding sensor Detects paper transported from the

main unit into the junction box.

S23 Movable tray shift motor sen-

sor

Detects the rotation of the movable tray

shift motor.

S25 Connection sensor Detects that the Finisher is released

from the main unit.

SW1 Front cover switch Cuts off the drive current (+24V) when

the opening status of the front cover is

detected.

SW2 Stationary tray opening/clos-

ing switch

Detects the opening (lifting) of the stationary tray.

SW3 Stapler interference switch Automatically cut off the power supply

to the stapler on detecting the no-operation area for the stapler unit.

SW4 Connection switch Cuts off drive current (24V) when it

detects that the Finisher is released

from the main unit.

P7-I23 P.2-7 "Fig. 2-7"

P7-I23 P.2-7 "Fig. 2-7"

P5-I19 P.2-7 "Fig. 2-7"

P5-I19 P.2-7 "Fig. 2-7"

P8-I20 P.2-7 "Fig. 2-7"

P8-I20 P.2-7 "Fig. 2-7"

P10-I17 P.2-7 "Fig. 2-7"

P10-I17 P.2-7 "Fig. 2-7"

P10-I52 P.2-7 "Fig. 2-7"

P11-I24 P.2-7 "Fig. 2-7"

P11-I24 P.2-7 "Fig. 2-7"

P10-I17 P.2-7 "Fig. 2-7"

P4-I15 P.2-7 "Fig. 2-7"

P4-I15 P.2-7 "Fig. 2-7"

P12-I2 P.2-7 "Fig. 2-7"

P11-I20 P.2-7 "Fig. 2-7"

P11-I20 P.2-7 "Fig. 2-7"

P11-I20 P.2-7 "Fig. 2-7"

P15-I14/

P.2-7 "Fig. 2-7"

P16-I8

P12-I2 P.2-7 "Fig. 2-7"

P13-I28 P.2-7 "Fig. 2-7"

P15-I19/

P.2-7 "Fig. 2-7"

P16-I41

- P.2-7 "Fig. 2-7"

- P.2-7 "Fig. 2-7"

P13-I3 P.2-7 "Fig. 2-7"

2

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

2 - 11

GENERAL DESCRIPTION

Page 24

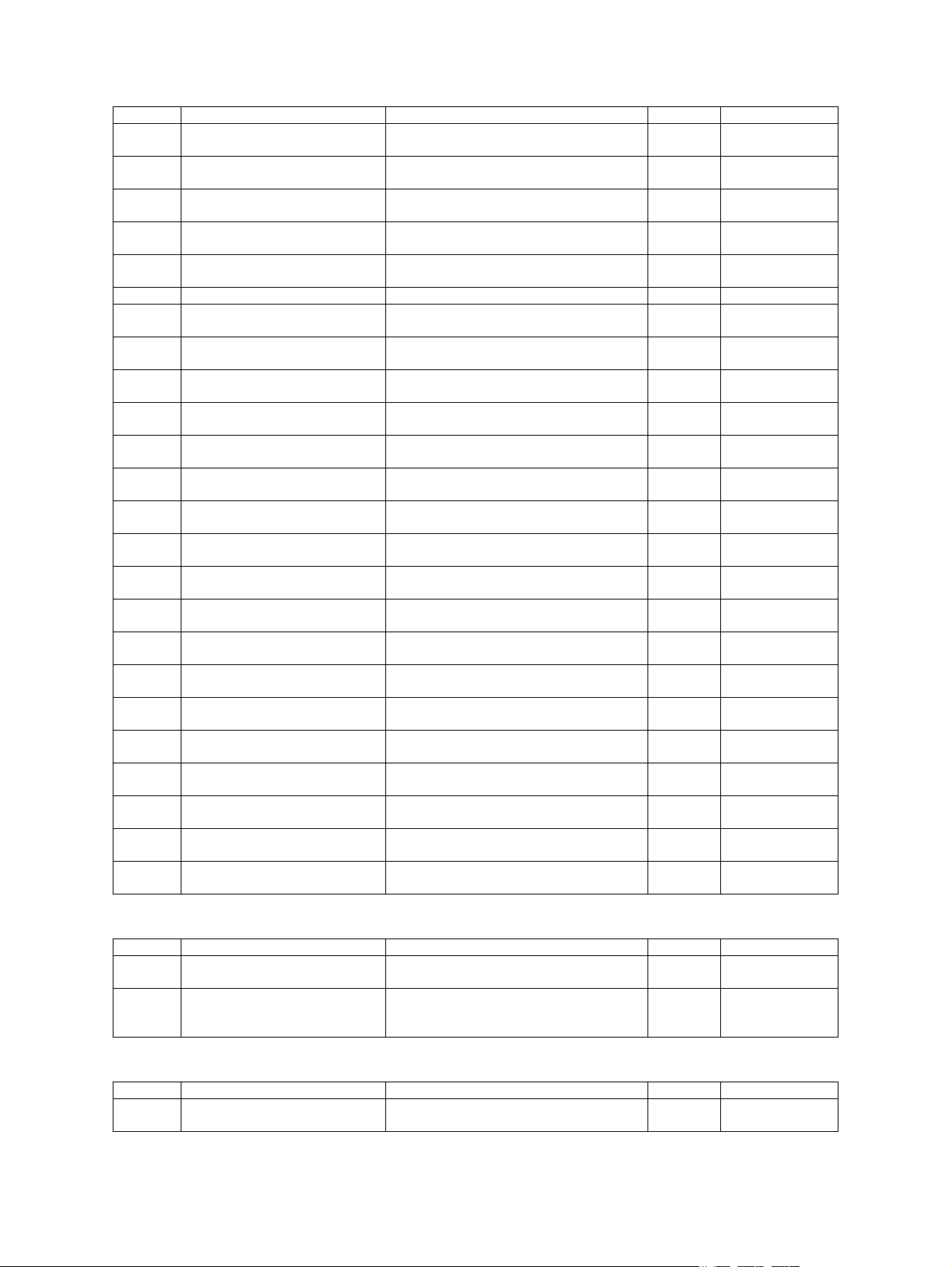

8. Sensors and switches (Saddle section: MJ-1104)

Symbol Name Function P-I Remarks

S26 Junction box paper detection

sensor

S27 Transport path-2 sensor Detects the paper transported to the

S28 Transport path-3 sensor Detects the paper transported to the

S29 Ejecting roller sensor Detects the rotation of the assisting

S30 Stacker paper detection sen-

sor

S31 Exit sensor Detects paper exit from the EFS Unit. P24-I7 P.2-7 "Fig. 2-7"

S32 Saddle tray paper detection

sensor

S33 Stacker home position sensor Detects the home position of the

S34 Folding motor encoder sensor Detects the rotation of the Folding

S35 Folding blade home position

sensor

S36 Side alignment home position

sensor

S38 Paper holding home position

sensor

S39 Additional folding home posi-

tion sensor

S41 Exit transport sensor Detects the stop position of the Addi-

S42 Additional folding motor

encoder sensor

S43 Front saddle stapler home

position sensor

S44 Rear saddle stapler home

position sensor

S45 Front saddle staple empty

sensor

S46 Rear saddle staple empty

sensor

S47 Front saddle staple top posi-

tion sensor

S48 Rear saddle staple top posi-

tion sensor

S49 Front saddle stapler cartridge

sensor

S50 Rear saddle stapler cartridge

sensor

SW5 Saddle unit opening/closing

switch

Detects the presence of paper within

the junction box.

switch back Unit.

switch back Unit.

roller.

Detects the presence/absence of the

paper in the stacker.

Detects the presence/absence of the

paper on the saddle tray.

stacker.

motor.

Detects the home position of the folding

blade.

Detects the home position of the side

alignment plate.

Detects the home position of the paper

holding unit.

Detects the home position of the Additional folding roller.

tional folding.

Detects the rotation of the Additional

folding motor..

Detects the home position in the front

stapler for the stapling operation.

Detects the home position in the rear

stapler for the stapling operation

Detects the empty status of front staples in the stapler cartridge.

Detects the empty status of rear staples in the stapler cartridge.

Detects the staple top position in the

front stapler.

Detects the staple top position in the

rear stapler.

Detects the presence/absence of the

stapler cartridge in the front stapler.

Detects the presence/absence of the

stapler cartridge in the rear stapler.

Cuts off drive current (24V) when it

detects that the saddle unit is opened.

P16-I8 P.2-7 "Fig. 2-7"

P28-I2 P.2-7 "Fig. 2-7"

P28-I2 P.2-7 "Fig. 2-7"

P27-I10 P.2-7 "Fig. 2-7"

P27-I21 P.2-7 "Fig. 2-7"

P18-I8 P.2-7 "Fig. 2-7"

P20-I4 P.2-7 "Fig. 2-7"

P19-I26 P.2-7 "Fig. 2-7"

P19-I26 P.2-7 "Fig. 2-7"

P23-I3 P.2-7 "Fig. 2-7"

P21-I20 P.2-7 "Fig. 2-7"

P24-I7 P.2-7 "Fig. 2-7"

P24-I7 P.2-7 "Fig. 2-7"

P24-I7 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P22-I5 P.2-7 "Fig. 2-7"

P17-I10 P.2-7 "Fig. 2-7"

9. PC board (Finisher section : Common for MJ-1103/1104)

Symbol Name Function P-I Remarks

FIN Finisher control PC board

Controls the Finisher P3-I37 P.2-7 "Fig. 2-7"

(FIN board)

I/F Interface PC board (I/F board) Transmits signals among the punch

P13-I5 P.2-7 "Fig. 2-7"

control PC board, finisher control PC

board and saddle control PC board.

10.PC board (Saddle section: MJ-1104)

Symbol Name Function P-I Remarks

SDL Saddle control PC board

(SDL board)

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

Controls the Saddle Stitch Finisher. P18-I58 P.2-7 "Fig. 2-7"

2 - 12

Page 25

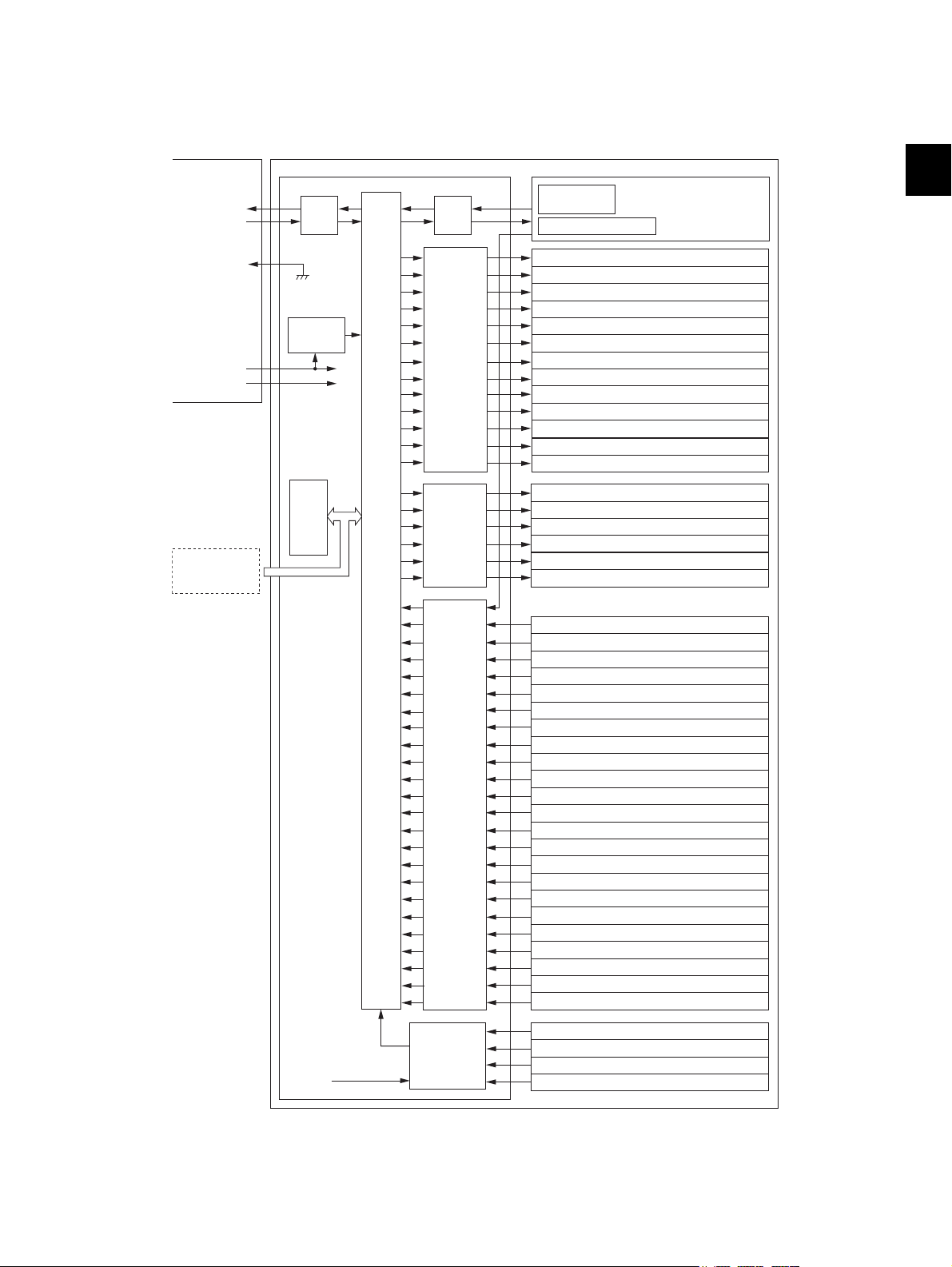

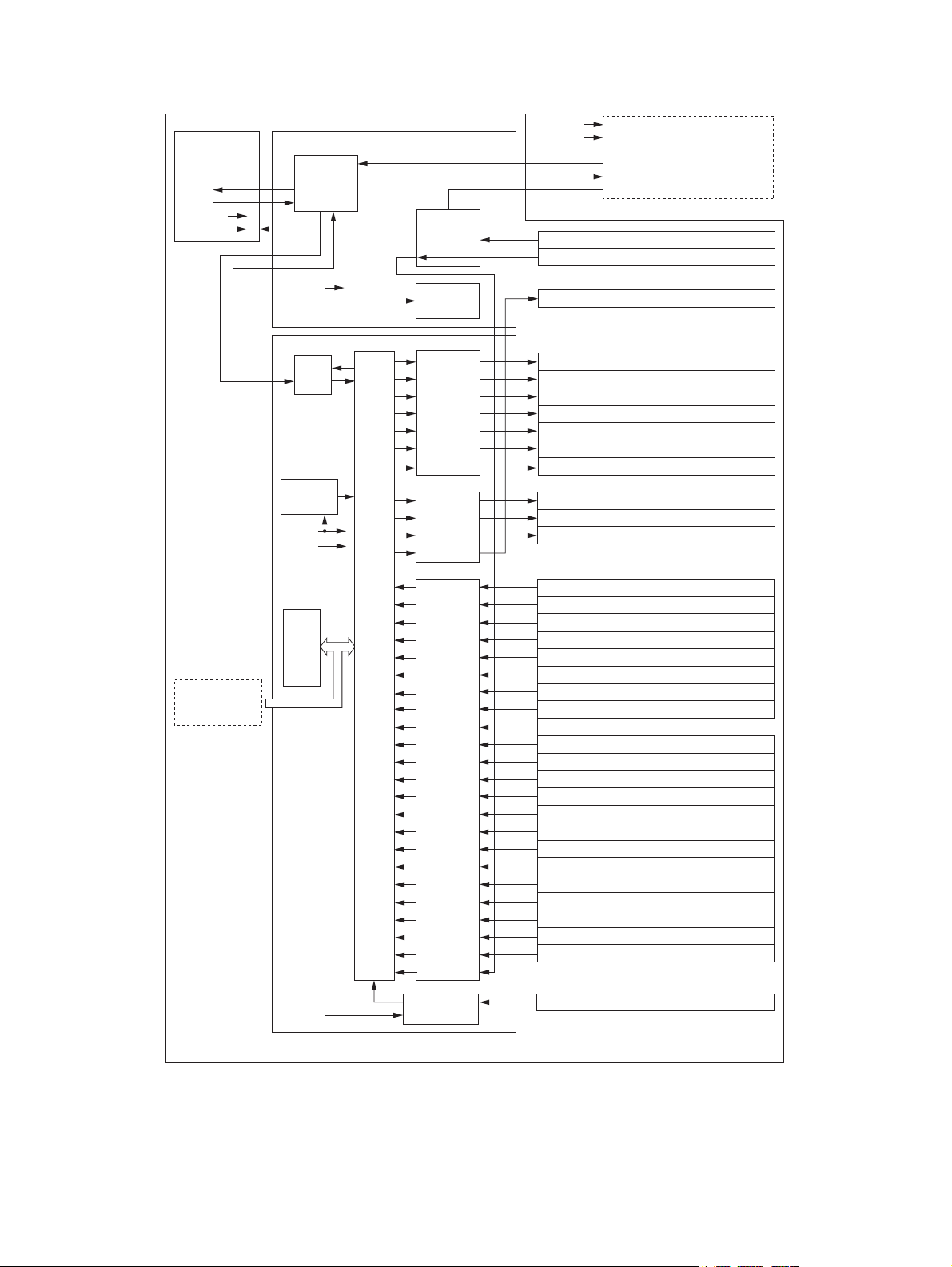

2.5 Diagram of Signal Blocks

GND

DC 24V

DC 5V

FIN board

I/F board

Finisher

TxD

RxD

FINCON

Equipment

Driver

Sensor

input

circuit

I/F

I/F

Reset

circuit

CPU

Stapler unit shift motor (M9)

Paper pusher arm motor (M10)

Shutter clutch (CLT1)

Paper exit guide clutch (CLT2)

Catching solenoid (SOL1)

Buffer roller lift solenoid (SOL2)

Patting solenoid (SOL3)

Gate solenoid (SOL4)

Entrance sensor (S1

)

Buffer tray home position sensor (S3)

Transport sensor (S2

)

Paper pusher home position sensor (S6)

Paddle home position sensor

(S3)

Shutter opening/closing sensor

(S4)

Rear alignment motor (M6)

Transport motor (M7)

Stack transport motor (M8)

Paddle motor (M3)

Buffer roller drive motor (M4)

Front alignment motor (M5)

Entrance motor (M1)

Buffer tray guide motor (M2)

Paper pusher home position sensor (S7

)

Drive

circuit

Exit motor (M11)

Movable tray shift motor (M12)

Stapler motor (M13)

Rear alignment plate home position sensor (S8)

Stack exit belt home position sensor (S9)

Stapler unit home position sensor (S10)

Stapler Interference sensor (S11

)

Finishing tray paper detection sensor (S12

)

Movable tray position-A sensor (S13

)

Movable tray position-B sensor

(

S14

)

Movable tray position-C sensor (S15

)

Movable tray paper-full sensor (S16

)

Movable tray paper exist sensor (S17

)

Stationary tray paper-full sensor (S18

)

Stapler home position sensor (S19)

Staple top position sensor (S20

)

Staple empty sensor (S21

)

Movable tray shift motor sensor (S23)

Connection sensor (S25)

Front cover switch (SW1

)

Stationary tray opening/closing switch (SW2

)

Download jig

ROM

Power

control

circuit

DC 24V

Connection switch (SW4)

Stapler Interference switch (SW3

)

Feeding sensor(S22)

Serial branch

circuit

[A] Finisher section

2

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

Fig. 2-9

2 - 13

GENERAL DESCRIPTION

Page 26

[B] Saddle section

DC 24V

DC 5V

SDL board

I/F board

Finisher

TxD

RxD

TxD

RxD

Driver

I/F

Reset

circuit

CPU

Folding blade clutch (CLT3)

Folding blade clutch (CLT4)

Assisting roller solenoid (SOL6)

Rear saddle stapler motor (M19)

Additional folding motor (M20)

Saddle transport motor (M16)

Folding motor (M17)

Front saddle stapler motor (M18)

Stacker motor (M14)

Transport path switching solenoid (SOL5)

Side alignment motor (M15)

Feeding sensor (S22)

Junction box paper detection sensor (S26)

Drive

circuit

Serial

branch

circuit

Detection

circuit

Signal

switching

circuit

Cover open sensor (S37)

Download jig

ROM

Power control

circuit

DC 24V

Sensor

input

circuit

Transport path-2 sensor (S27)

Exit sensor (S31)

Transport path-3 sensor (S28)

Saddle tray paper detection sensor (S32)

Ejecting roller sensor (S29)

Stacker paper detection sensor (S30)

Stacker home position sensor (S33)

Folding motor encoder sensor (S34)

Folding braid home position sensor (S35)

Side alignment home position sensor (S36)

Paper holding home position sensor (S38)

Additional folding home position sensor (S39)

Exit transport sensor (S41)

Additional folding motor encoder sensor (S42)

Front saddle stapler home position sensor (S43)

Rear saddle stapler home position sensor (S44)

Front saddle staple empty sensor (S45)

Rear saddle staple empty sensor (S46)

Front saddle staple top position sensor (S47)

Rear saddle staple top position sensor (S48)

Front saddle staple cartridge sensor (S49)

Rear saddle staple cartridge sensor (S50)

Option

DC 24V

DC 24V

DC 5V

DC 5V

DC 24V

DC 5V

TxD

RxD

FIN board

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

Fig. 2-10

2 - 14

Page 27

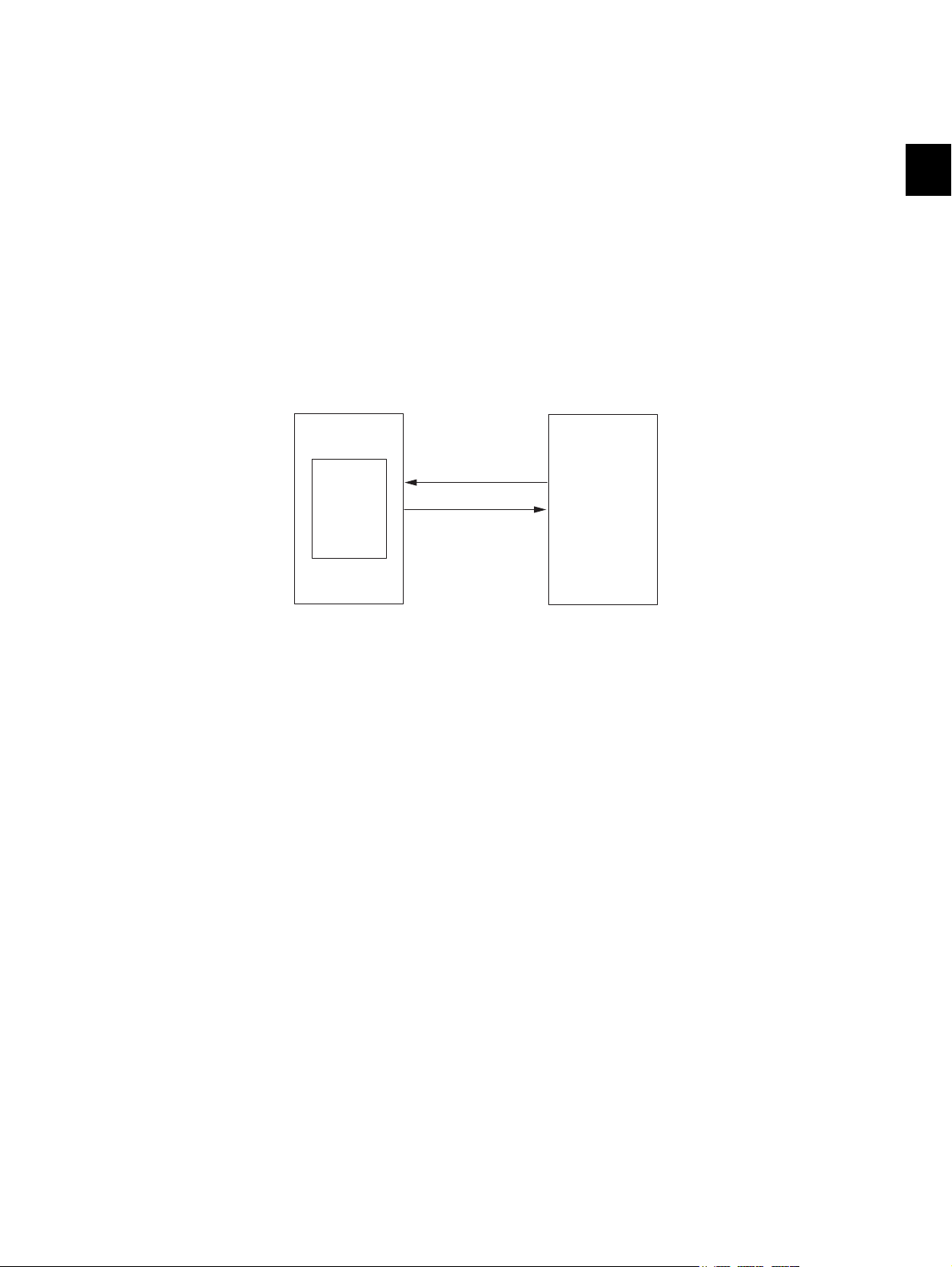

2.6 Description of Interface Signals

TxD

RxD

Finisher

Equipment

Converter

PC board

The 2 lines; TxD and RxD are used to transmit/receive signals between the equipment and the Finisher.

When the Finisher is connected, the equipment detects the power supply signal (MFP-24V-ON) and

confirms that the Finisher is connected to it with the status of the connection switch (SW4) and an MFPCONNECT-SEN signal from the connection sensor (S25).

TXD: Sent data (transmitted from the Equipment to the Finisher)

RXD: Received data (transmitted from the Finisher to the Equipment)

MFP-24-V-ON: Equipment 24V power supply signal (Low level - 24V power supplied)

MFP-CONNECT: Equipment connection switch (Connected - 24V power supplied)

MFP-CONNECT-SEN: Equipment connection confirmation signal

(Low level - Connected to the equipment)

Data communication (RxD and TxD) between the equipment and the Finisher has adopted the serial

communication system which does not allow checking whether the signals are transmitted/ received

properly using testing devices in the field.

2

Fig. 2-11

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

GENERAL DESCRIPTION

2 - 15

Page 28

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

GENERAL DESCRIPTION

2 - 16

Page 29

3. DESCRIPTION OF OPERATIONS

3.1 Basic Operations

3.1.1 GENERAL DESCRIPTION

This machine receives paper transported from the connected device with its junction box, and then

transports the paper to the stationary tray or the movable tray of the Finisher section or the saddle tray

of the saddle stitch section.

Stack modes available in the Finisher section are; the simple stack mode which directly exits paper to

the stationary tray or the movable tray, the job offset stack mode which exits stacks of paper by slightly

shifting them to the front and rear alternately, and the staple stack mode which staples and exits stacks

of paper.

In the job offset stack mode and the staple stack mode, stacks of paper are exited to the movable tray.

A stack mode available in the saddle stitch section is the center-binding mode which binds a stack of

paper at its center by stapling at two positions and then folds in half again to exit it to the saddle tray.

• Simple stack mode

When the non-sort mode is set, paper exits in the procedure shown below.

A Paper is output to the stationary tray.

B Paper is output to the movable tray via the buffer tray.

Junction boxMovable tray Buffer tray

3

Stationary tray

B

A

Fig. 3-1

• Bundle job offset mode/ stapling stack mode

When the sort copying and the stapling function are set, paper exits in the procedure shown below.

1 Paper is transported to the buffer tray.

2 Paper is dropped from the buffer tray onto the finishing tray.

3 Paper stucked on the finishing tray is aligned and stapled, and then the bundled paper is output

to the movable tray.

Junction boxMovable tray Buffer tray

3

1

2

Finishing tray

Stapler unit

Fig. 3-2

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

3 - 1

DESCRIPTION OF OPERATIONS

Page 30

• Center-binding mode

Paper is exited following the procedure below when the Saddle Stitch Finisher is installed.

1 The stacker is moved to the stapling position according to the detected paper size.

2 Paper is transported to the stacker and then side alignment operation is performed.

3 The stack of paper is stapled after the alignment for the last page is finished.

4 The stacker is moved to the paper folding position to fold the paper.

5 The paper is transported to the additional folding position to be folded again.

6 The paper is exited to the saddle tray.

Junction box

Side alignment Unit

Stapler unit

Fold unit

EFS unit

Saddle tray

2

3

Stacker

4

5

6

1

4

Fig. 3-3

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 2

Page 31

3.1.2 Junction Box

Feeding sensor

Junction box paper detection sensor

Feeding roller

Junction roller

Transport path switching solenoid

Flapper

Entrance roller

Entrance motor

Paper transported from the connected device is then detected by the feeding sensor (S22) and caught

with the feeding roller. Then it is transported to the Finisher section or the saddle stitch section after the

transport path switching solenoid (SOL5) switches its transport path with a flapper.

When it is transported to the Finisher section, the flapper does not move but the entrance roller transports it to the Finisher section.

When it is transported to the saddle stitch section, the transport path switching solenoid (SOL5) is

turned ON to switch the transport path with the flapper. The paper is then transported to the saddle

stitch section with the junction roller. The junction box paper detection sensor (S26) detects the passing

of the paper.

The feeding roller and the junction roller are driven by the entrance motor (M1) of the Finisher section.

3

Fig. 3-4

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

DESCRIPTION OF OPERATIONS

3 - 3

Page 32

3.1.3 Simple Stack Mode

Entrance motor

Gate solenoid

Gate flap

Entrance roller

Entrance sens

In this mode the transported paper is exited to the stationary tray or the movable tray directly, without

any extra operation.

During the exiting process to the movable tray, the shutter is lifted not to bring the paper into the finishing tray side and the movable tray is lifted up and down according to the stack height of paper.

[A] Finisher paper feeding section

Paper transported from the junction box is then caught with the entrance roller driven by the entrance

motor (M1).

When paper is exited to the stationary tray, the gate solenoid (SOL4) is turned ON to move down the

gate flapper. When exited to the movable tray, the gate solenoid (SOL4) is turned OFF to transport the

paper to the buffer tray.

The paper transport is detected by the entrance sensor (S1).

Fig. 3-5

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 4

Page 33

[B] Paper exit to the stationary tray

Exit motor

Entrance sensor

Stationary

tray roller

Stationary tray

paper-full sensor

Paper transported from the Finisher feeding section to the stationary tray side is exited to the stationary

tray with the stationary tray roller driven by the exit motor (M11).

The entrance sensor (S1) detects the paper transport to the stationary tray.

The stationary tray paper-full sensor (S18) detects the overload of paper on the stationary tray.

3

Fig. 3-6

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

3 - 5

DESCRIPTION OF OPERATIONS

Page 34

[C] Paper exit to the movable tray

Paper transported from the Finisher feeding section to the movable tray side is transported to the buffer

tray with the exit roller driven by the exit motor (M11).

Paper transport is detected by the transport sensor (S2).

Transport sensor

Buffer tray

Exit roller

Exit motor

Fig. 3-7

The paper transported to the buffer tray it then exited to the movable tray by the buffer rollers driven by

the buffer roller drive motor (M4).

At this stage, the shutter clutch (CLT1) is turned ON and the shutter is pulled up by the drive of the

transport motor (M7) to prevent the paper from being transported to the finishing tray.

The opening and closing statuses of the shutter is detected by the shutter opening/closing sensor (S4).

Shutter

Buffer roller

Buffer roller

drive motor

Buffer tray

Shutter opening/

closing sensor

Buffer tray

Transport motor

Shutter clutch

Fig. 3-8

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 6

Page 35

[D] Operation of Movable Tray

The movable tray is shifted up and down by the drive from the movable tray shift motor (M12) according

to the paper exit from the buffer tray or finishing tray, and the amount of the paper stack. Rotation of the

movable tray shift motor is detected by the movable tray shift motor sensor (S23). Whether paper is set

on the movable tray or not is detected by the movable tray paper sensor (S17).

Detecting the position of the movable tray is performed as follows.

1. Home position of the movable tray when the paper is output from the buffer tray

The movable tray is shifted up during initializing until the movable tray paper-full sensor (S16) is

turned ON. After that, the tray is moved down for a specified period of time and it is stopped where

the movable tray position-A sensor (S13) is turned ON. This will be the home position.

2. Home position of the movable tray when the paper is output from the finishing tray

The movable tray is shifted down from the home position when the paper is output from the buffer

tray, and the tray is stopped where the movable tray position-C sensor (S15) is turned ON. This will

be the home position.

3. Position of the movable tray when the paper loading capacity is 1,500 to 3,000 sheets

If the movable tray paper-full sensor (S16) is turned ON when the movable tray is in either the home

position when the paper is output from the buffer tray or the home position when the paper is output

from the finishing tray, it goes down to the position where the movable tray position-B sensor (S14)

is turned ON. This is the position of the movable tray when the paper loading capacity is 1,500 to

3,000 sheets.

4. Position of the movable tray when the paper loading capacity is 3,000 sheets or more

When the movable tray is in the position of the paper loading capacity of 1,500 to 3,000 sheets, and

the movable tray paper-full sensor (S16) is turned ON, the tray is shifted to the position where the

movable tray position-A sensor (S13) is turned OFF. This is the position of the movable tray when

the paper loading capacity is 3,000 or more.

3

Movable tray position Movable tray position

A sensor (S13)

(1) ON OFF OFF

(2) ON OFF ON

(3) ON ON ON

(4) ON ON OFF

Movable tray position

B sensor (S14)

* ON: The sensor signal is interrupted by the rib of the sensor rail.

OFF: The sensor signal is not interrupted by the rib of the sensor rail.

Movable tray position

C sensor (S15)

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

3 - 7

DESCRIPTION OF OPERATIONS

Page 36

Movable tray paper-full sensor

Movable tray

position-A sensor

Movable tray

paper exist sensor

Movable tray

position-C sensor

Movable tray

position-B sensor

Movable tray shift motor

Movable tray

shift motor sensor

Fig. 3-9

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 8

Page 37

3.1.4 Job offset stack mode / Staple stack mode

The job offset stack mode exits stacks of paper by slightly shifting them to the front and rear alternately,

and the staple stack mode staples and exits stacks of paper. In both modes, paper transported from the

feeding section is stacked on the buffer tray in the unit of 1 to 3 sheets.

The stacked paper is then moved to the finishing tray by the active drop mechanism. On the finishing

tray the alignment of the stacks of paper and the job offsetting are performed.

In case a stack mode shifts to the staple stack mode after this, the stack of paper is stapled and exited

to the movable tray.

[A] Paper transport section

At this stage, the buffer roller lift solenoid (SOL2) is turned ON to raise the buffer rollers and the buffer

tray is moved by the buffer tray guide motor (M2) to the position where it matches with the paper width.

The home position of the buffer tray is detected by the buffer tray home position sensor (S5).

Buffer tray guide motor

Buffer tray

home position sensor

Buffer roller lift solenoid

3

Buffer roller

Buffer tray

Fig. 3-10

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

3 - 9

DESCRIPTION OF OPERATIONS

Page 38

[B] Mulch-active drop mechanism section

Paper pusher home position sensor

Paper holder cam

Catching

solenoid

Paper pushing arm motor

Paper pushing plate

Paddle guide

Catching pad

The paper transported to the buffer tray is then moved to the finishing tray by the mulch-active drop

mechanism to be aligned or stapled.

(1) The paper on the buffer tray is pulled into the finishing tray side by the reverse rotation of the

buffer roller drive motor (M4).

In this step the paper pushing arm motor (M10) holds the trailing edge of the paper with the paper

pushing plate.

Then the catching solenoid (SOL1) is turned ON to rotate the catching pad, and the catching pad

thus catches the paper with the paddle guides.

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

Fig. 3-11

3 - 10

Page 39

(2) When the buffer roller lift solenoid (SOL2) is turned ON, the buffer rollers are lifted up, and then

Buffer tray guide motor

Buffer tray

Buffer tray

Buffer roller

lift solenoid

Patting solenoid

Paper tapping arm

Buffer roller

Paddle motor

Transport motor

Stack transport roller-1

Stack transport roller-2

Finishing tray

paper detection sensor

Paddle home position sensor

the buffer tray guide motor (M2) opens the buffer tray.

The paper on the buffer tray is thus dropped onto the finishing tray.

At this stage, the patting solenoid (SOL3) is turned ON to drop the paper tapping arm so that the

paper will certainly be dropped onto the finishing tray.

3

(3) The paper dropped onto the finishing tray is then pulled into the finishing position by the paddles

driven by the paddle motor (M8) and the stack transport rollers-1 and -2 driven by the transport

motor (M7).

The finishing tray paper detection sensor (S12) detects whether paper is on the finishing tray or

not.

The home position of the paddles is detected by the paddle home position sensor (S3).

Fig. 3-12

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

Fig. 3-13

3 - 11

DESCRIPTION OF OPERATIONS

Page 40

[C] Bundle Job Offset Operation

Stapler unit shift motor

Stapler unit

home position sensor

Stapler interference switch

Stapler interference

sensor

The bundle job offset operation is to sort bundles of paper by placing the first bundle a little forward and

placing the next bundle a little backward, and repeating this set of movement.

The paper transported to the finishing tray is bundled and each bundle is placed by the alignment plates

driven by the front alignment motor (M5) and the rear alignment motor (M6).

The home position of each alignment plate is detected by the front alignment plate home position sensor (S7) and the rear alignment plate home position sensor (S8).

Alignment plateAlignment plate

Front alignment plate

home position sensor

Front alignment motor

Rear alignment plate

home position sensor

Rear alignment motor

Fig. 3-14

[D] Stapling Operation

The stapling operation is to staple a specified number of paper with the stapler unit.

The stapler unit is moved to the stapling position (the position differs depending on the paper size) by

the stapler unit shift motor (M9).

The home position of the stapler unit is detected by the stapler unit home position sensor (S10).

The stapler interference switch (SW3) detects the no-operation area for the stapling operation and cuts

off the power supply to the stapler while it is switched ON.

The stapling operation is also stopped in the area where while the stapler interference sensor (S11) is

turned ON to prevent the stapler from interfering with other mechanical sections in the equipment.

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

Fig. 3-15

3 - 12

Page 41

[E] Paper exiting operation

Bundles of the paper aligned or stapled on the finishing tray are then pulled up by the paper exit guide

driven by the stack transport motor (M8) with the turning ON of the paper exit guide clutch (CLT2).

Then the paper is exited by the paper exit belt driven by the stack transport motor (M8) and the stack

transport rollers-1 and -2 driven by the transport motor (M2) onto the movable tray.

The home position of the paper exit belt is detected by the stack exit belt home position sensor (S9).

Stack transport roller-2

3

Paper exit belt

Stack transport motor

Paper exit guide

clutch

Stack exit belt

home position sen

Transport motor

Stack transport roller-1

Paper exit guide

Fig. 3-16

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

3 - 13

DESCRIPTION OF OPERATIONS

Page 42

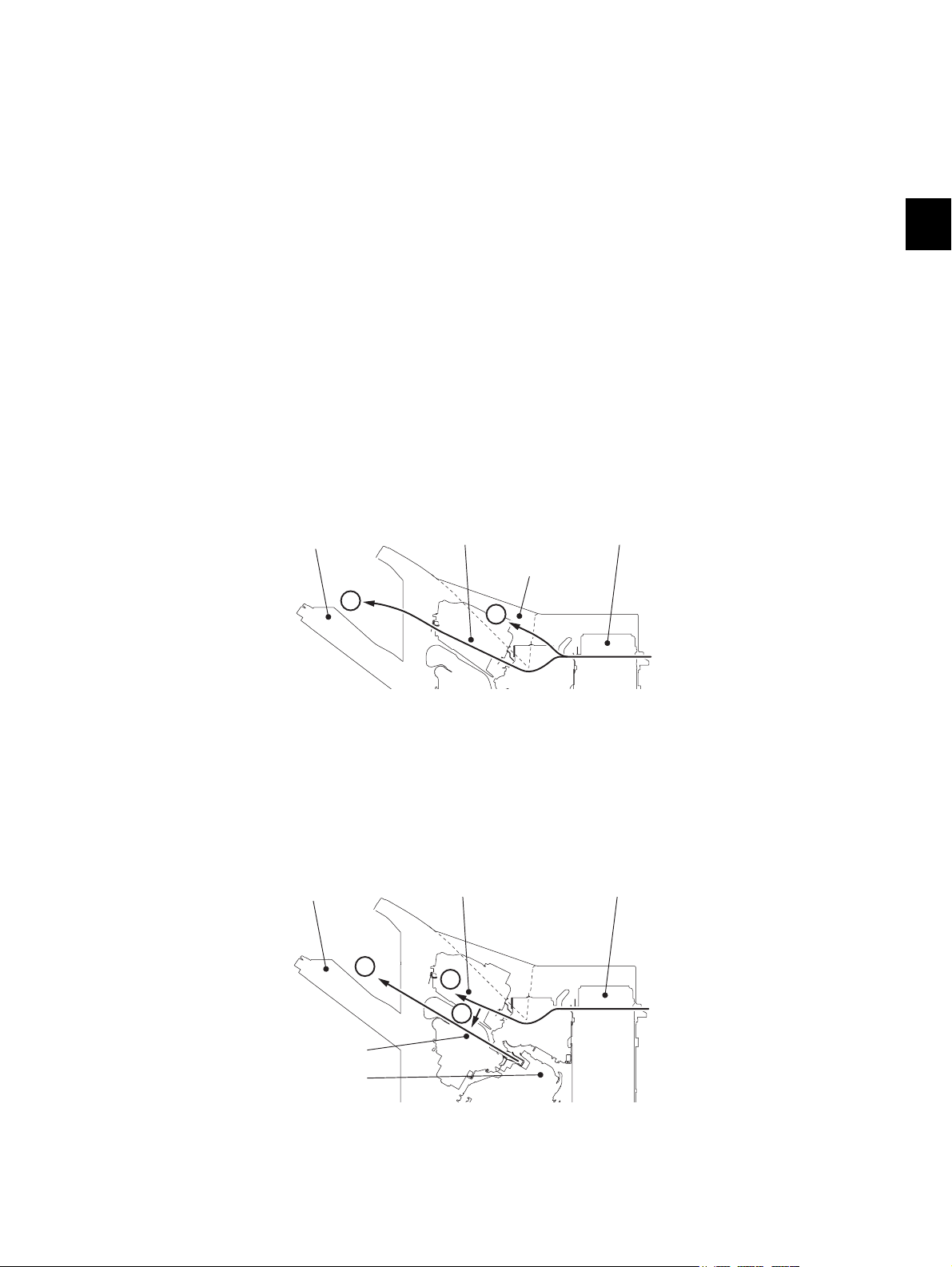

3.1.5 Operation in the saddle stitch section

Saddle transport

motor

Junction box

paper detection

sensor

Junction box

Transport path-2

sensor

Transport path-3

sensor

Assisting roller

solenoid

Transport roller

Ejecting roller sensor

Ejecting roller

Assisting roller

Saddle transport

motor

Junction box

paper detection

sensor

Transport path-2

sensor

Transport path-3

sensor

Assisting roller

solenoid

Transport roller

Ejecting roller

sensor

Ejecting roller

Assisting roller

The center-binding mode binds a stack of paper at its center by stapling at two positions and then folds

in half again to exit it to the saddle tray. In this mode paper transported from the feeding section is

stacked on the stacker. The stacks of paper are aligned on the stacker and moved to the stapling position together with the stacker. Then the moved stacks are fixed and stapled, and then moved to the folding position. Then they are folded with the folding blade and the folding roller. After this, the folded

stacks are again folded and exited to the saddle tray.

[A] Saddle stitch feeding section

Paper transported from the junction box is then transported to the stacker with the transport roller, ejecting roller and assisting roller driven by the saddle transport motor (M16).

The junction box paper detection sensor (S26), transport path-2 sensor (S27), transport path-3 sensor

(S28) and ejecting roller sensor (S29) detect the passing of the paper.

When the ejecting roller sensor (S29) detects that paper has passed, the assisting roller solenoid

(SOL6) is turned ON to contact the assisting roller with the paper to transport it to the stacker.

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

Fig. 3-17

3 - 14

Page 43

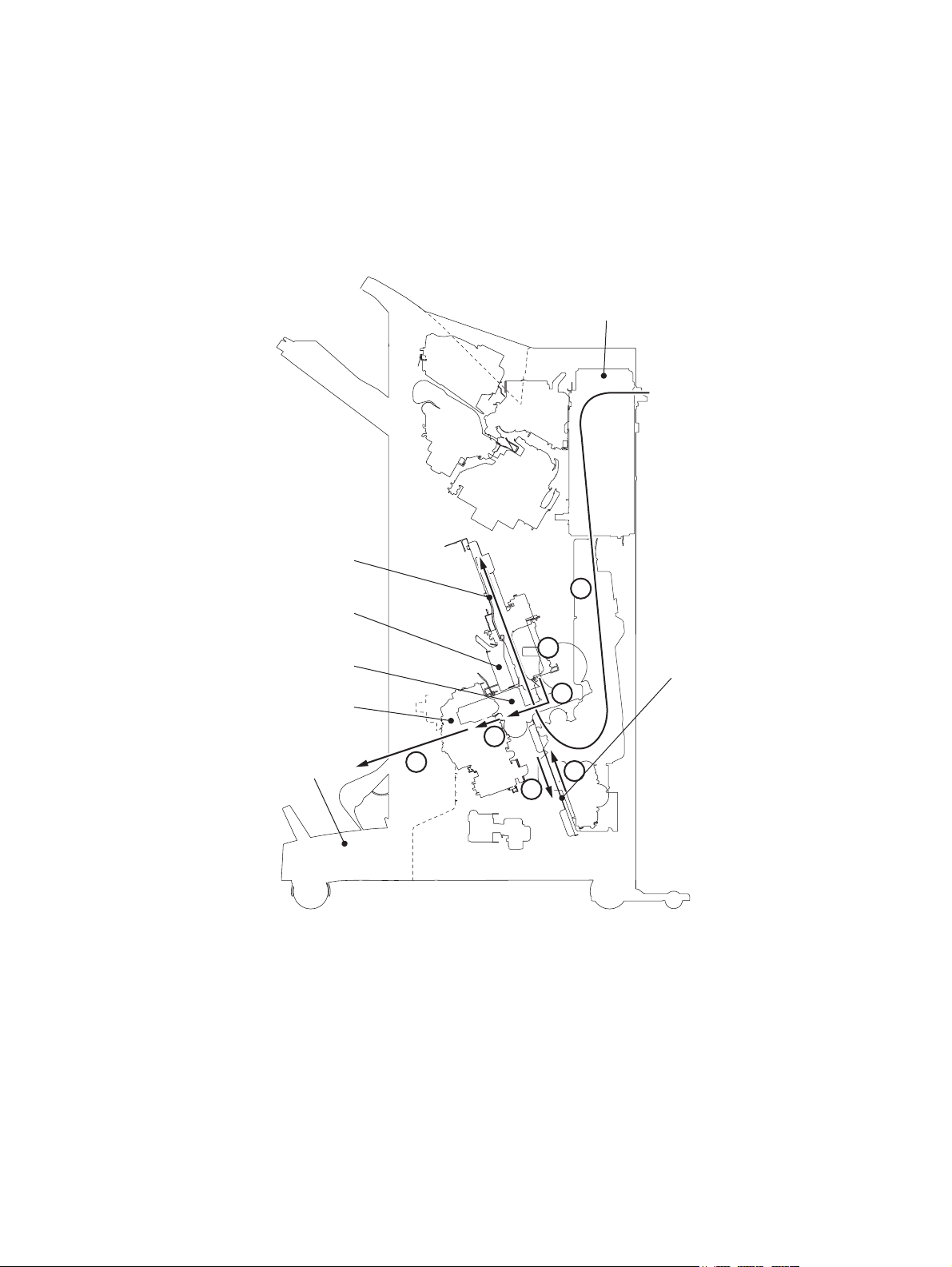

[B] Stack transport

Stacker carrier

Stacker home position sensor

Stacker motor

Stacker paper detection sensor

Side alignment motor

Jog

Side alignment

home position

sensor

Jog

A stacker carrier is moved to the stapling position or the folding position by the stacker motor (M14).

The home position of the stacker is detected by the stacker home position sensor (S33).

The presence of paper in the stacker is detected by the stacker paper detection sensor (S30).

3

Fig. 3-18

[C] Side alignment

Stacks of paper transported to the stacker are aligned to fix their sideways deviation with a jog moved

by the side alignment motor (M15).

The home position of the jog is detected by the side alignment home position sensor (S36).

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

Fig. 3-19

DESCRIPTION OF OPERATIONS

3 - 15

Page 44

[D] Paper holding

Paper holding home position sensor

Paper holding clutch

saddle transport motor

Paper holding damper

Paper holding cam

The paper holding clutch (CLT4) is turned ON to let the saddle transport motor (M16) drive the paper

holding cam.

The home position of the paper holding cam is detected by the paper holding home position sensor

(S38).

[E] Stapling

Stacks of paper aligned and fixed at the stapling position are stapled with two stapler units on the front

and rear sides.

Fig. 3-20

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 16

Page 45

[F] Folding

The folding blade is pressed onto the center of the stack of paper stapled and moved to the folding

position, and then the folding roller lets the stack of paper sandwich the blade so that the stack will be

folded again.

The folding blade clutch (CLT3) is turned ON to press the folding blade to the stack of paper by rotating

the blade cam driven by the folding motor (M17).

The rotation of the folding motor (M17) is detected by the folding motor encoder sensor (S34).

Folding motor encoder sensor

Folding motor

Folding blade clutch

Folding blade cam

Folding blade

Folding blade cam

3

Fig. 3-21

Folding blade

home position

sensor

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

3 - 17

DESCRIPTION OF OPERATIONS

Page 46

After this, the stack of paper is folded as it passes the folding roller driven by the folding motor (M17).

Folding motor encoder sensor

Folding motor

Folding blade clutch

Exit transport sensor

Folding roller

Fig. 3-22

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 18

Page 47

[G] Additional folding / exiting

Additional folding

home position sensor

Additional folding carrier

Additional

folding carrier

roller

Additional

folding motor

Additional folding

motor encoder sensor

Exit transport sensor

Folding motor

Saddle tray

Saddle exit roller

Exit sensor

Folding roller

Stack tray paper

detection sensor

The stack of paper folded by the folding roller is stopped with the exit transport sensor (S41) at the stopping position. The folded paper is then folded again by moving the additional folding carrier roller forward and backward.

The home position of the additional folding carrier is detected by the additional folding home position

sensor (S39).

The additional folding carrier is driven by the additional folding motor (M20). The rotation of the additional folding motor (M20) is detected by the additional folding motor encoder sensor (S42).

3

After this, the paper is exited to the saddle tray with the saddle exit roller driven by the folding motor

(M17).

The passing of the paper is detected by the exit sensor (S31).

The presence of paper on the saddle tray is detected by the stack tray paper detection sensor (S32).

Fig. 3-23

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

Fig. 3-24

DESCRIPTION OF OPERATIONS

3 - 19

Page 48

3.2 Flow Chart

[A] Simple stack mode

START

Entrance motor ON

Exit motor ON

Entrance sensor ON?

YES

Gate solenoid ON?

YES (Paper exit to the stationary tray)

End

NO

NO

(Paper exit to the

movable tray)

Paper jam

Transport sensor ON?

YES

NO

Shutter clutch ON

Transport motor ON

Shutter opening/closing sensor ON

Movable tray shift motor ON

Movable tray paper-full sensor ON

Movable tray shift motor ON (Reverse)

Movable tray position sensor ON

Movable tray upper position sensor ON

Movable tray lower position sensor ON

Buffer roller drive motor ON

Paper jam

End

Fig. 3-25

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 20

Page 49

[B] Bundle job offset mode/ stapling stack mode

START

Paper jam

Entrance sensor ON?

Entrance motor ON

Exit motor ON

Stapler unit shift motor ON

Stapler unit home position sensor ON

Stapler Interference switch ON

Stapler Interference sensor ON

Patting solenoid ON

Buffer tray guide motor ON

Buffer tray home position sensor ON

Paddle motor ON

Paddle home position sensor ON

NO

Finishing tray paper

detection sensor ON?

Paper jam

YES

NO

Paper holding arm motor ON

Catching solenoid ON

Buffer roller lift solenoid ON

Buffer roller drive motor ON (Reverse)

Buffer tray guide motor ON

Buffer tray home position sensor ON

Paper exit guide clutch ON

Paper exit guide clutch ON

Stack transport motor ON

Stack exit belt home position sensor ON

End

Shutter clutch ON

Transport motor ON

Shutter opening/closing sensor ON

Movable tray shift motor ON

Movable tray paper-full sensor ON

Movable tray shift motor ON (Reverse)

Movable tray position sensor ON

Movable tray upper position sensor ON

Movable tray lower position sensor ON

YES

Buffer roller lift solenoid ON

Paper jam

NO

YES

Transport sensor ON?

Staple stack mode

Front alignment motor ON

Front alignment plate home position sensor ON

Rear alignment motor ON

Rear alignment plate home position sensor ON

3

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

Fig. 3-26

3 - 21

DESCRIPTION OF OPERATIONS

Page 50

[C] Center-binding mode

START

Entrance motor ON

Feeding sensor ON?

YES

Transport path-2 sensor ON?

YES

Saddle transport motor ON

Ejecting roller sensor ON?

YES

Assisting roller solenoid ON

NO

NO

NO

Rear saddle stapler motor ON

Rear saddle stapler home position sensor ON

Rear saddle staple empty sensor ON

Rear saddle staple cartridge sensor ON

Paper jam

Front saddle stapler motor ON

Front saddle stapler home position sensor ON

Front saddle staple empty sensor ON

Front saddle staple cartridge sensor ON

Paper jam

Stacker motor ON

Paper holding clutch ON

Saddle transport motor ON

Paper jam

Folding blade clutch ON

Folding motor ON

Stacker paper detection sensor ON?

YES

NO

Side alignment motor ON

Paper holding clutch ON

Saddle transport motor ON

Paper jam

Exit transport sensor ON?

Additional folding motor ON

Folding motor ON

Exit sensor OFF

Fig. 3-27

End

YES

YES

NO

NO

Paper jam

Paper jam

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 22

Page 51

3.3 Description Of Circuit

3.3.1 Finishier section

[A] Buffer roller drive circuit

The buffer roller drive circuit controls the rotation and stoppage, rotational direction and motor current of

the buffer roller drive motor.

The buffer roller drive motor is driven by pulse signals (MT4-OUT1A, MT4-OUT1B, MT4-OUT2A and

MT4-OUT2B) output from the motor driver (IC47) under the command of a clock signal (TIOCA4), a

rotational direction signal (MOT4-DIR) and a current setting signals (MOT4-CUR1 and MOT4-CUR0)

from the CPU of the finisher control PC board, and thus this motor rotates the buffer roller.

3

TIOCA4

MOT4-

DIR

MOT4-

CUR1

MOT4-

CUR0

Motor rotation Remarks

Clock signal H L H Normal (Low power) Paper is transported to the movable tray.

Clock signal H L L Normal (Normal power)

Clock signal L L H Reverse (Low power) Not used.

Clock signal L L L Reverse (Normal

power)

--H- Stop

Finisher control PC board

VM

3.3V

CN11

MT4-OUT1A

MT4-OUT2A

MT4-OUT1B

MT4-OUT2B

Buffer roller

drive motor

(M4)

IC21

CPU

MOT4-DIR

MOT4-CUR0

MOT4-CUR1

P-RESET

P-RESET

TIOCA4

Current

control

circuit

13

16

20

17

5

IC47

Motor driver

SG

Fig. 3-28

24

1

21

4

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

DESCRIPTION OF OPERATIONS

3 - 23

Page 52

[B] Paper pushing arm motor drive circuit

IC21

CPU

TIOCC0

MOT10-DIR

MT10-OUT1A

VM

MT10-OUT2A

MT10-OUT1B

MT10-OUT2B

SG

MOT10-CUR0

24

4

1

21

5

MOT10-CUR1

16

20

13

P-RESET

P-RESET

3.3V

Paper pushing

arm motor

(M10)

IC49

Motor driver

Finisher control PC board

CN19

17

Current

control

circuit

The paper pushing arm motor drive circuit controls the rotation and stoppage, rotational direction and

motor current of the paper pushing arm motor.

The paper pushing arm motor is driven by pulse signals (MT10-OUT1A, MT10-OUT1B, MT10-OUT2A

and MT10-OUT2B) output from the motor driver (IC49) under the command of a clock signal (TIOCC0),

a rotational direction signal (MOT10-DIR) and a current setting signals (MOT10-CUR1 and MOT10CUR0) from the CPU of the finisher control PC board, and thus this motor holds the paper with the

paper pushing plate.

TIOCC0

MOT10

-DIR

MOT10

-CUR1

MOT10

-CUR0

Motor rotation Remarks

Clock signal H L H Normal (Low power) The trailing edge of the paper is held down

Clock signal H L L Normal (Normal power)

by the paper pushing plate.

Clock signal L L H Reverse (Low power) Not used

Clock signal L L L Reverse (Normal

power)

--H- Stop

Fig. 3-29

MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

DESCRIPTION OF OPERATIONS

3 - 24

Page 53

[C] Buffer tray guide motor drive circuit

IC21

CPU

TIOCA5

MOT2-DIR

MOT2-OUT1A

VM

MOT2-OUT2A

MOT2-OUT1B

MOT2-OUT2B

SG

MOT2-CUR0

24

4

1

21

5

MOT2-CUR1

16

20

13

P-RESET

P-RESET

3.3V

Buffer tray

guide motor

(M2)

IC48

Motor driver

Finisher control PC board

CN11

17

Current

control

circuit

The buffer tray guide motor drive circuit controls the rotation and stoppage, rotational direction and

motor current of the buffer tray guide motor.

The buffer tray guide motor is driven by pulse signals (MOT2-OUT1A, MOT2-OUT1B, MOT2-OUT2A

and MOT2-OUT2B) output from the motor driver (IC48) under the command of a clock signal (TIOCA5),

a rotational direction signal (MOT2-DIR) and a current setting signals (MOT2-CUR1 and MOT2-CUR0)

from the CPU of the finisher control PC board, and thus this motor opens or closes the buffer tray guide.

TIOCA5

MOT2-

DIR

Clock signal H L H Normal (Low power) The guide is closed.

Clock signal H L L Normal (Normal power)

Clock signal L L H Reverse (Low power) The guide is opened.

Clock signal L L L Reverse (Normal

--H- Stop

MOT2-

CUR1

MOT2-

CUR0

Motor rotation Remarks

power)

3

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved MJ-1103/1104

Fig. 3-30

DESCRIPTION OF OPERATIONS

3 - 25

Page 54

[D] Front / rear alignment motor drive circuit

The front / rear alignment motor drive circuit controls the rotation and stoppage, rotational direction and