Page 1

MJ-1101 Service Manual Addendum

Supplement to the Troubleshooting Section

TOSHIBA

Page 2

Index

TOSHIBA

Error Code Page

EA20 1,2,3,4,13,14

EA40 5,13,14

EA60/CC30 6,7,8,9

EA70 /CC41 6,7,8,9,13,14

EAEO 10

CB31 11,12

*Recommended Lubricant Molykote EM-30L - 6LE36904000

i

Page 3

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

g

)

EA20

- Paper jams at the

entrance section of

the Finisher (or the

Hole Punch Unit)

- Folded paper edge

- Paper jams C2in the

buffer tray section

- C2Paper exit

problems on the

finishing tray

1. Improper installation height

(Paper is not properly transported

from the equipment to the

Finisher if each height is

improper.)

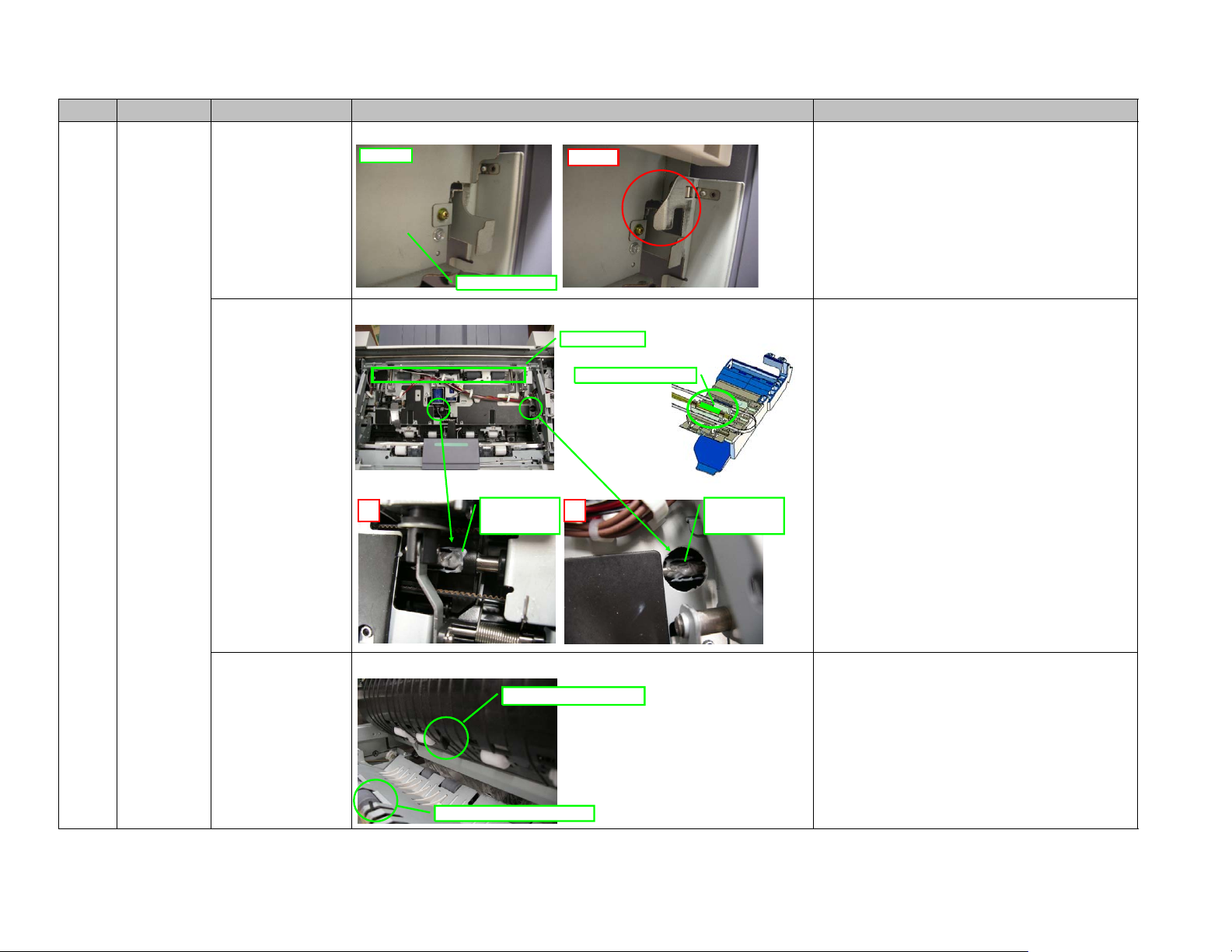

A. Confirm that the Finisher is installed horizontally (the height of its front side and that of its rear side are the

same

.

The length of the arrows should be the same.

B. To keep the installation height of the Finisher stable, it is preferable that the casters are faced to the equipment

side.

Caster

㪜quipment side

C. When installing the Finisher in the equipment, make sure that the height of the Finisher is proper. If it is not, the

e Unit exit Mylar may be deformed, and thus the deformed Mylar may obstruct the paper transportpath.

Brid

Improper

case

Installation height

- Note that the height should be different between the cases when the Finisher

is installed in e-STUDIO281c/351c/451c and when installed in eSTUDIO352/452 or e-STUDIO2500c/3500c/3510c.

- Confirm the height every time you move the equipment.

2. Bridge Unit exit Mylar deformed

Check if the Mylar attached to the exit of the Bridge Unit is deformed and obstructing the paper transport path.

Correct it if deformed.

Normal Abnormal

Deformed Mylar

Paper transport path

㪈

㪄㩷Note that the height should be different between the cases when the Finisher

is installed in e-STUDIO281c/351c/451c and when installed in eSTUDIO352/452 or e-STUDIO2500c/3500c/3510c.

Page 4

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

EA20

- Paper jams at the

entrance section of

the Finisher (or the

Hole Punch Unit)

- Folded paper edge

- Paper jams C2in the

buffer tray section

- C2Paper exit

problems on the

finishing tray

3. Improper connection between

the equipment and the Hole

Punch Unit

(Paper is not properly transported

from the equipment to the Hole

Punch Unit if they are not

connected correctly.)

4. False operation of the buffer

guide

(Paper jams may occur if the load

is applied to the buffer guide

during its opening or closing

movement.)

When the Hole Punch Unit is installed, check if the connection point is shifted forward or backward.

Normal

Hole Punch Unit

Remove the stationary tray and apply grease "Molykote EM-30L" (the size of 5 grains of rice) to the buffer guide

shaft.

Abnormal

Buffer roller

Buffer guide shaft

5. False operation of the entrance

sensor or the transport sensor

(An error may occur when the

entrance sensor or the transport

sensor does not perform proper

detection.)

㪸

A. Check if the wires of the entrance sensor or the transport sensor are being caught or short circuited, or any of

their connectors is disconnected.

Molykote EM-30L

(the size of 5

grains of rice)

Transport sensor actuator

Entrance sensor actuator

㪹

㪉

Molykote EM-30L

(the size of 5

grains of rice)

a: Slide the buffer guide to the center and lubricate between the shafts of the

front buffer guide.

b: Slide the buffer guide forward or backward and lubricate between the shafts

of the rear buffer guide.

* Be sure to lift up the buffer roller before sliding the guide.

If the entrance sensor does not retract quickly, replace the spring

with a new one P/N 6LB09015000 SPG-FEED-SNSR-1.

Page 5

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

p

EA20

- Paper jams at the

entrance section of

the Finisher (or the

Hole Punch Unit)

- Folded paper edge

- Paper jams C2in the

buffer tray section

- C2Paper exit

problems on the

finishing tray

5. False operation of the entrance

sensor or the transport sensor

(An error may occur when the

entrance sensor or the transport

sensor does not perform proper

detection.)

6. False operation of the paper

exit guide

(An error may occur when the

paper exit guide is not operating

properly because paper may

remain on the finishing tray or not

exit properly during sort or

stapling exit.)

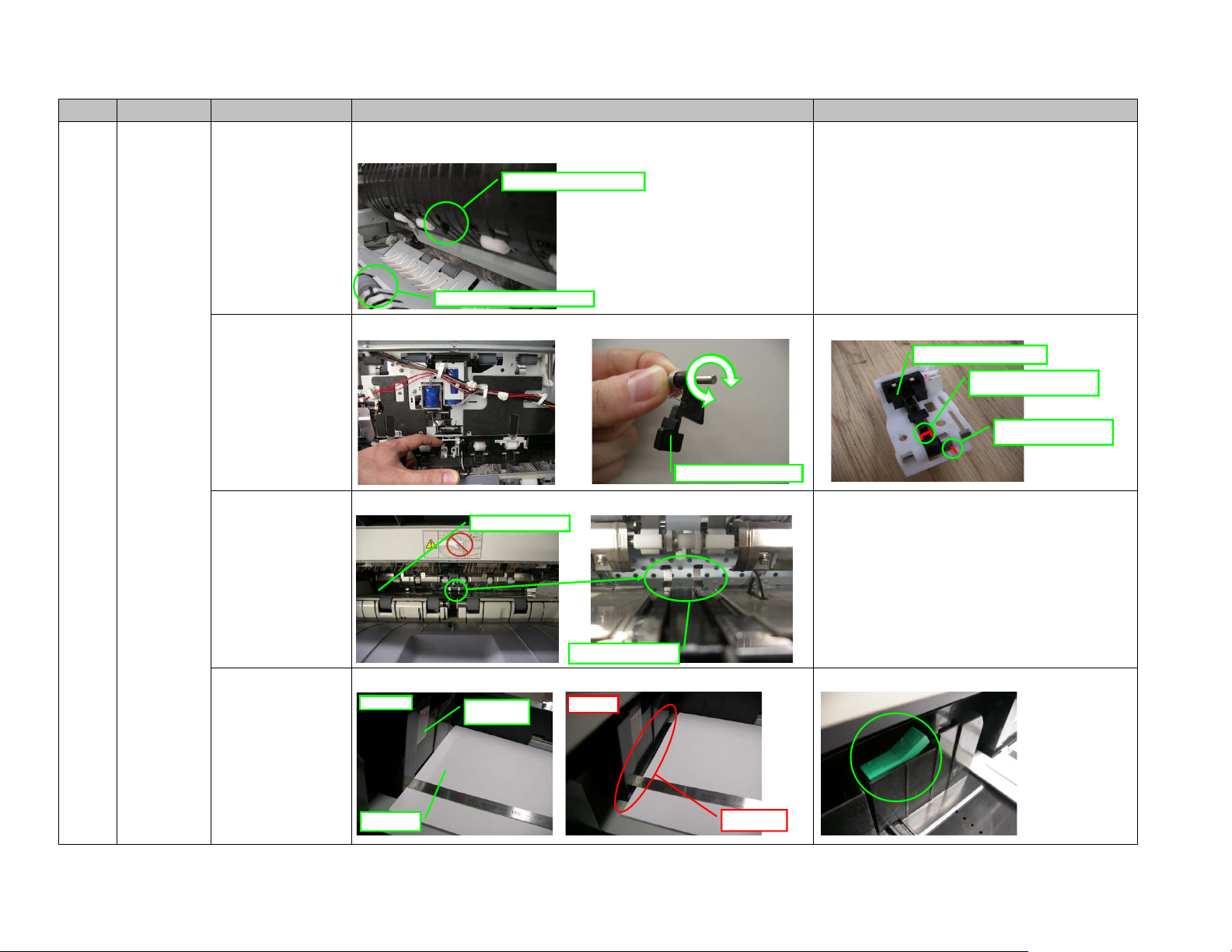

B. Check if the actuators of the entrance sensor and the transport sensor are operating smoothly. If they are not,

remove the actuator and check if there is any paper dust or foreign matter between the shaft and the hole. Clean if

there is.

Transport sensor actuator

Entrance sensor actuator

Operation check of the transport sensor actuator: Rotate the shaft slowly. If the actuator is not rotated together, its

o

eration is normal.

Transport sensor actuator

Replace SPG-SFFD-SUPT-SF (6LB090140) if the paper exit guide is not operating properly.

Finishing tray

Transport sensor actuator

Hook this to the actuator.

Hook this onto the bracket.

Paper exit guide

7. Paper not placed properly in

the drawer

(Paper may be skewed if there is

extra gap between the paper and

the side wall in the drawer and

thus may cause a jam on the

Finisher transport path.)

Normal

Paper

Side wall

Abnormal

Gap

㪊

Be sure to lock the side wall.

Page 6

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

EA20

- Paper jams at the

entrance section of

the Finisher (or the

Hole Punch Unit)

- Folded paper edge

- Paper jams C2in the

buffer tray section

- C2Paper exit

problems on the

finishing tray

8. Drive not transmitted from the

gear in the paper transport

section

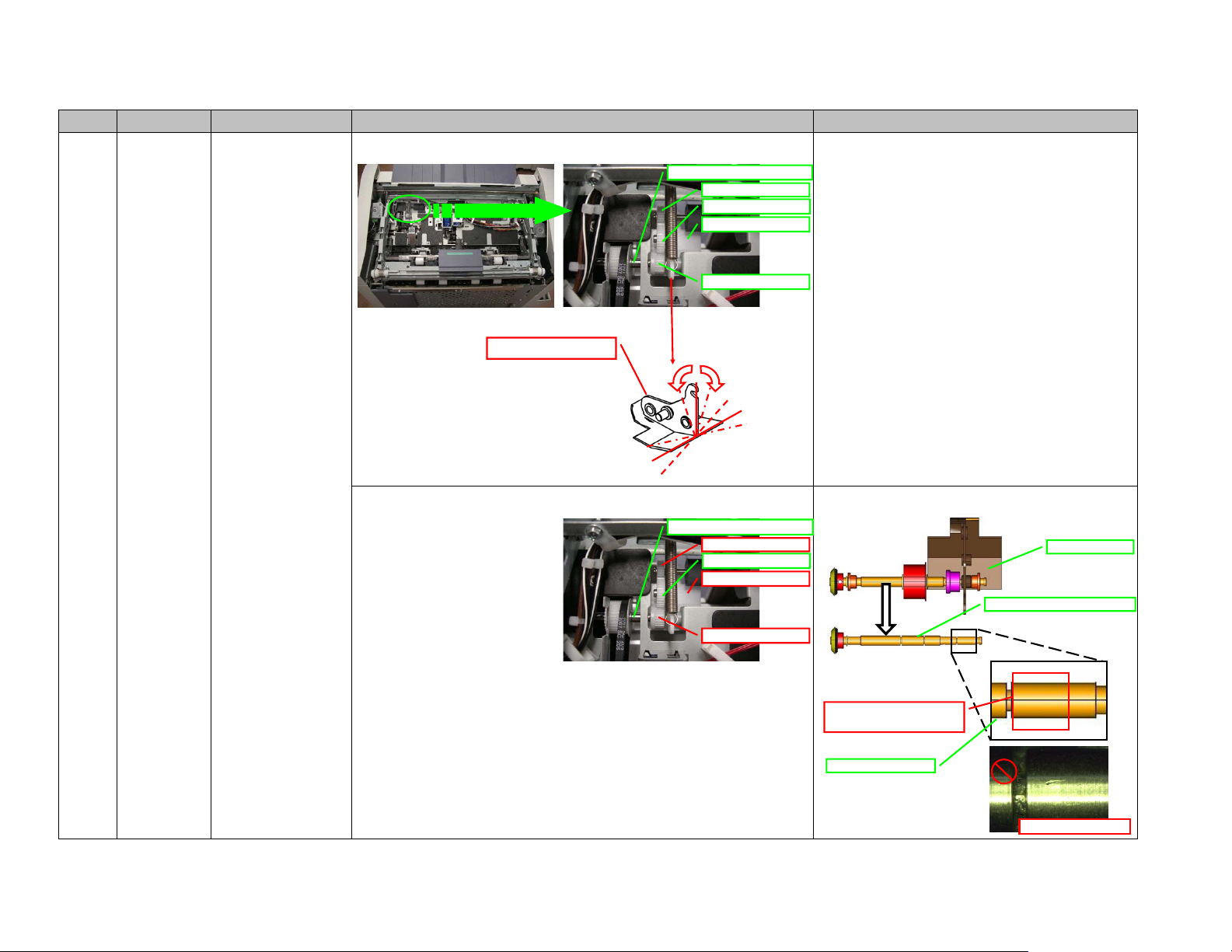

A. Check if there is any rattling on ASYS-LVR-E-RLR-BUF. If there is, replace ASYB-SFT-EXT-RLR-DRV-BUF,

ASYS-LVR-E-RLR-BUF, GEAR-IDLER-EXT-BUF, GEAR1-EXT-RLR-BUF and GEAR2-EXT-RLR-BUF.

ASYB-SFT-EXT-RLR-DRV-BUF

GEAR1-EXT-RLR-BUF

GEAR-IDLER-EXT-BUF

ASYS-LVR-E-RLR-BUF

GEAR2-EXT-RLR-BUF

Check that there is no rattling.

B. Check if the gear teeth of GEAR-IDLER-EXT-BUF, GEAR1-EXT-RLR-BUF and GEAR2-EXT-RLR-BUF mesh

correctly. If any of them does not mesh correctly, replace ASYB-SFT-EXT-RLR-DRV-BUF, ASYS-LVR-E-RLRBUF, GEAR-IDLER-EXT-BUF, GEAR1-EXT-RLR-BUF or GEAR2-EXT-RLR-BUF.

㪋

ASYB-SFT-EXT-RLR-DRV-BUF

GEAR1-EXT-RLR-BUF

GEAR-IDLER-EXT-BUF

ASYS-LVR-E-RLR-BUF

GEAR2-EXT-RLR-BUF

When replacing, be sure not to scratch the shaft (ASYB-SFT-EXT-RLR-DRVBUF).

LVR-E-RLR-BUF

ASYB-SFT-EXT-RLR-DRV-BUF

Do not scratch this area.

SFT-EXT-RLR-DRV-BUF

Scratch on the shaft

Page 7

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

perj

g

Pa

EA40

ammin

(A cover-open error occurs if the

stationary tray is left open

because the stationary tray

opening/closing switch performs

false detection during operation.)

2. Stationary tray opening/closing

switch actuator deformed

(A cover-open error occurs if the

actuator is deformed because the

stationary tray opening/closing

switch cannot be turned and

performs false detection.)

Close the stationary tray securely if it is open.1. Stationary tray left open

Tray closed Tray opened

Stationary tray

Replace PLT-OPEN-SW-BUF if the actuator is deformed.

Actuator

deformed (MJ-1101)

(A cover-open error occurs if the

actuator is deformed because the

front cover switch cannot be

turned and it performs false

detection.)

deformed (MJ-6101)

(A cover-open error occurs if the

actuator is deformed because the

front cover switch cannot be

turned and performs false

detection.)

Replace HNDL-DOOR if the actuator is deformed or damaged.3. Front cover switch actuator

MJ-1101

Actuator

Replace COVER-F-DOOR-P if the actuator is deformed or damaged.3. Front cover switch actuator

MJ-6101

Actuator

㪌

Page 8

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

g

EA70

EA60

CC30

CC41

- When more than one

sheet of paper is

loaded on the buffer

tray, the first sheet is

pushed out of the tray

by the second sheet.

- When more than one

sheet of paper is

loaded on the buffer

tray, the leading edge

of the second sheet is

caught and thus a

paper jam occurs.

- When paper is

transported from the

buffer tray to the

finishing tray, the

paper is run on the

front or rear alignment

plate.

- When paper is

loaded on the finishing

tray, the front and rear

alignment plates

excessibly push the

paper.

- When paper is

transported from the

finishing tray to the

movable tray, the

paper exit guide

catches the paper and

thus a motor error

occurs because the

paper cannot exit.

1. Catching pad deformed or

damaged

(Paper is not aligned properly due

to the deformed or damaged

catching pad.)

2. Catching pad link arm

deformed, damaged or removed

(Paper is not aligned properly

because the link arm of the

catching pad is deformed,

damaged or removed.)

3. Improper roller gap on the

buffer roller guide and buffer tray

Check if the catching pad in the Finisher paper exit section is properly attached. Replace it if it is deformed or

ed.

dama

Normal

Catching pad

Check if the catching pad in the Finisher paper exit section is properly attached. If its link arm is deformed,

damaged or removed, replace ARM-SOL-ALIGN (6LB100080).

Abnormal

Facing down

Catching pad link arm

Turn the power OFF. Then check the gap between rollers on the buffer roller guide and the buffer tray while the

buffer roller is left lowered. If the gap does not reach 0.3 mm, replace the buffer roller guides (LVR-E-RLR-BUF)

on both front and rear sides.

Buffer roller guide

Check the gap within the range 7 mm from the edge of the buffer roller guide.

0.3 mm or

Buffer tray

more

Buffer roller guide

Buffer roller

RLR-EXIT-BUFFER

Roller on the buffer tray

RLR-EXIT-TRY

Within the range 7 mm

from the edge

Buffer roller guide

LVR-E-RLR-BUF

㪍

Page 9

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

EA70

EA60

CC30

CC41

- When more than one

sheet of paper is

loaded on the buffer

tray, the first sheet is

pushed out of the tray

by the second sheet.

- When more than one

sheet of paper is

loaded on the buffer

tray, the leading edge

of the second sheet is

caught and thus a

paper jam occurs.

- When paper is

transported from the

buffer tray to the

finishing tray, the

paper is run on the

front or rear alignment

plate.

- When paper is

loaded on the finishing

tray, the front and rear

alignment plates

excessibly push the

paper.

- When paper is

transported from the

finishing tray to the

movable tray, the

paper exit guide

catches the paper and

thus a motor error

occurs because the

paper cannot exit.

4. Improper spacing on the edge

section of the buffer roller guide

and the buffer tray upper section

5. Motor bracket deformed

(The bracket of the buffer tray

guide motor or the buffer roller

drive motor is deformed and thus

drive is not transmitted.)

Turn the power OFF and pull the plunger of the buffer roller lift solenoid by hand. Then check the spacing on the

edge section of the buffer roller guide and the buffer tray upper section while the buffer roller is lifted up. If the

edge section of the buffer roller guide is not lower than the buffer tray upper section, replace STAY-BUFFER.

Buffer roller lift solenoid

Normal

STAY-BUFFER

Buffer tray upper section

RLR-EXIT-TRY

Buffer roller

RLR-EXIT-BUFFER

Buffer roller edge section

LVR-E-RLR-BUF

If the buffer tray guide motor bracket (HLDR-TRAY-BUF) or the buffer roller drive motor bracket (HLDR-MOTRBUFFER) is deformed, replace it.

Buffer tray

- If the joint surfaces of the stationary tray and the rear lower cover (or the

control panel unit) are shifted 4 mm or more, the motor bracket may be

deformed.

- Do not hold the stationary tray when unpacking.

Buffer roller drive motor

Normal

Buffer tray guide motor

Abnormal

A gap appears due to the

deformed bracket.

㪎

Page 10

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

EA70

EA60

CC30

CC41

- When more than one

sheet of paper is

loaded on the buffer

tray, the first sheet is

pushed out of the tray

by the second sheet.

- When more than one

sheet of paper is

loaded on the buffer

tray, the leading edge

of the second sheet is

caught and thus a

paper jam occurs.

- When paper is

transported from the

buffer tray to the

finishing tray, the

paper is run on the

front or rear alignment

plate.

- When paper is

loaded on the finishing

tray, the front and rear

alignment plates

excessibly push the

paper.

- When paper is

transported from the

finishing tray to the

movable tray, the

paper exit guide

catches the paper and

thus a motor error

occurs because the

paper cannot exit.

6. STAY-BUFFER deformed Remove the bracket of the buffer roller lift solenoid. Then check that STAY-BUFFER is not deformed using a

7. Improper installation of

alignment plates

scale or other straight tool. Replace it if it is deformed.

STAY-BUFFER

Scale

AbnormalNormal

A gap appears if it is deformed.

If the front or rear alignment plate is removed or its installation is improper, reinstall it. (The alignment plates must

not be risen even if they are tilted to the right or left.)

Alignment plate

Rising of the plate

8. Stack transport motor belt out

of gear

If the stack transport motor belt is loose, retighten it, or replace the motor bracket (BRKT-MOTR-SF) to retighten

the belt.

㪏

Page 11

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

p

pap

EA70

EA60

CC30

CC41

- When more than one

sheet of paper is

loaded on the buffer

tray, the first sheet is

pushed out of the tray

by the second sheet.

- When more than one

sheet of paper is

loaded on the buffer

tray, the leading edge

of the second sheet is

caught and thus a

paper jam occurs.

- When paper is

transported from the

buffer tray to the

finishing tray, the

paper is run on the

front or rear alignment

plate.

- When paper is

loaded on the finishing

tray, the front and rear

alignment plates

excessibly push the

paper.

- When paper is

transported from the

finishing tray to the

movable tray, the

paper exit guide

catches the paper and

thus a motor error

occurs because the

paper cannot exit.

10. Abnormalities in paper

transport section

11. Insufficient ejection of

front/rear transport roller

12. Wrong operation by users

during printing

Check if there is any scratch, foreign matter, paper dust or remained paper that disturb the paper transport in the

er transport section. Remove if any.

Paper transport

section

If the front and rear transport rollers are not ejected from the transport guide at 0.5 mm or more, replace the

trans

ortguide(GUIDE-FEED-LOW).

0.5 mm or more

Front transport roller

Transport guide

An EA70 error may occur if paper exit is disturbed during printing.

㪹㪸

Rear transport roller

㪐

Page 12

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

EAE0 1. Loose connection

Paper jamming A. Check if the interface cable of the Finisher is connected securely. Reconnect it if not.

(Loose connection may cause

false operation or detection.)

Interface cable

B. Check if the connectors (CN12 and CN14) of the Finisher control PC board are connected securely. Reconnect

them if not.

Connector

C. Check if the connectors (CN1 and CN2) of the CNV board are connected securely and the locking support is

installed properly. Reconnect them if not.

Locking support

2. Movable tray paper exist

sensor harness (HRNS-SFTTRY)

short circuited

(Loose connection may cause

false operation or detection.)

Connector

Check if the harness (HRMS-SFTTRY) of the movable tray paper exist sensor is short circuited or if its wiring is

proper. Replace the harness if it is short circuited.

Abnormal

HRNS-SFTTRY (6LB12426000)

㪈㪇

The harness wiring must be under the screw and inside of the Mylar, and the

harness must be wired along with the groove of the plate as shown on the left.

Be sure that the harness is covered by the Mylar.

Page 13

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

(

)

y

CB31

- The movable tray is

lifted up after the

power is turned ON.

An error occurs when

it stops at the upper

limit position.

(Initialization does not

finish.)

- The movable tray is

lowered after the

power is turned ON.

An error occurs before

it is lowered to the

specified position.

Initialization finishes.

tray paper-full sensor due to its

deformed/damaged actuator (The

actuator not ejected)

2. False detection caused by the

removed actuator spring of the

movable tray paper-full sensor

(The actuator not ejected)

If the actuator cannot be ejected due to its deformation or damage, replace ACTR-01-SNSR-VER01-TRAY.1. False detection of the movable

Normal

Reinstall SPG-ACTR-01-TRAY if it is removed.

Normal

Abnormal

Not ejected

Abnormal

Not ejected

3. Improper installation of the

movable tray

(An error occurs if the actuator of

the movable tray paper-full sensor

cannot be pushed due to the

improper installation of the

movable tray.)

The movable tray may not be installed properly (the stay of the movable tray may run on the boss). Reinstall the

movable tra

Normal

.

Movable tray stay

Screwed

Abnormal

Run on the boss

㪈㪈

Page 14

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

CB31 An error occurs

because the movable

tray cannot be lowered

(or lifted up) to the

specified position after

printing operation.

1. The movable tray cannot be

lowered or lifted up because the

load is applied to the movable tray

by the contact of the tray and

COVER-RAIL-FRONT (or

COVER-RAIL-REAR).

Check if the inner hooks of COVER-RAIL-FRONT and COVER-RAIL-REAR are properly latched. Reinstall them if

not.

Abnormal

The movable tray and COVERRAIL-FRONT contact.

COVER-RAIL-REAR

COVER-RAIL-FRONT

㪈㪉

Page 15

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

)

)

CC41

EA20

EA40

EA70

- Paper jams at the

entrance section of

the Finisher (or the

Hole Punch Unit)

- Folded paper edge

- Improper closing of

the stationary tray

1. Motor bracket deformed

(The bracket of the buffer tray

guide motor or the buffer roller

drive motor is deformed and thus

drive is not transmitted.)

If the buffer tray guide motor bracket (HLDR-TRAY-BUF) or the buffer roller drive motor bracket (HLDR-MOTRBUFFER

is deformed, replace it.

Buffer tray guide motor

Buffer roller drive motor

- If the joint surfaces of the stationary tray and the rear lower cover (or the

control panel unit) are shifted 4 mm or more, the motor bracket may be

deformed.

- Do not hold the stationary tray when unpacking.

2. Improper installation height

(Paper is not properly transported

from the equipment to the

Finisher if each height is

improper.)

Normal

A gap appears due to the

deformed bracket.

A. Confirm that the Finisher is installed horizontally (the height of its front side and that of its rear side are the

.

same

The length of the arrows should be the same.

B. To keep the installation height of the Finisher stable, it is preferable that the casters are faced to the equipment

side.

Equipment side

Abnormal

Caster

- Note that the height should be different between the cases when the Finisher

is installed in e-STUDIO281c/351c/451c and when installed in eSTUDIO352/452 or e-STUDIO2500c/3500c/3510c.

- Confirm the height every time you move the equipment.

㪈㪊

Page 16

Error code Phenomenon Possible cause Items to confirm / Countermeasures Precautions / Remarks

quip

CC41

EA20

EA40

EA70

- Paper jams at the

entrance section of

the Finisher (or the

Hole Punch Unit)

- Folded paper edge

- Improper closing of

the stationary tray

3. Tilted Finisher

(Paper is not properly transported

from the equipment to the

Finisher if the Finisher is tilted.)

If the Finisher is tilted as shown below, adjust the height of each caster to make the Finisher horizontal to the

ment.

e

Normal

Abnormal

Caster

If the Finisher is tilted, the fixing screw of the Bridge Unit and the stationary tray

may be contacted when the stationary tray is opened or closed.

Bridge Unit fixing screw

4. Improper exit of large paper Secure enough space for drawing out the sub-tray when installing the Finisher. If the Finisher is installed as

5. Improper connection between

the equipment and the Hole

Punch Unit

(Paper is not properly transported

from the equipment to the Hole

Punch Unit if they are not

connected correctly.)

shown in the picture below, the trailing edge of large paper may be jammed when it is exiting.

Sub-tray

Wall

When the Hole Punch Unit is installed, check if the connection point is shifted forward or backward.

Normal

Hole Punch Unit

Abnormal

㪈㪋

Be sure to draw out the sub-tray when large paper is used. Otherwise false

stacking, paper dropping or an EA70 error may occur.

Page 17

MJ-1101 Service Manual Addendum Version 01

Loading...

Loading...